Rake type lifting frame and dismantling method for reinforced concrete groove-shaped roof boards

A technology for reinforced concrete and roof slabs, which is applied in building maintenance, construction, building construction, etc., can solve problems such as time-consuming, difficult roof slab removal, and complicated roof slab removal process, so as to shorten the demolition time, improve operation efficiency and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

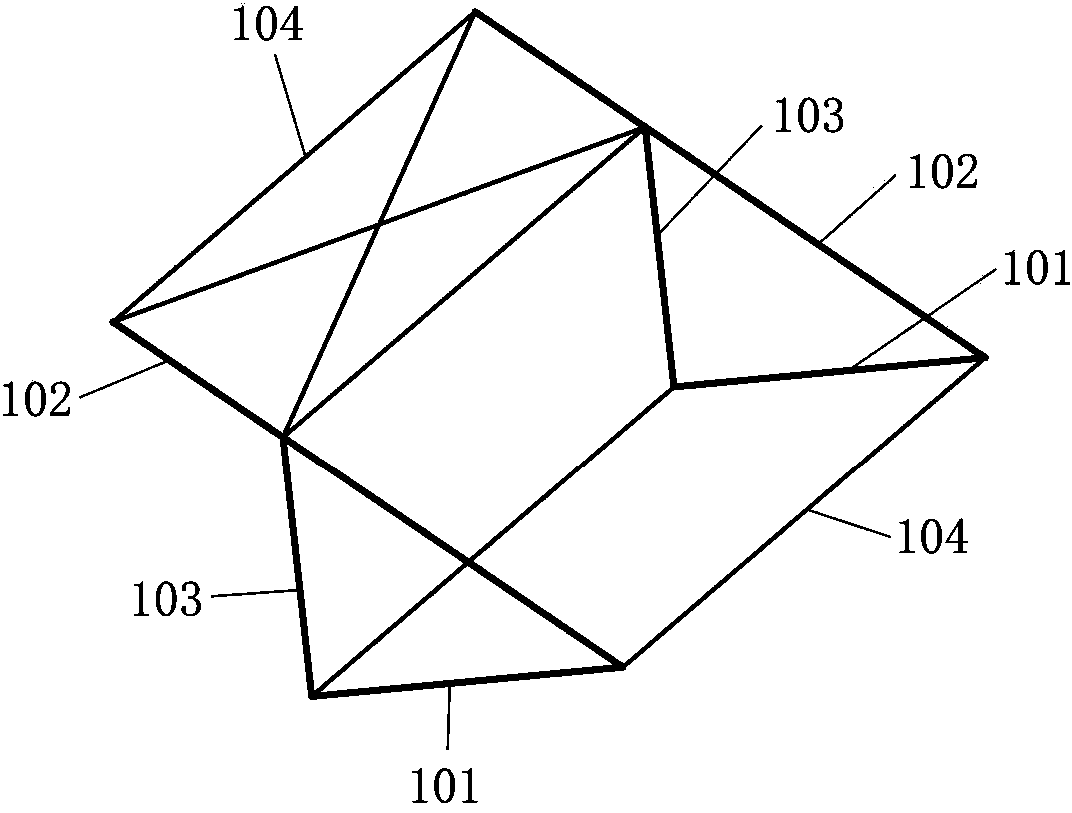

[0020] figure 1 It is a structural schematic diagram of a rake hoisting frame according to an embodiment of the present invention.

[0021] refer to figure 1 According to one aspect of the present invention, there is provided a rake-type hoisting frame 10 for removing reinforced concrete trough roof panels (hereinafter referred to as roof panels), the rake-type hoisting frame 10 includes: two bottom brackets 101, mutually They are arranged horizontally in parallel, and the two bottom brackets 101 are located outside the opposite ends of the length direction (perpendicular to the bottom brackets 101) of the roof panel W to be removed, that is, the distance between the two bottom brackets 101 is slightly longer than that of the roof. The length of the panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com