Patents

Literature

69results about How to "Shorter dismantling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

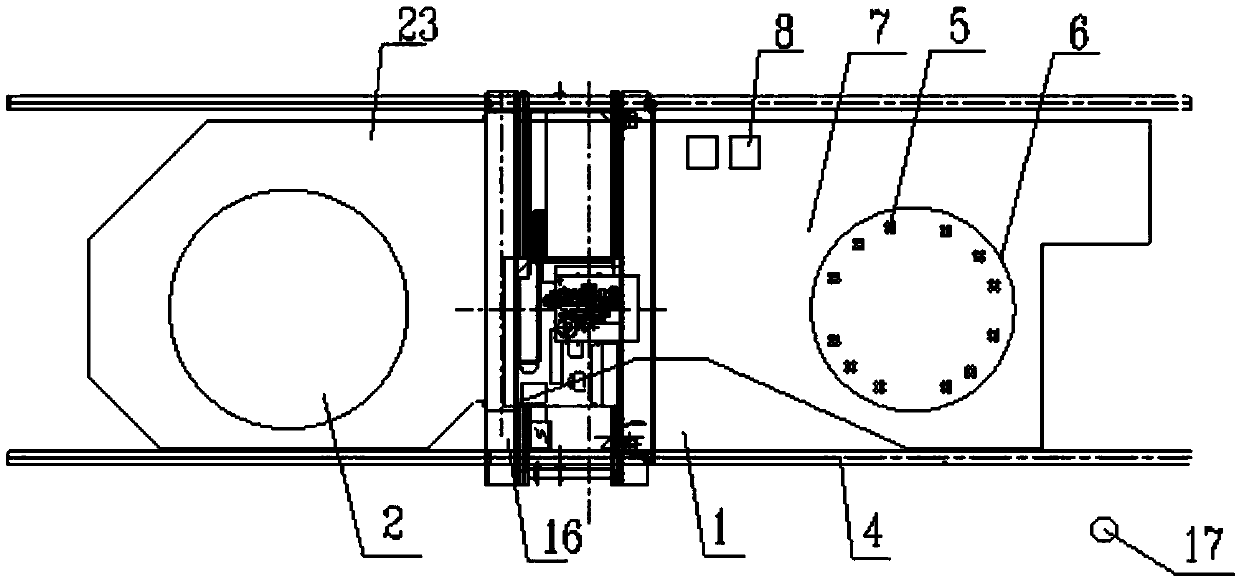

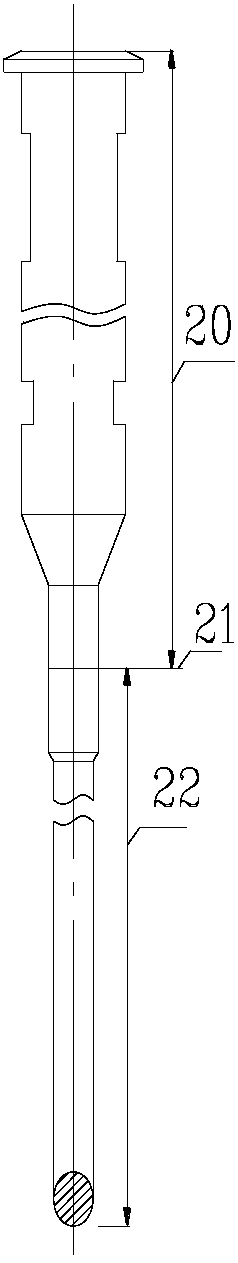

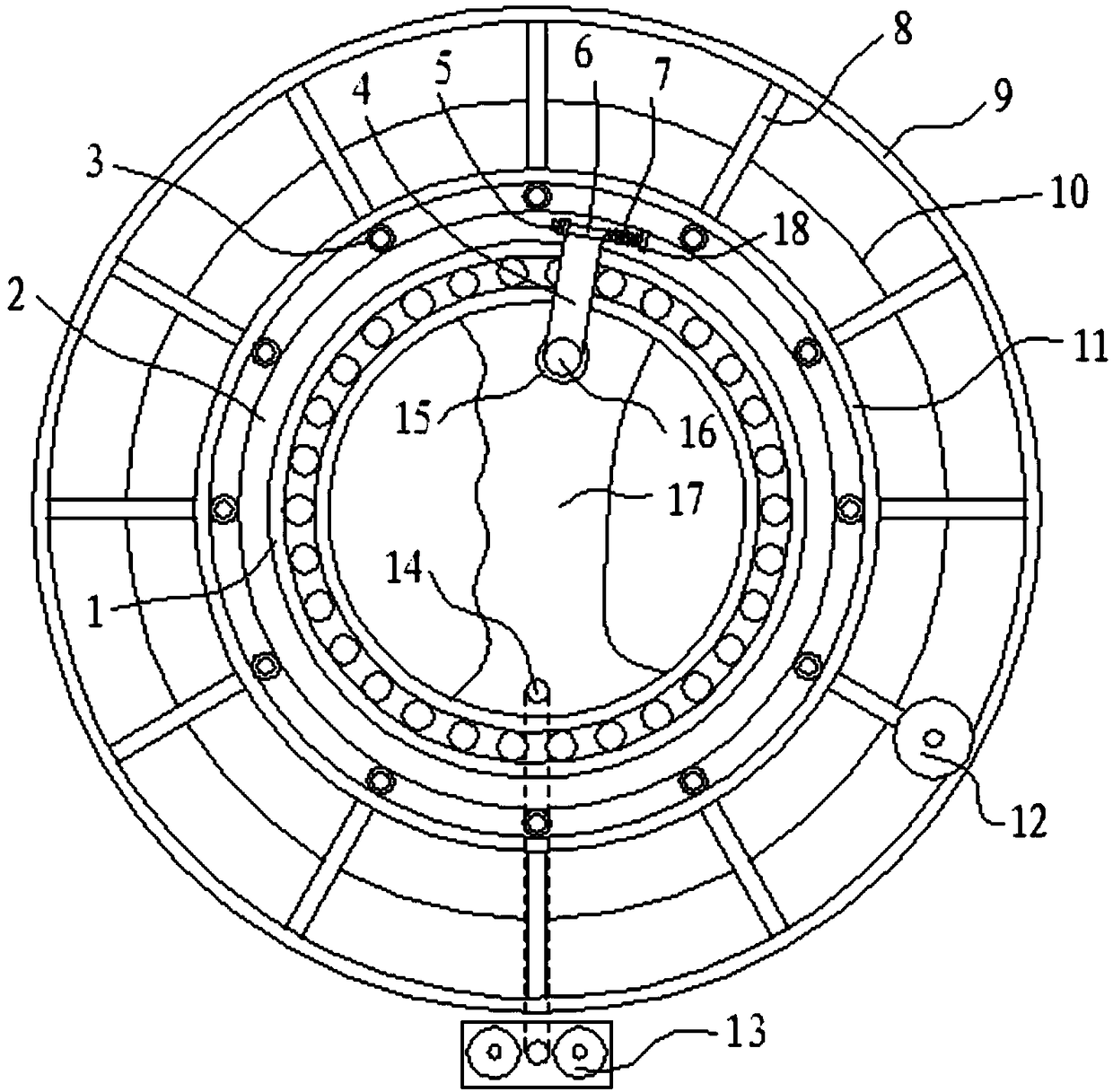

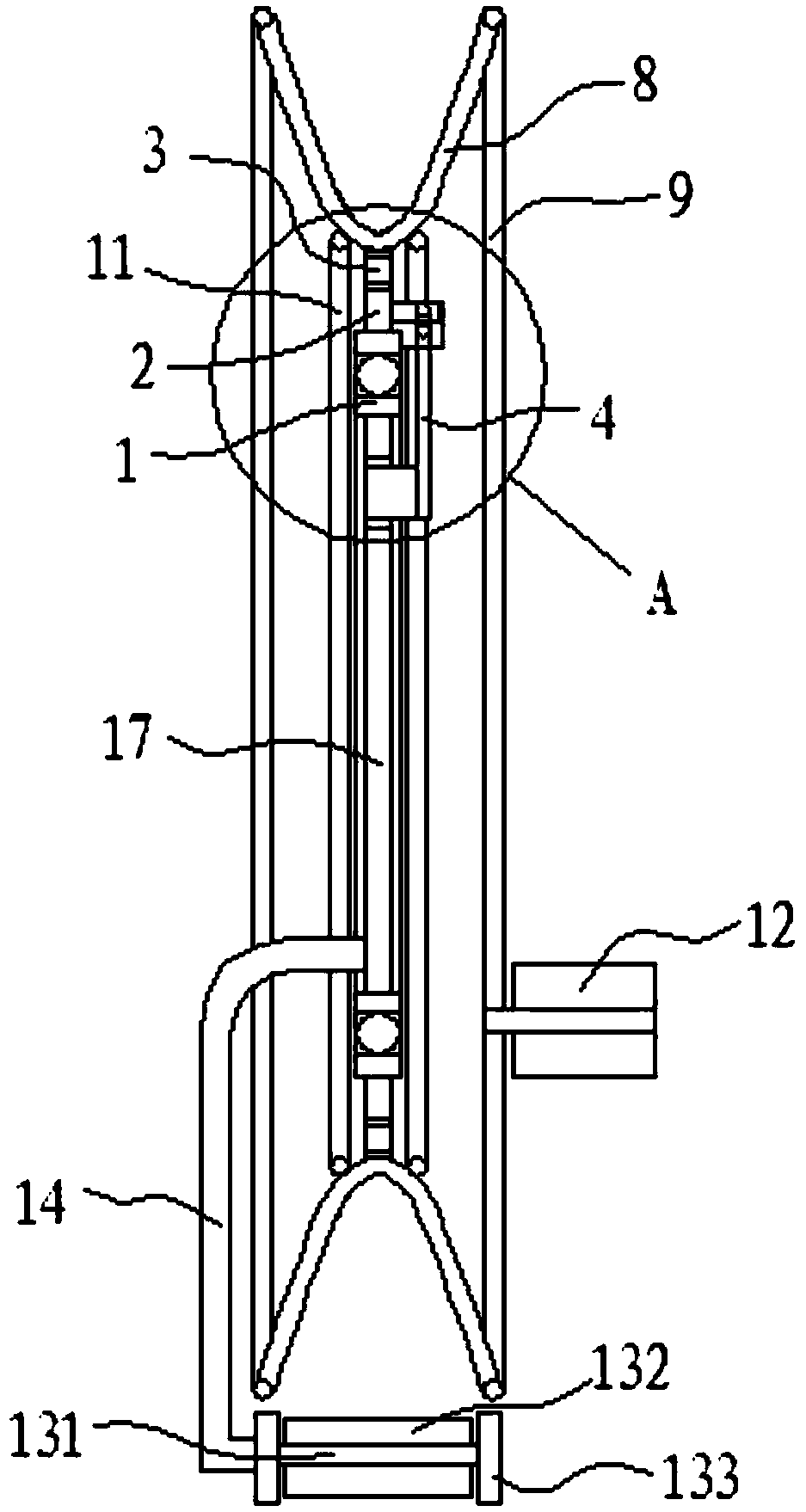

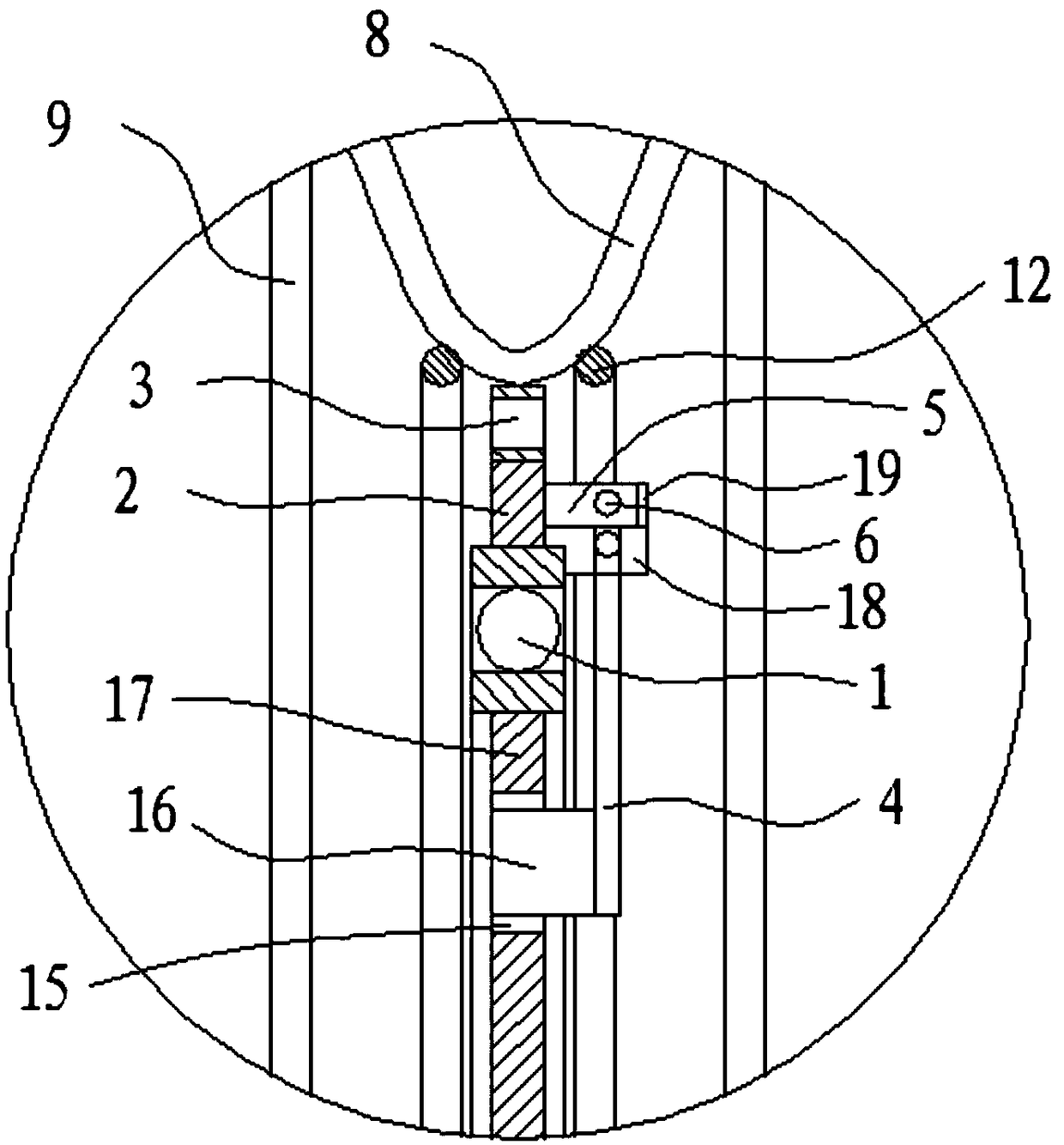

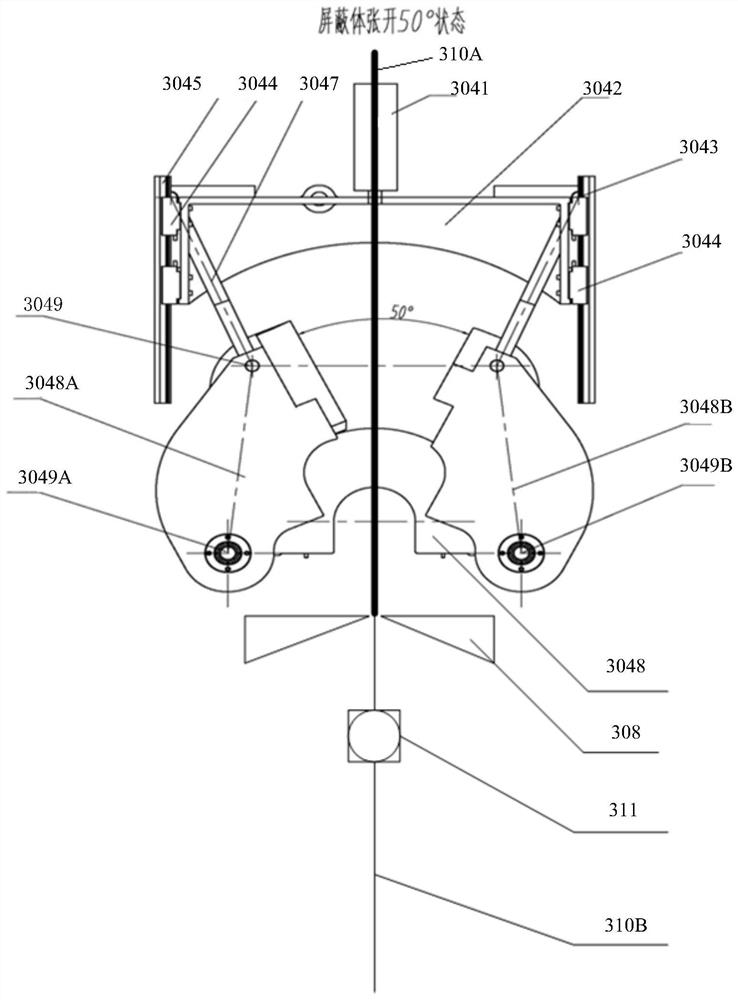

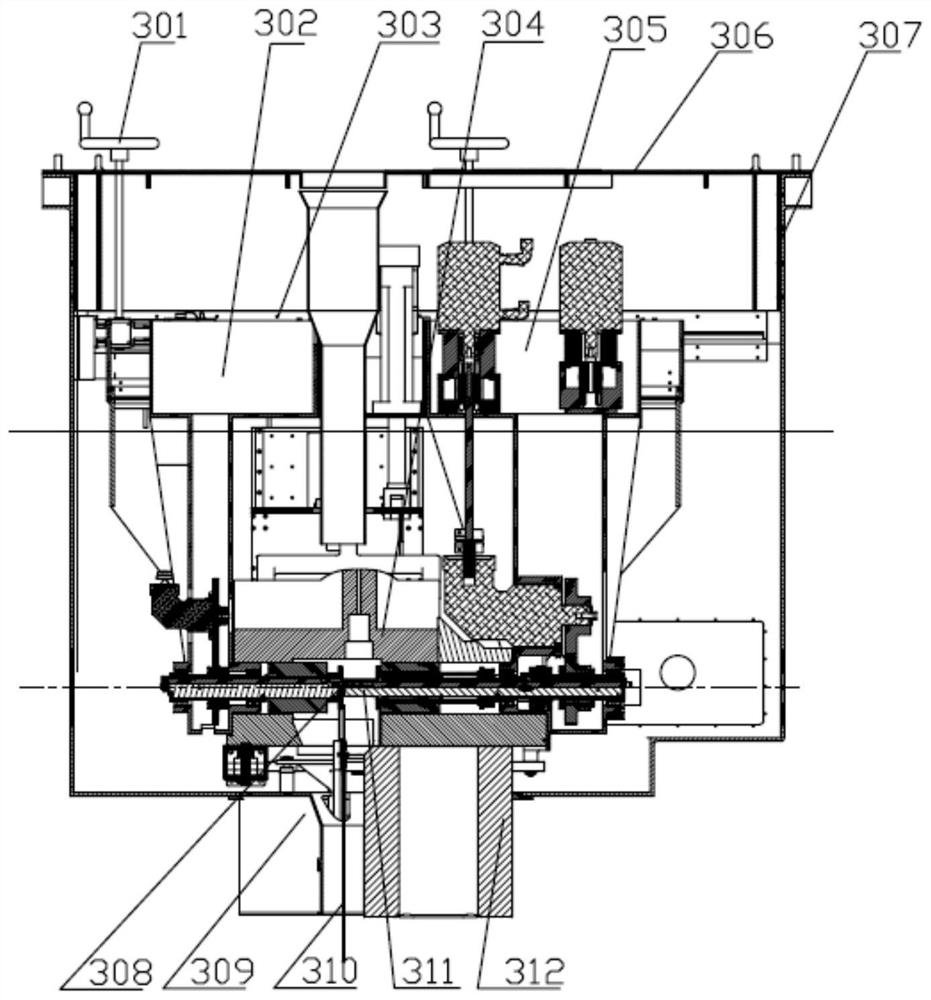

Disassembling technology and dedicated disassembling device of detector assemblies

ActiveCN107767976AShorter dismantling timeReduce exposure timeNuclear energy generationReactor fuel elementsRadiation protectionHigh-level waste

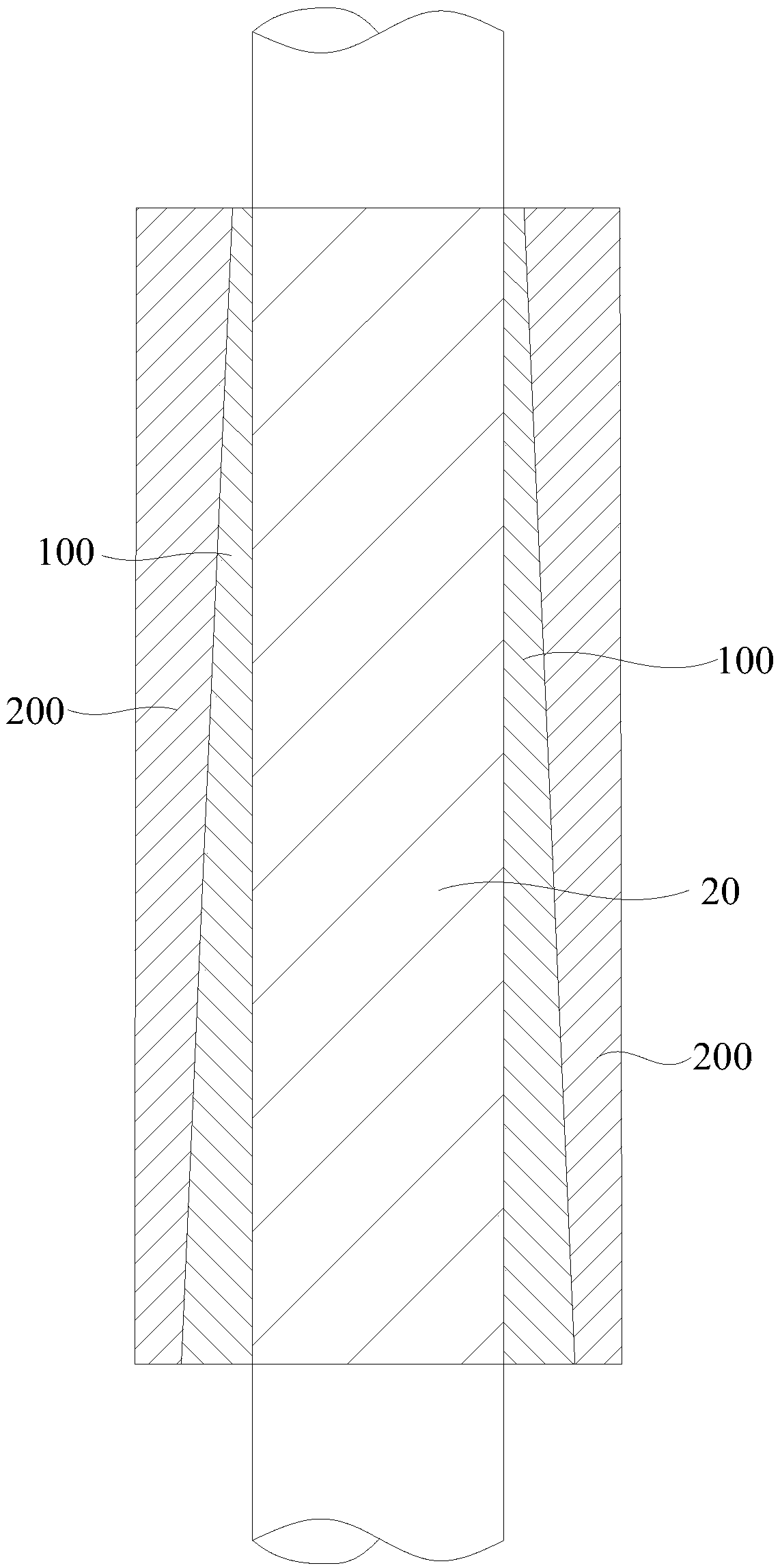

The invention discloses a disassembling technology and a dedicated disassembling device of detector assemblies. The disassembling technology comprises the following steps: moving a big and small vehicle assembly, releasing a gripping apparatus, lifting the gripping apparatus after gripping and disassembling one detector assembly, and clamping and cutting off the detector assembly by a shearing andshrinking assembly; putting the end part of the detector assembly into a low-level waste container; driving the detector assembly to rotate by a winding module in the shearing and shrinking assembly,pulling out the detector assembly from a guiding structure under the action of the shearing and shrinking assembly, coiling the detector assembly after winding into a tubular shape, and descending into a temporary storage container; disassembling other detector assemblies in the same group by repeating the steps; moving the big and small vehicle assembly after completing disassembly, winding thedetector assemblies, and descending into high-level waste containers; continuously disassembling detector assemblies in other groups by repeating the steps; recovering components to original storage places after completing the disassembly of all detector assemblies. According to the disassembling technology disclosed by the invention, a whole pull-out process is reasonably designed, the operatingtime is shortened, and good radiation protection is achieved by utilizing the shield of water in a refueling pool.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

