Patents

Literature

31results about How to "Reduced reload time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

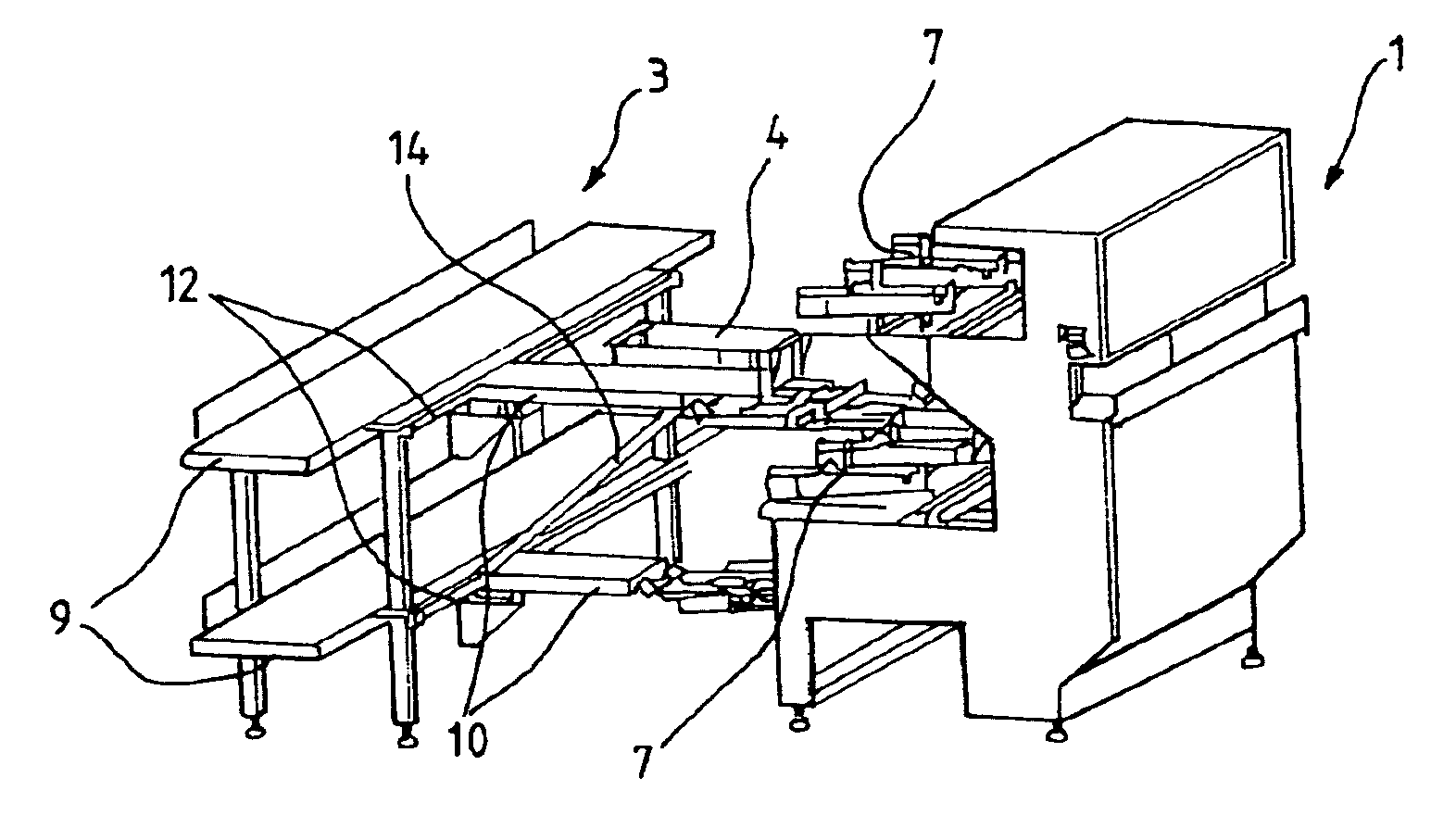

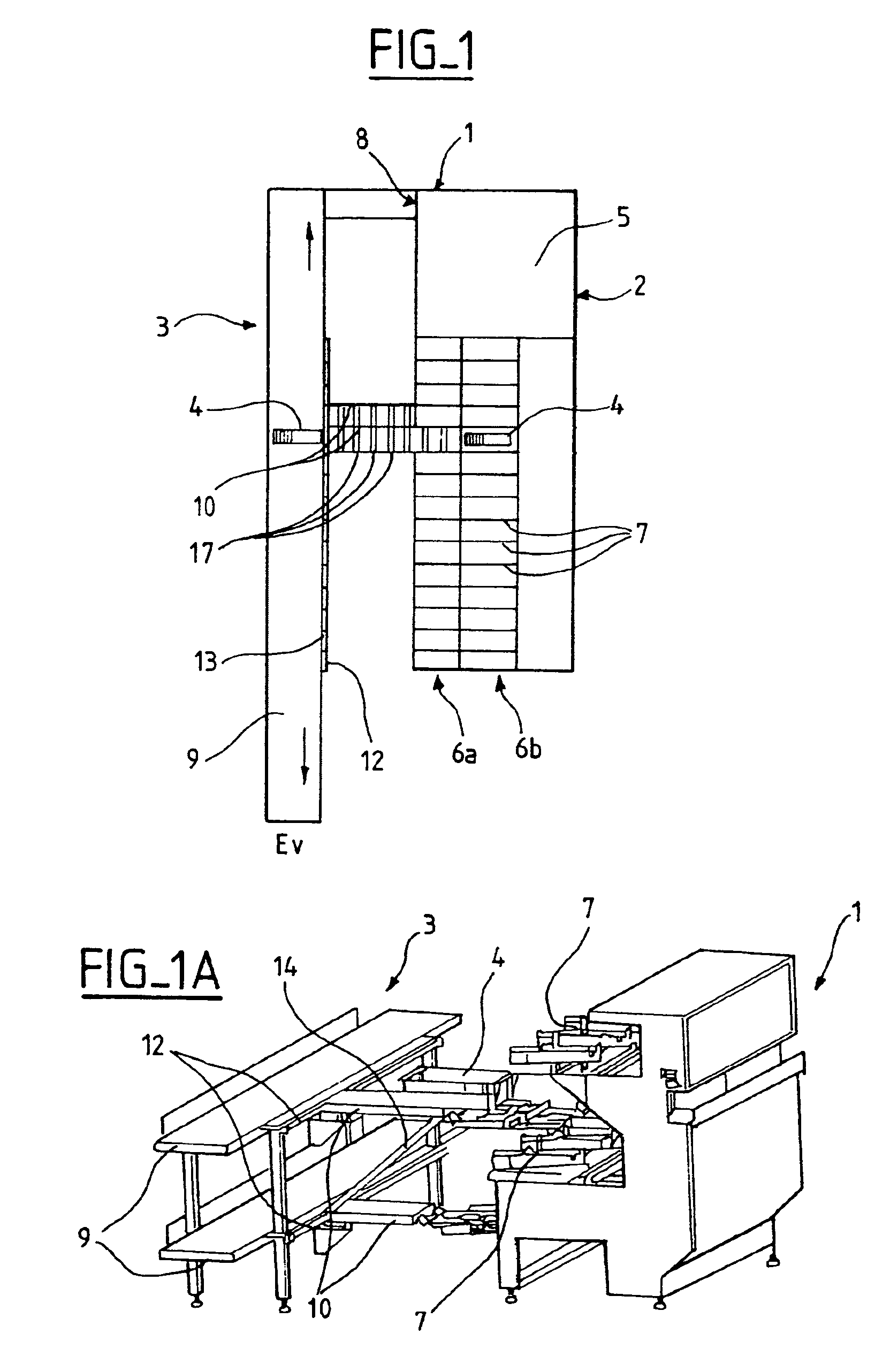

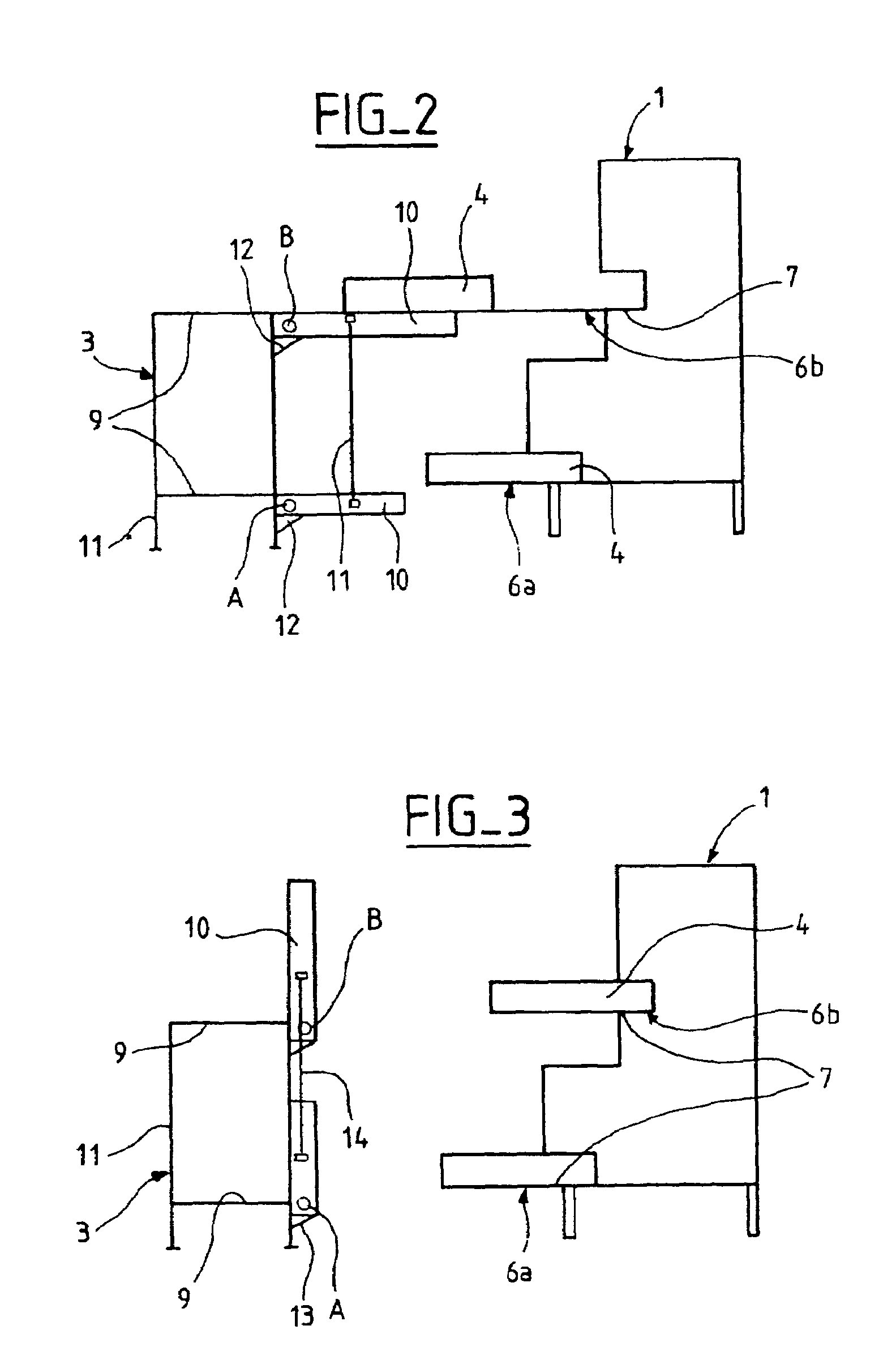

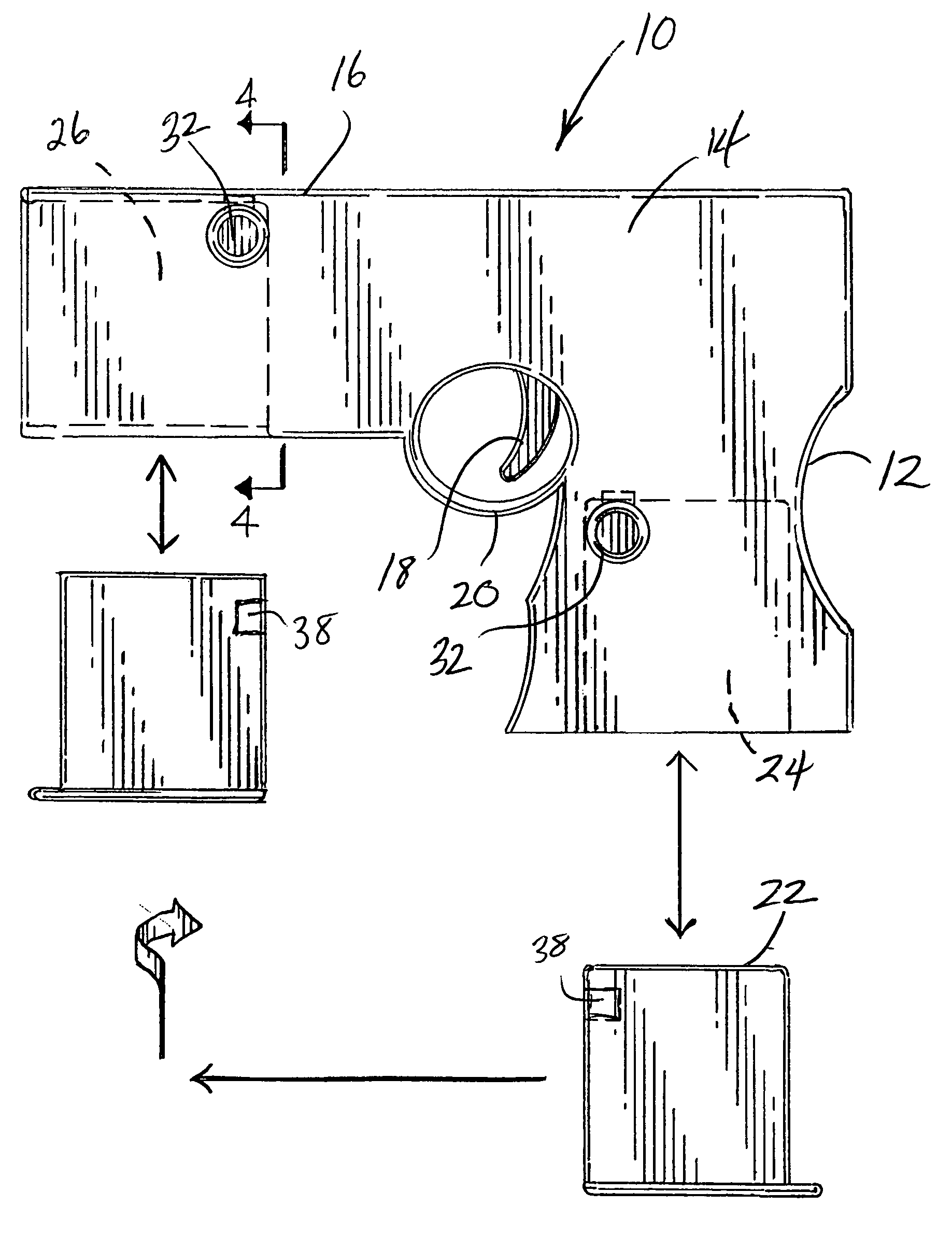

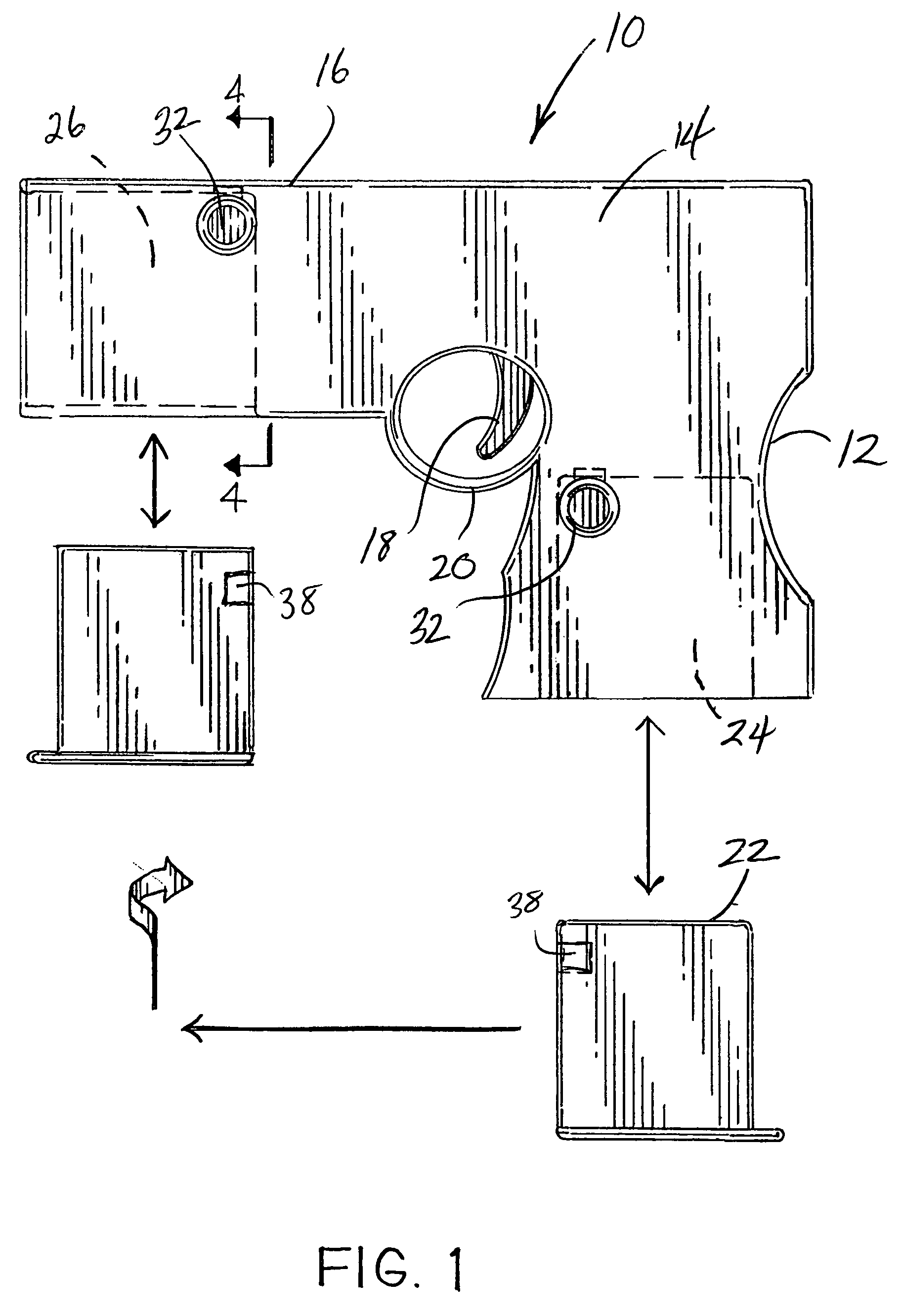

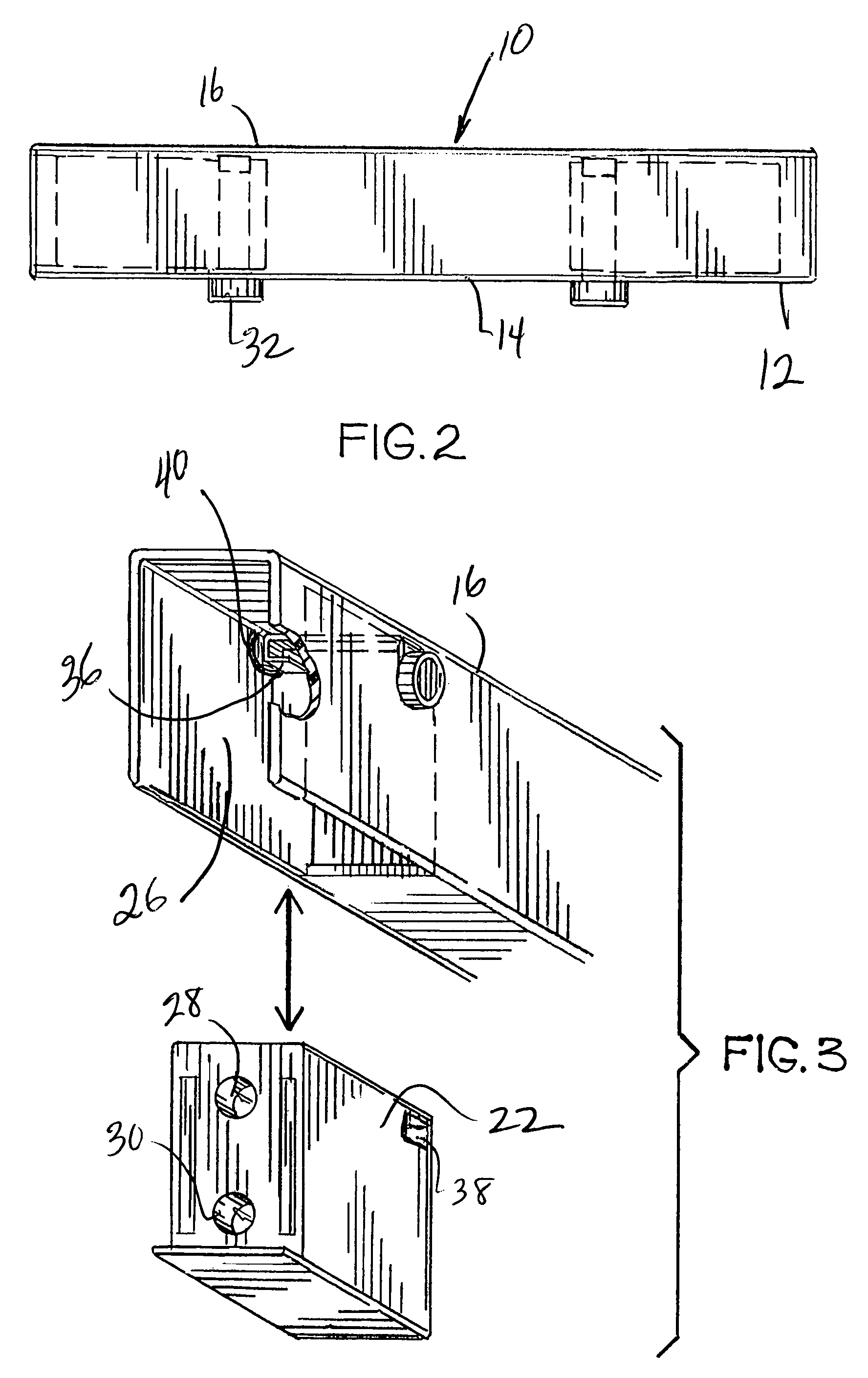

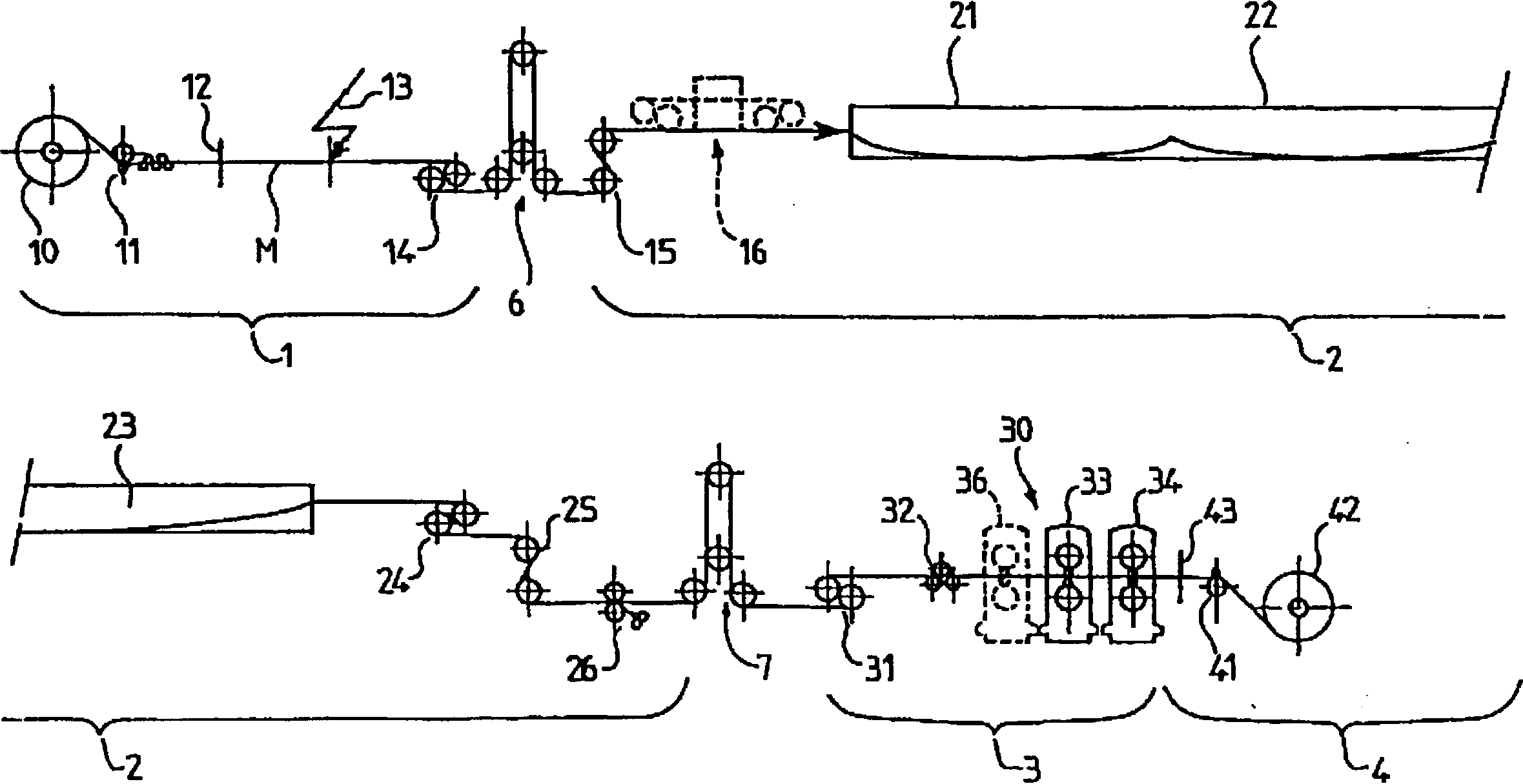

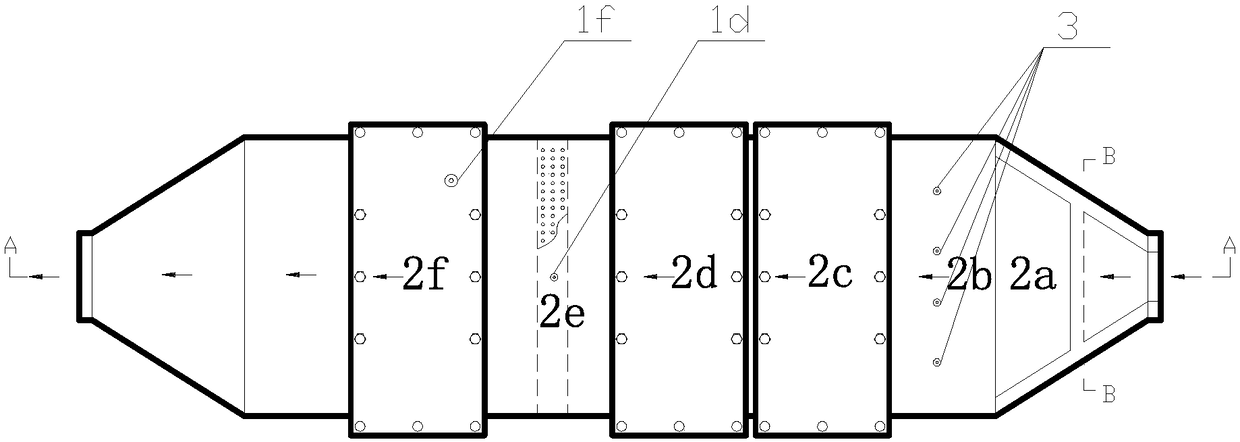

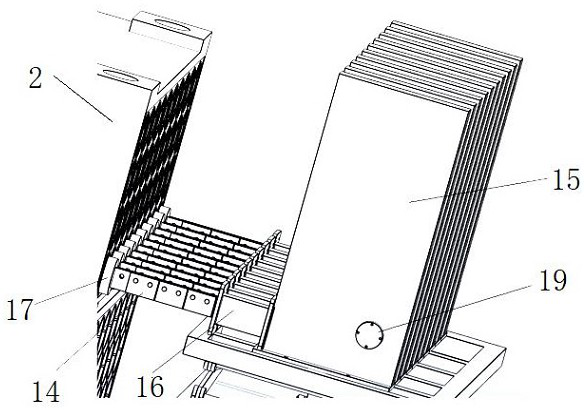

Postal sorting machine including a bin-transfer structure

InactiveUS7080739B2Minimizes manual operationReduced reload timeCharacter and pattern recognitionSortingEngineering

A postal sorting machine (1) comprises sort outlets (7) distributed in one or more horizontal rows that are superposed and parallel. A bin transfer structure (3) is placed along said rows of sort outlets (7), said transfer structure (3) comprising one or more superposed bin conveyors (9) extending parallel to respective rows of sort outlets and one or more superposed gangways (10) that are movable along the rows of sort outlets (7), each extending between a row of sort outlets (7) and a corresponding bin conveyor (9) to enable at least one storage bin (4) to be transferred from a sort outlet (7) to a corresponding bin conveyor (9).

