Method for directional dumping demolition of blast furnace body

A technology of blast furnace and body, which is applied in the field of directional dumping and demolition of blast furnace body, which can solve the problems of high safety risk, long time, corrosion of steel structure, etc., and achieve the effect of reducing construction workload, shortening demolition time and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example one

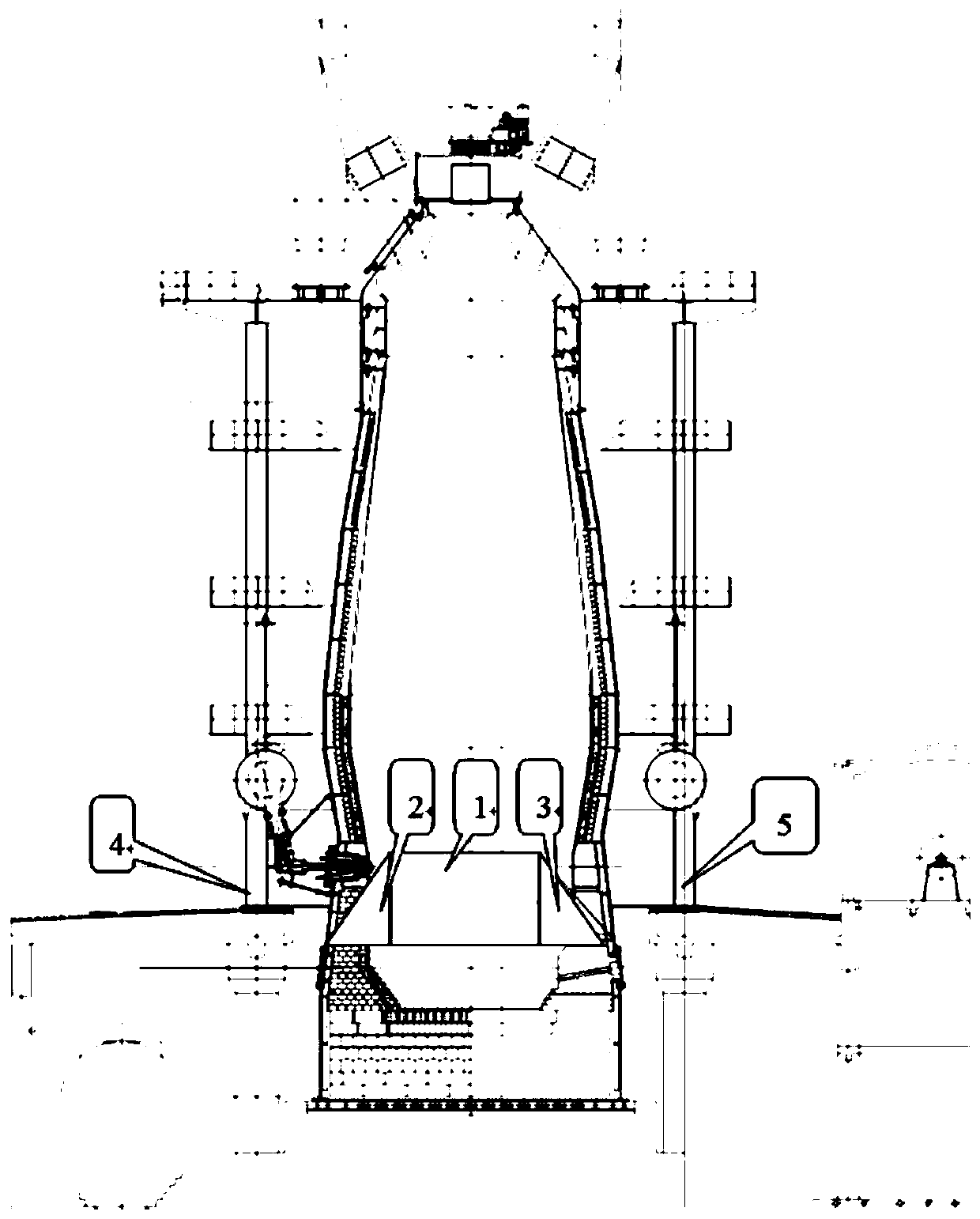

[0022] See figure 1 , A method for directional dumping and dismantling of a blast furnace body includes the following steps:

[0023] 1) Dismantle the blast furnace body's hot air enclosure, gas gravity dust collector, washing tower and pipes, electromagnetic station, hoisting room and diagonal bridge in advance to isolate the blast furnace steel structure;

[0024] 2) Design high body furnace shell, cold plate, steel structure cutting, cleaning, and column cutting plan;

[0025] 3) Set up damping ditch and damping pad for dumping of blast furnace body;

[0026] 4) Break the blast furnace frame column by disintegrating and hitting the blast furnace with the help of a crusher;

[0027] 5) After the frame is dumped, the blast furnace body is pulled for directional dumping, and the steel structure is disassembled and transported on the ground.

[0028] Directional dumping method of blast furnace

[0029] Including the scope of the dismantled blast furnace hearth to the t...

Example Embodiment

[0048] Example two

[0049] Step 1: Before dismantling the main body of the blast furnace, dismantle the equipment and facilities around the main body in advance. The dismantling content includes the gas downpipe, gravity dust collector, washing tower and other gas dust removal systems; hot air enclosure and chimney, feeding system hoisting room, Electromagnetic station and diagonal bridge (or belt corridor) isolate the blast furnace body.

[0050] Step 2: Clean up the site around the blast furnace body.

[0051] Step 3: Soil layer stacking:

[0052] (1) Fill the blast furnace to a height of about +3m from the concrete base of the furnace body, make a slope and compact it to facilitate the construction of the mechanical station and the evacuation of personnel.

[0053] (2) Check the construction site. If it is not level or compact, it should be filled and compacted to ensure that the site is open and the emergency passage is free of obstructions, so that in case of emergency, the const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com