Patents

Literature

949results about "Form treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

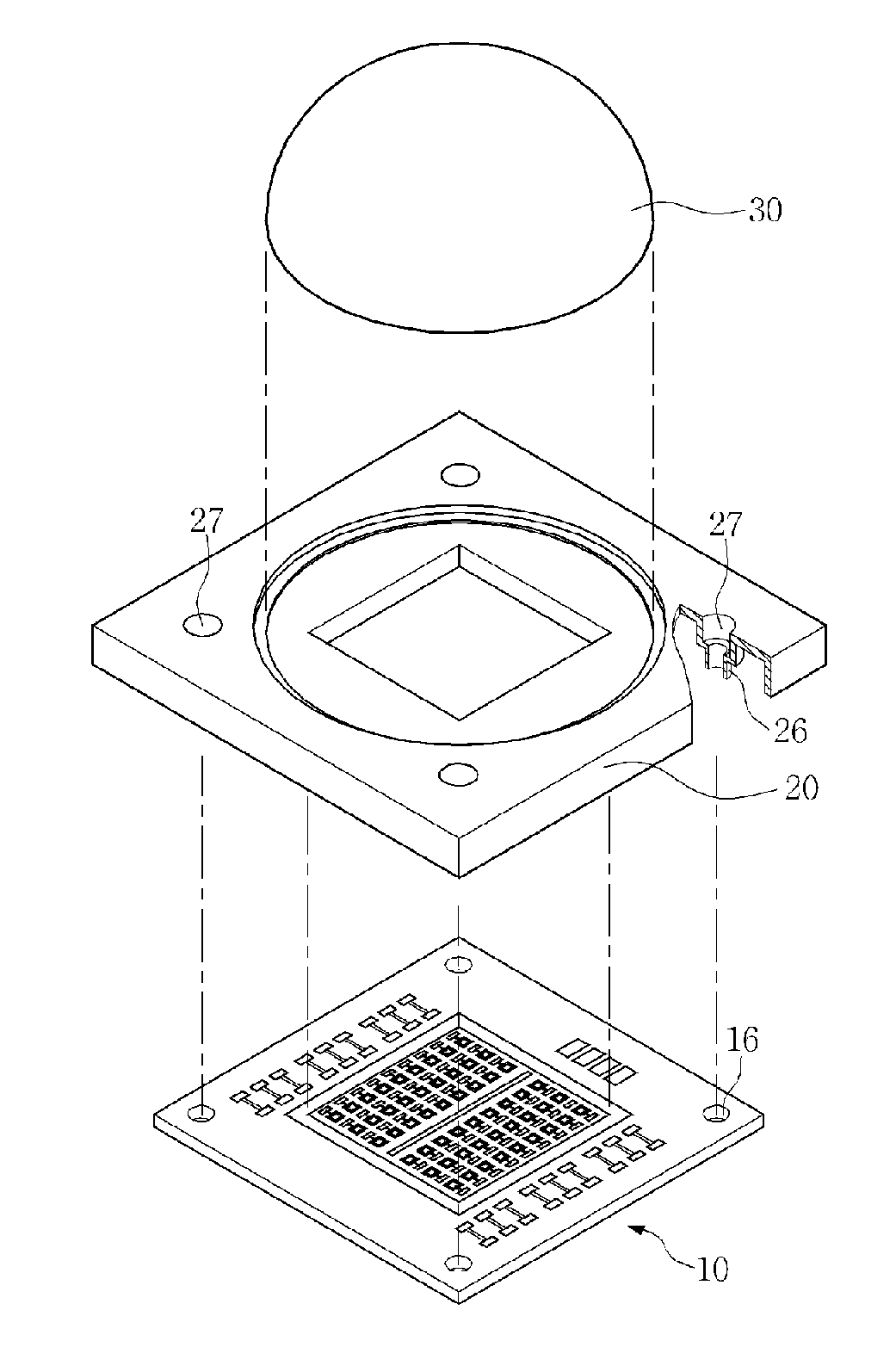

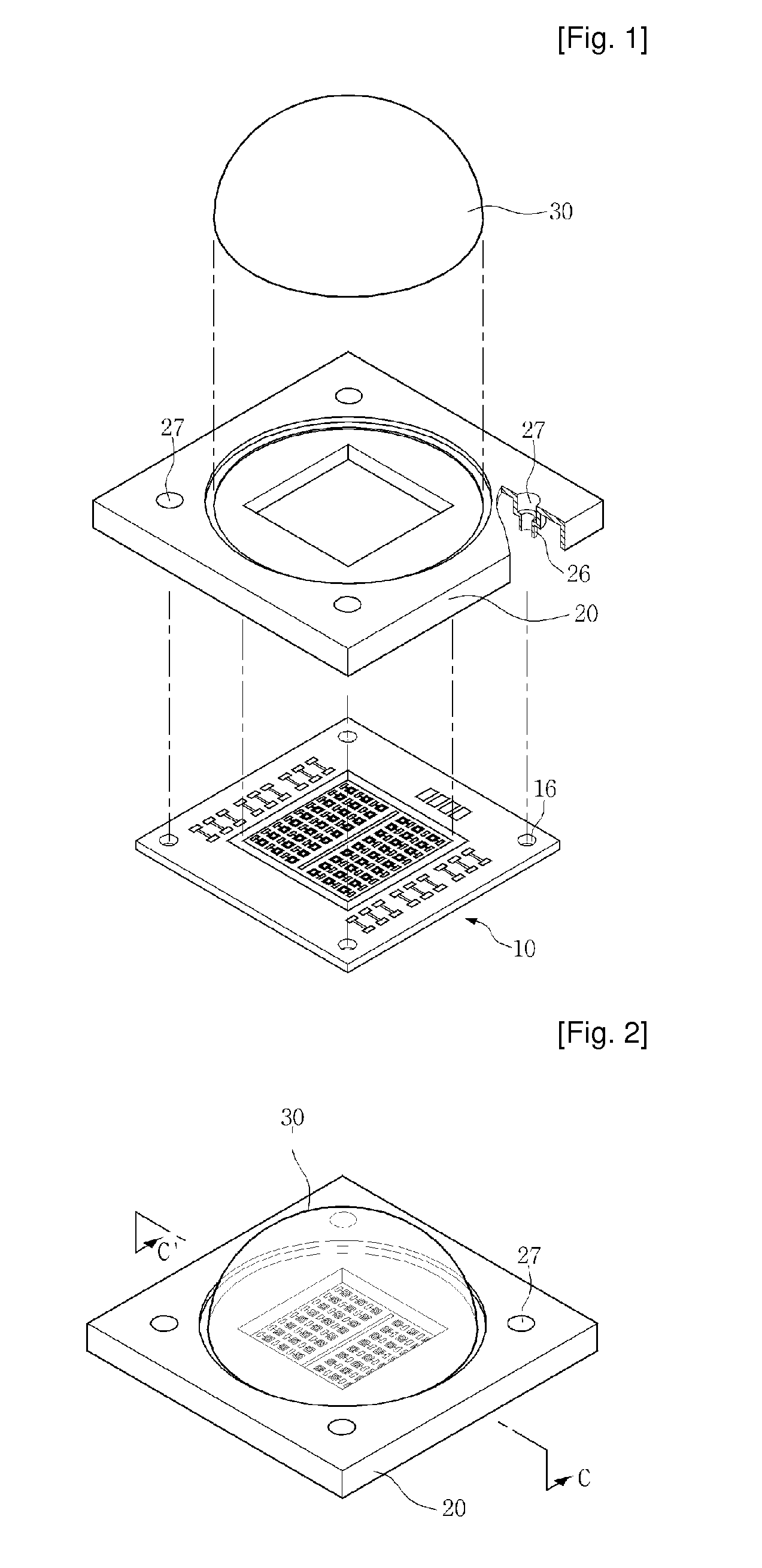

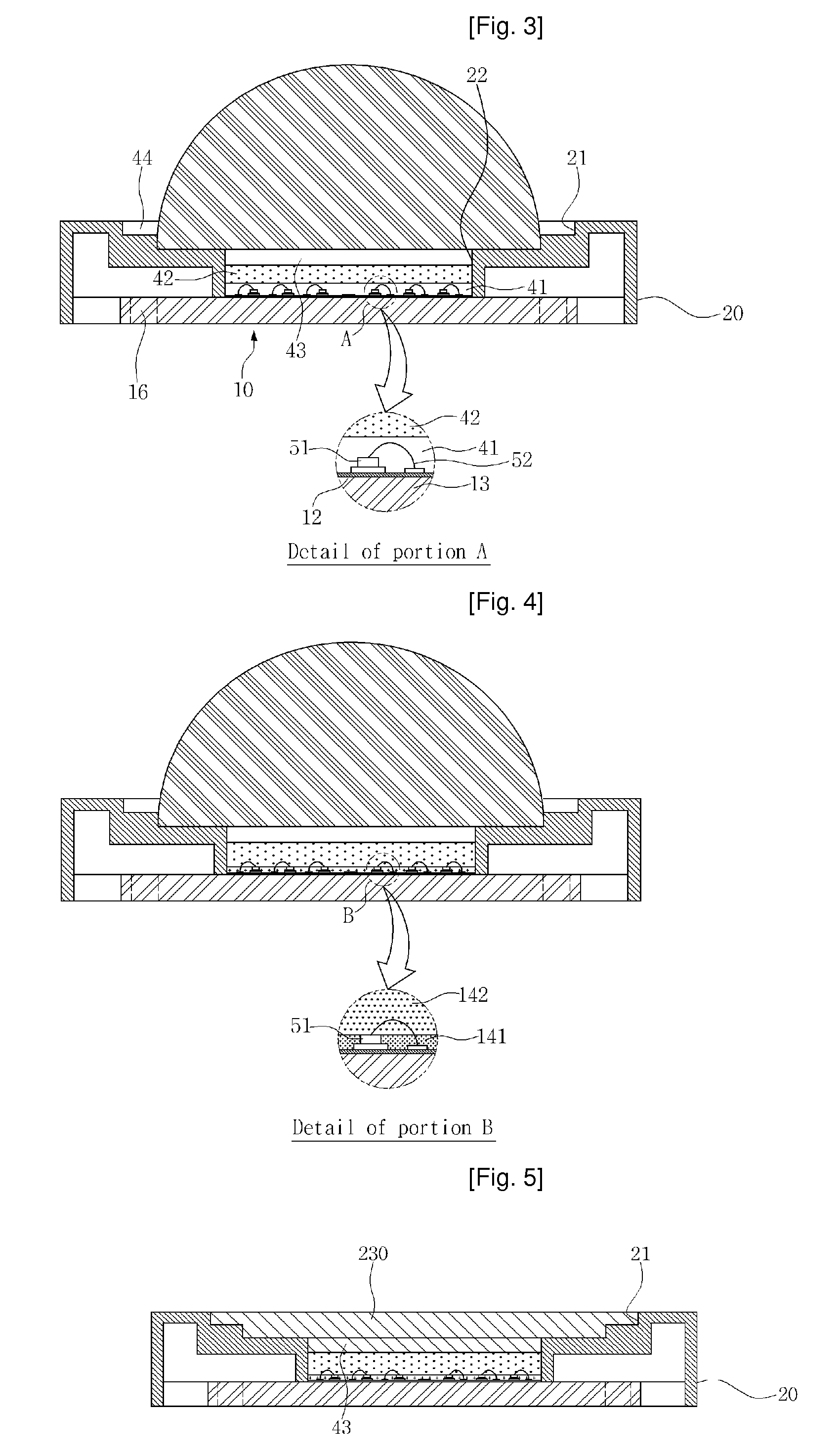

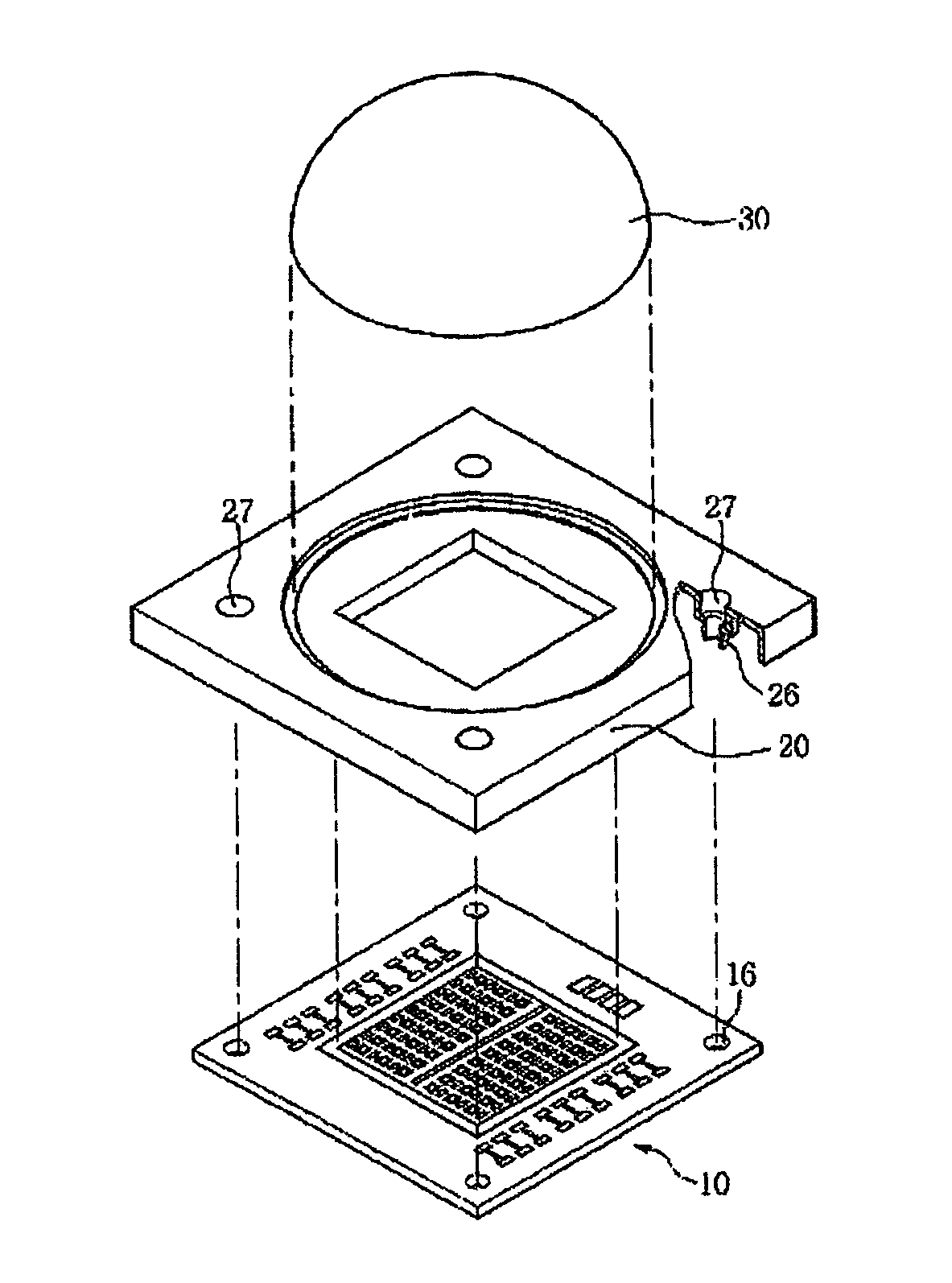

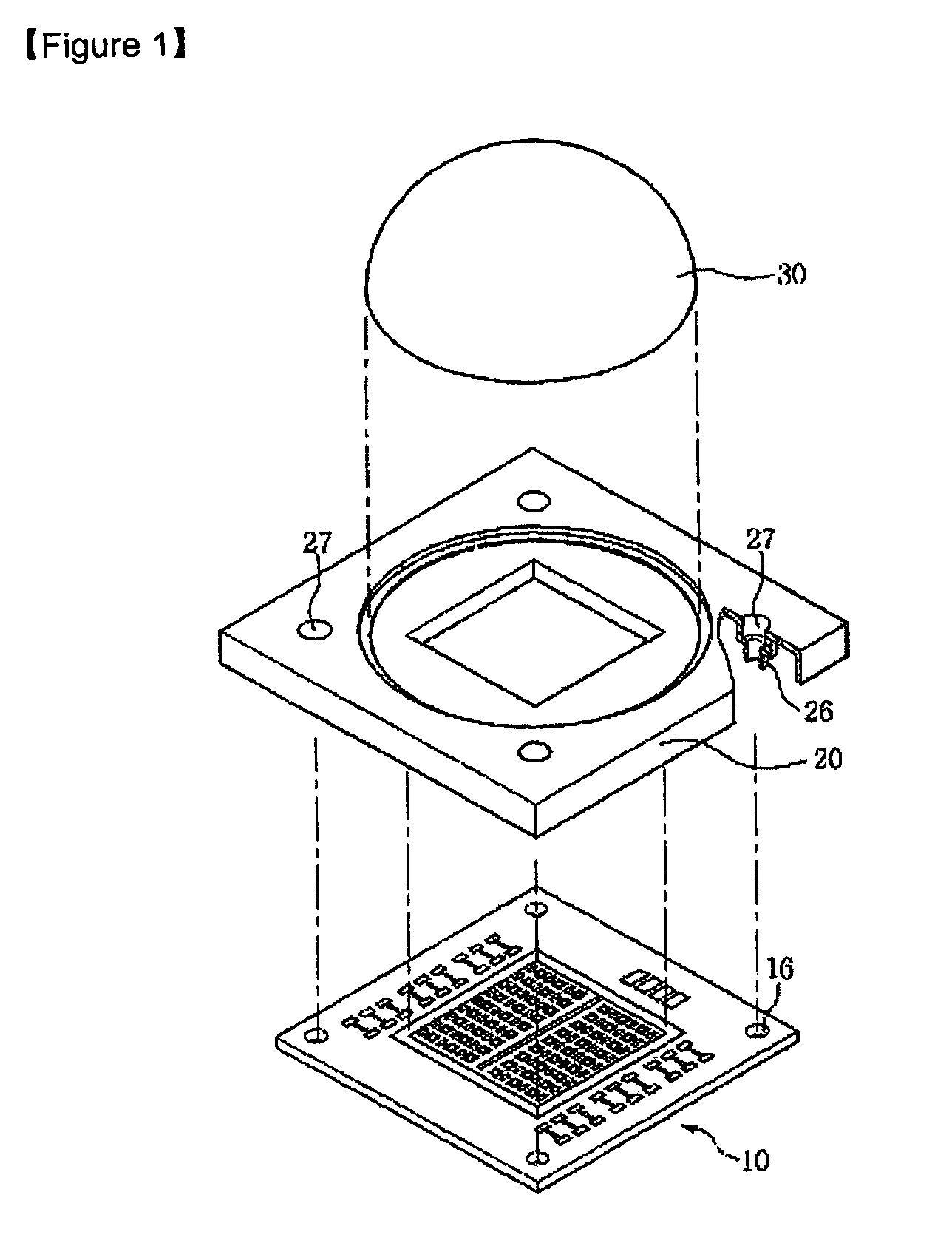

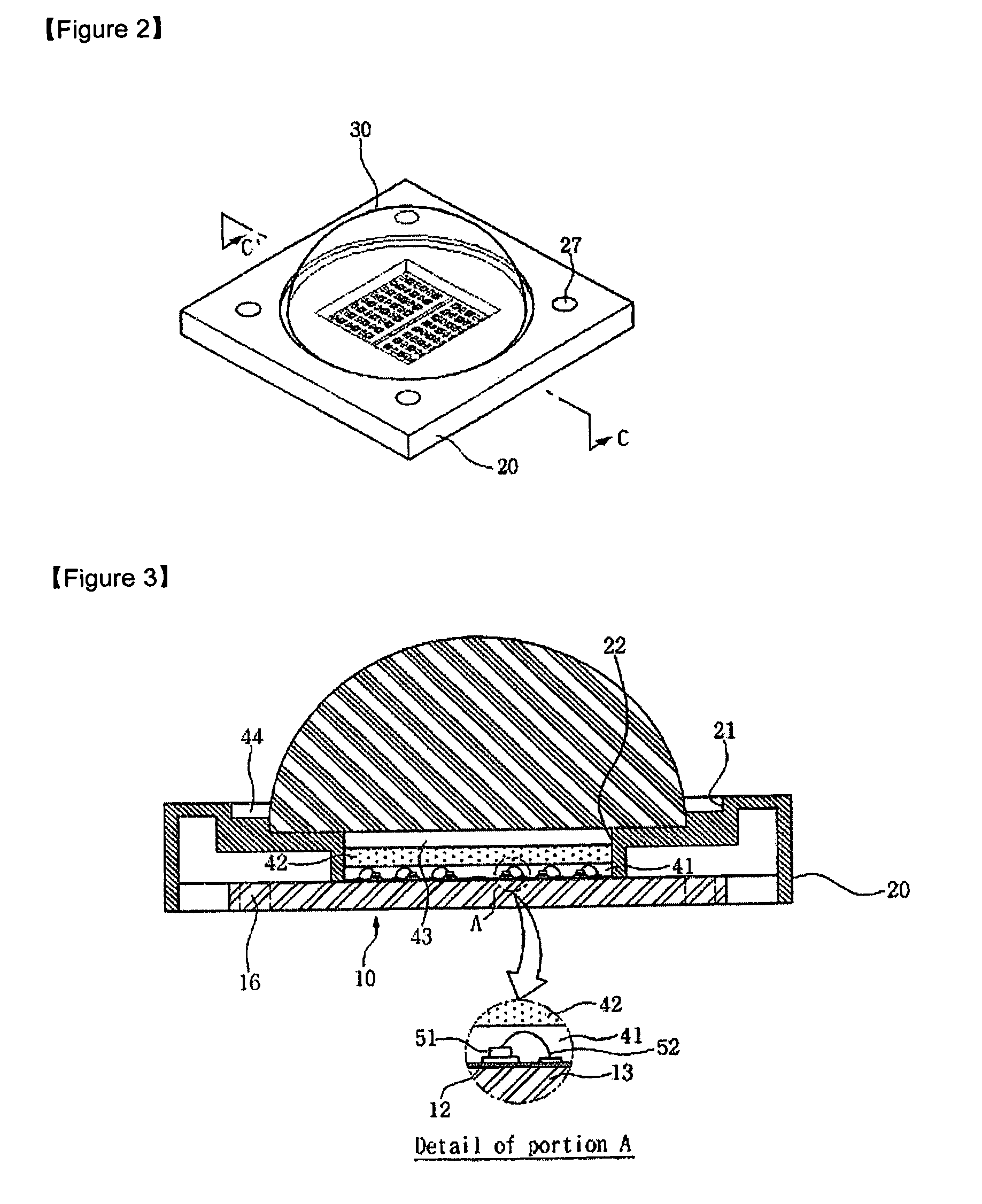

LED module for illumination

InactiveUS20090122514A1Improve cooling effectThermal resistancePoint-like light sourcePortable electric lightingEpoxyEngineering

The present invention relates to an LED module for illumination, and more particularly, to an LED module for illumination capable of enhancing light emitting efficiency by having a light emitting structure, in which the thickness of an insulation substrate with an electrode pattern formed on a top portion thereof is minimized, a heat radiation substrate is formed by integrally attaching a radiator to a bottom surface of the insulation substrate, and LED elements are attached to the electrode pattern of the heat radiation substrate through silver epoxy with excellent heat conductivity as an adhesive agent, so that heat generated from the LED elements can effectively radiate through the radiator, white light is effectively generated from the light emitted from the LED elements, and the white light can be emitted to the outside maximally.

Owner:KIM WEON

LED module for illumination

InactiveUS7740373B2Improve cooling effectLife span of the LED element can be extendedPoint-like light sourcePortable electric lightingWhite lightHeat spreader

The present invention relates to an LED module for illumination, and more particularly, to an LED module for illumination capable of enhancing light emitting efficiency by having a light emitting structure, in which the thickness of an insulation substrate with an electrode pattern formed on a top portion thereof is minimized, a heat radiation substrate is formed by integrally attaching a radiator to a bottom surface of the insulation substrate, and LED elements are attached to the electrode pattern of the heat radiation substrate through silver epoxy with excellent heat conductivity as an adhesive agent, so that heat generated from the LED elements can effectively radiate through the radiator, white light is effectively generated from the light emitted from the LED elements, and the white light can be emitted to the outside maximally.