Owner:SOLYSTIC

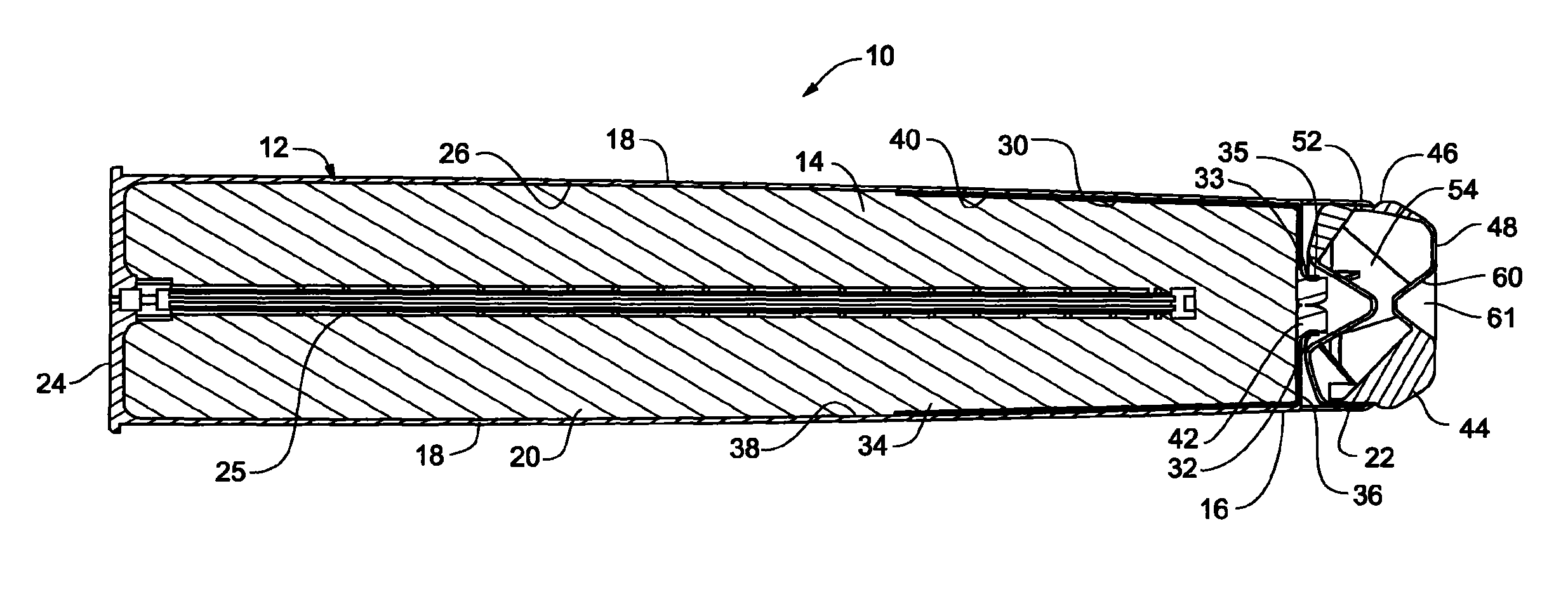

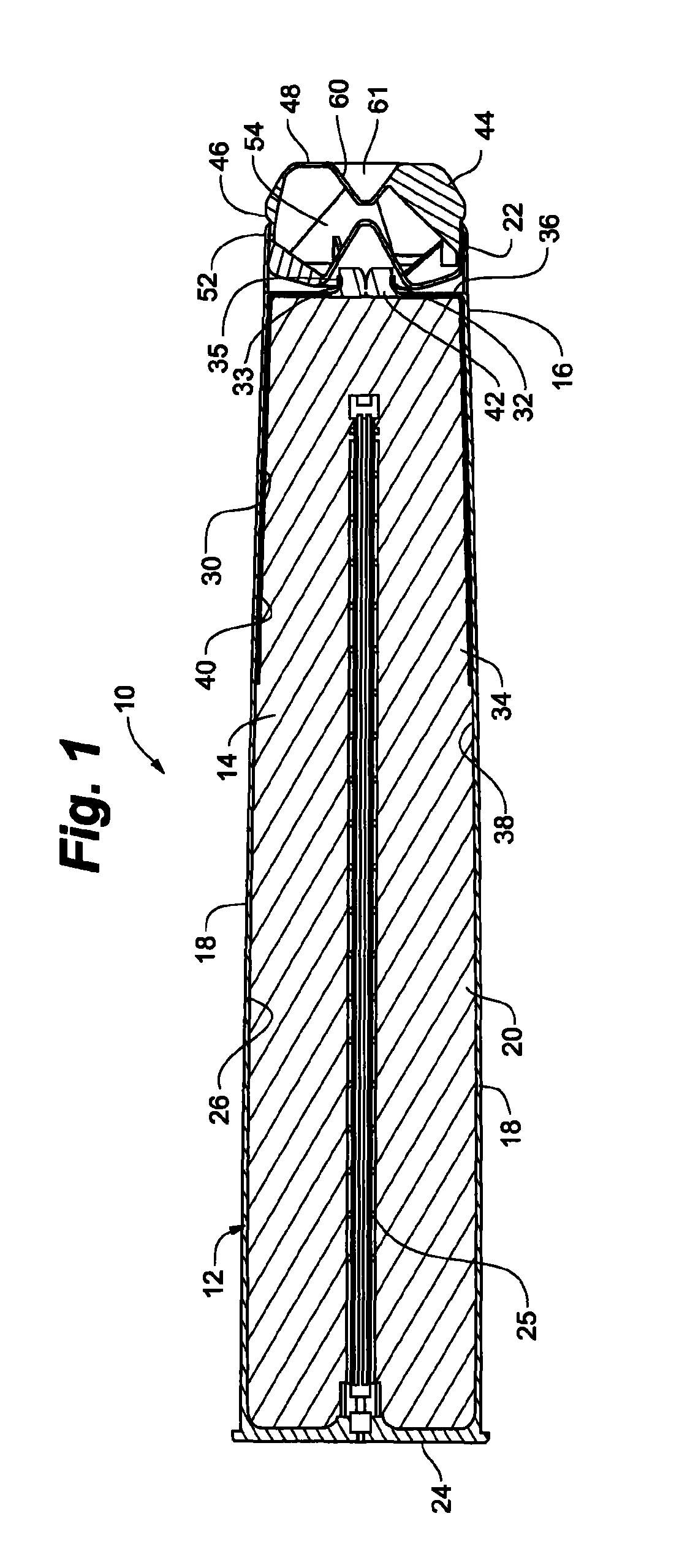

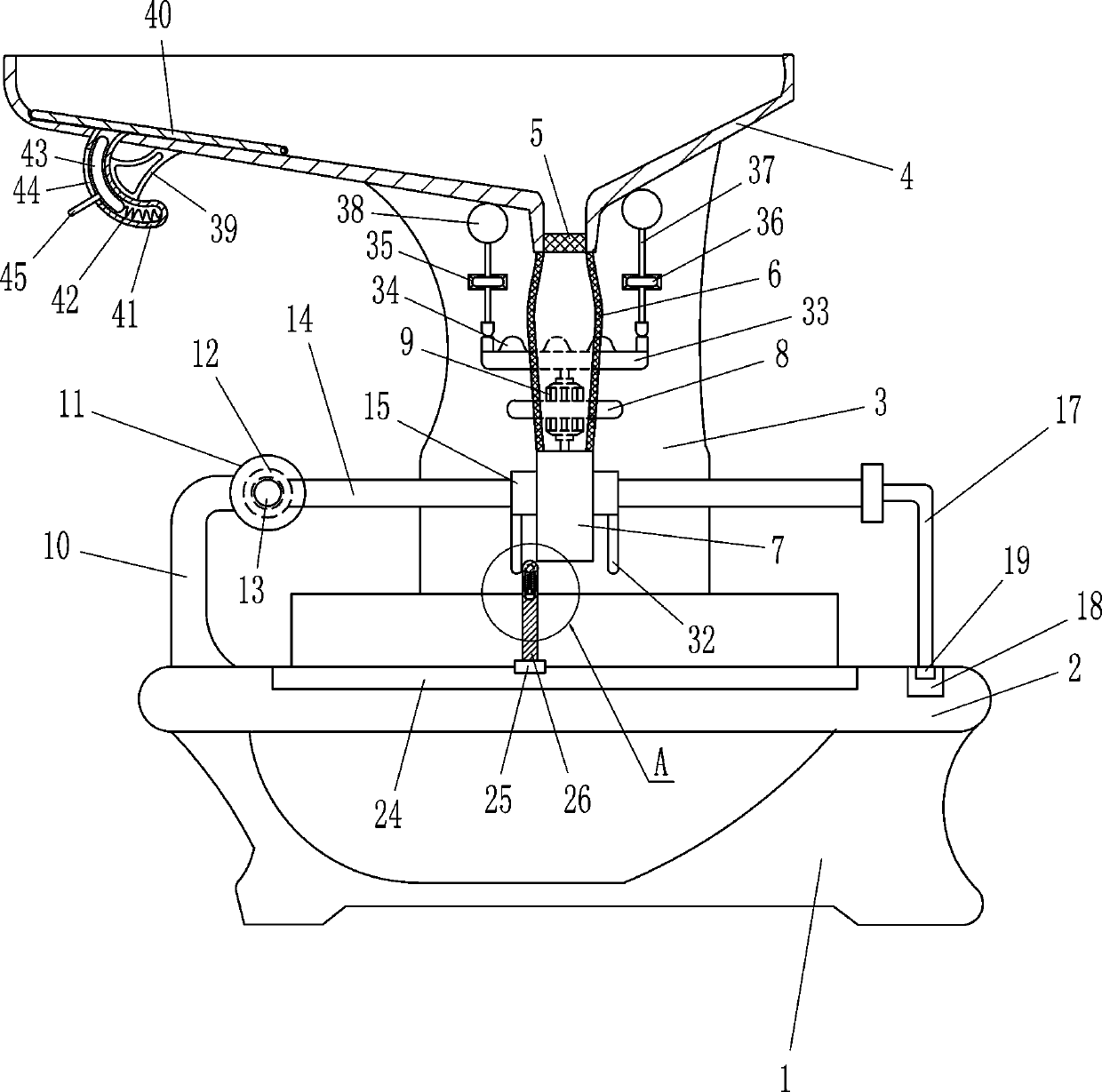

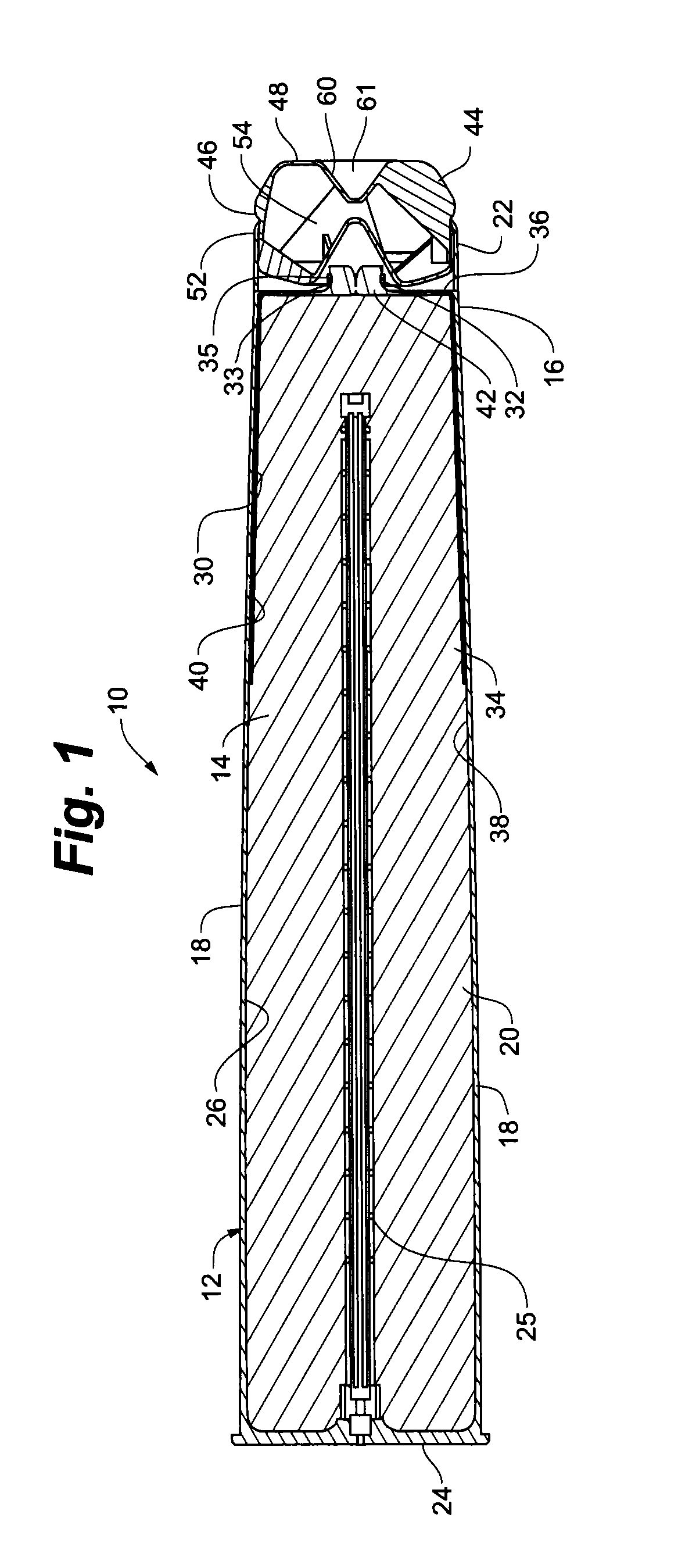

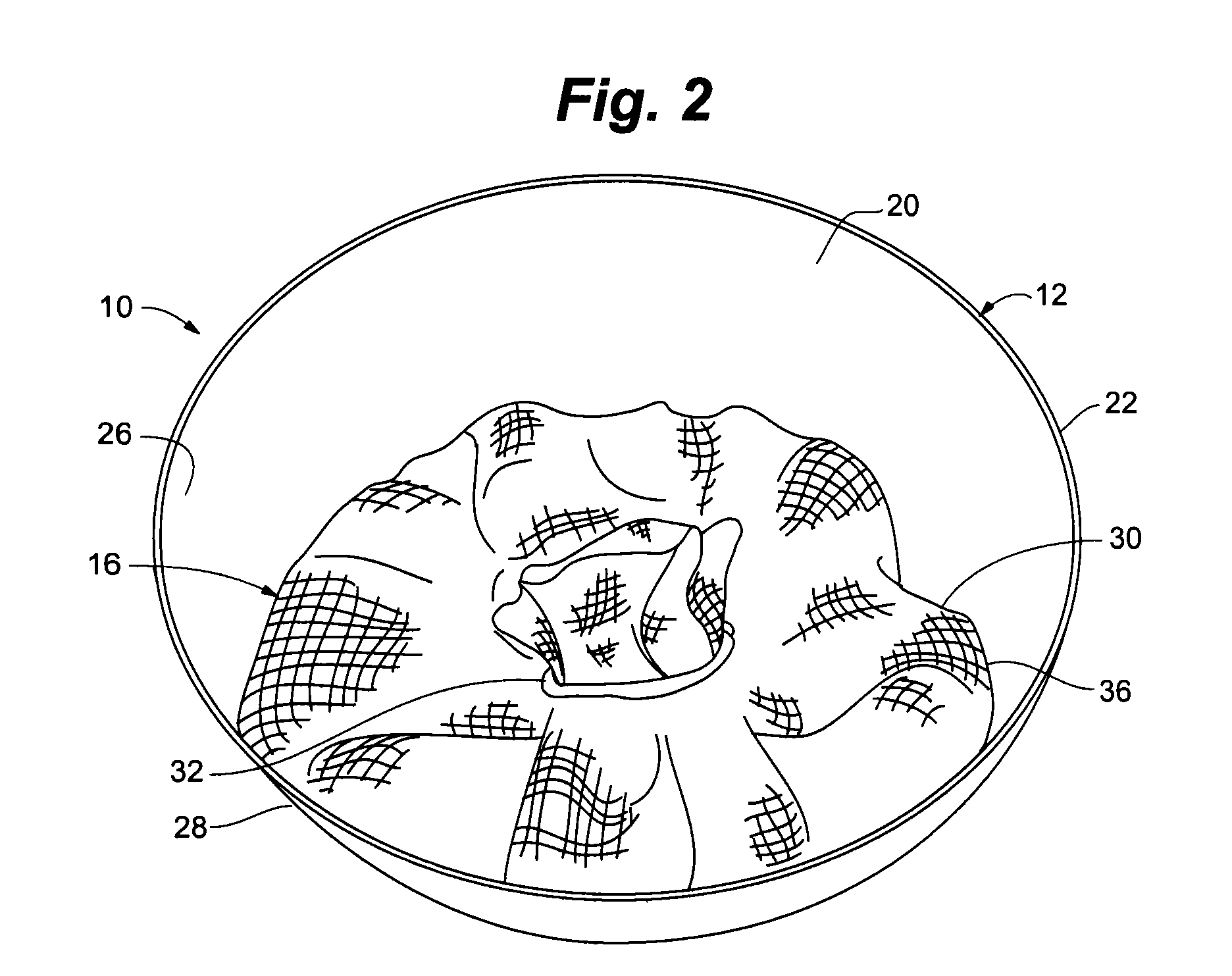

Non-lethal electrical discharge weapon having a bottom loaded cartridge

InactiveUS8015905B2Reduced reload timeShorten the timeAircraft componentsAmmunition projectilesTaserMechanical engineering

