Patents

Literature

98results about How to "Reduce the number of corrections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

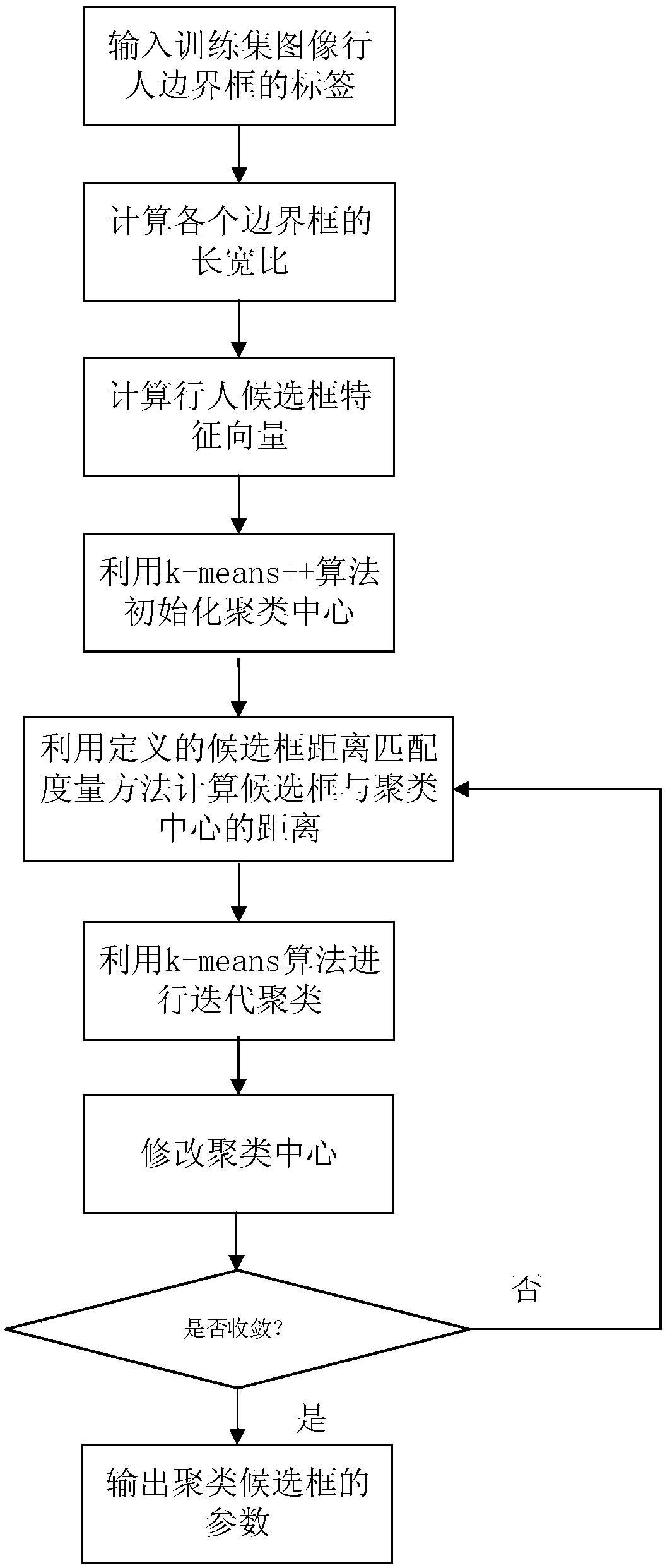

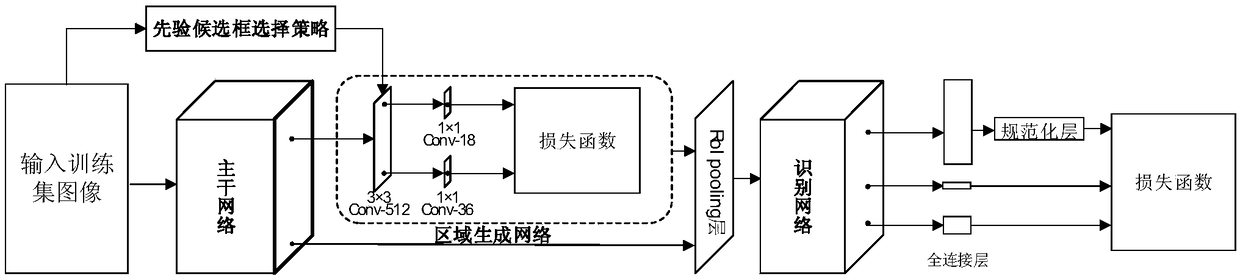

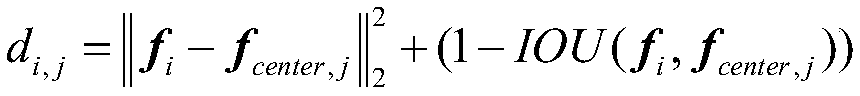

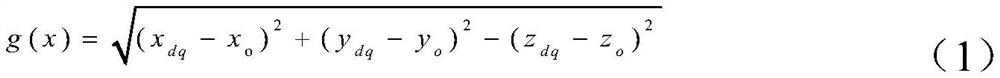

A pedestrian search method and device based on a priori candidate box selection strategy

ActiveCN109165540AFix the issue that the size is not suitable for pedestrian searchReduce the number of correctionsBiometric pattern recognitionFeature vectorEuclidean vector

The invention discloses a pedestrian search method and device based on a prior candidate frame selection strategy. The method comprises the following steps: constructing a pedestrian candidate frame eigenvector according to the length and width of all pedestrian boundary frames in the training set, including two elements of the aspect ratio and the length; through a k-means + + algorithm, selecting the initialization clustering center; using the k-means algorithm for iterative clustering, and obtaining a priori candidate box after clustering; inputting the pedestrian images in the training setinto a pre-defined pedestrian search network, generating the candidate pedestrians by using a priori candidate boxes and recognizing the pedestrian identity, and obtaining the trained pedestrian search network by training; training pedestrian probes and surveillance scene images through the pedestrian search network to obtain pedestrian probes features and candidate pedestrian features in the surveillance image, and by calculating the similarity of the two features, locating the pedestrian probes in the surveillance image and its specific location. The invention can effectively improve the precision and speed of pedestrian search.

Owner:深圳市感动智能科技有限公司 +1

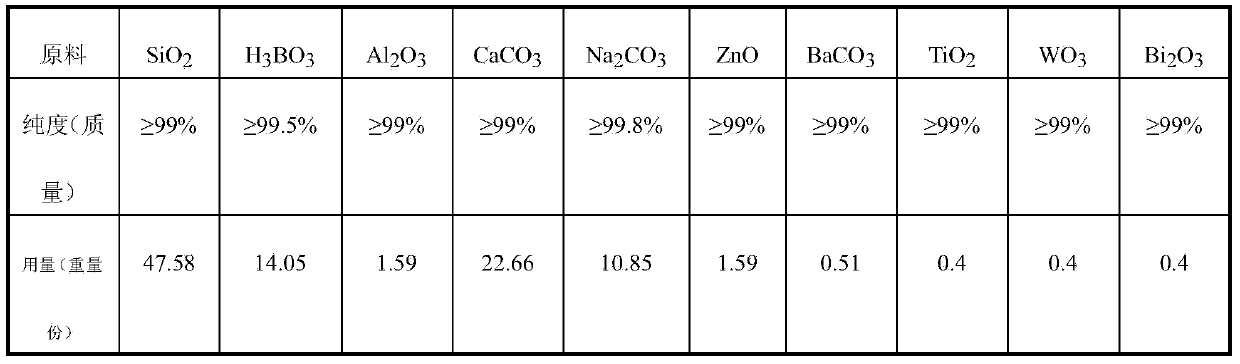

Method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength

InactiveCN103770035ASolve complexitySolve the costAbrasion apparatusGrinding devicesBoron trioxideTungsten trioxide

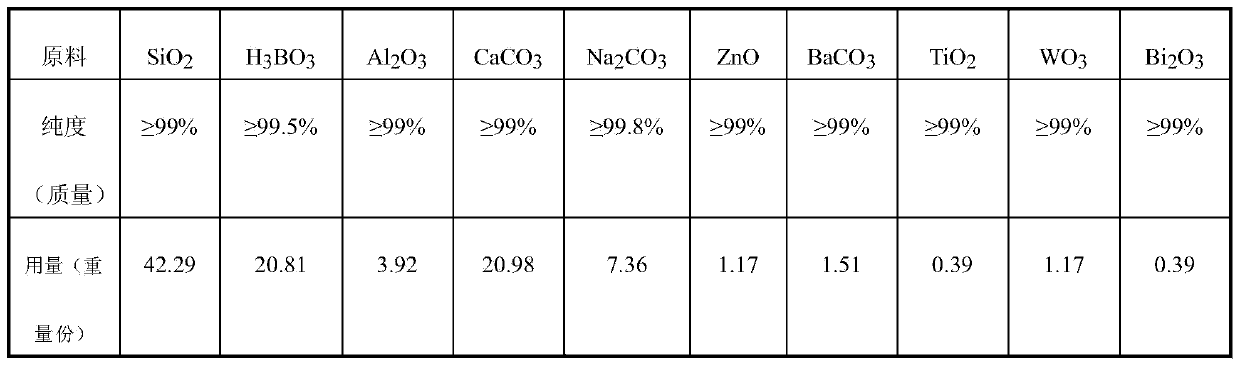

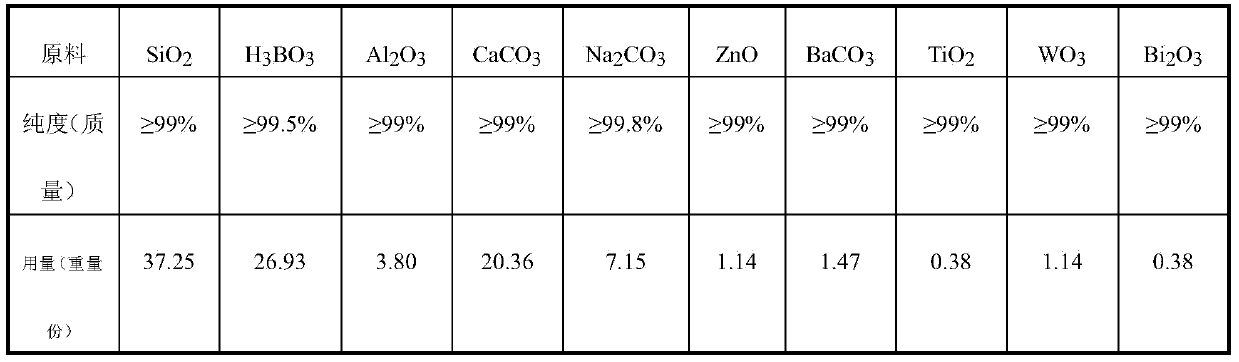

The invention provides a method for preparing diamond grinding wheel ceramic bond with low sintering temperature and high strength. The method includes the following steps of (1) mixture calculation, (2) melting and (3) water quenching and grinding, wherein the step (1) includes that raw mineral materials and chemical materials are used as the source of oxide, the mixture calculation is performed according to the oxide and the content thereof in the raw mineral materials and the chemical materials, and oxide compositions and contents thereof by weight part in the materials meet the following requirement, that is to say 40-60 parts of silicon dioxide, 10-30 parts of diboron trioxide, 2-6 parts of aluminum oxide, 12-16 parts of calcium oxide, 2-8 parts of sodium oxide, 0.5-2 parts of zinc oxide, 0.5-1.5 parts of barium oxide, 0.5-1 part of titanium dioxide, 0.5-2 parts of tungsten trioxide and 0.5-1 part of bismuth oxide, and after the step (3), the diamond grinding wheel ceramic bond with the low sintering temperature and the high strength can be obtained. The method is simple in preparing process and low in costs, and the obtained diamond grinding wheel ceramic bond is good in performances.

Owner:WUHAN UNIV OF TECH

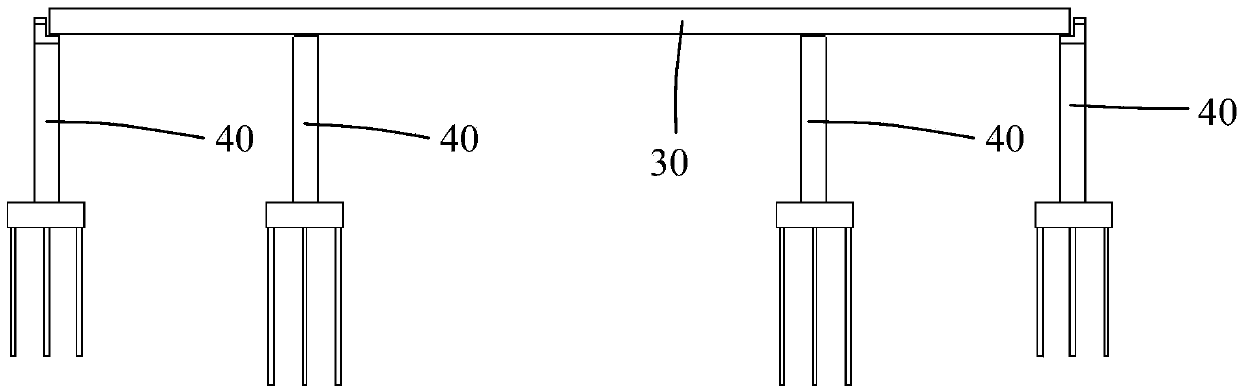

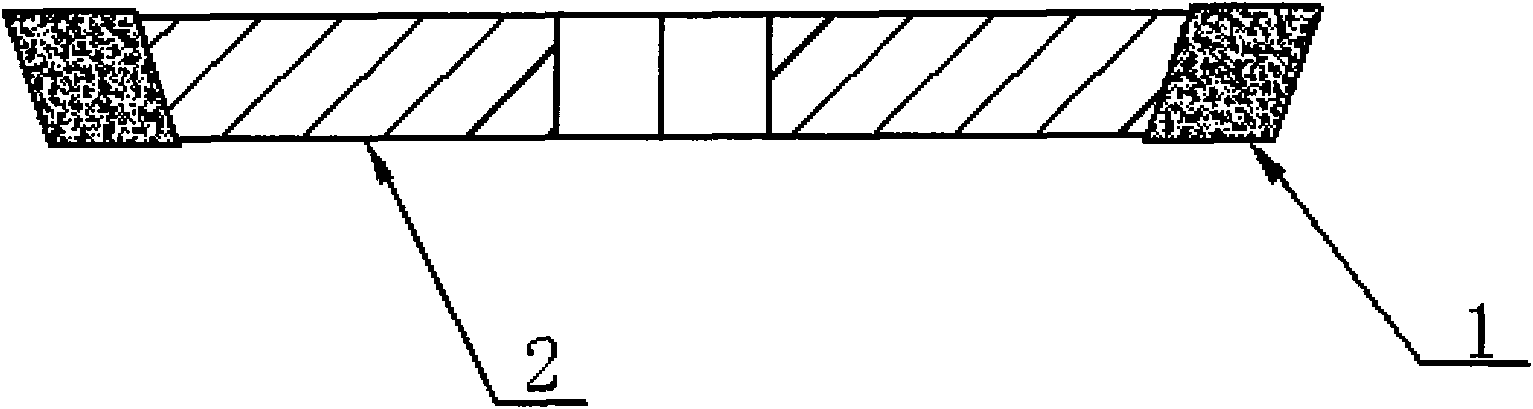

Walking type jacking construction method and device for large-span reinforced concrete combined beams

ActiveCN103993560AEasy to operateGuaranteed durationBridge erection/assemblyReinforced concreteEngineering

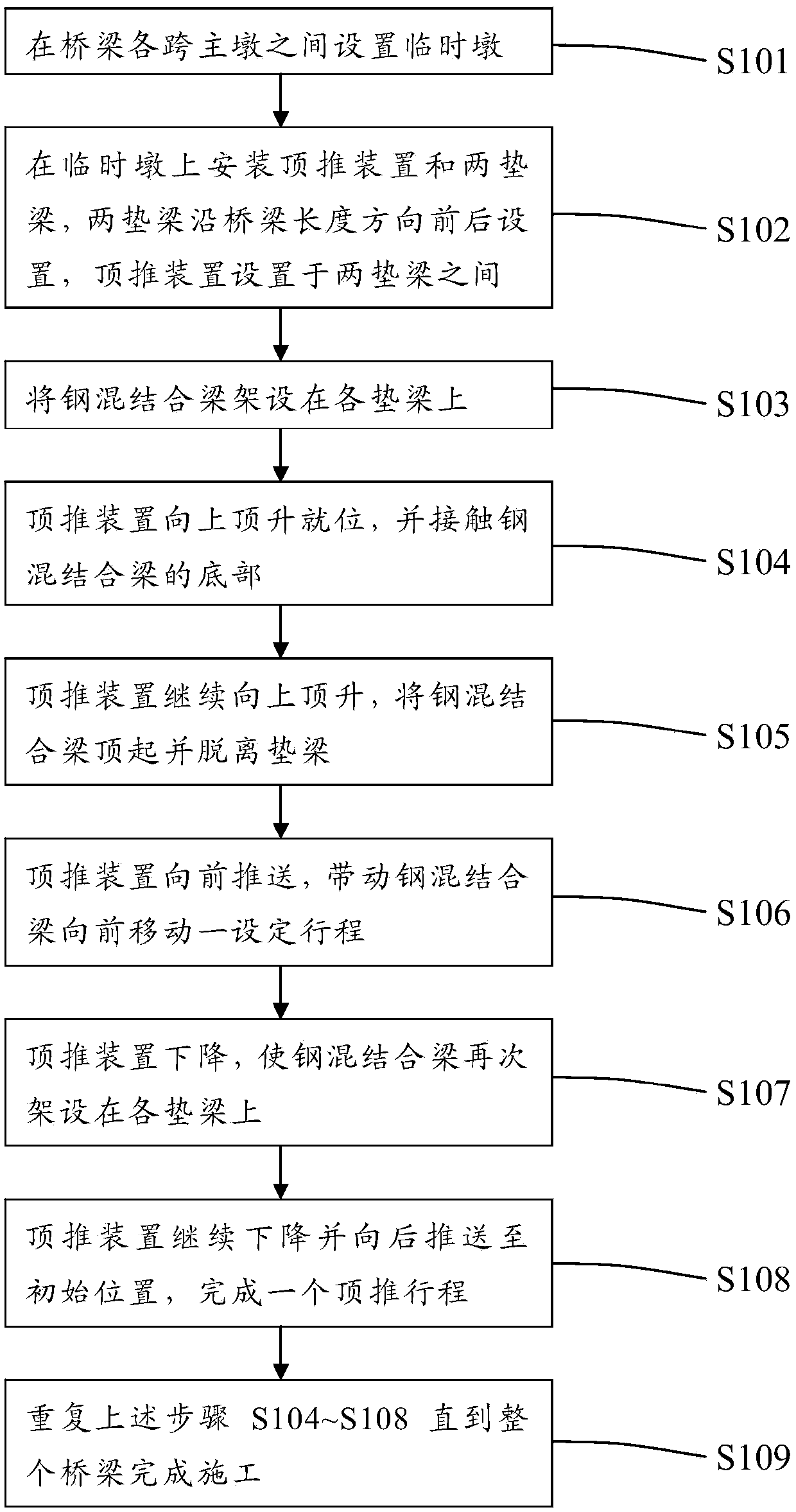

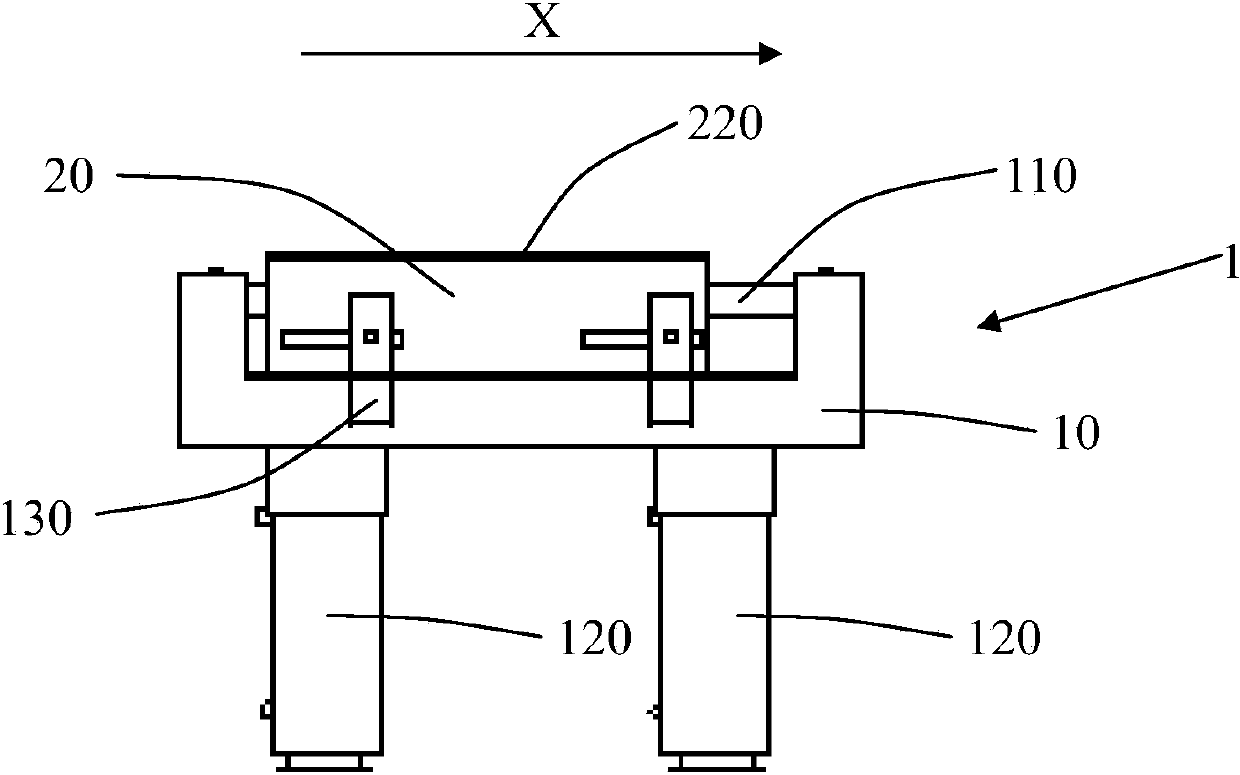

The invention provides a walking type jacking construction method and device for large-span reinforced concrete combined beams. The walking type jacking construction method comprises the following steps that temporary piers are arranged between all main piers of a bridge girder; a jacking device and two bearing beams are installed on each temporary pier, wherein each jacking device is arranged between the corresponding two bearing beams; the reinforced concrete combined beams are arranged on the bearing beams of the temporary piers; the jacking devices carry out upward jacking in place and make contact with the bottoms of the reinforced concrete combined beams; the jacking devices continue to carry out upward jacking, jack the reinforced concrete combined beams and break away from the bearing beams; the jacking devices are pushed forward and drive the reinforced concrete combined beams to move forward by a set stroke; the jacking devices descend so that the reinforced concrete combined beams can be arranged on the bearing beams of the temporary piers in a supporting mode again; the jacking devices continue to descend to the initial positions and are pushed backwards to the initial positions, so that a jacking stroke is finished; the above steps are conducted repeatedly until construction of the whole bridge girder is completed. According to the walking type jacking construction method and device for the large-span reinforced concrete combined beams, manpower, material resources and financial resources are saved on the premise of guaranteeing the construction period; meanwhile, the walking type jacking construction method and device for the large-span reinforced concrete combined beams have the advantages that construction and operation are convenient, safety and reliability are realized, efficiency is high, the construction period is short, and the comprehensive cost is low.

Owner:SHANGHAI TUNNEL ENG CO LTD +3

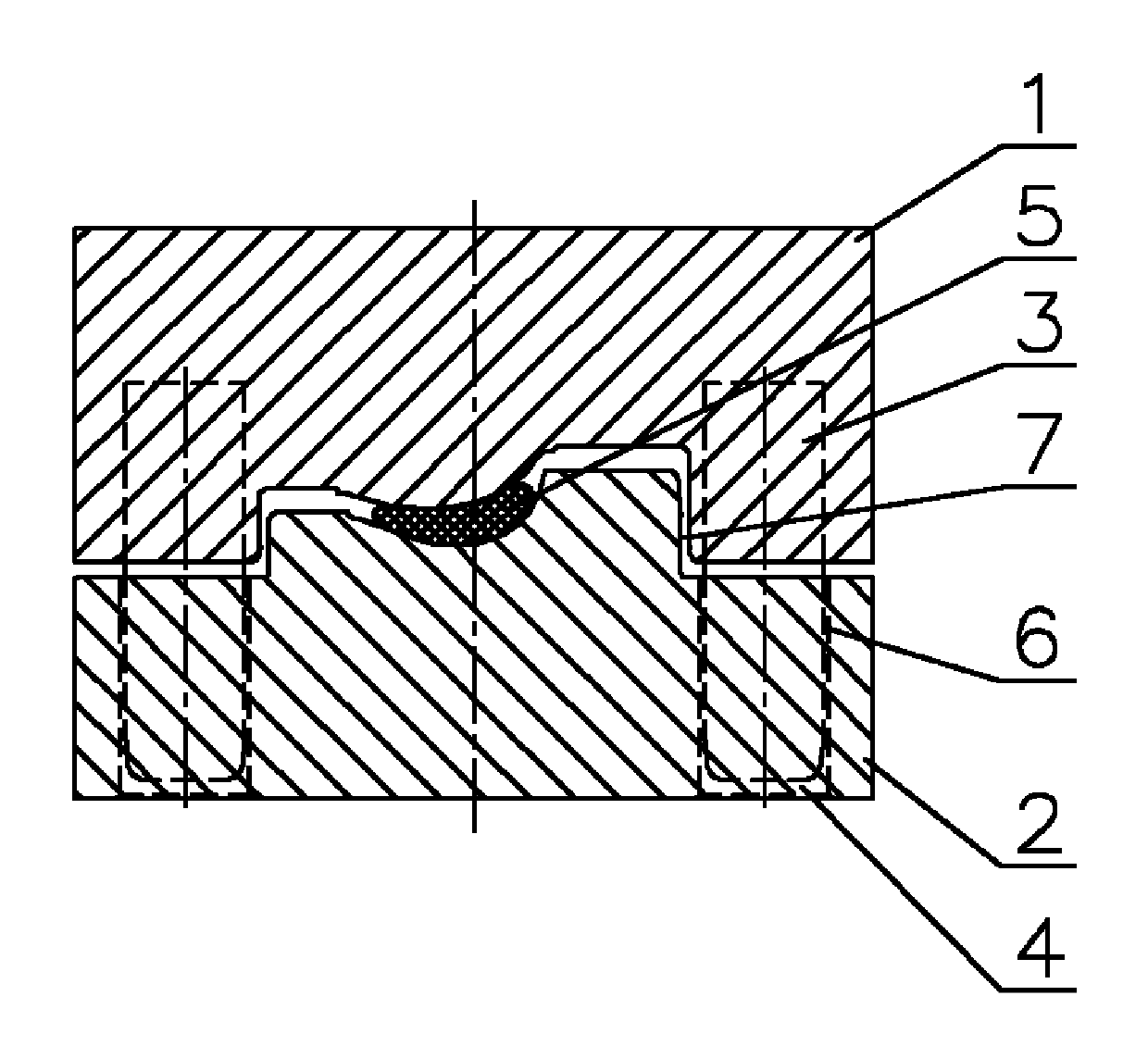

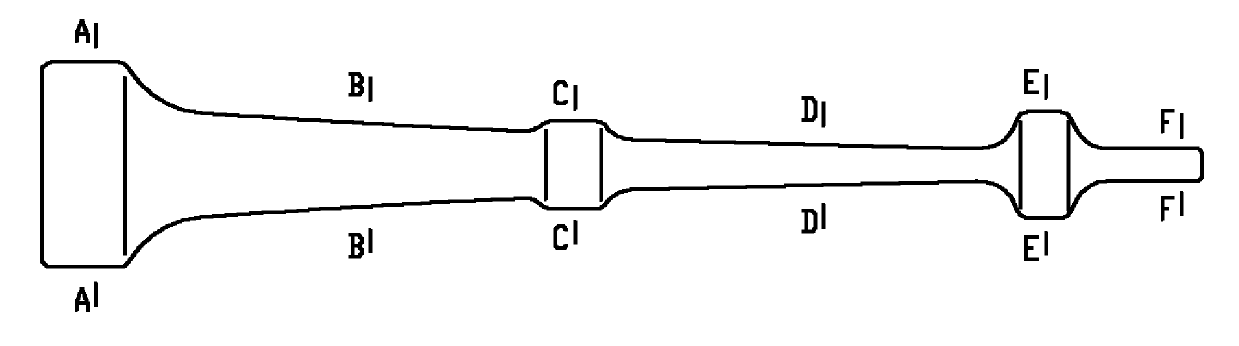

Die forging process and special die for final stage blade of large half-RPM (Revolution per Minute) nuclear turbine

InactiveCN101947633AIncrease productivityGuaranteed accuracyForging/hammering/pressing machinesEngine componentsSquare cross sectionElectro hydraulic

The invention provides a die forging process for a final stage blade of a large half-RPM (Revolution per Minute) nuclear turbine. The die forging of only single forging die is required to ensure the die forging forming of a blade forge piece, so that the manufacturing cost of the blade is reduced, the die forging cycle is shortened, and the processing efficiency is improved; moreover, the correction times inside the die of the blade forge piece is effectively reduced, and the production capacity of forging is increased. The invention has the technical scheme comprising the following steps of: upsetting a bar by using an oil press, stretching the bar in radial direction to prepare a blank, and forging the stretched blank in a forging die for forming; then, thermally cutting off the flashing fins for the die forging, and thermally correcting for the die forging; and finally, thermally treating. The process is characterized in that the radial stretching for preparing the blank adopts an electro-hydraulic hammer to carry out free forging and stretching to prepare the blank, and the blank is optimized into the structure with most circular cross sections and partial flat square cross sections. The invention also provides a special die which comprises an upper die and a lower die, wherein the four corner endss of the upper die are provided with guide pillars, and the lower die is correspondingly provided with guide sleeves. The special die is characterized in that the outer sides of the die cavities of the upper die and the lower die are side upright wall structures which are mutually overlapped, and the guide pillars and the guide sleeves are respectively arranged on the side upright wall structures of the upper die and the lower die.

