Die forging process and special die for final stage blade of large half-RPM (Revolution per Minute) nuclear turbine

A half-rotation speed, steam turbine technology, applied in the direction of manufacturing tools, mechanical equipment, engine components, etc., can solve the problems of inability to continue, high cost of blade manufacturing, and low forging production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

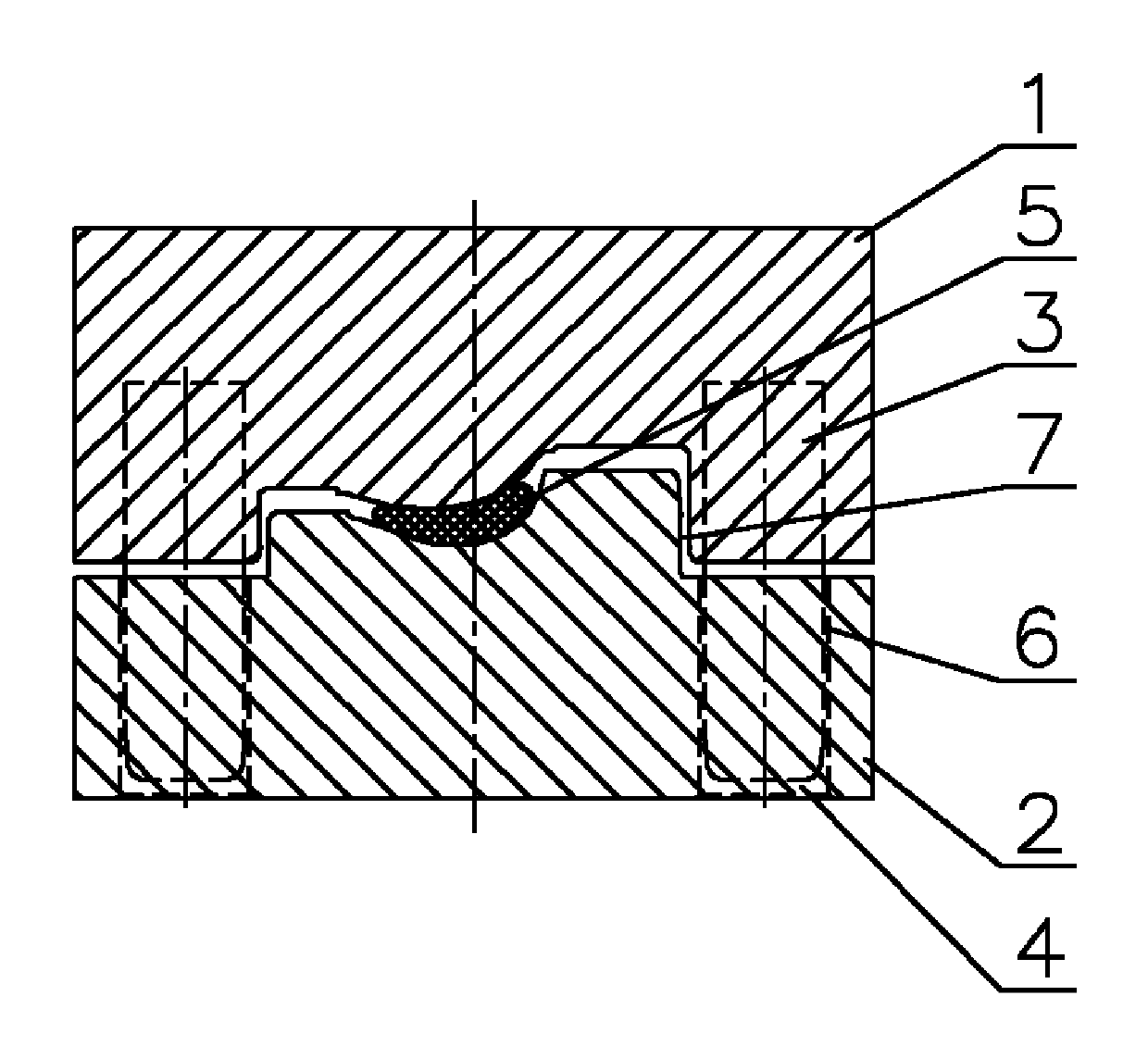

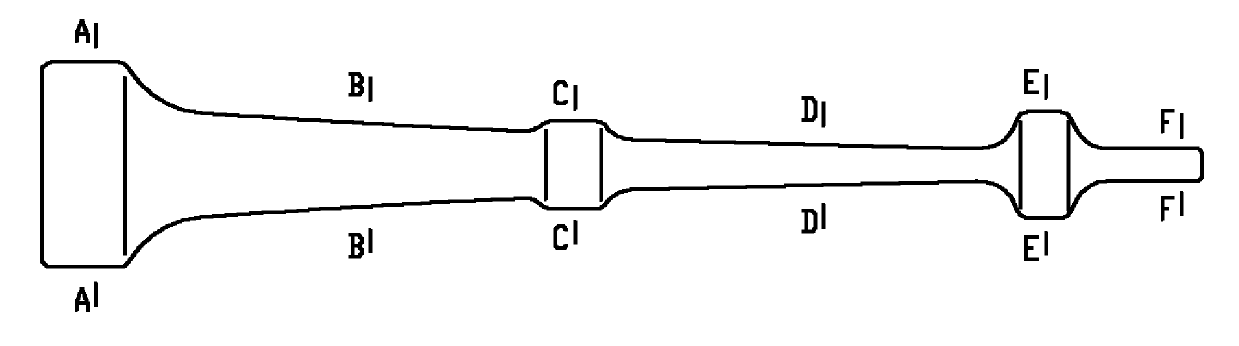

[0017] The process of the present invention is to use a hydraulic press to upset the bar, and then use electro-hydraulic hammer free forging to radially elongate the bar to make a billet. See figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the cross-section of the billet structure is partially flat square except for the circle ( image 3 , Figure 5 and Figure 7 The double dotted line in the middle indicates that the three sections can be properly flattened according to the forming requirements), and the single forging die forging adopts a forging process with one cavity and multiple fires to control the deformation amount of each fire to achieve the effect of pre-forging and final forging. The drawn billet is put into the forging die for forging and forming, the edge is eagerly trimmed, the heat is corrected in the mold, and then heat treatment is carried out. After the heat treatment, manual correction at room temperature is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com