Owner:PARK SAMUEL SUNG WAN

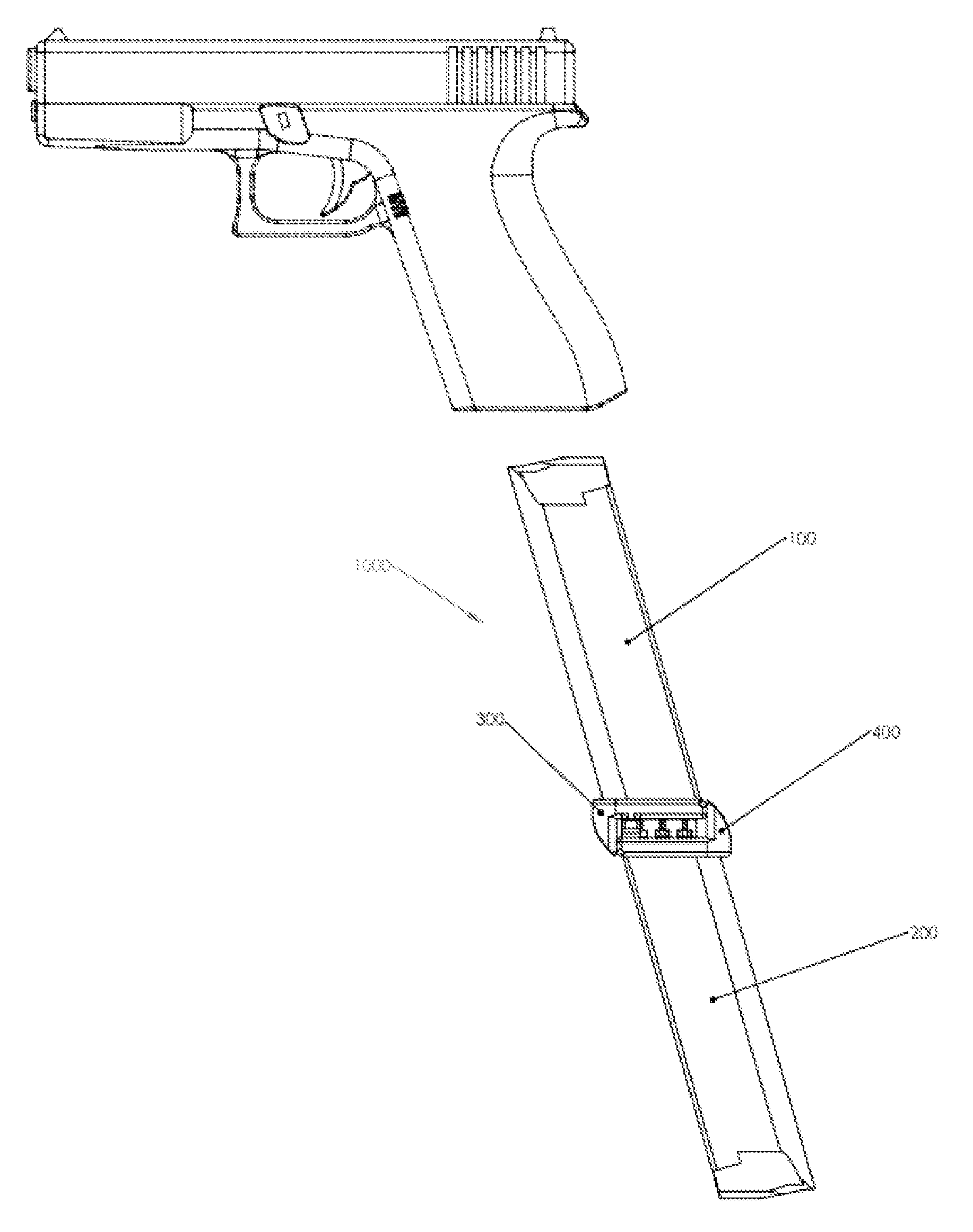

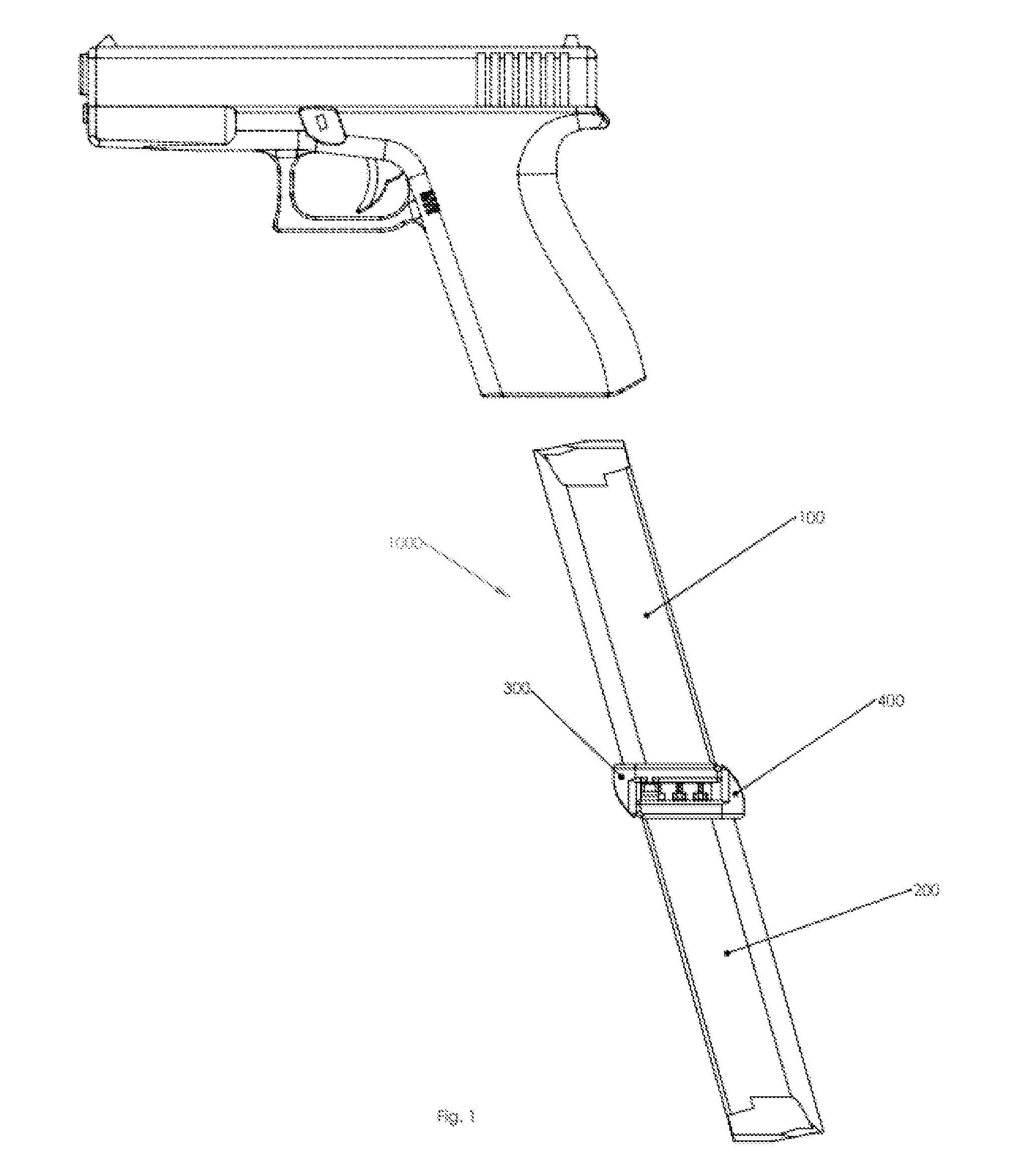

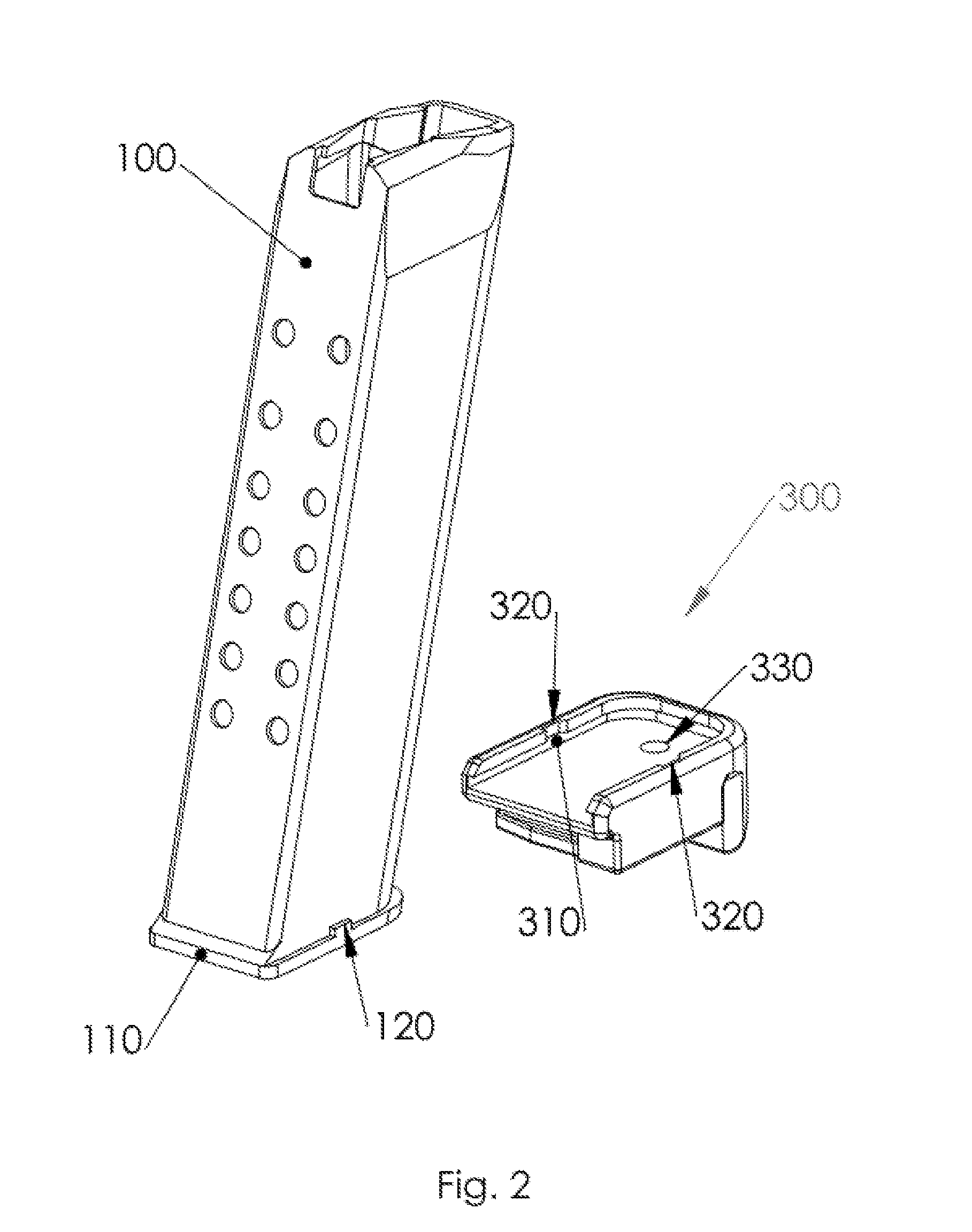

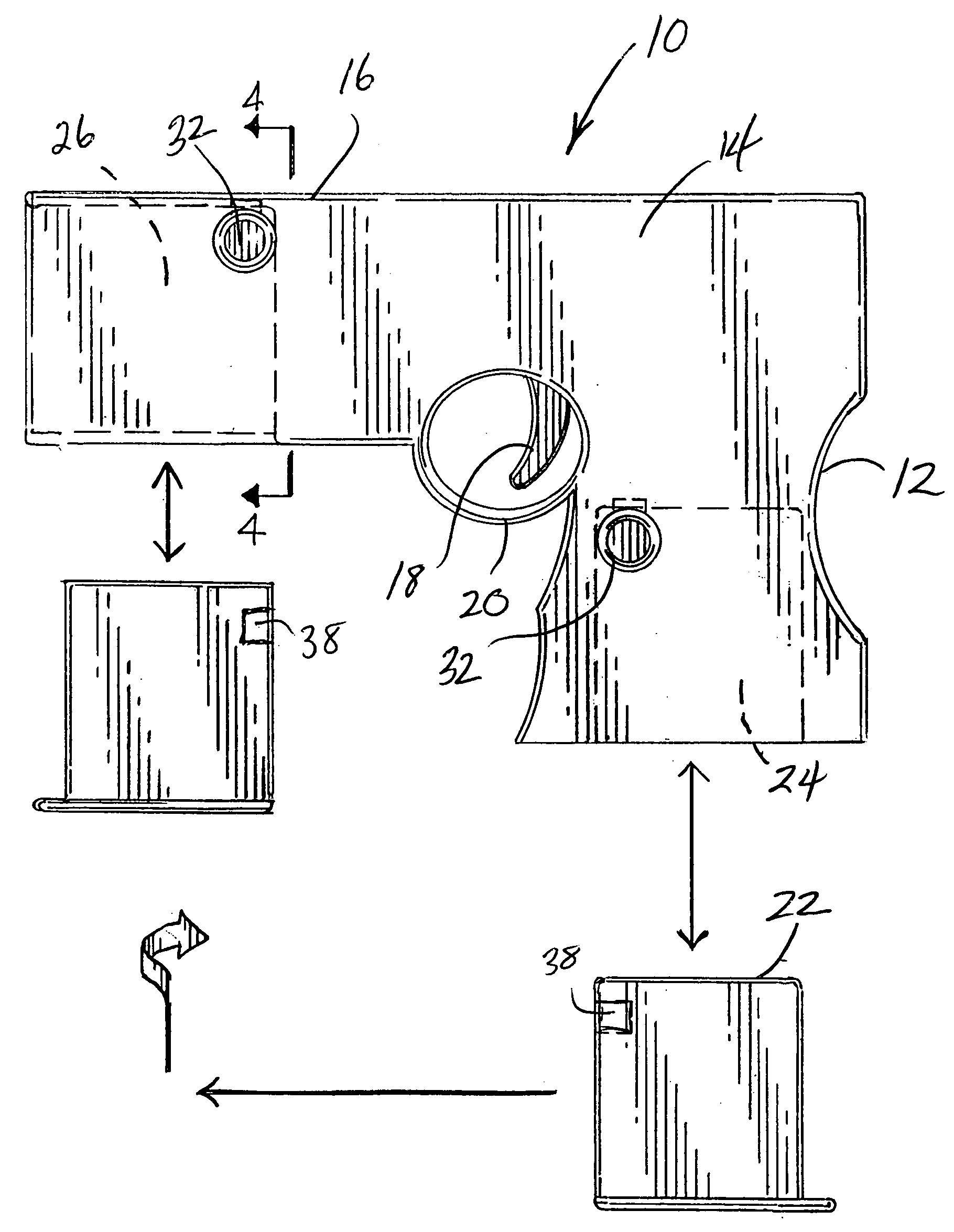

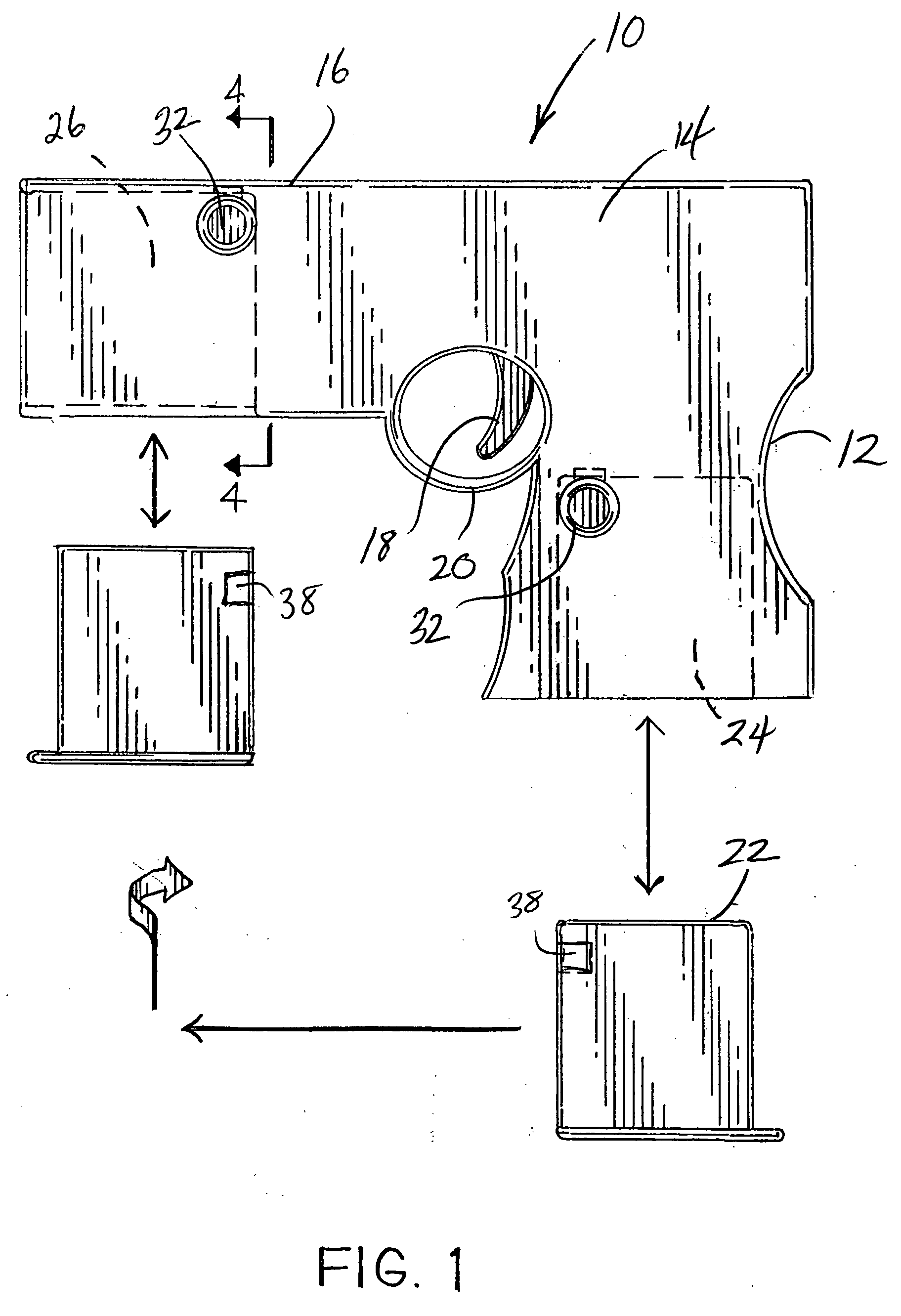

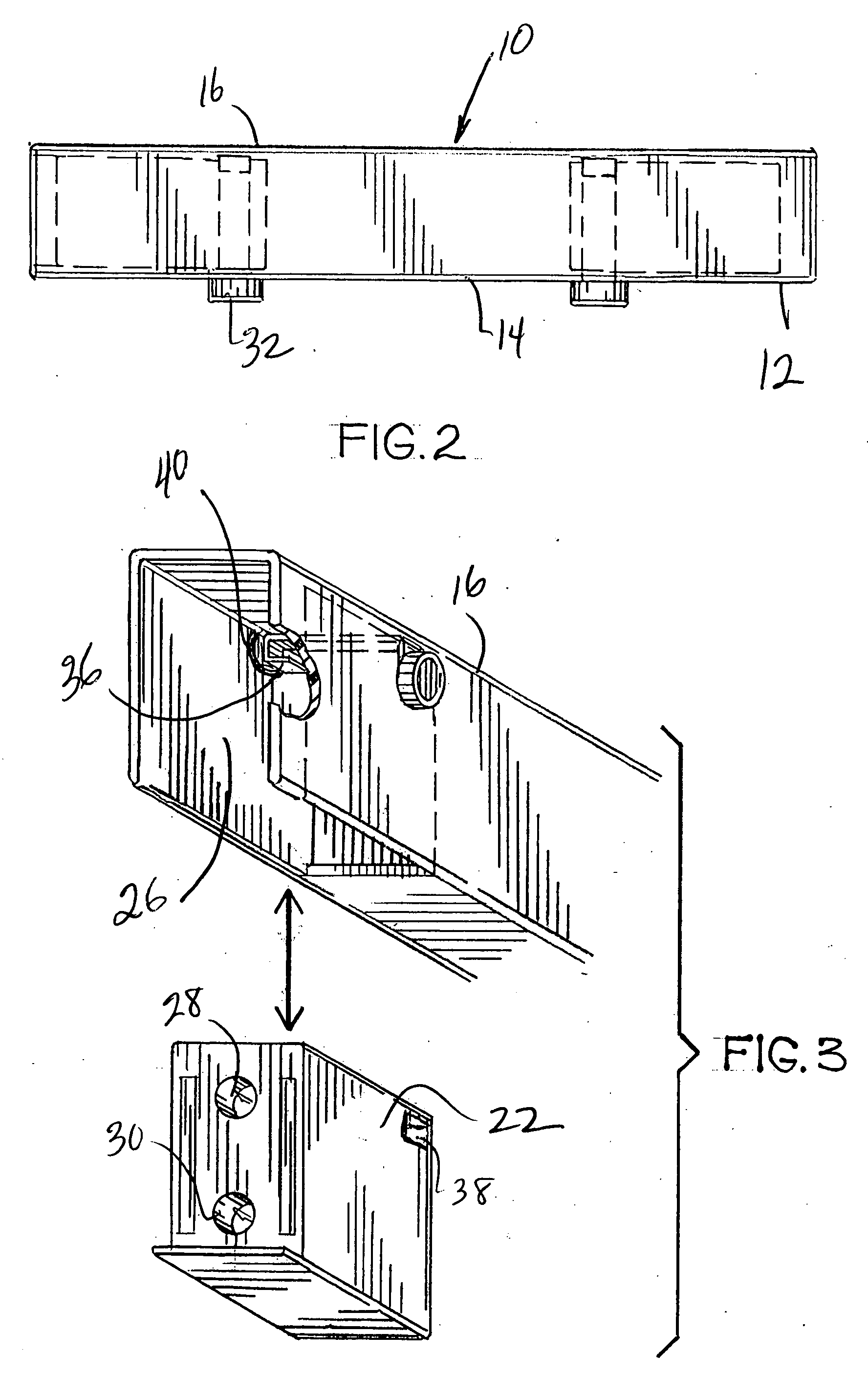

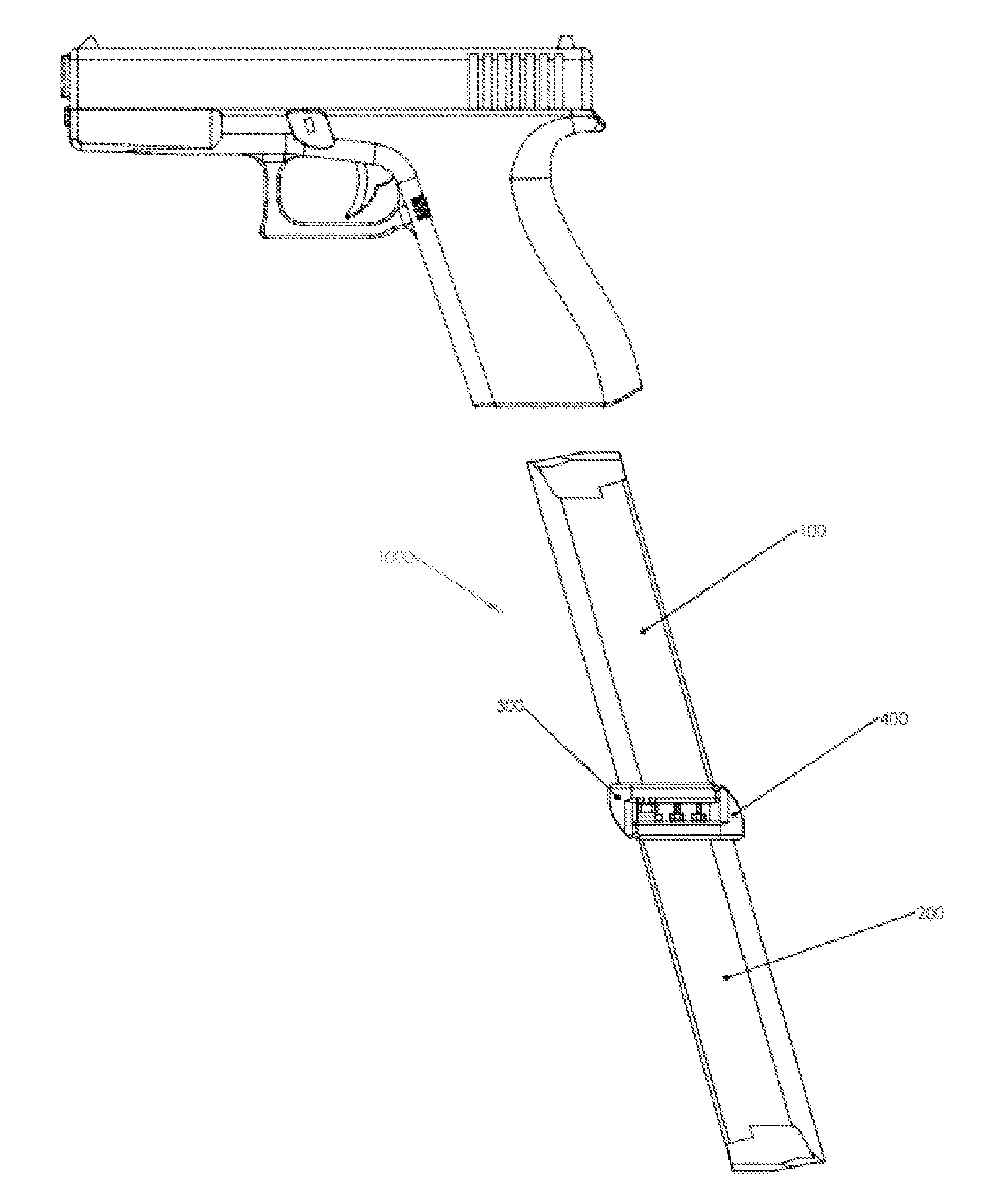

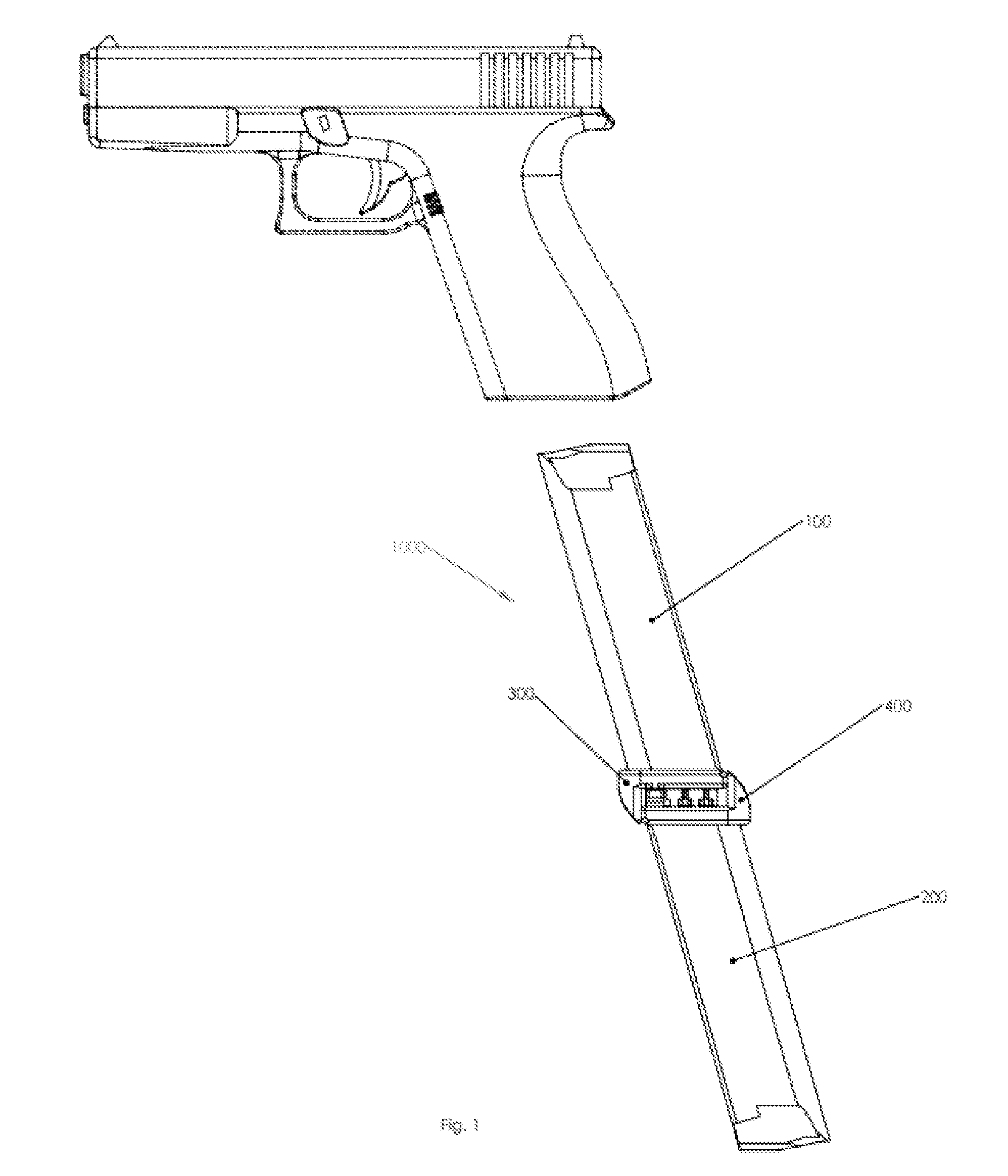

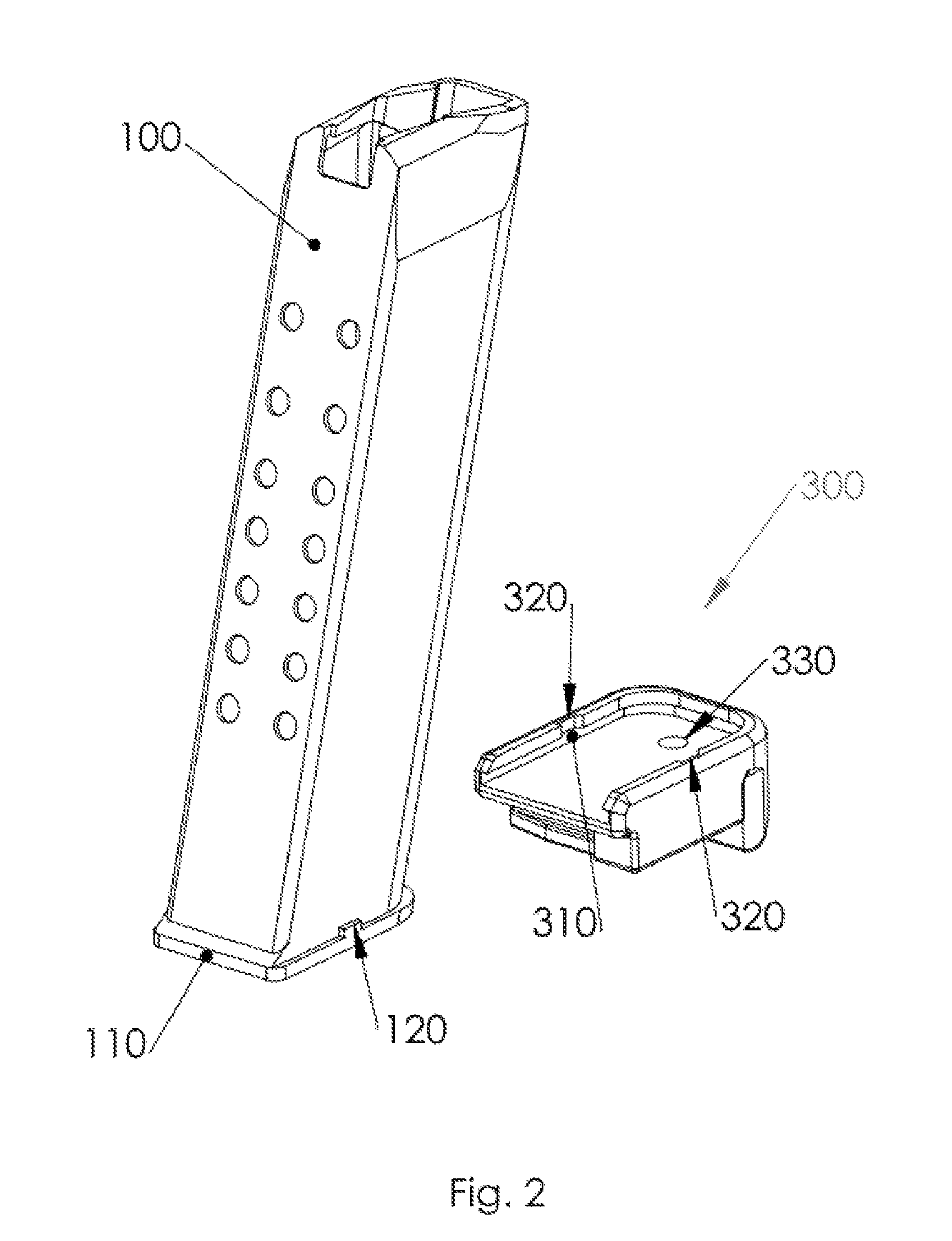

Dual Magazine Assembly

ActiveUS20160003567A1Shorten reloading timeEasy to assemble and disassembleAmmunition loadingMechanical engineeringEngineering

An dual magazine assembly that has many novel features desirable by modern military and law enforcement professionals that consists of two magazine adaptors that replace the standard bottom magazine plates of a firearm. These adaptors once mated with identical magazine housings can then be quickly attached to each other in order to shorten the magazine reloading time by rotating the spent primary magazine towards the bottom and inserting the secondary magazine thus doubling the capacity and allowing for faster firing of rounds from the secondary magazine.

Owner:PURKISS JOSHUA

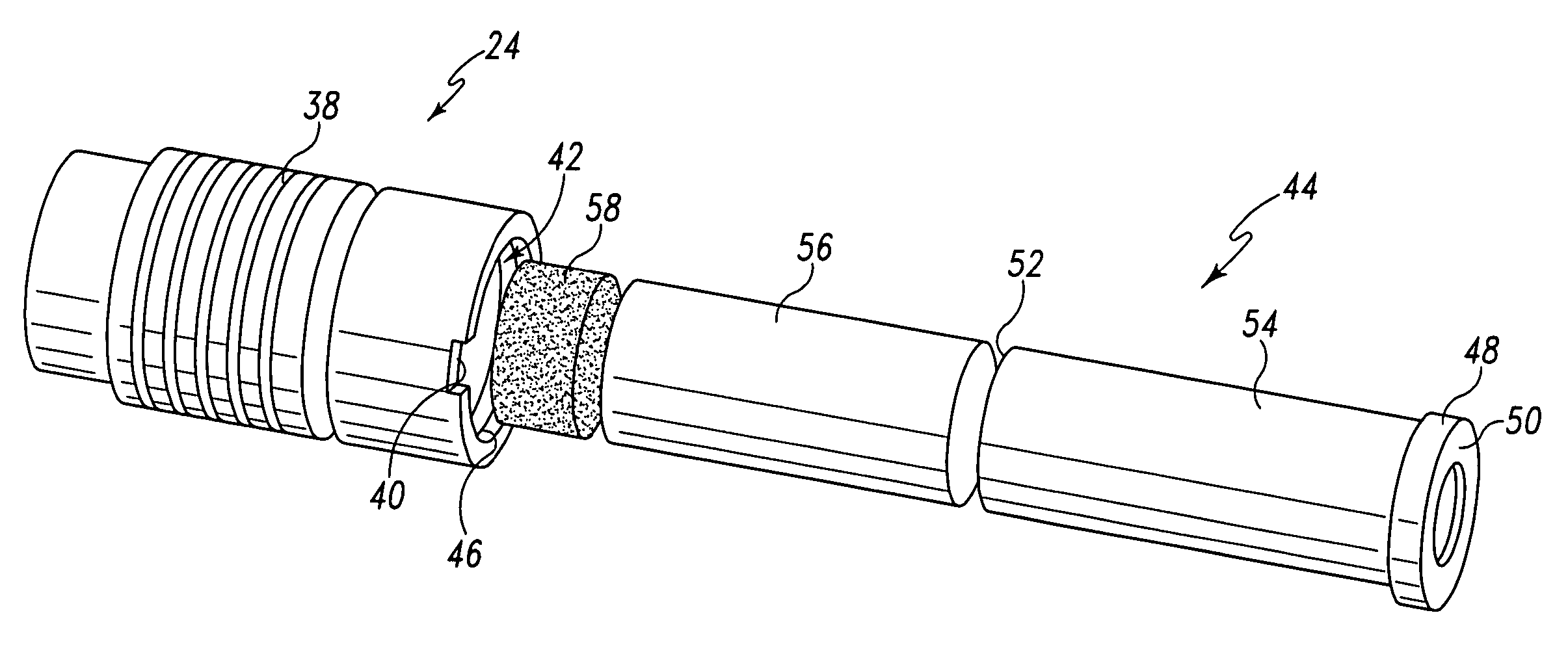

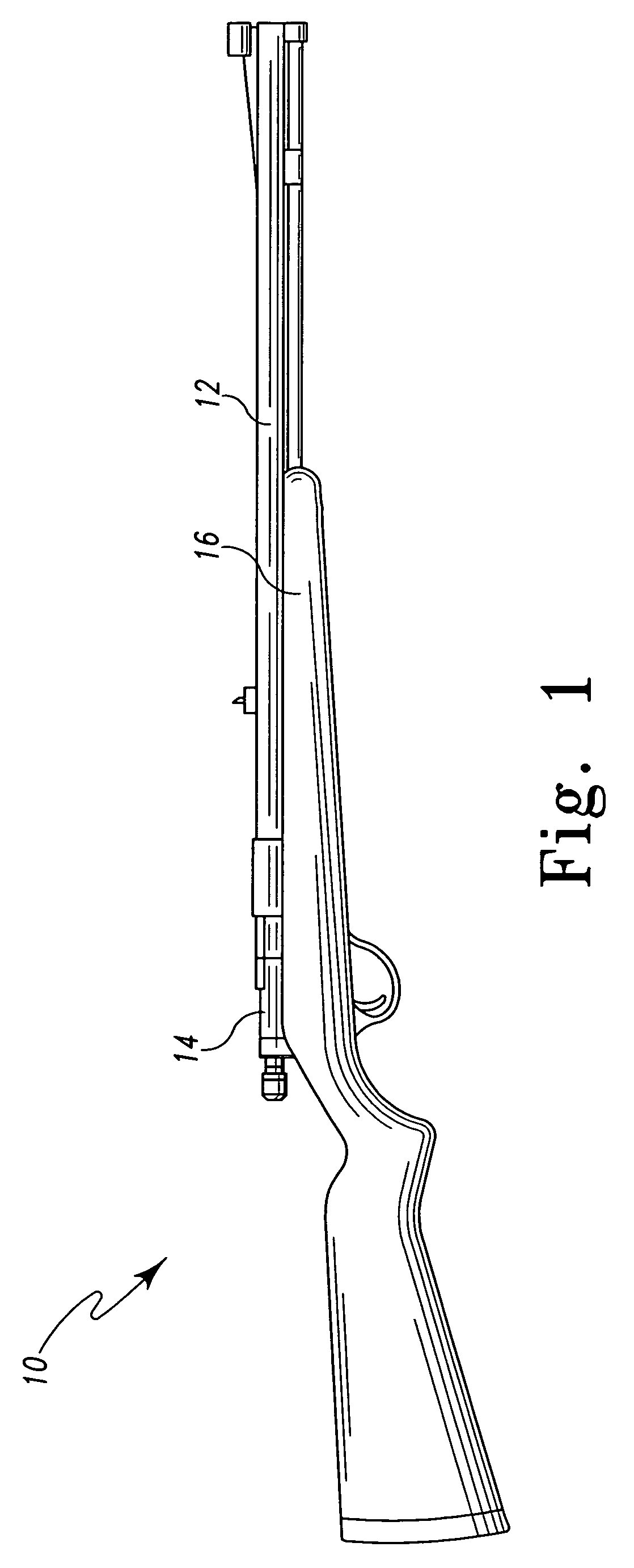

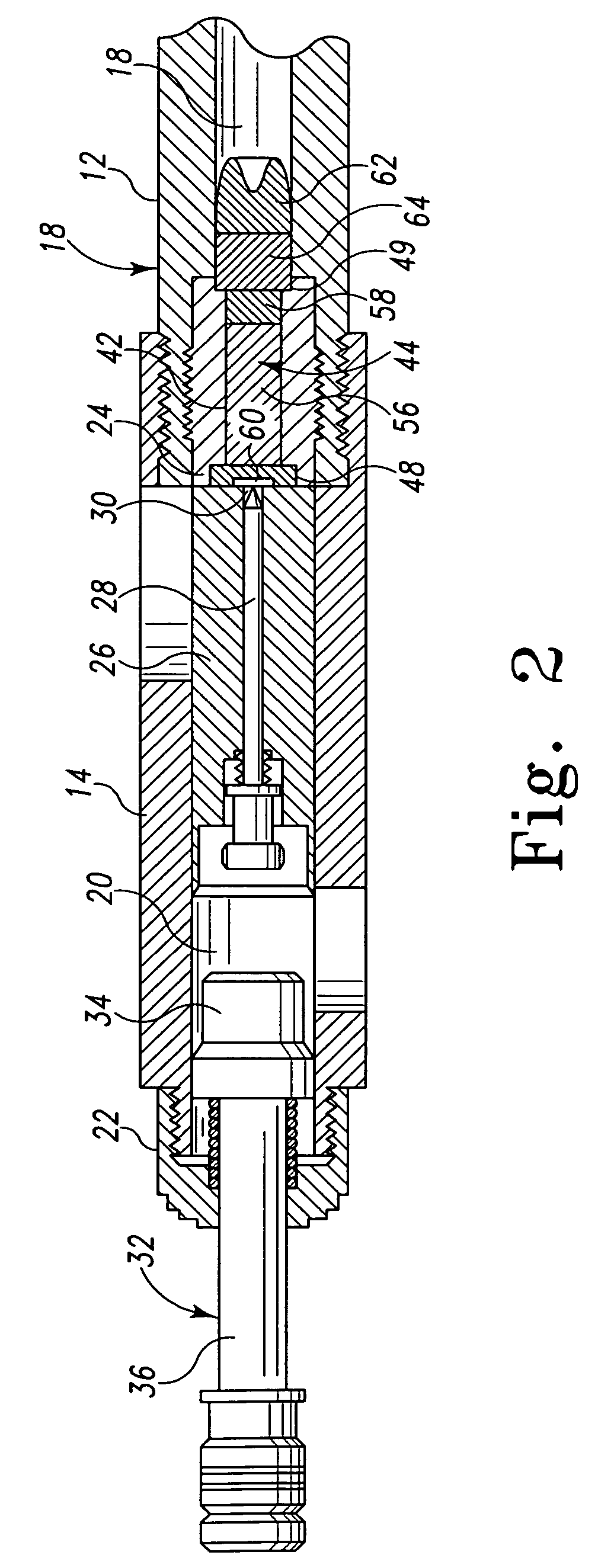

System for loading a muzzle-loading firearm with smokeless or black powder

InactiveUS20060086029A1Reduce maintenanceEliminates potentialMuzzle-loading smallarmsShoulder-fired smallarmsEngineeringMechanical engineering

The present invention discloses a method and system of loading an in-line muzzle-loading firearm. A projectile is rammed into a muzzle end of a barrel of the in-line muzzle-loading firearm such that a bottom portion of the projectile is adjacent or in close proximity with the breech end of a breech plug. A pre-measured powder cartridge is then inserted within a cartridge receiving bore of the breech plug such that a forward end of the pre-measured powder cartridge is adjacent a bottom portion of the projectile and a rim of the cartridge engages a first annular lip of the breech plug. The cartridge may then be secured within the breech plug by action of a bolt mechanism or a break open receiver mechanism.

Owner:KIRKJACK HLDG

Non-lethal electrical discharge weapon having a bottom loaded cartridge

InactiveUS20060225333A1Shorten the timeImprove loading timeAmmunition projectilesElectrical apparatusEngineeringTaser

The present invention comprises a pistol-shaped Taser™-type weapon wherein the cartridge containing a pair of the wire-tethered darts is loaded into the cartridge receiving chamber from beneath the weapon, that is, in an upward movement of the cartridge with the weapon pointed toward the target. This type of loading is referred to herein as a “bottom loading” mechanism or system. The bottom loading mechanism of the present invention has significant advantages over conventional cartridge loading designs. One advantage is reduced reload time.