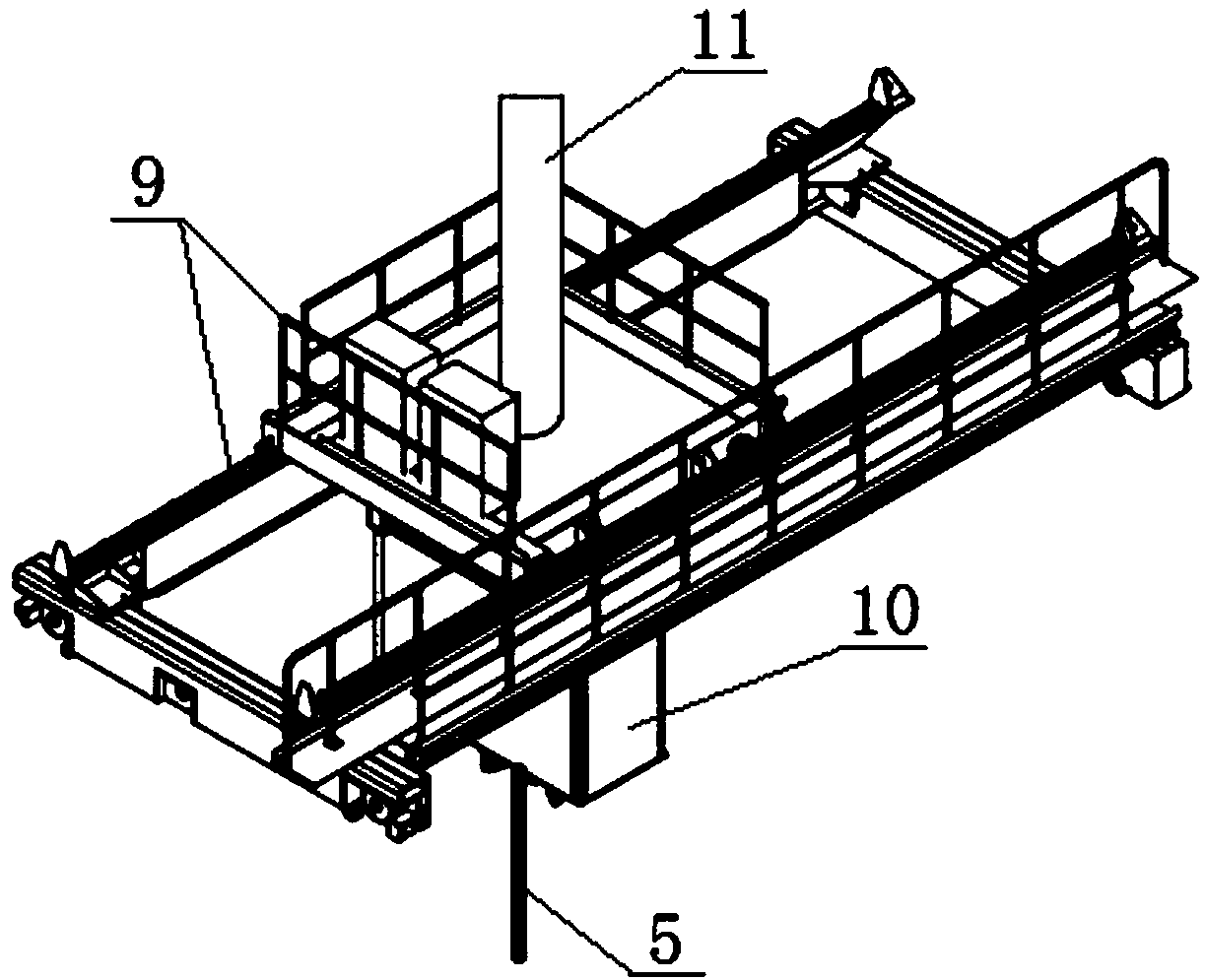

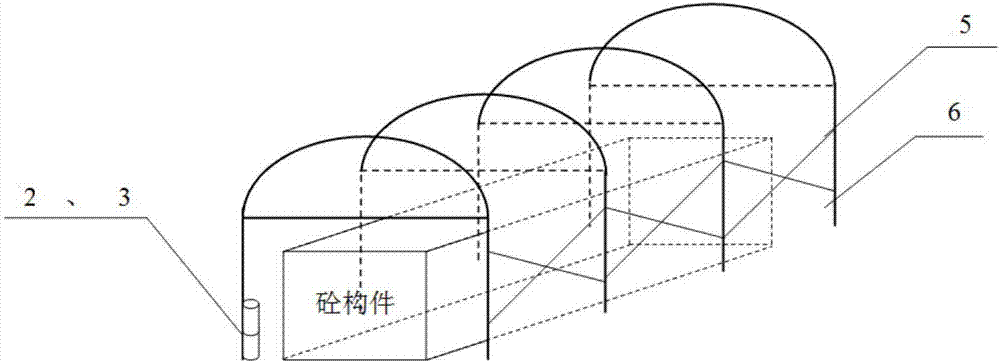

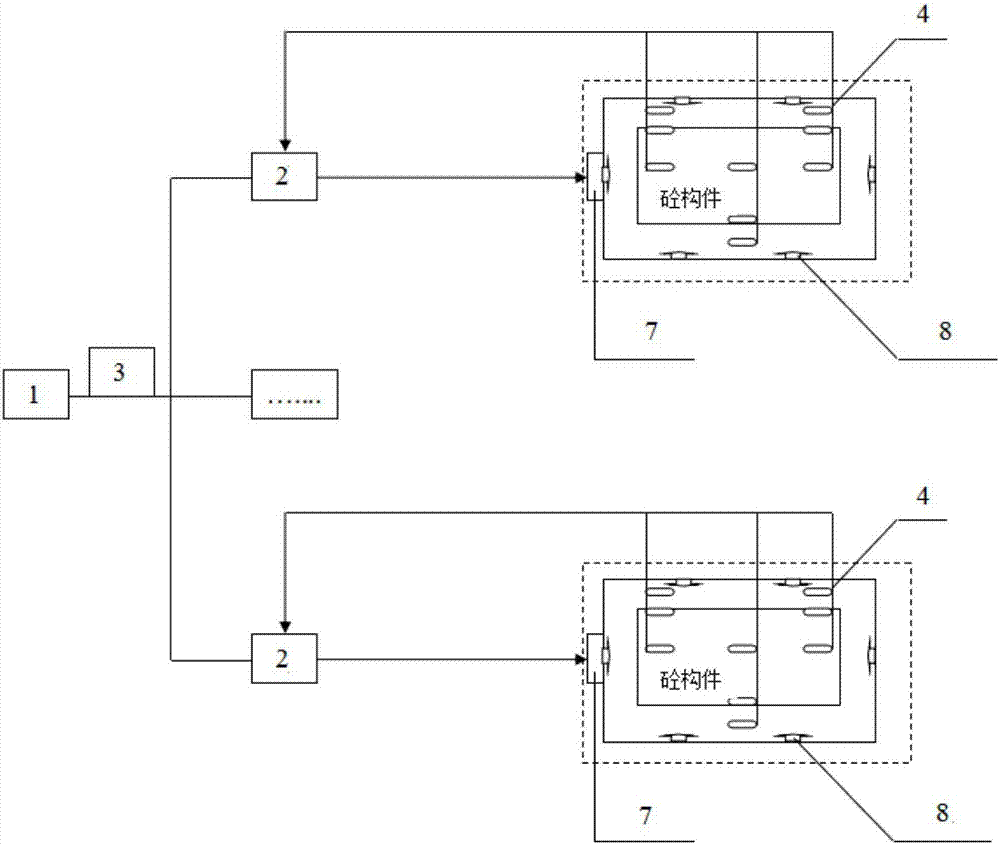

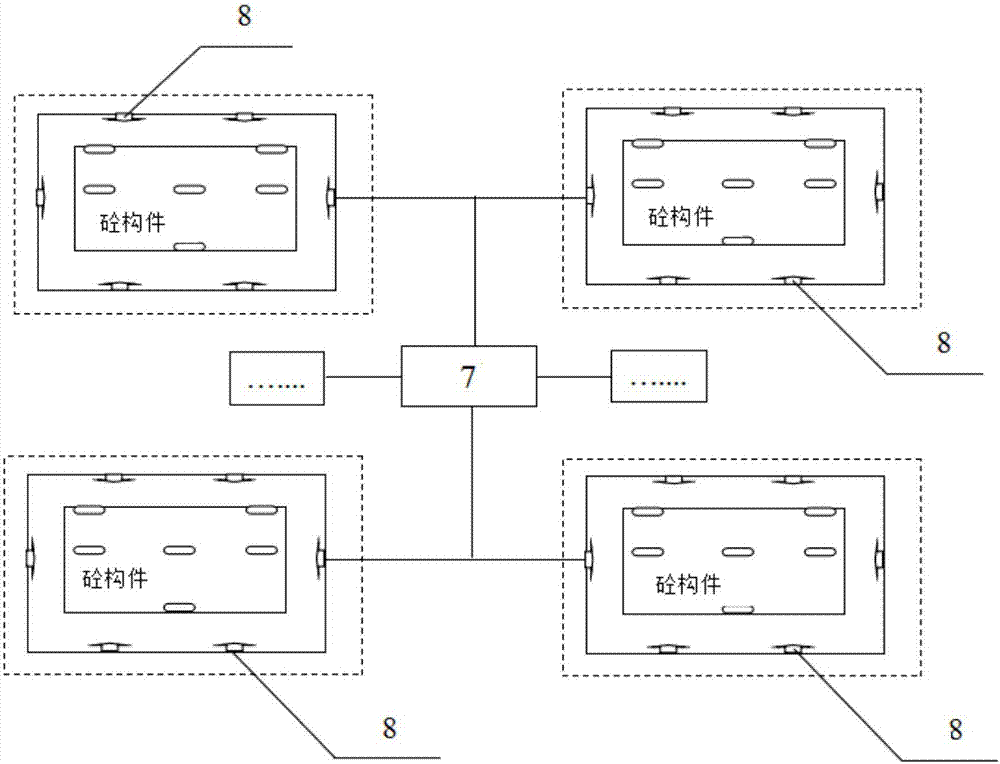

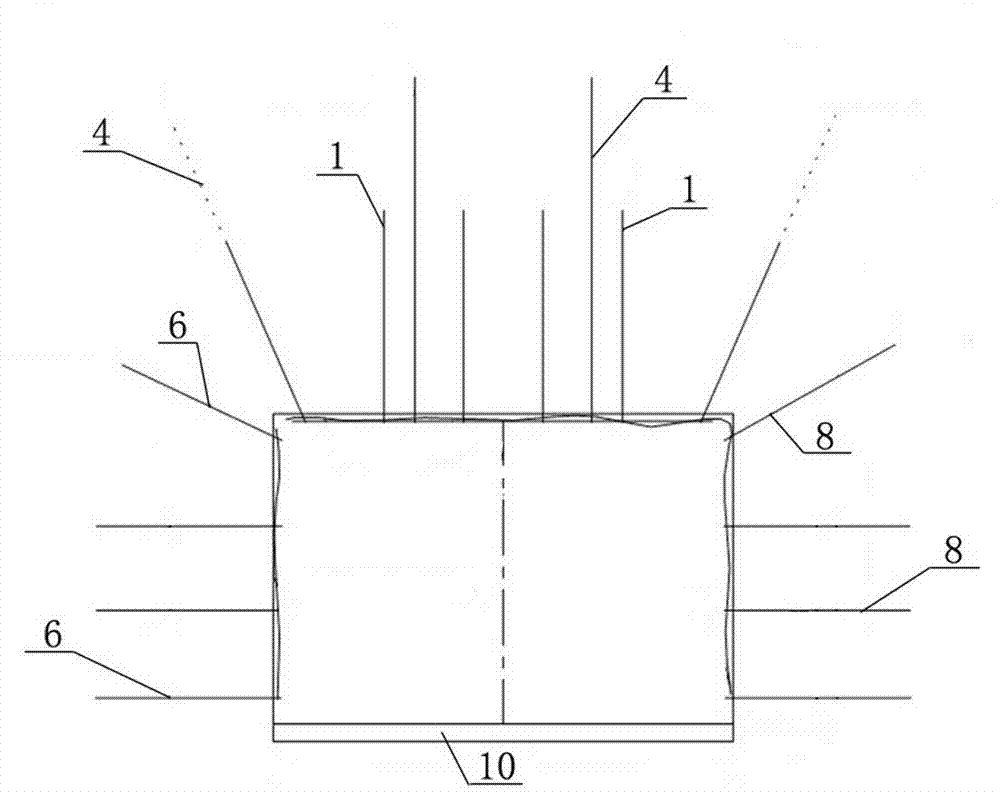

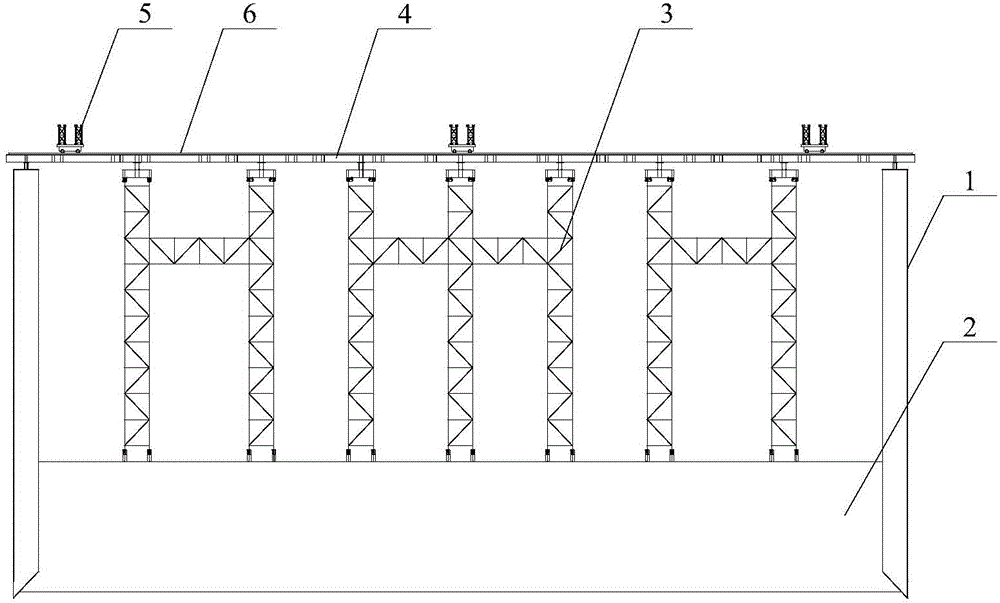

Remote intelligent type maintenance system for prefabricated concrete components

InactiveCN106891429AShorter dismantling timeImprove turnover efficiencyCeramic shaping apparatusTemperature controlSocial benefits

A remote intelligent type maintenance system for prefabricated concrete components comprises an intelligent monitoring system and maintenance system bodies. The intelligent monitoring system comprises a master monitoring device, distributed type data collecting and controlling devices, a wireless data receiving and transmitting device and a plurality of temperature sensors. Each maintenance system body is composed of a telescopic framework, heat preservation canvas, a temperature-control heating and water storing device and a spraying device. The remote intelligent type maintenance system for the prefabricated concrete components can relieve the labor intensity of workers, improve the maintenance efficiency of the prefabricated concrete components, shorten the formwork removal time of the concrete components, effectively lower the risks of cracks and other defects of the prefabricated concrete components and significantly improve the durability of concrete and has great economic and social benefits.

Owner:YUNNAN INST OF BUILDING RES +2

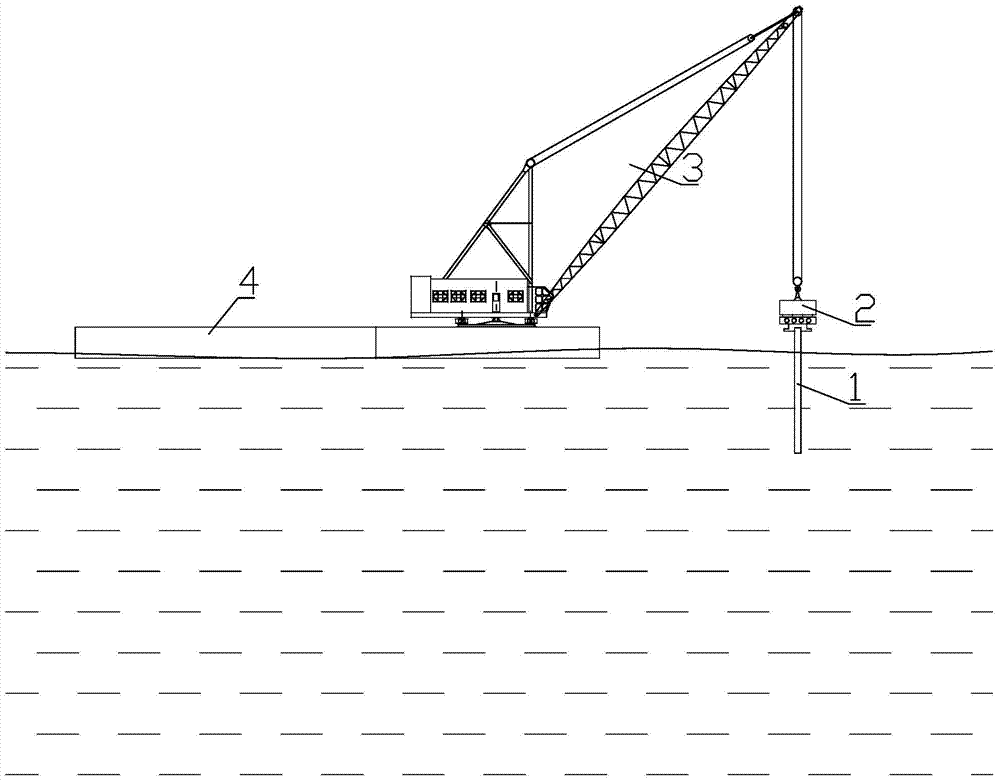

A method for pulling out underwater steel pipe piles for temporary projects of bridges

InactiveCN104196026AEasy turnoverShorter dismantling timeBulkheads/pilesOperabilityUltimate tensile strength

The invention discloses a method for pulling out underwater steel pipe piles for temporary projects of bridges. The method comprises the following steps: firstly, the model number of a vibration hammer and lifting equipment are selected through calculation, a transporting barge is prepared, and a complete set is formed and enters an operation area; then, the top of a steel pipe pile is leveled; the lifting equipment arrives at the operation area, an anchor is cast in place according to the length of a lifting arm and the operation radius, and meanwhile, the vibration hammer and the transporting barge are in place near the steel pipe pile; the vibration hammer is started to sink down the steel pipe pile, and then, the pile is pulled through vibration; after the steel pipe pile ascends, the lifting equipment directly pulls the pile until the steel pipe pile is separated from a mud surface; and finally, the steel pipe pile drops on the transporting barge, and the vibration hammer frees the pile to finish the pile pulling. In addition, a two-section pulling method is suitable for the steel pipe pile with the length more than 45 m; firstly the steel pipe pile is pulled out partially; then, the part of the steel pipe pile above a water surface is cut off; and finally, the remainder part of the steel pipe pile is pulled out. The method has the advantages of strong operability, low labor intensity, convenience for use, safety, environmental protection, quickening of construction progress and reduction of construction cost.

Owner:TIANJIN 20 CONSTR

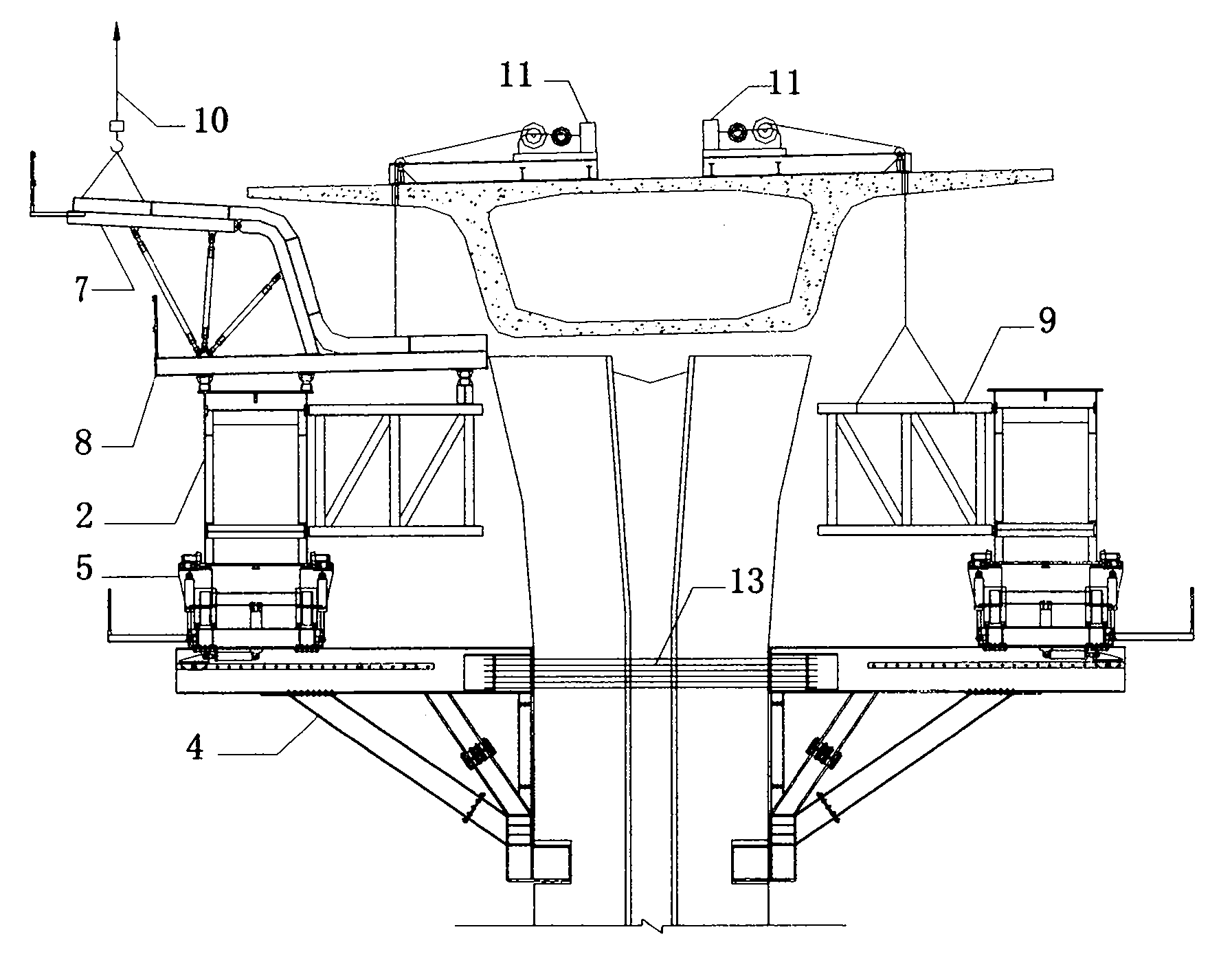

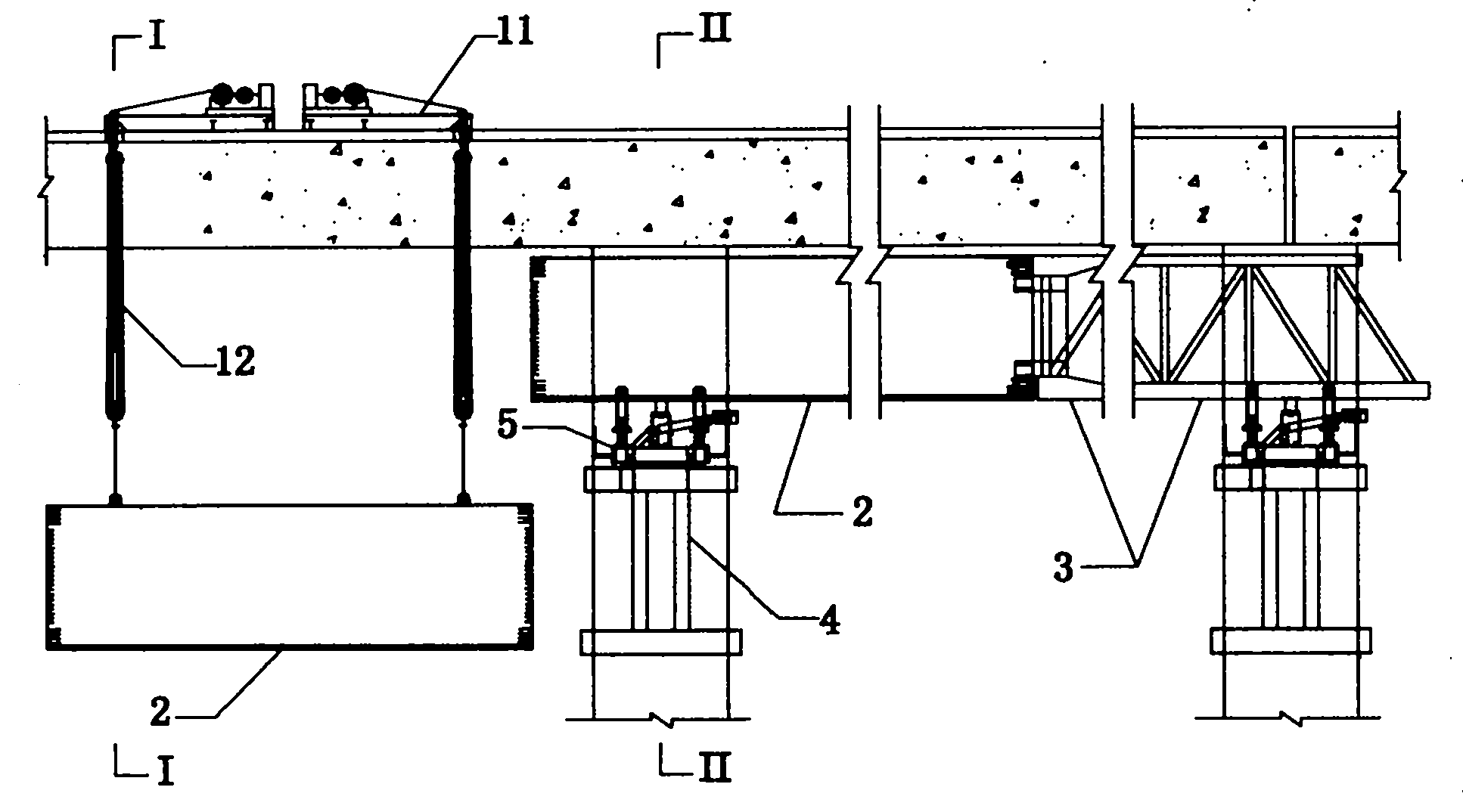

Construction process for overhead back-up movement and dismantlement of movable shuttering form

InactiveCN101818479AAvoid lateral instabilityShorter dismantling timeBridge erection/assemblyForm treatmentStructural engineeringTruck

The invention belongs to the field of bridge construction processes, is applied in the construction of a movable shuttering form for a cast-in-place box girder, and particularly relates to a construction process for the overhead back-up movement and dismantlement of a movable shuttering form after a cast-in-place box girder is completely constructed by the movable shuttering form. The process is characterized in that: a back guide girder, a main beam, a front guide girder, a bracket, a cart, an external mould plate, a mould plate beam, a middle beam and bracket tensioning fining twisted steel on both sides of the bride need to be removed; the cart transversely moves on the bracket to open the movable shuttering form, a winder is arranged on a concrete box girder, the external mould plate is removed by the winder and by the drawing and hoisting operation of a truck crane, the mould plate beam and the middle beam are removed from the top to the bottom in sequence, only the back guide girder, the main beam and the front guide girder remain, the main beam of the movable shuttering form is removed, and finally the last section of main beam and the front guide girder are moved. The process has the advantages of speeding up the construction, reducing construction equipment, guaranteeing the construction safety and lowering construction cost.