Owner:KIM WEON

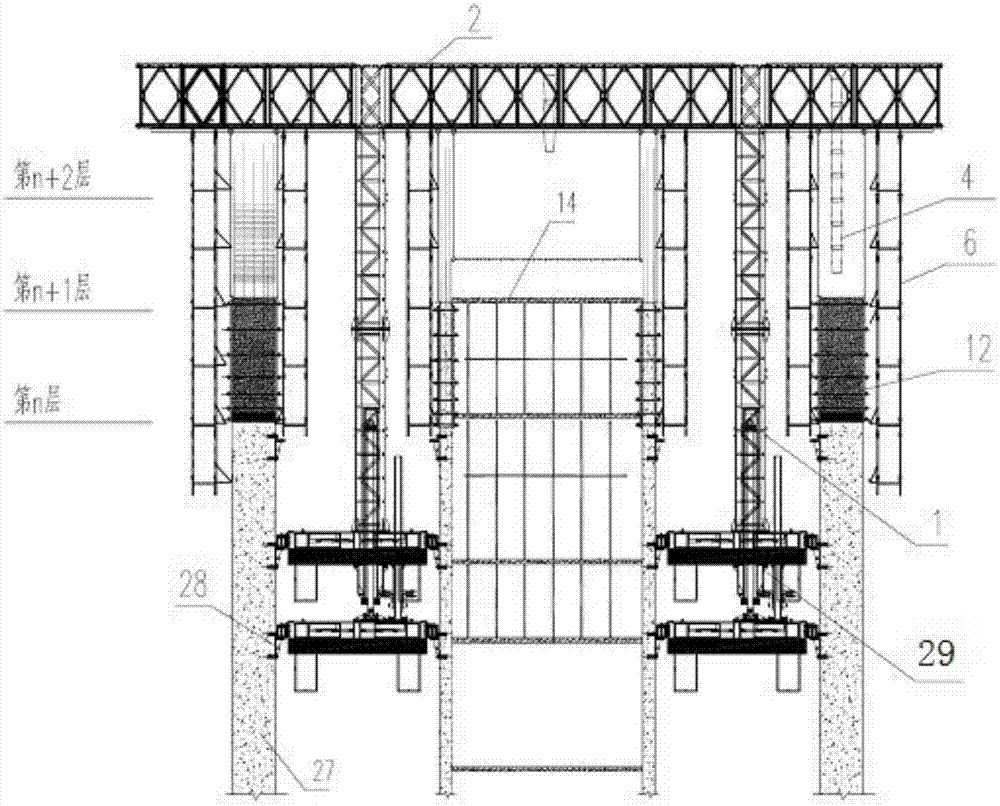

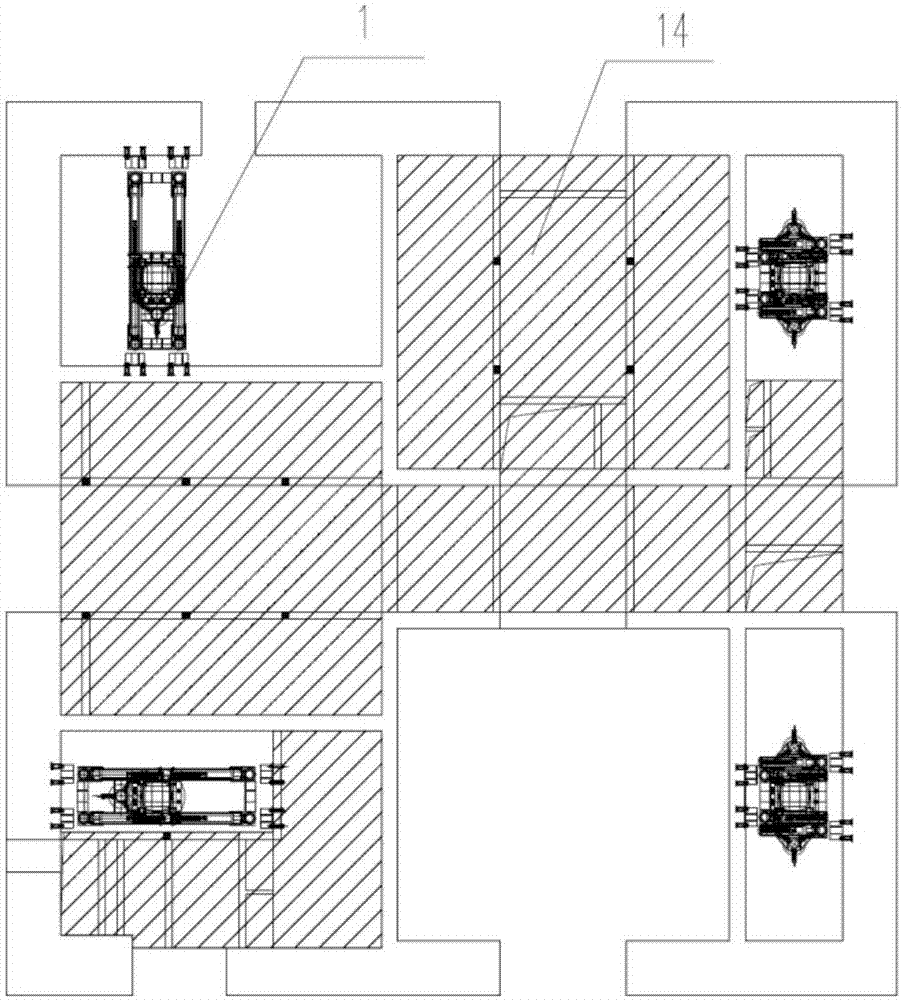

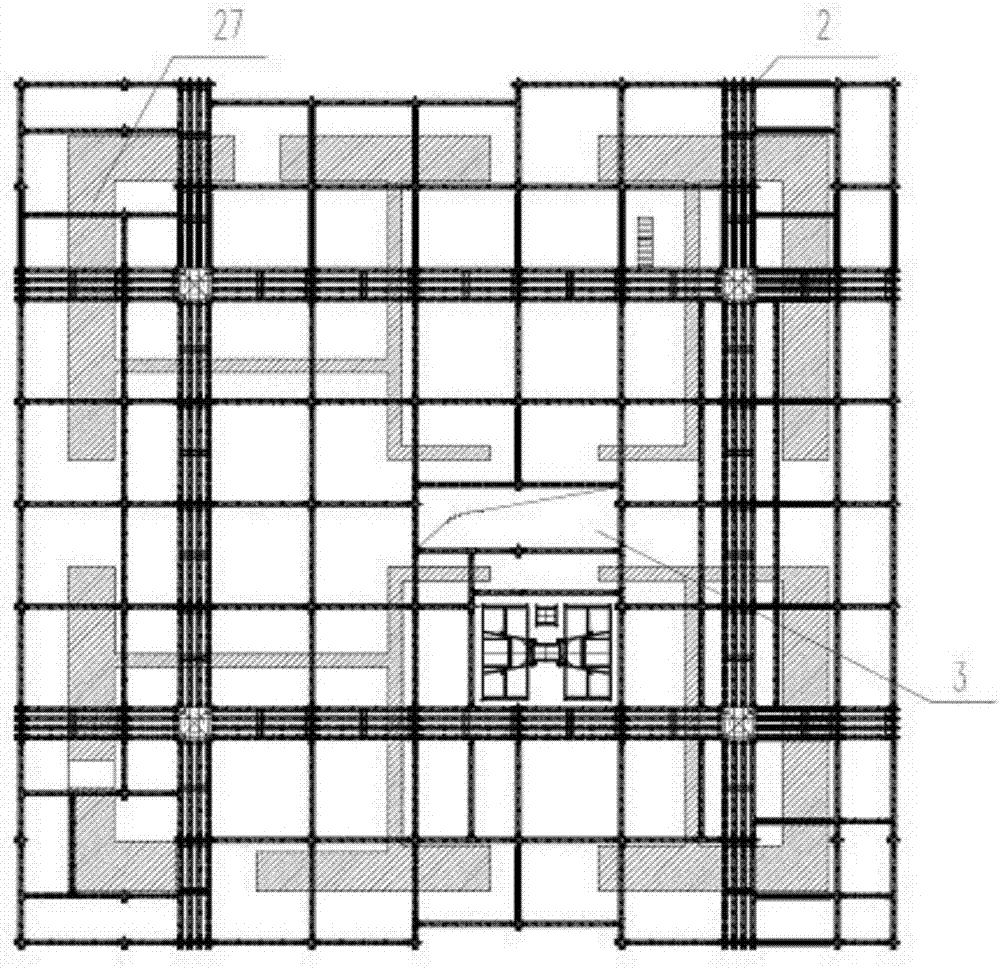

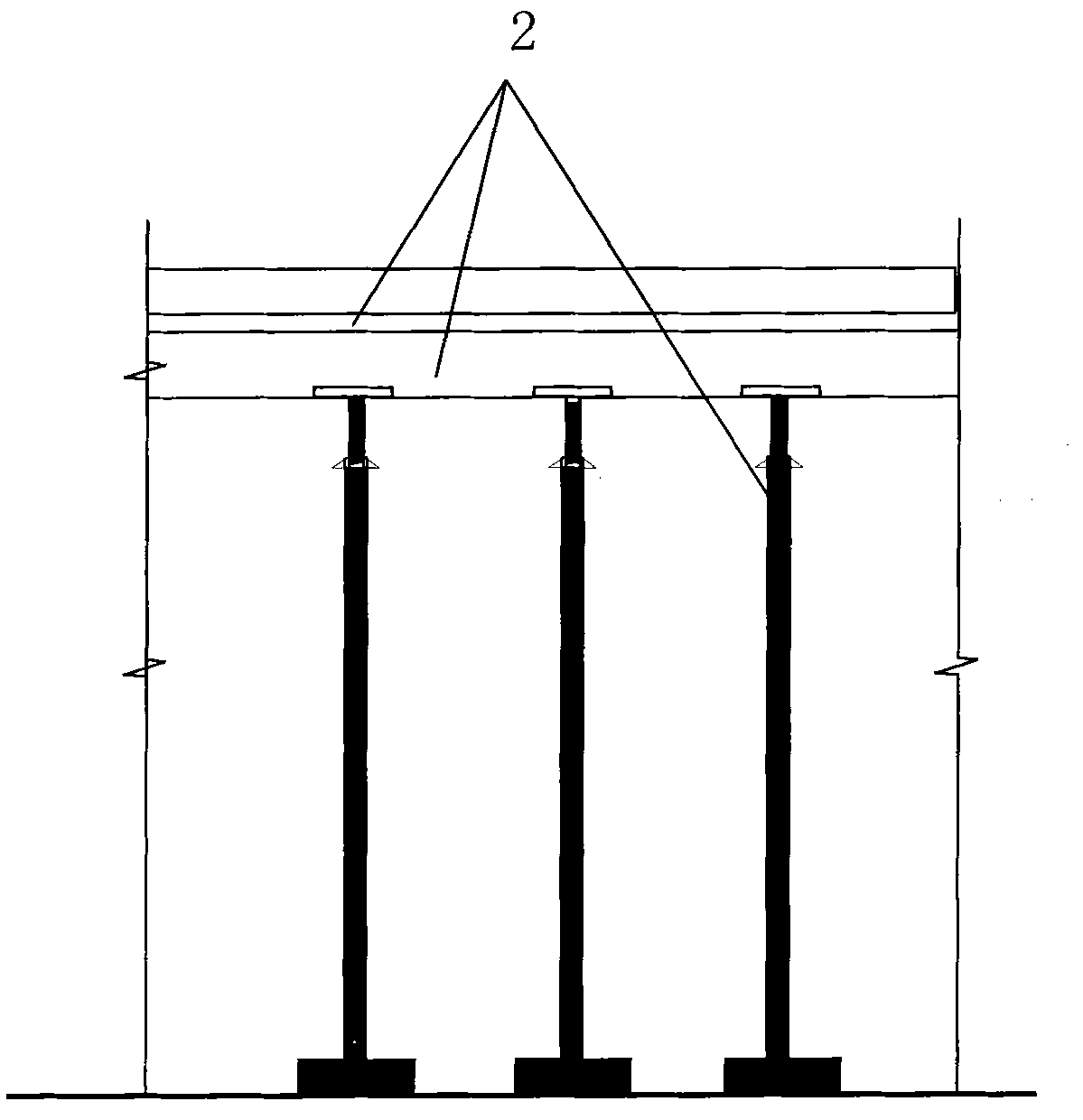

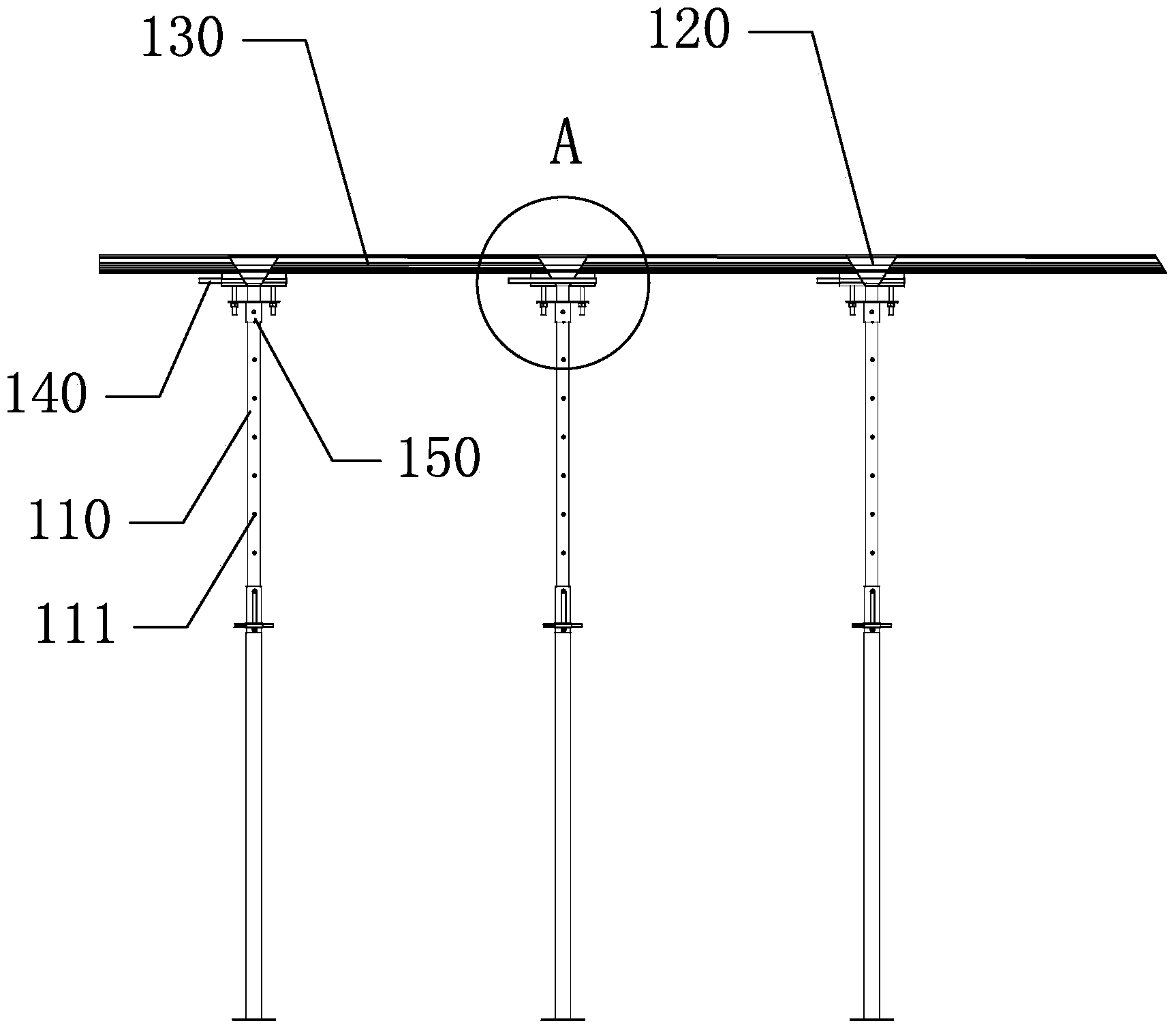

Super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system and construction method

InactiveCN106869489AReduce productionReduce consumptionForms/shuttering/falseworksForm treatmentSupporting systemControl system

The invention discloses a super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system which comprises a truss platform system, a hanger enclosure system, a supporting system, a formwork system and a hydraulic control system. The formwork system is an aluminum alloy formwork system. The aluminum alloy formwork system comprises vertical wall formworks and horizontal formworks. Each vertical wall formwork comprises a plurality of aluminum alloy standard unit plates spliced transversely, and C-shaped aluminum alloy grooves located in the aluminum alloy standard unit plates. Each horizontal formwork is formed by splicing a plurality of aluminum alloy bulk slicing plates. The horizontal formworks on the different layers are formed by splicing the aluminum alloy bulk slicing plates different in quantity. The horizontal formworks are connected with the vertical wall formworks through the C-shaped aluminum alloy grooves. According to the super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system provided by the invention, synchronous construction of horizontal structures and vertical structures of a core tube is achieved.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

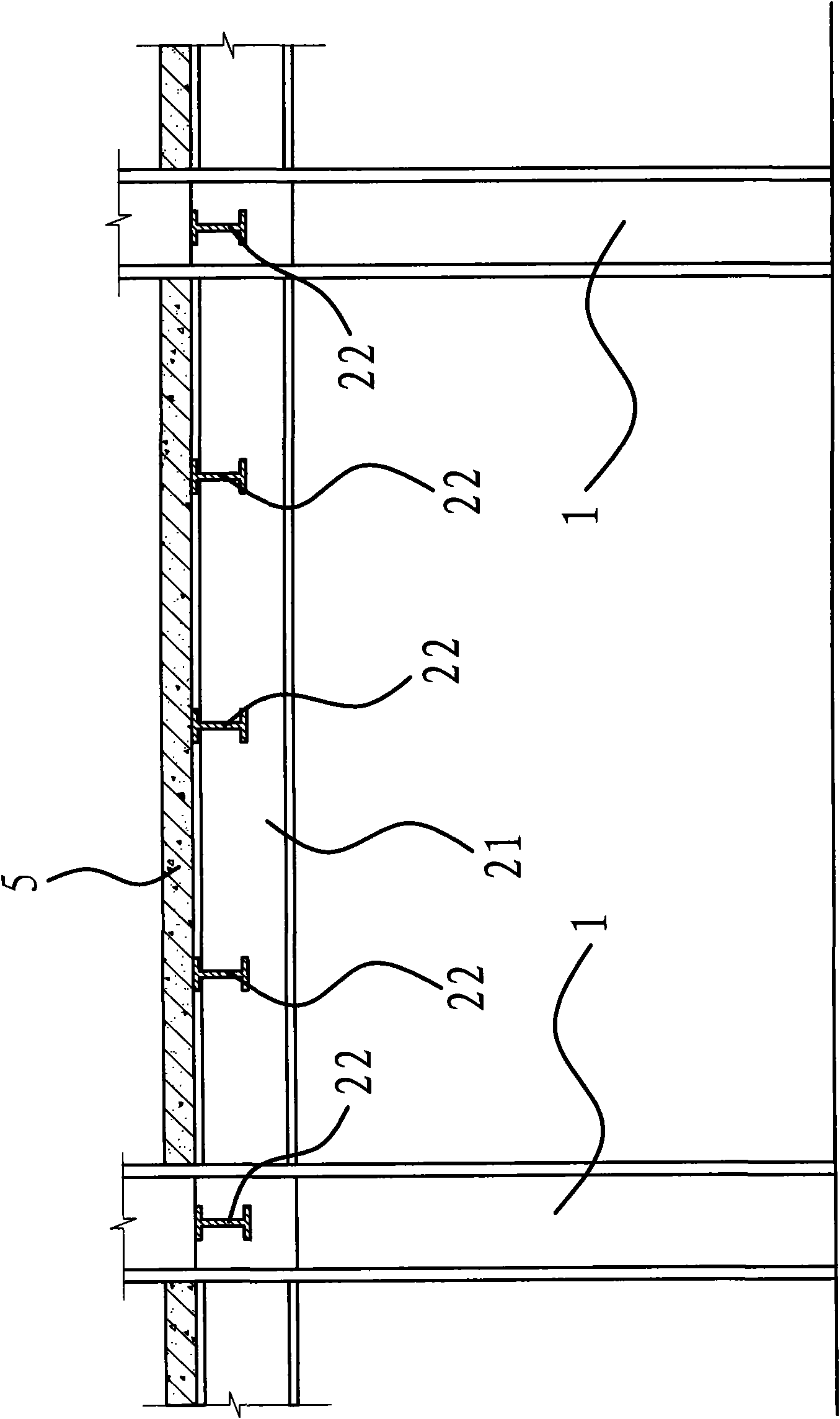

Transformation and construction method used for facing bare concrete of existing building outer wall

ActiveCN103470067AMeet the stiffness requirementsEasy to fixBuilding repairsForms/shuttering/falseworksRebarMaterials science

The invention discloses a transformation and construction method used for facing bare concrete of an existing building outer wall. The method comprises the steps of processing of a formwork, binding of reinforcing steel bars, installation of bare formwork, casting of the bare concrete, removal of the bare formwork, maintenance of the bare concrete, cutting of visible joints, blocking and repairing of split bolt holes and coating of protective paint. According to the method, a steel formwork of which the inner surface is attached to a stainless steel board servers as the bare formwork,, reinforcing steel bar meshes serve as structural bars, the self-compaction bare concrete serves as a bare concrete mixture, and the construction of a thin-type bare concrete faced wall is finished in the mode that many times of rolling over construction are conducted from the bottom to the top of the existing building outer wall. The method not only improves the appearance quality of the bare concrete, but also ensures close integration between the newly-cast bare concrete and the existing building outer wall.

Owner:WUDA JUCHENG STRUCTURE CO LTD

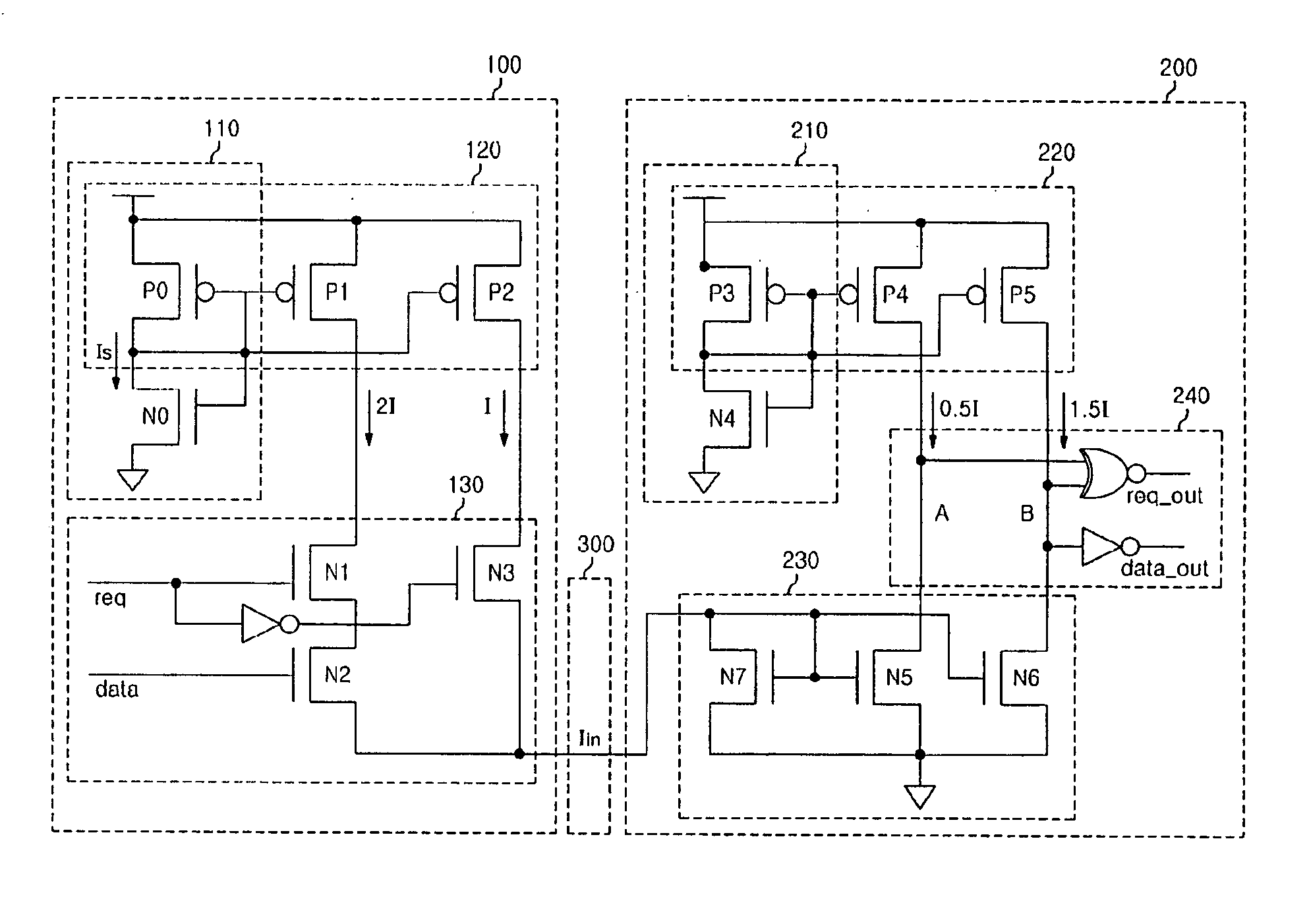

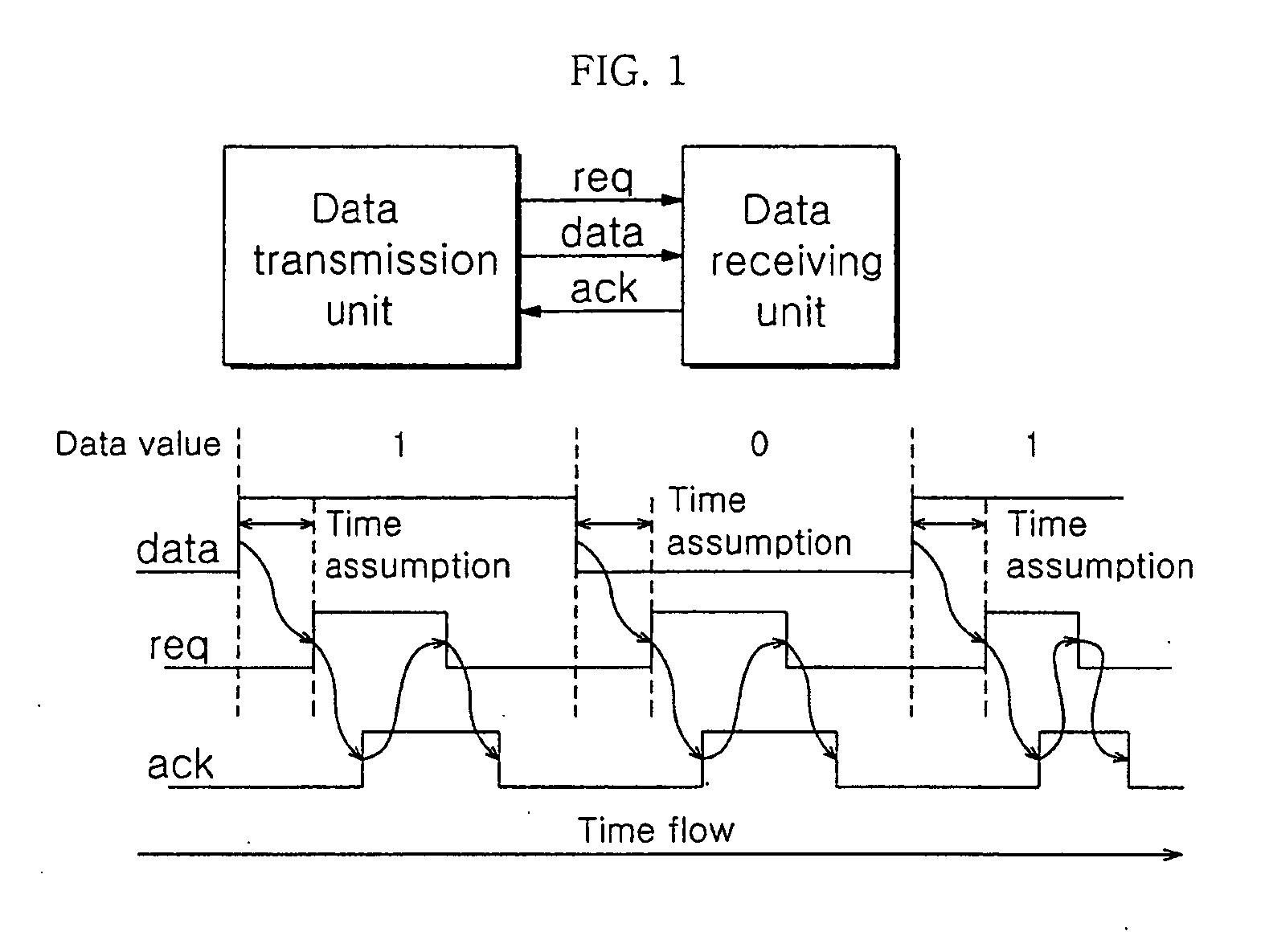

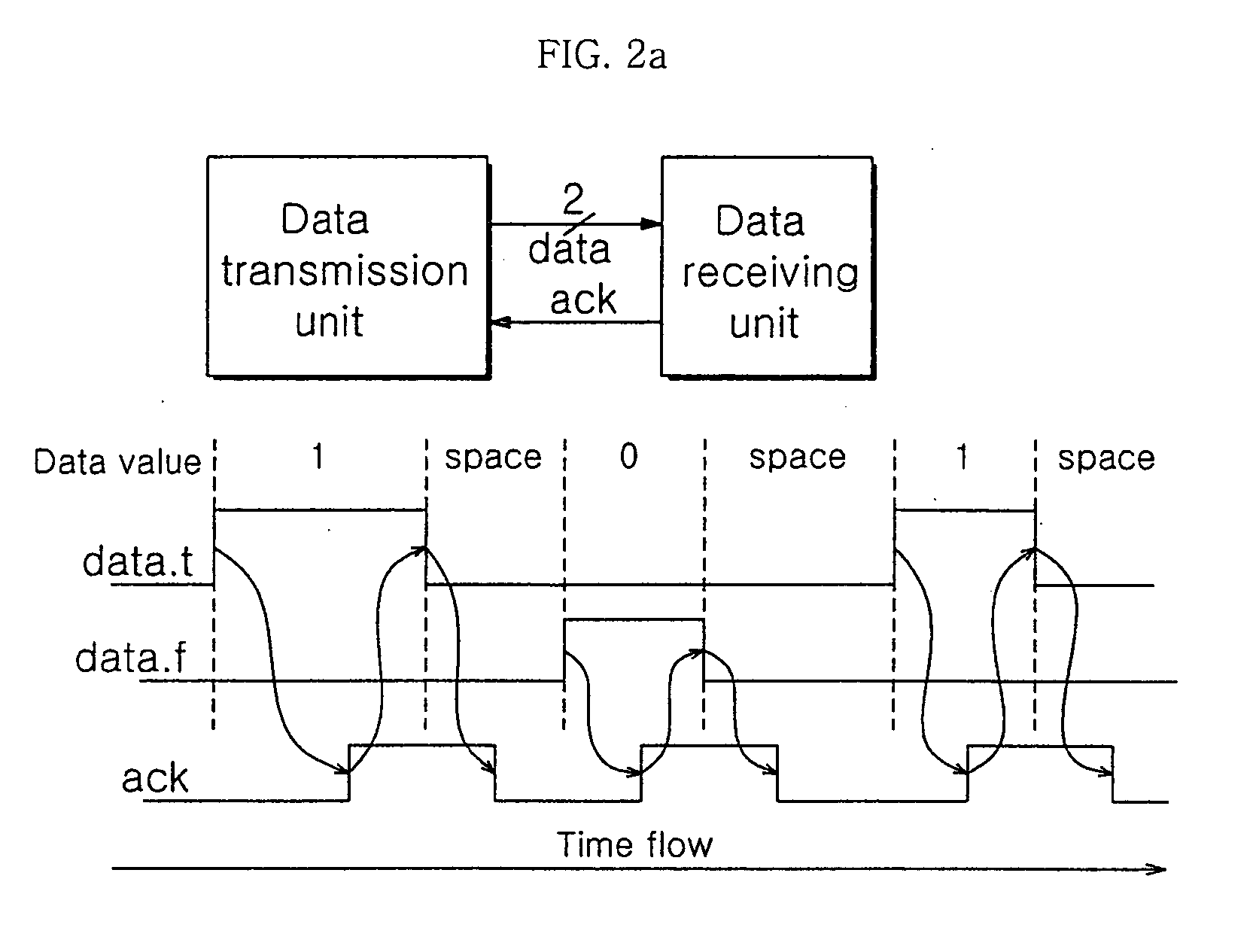

Delay-insensitive data transfer circuit using current-mode multiple-valued logic

InactiveUS20050200388A1Reduce in quantityReduce designReliability increasing modificationsData switching detailsData signalDelayed time

The present invention relates to a delay-insensitive DI data transfer circuit based on a current-mode multiple-valued logic for transferring data regardless of a delay time of transmission according to a length of wire. The delay-insensitive data transfer circuit of the present invention, in a delay-insensitive data transfer circuit transferring an input request signal and a data signal from a data transmission unit to a data receiving unit, comprises: an encoder for outputting a signal which has been converted to current-level signals in response to voltage-level input of data signal and request signal from the data transmission unit; and a decoder for restoring the voltage-level signals from the current-level signals of the encoder, abstracting a data signal and a request signal from the restored voltage-level signals, and outputting the data signal and the request signal to the data receiving unit.

Owner:GWANGJU INST OF SCI & TECH

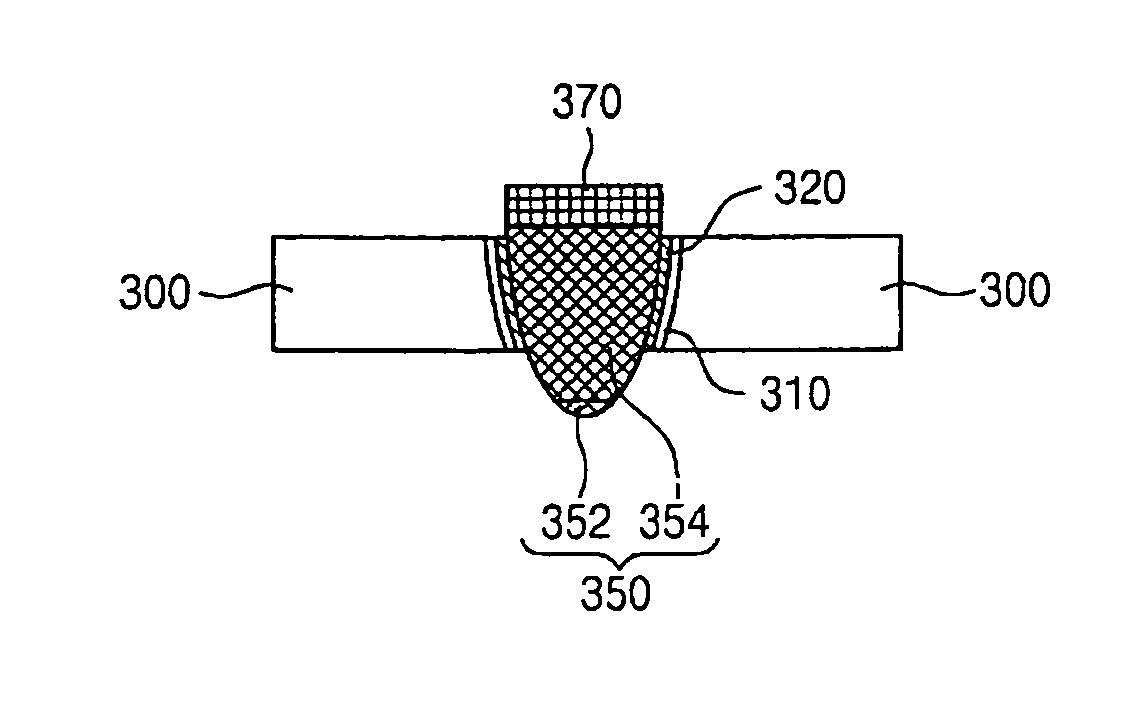

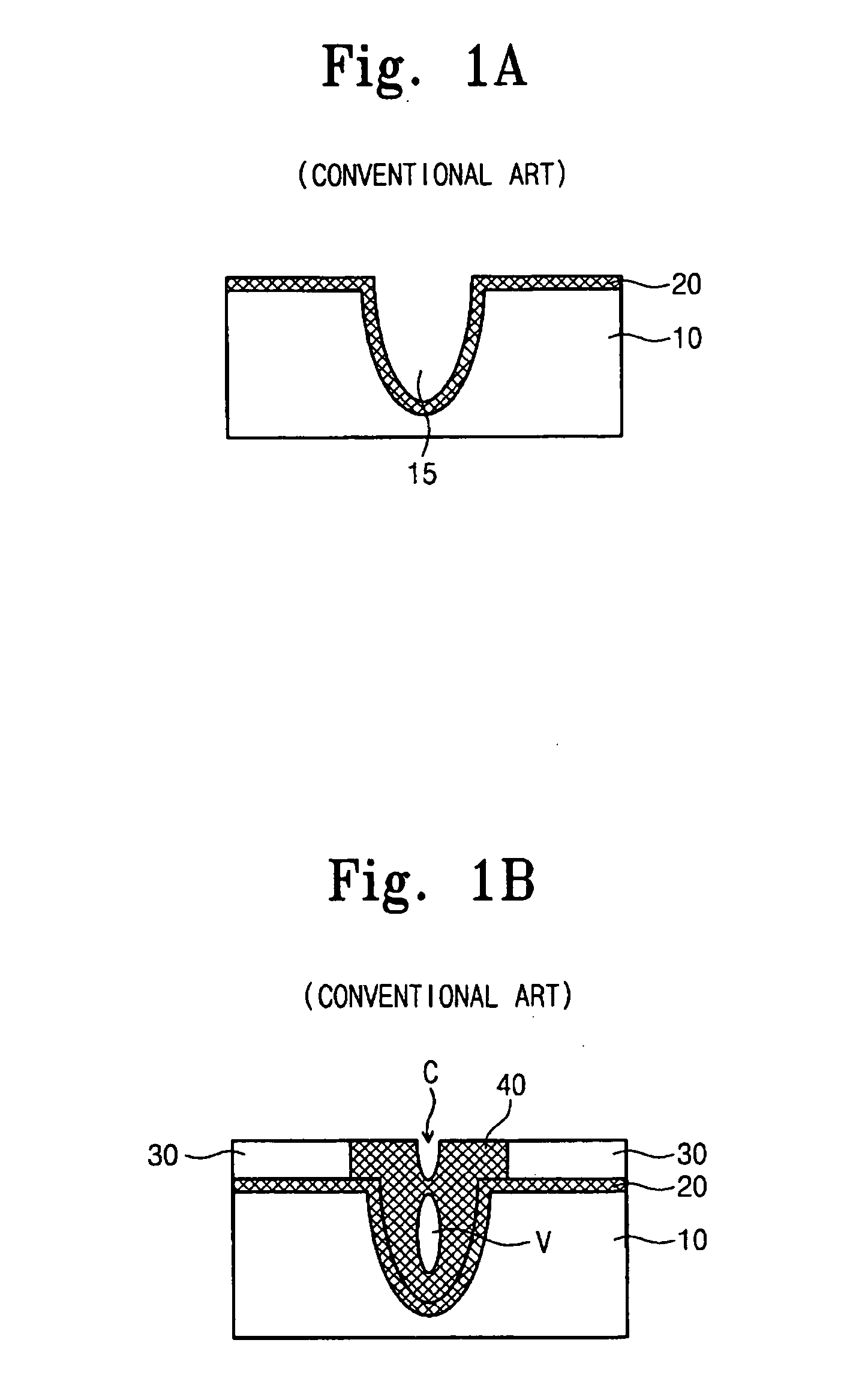

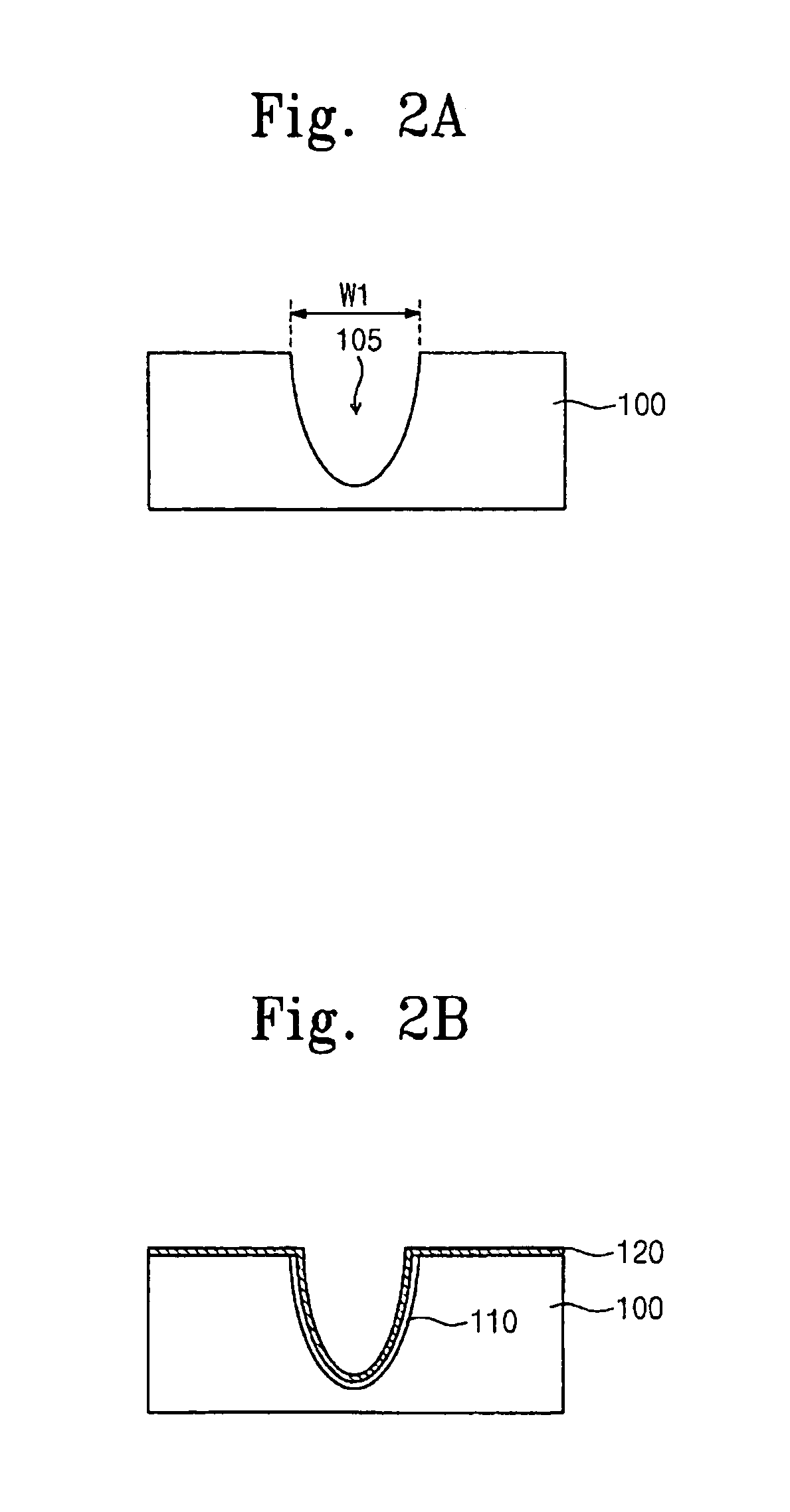

Semiconductor devices and methods of forming the same

InactiveUS20080157287A1Improve electrical performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialAdemetionine

A semiconductor device and methods of forming the same are provided. The methods may include forming a hole in a preliminary semiconductor substrate, forming an insulating layer in the hole of the preliminary semiconductor substrate, forming a plating conductive layer on the insulating layer and the preliminary semiconductor substrate, forming a seed metal layer contacting the plating conductive layer at a lower portion of the hole and growing the seed metal layer to form a through-silicon via (TSV). The TSV may be formed through an electroplating process such that the seed metal layer grows from the lower portion of the hole to an upper portion of the hole.

