Construction method of ultrahigh facing bare concrete vertical column

A technology of fair-faced concrete and construction method, which is applied in formwork/template/work frame, formwork treatment, and on-site preparation of building components, etc. Edge corners, uneven surface color and other problems, to achieve the effect of reducing template assembly time, good visual quality and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

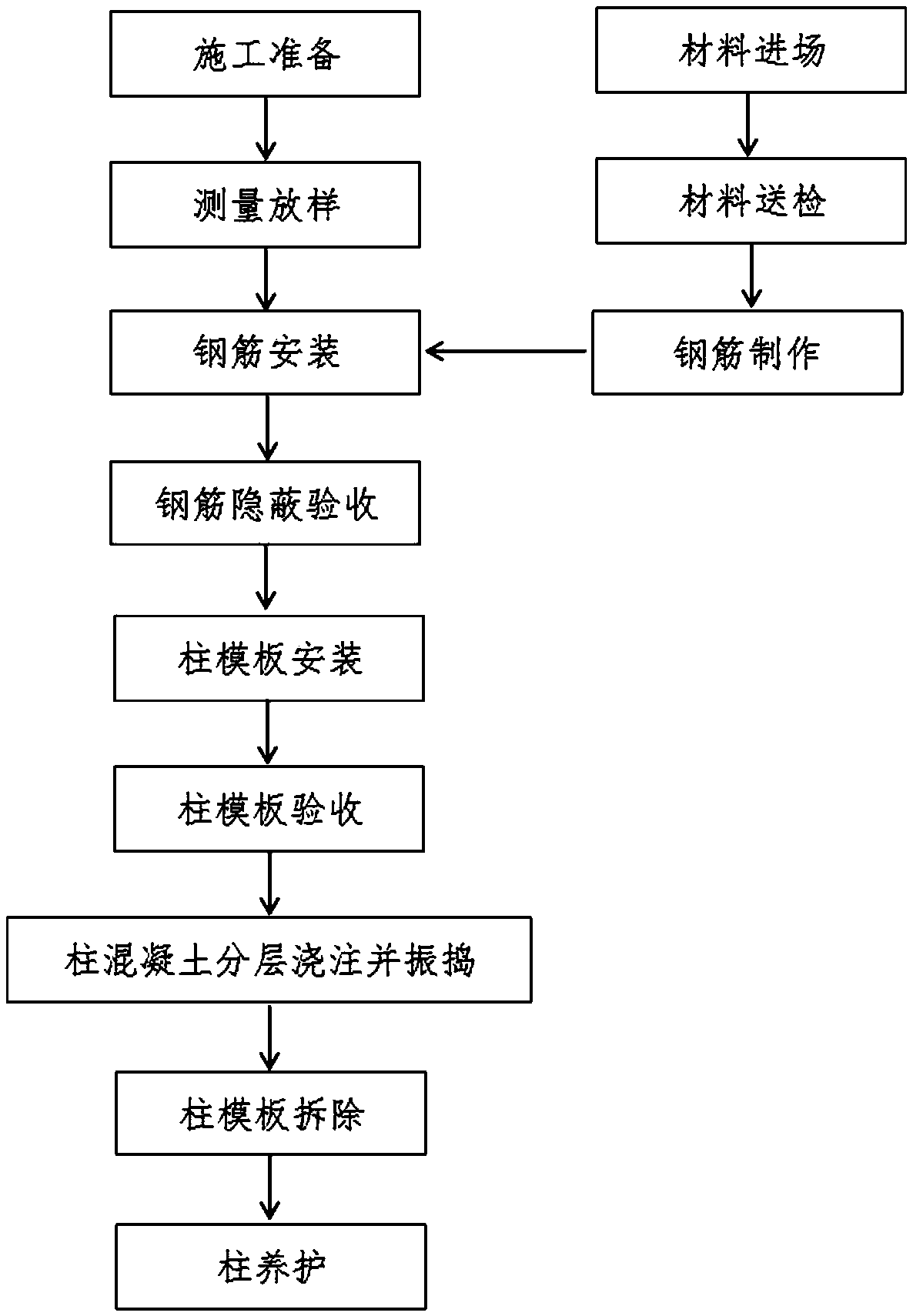

Method used

Image

Examples

Embodiment Construction

[0024] The newly built Beijing-Zhangjiakou Railway Changping Station ZFSG1 platform windshield column is a finished fair-faced concrete structure, with a height of 4057mm, complex shape, and extremely dense reinforcement; the Taizicheng station building column is a 6.5m high-faced fair-faced concrete structure. The appearance quality of facing fair-faced concrete cannot be guaranteed by the construction technology of ordinary concrete columns. The construction technology of the ultra-high facing fair-faced concrete column of the present invention greatly reduces construction difficulty, ensures construction safety, and improves construction quality.

[0025] Specially formulated steel formwork and concrete conduit measures are used to ensure the geometric dimension accuracy of super-high special-shaped column concrete. The thickness of the panel is 5mm, and the back corrugation is made of 12# channel steel; the height is 4.057 meters (the height of the column formwork of Taizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com