Nuclear reactor detector assembly dismounting device

A detector assembly and nuclear reactor technology, which is applied in the fields of reactor fuel elements, reactors, nuclear engineering, etc., can solve the problems of undiscovered detector assembly dismantling and replacement equipment, etc., and achieves short dismantling time, compact structure and good shielding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

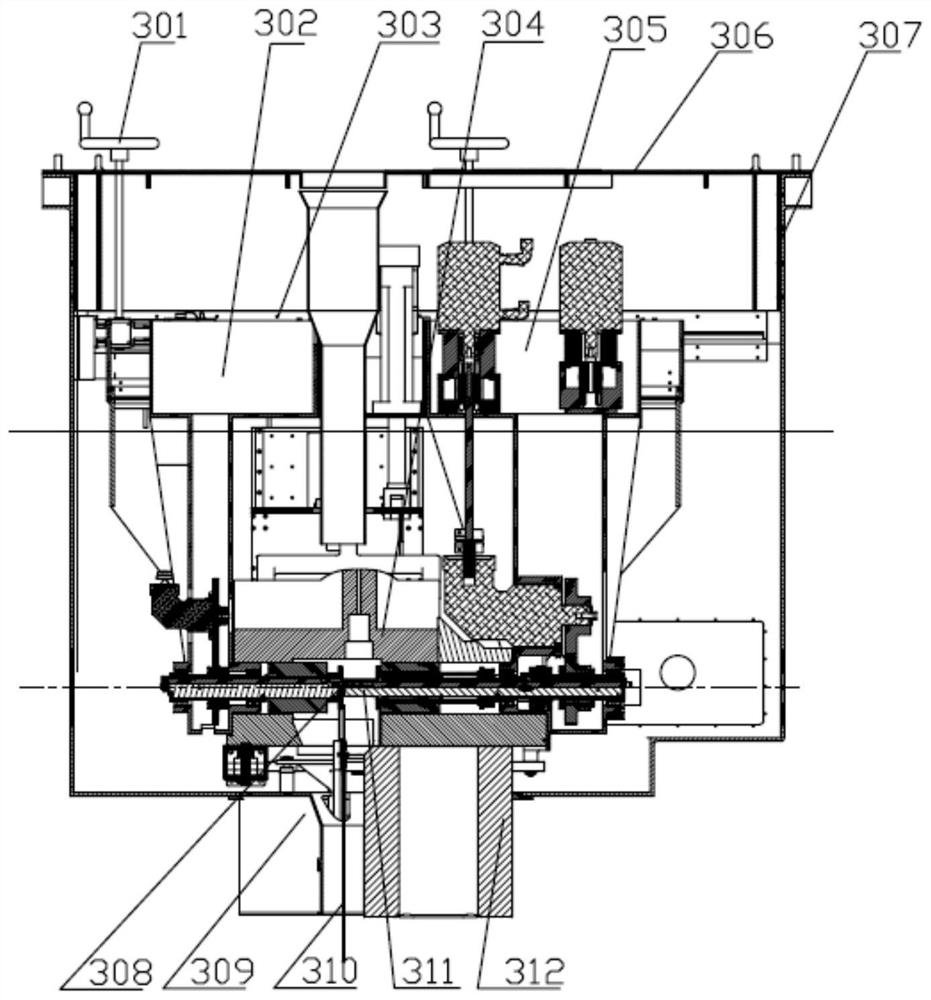

[0100] see Figure 14-Figure 17 As shown, the dismantling device for the nuclear reactor detector assembly is composed of the following components in combination and modularization,

[0101] Detector component gripper 1, large and small car components 2, shearing and winding device 3, vision centering device 4, monitoring device 5, high storage container and storage rack 6; among them,

[0102] The large and small cart assembly 2 is arranged in the nuclear reactor building and is located directly above the detector assembly; the large and small cart assembly 2 includes a cart 202 moving in the Y direction and a trolley 204 moving in the X direction, and the cart 204 is assembled on the cart 202;

[0103] The detector assembly gripper 1 is configured on the upper top surface of the trolley 204. The detector assembly gripper 1 includes an outer cylinder assembly 105 whose longitudinal axis is arranged along the Z direction, and a gripper assembly 104 that moves up and down along...

Embodiment 2

[0138] On the basis of the above examples, if figure 1 , figure 2 as shown,

[0139] like figure 1 , figure 2 Schematic side view of the shielding structure for removal of the nuclear reactor detector assembly.

[0140] figure 1 with figure 2 The shield structure shown is image 3 The shielding structure 304 in.

[0141] The subsequent front and back refer to the direction facing the legend paper and the direction facing away from the paper as shown in the figure.