Owner:WUXI TURBINE BLADE

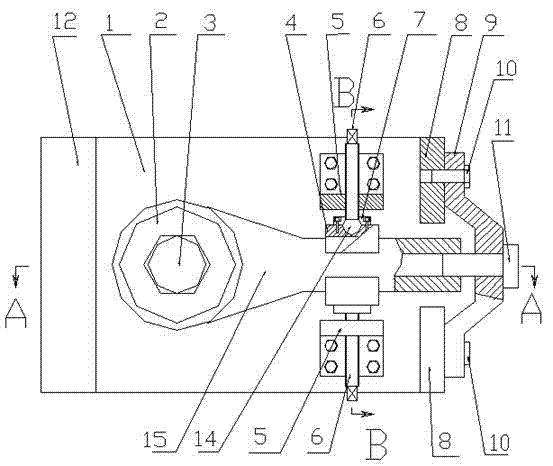

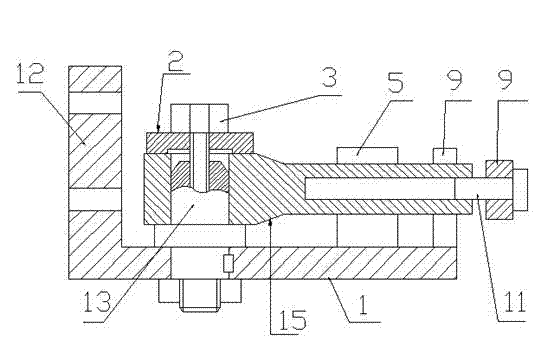

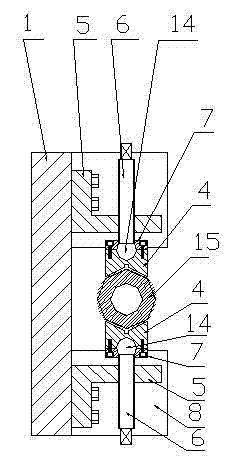

Thread machining technology equipment for a connecting rod of a press machine

InactiveCN102398092AReduce the number of correctionsOvercome the pitfalls of benchmark changesThread cutting machinesPositioning apparatusMachine pressEngineering

The thread machining technology equipment for a connecting rod of a press machine relates to SII series press machine integral-type connecting rod thread machining technology and equipment, which essentially, by mounting the dead plate on the plane chuck of horizontal ordinary lathe, fixes the whole equipment. Fix the crankshaft hole of the connecting rod of workpiece to be processed on the mandrel. Insert the correction pin shaft on the bridge frame into the thread bottom hole of the connecting rod, and after precorrection, take down the bridge frame and the correction pin shaft so as to process the workpiece. The invention has advantages of relatively high working efficiency and the ability to improve product quality.

Owner:江苏华商企业管理咨询服务有限公司

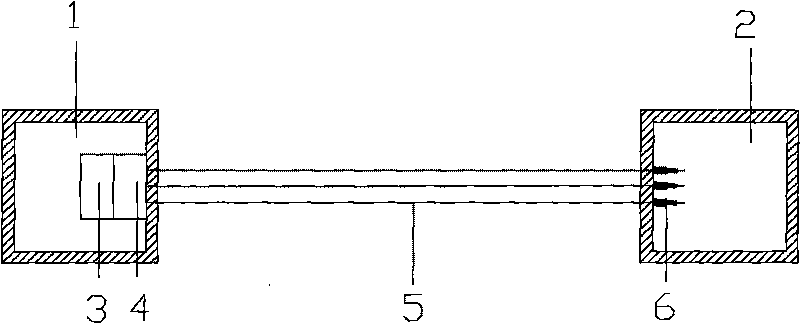

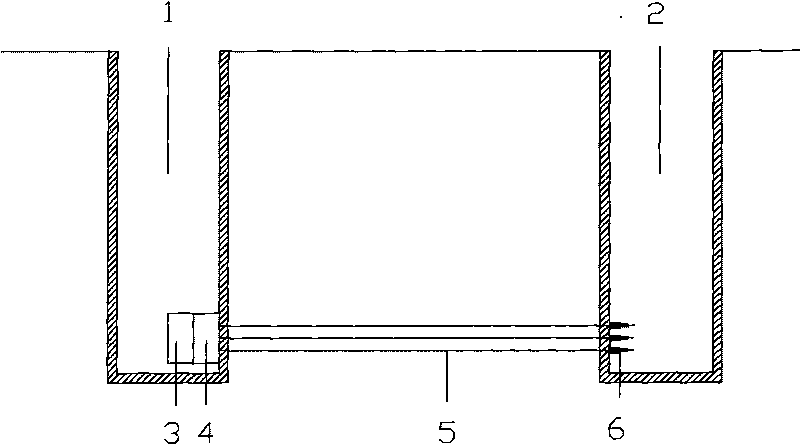

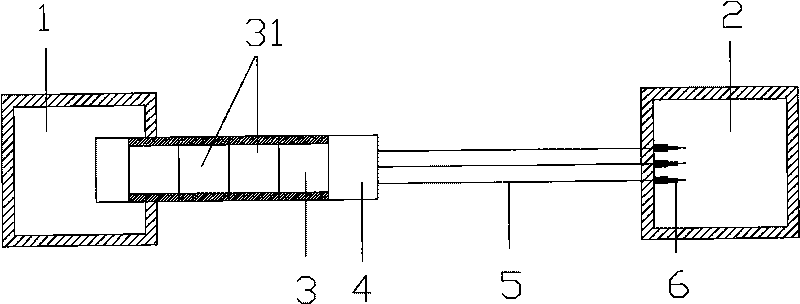

Method for slurry-water balance type pipe-pulling construction of underground pipeline

ActiveCN101701646AAdaptableReduce the number of correctionsPipe laying and repairReinforced concreteTube drawing

The invention provides a method for the slurry-water balance type pipe-pulling construction of an underground pipeline, which relates to the technical field of underground construction and aims at improving the applicability to the construction site and the construction efficiency. The method comprises the following steps: constructing a starting well and a receiving well at both ends of a pipeline design axis; then installing a horizontal pull device in the receiving well; laying a plurality of strings of coaxial bracing cables between the two working wells by using a horizontal directional drilling technology, wherein one end of each bracing cable is locked by the horizontal pull device in the receiving well, and the other end of each bracing cable is axisymmetrically fixed on the front end of an excavator head; and applying pull to the groups of bracing cables by the horizontal pull device in the receiving well when the excavator head excavates so that all pipe joints are driven into an excavating stratum by the excavator head. The method is suitable for pipelines which have various cross-sectional dimensions and are in the steel reinforced concrete structure or the steel structure.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

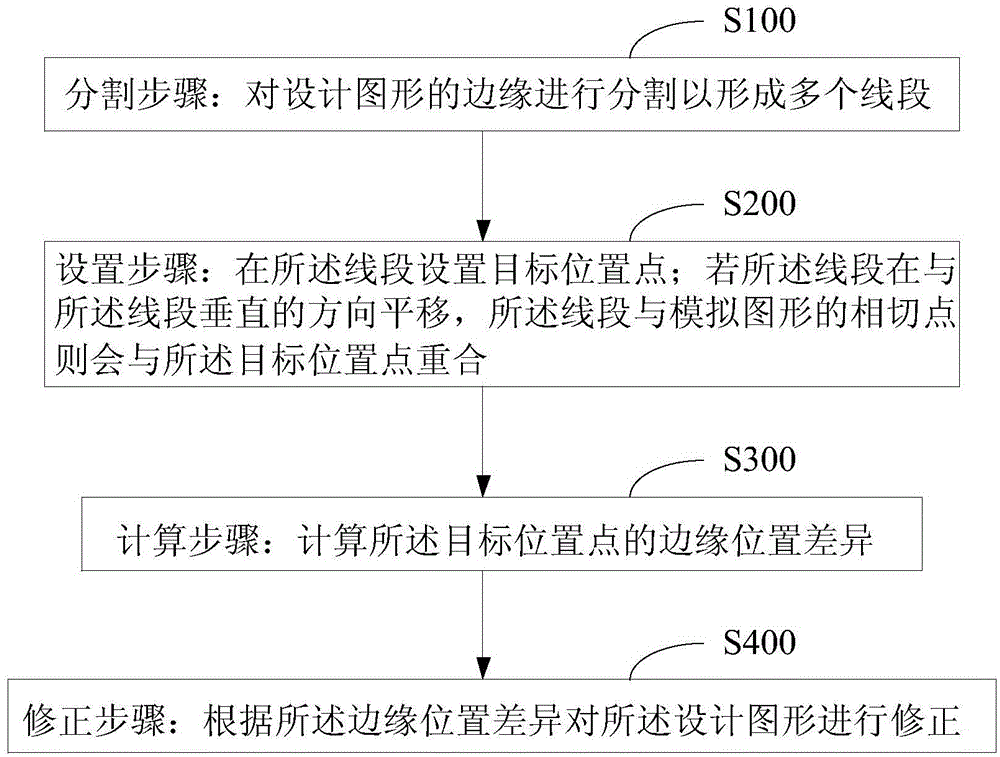

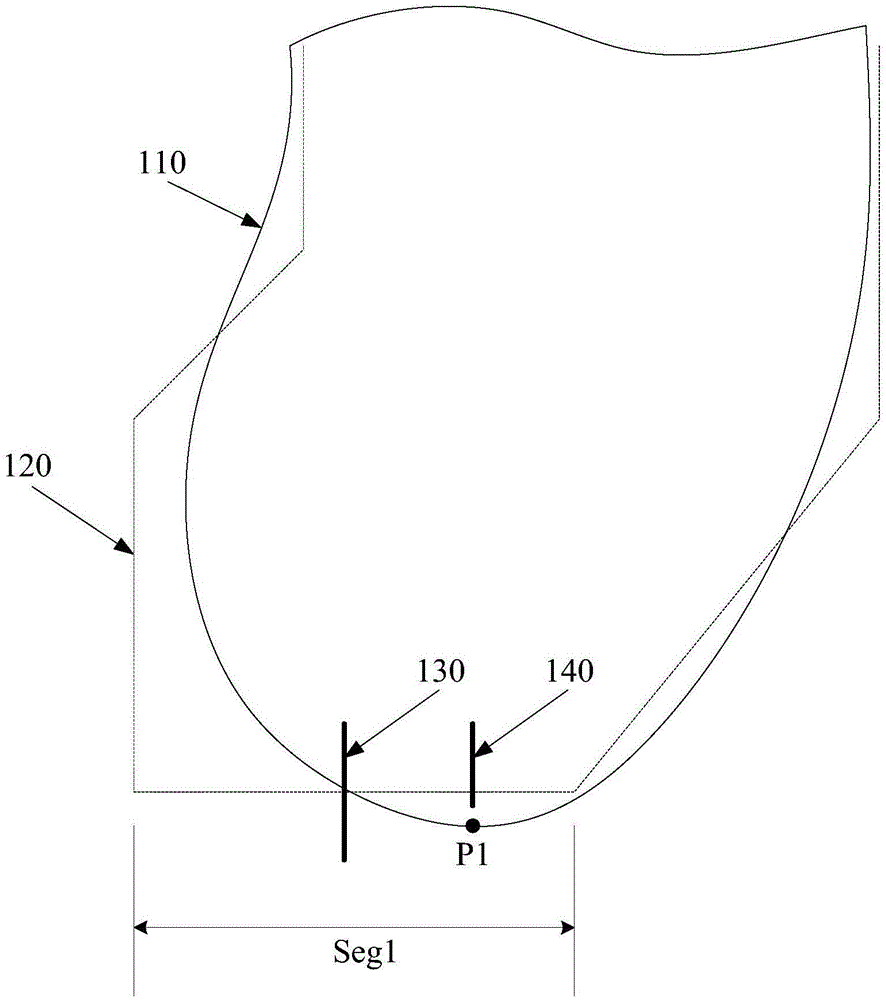

Optical proximity effect correcting method and system

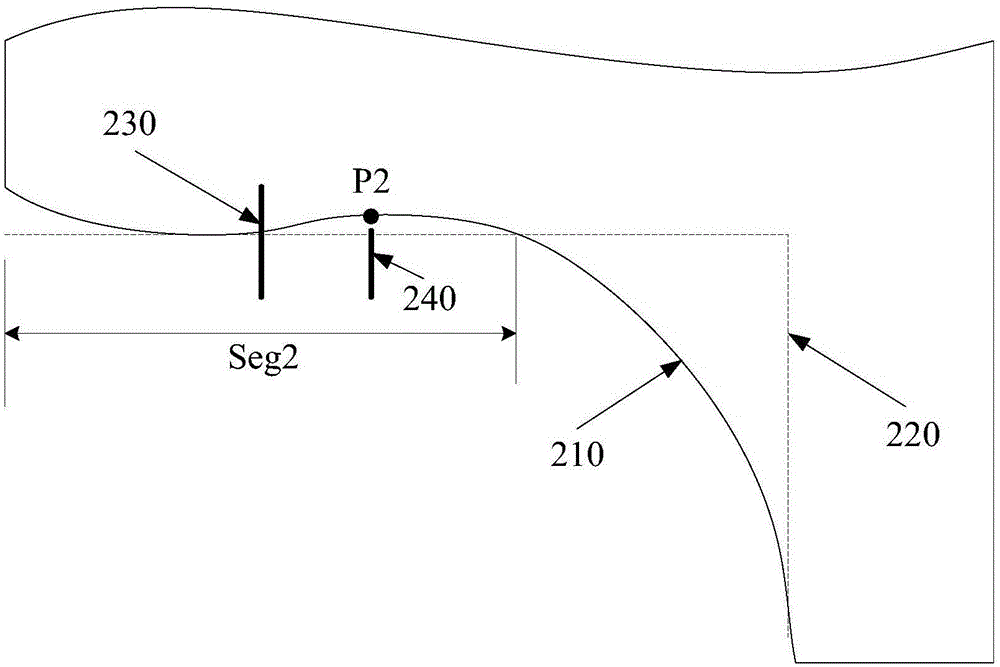

ActiveCN106483758AReduce the number of correctionsDegree of reductionPhotomechanical apparatusCAD circuit designImage correctionEngineering

The invention provides an optical proximity effect correcting method. A setting mode of a target position of a line segment is not fixed, but is changed along with a graph, and generally, the curve endpoint of an analog graph corresponding to the line segment is used as the reference position of the target position. The curve endpoint can be judged by the following method: if the line segment translates in a direction perpendicular to the line segment, a point, which is tangential to the analog graph, of the line segment is the curve endpoint, and at the moment, the curve endpoint coincides with the target position. For the line segment, EPE at the position, which corresponds to the curve endpoint, of the line segment is maximum generally, image correction is performed according to the EPE, correction frequency can be reduced effectively, insufficient correction degree or excessive correction degree is reduced, an analog result is matched with a target value, and the correction efficiency and the correction precision are improved. The invention further provides an optical proximity effect correcting system.

Owner:CSMC TECH FAB2 CO LTD

Full-automatic washing machine washing process

ActiveCN1544744AReduce the number of correctionsLess water consumptionControl devices for washing apparatusTextiles and paperProcess engineeringEngineering

The invention provides a washing program method of full-automatic washer, and its character: number of unbalanced times is accumulated in the whole course of the washing program. It eliminates the mode that existing techniques accumulate number of unbalanced times by using single rinsing program as a segment but accumulates number of unbalanced times by adopting the whole washing program as the basis of accumulation alarm, thus largely reducing unnecessary number of correction times, reducing unnecessary water consumption and shortening the washing delay time due to correction of unbalance.

