An anti-molecular sieve pulverization oxygen production host adsorption tower

A molecular sieve and adsorption tower technology, applied in the field of anti-molecular sieve pulverization oxygen generator adsorption tower, can solve the problems of not monitoring the internal oxygen production in real time, reducing the service life of the oxygen generator, affecting the use effect and life, etc., to improve the product. Quality, simple structure, and the effect of reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

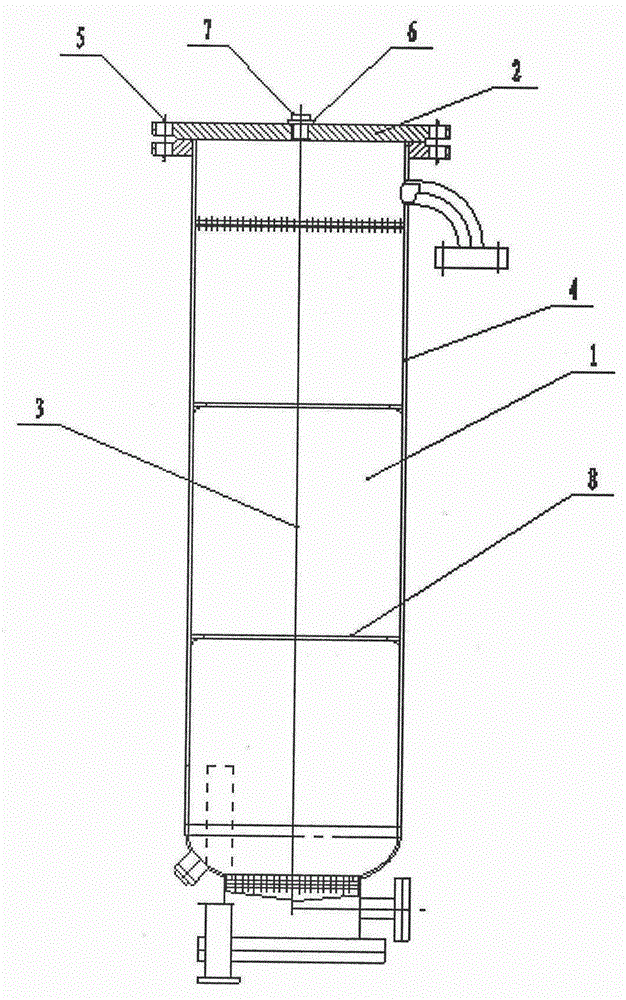

[0022] Such as figure 1 As shown in the figure, an adsorption tower for preventing molecular sieve pulverization and oxygen production main engine includes: cylinder 1, upper cover 2, molecular sieve 3, molecular sieve 3 is installed inside cylinder 1, upper cover 2 is installed on the upper part of cylinder 1, and molecular sieve 3 passes through The upper and lower flower plates 8 are fixed inside the cylinder body 1. The upper part of the cylinder body 1 is exactly the same as the cylinder body 4. The upper part of the cylinder body 1 and the upper cover 2 are fixed by bolts 5. There is a threaded hole 6 in the center of the upper cover 2. , A plug 7 is installed in the threaded hole 6, and the plug 7 is a hollow bolt inside.

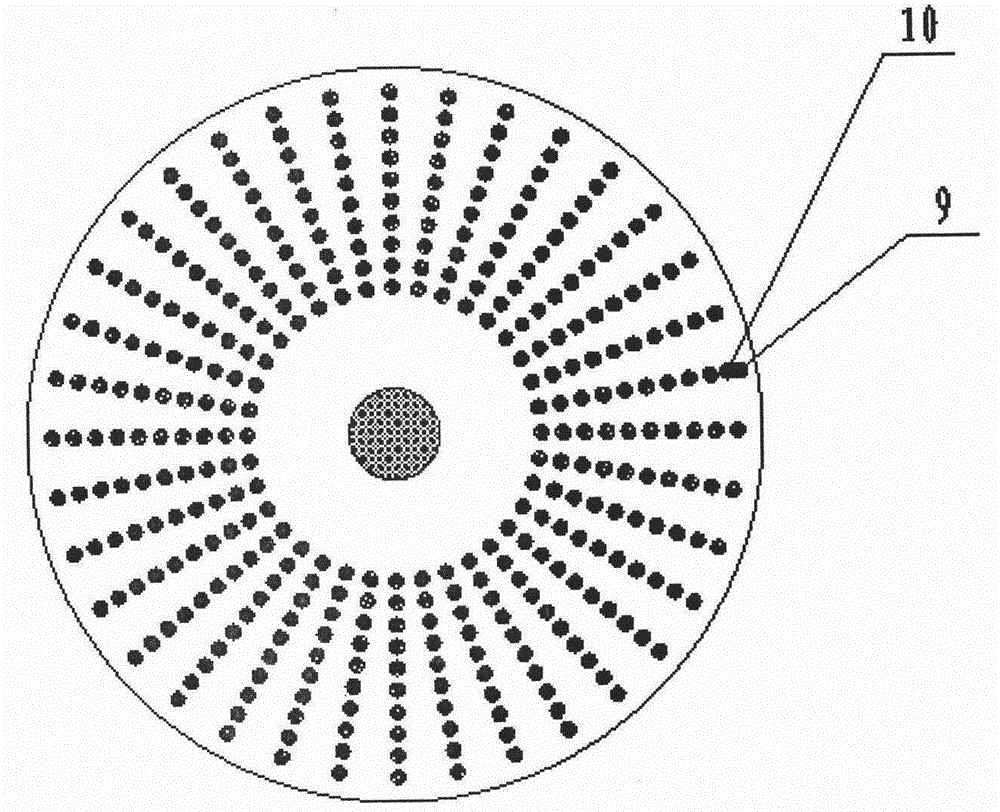

[0023] Such as figure 2 As shown, the flower plate 8 is provided with a small hole 9 allowing air to flow freely, and the inside of the small hole 9 is filled with a silk screen 10 .

[0024] see figure 1 figure 2 , the present invention mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com