Owner:SAMSUNG ELECTRONICS CO LTD

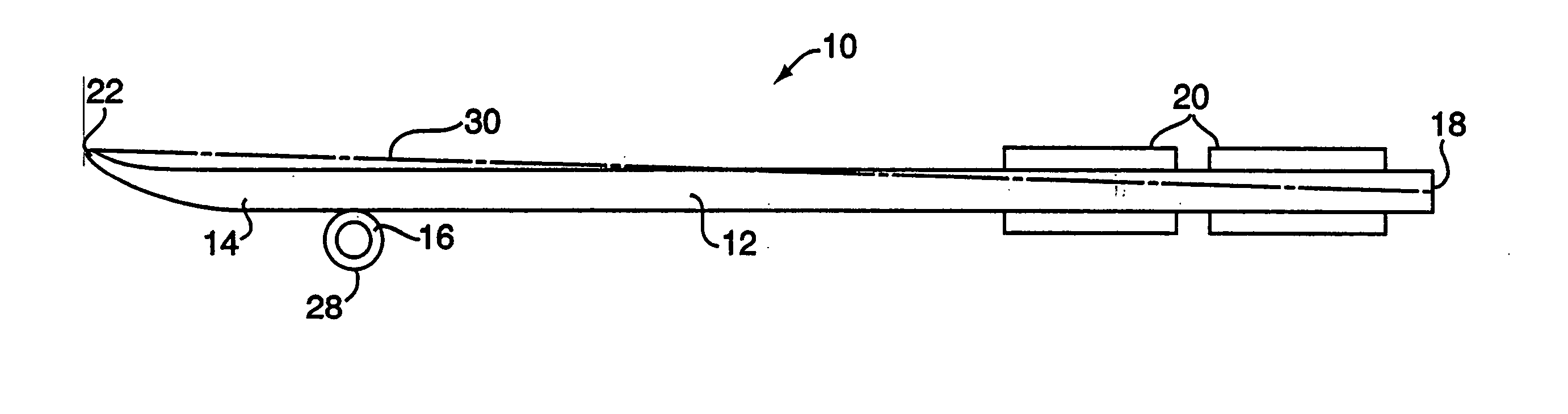

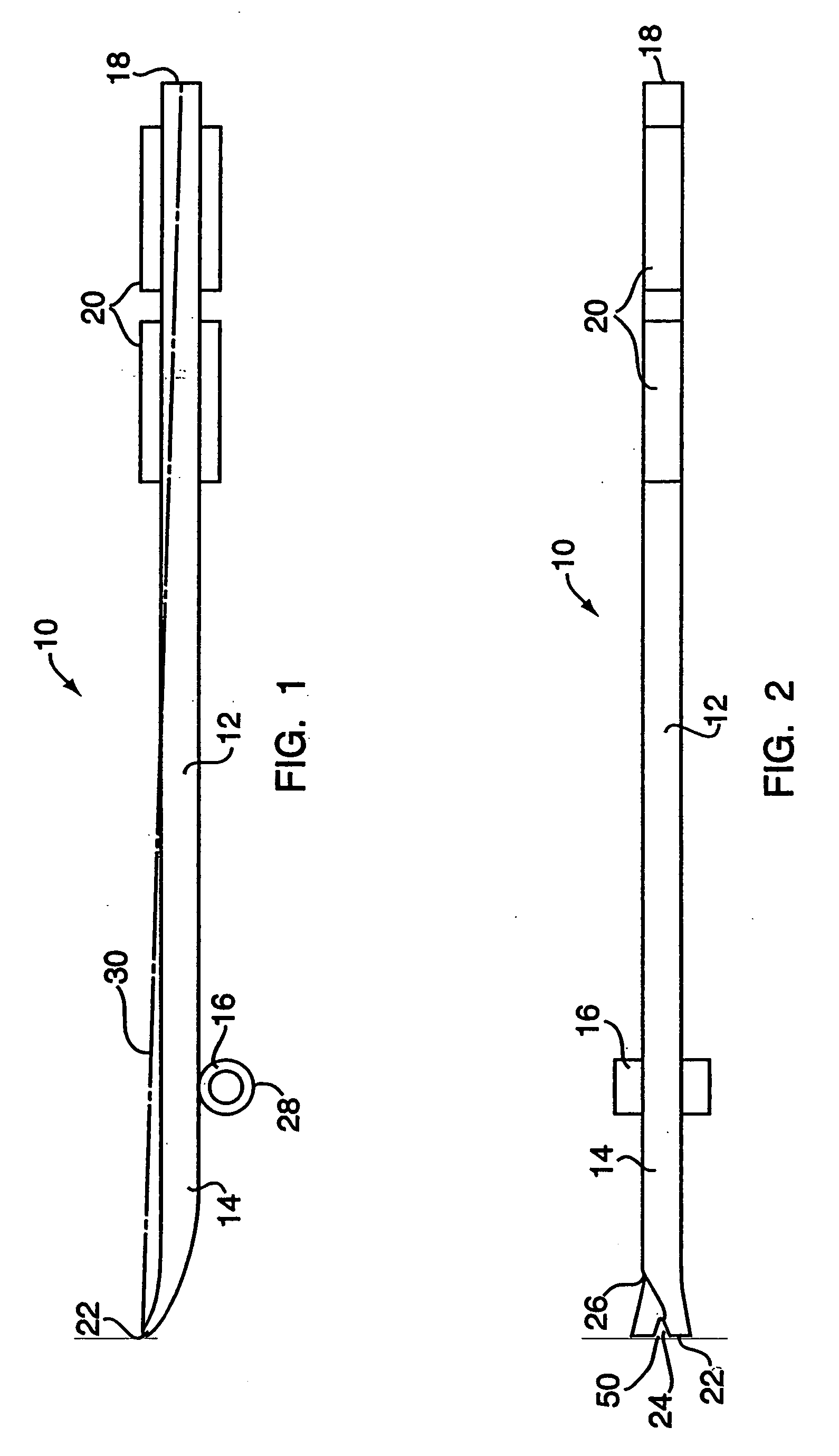

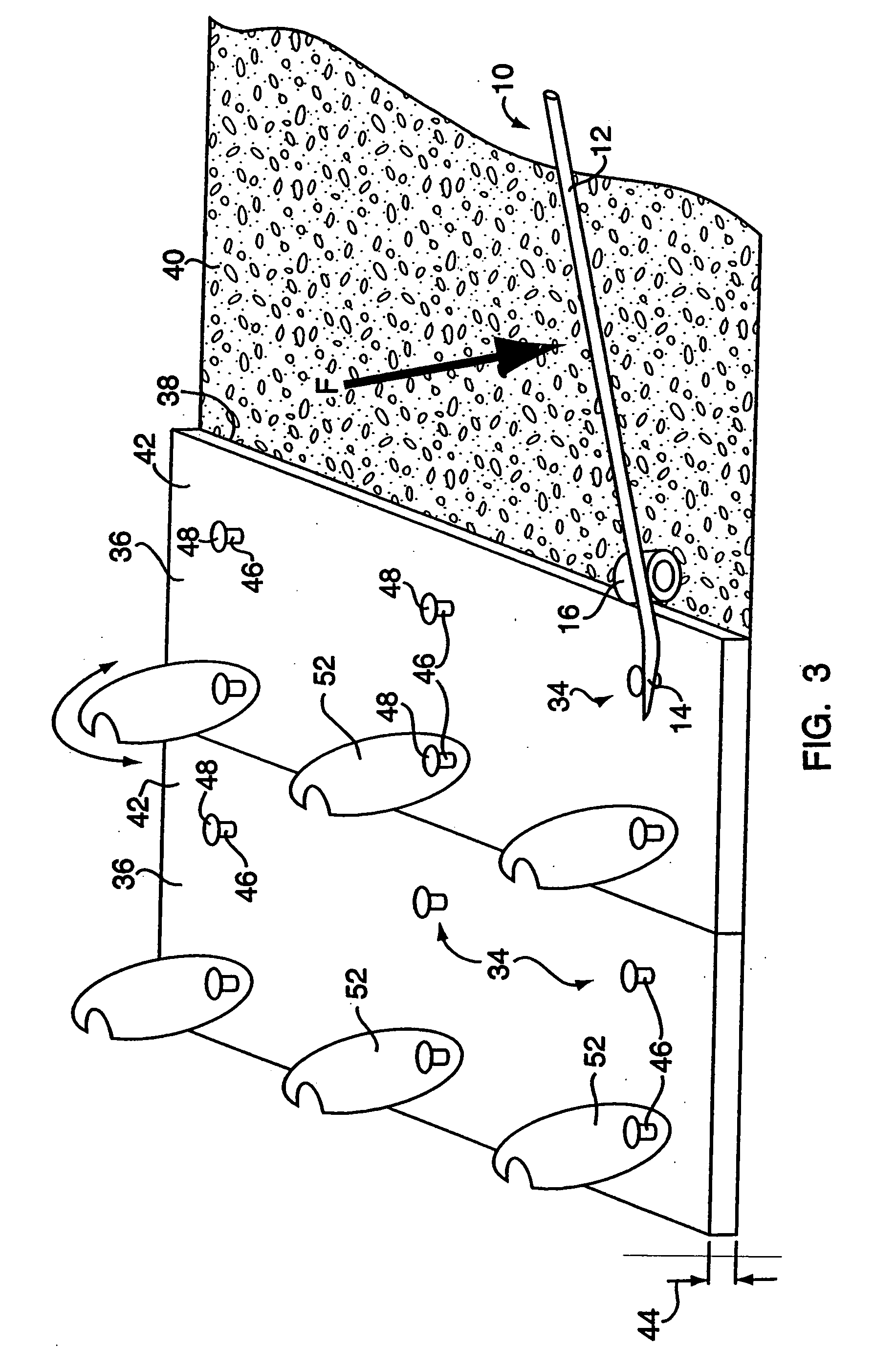

Method and apparatus for removing modular forms

A method and apparatus for removing modular forms includes a lever arm having a first longitudinal end and a second longitudinal end. A projection such as a hardened steel pin extends beyond the first longitudinal end for engaging a hole defined in a form. The projection extends in a direction generally parallel to a longitudinal axis of the lever arm. A fulcrum is coupled to the lever arm. The fulcrum is disposed closer to the first longitudinal end relative to the second longitudinal end. A knuckle guard is coupled to and is disposed on a same side of the lever arm relative to the fulcrum. The knuckle guard is disposed closer to the second longitudinal end relative to the first longitudinal end.

Owner:FORM PULLER TOOL CO

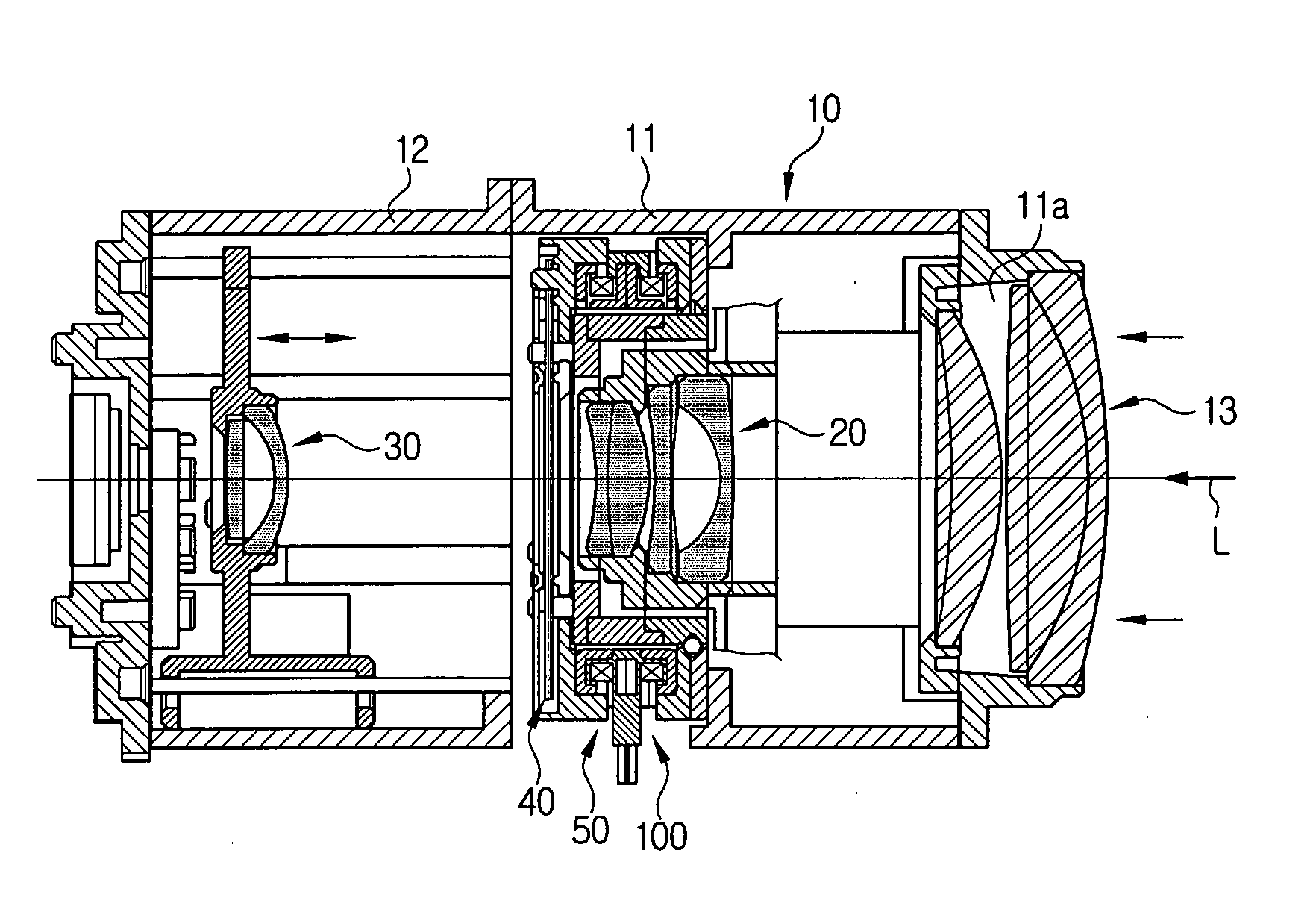

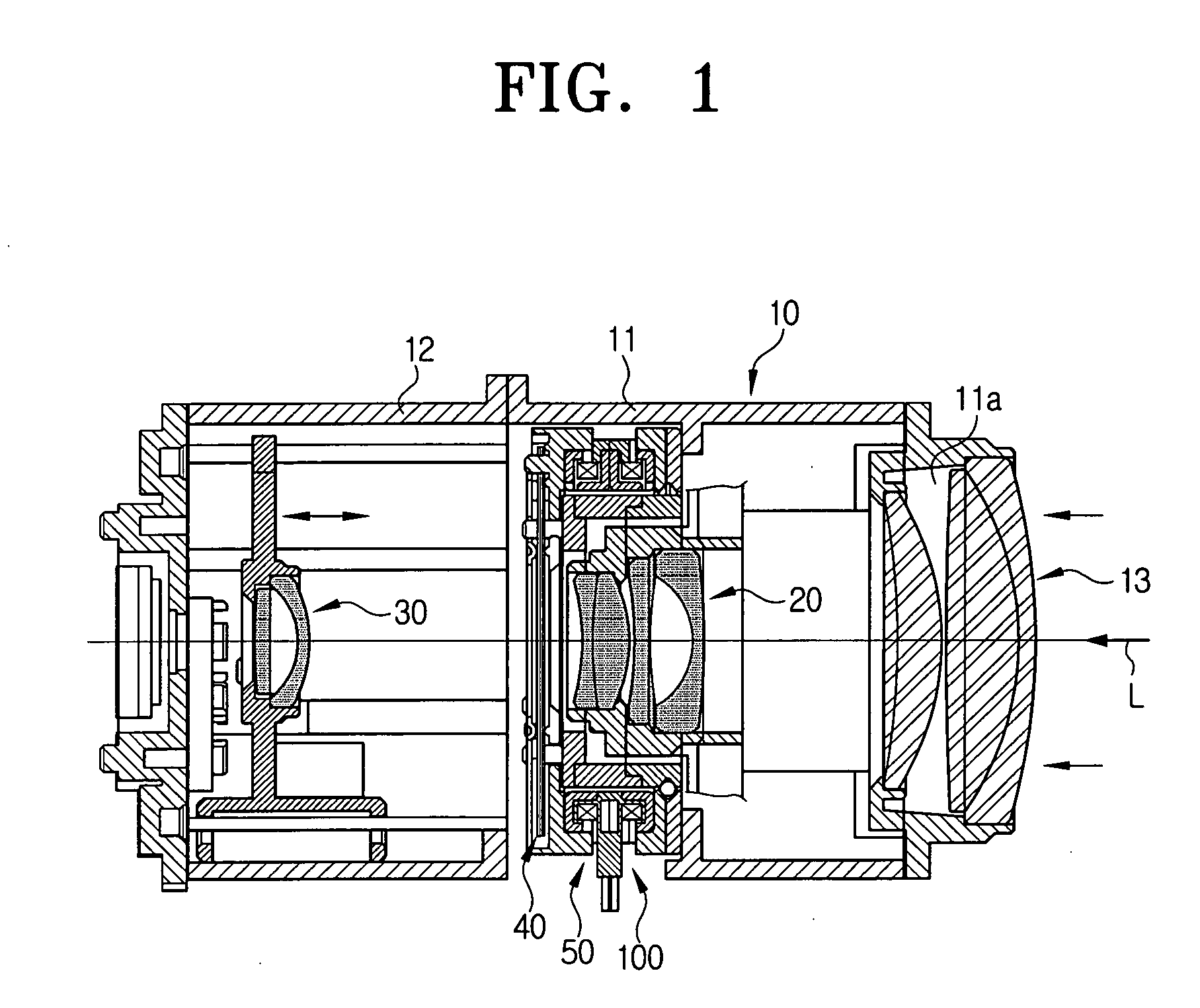

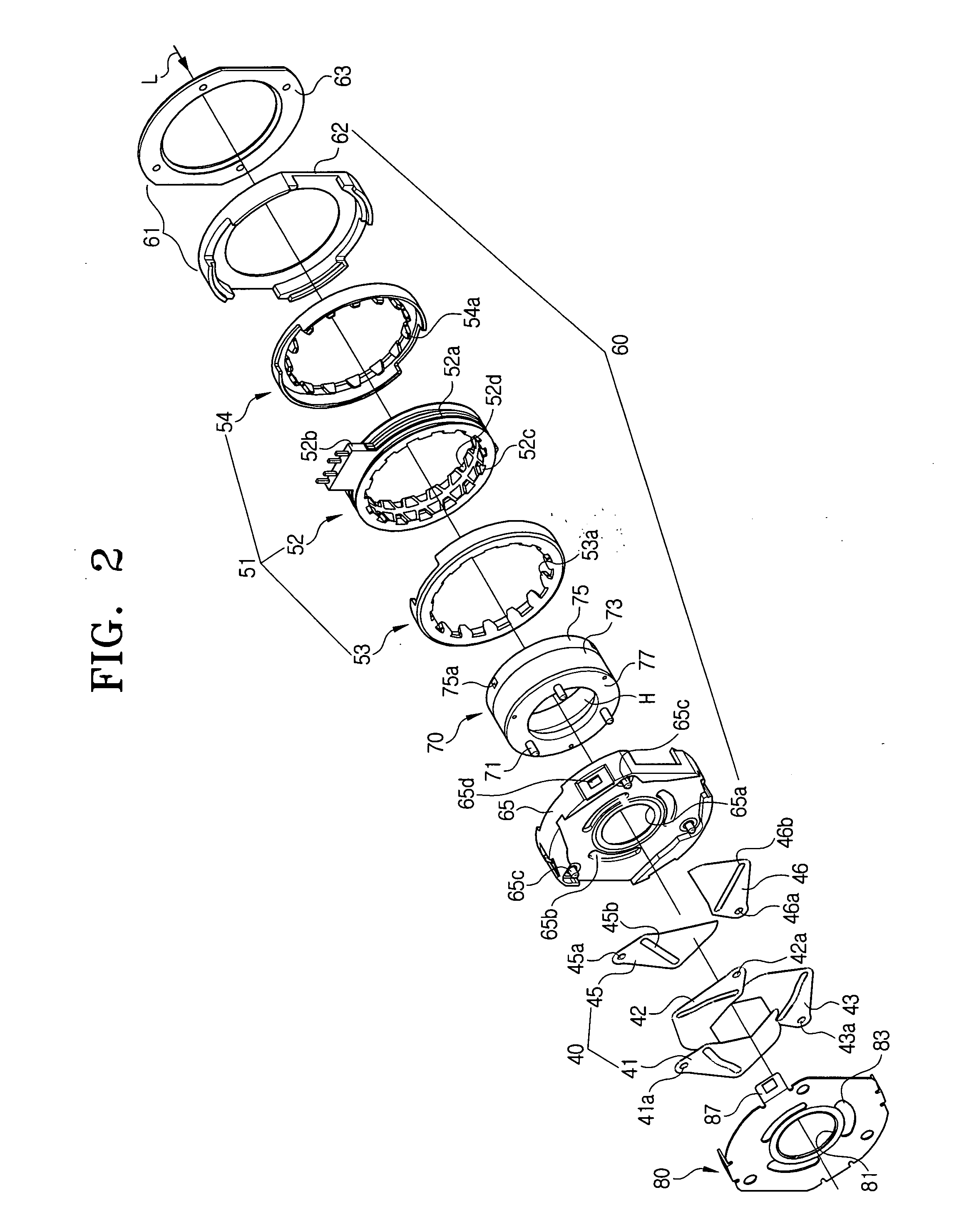

Iris diaphragm, iris diaphragm driving device and camera unit having the same, and iris diaphragm control method

InactiveUS20050238347A1Simple structureReduce the amount requiredTelevision system detailsColor television detailsOptoelectronicsLight filter

An iris diaphragm includes at least one lens shutter to adjust the size of an aperture that incident light passes through according to movement of the at least one lens shutter. At least one ND filter is installed to move independently of the lens shutter to reduce the amount of incident light by covering the aperture stopped-down by the lens shutter according to the movement of the at least one ND filter.

