Patents

Literature

39results about How to "Avoid wasting material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

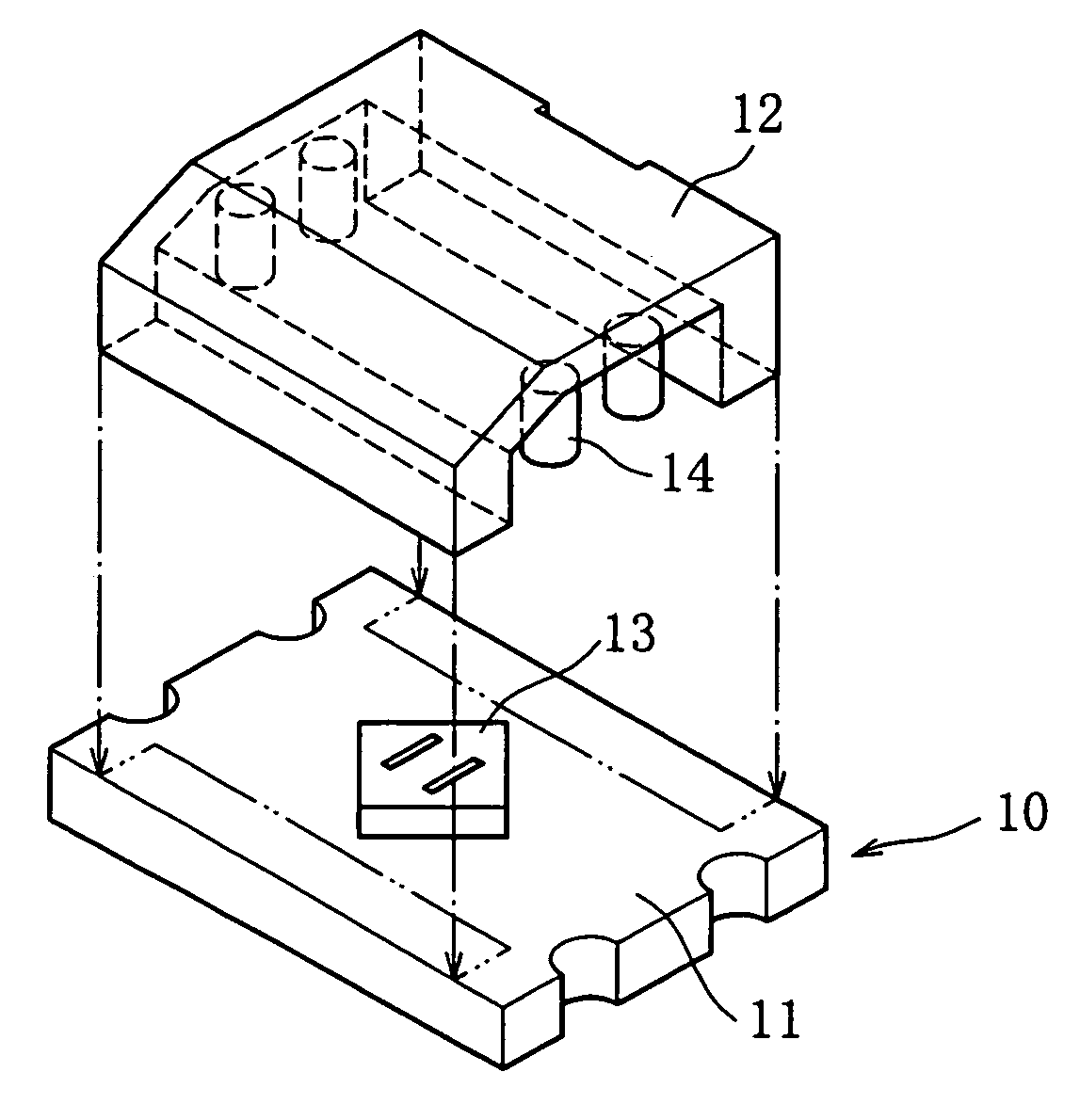

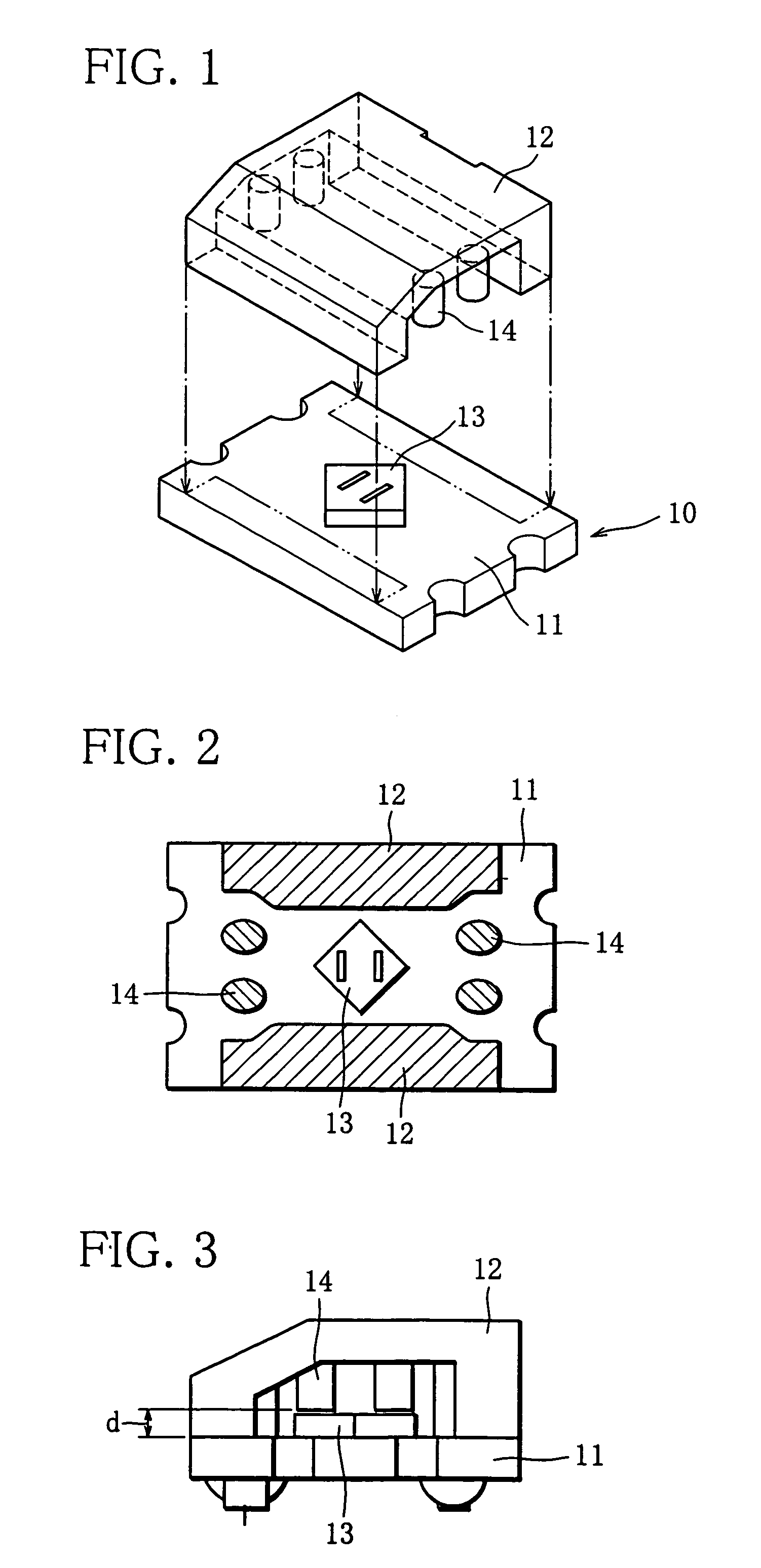

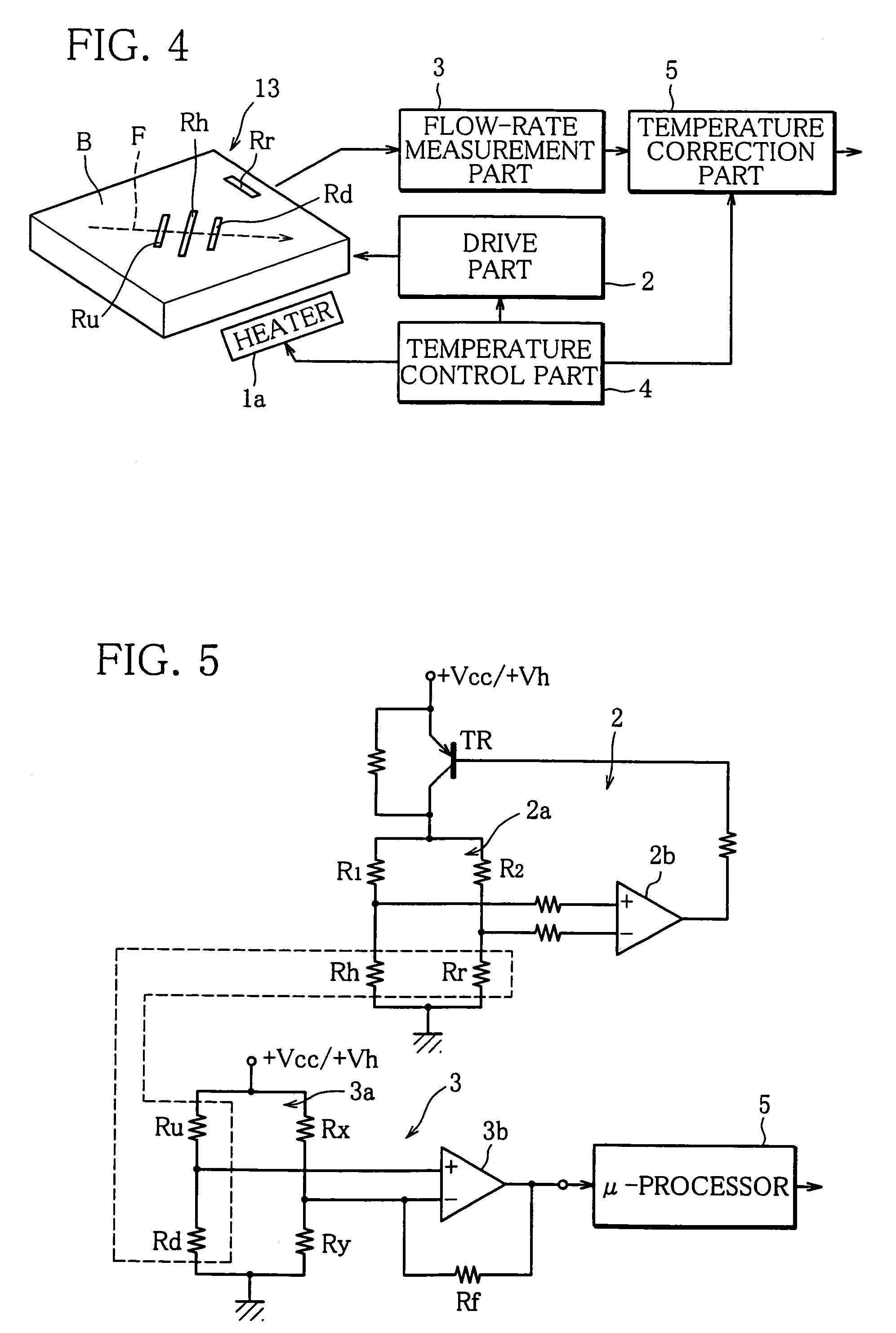

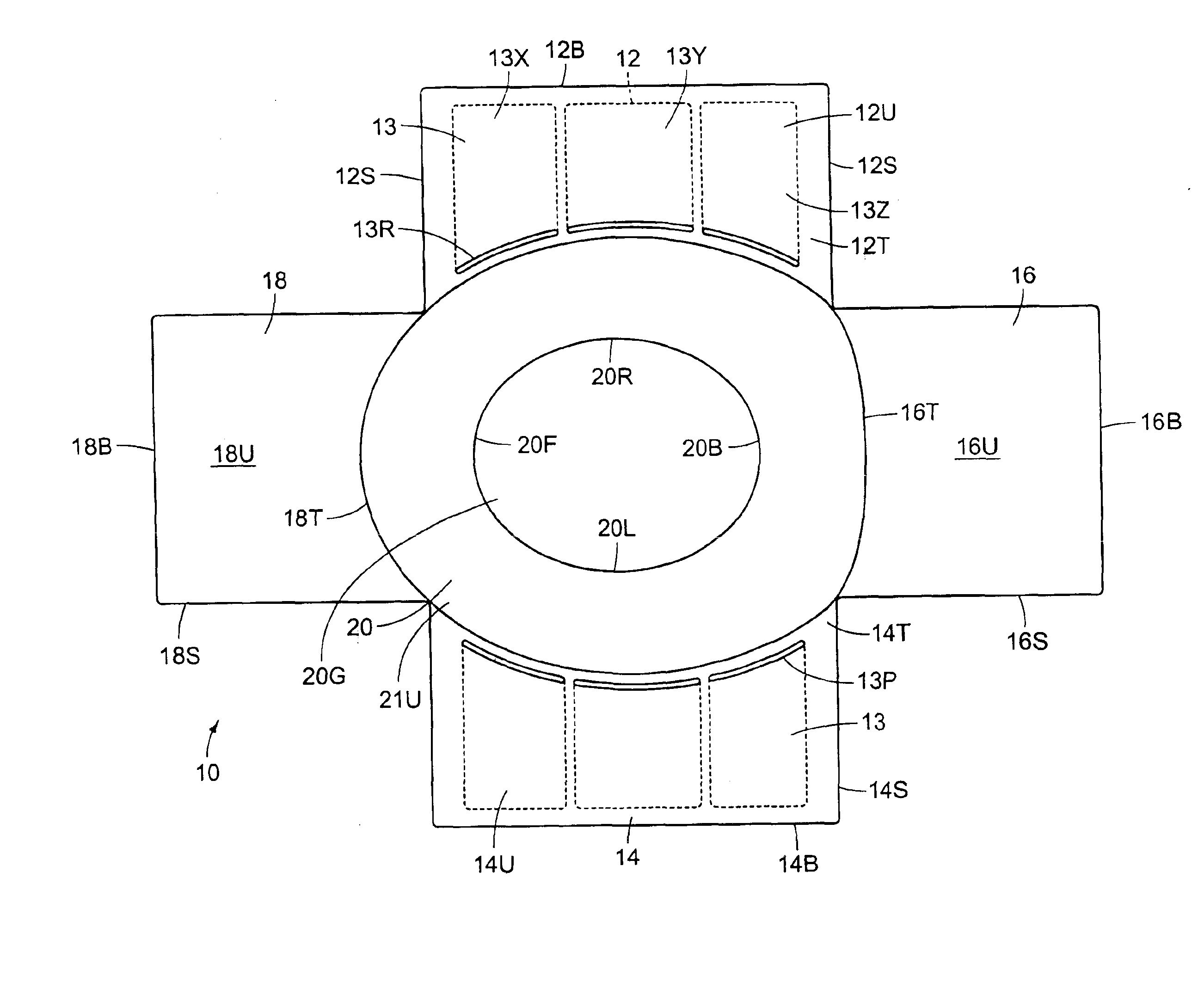

Smoking device including a flowmeter

InactiveUS7082825B2Improve responseWaste of materialVolume/mass flow by thermal effectsVolume meteringEngineeringWaste material

A waste-material entry prevention member arranged upstream of a flow sensor is a rod- or plate-like member protruding halfway across the cross-section of a flow passage. Hence, vortexes or energy of the vortexes produced in fluid flowing by the waste-material entry prevention member is diffused by a stream of the fluid passing through a space left between the waste-material entry prevention member and the wall surface of the flow passage which the waste-material entry prevention member faces. Thus, production of vortexes is held down. Further, by making the flow sensor generate heat or heating the flow sensor, thermophoresis of the fluid is caused near the surface of the flow sensor. By this, particles contained in the fluid are prevented from accumulating on the flow sensor.

