Furnace lining dismounting device for vacuum furnace

A vacuum furnace and furnace lining technology, applied in the direction of lifting devices, transportation and packaging, load hanging components, etc., can solve the problems of low production efficiency, high cost of leak detection and shutdown, and long shutdown time, so as to improve production efficiency , reduce the cost of leak detection and downtime, and reduce the effect of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

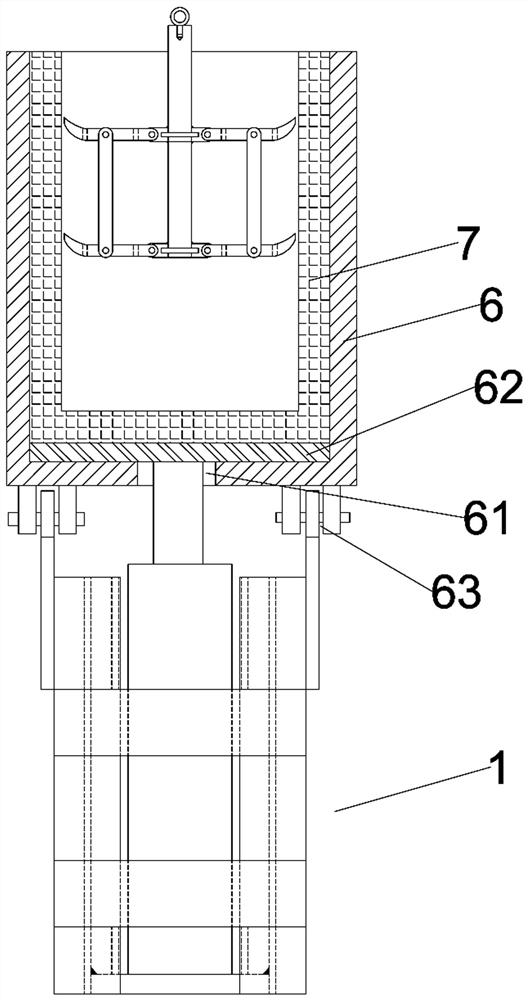

[0037]A furnace lining removal device in a vacuum furnace, comprising a lining ejection mechanism and a lining lifting mechanism; the lining ejection mechanism includes a positioning steel frame 1, a connecting plate 2 arranged on the top of the positioning steel frame for connecting the vacuum furnace, and An installation seat cavity 3 with an open upper end arranged in the steel frame, and a jack is arranged in the installation seat cavity; the furnace lining lifting mechanism includes a main hanger 4 and at least three circumferentially evenly distributed on the main hanger. A plurality of horizontal hanging claws 5, the main hanger and the horizontal hanging claw are hinged, the maximum angle between the horizontal hanging claw and the main hanger is 90 degrees, and the outer end of the horizontal hanging claw is provided with The claw end 54 is formed by extending outward and upward in an arc.

[0038] When this application is in use, first place the jack vertically in th...

