Double-wall steel cofferdam construction multifunctional platform and construction method thereof

A double-wall steel cofferdam, multi-functional technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of high construction cost, large amount of steel consumption, separate installation, etc., to achieve the goal of reducing construction cost, reducing steel consumption, and reducing installation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

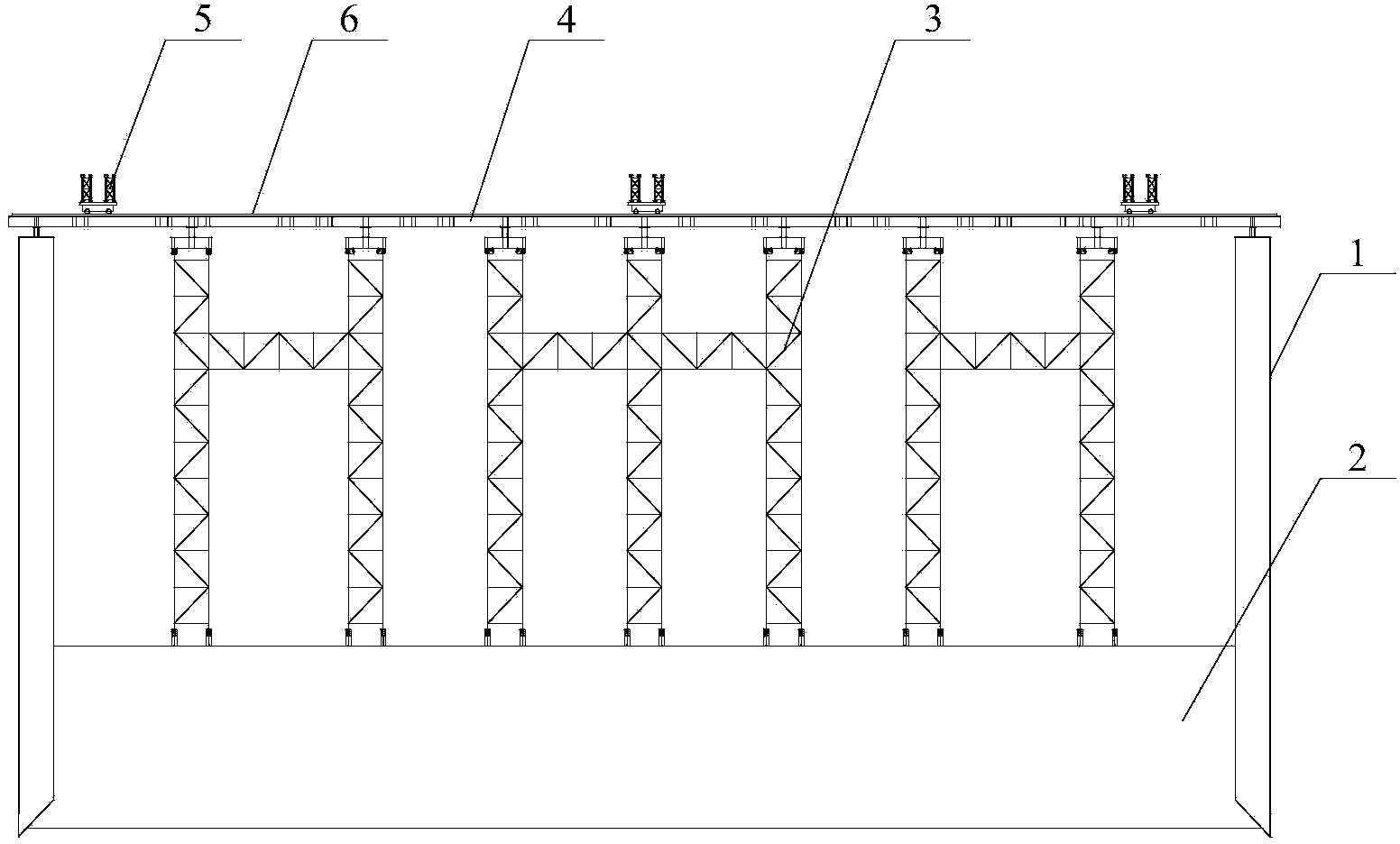

