Novel assembling method for bent cap bearing frame

A cover beam load-bearing frame, a new type of technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of support foundation and ground transportation difficulties, small space occupied by the ground, cumbersome construction, etc., and shorten the installation and removal time , Ground traffic is smooth, and the effect of reducing the amount of on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The patent application of the present invention will be described in further detail below in conjunction with the drawings.

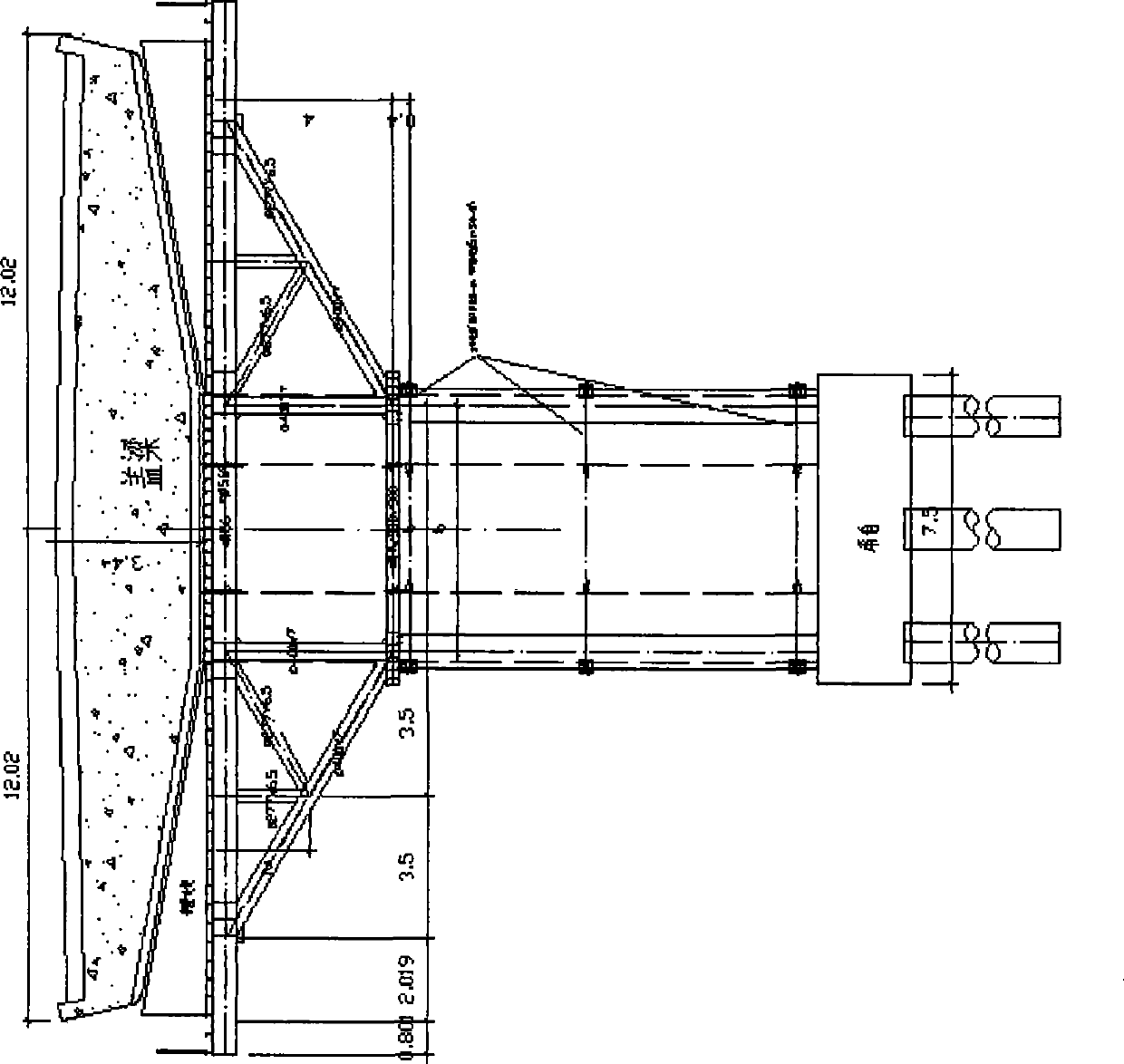

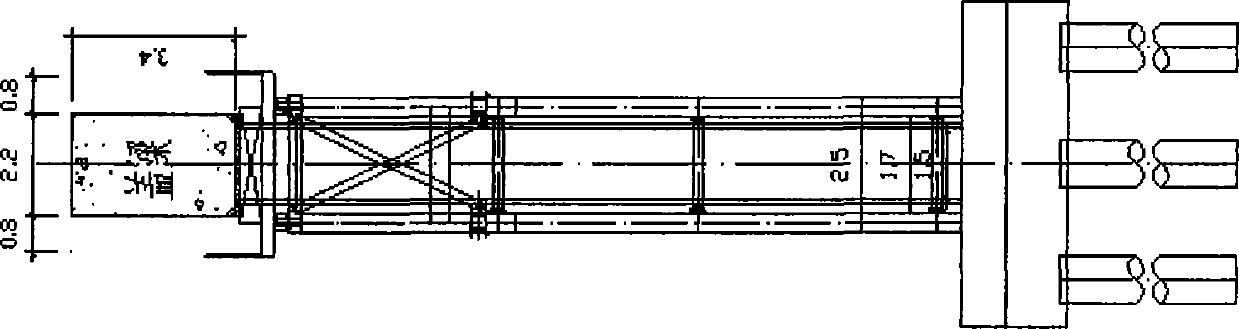

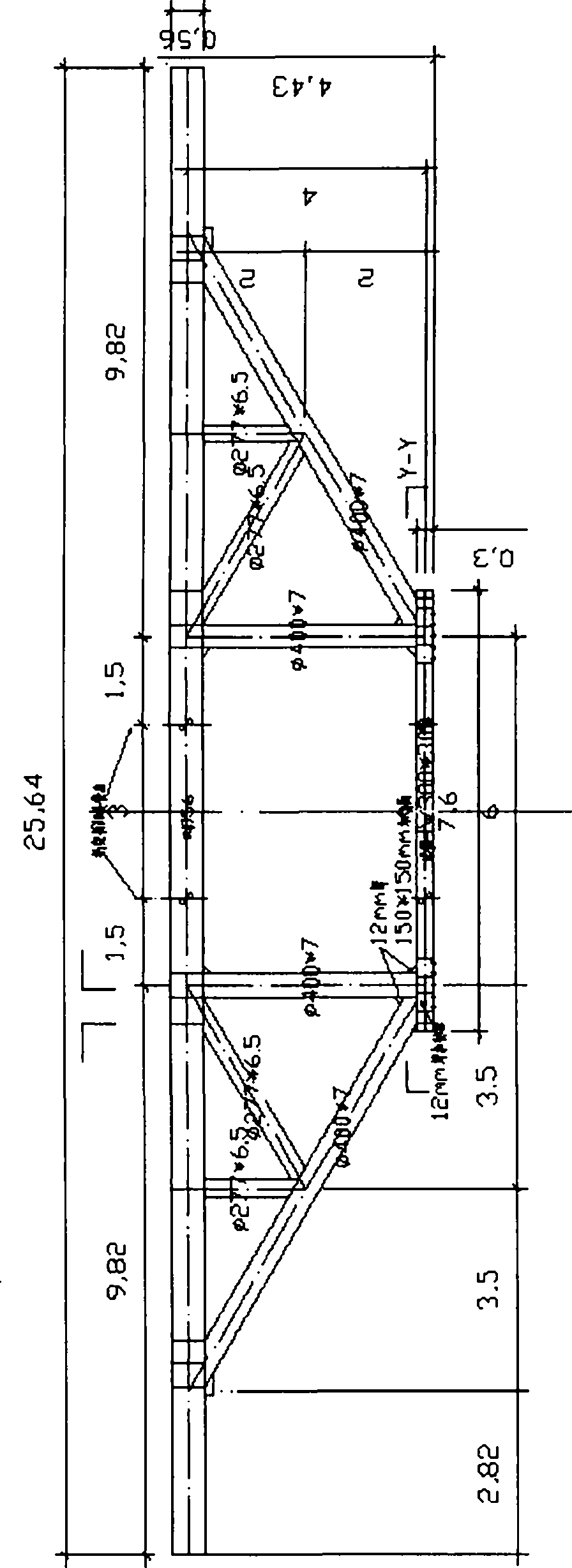

[0012] exist figure 1 In the middle, the pole is made of double φ400×7mm steel pipes. In order to adjust the height easily, a modular pup joint is made and connected by a flange. The steel is twisted to connect the uprights to the reinforced concrete columns. The trusses are welded with φ400×7mm, φ277×6.5mm steel pipes and I56 I-beams. For the convenience of transportation, they are divided into three sections during processing and connected by flanges. [28 channel steel and φ25 precision-rolled rebar are used between the two trusses connected into a whole. The distribution beam at the bottom of the cover beam is made of I16 I-beam, installed on the truss with a distance of about 50cm, and each end protrudes 800mm from the cover beam surface to provide an operating platform for construction personnel. Around the platform, φ48×3.5mm steel pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com