Rapid profiling machining operation method for new sample piece of automobile engine part

A technology of automobile engine and profiling processing, which is applied in computer control, program control, instruments, etc., can solve the problems of unsatisfactory processing accuracy, increased manufacturing cost, time-consuming and laborious processing, etc., so as to improve the processing efficiency of new products and reduce the number of corrections , The effect of improving programming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

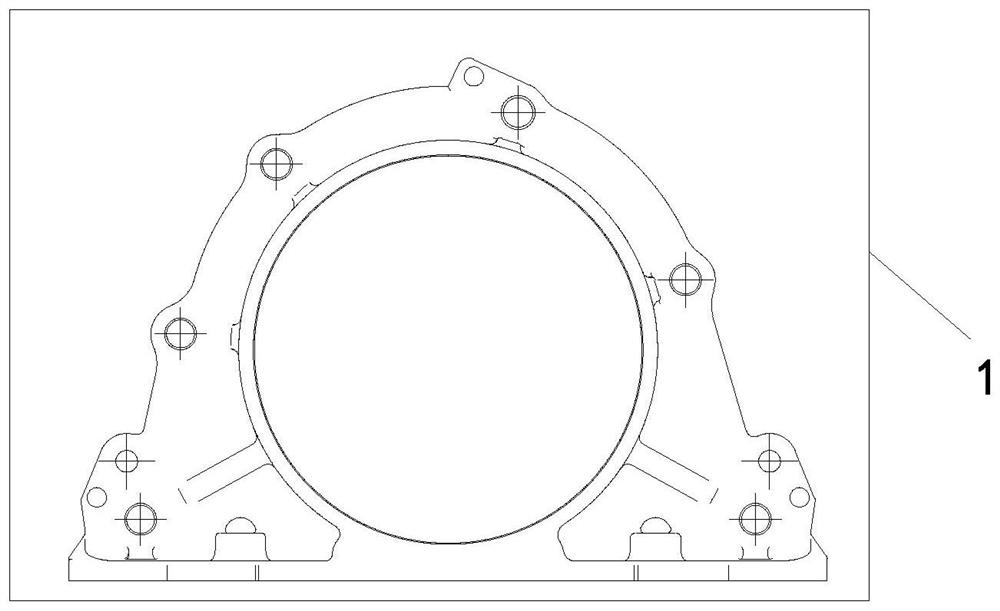

[0034] In order to better understand the purpose, structure and function of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] The technical scheme of the present invention is to analyze the three-dimensional digital model and the part drawing of the new shell-and-disc automobile engine sample, carefully study the part structure, study the processing technology, formulate the processing plan, carefully design the fixture, and complete the operation method of rapid processing.

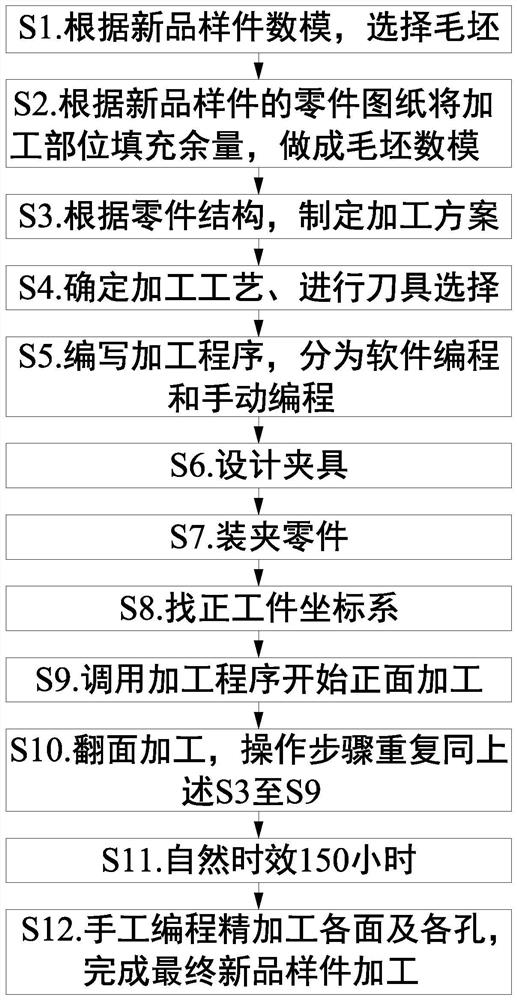

[0036] The specific operation steps are as follows:

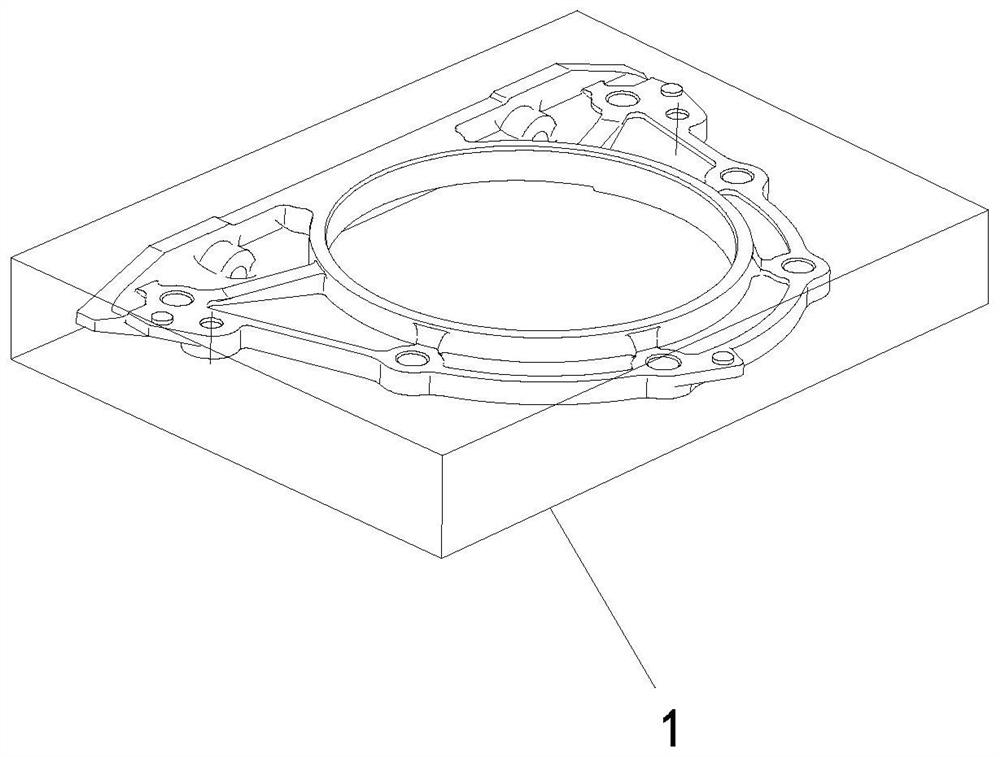

[0037] Step 1: Analyze the digital model of the new product sample and select blank 1.

[0038] The new sample of automobile engine is processed by multi-axis CNC machine tool. According to the three-dimensional digital model of the new product sample, the actual size of the part is determined, and the aluminum block that can completely contain the new product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com