Owner:SAMSUNG ELECTRONICS CO LTD

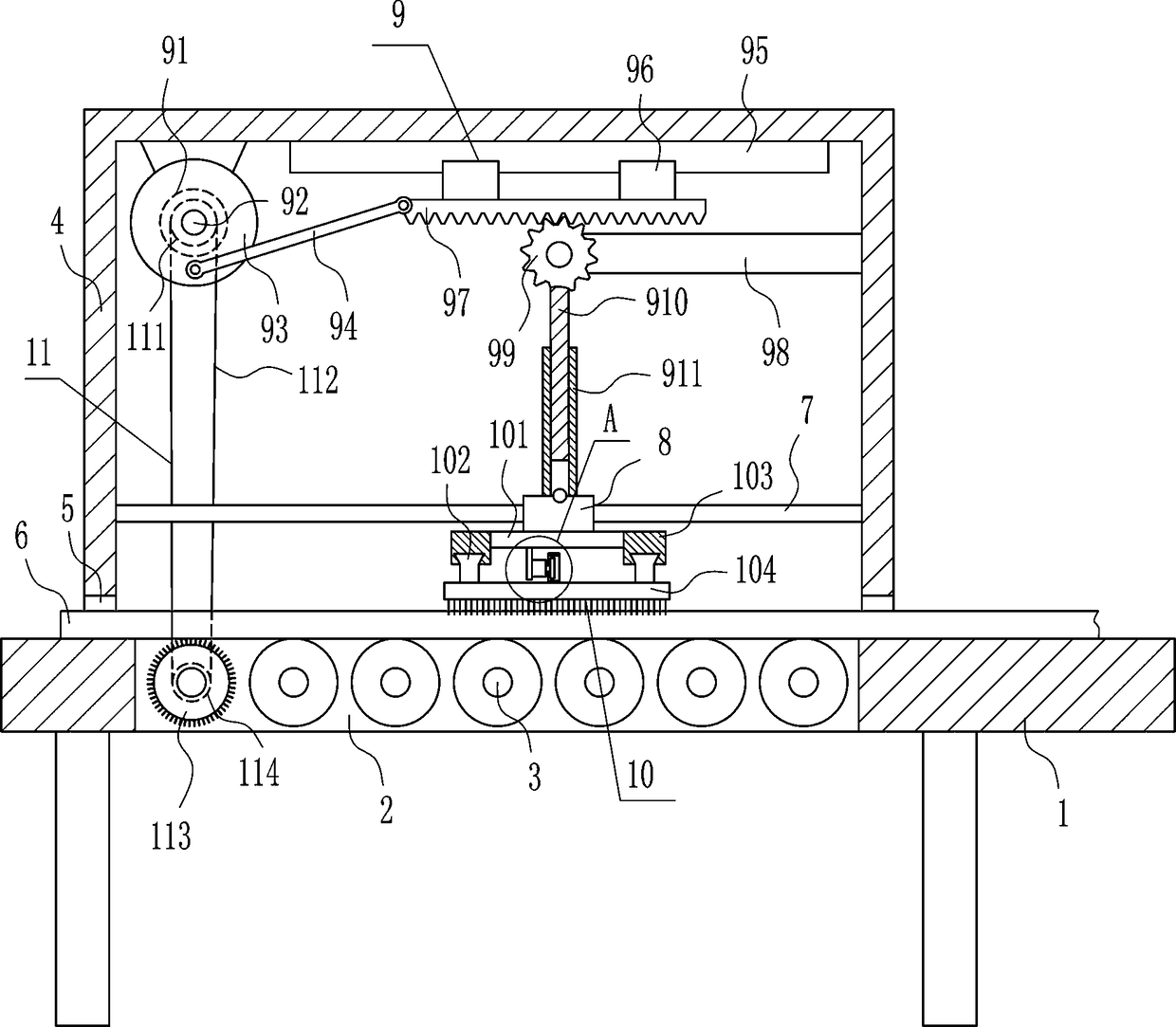

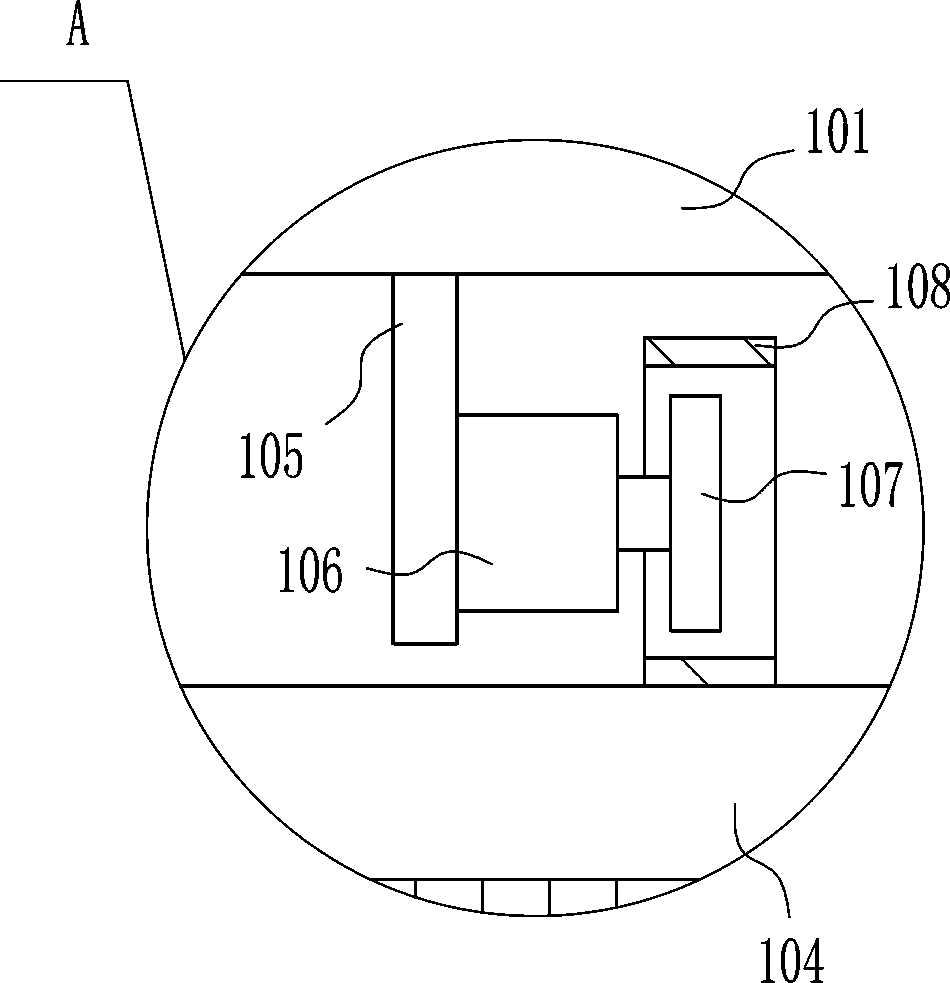

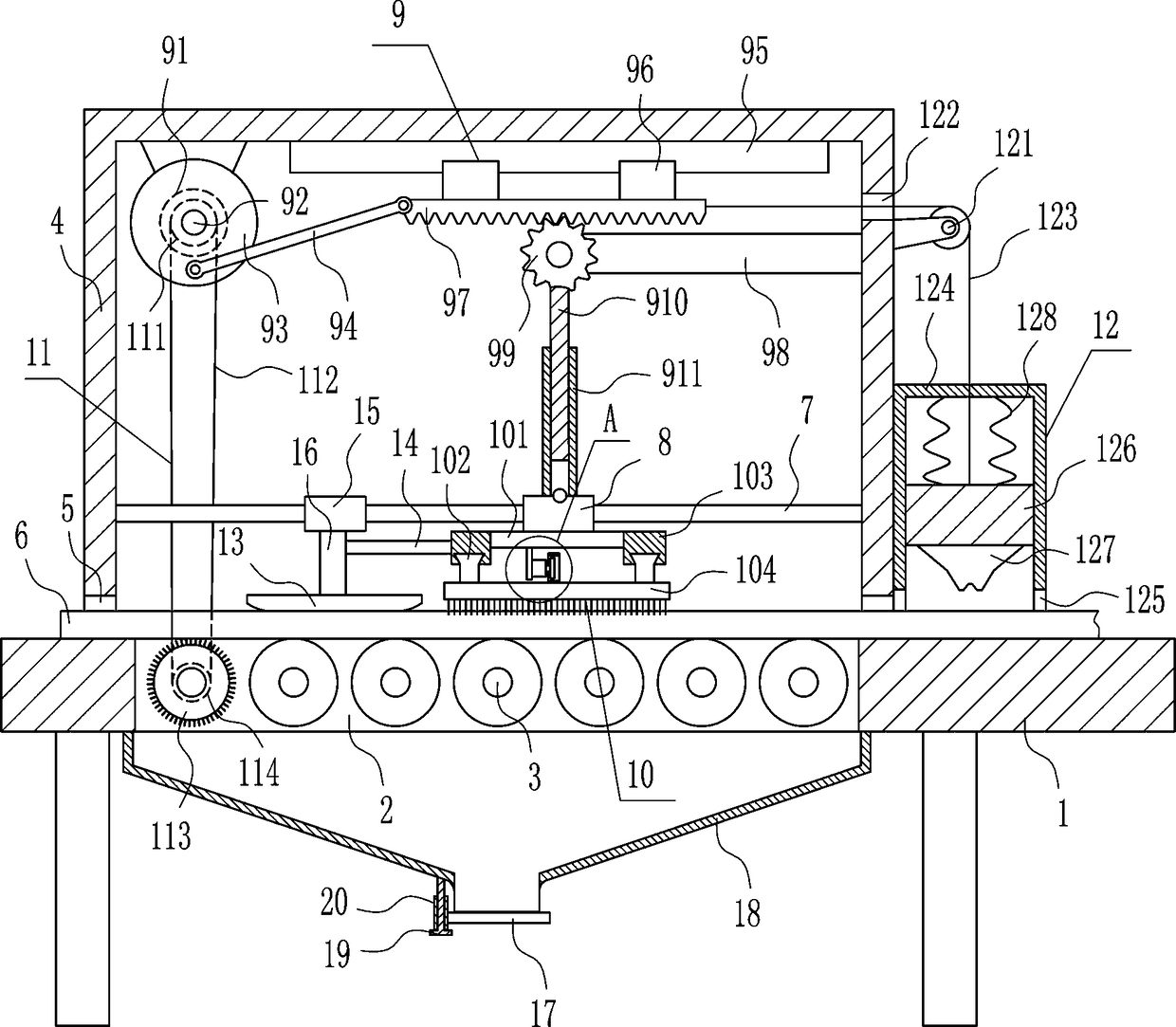

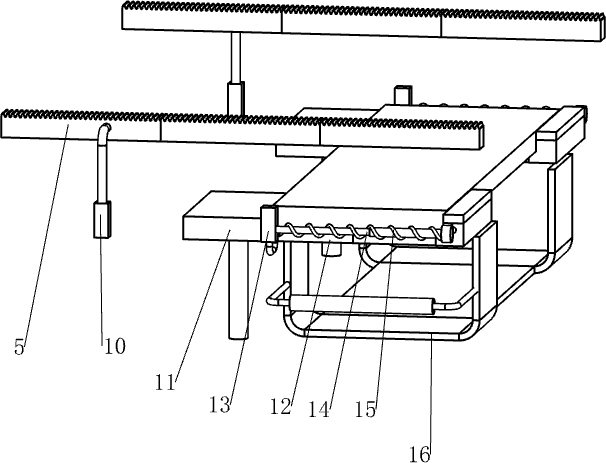

Building formwork surface cleaning equipment

The invention relates to cleaning equipment, in particular to building formwork surface cleaning equipment which is time-saving, labor-saving, needless of a person to clean the surface of a formwork,excellent in cleaning effect and low in labor intensity. The building formwork surface cleaning equipment comprises an operation platform, an opening is formed in the left side of the operation platform, rollers are uniformly arranged in the opening in a spaced manner, a frame is mounted on the left side of the top of the operation platform, a first through hole is formed in the lower portion on each of left and side sides of the frame, and a guide rod is mounted between the lower portion of the left side face and the lower portion of the right side face in the frame. Through a second cleaningdevice, the other side of a formwork can be cleaned preliminarily, so that cleaning effect of a hairbrush on the formwork is better; through a tapping device, impurities on the formwork can be tappedfirst, so that the hairbrush can clean the surface of the formwork better, higher neatness in cleaning is realized, and excellent cleaning effect and low labor intensity are realized.

Owner:江苏义诚巨新建筑科技有限公司

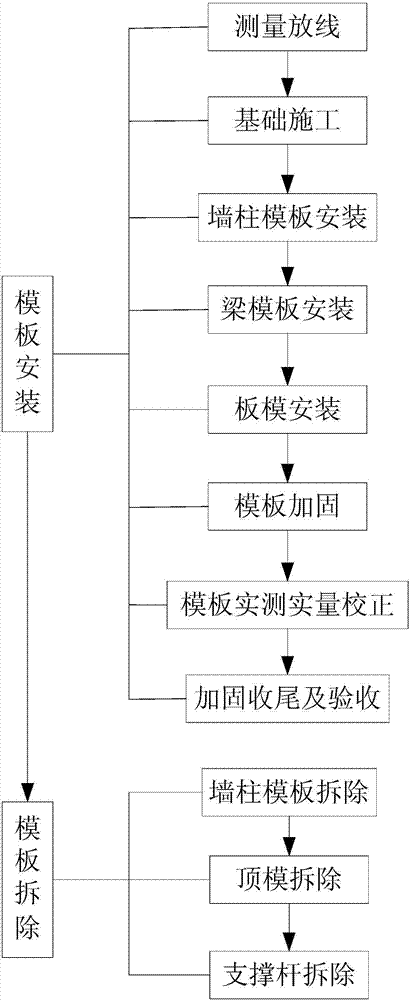

Construction method for high-rise building aluminum alloy formwork

InactiveCN106988525ASave time in transitImprove construction qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksHigh riseAluminium alloy

The invention belongs to the technical field of building construction and relates to a construction method for a high-rise building aluminum alloy formwork. The construction method comprises the following steps of (1), formwork mounting which comprises the steps of (1.1) measuring and paying off, (1.2) foundation construction, (1.3) wall column formwork mounting, (1.4) beam formwork mounting, (1.5) formwork mounting, (1.6) formwork reinforcement, (1.7) formwork actual measuring rectifying comprising (1.7.1) wall column actual measuring rectifying and (1.7.2) top plate actual measuring rectifying, and (1.8) reinforcing ending and acceptance inspection; and (2) formwork dismounting which comprises the steps of (2.1) wall column formwork dismounting, (2.2) top mould dismounting and (2.3) supporting rod dismounting. The construction method for the high-rise building aluminum alloy formwork has the beneficial effects that the concrete construction quality is obviously improved, the construction period is greatly shortened, and cost is reduced.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

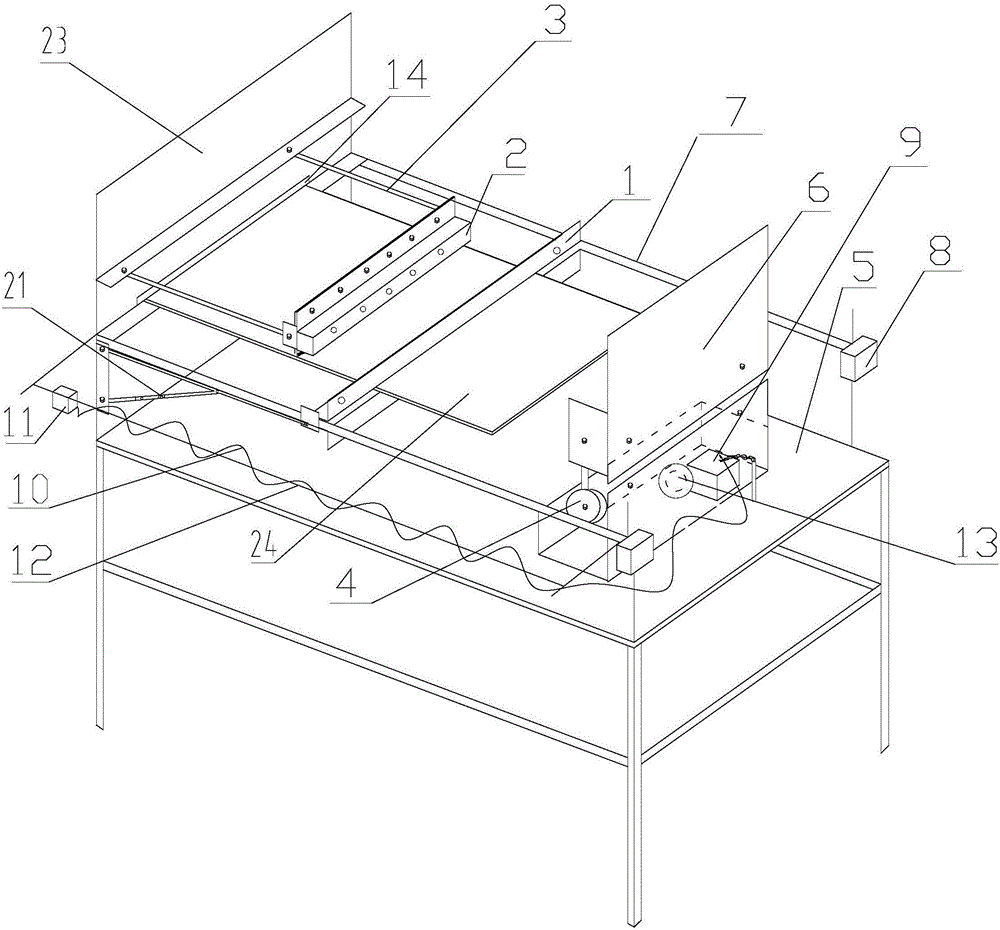

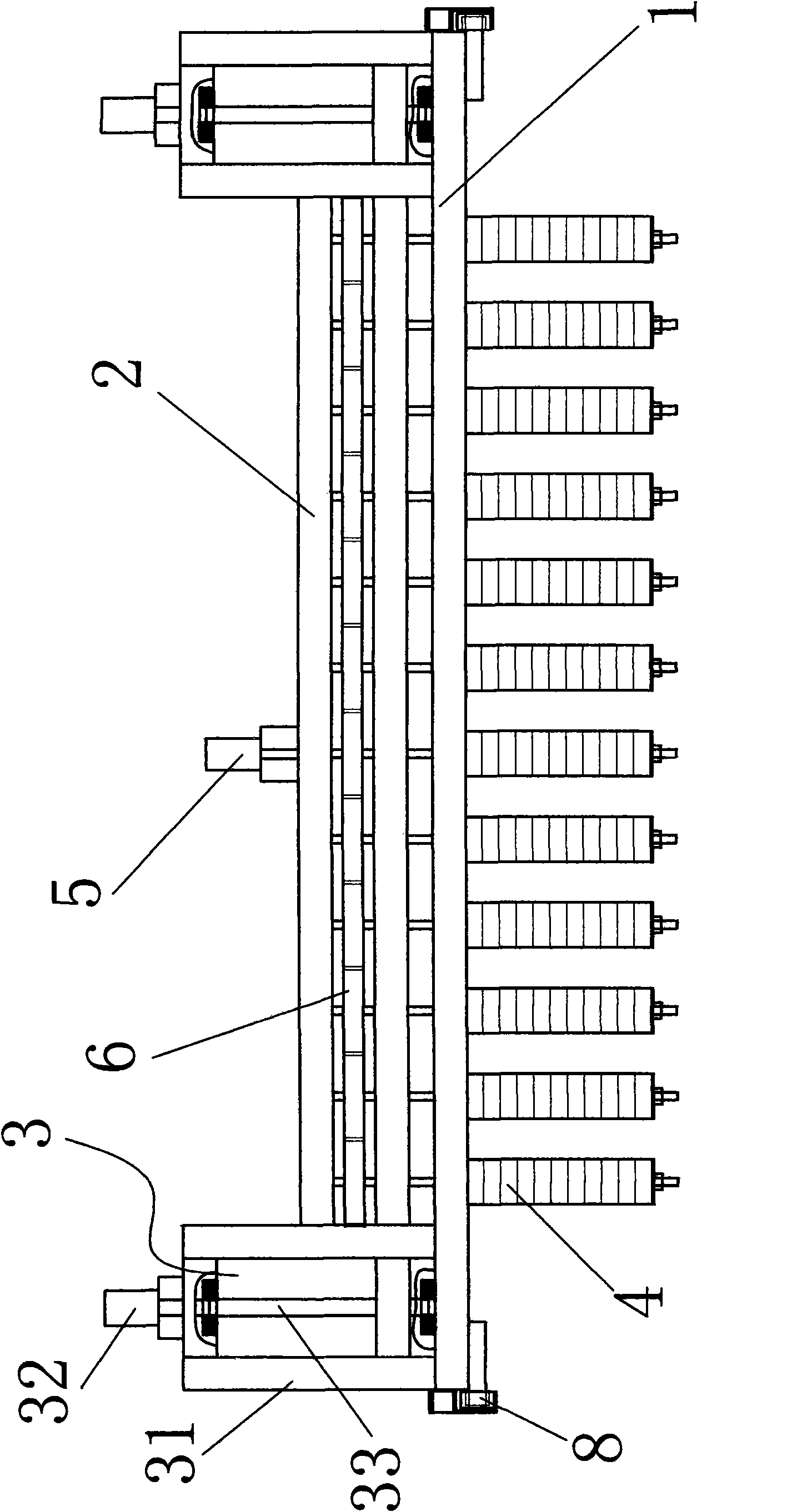

Automatic cleaning and brushing apparatus and method for forms

Automatic cleaning and brushing apparatus and method for forms are provided; the apparatus comprises a form cleaning apparatus platform, a traveling pusher, traveling rails, a form cleaning clamp, a release agent auto-spray brushing device, and a retaining plate; the retaining plate is fixed to one end of the form cleaning apparatus platform and is provided with a form exit; the traveling rails are mounted on two sides of the form cleaning apparatus platform, the traveling pusher is disposed opposite the retaining plate, the traveling pusher travels on the traveling rails through wheels, the form cleaning clamp is disposed between the traveling pusher and the retaining plate, two ends of the form cleaning clamp are fixedly connected to the retaining plate through support frames, and the release agent auto-spray brushing device is fixed to the retaining plate through a support and is disposed above a form. The Automatic cleaning and brushing apparatus and method have the advantages that the structure is simple, operating is convenient, and manufacture cost is low; labor is replaced by machinery, less staff is required, construction speed is increased, and construction cost is lowered; concrete project construction quality is improved, and forms can be reused more times.

Owner:CHINA THIRD METALLURGICAL GRP

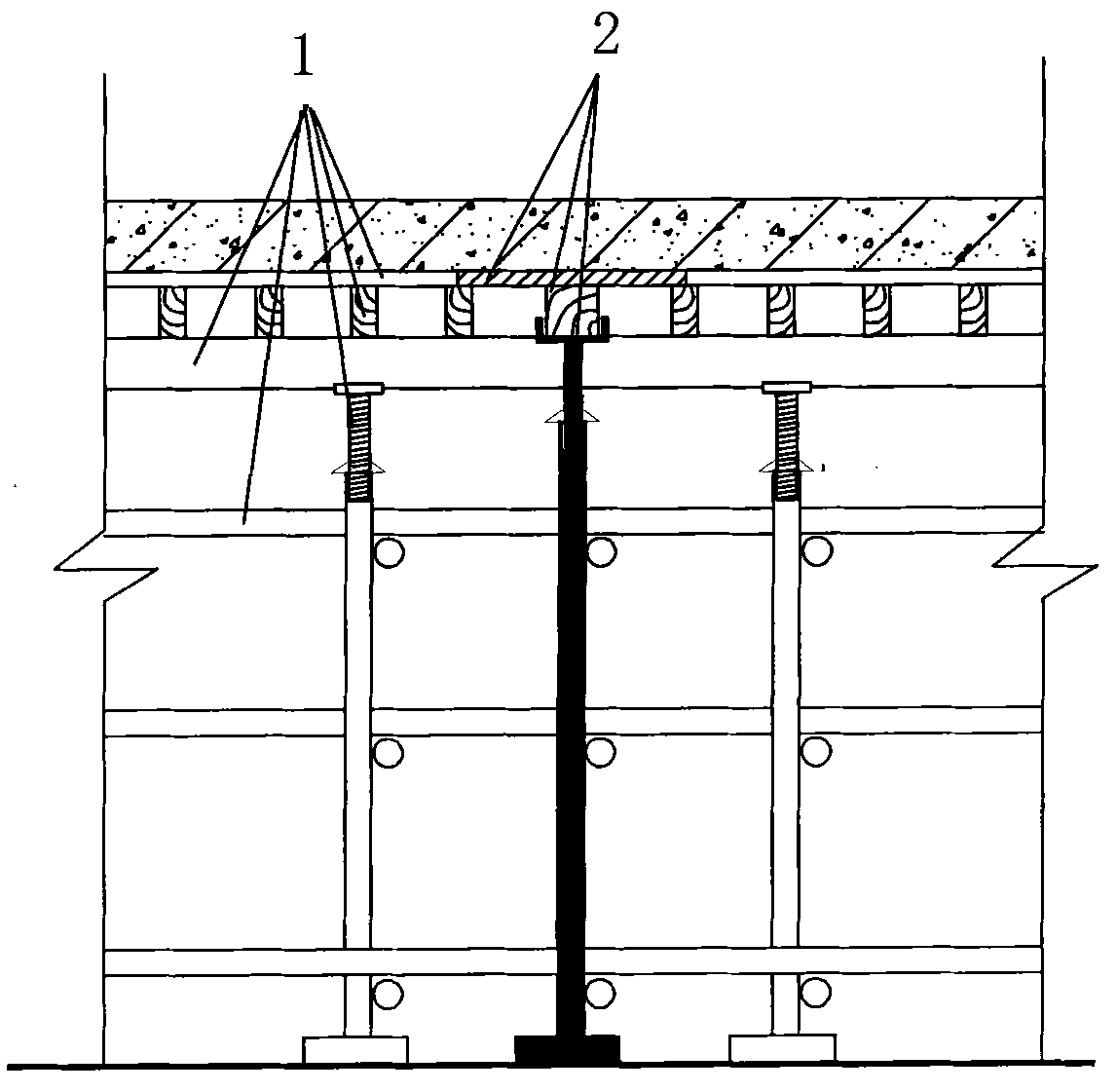

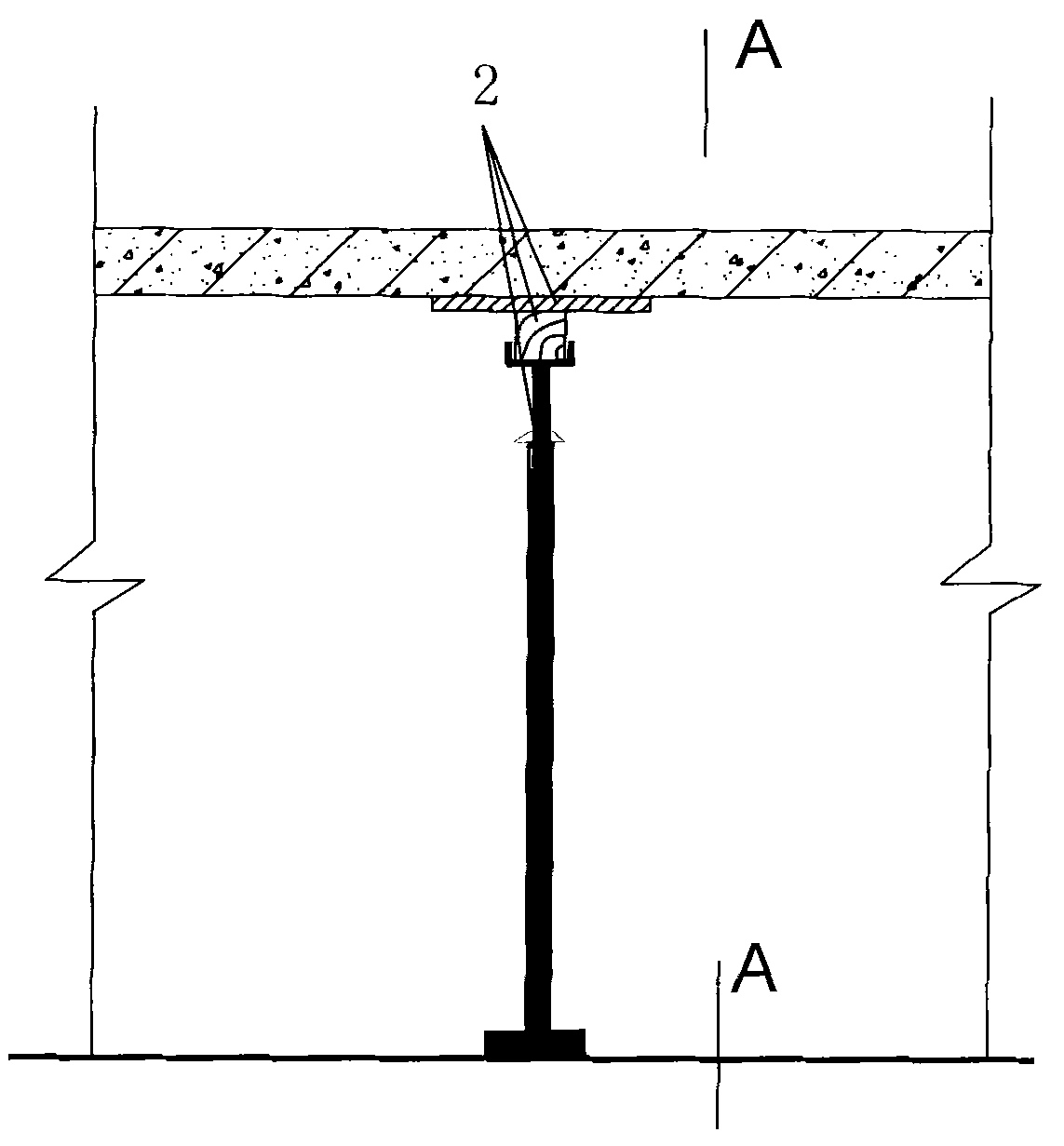

Construction method for pouring after settlement of reinforced concrete continuous beam with cohesive pre-stress

InactiveCN101775903AReduce construction costsSimple construction processBuilding material handlingForm treatmentFalseworkFloor slab

The invention relates to a construction method for pouring after the settlement of reinforced concrete continuous beam with cohesive pre-stress, which belongs to the technical field of reinforced concrete construction. The template construction of a primary beam, a secondary beam and a floor slab of a reinforced concrete frame structure adopts an early dismantling system framework; the pre-stressed reinforced concrete of the main beam is erected on two spans of brackets, and respectively meets the erection requirements; the tension ends on both sides of the two spans are respectively provided with beam haunches on both sides of the brackets; the beam haunches are respectively designed into the tension ends; pres-stressed reinforced concrete and cast concrete are paved according to the design requirements; after the concrete of the main beam reaches 14 days and 80percent of design strength, the pre-stressed beam on the right side is tensioned; after tensioning, the template early dismantling supporting scaffold of the span is dismantled; the early dismantling system supporting scaffold at the bottom of the pre-stressed beam on the left side is not dismantled, and the concrete at the settled pouring part after settlement is poured after structural settlement, and micro expansion concrete is used to cast the settled poured belt; and after the poured belt concrete after the main beam reaches 14 days and 80percent of design strength, the pre-stressed beam of the span on the left side is tensioned. And the construction method has the advantages of lower construction cost and simple process.

Owner:BEIJING SHOUGANG CONSTR GROUP

Refinement to the construction systems for structures in reinforced concrete or some other material of high-precision intergral modular forms

InactiveUS20060260238A1Foundation engineeringForms/shuttering/falseworksReinforced concreteArchitectural engineering

Improvements to systems for building structures of reinforced concrete or other materials using high precision modular, integral coffering of the type of systems that use standardized panels preparing integral cofferings in which the reinforcements and various installations are placed, building the coffering on a foundation slab with the help of a layout template, in which the foundation slab is built using a mould based on modular pieces whose faces form a straight dihedral and squares for the corners the pieces of which are fixed with centering clips with angular reinforcements to fix stabilizers and anchorings, these pieces to having lugs for centering the layout template. Wall templates are also used to lay out the partitions and walls, with all their installations, and new means and panels for specific building solutions.

Owner:SISTEMAS INDUSTRIALIZADOS BARCONS S L

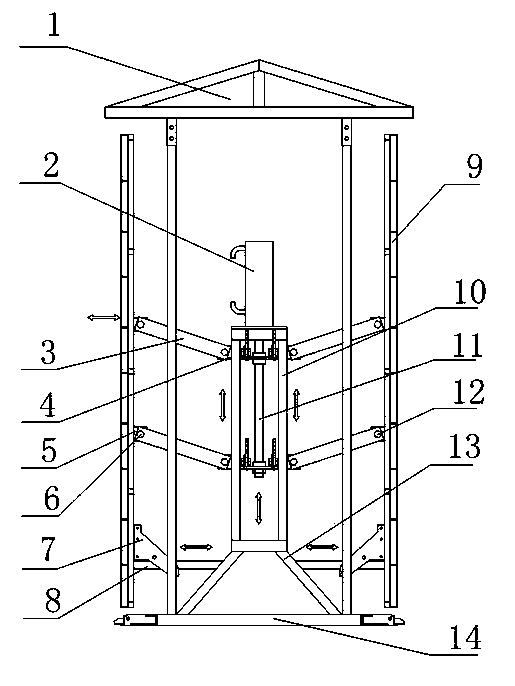

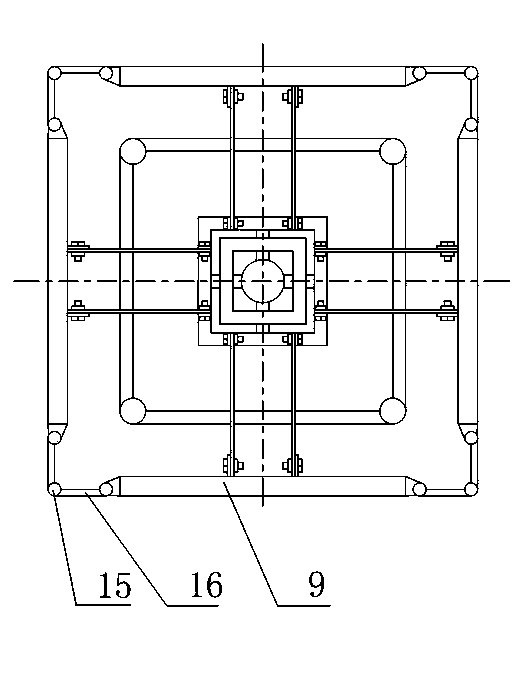

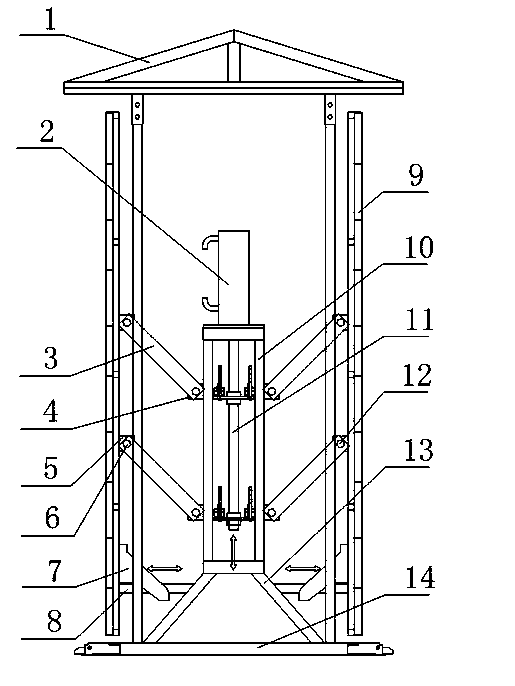

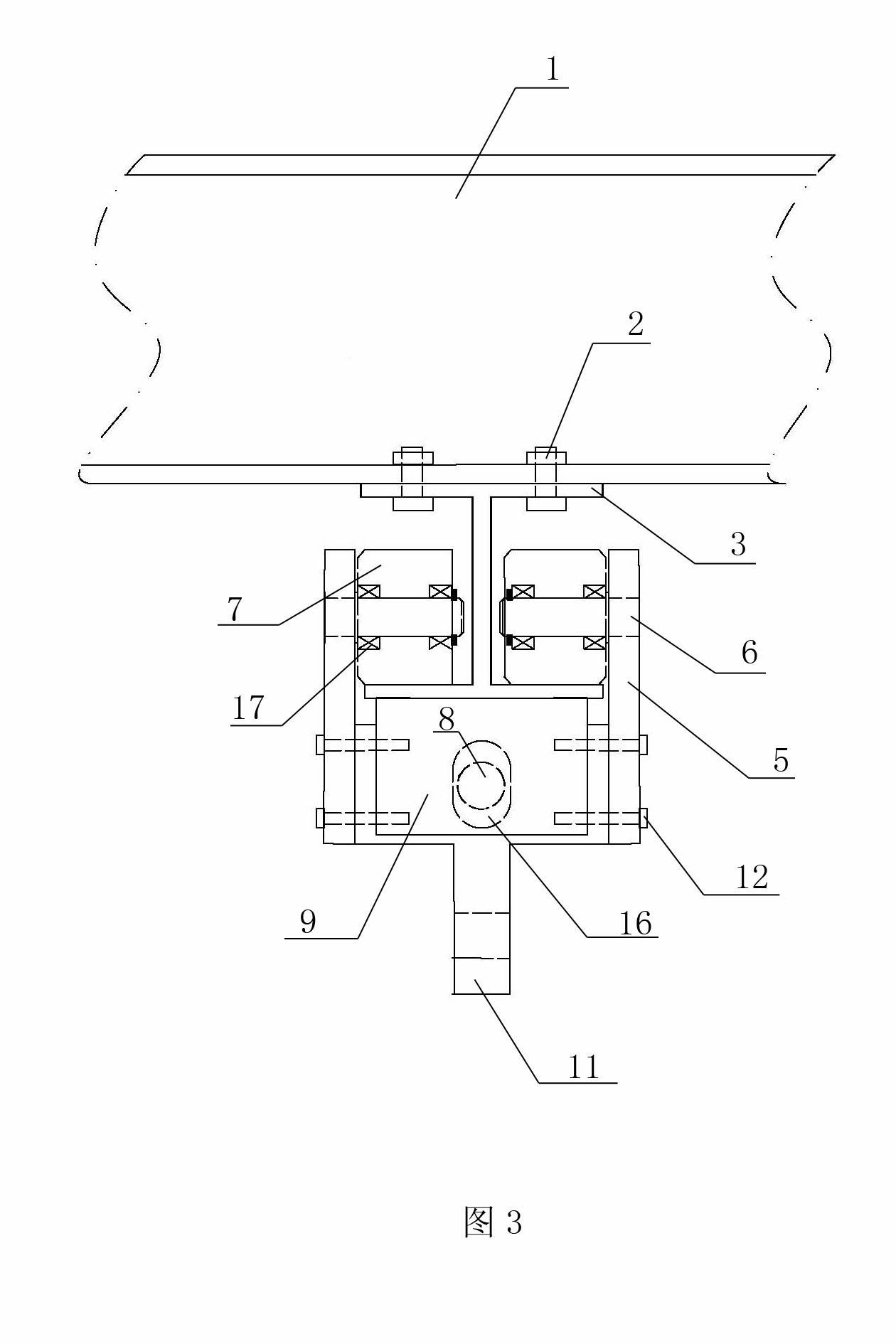

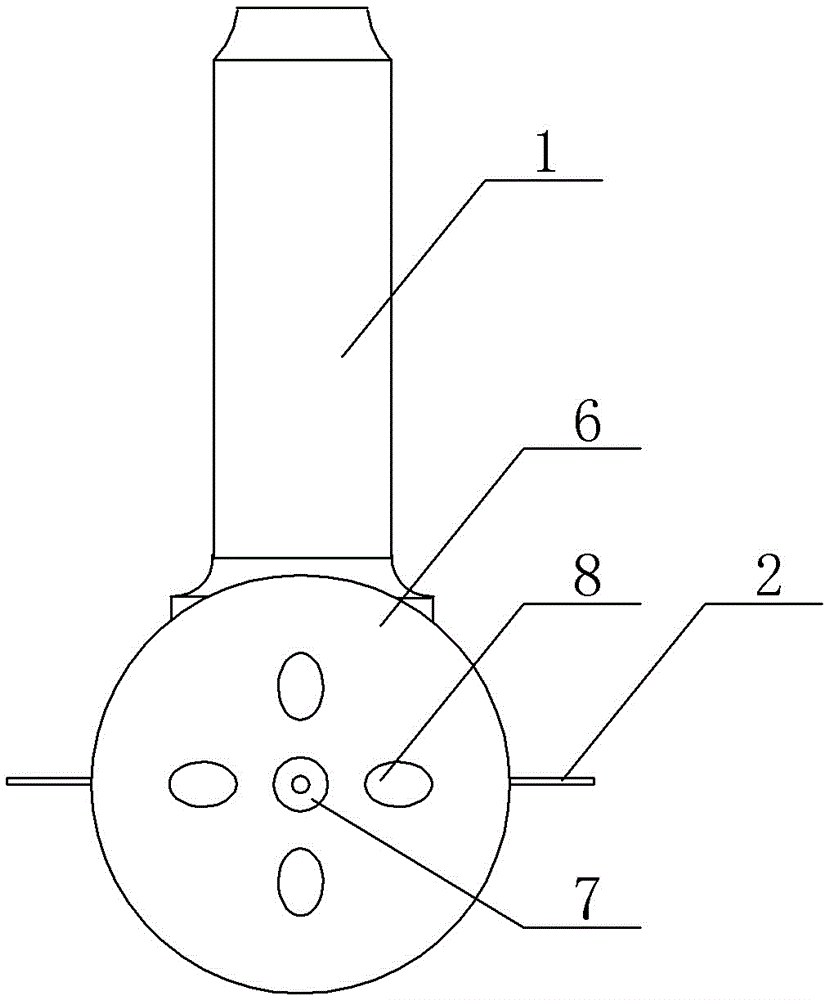

Hydraulic telescopic device for elevator shaft mold and operating method thereof

ActiveCN103806644ALow costLow quality requirementsForms/shuttering/falseworksBuilding material handlingAutomatic controlPulley

