Diamond strong slotted grinding wheel specially used for copper-powder-based numerical control grinder

A CNC grinding machine and diamond technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the retention of the grinding wheel profile, reducing the machining accuracy of the grinding wheel, poor heat dissipation performance, etc., reducing the number of grinding wheel corrections, grinding wheel The effect of prolonging the life and increasing the depth of the groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

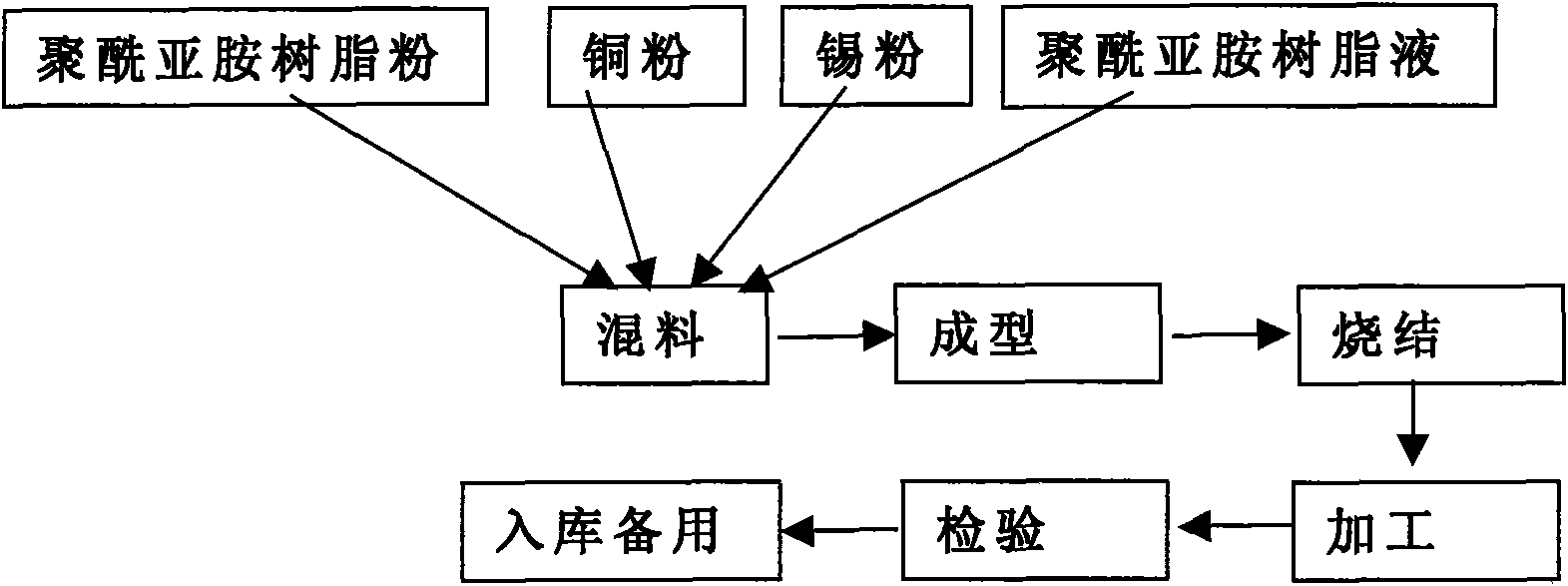

[0033] A substrate for a diamond grooved grinding wheel dedicated to a CNC grinding machine, the components and contents of which are:

[0034] Polyimide resin powder 20%

[0035] Copper (Cu) powder 60%

[0036] Tin (Sn) powder 18%

[0037] Phenolic resin solution 2%

[0038] The above percentages are percentages by weight;

[0039] Described polyimide resin powder technical condition is:

[0040] Appearance: yellow superfine powder

Density: 1.3g / cm 3

Content: ≥99%

Melting point: 135~145℃

Purity: 99%

Martin heat resistance temperature: 260°C

Tensile strength: 113.4MPa

Average particle size: 30~40μm

Softening point: 110~120℃

Curing temperature: 230°C

Water absorption: 0.2~0.3%

Bending strength: >1000MPa

[0041] Described copper (Cu) powder technical condition is:

[0042]

[0043]

[0044] The technical conditions of the tin (Sn) powder are: the Sn content is greater than or equal to 99%, and the pa...

Embodiment 2

[0047] A substrate for a diamond grooved grinding wheel dedicated to a CNC grinding machine, the components and contents of which are:

[0048] Polyimide resin powder 20%

[0049] Copper (Cu) powder 57%

[0050] Tin (Sn) powder 20%

[0051] Phenolic resin solution 3%

[0052] The above percentages are percentages by weight;

[0053] Described polyimide resin powder technical condition is:

[0054] Appearance: yellow superfine powder

Density: 1.3g / cm 3

Content: ≥99%

Melting point: 135~145℃

Purity: 99%

Martin heat resistance temperature: 260°C

Tensile strength: 113.4MPa

Average particle size: 30~40μm

Softening point: 110~120℃

Curing temperature: 230°C

Water absorption: 0.2~0.3%

Bending strength: >1000MPa

[0055] Described copper (Cu) powder technical condition is:

[0056]

[0057] The technical conditions of the tin (Sn) powder are: the Sn content is greater than or equal to 99%, and the particle size ...