Owner:YAMATAKE HONEYWELL CO LTD

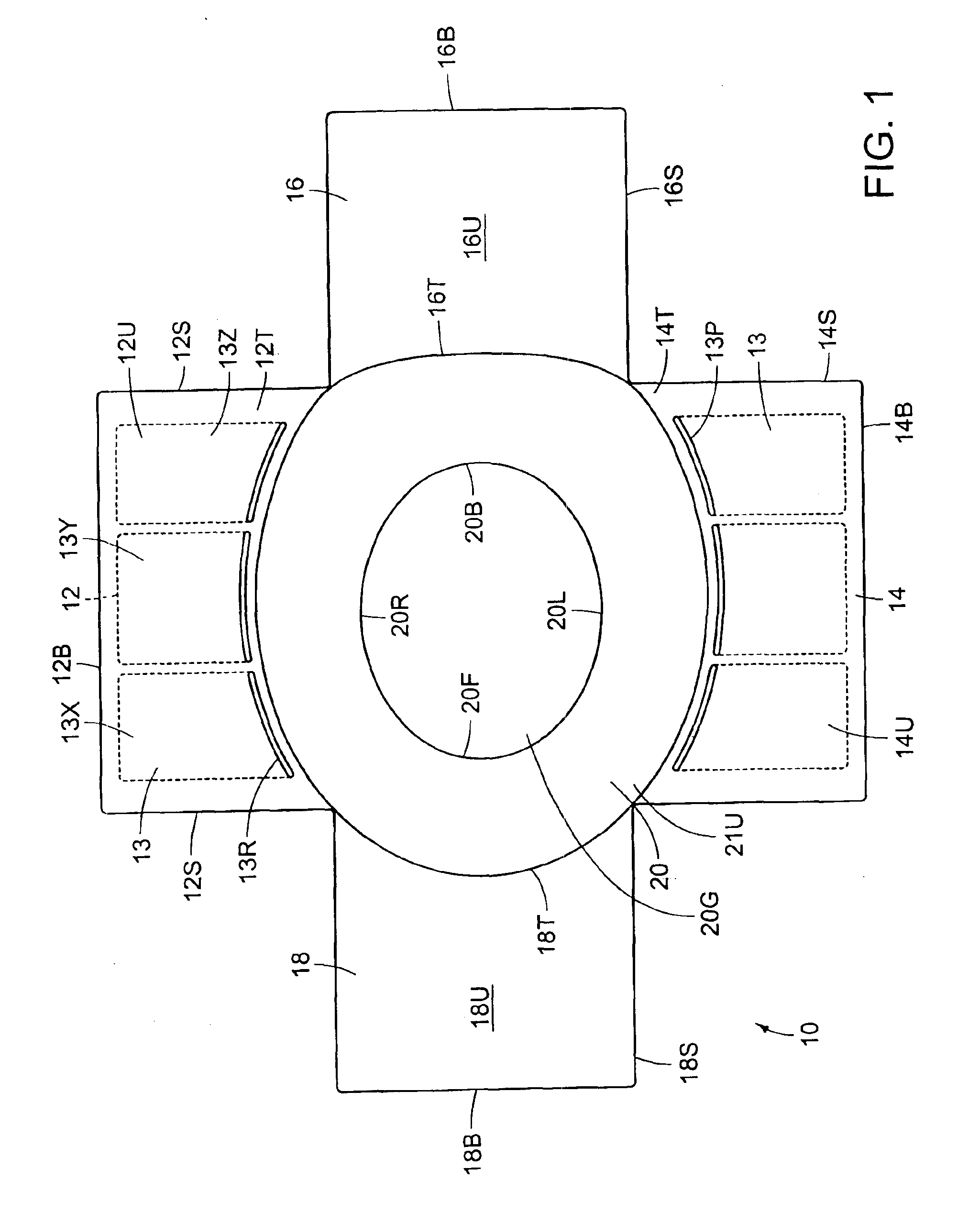

Portable toilet bowl cover

A portable toilet bowl cover, for selectively and substantially covering an existing toilet bowl, in order to prevent waste which may be present on portions of the toilet bowl from contacting the skin and clothing of an individual who sits upon the seat of the toilet bowl. The toilet bowl cover comprises a circular central seat pad having a left flap, a right flap, a front flap, and a back flap extending therefrom. The left flap and the right flap each have pockets for selectively storing various toiletries. In use, the central seat pad covers the seat of the toilet bowl, and the flaps substantially cover the bowl portion and the lid of the toilet bowl, thereby preventing waste material present upon the seat, the bowl portion, and the lid from coming into contact with the individual seated upon the toilet seat.