The invention discloses a hydraulic telescopic device for an elevator shaft mold. The hydraulic telescopic device comprises the shaft mold formed by several telescopic templates into a circle, wherein several angle molds are arranged between adjacent telescopic templates in the telescopic templates, a hydraulic rod and a support are arranged in the shaft mold, a drive screw is arranged in the support, and the two ends of a connecting rod mechanism set are connected with the drive screw and the corresponding telescopic templates respectively. The hydraulic rod lifts and drives the drive screw to lift, horizontal pulley frames and synchronization regulation connecting rods extend outwards, horizontal telescopic beams move outwards, the telescopic templates are pushed to move outwards in position, and the situation that the horizontal telescopic beams, the synchronization regulation connecting rods and fixing rods are on the same straight line is achieved. At the moment, the hydraulic telescopic device is in the maximum telescopic state. The hydraulic telescopic device and the operating method of the hydraulic telescopic device are not high in cost, the hydraulic telescopic device is automatically machined and can be repeatedly used, operations can be completed by one person, the requirement for quality of operation staff is not high, and the hydraulic telescopic device is easy to operate, is automatically controlled by a hydraulic system and is low in safety dangerousness.

Owner:CHINA MCC5 GROUP CORP

Die cleaning equipment for cleaning lightweight concrete wall plate die

The invention discloses die cleaning equipment for cleaning lightweight concrete wall plate die, which comprises a fixed base. A lifting rack is arranged on the fixed base, a lifting transmission device which can lift the rack up or drop the rack down is also arranged on the fixed base, a plurality of rotatable die cleaning steel brush wheels are connected below the rack, a die cleaning electric motor used for driving the die cleaning steel brush wheels to rotate is arranged above the rack, and the die cleaning electric motor and the die cleaning steel brush wheels are connected mutually by a transmission mechanism. The invention aims to overcome defects in the prior art and provide safe and reliable die cleaning equipment with the advantages of simple structure, automatic operation and quick and convenience for cleaning the die .

Owner:中山建华墙体材料有限公司

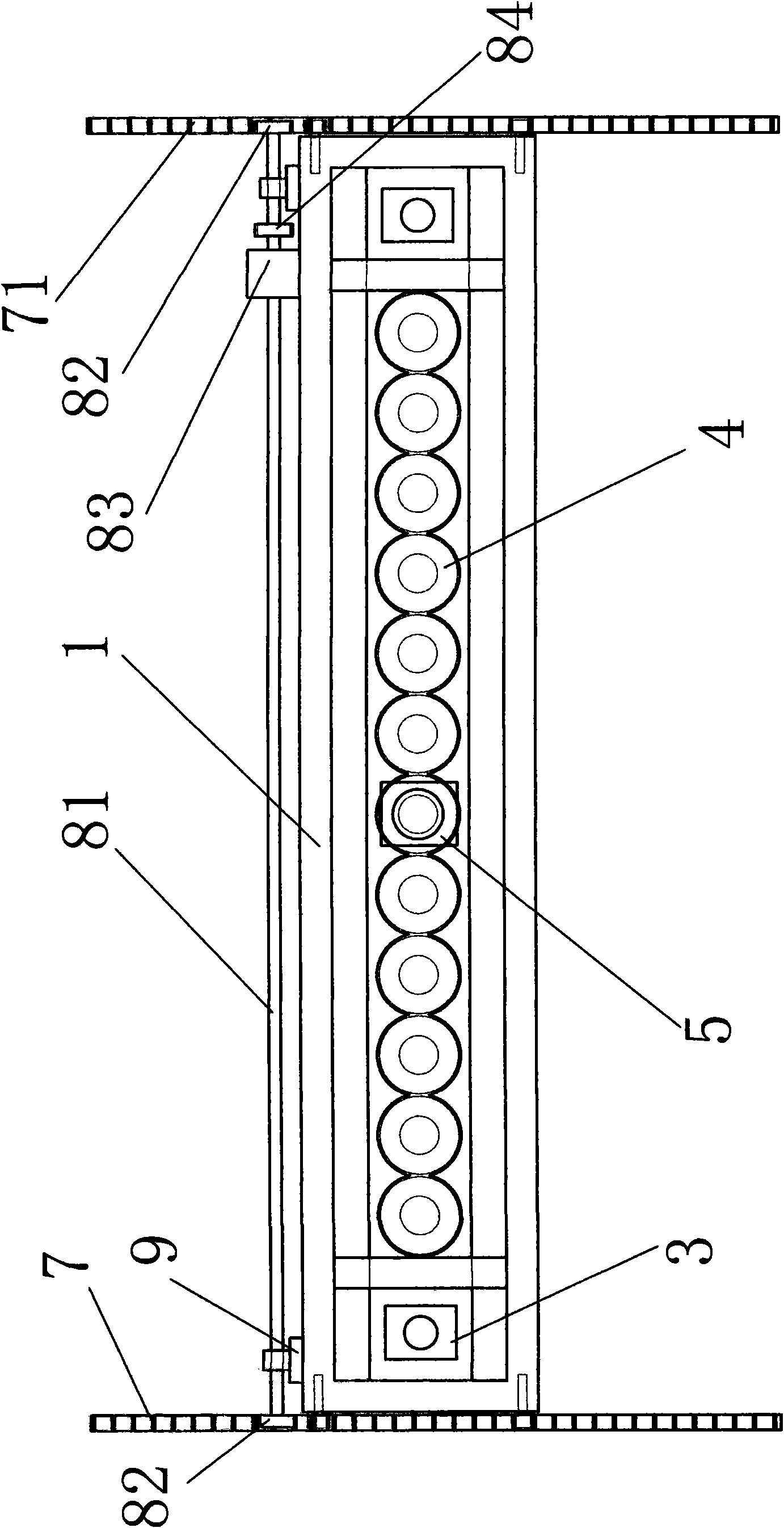

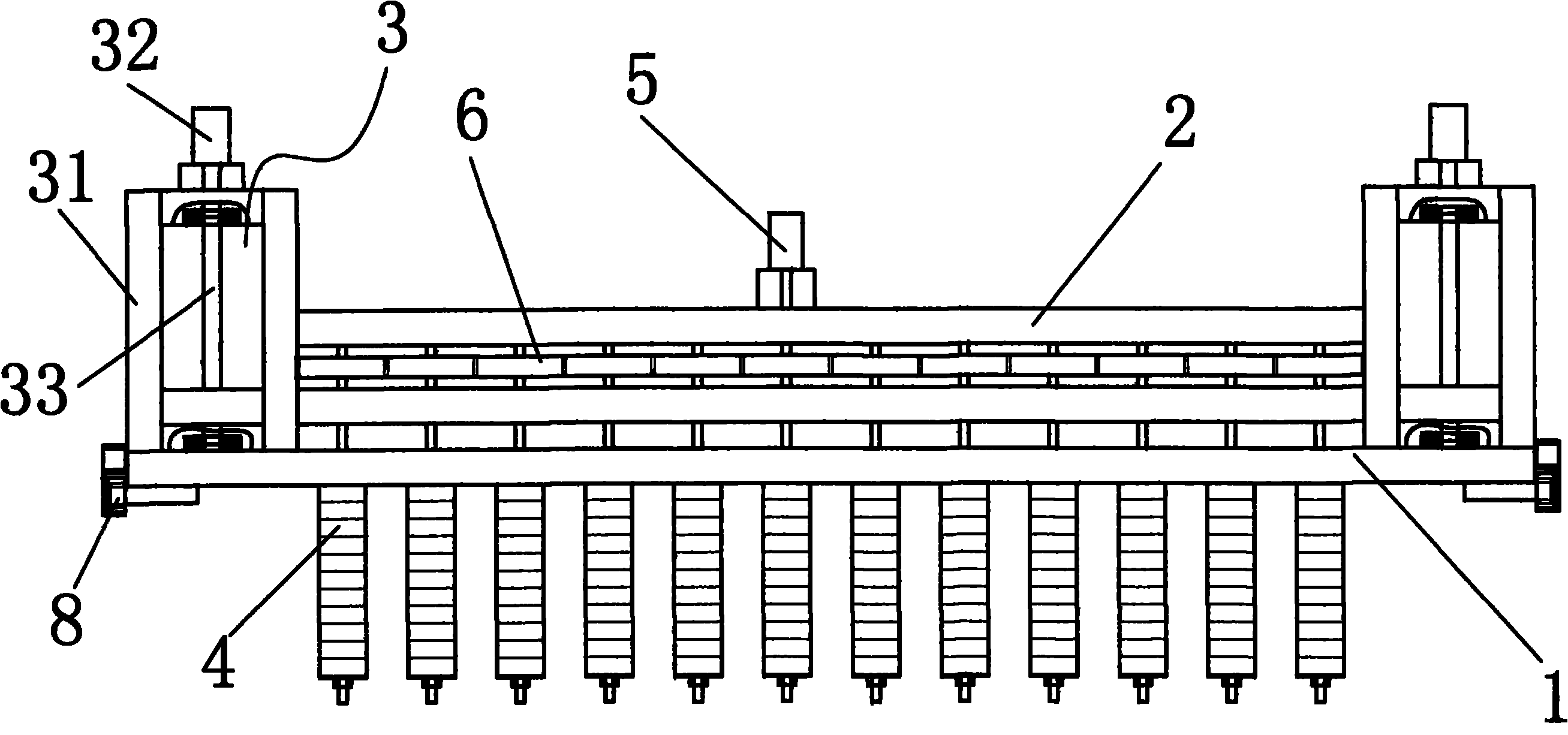

Mould releasing and combining device for large steel form and assembling method thereof

ActiveCN102121311AReach ejectionTo achieve the purpose of moldForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksVertical edgeTraveling block

The invention relates to a mould releasing and combining device for a large steel form. The device comprises a bearing rail, a pulley consisting of a roller, an inversed T-shaped roller frame and a roller shaft, wherein the roller is sleeved on the bearing rail; the inversed T-shaped roller frame is screwed with an adjusting screw rod which is fixed at the bottom surface of the bearing rail; the large steel form is connected to the vertical edge of the inversed T-shaped roller frame; and the adjusting screw rod and the screw hole on the roller frame rotate relatively by rotating the adjusting screw rod, and the pulley is driven to move along a profile steel rail, so that the large steel form hung under the pulley moves horizontally, and the effect of releasing or combining the mould of the large steel form can be achieved. The mould releasing and combining device has the advantages of simple structure, time and labor conservation and the like, and can be widely applied to mould releasing and combining of the large steel form by adopting a jack-up steel construction platform.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Silicon-titanium mixed oxide powder

A silicon-titanium mixed oxide powder contains aggregates of primary particles selected from amorphous silicon dioxide particles, crystalline titanium dioxide particles, and silicon-titanium mixed oxide particles each having an amorphous silicon dioxide fraction and a crystalline titanium dioxide fraction. The silicon-titanium mixed oxide particles predominate in the powder. The powder exhibits a BET surface area of from 20 to 200 m2 / g, and a titanium dioxide content in a range of from greater than 10 wt. % to less than 70 wt. %. An X-ray diffractogram of the powder exhibits the diffraction patterns of rutile and anatase, with a rutile / anatase ratio of from 2:98 to 98:2. The powder can be produced by vaporizing a silicon halide and a titanium halide at temperatures of less than 180° C., performing combustion with hydrogen and air in a reaction chamber that is closed off from the earth's atmosphere, separating the solids from gaseous substances, and subsequently removing halide-containing substances from the solids to the greatest possible extent by treatment with steam at temperatures of from 250 to 700° C. The powder can be used in toners.

Owner:EVONIK DEGUSSA GMBH

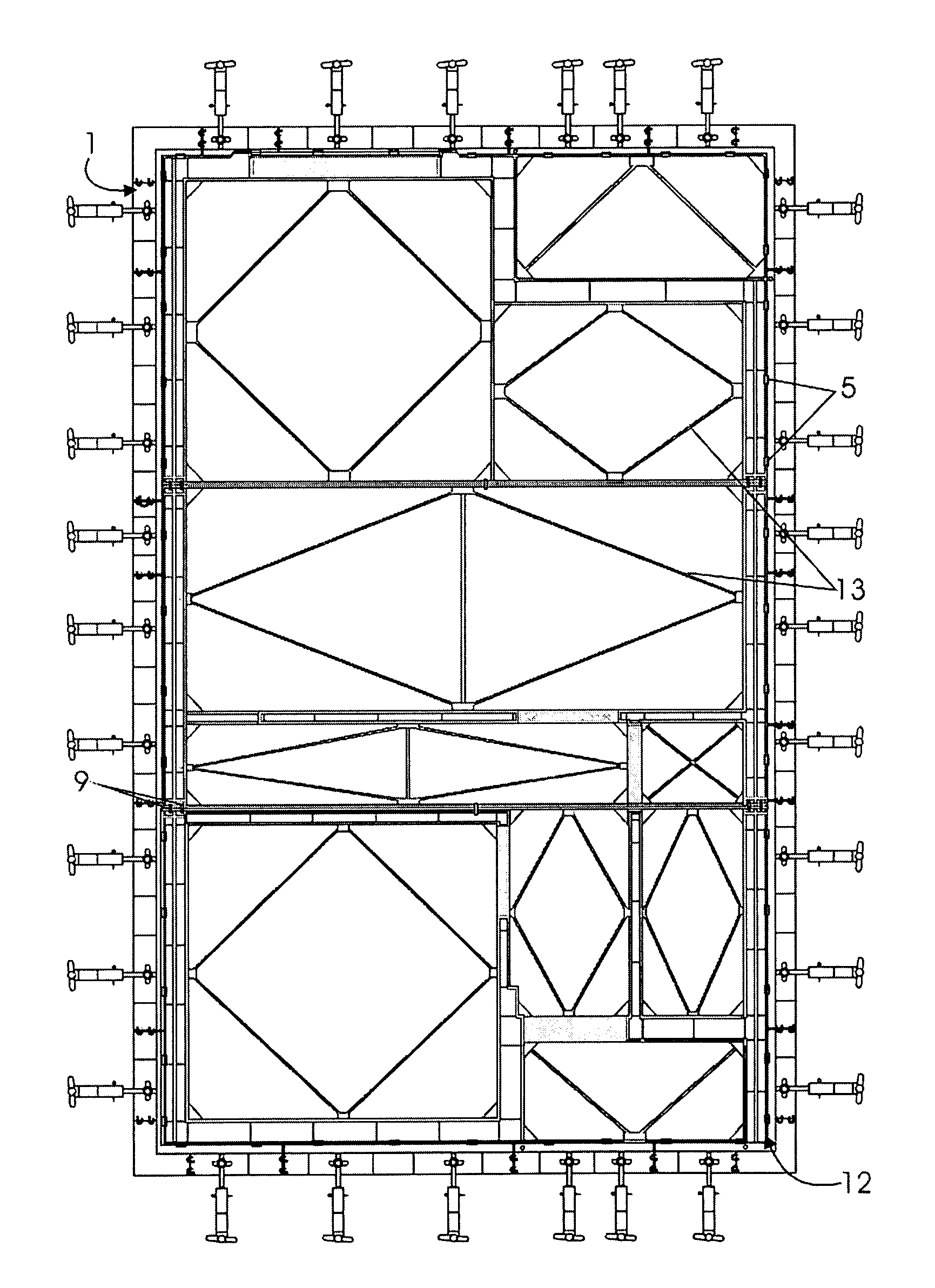

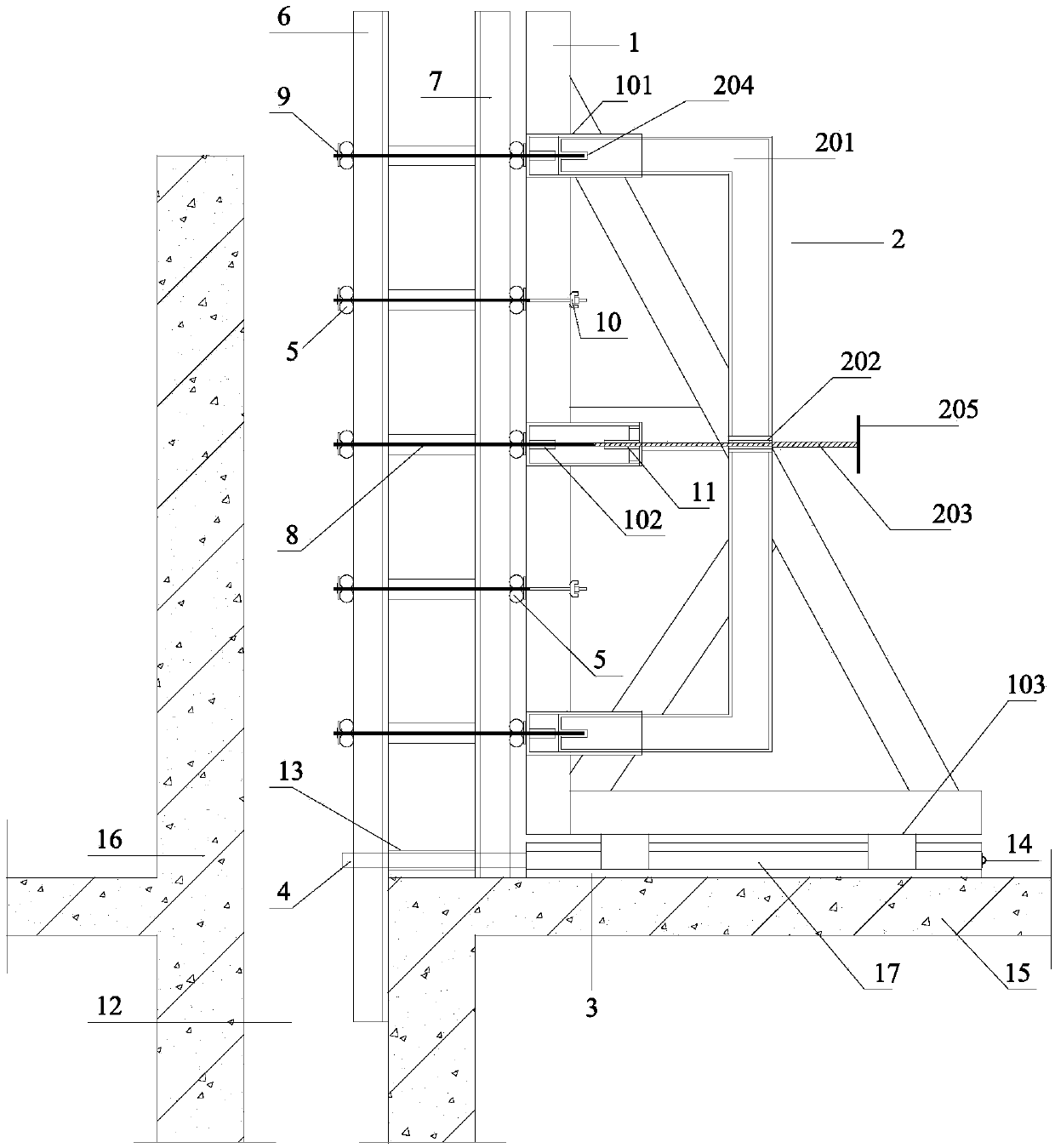

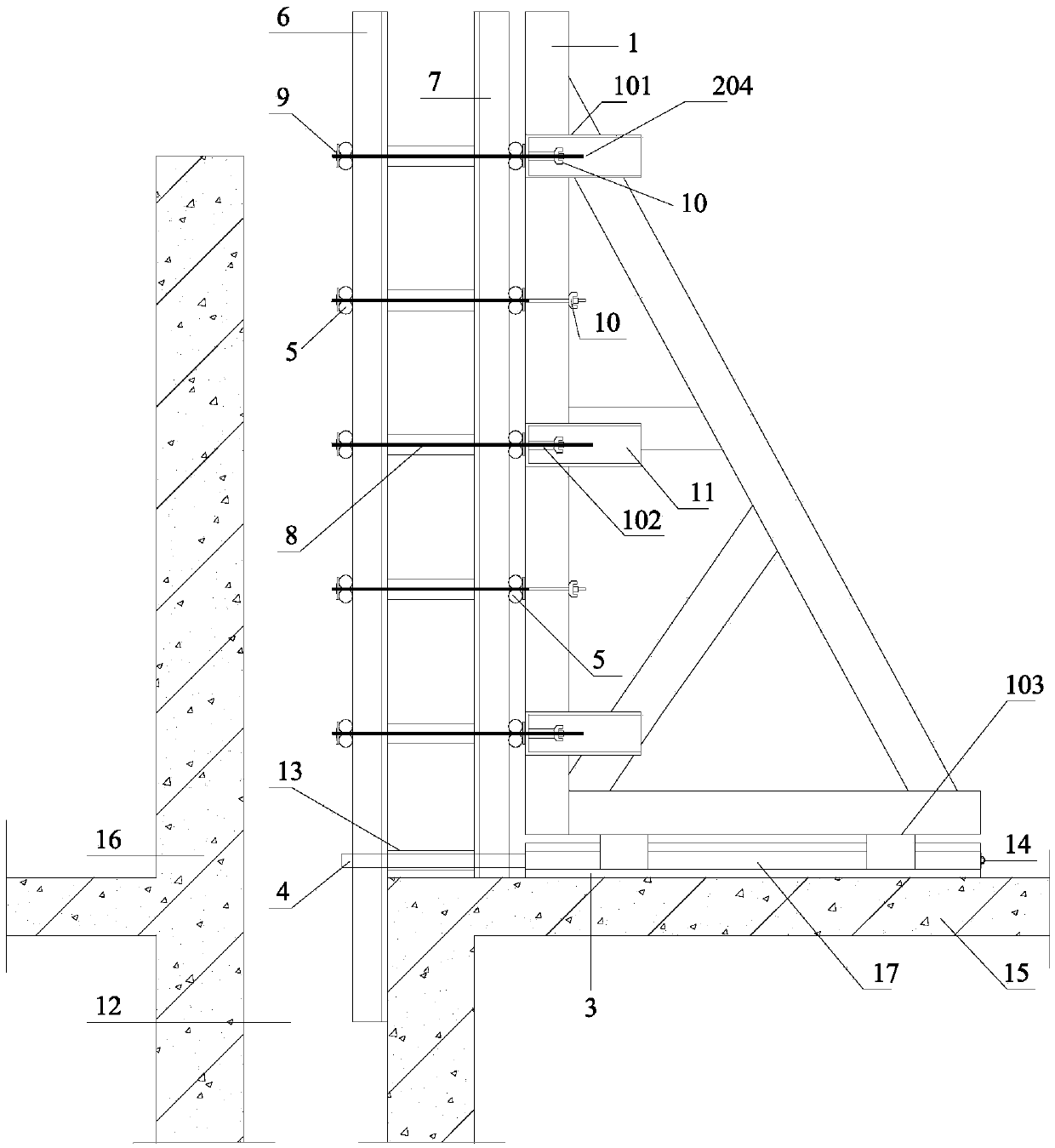

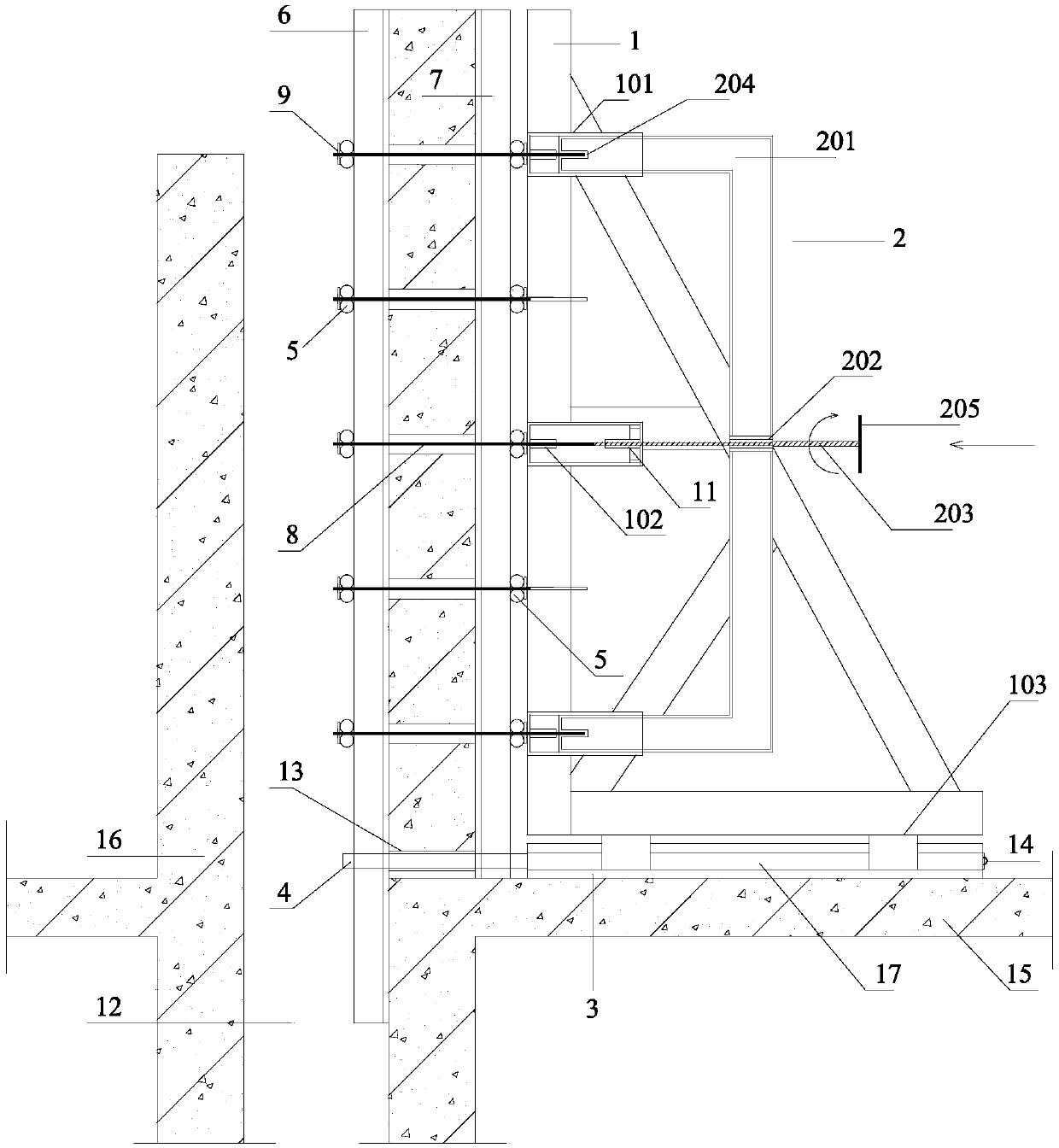

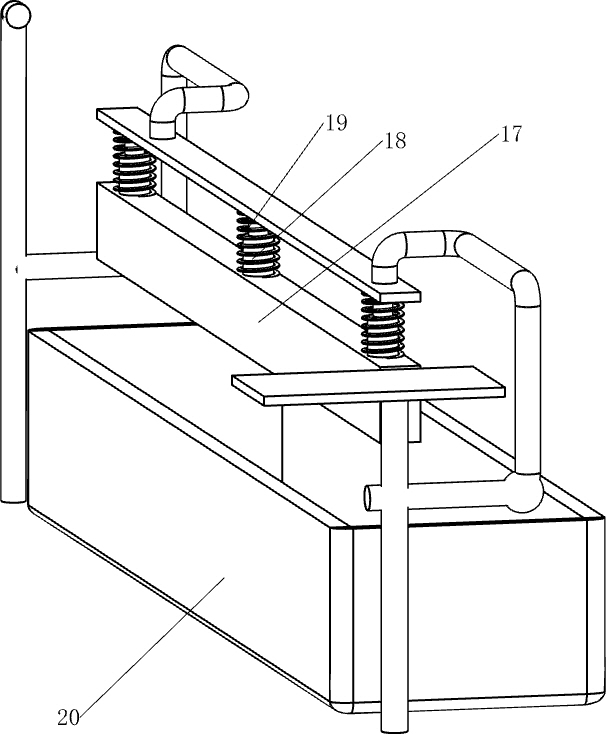

Deformation joint post-section shear wall sliding-pushing type installation and disassembling template erection system and construction method

InactiveCN109680830APrevent subsidenceAvoid leaningWallsForms/shuttering/falseworksEngineeringConsumables

The invention relates to a deformation joint post-section shear wall sliding-pushing type installation and disassembling template erection system and a construction method. The construction method comprises the main construction steps of: installing a sliding guide rail; installing a sliding type single-sided bracket; pushing off an inside template by utilizing a screwing pushing device; recovering the sliding type single-sided bracket; hanging an outside template away. According to the invention, the templates are supported by utilizing a supporting steel pipe extending out of the sliding guide rail, and the sliding type single-sided bracket and cross-pulling screws are combined so as to fix the templates; then by screwing the screwing pushing device and further pushing the cross-pullingscrews, the inside template is pushed away; finally, the sliding-type single-sided bracket is recovered and the outside template is hung away. According to the invention, components mostly are precastand recoverable; the template erection system is convenient to install and rapid in construction; meanwhile, a constructed shear wall is high in quality and high in template recyclability rate; problems of a great amount of consumables for installing and disassembling the templates, long period, easiness for damaging the templates and the shear wall and the like in the prior art are solved; the deformation joint post-section shear wall sliding-pushing type installation and disassembling template erection system and the construction method are obvious in economic beneficial effects.