Owner:PARK SAMUEL SUNG WAN

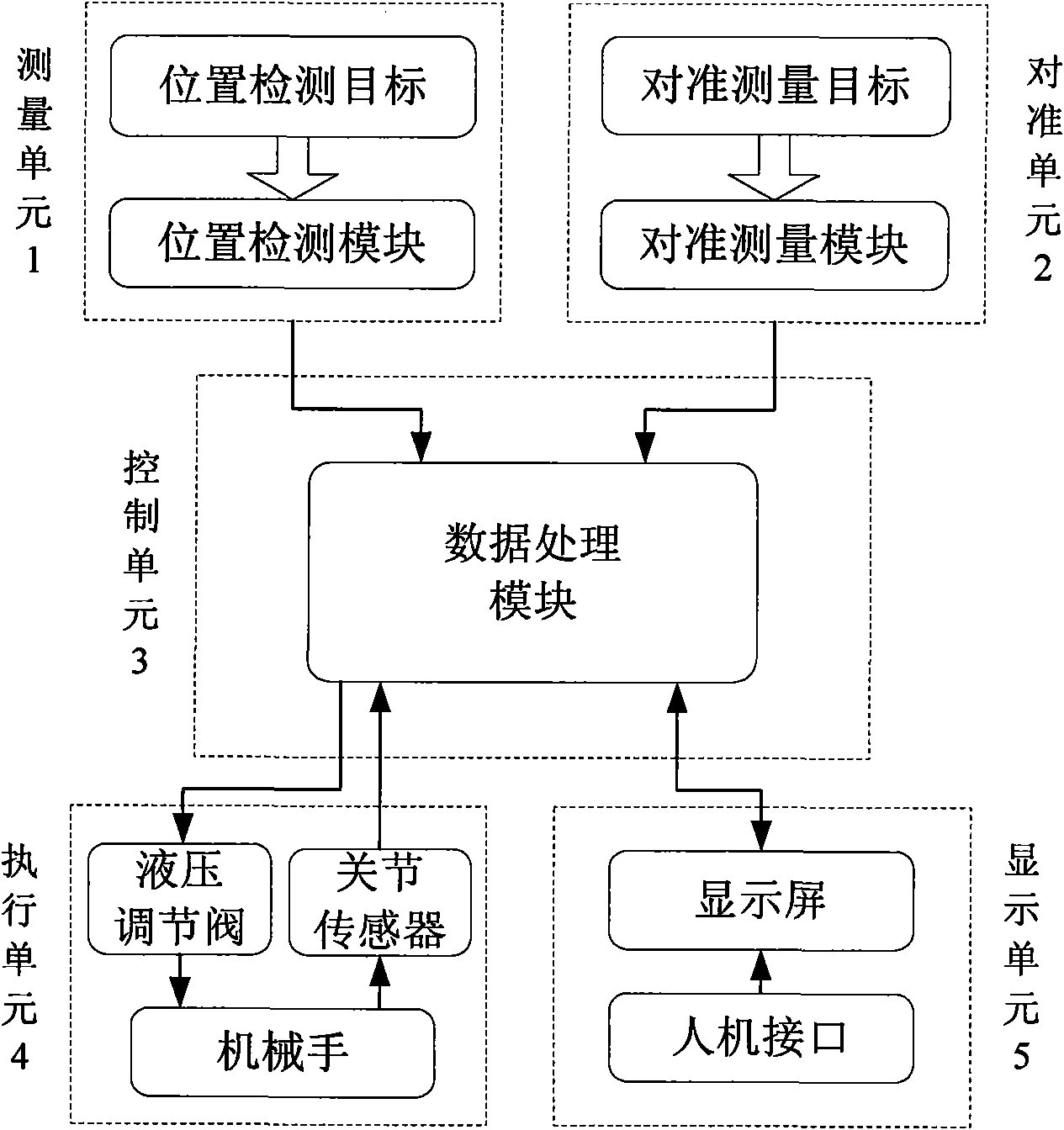

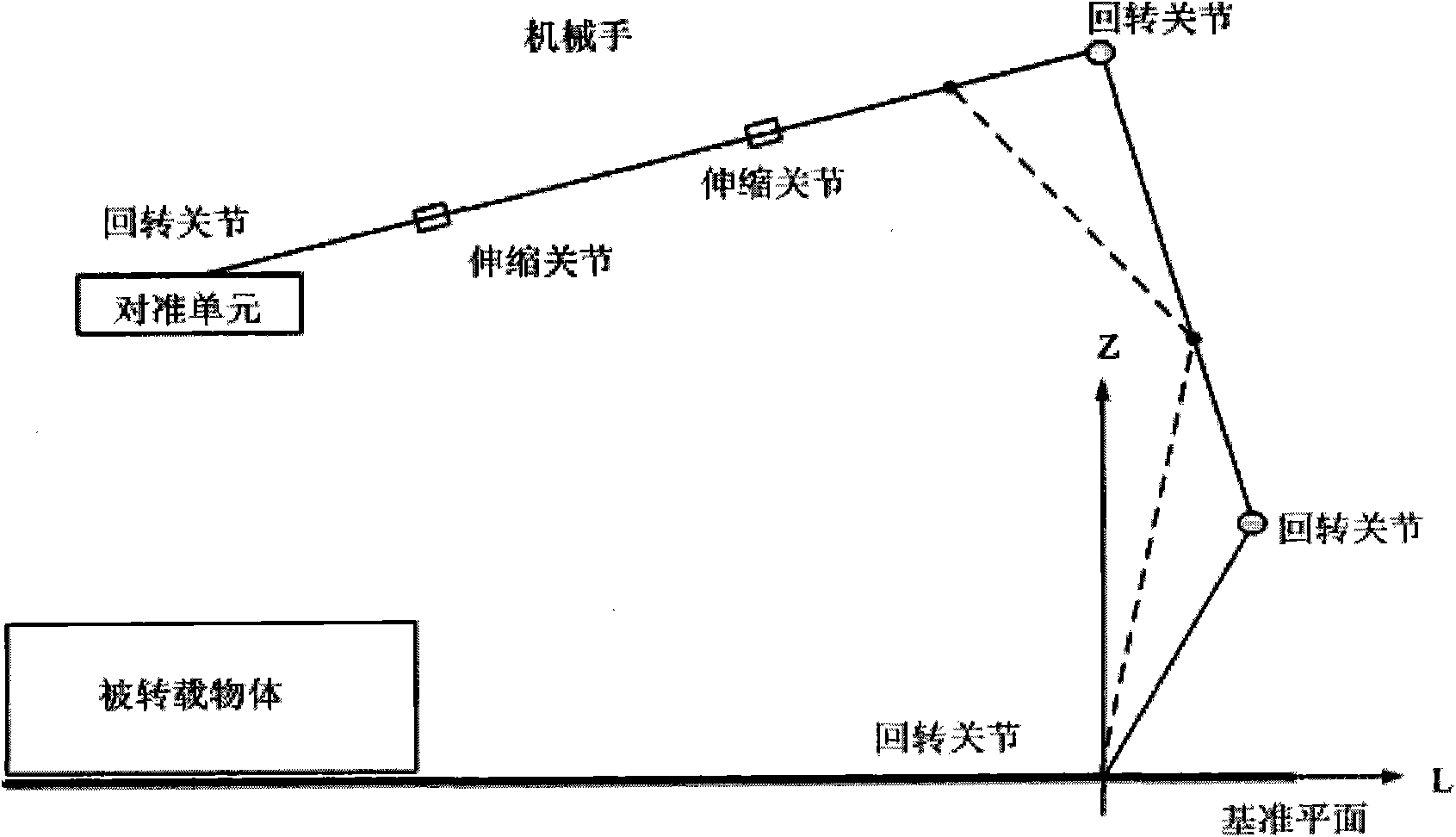

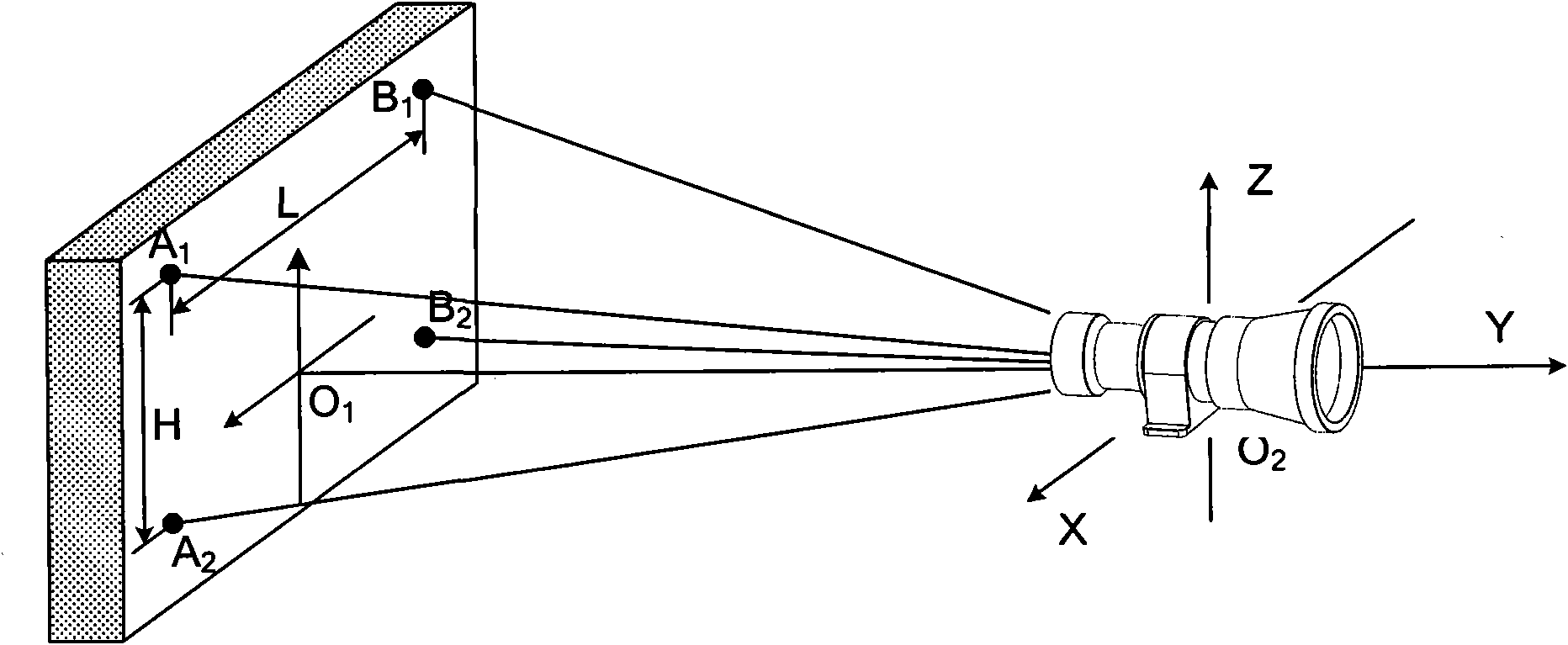

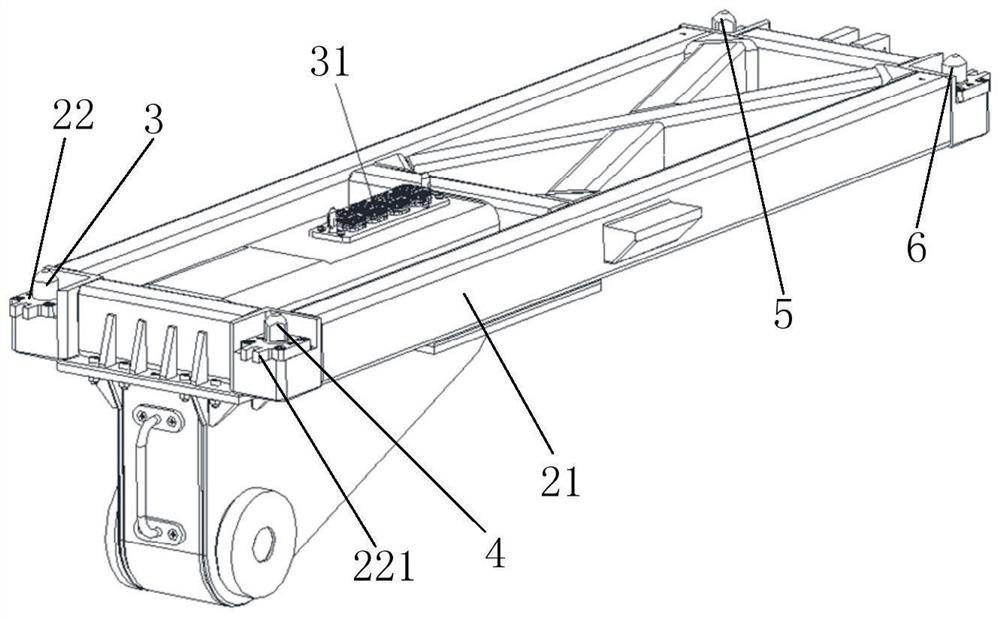

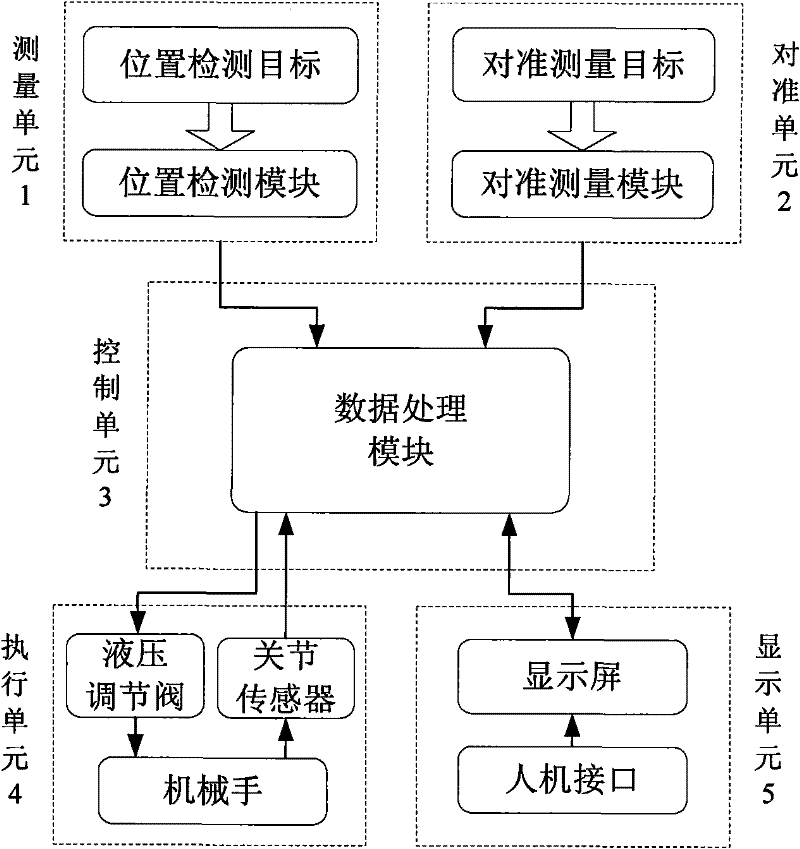

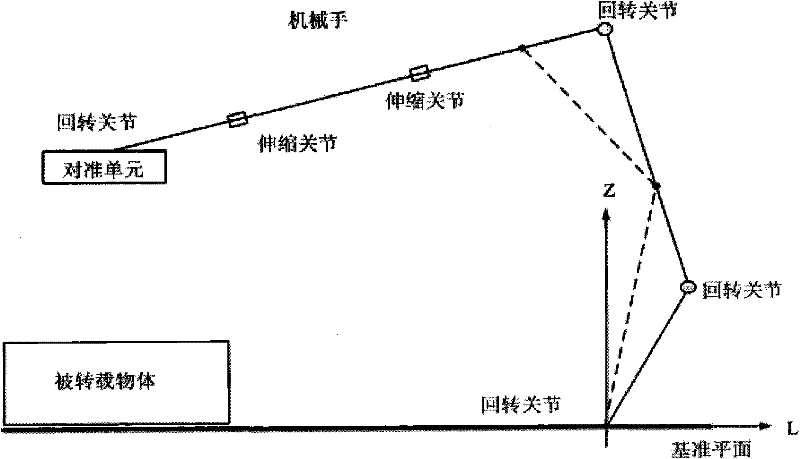

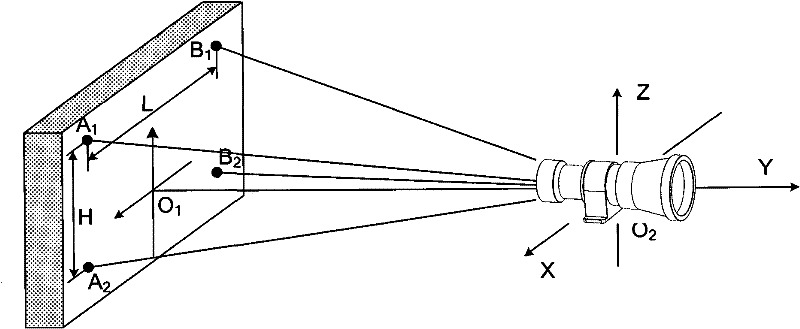

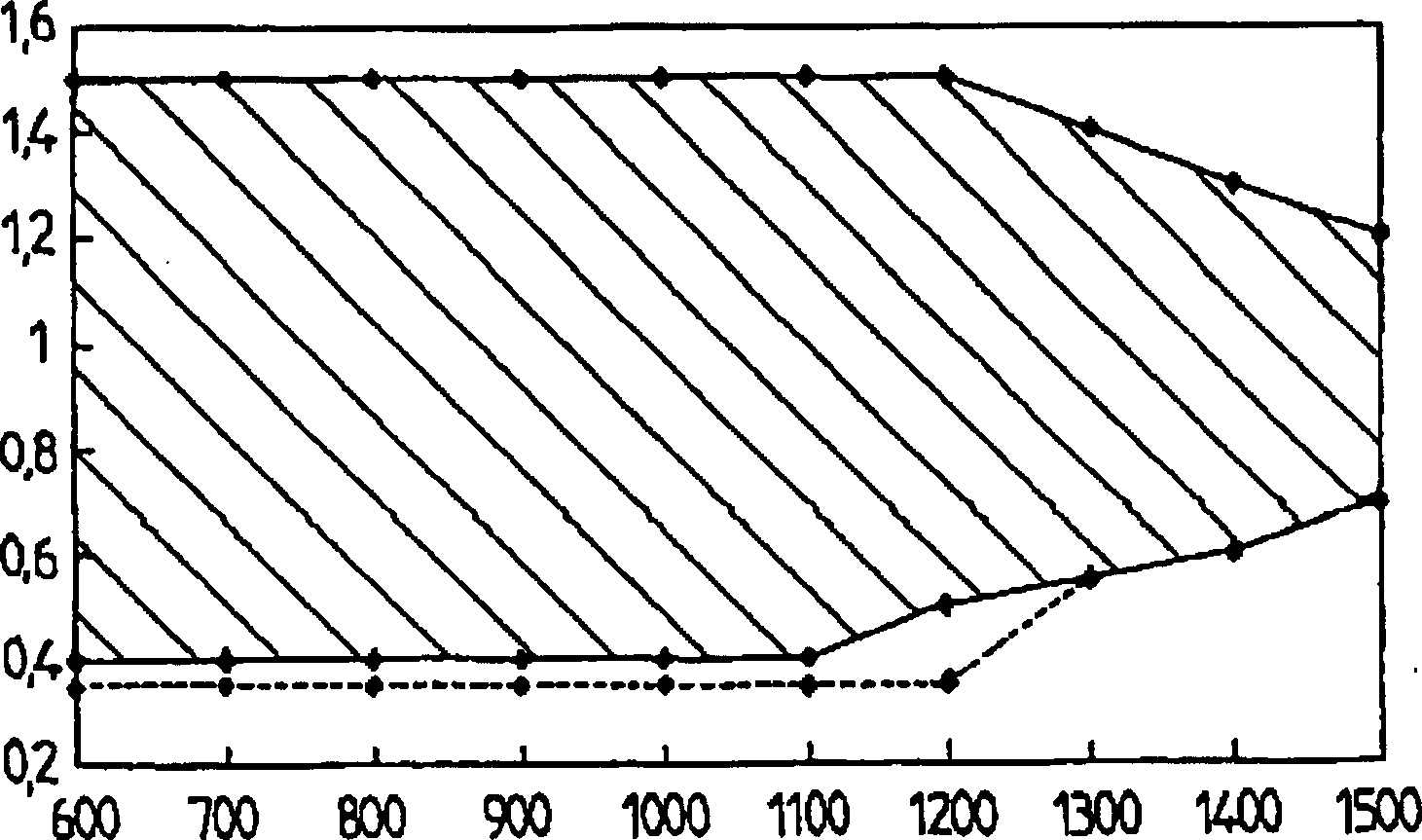

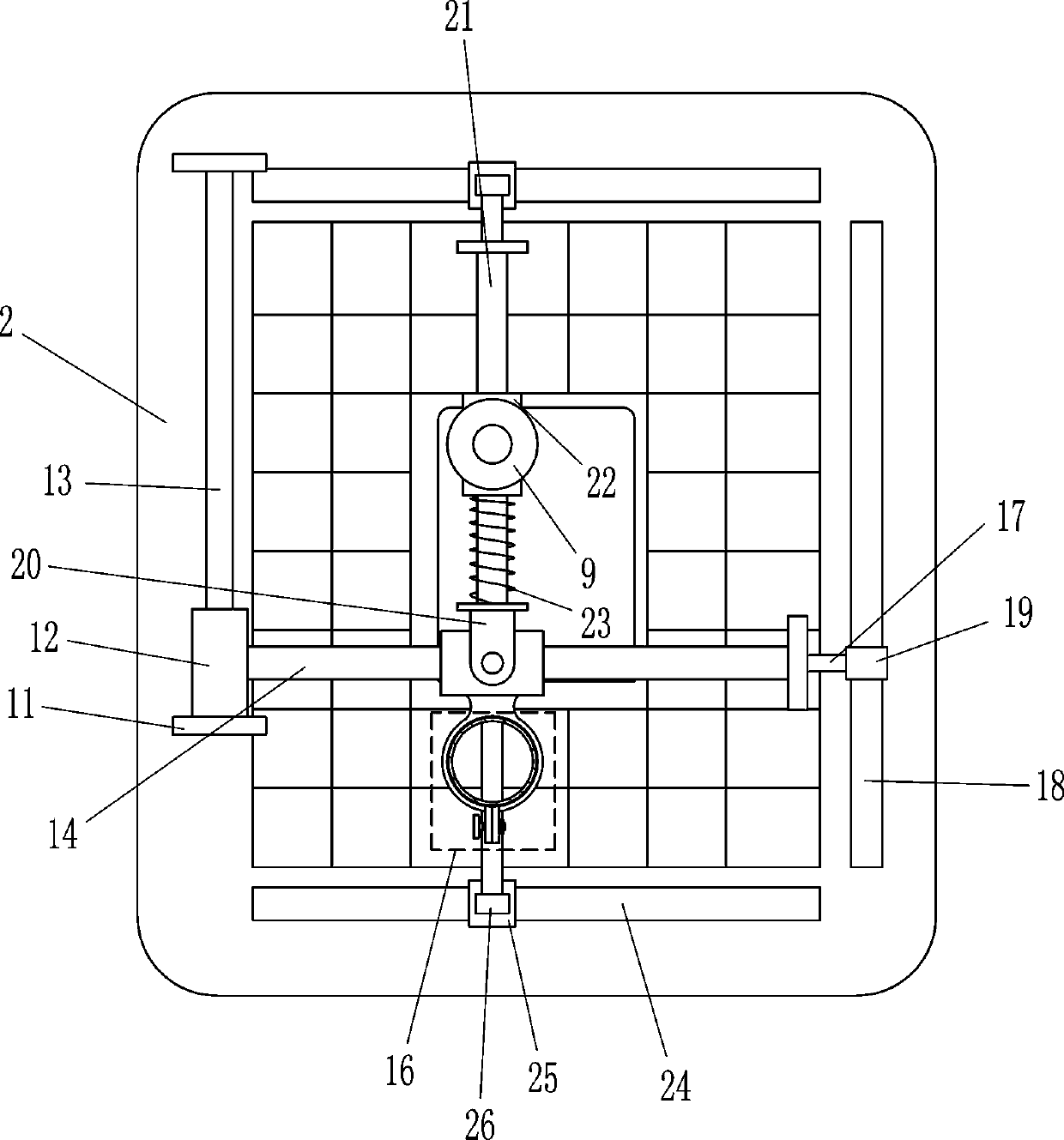

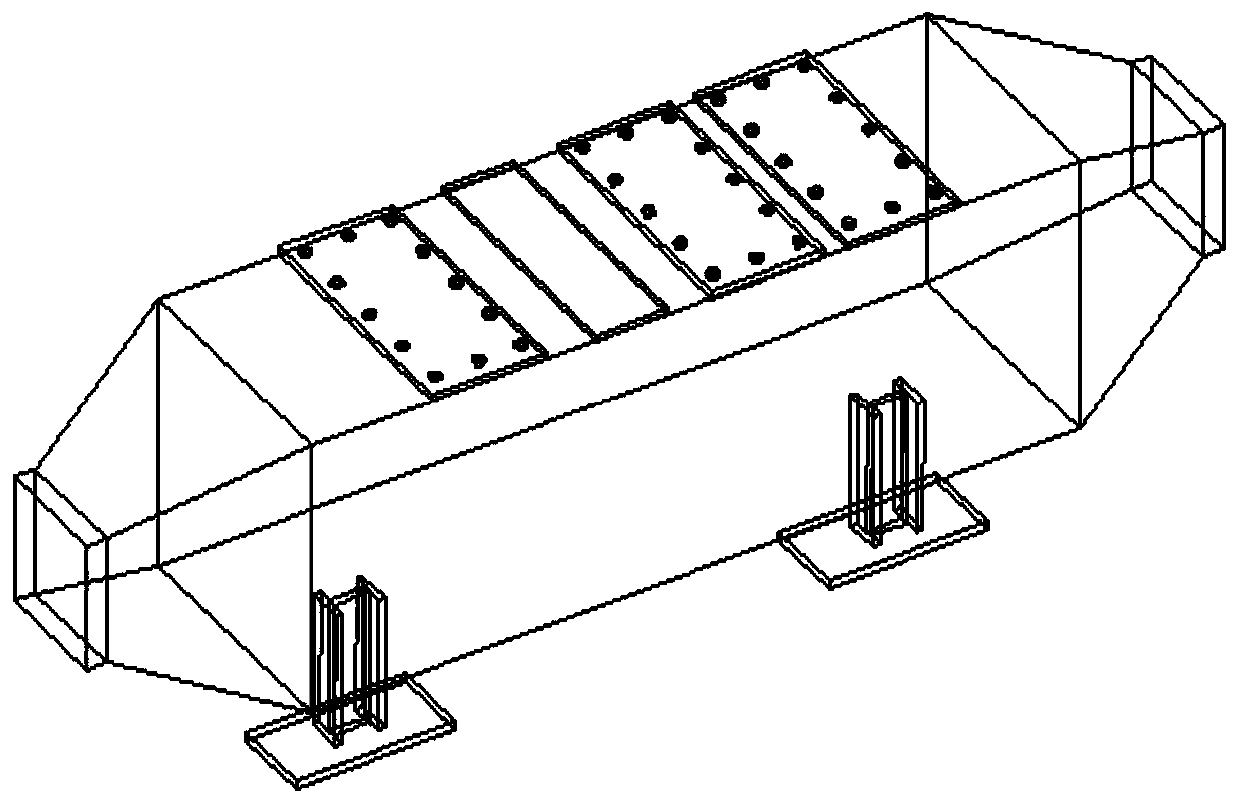

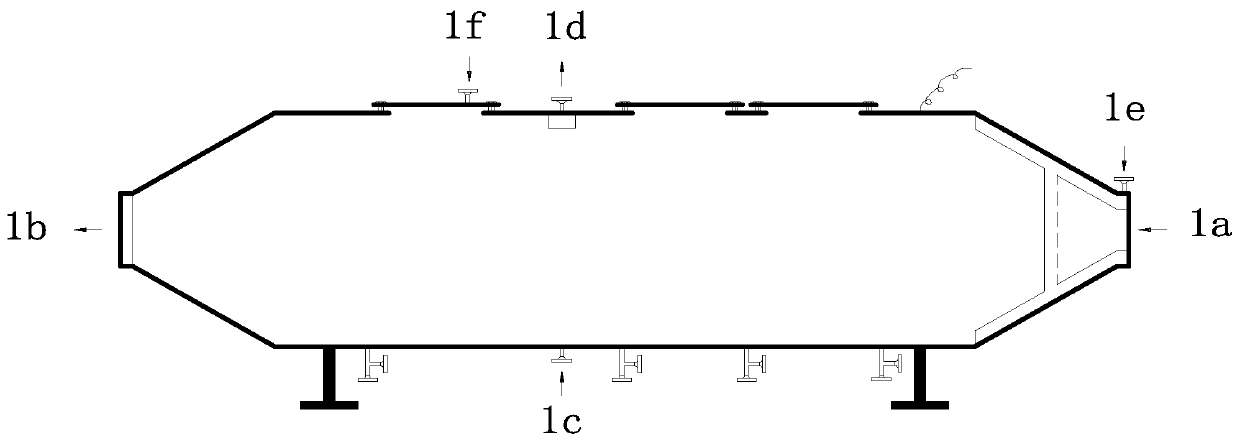

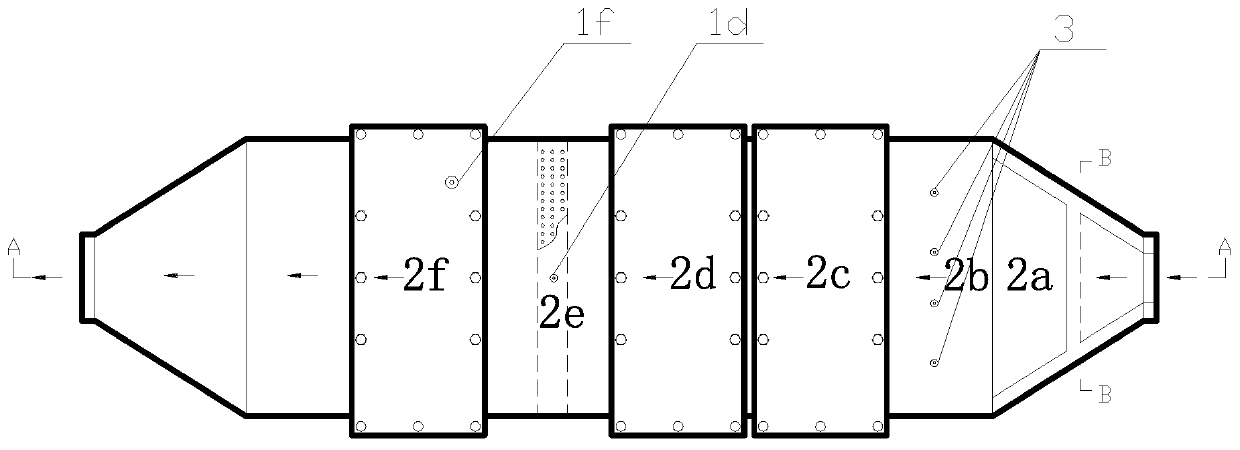

High-precision fully-automatic large transfer system

InactiveCN101913147AImprove use valueReduced reload timeProgramme-controlled manipulatorTransfer systemExecution unit

The invention relates to a high-precision fully-automatic large transfer system which is used for transferring heavy goods in a larger space range. The fully-automatic transfer system comprises a measuring unit 1, an alignment unit 2, a control unit 3, an execution unit 4 and a display unit 5, wherein the control and connection relation of each unit is as follows: the measuring unit 1 is responsible for providing spatial relative coordinates of an original point and a target point of a manipulator and transmitting the spatial relative coordinates to the control unit 3, the control unit 3 sets the tracks according to the data to drive an execution mechanism, and finally, the positioning control of the manipulator is finished; and the control unit 3 controls a hydraulic regulation valve in the execution unit 4 according to the measuring data of the measuring unit 1 and simultaneously carries out real-time adjustment according to the data fed back by sensors installed at each joint and the measuring result of the alignment unit 2, and finally, various kinds of control information is transferred to the display unit 5 to be displayed. The invention has the advantages of fully-automatic operation of program control, high transferring speed and very high positioning precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Dual magazine assembly

ActiveUS9354006B2Reduced reload timeEasy to disassembleAmmunition loadingEngineeringMechanical engineering

An dual magazine assembly that has many novel features desirable by modern military and law enforcement professionals that consists of two magazine adaptors that replace the standard bottom magazine plates of a firearm. These adaptors once mated with identical magazine housings can then be quickly attached to each other in order to shorten the magazine reloading time by rotating the spent primary magazine towards the bottom and inserting the secondary magazine thus doubling the capacity and allowing for faster firing of rounds from the secondary magazine.

Owner:PURKISS JOSHUA

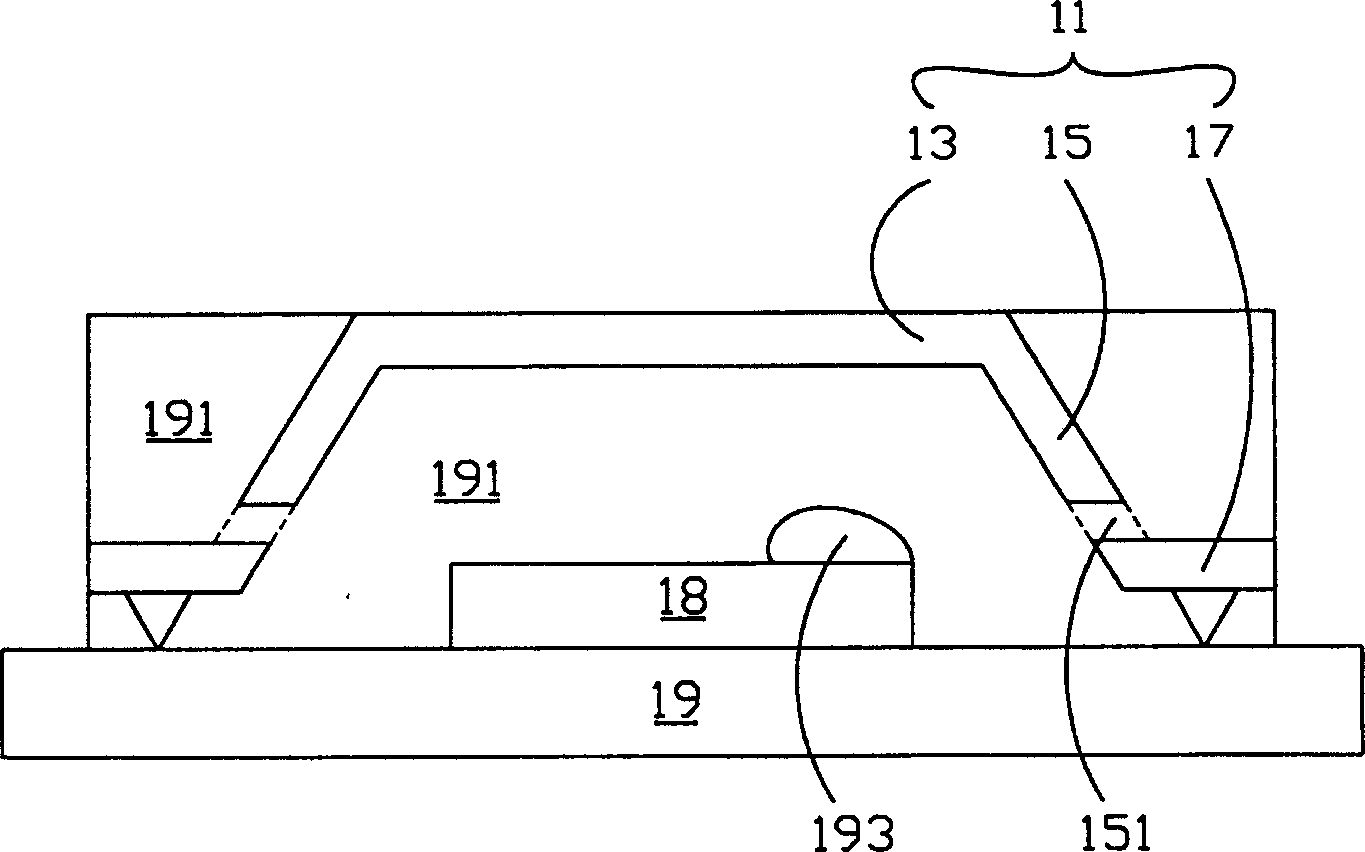

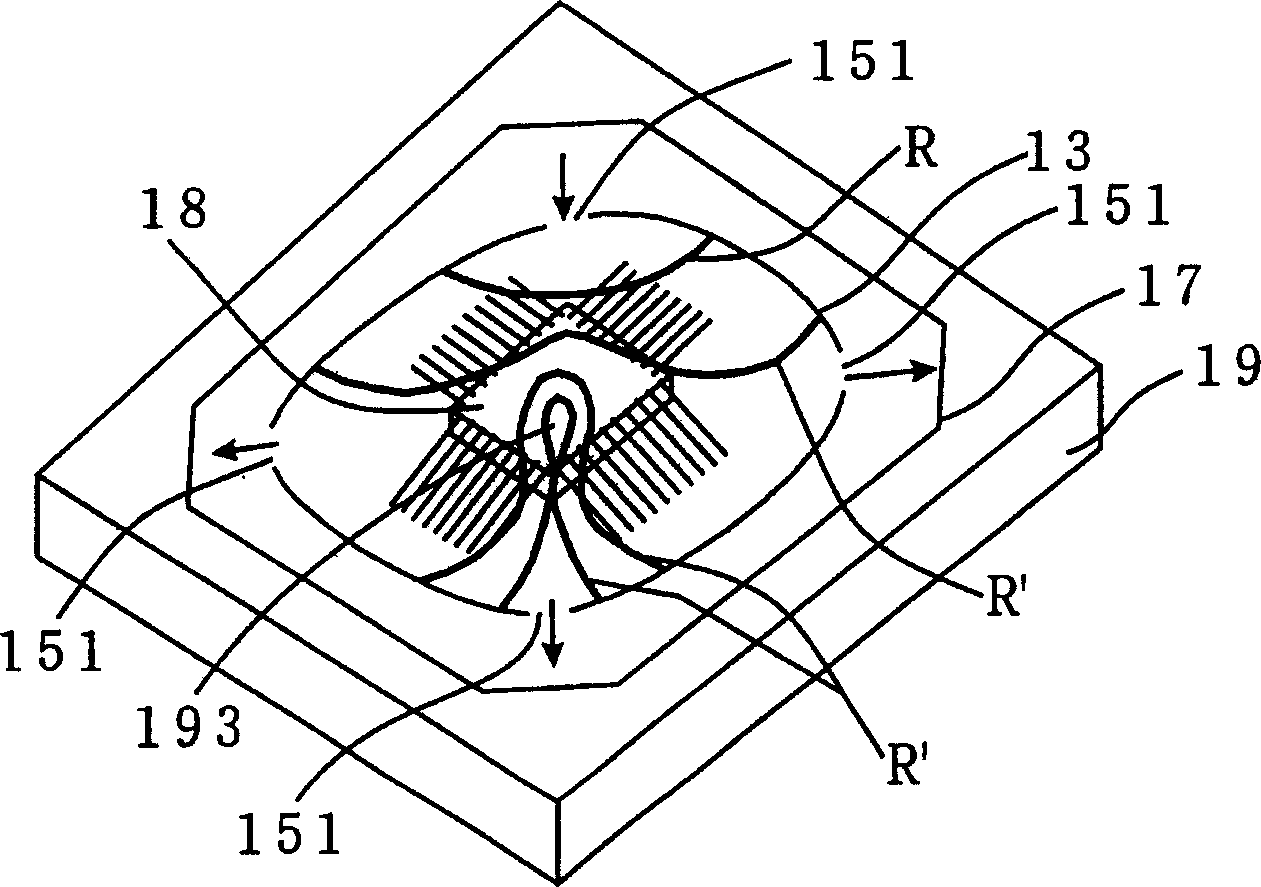

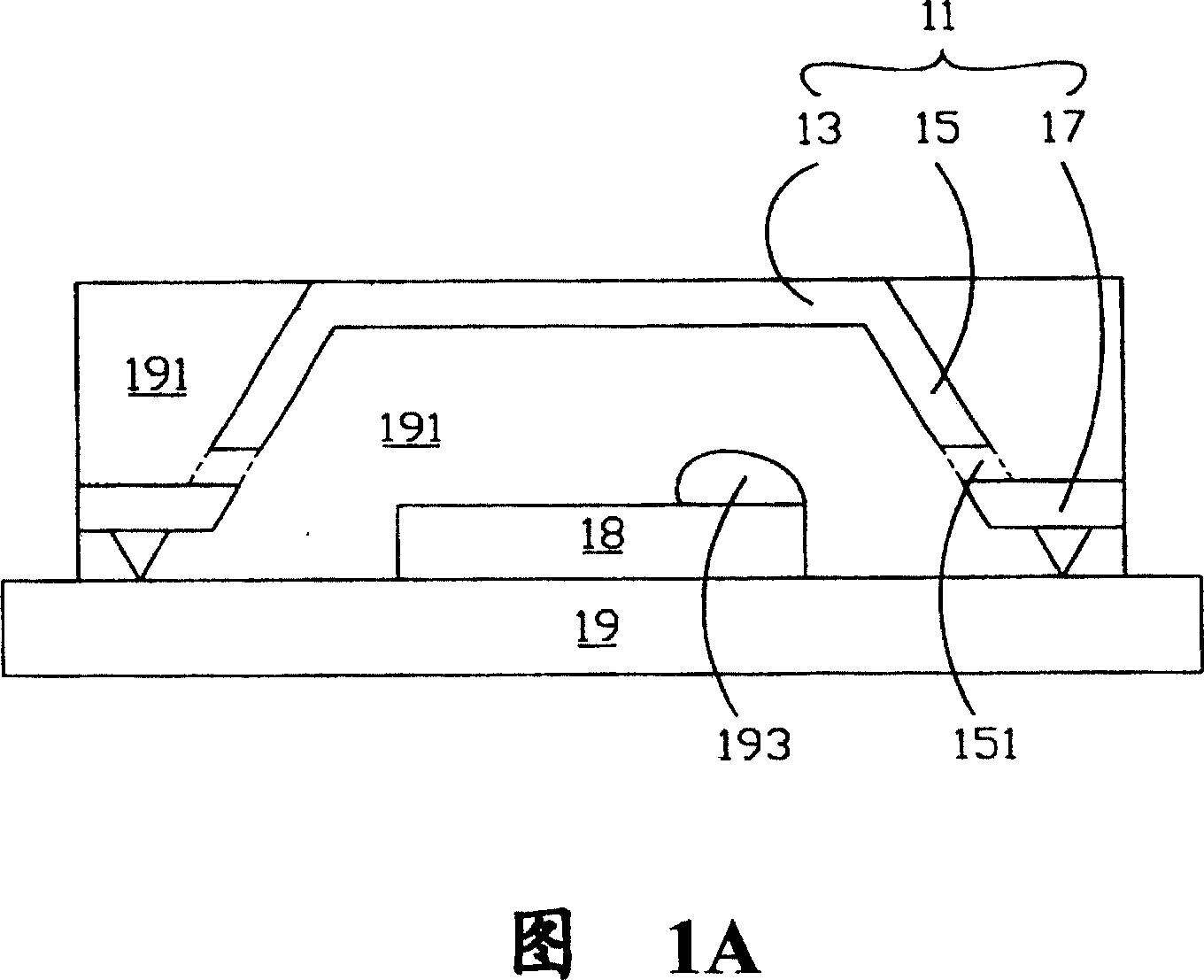

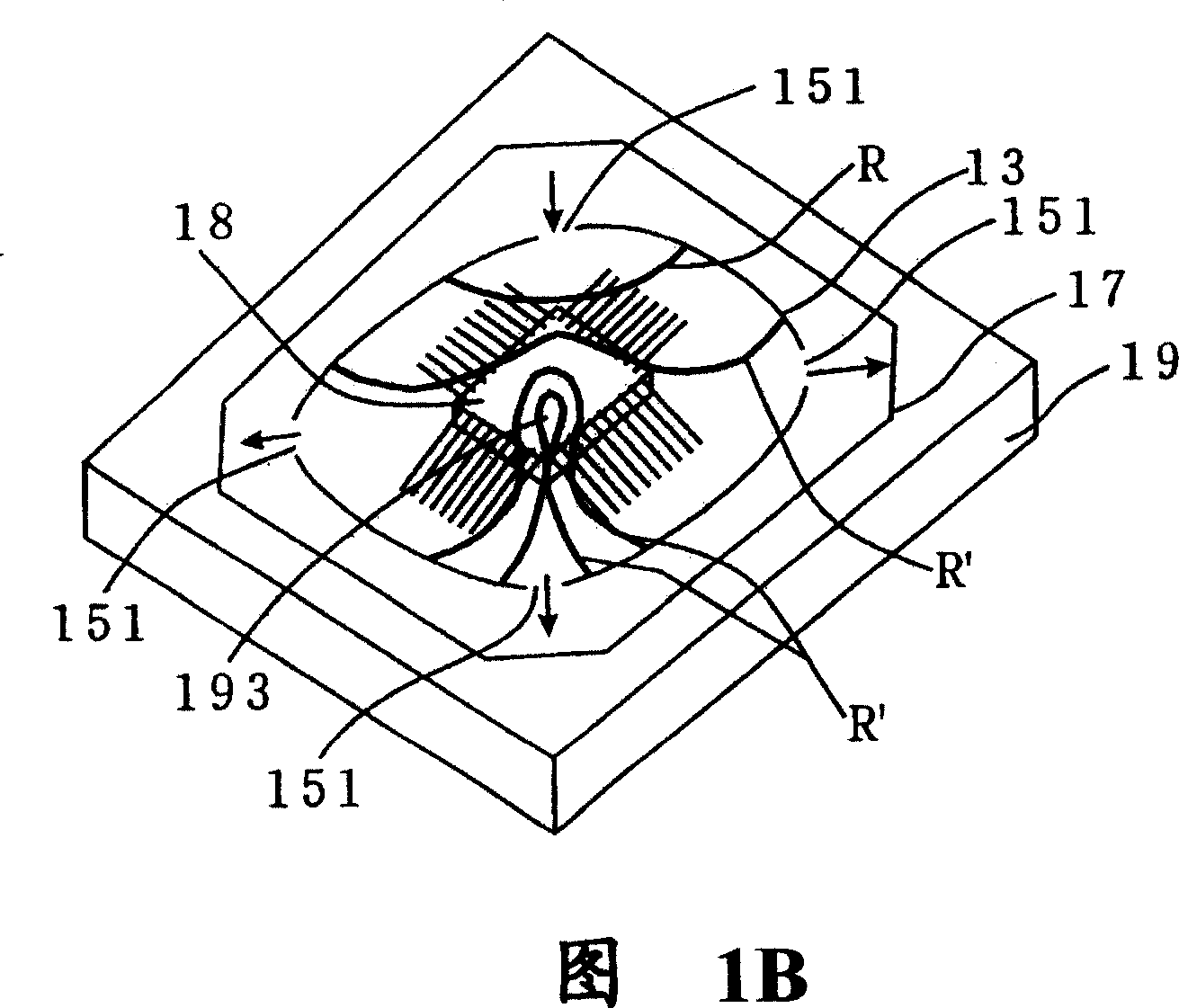

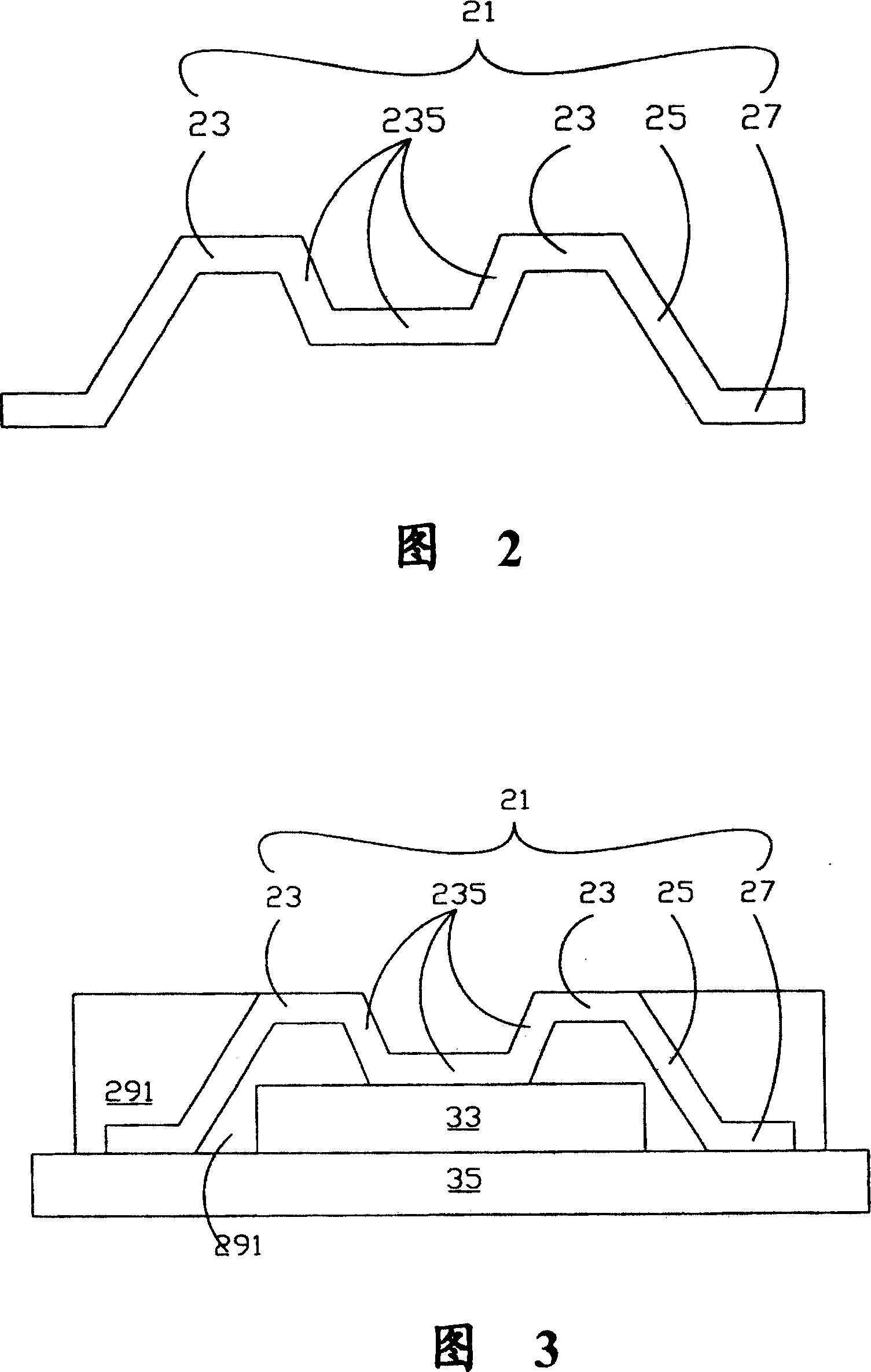

Wafer radiating element

InactiveCN1622319AAvoid damageGuaranteed mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesEngineeringRadiating element

The chip heat radiating element is for chip to radiate heat. The chip heat radiating element has one top plate and side walls, and the top plate is bent and extended to connected side walls and has notched part to contact with chip.