Owner:CCCC SHEC SECOND ENG

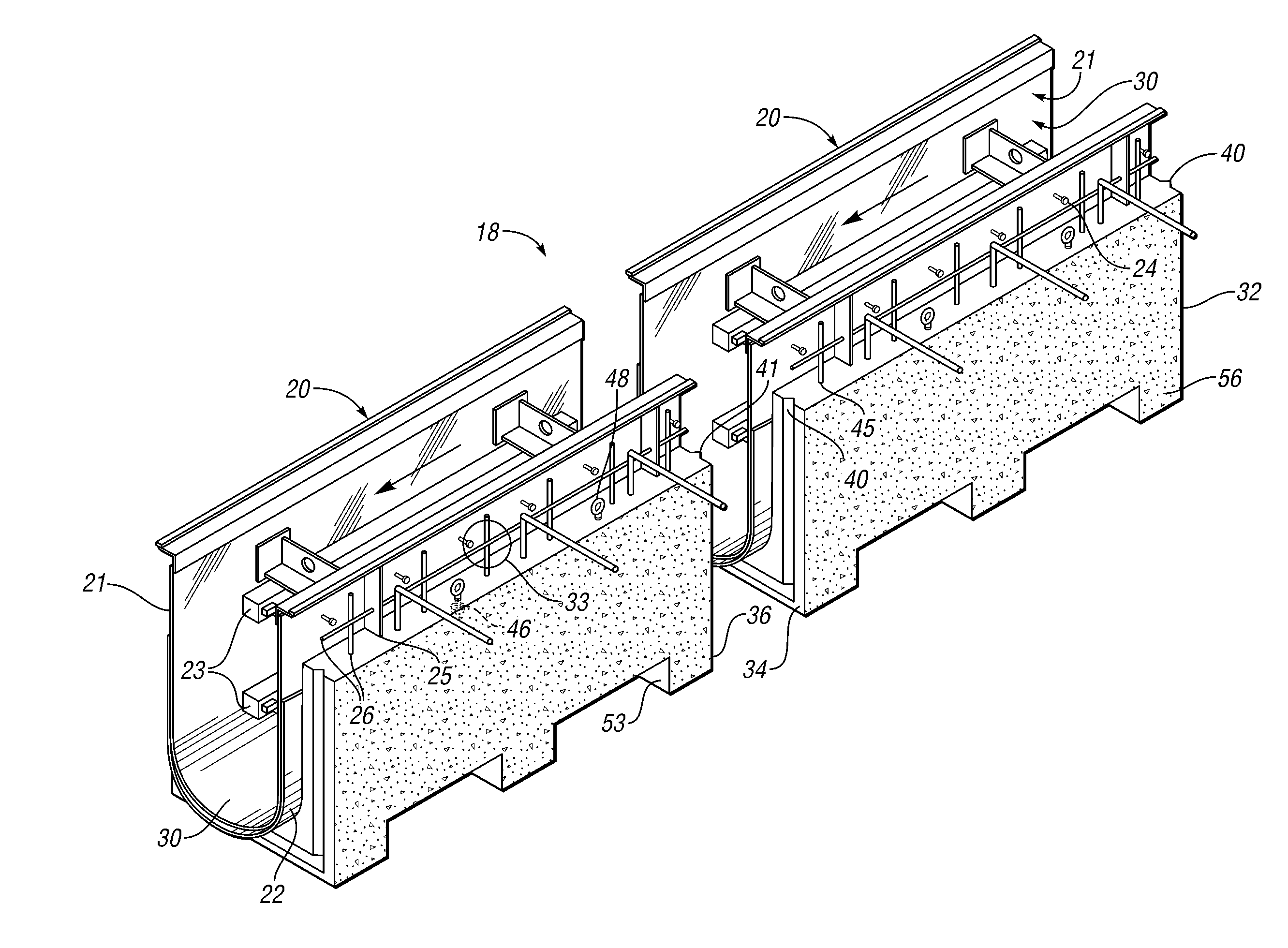

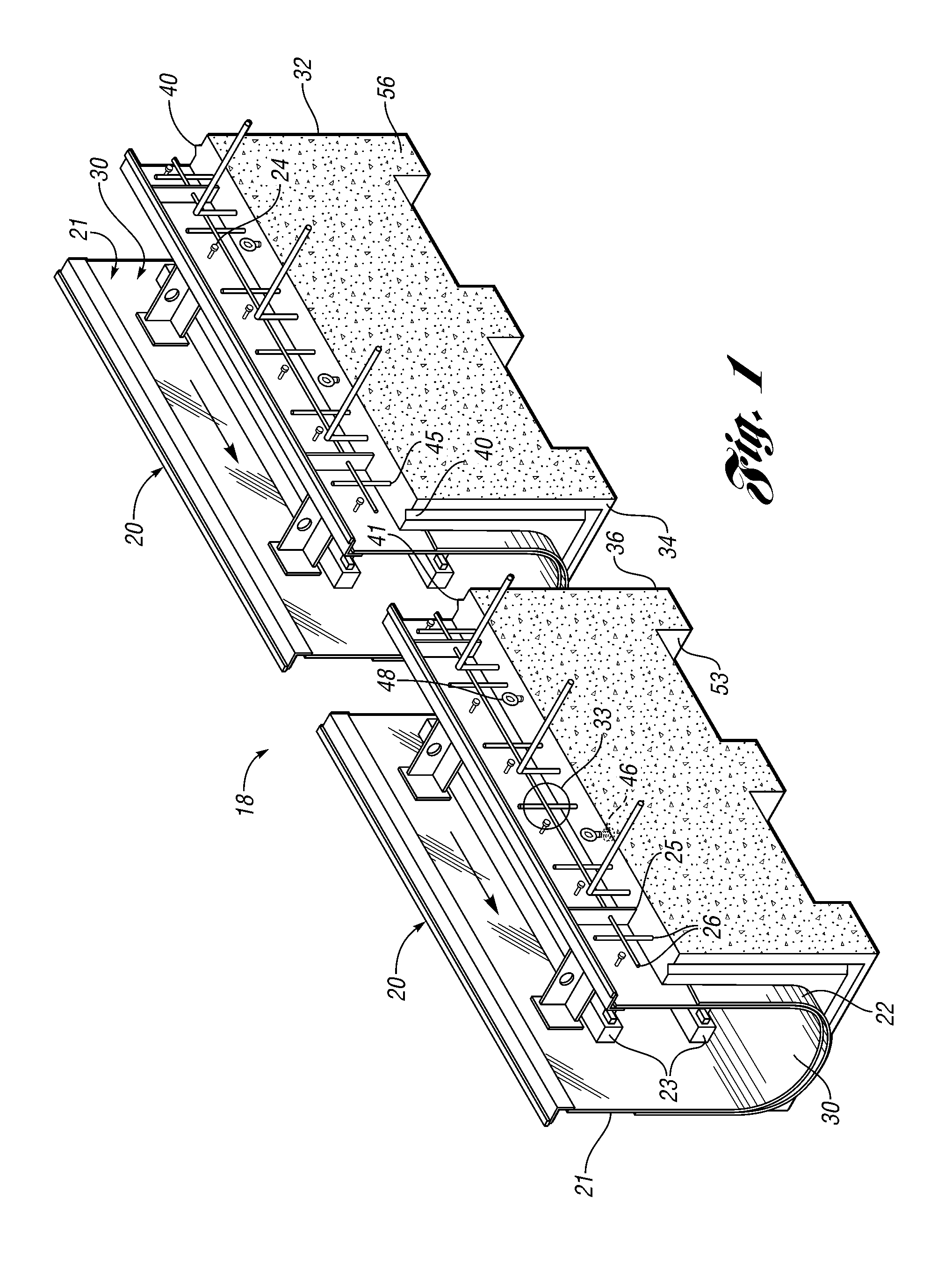

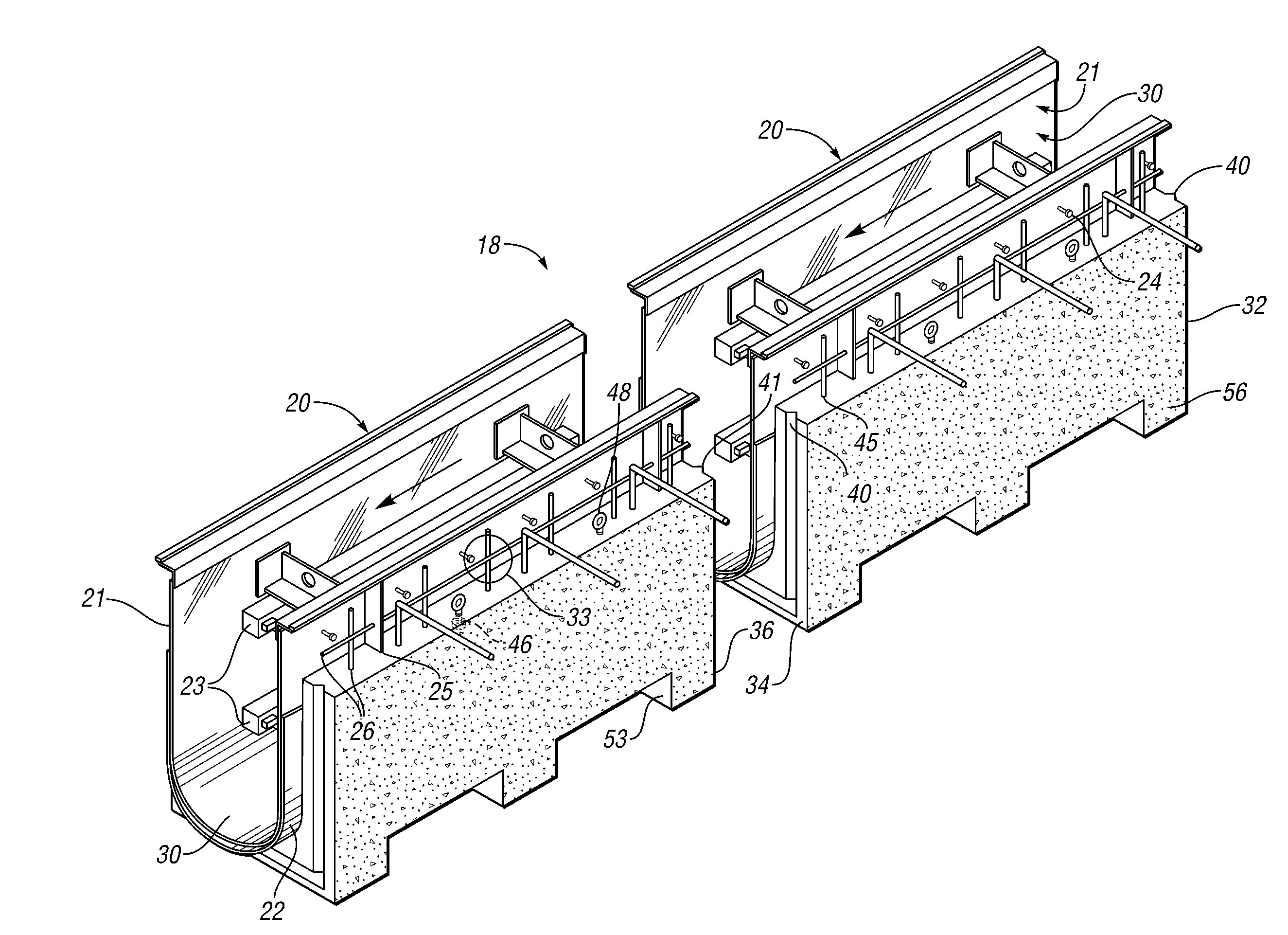

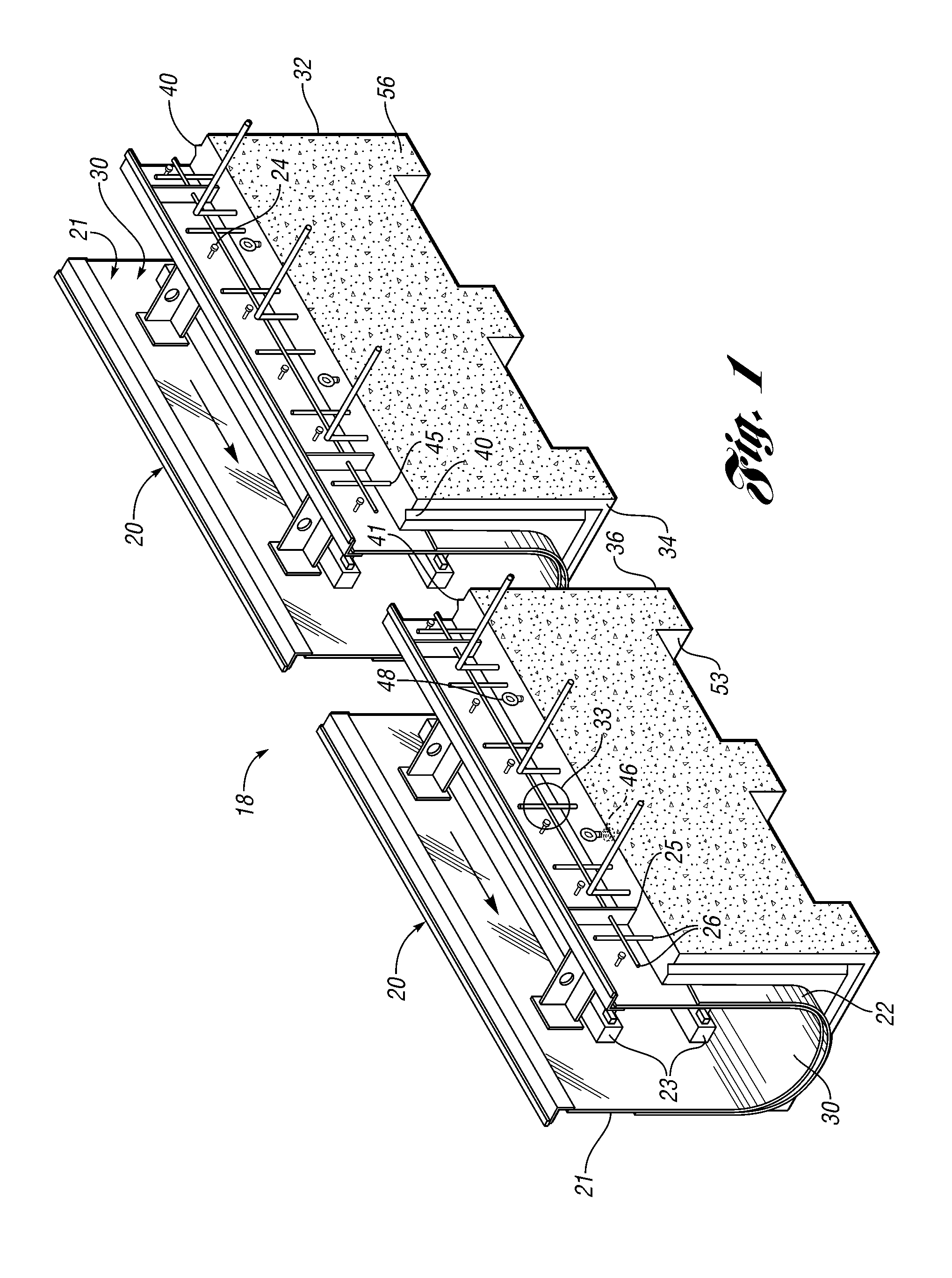

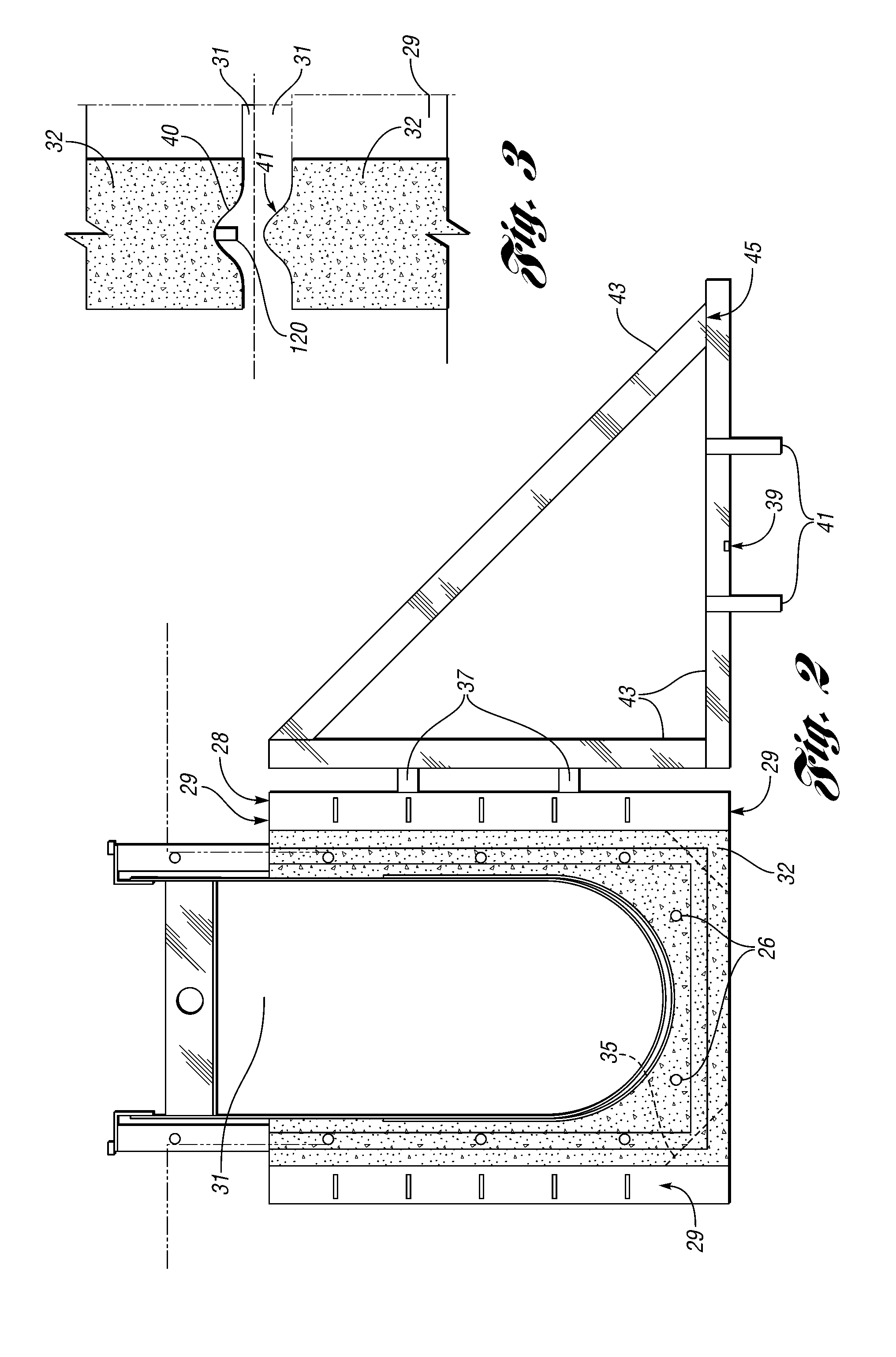

Precasting of fabricated flumes for machining coolant systems

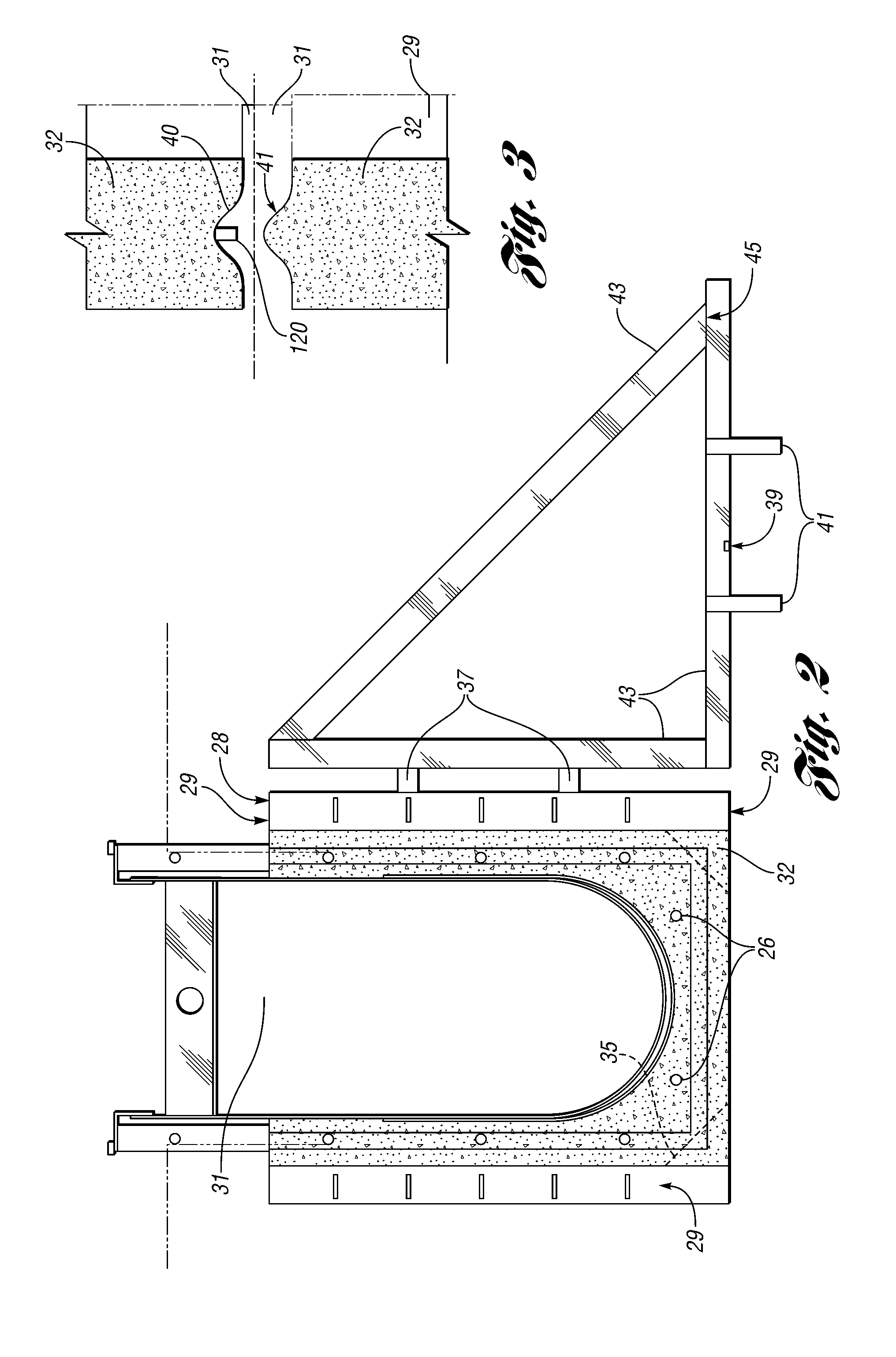

InactiveUS20080095582A1Reduces excavation requirementOvercome disadvantagesPipesWater-power plantsEngineeringCoolant

A method and apparatus for constructing machinery flumes couples precast, fabricated sections of flume having a channel lining in a concrete cast. The sections are assembled to seal end to end forming a continuous trough in which assembly work is contained to reduce installer exposure, reduce field installation time and reduce construction costs for flume systems. Preferably, an end of a lining extends beyond the cast sheath for connection with an overlapped portion of an adjacent precast section's lining.

Owner:ARISTEO CONSTR

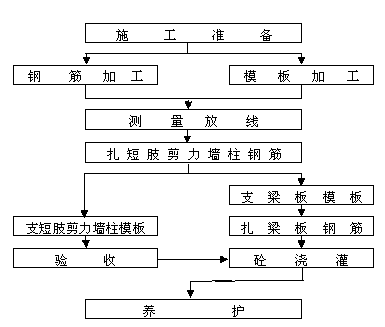

Main structure construction method by sequentially processing beam slab frameworks, short-leg shear wall and column frameworks

InactiveCN103266766AConstruction duration shortenedShorten the time intervalBuilding material handlingFloor slabConcrete beams

The invention relates to a main structure construction method by sequentially processing beam slab frameworks, short-leg shear wall and column frameworks. The method includes the following steps: a, strapping short-leg shear wall and column rebars; b, mounting the beam slab frameworks; c, calibrating the shear wall and column rebars before strapping beam rebars, immediately performing inspection after strapping the beam rebars, and then strapping floor slab rebars; d, mounting the short-leg shear wall and column frameworks when strapping the floor slab rebars; and e, simultaneously pouring concrete to beam slabs, floor slabs and short-leg shear walls and columns. In the method, mounting of the short-leg shear wall and column frameworks and strapping of the beam slab rebars and the floor slab rebars which are completely not in the same working face can be performed simultaneously, and the mounting of the short-leg shear wall and column frameworks becomes a non-critical work from a critical work and does not occupy construction periods, so that main engineering construction duration of the whole frame shear structure is reduced, and a main structure construction period and time intervals in shutdown and waiting of labor force are greatly shortened.

Owner:JIANGNAN CONSTR CO LTD DONGYANG ZHEJIANG

Cable cutting device and cable-stayed dismantling construction method

PendingCN109137763AShorter dismantling timeEnsure safetyBridge erection/assemblyBridge strengtheningCable stayed

The invention discloses a cable cutting device and a cable dismantling construction method. The first anchor and the second anchor are sleeved on the cable at intervals, and then the first cable is clamped on the first anchor and the second cable is clamped on the second anchor. A steel strand is stretched with a jack to apply a pretension force to the first and second cable clamps while the cablebody is partially unloaded between the cable clamps and the steel strand bears a portion of the cable force. Tighten the retaining nut and loosen the jack to transfer the cable force on the strandedwire to the tie rod. The cable body is cut in stages, in which the cable force decreases gradually and the force on the tie rod increases gradually until the cable is completely cut off. Loosen the retaining nut, remove the cable cutting device and remove the cut cable. By using the device to cut the stay cable, the impact force is not generated when the stay cable is cut, and the adjacent stay cable is not broken, or the main beam is cracked or even broken, so as to ensure the safety and greatly save the removal time of the stay cable.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

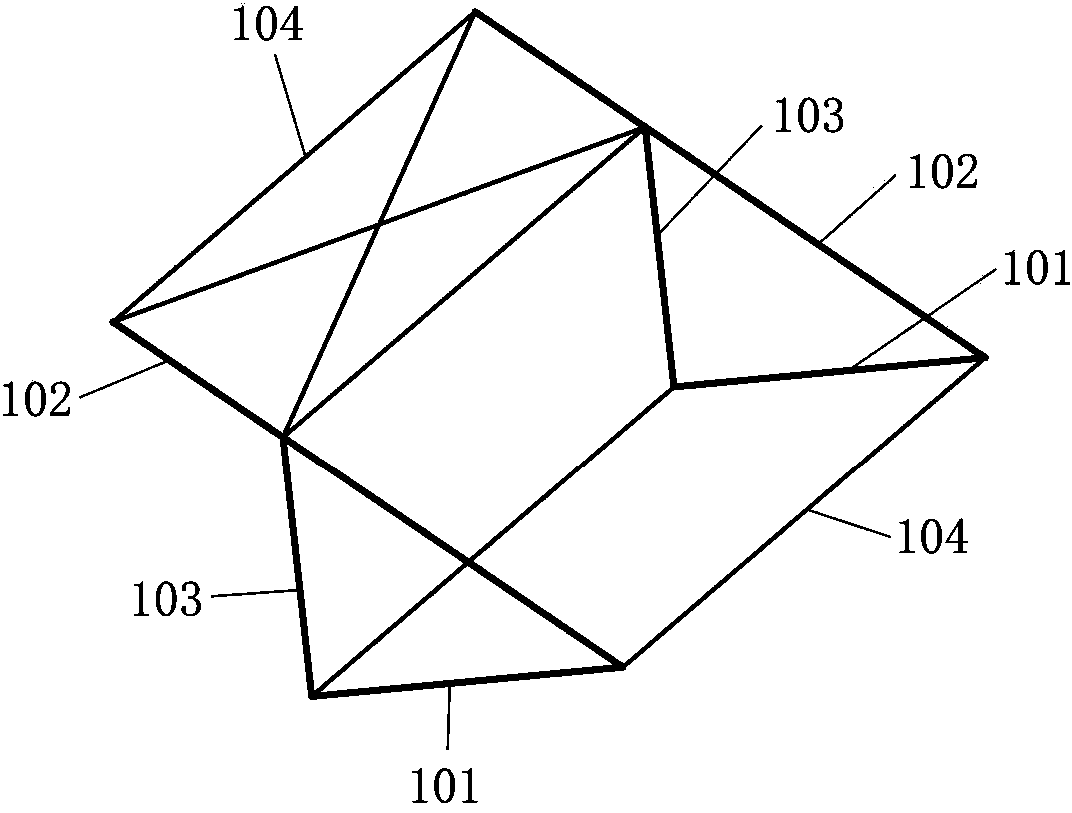

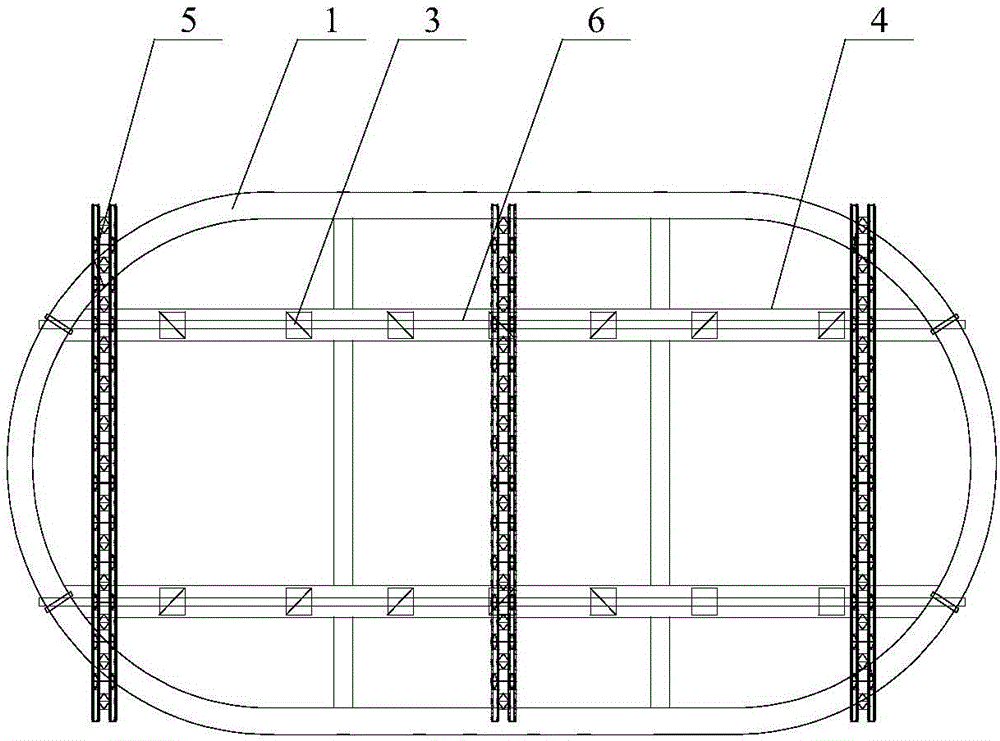

Large earthed concrete tank dome steel support structure and mounting method thereof

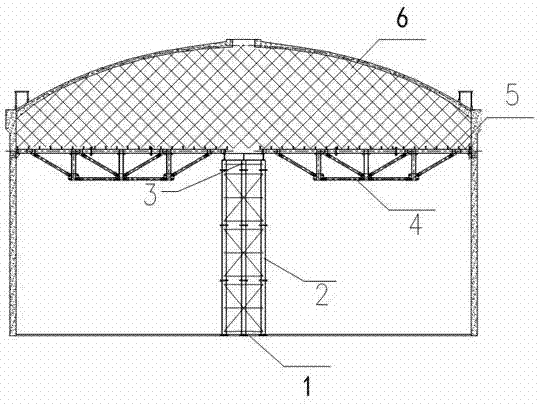

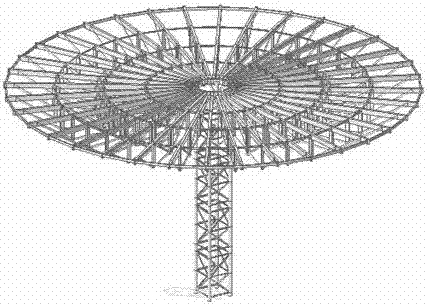

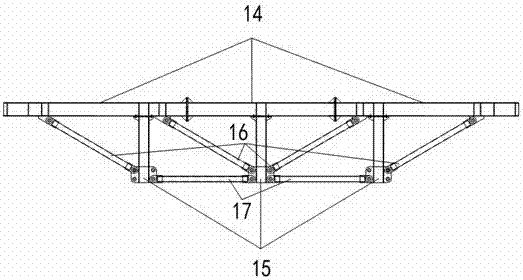

PendingCN107989447AImprove construction progressImprove ergonomicsBuilding material handlingBulk storage containerCircular discOperational safety

The invention discloses a large earthed concrete tank dome steel support structure, comprising an all-round scaffold, a latticed column foundation, a standard segment jig, a support frame center disc,trusses and I-beams; the latticed column foundation is arranged in the center of a tank chamber; a plurality of latticed columns are fixedly connected to the latticed column foundation to form the standard segment jig; the support frame center disc is fixed to the uppermost latticed column; in construction of a last standard segment of a tank wall, embedded parts are necessarily embedded to weldsteel brackets; after the tank wall is cast and a formwork is removed, the steel brackets can be welded to embedded plates; one end of each truss is fixed to the corresponding bracket part on the tankwall of a concrete tank, and the other end of each truss is fixed to the support frame center disc; the I-beams and wooden pads are laid on the upper portions of the trusses. The invention also discloses a mounting method of the large earthed concrete tank dome steel support structure. The large earthed concrete tank dome steel support structure has high bearing capacity and good structural system stability, poor forming quality of a dome due to foundation settlement is avoided, a jig system has large space for operation and good operational safety, and operations can be better ensured for workers.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

