Assembly type multifunctional microphone array frame device

A microphone array, multi-functional technology, applied in the direction of the transducer shell/cabinet/bracket, etc., can solve the problems that cannot meet the requirements of the microphone acoustic test, the height of the tripod or the support is limited, and the versatility of the array frame is not strong. Achieve the effect of reducing preparation time, facilitating transportation and assembly, and avoiding space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

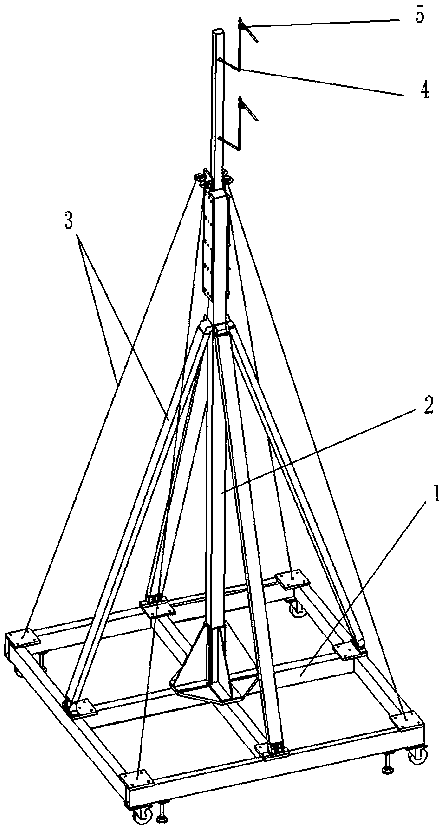

[0029] Such as image 3 As shown, it is a schematic diagram of a single-piece assembled multifunctional microphone array frame after assembly. Its structure is simple and easy to disassemble. Seat 5 etc. are assembled.

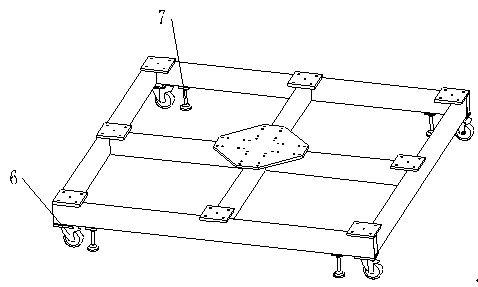

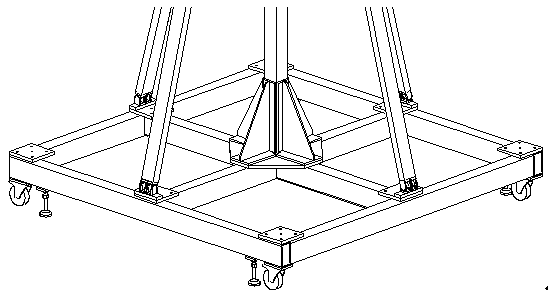

[0030] Such as figure 1 As shown, the movable base 1 of the present invention is a frame structure, which is welded by four steel pipes in the outer frame and four steel pipes in the inner frame. There is a platform in the middle of the four steel pipes in the inner frame, and the pre-drilled holes on the platform are convenient for connecting the columns. There is a small platform above the four corners where the outer frame and the inner frame intersect, and a hole is pre-punched in the middle of the platform to connect with the reinforcement auxiliary device. A small platform is also respectively arranged above the four corners of the movable base 1, and holes are pre-punched in the middle of the platform to connect spare eyebolts. The bottom of the fou...

Embodiment 2

[0037] Such as Figure 4 As shown, taking the 30-channel far-field microphone array rack device as an example, the implementation process of the present invention is given.

[0038] According to the requirements of the test project and test settings, the overall length of the microphone array frame is 12 meters, and the height is 11 meters. The microphones are arranged in three rows, with 10 channels of microphones in each row, and all microphones must point to the same given position. In order to achieve the above purpose and ensure the stability of the entire array rack, 4 pieces such as image 3 The assembled device shown (in which the column 2 includes two sections of aluminum profiles of different thicknesses) is assembled with 6 aluminum profile brackets, 30 array struts 4 and 30 universal adjustment seats 5 .

[0039] After the processing is completed, the single-piece movable base 1 is as follows figure 1 As shown as a whole, other aluminum profiles, array struts 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com