A method for catalytic combustion to remove volatile organic compounds

A technology of organic compounds and catalytic combustion, applied in combustion methods, chemical instruments and methods, separation methods, etc., to achieve stable operation, realize recycling, and reduce investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

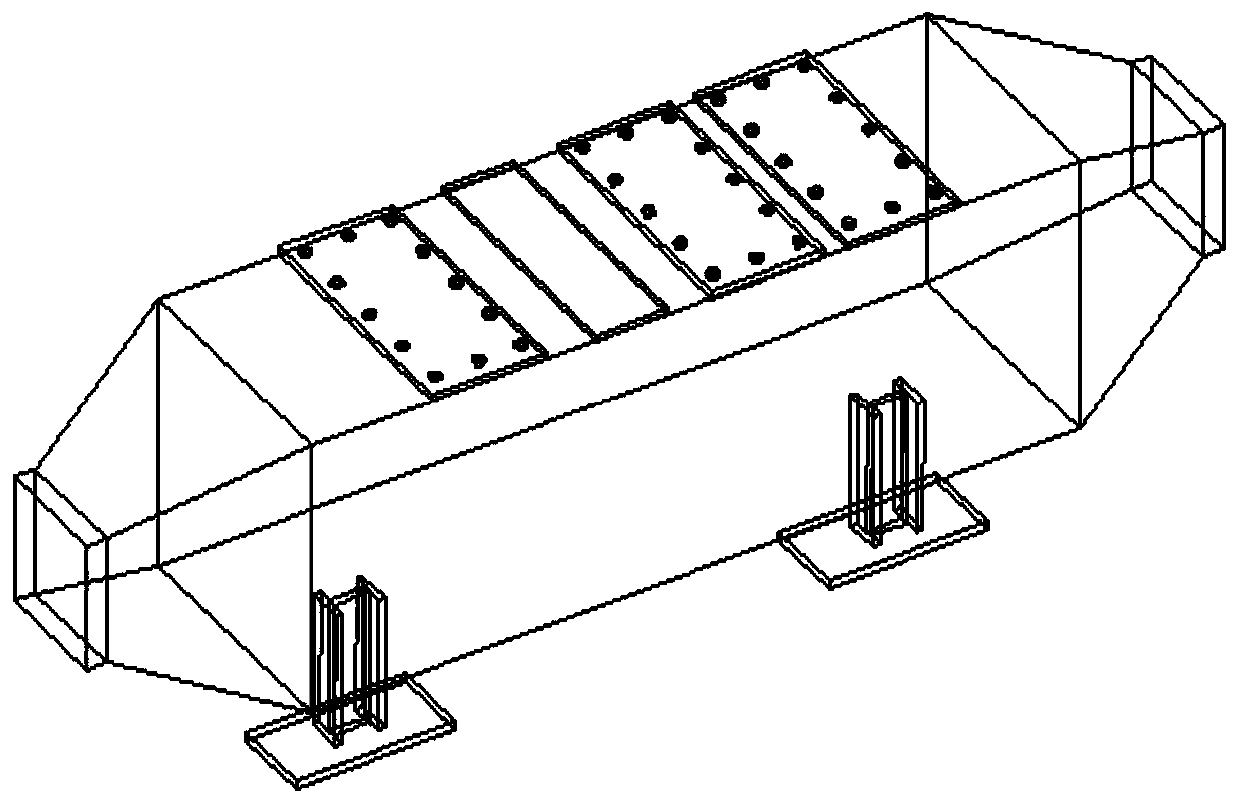

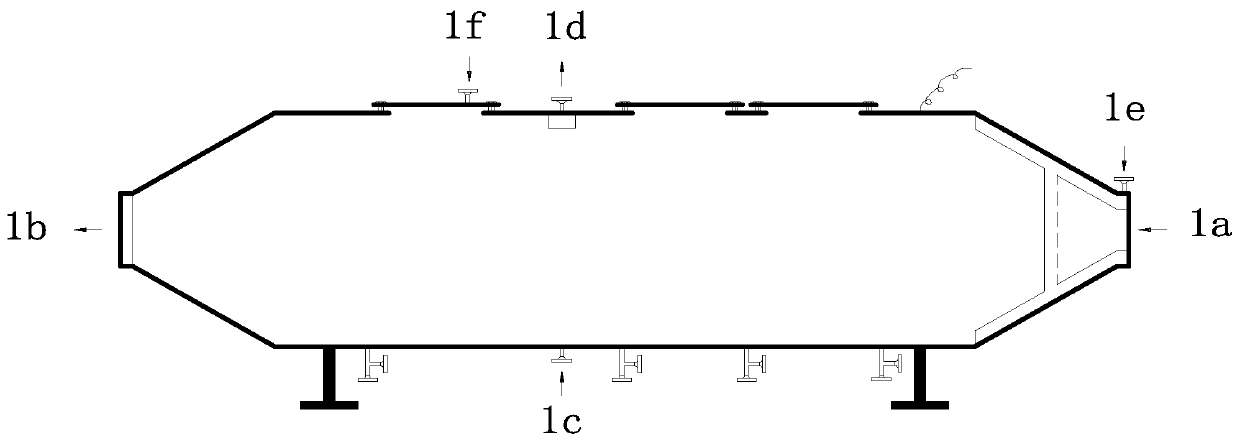

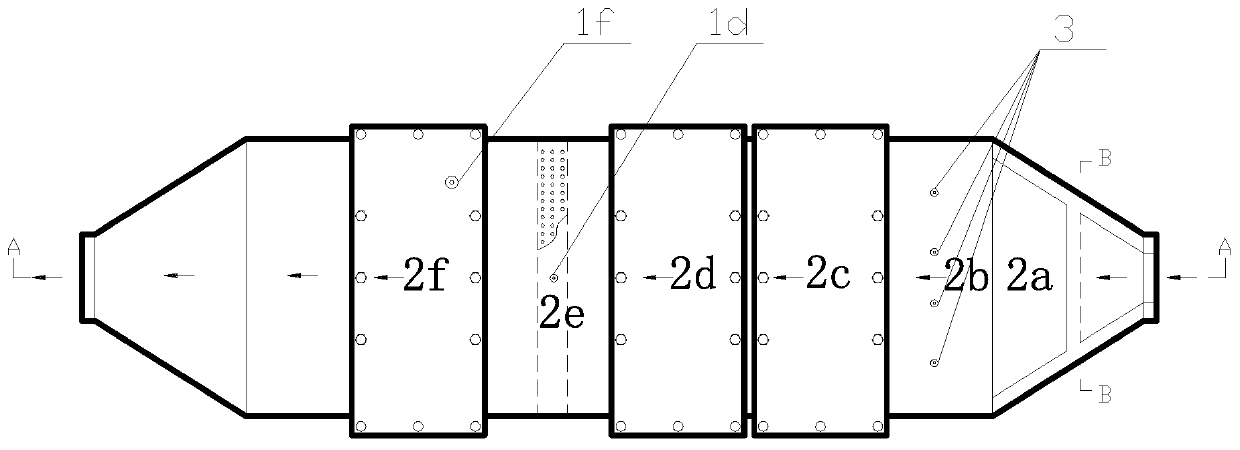

[0026] Attached below Figure 1-5 The present invention is described in detail with specific examples, but the protection scope of the present invention is not limited.

[0027] Such as figure 1 As shown, a device for removing volatile organic compounds by catalytic combustion. The device of the present invention is a horizontal box structure. After the raw material gas and air are mixed in the gas mixing section 2a at the entrance of the device, they enter the gas preheating section 2b of the device in turn. , Catalytic reaction I section 2c, catalytic reaction II section 2d, heat exchange section 2e and adsorption section 2f.

[0028] The area where the present invention realizes the removal of volatile organic compounds is mainly the catalytic reaction section I section 2c, the catalytic reaction section II section 2d, the heat exchange section 2e and the adsorption section 2f, wherein the catalytic reaction section I section 2c realizes the preliminary removal of volatile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com