Owner:SILICON INTEGRATED SYSTEMS

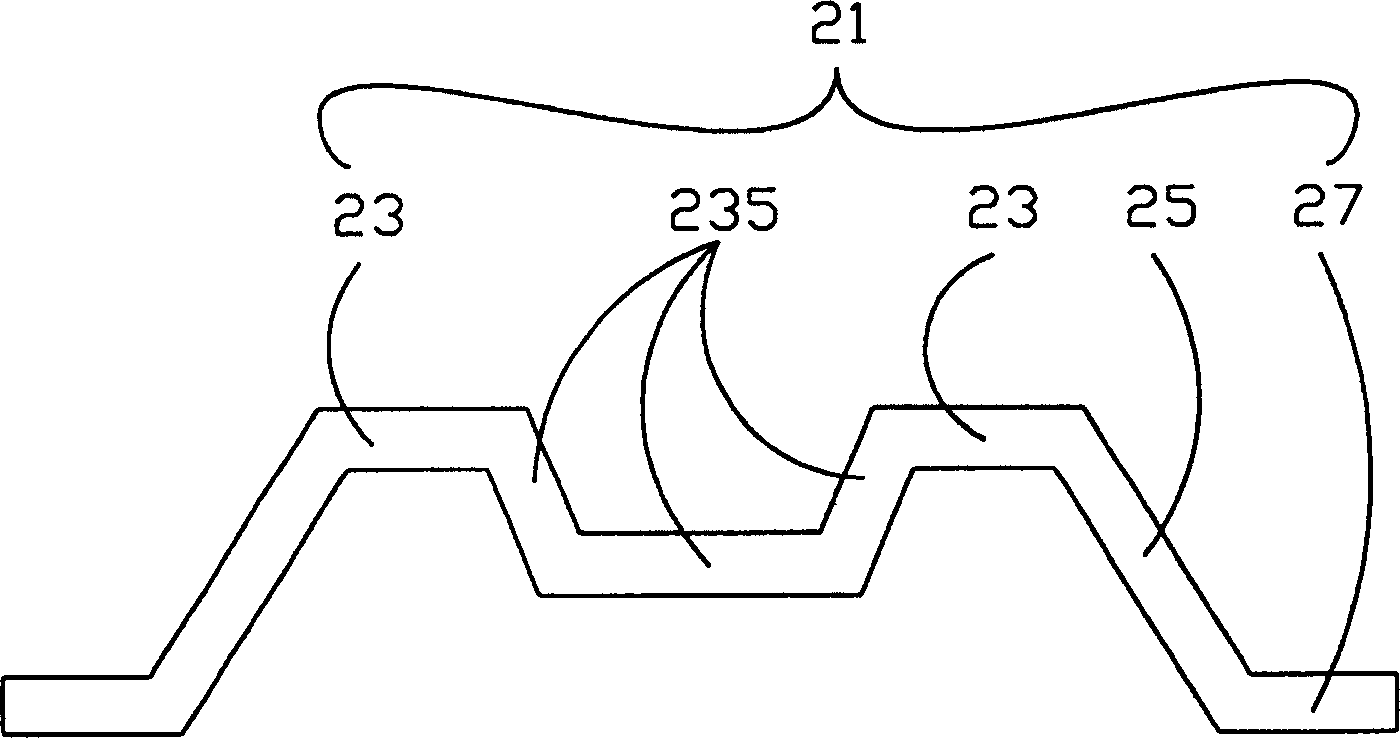

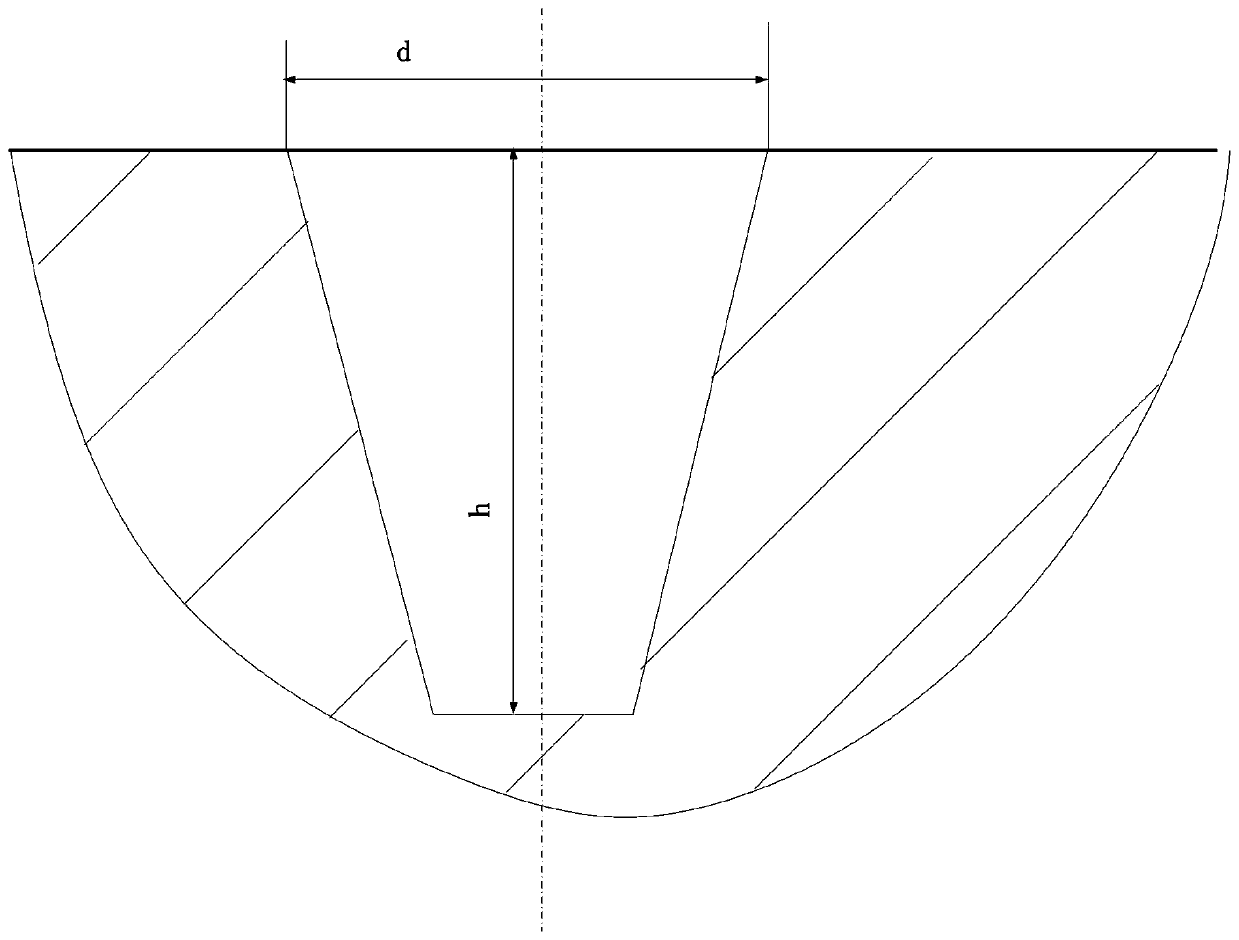

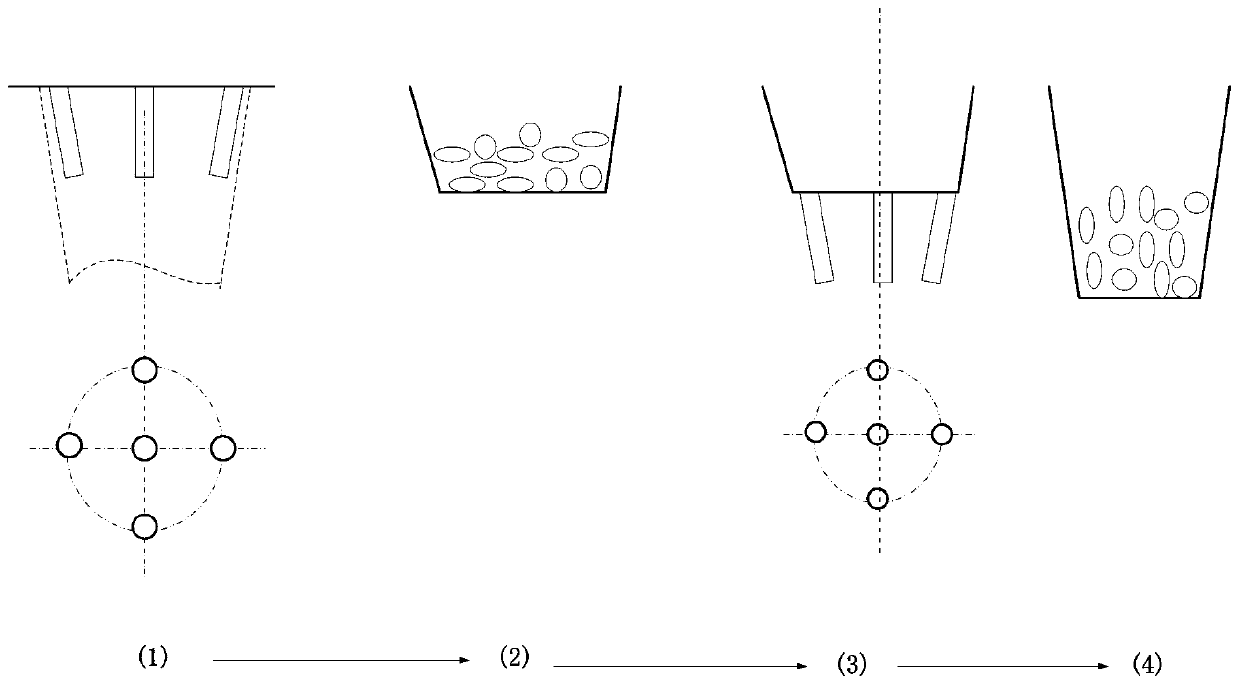

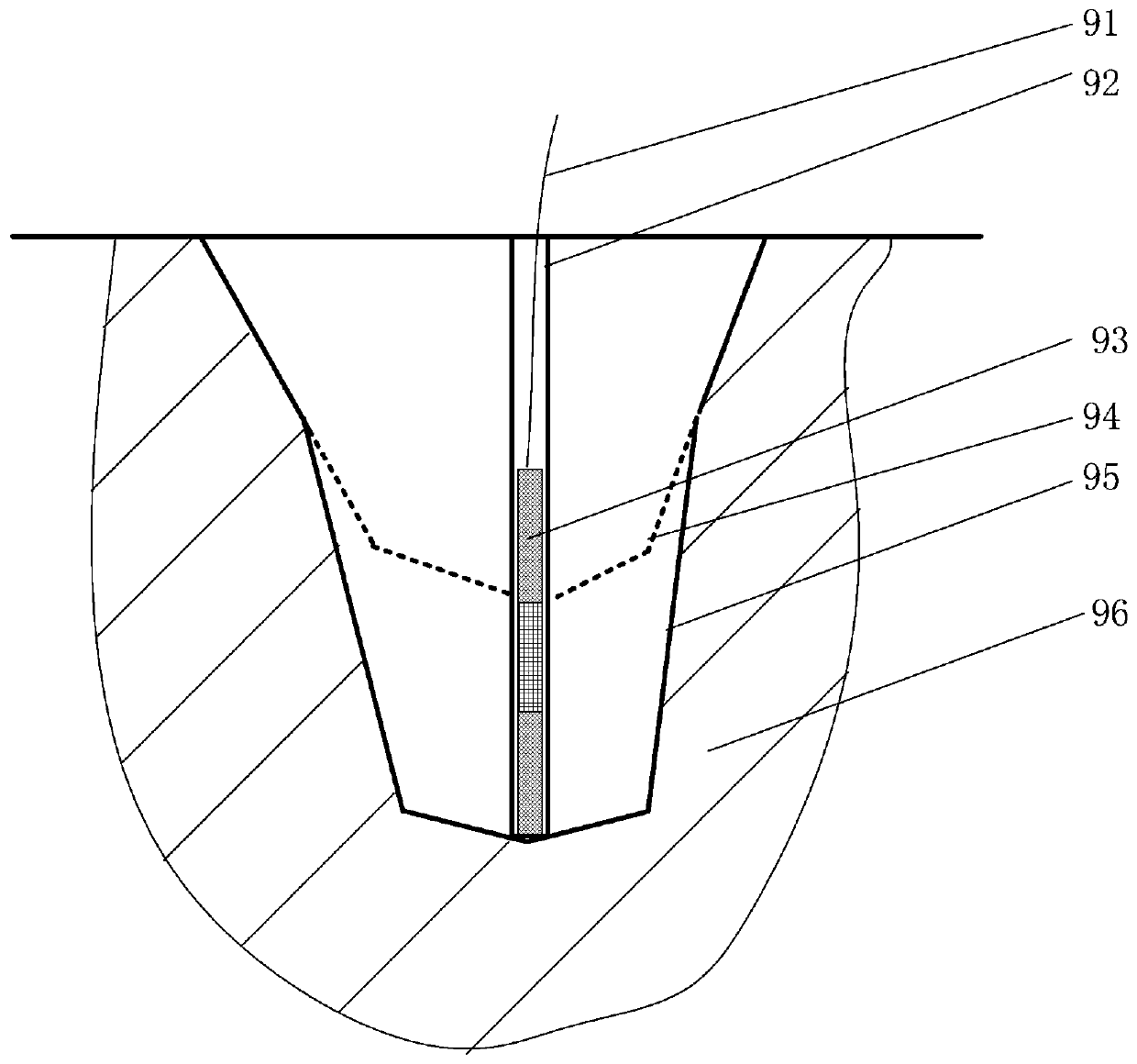

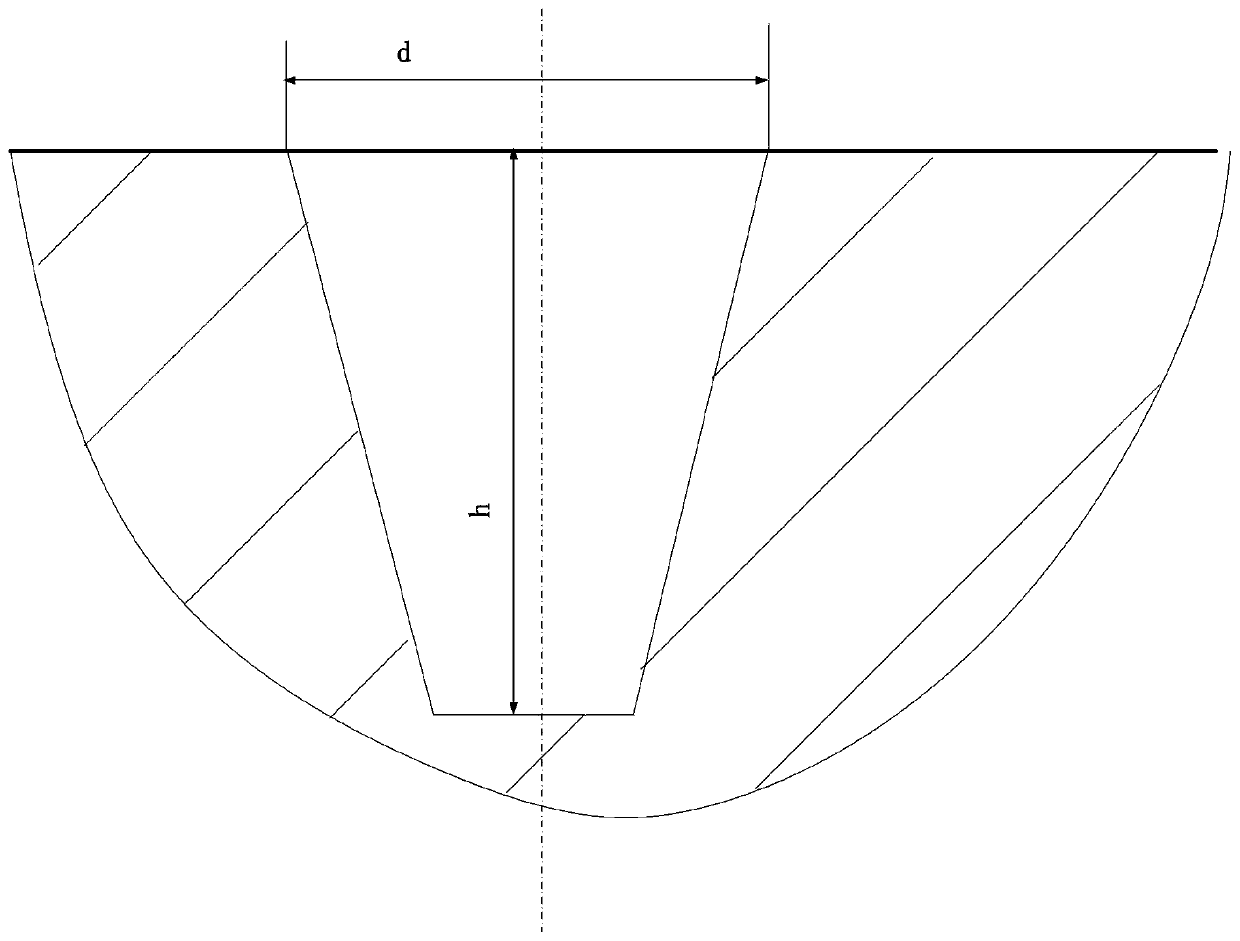

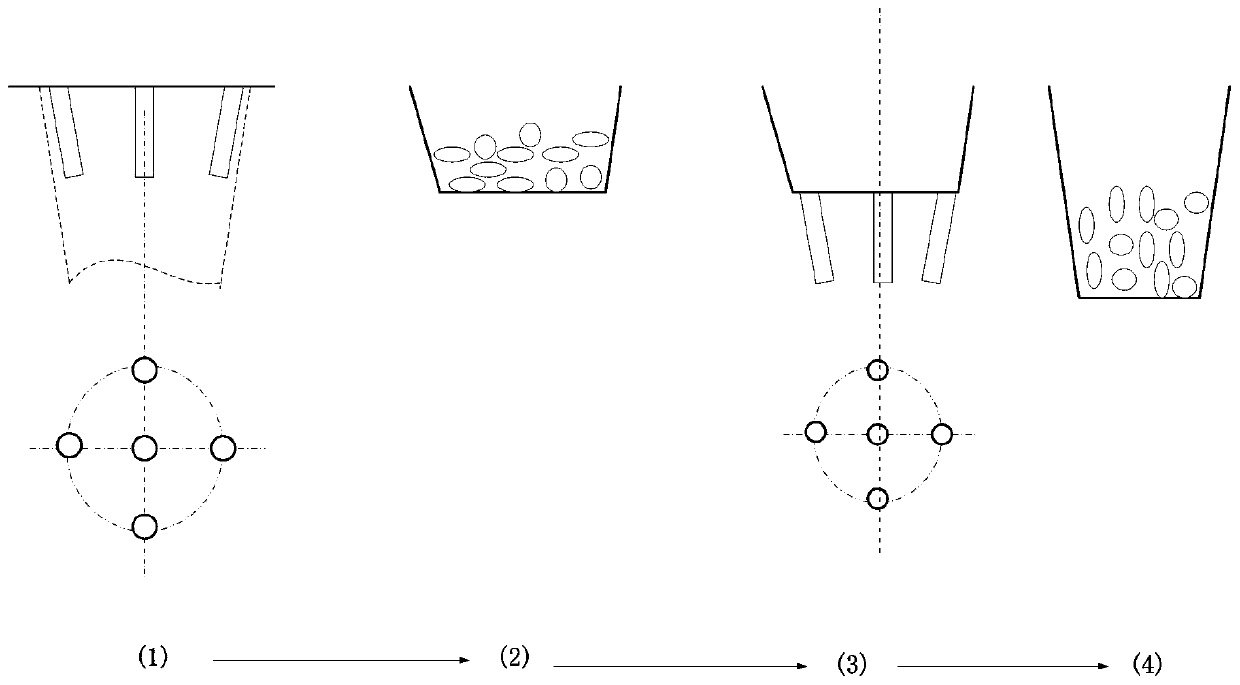

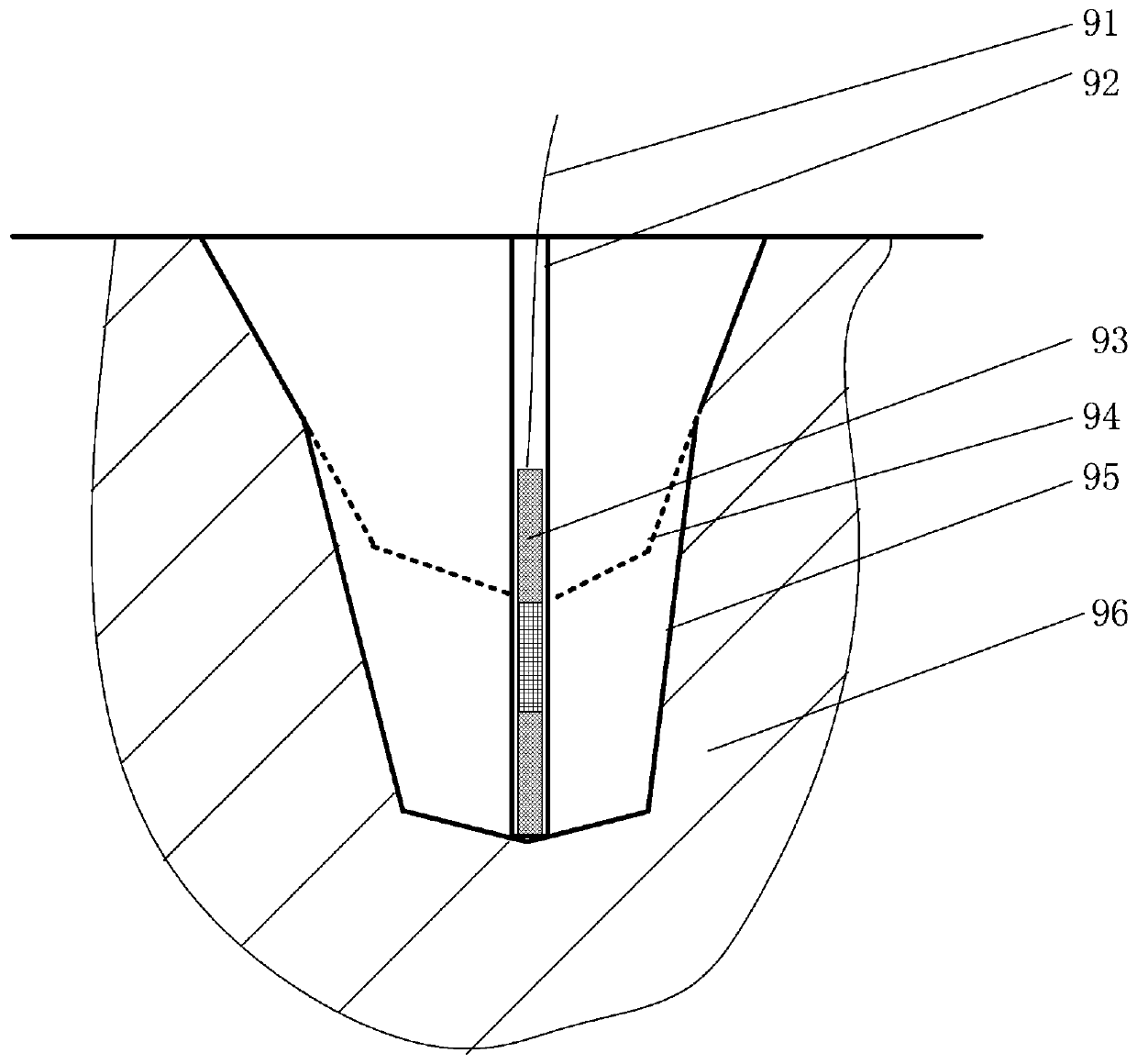

Blasting device and method for rapid forming of V-shaped pit body in hard rock and slag throwing

ActiveCN110243242AMeet the needs of rapid prototypingProcess controlClimate change adaptationBlastingChipsealSlag

The invention discloses a blasting device and method for rapid forming of a V-shaped pit bot in hard rock and slag throwing. The blasting device comprises an initiation assembly (21), an upper powder grain unit (22), an explosive-proof pipe (23), a lower powder grain unit (24) and a throwing unit (25) which are are sequentially arranged from top to bottom; after the initiation assembly (21) is initiated, the upper powder grain unit (22) is detonated, the lower powder grain unit (24) is detonated after a period of delay through the explosion-proof tube (23), rock is subjected to delayed blasting, and the throwing unit (25) at the tail end is detonated to realize throwing of broken stones. According to the invention, through a method for creating a secondary free face, a conventional multi-time reaming charge blasting operation is optimized into standard and modularized combined charge, long-time explosion isolation of up-down charge in a hard hole is realized through research on the explosion isolation mechanism of the charge, and the two-time initiation and one-time throwing are formed, so that a V-shaped pit meeting the size parameter requirement is well formed.

Owner:ARMY ENG UNIV OF PLA

detonating device and method for rapidly forming V-shaped pit in hard rock

The invention discloses a detonating device and method for rapidly forming a V-shaped pit in a hard rock. The blasting device comprises a detonation component (21), an upper explosive column unit (22), an explosive-proof pipe (23) and a lower explosive column unit (24) which are sequentially arranged from top to bottom (23); and after the detonation component (21) is detonated, the upper explosivecolumn unit (22) is detonated, detonation is delayed for a period of time through an explosion-proof pipe (23), and then the lower explosive column unit (24) is detonated, so that the rock is subjected to delay detonating. According to the detonating device and method for rapidly forming the V-shaped pit in the hard rock, through a method of creating a secondary free surface, the multi-hole charging and detonating operation in the past adopts standard and modularized combined charging optimally, an explosive-loading and explosion-proof mechanism is studied, so that long-time interval explosion when the explosive is loaded into the upper and lower portions of a hard hole is realized, so that the V-shaped pit meeting the requirement of the size parameter is well formed.

