Composite plastic sheet and making method thereof

A technology of composite plastics and production methods, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., and can solve problems such as large molding shrinkage, affecting the field of use, and easy warping of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

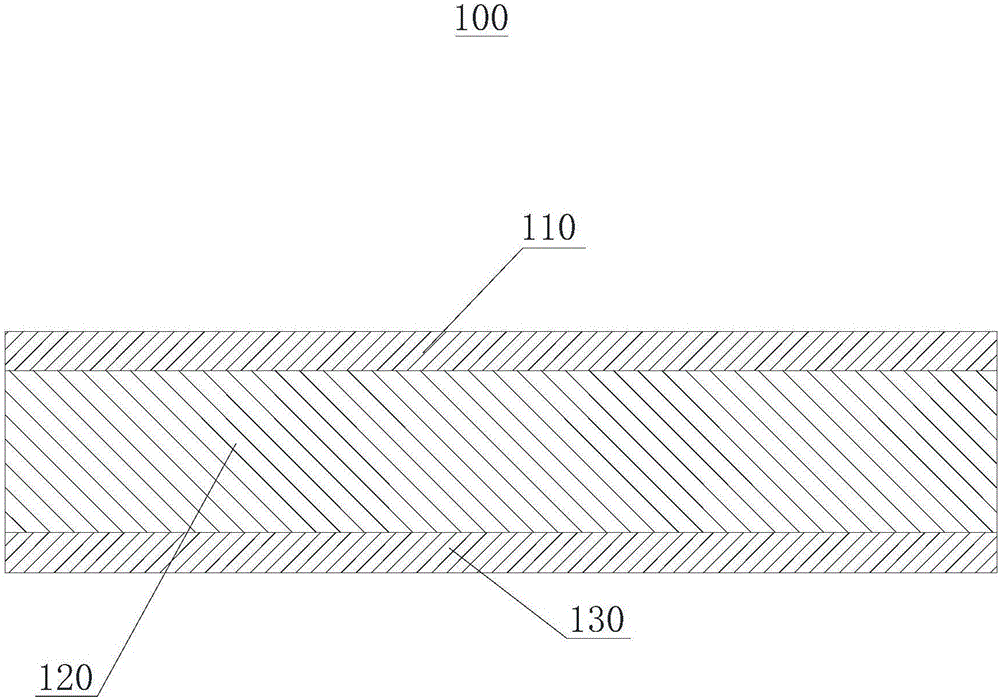

[0046] In this embodiment, a composite plastic sheet 100, such as figure 1 As shown, it includes a first composite layer 110 , a second composite layer 120 and a third composite layer 130 , and the second composite layer 120 is disposed between the first composite layer 110 and the third composite layer 130 . The first composite layer 110 is made of 82 parts by weight of polypropylene, 5 parts of metallocene polyolefin elastomer, 3 parts of polyethylene and 2 parts of color masterbatch. The second composite layer 120 is made of 78 parts by weight of polypropylene, 3 parts of metallocene polyolefin elastomer, 4 parts of polyethylene, 5 parts of filler and 2 parts of color masterbatch. The third composite layer 130 is made of 84 parts by weight of polypropylene, 6 parts of metallocene polyolefin elastomer, 4 parts of polyethylene and 3 parts of color masterbatch.

[0047] Wherein, the filler is formed by uniformly mixing 73 parts by weight of 2000 calcium carbonate and 21 parts...

Embodiment 2

[0055] In the present embodiment, a kind of composite plastic sheet 100, it is also such as figure 1 As shown, it includes a first composite layer 110 , a second composite layer 120 and a third composite layer 130 , and the second composite layer 120 is disposed between the first composite layer 110 and the third composite layer 130 . Both the first composite layer 110 and the third composite layer 130 are made of 85 parts by weight of polypropylene, 6 parts of metallocene polyolefin elastomer, 5 parts of polyethylene and 4 parts of color masterbatch. The second composite layer 120 is made of 80 parts by weight of polypropylene, 4 parts of metallocene polyolefin elastomer, 6 parts of polyethylene, 7 parts of filler and 3 parts of color masterbatch.

[0056] Wherein, the filler is formed by uniformly mixing 75 parts by weight of 2000 calcium carbonate and 24 parts of 1500 mesh starch.

[0057] The thickness ratio of the first composite layer 110 , the second composite layer 12...

Embodiment 3

[0063] In the present embodiment, a kind of composite plastic sheet 100, it is also such as figure 1 As mentioned above, it includes a first composite layer 110 , a second composite layer 120 and a third composite layer 130 , and the second composite layer 120 is disposed between the first composite layer 110 and the third composite layer 130 . Both the first composite layer 110 and the third composite layer 130 are made of 88 parts by weight of polypropylene, 8 parts of metallocene polyolefin elastomer, 6 parts of polyethylene and 5 parts of color masterbatch. The second composite layer 120 is made of 83 parts of polypropylene, 6 parts of metallocene polyolefin elastomer, 7 parts of polyethylene, 9 parts of filler and 5 parts of color masterbatch in parts by weight.

[0064] Wherein, the filler is formed by uniformly mixing 78 parts by weight of 2000 calcium carbonate and 27 parts of 1500 mesh starch.

[0065] The thickness ratio of the first composite layer 110 , the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com