Owner:HAIER GRP CORP +1

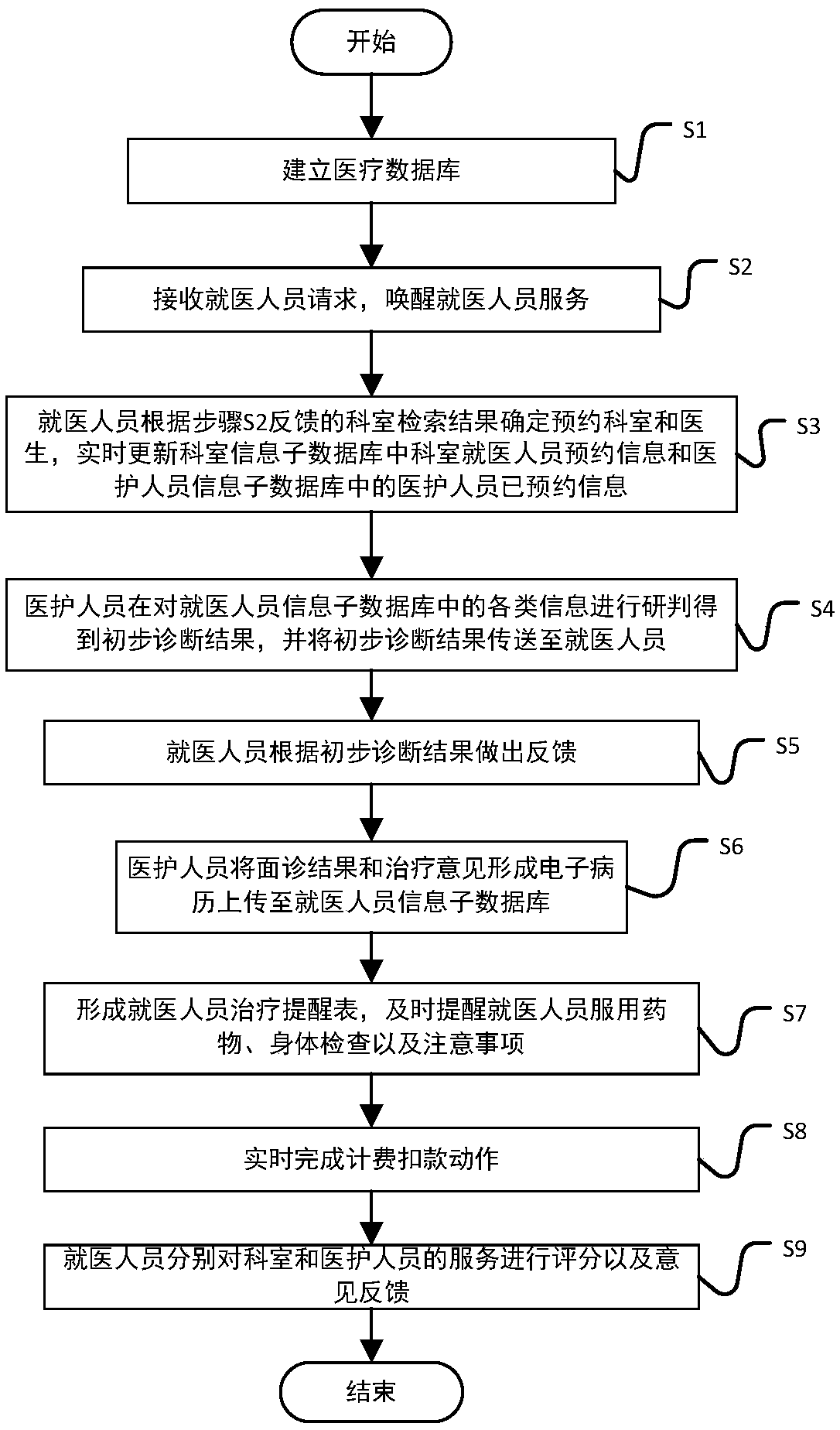

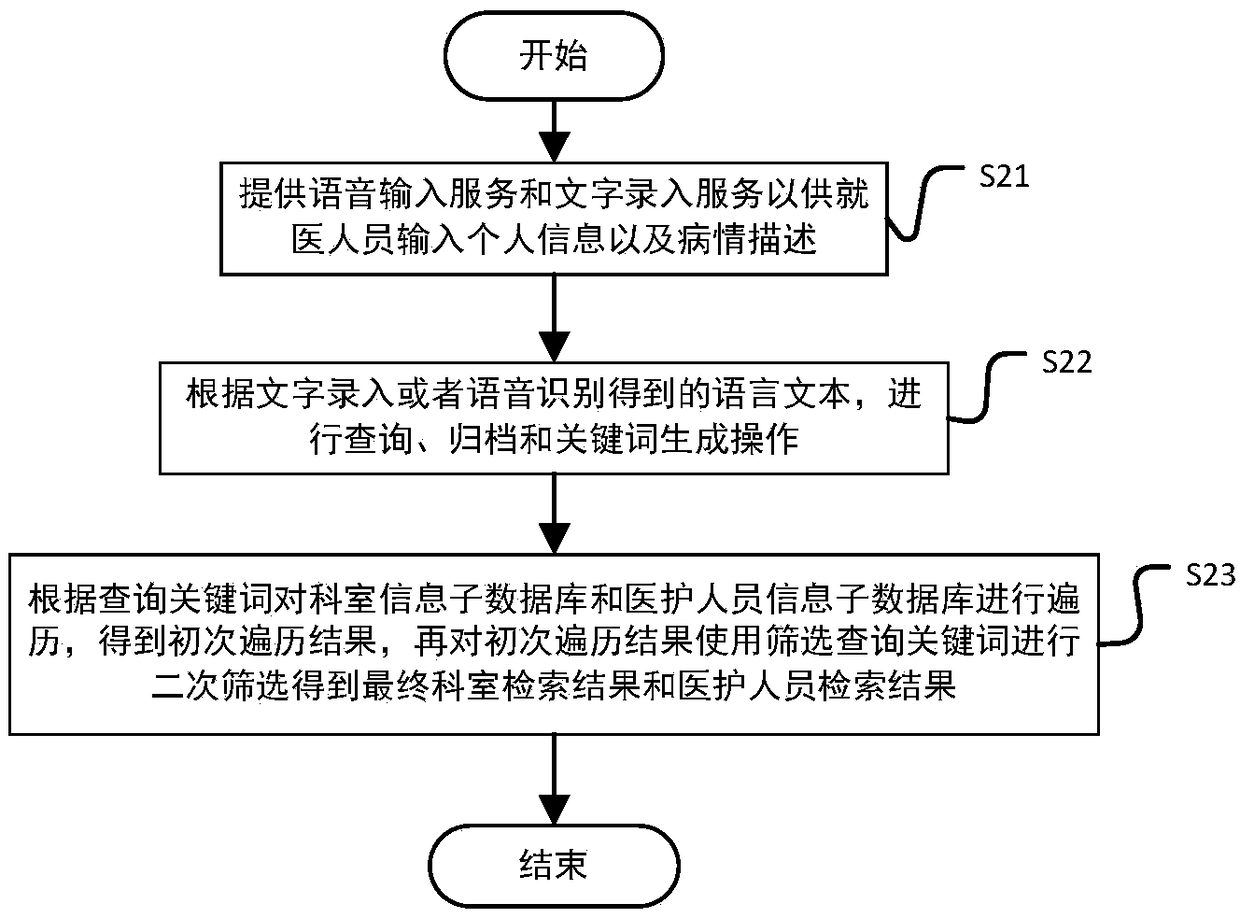

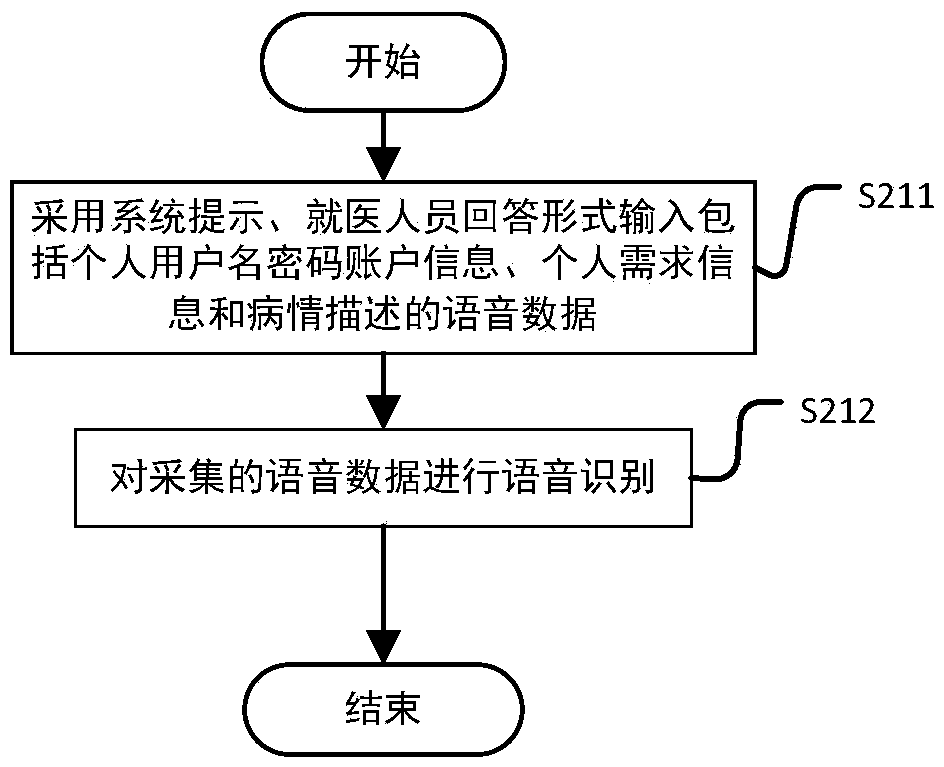

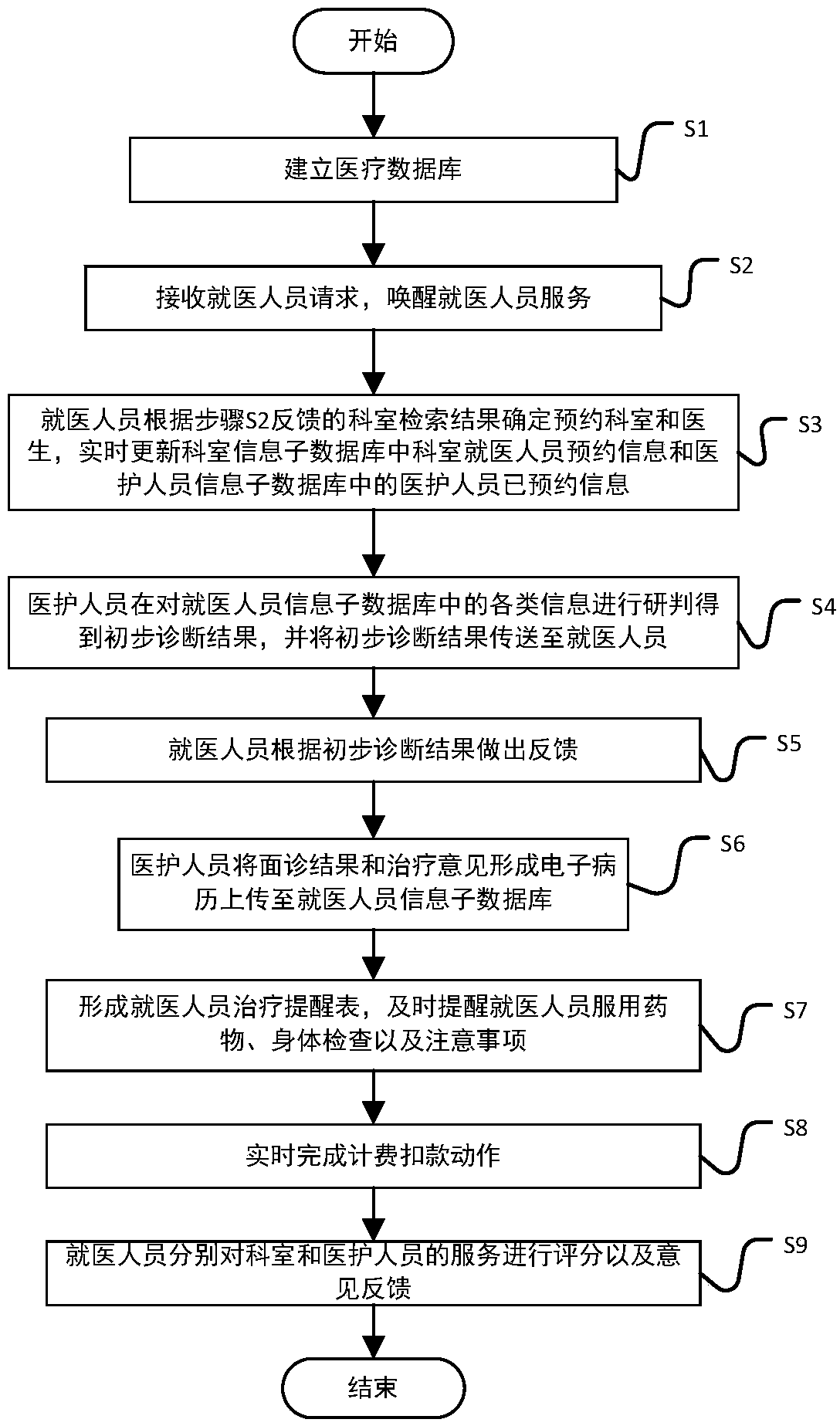

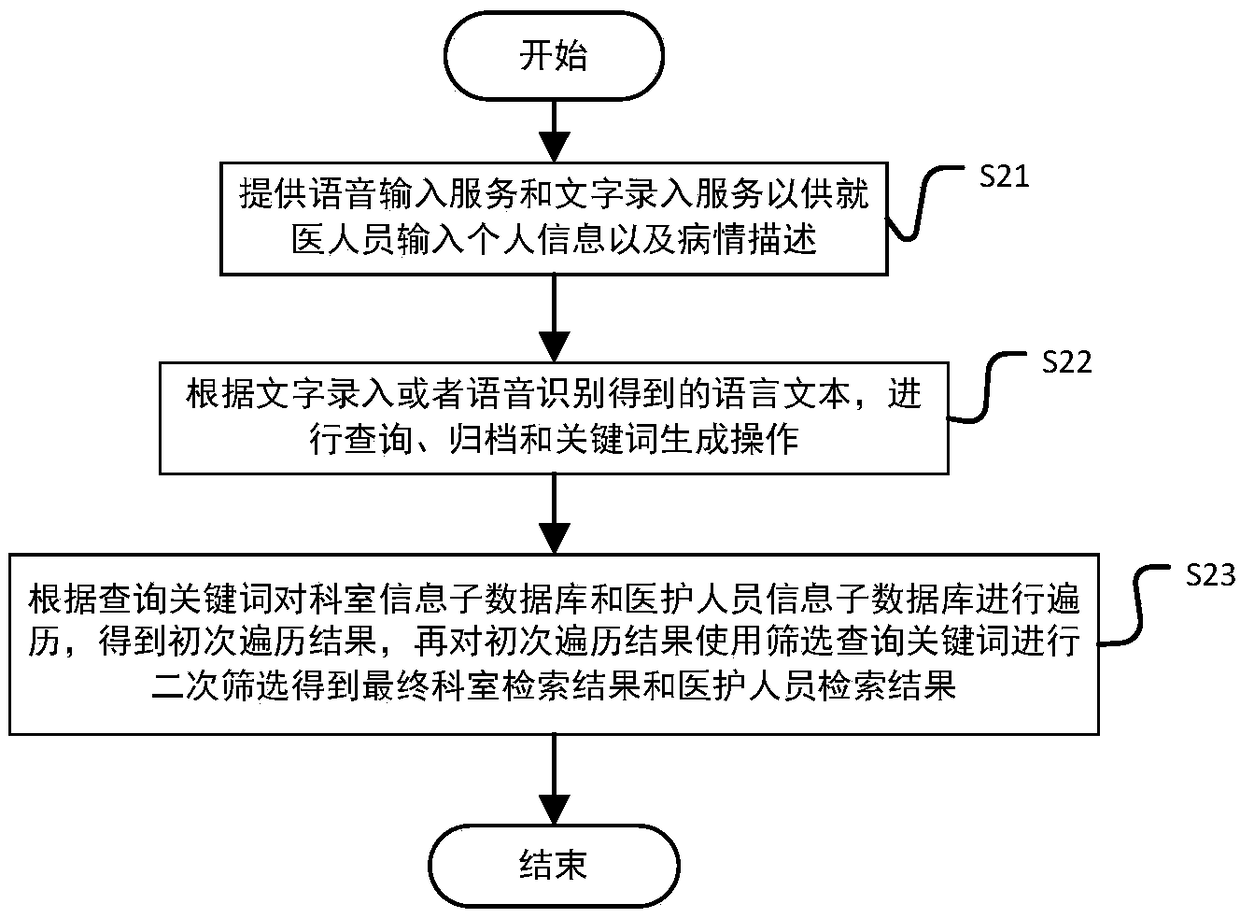

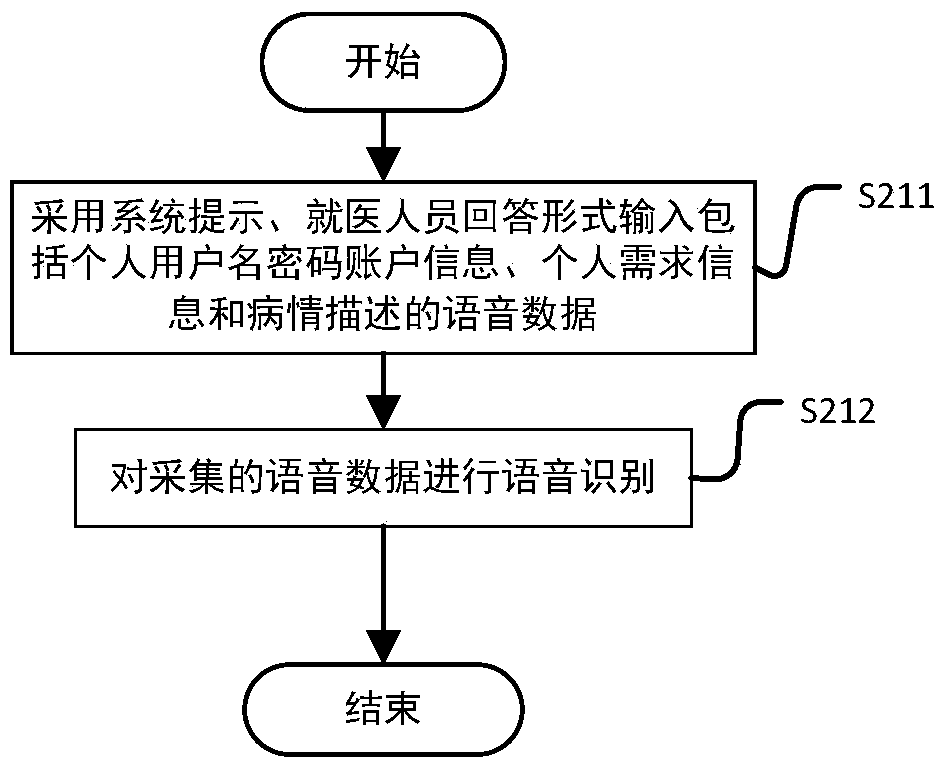

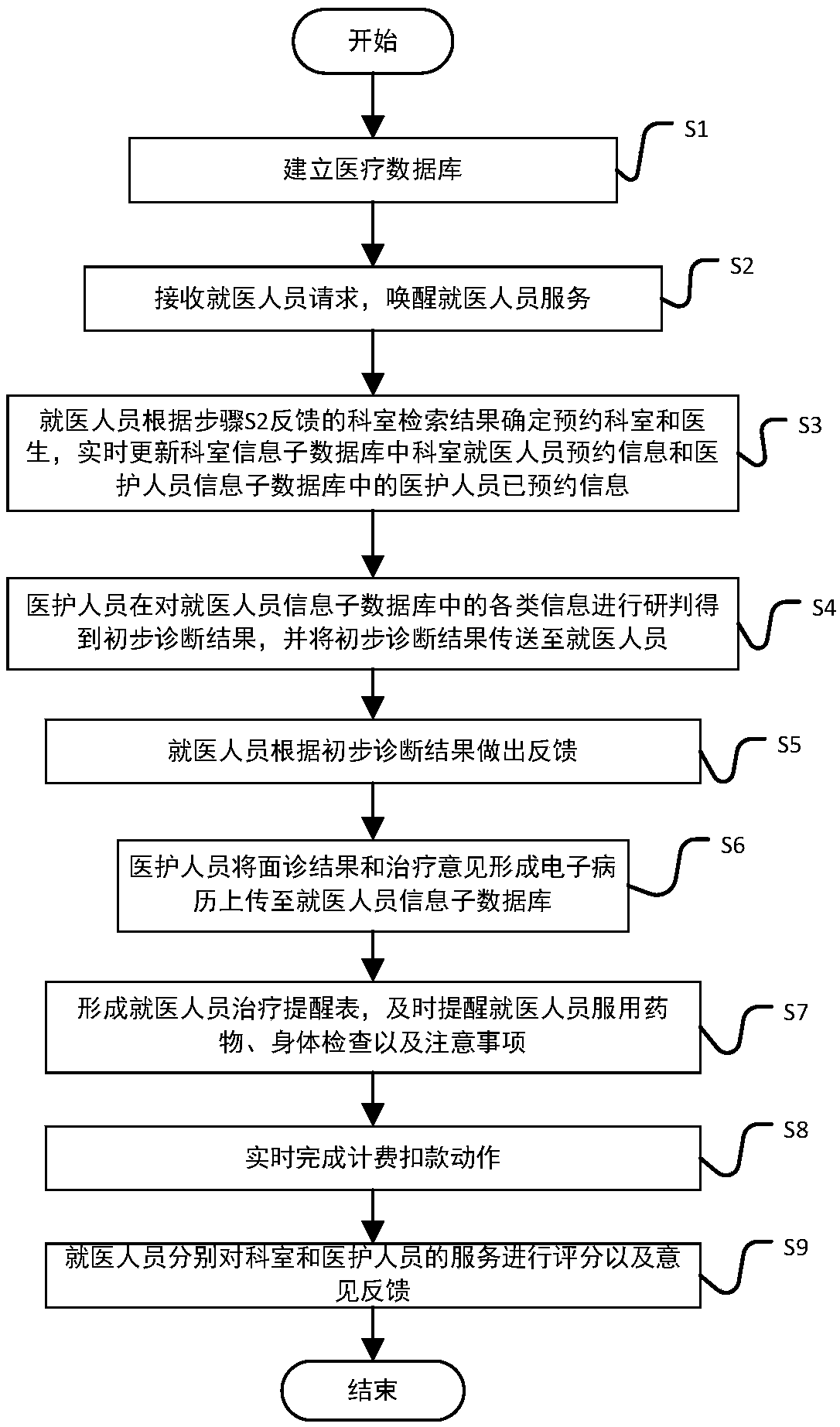

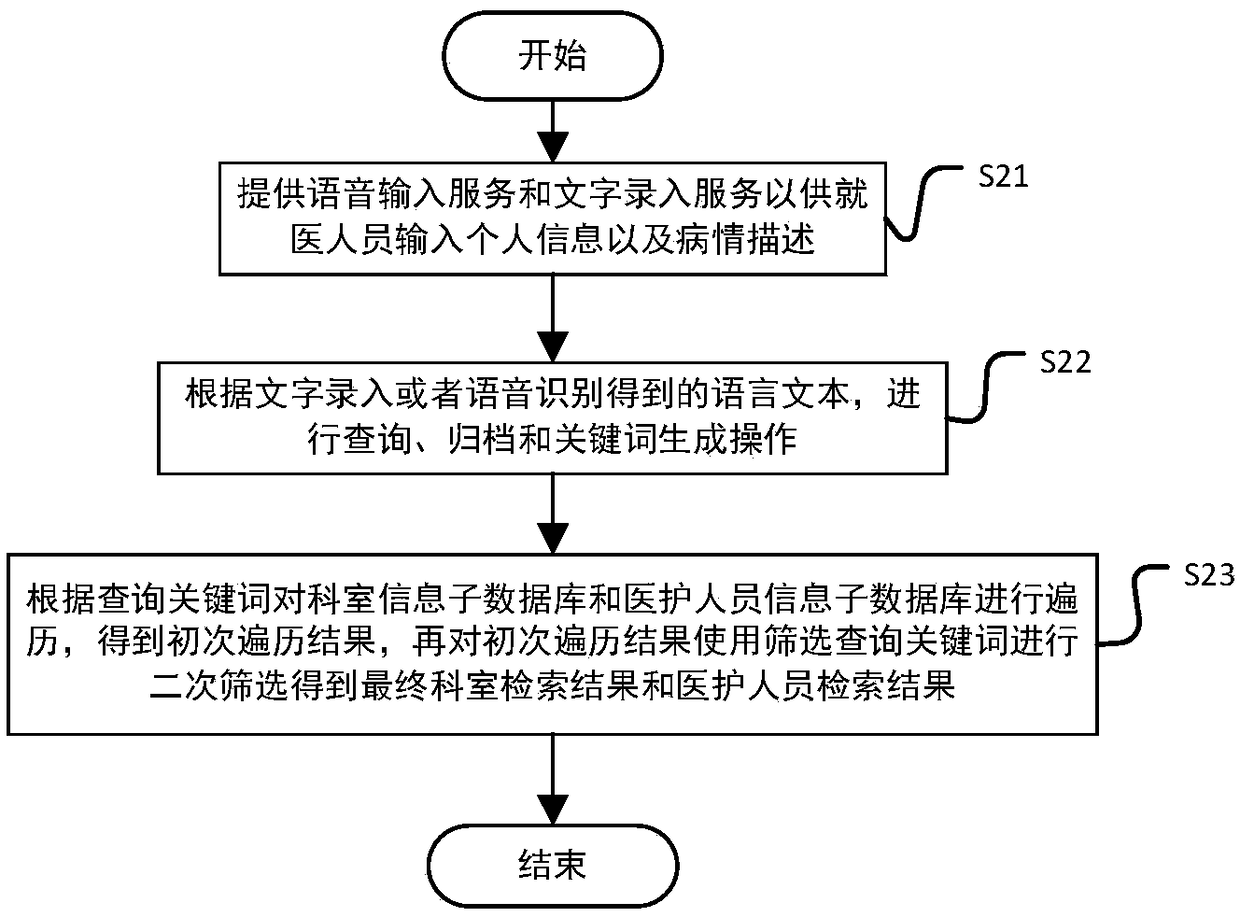

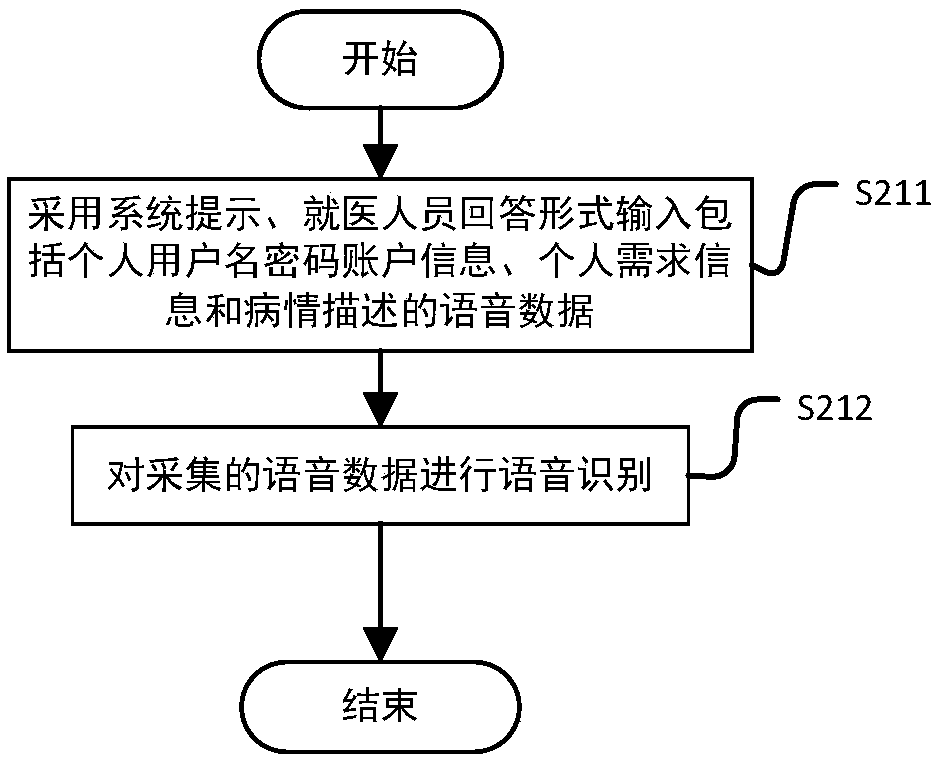

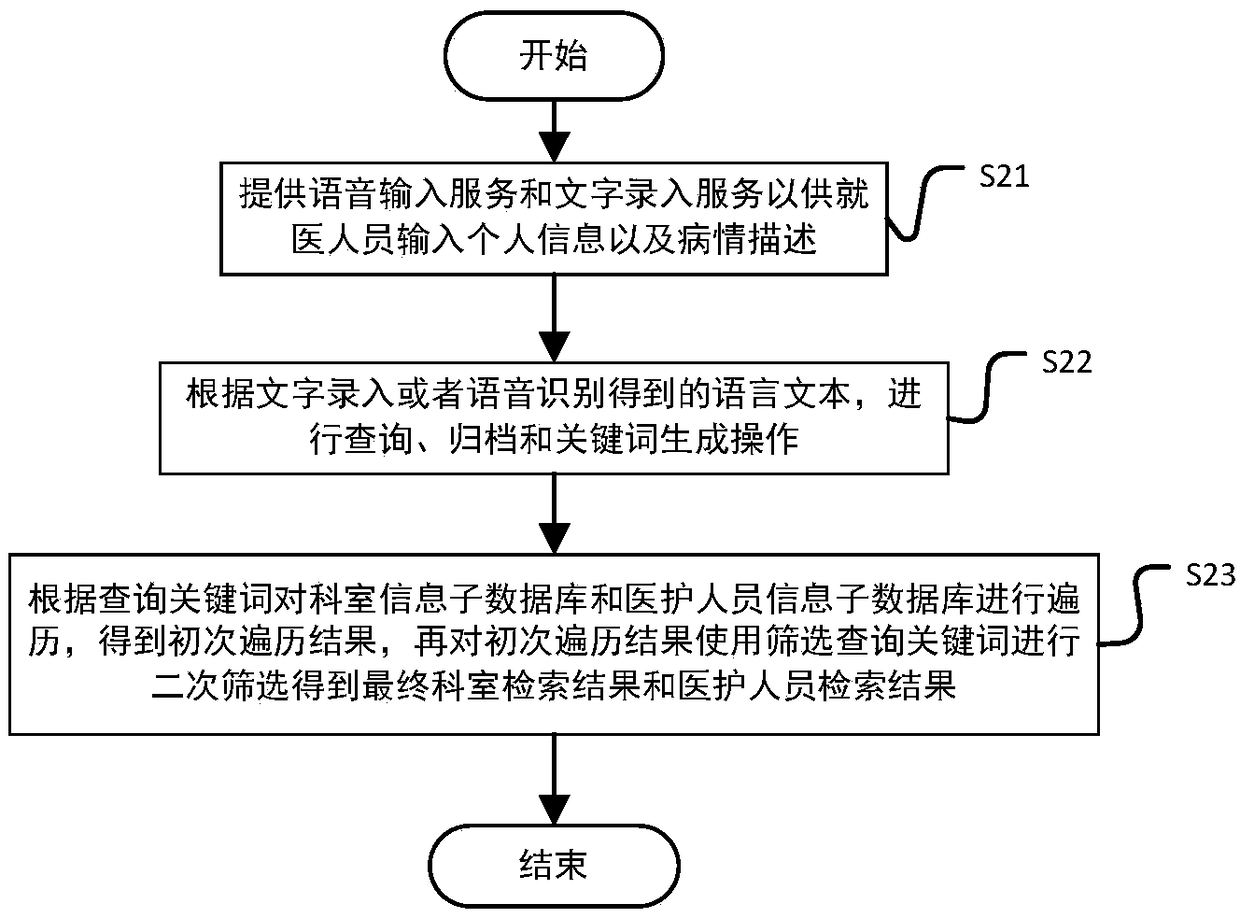

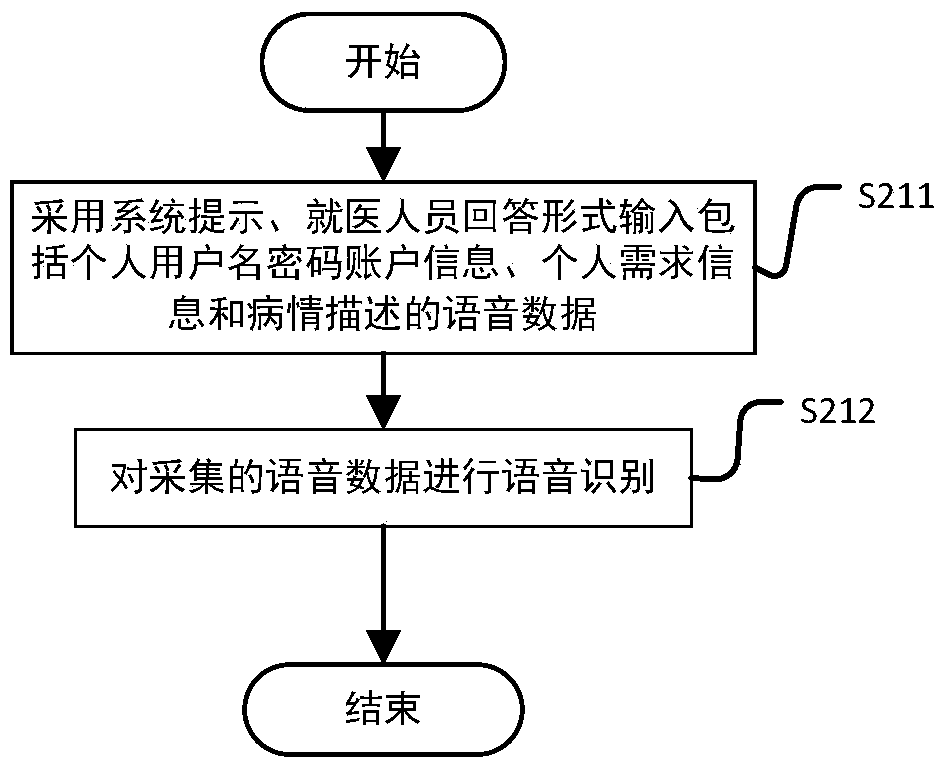

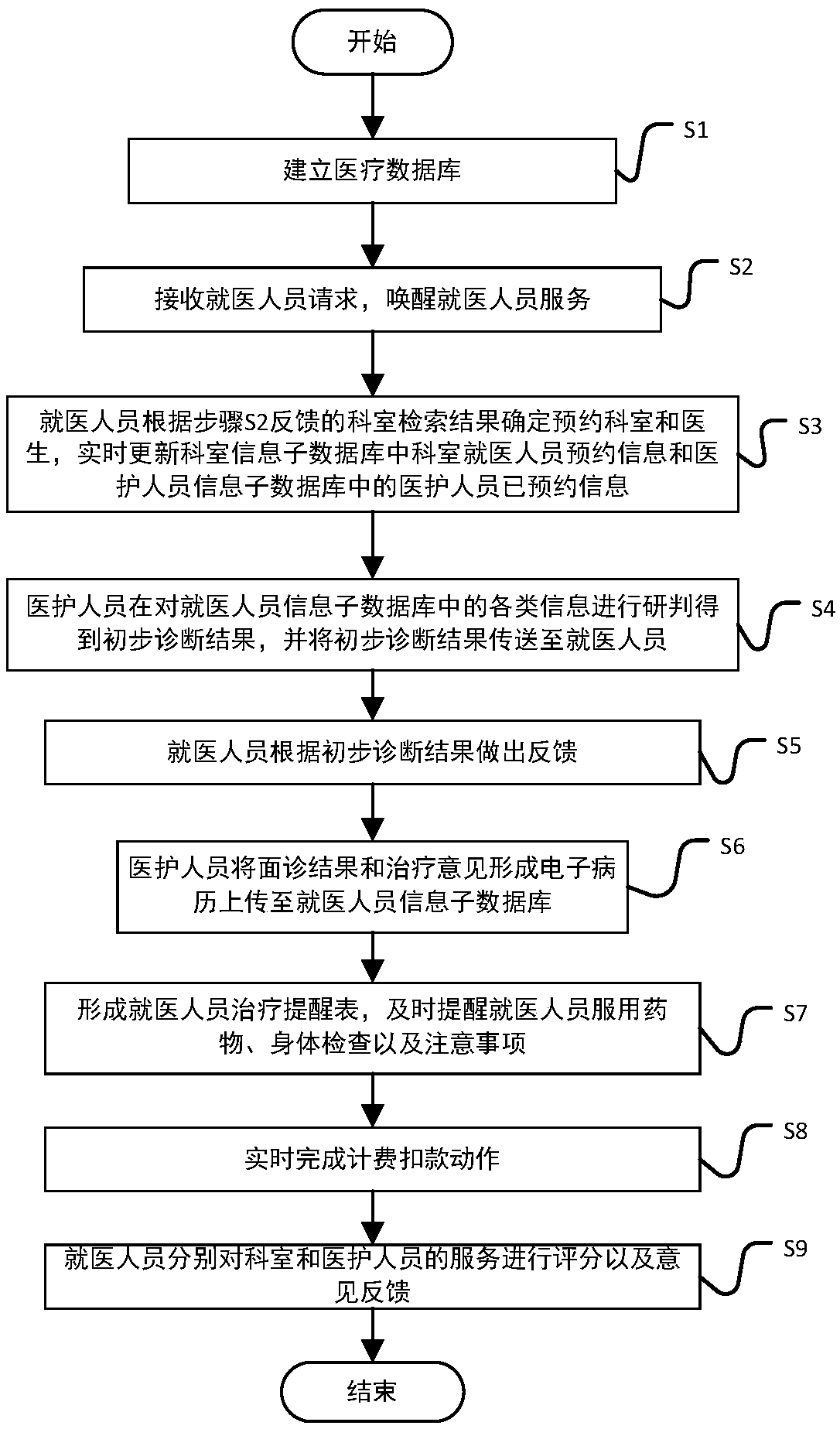

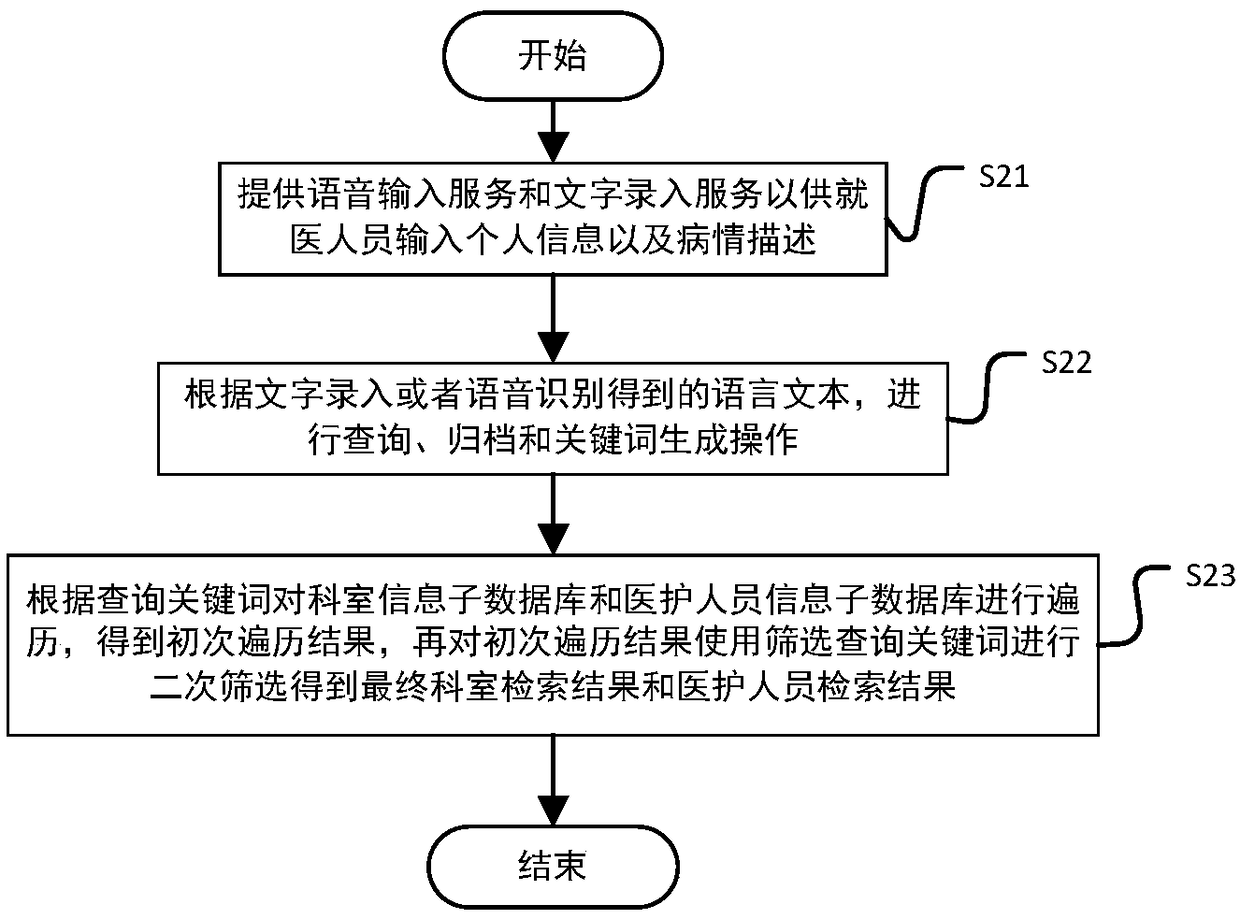

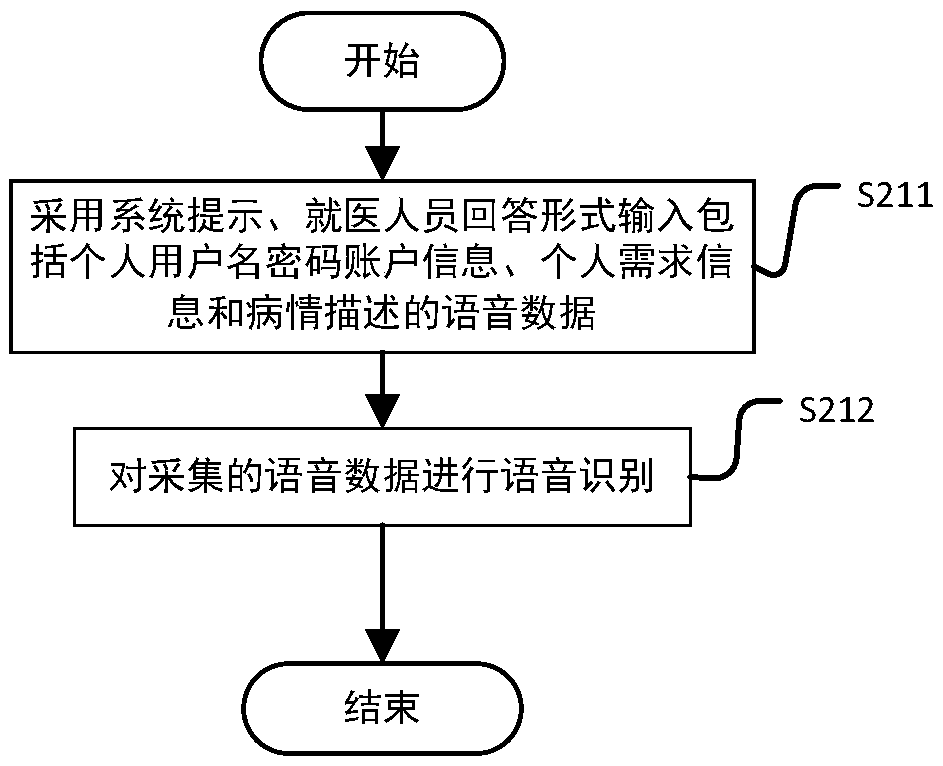

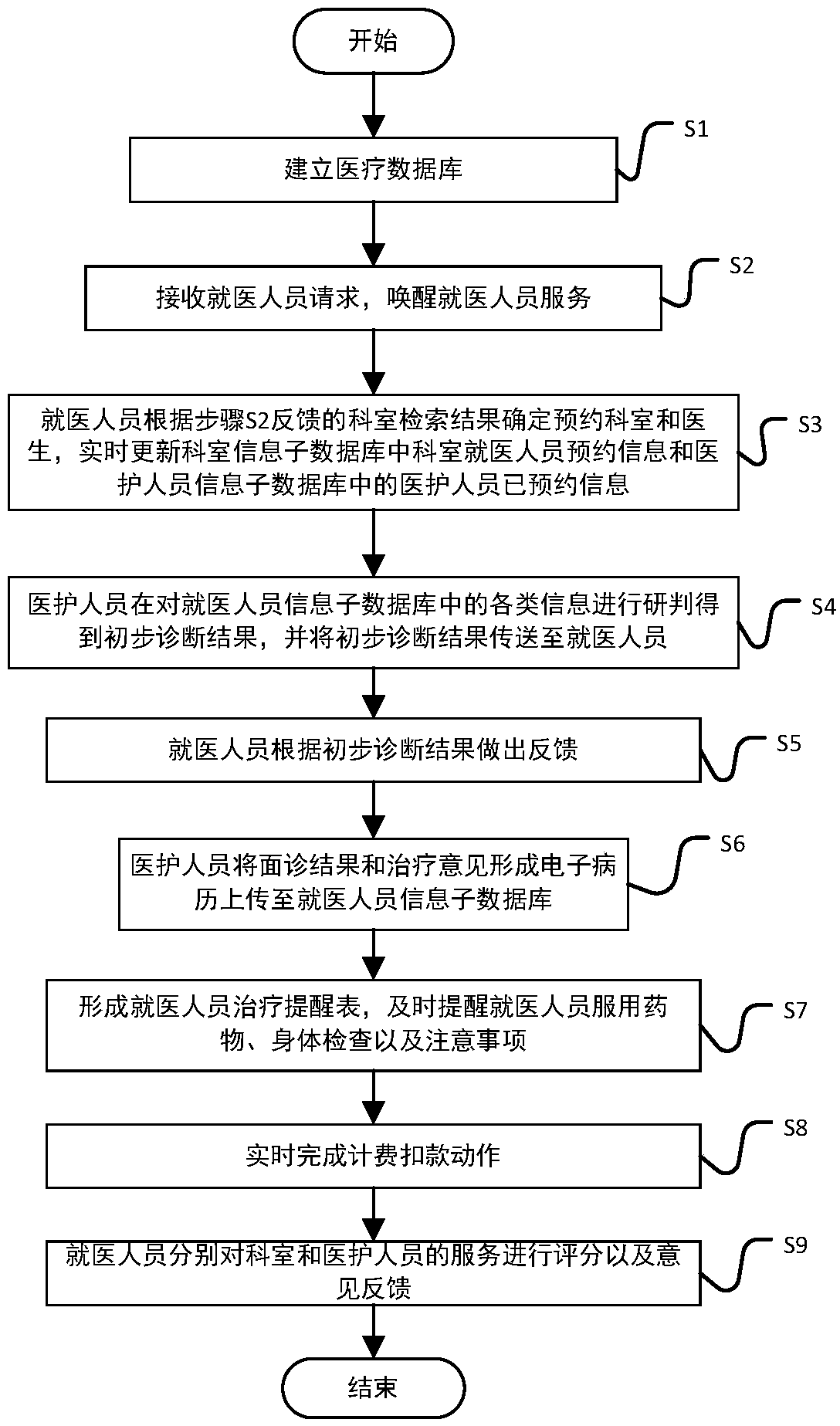

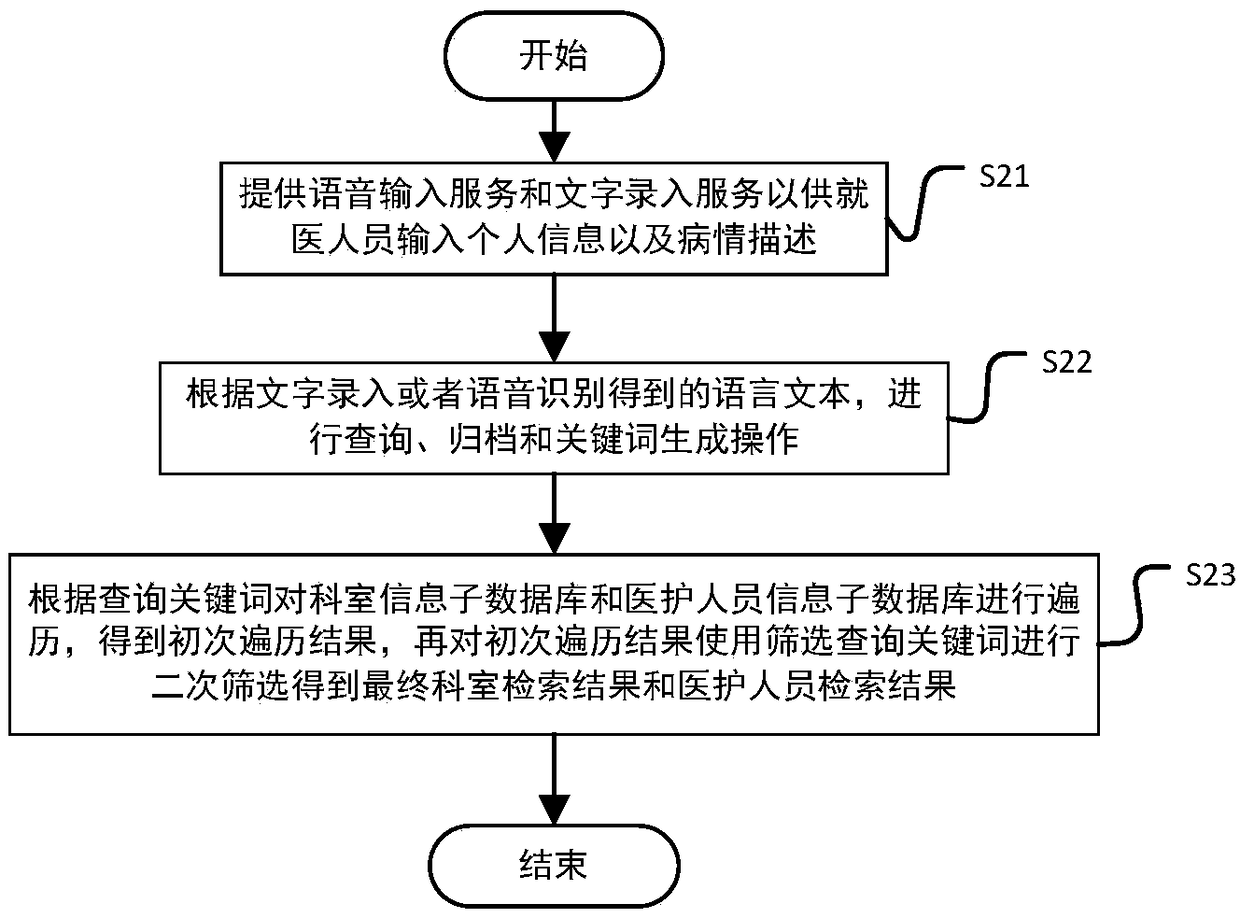

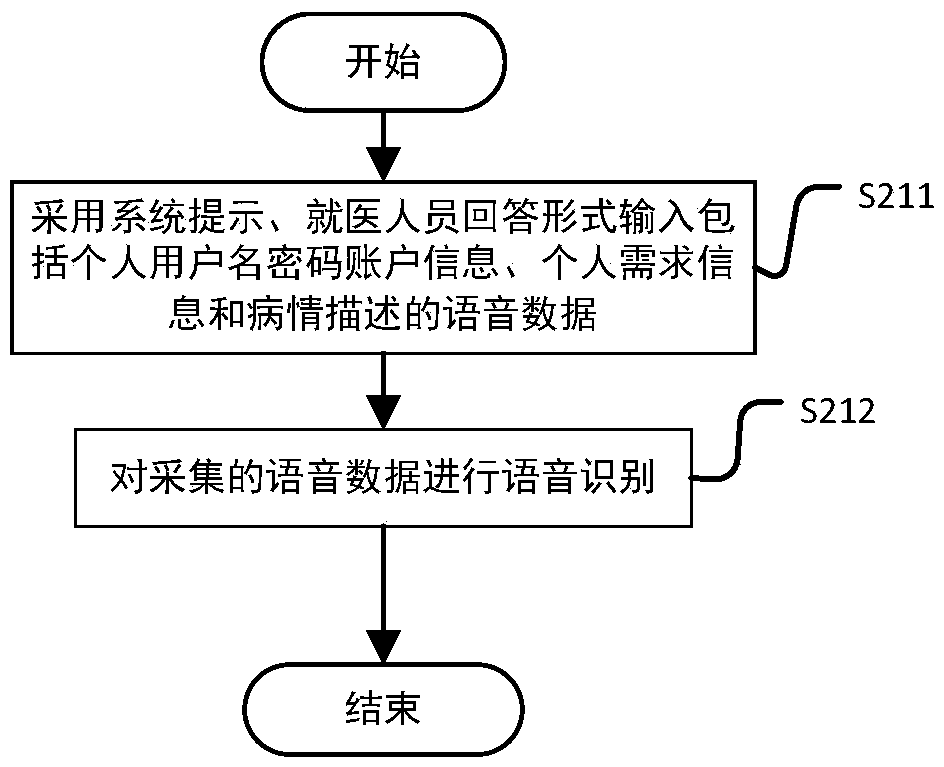

Fast and accurate medical service method and system for patients

InactiveCN109065185AExact sentence controlIncrease speedMedical communicationHealthcare resources and facilitiesScientific methodMedical staff

The invention discloses a fast and accurate medical service method and system for patients. The method comprises steps of establishing a medical database, receiving requests, waking up medical treatment-needing person service, making an appointment, initial diagnosis and diagnosis result feedback. The system comprises a server storage module, a medical treatment-needing person client module, an appointment selection determination module, a medical staff client module, a communication module, a voice input processing module, a text input module, a query archiving keyword generation module, a screening retrieval result generation module and a feedback module. The method and the system are advantaged in that problems that the medical procedure is cumbersome and difficult to register in the prior art can be solved, medical service efficiency and portability can be effectively improved, the waiting time is reduced for medical treatment-needing persons, the medical care pressure is alleviated, the accurate and efficient self-service is achieved through the Internet technology, and properties of high system intelligence degree, advanced and scientific methods, relatively high practical value and broad application prospects are further achieved.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

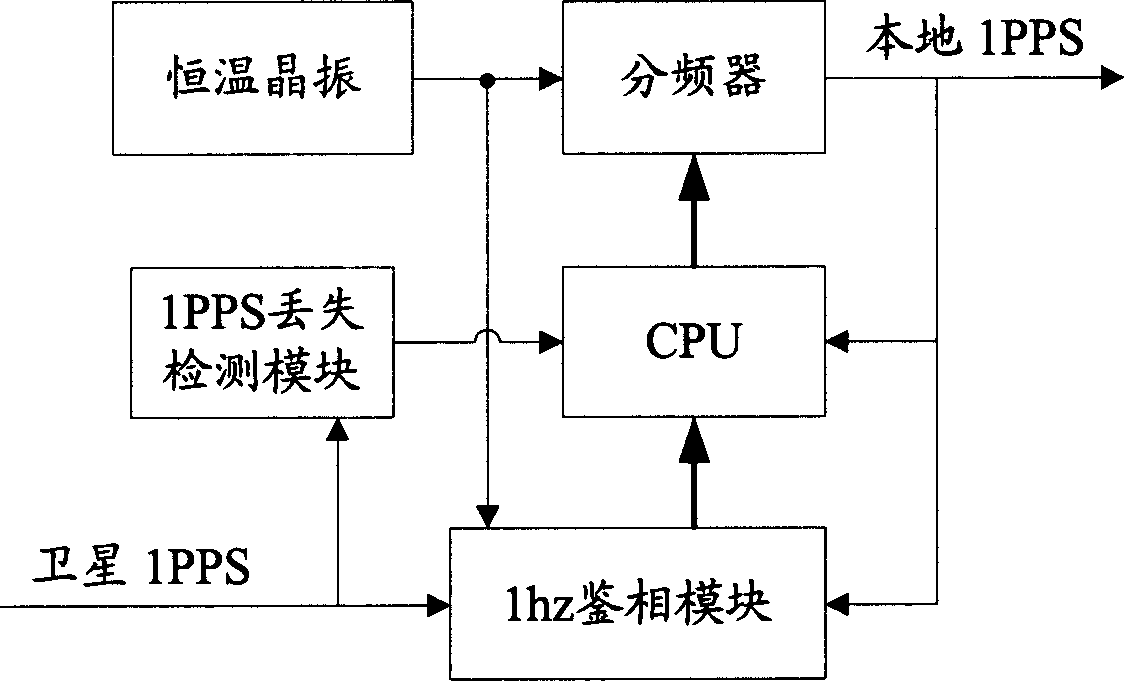

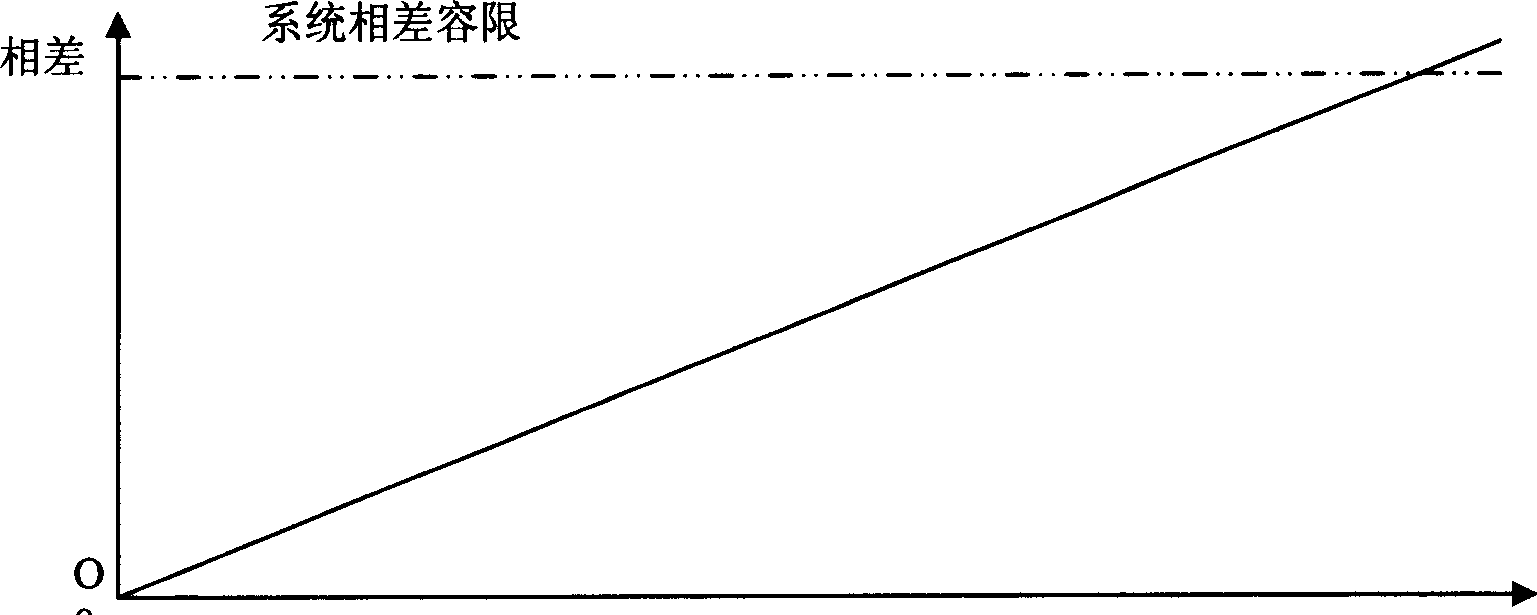

