Blasting device and method for rapid forming of V-shaped pit body in hard rock and slag throwing

A hard rock and fast technology, applied in the direction of blasting, etc., can solve the problems of rapid prototyping, long working time, and high consumption of explosives that are difficult to meet in military applications, so as to reduce the workload of manual slag removal, shorten the filling time, and improve the blasting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

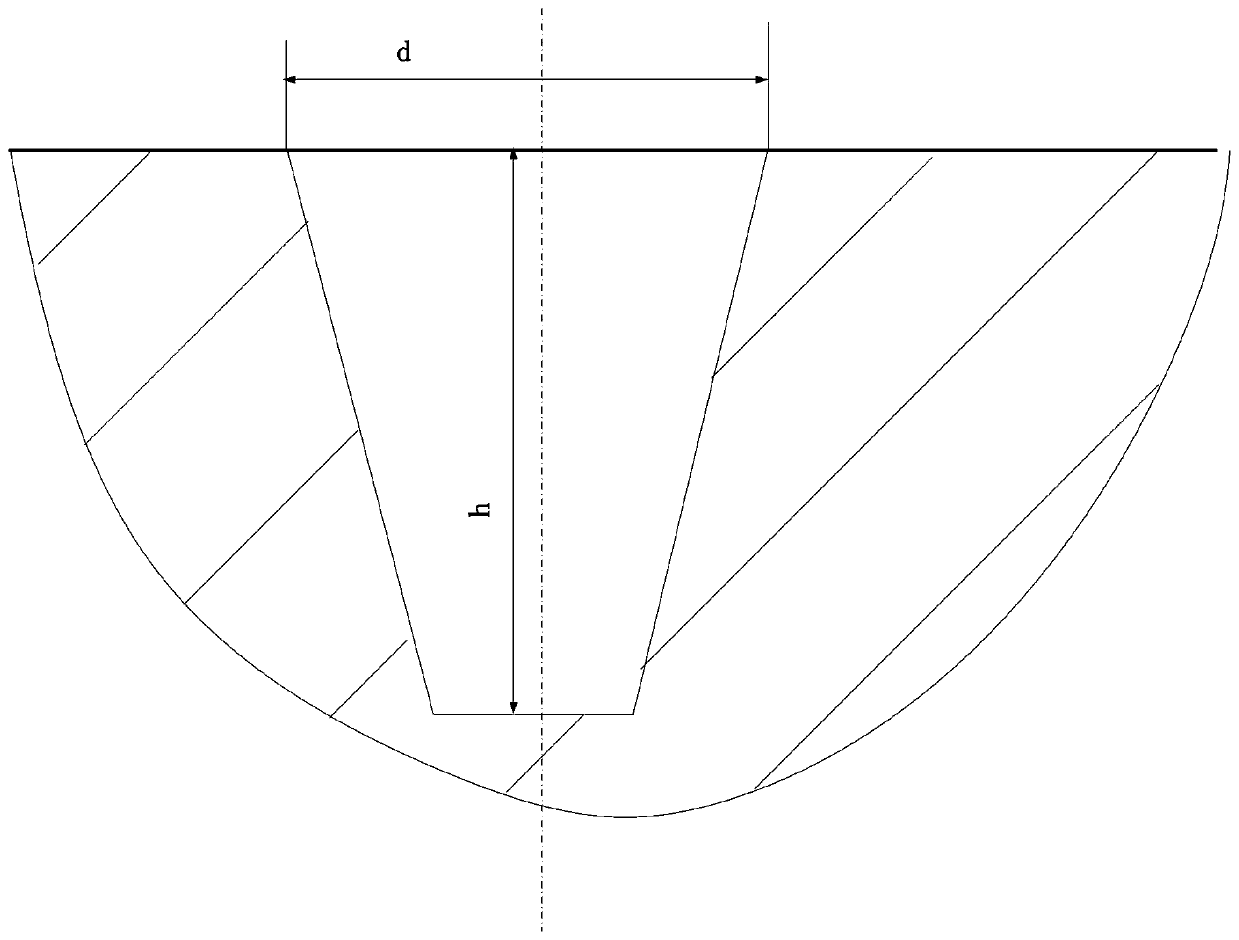

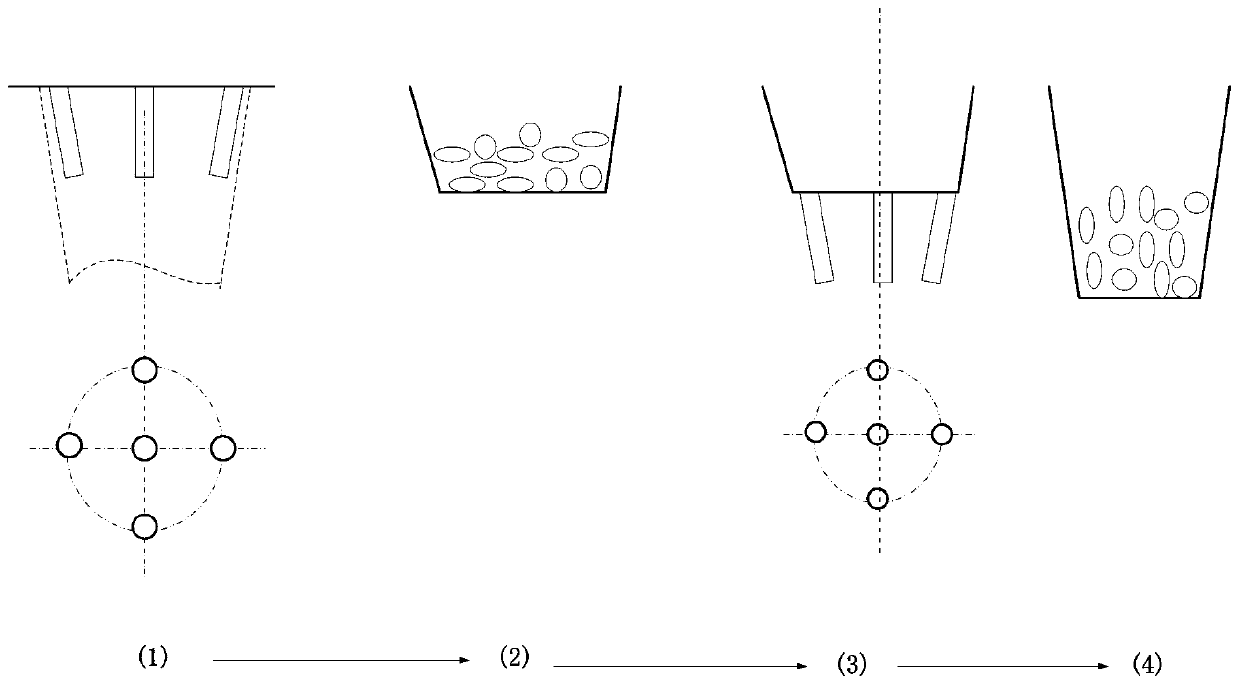

[0041] The purpose of the present invention is to form a V-shaped pit body of a special size by one-time blasting on a hard rock, improve the efficiency of the pit body formation, and avoid the operational risk caused by the blasting construction of secondary filling explosives. The adopted scheme is in A blasting device with two-stage explosives installed after drilling a hole in the rock, and controlling the delay between the upper explosive and the lower explosive, so that the upper charge creates an air surface for the lower charge, reducing the blasting time of the two charges The minimum resistance line, using less charge to achieve greater throwing effect, thus realizing the rapid prototyping of the pit body in one blast.