[0142] Shielding structures, including:

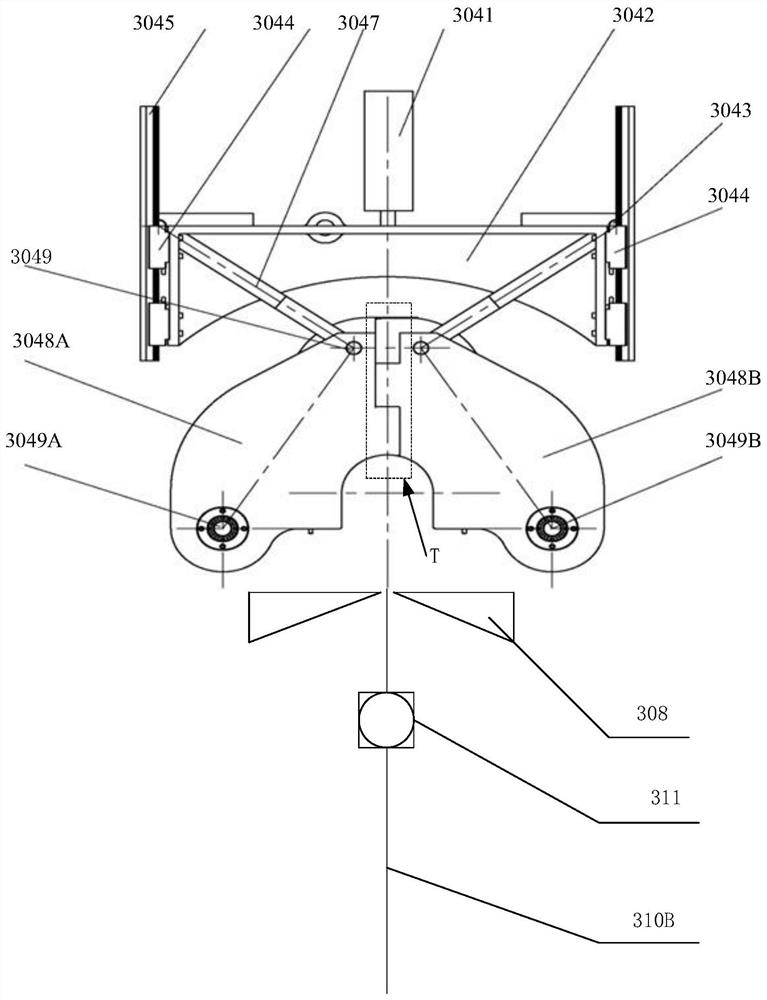

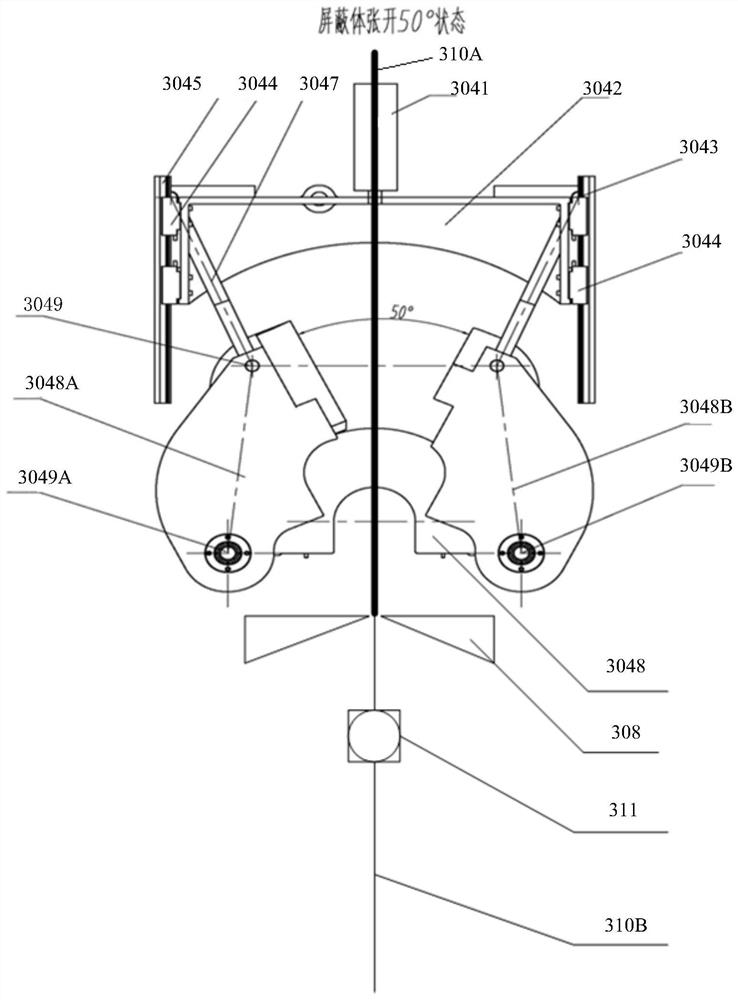

[0143] The left shield body 3048A, the right shield body 3048B, the left shield shaft 3049A, and the right shield shaft 3049B; the left shield body 3048A is rotatably connected around the left shield shaft 3049A, and the right shield body 3048B is rotatably connected around the right shield shaft 3049B; the left shield body Shaft 3049A and right shielding shaft 3049B are at the same level. The distance between left shielding shaft 3049A and right shielding shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com