Owner:ADAMS TIFFANY

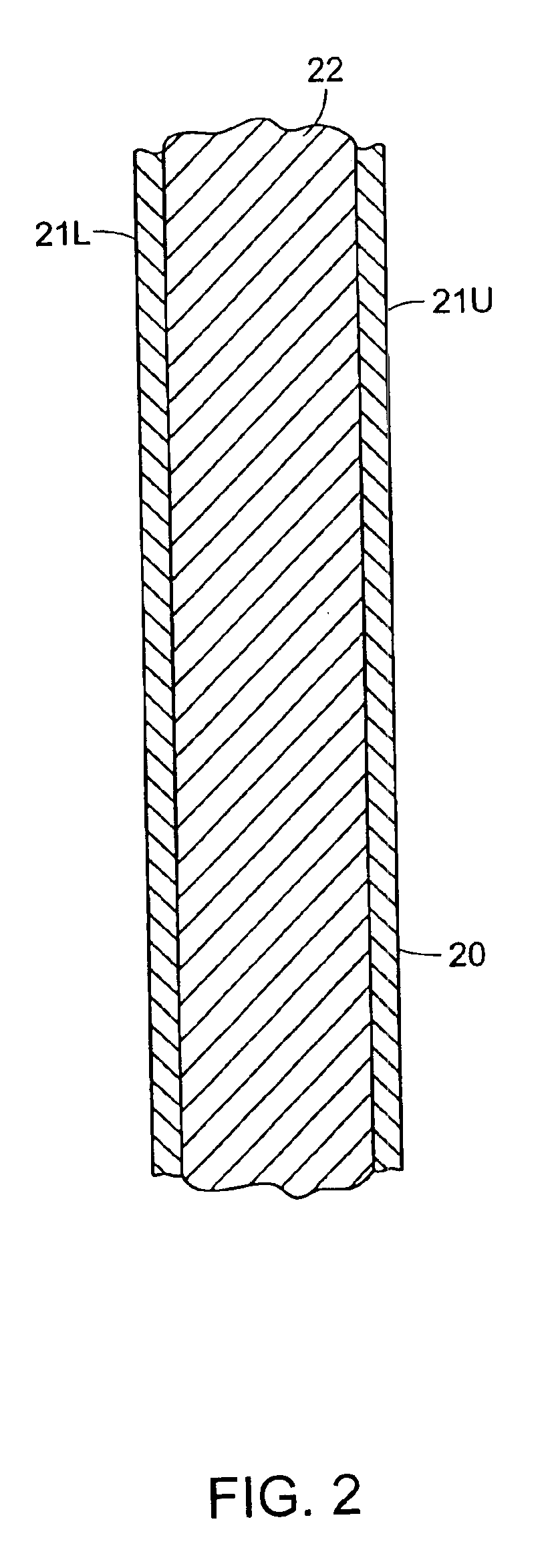

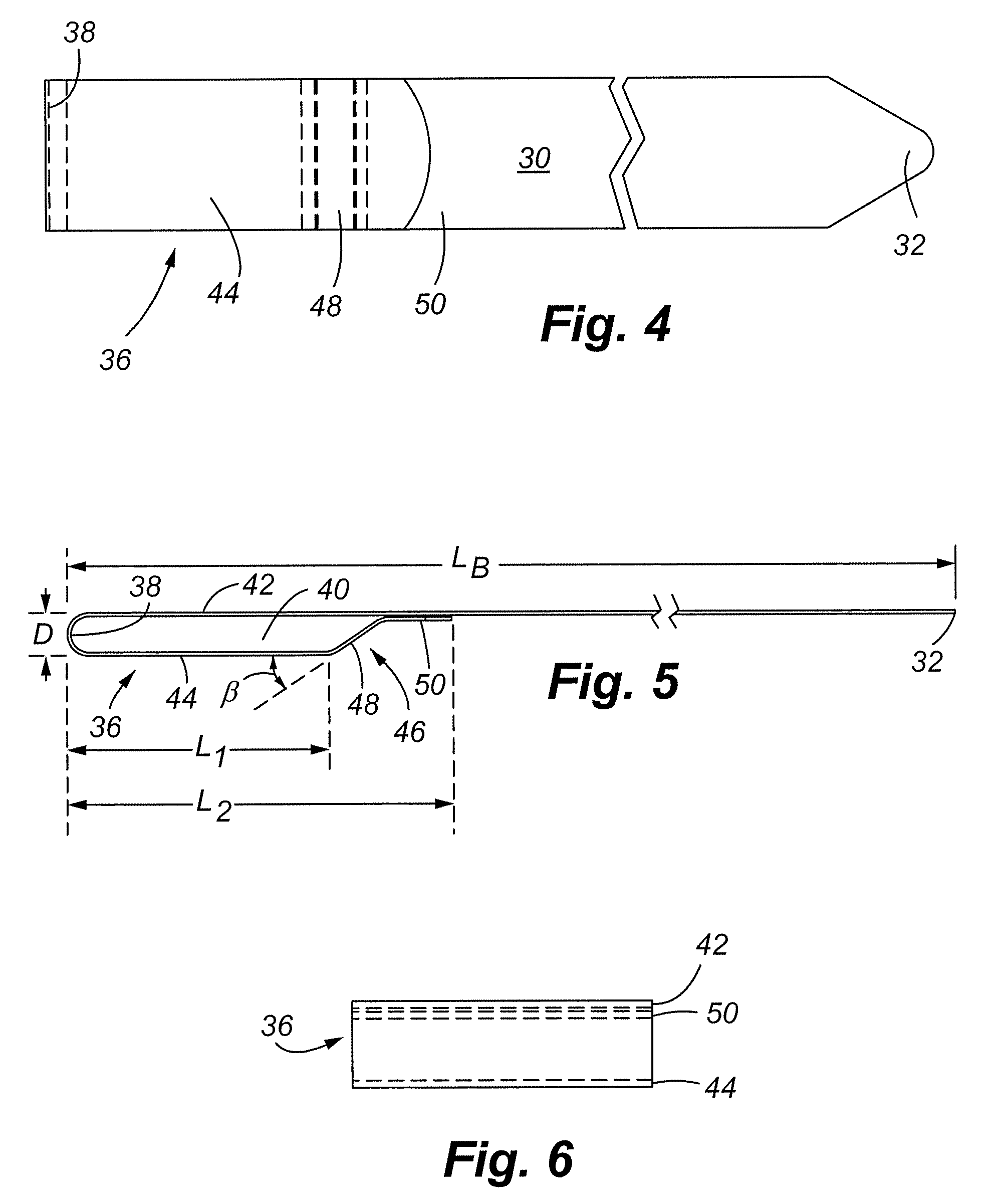

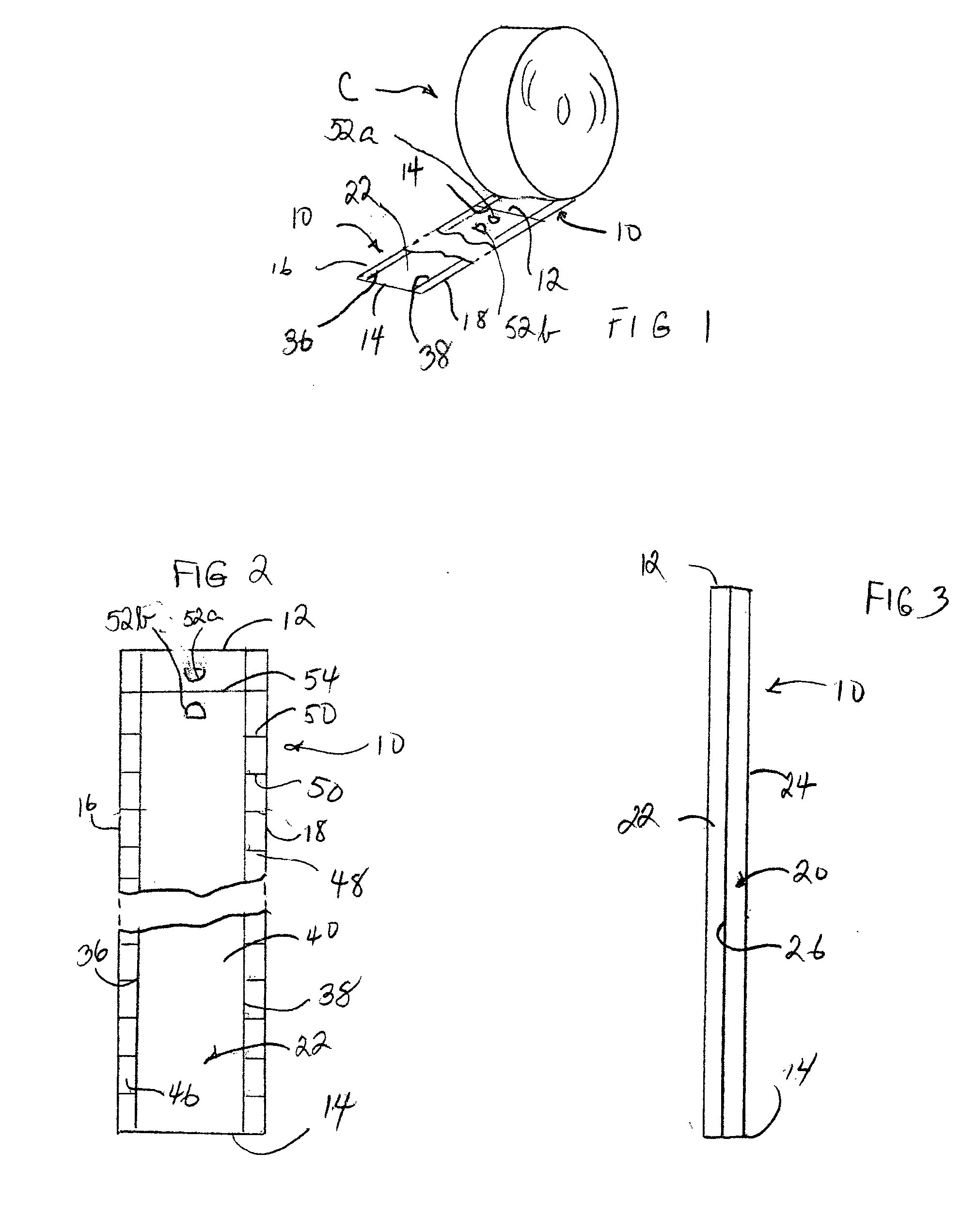

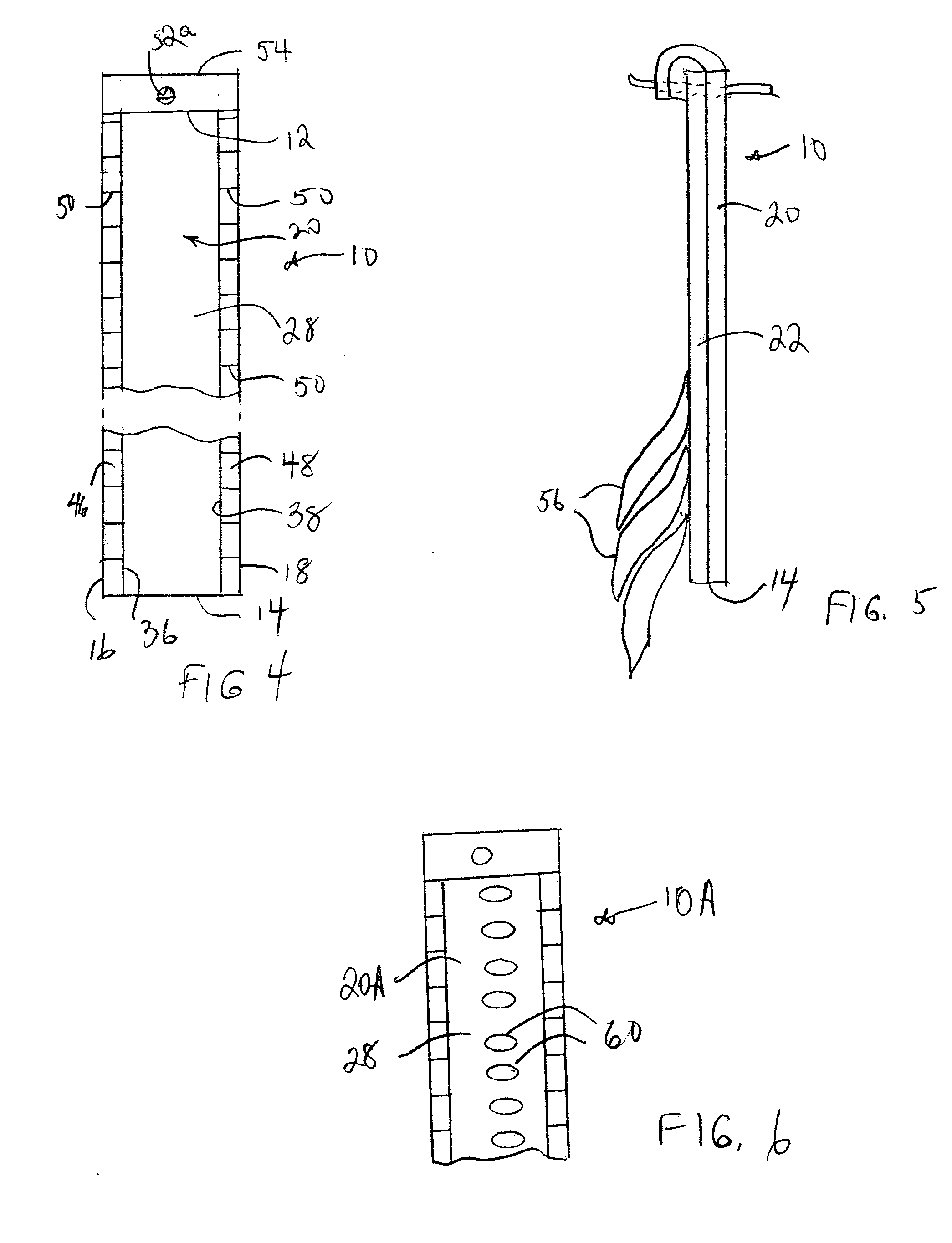

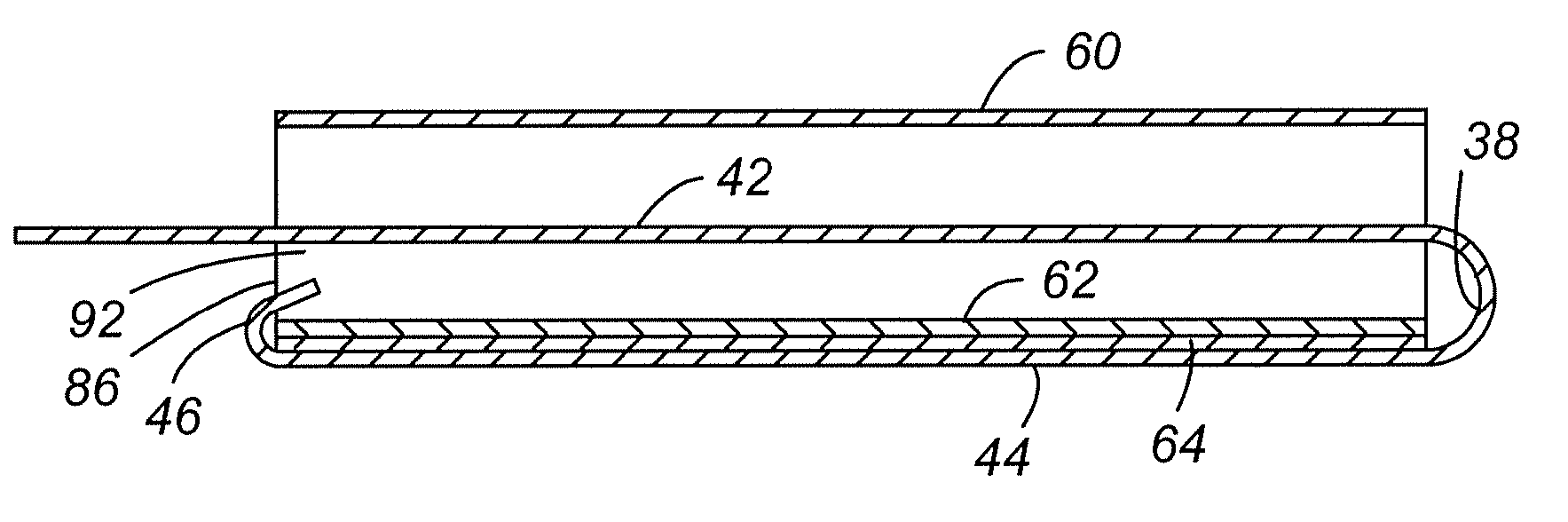

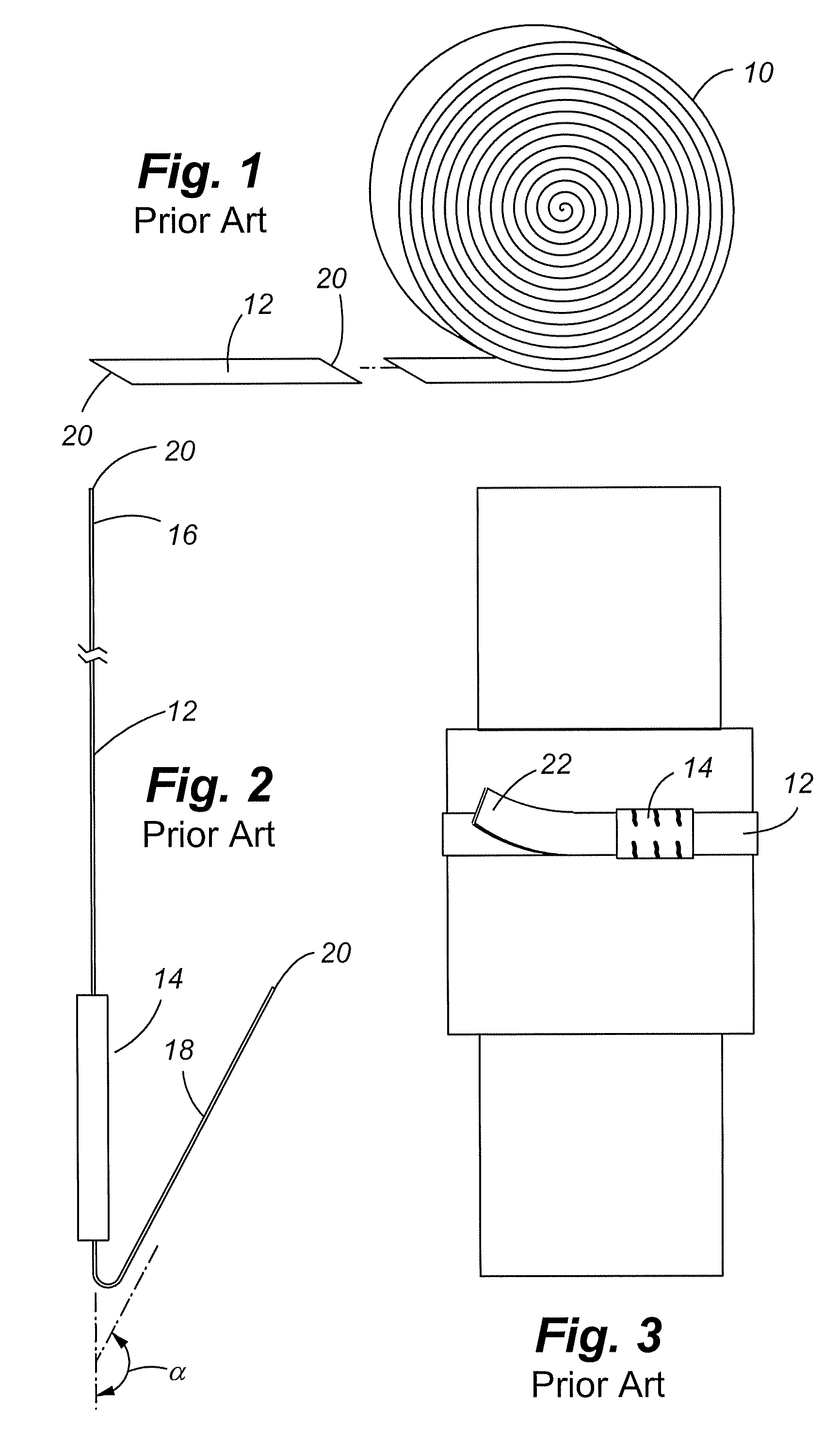

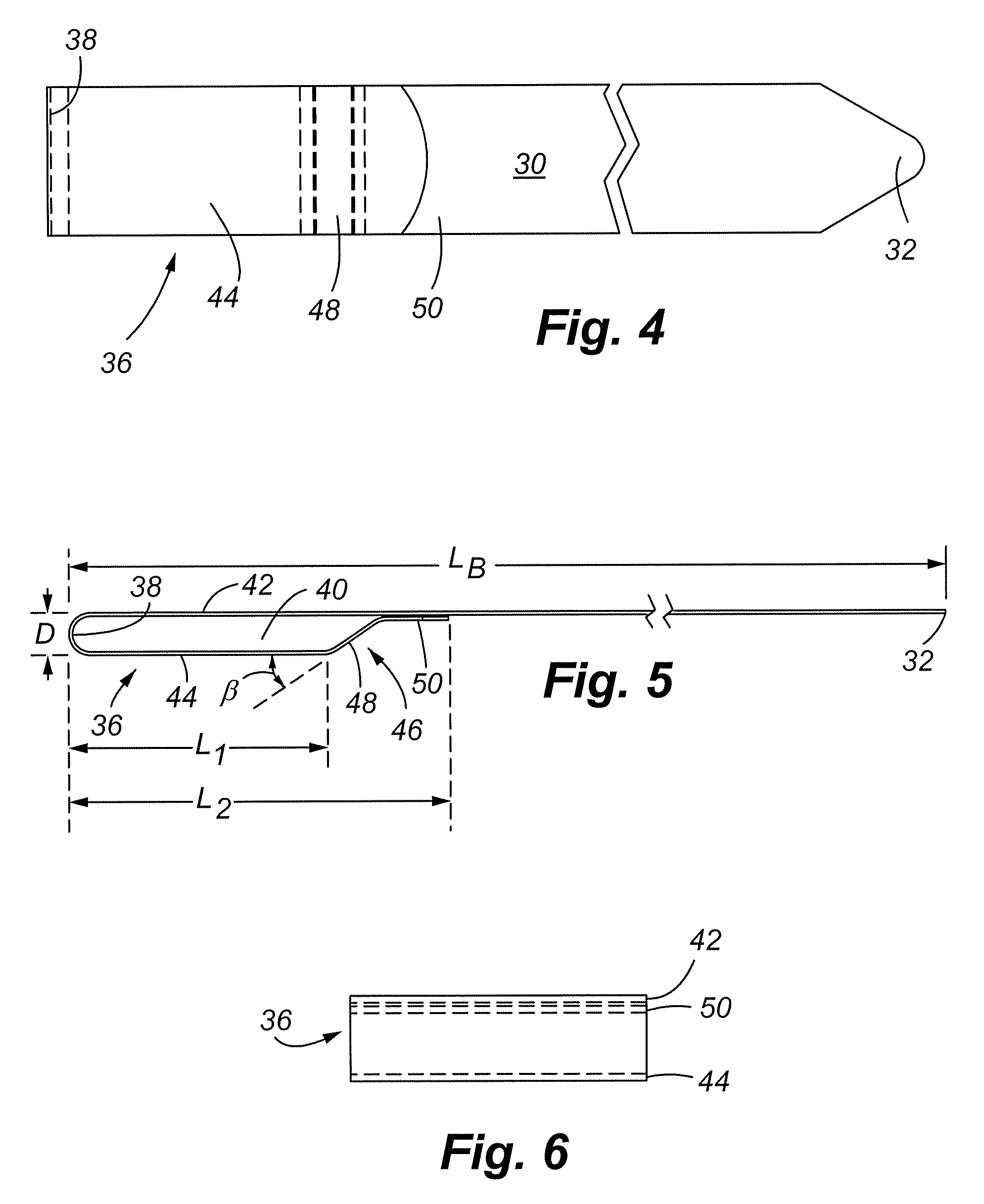

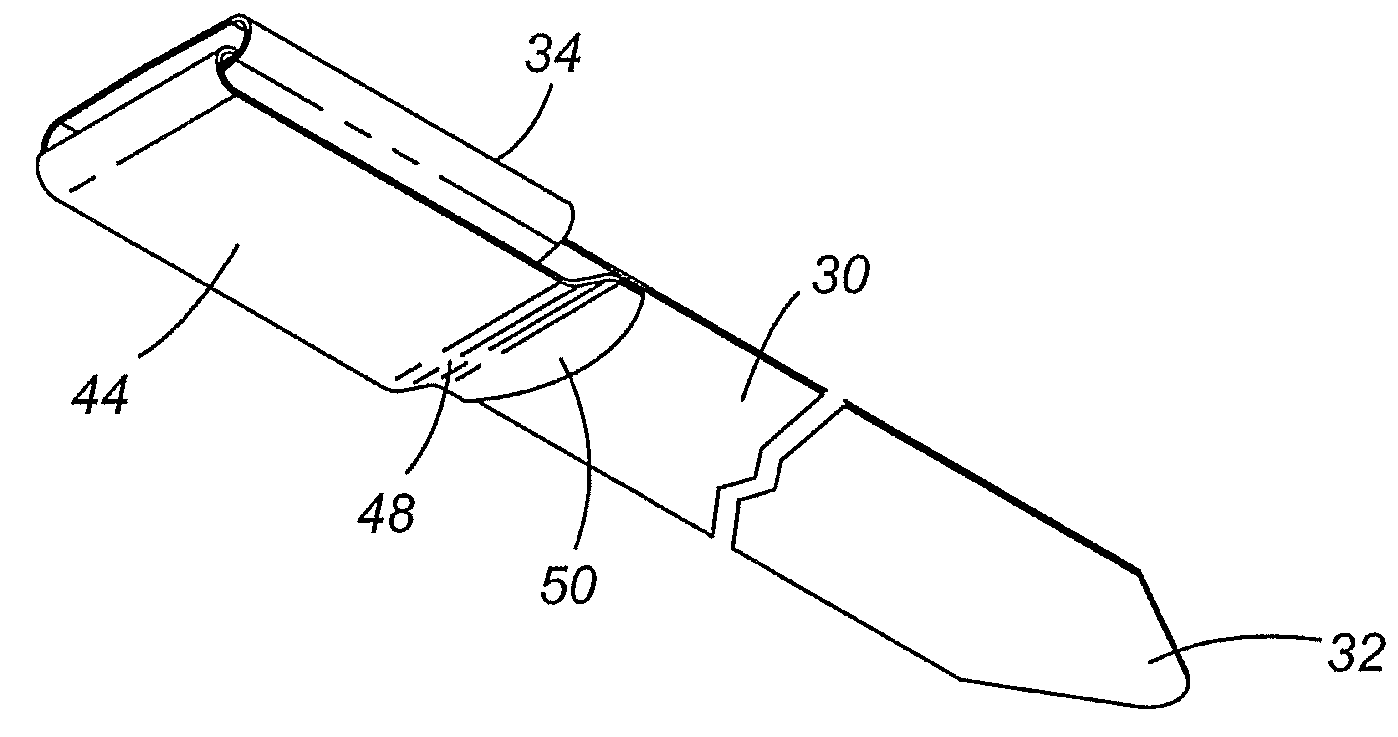

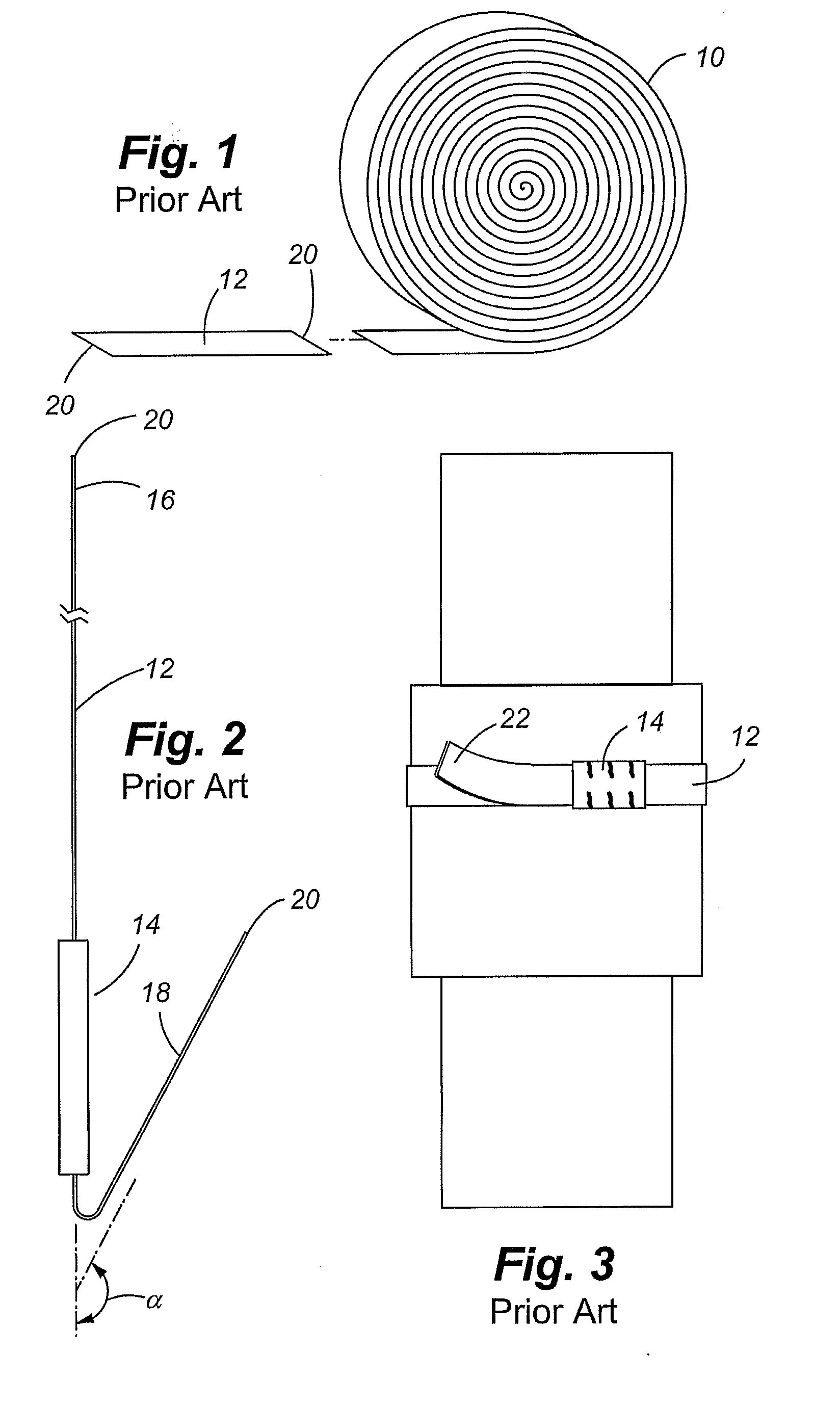

Free end band and seal

A pre-cut and preformed free end band and seal of a predetermined length, and method of making and using the same is disclosed. The band is preformed with a substantially closed loop of band material to capture a seal to provide a preassembled band and seal wherein the seal is generally inhibited from being dislodged during packing, shipment, handling and installation. The band and seal are also formed in a manner to facilitate relative positioning of the band and seal as well as placement of a crimping tool relative to the band and seal for optimized crimping of the band and seal.

