Mechanical locking and deblocking device

An unlocking device and mechanical locking technology, which is applied in the field of mechanical devices, can solve the problems of increasing the total filling time, low reliability, cumbersome operation, etc., and achieve the effects of reducing filling time, high reliability, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

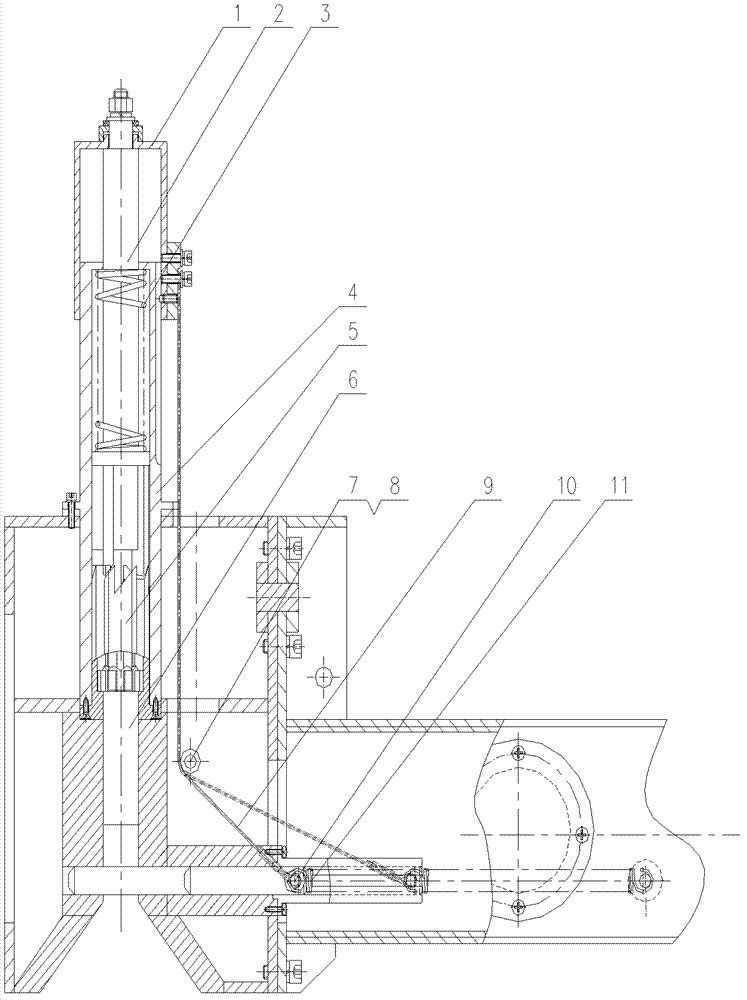

[0018] The mechanical locking and unlocking device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

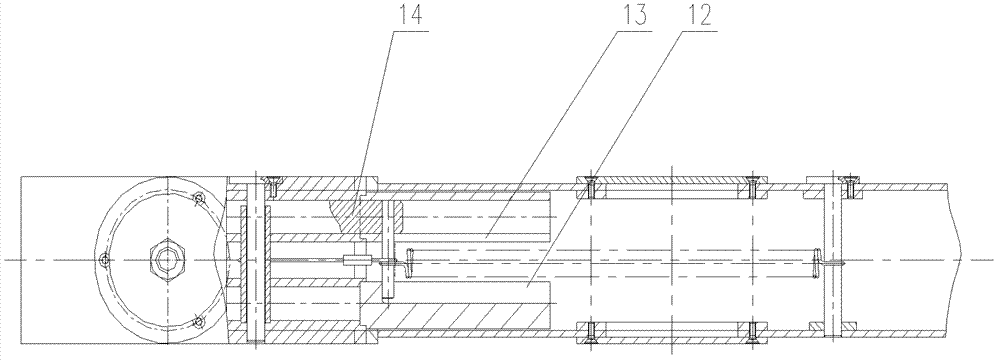

[0019] figure 1 , 2 Among them, a kind of mechanical locking and unlocking device of the present invention, its main part is made up of rod 2, push rod 6, lower guide rod 5, steel wire rope 9, lifting pin 14. When installing, insert the rod 2 and the push rod 6 into the lower guide rod 5 and make it fall to the bottom, the rod 2 is set above the push rod 6, one end of the wire rope 9 is fixed with the guide body 1, and the other end is connected with the lifting pin 14 .

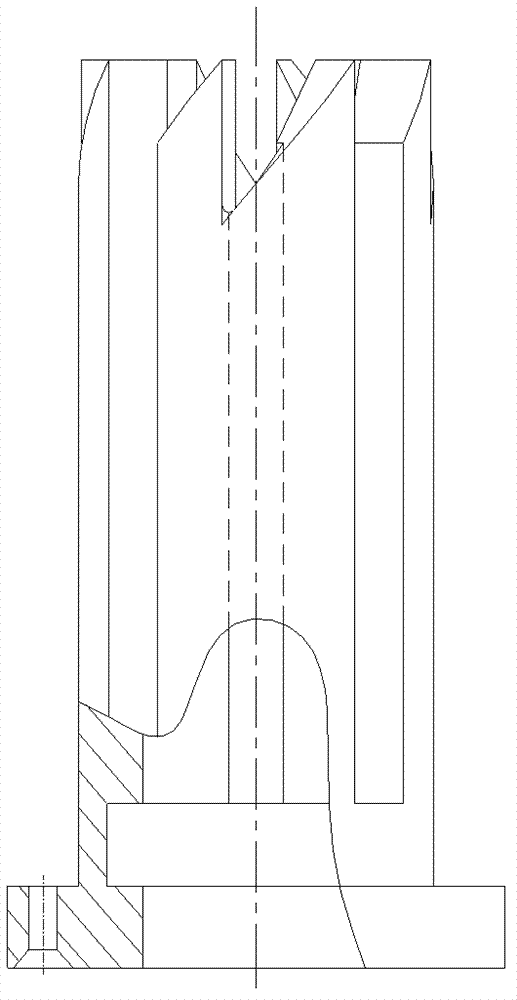

[0020] image 3 The shown lower guide rod 5 is fixed on the guide cylinder 4, and four deep grooves are arranged on its side, which are evenly distributed around the lower guide rod 5; The slots are connected.

[0021] Figure 4 The shown push rod 6 is contained in the lower guide rod 5, wherein one end of the polished rod is downward, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com