Owner:ARMY ENG UNIV OF PLA

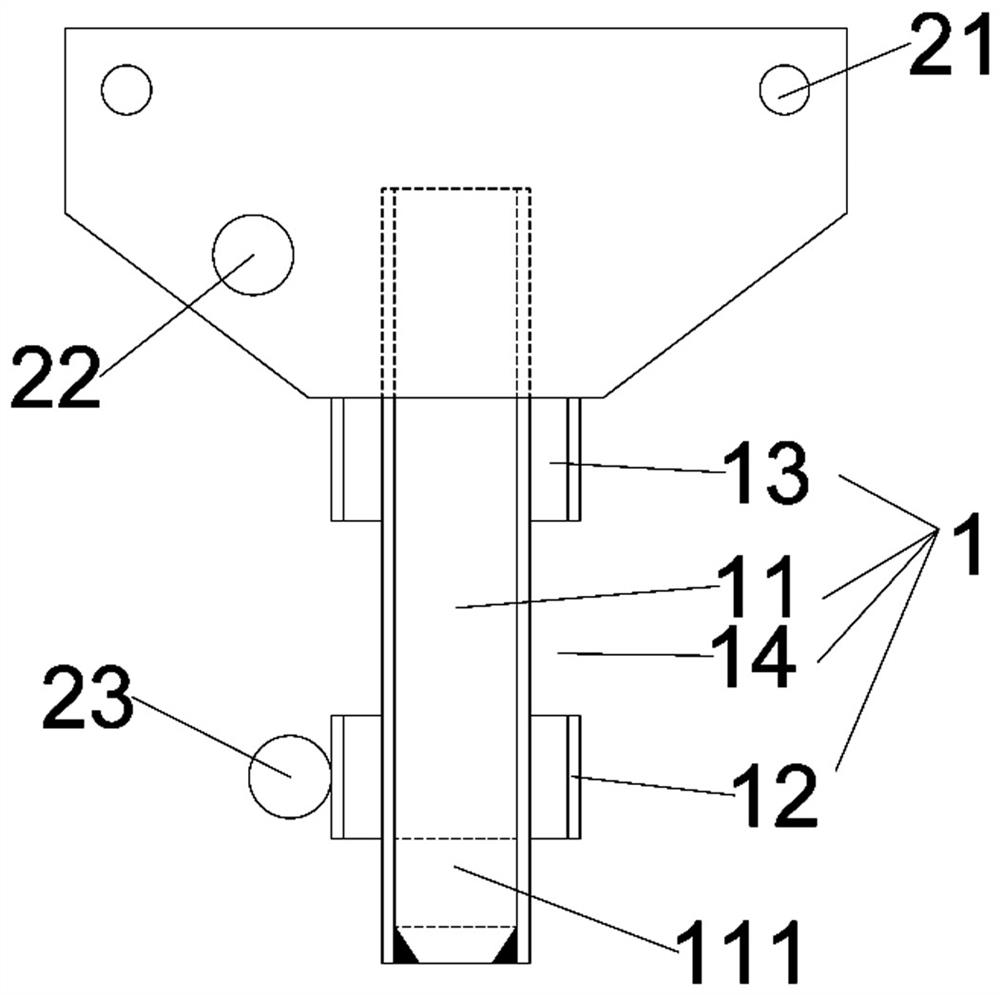

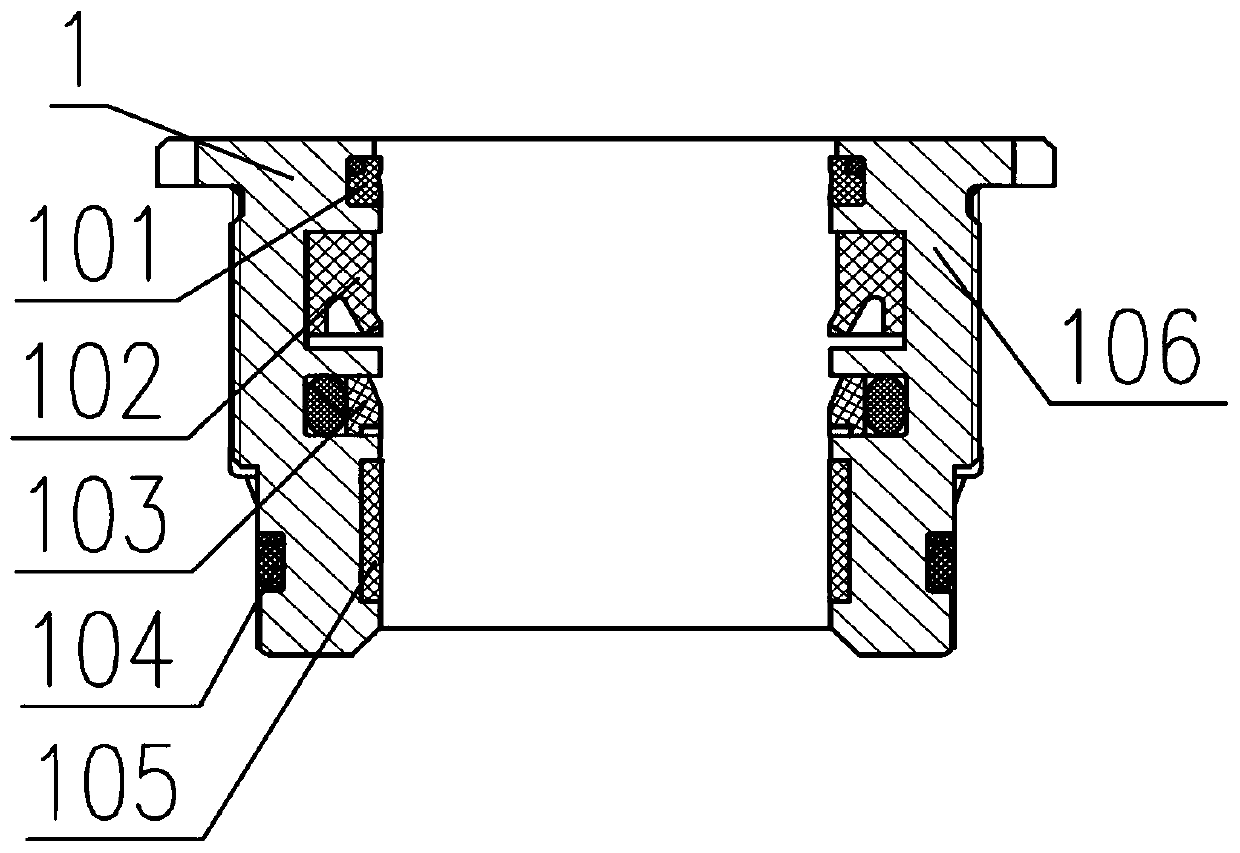

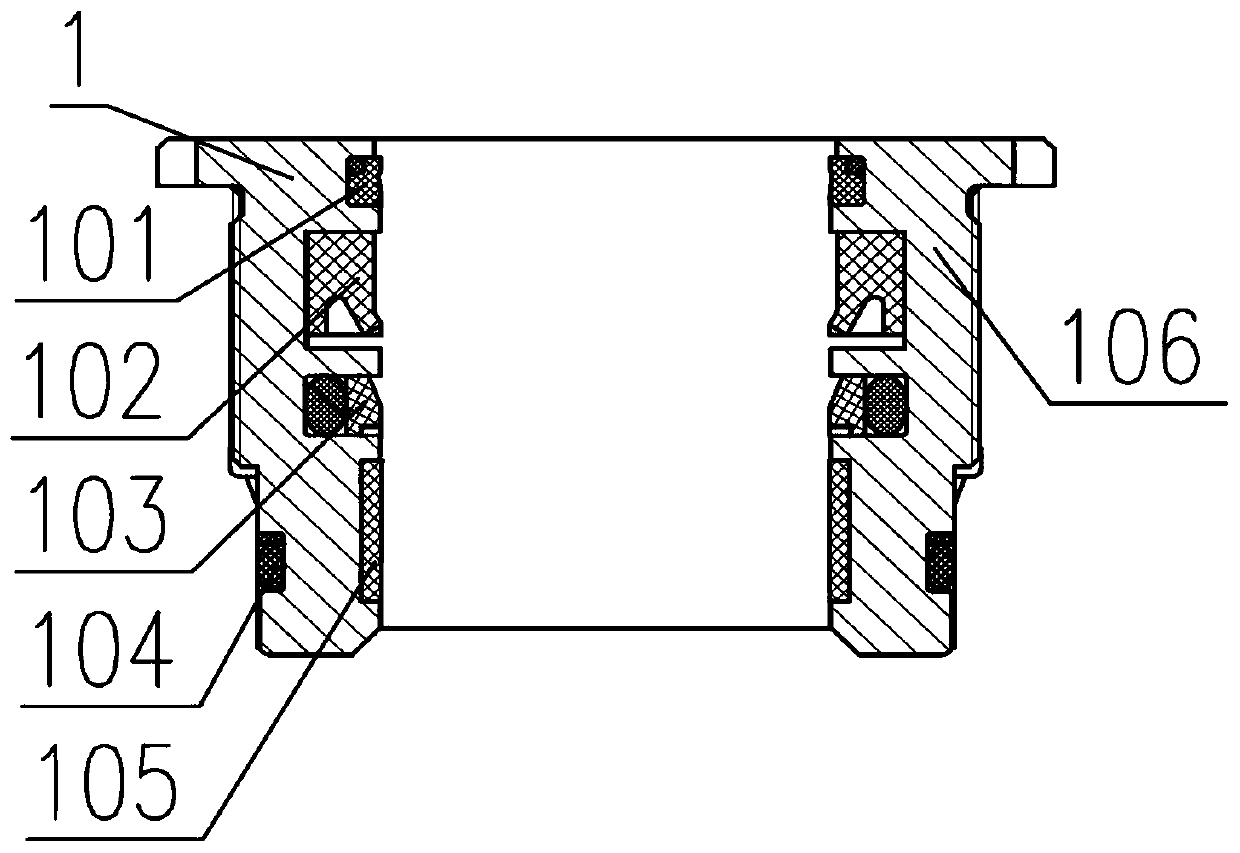

Connecting structure suitable for missile launcher loading

PendingCN111649622AReduced reload timeImprove reliabilityCoupling device detailsLaunching weaponsIn vehicleMissile

The invention provides a connecting structure suitable for missile launcher loading. The connecting structure comprises a missile united loading module, a missile launcher and a vehicle-bone launchingcontrol cable, wherein the missile united loading module is provided with a united loading frame cable, the united loading frame cable adopts a one-driving-four structure mode and comprises a rectangular connector plug, and the vehicle-bone launching control cable comprises a rectangular connector socket; the rectangular connector socket is arranged on the upper portion of a launcher body, and the rectangular connector plug is arranged on the lower portion of a missile united loading frame; and when the missile united loading module is arranged on the missile launcher, the rectangular connector plug can be connected into the rectangular connector socket in a matched and inserted mode, so that rapid inserting connection of a large-diameter missile launching cable is achieved. According tothe connecting structure suitable for missile launcher loading, the connection of the electrical plug is completed while a launcher structure is loaded with the united loading module, so that the loading time is saved, the loading efficiency is improved, and the reliability and the firmness of the connection are improved.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

High-precision fully-automatic large transfer system

InactiveCN101913147BImprove use valueReduced reload timeProgramme-controlled manipulatorTransfer systemEngineering

The invention relates to a high-precision fully-automatic large transfer system which is used for transferring heavy goods in a larger space range. The fully-automatic transfer system comprises a measuring unit 1, an alignment unit 2, a control unit 3, an execution unit 4 and a display unit 5, wherein the control and connection relation of each unit is as follows: the measuring unit 1 is responsible for providing spatial relative coordinates of an original point and a target point of a manipulator and transmitting the spatial relative coordinates to the control unit 3, the control unit 3 setsthe tracks according to the data to drive an execution mechanism, and finally, the positioning control of the manipulator is finished; and the control unit 3 controls a hydraulic regulation valve in the execution unit 4 according to the measuring data of the measuring unit 1 and simultaneously carries out real-time adjustment according to the data fed back by sensors installed at each joint and the measuring result of the alignment unit 2, and finally, various kinds of control information is transferred to the display unit 5 to be displayed. The invention has the advantages of fully-automaticoperation of program control, high transferring speed and very high positioning precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

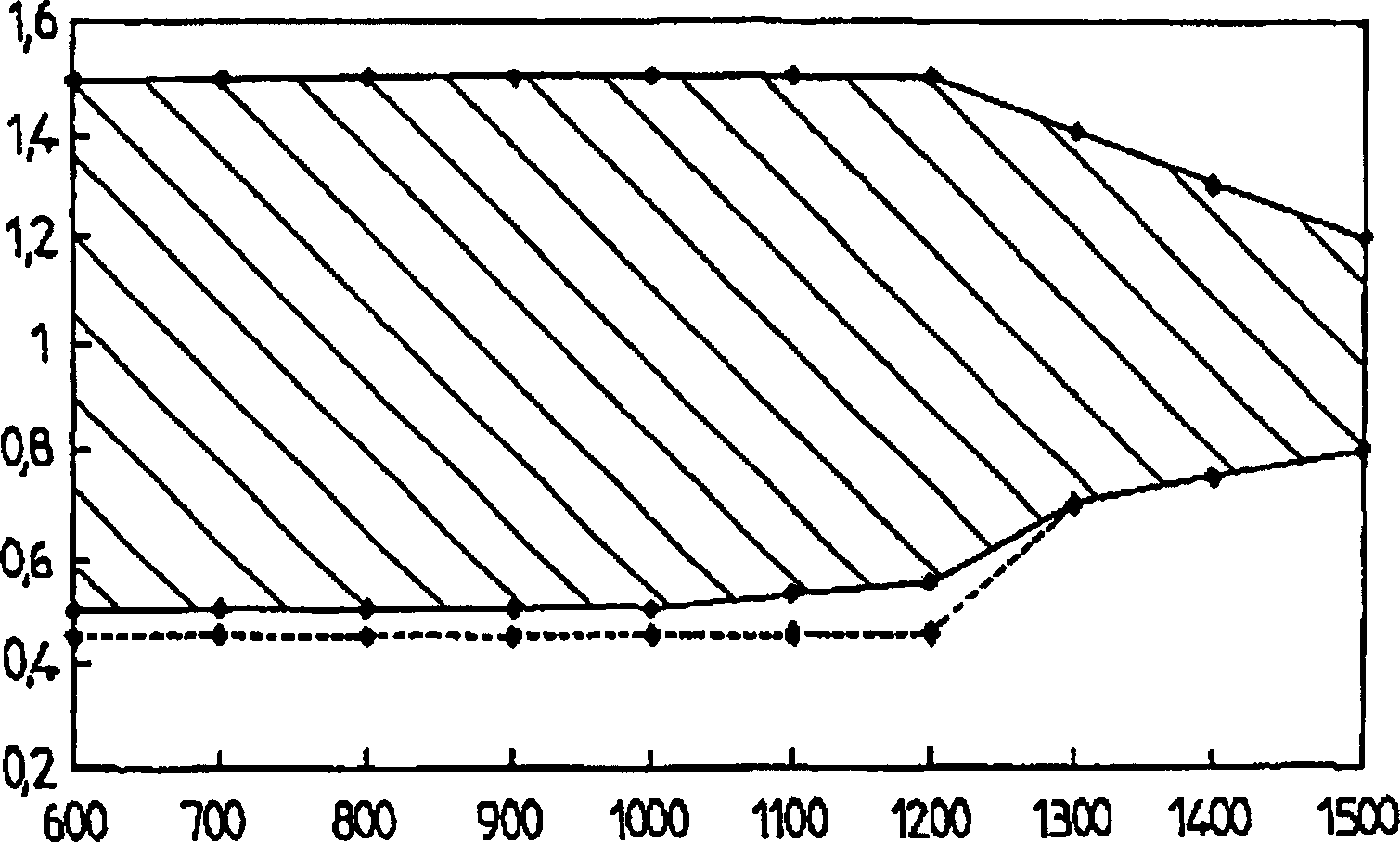

Cold rolling method and apparatus

InactiveCN1226107CWon't be corrodedQuality assuranceMetal rolling stand detailsWork treatment devicesCouplingRolling speed

The invention relates to a method for rolling a metal band in a continuous line installation with coupling of the pickling and cold rolling processes. According to the invention, the composition of the pickling fluid is determined to allow the running of the band in the bath at a minimum speed of a few meters per minute, and similar running speeds are maintained in the pickling and rolling sections, during the operating phases, whereas the rolling conditions are determined in order to maintain the requested quality of the band at a minimum rolling speed that may be as low as 1 meter per minute.

Owner:VAI CLECIM (FR)

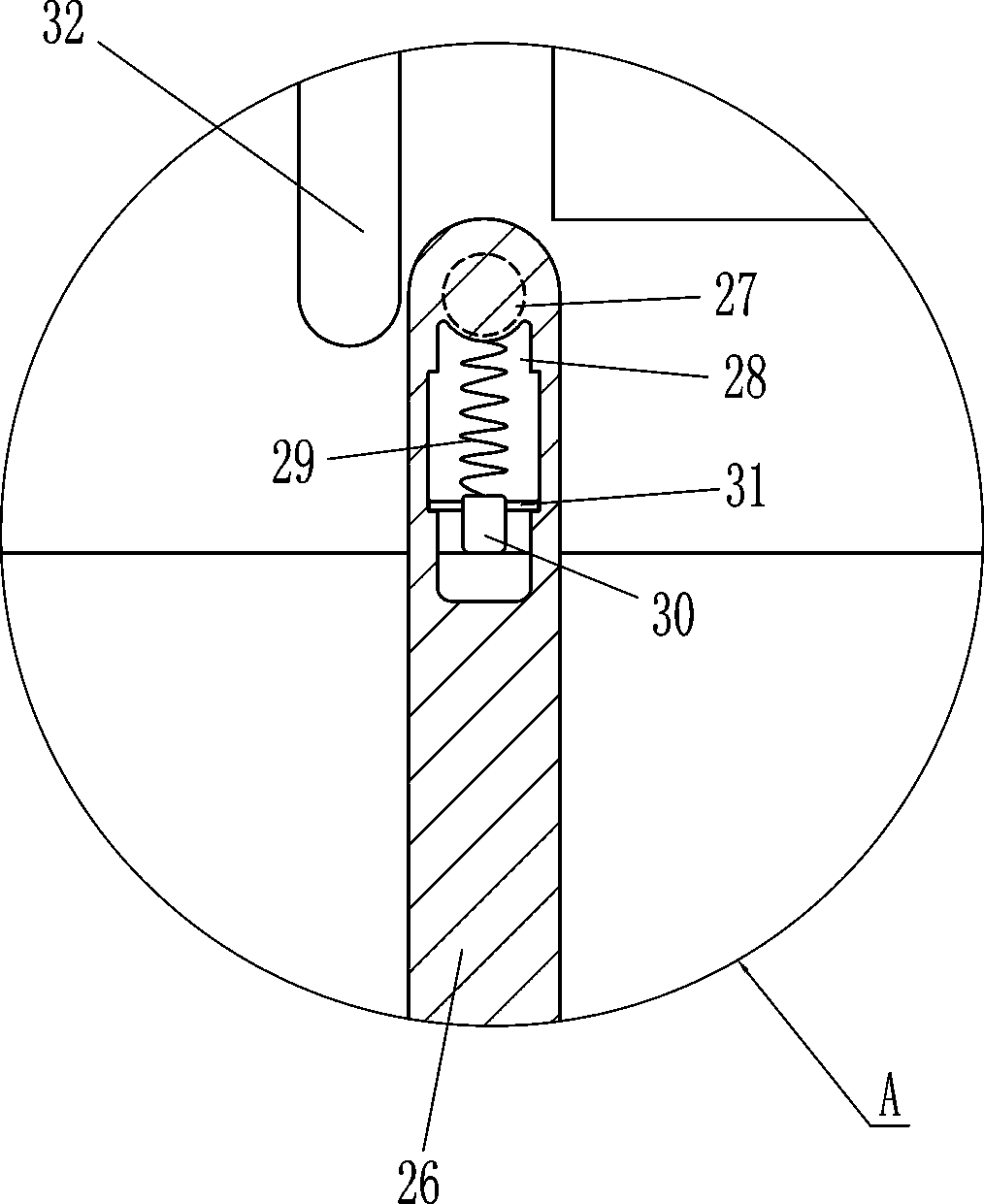

Mechanical locking and deblocking device

ActiveCN102408058BReduced reload timeSimple structureSecuring devicesLoad-engaging elementsEngineeringWire rope

The invention discloses a mechanical locking and deblocking device which comprises a guide body, a spring, a guide cylinder, a lower guide rod, a push rod, a drivepipe, a hoisting pin, a pin shaft, a spring, a sleeve, a rod and a steel wire rope, wherein one end of the steel wire rope is fixed on the guide body, and the other end of the steel wire rope is connected with the hoisting pin. The hoisting pin can automatically realize locking and hoisting hoisted objects, can automatically delock after the hoisting without additional locking and delocking process. The device has the characteristics of simple structure and high reliability, and is rapid in locking and delocking.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

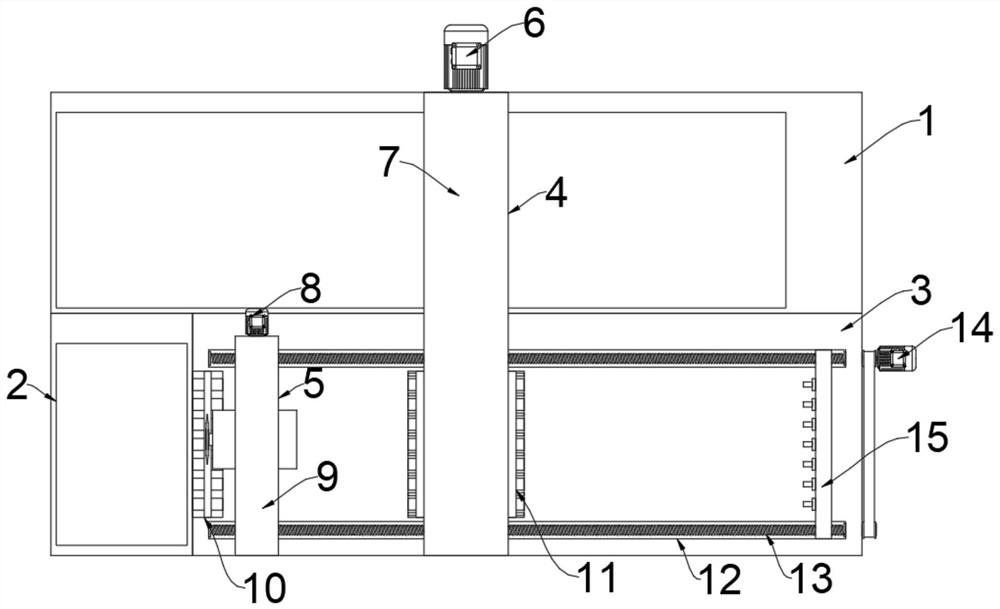

Method of catalytic combustion for removing volatile organic compounds (VOCs)

ActiveCN108096992AImprove removal efficiencyImprove loading procedureGas treatmentDispersed particle separationSorbentEmission standard

The invention relates to a method of catalytic combustion for removing VOCs, and belongs to the field of waste gas purification. A gas raw material containing the VOCs is fed from a raw material gas inlet of a catalytic combustion VOCs removal device, and is subjected to two times of catalytic reactions and one time of adsorption removal; then the reaction tail gas, which reaches emission standard, flows out from the catalytic combustion VOCs removal device via an exhaust gas outlet. The system has a smart design, compact structure and stable operation. The removal method can effectively utilize the energy in the catalytic reactions, so that removal rate of the VOCs can reach more than 97%, wherein the adsorbent can be recycled, thus reducing investment and operation costs.

Owner:DALIAN UNIV

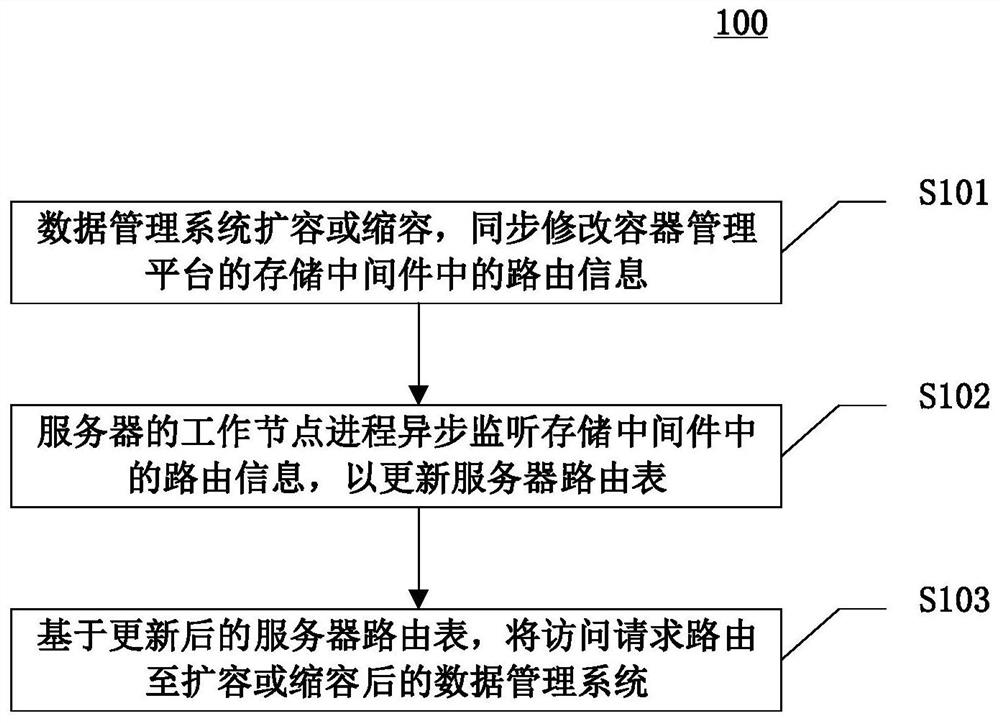

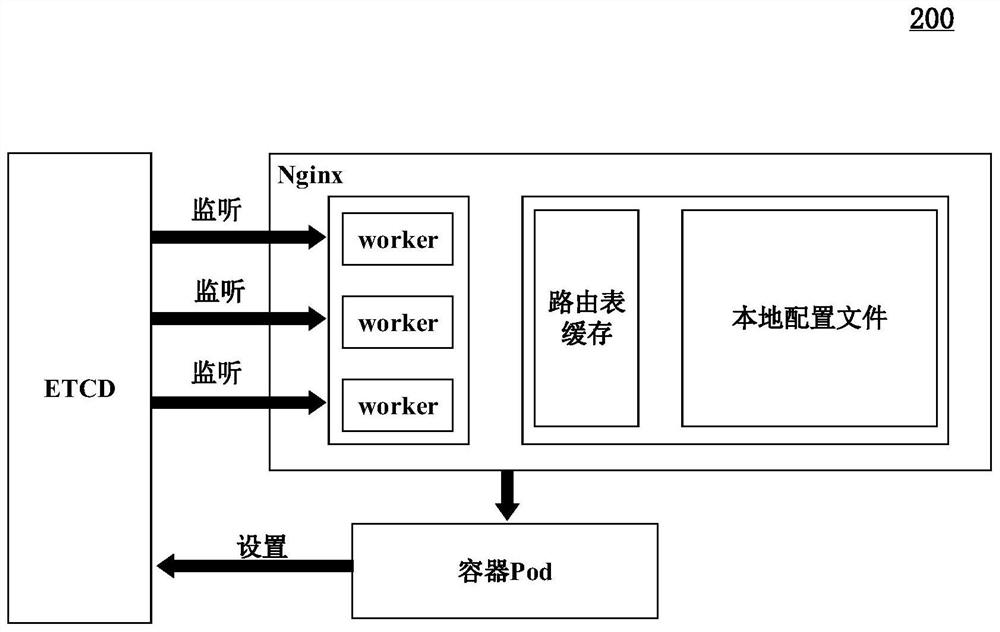

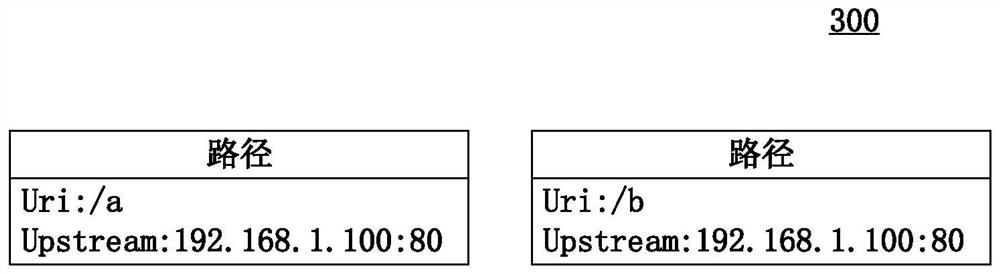

Route updating method, device and equipment and computer readable medium

ActiveCN113079098AReduced reload timeRouting updateData switching networksMiddlewareManagement system

The invention discloses a route updating method, device and equipment and a computer readable medium, and relates to the technical field of computers. A specific embodiment of the method comprises the following steps: expanding or reducing the capacity of a data management system, and synchronously modifying routing information in storage middleware of a container management platform; allowing the working node process of the server to asynchronously monitor the routing information in the storage middleware so as to update a server routing table; and based on the updated server routing table, routing the access request to the data management system after capacity expansion or capacity reduction. According to the embodiment, the server reloading time consumption is reduced, and routing updating is further realized.

Owner:BEIJING WODONG TIANJUN INFORMATION TECH CO LTD +1

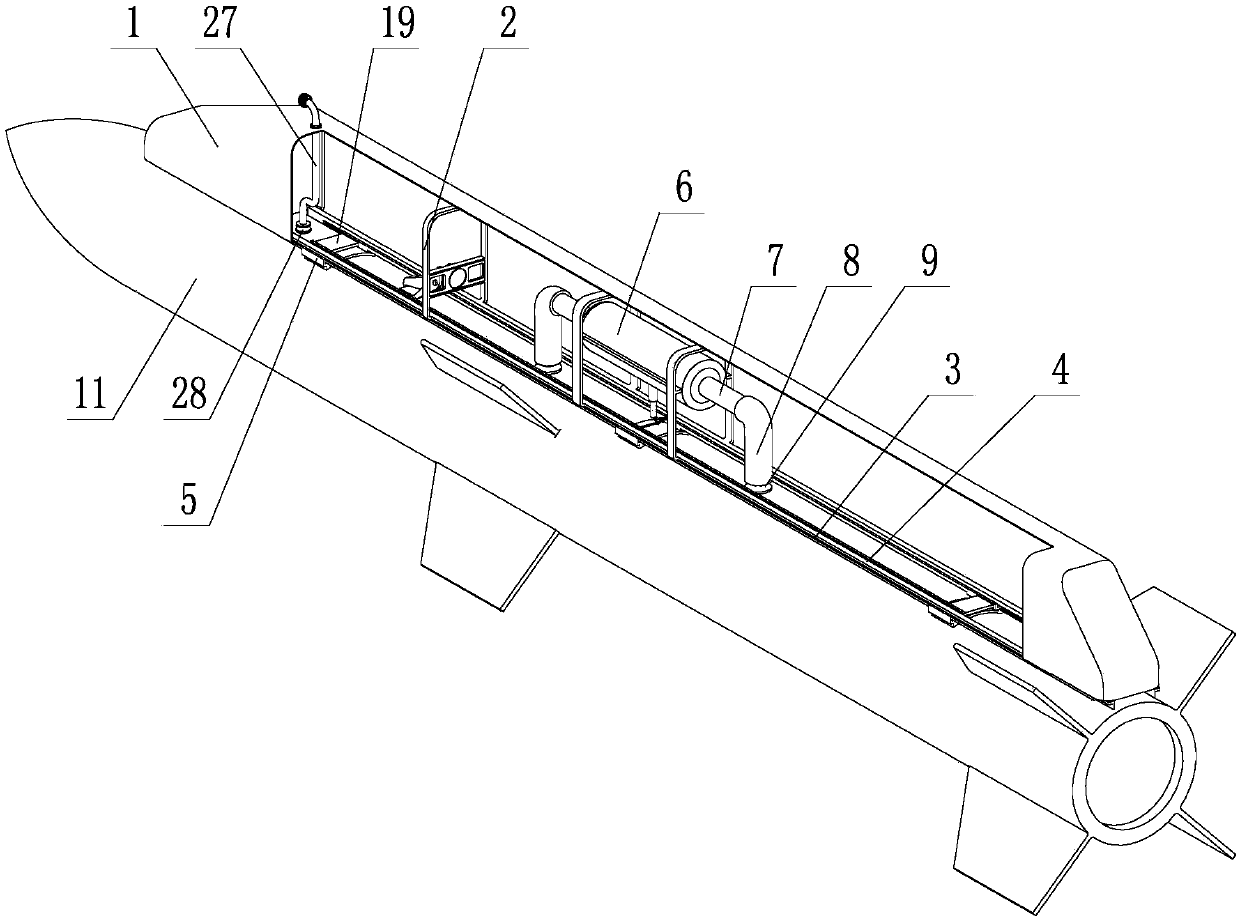

A dual-mode launching device for airborne missiles

InactiveCN106643294BImprove combat capabilityReduced reload timeLaunching weaponsCombustion chamberDual mode

The invention discloses a dual-mode launcher for an airborne missile. A shell is fixedly connected to a missile carrier, a plurality of ribs are fixedly installed inside the shell, two guide rail fixing racks arranged in parallel are fixedly connected to the ribs, each guide rail fixing rack is provided with a guide rail fixing port, two guide rails are respectively located inside the guide rail fixing ports of the guide rail fixing racks, a slide block is hung on the two guide rails, and the lower end of the slide block is fixedly connected with a missile body; a cartridge combustion chamber is fixedly arranged on the ribs, high-pressure jet ports at two ends of the cartridge combustion chamber are respectively connected with a missile ejection gas-guide tube, a missile ejection piston barrel is arranged vertical to the missile body, the upper opening of the missile ejection piston barrel is communicated with the missile ejection gas-guide tube, a missile ejection push rod is located inside a missile ejection piston barrel body, the missile ejection push rod has axial telescopic degree of freedom relative to the missile ejection piston barrel, and a guide rail and slide block separation driving mechanism is connected between each guide rail and the cartridge combustion chamber; a buffer is installed between the two guide rails; and a latching mechanism is installed between the ribs and the missile body.

Owner:SHENYANG AEROSPACE UNIVERSITY

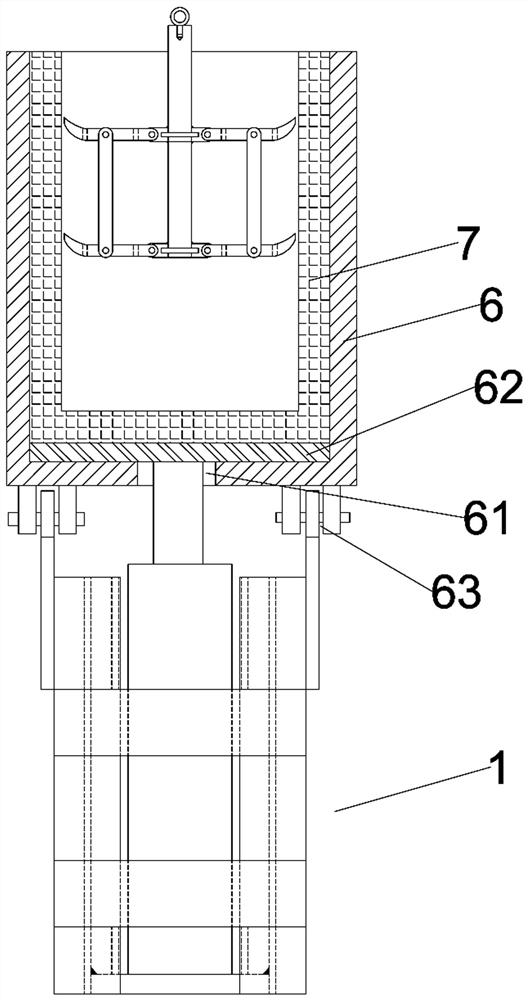

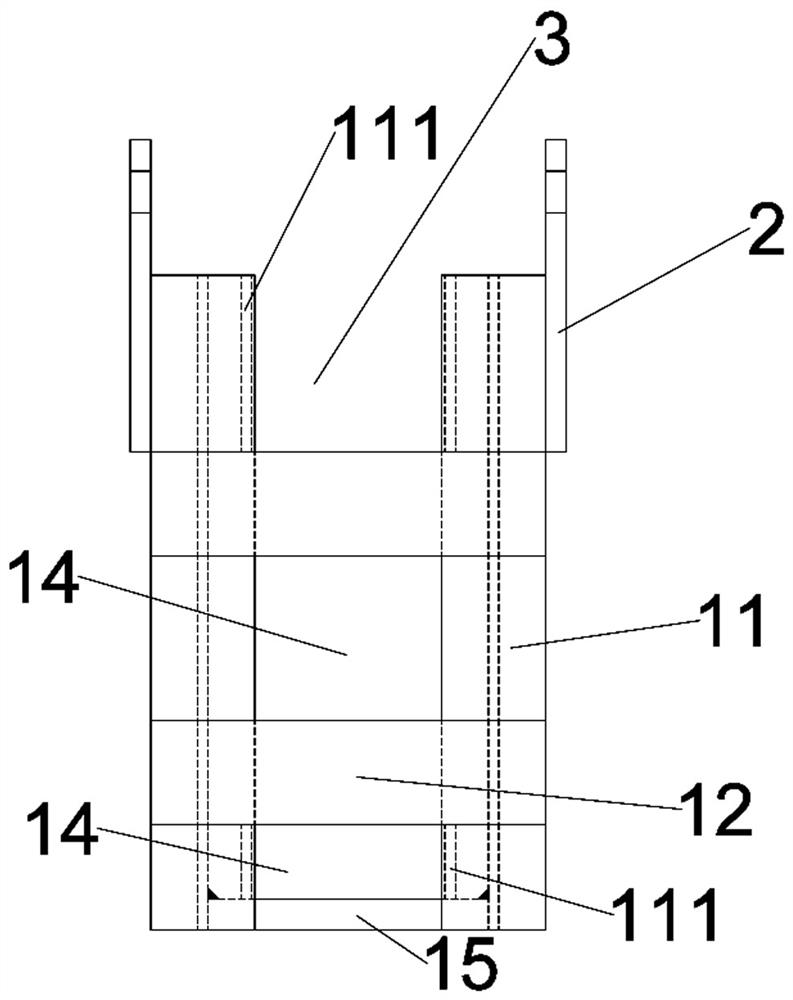

Furnace lining dismounting device for vacuum furnace

PendingCN112279059AReduce downtimeIncrease productivityLifting devicesMetal working apparatusVacuum furnaceMechanical engineering

The invention belongs to the field of steelmaking equipment, and particularly relates to a lining dismounting device for a vacuum furnace. The lining dismounting device comprises a furnace lining ejection mechanism and a furnace lining hoisting mechanism; the furnace lining ejection mechanism comprises a positioning steel frame, a connecting plate and a mounting seat cavity, and a jack is arrangedin the mounting seat cavity; the furnace lining hoisting mechanism comprises a main hoisting rod and at least three transverse hoisting claws evenly distributed on the main hoisting rod in the circumferential direction, the main hoisting rod is hinged to the transverse hoisting claws, the maximum included angle between the unfolded transverse hoisting claws and the main hoisting rod is 90 degrees, and the outer ends of the transverse hoisting claws are provided with claw ends extending outwards and upwards in an arc mode. According to the dismounting device, the furnace lining can be dismounted in the furnace within 8 hours or more after the furnace service is finished, an induction furnace does not need to be moved to another workshop for dismounting the furnace lining, the furnace shutdown time between the furnace service can be shortened after improvement, the production efficiency is improved, and the leakage detection and shutdown cost is reduced; and particularly, the dismounting time of the cold start boiler after a fault occurs can be greatly reduced.