Owner:BAND IT IDEX

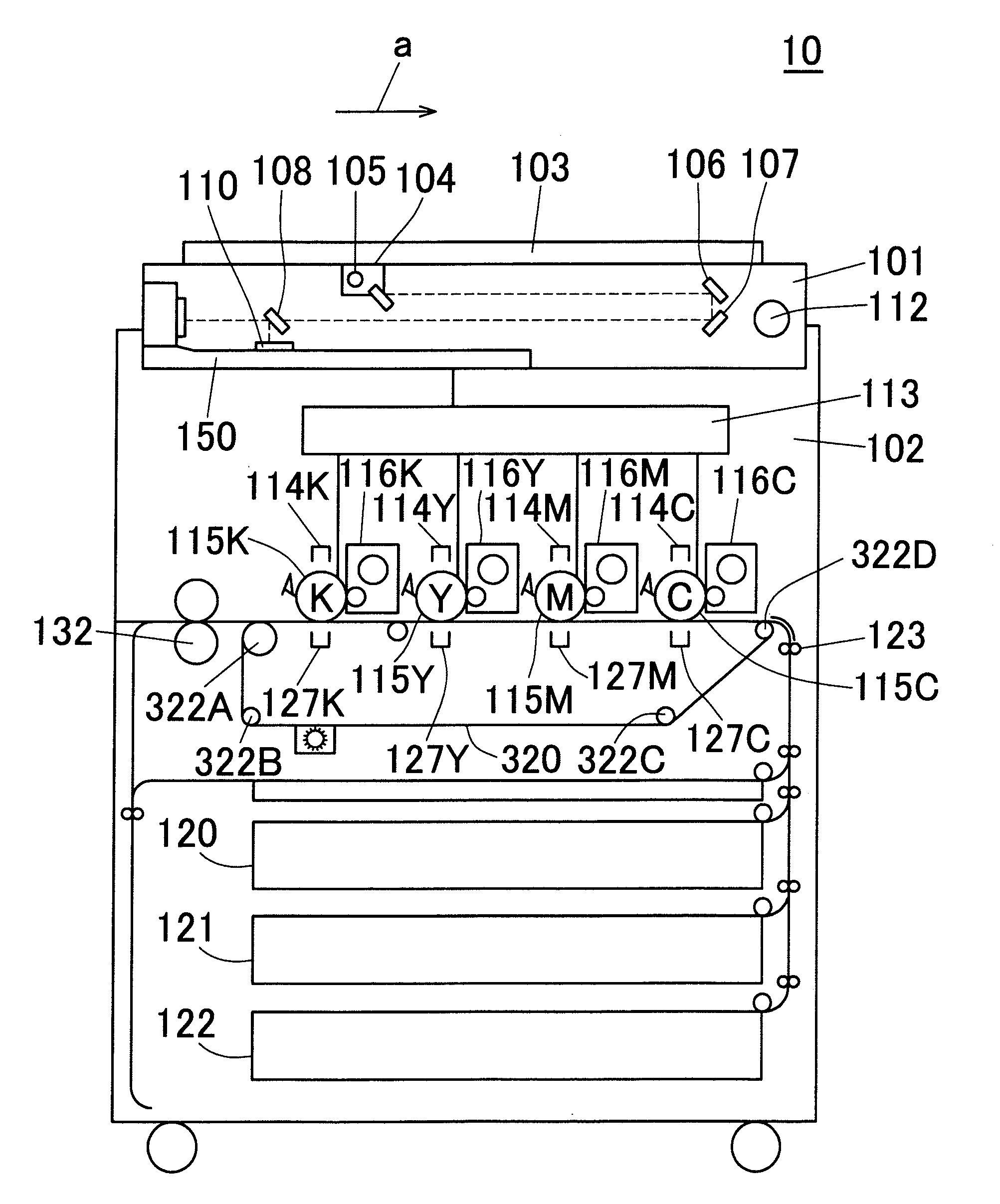

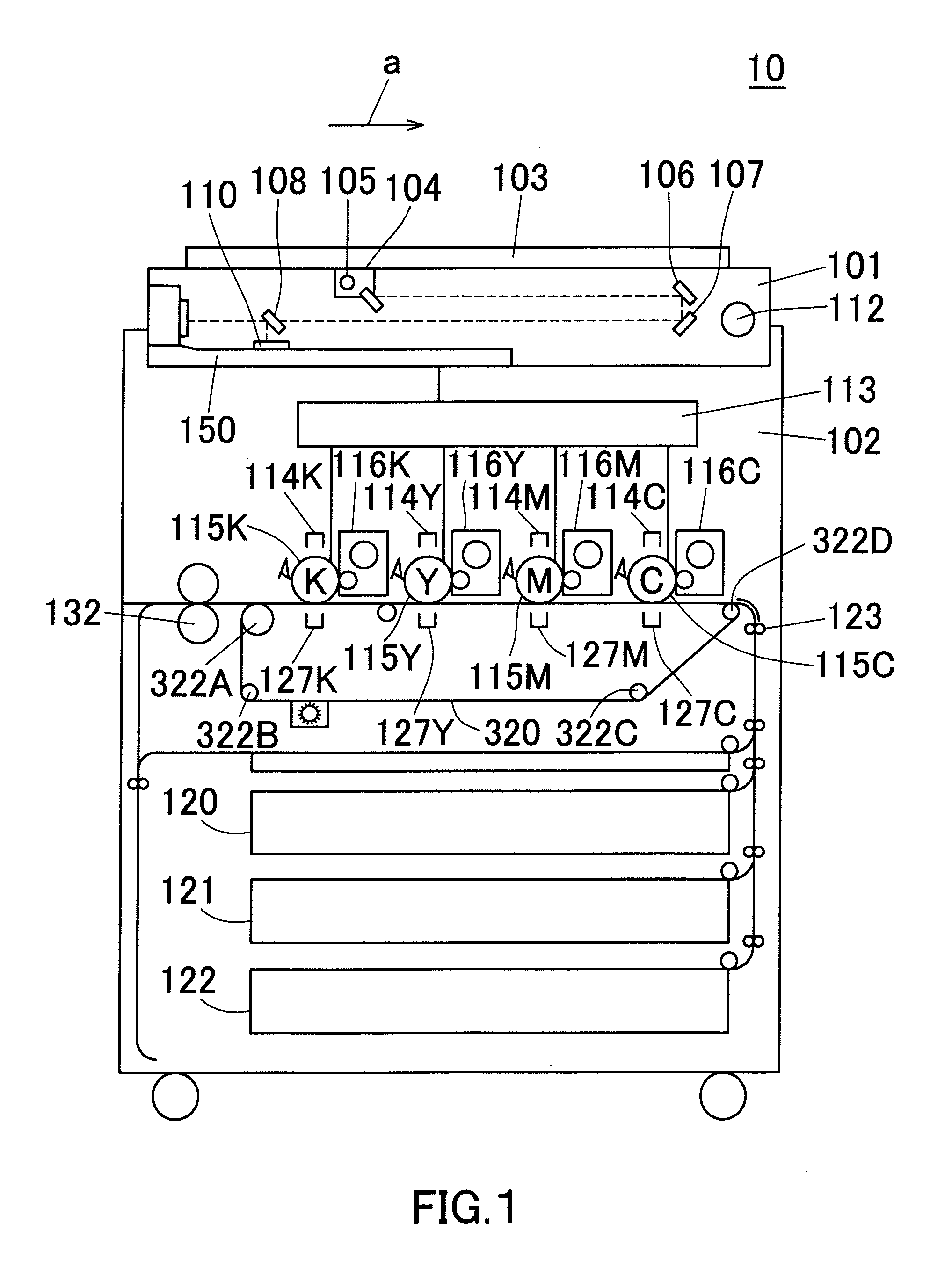

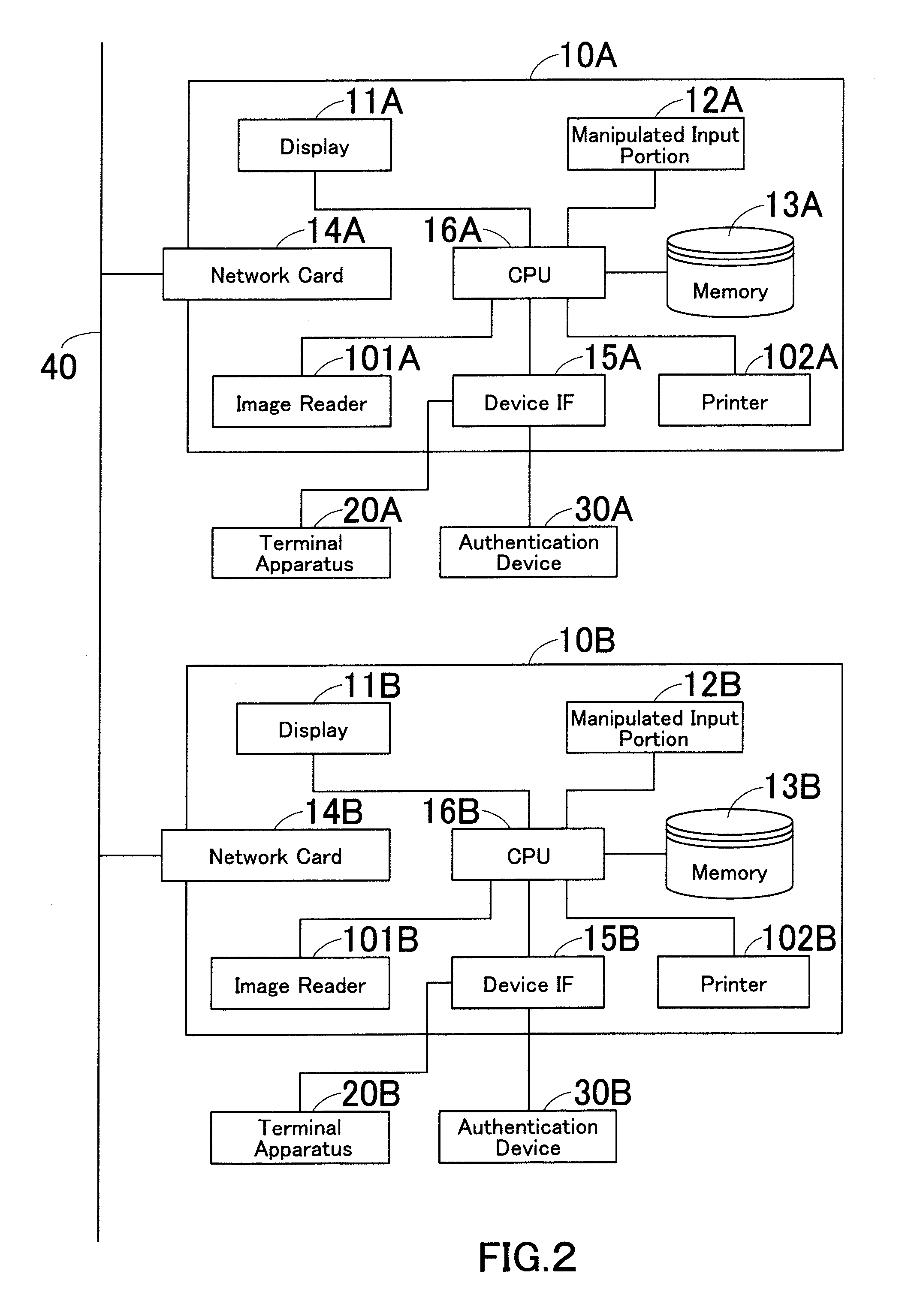

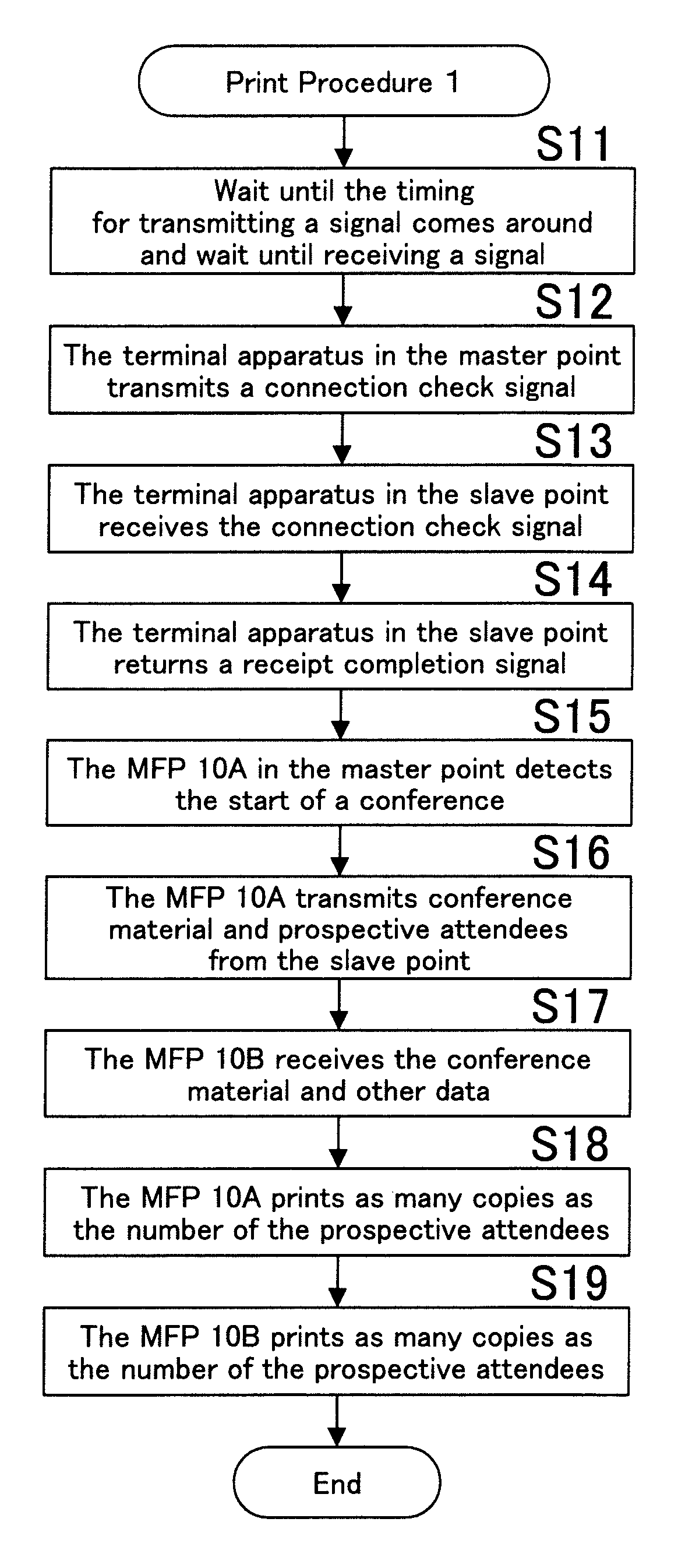

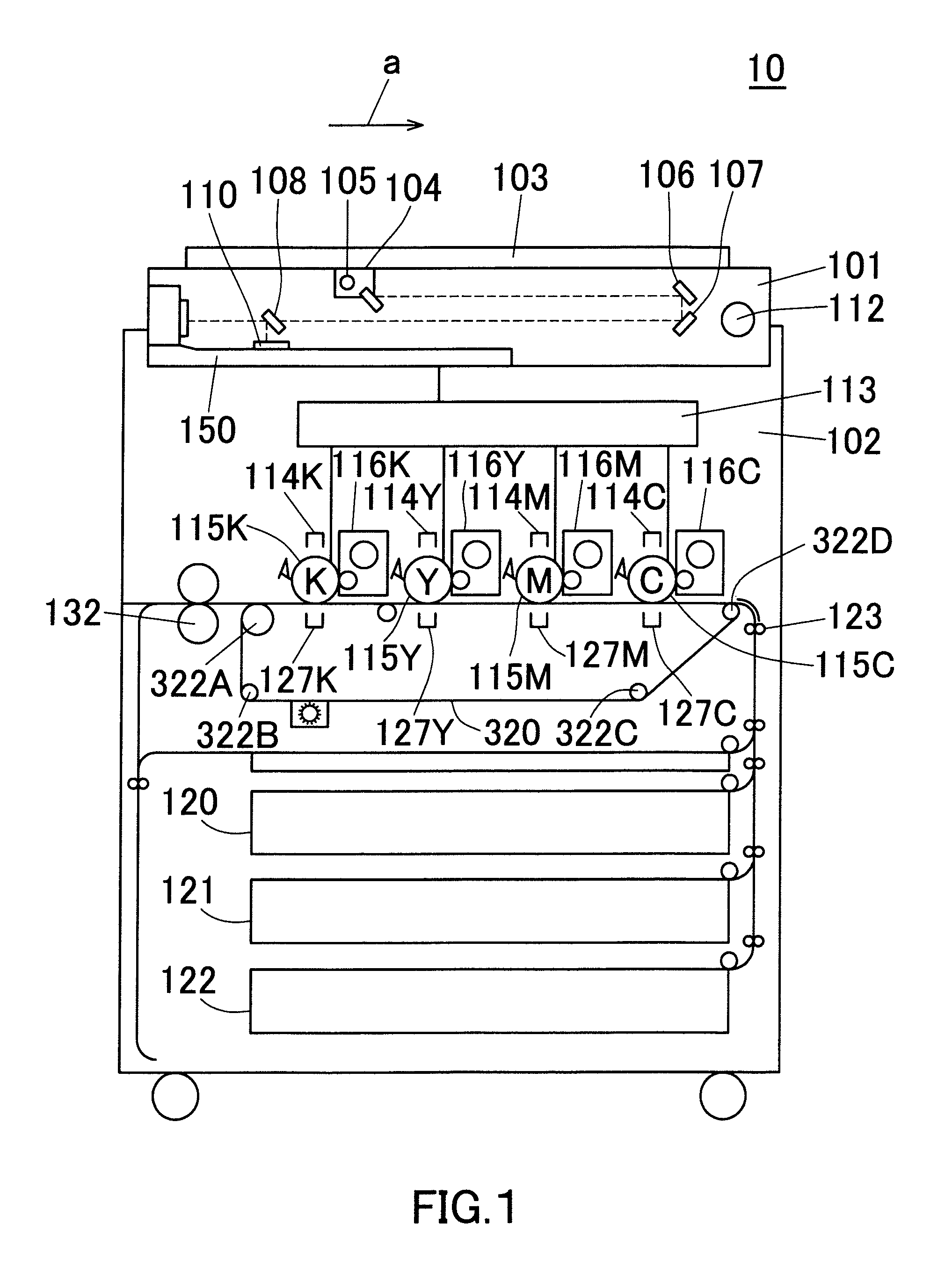

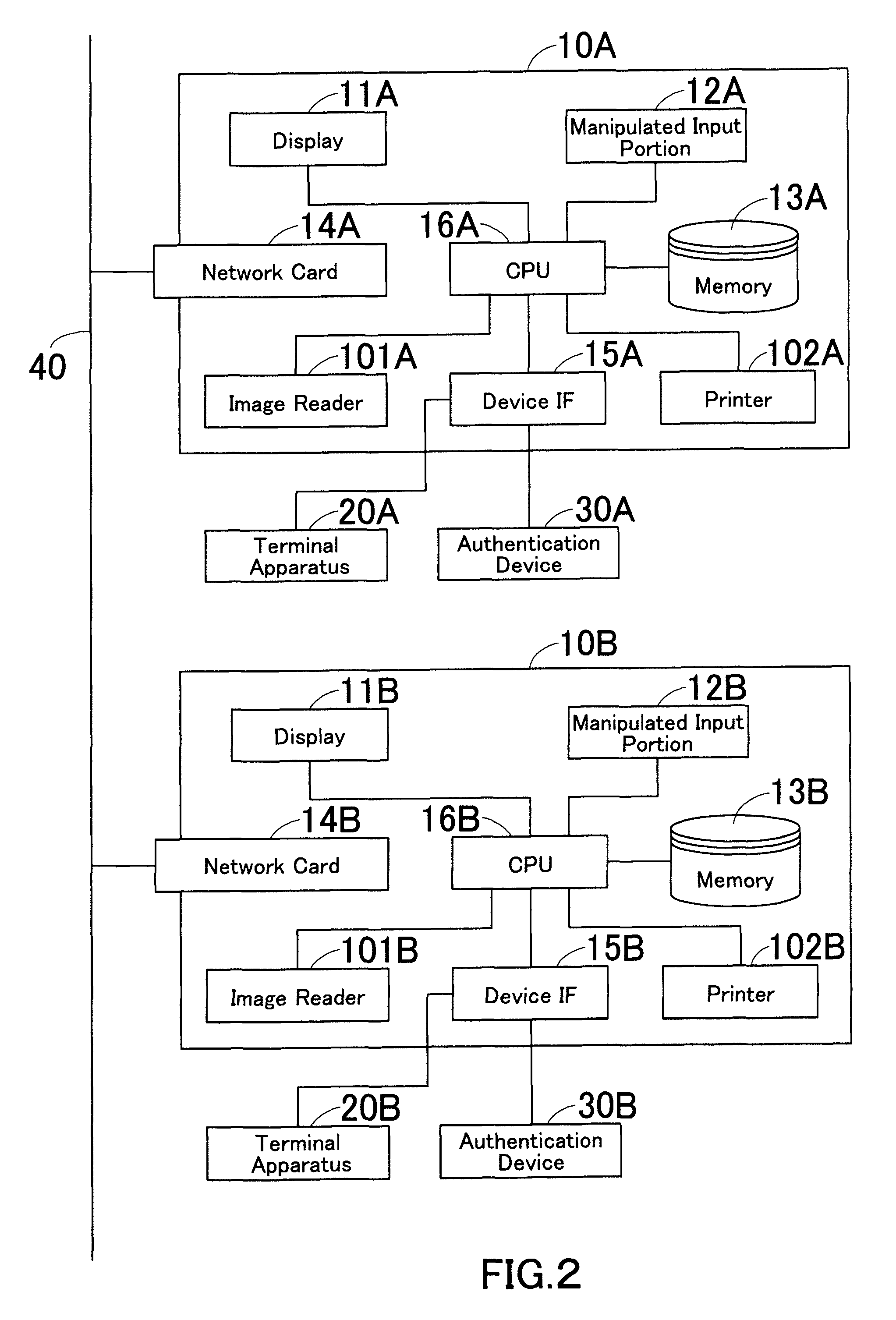

Print system for conferencing and print method thereof

ActiveUS20100073720A1Eliminate riskAvoid wasting materialDigitally marking record carriersDigital computer detailsPresent methodInternetworking

A print system for conferencing includes a plurality of print apparatuses that are provided in a plurality of conference locations and interconnected via a network; a storage that registers in itself, data of conference material and information of prospective attendees from the respective conference locations; and a detector that detects the start of a conference. Each of the print apparatuses obtains and records the registered data of conference material and information of prospective attendees from the conference location where the print apparatus is provided, then prints as many copies of conference material as the number of the prospective attendees, if the start of a conference is detected.