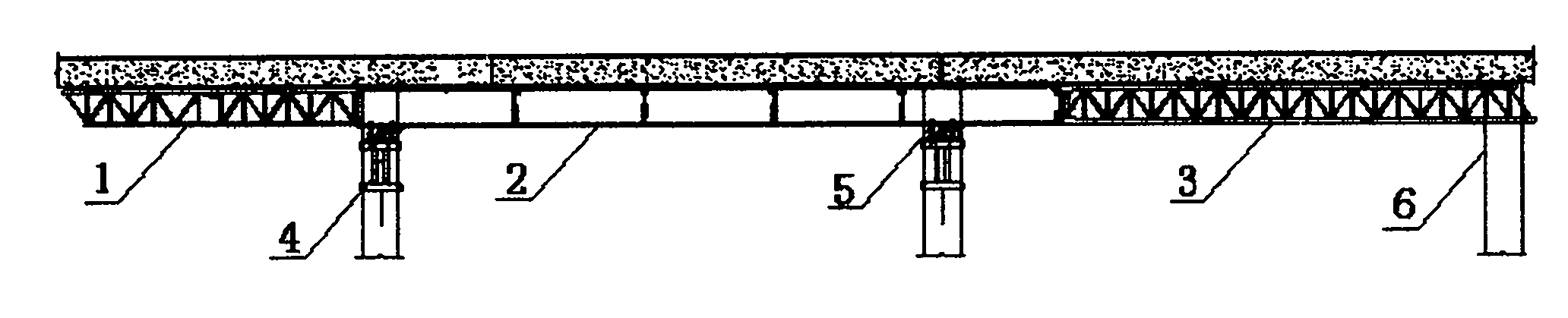

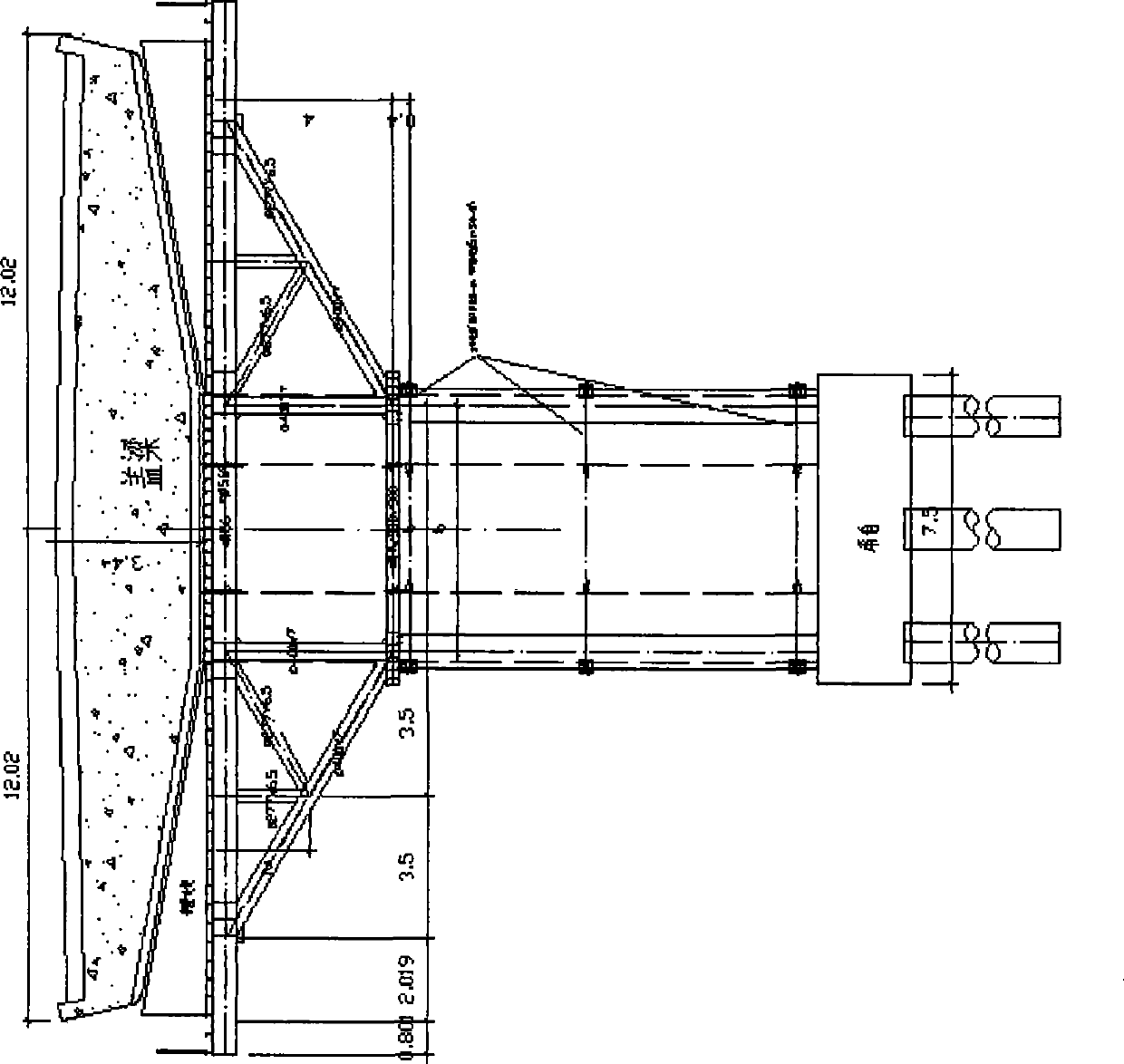

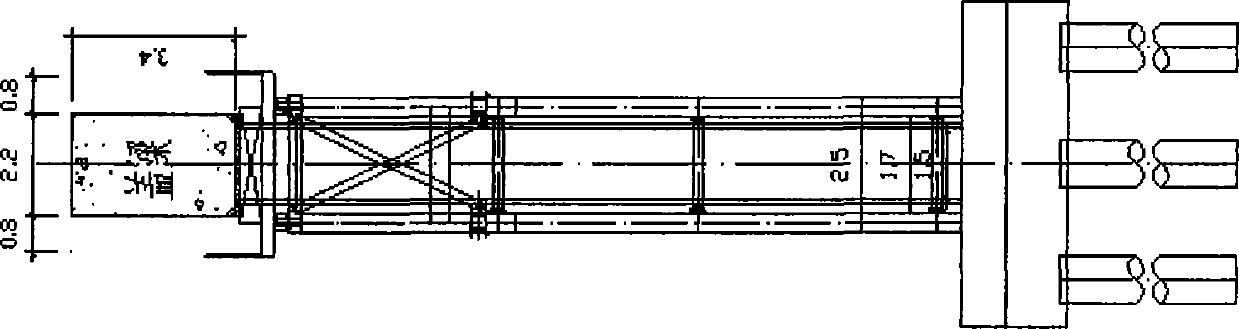

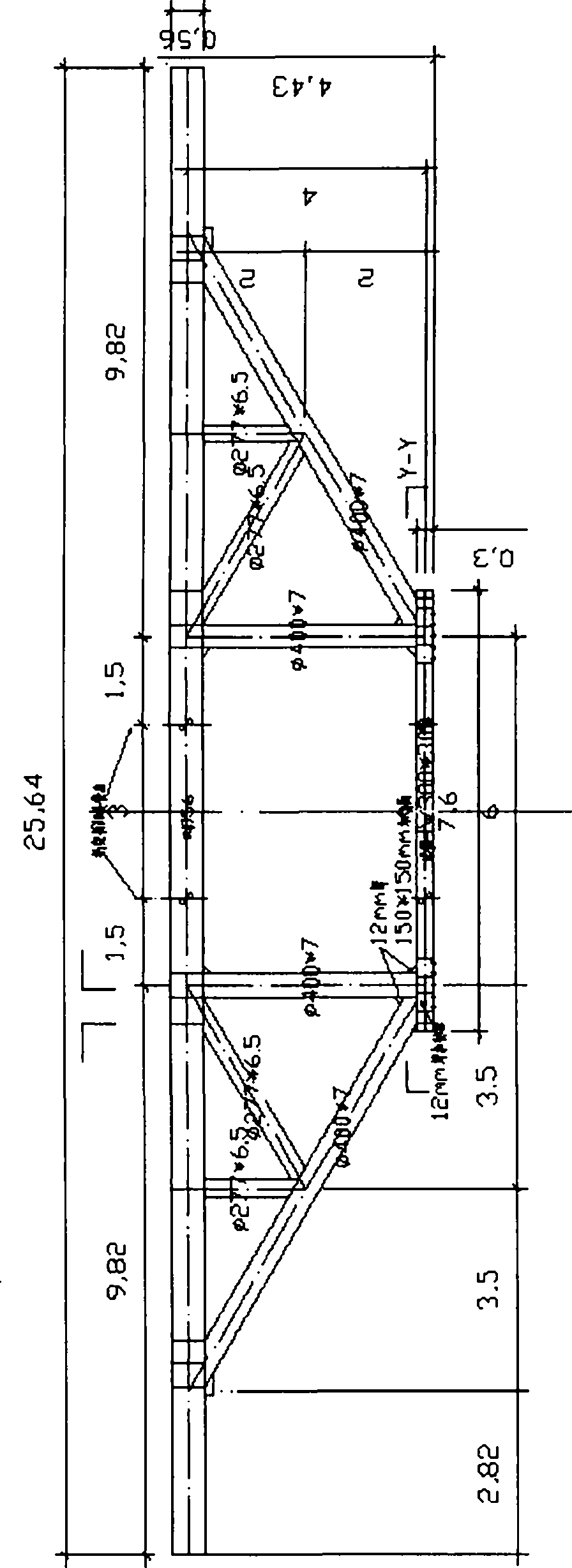

Novel assembling method for bent cap bearing frame

InactiveCN103866692AReduce the scope of layoutSmooth ground trafficBridge erection/assemblySteel tubeRebar

The invention relates to a novel assembling method for a bent cap bearing frame without a full framing. Steel pipes with the sizes of Phi 400*7 mm and Phi 277*6.5 mm and I56 I-beams are used for manufacturing trusses; steel pipes with the size of Phi 400*7 mm are used for manufacturing bearing vertical uprights; the trusses and the vertical uprights are connected through high-strength bolts. the two trusses are connected by using precision rolling deformed steel bars and [28 channel steel therebetween; the trusses and the vertical uprights are clasped with reinforced concrete upright posts by using [20 channel steel; the bent cap load is transmitted to the trusses, the vertical uprights, a bearing platform and a pile foundation through bottom die distribution beams at the top of the trusses. According to the novel assembling method for the bent cap bearing frame, the reinforcement processing is carried out without a foundation, vertical uprights are few, the occupied area of the ground is small, an overall processing manner is adopted, the work amount of manual operation for installation is less, and the installation is simpler.

Owner:HONGRUN CONSTR GROUP STOCK

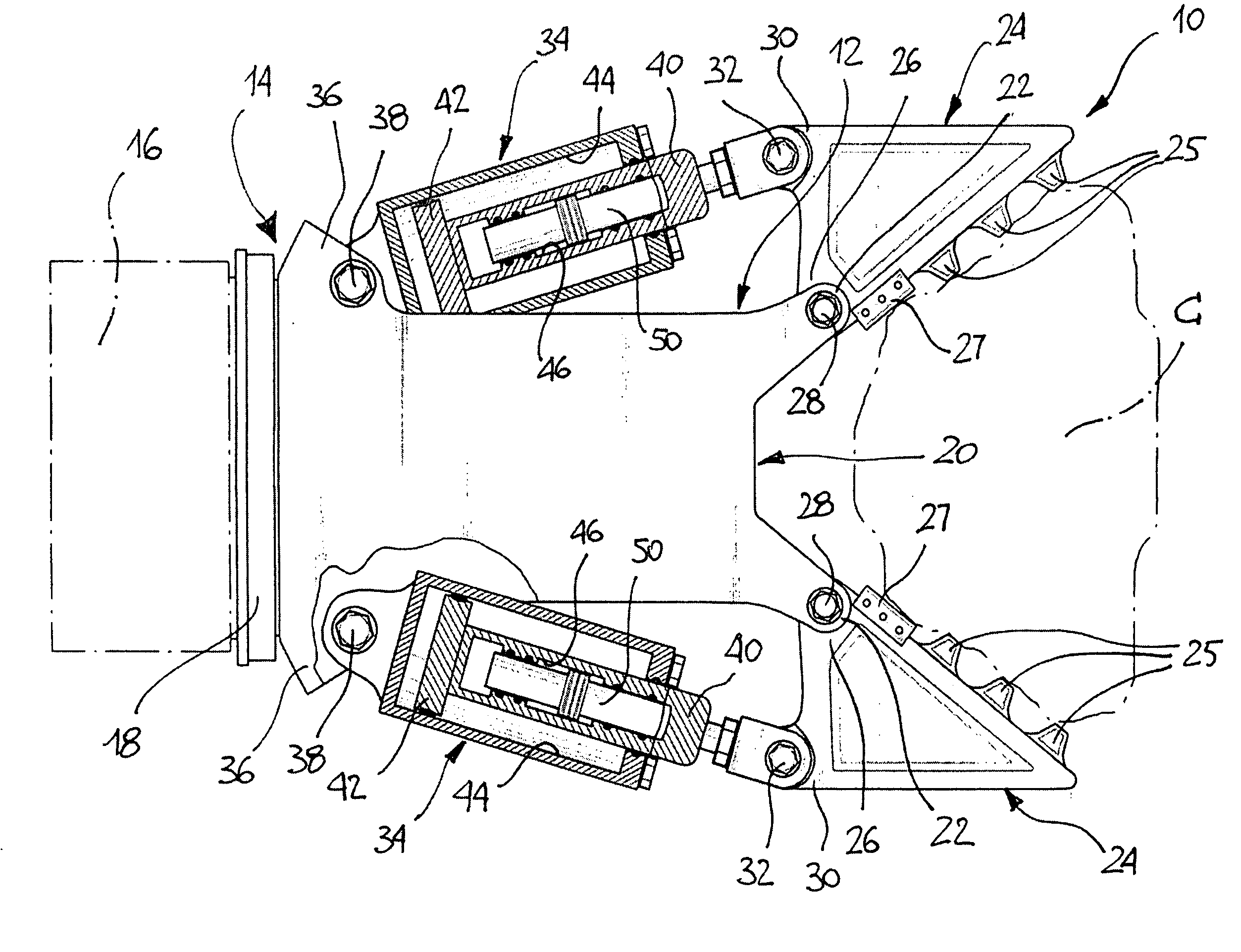

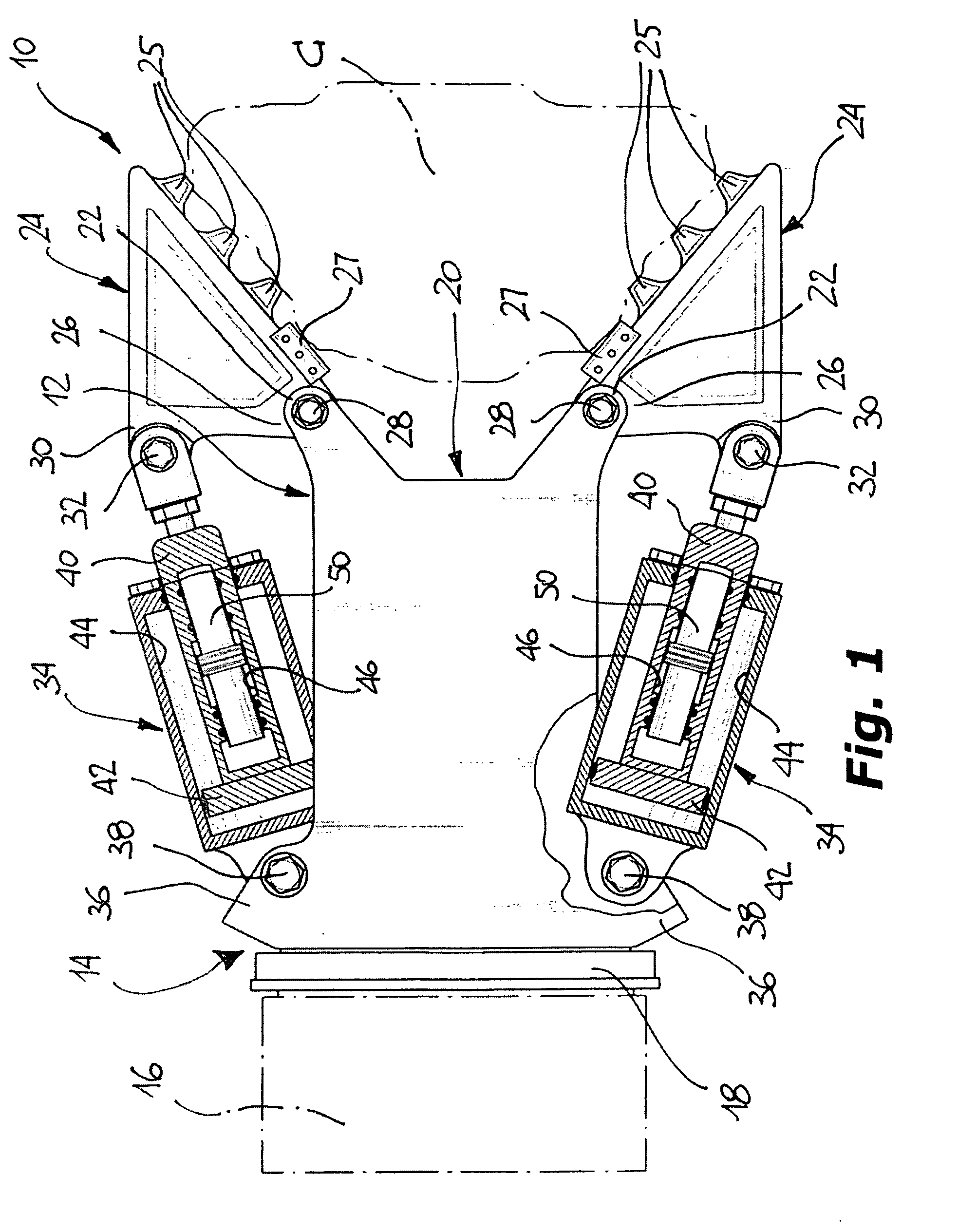

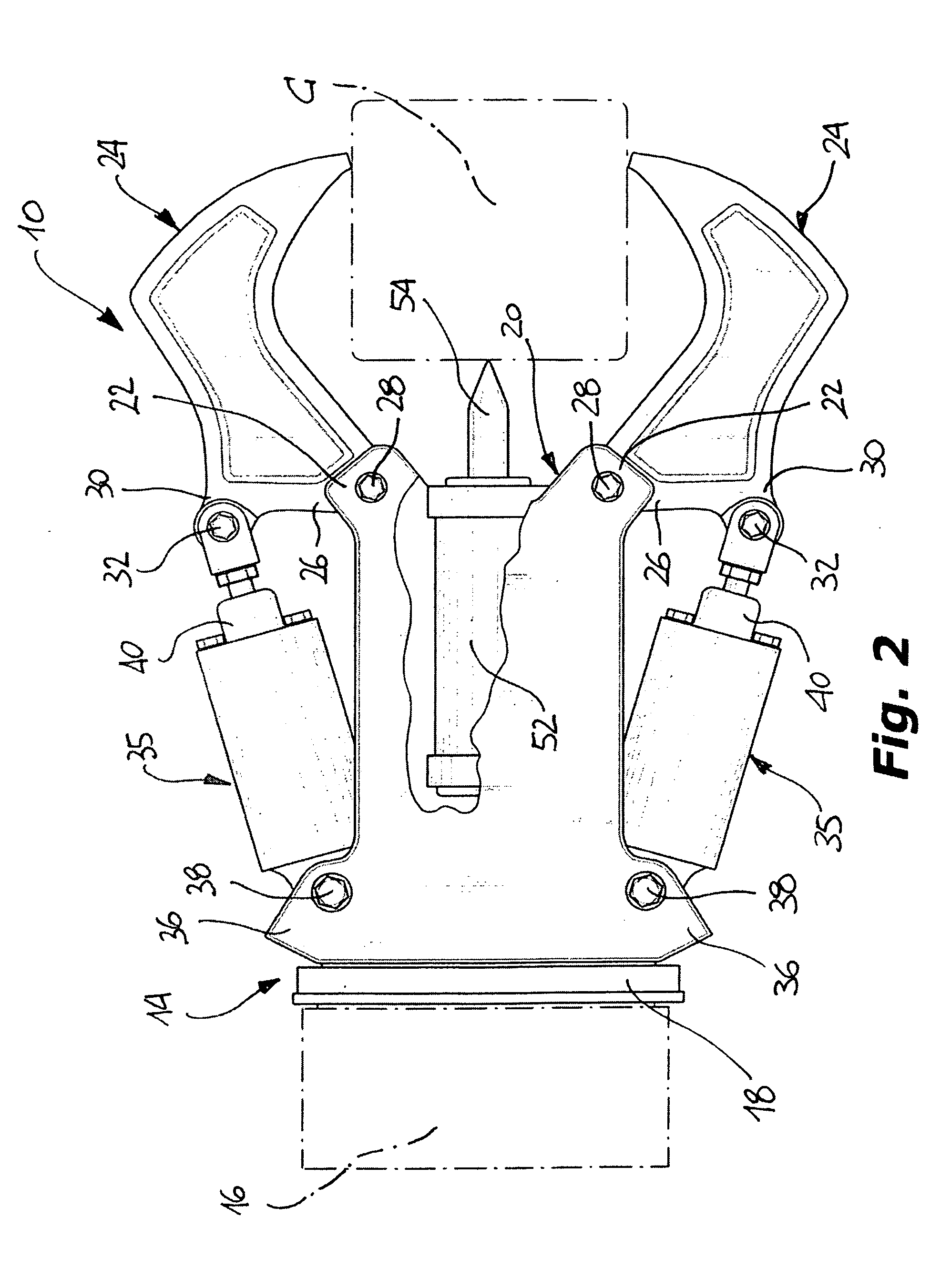

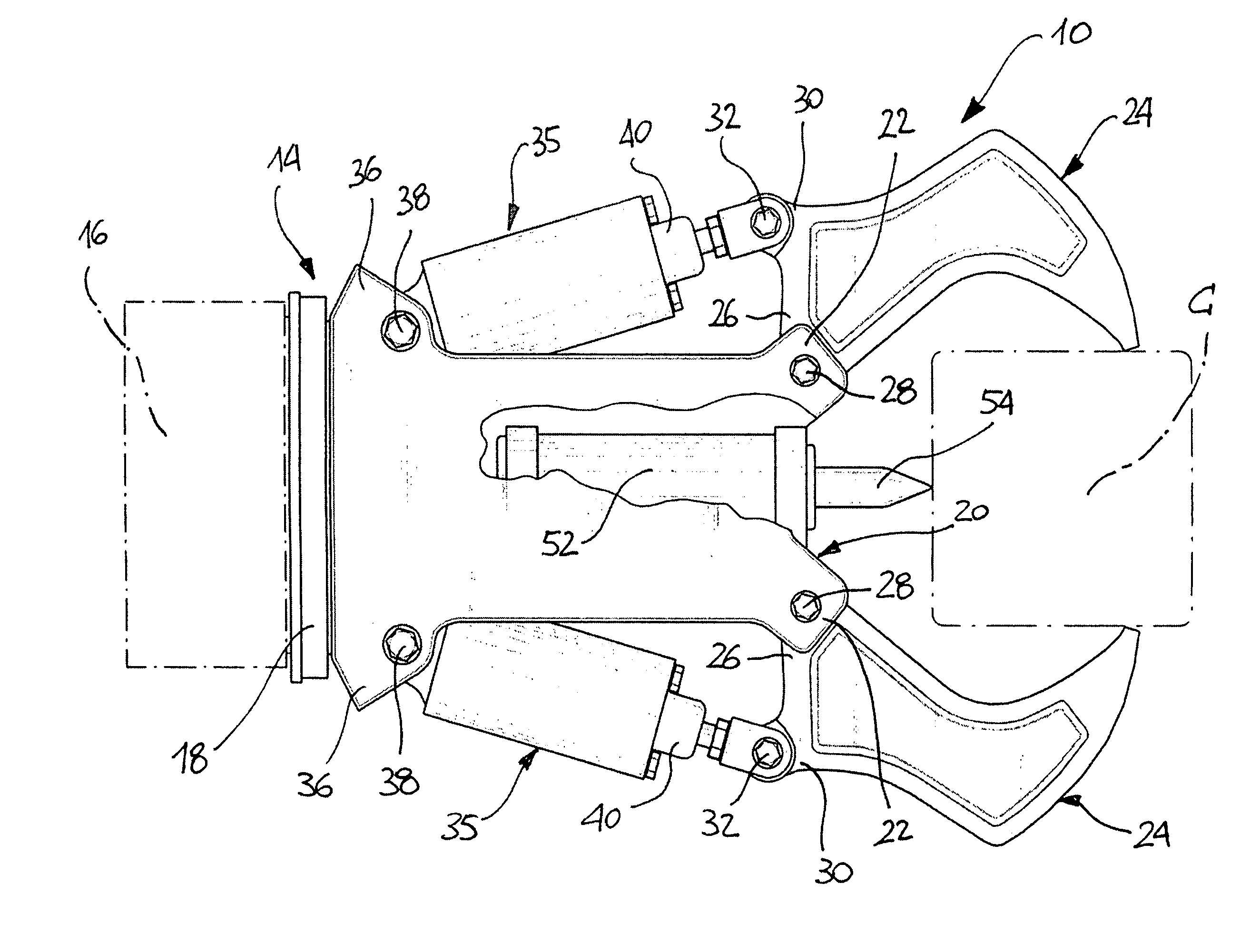

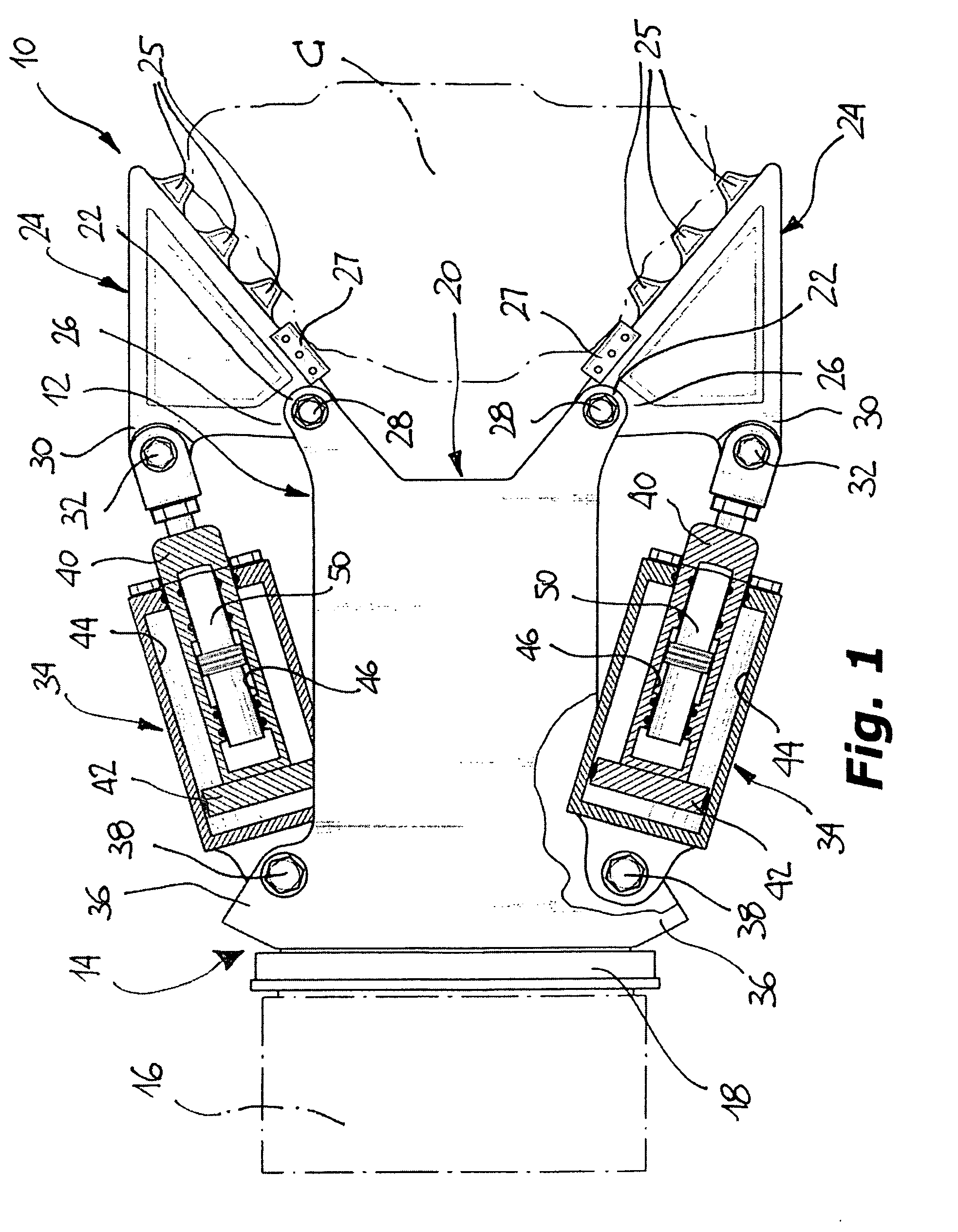

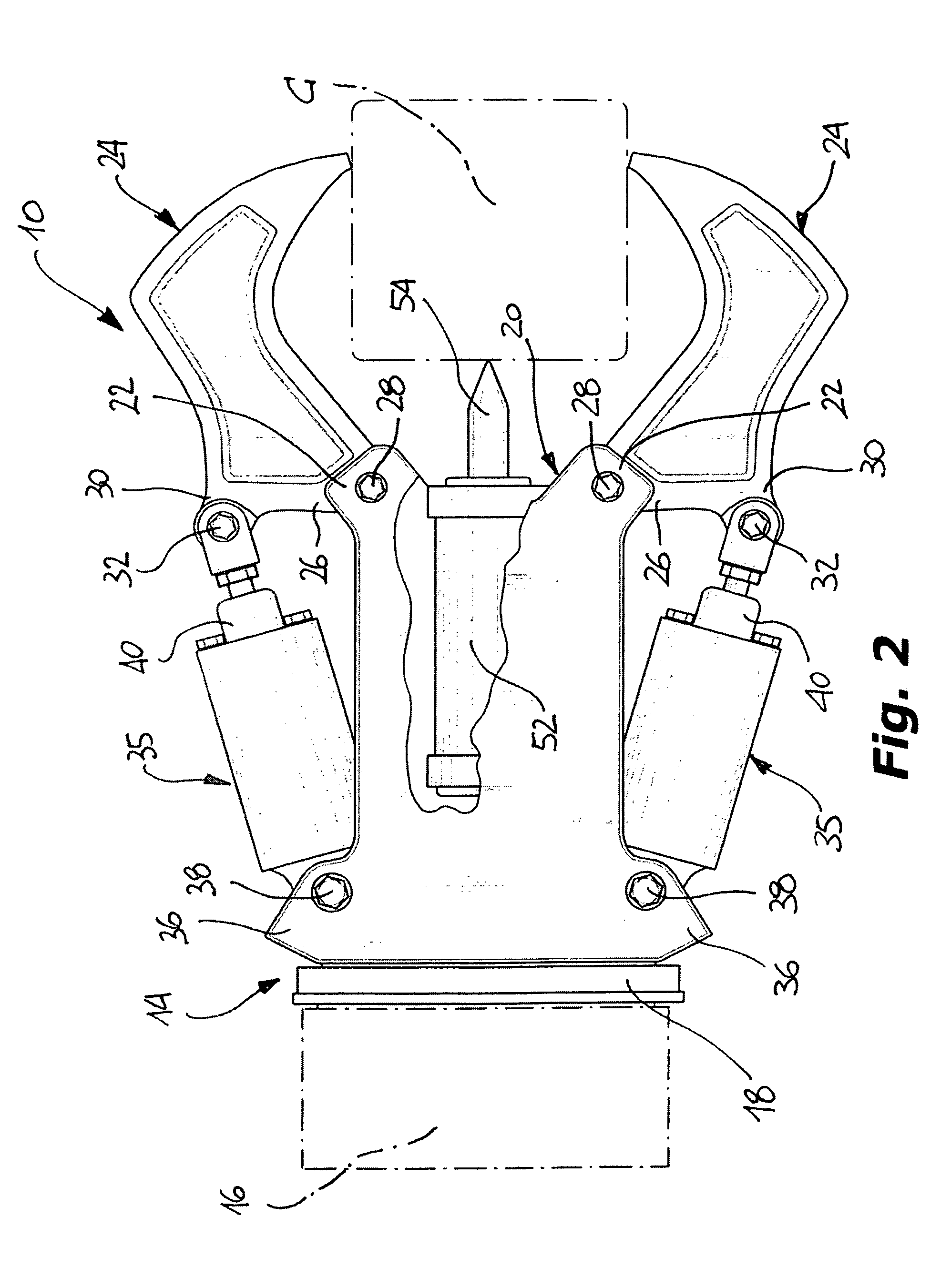

Crushing Apparatus for Demolition or Similar Works

Crushing apparatus for demolition or similar works A crushing apparatus for demolition works comprises a main body having a connecting portion intended to be connected to the end of a handling arm, and at least a swingable jaw articulated to the main body at a distal portion with respect to the connecting portion, which is adapted to allow, during a demolition work, that a member to be demolished is grasped. Actuator devices are interposed between each swingable jaw and the main body, which are intended to control the movement of the respective jaw. The apparatus comprises percussion devices adapted to carry out an action of percussion on a member to be demolished, while it is grasped by said at least one jaw.

