Weighing arm installation structure of bale rotary table

A technology of installation structure and rotary table, which is applied in the direction of manufacturing tools, casting molten material containers, indicating equipment/measuring equipment configuration, etc., can solve the problems of long time occupation of the total construction period, unfavorable safety construction, equipment damage, etc., to reduce construction cost, speed up the construction progress, and the effect of smooth reassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

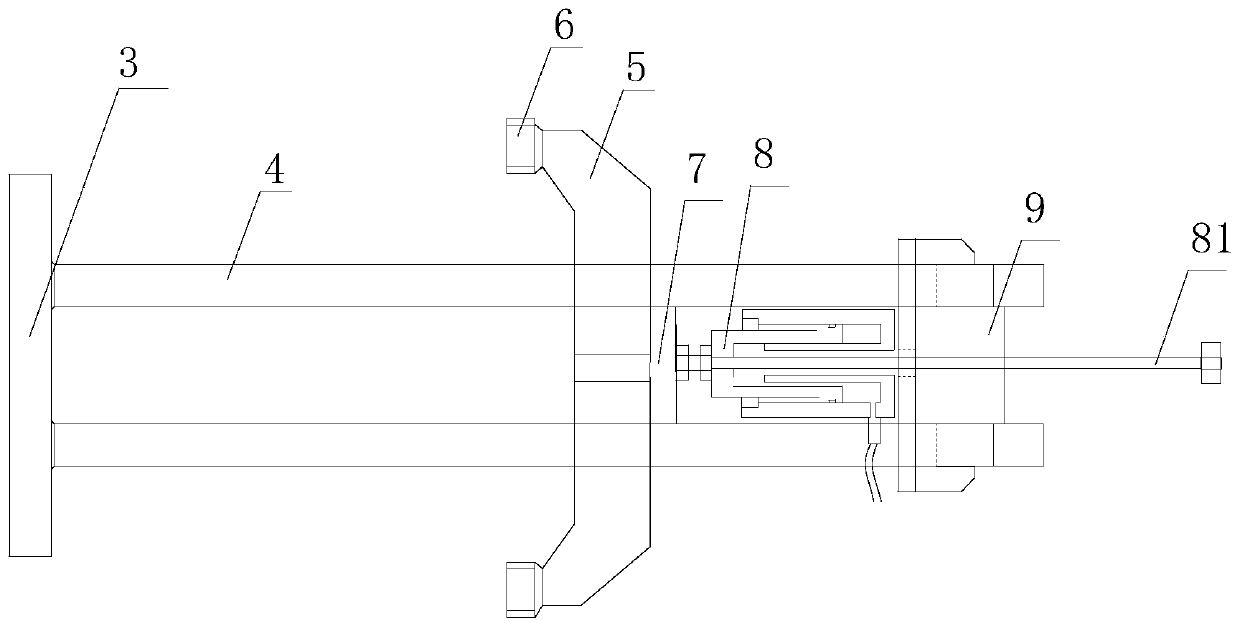

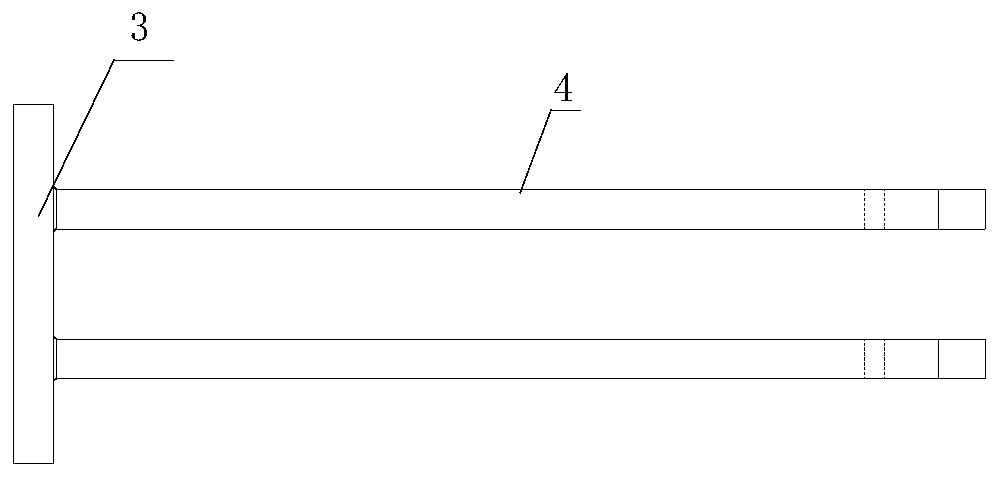

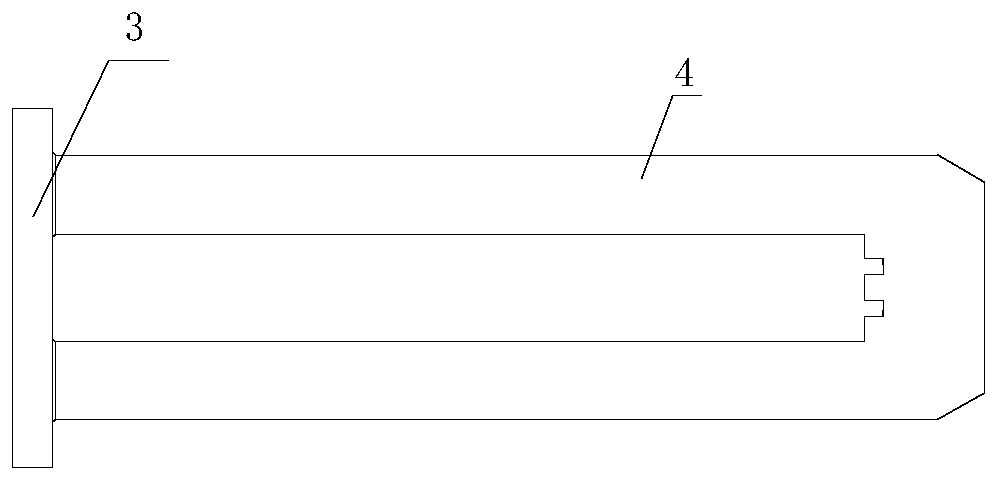

[0025] Such as Figure 1~6 As shown, this embodiment relates to a weighing arm installation structure of a large-package rotating platform, which is applied to install the weighing arm 2 on the trunnion 1. Specifically, the installation structure includes a steel structure top frame, an indenter 5, and a hollow Hydraulic jack 8 and base 9; the jack frame includes a fixed plate 3 and two U-shaped frames 4 arranged opposite each other. The open ends of the two U-shaped frames 4 are vertically fixed on the fixed plate 3; the base is detachably fixed At the end of the top frame away from the fixed plate 3, specifically, the base is vertically inserted in the cavity on the closed side of the two U-shaped frames 4 and is detachably connected to the two U-shaped frames 4; the indenter 5 is roughly U-shaped structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com