Owner:KONICA MINOLTA BUSINESS TECH INC

Sealable and disposable receptacle for biologic waste products

Owner:GILL ZORA SINGH +1

Product display hanger

InactiveUS20070138118A1Minimizes debris collectionMinimizes waste recycling problemShow shelvesShow hangersEngineeringMechanical engineering

A product display hanger includes a substrate with an adhesive applied to one surface. A release liner is disposed on the substrate and may include two substantially parallel die cuts formed therein. Thus, a portion or all of the release liner between the die cuts can be separated from the substrate to expose the adhesive on the substrate. Portions of the release liner remaining on the substrate have indicia thereon for identifying the preferred alignment and spacing for products to be displayed or other visible indicia or holes may be provided as a means of guidance for mounting product. At least one hanger hole may be formed near one end of the display hanger for suspending the display hanger from a hook.

Owner:HUBER W RENE

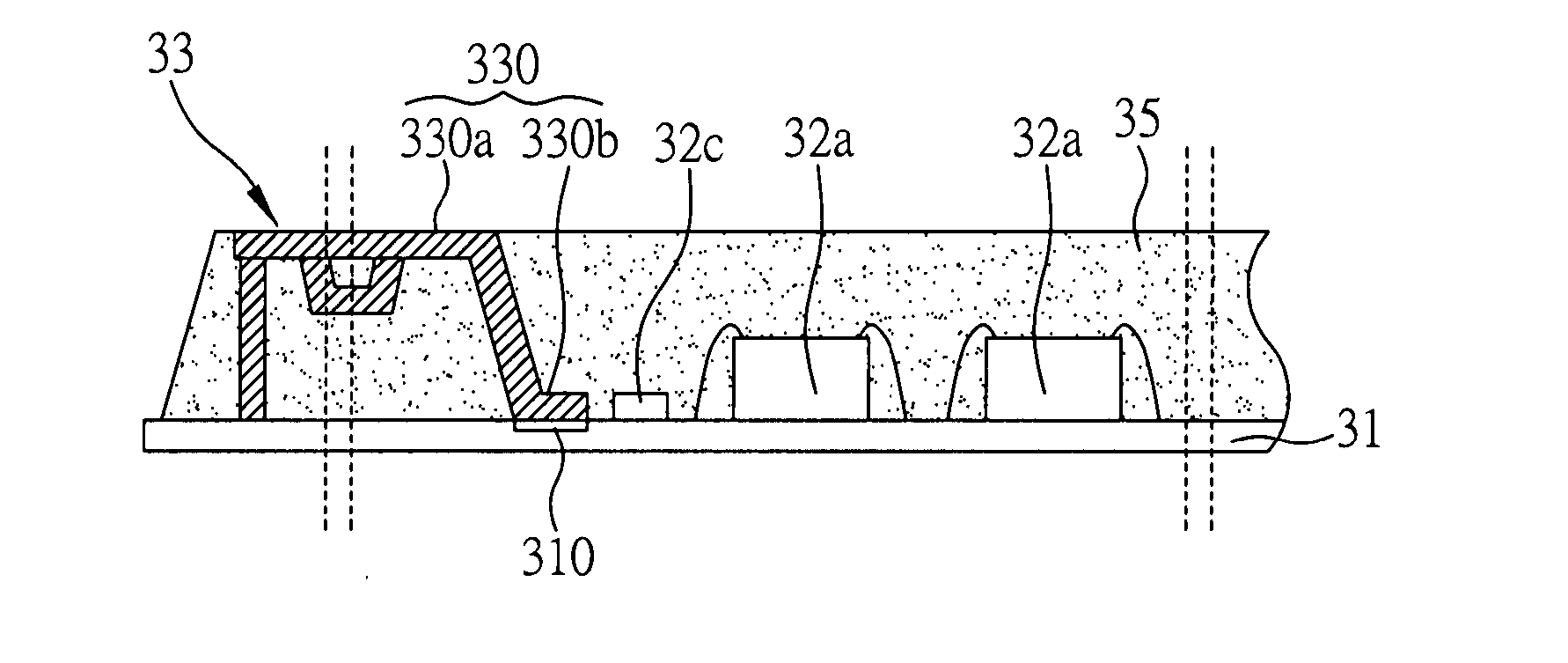

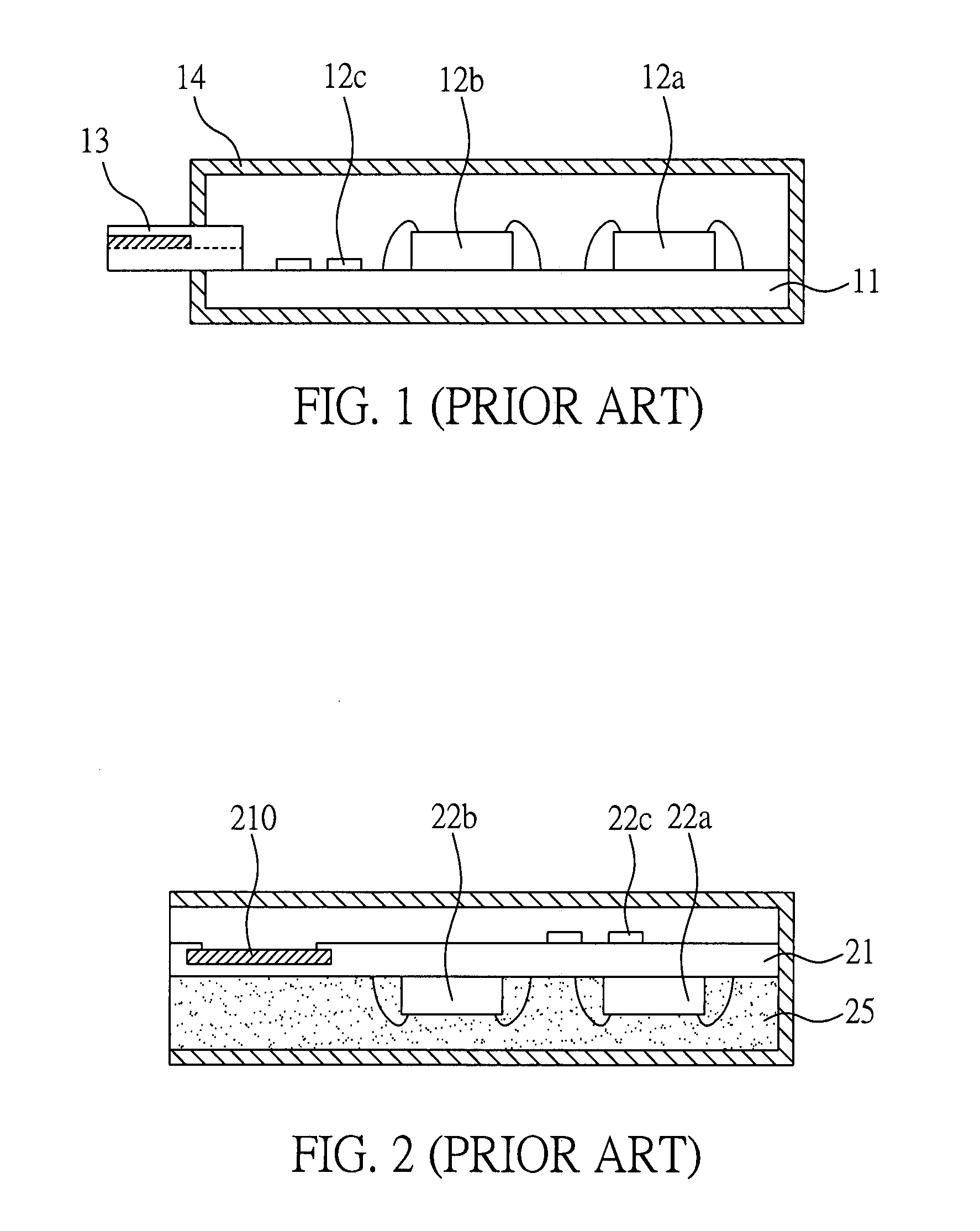

Semiconductor package and method of making the same

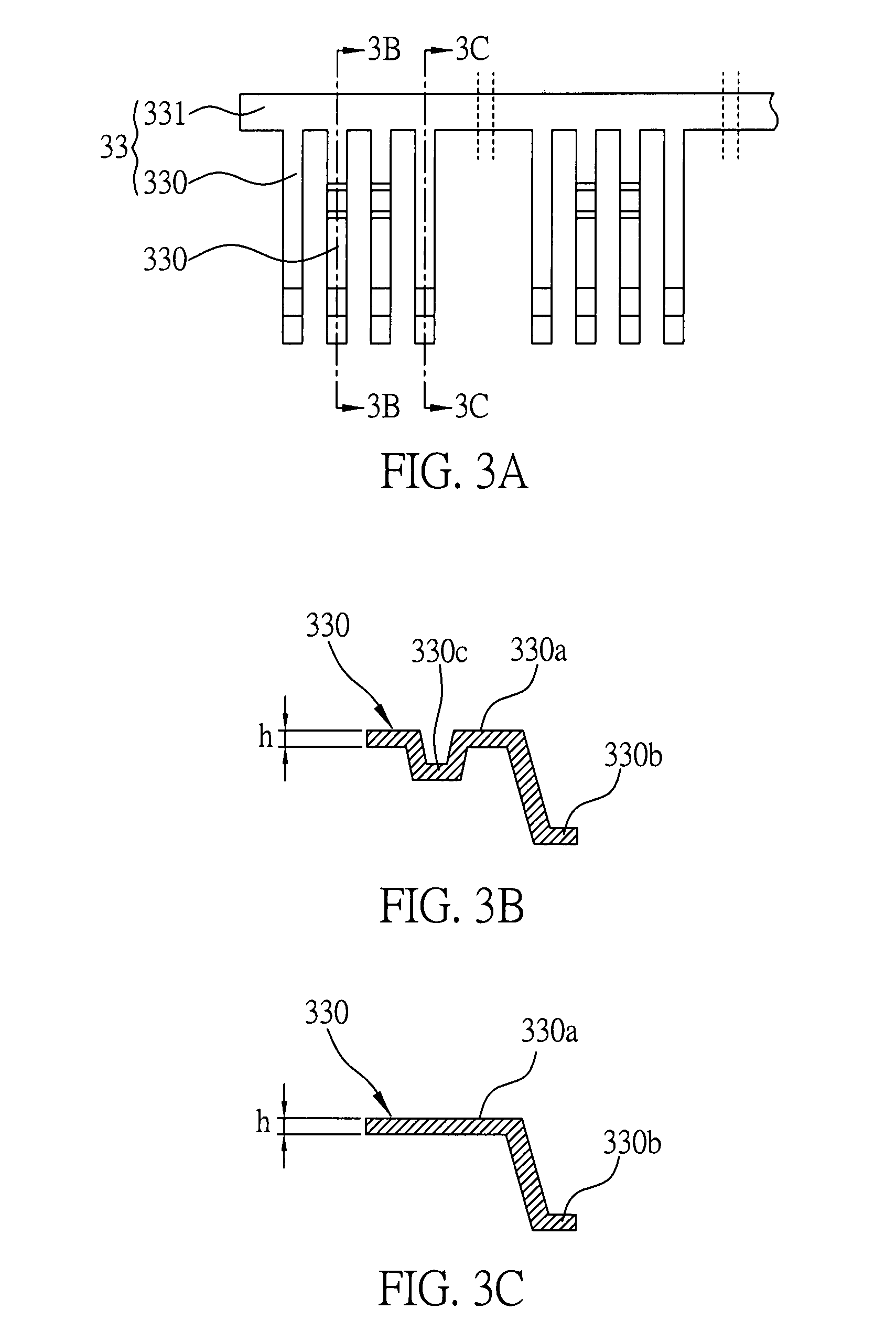

InactiveUS20080009153A1Minimized in sizeAvoid problemsElectrically conductive connectionsSemiconductor/solid-state device detailsSemiconductor packageElectrical connection

A semiconductor package and its fabrication method are disclosed. The fabrication method has the steps of: providing at least a lead frame having a plurality of terminal leads formed with flat portions and contacting portions, providing at least a circuit board having a plurality of electrical connection pads, mounting the contacting portions on and electrically connecting to the electrical connection pads, attaching and electrically connecting electronic elements to the circuit board, forming an encapsulant for encapsulating the lead frames and the electronic elements but uncovering the flat portions of the terminal leads, and cutting around the circuit board along a cutting path that crosses through each of the terminal leads so as to allow each of the terminal leads to be electrically independent, wherein the terminal leads are employed to act as the electrical terminals of USB memory cards for storing or retrieving data.