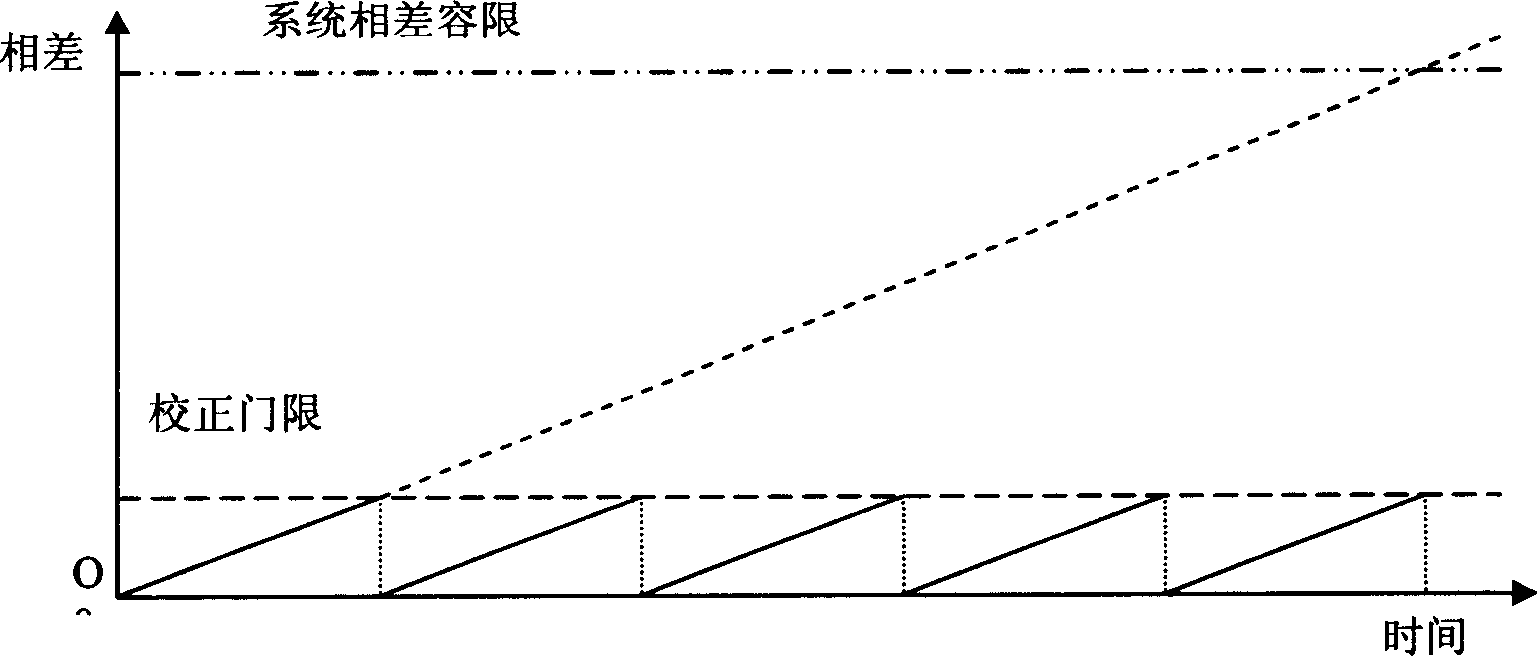

Method for improving satellite time synchronism pulse keeping performance

InactiveCN1909410ASimple hardware structureLow costPulse automatic controlRadio transmissionSatelliteSynchronism

The invention relates to a method for improving the synchronous impulse keep property of planet, wherein it comprises: CPU sets the phase difference correct threshold value and the correct threshold value of phase difference change speed; based on the phase-difference correct threshold value, adjusting the phase of local second impulse; CPU records and stores the phase differences between one group of local second impulse and planet second impulse in FIFO; CPU calculates the phase difference change average speed of local and planet second impulses; CPU judges if the average speed is higher or equal to the correct threshold value of phase difference change speed; if it, executing next step; or else, feeding back to the first two steps; CPU based on the average speed, adjusts the mode of frequency divider. The invention can reduce the phase difference increase speed, and reduce the phase difference correct times of local IPPS, to improve the kept time of local 1PPS.

Owner:HUAWEI TECH CO LTD

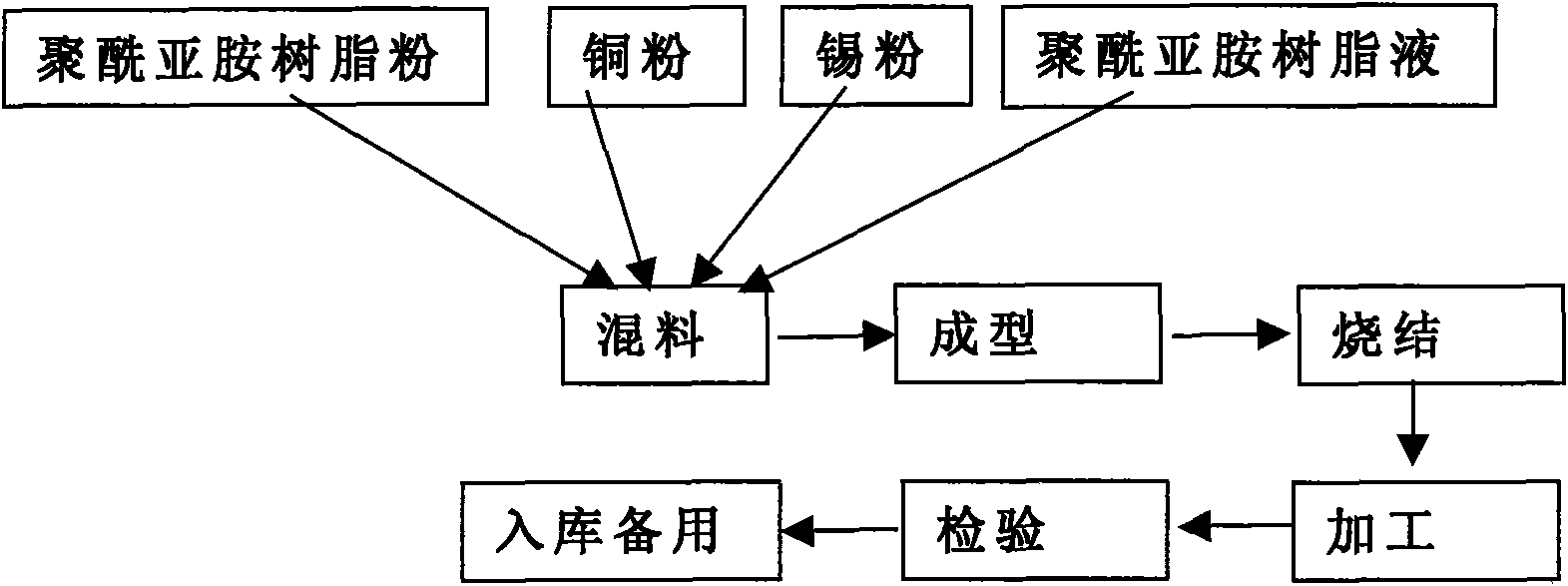

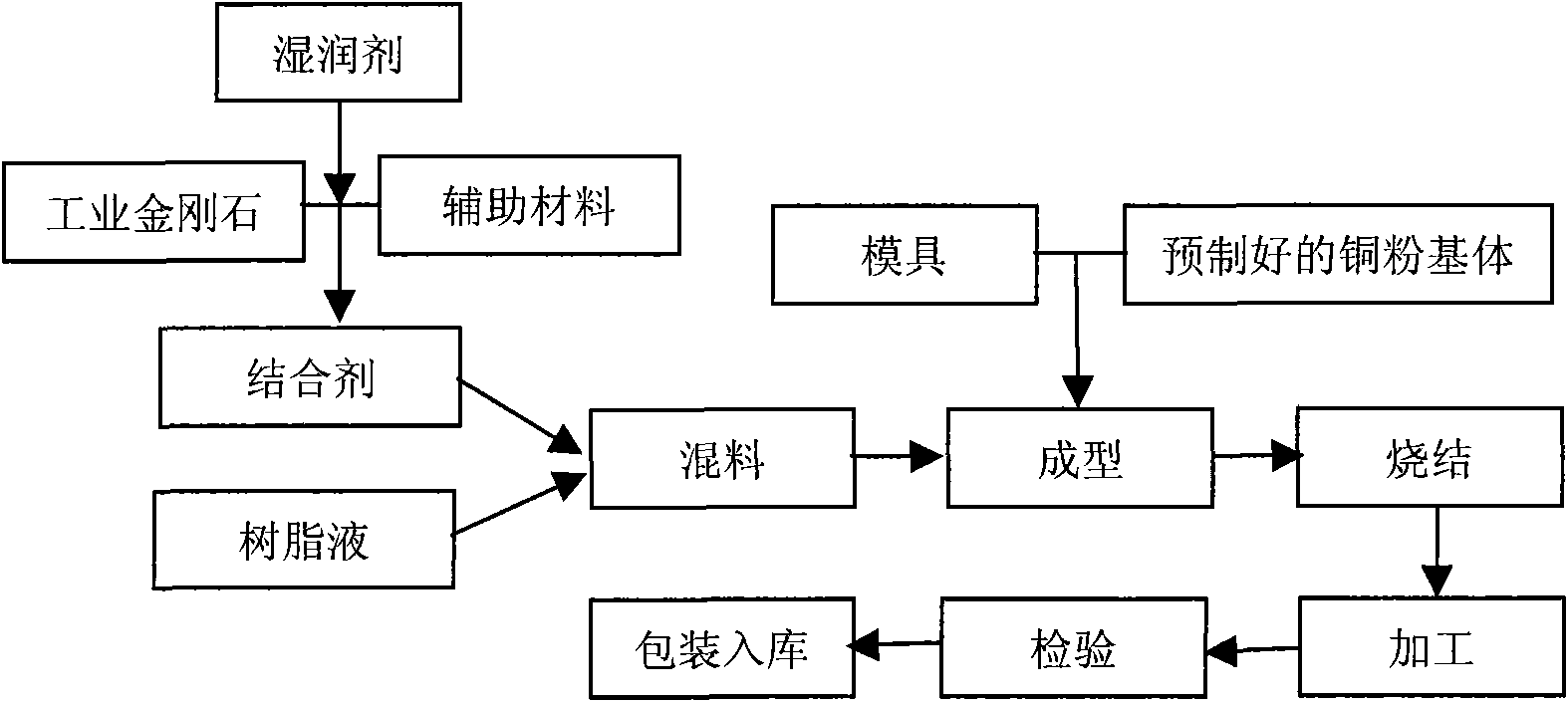

Diamond strong slotted grinding wheel specially used for copper-powder-based numerical control grinder

The invention discloses a copper powder substrate of a diamond strong slotted grinding wheel specially used for a numerical control grinder, comprising the following compositions and contents by weight percentage: 15-20% of polyimide resin powder, 50-60% of copper (Cu) powder, 10-20% of tin (Sn) powder and 2-3% of phenol formaldehyde resin liquid; the copper powder substrate obtained by the above formula has excellent heat dissipation performance and excellent strength and rigidity, and can be perfectly combined with the novel grinding wheel formula; when the diamond grinding wheel adopting the substrate is used for a five-axis linked numerical control grinder, the strong slotting is realized, the slotting depth of the grinding wheel is obviously improved, the correcting times of the grinding wheel is reduced, the working efficiency is improved by 25% and the service life of the grinding wheel is prolonged by more than 15%.