Owner:杭州昂创科技有限公司

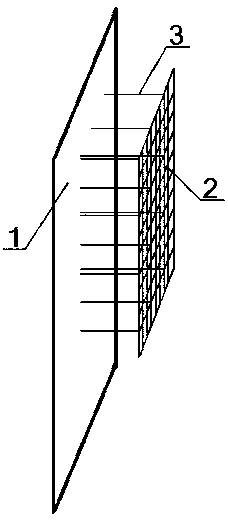

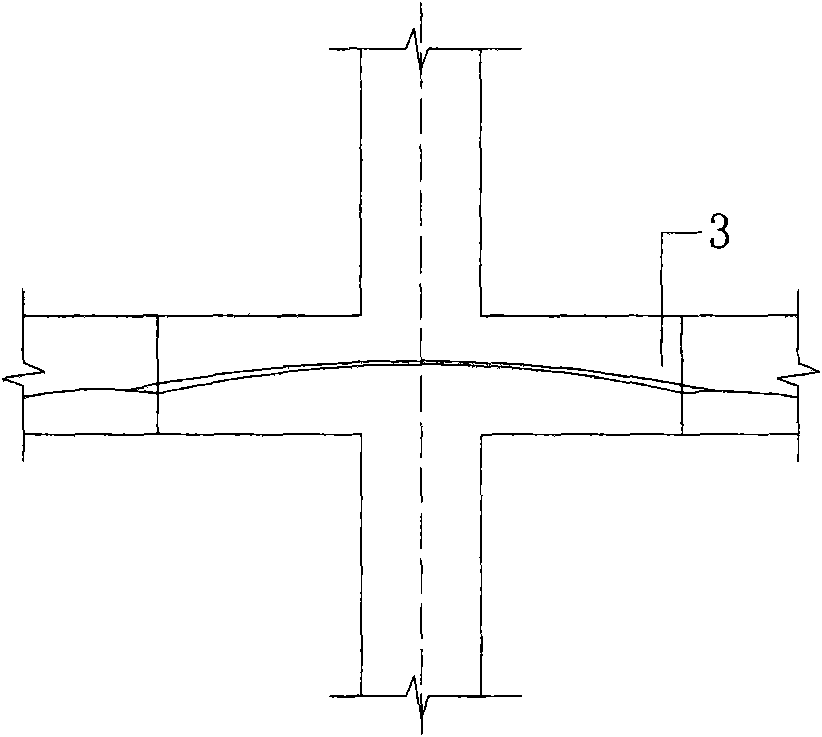

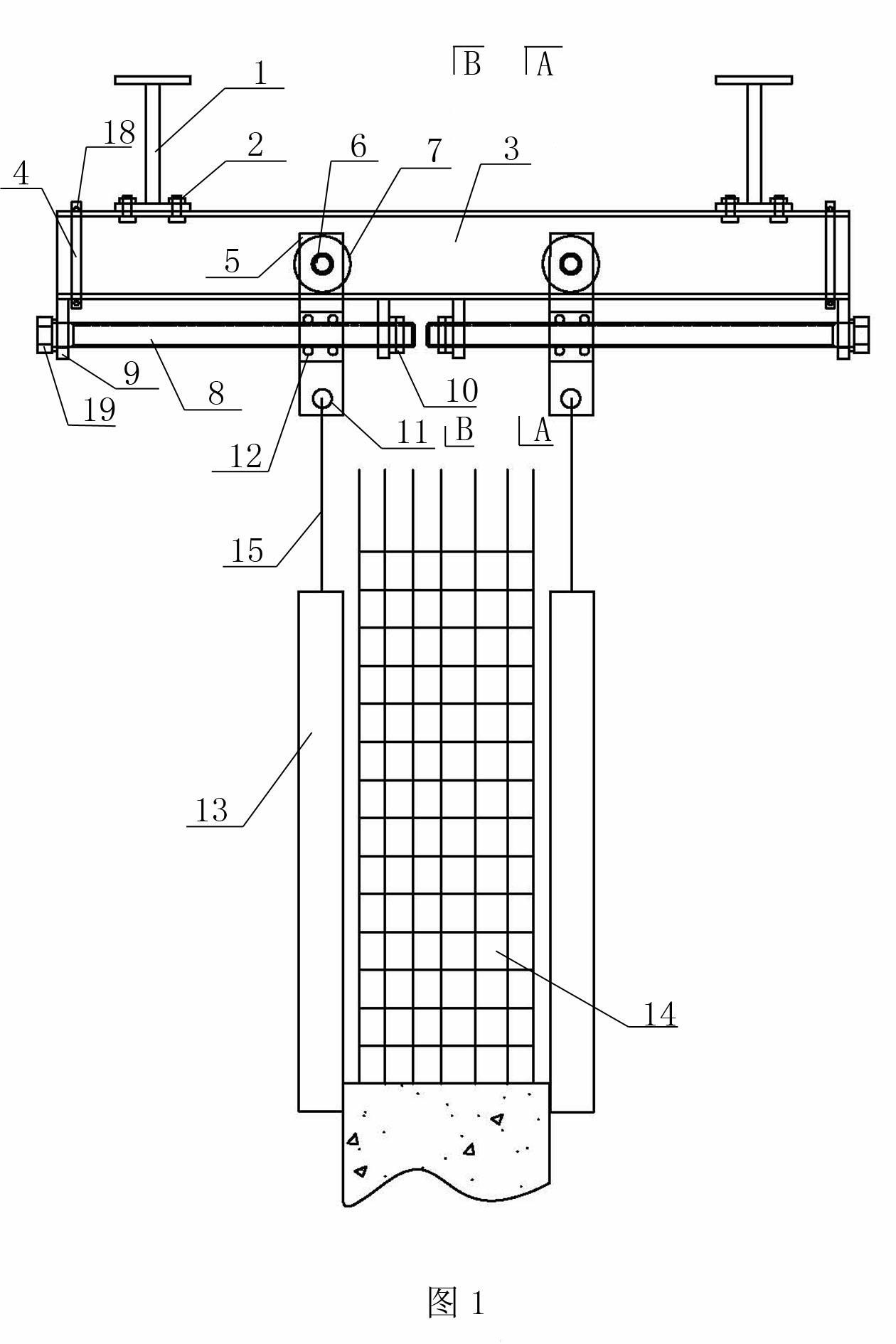

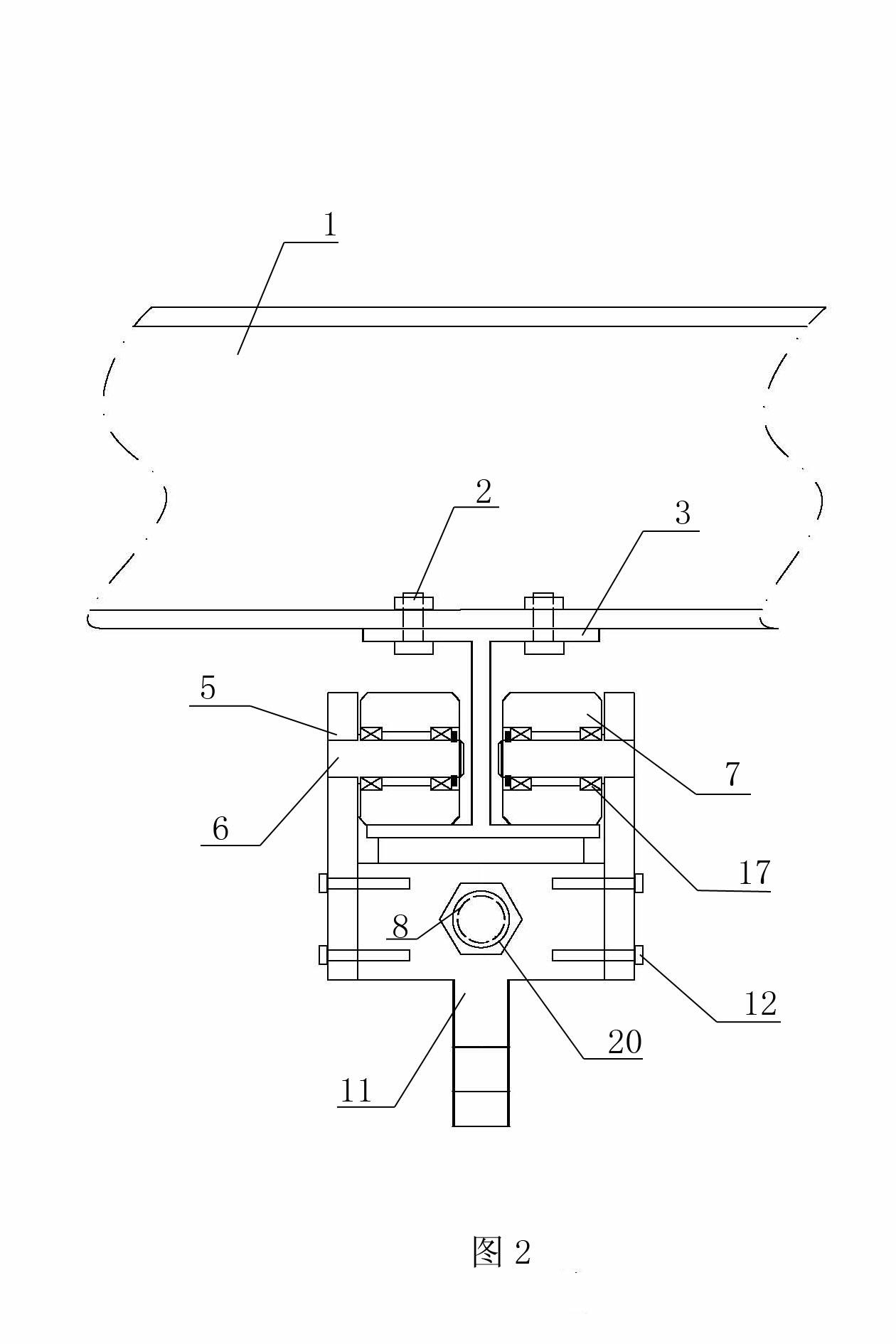

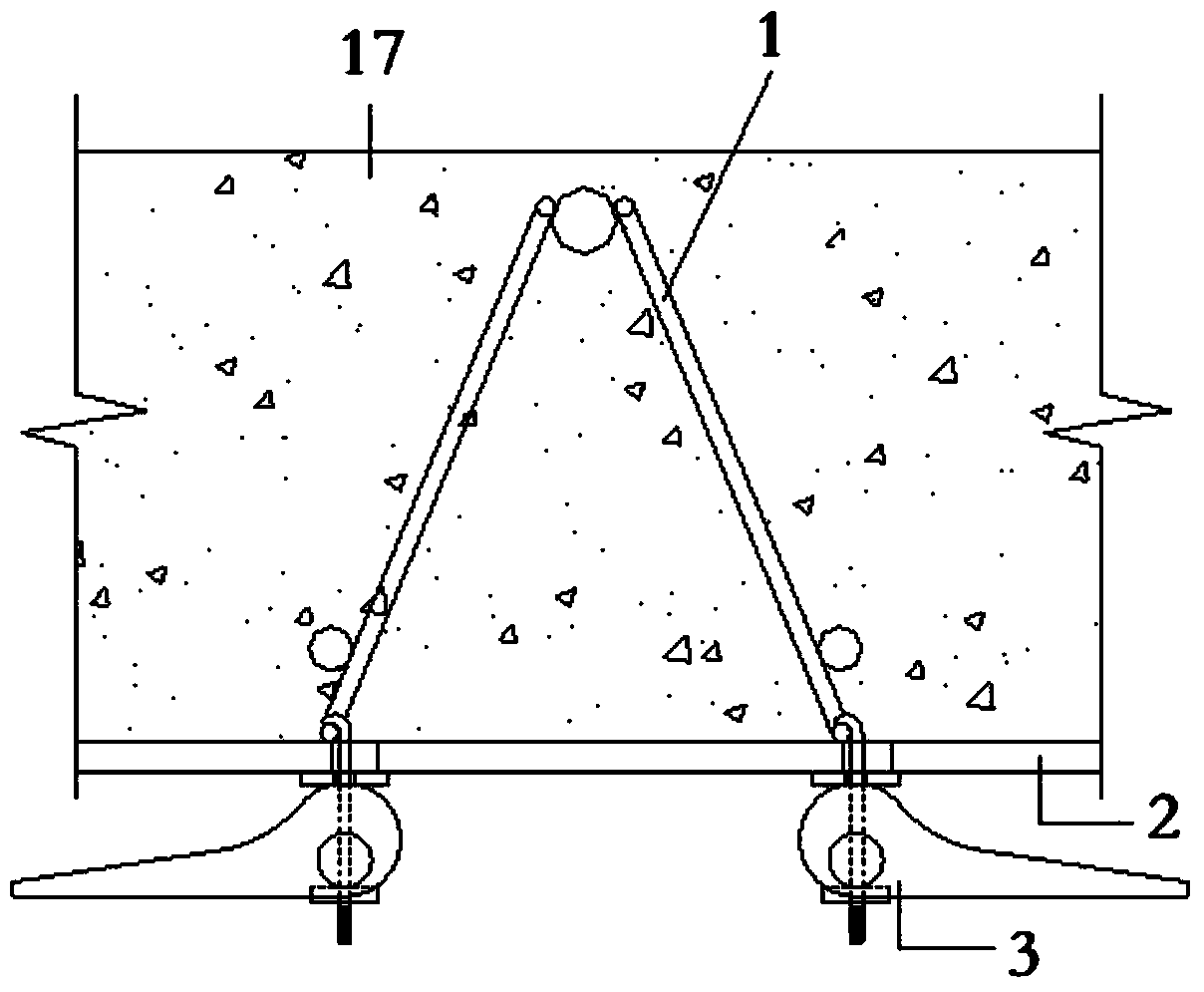

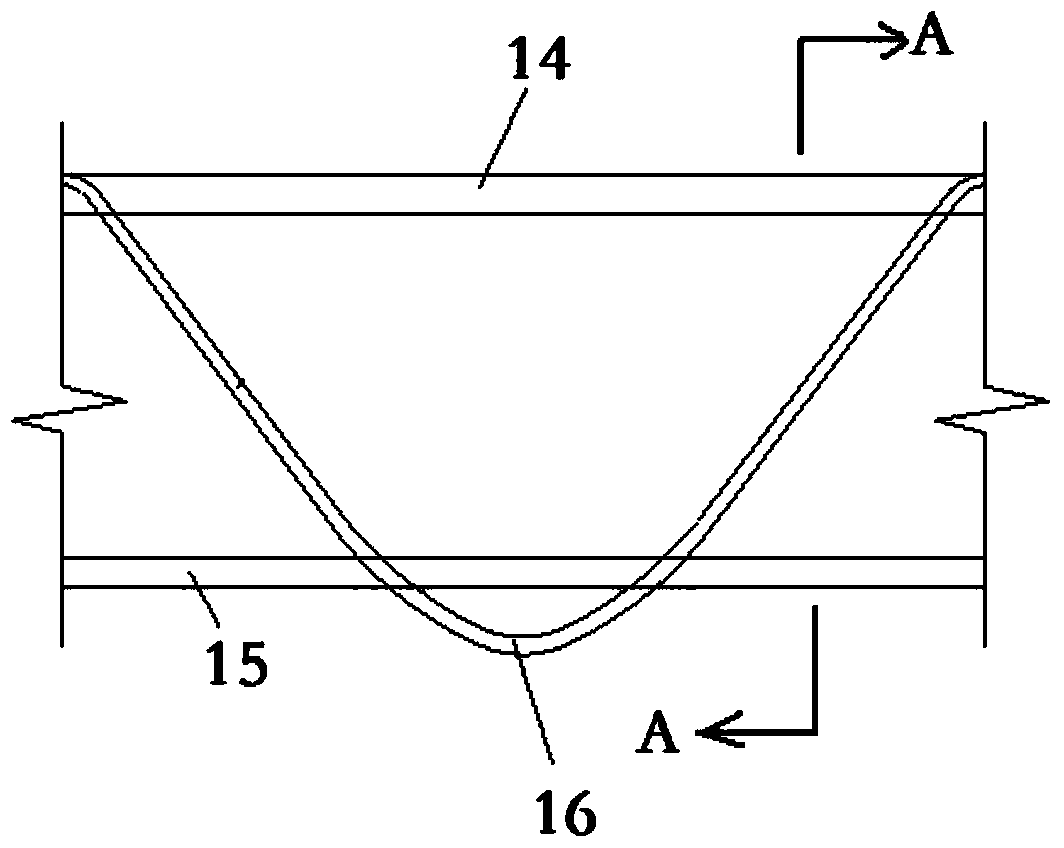

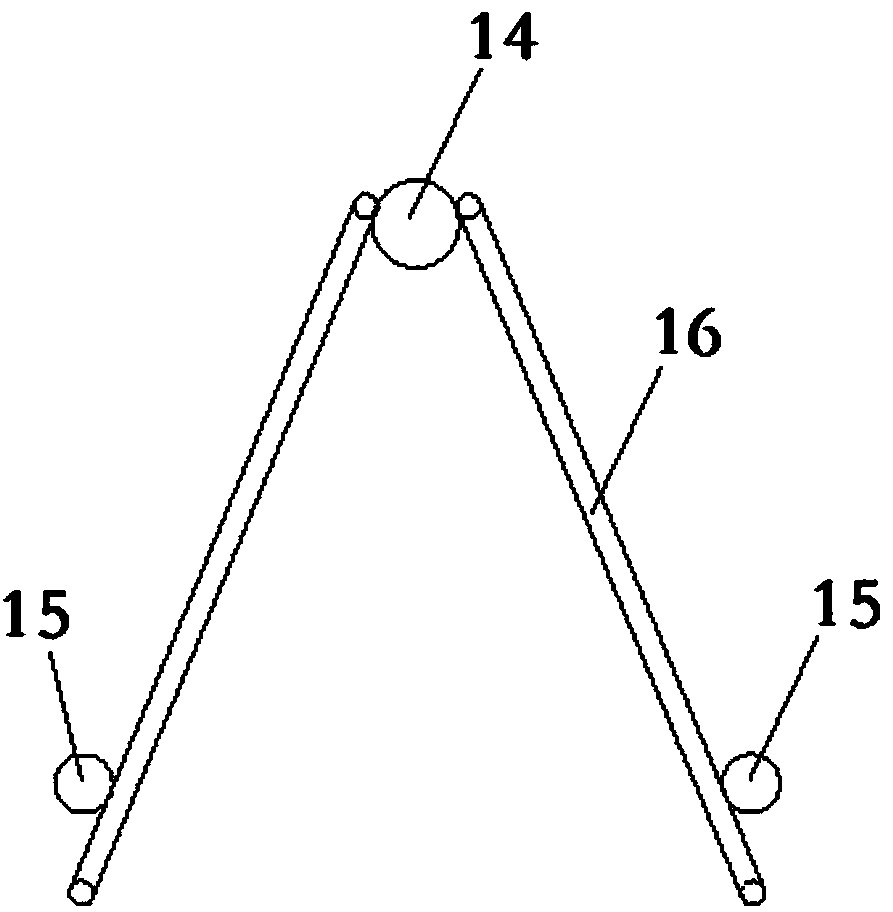

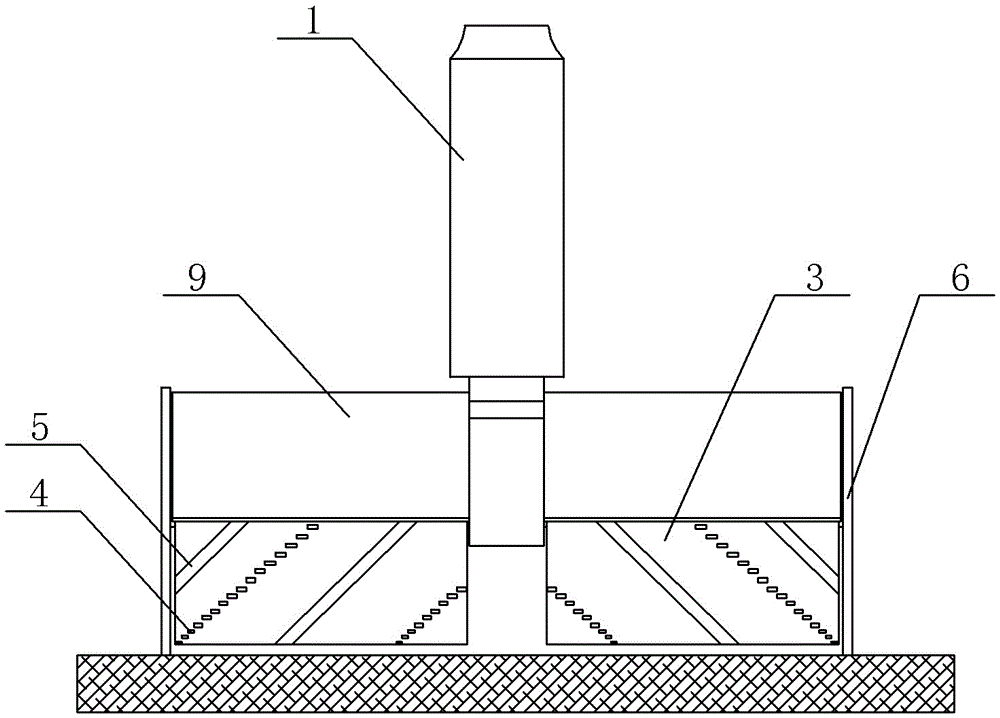

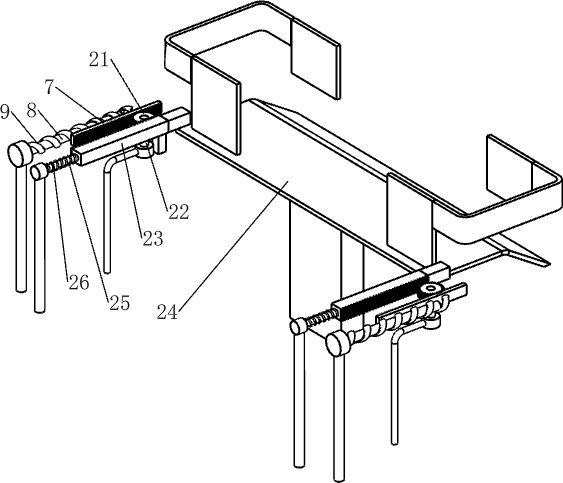

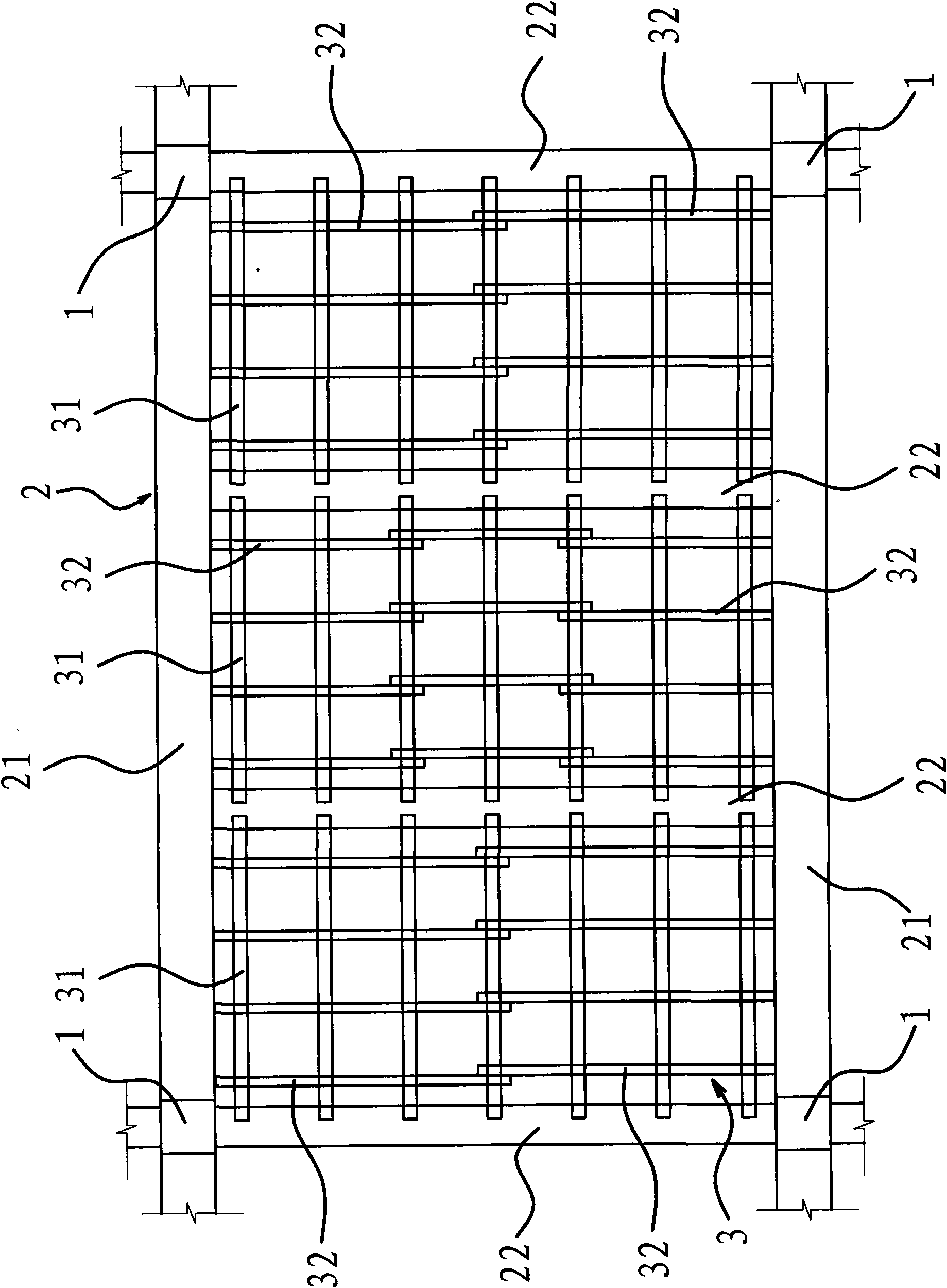

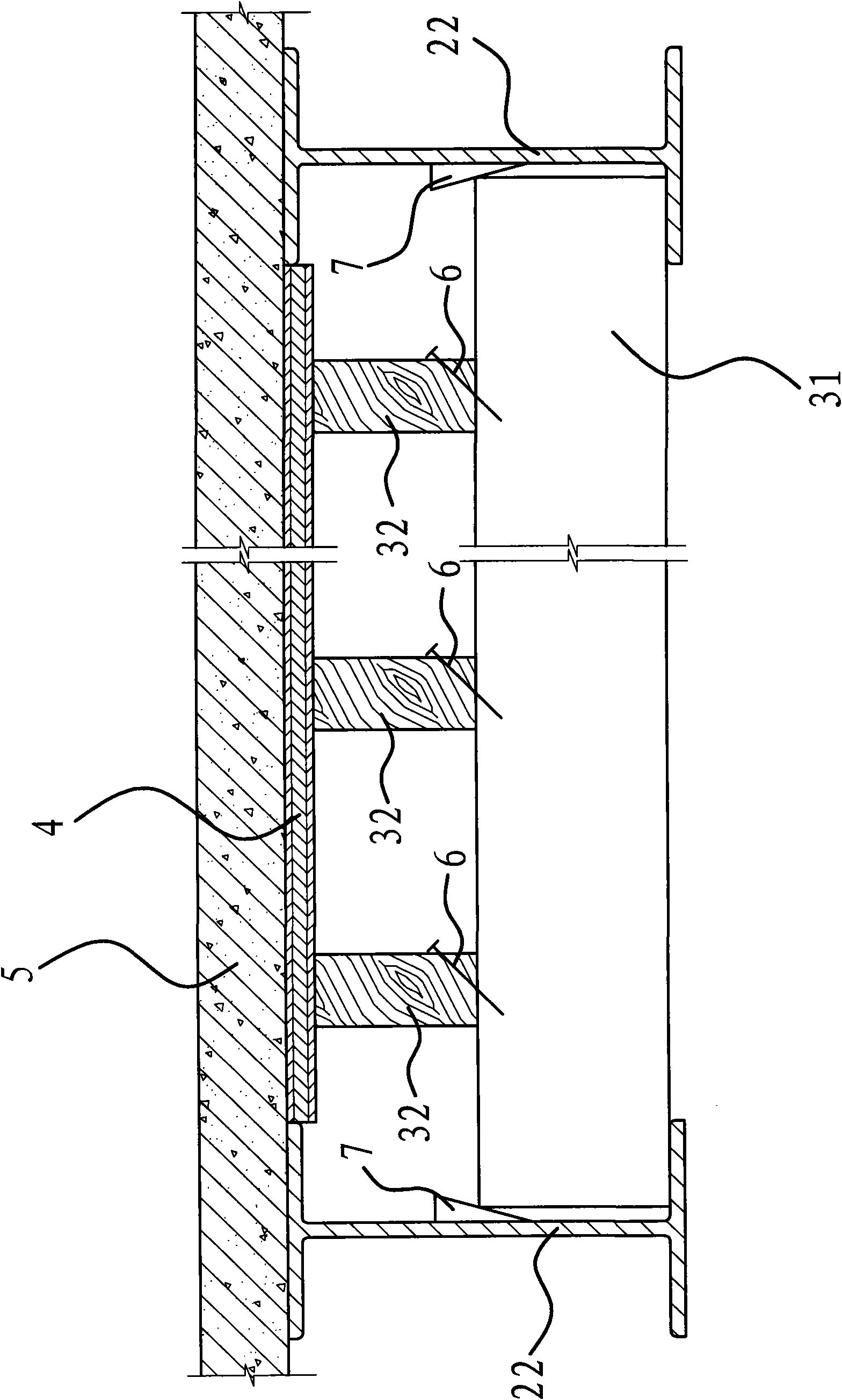

Formwork panel dismountable and thickness adjustable combined steel bar truss floor bearing plate

The invention discloses a formwork panel dismountable and thickness adjustable combined steel bar truss floor bearing plate which comprises a steel bar truss (1), a formwork panel (2) and bearing fasteners (3), and is characterized in that the bearing fasteners (3) comprise hook heads (5), hole bearing pads (6), connecting screw rods (7), adjusting nuts (8), hole force transmission steel shafts (9) and bearing spanners (10). According to the formwork panel dismountable and thickness adjustable combined steel bar truss floor bearing plate, the formwork panel is free from a welding point, and the floor bearing plate is free from deformation, is convenient to mount and dismount, can be used repeatedly, is suitable for the formwork panels in various types and with different thicknesses, lowers the production cost effectively, and has a broad market prospect.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

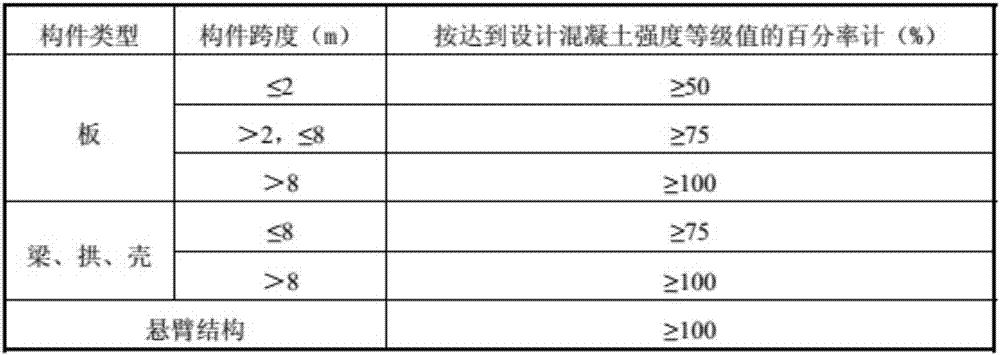

Beam-slab framework early removal construction method

InactiveCN102121314AReduce consumption costsShorten the construction period of the structureForms/shuttering/falseworksBuilding material handlingSupporting systemKeel

The invention provides a beam-slab framework early removal construction method. The method comprises the following steps: (1) span changing treatment is performed, wherein a technical measure of adding a single row of upright poles under a secondary joist of 10*10cm square lumber at the bottom of a longitudinal mid-span part of a slab for supporting is adopted, the square lumber secondary joist separates the slab with the span more than 4m into a bidirectional plate structure with the early removal span between 2 and 4m in a beam support mode; and in the same way, the technical measure that double poles are vertically added at the bottom of the beam every other 2.6 to 4m for a supporting is adopted, and the beam is turned into a framework removal structure with the early removal span between 2.6 and 4m; (2) the structure strength, rigidity and crack width in framework early removal are determined and calculated according an existing formula, and when the calculation results meet requirements at the same time, early removal construction is permitted; and (3) framework early removal construction is performed, wherein after the lowest permitted framework removal strength is determined, the actual early removal strength of concrete is calculated on the basis of the pressure testing strength of a test block is maintained under the same condition; whether the actual early removal strength is more than the calculated early removal strength or not is judged, and if the actual early removal strength is more than the calculated early removal strength, a later removal support system can be maintained, and other framework supports are removed.