Owner:SILICONWARE PRECISION IND CO LTD

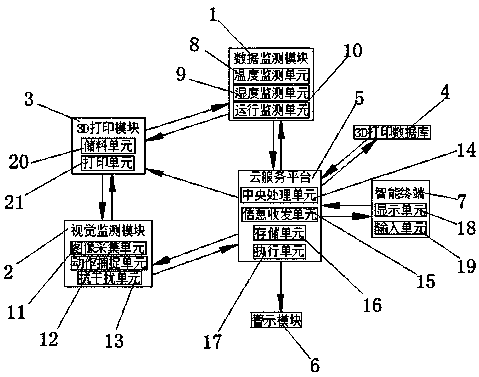

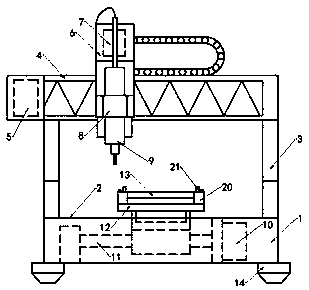

3D printing intelligent monitoring system and application method

InactiveCN109228358ALow costAvoid wasting materialAdditive manufacturing apparatus3D object support structuresData monitoring3D printing

The invention discloses a 3D printing intelligent monitoring system. The 3D printing intelligent monitoring system comprises a data monitoring module, a vision monitoring module, a 3D printing module,a 3D printing database, a cloud service platform, a warning module and an intelligent terminal, wherein the input end of the cloud service platform is separately connected with output ends of the data monitoring module, the vision monitoring module, the 3D printing database and the intelligent terminal, the data monitoring module comprises a temperature monitoring unit, a humidity monitoring unitand an operation monitoring unit, the vision monitoring module comprises an image acquisition unit, an action capturing unit and an anti-interference unit, the cloud service platform comprises a central processing unit, an information transceiving unit, a storage unit and an execution unit, and the intelligent terminal comprises a display unit and an input unit. By adopting the 3D printing intelligent monitoring system, the printing process can be conveniently monitored, the problems can be discovered and treated in time, the cost is reduced, and the material waste is avoided; and the invention also provides an application method of the 3D printing intelligent monitoring system. The 3D printing intelligent monitoring system is convenient and rapid in operation and convenient in popularization.

Owner:白明号

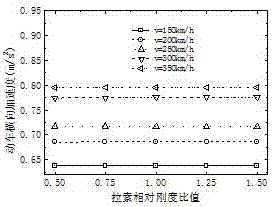

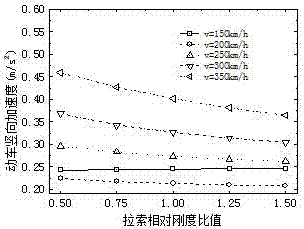

Method of controlling rigidity of long span cable-stayed bridge of railway through stay cable

InactiveCN107145664AStiffness controlEasy to meet stiffness requirementsGeometric CADDesign optimisation/simulationVehicle dynamicsCable stayed

The invention relates to the technical field of cable-stayed bridges and in particular relates to a method of controlling rigidity of a long span cable-stayed bridge of a railway through a stay cable. The method analyzes influence rules of the cable-stayed bridge on bridge dynamic characteristic, vehicle dynamic response and bridge dynamic response under different numerical values by establishing a long span cable-stayed bridge model of the railway and a bridge model by means of a dynamic analytical method, and performs judgment by taking an evaluating index system of a vehicle-bridge system as an index to obtain influence conditions on the integral rigidity of the bridge under different rigidity numerical values so as to further obtain a reasonable value range of the rigidity of the stay cable, thereby providing basis for valuing and designing the rigidity of the stay cable; the integral rigidity of the long span cable-stayed bridge of the railway is better controlled through the rigidity of the stay cable, so that the long span cable-stayed bridge of the railway achieves a breakthrough on the rigidity control technology; the technical problem is solved, so that the long span cable-stayed bridge of the railway is promoted, and a lot of engineering investment cost is saved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