Embodiment 2

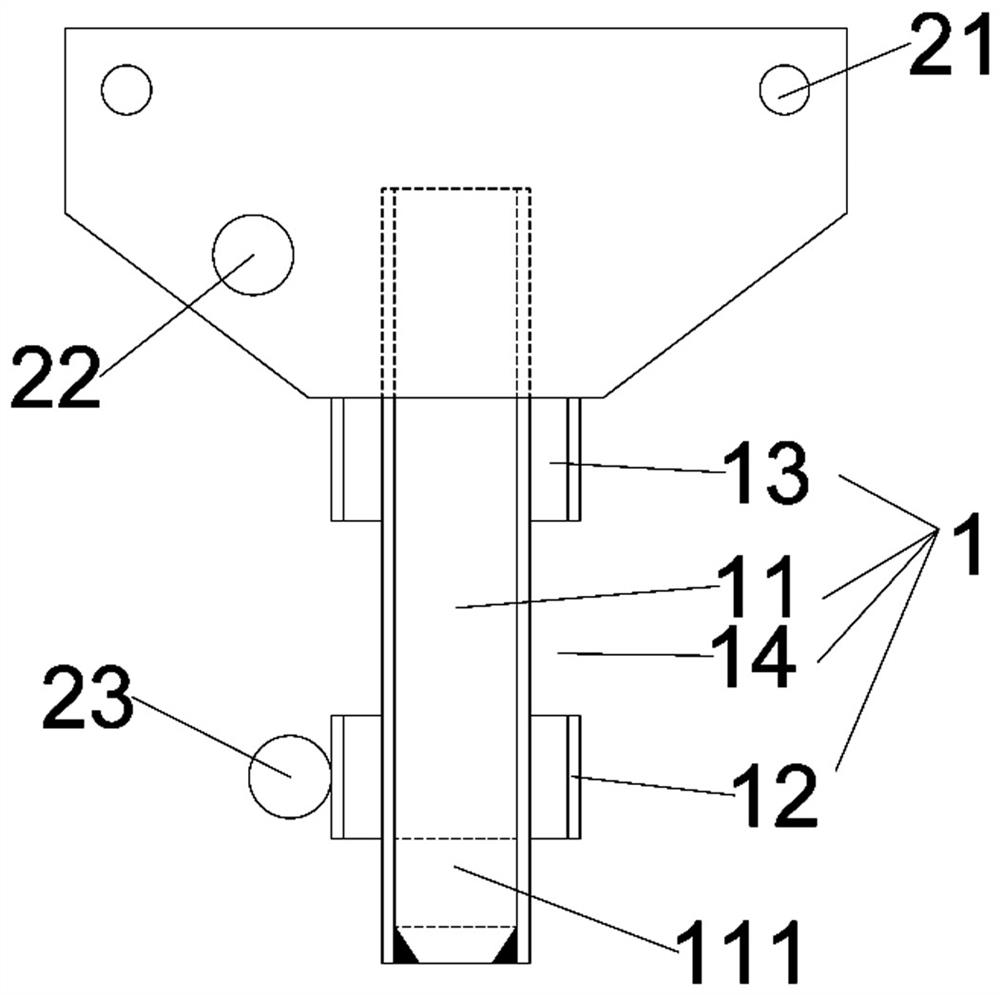

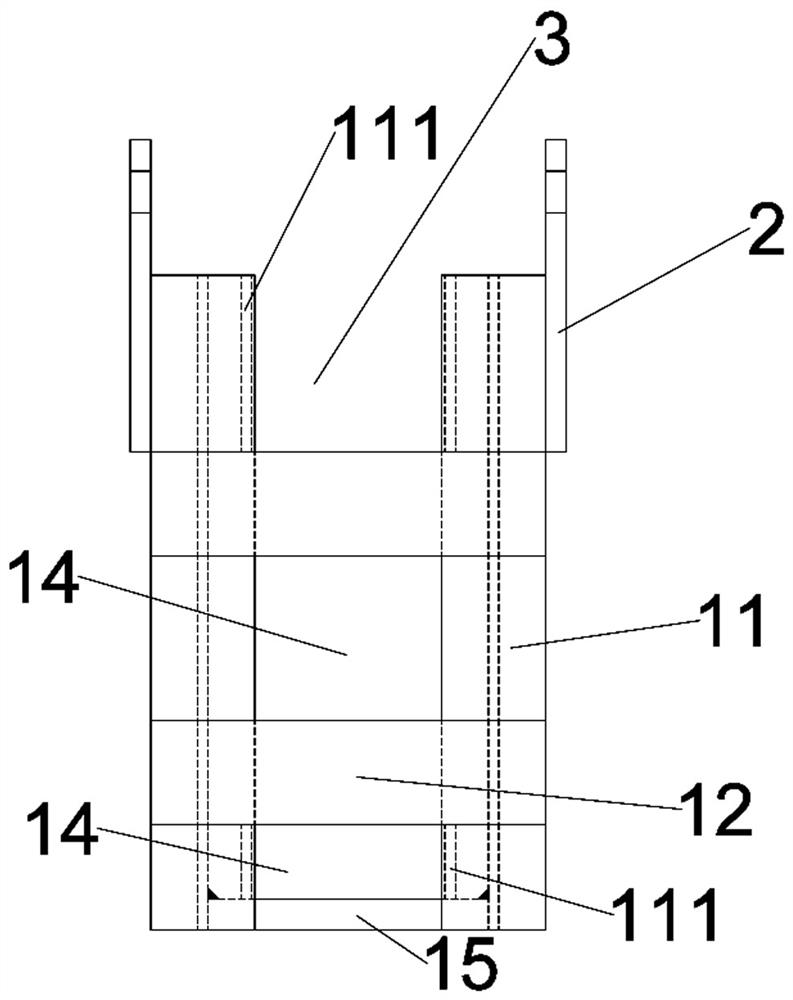

[0040] The difference from the above embodiment is that the positioning steel frame includes at least a pair of main columns 11 located opposite to the two sides of the mounting seat cavity, and a connecting piece 12 connected between the main columns, and the connecting plates are symmetrically arranged on a pair of There are two on the main column, and the connecting plate is arranged on the outside of the main column, the upper end of the connecting plate extends upward beyond the top of the main column, and at least two connecting holes 21 are opened on the protruding part of each connecting plate. The existing furnace shell is designed with its own rack slot for positioning when it is hoisted to the disassembly workshop. The connecting plate designed in this application is docked with the existing rack slot, so as to ensure that the lining ejection mechanism is installed stably, and the jack and furnace The alignment of the furnace mouth at the bottom is accurate, and the ...

Embodiment 3

[0042] The difference from the above embodiment is that the positioning steel frame includes a pair of symmetrically arranged main columns, and the two sides of the main columns are correspondingly provided with pad width pieces 13, and the connecting piece is a pad connected to the two main columns. The bridge connecting plate between the wide pieces; on each side of the main column, at least two pad width pieces are arranged at intervals from top to bottom, and the bridging plates are at least two corresponding; the ones on the same side of the main column A communication port 14 is formed between the upper and lower bridging plates to connect the mounting cavity with the outside world, and / or a communication port is left between the bottom bridging plate and the bottom end of the main column to communicate the mounting cavity with the outside world .

[0043] The distance between the two main columns is first set according to the size required for the installation of the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com