Owner:CORIMAG

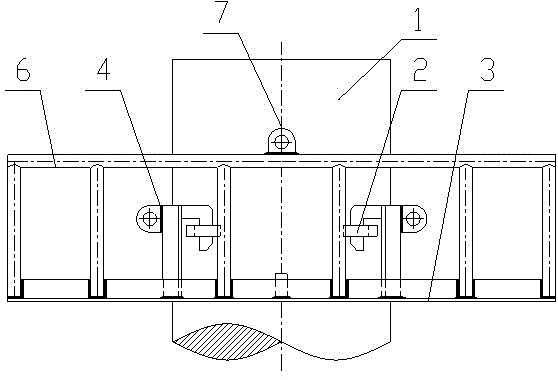

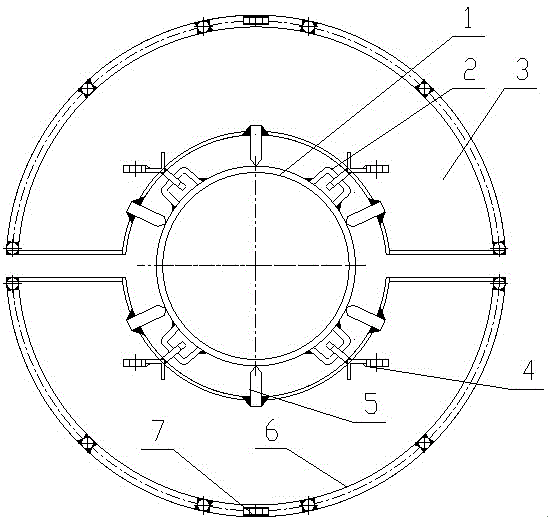

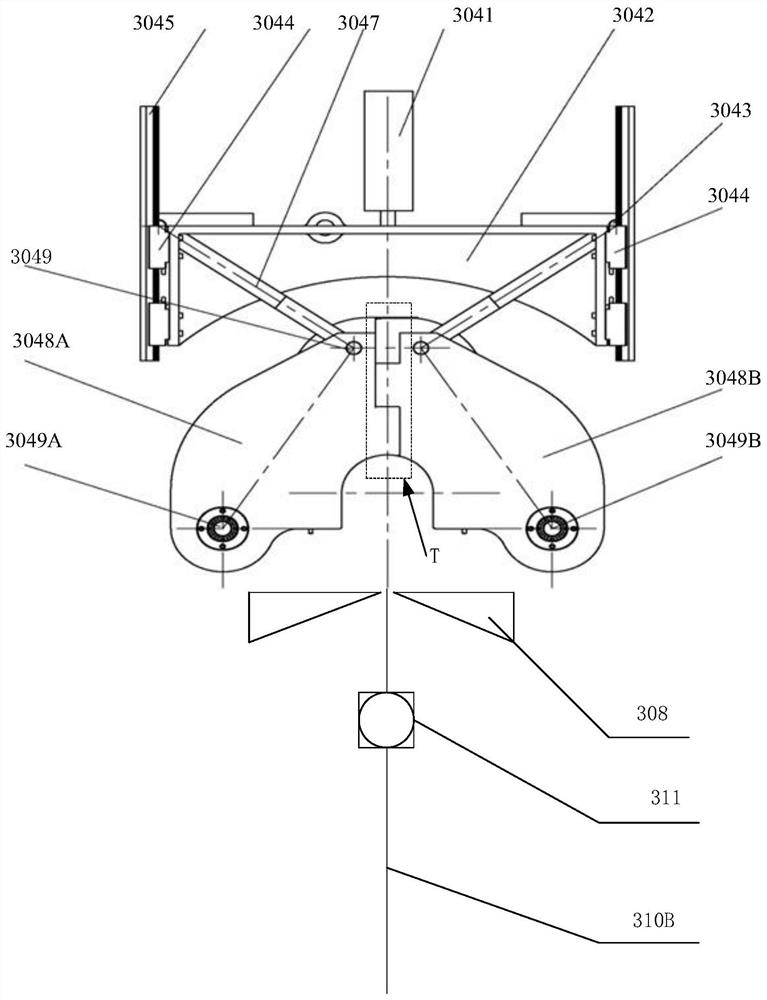

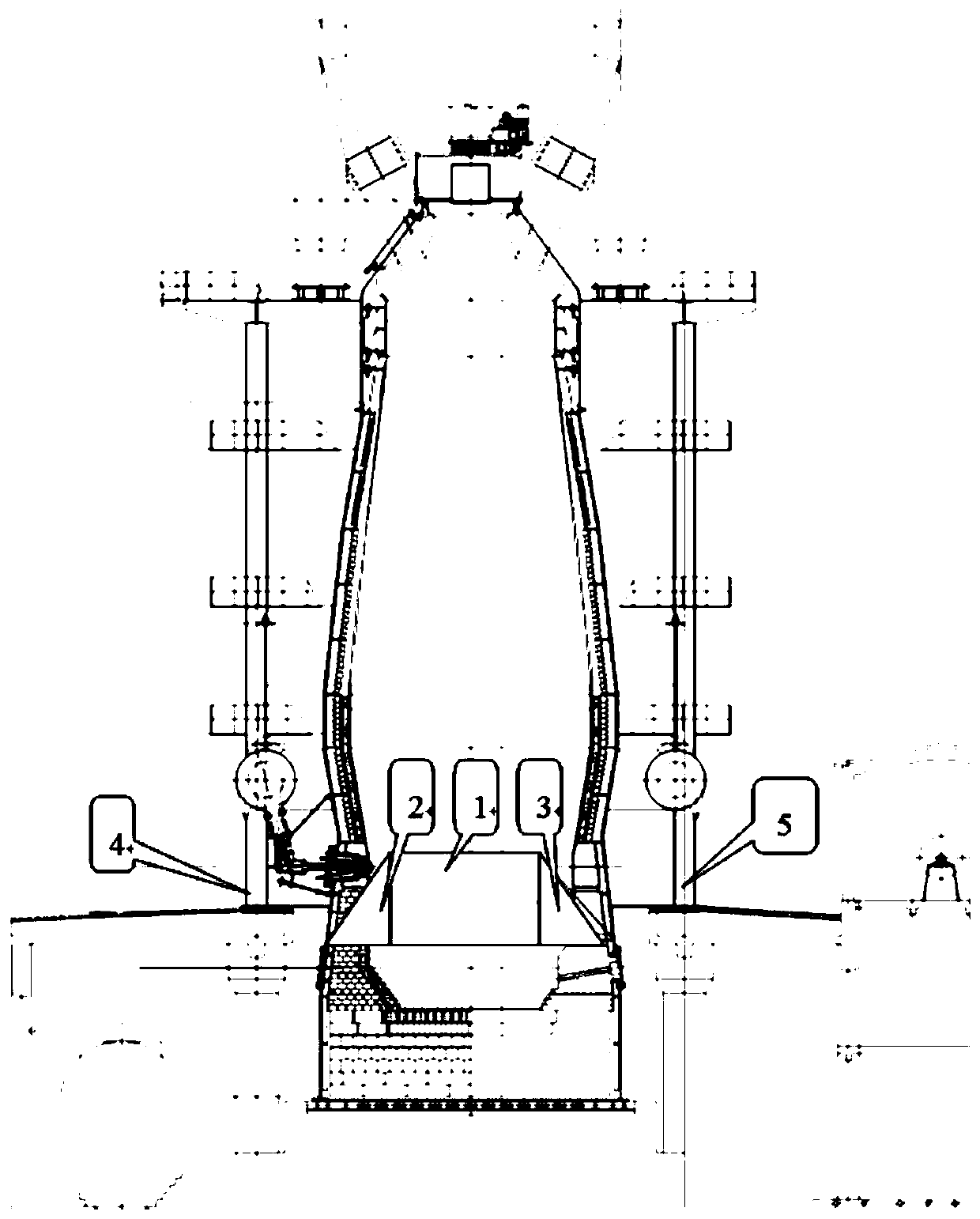

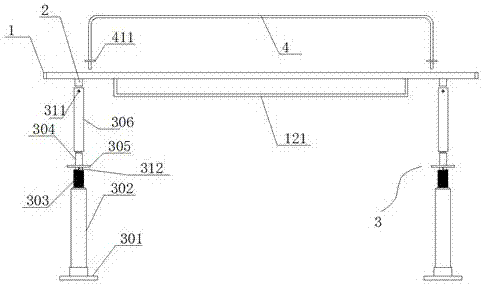

Special operation platform suitable for single pile offshore construction

InactiveCN104452715AReduce setup timeShorter dismantling timeArtificial islandsUnderwater structuresEngineeringOffshore construction

The invention provides a special operation platform suitable for single pile offshore construction. The platform comprises a single pile pipe and two platform bottom plates which are semicircular and surround the periphery of the single pile pipe, the inner ring edges of the platform bottom plates are hung on the outer wall of the single pile pipe, and railings are arranged on the outer ring edges of the platform bottom plates. Lug hooks are welded to the inner ring edges of the platform bottom plates through channel steel, inner hole hanging blocks are welded to the outer wall of the single pile pipe, lugs are arranged on the railings, and each lug is located between every two corresponding lug hooks which are in the same horizontal plane. By means of the operation platform, time for erecting or dismantling a temporary operating platform with piles arranged in the sea is greatly reduced, a lot of construction cost is reduced, and construction safety is guaranteed.

Owner:中石化胜利油建工程有限公司

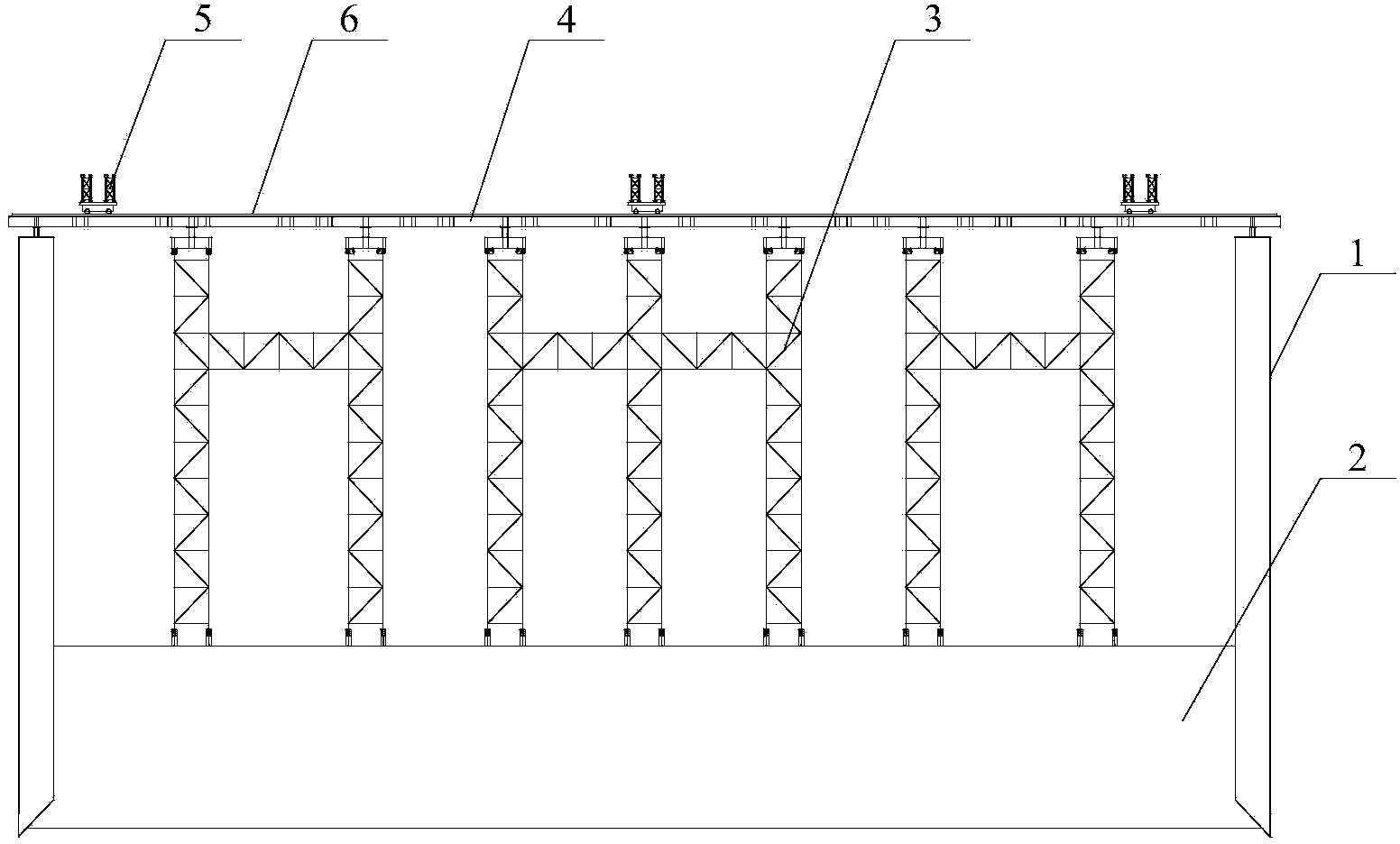

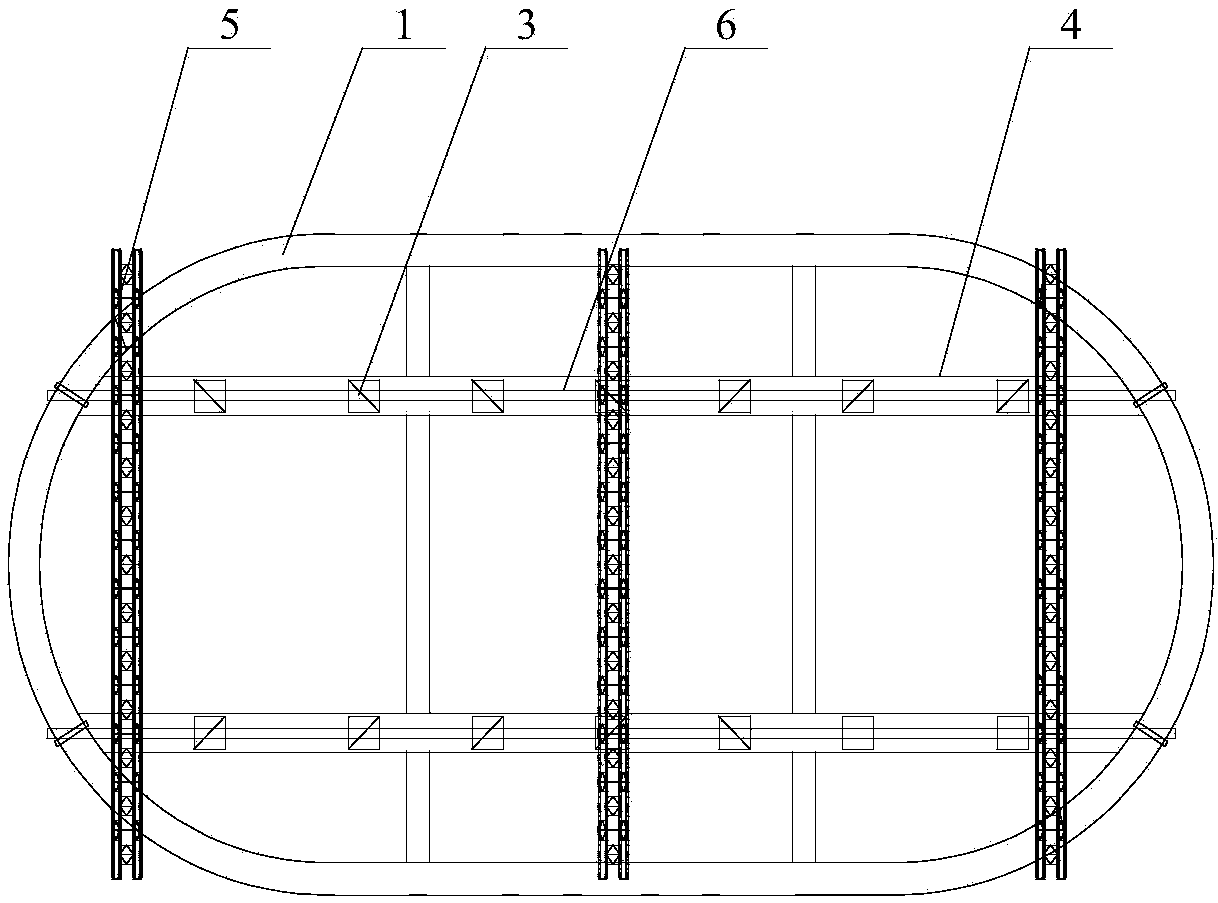

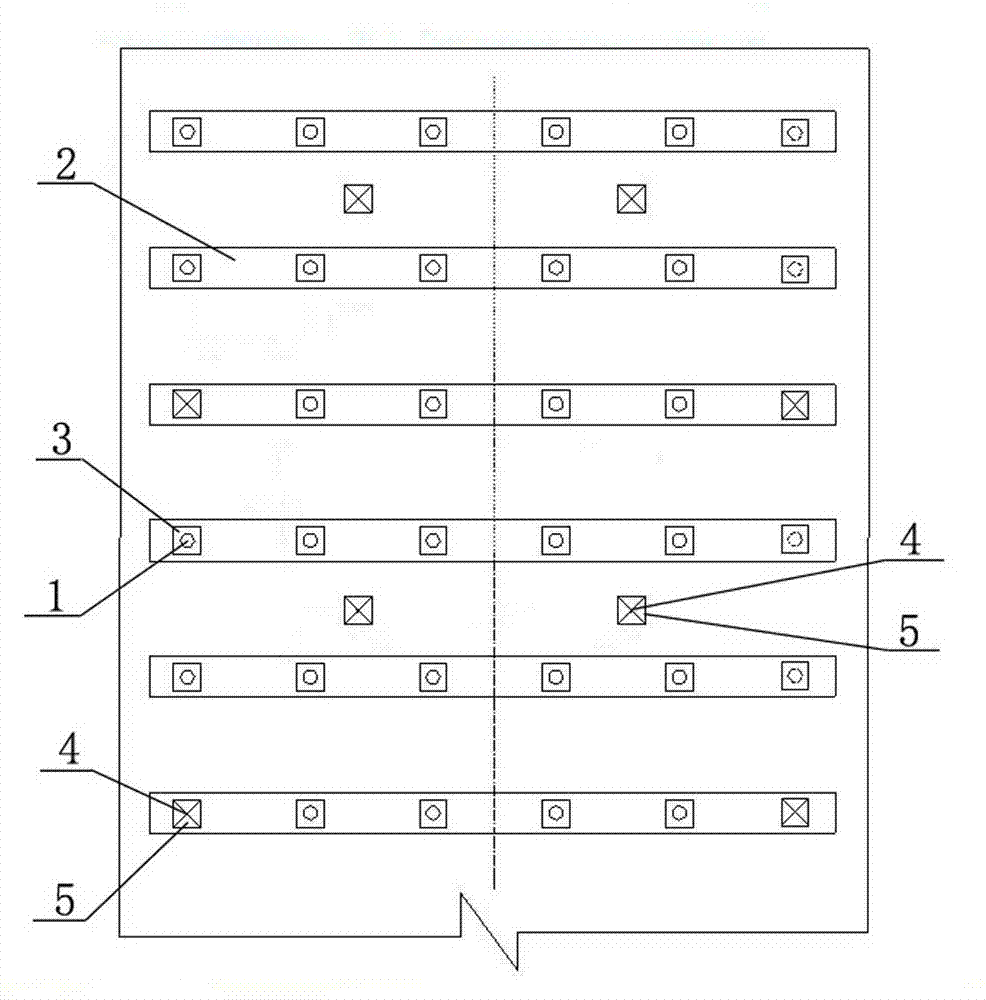

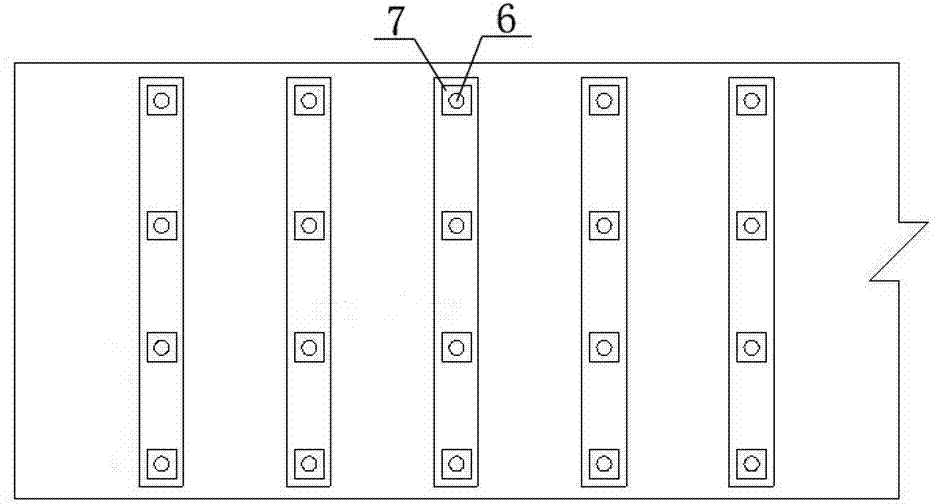

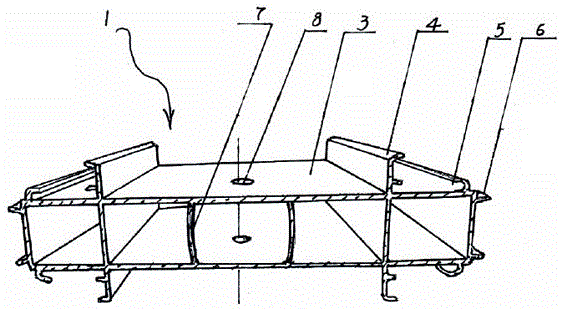

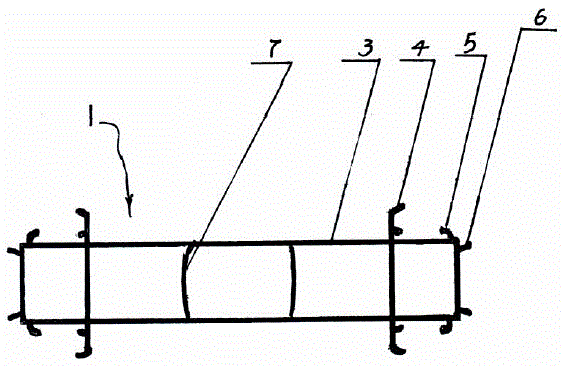

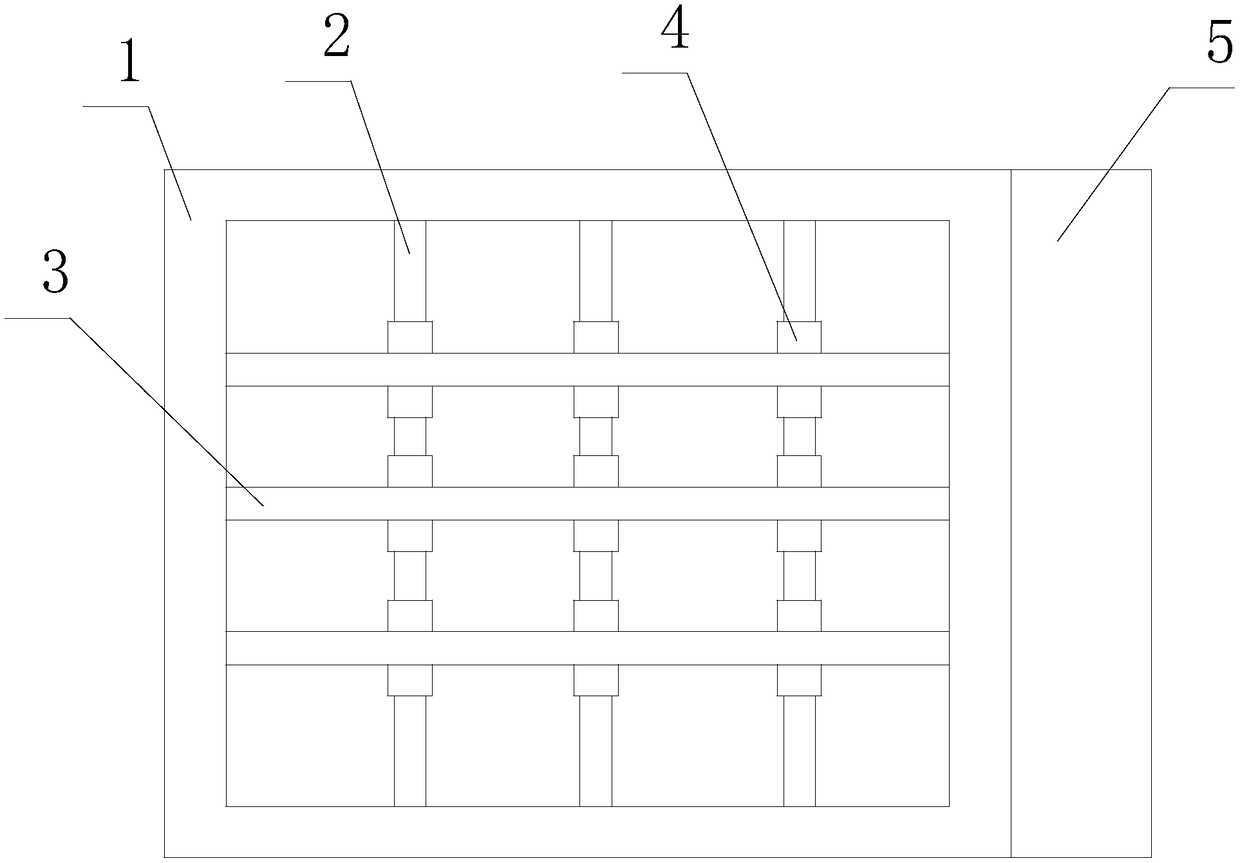

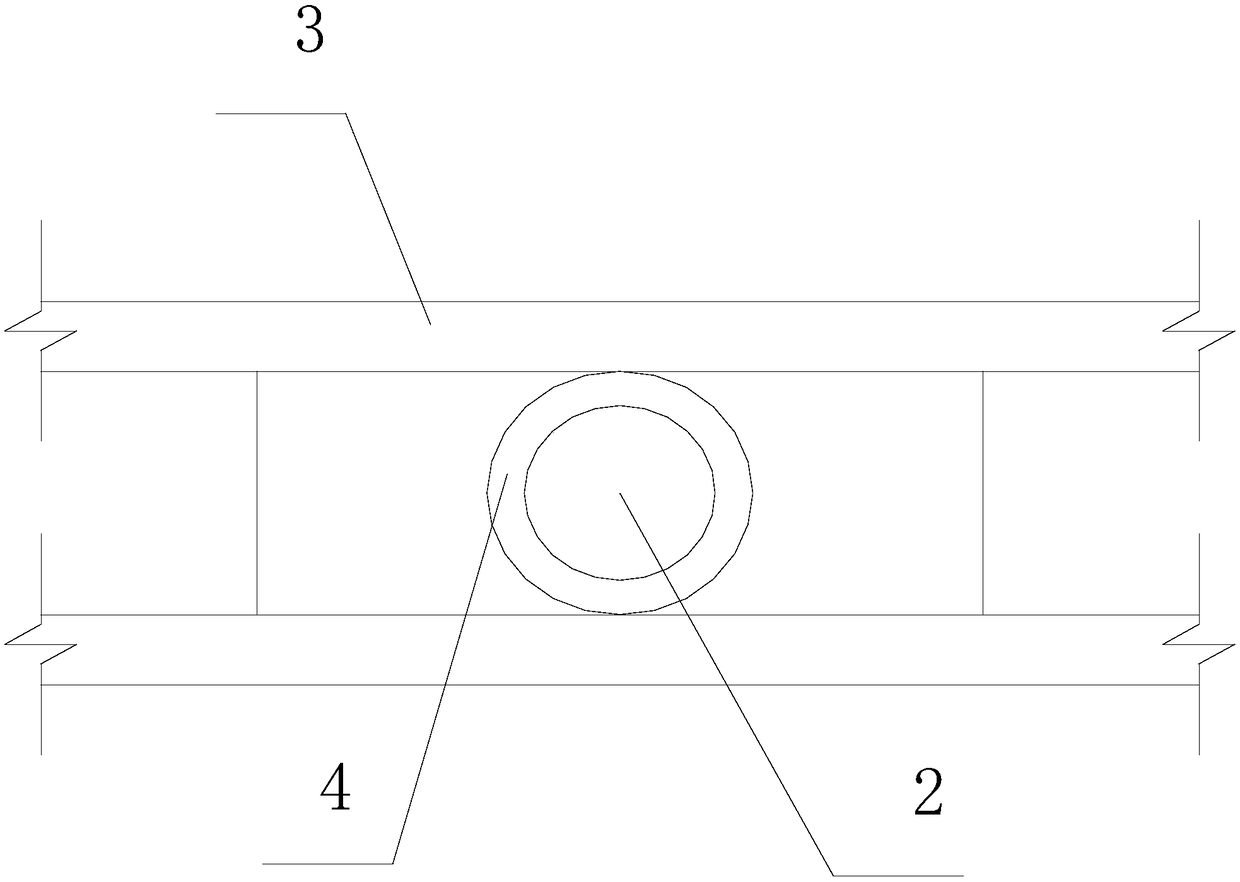

Double-wall steel cofferdam construction multifunctional platform and construction method thereof

