Deformation joint post-section shear wall sliding-pushing type installation and disassembling template erection system and construction method

A deformation joint and shear wall technology is applied in the field of shear wall formwork construction in the post-deformation joint of a high-rise building structure, and can solve the problems of easy damage to the crowbar-type formwork removal, long formwork installation and disassembly period, and poor support reliability. , to achieve the effect of convenient construction, high turnover rate and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

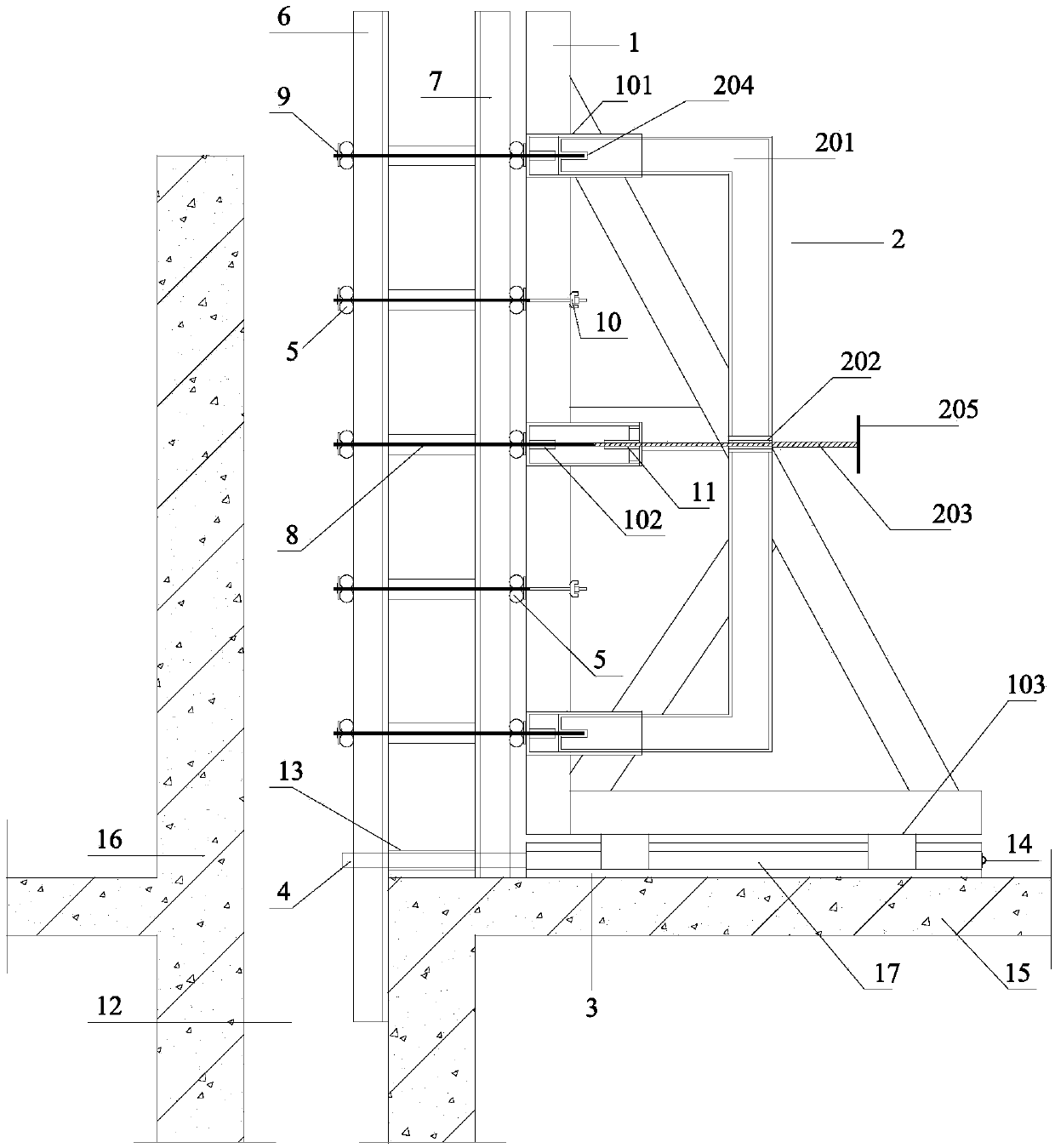

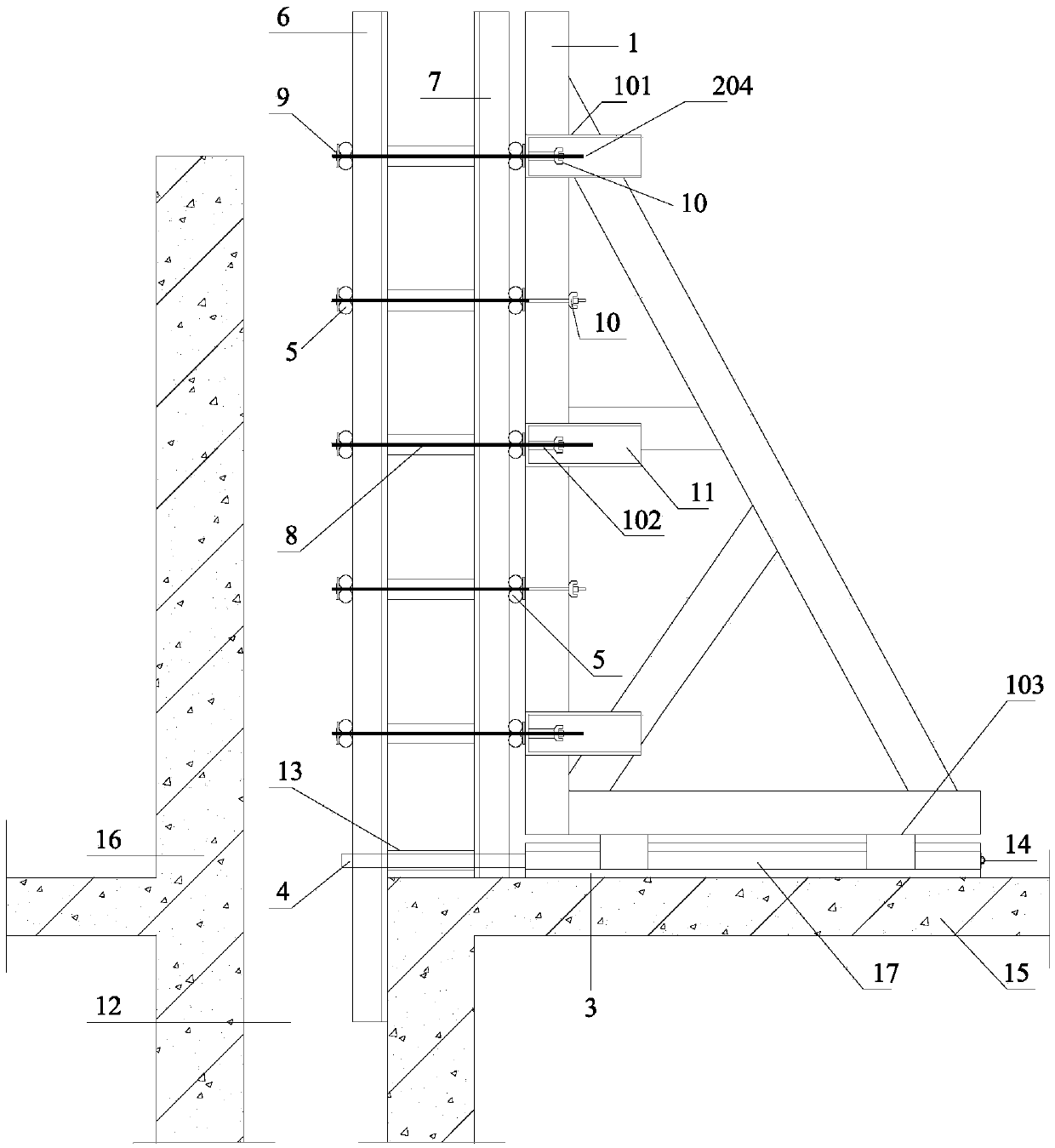

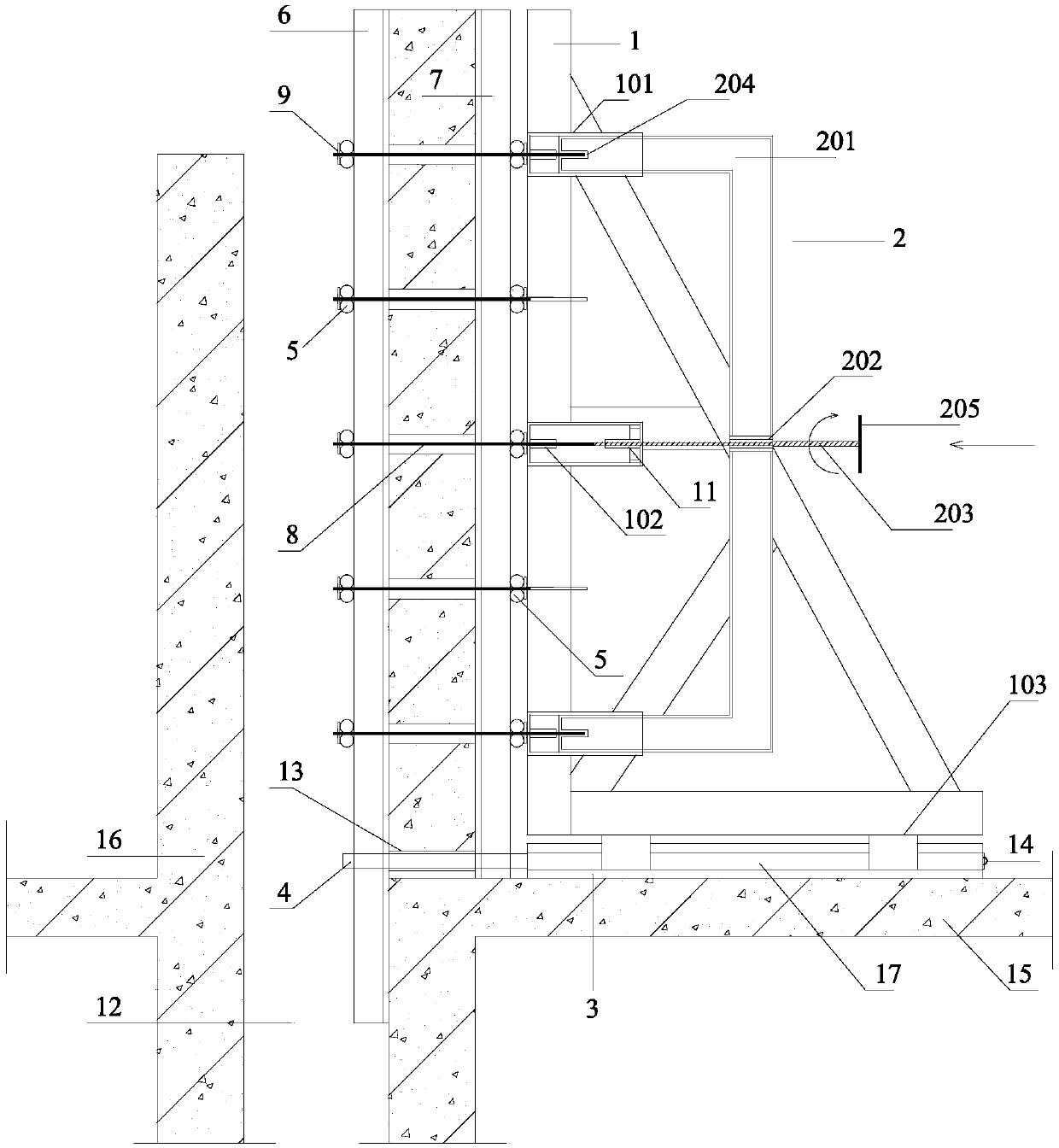

[0038] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples. In the construction of shear wall formwork engineering in the post-deformation joint section of a high-rise building structure, the sliding and pushing-type installation and removal formwork support system and construction method of the post-deformation joint section shear wall are adopted.

[0039] Such as figure 1 , figure 2 As shown, the sliding and pushing type installation and dismantling formwork support system of the shear wall in the post-deformation joint section of the present invention includes a sliding single-sided bracket 1, a screwing and pushing device 2, a sliding guide rail 3, a supporting steel pipe 4, and an inner Template 6, outer template 7, pull screw 8; three guiding steel pipes 101 are arranged on the sliding type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com