Composite beam die and method for making composite beam with composite beam die

A technology of composite beams and molds, which is applied to the connection parts of formwork/formwork/work frame, formwork/formwork/work frame, formwork processing, etc., which can solve the problem of labor-consuming, time-consuming and material-consuming, affecting construction operation space, etc. problems, to achieve the effect of convenient construction, saving materials required for the project, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

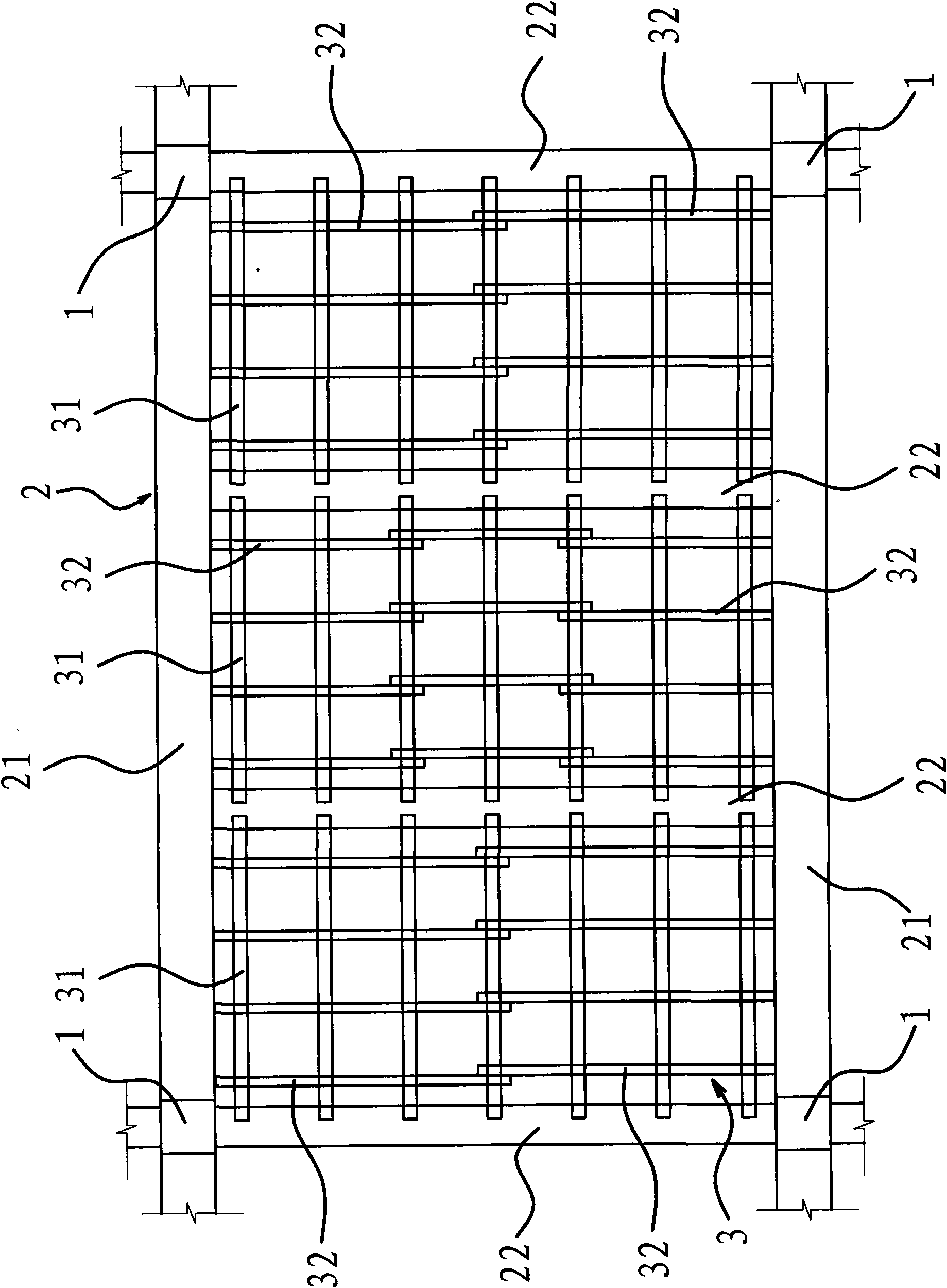

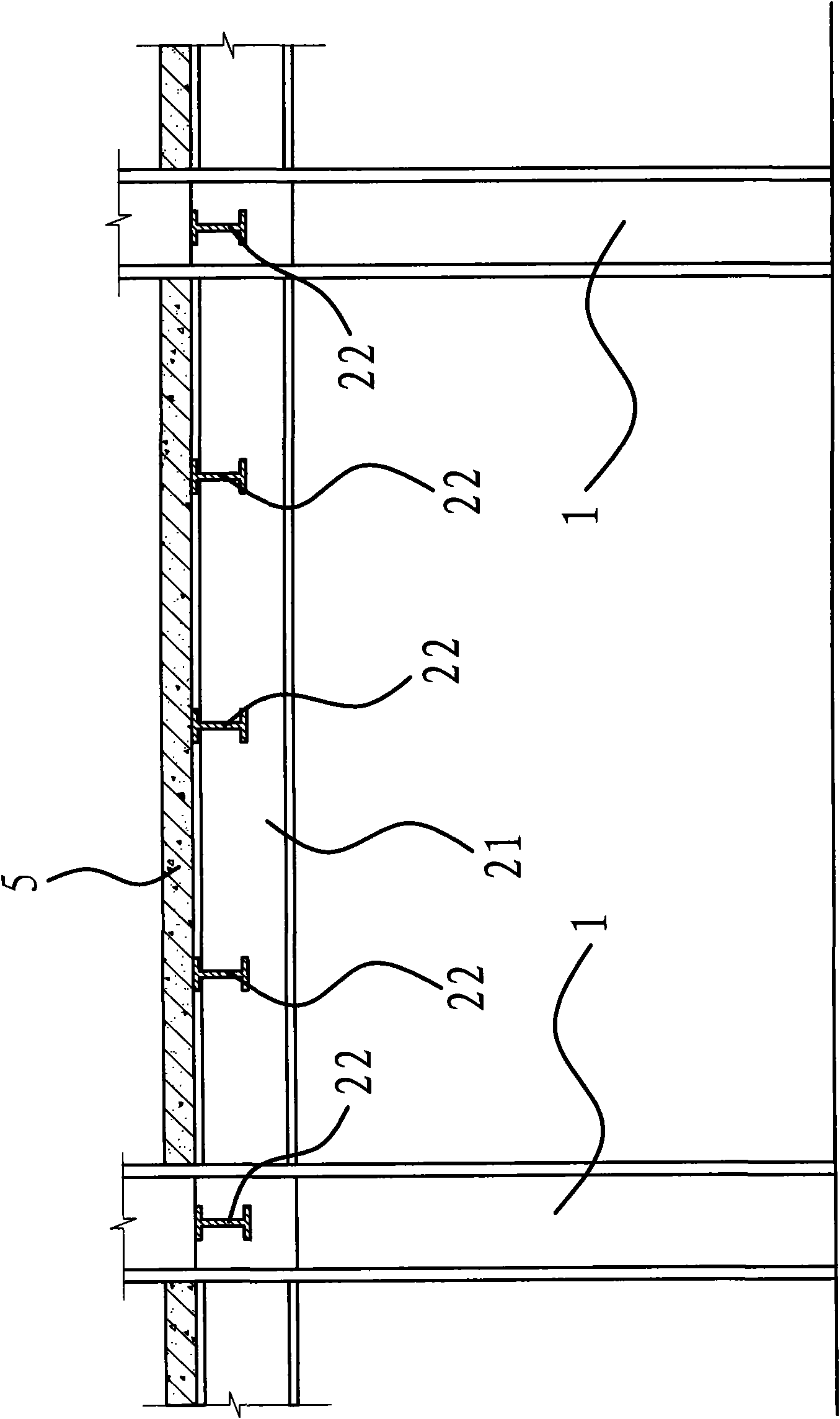

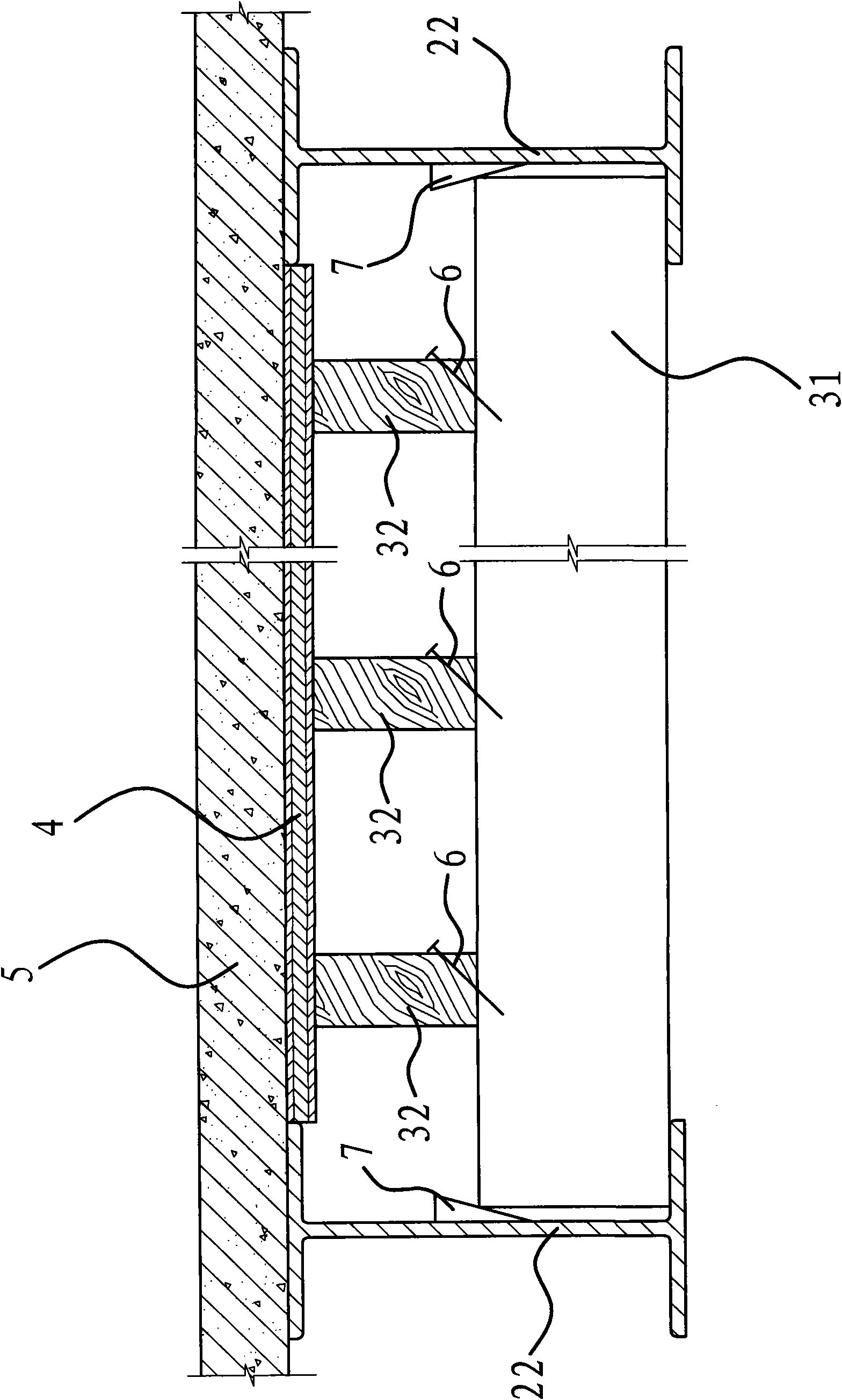

[0036] Such as image 3 As shown, the composite beam includes an I-shaped steel beam 2 fixed on the column 1 and a concrete floor 5 poured on the upper surface of the steel beam 2 . The composite beam mold includes corrugated 3 and formwork 4.

[0037] Specifically, the formwork 4 is made of plywood, and the flute 3 is made of wooden materials. In this embodiment, the flute 3 is square wood with a rectangular cross section. The flutes 3 are located on the bottom surface of the template 4 and include several main flutes 31 and several secondary flutes 32 . The main flute 31 is evenly distributed on the lower part of the formwork 4 and the two ends of the main flute 31 can be fixed on the steel beam 2. The smaller surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com