Owner:苏州赛尔科技有限公司

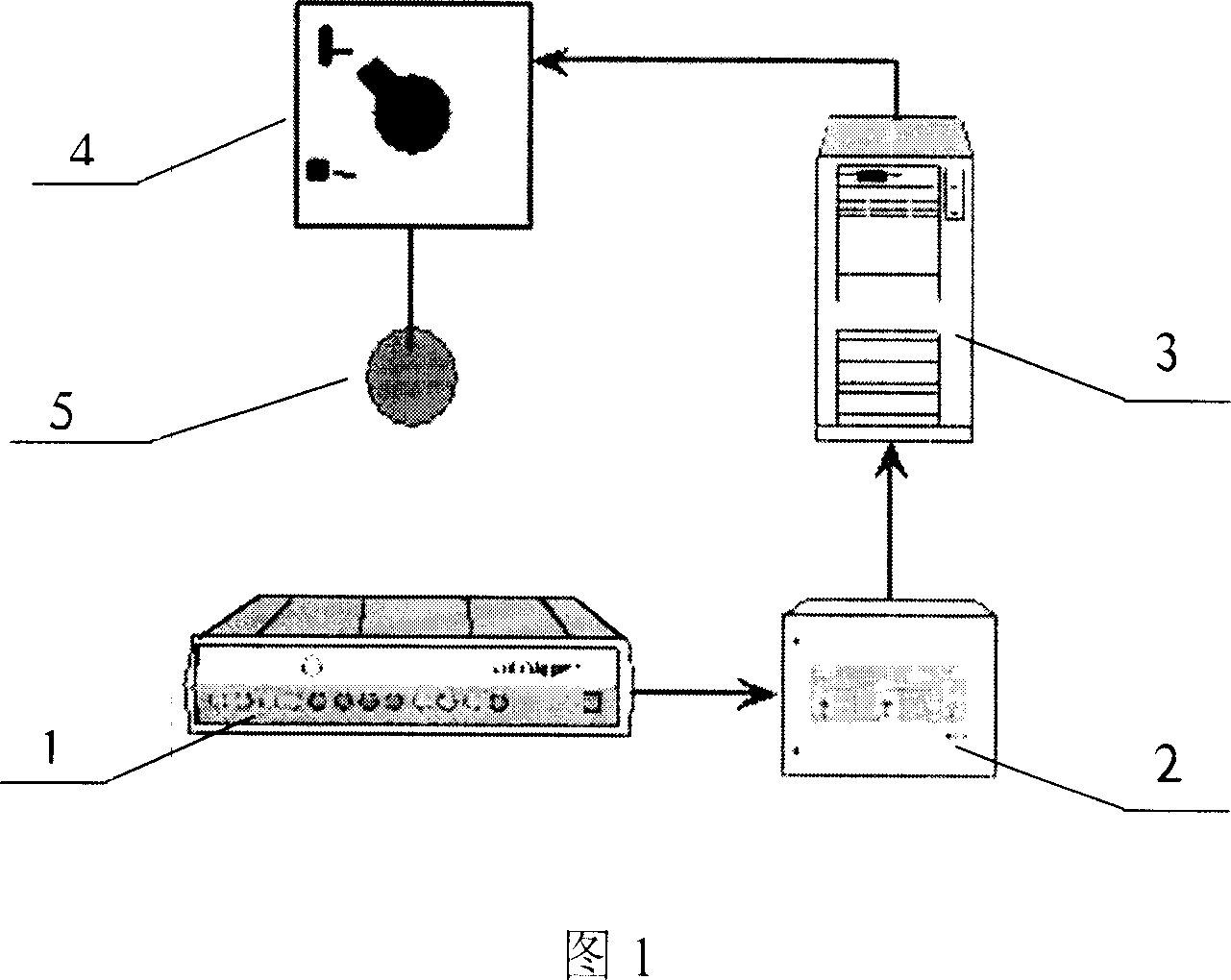

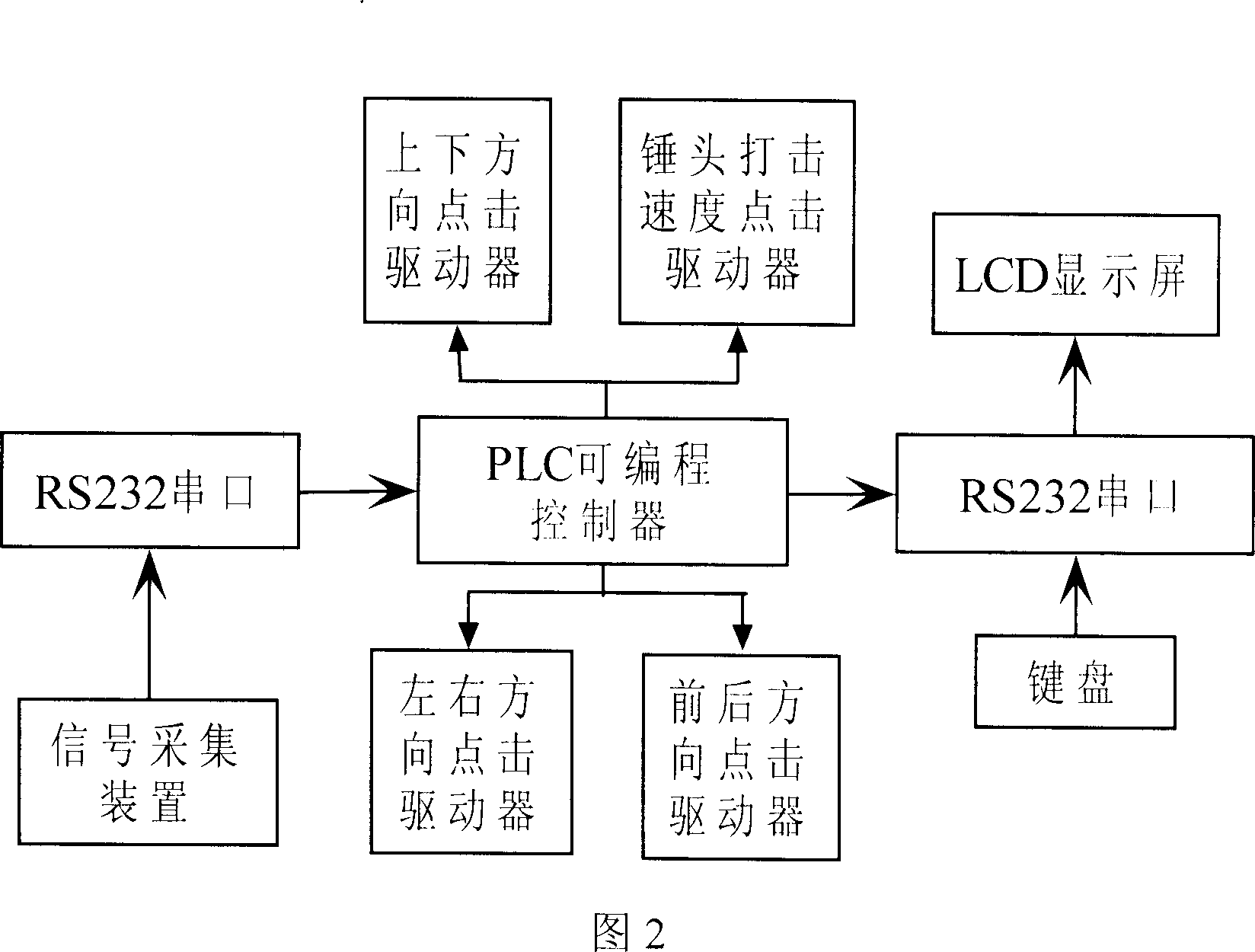

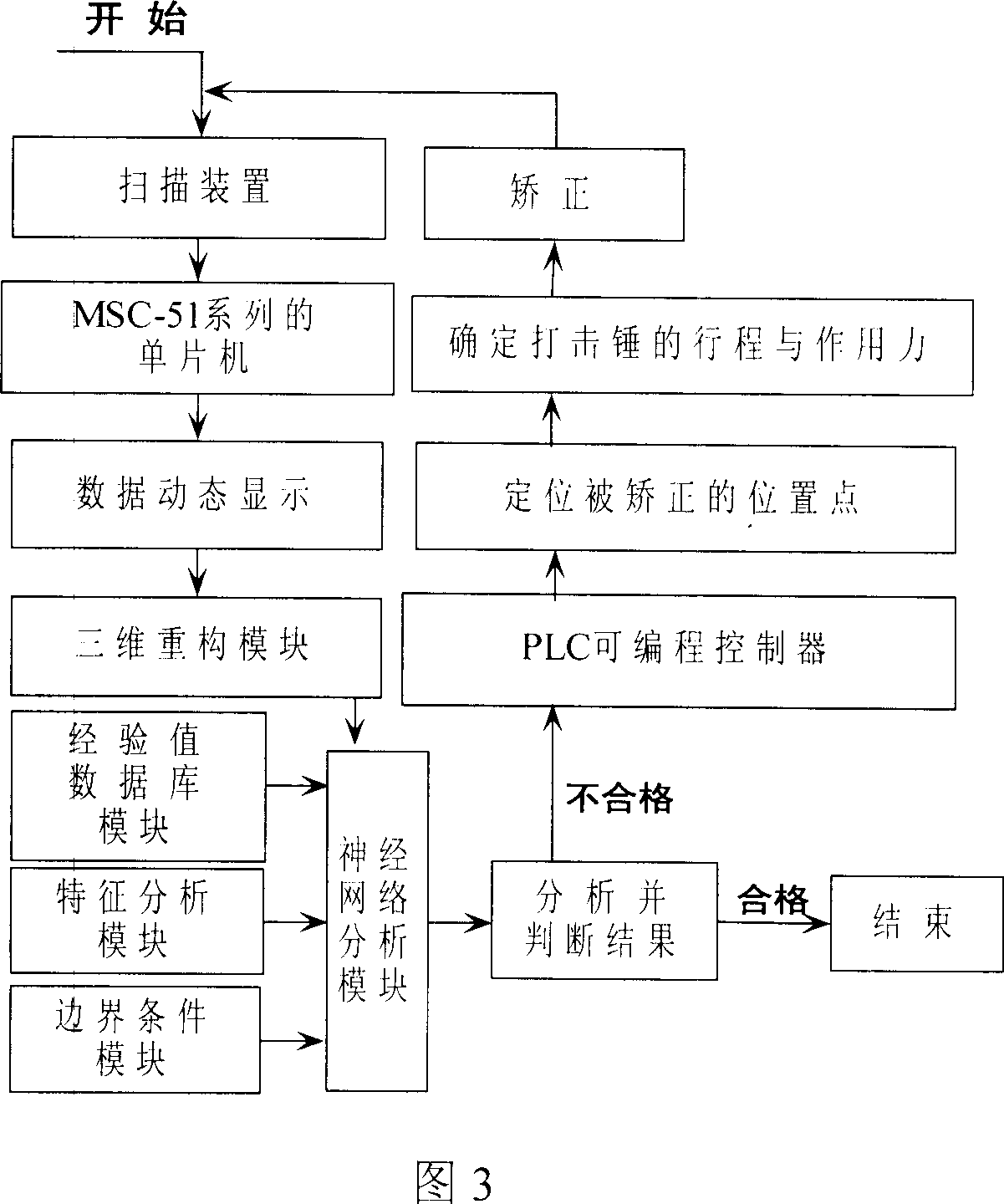

Intelligent work piece correcting system and correcting method thereof

InactiveCN1975618AReduce the number of correctionsFix orthoticsTotal factory controlProgramme control in sequence/logic controllersHuman bodyEngineering

This invention relates to a kind of intelligence workpiece corrective system and its correcting method , includes the working table, PC machine, controller, strike hammer, one end of the said working table sets up signal collection device, the said signal collection device includes the scan device and processor connected mutually, PC machine links with the processor of the said signal collection device, the controller includes actuating mechanism and treatment element connected mutually, the treatment element of the controller links with the said PC machine, the actuating mechanism of the said controller links the strike hammer. And this system has adopt automation treating , has resolved the correcting problem of the cosh material and specially appointed stick type workpiece geared to the needs of medium-sized and small enterprises, has improved the production efficacy, and the system has decreased the correcting number of the workpiece on maximal degree, has removed various unnecessary treating error; On the other hand, has changed the tradition work manner that the scene work of the worker, has realized the long-range supervisory control to deformation workpiece, has kept away the noise and other bad factor's damage effect to the human body.

Owner:SOUTH CHINA UNIV OF TECH

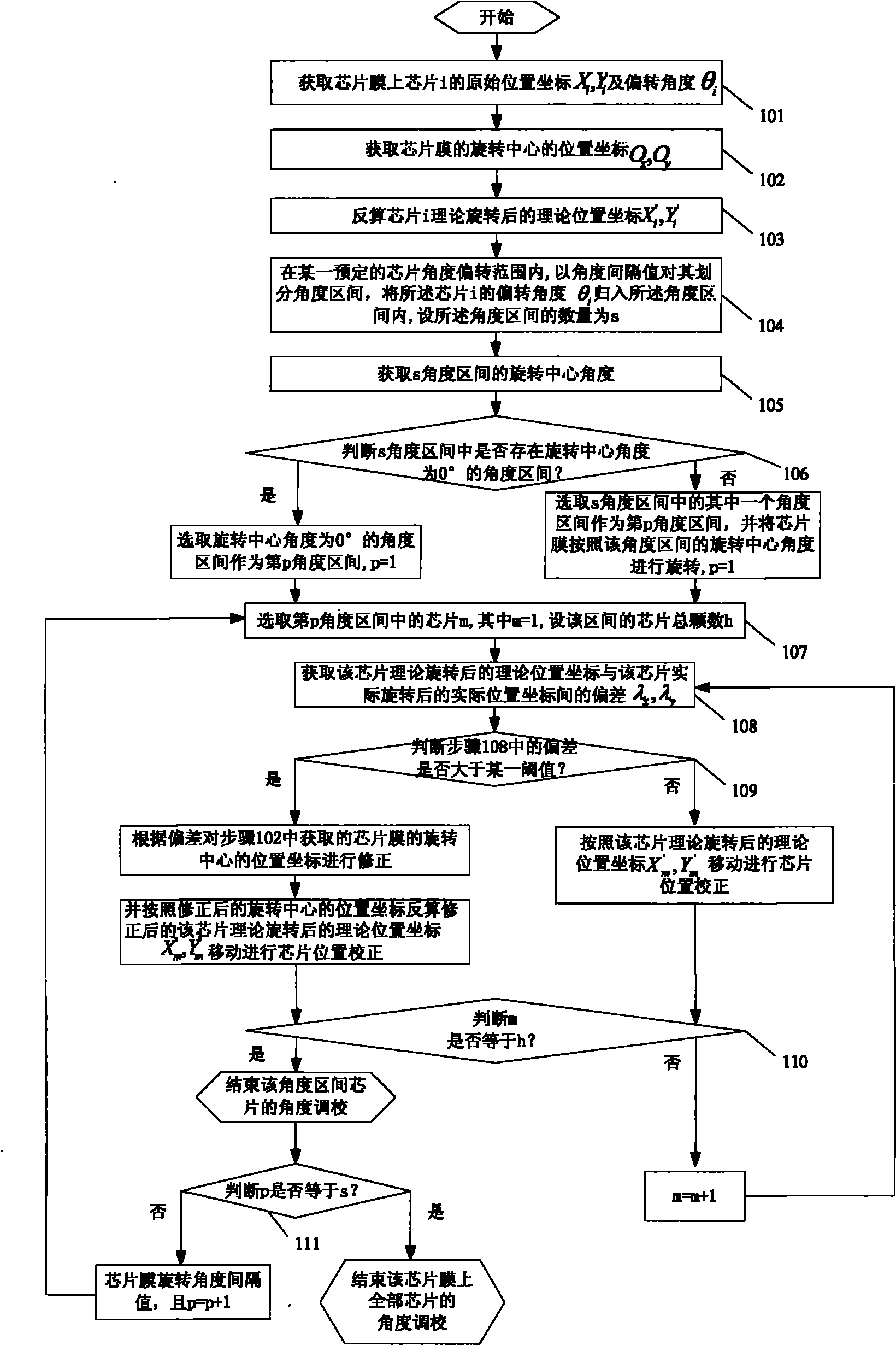

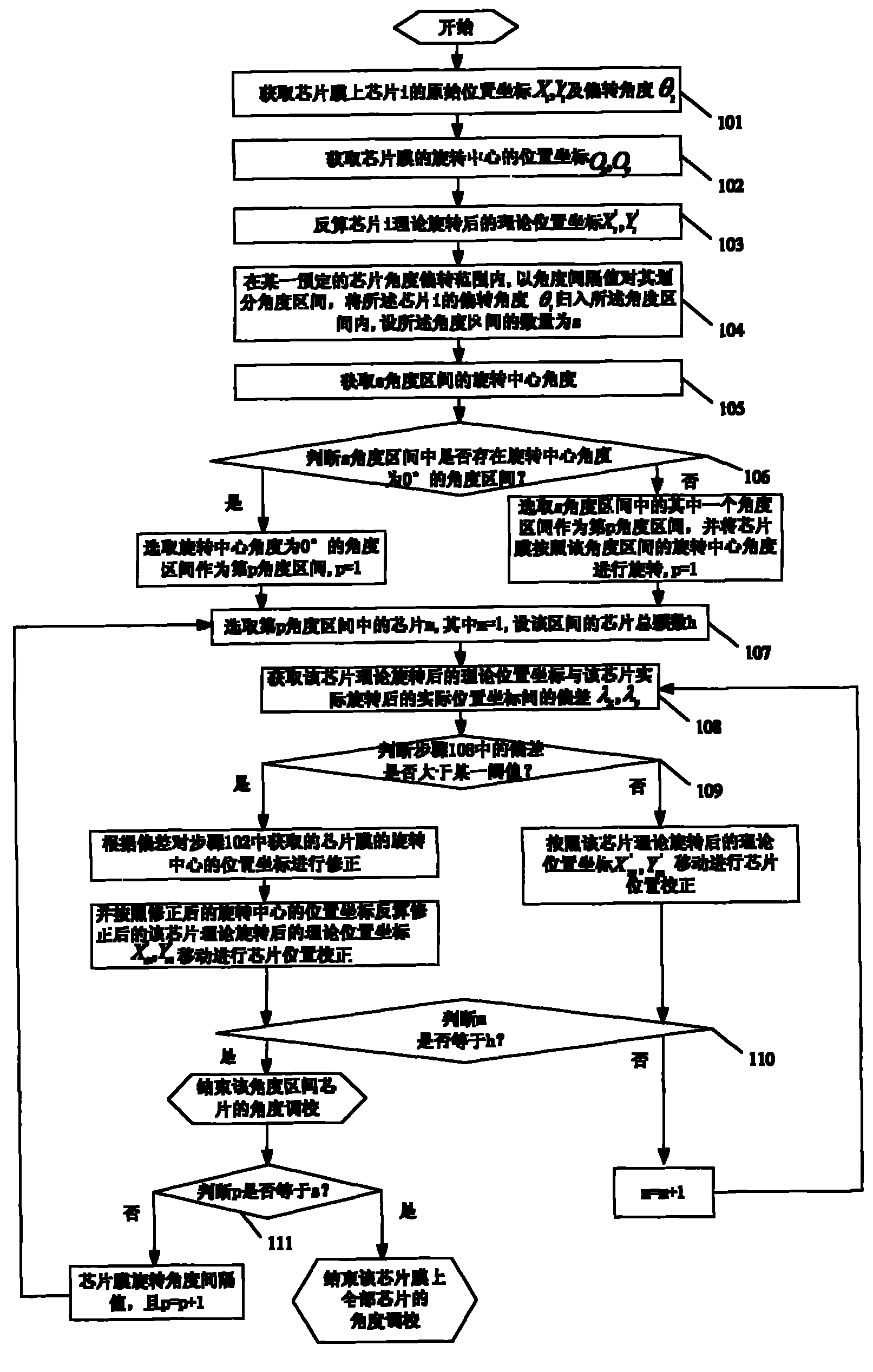

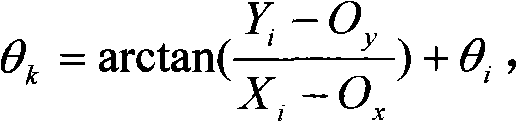

Method for fast tuning angle of LED chip

The invention relates to a method for fast tuning the angle of LED chip. The method mainly comprises: including the chip into an angle interval; obtaining a rotating pivot angle of the angle interval; selecting the p angle interval, and rotating the chip film according to the rotating pivot angle of the angle interval, wherein, p is equal to 1; positioning the chip m according to the theoretical position coordinates X'm and Y'm after theoretical rotation, and obtaining deviation Lambada x and Lambada y between X'm and Y'm and the actual position of the chip after actual rotation; judging whether Lambada x and Lambada y are larger than a certain threshold, if yes, amending Ox and Oy according to Lambada x and Lambada y and correcting the position of the chip; if no, correcting the position of the chip according to the theoretical position coordinates X'm and Y'm after theoretical rotation; judging whether the chip in the p angle interval is selected and finished, if yes, ending the angle tuning of the chip in the angle interval; proceeding to the angle tuning of the chip of the next angle interval. The invention can improve accuracy of chip angle tuning, effectively reduce the overall chip tuning times and enhance chip angle tuning efficiency, and increase chip sorting speed.