ActiveCN103397649AShorter dismantling timeSave installation timeFoundation engineeringJoistDouble walled

The invention discloses a double-wall steel cofferdam construction multifunctional platform which adopts the scheme that a bottom isolation cabin is arranged at the bottom of the inner side of the steel cofferdam; a plurality rows of uprights vertical to the upper surface of the bottom isolation cabin are arranged on the bottom isolation cabin; a horizontal track beam is mounted at the tops of each row of the uprights; a steel rail parallel to each track beam is mounted at the top of each track beam; a moving joist barrow is arranged on each steel rail; a plurality of horizontal bearing beams are arranged on the inner wall of the steel cofferdam; drilling platform main beams are erected at the tops of the bearing beams, and are erected at the tops of the track beams; a plurality of vertical steel casings are mounted on the drilling platform main beams. According to the invention, the uprights and track beams fixed at the tops of the uprights are arranged inside the steel cofferdam, and a mud suction platform and a drilling platform can be erected on the track beams in sequence, so that mud suction platform dismantling time can be shortened, and drilling platform mounting time can be reduced; besides, the use quantity of steel materials can be reduced and manufacturing cost is reduced as the mud suction platform and the drilling platform can be combined.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

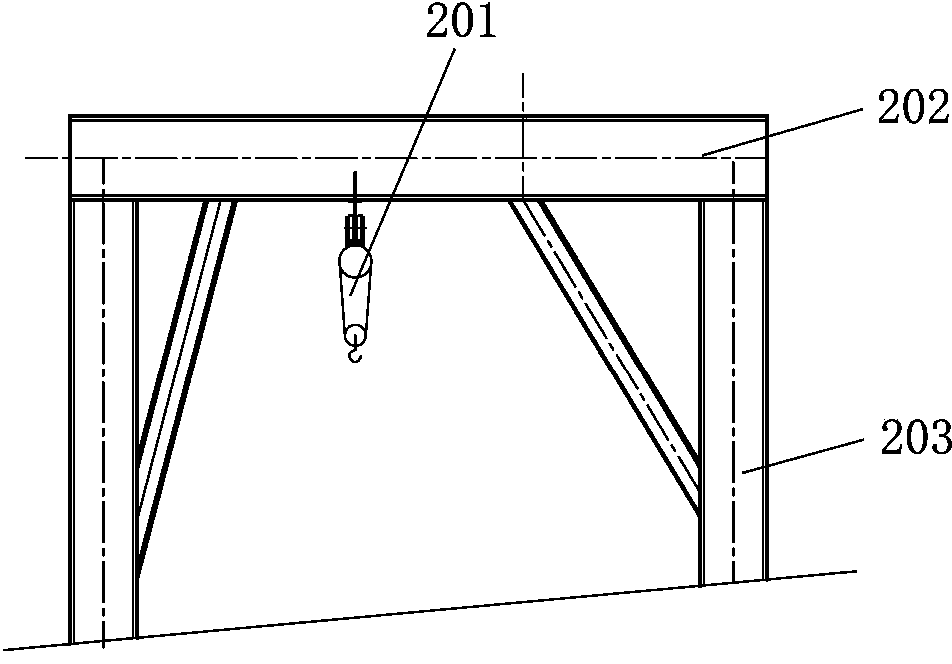

Rake type lifting frame and dismantling method for reinforced concrete groove-shaped roof boards

InactiveCN103741964AShorter dismantling timeImprove work efficiencyBuilding repairsReinforced concreteRebar

The invention discloses a rake type lifting frame and a dismantling method for reinforced concrete groove-shaped roof boards. The dismantling method for the reinforced concrete groove-shaped roof boards can conveniently dismantle the roof boards. The rake type lifting frame comprises two base supports, two inclined supports, two vertical supports and a plurality of horizontal supports; the two base supports which are horizontally arranged in a mutually parallel mode are arranged on external side at opposite two ends in the length direction of the roof boards to be dismantled; one ends of the two inclined supports and one ends of the two base supports are fixed; one ends of the two inclined supports upwardly extend obliquely in a mutually parallel mode; the length of the two vertical supports is identical; the two vertical supports are fixedly connected between the fixed base supports and inclined supports to support the inclined supports; the plurality of horizontal supports are connected between the two base supports and the two inclined supports; portions of the two inclined supports, which upwardly extend obliquely from connecting points of the vertical supports, are provided with two manual hoists which are used for lifting the roof boards; the horizontal distance between the two manual hoists which are arranged on the same inclined support is less than the width of the rood boards.

Owner:PANGANG GRP ENG TECH

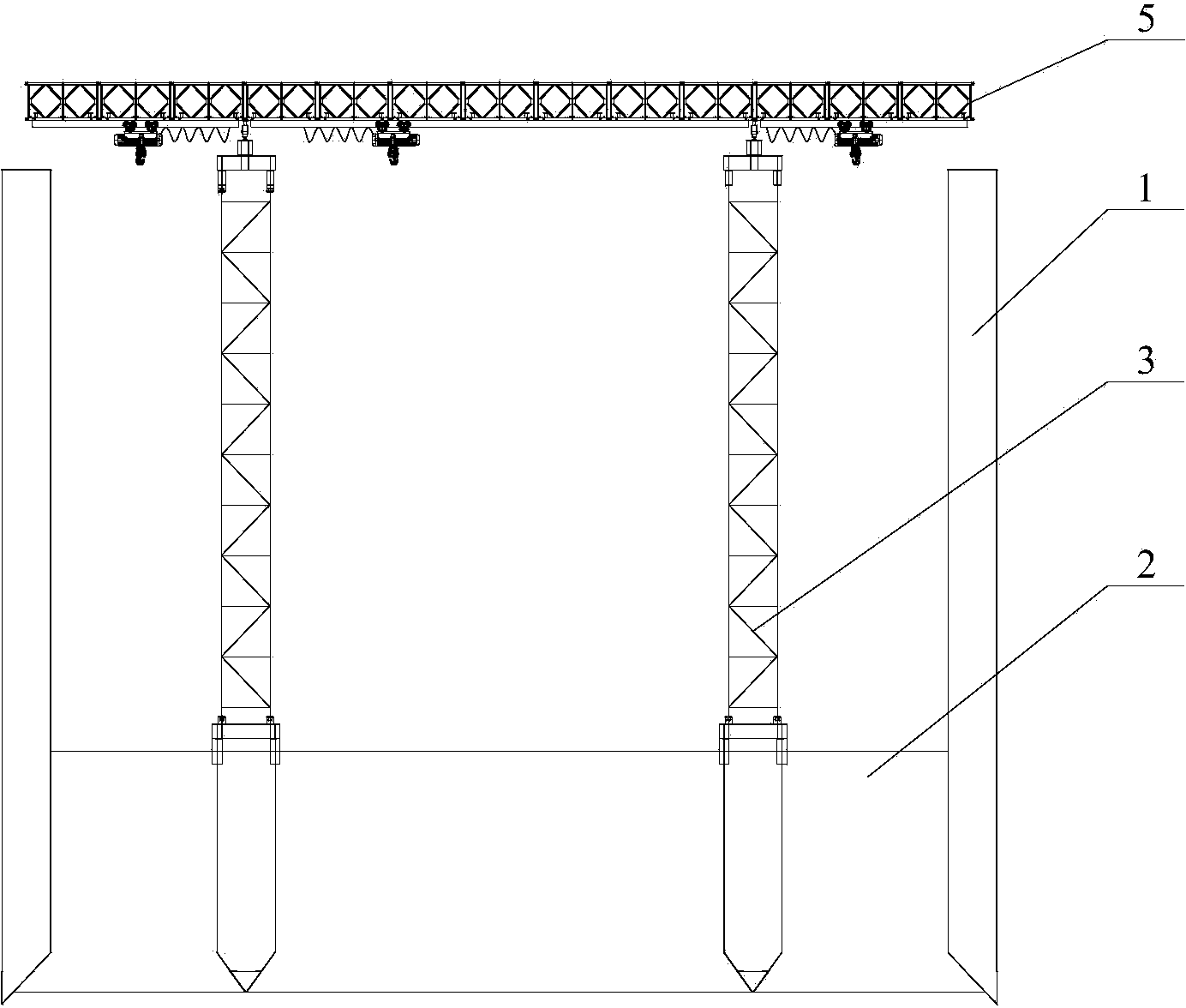

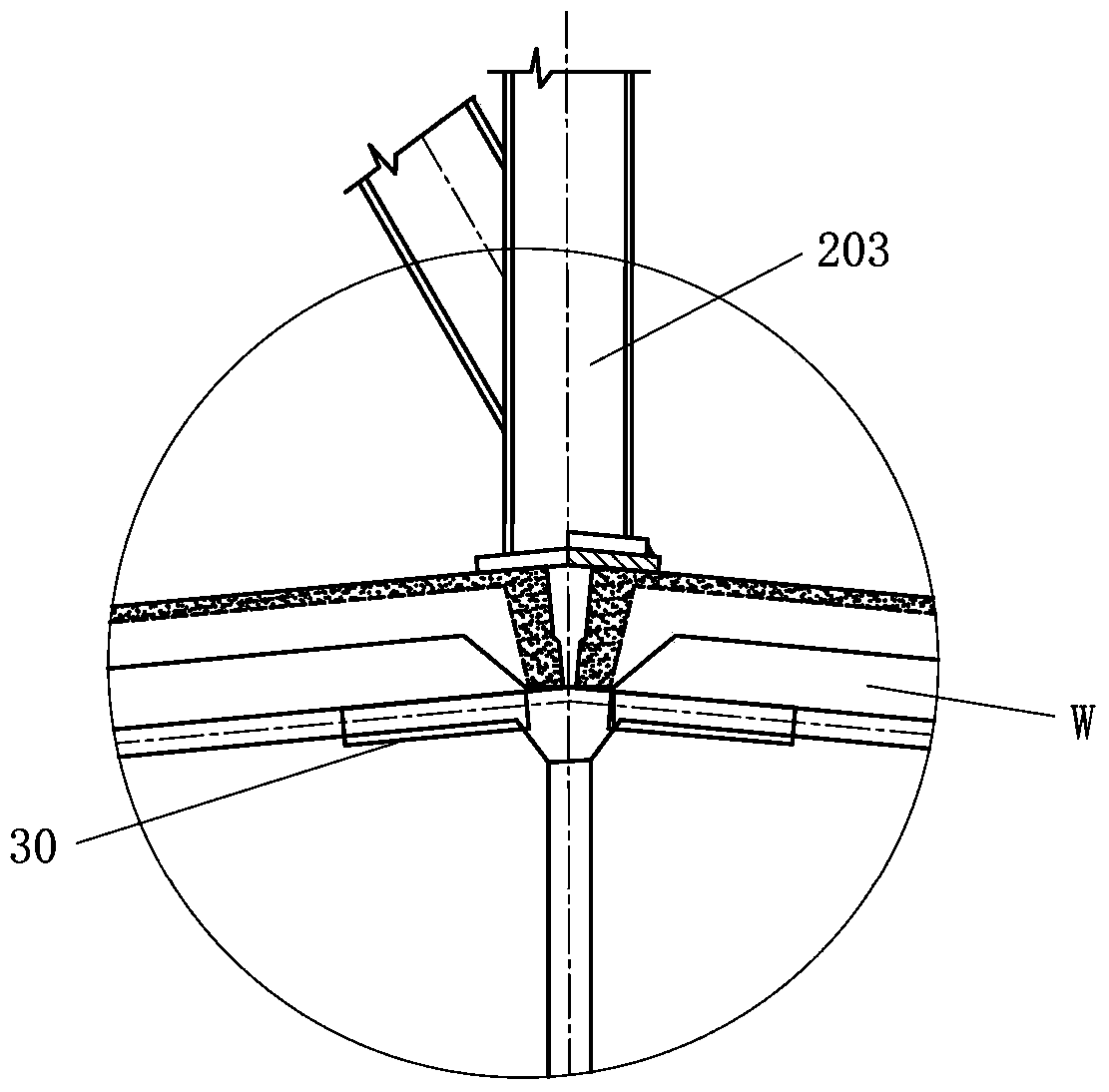

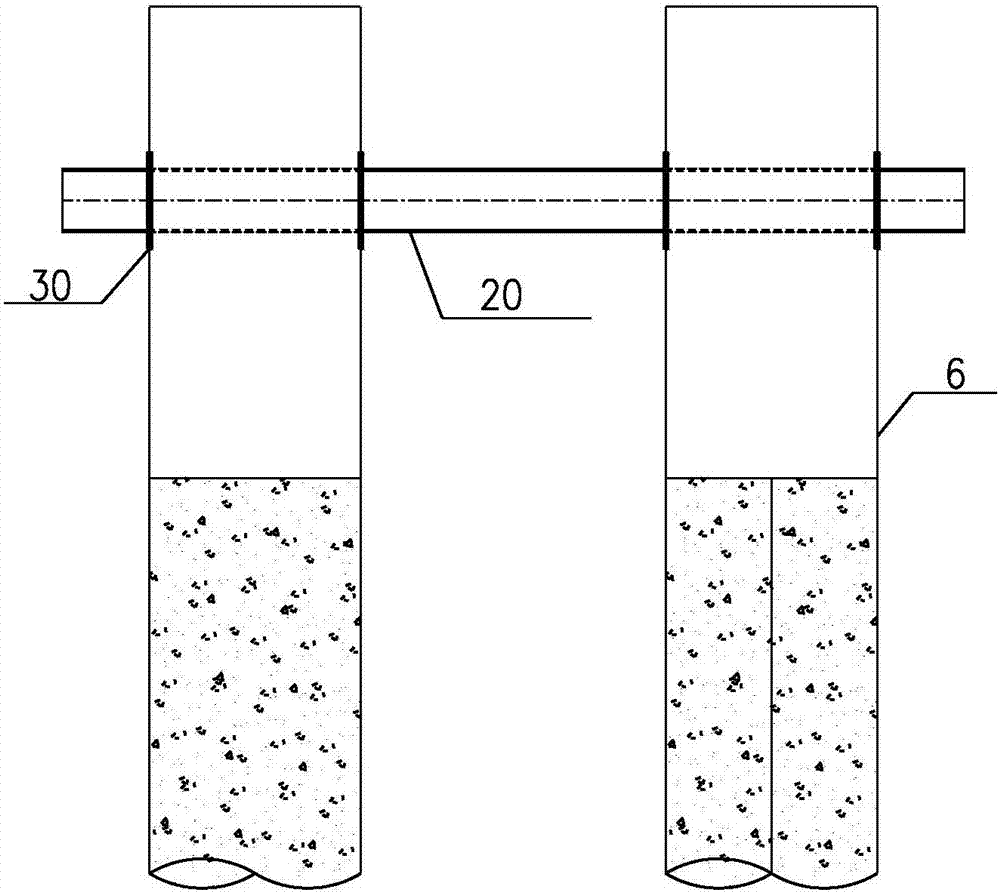

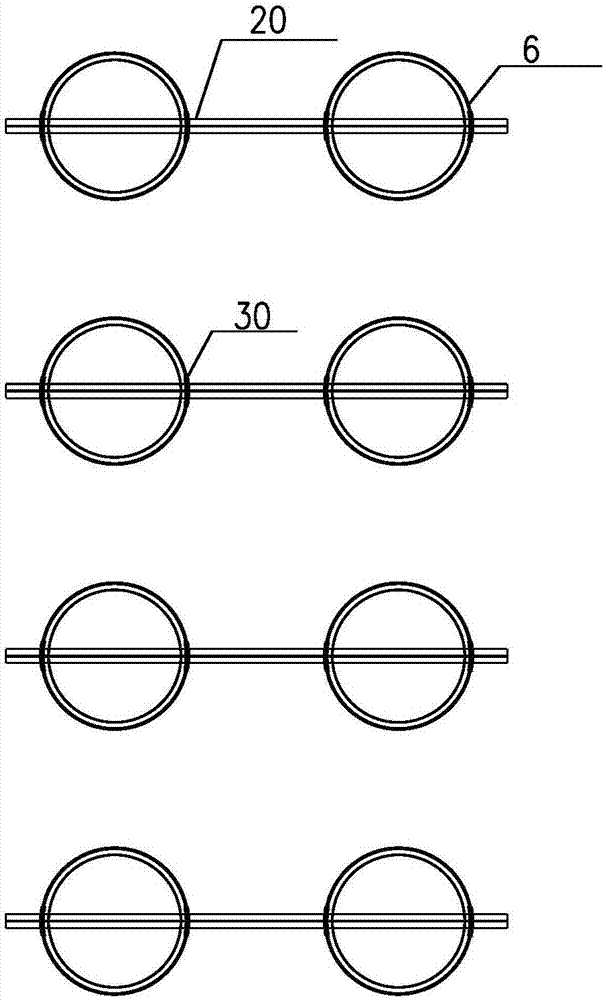

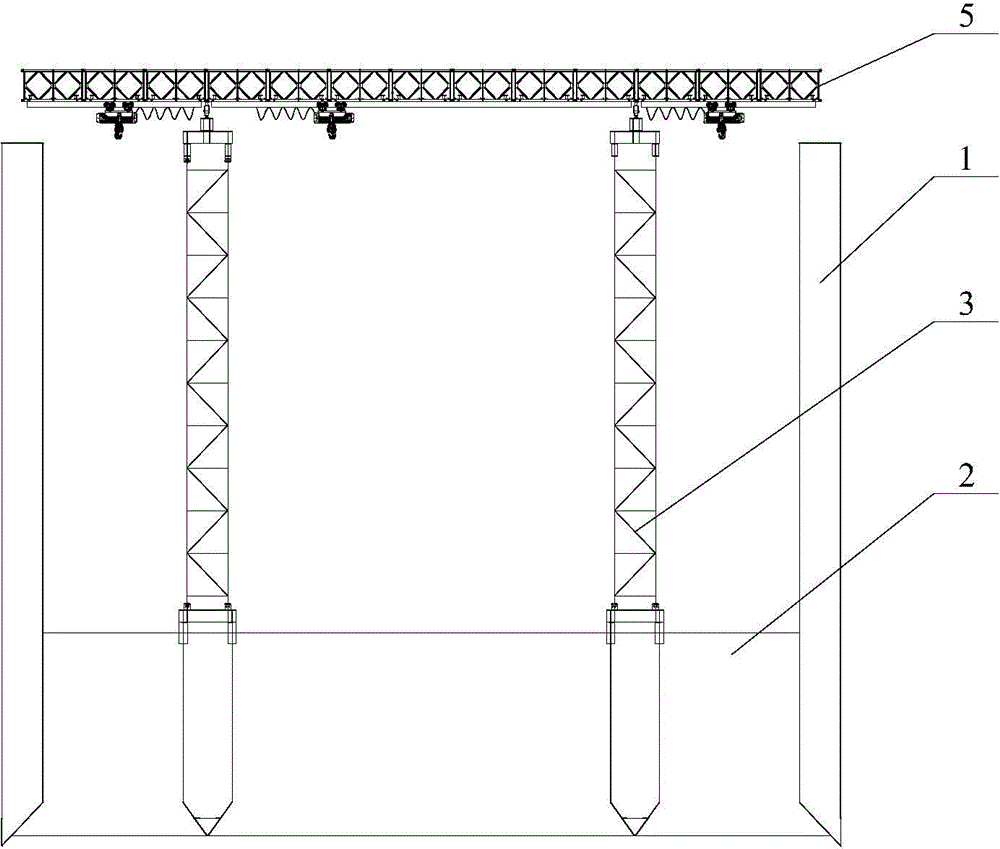

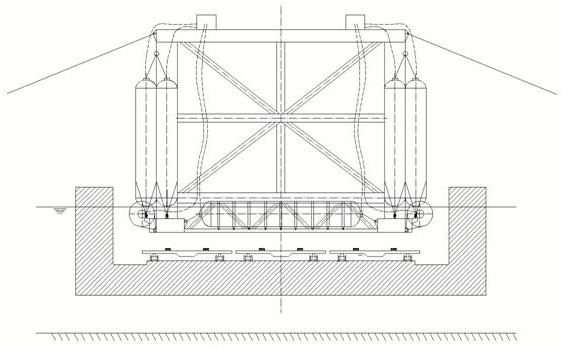

Steel suspension box hoisting system with integral hoisting function and hoisting method of steel suspension box hoisting system

ActiveCN107142954AReduce security risksReduce serious safety hazardsArtificial islandsUnderwater structuresCantileverMechanical engineering

The invention discloses a steel suspension box hoisting system with an integral hoisting function and a hoisting method of the steel suspension box hoisting system, and belongs to the field of sub-beam structure construction. The steel suspension box hoisting system comprises a steel suspension box and an assembly platform of the steel suspension box, wherein the assembly platform comprises a plurality of steel protective cylinders and a plurality of platform beams; penetrating open pores are prefabricated on the protective cylinder walls of all the steel protective cylinders; positioning-guiding mechanisms are arranged at the open pores of all the steel protective cylinders; a whole row of steel protective cylinders movably penetrate through each platform beam through the open pores of the steel protective cylinders; the two ends of each platform beam are exposed from the steel protective cylinders arranged at the two ends of the row; and the steel suspension box comprises the following four parts: a baseplate structure, a wall body structure, cantilever beams, as well as laterally stable supports and section steel suspension rods. By adoption of the steel suspension box hoisting system disclosed by the invention, the safety risk of detaching the assembly platform can be reduced; the time to establish and detach the assembly platform can be shortened to the greatest extent, the work efficiency can be improved, and the engineering progress can be accelerated; materials adopted for the assembly platform can be recycled to the greatest extent; and meanwhile, the difficulty in hoisting construction of the steel suspension box and the labor consumption can be reduced, the construction period can be shortened, and the mounting precision can be easier to control.

Owner:CCCC SHEC FOURTH ENG +1

Precasting of fabricated flumes for machining coolant systems

A method and apparatus for constructing machinery flumes couples precast, fabricated sections of flume having a channel lining in a concrete cast. The sections are assembled to seal end to end forming a continuous trough in which assembly work is contained to reduce installer exposure, reduce field installation time and reduce construction costs for flume systems. Preferably, an end of a lining extends beyond the cast sheath for connection with an overlapped portion of an adjacent precast section's lining.

Owner:ARISTEO CONSTR

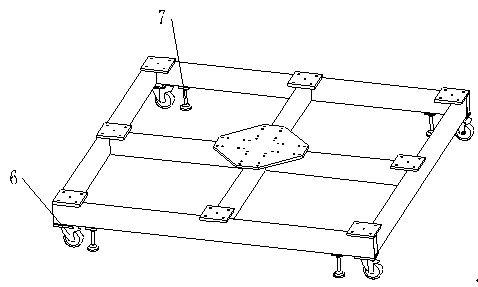

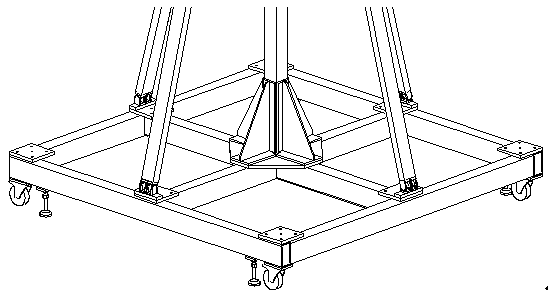

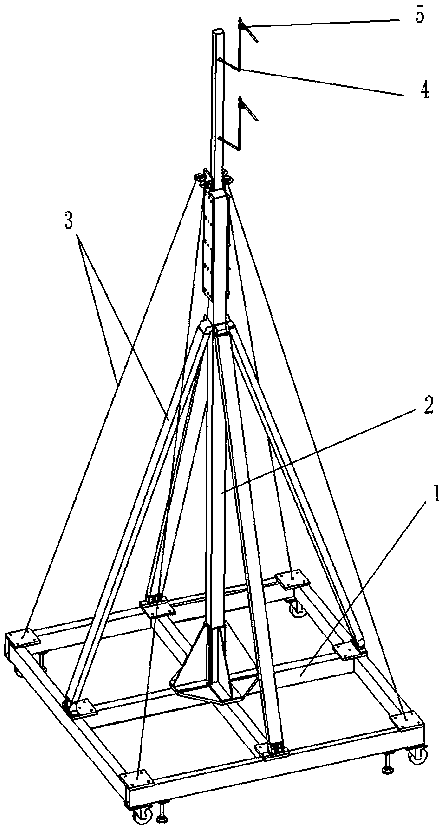

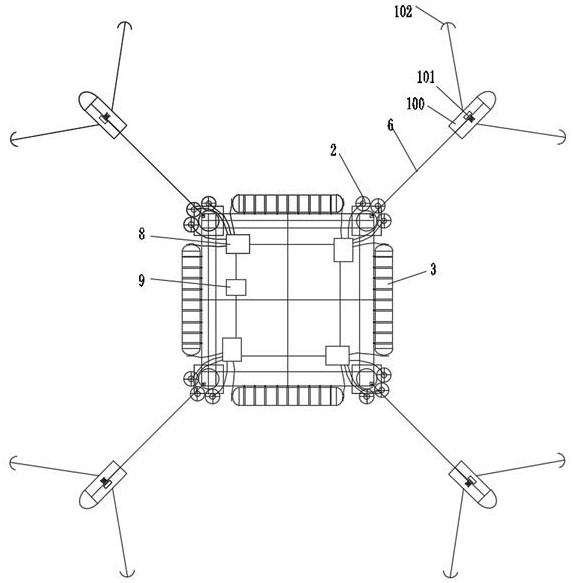

Assembly type multifunctional microphone array frame device

InactiveCN109640202AEasy to storeEasy to transportTransducer casings/cabinets/supportsEngineeringMicrophone array

The invention discloses an assembly type multifunctional microphone array frame device. The device comprises bases and supporting frames set on the bases. Each supporting frame comprises a supportingvertical post and a plurality of array units which are connected with the supporting vertical post. Each array unit is formed by splicing a plurality of supporting rods with the same structure. The supporting rods and the supporting vertical posts are the same in structure. Sliding slots for positioning and fixing are set on each face. Struts for fixing microphones are set in the sliding slots. Locations of the microphones can be adjusted through sliding of the struts. Compared with a conventional array frame, the assembly type multifunctional microphone array frame device has the major advantage of disassembly. Huge array frames can be stored easily, so relatively high space waste is avoided. Proximate matters are taken as major components of the array frames, so the array frames can be randomly combined, the same supporting frames can be combined into the array frames satisfying different shape requirements, and different wind tunnel tests are satisfied.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