Owner:湖州久立永兴特种合金材料有限公司

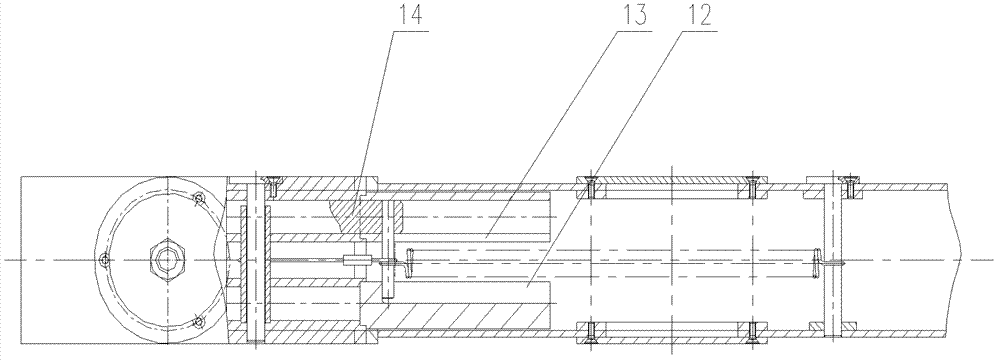

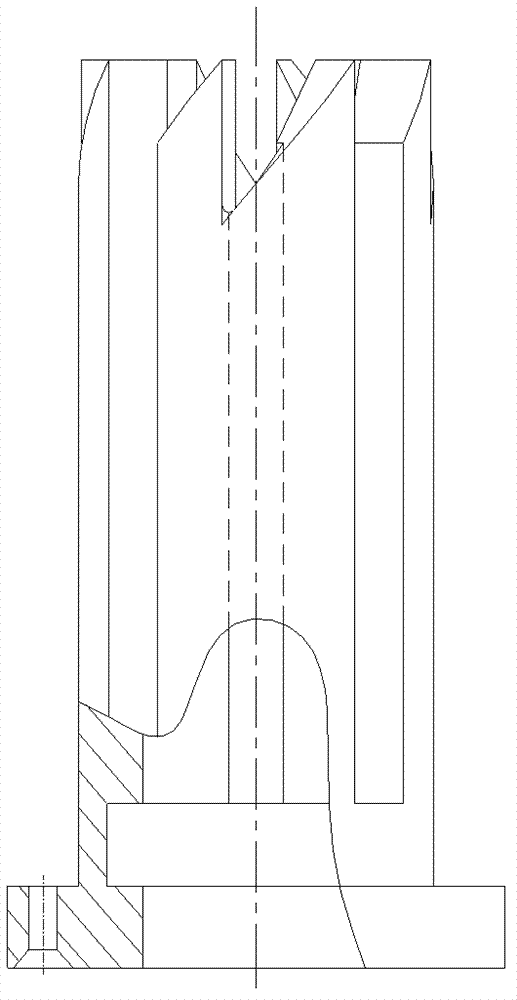

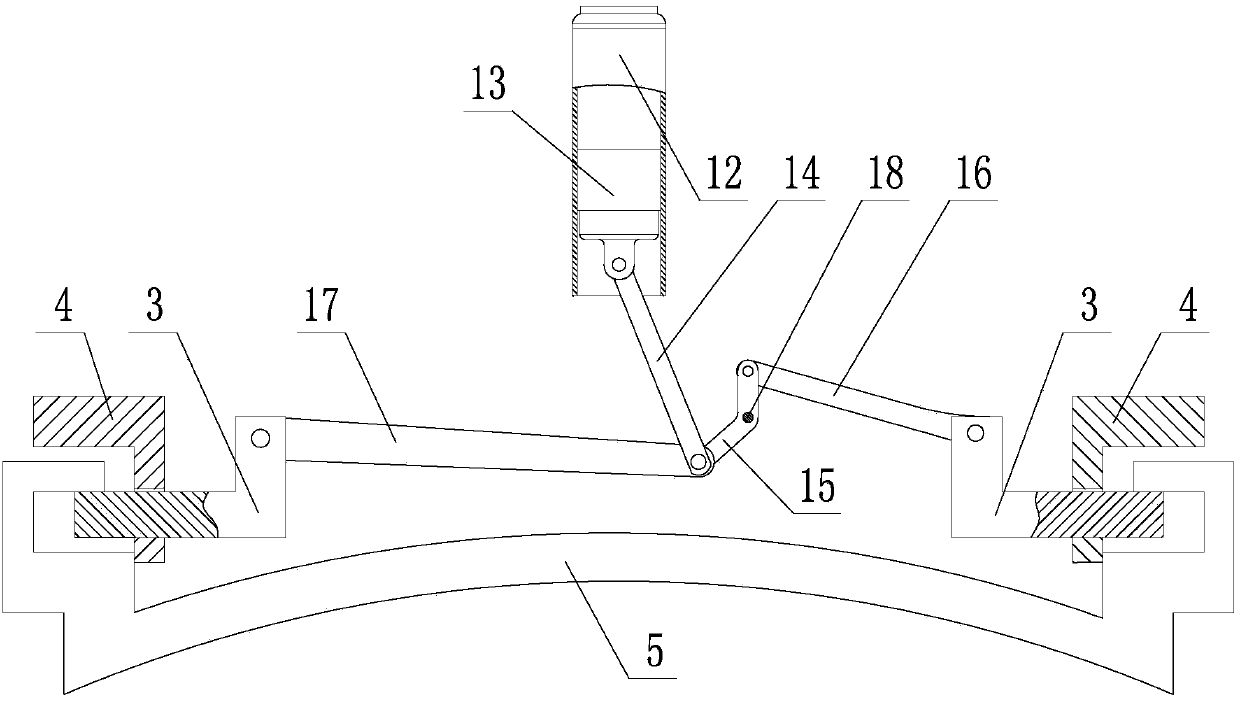

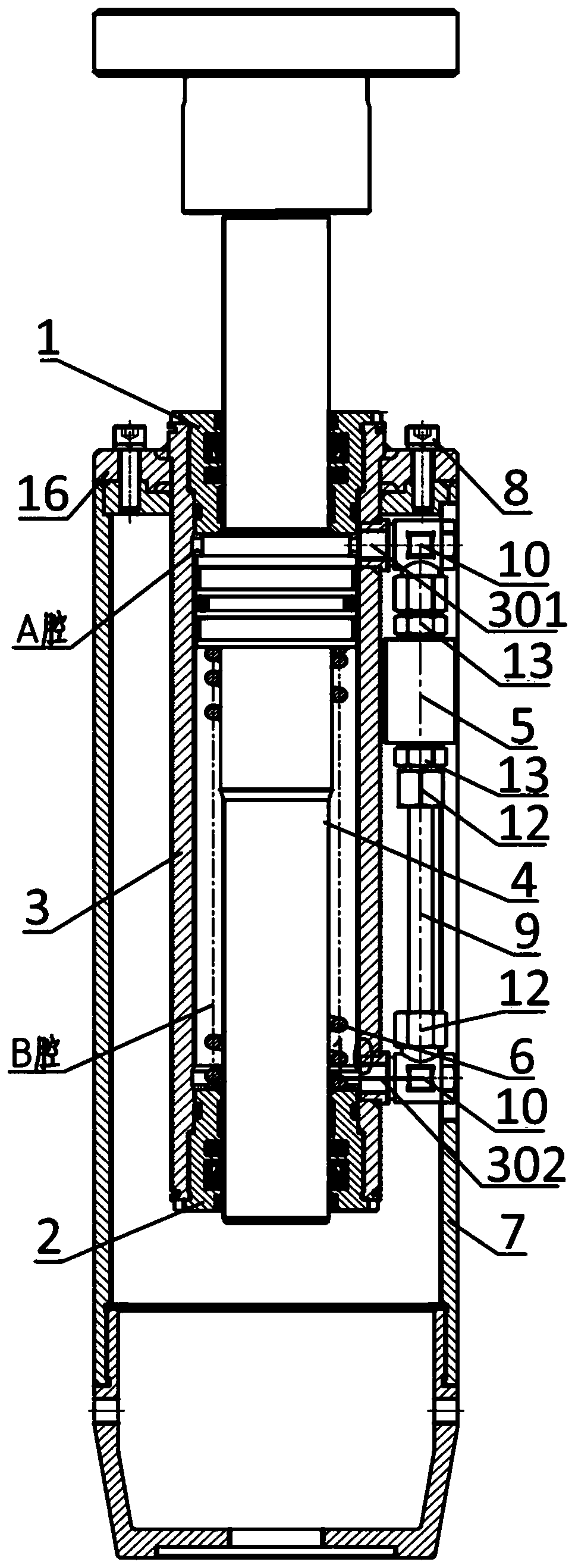

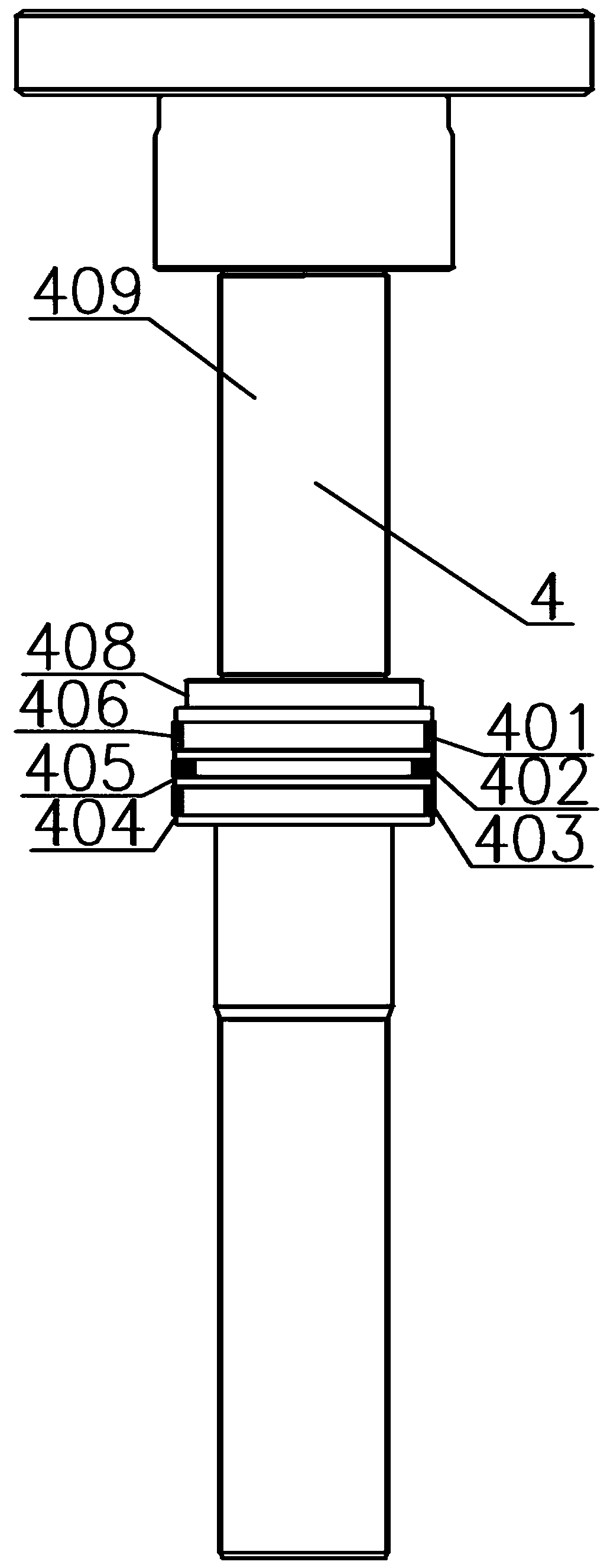

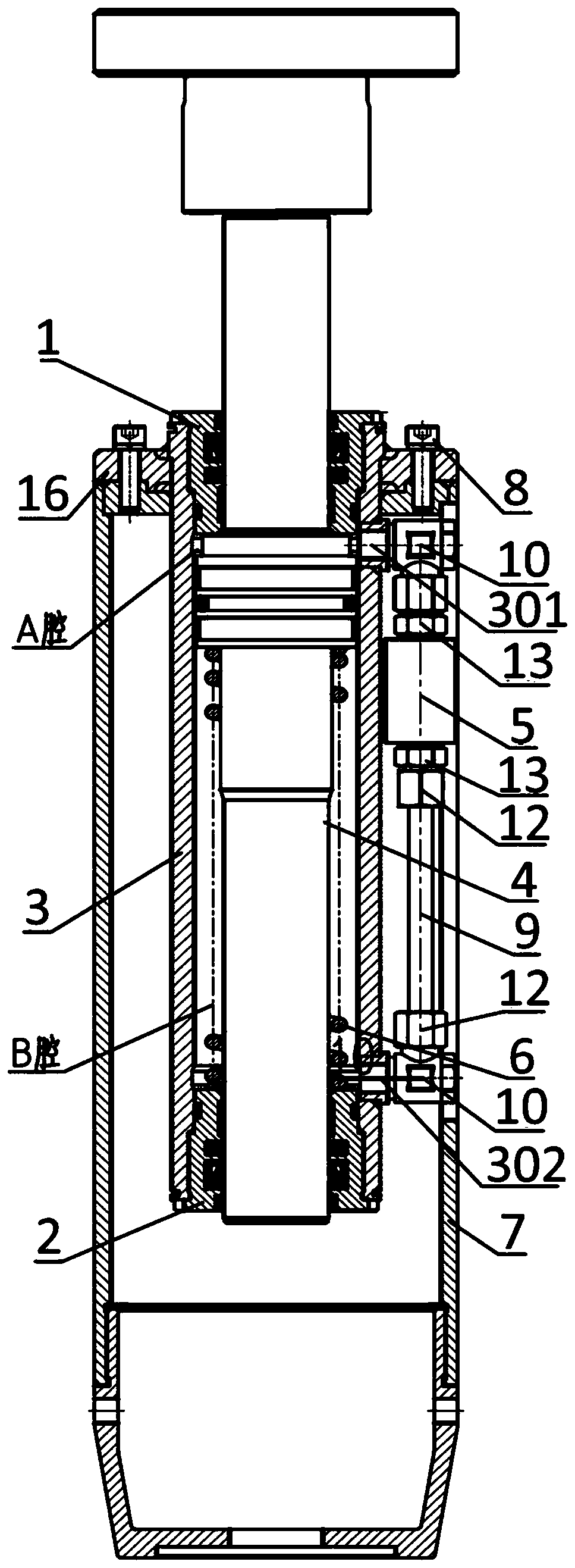

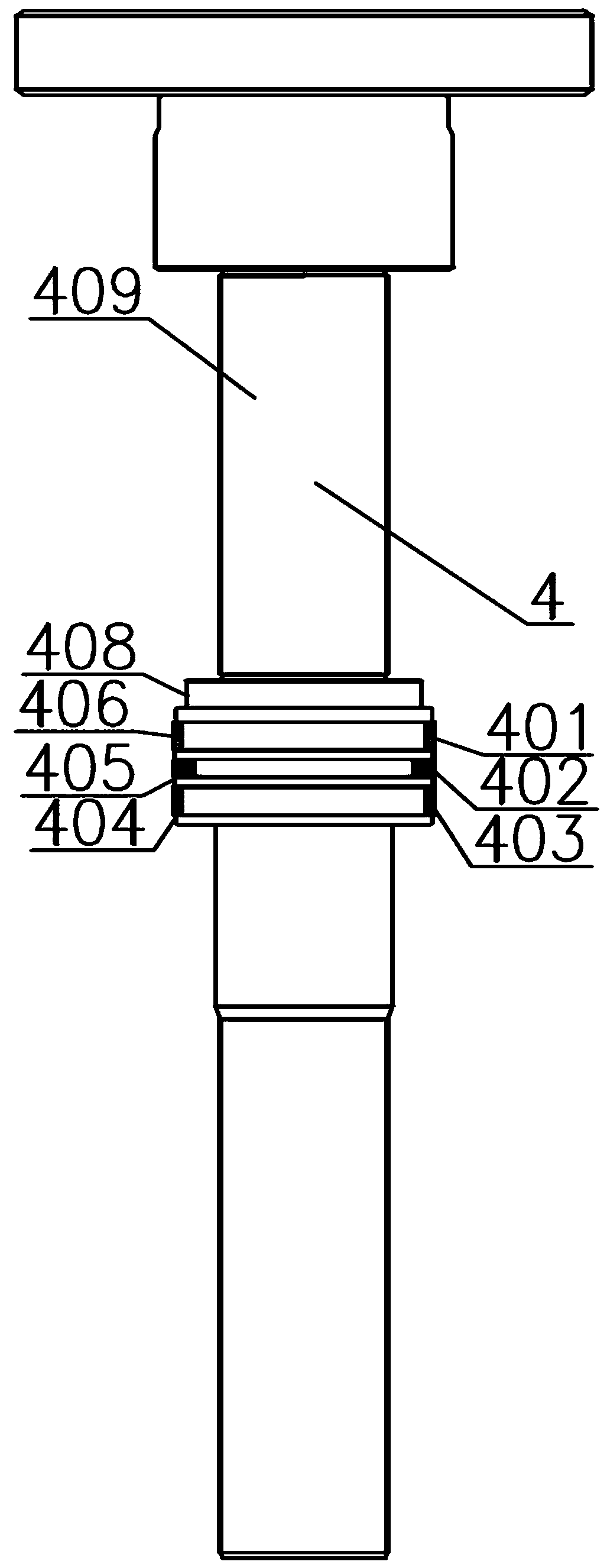

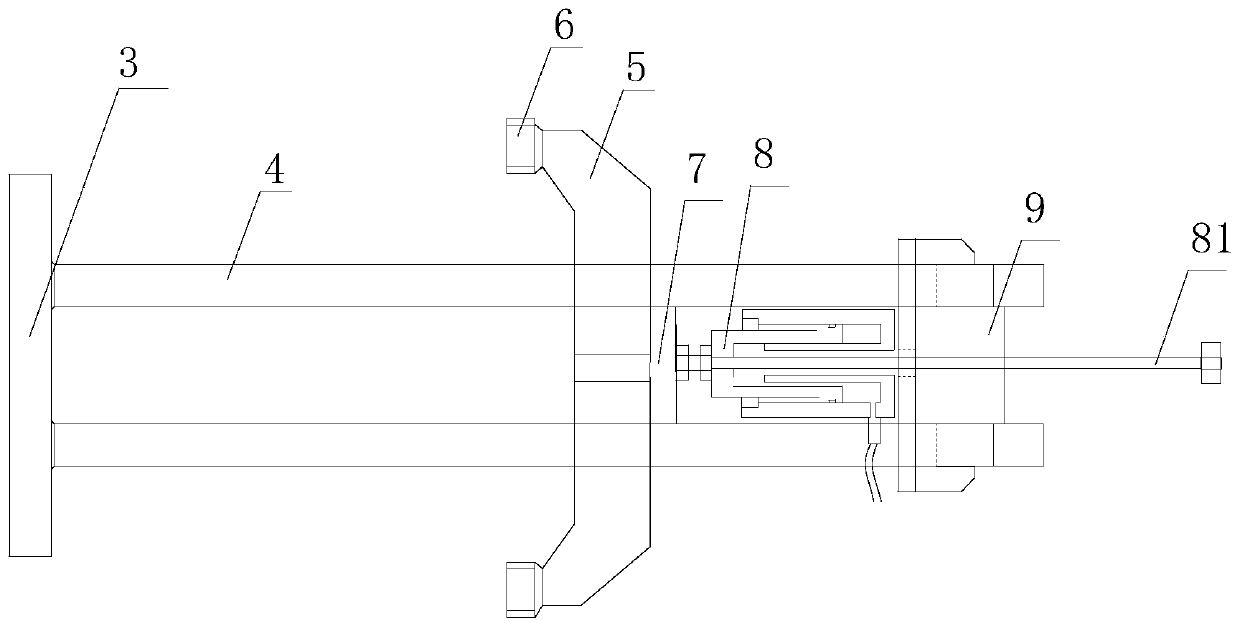

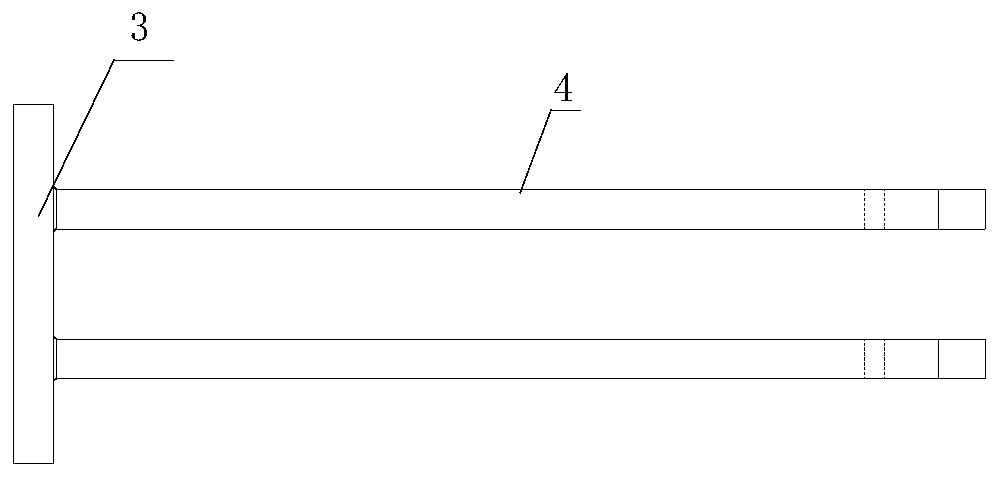

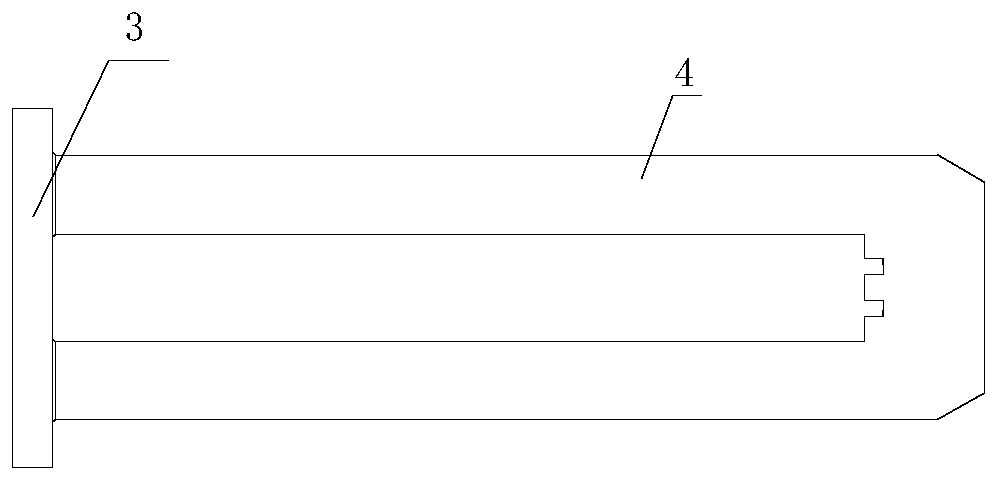

A device and simulation method for simulating projectile movement during bomb delivery

ActiveCN110398177BReduce usageReduced reload timeAmmunition testingFluid-pressure actuatorsStructural engineeringOil intake

The invention relates to a device for simulating the ammunition motion in an ammunition delivery process and a simulating method of the device. The device comprises three parts including a basic assembly, a piston assembly and an energy supply assembly. The basic assembly comprises a shell, a cylinder barrel arranged in the shell, an upper end cover and a lower end cover, wherein the upper end cover and the lower end cover are fixedly installed at the two ends of the cylinder barrel respectively; the piston assembly comprises a piston rod which makes reciprocating piston motion in the cylinderbarrel, penetrates through the upper end cover and the lower end cover, and is in clearance fit with the upper end cover and the lower end cover; the energy supply assembly comprises a cavity A oil inlet and a cavity B oil inlet which are formed in the same side of the two ends of the cylinder barrel respectively, hinged-type pipe joints, oil pipe assemblies and a first spring, wherein the hinged-type pipe joints are connected with the cavity A oil inlet and the cavity B oil inlet respectively, the oil pipe assemblies are connected through the hinged-type pipe joints, and the spring sleeves the lower end of the piston rod and is cushioned on the end face of the lower end cover. The device can continuously simulate the ammunition motion in the ammunition delivery process to shorten the loading time, and the test efficiency is improved.

Owner:南京理工军邦特种智能装备研究院有限公司

Wafer radiating element

InactiveCN100369245CAvoid damageGuaranteed mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesRadiating elementElectrical and Electronics engineering

The chip heat radiating element is for chip to radiate heat. The chip heat radiating element has one top plate and side walls, and the top plate is bent and extended to connected side walls and has notched part to contact with chip.

Owner:SILICON INTEGRATED SYSTEMS

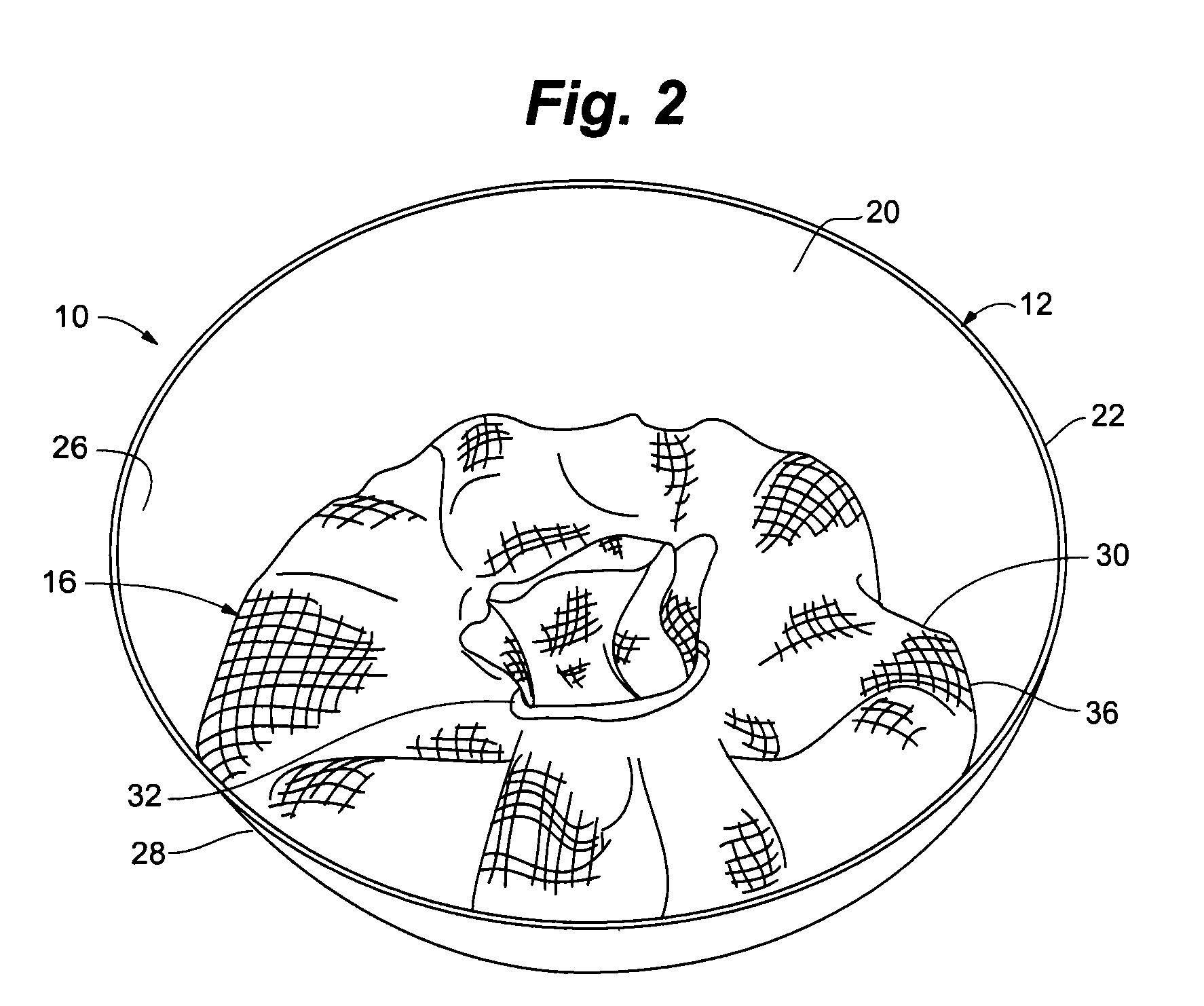

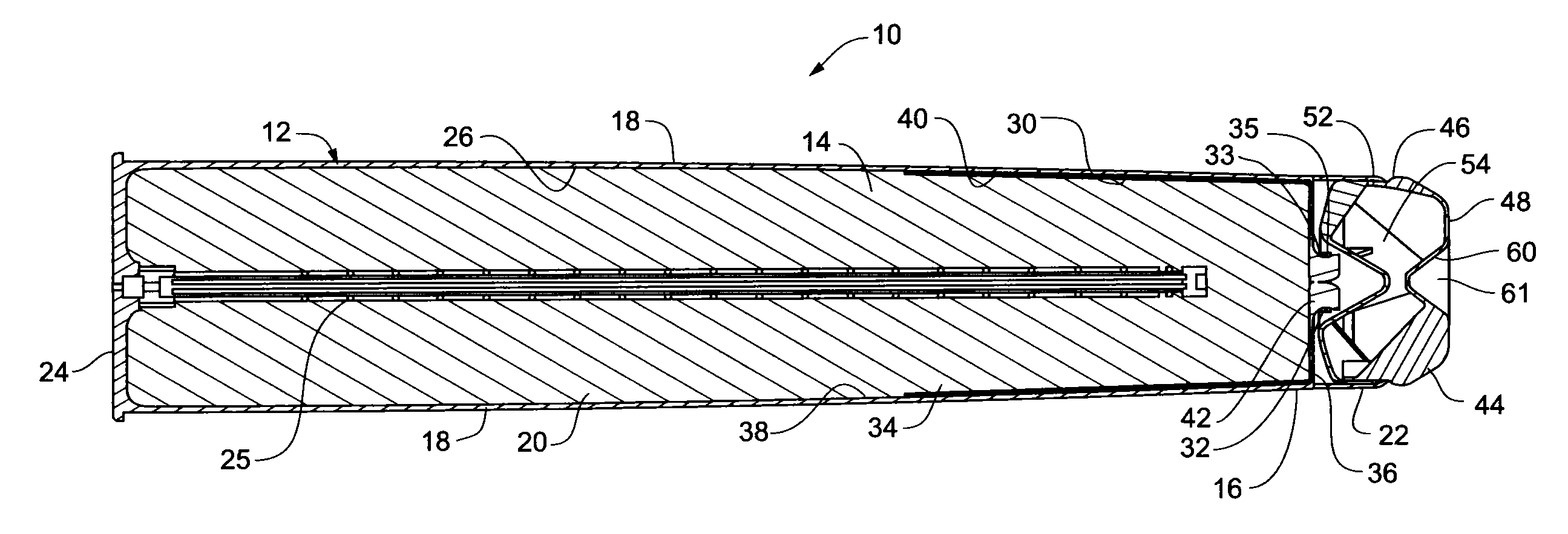

Cartridge assembly having an integrated retention system

InactiveUS8627770B2Reduced reload timePremature ignitionAmmunition projectilesShotgun ammunitionInterior spacePropellant

A cartridge assembly for large bore gun systems having an integrated retention assembly for maintaining propellant charges within the cartridge case. The cartridge case having an interior space for receiving propellant charges and an open proximate end through which the propellant charges can be fed. An insulating sleeve defining an interior channel is affixed to the cartridge case and extends out of the proximate end of the cartridge case. The interior channel serves as a chute through which propellant charges can be fed. After the propellant charges are loaded, the insulating sleeve is crimped closed to retain the propellant charges within the cartridge case. A closure plug can be inserted into the proximate end of the cartridge case after the insulating sleeve is crimped closed.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

Bullet clamp for sighting telescope

InactiveCN111578781AReduce weightReduce reload timeAmmunition loadingEngineeringMechanical engineering

The invention discloses a bullet clamp for a sighting telescope. The bullet clamp for the sighting telescope comprises a cover body and a base, the cover body and the base are fixedly installed, the cover body is evenly provided with a plurality of bullet containing holes according to the circumference, and a magnet piece is arranged between the cover body and the base. When the bullet clamp is used, the clamp is installed and fixed to the sighting telescope, a bullet is taken down from the clamp after one bullet is shot, the bullet changing time is greatly shortened, and a base annular groovenot only relieves the weight of the clamp but also can fixedly install the magnet piece to adsorb small bullets with diameters less than the bullet containing holes.