Owner:李万山 +2

Portable concrete template surface cleaning device

The invention relates to a building construction template cleaning device, and particularly relates to a portable concrete template surface cleaning device. The portable concrete template surface cleaning device includes a hand-held power device, a cutter shaft and a roller; one end of the hand-held power device is provided with a motor and a transmission device which is connected to the motor; the cutter shaft is a cylinder, and the transmission device is connected to a rotatable shaft of the cylinder; the outer surface of the cylinder is provide with bump zones and hairbrush zones which are spirally distributed, wherein the bump zones and the hairbrush zones are alternately arranged, and the diameter of a rotatable surface of each bump zone is smaller than that of each hairbrush zone; the roller is arranged on the rotatable shaft at the outer side of the cylinder, and the roller and the cylinder are connected by a bearing; an outer edge of the roller is arranged on a concrete template; and the diameter of a rotatable surface of the roller is larger than that of the diameter of a rotatable surface of each bump zone. The portable concrete template surface cleaning device is low in cost, is portable, is convenient in use, and can clean a surface of the concrete template on site.

Owner:徐州华固混凝土有限公司

Building construction formwork waste removing device

The invention relates to a clearing device, in particular to a building construction formwork waste removing device. The building construction formwork waste removing device is capable of automatically collecting a building construction formwork after a cement block on the formwork is shoveled. The building construction formwork waste removing device comprises a rack, a removing assembly and a collecting assembly, wherein the removing assembly is installed on the rack, and the collecting assembly is installed on the rack. According to the building construction formwork waste removing device, cement on the building construction formwork is removed through the removing assembly, after cement removing work is completed, the building construction formwork subjected to the removing work can becollected, subsequent taking and using are facilitated, meanwhile, workers only need to place the building construction formwork on a discharging frame, the building construction formwork which is notsubjected to the cement removing work can be automatically pushed onto the collecting assembly to be subjected to the cement removing work, and the workload of workers is reduced.

Owner:山东鲁王建工有限责任公司

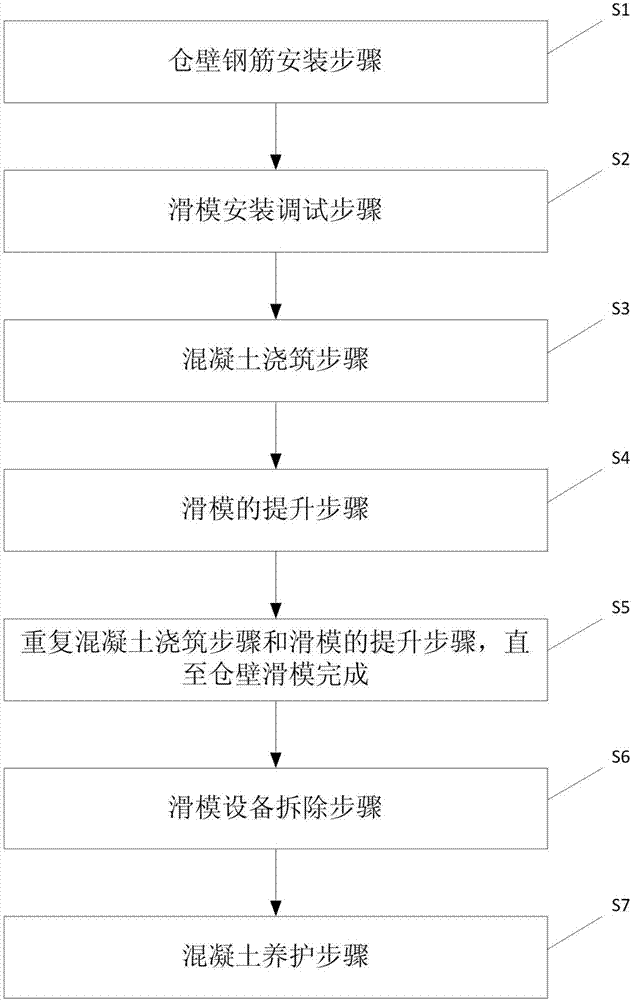

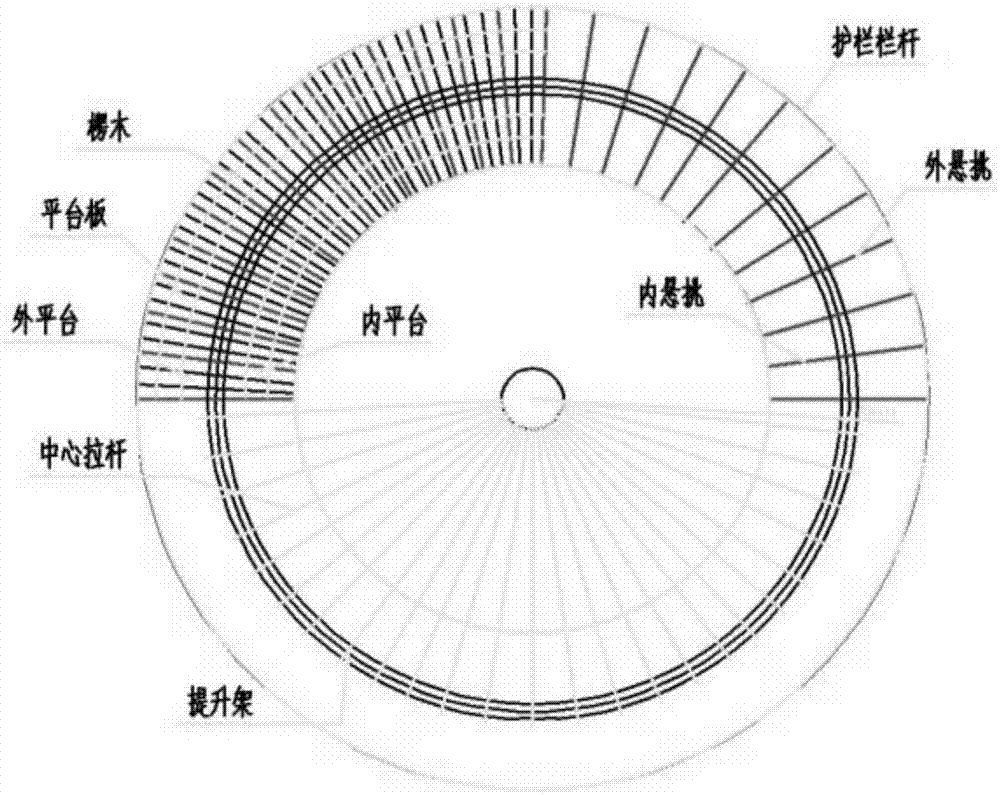

Construction method of sliding formwork for large-diameter silo

InactiveCN107882321ASave materialLabor savingForms/shuttering/falseworksBuilding material handlingFalseworkThree stage

The invention discloses a construction method of a sliding formwork for a large-diameter silo. The construction method comprises the steps that 1, silo wall steel bar mounting is conducted; 2, slidingformwork mounting and debugging are conducted; 3, concrete pouring is conducted; 4, sliding formwork lifting is conducted, wherein tank wall sliding formwork lifting is divided into three stages, namely primary sliding, normal sliding rising and tank wall top formwork sliding rising; 5, concrete pouring and sliding formwork lifting are repeated till the silo wall sliding formwork is completed; 6,sliding formwork device dismantling is conducted; and 7, concrete curing is conducted. According to the construction method, only one set of formworks is used, the formworks and an operating platformare lifted through a hydraulic jack, formwork supporting and scaffold setting up are not needed any longer, and thus the formworks, scaffold materials and manual work can be greatly saved; continuousoperation is kept during construction, various working procedures are simplified, the sections of the formworks do not need to be mounted and dismounted completely, and thus the construction speed ishigh; and concrete adopts continuous pouring, construction joints can be reduced, and integrality of a building can be ensured.