Owner:DG HUST MFG ENG RES INST +1

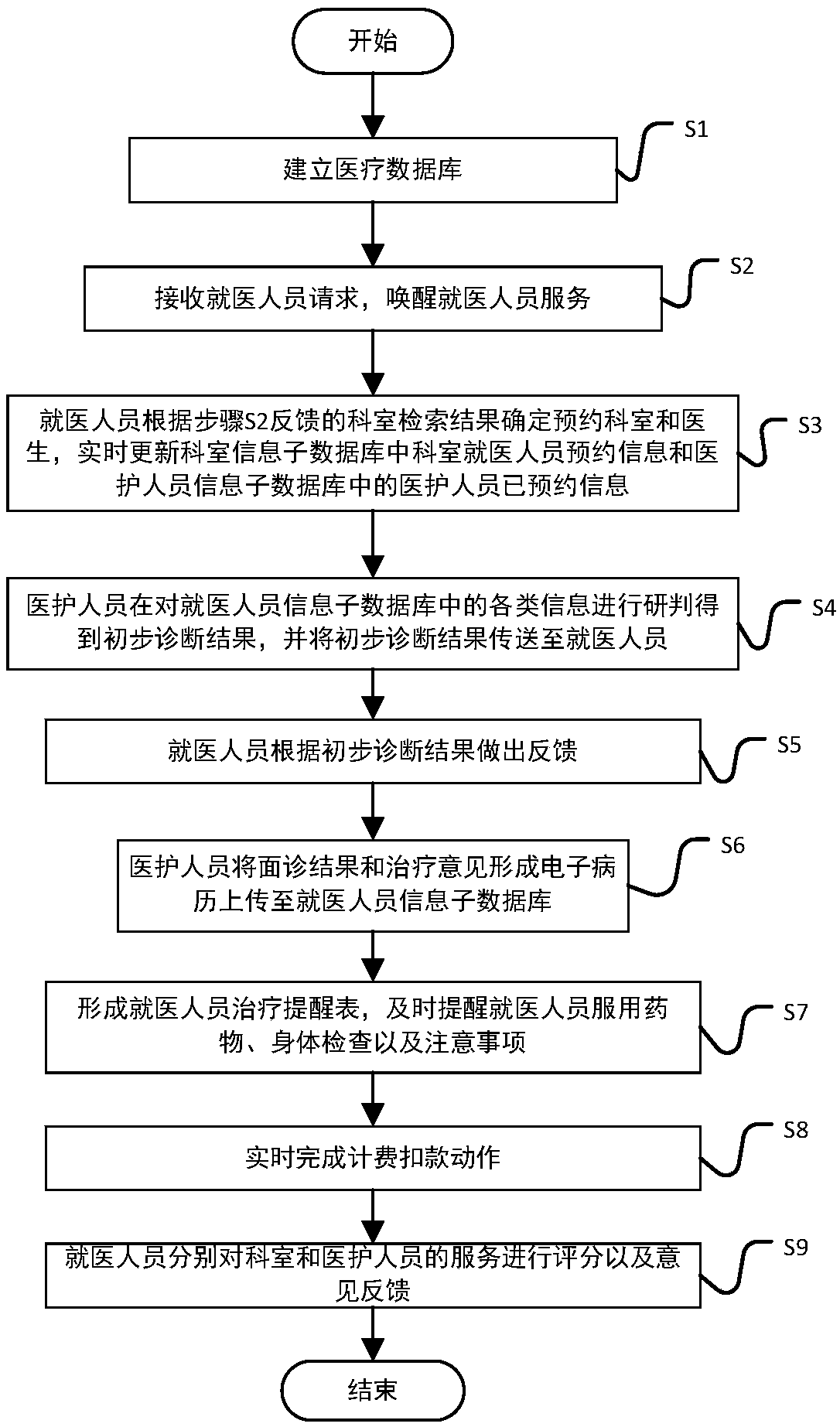

Medical whole-process intelligent service method and system

InactiveCN109003663AExact sentence controlIncrease speedMedical communicationHealthcare resources and facilitiesThe InternetClient-side

The invention discloses a medical whole-process intelligent service method and system. The method comprises the steps of establishing a medical database, receiving the request, awakening the medical personnel service, confirming the appointment, preliminary diagnosis and diagnosis result feedback and the like. The system comprises a server storage module, a medical personnel client module, an appointment selection determination module, a medical personnel client module, a communication module, a voice input processing module, a text input module, a query and archiving keyword generation module, a screening and retrieval result generation module and a feedback module. The problems that the present medical procedure is tedious and registration is difficult can be solved, the efficiency and the portability of the medical service can be effectively improved, waiting time of the medical personnel can be reduced, the medical pressure can be alleviated, the accurate and efficient self-servicecan be realized through the Internet technology, the system has high intelligent degree, the method is advanced and scientific, and the practical value is high and the application prospect is wide.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

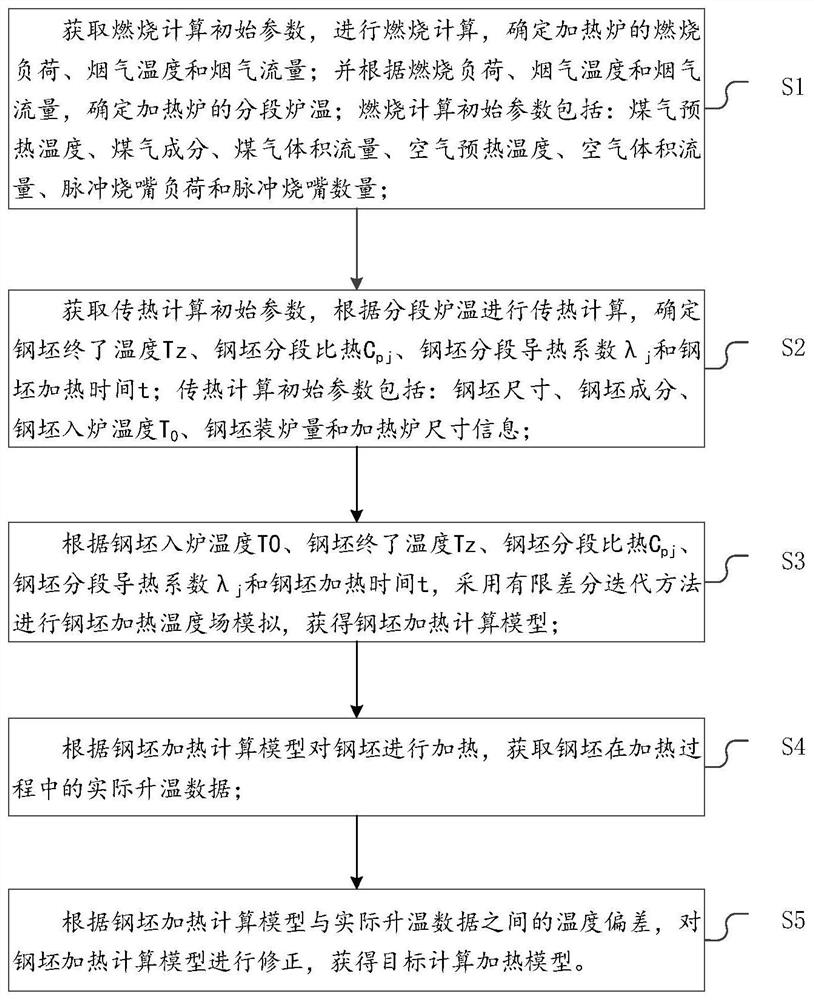

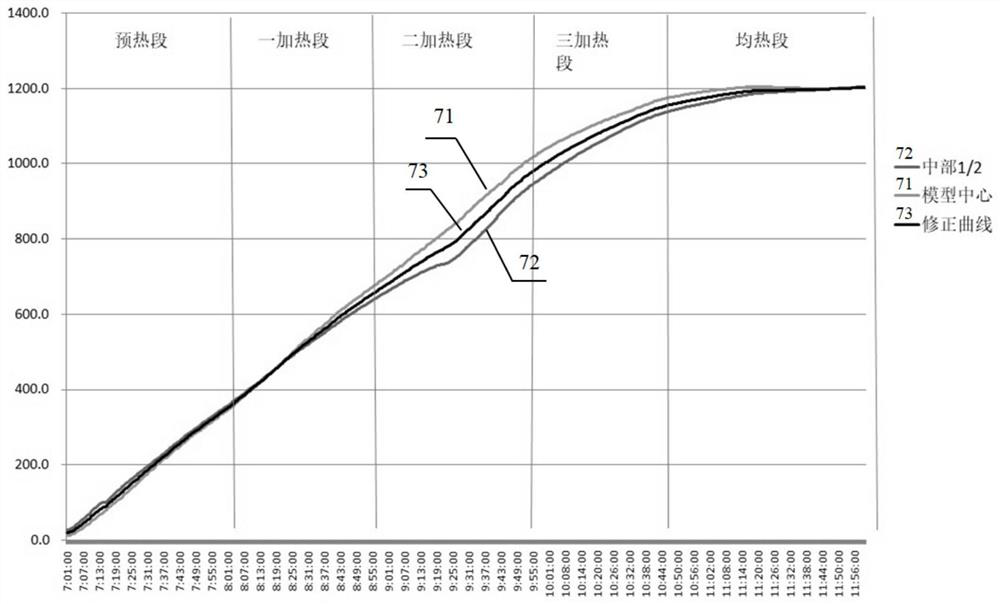

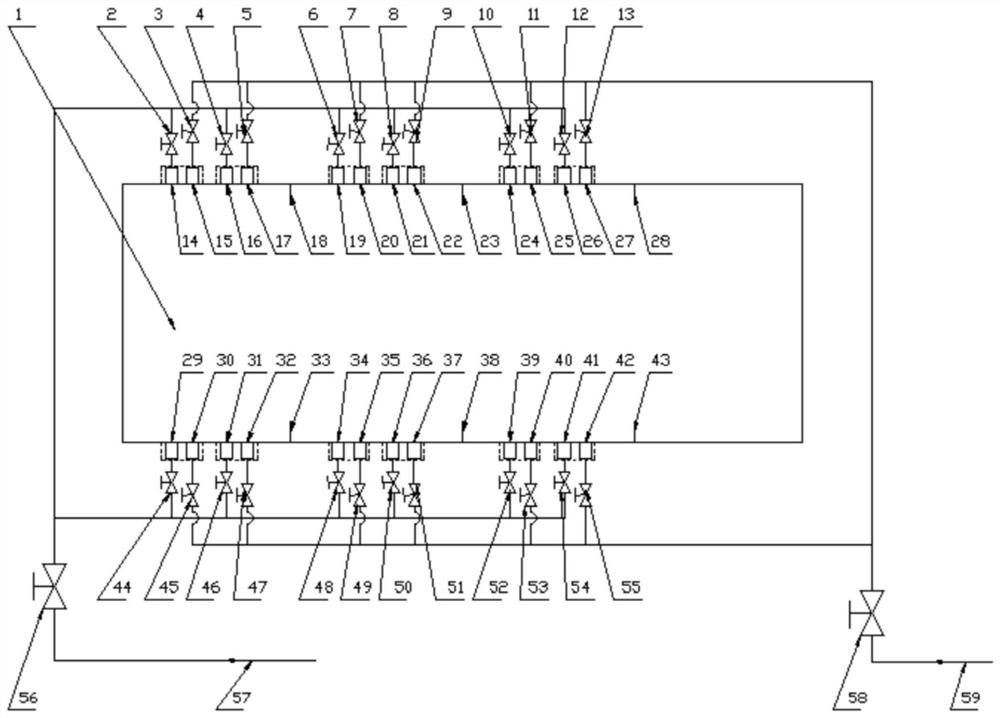

Optimization method and optimization device for billet heating model and electronic equipment

PendingCN111950176AImprove calculation accuracySpeed up iterationDesign optimisation/simulationHeat treatment process controlFurnace temperatureHeating time

The invention discloses an optimization method for a billet heating model, which comprises the following steps: carrying out combustion calculation, and determining the combustion load, flue gas temperature and flue gas flow of a heating furnace; determining the segmented furnace temperature of the heating furnace according to the combustion load, the flue gas temperature and the flue gas flow; conducting heat transfer calculation according to the segmented furnace temperature, and determining the billet final temperature Tz, the billet segmented specific heat Cpj, the billet segmented heat conduction coefficient lambda j and the billet heating time t; performing billet heating temperature field simulation by adopting a finite difference iteration method to obtain a billet heating calculation model; heating the steel billet according to the steel billet heating calculation model to obtain actual temperature rise data of the steel billet; correcting the billet heating calculation modelaccording to the billet heating calculation model and the actual temperature rise data; according to the optimization method, combustion, heat transfer, billet temperature field simulation and a heating model correction process are integrated, and effective control over billet heating temperature and quality is achieved.

Owner:SHOUGANG CORPORATION

Medical self-service method and system based on mobile internet

InactiveCN109065132AExact sentence controlIncrease speedHealthcare resources and facilitiesComputer moduleSelf-service

The invention discloses a medical self-service method and system based on the mobile internet. The method comprises steps of establishing a medical database, receiving requests, waking up medical treatment-needing person service, making an appointment, initial diagnosis and diagnosis result feedback. The system comprises a server storage module, a medical treatment-needing person client module, anappointment selection determination module, a medical staff client module, a communication module, a voice input processing module, a text input module, a query archiving keyword generation module, ascreening retrieval result generation module and a feedback module. The method and the system are advantaged in that problems that the medical procedure is cumbersome and difficult to register in theprior art can be solved, medical service efficiency and portability can be effectively improved, the waiting time is reduced for medical treatment-needing persons, the medical care pressure is alleviated, the accurate and efficient self-service is achieved through the Internet technology, and properties of high system intelligence degree, advanced and scientific methods, relatively high practicalvalue and broad application prospects are further achieved.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

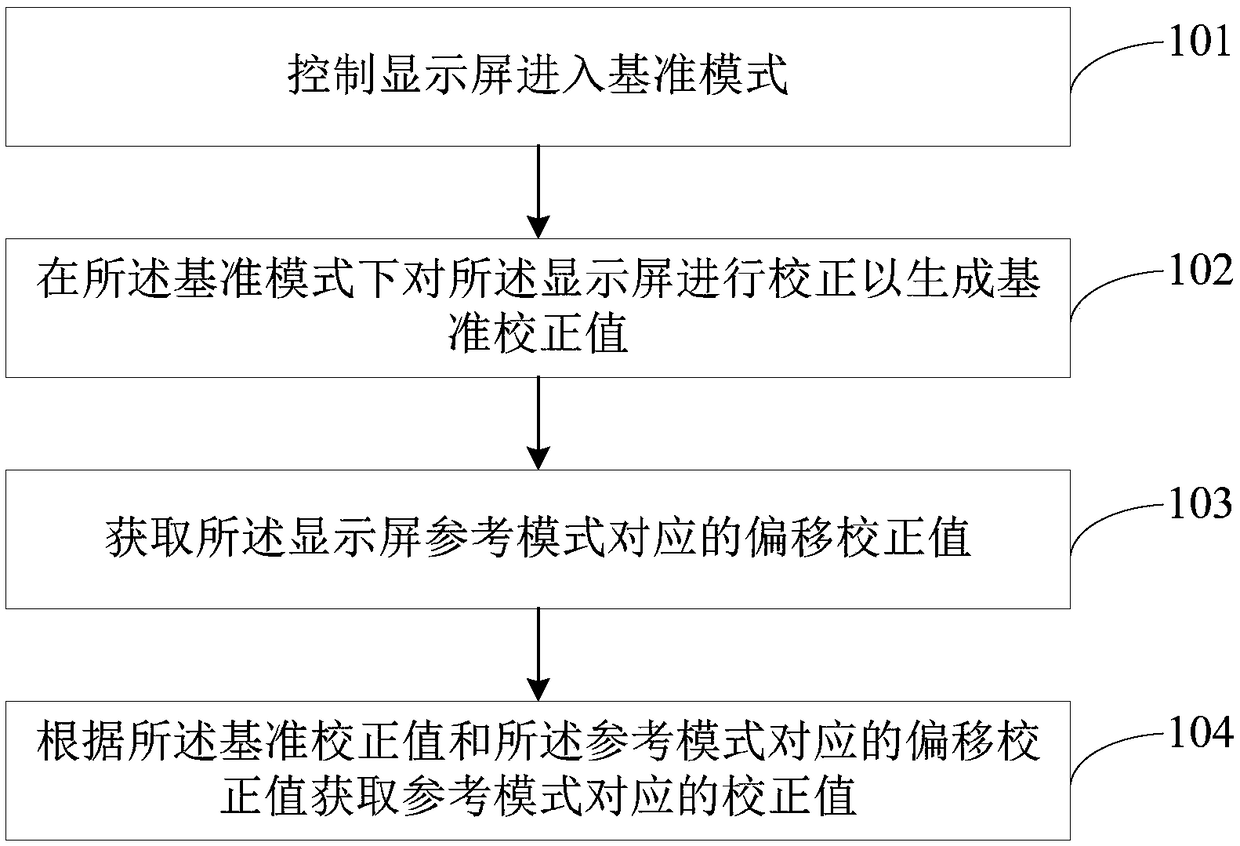

Display screen correction optimizing method, device thereof, electronic equipment and storage medium

ActiveCN109410839AReduce the number of correctionsImprove calibration efficiency and throughputStatic indicating devicesElectric equipmentElectronic equipment

The invention provides a display screen correction optimizing method, a device thereof, electronic equipment and a storage medium, wherein the display screen correction optimizing method, the device thereof, the electronic equipment and the storage medium belong to the field of electronic technology, wherein the method comprises the steps of controlling the display screen to enter a standard mode;in the standard mode, correcting the display screen for generating a standard correction value; obtaining an offset correction value which corresponds with the reference mode of the display screen; and obtaining a correction value which corresponds with the reference mode according to a standard correction value and the offset correction value that corresponds with the reference mode. Therefore,through the correction optimizing method of the display screen, not only is the number of corrections reduced for improving correction efficiency and production power, but also high displaying qualityand high optical effect of the display screen are ensured, thereby improving user experience.

Owner:BOE TECH GRP CO LTD +1

Edge cover paint and method for forming thick coating film on edge of steel material by using the paint

InactiveCN101063013AInhibition formationEnough film thicknessRubber derivative coatingsMagnetic paintsMagnetizationSolid content

This invention relates to a method for effectively forming thick coating film to improve the corrosion prevention of magnetic steel-materials edge, especially shrap edge generated by mechanical cutting. An edge cover paint which contains magnetic substance powder three to 40% of the weight in coating material solid content is used, when coating with the said paint or before paint solidifying (losing fluidity)after coating, the object to be coated such as steel is in the magnetic field, and thick film can be form in the edge using the magnetization characteristic difference of edge and adjacent plane.

Owner:CHUGOKU MARINE PAINTS

Medical treatment guiding online convenient implementation method and system

InactiveCN109036532AExact sentence controlIncrease speedHealthcare resources and facilitiesText entryThe Internet

The invention discloses a medical treatment guiding online convenient implementation method and system. The method comprises the steps of establishing a medical database, receiving a request, waking up medical personnel, determining a reservation, performing preliminary diagnosis, and performing diagnosis result feedback; the system comprises a server storage module, a medical personnel client module, a reservation selection determination module, a medical personnel client module, a communication module, a voice input processing module, a text entry module, a query and filing keyword generation module, a screening retrieval result generation module and a feedback module. According to the invention, the problems that an existing medical treatment procedure is tedious and the registration isdifficult can be solved, the efficiency and portability of medical services can be effectively improved, the waiting time of the medical personnel is reduced, and medical pressure is relieved, accurate and efficient self-service is achieved through the internet technology, and the system is high in intelligent degree, the method is advanced and scientific, and the method and system have high practical values and wide application prospects.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

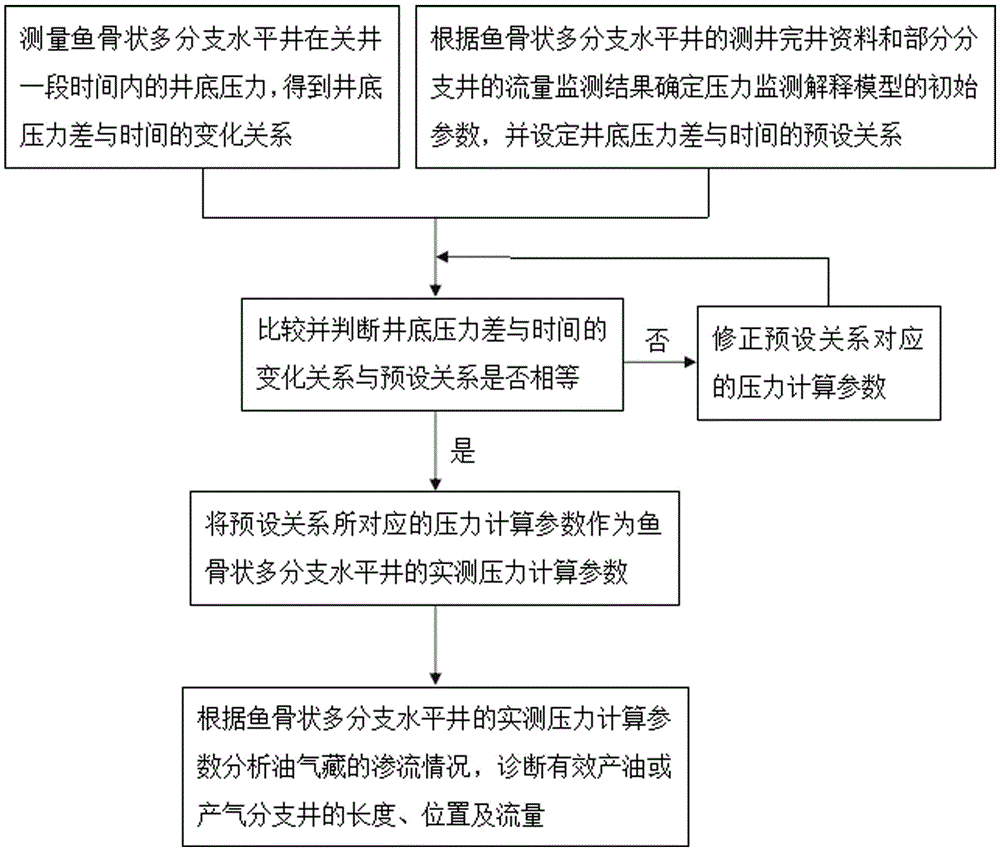

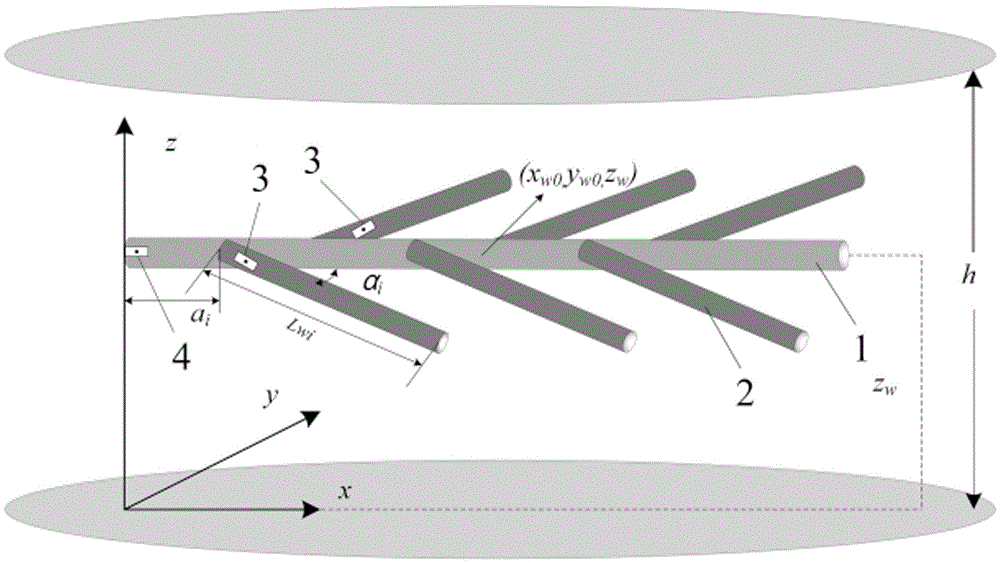

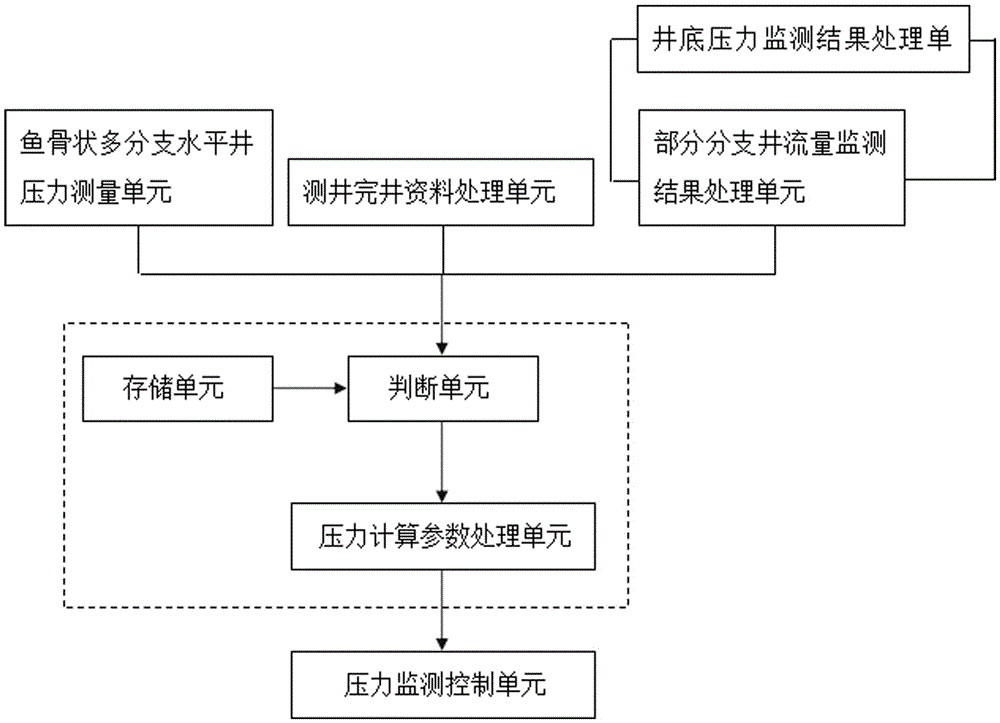

Method for diagnosing oil (gas) production position of fishbone-shaped multi-branch horizontal well and system thereof

ActiveCN105550438AReduce the number of correctionsIncrease productivityData processing applicationsDesign optimisation/simulationBottom hole pressureWell stimulation

The invention relates to a method for diagnosing an oil (gas) production position of a fishbone-shaped multi-branch horizontal well. The method comprises the following steps: measuring bottom hole pressures within a period of well closure time to obtain a change relation of a bottom hole pressure difference and time; determining an initial parameter of a pressure monitoring interpretation model according to logging well completion data and the flow monitoring results of a part of branch wells; and comparing whether the change relation of the bottom hole pressure difference and time is equal to a preset relation, if so, executing a next step, and if not, correcting the change relation to obtain an actually measured pressure calculation parameter, so as to diagnose the length, the position and the flow of each oil (gas) production branch well. The invention further relates to a diagnostic system, comprising a pressure measurement unit, a judgment unit, a pressure calculation parameter processing unit, a pressure monitoring control unit, a logging well completion data processing unit and a flow monitoring result processing unit of a part of branch wells. The method and the system are used for directionally regulating well stimulation by considering the influence of oil production or gas production nonuniformity of the branch wells.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

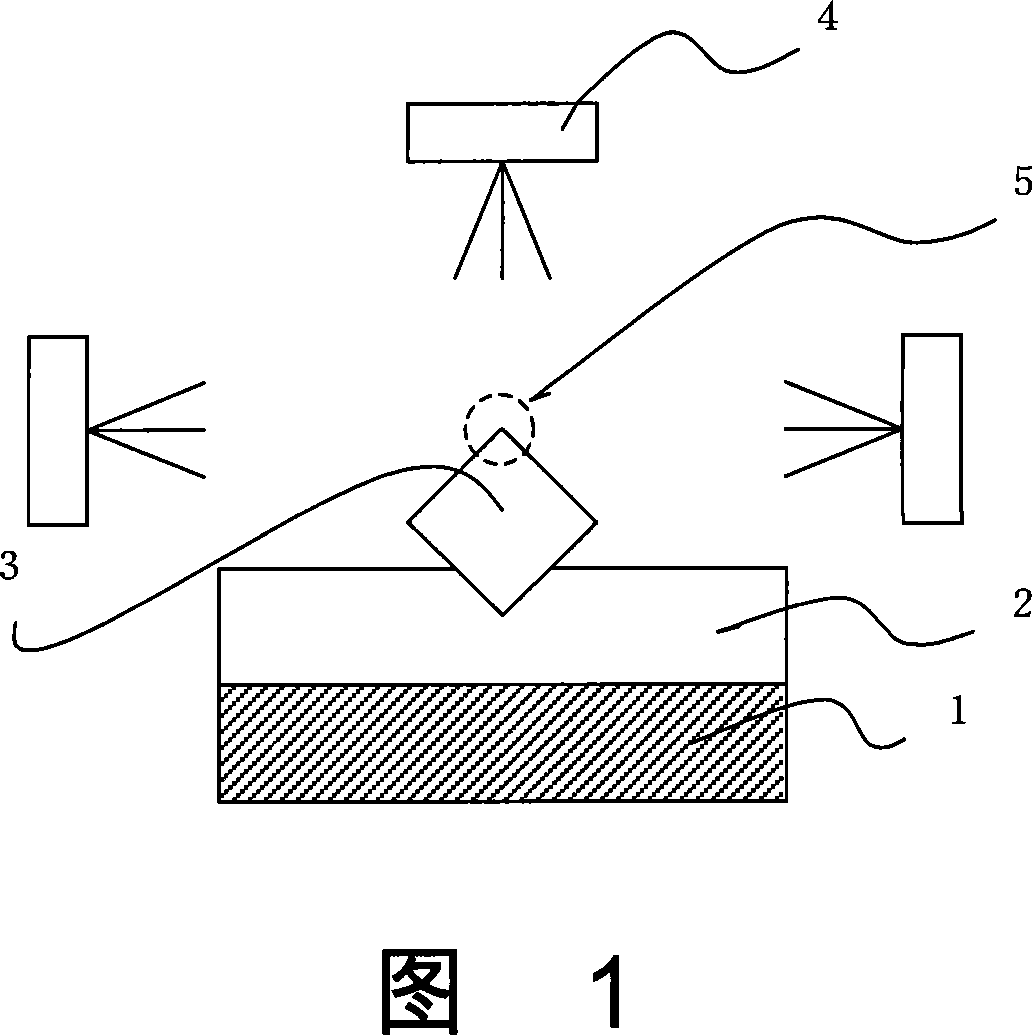

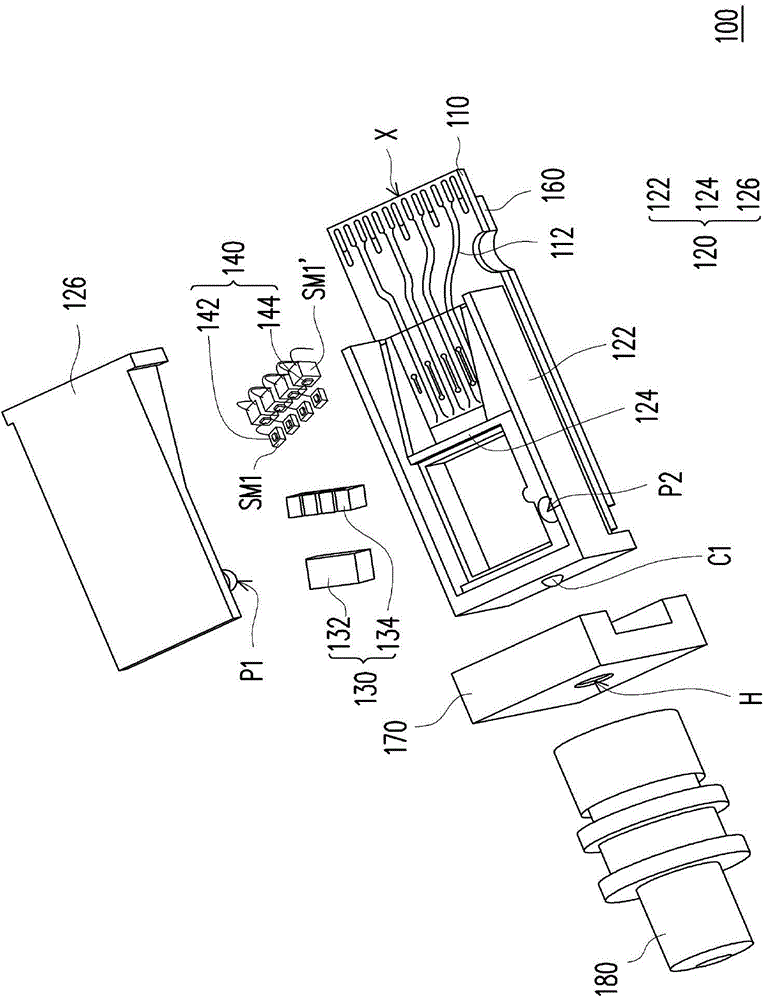

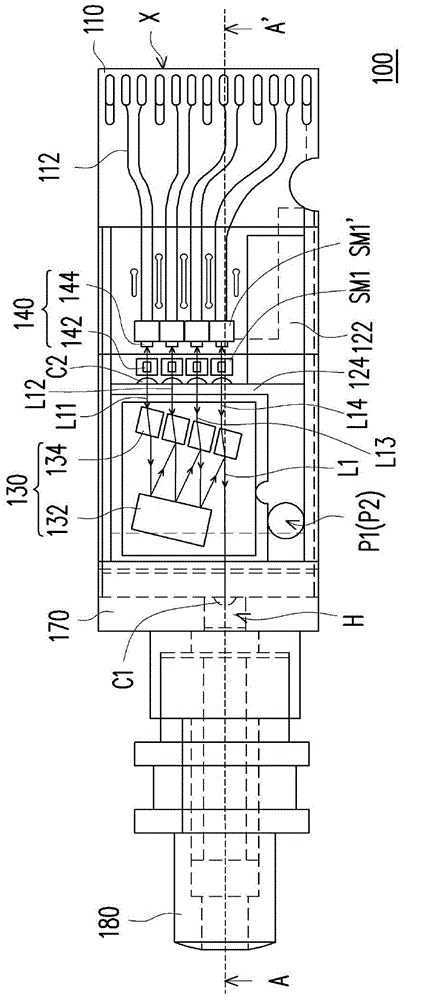

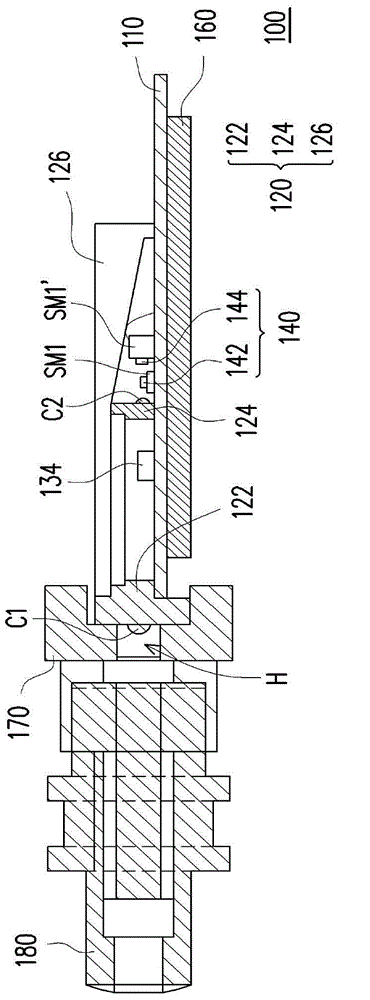

Hybrid integrated optical sub-assembly

InactiveCN106291836AOmit additional packaging processReduce volumeCoupling light guidesOptical processingPhotoelectric conversion