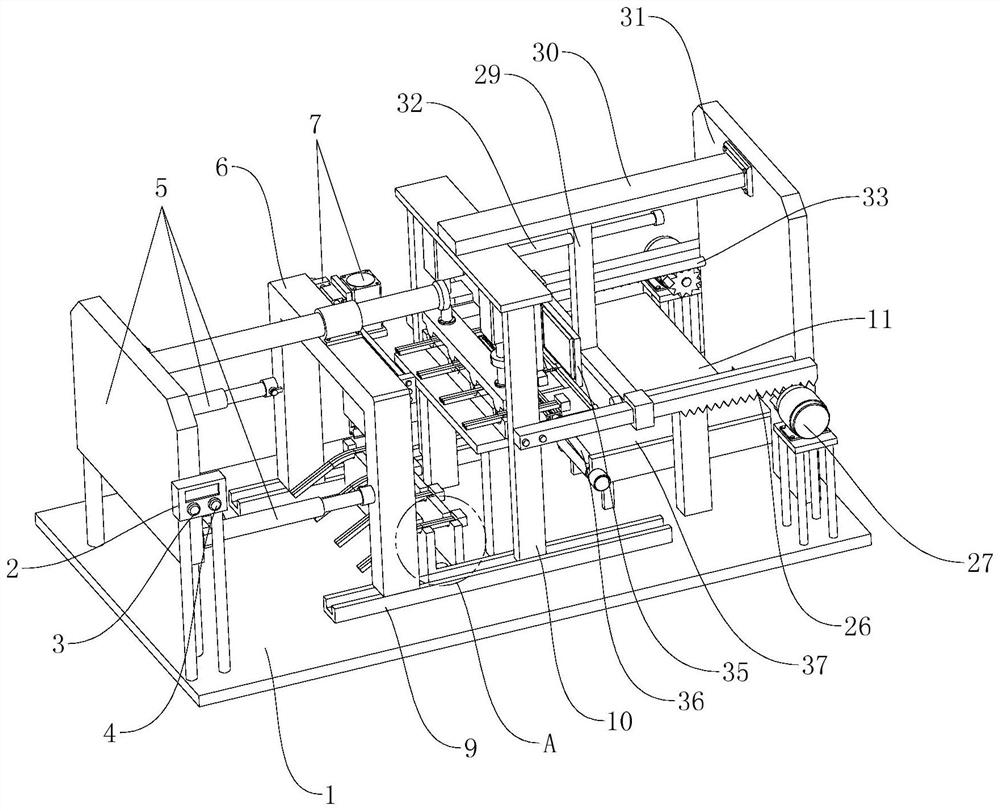

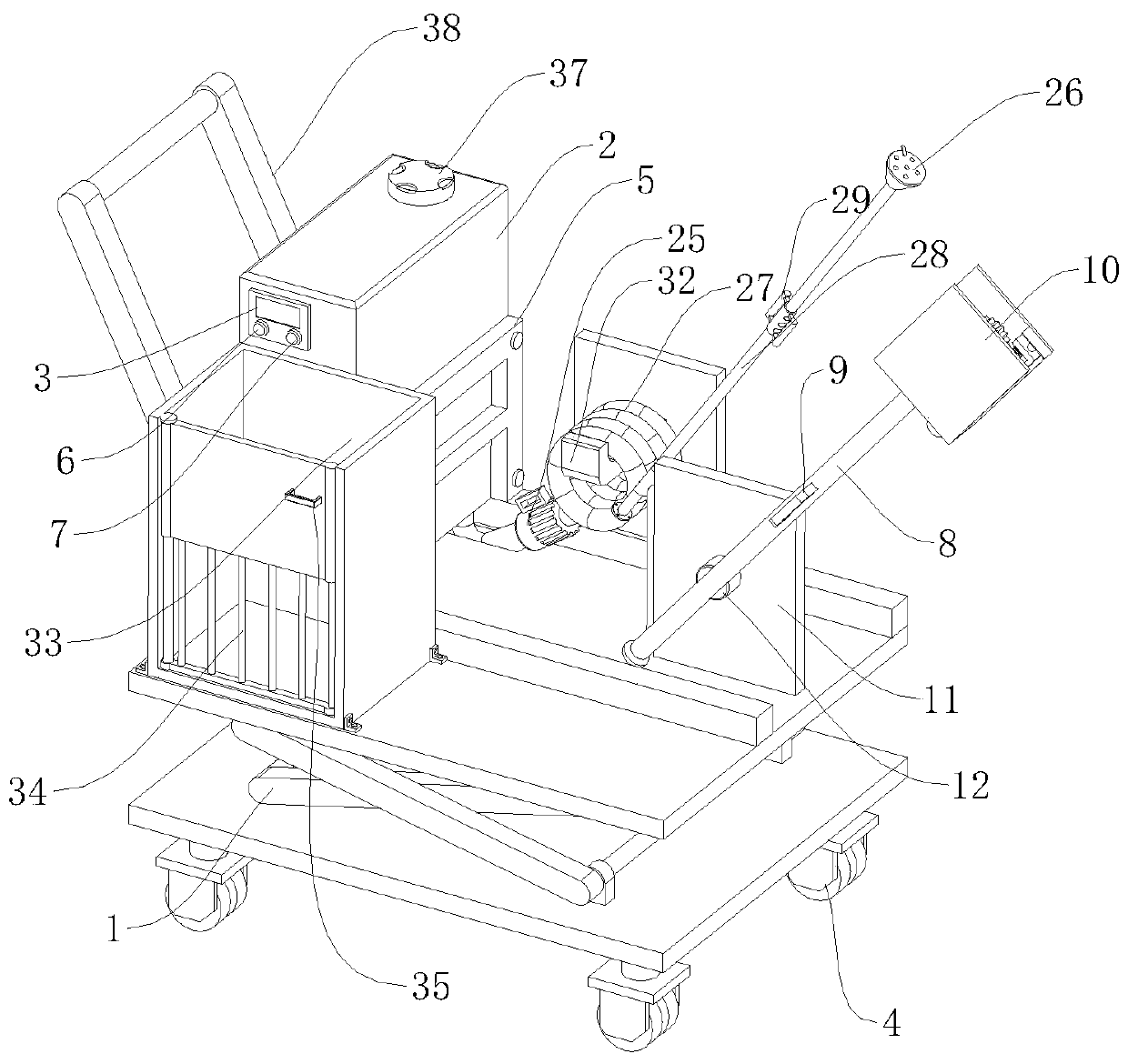

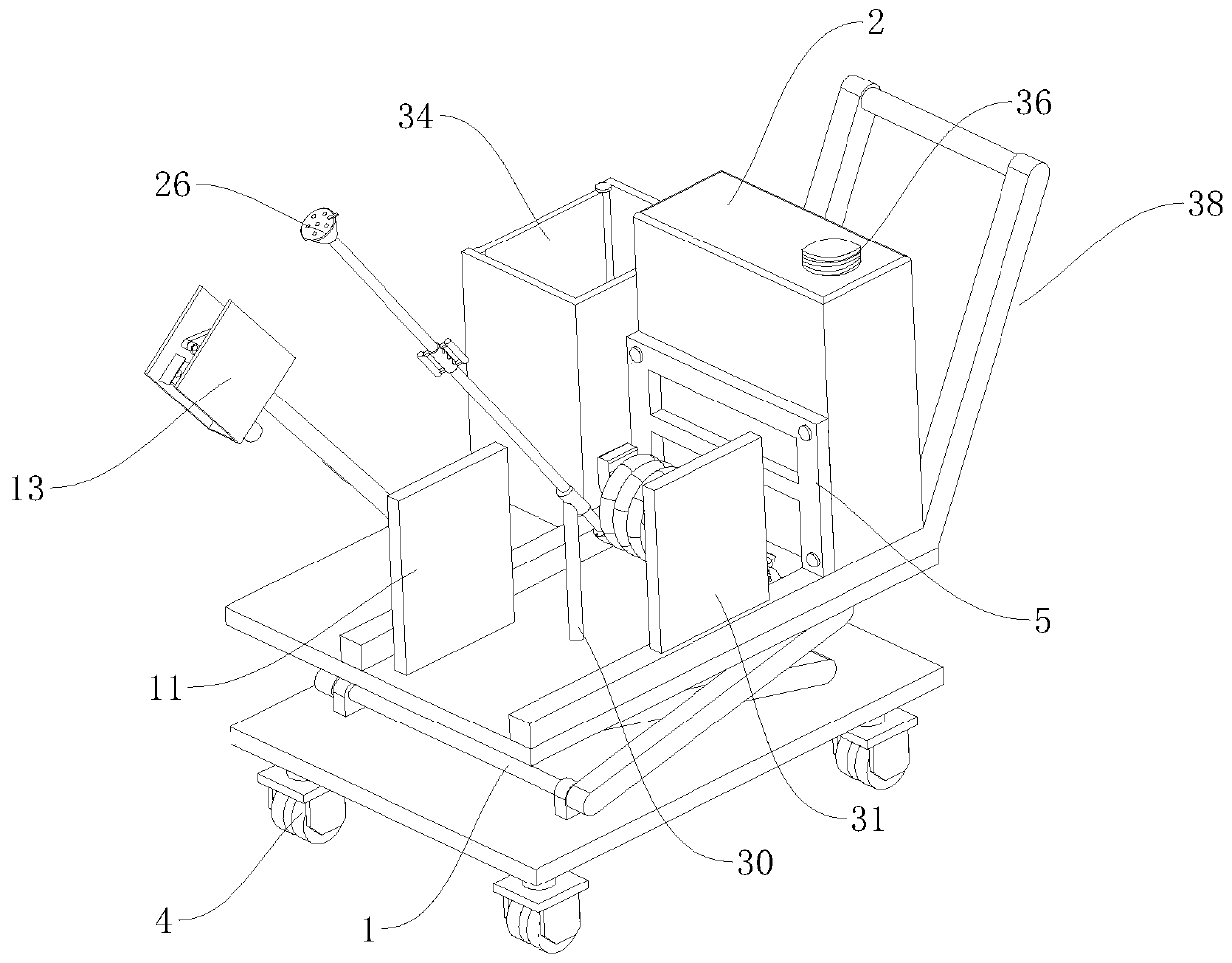

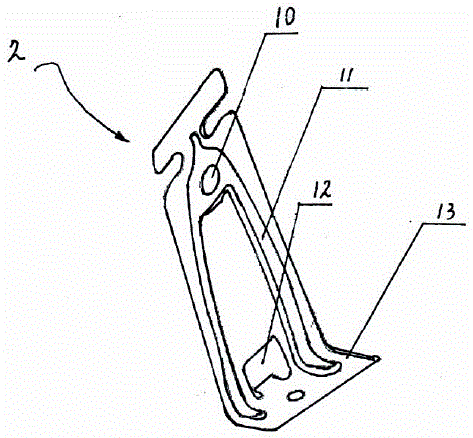

Terminal dismounting device for automobile wire harness recovery

InactiveCN111653912AReduce laborSave loading timeVehicle connectorsLine/current collector detailsCable harnessElectrical and Electronics engineering

The invention relates to the field of dismantling equipment, and specifically relates to a terminal dismounting device for automobile wire harness recovery. The device comprises a base and a controller. The device further comprises a feeding mechanism, a stripping mechanism and a discharging mechanism. The feeding mechanism is arranged at one end of the top of the base so as to feed the automobilewire harness to the stripping mechanism. The stripping mechanism is arranged beside the feeding mechanism so as to strip the terminals of the automobile wire harness fed by the feeding mechanism. Thedischarging mechanism is arranged below the stripping mechanism so as to discharge the automobile wire harness of which the terminal is removed. The feeding mechanism comprises a pushing assembly, aninverted-U-shaped supporting rod, a driving assembly and a clamping assembly. The stripping mechanism comprises an inverted-U-shaped supporting frame, a supporting table, a pressing assembly and a sliding assembly. According to the terminal dismounting device for automobile wire harness recovery, manual dismounting is replaced with automatic equipment, automobile wire harness terminals can be dismounted in batches, meanwhile, the terminal dismounting device has the discharging function, convenience and practicability are achieved, the dismounting time is saved, and the production cost of enterprises and factories is saved.

Owner:叶连波

Building construction formwork dismantling method

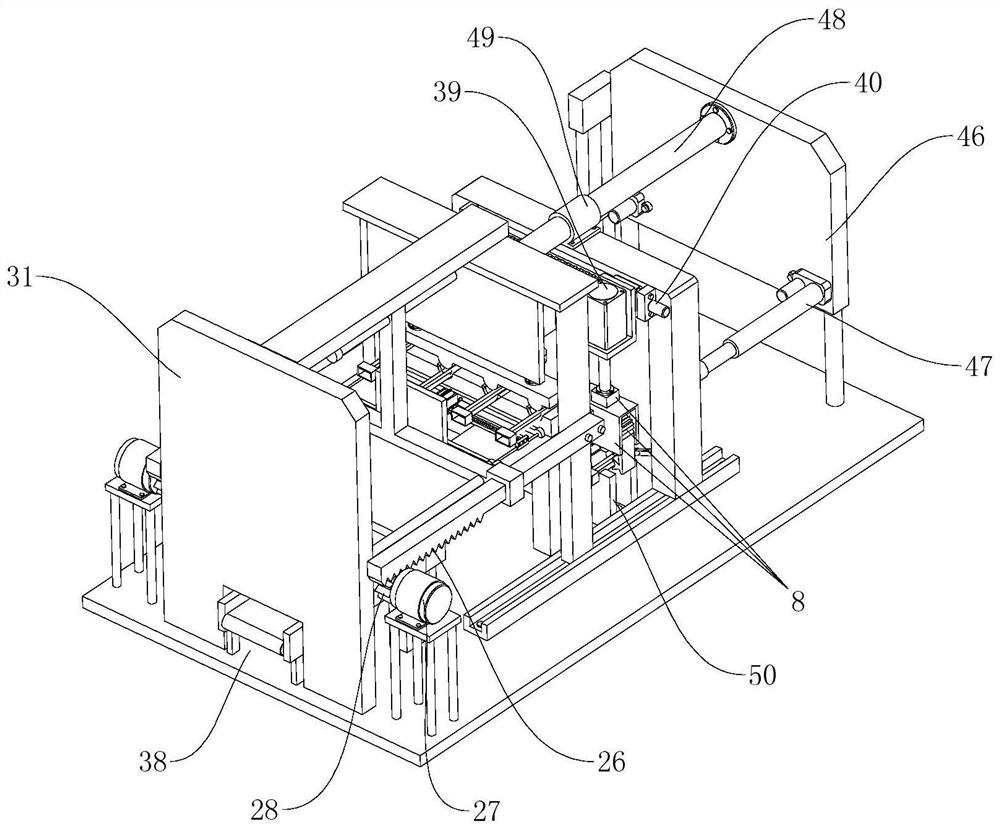

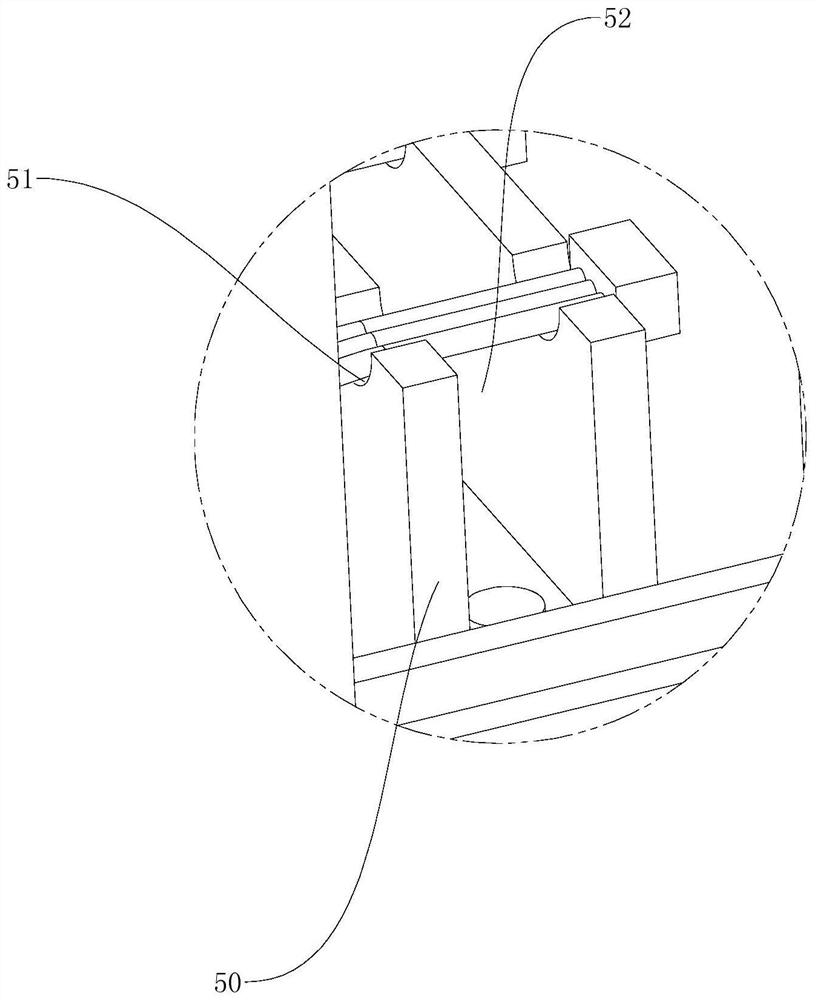

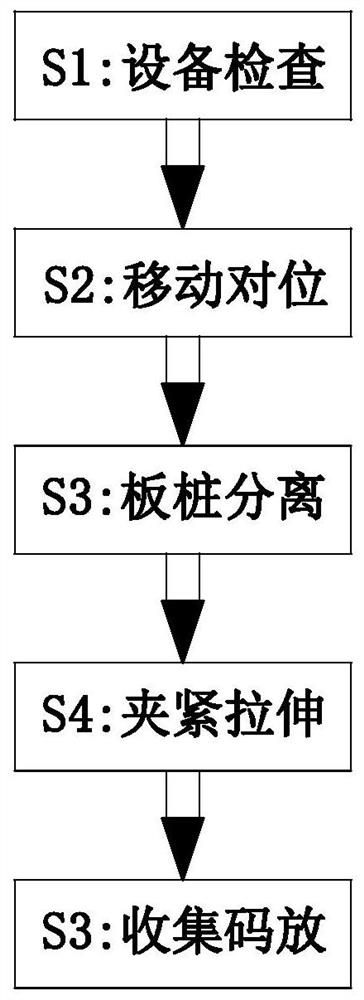

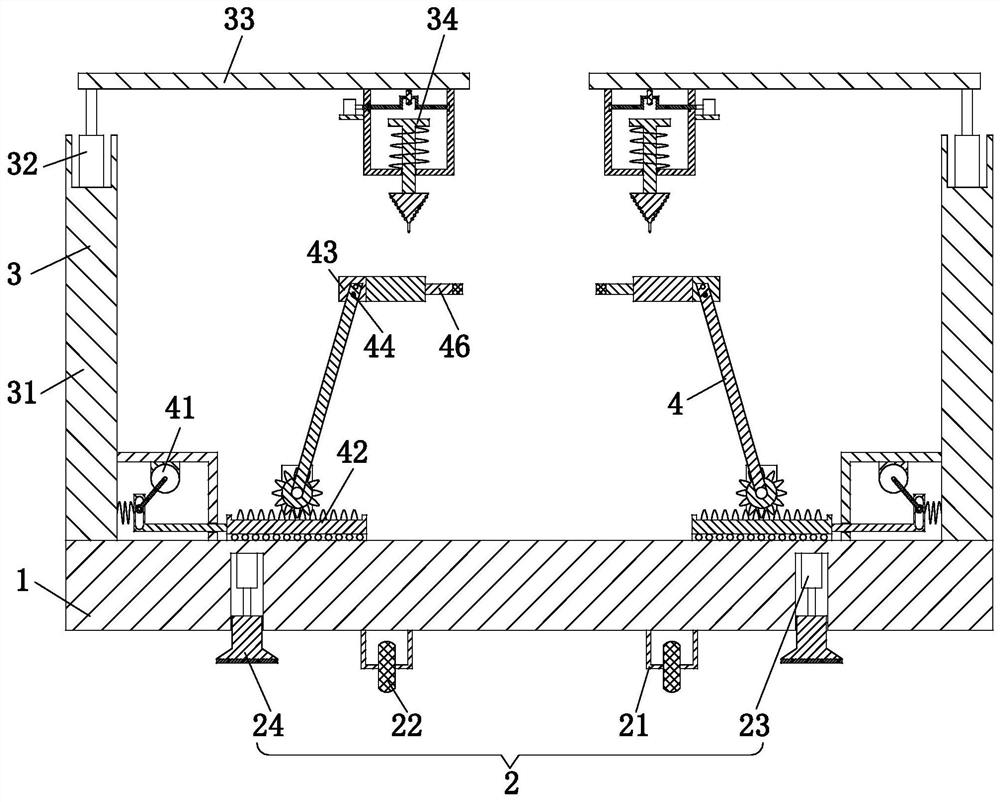

InactiveCN112709433ALow costReduce investmentForm treatmentArchitectural engineeringPersonal security

The invention relates to a building construction formwork dismantling method. A bottom plate, a moving device, a dismantling device and stretching devices are included, wherein the moving device is arranged at the lower end of the bottom plate; and the stretching devices are symmetrically arranged at the left end and the right end of the upper end face of the bottom plate and symmetrically mounted on the inner side of the dismantling device. The building construction formwork dismantling method can solve the following problems that in the actual operation process of an existing building construction formwork dismantling method, a building construction formwork is dismantled manually, the mechanical strength is large, dismantling is difficult, and consequently the dismantling efficiency is low; and b, manual dismantling is adopted, the input labor force is large, the building construction formwork needs to be supported manually in the dismantling process, and certain harm may be caused to the personal safety of dismantling workers.

Owner:盐城墨攻建筑工程有限公司

Terminal dismantling device for automobile wire harness recovery

ActiveCN110170808ARealize highly integrated workReduce laborVehicle connectorsLine/current collector detailsMechanical engineeringCable harness

The invention relates to the field of dismantling equipment, in particular to a terminal dismantling device for automobile wire harness recovery. The terminal dismantling device for automobile wire harness recovery comprises a base and a controller and also comprises a feeding mechanism, a peeling mechanism and a discharging mechanism. The feeding mechanism is arranged at one end of the top of thebase to feed an automobile wire harness to the peeling mechanism. The peeling mechanism is arranged next to the feeding mechanism to peel a terminal of the automobile wire harness fed by the feedingmechanism. The discharging mechanism is arranged below the peeling mechanism to discharge the dismantled automobile wire harness. The feeding mechanism comprises a pushing assembly, a reversed U-shaped supporting rod, a driving assembly and a clamping assembly. The peeling mechanism comprises a reversed U-shaped supporting rack, a supporting table, a compression assembly and a sliding assembly. The terminal dismantling device for automobile wire harness recovery dismantles the terminal of the automobile wire harness by means of automatic equipment replacing manual operation and dismantles theterminals of the automobile wire harnesses in batches. Meanwhile, the terminal dismantling device has a discharging function, is convenient and practical, saves the dismantling time, and saves the production costs of an enterprise and a plant.

Owner:嘉善哈耐斯电子科技有限公司

Portable tool for erecting and dismounting power transmission line grounding wire and using method thereof

PendingCN108631211AReduce setup timeShorter dismantling timeApparatus for overhead lines/cablesEngineeringUltimate tensile strength

The invention discloses a portable tool for erecting and dismounting a power transmission line grounding wire and a using method thereof. The portable tool comprises a bearing, a handle is fixedly connected to the inner side of the inner ring of the bearing, and a fixing ring is fixedly connected to the outer side of the outer ring of the bearing. The outer side of the fixing ring is fixedly connected with a bottom ring and a plurality of U-shaped grooves through a plurality of rings, and two symmetric outer rings are fixedly connected to the outer side of the U-shaped grooves, and a pluralityof soft ropes are arranged in the U-shaped grooves. When the portable tool is used, the operation is simple and convenient, the labor cost can be greatly reduced, and the labor intensity is also reduced. The working efficiency of erecting and dismounting a ground wire is improved, and a good use effect is achieved.