Embodiment 3

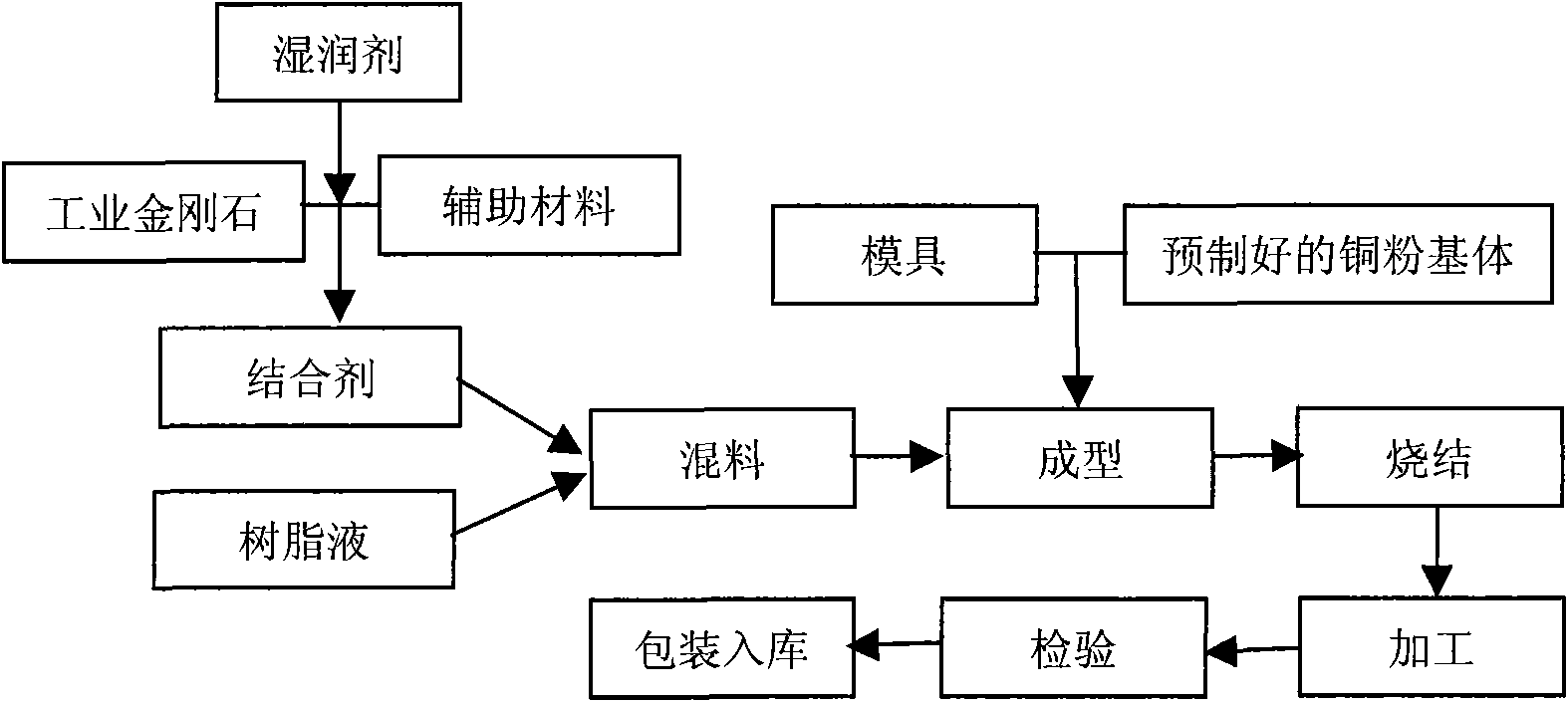

[0065] Embodiment three: the method for preparing copper powder-based grinding wheel by using the substrate of embodiment one or embodiment two is prior art, and its process flow chart is as attached image 3 As shown, the specific steps are:

[0066] (1) Mixing: Put the abrasive (diamond or cubic boron nitride) and auxiliary materials (green or black silicon carbide) weighed in proportion into the mixer, add a wetting agent and mix evenly, and then mix the binder and resin The solution is slowly put in separately until it is fully mixed, and after passing the inspection, put it into the container for later use;

[0067] (2) Forming: Put the prefabricated copper powder matrix in the mold, then slowly put the mixed molding material into the mold, scrape it flat, and place it on the operating table of the hydraulic press, at a maximum temperature of 230°C, Hot pressing to the set height or flattening (during fixed mold molding).

[0068] (3) Sintering: Put the pressed grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com