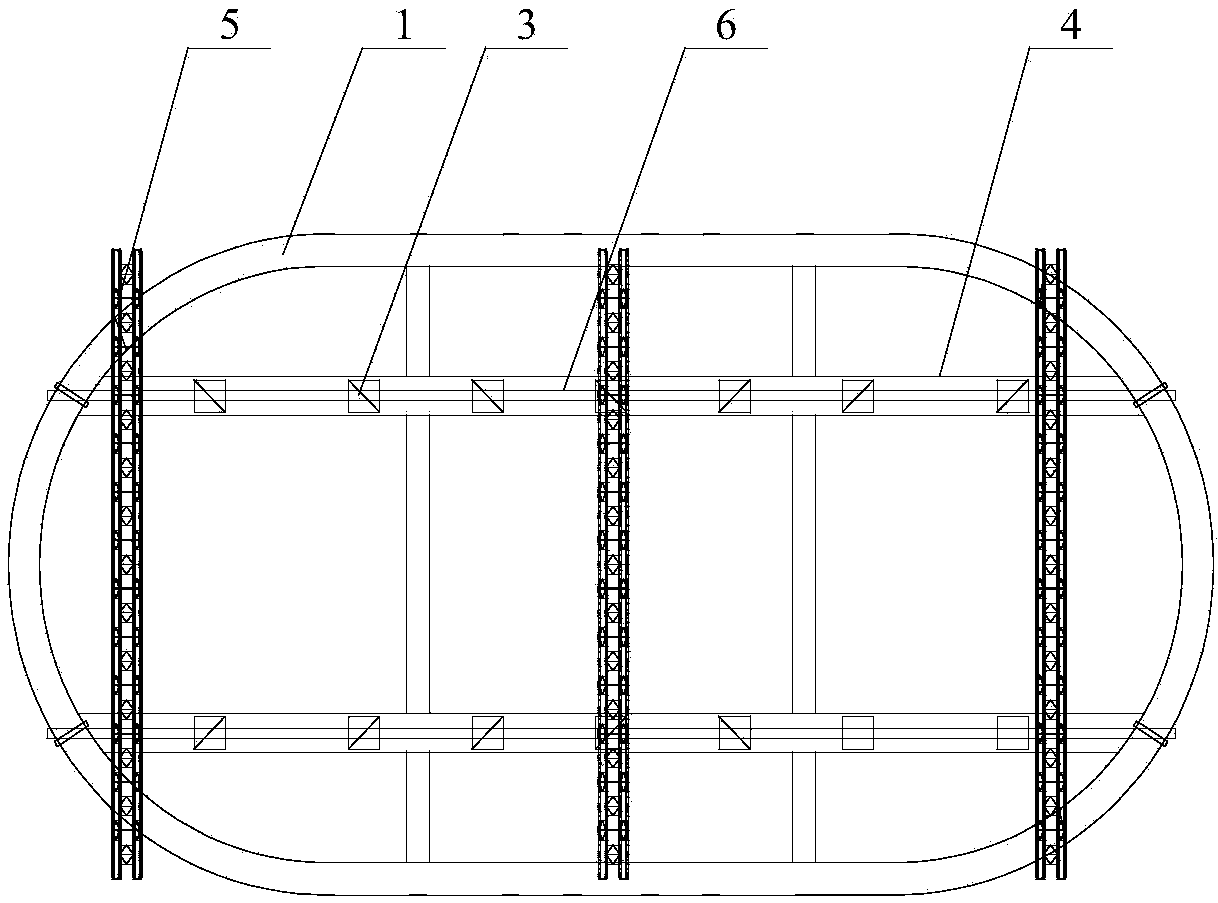

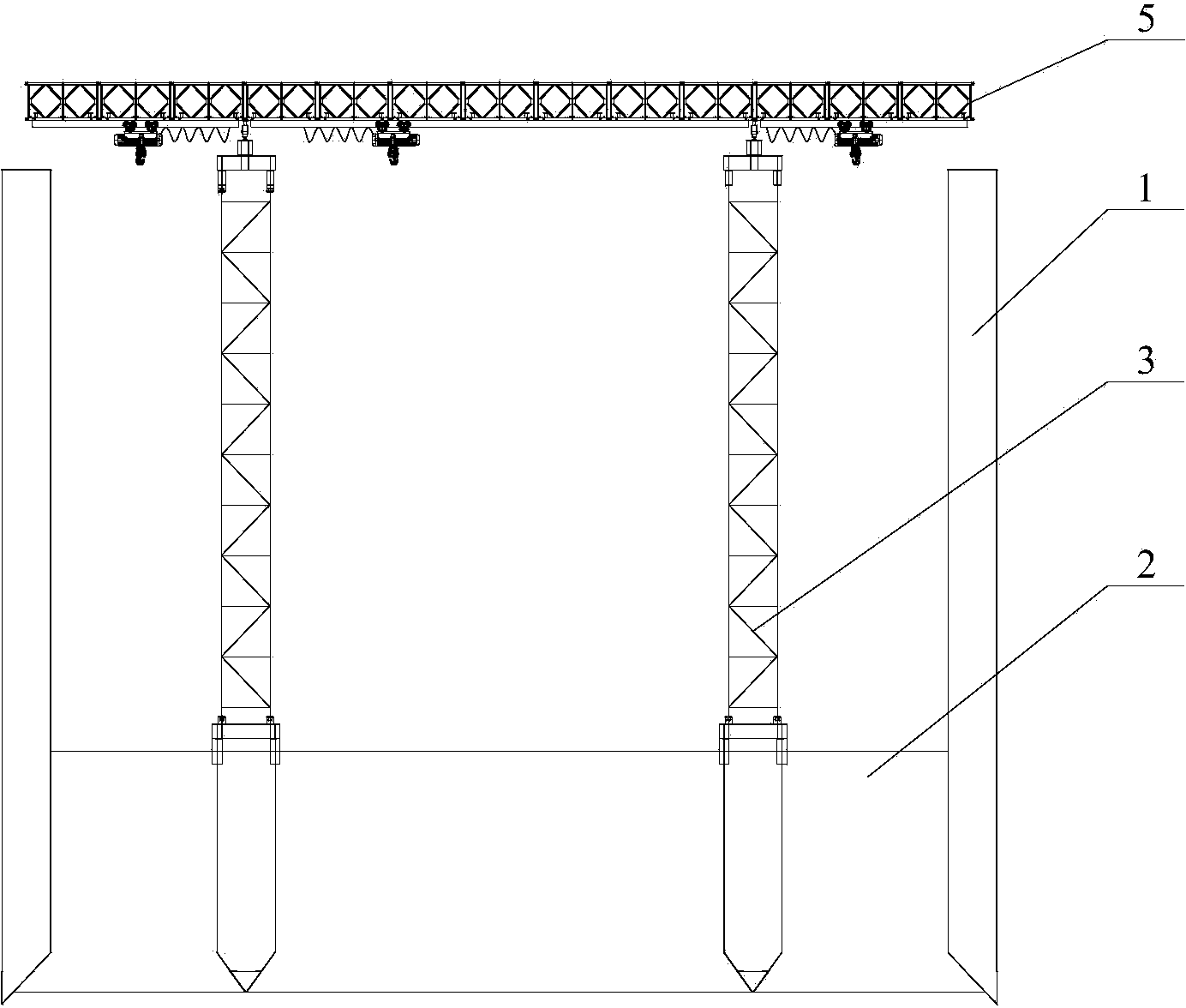

[0020] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 , Figure 8 As shown, the double-walled steel cofferdam 1 construction multi-functional platform provided by the present invention, the inner bottom of the steel cofferdam 1 is provided with a bottom compartment 2, and the bottom compartment 2 is provided with 2 rows of columns 3 perpendicular to its upper surface, each row The uprights 3 inside are evenly distributed, arranged parallel to each row, and a track beam 4 arranged horizontally is installed on the top of each row of uprights 3, and a rail 6 parallel to it is installed on the top of each track beam 4. Be provided with mobile truss car 5, and mobile truss car 5 is 3. The inner wall of the steel cofferdam 1 is provided with two horizontal pad beams 8, the two ends of the pad beams 8 are fixed on the inner wall of the steel cofferdam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com