Construction process for overhead back-up movement and dismantlement of movable shuttering form

A technology of mobile formwork and construction technology, which is applied in the field of bridge construction technology, can solve the problems of wasting time and large damage to concrete box girders, and achieve the effect of saving demolition time and avoiding multiple transfers of demolition equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

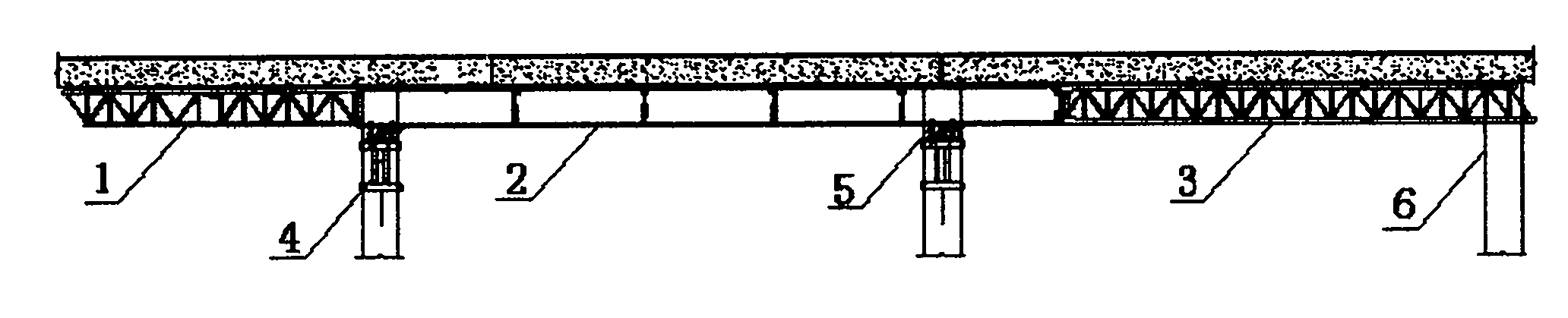

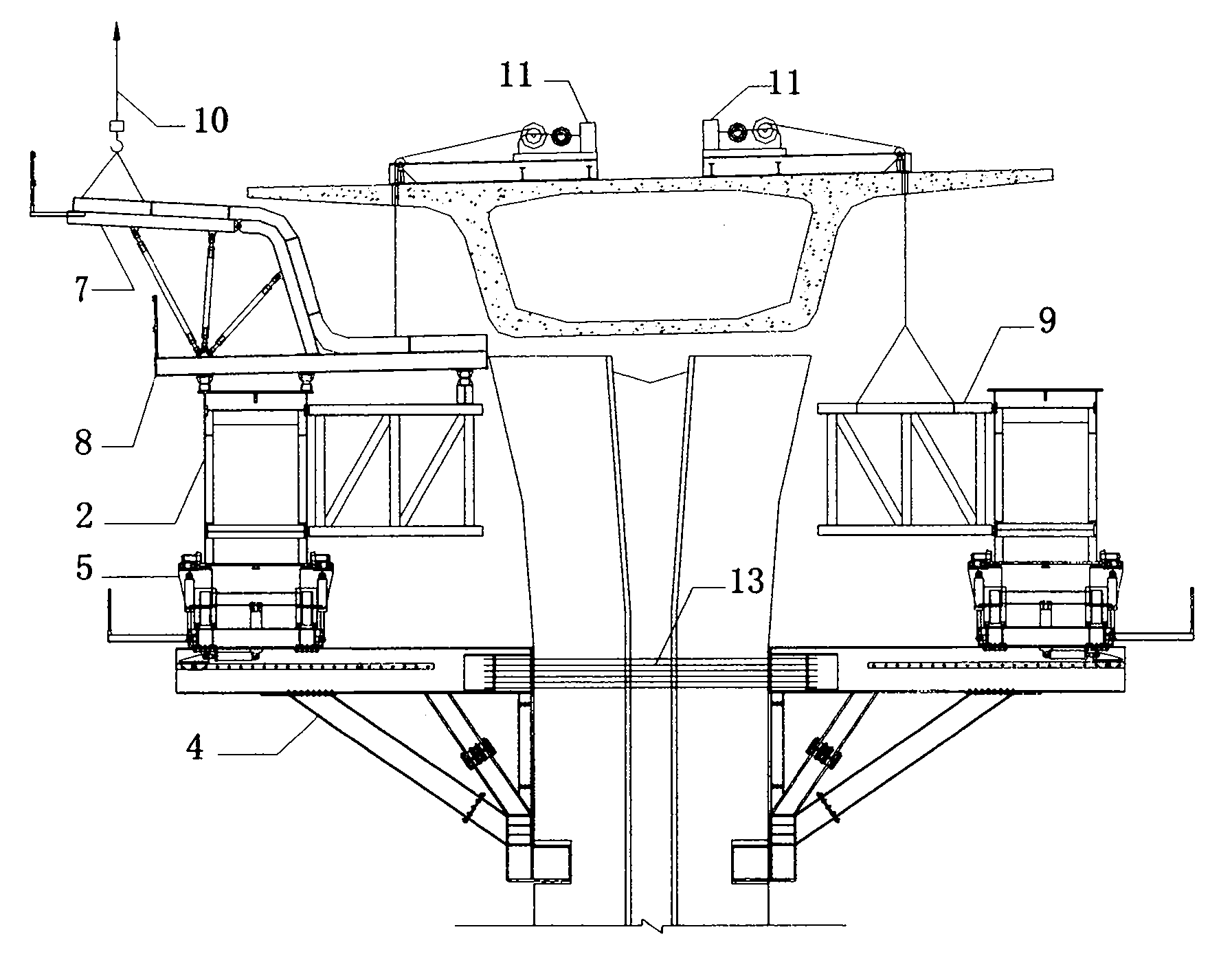

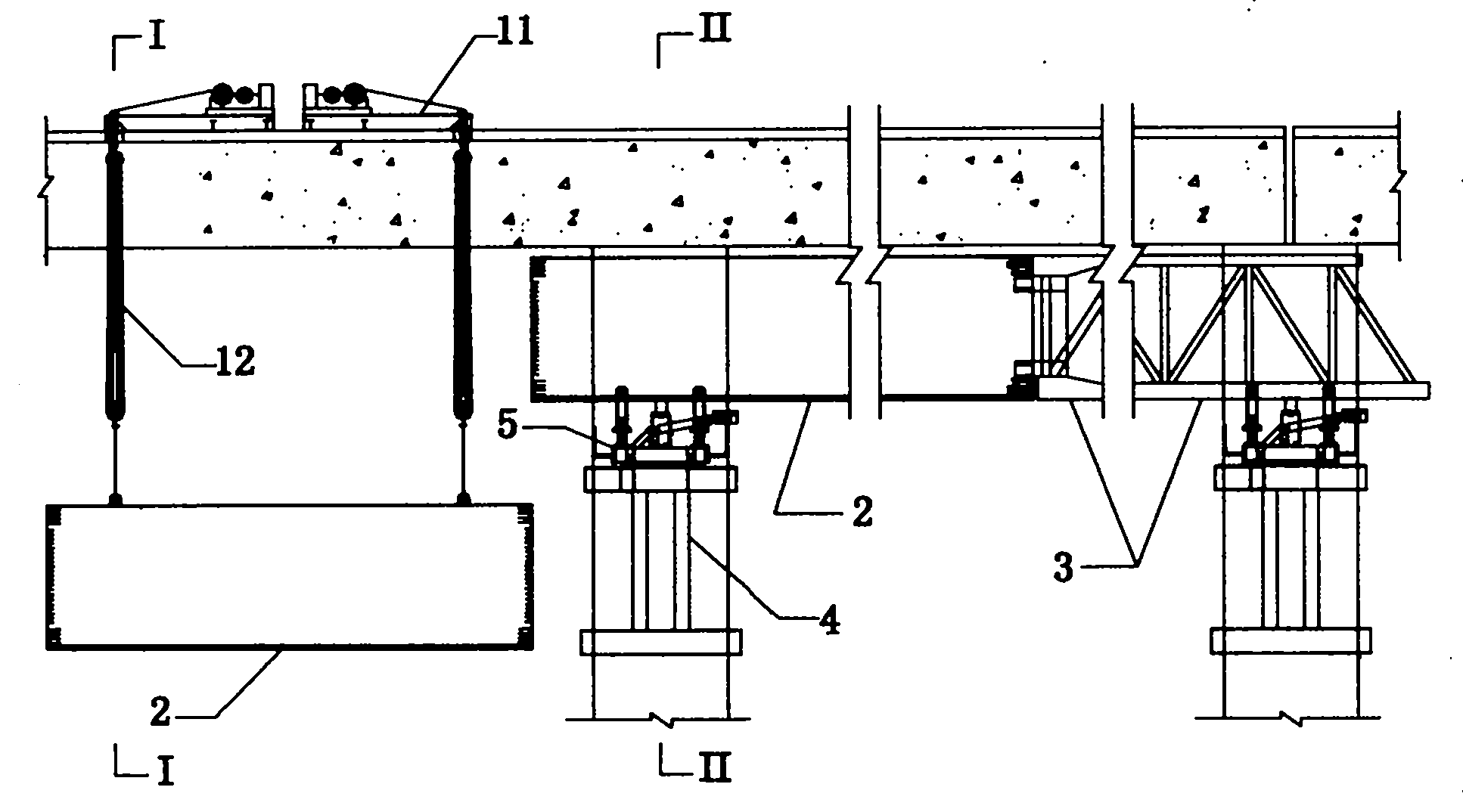

[0016] like figure 1 , figure 2 As shown, the construction process of mobile formwork retreating in the air, dismantling and dismantling, including the rear guide beam 1, main beam 2, front guide beam 3, corbel 4, trolley 5, outer formwork 7, formwork beam 8, and middle beam that need to be removed on both sides of the bridge 9. The corbel pair pulls the fine-rolled rebar 13; use the trolley 5 to move laterally from the corbel 4 to open the mobile formwork, install the hoist 11 on the concrete box girder, and use the hoist 11 and the car crane to pull the outer formwork 7 , remove the formwork beam 8 and middle beam 9 from top to bottom in turn, leaving only the rear guide beam 1, main beam 2 and front guide beam 3, then remove the main beam 2 of the mobile formwork, and finally remove the last section of the main beam 2 and the front guide beam 3.

[0017] Remove the main beam 2 of the mobile formwork (excluding the last main beam 2) as image 3 , Figure 4 shown. Fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com