Owner:ELASER TECH

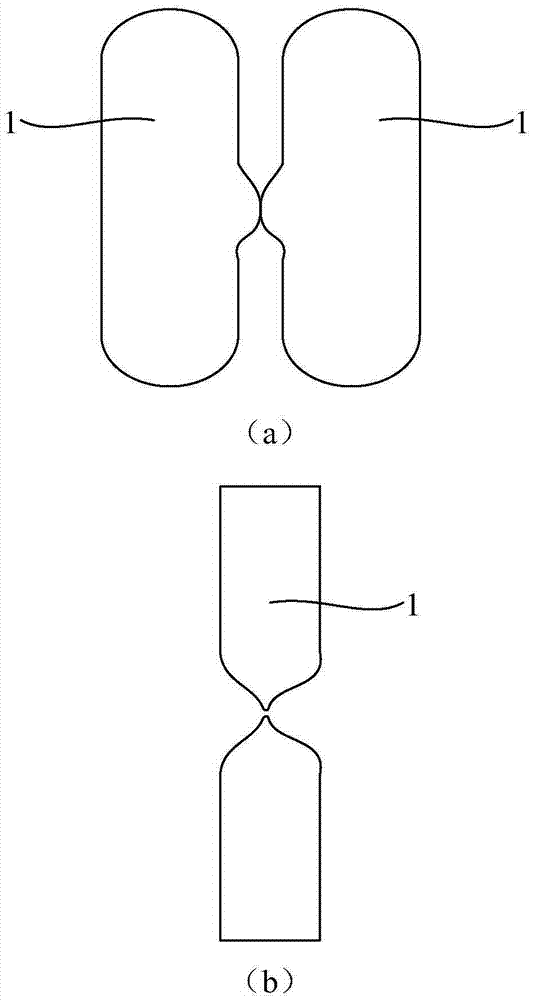

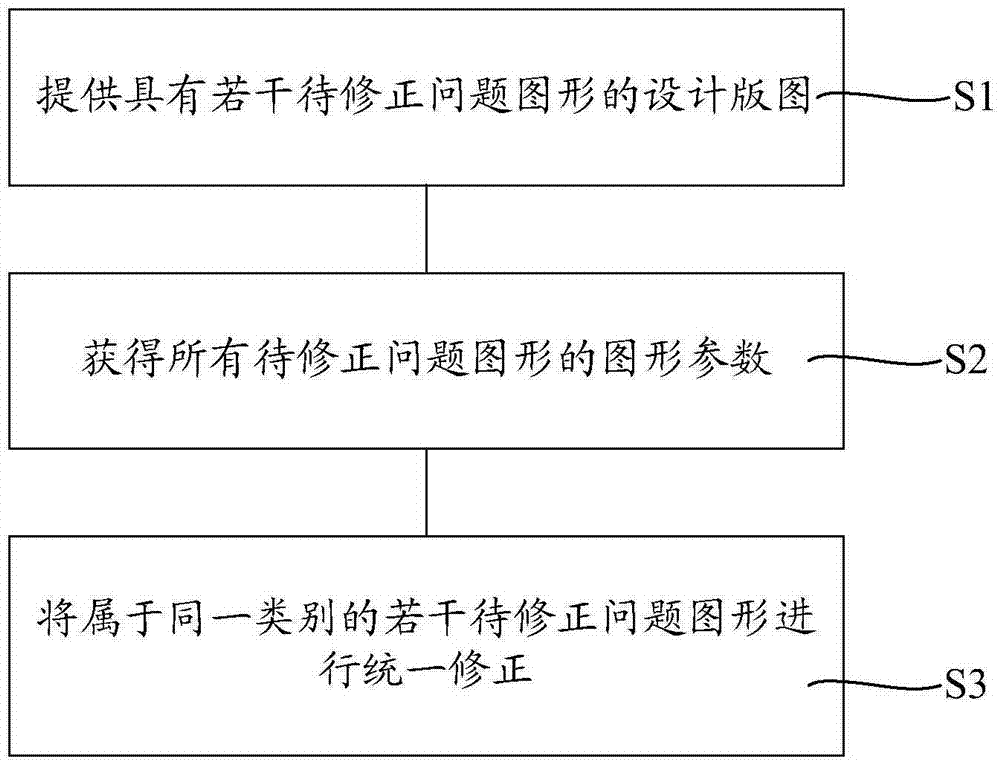

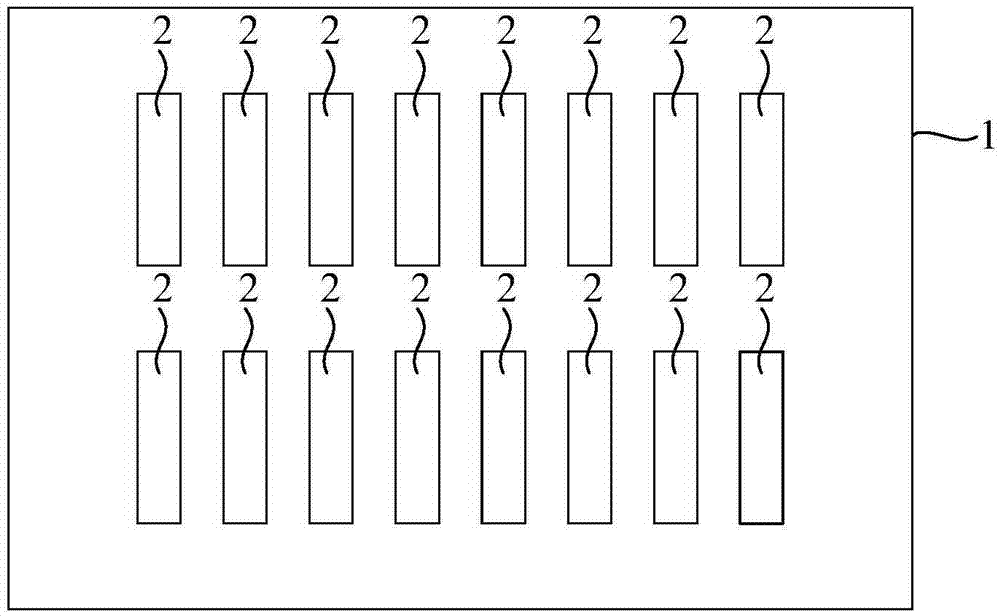

Optical proximity correction method

ActiveCN106873305AReduce the number of correctionsShorten the time taken for correctionOriginals for photomechanical treatmentGraphicsAlgorithm

The invention discloses an optical proximity correction method. The optical proximity correction method comprises the steps of providing a design layout of an integrated circuit, wherein the design layout comprises a plurality of to-be-corrected faulty graphs; measuring graph parameters of all the to-be-corrected faulty graphs; and performing unified correction on a plurality of to-be-corrected faulty graphs of the same category in all the to-be-corrected faulty graphs in the same step according to the graph parameters of all the to-be-corrected faulty graphs. According to the technical scheme of the invention, the multiple to-be-corrected faulty graphs of the same category in all the to-be-corrected faulty graphs are subjected to unified correction in the same step, so that correction on the to-be-corrected faulty graphs of the same category one by one is avoided; and therefore, the number of correction times of the to-be-corrected faulty graphs is reduced, optical proximity correction time is shortened, and correction efficiency is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

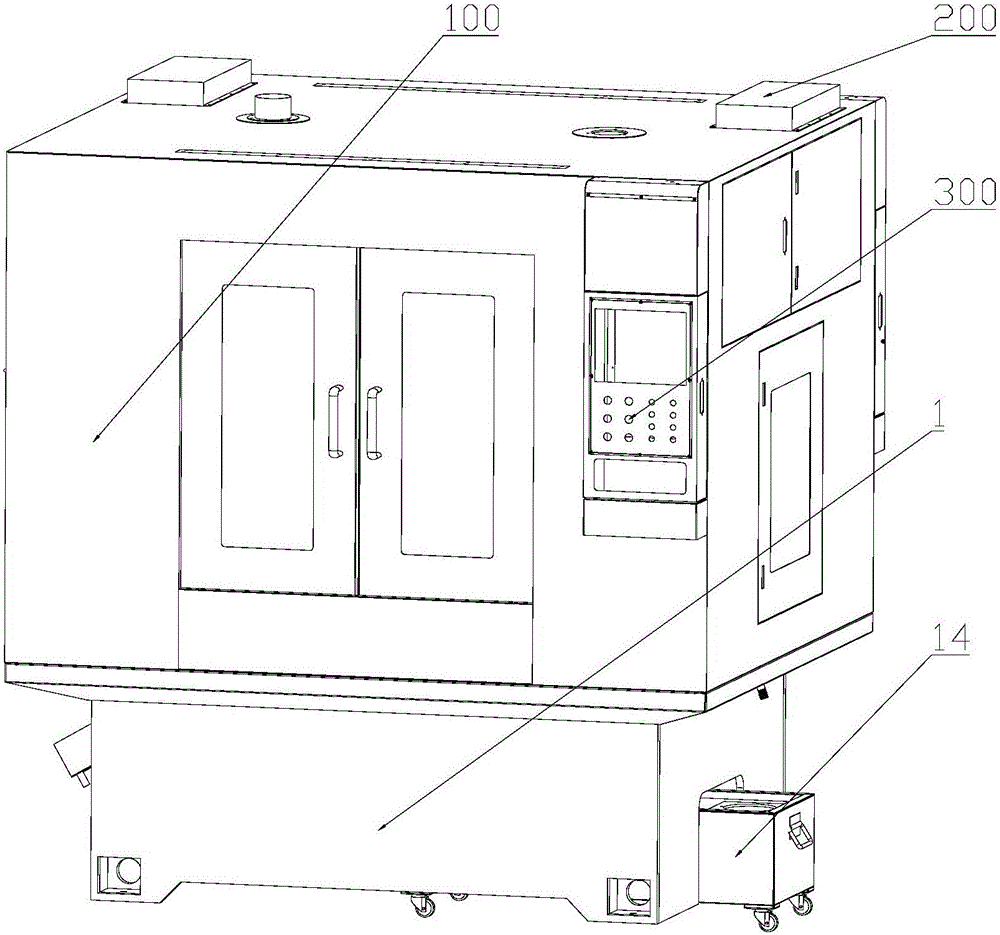

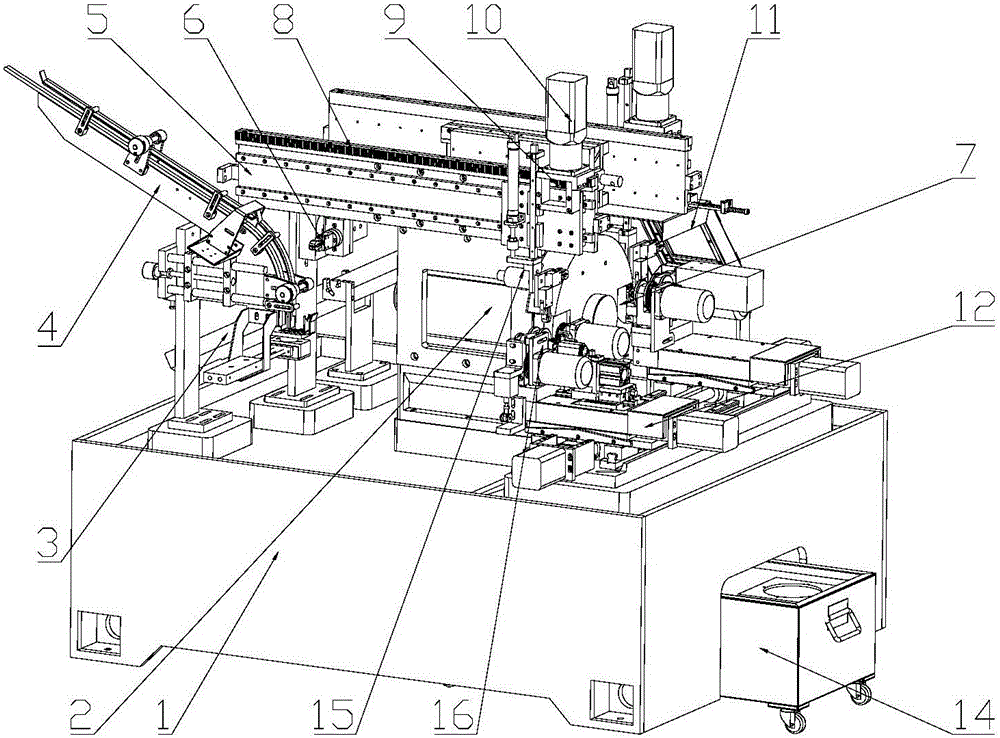

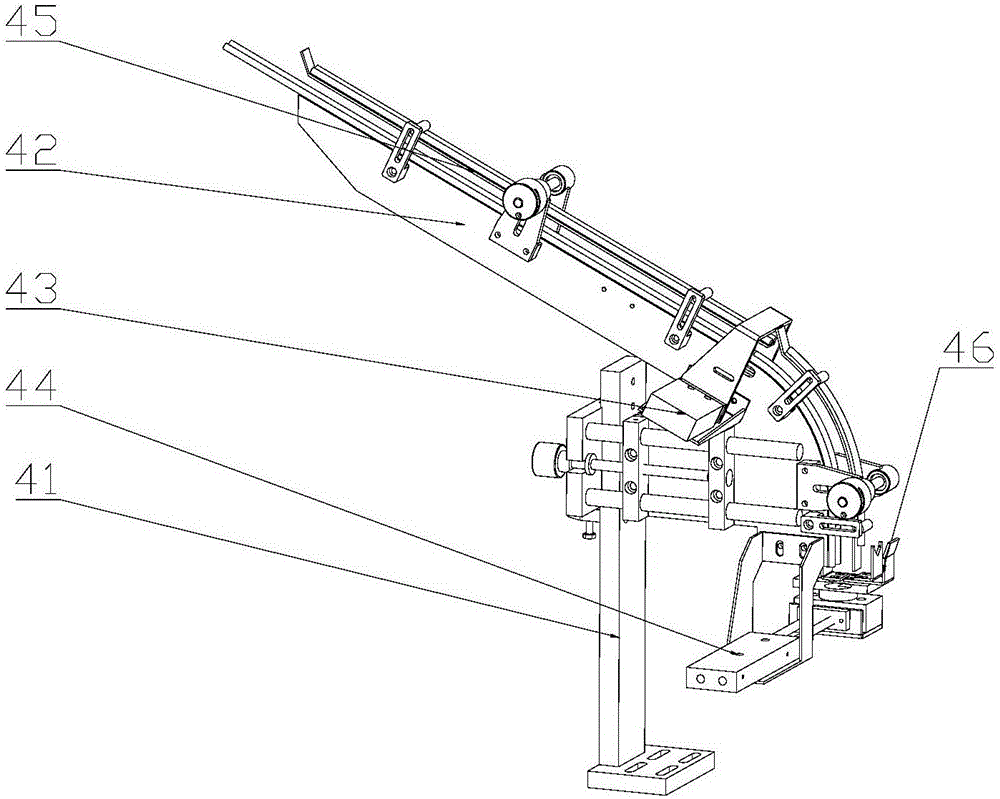

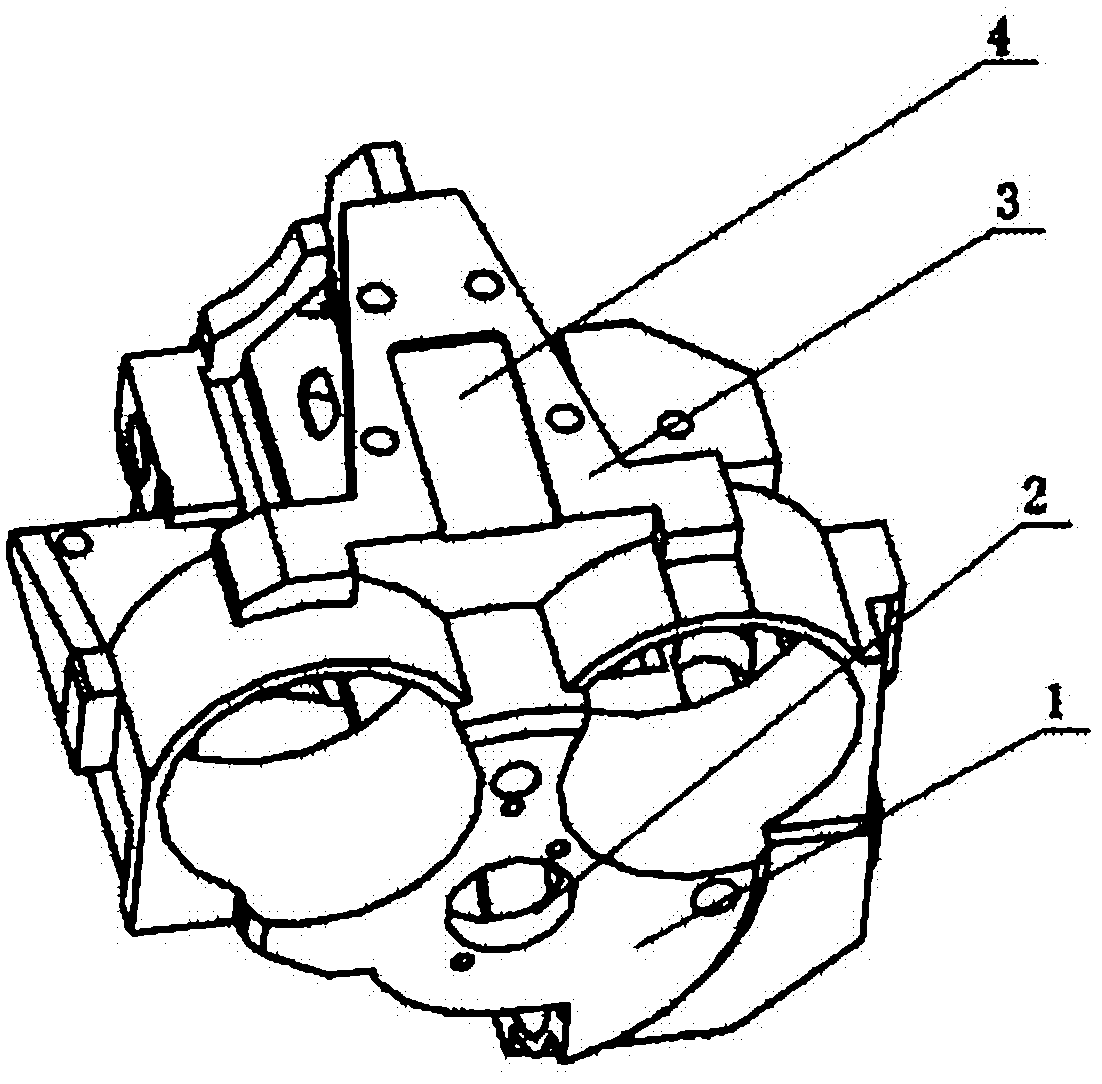

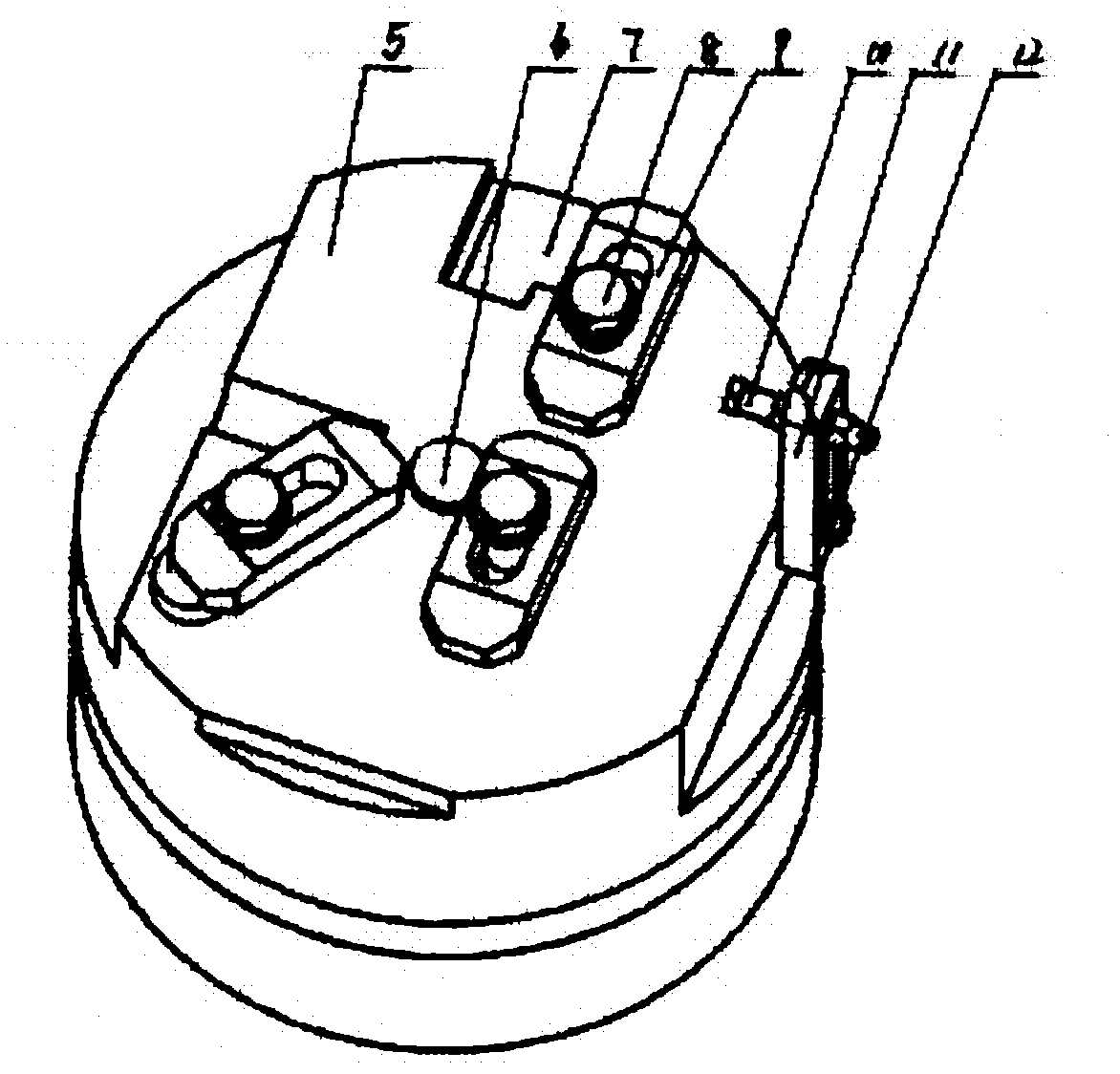

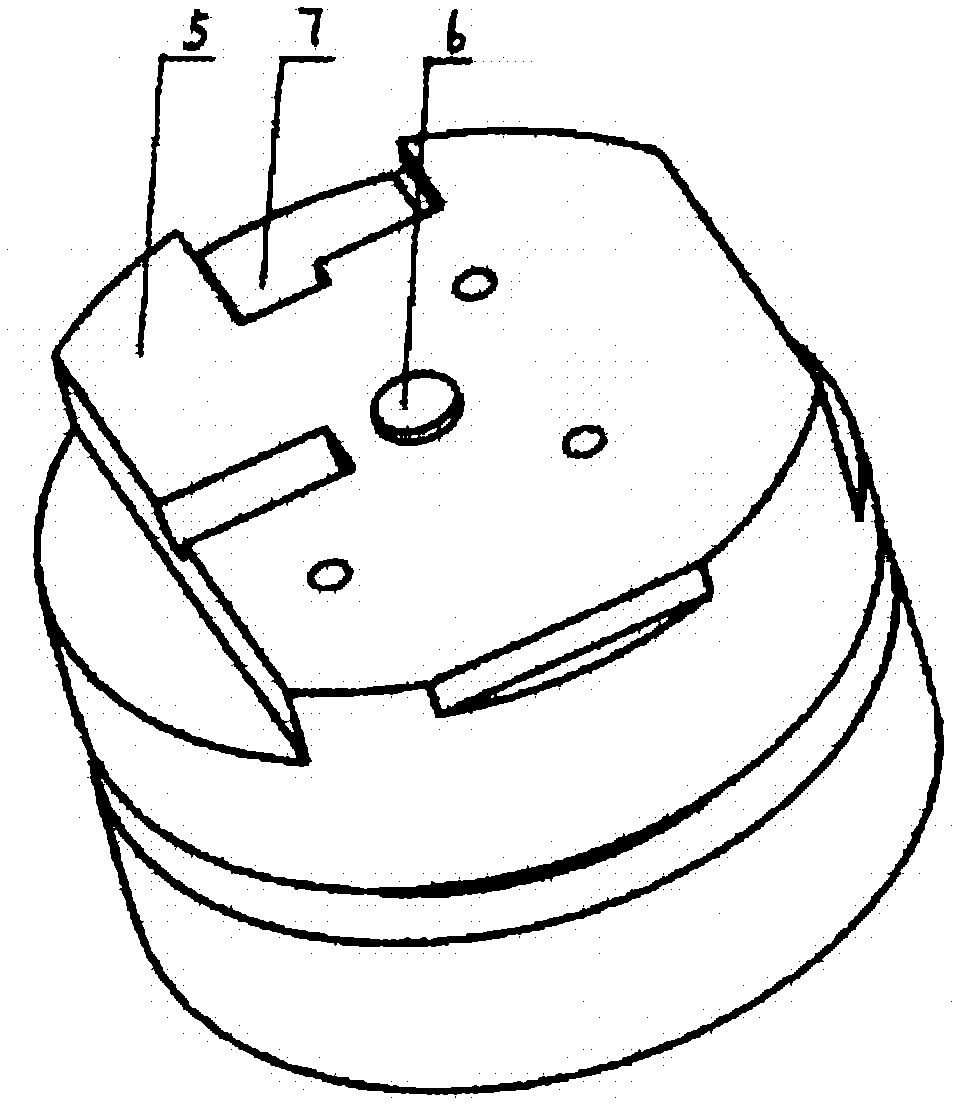

Multifunctional combined grinding machine for valve

PendingCN105881170AMeet precision and qualityReduce the number of correctionsGrinding carriagesGrinding drivesEngineeringSlide plate

The invention discloses a valve multifunctional combined grinding machine, which comprises a machine base and a protective cover. The protective cover is installed on the upper part of the machine base. Heat exchangers and oil mist recovery devices are installed at the electrical cabinets on both sides of the top of the protective cover. There is a control panel at the top, and the two sides in the middle of the top of the machine base are respectively equipped with a material conveying assembly, an upper and lower arm assembly, a servo motor and a feeding slide assembly. There is a gear corresponding to the rack. The motorized spindle assembly is installed on the top of the machine base between the two conveying assemblies. The electric spindle assembly is equipped with a grinding wheel. The guide wheel assembly, the feed slide assembly on the other side of the top middle of the machine base is equipped with an oil-proof assembly on the back of the grinding wheel corresponding to the grinding wheel, and the station rotation assembly is installed on the material delivery assembly on the middle side of the top of the machine base. Seven processes Completed at one time, the tolerance control is unified, and the yield of the product is improved.

