Die cleaning equipment for cleaning lightweight concrete wall plate die

A light-weight concrete and mold-clearing technology, applied in the treatment of mold shells, the preparation of building components on site, and construction, etc., can solve the problems of increased production costs, low efficiency, easy to accidentally hurt people's eyes, etc., and reduce labor intensity. , The structure of the equipment is simple, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

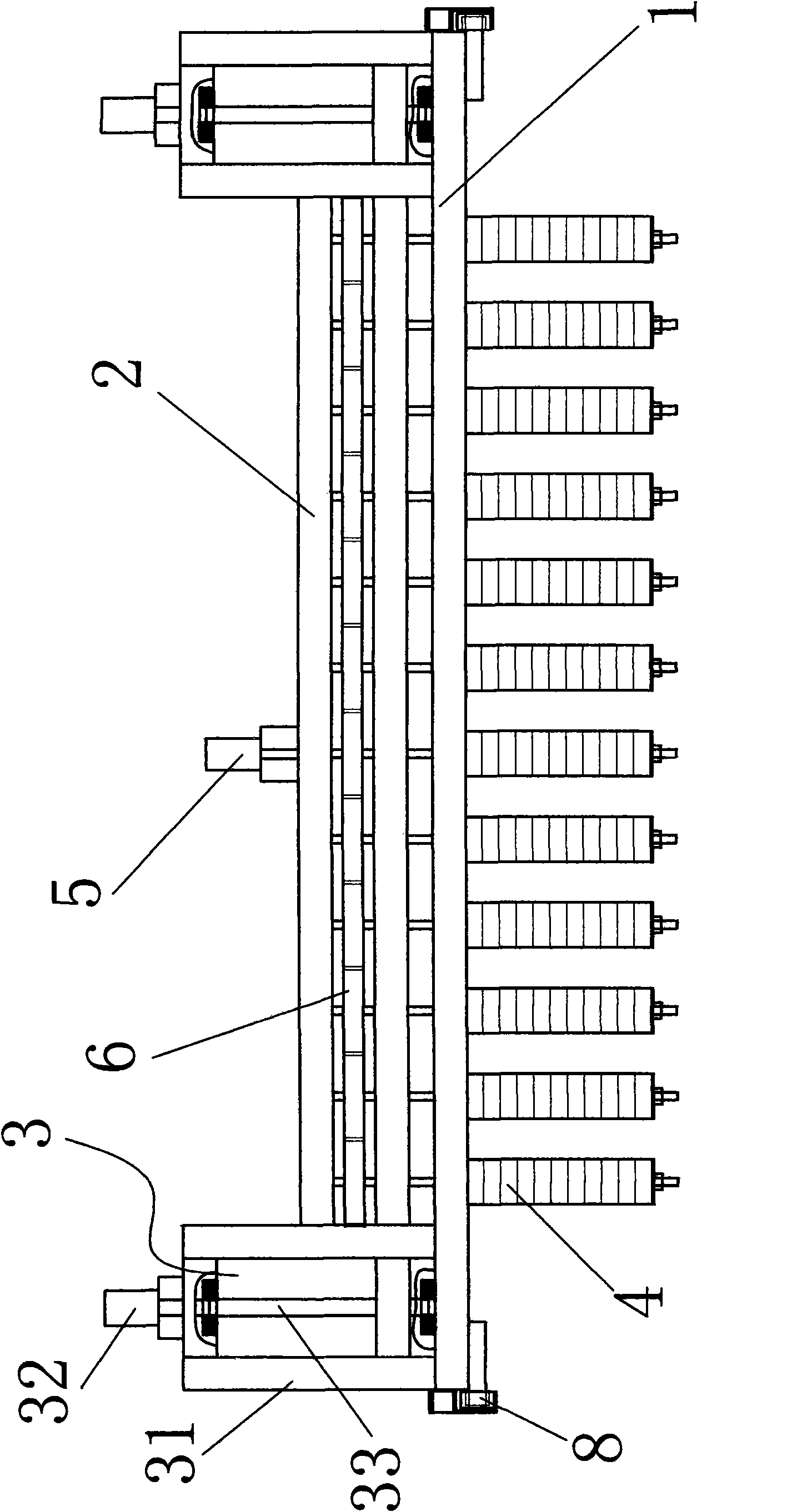

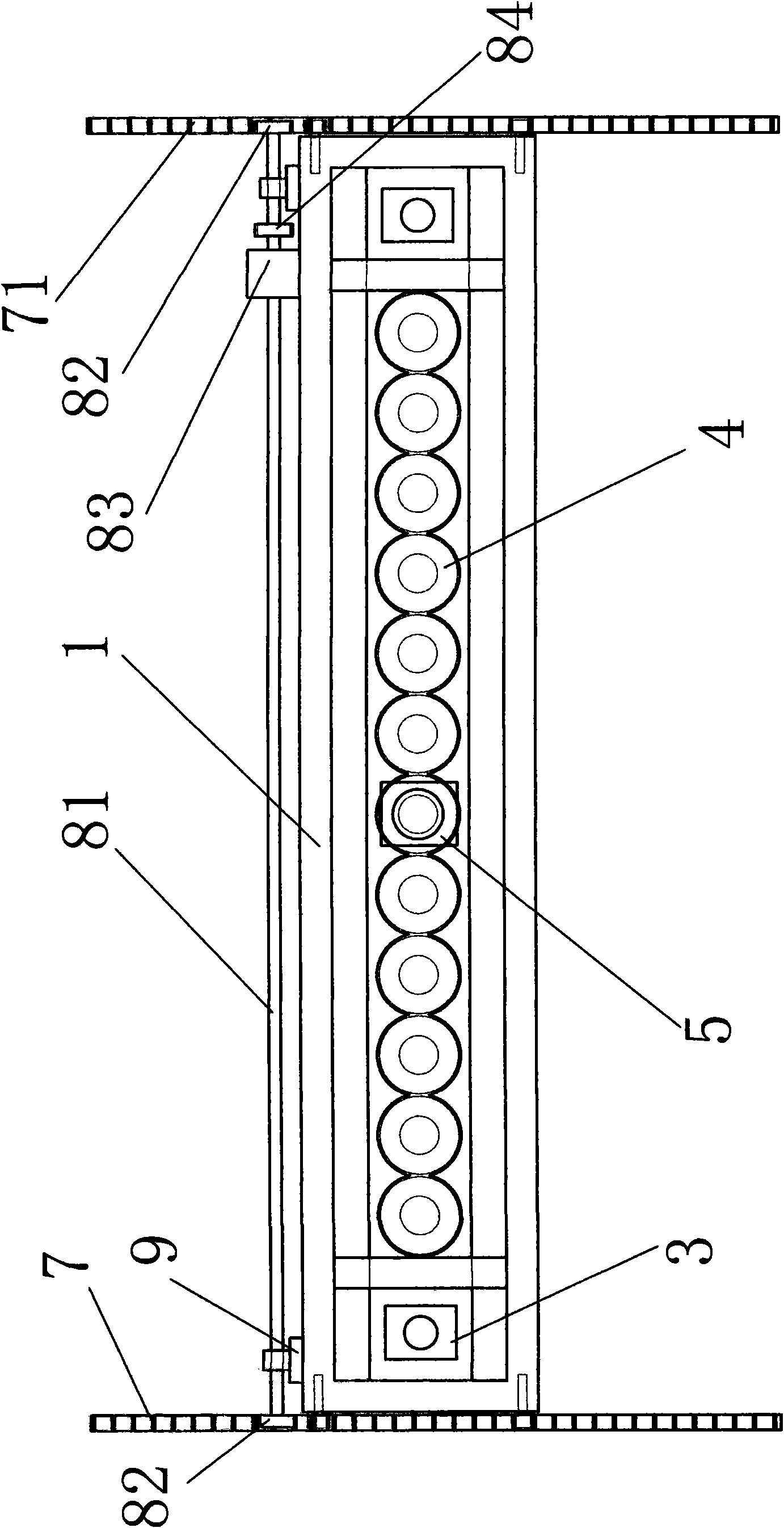

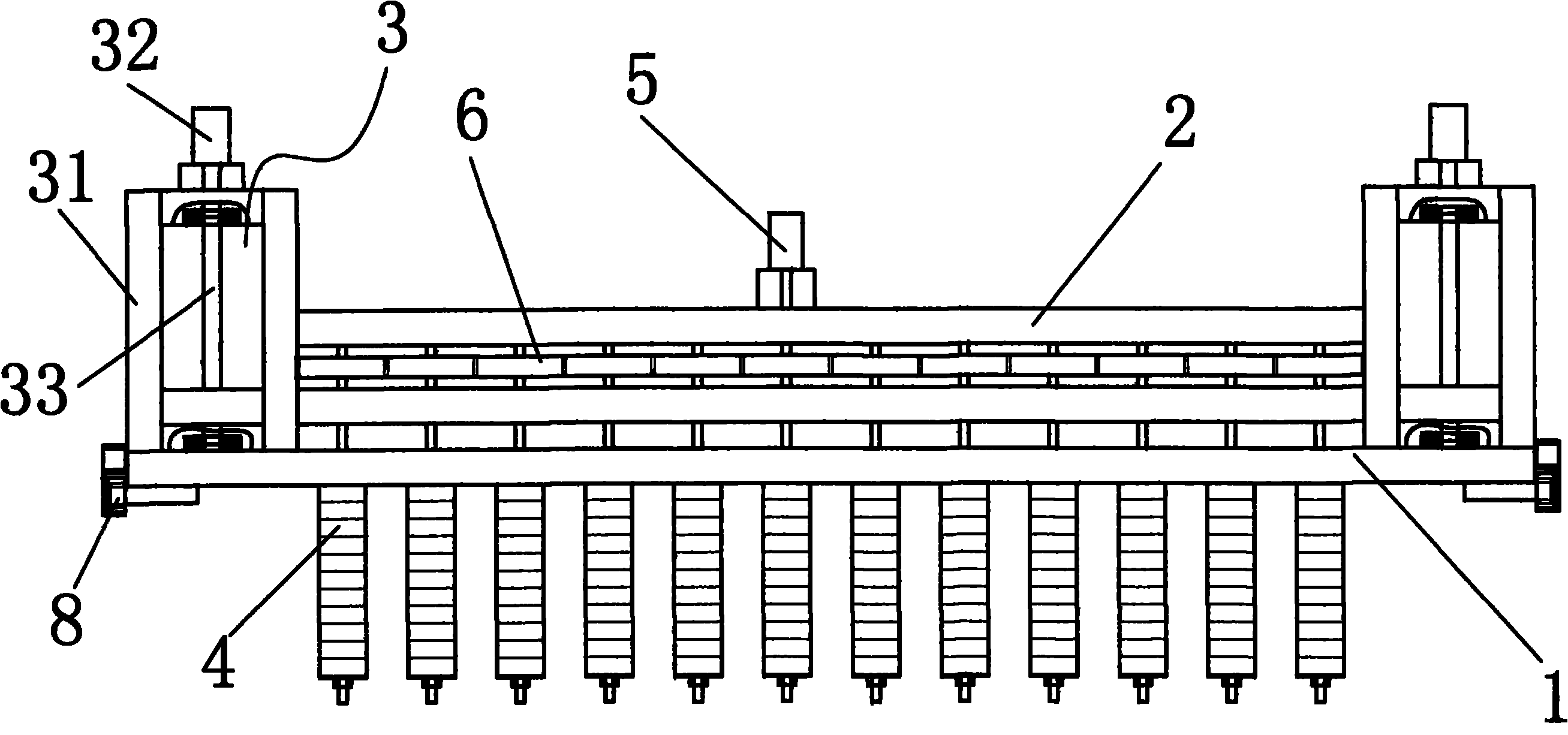

[0017] Such as Figures 1 to 2 The mold cleaning equipment for cleaning lightweight concrete wallboard molds shown includes a fixed seat 1, on which a liftable frame 2 is arranged, and on the described fixed seat 1, a There is a lifting transmission device 3 that can lift or descend the frame 2. In the present invention, two lifting transmission devices 3 are arranged on the fixed base 1, and the lifting transmission devices 3 are respectively arranged on the frame 2. On both ends, a plurality of rotatable mold-cleaning steel brush wheels 4 are connected below the frame 2. In the present invention, there are twelve mold-cleaning steel brush wheels 4, which are above the frame 2. There is a mold cleaning motor 5 that drives the mold cleaning steel brush wheel 4 to rotate, and the mold cleaning motor 5 and the mold cleaning steel brush whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com