Owner:GUIZHOU POWER GRID CO LTD

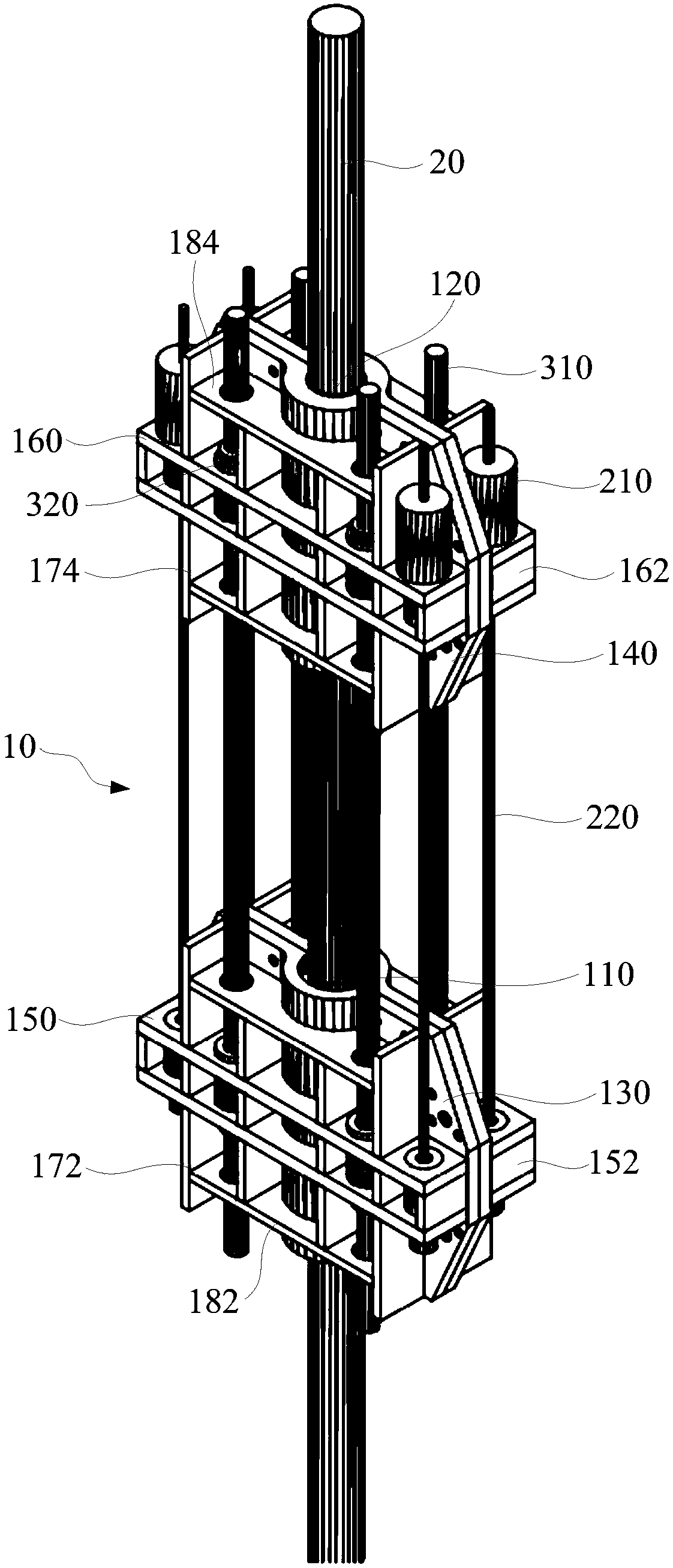

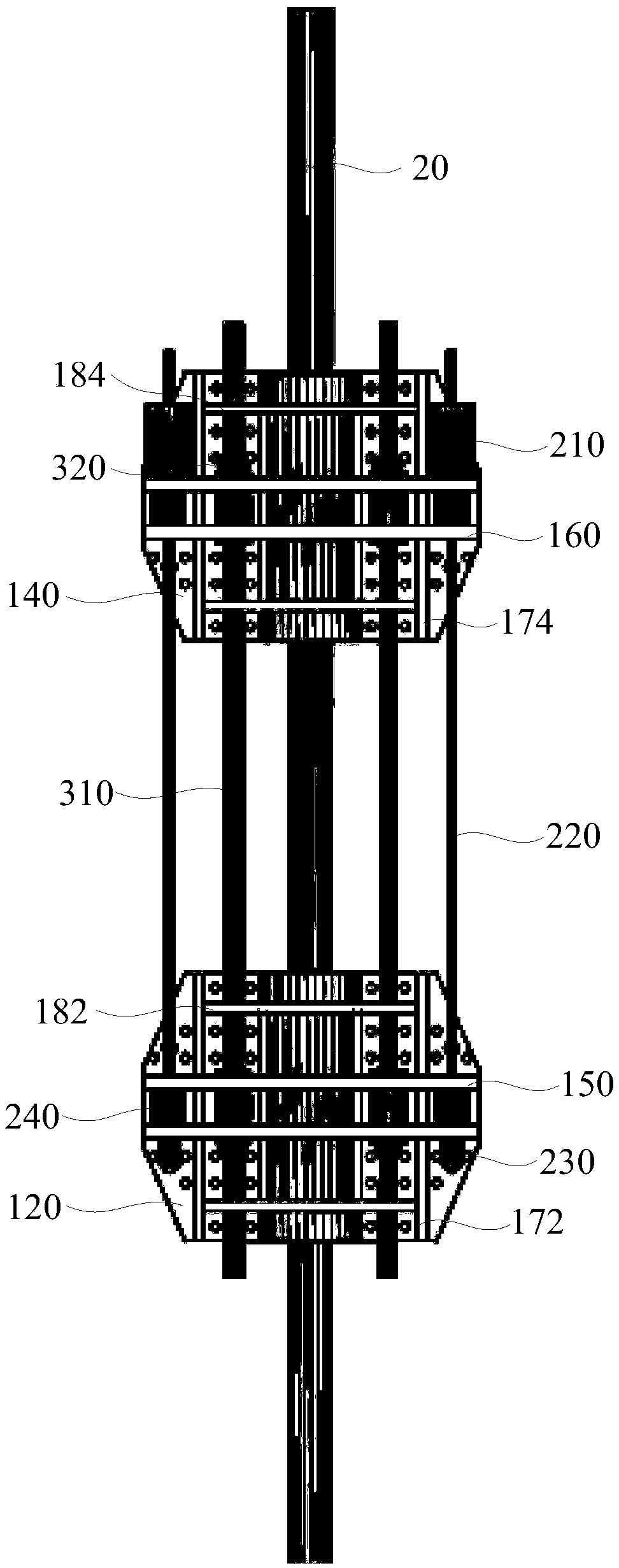

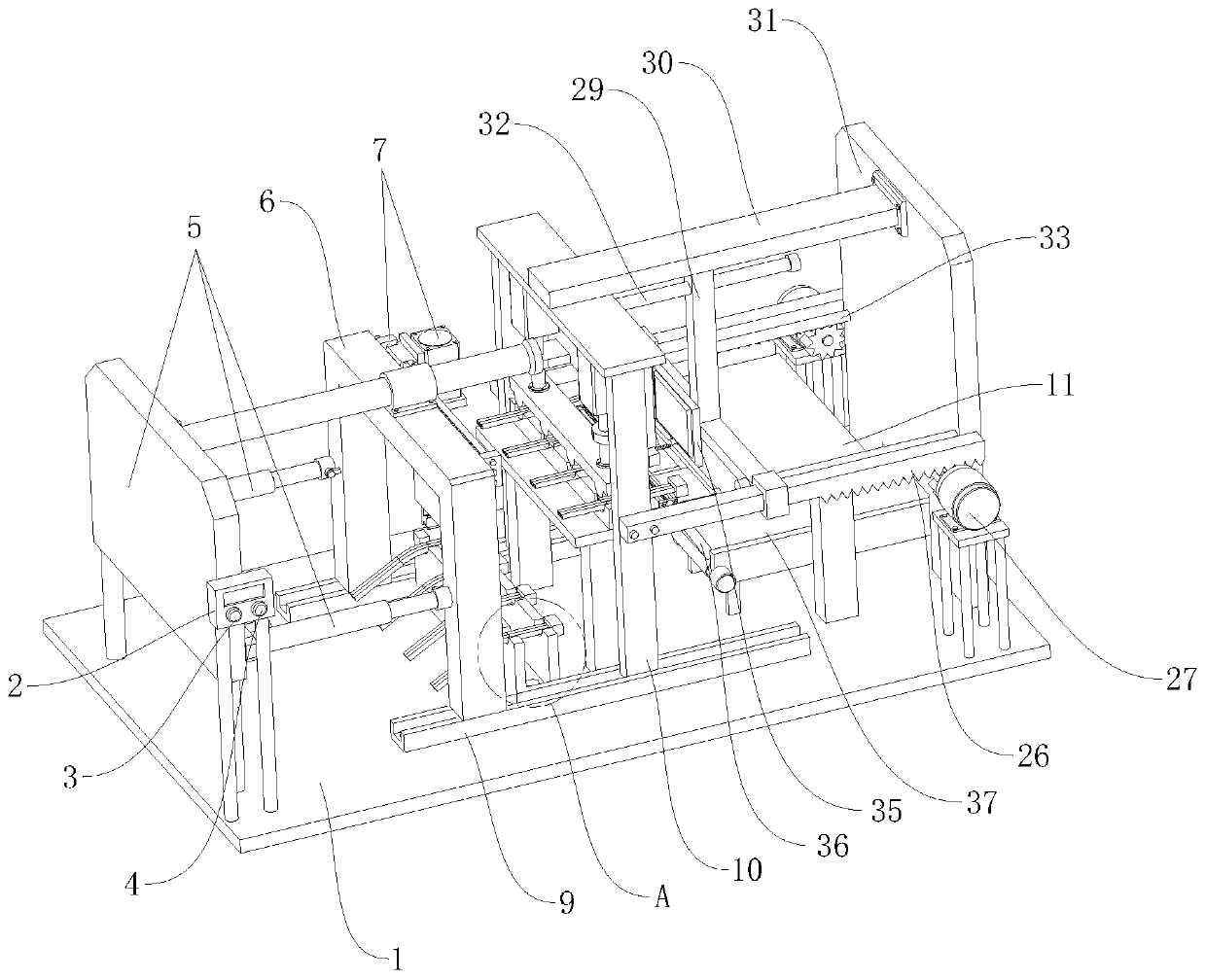

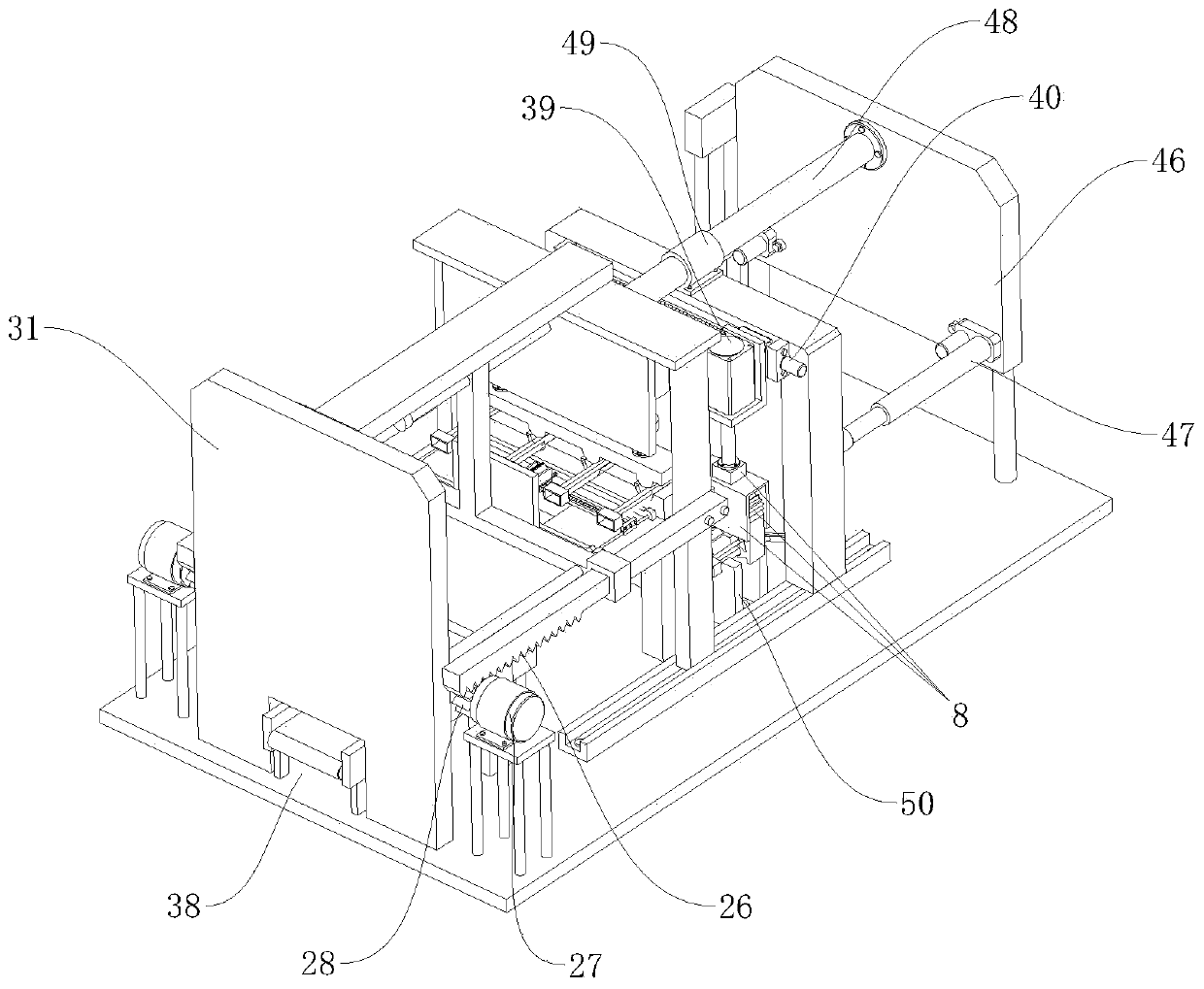

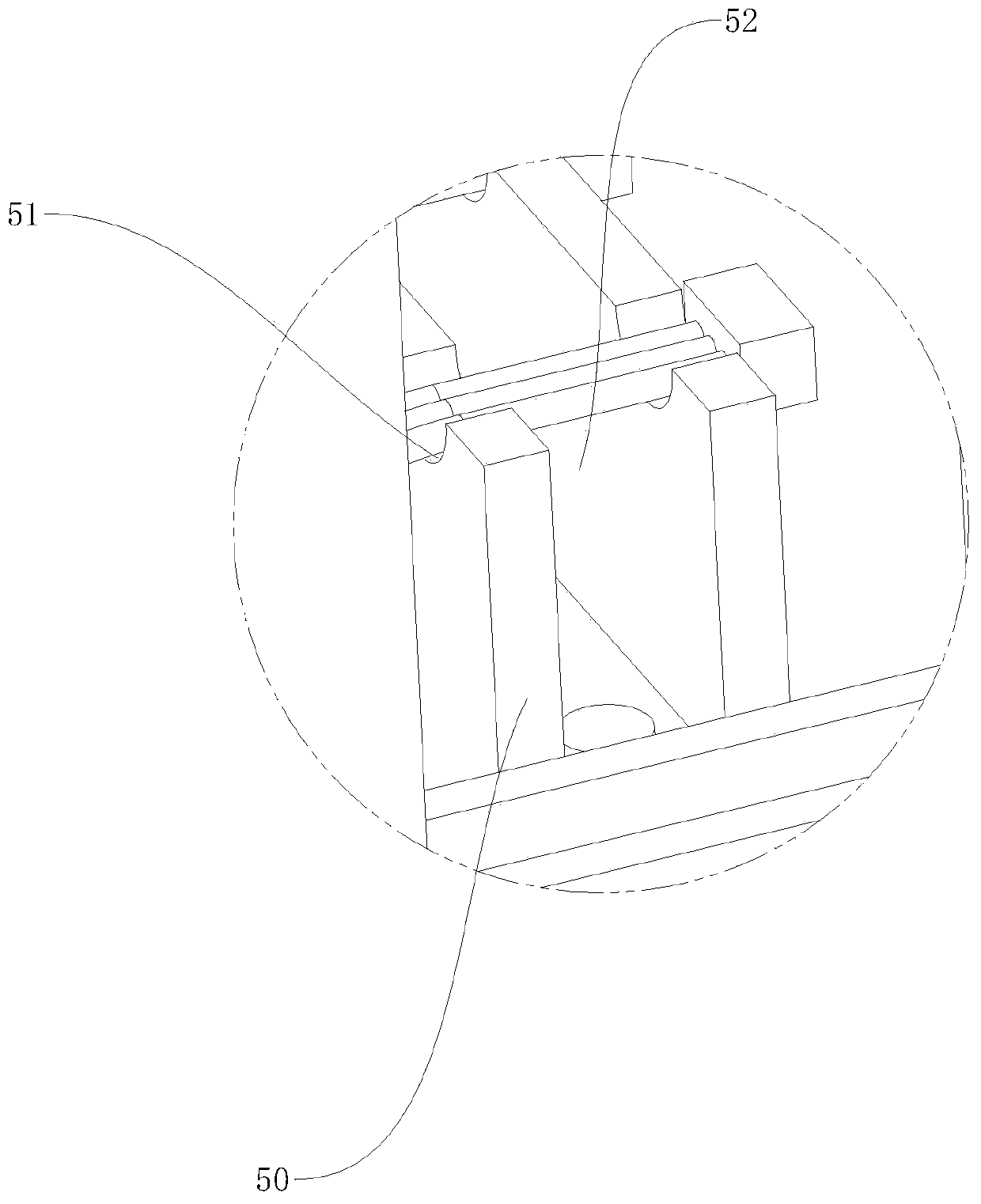

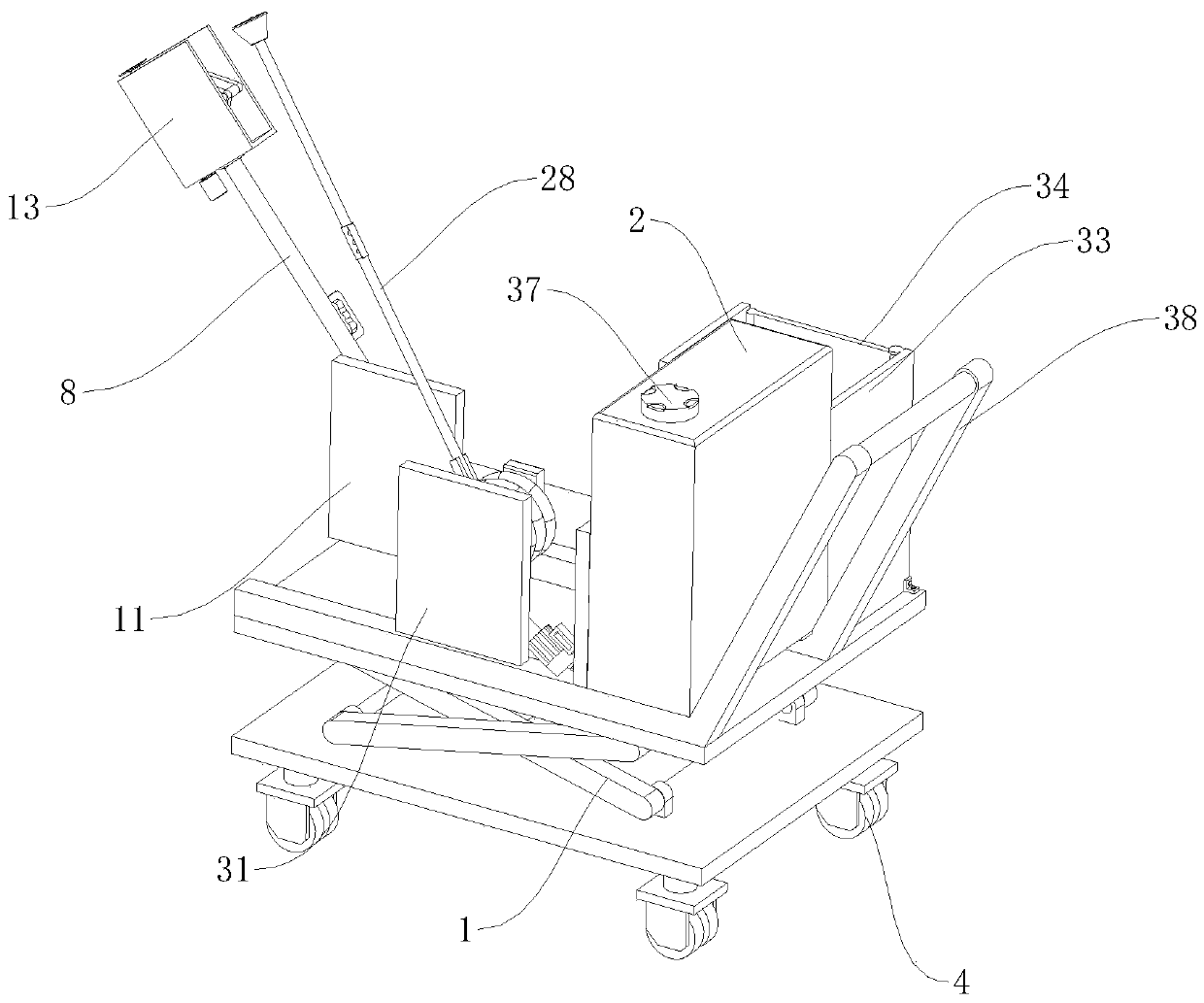

Nuclear reactor detector assembly dismounting device

ActiveCN112259267AHigh positioning accuracyImprove robustnessNuclear energy generationReactor fuel elementsNuclear reactorMechanical engineering

The invention discloses a nuclear reactor detector assembly dismounting device. According to the device, firstly, a large and small vehicle assembly is used for coarse positioning to the position above a to-be-dismounted detector assembly, then, a visual centering device is used for fine positioning to the position over the to-be-dismounted detector assembly, then, a detector assembly gripping apparatus is hoisted to the large and small vehicle assembly, and the detector assembly is pulled out of a reactor internals to a preset height; the shearing and winding device shears off the detector assembly, and the low-level section is hoisted by the detector assembly gripping apparatus under the cooperation of a crane and is stored in the low-level container; the high-level section is wound intomultiple layers by a shearing winding device and is stored in a temporary storage container; after the four storage containers are full, the four storage containers are integrally transferred into ahigh-level storage container; and the high-level storage container is transferred into a spent fuel pool after the high-level storage container is completely disassembled. The nuclear reactor detectorassembly dismounting device is good in reliability, high in efficiency, simple to operate and good in radiation protection performance.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Old wall painting layer dismounting equipment for decoration

The invention relates to the field of dismantling equipment, in particular to old wall painting layer dismounting equipment for decoration. The old wall painting layer dismounting equipment for decoration comprises a lifter. A water storage tank and a controller, the water storage tank is arranged at one end of the top of the lifter through a fixing frame, the controller is arranged on the outer wall of the water storage tank, a first switch button and a second switch button are arranged on the controller. The old wall painting layer dismounting equipment for decoration further comprises a spraying mechanism and a shoveling mechanism. The spraying mechanism is arranged at the other end of the top of the lifter so as to spray water to soak an old wall painting layer during dismantling, theshoveling mechanism is arranged beside the spraying mechanism and used for shoveling the soaked old wall painting layer. The invention discloses the old wall painting layer dismounting equipment for decoration. The automatic equipment is used for replacing a manual dismantling mode, the dismantling time of the painting layer is saved, the working efficiency is further improved, meanwhile, a scientific mode that the painting layer is soaked firstly and then dismantled is applied, so that the painting layer is easier to dismantle, the dismantling effect is good, and the wall body part below thepainting layer cannot be damaged.

Owner:叶丽

Full coal roadway safe and speedy drivage supporting method

The invention provides a full coal roadway safe and speedy drivage supporting method which solves the problem that the existing supporting form and parameter selection are unreasonable. According to the method, a top plate, two side walls and a bottom plate of a roadway are supported and reinforced respectively, wherein the top plate is supported through a combination of anchor rods, iron wire gauze, W-shaped steel bands and anchor cables, the two side walls are supported through a combination of anchor rods and supporting nets, and the bottom plate is reinforced by pouring of concrete layers. According to the method, the reasonable selection and standard design of anchor supporting parameters are researched from the aspect of mutual matching between the anchor rods and matched materials of the anchor rods, between the anchor rods and the anchor rod supporting parameters and between the anchor rod supporting parameters and the roadway mine pressure behavior, and therefore the method lays the good foundation for fully improving the quality of anchor rod supporting and achieving the high yield and high efficiency of mines. According to the method, various supporting and combined supporting forms are adopted, especially the combined supporting of the anchor rods, the anchor cables, the steel bands and the nets is adopted, deformation of surrounding rock is effectively controlled, supporting strength is appropriate and materials are not wasted.

Owner:DATONG COAL MINE GRP

Crushing apparatus for demolition or similar works

InactiveUS7971816B2Simple structureReduce manufacturing costMowersBuilding repairsDistal portionEngineering

Owner:CORIMAG

Double-wall steel cofferdam construction multifunctional platform and construction method thereof

ActiveCN103397649BShorter dismantling timeSave installation timeFoundation engineeringDouble wallJoist

The invention discloses a double-wall steel cofferdam construction multifunctional platform which adopts the scheme that a bottom isolation cabin is arranged at the bottom of the inner side of the steel cofferdam; a plurality rows of uprights vertical to the upper surface of the bottom isolation cabin are arranged on the bottom isolation cabin; a horizontal track beam is mounted at the tops of each row of the uprights; a steel rail parallel to each track beam is mounted at the top of each track beam; a moving joist barrow is arranged on each steel rail; a plurality of horizontal bearing beams are arranged on the inner wall of the steel cofferdam; drilling platform main beams are erected at the tops of the bearing beams, and are erected at the tops of the track beams; a plurality of vertical steel casings are mounted on the drilling platform main beams. According to the invention, the uprights and track beams fixed at the tops of the uprights are arranged inside the steel cofferdam, and a mud suction platform and a drilling platform can be erected on the track beams in sequence, so that mud suction platform dismantling time can be shortened, and drilling platform mounting time can be reduced; besides, the use quantity of steel materials can be reduced and manufacturing cost is reduced as the mud suction platform and the drilling platform can be combined.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

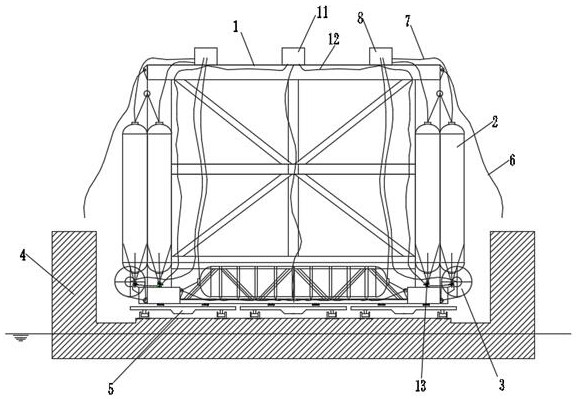

Mounting device utilizing gasbag floating aid to automatically float, sink and position steel frame and construction method thereof

PendingCN111809591AEliminate impact and slap effectsReduce dependenceArtificial islandsUnderwater structuresMarine engineeringSteel frame

The invention discloses a mounting device utilizing gasbag floating aid to automatically float, sink and position a steel frame. The mounting device is arranged on a steel frame, wherein at least onevertical gasbag is arranged on each vertical side of the steel frame; at least one horizontal gasbag is arranged on each transverse side of the bottom of the steel frame; a plurality of hoisting ringsare arranged on the steel frame; the vertical gasbag and the horizontal gasbag are connected to a hoisting belt; a hydraulic hook releaser is connected between the hoisting belt and the hoisting ring; the vertical gasbag and the horizontal gasbag are provided with gas charge and discharge control valves; the gas charge and discharge control valves are in signal connection to a central gas chargeand discharge controller; and the outer sides of four corners of the steel frame are connected to positioning ships with positioning anchor cables through mooring ropes. The mounting device has the beneficial effects that: the mounting device can automatically float in a dock directly, floats and is pulled to a specified mounting site, remarkably reduces dependence on ship equipment resources, reduces construction cost, and shortens a construction period.

Owner:SHANDONG NANHAI AIRBAG ENG

Method for directional dumping demolition of blast furnace body

InactiveCN111394530AShorter dismantling timeReduce the amount of construction workBlast furnace componentsBlast furnace detailsHot blastMining engineering

Owner:MAANSHAN IRON & STEEL CO LTD

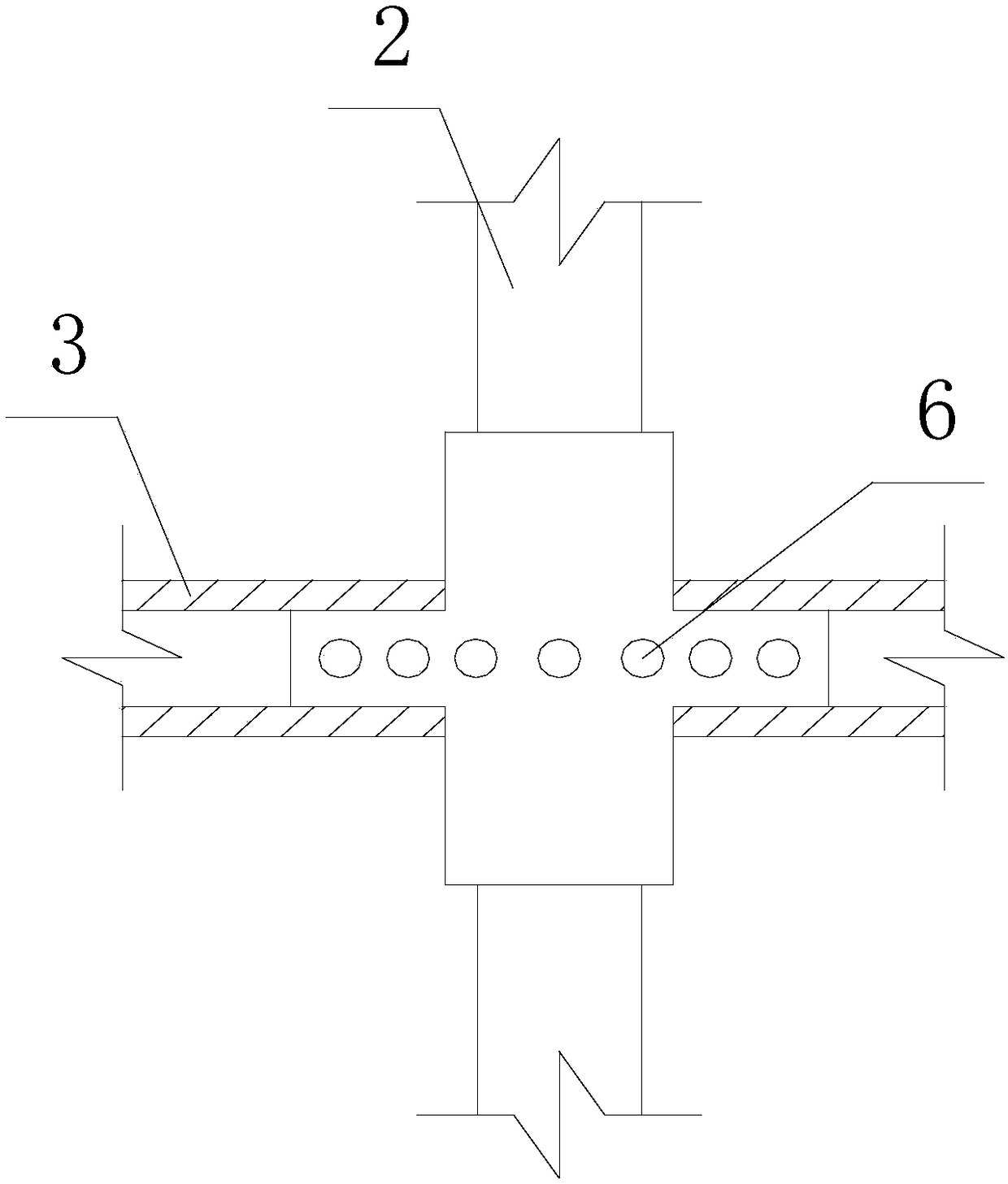

A pull seam connection mechanism for shear wall structures

ActiveCN104264864BImprove the protective effectEnsure safetyWallsShock proofingEngineeringVertical load

The invention relates to a shear wall structure pull seam connection mechanism, which includes components and clips. Working surfaces and clip slots are arranged on the upper and lower bottom surfaces of the components, and the clip slots are placed on both sides of the working surface. The working surface and the card slot correspond to the working surface and the card slot on the lower bottom surface respectively, a water baffle is provided on the edge of the card slot, and a card position is provided on the card part, and the card position on the card part and the card part on the component The slots match correspondingly, and when the card position is inserted into the card slot, the card piece can move along the card slot. In the present invention, components are arranged in the fully poured shear wall structure, that is, a damping device is arranged in the shear wall structure, so as to guide and disperse the vertical load pressure between layers to the beam or column under reasonable stress, thereby protecting the shear force Beams or columns at the bottom of the wall will not crack due to excessive pressure. The component is novel in structure, light in weight, convenient in transportation and construction, has good waterproof effect, and effectively improves the construction quality of the shear wall and the safety performance of the wall structure.

Owner:ZHONGTIAN CONSTR GROUP

Equipment convenient for mounting bridge support

ActiveCN108221707APromote sportsImprove securityBridge erection/assemblyPhotovoltaic energy generationEngineeringRebar

The invention discloses equipment convenient for mounting a bridge support. A longitudinal clamping bar and a horizontal clamping bar are movably arranged inside a frame, and an included angle betweenthe longitudinal clamping bar and the horizontal clamping bar is 90 degrees; the intersected longitudinal clamping bar and horizontal clamping bar are movably connected by virtue of a sleeve; a through hole which is transversely cut-through is formed in the horizontal clamping bar, and the sleeve longitudinally moves along the horizontal clamping bar in the through hole; spring balls are longitudinally arranged along the horizontal clamping bar on the outer surface of the sleeve; the longitudinal clamping bar is arranged inside the sleeve, and the sleeve longitudinally moves along the longitudinal clamping bar; and balls are arranged along the longitudinal direction of the longitudinal clamping bar on the inner wall of the sleeve. The equipment convenient for mounting the bridge support has the advantages that an embedded reinforcement is effectively limited from an embedding process to a moment before mounting by virtue of structural design of the sleeve, the longitudinal clamping bar and the horizontal clamping bar, when the bridge support is mounted, a mounting process is more convenient, working procedures are reduced, operation time is shortened, and construction safety is effectively improved.

Owner:CHINA MCC5 GROUP CORP

Mounting bracket for construction site

InactiveCN107288330AAvoid strainFlexible adjustmentBuilding scaffoldsArchitectural engineeringBuilding construction

The invention discloses a mounting bracket for a construction site, which comprises a bracket plate, four insertion rods are arranged symmetrically on the bottom of the bracket plate, and the insertion rods are arranged at a position close to the top corner of the bracket plate, and the bracket A leg assembly is provided below the board, and the leg assembly includes a bottom plate and a fixed rod sleeved in the bottom plate. The inside of the fixed rod is equipped with a threaded adjustment rod, and the top of the threaded adjustment rod is provided with a A polished rod part, a limit plate is arranged outside the polished rod part, a sleeve rod is fitted above the polished rod part, the polished rod part is inserted into the sleeve rod, the insertion rod is inserted into the sleeve rod, the The polished rod part and the inserted rod are respectively connected to the set rods; this device can be flexibly adjusted according to the height of the floor to be constructed, so that the construction workers can carry out construction with the best posture, avoiding physical strain, At the same time, the construction quality can also be improved.

Owner:王怡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com