A pull seam connection mechanism for shear wall structures

A connection mechanism and shear wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of irregular structure, inconvenient, large randomness, etc., to facilitate construction and transportation, reduce workload, and ensure The effect of safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

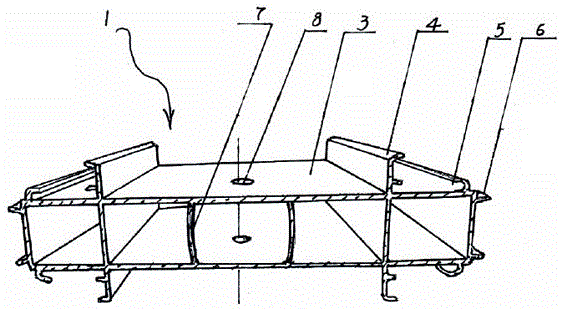

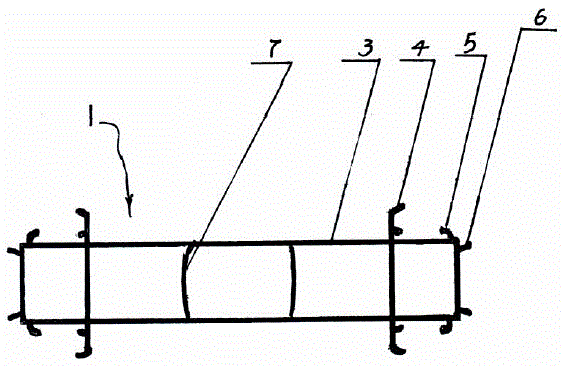

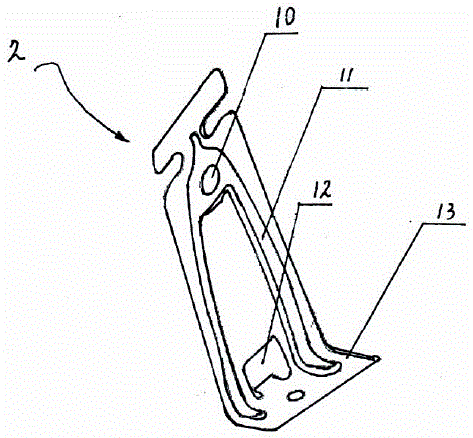

[0023] With reference to the accompanying drawings, describe it in detail.

[0024] exist Figure 1~5 Among them, a shear wall structure drawing seam connection mechanism, including components and clips, the clips are installed on the components, and the upper and lower bottom surfaces of the components are provided with working surfaces (pressure bearing surfaces) and clamping grooves, and the clamping grooves are placed On both sides of the working surface, the working surface and the card slot on the upper bottom surface correspond to the working surface and the card slot on the lower bottom surface respectively, and a water baffle is provided on the side of the card slot; At the bottom position of the clip, the clip on the clip corresponds to the slot on the component, and when the clip of the clip is inserted into the slot in the component, the clip can move along the slot.

[0025] During construction, the component 1 of the present invention is buried in the pre-set sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com