Owner:中铁建设集团南方工程有限公司

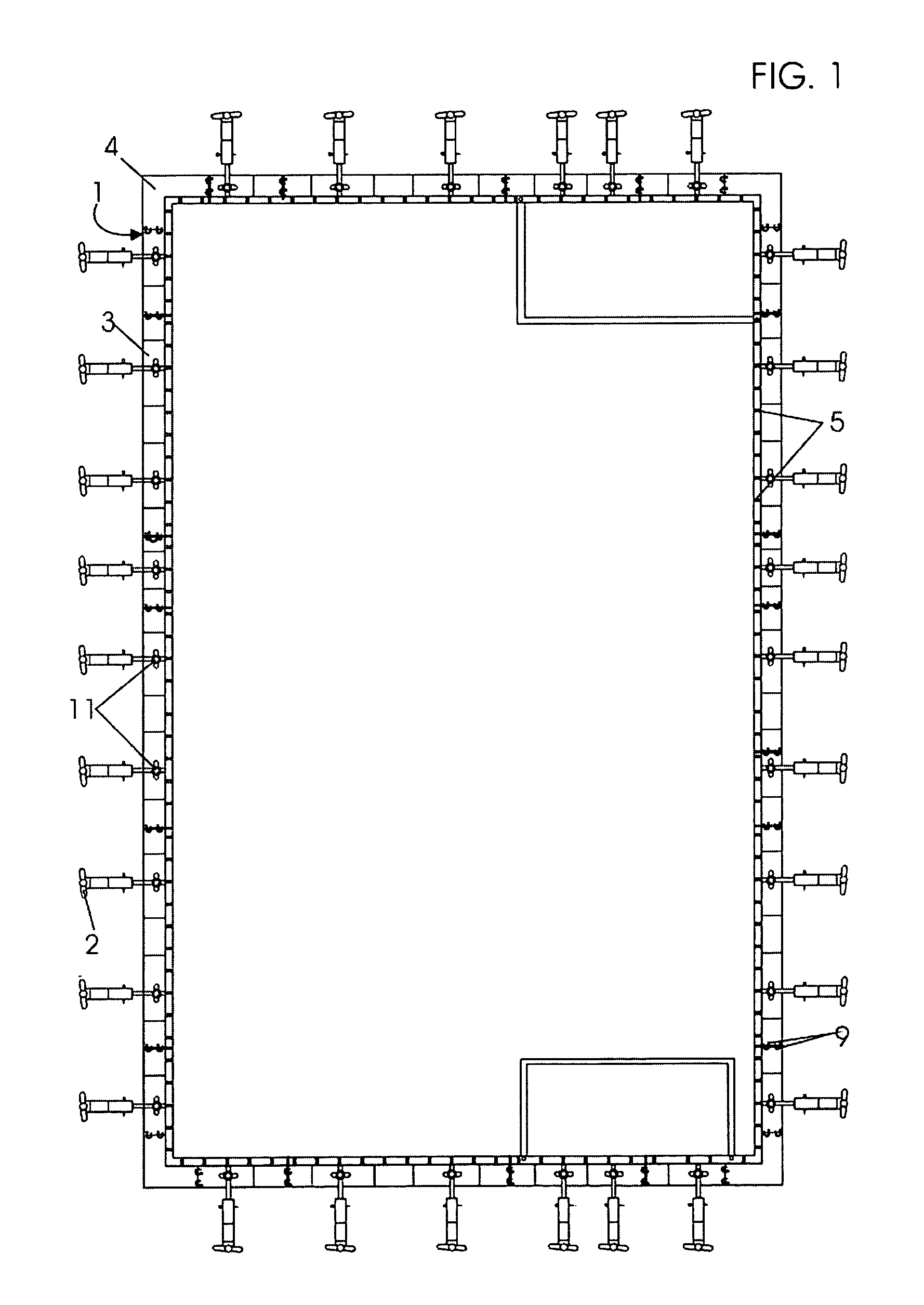

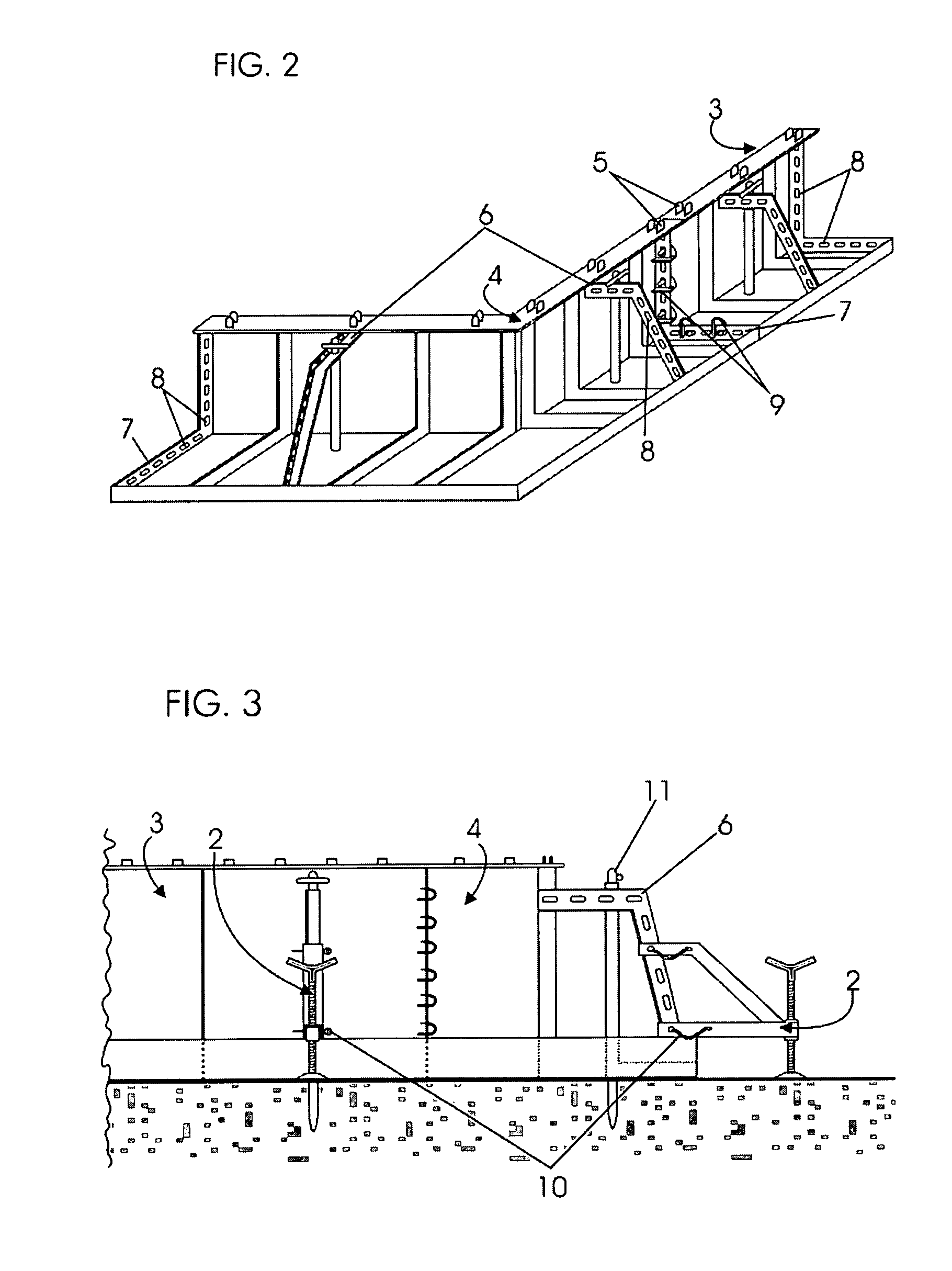

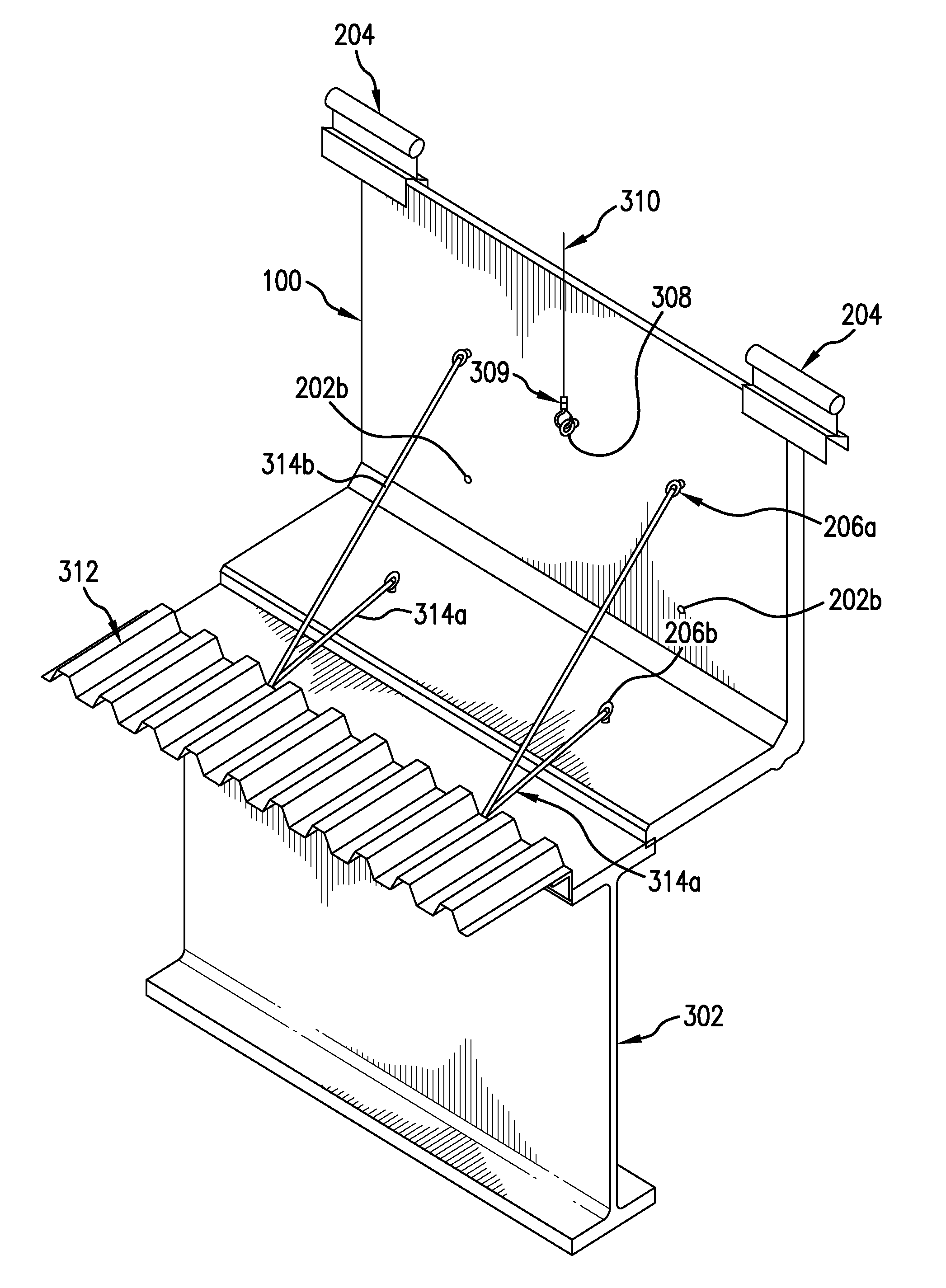

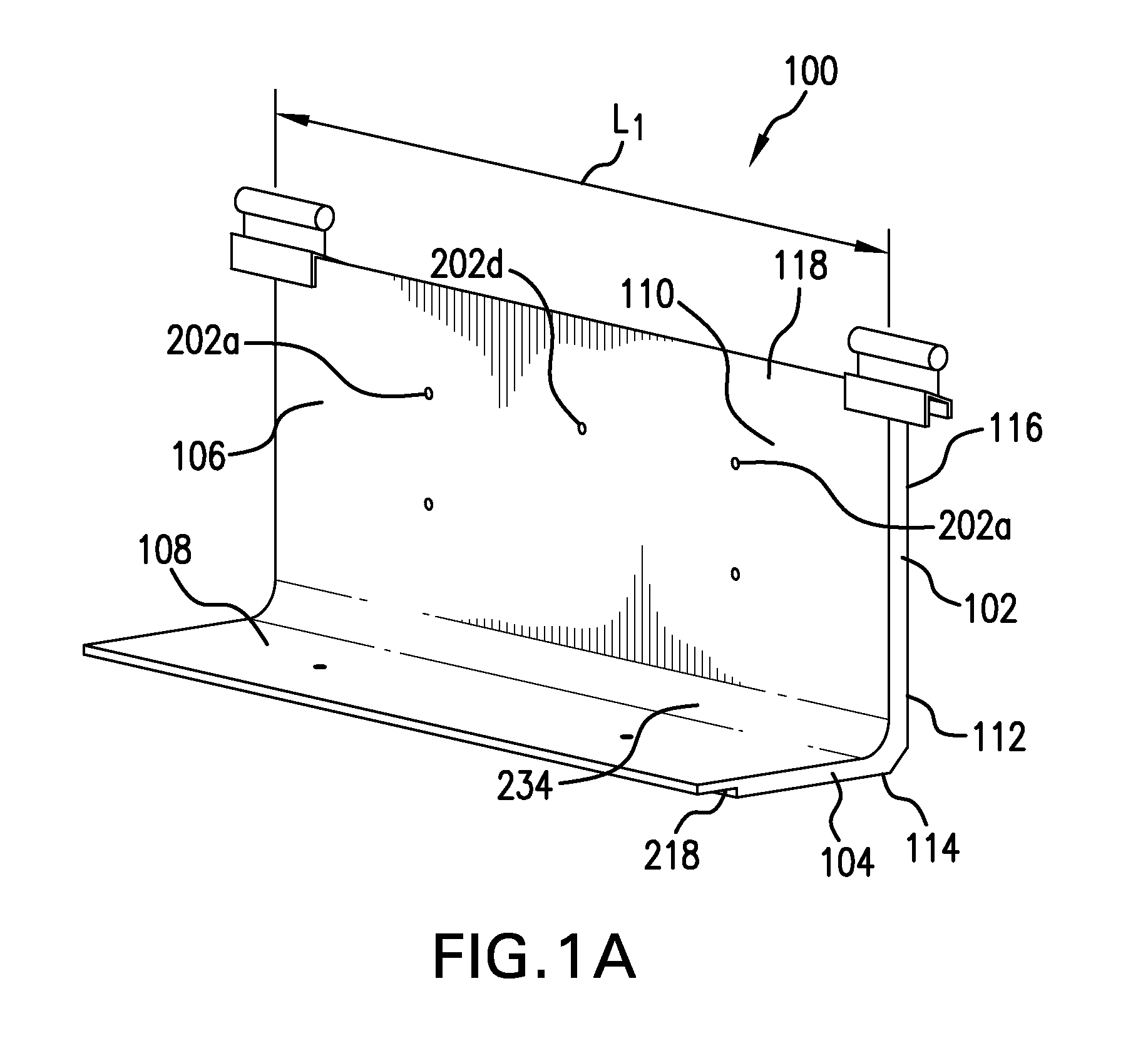

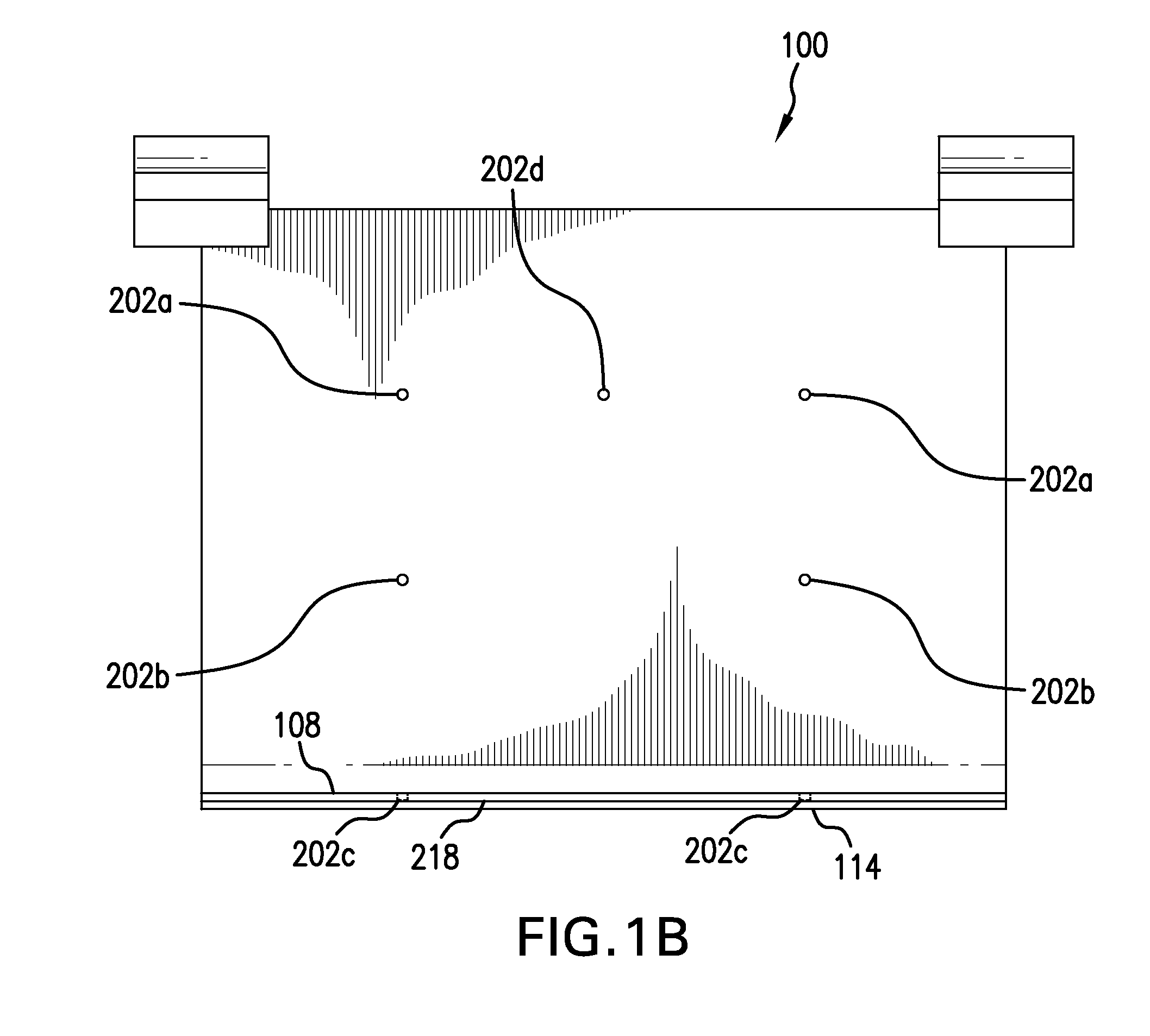

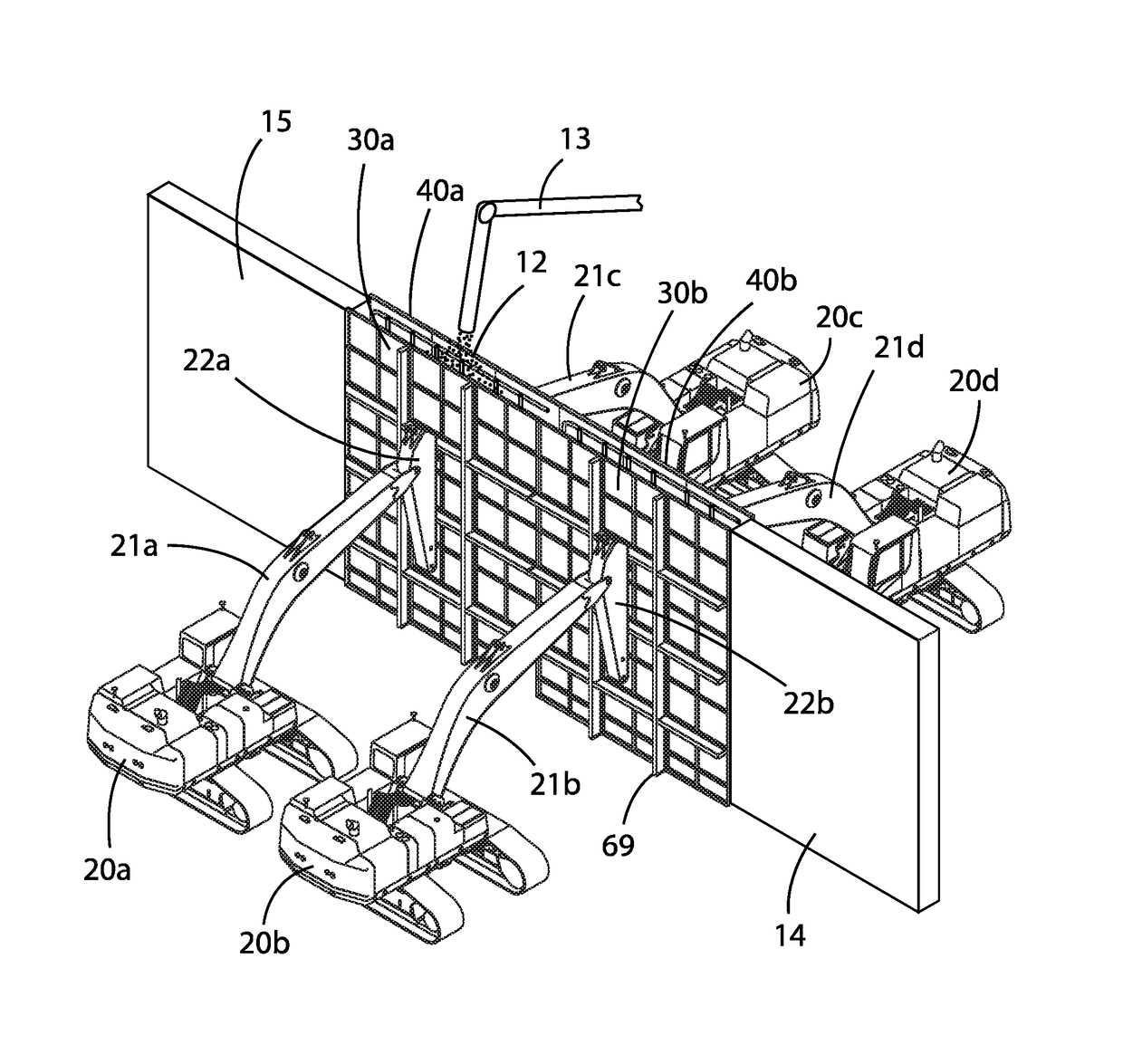

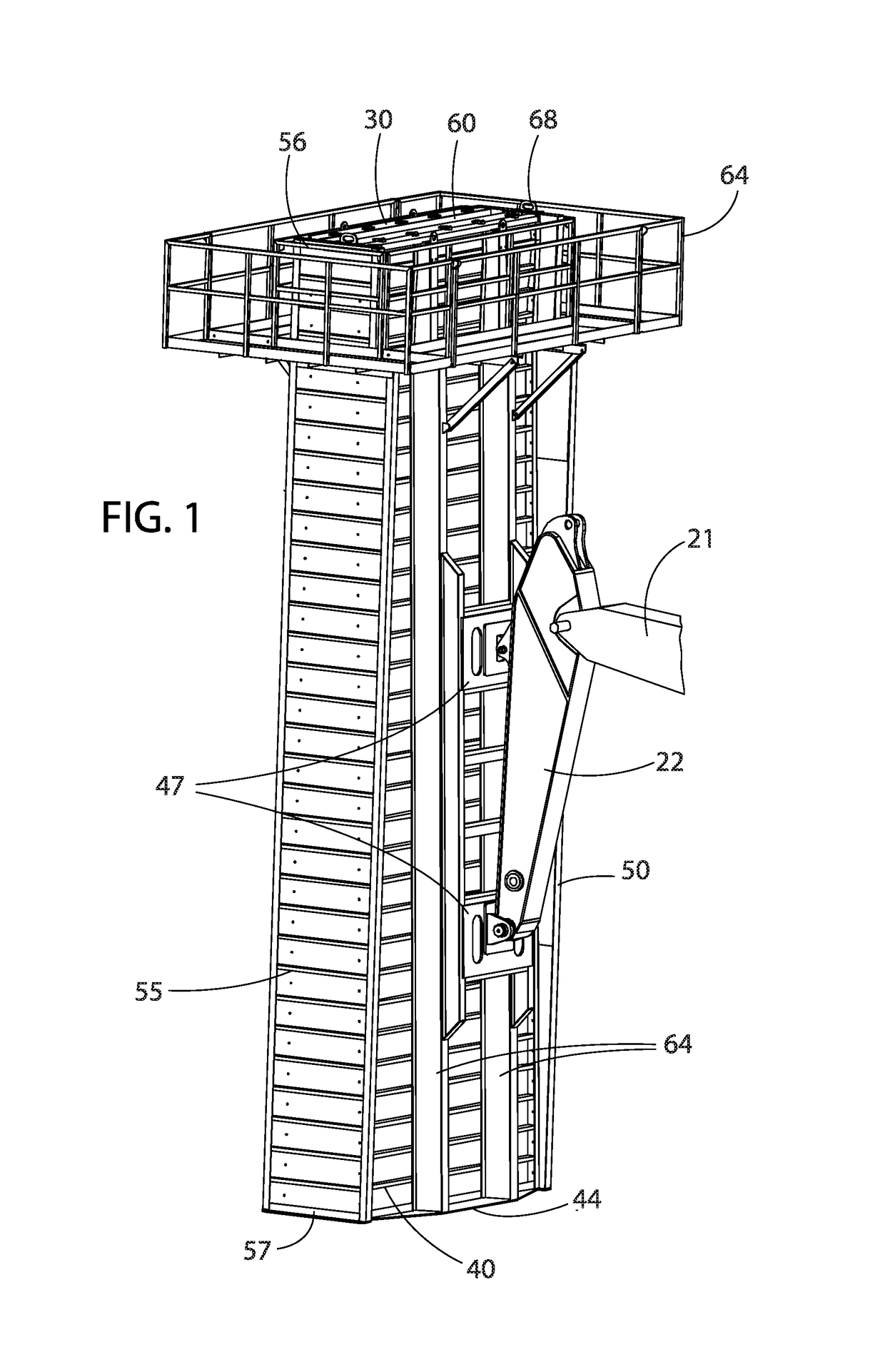

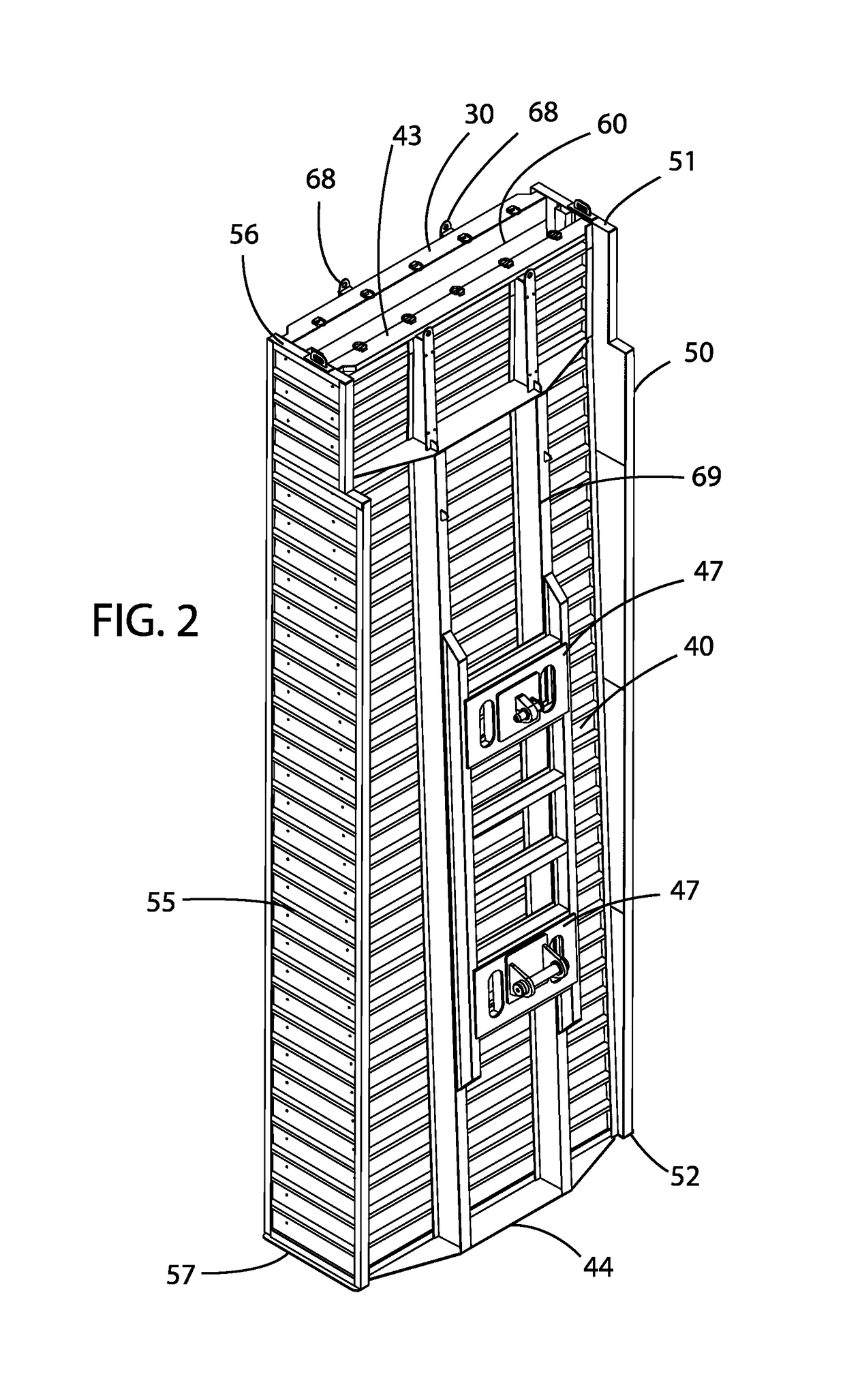

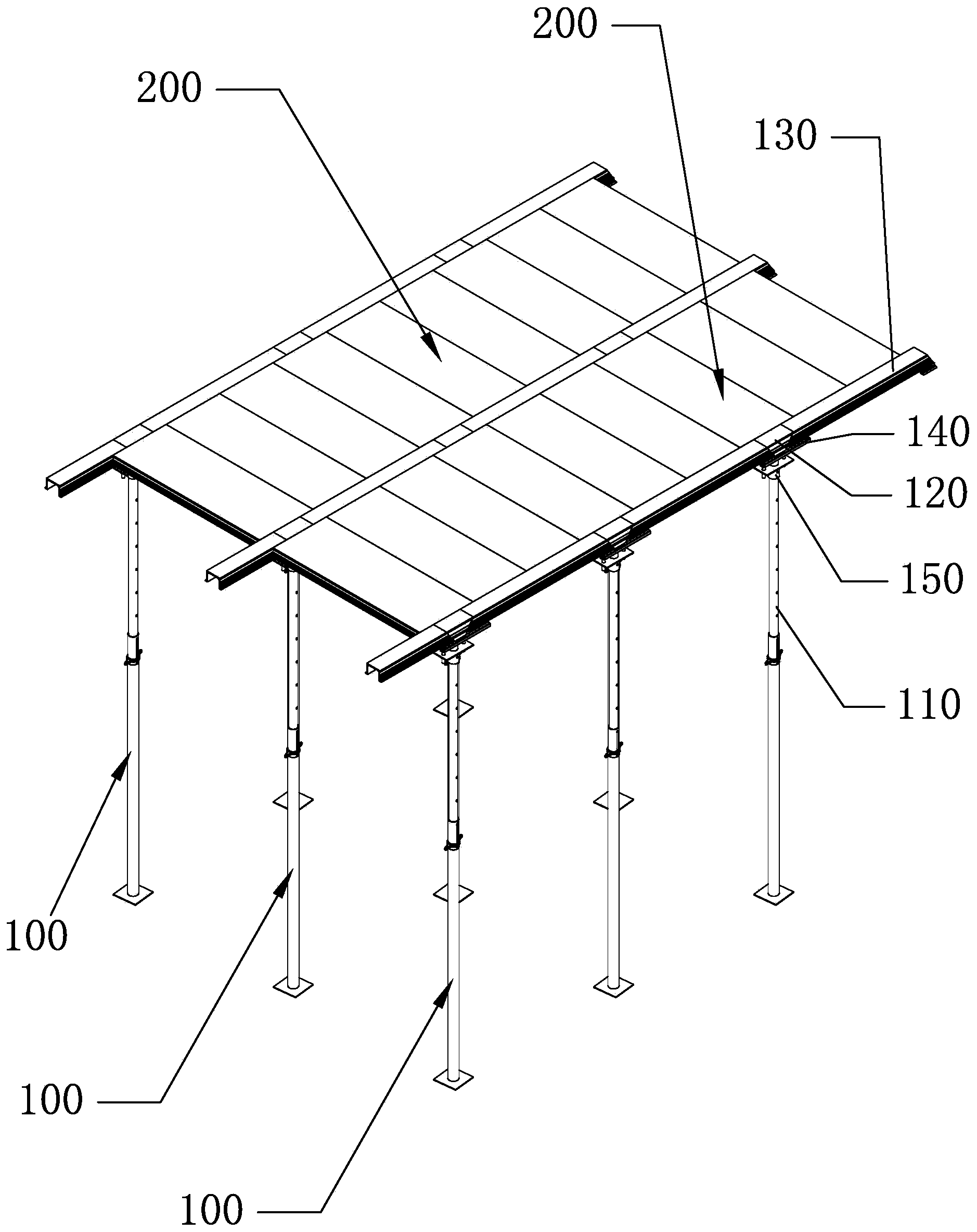

Concrete forming system

ActiveUS9988823B1Great contributionCeramic shaping plantsForms/shuttering/falseworksCivil engineering

A concrete forming system for reducing the time and labor required for the framing, pouring, and curing of concrete walls. The concrete forming system generally includes concrete forms including a first wall, a second wall opposing the first wall, and a pair of sidewalls. A cavity is formed between the walls; with an opening being fluidly connected to the cavity. A first vehicle is connected to the first wall and a second vehicle is connected to the second wall. Using the vehicles, the positioning and orientation of the walls may be adjusted. After the walls have been placed and oriented, the vehicles will hold the walls in place as concrete is poured into the cavity through the opening. The concrete is allowed to cure into a structure; after which the vehicles and walls may be moved to another location to repeat the process.

Owner:TGR CONSTR INC

Nanometer titania reinforced concrete mold release agents

ActiveCN105345919AExcellent mold releaseSmooth demouldingCeramic shaping apparatusForm treatmentReinforced concreteRosin

The invention discloses nanometer titania reinforced concrete mold release agents, and relates to the technical field of concrete mold releasing. The nanometer titania reinforced concrete mold release agents comprise, by weight, 5-8 parts of nanometer titania, 80-90 parts of glycerol ester of rosin, 50-60 parts of polyether modified silicone, 15-20 parts of zeolite powder, 15-20 parts of volcanic soil, 12-18 parts of octadecanamide, 10-15 parts of polyamide resin, 10-15 parts of saponin powder, 10-15 parts of emulsified oil, 8-12 parts of spans, 6-10 parts of lubricating grease, 6-10 parts of rice bran wax, 4-7 parts of tartaric acid, 30-40 parts of mandarin oil and 300-350 parts of water. The nanometer titania reinforced concrete mold release agents have good mold release performance, enable a mold plate and concrete to be smoothly released, keep the surface of concrete smooth and keep edges tidy and undamaged.

Owner:滁州京安工贸有限责任公司

Template fast disassembling system

ActiveCN103470021AAvoid falling on the groundReduce lossForming/stuttering elementsForm treatmentKeelComputer science

The invention relates to a template fast disassembling system, comprising early disassembling supports and multiple templates; each template is erected between two adjacent rows of early disassembling supports; each row of early disassembling supports comprise multiple support posts, early disassembling heads and main keels; each early disassembling head is arranged above each support post; every two main keels are detachably connected to two ends of each early disassembling head and are adjustably connected onto the support post below the early disassembling head up and down. Every two main keels of the template fast disassembling system can be detachably connected to two ends of each early disassembling head and are adjustably connected onto the support post below the early disassembling head up and down; when every two main keels are disassembled from each early disassembling head, the multiple main keels can be wholly downwards adjusted relative to the multiple early disassembling heads, so the multiple templates can descend to the height capable of being touched by hands. In such a mode, the condition that the templates directly fall onto the ground from a high position is avoided, the template loss is reduced, workers do not need to disassemble the templates at the high position and the working above the ground of the workers is reduced.

Owner:HUI LINDA TECH

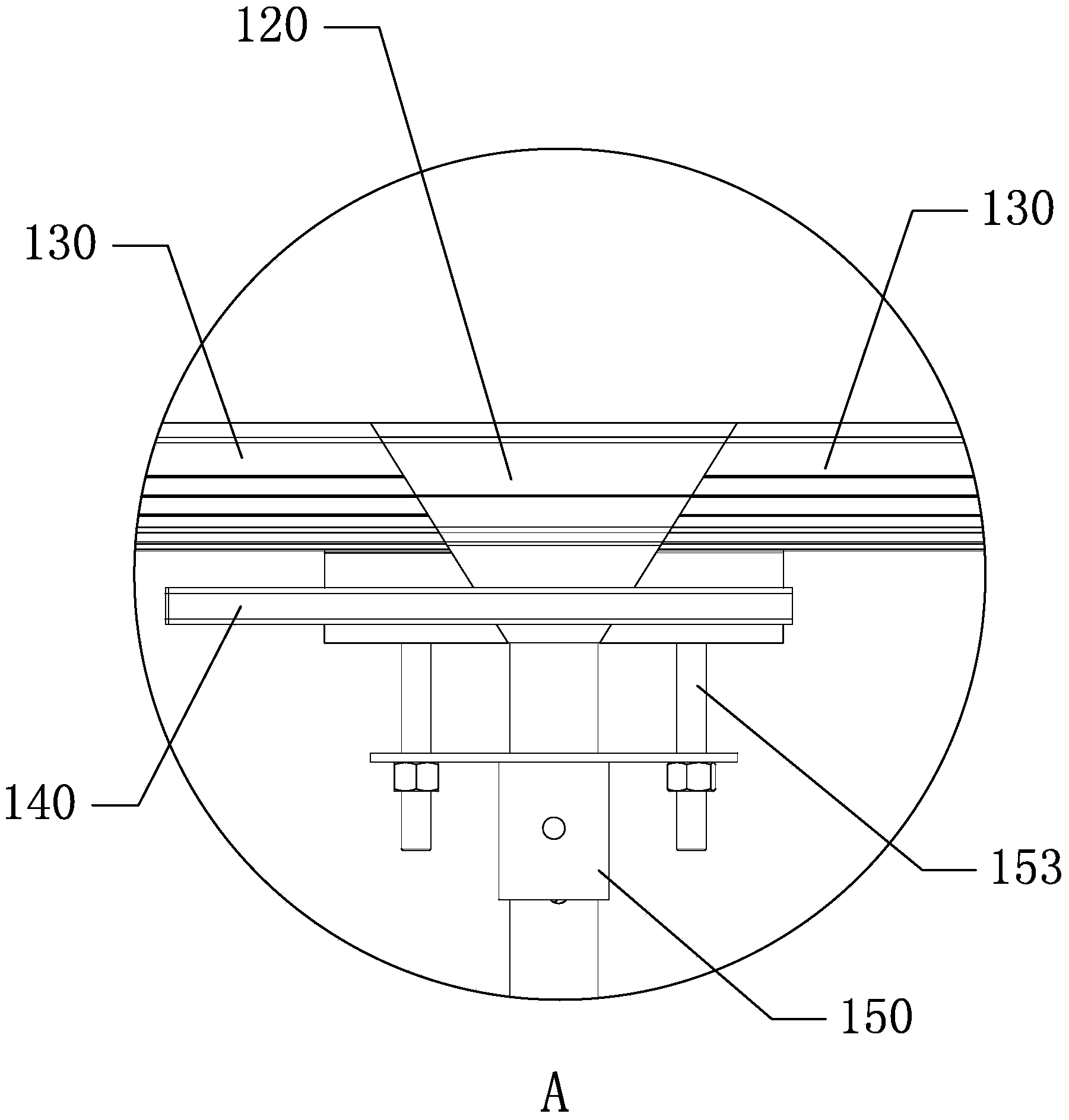

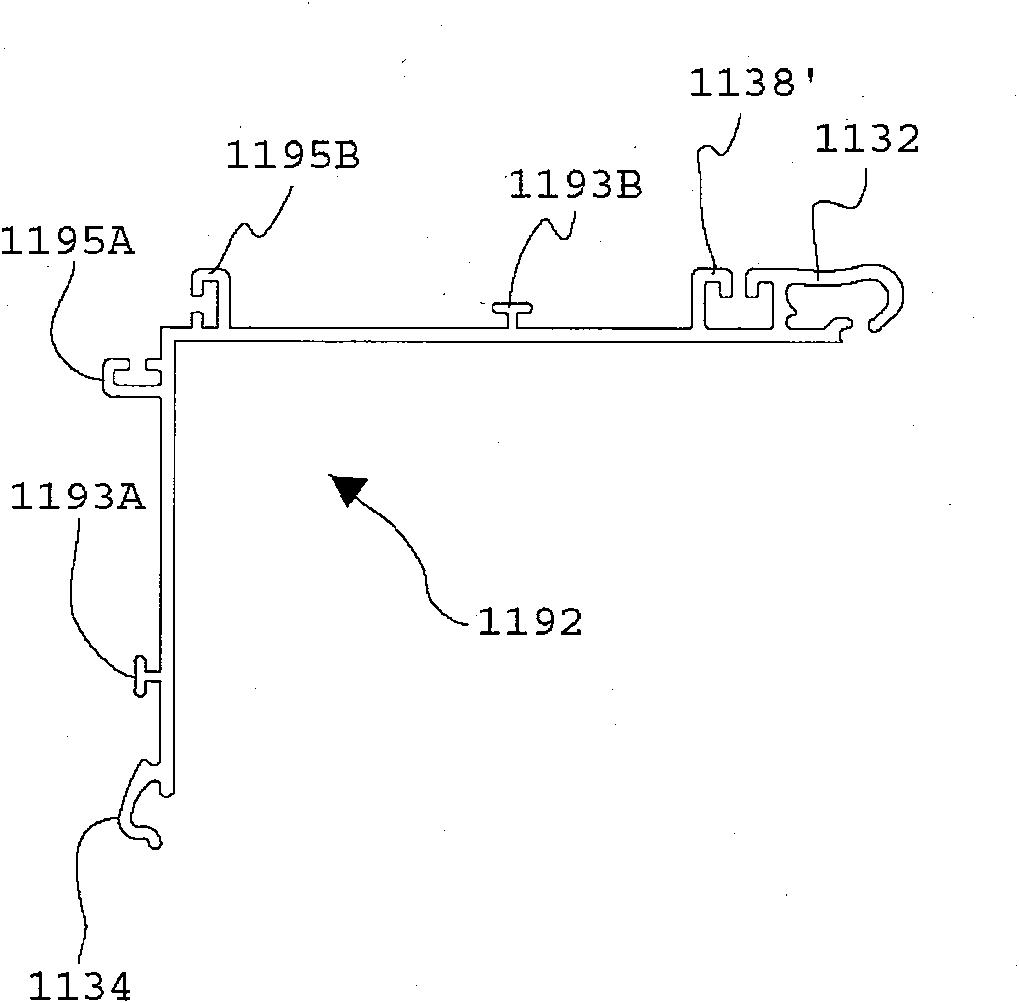

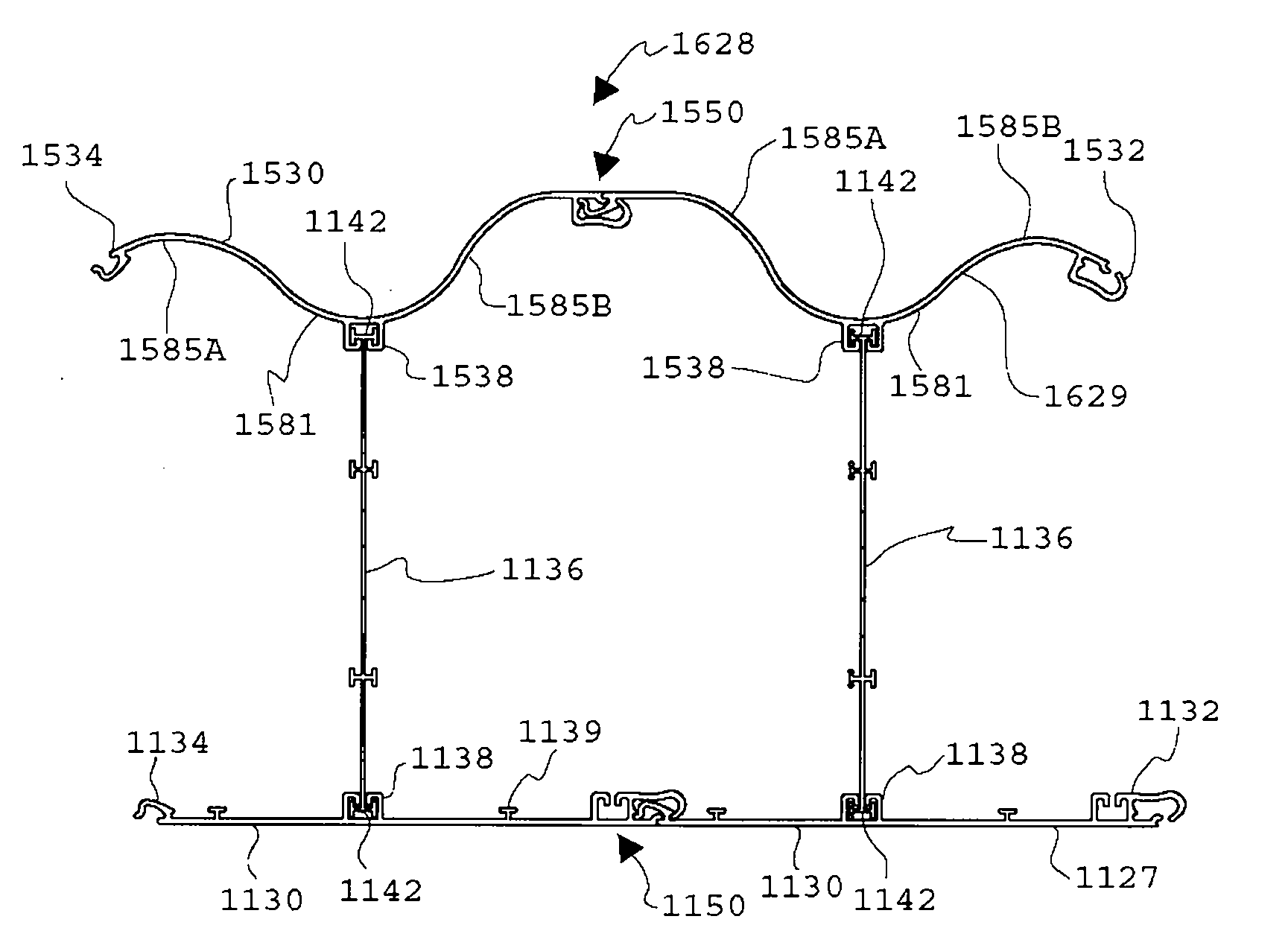

Pivotally activated connector components for form-work systems and methods for use of same

A stay-in-place form for casting concrete structures comprises a plurality of elongate panels interconnectable in edge-to-edge relationship via complementary connector components on their longitudinal edges to define at least a portion of a perimeter of the form. Each panel comprises a first contoured connector component comprising a protrusion on a first longitudinal edge thereof and a second contoured connector component comprising a receptacle on a second longitudinal edge thereof. The panels are connectable to one another in edge-to-edge relationship by positioning the protrusion of a first panel in or near the receptacle of a second panel and effecting relative pivotal motion between the first connector component of the first panel and the second connector component of the second panel to extend the protrusion of the first panel into the receptacle of the second panel.

Owner:CFS CONCRETE FORMING SYST

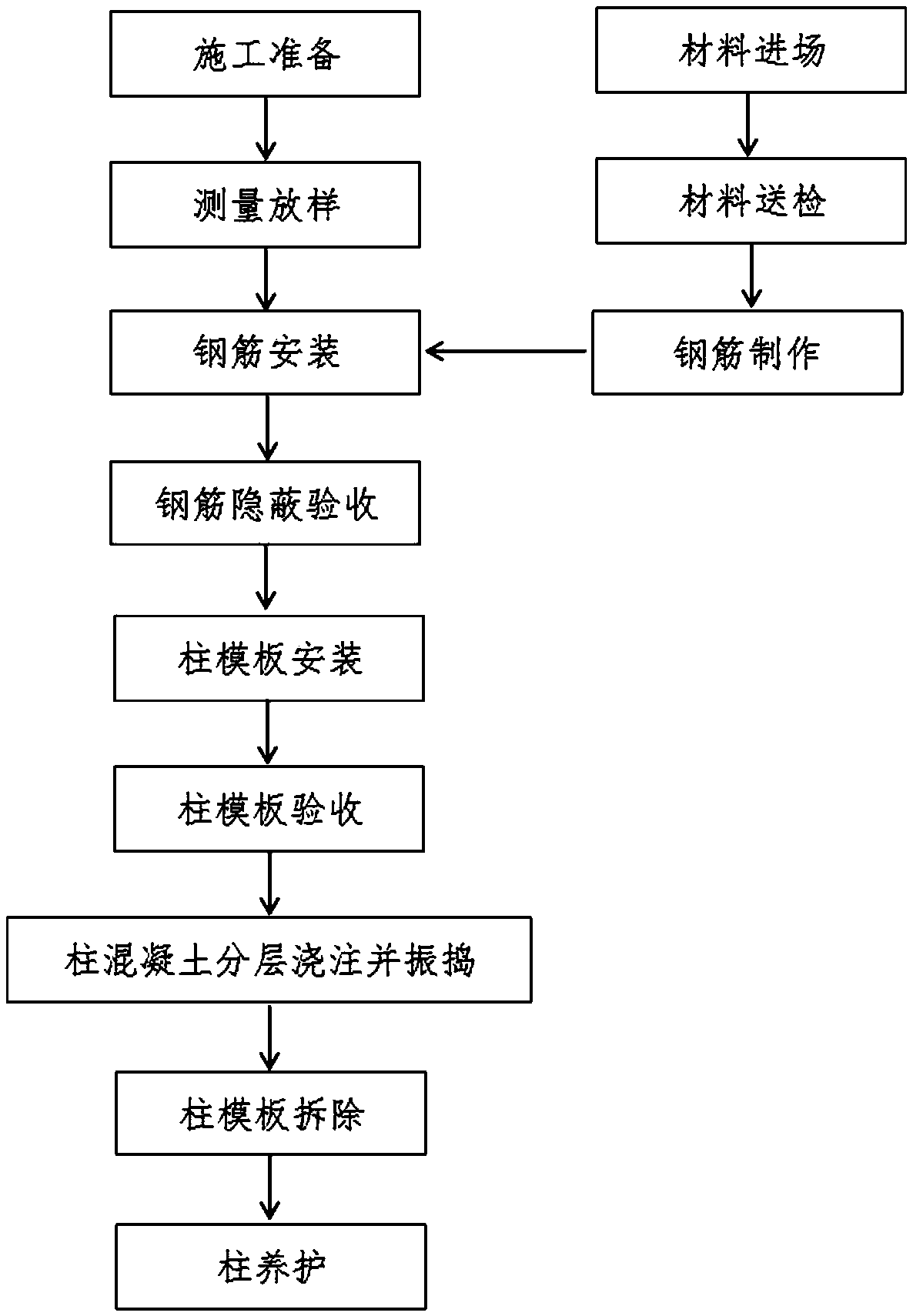

Construction method of ultrahigh facing bare concrete vertical column

InactiveCN110107085AAccurate shapeQuality improvementForms/shuttering/falseworksBuilding material handlingProcess optimizationEngineering

The invention relates to a concrete vertical column construction process, in particular to a construction method of an ultrahigh facing bare concrete vertical column. A traditional concrete column construction process is integrated and improved through process optimization of all links such as the match ratio of bare concrete, quality control of raw materials, a material of formworks, a material of a release agent, formwork mounting and dismounting, pouring and vibration of the bare concrete, rain shed curing of the bare concrete, and protection of a finished bare concrete product. According to the process, the problems that as for a special-shaped facing bare concrete column, modelling construction is difficult, and the appearance quality is difficult to guarantee are effectively solved,it is guaranteed that the facing bare concrete is poured to be formed at a time, pitted surface bubbles are avoided, the color is uniform, and opposite joints of the formworks are regular and uniform,and have the mechanism and texture of the concrete.

Owner:CHINA RAILWAY SIXTH GROUP +1

Composite beam die and method for making composite beam with composite beam die

The present invention provides a composite beam die and a method for making a composite beam with a composite beam die, belonging to the technical field of buildings. The present invention solves the problems that the existing concrete floor pouring method wastes labour, time and materials and influences construction operation space. The composite beam die comprises a template and a plurality of ribs uniformly arranged on the bottom surface of the template. The method for making a composite beam with a composite beam die is conducted by the following steps: mounting a girder, mounting a composite beam die, arranging steel ribs of the same length with that of an interface required on a template, pouring concrete to the interface required, forming an integral floor slab and removing the composite beam die after the concrete is hardened and molded. The composite beam die has the advantages of light dead weight, convenient production and manufacture, low price, capability of being repeatedly used and engineering cost reduction. The method for making a composite beam with a composite beam die is reasonable in design, saves materials required by engineering, reduces occupation space required by construction, and reduces influence on the normal conduction of other construction procedures.

Owner:TAIZHOU BUILDING INSTALLATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com