Owner:郭新建

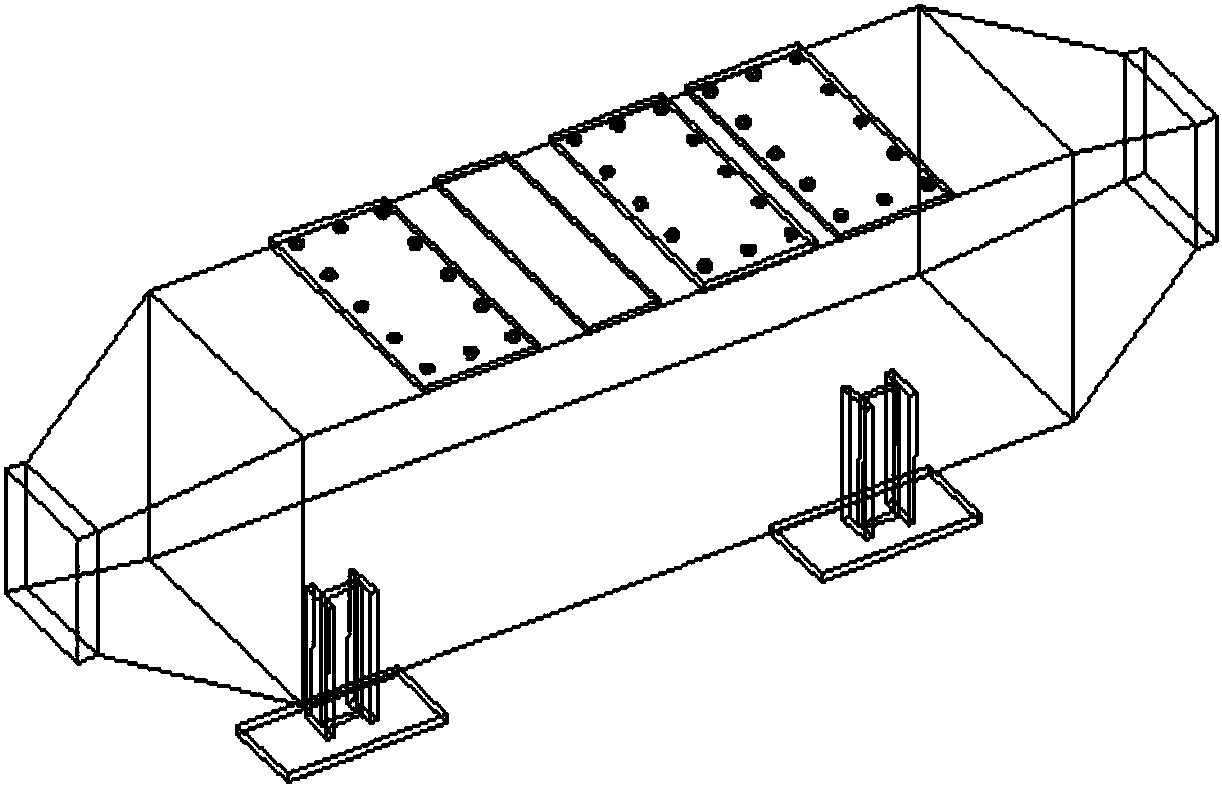

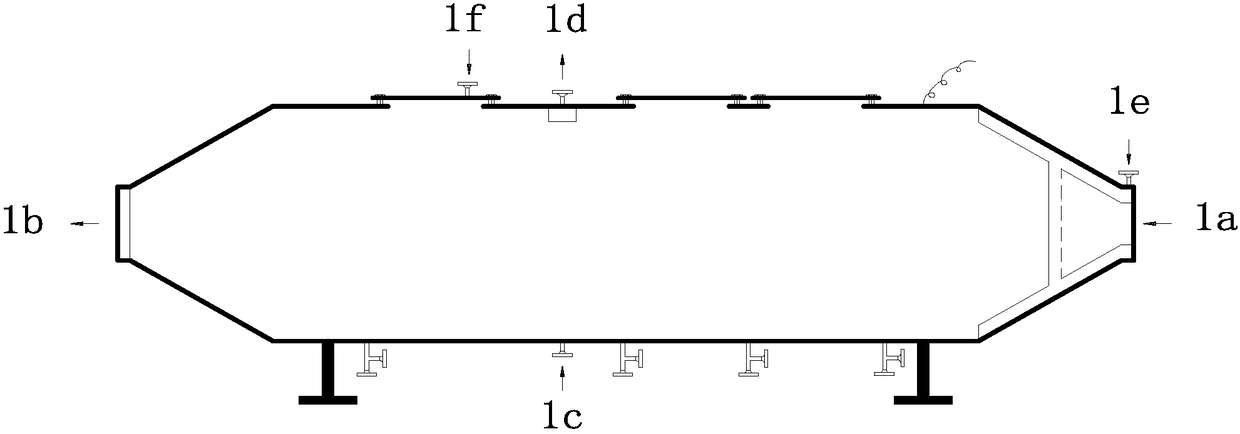

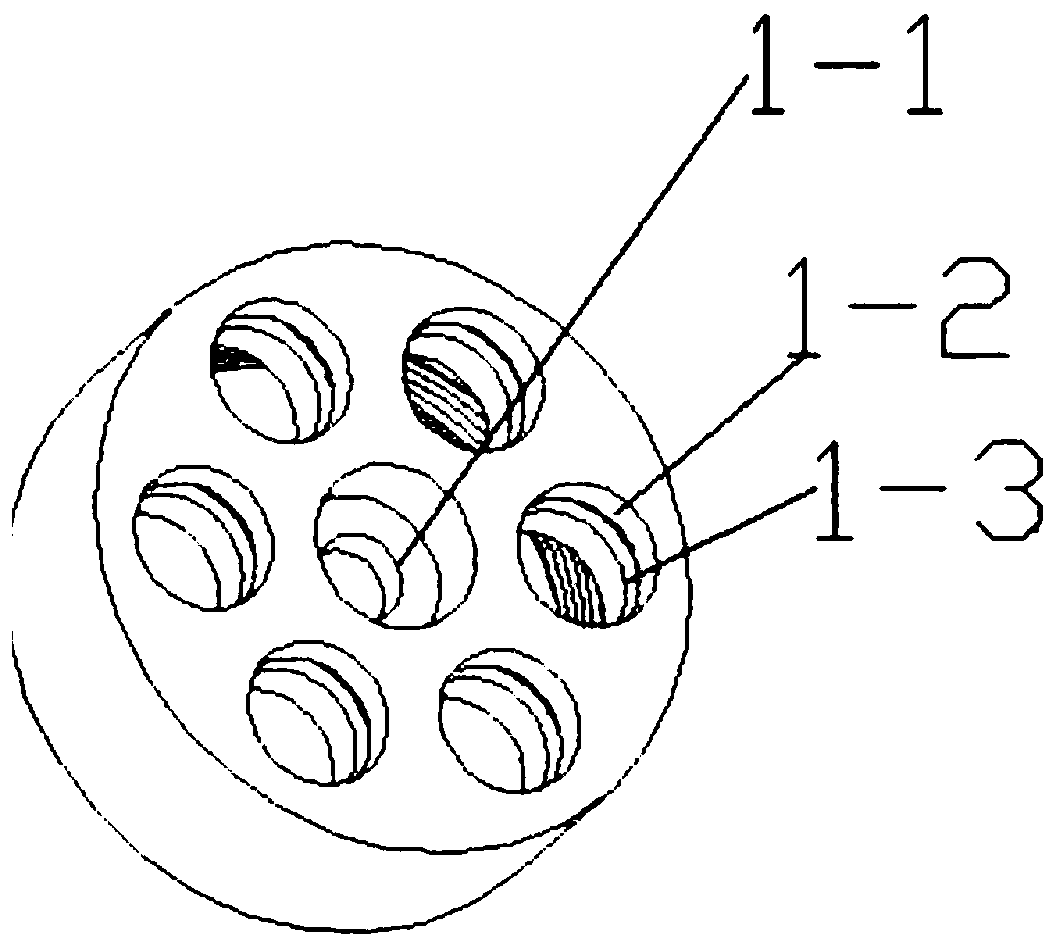

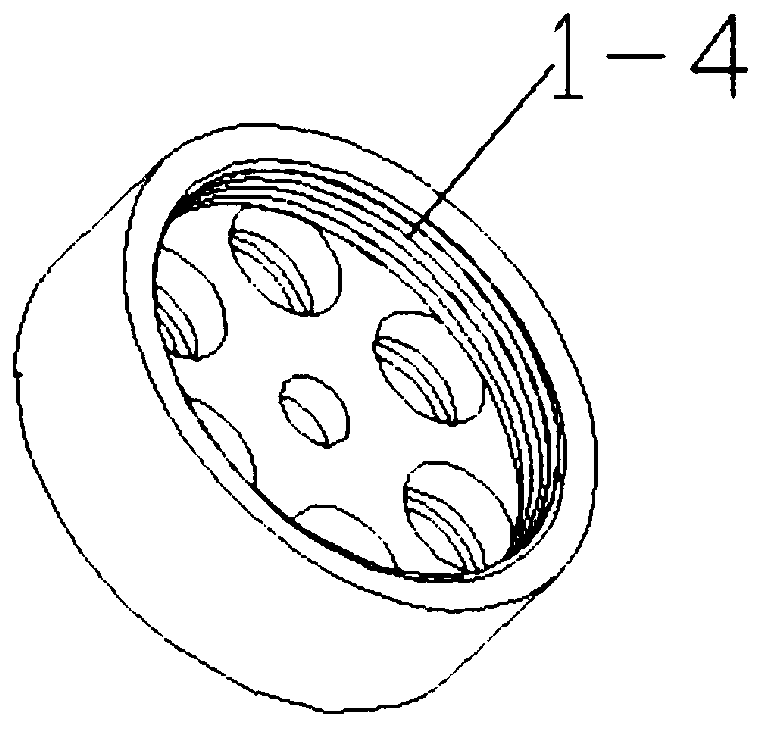

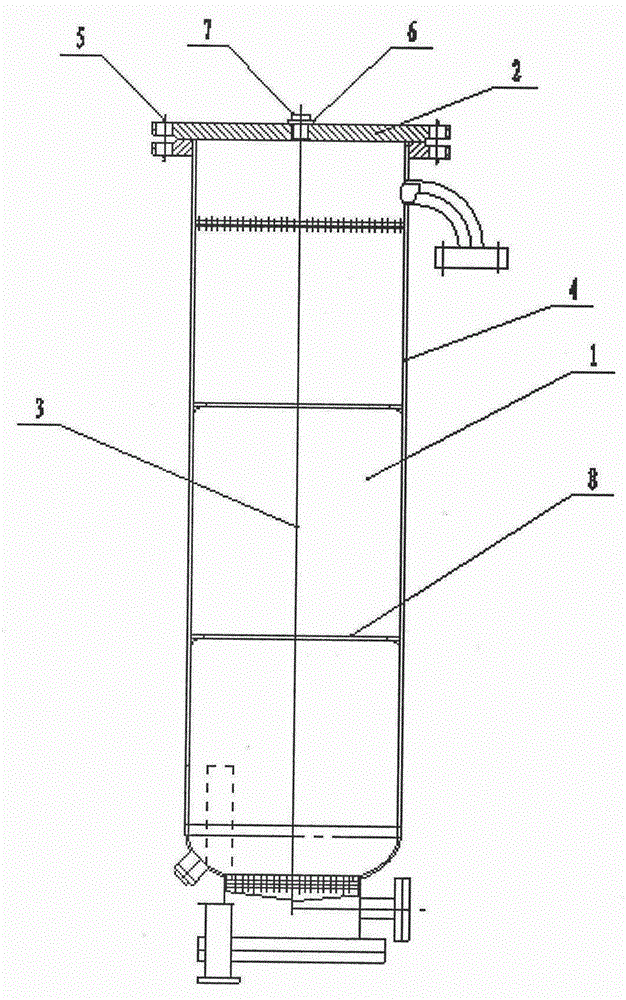

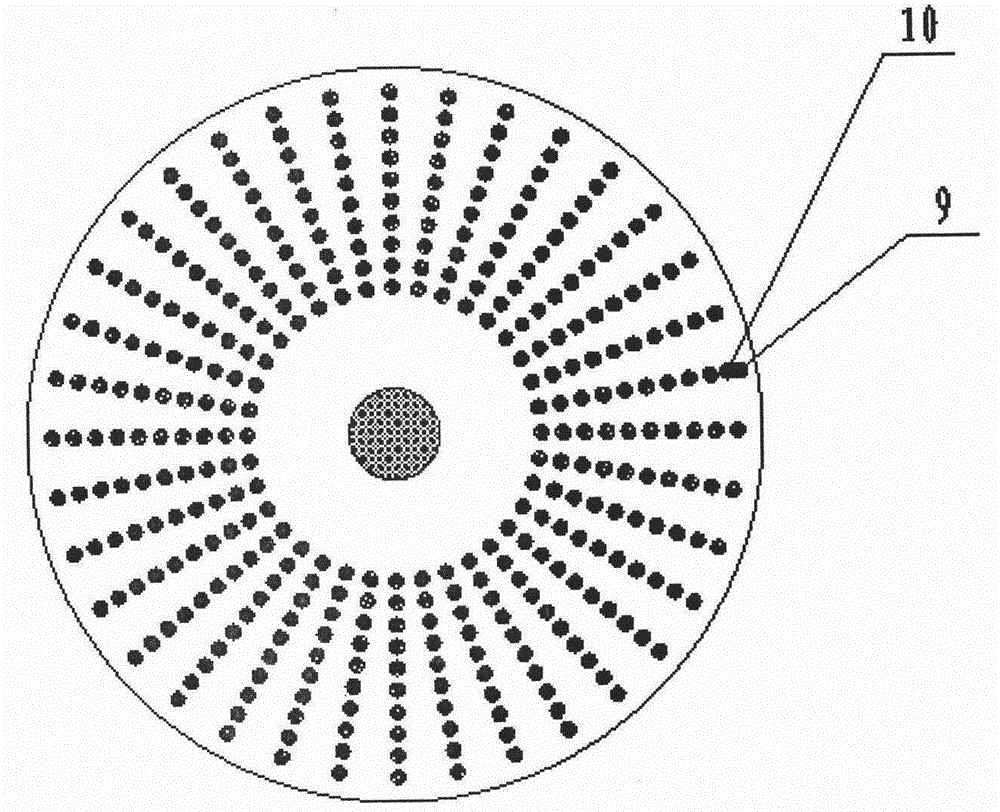

An anti-molecular sieve pulverization oxygen production host adsorption tower

ActiveCN103272456BEasy to fillLarge caliberDispersed particle separationOxygen preparationMolecular sieveEngineering

The invention belongs to the technical field of medical oxygen making, and provides a molecular sieve pulverizing-proof oxygen-making main engine adsorbing tower with simple structure and convenience in maintenance. The molecular sieve pulverizing-proof oxygen-making main engine adsorbing tower comprises a barrel shell, an upper cover and a molecular sieve, wherein the molecular sieve is mounted at the inner part of the barrel shell; the upper cover is mounted at the upper part of the barrel shell; the molecular sieve is fixed at the inner part of the barrel shell through an upper pattern card and a lower pattern card; small holes are formed in the pattern cards to enable the air to flow freely; silk nets are filled in the inner parts of the small holes; a cylinder with the same shape with a barrel body is arranged at the upper part of the barrel shell; the upper cover is fixed at the upper part of the barrel shell through screw bolts; a threaded hole is formed in the center of the upper cover; a screwed plug is mounted in the threaded hole; and the screwed plug is an inner hollow screw bolt. The tower is mainly applied to the technical field of the medical oxygen making, solves the trouble of filling and extracting the molecular sieve, and improves the oxygen producing quality of an oxygenerator.

Owner:山西卫弋医疗科技有限公司

Soil scattering equipment for garden potted plants

InactiveCN110169283AReduce workloadReduced reload timeCultivating equipmentsFlower-pot fillingElectric machineryNutrient

The invention relates to soil scattering equipment, in particular to soil scattering equipment for garden potted plants. The technical problem is to provide the soil scattering equipment for garden potted plants, which can automatically load nutrient soil, has high loading efficiency and automatically smoothes the nutrient soil. The soil scattering equipment for garden potted plants comprises a base seat, a bottom plate, a mounting plate, a collecting frame, a screen mesh, a rubber hose, an output pipe, a mounting seat, a motor, a first mounting frame and the like, wherein the bottom plate isarranged at the top of the base seat; the mounting plate is arranged on the rear side of the bottom plate; the collecting frame is arranged at the top of the mounting plate; the screen mesh is arranged at the lower part in the collecting frame; the rubber hose is arranged at the bottom of the collecting frame; the output pipe is arranged at the bottom of the rubber hose; and the mounting seat is arranged in the middle of the front side of the mounting plate. The nutrient soil can be automatically filled through the arranged motor and the output pipe, so that the workload of people is reduced,and the manual filling time of people is shortened; and moreover, the amount of the nutrient soil in each flowerpot does not have large deviation, so that people can master the water addition amount of potted plants.

Owner:欧美英

Cartridge assembly having an integrated retention system

InactiveUS20120204751A1High tensile strengthHigh strengthCartridge ammunitionInterior spaceEngineering

A cartridge assembly for large bore gun systems having an integrated retention assembly for maintaining propellant charges within the cartridge case. The cartridge case having an interior space for receiving propellant charges and an open proximate end through which the propellant charges can be fed. An insulating sleeve defining an interior channel is affixed to the cartridge case and extends out of the proximate end of the cartridge case. The interior channel serves as a chute through which propellant charges can be fed. After the propellant charges are loaded, the insulating sleeve is crimped closed to retain the propellant charges within the cartridge case. A closure plug can be inserted into the proximate end of the cartridge case after the insulating sleeve is crimped closed.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

Device for simulating ammunition motion in ammunition delivery process and simulating method of device

ActiveCN110398177AReduced reload timeImprove test efficiencyAmmunition testingFluid-pressure actuatorsSupply energyTest efficiency

The invention relates to a device for simulating the ammunition motion in an ammunition delivery process and a simulating method of the device. The device comprises three parts including a basic assembly, a piston assembly and an energy supply assembly. The basic assembly comprises a shell, a cylinder barrel arranged in the shell, an upper end cover and a lower end cover, wherein the upper end cover and the lower end cover are fixedly installed at the two ends of the cylinder barrel respectively; the piston assembly comprises a piston rod which makes reciprocating piston motion in the cylinderbarrel, penetrates through the upper end cover and the lower end cover, and is in clearance fit with the upper end cover and the lower end cover; the energy supply assembly comprises a cavity A oil inlet and a cavity B oil inlet which are formed in the same side of the two ends of the cylinder barrel respectively, hinged-type pipe joints, oil pipe assemblies and a first spring, wherein the hinged-type pipe joints are connected with the cavity A oil inlet and the cavity B oil inlet respectively, the oil pipe assemblies are connected through the hinged-type pipe joints, and the spring sleeves the lower end of the piston rod and is cushioned on the end face of the lower end cover. The device can continuously simulate the ammunition motion in the ammunition delivery process to shorten the loading time, and the test efficiency is improved.

Owner:南京理工军邦特种智能装备研究院有限公司

Weighing arm installation structure of bale rotary table

ActiveCN111054910AThe reinstallation process is smoothSafe reloading processMelt-holding vesselsCasting parameters measurement/indication devicesRotary stageJackscrew

The invention relates to the technical field of equipment installation, in particular to a weighing arm installation structure of a bale rotary table. The structure utilizes a fixed plate and two U-shaped frames which are arranged oppositely up and down as a top frame, a pressure head capable of sliding along the top frame is arranged in the top frame, a base is arranged at one end, far away fromthe fixed plate, of the top frame, a hollow hydraulic jack is arranged between the pressure head and the base, so that the pressure head is pushed by the hollow hydraulic jack to stably press a wholeweighing arm into a trunnion, the whole weighing arm reloading process is stable and safe, the construction progress is accelerated on the basis of ensuring the construction safety, the reloading timeis greatly shortened, and the time for occupying the total construction period is further shortened; and moreover, the installation structure can be recycled, so that the construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

A method for catalytic combustion to remove volatile organic compounds

ActiveCN108096992BImprove removal efficiencyImprove loading procedureGas treatmentDispersed particle separationSorbentEmission standard

Owner:DALIAN UNIV

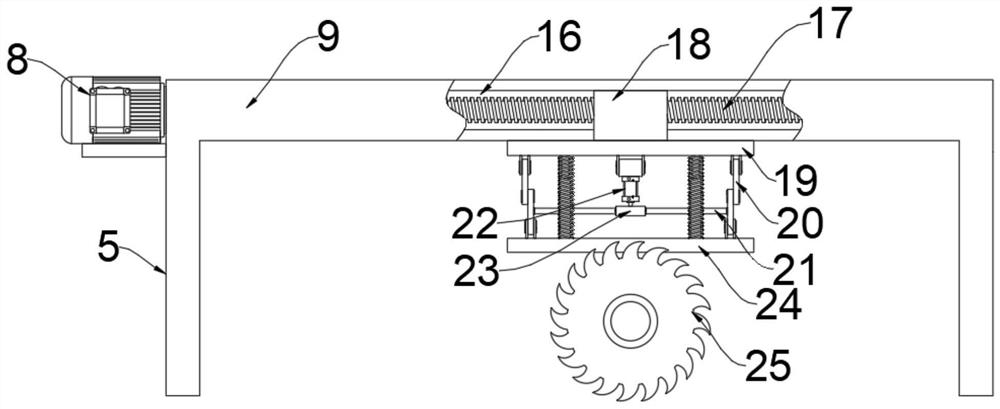

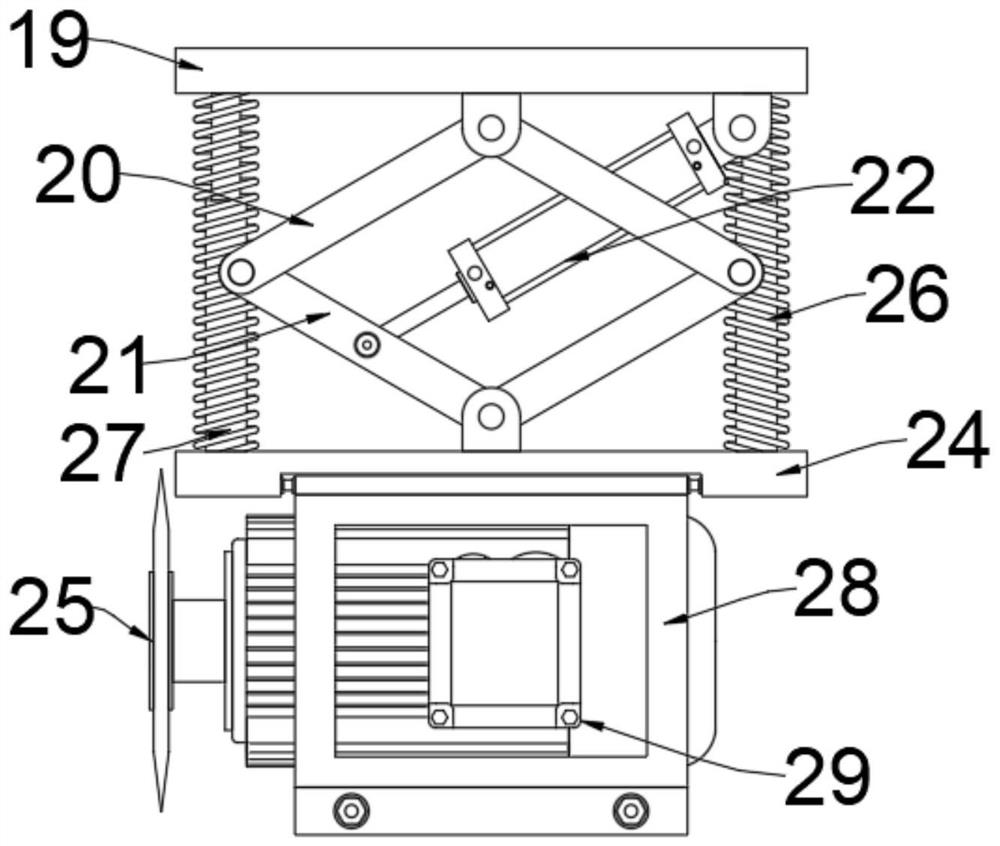

High-temperature cutting device for metal steel pipes and cutting method of high-temperature cutting device

InactiveCN113070523AReduced reload timeImprove work efficiencyMetal sawing devicesElectric machinePipe

The invention discloses a high-temperature cutting device for metal steel pipes and a cutting method of the high-temperature cutting device, relates to the related field of metal steel pipes, and aims to solve the problems that most of current cutting devices are used for cutting single steel pipes, and part of the cutting devices for cutting the steel pipes in batches are tedious in use process, need manual auxiliary work, are low in automation degree, and low in working efficiency. A second containing box is fixedly connected to one side of the front end of a first containing box, a supporting table top is fixedly connected to the front end of the first containing box along one side of the second containing box, first sliding grooves are formed in the front end and the rear end of the upper end face of the supporting table top, and first lead screws are installed in the first sliding grooves. A third driving motor is installed on the outer side of the supporting table top along one sides of the first lead screws, an alignment unit is arranged on one side of the upper end of the supporting table top and comprises a third C-shaped supporting frame, and third sliding blocks are fixedly connected to the two sides of the lower end of the third C-shaped supporting frame.

Owner:南京万鹏金属制品有限公司

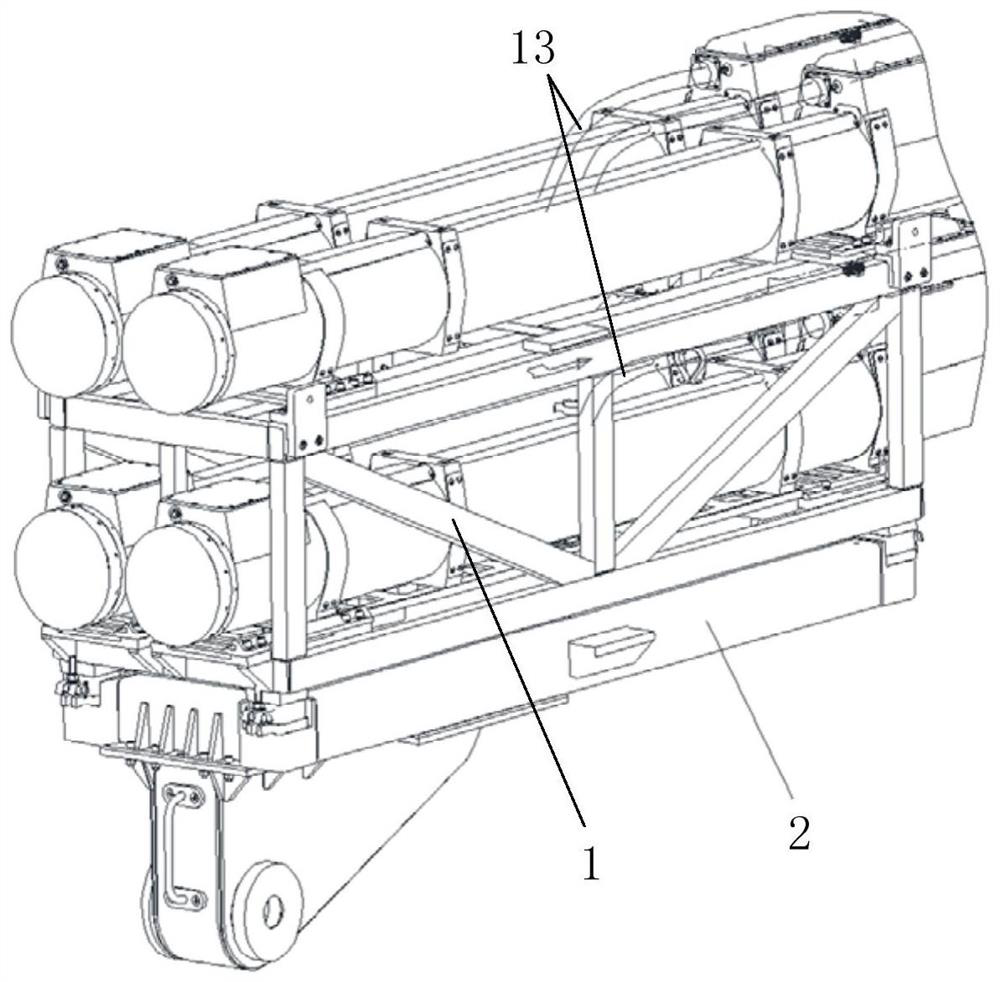

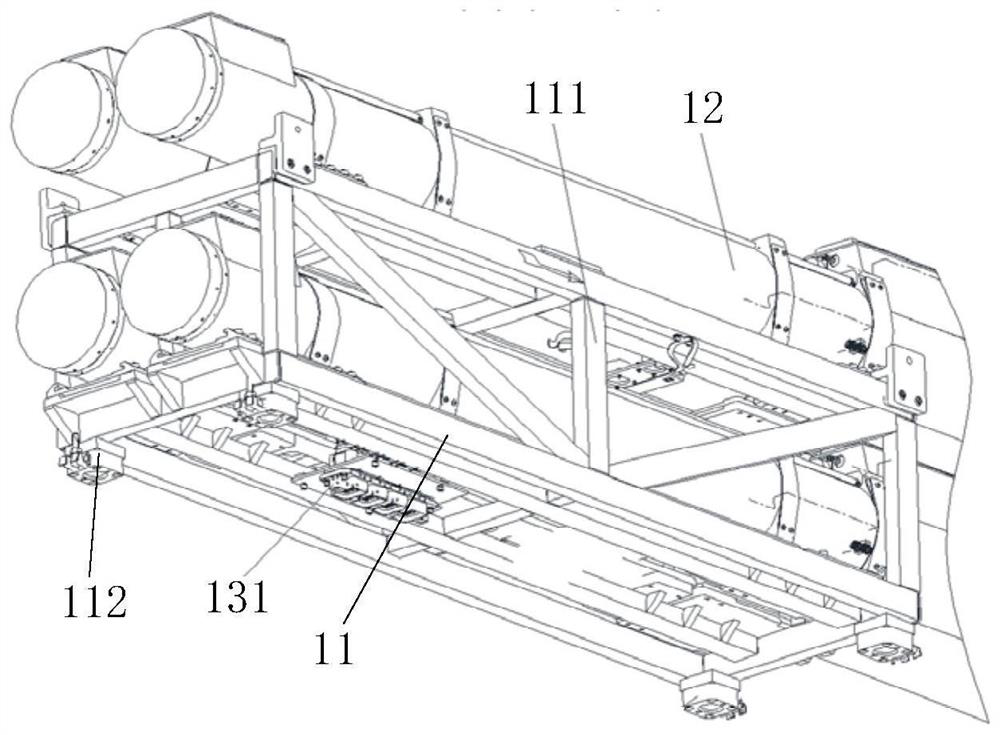

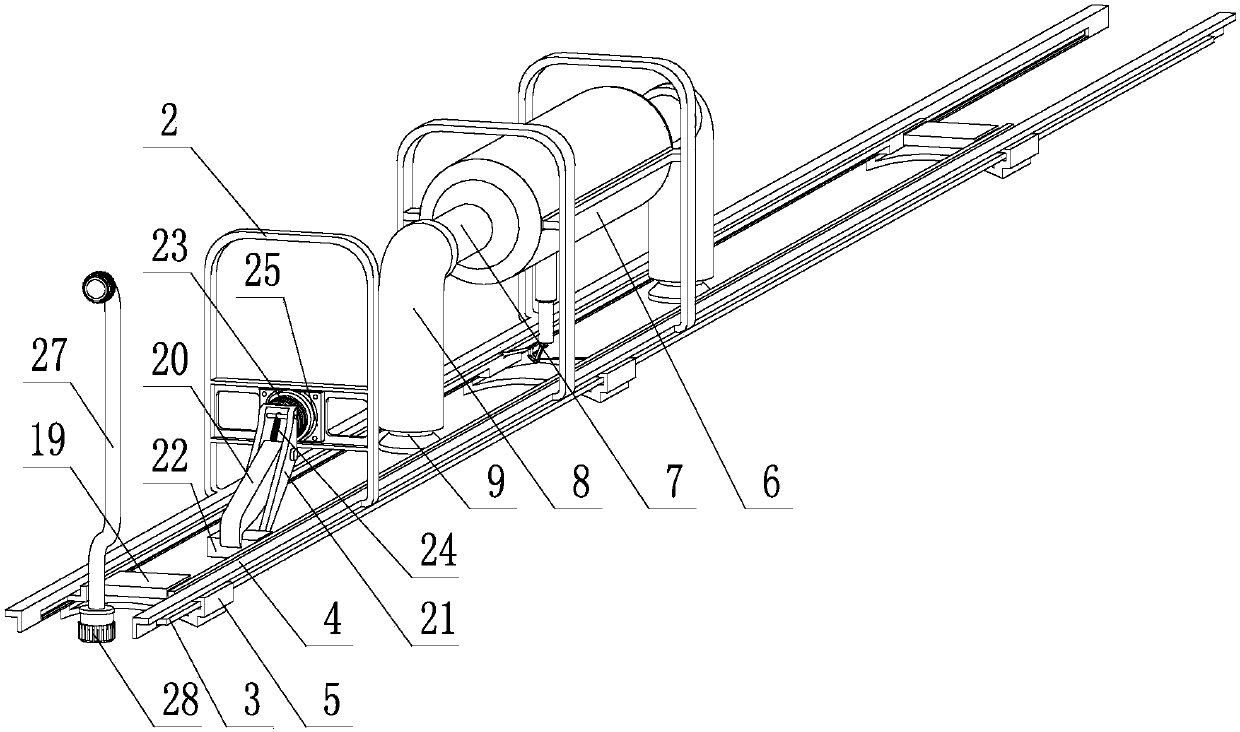

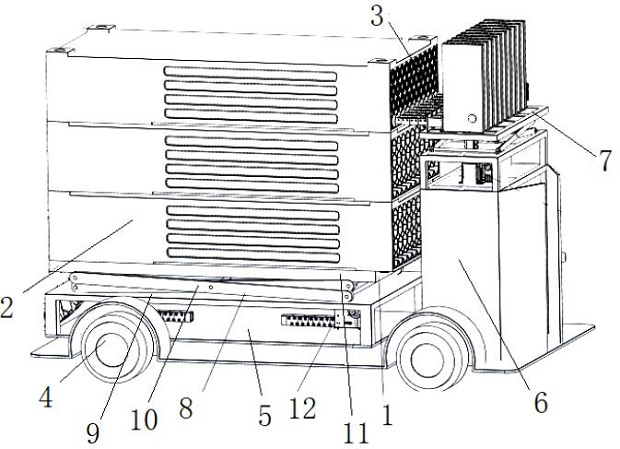

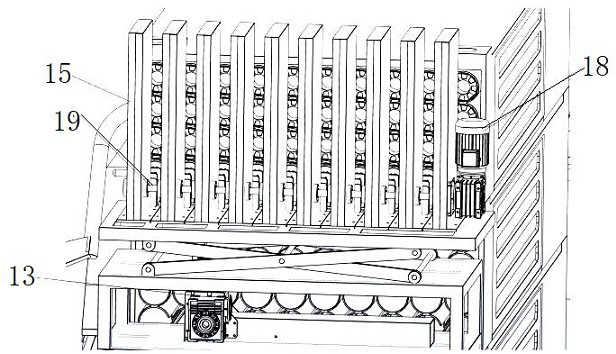

Rapid loading system for rocket launcher

InactiveCN114322642AFast reloadReduced reload timeAmmunition loadingStructural engineeringLaunch craft

The invention relates to a quick loading system for rocket launchers, which consists of a loading vehicle, a loading box and a pushing mechanism, a platform is arranged at the front end of the top of the loading vehicle, and a loading box lifting mechanism is fixed on the platform; a box body is arranged at the rear end of the top of the filling vehicle, a containing table is arranged at the top of the box body, a shear fork mechanism is arranged at the bottom of the containing table, and the pushing mechanism is fixed to the top of the containing table and composed of a row of pushing rigid chains arranged side by side. Compared with an original manual loading and lifting appliance loading mode, the loading box prepared in advance can be used for pushing a row of rocket projectiles into a launcher at a time through the rigid chain pushing mechanism at the speed of 300 mm / s, loading of a row of rocket projectiles with the length of 6 m can be completed only in 20 seconds, and the loading efficiency is greatly improved. Five rows of rocket projectiles in the whole loading box can be loaded within two minutes, so that the loading speed is high, the loading time is greatly shortened, and real-time loading can be efficiently completed on a field battlefield.

Owner:JIANGSU EFFICIENCY ROBOTICS SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com