Mounting device utilizing gasbag floating aid to automatically float, sink and position steel frame and construction method thereof

A positioning installation and construction method technology, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of inability to meet the positioning accuracy requirements of the installation site, difficulty in removing buoyant fixed points, high equipment usage costs, etc., and achieve reduction The effect of reducing the risk of accidents in underwater operations, reducing the amount of manual labor, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

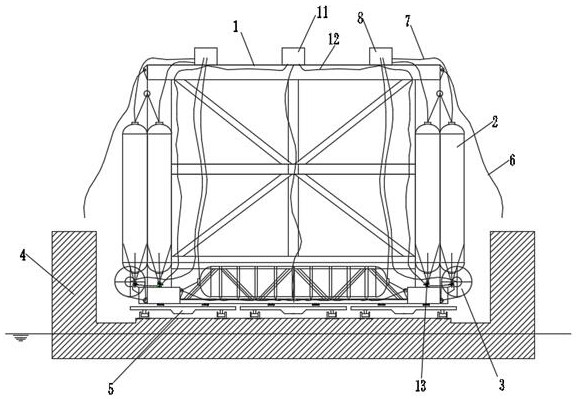

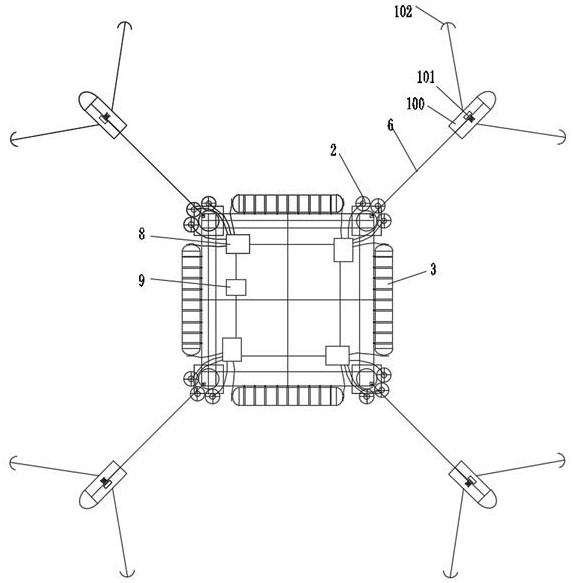

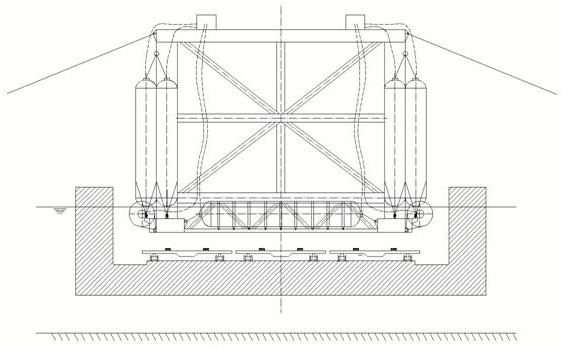

[0026] like figure 1 , 2 . As shown in 5, a self-floating and diving positioning installation device for a steel frame using airbags to help float is arranged on a steel frame 1, and at least one vertical airbag 2 is arranged on each vertical edge of the steel frame 1, and the steel frame 1. At least one horizontal airbag 3 is arranged on each horizontal edge of the bottom, and several lifting rings are arranged on the steel frame 1. Both the vertical airbag 2 and the horizontal airbag 3 are connected with a sling, and a hydraulic uncoupling device is connected between the sling and the lifting ring. Both the airbag 2 and the horizontal airbag 3 are provided with inflation and deflation control valves, and the signals of the inflation and deflation control valves are connected to the central inflation and deflation controller. Ship 100. The head of the horizontal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com