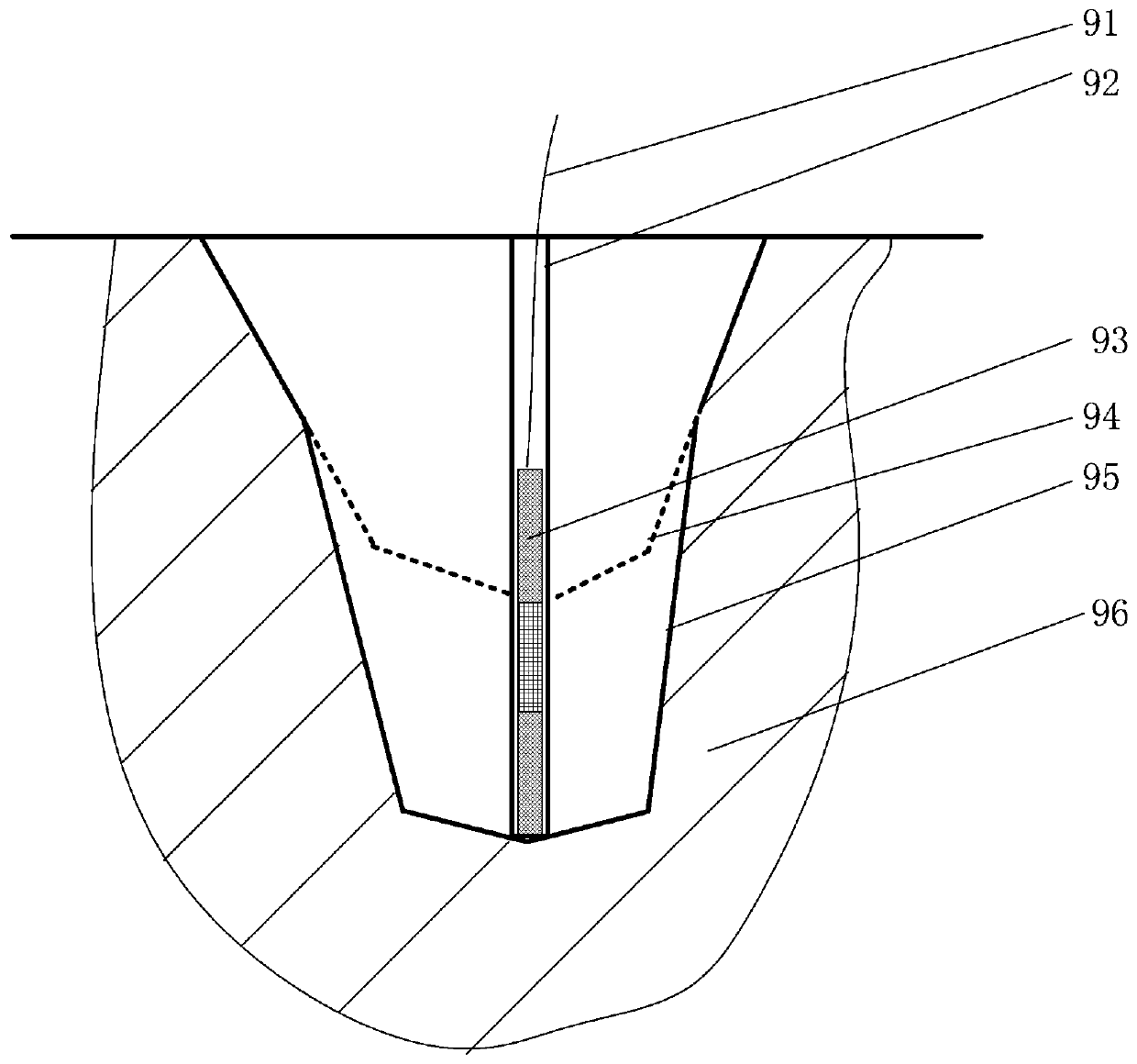

[0042] Such as image 3 As shown, the main technical route of the present invention is as follows: first, a hand-held drill is used to drill a vertical blast hole 92 in the rock 96, and then the blasting device 93 of the present invention, which inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com