Owner:SUZHOU TIANZHIJIAO PRECISION MACHINERY CO LTD

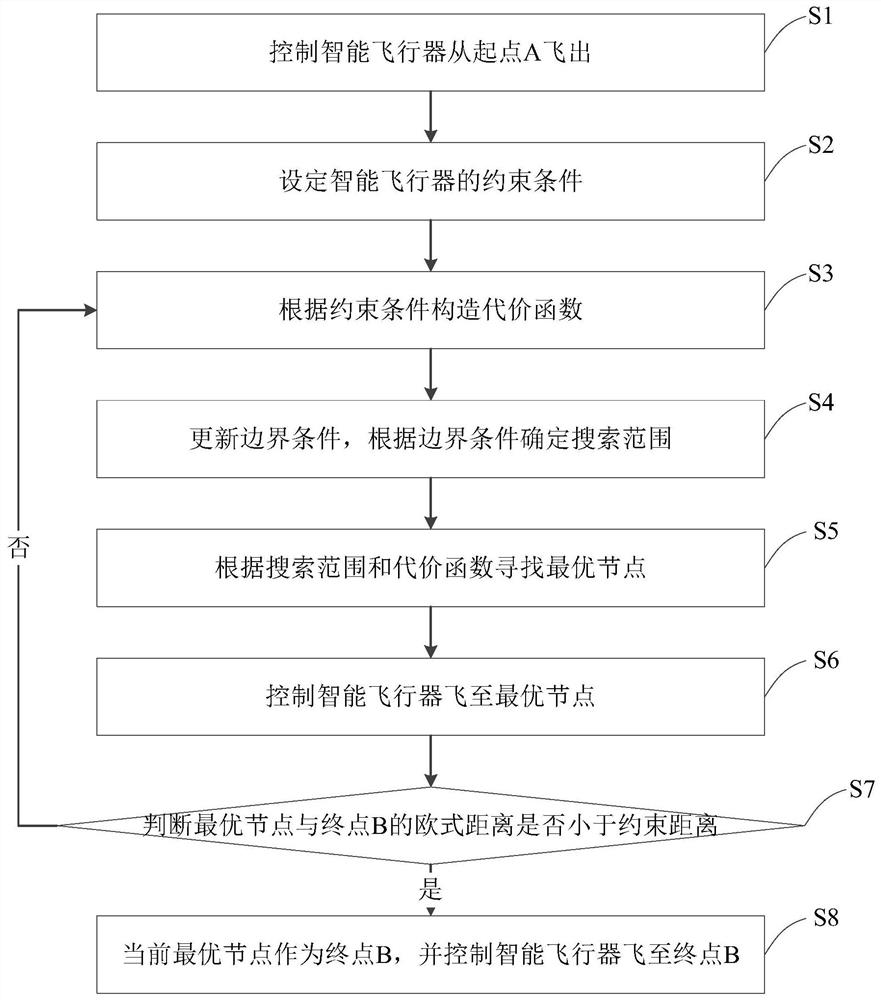

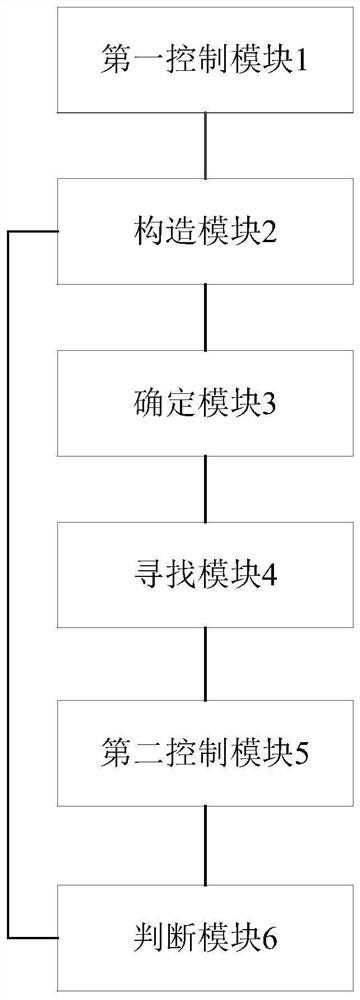

Method and device for quickly planning flight path of intelligent aircraft under multiple constraint conditions

InactiveCN112066991APurposeful planningSave time complexityNavigational calculation instrumentsPosition/course control in three dimensionsFlight vehicleSimulation

The invention provides a method and a device for quickly planning a flight path of an intelligent aircraft under multiple constraint conditions. The method comprises the following steps: controlling the intelligent aircraft to fly out from a starting point; setting constraint conditions of the intelligent aircraft; constructing a cost function according to the constraint condition; updating boundary conditions, and determining a search range according to the boundary conditions; searching an optimal node according to the search range and the cost function; controlling the intelligent aircraftto fly to the optimal node; judging whether the Euclidean distance between the optimal node and the terminal point is smaller than the constraint distance or not; if so, taking the current optimal node as an end point, and controlling the intelligent aircraft to fly to the end point; otherwise, returning to the step of constructing the cost function according to the constraint condition. Therefore, the method has the advantages that the searching is more targeted and planned, the time complexity caused by continuously and blindly iteratively searching the optimal node is further saved, the searching is higher in effectiveness and lower in complexity, and the correction times can be sought as few as possible while the minimum track length is sought.

Owner:CHANGZHOU MICROINTELLIGENCE CO LTD

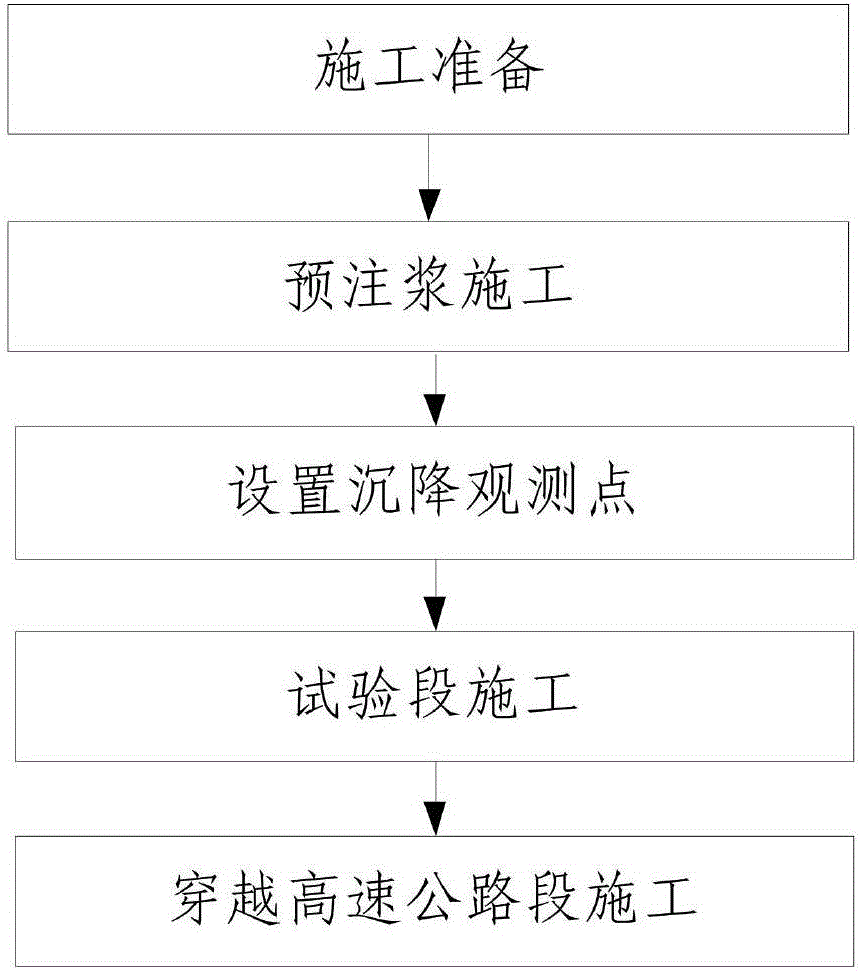

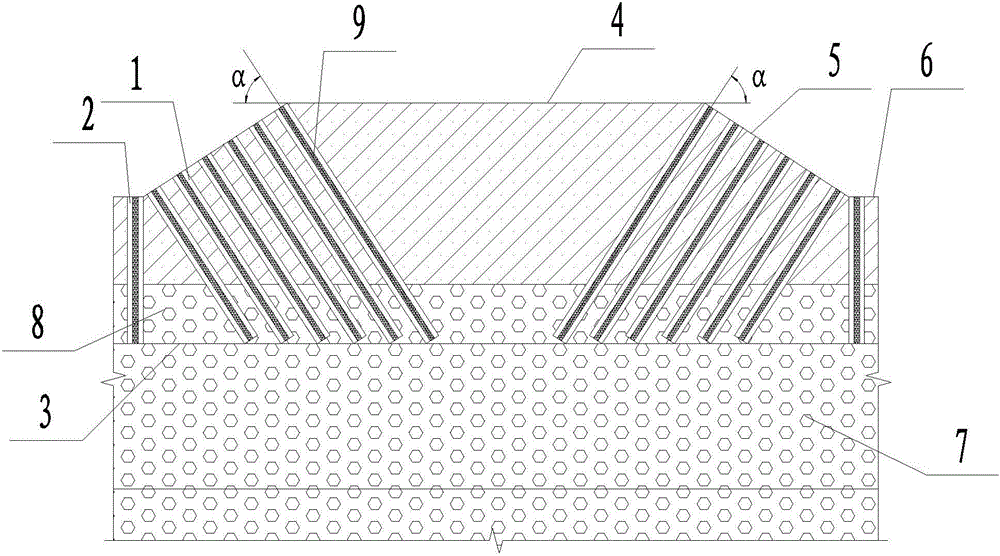

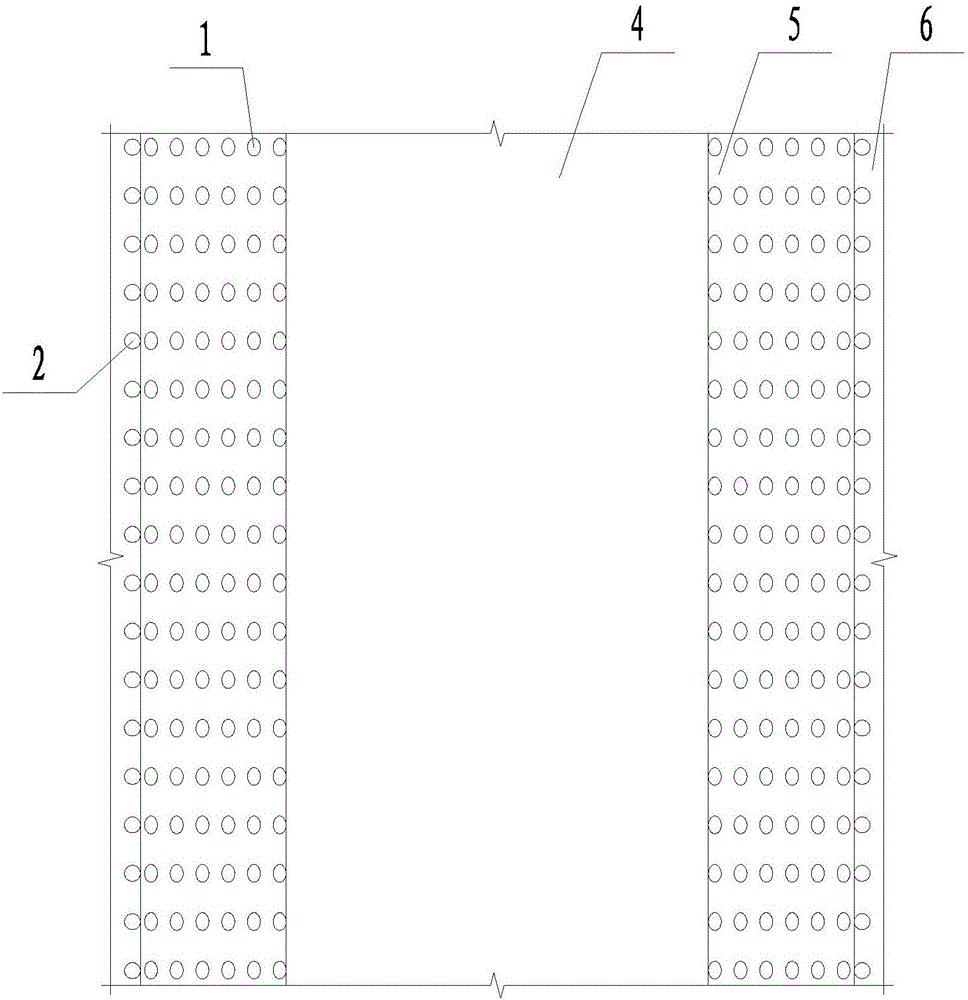

Construction method for enabling shallow shield tunnel to pass through highway

ActiveCN106677791AReduce the amount of misalignmentReduce the number of correctionsUnderground chambersTunnel liningObservation pointShield tunnelling

The invention discloses a construction method for enabling a shallow shield tunnel to pass through a highway. The construction method comprises the specific steps of first, construction preparation; second, preliminary grouting construction; third, settlement observation point setting; fourth, testing stage construction; and fifth, construction for passing through the highway. According to the construction method, the steps are simple, design is reasonable, and construction is convenient; slope grouting holes and ground grouting holes are formed to conduct preliminary grouting construction reinforcement on a reinforcement area above a tunnel shield area before shield construction, so that the personnel safety is guaranteed during tunnel shielding, the difficulty of shield construction is lowered, the stability of the ground surface of the highway is guaranteed during shield construction, and the construction process for enabling the shallow shield tunnel to pass through the highway is achieved.

Owner:中铁二十局集团第三工程有限公司

Medical on-line platform construction service method and system

InactiveCN109036585AExact sentence controlIncrease speedMedical communicationHealthcare resources and facilitiesText entryThe Internet

The invention discloses a medical on-line platform construction service method and system. The method comprises the steps of establishing a medical database, receiving a request, waking up medical personnel, determining a reservation, performing preliminary diagnosis, and performing diagnosis result feedback; the system comprises a server storage module, a medical personnel client module, a reservation selection determination module, a medical personnel client module, a communication module, a voice input processing module, a text entry module, a query and filing keyword generation module, a screening retrieval result generation module and a feedback module. According to the invention, the problems that an existing medical treatment procedure is tedious and the registration is difficult can be solved, the efficiency and portability of medical services can be effectively improved, the waiting time of the medical personnel is reduced, and medical pressure is relieved, accurate and efficient self-service is achieved through the internet technology, and the system is high in intelligent degree, the method is advanced and scientific, and the method and system have high practical valuesand wide application prospects.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

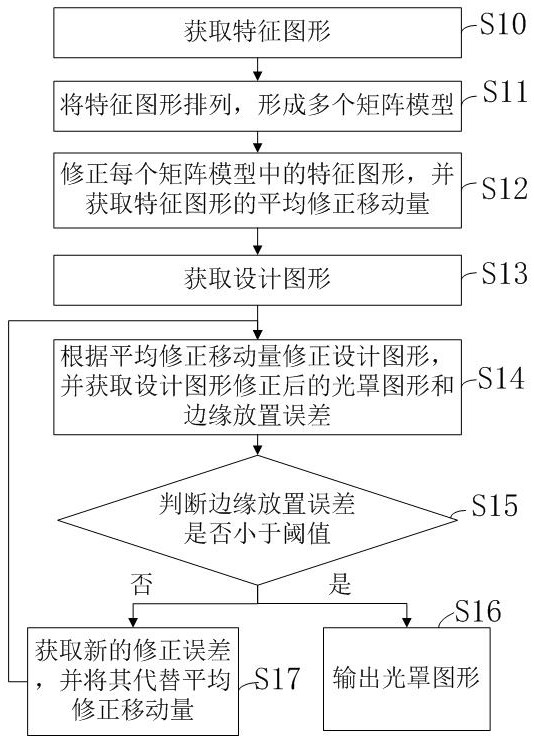

Method and system for correcting optical proximity effect

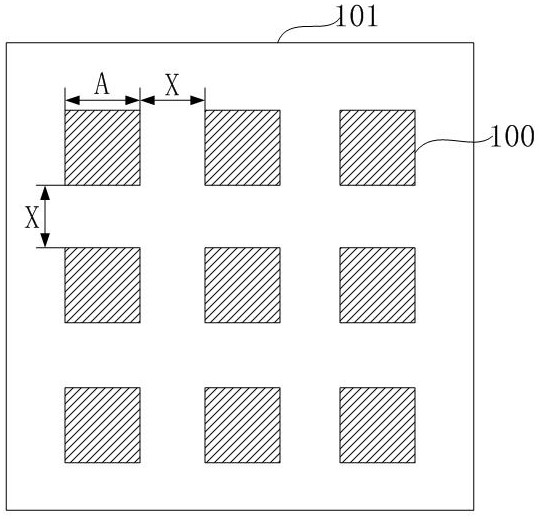

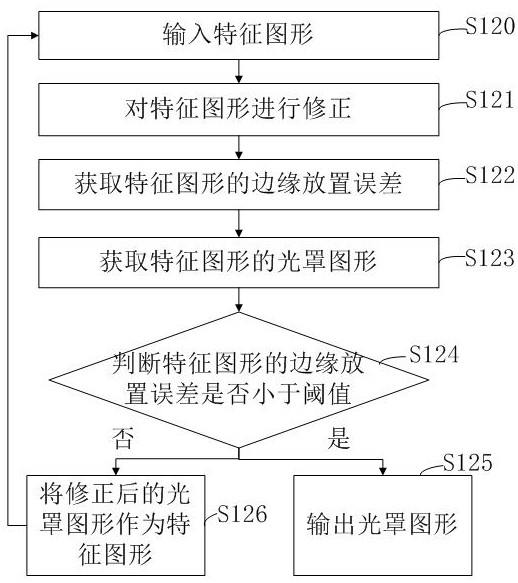

ActiveCN113281962ABest correction valueReduce the number of correctionsPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsAlgorithm

The invention discloses a method and system for correcting anoptical proximity effect. The method comprises the steps: obtaining feature patterns, and arranging the feature patterns to form a plurality of matrix models; correcting the feature graph in each matrix model, and obtaining an average correction movement amount of the feature graph; obtaining a design graph, and correcting the design graph according to the average correction movement amount; obtaining a revised photomask pattern of the design pattern and an edge placement error; judging whether the edge placement error is smaller than a threshold value or not; when the edge placement error is smaller than the threshold value, outputting the photomask pattern; and when the edge placement error is greater than or equal to the threshold value, obtaining a new correction movement amount, and correcting the design graph according to the new positive movement amount. According to the correction method and system for the optical proximity effect, the correction time and the correction frequency can be reduced.

Owner:南京晶驱集成电路有限公司

High-efficient medical guiding method and system

InactiveCN109119145AExact sentence controlIncrease speedHealthcare resources and facilitiesThe InternetComputer science

The invention discloses a high-efficient medical guiding method and system. The method comprises the following steps of establishing a medical database; receiving a request; awakening a treatment seeking personnel service; determining a reservation; carrying out preliminary diagnosis; and feeding back a diagnosis result and the like. The system comprises a server storage module, a treatment seeking personnel client module, a reservation selection determination module, a medical staff client module, a communication module, a voice input processing module, a text input module, a query archive keyword generation module, a screening retrieval result generation module and a feedback module. . In the invention, problems that existing medical procedures are complicated and registration is difficult can be solved; the efficiency and the portability of medical services can be effectively increased and the waiting time of treatment seeking personnel is shortened; medical pressure is alleviated,and an accurate and high-efficient self-service is realized through an Internet technology; and the intelligent degree of the system is high, the method is advanced and scientific, and a high practical value and a wide application prospect are possessed.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Numerical control processing method and special processing fixture for inertial platform body

ActiveCN102357815AReduced settling timeReduce the number of correctionsPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a numerical control processing method and a special processing fixture for an inertial platform body. The special processing fixture comprises a fixture A and a fixture B. The numerical control processing method comprises the following steps: (1) mounting and adjusting bases of the fixture A and fixture B; (2) processing a reference surface, a positioning surface and a positioning hole of the inertial platform body; (3) processing the positioning surface, a positioning slot and other parts of the inertial platform body; and (4) processing other surfaces of the inertial platform body. The invention provides a processing method and a processing tool capable of conveniently clamping and quickly adjusting. By adopting CAM (Computer Aided Manufacturing) programming, the processing method and the processing tool have the advantages of easy processing, centralized processes, low production cost, high production efficiency, high processing precision and the like. By adopting the processing method provided by the invention, the defects of the prior art, such as long processing time of a single piece, low efficiency, high manufacturing cost and the like, are overcome, and the process flow and the manufacturing time of the platform body can be greatly reduced. By twice clamping and positioning, the processing for all the surfaces of a part along six directions is finished on a double operating platform horizontal type processing center.

Owner:TIANJIN NAVIGATION INSTR RES INST

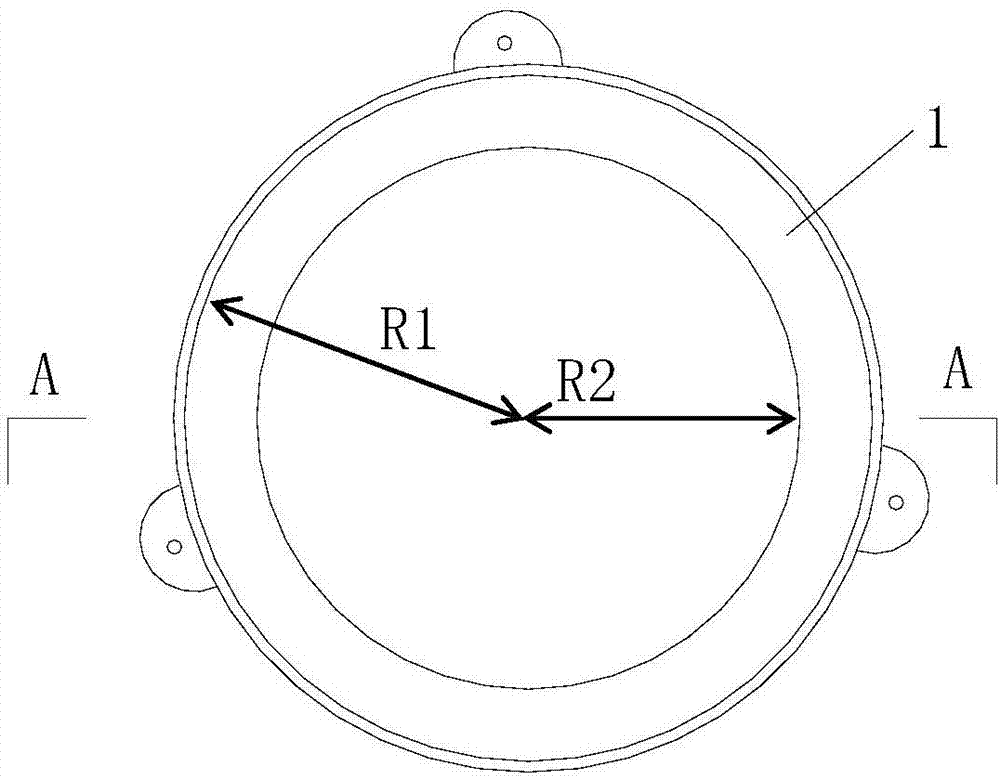

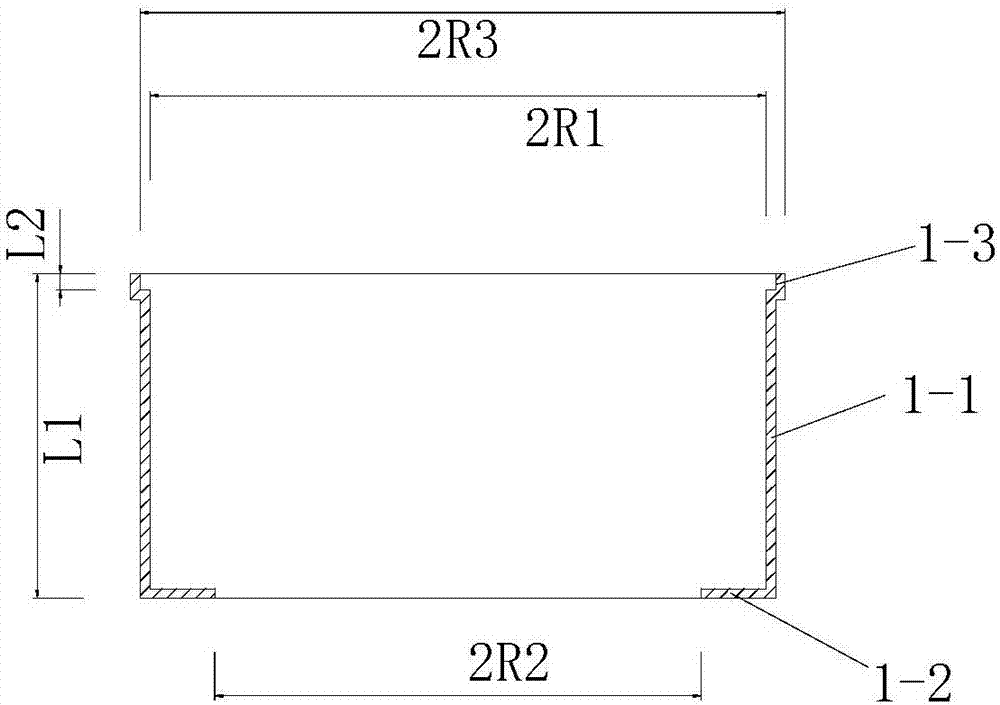

Adjustable reserved hole constructing mold and constructing method

PendingCN107237494ASimple structureReasonable designPipesForms/shuttering/falseworksFloor slabStructural engineering

The invention discloses an adjustable reserved hole constructing mold and constructing method. The adjustable reserved hole constructing mold comprises an outer mold, a horizontal bottom plate and an upper covering plate, wherein the horizontal bottom plate is located at the bottom of the inner side of the outer mold, the upper covering plate is installed on the upper part of the outer mold in a covering mode, and the upper covering plate is a round covering plate; the outer mold comprises a vertical cylinder, a horizontal base plate and an annular covering opening; and an eccentric hole is formed in the horizontal bottom plate for passing through of installed pipelines. The adjustable reserved hole constructing method comprises the following steps of step 1, supporting formwork of a cast-in-place slab; step 2, surveying a line of the pipeline installing position; step 3, fixing of the outer mold; step 4, constructing of the cast-in-place slab; step 5, installing of the horizontal bottom plate; step 6, installing of the pipeline; and step 7, sealing and blocking of a hole opening. According to the adjustable reserved hole constructing mold and constructing method, design is reasonable, construction is simple and convenient, and the using effect is good; and the position of through-floorslab pipeline can be adjusted through the horizontal bottom plate with the eccentric holes to guarantee installing precision of the pipeline, and the problems, existing in current reserved hole construction, that working process is complex, potential safety hazards exist in high altitude formwork supporting, and sealing and blocking quality of the hole opening is hard to be guaranteed can be effectively solved.

Owner:陕西建工第十一建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com