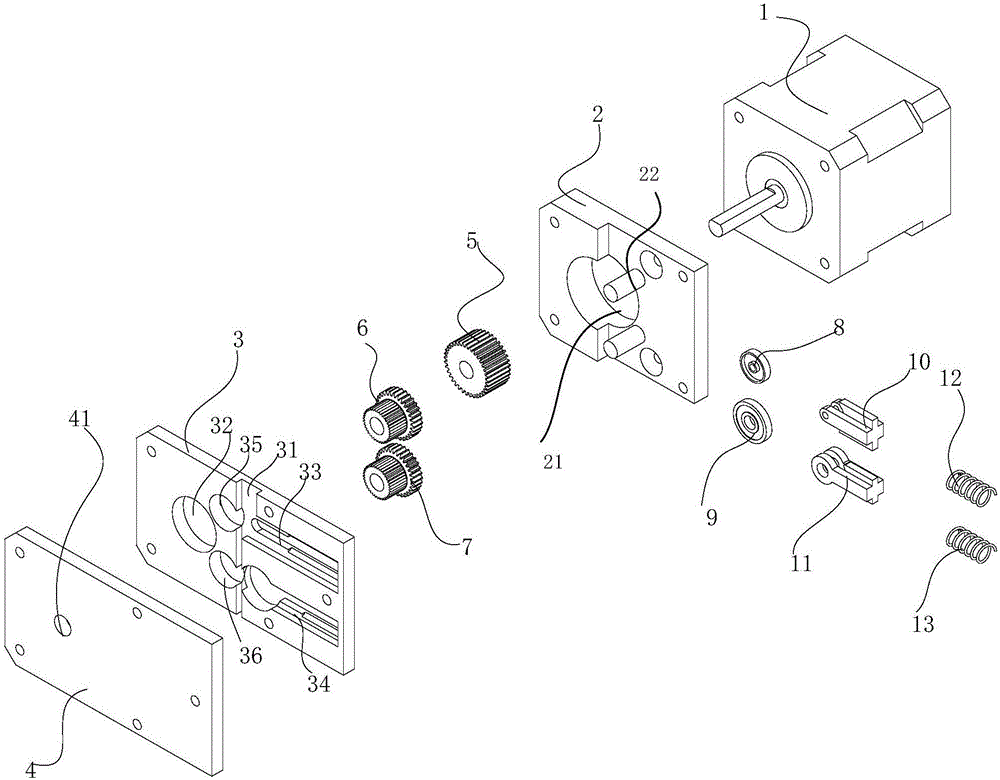

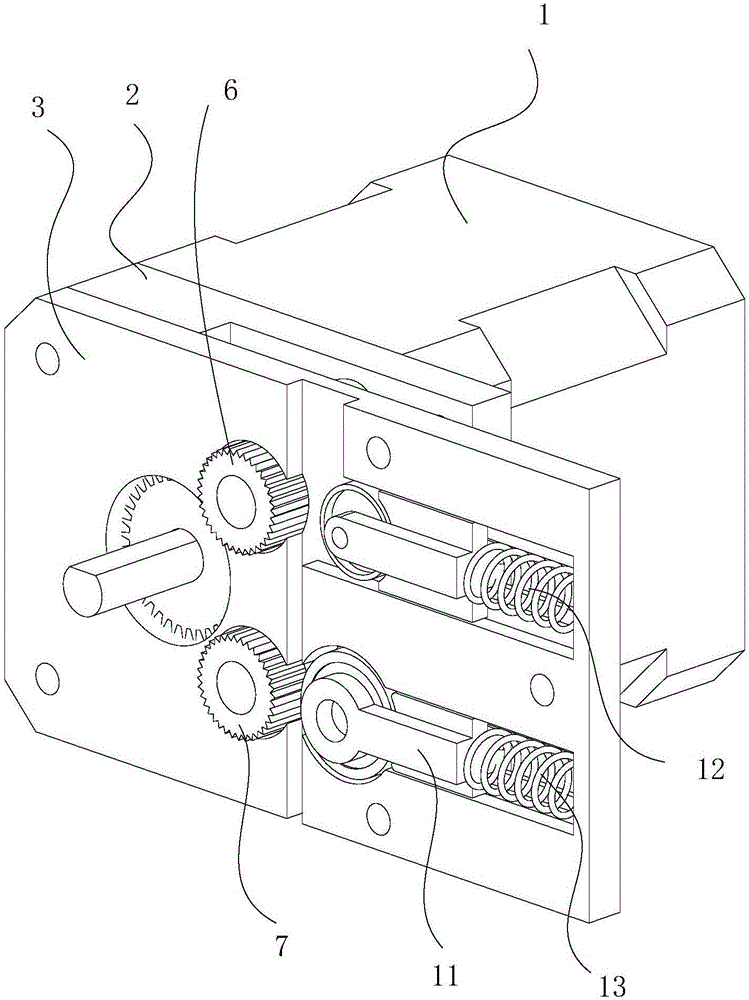

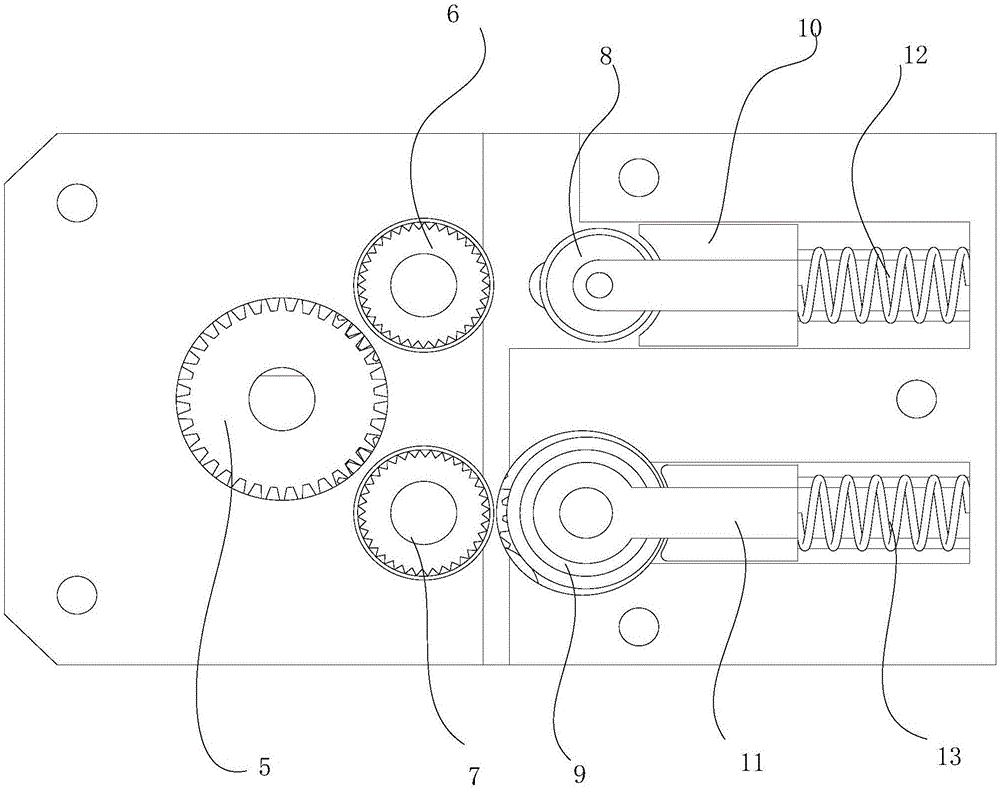

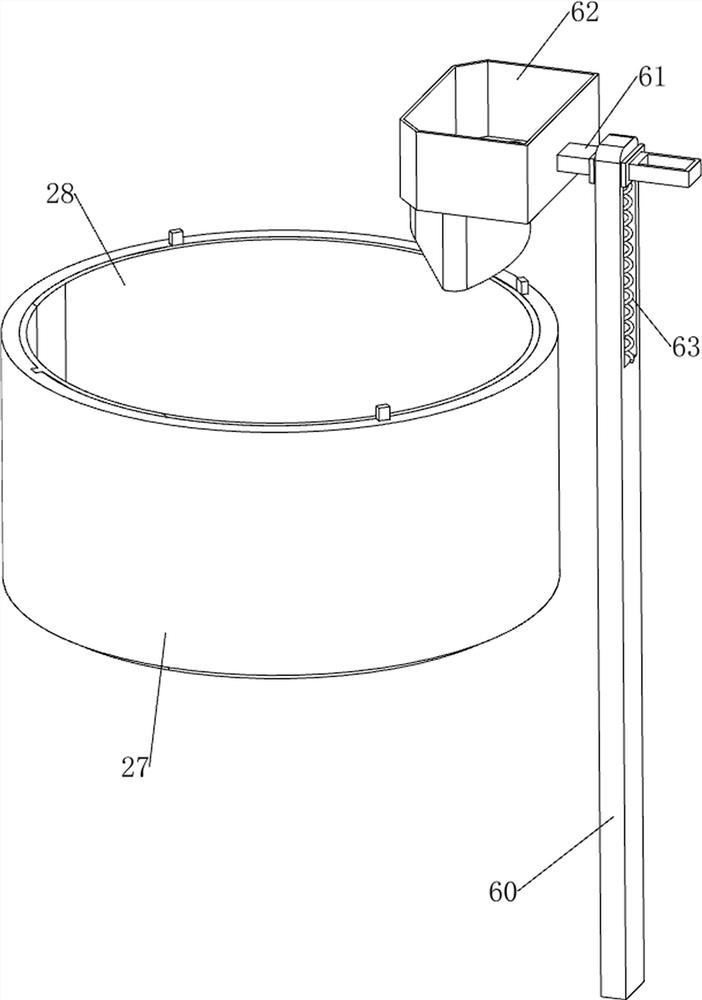

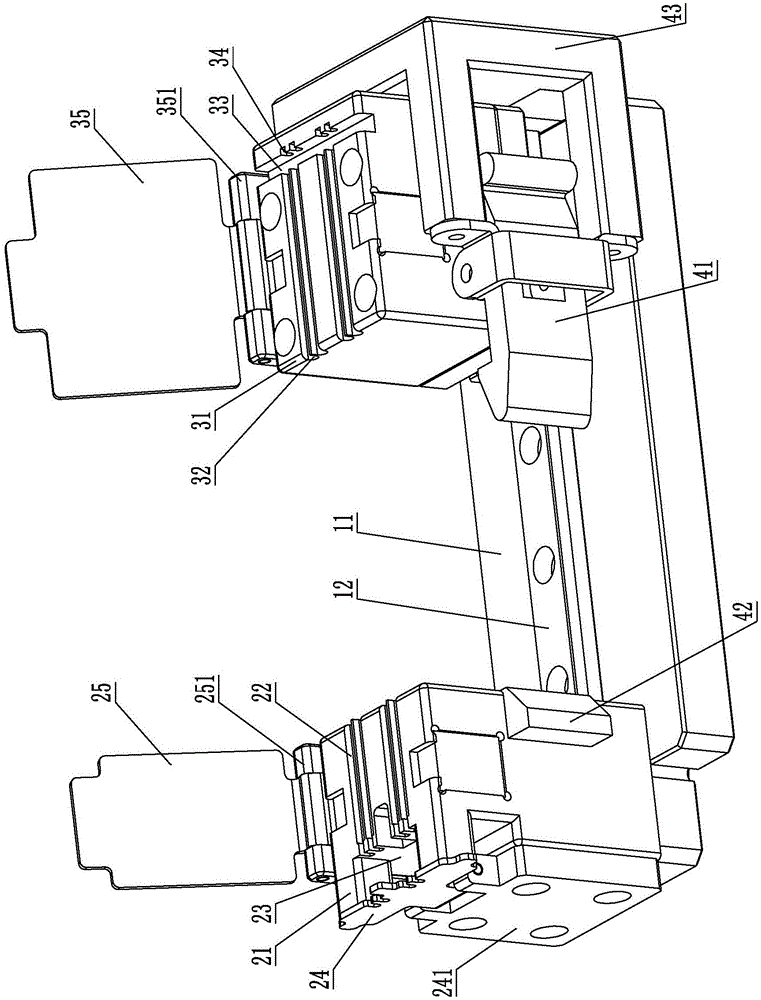

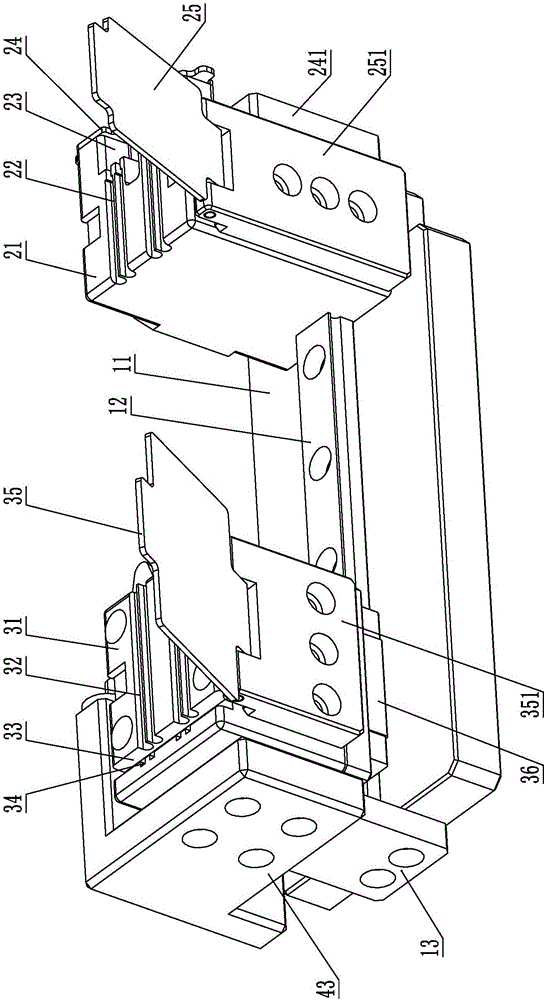

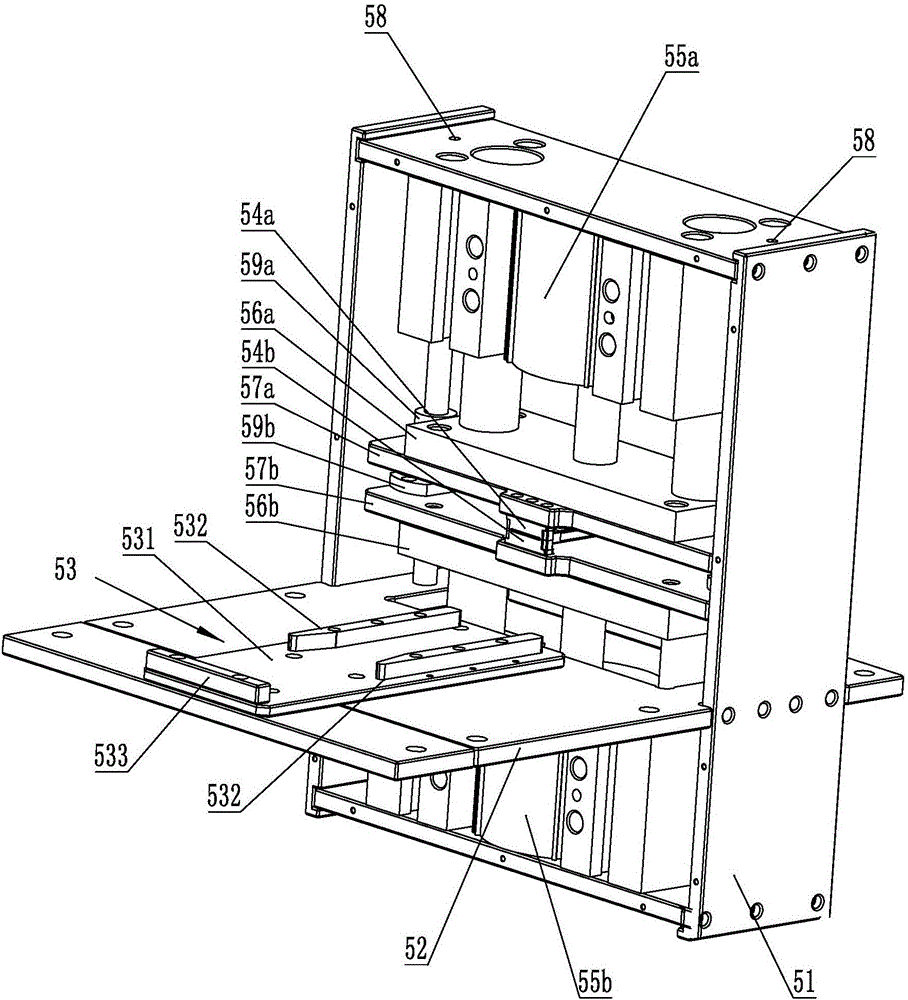

Novel wire feeding machine achieving automatic material replacing and continuous printing of material breakage

ActiveCN106584858AImprove work efficiencyAvoid wasting materialAdditive manufacturing apparatus3D object support structuresEngineeringWire breakage

The invention provides a novel wire feeding machine achieving automatic material replacing and continuous printing of material breakage. The novel wire feeding machine achieving automatic material replacing and continuous printing of material breakage comprises a motor, a wire feeding wheel installing plate, a bearing installing plate and a fixing plate which are sequentially arranged; the four portions are connected in a detachable manner; an output shaft of the motor is sleeved with a gear; a gear penetrate-out hole is formed in the wire feeding wheel installing plate which is further provided with an upper wire feeding wheel and a lower wire feeding wheel; the gear is engaged with the upper wire feeding wheel and the lower wire feeding wheel; a wire feeding channel, an upper wire feeding wheel containing hole, a lower wire feeding wheel containing hole, an upper installing groove and a lower installing groove are formed in the bearing installing plate, and the upper wire feeding wheel containing hole and the lower wire feeding wheel containing hole are located in one side of the channel, and the upper installing groove and the lower installing groove are located in the other side of the channel; the wire feeding channel is divided into an upper segment and a lower segment; and the channel upper segment is communicated with the upper installing groove and the upper wire feeding wheel containing hole and can contain a plurality of wire materials side by side at the same time. By means of the novel wire feeding machine achieving automatic material replacing and continuous printing of material breakage, when the wire materials are used up or because of accidental wire breakage, continuous printing cannot be performed, it is not needed to temporarily stop the printing process, and manual material replacing is not needed.

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

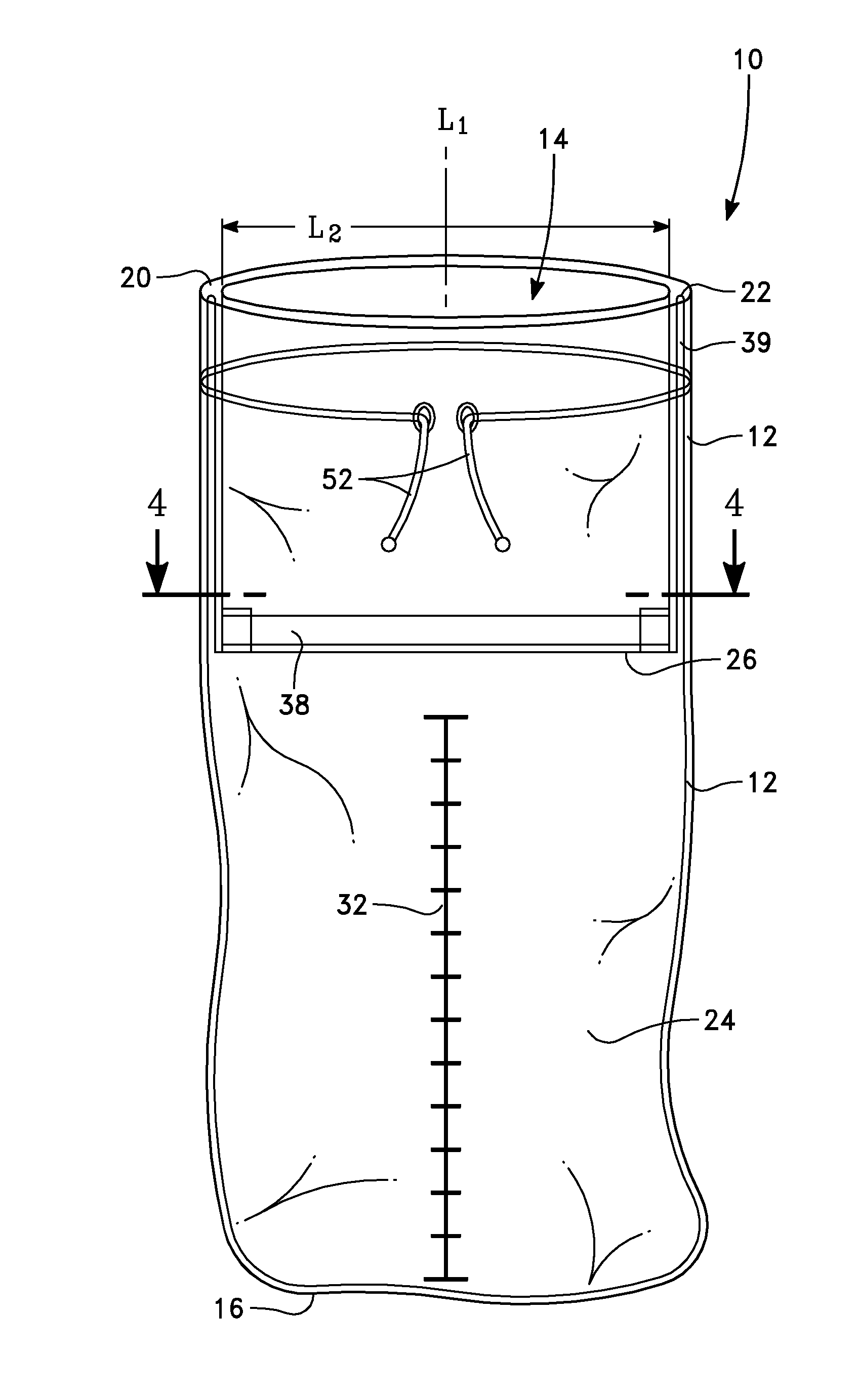

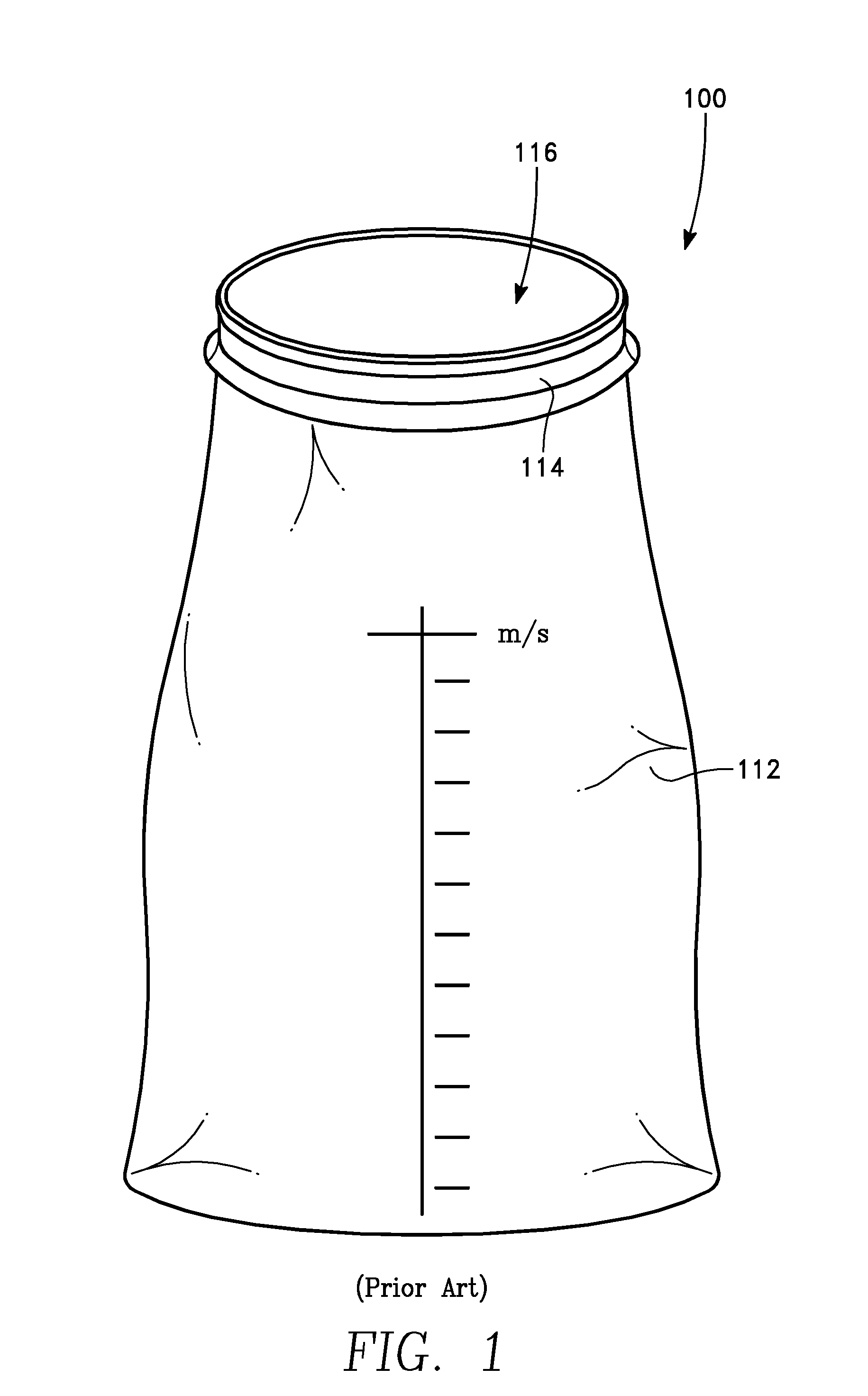

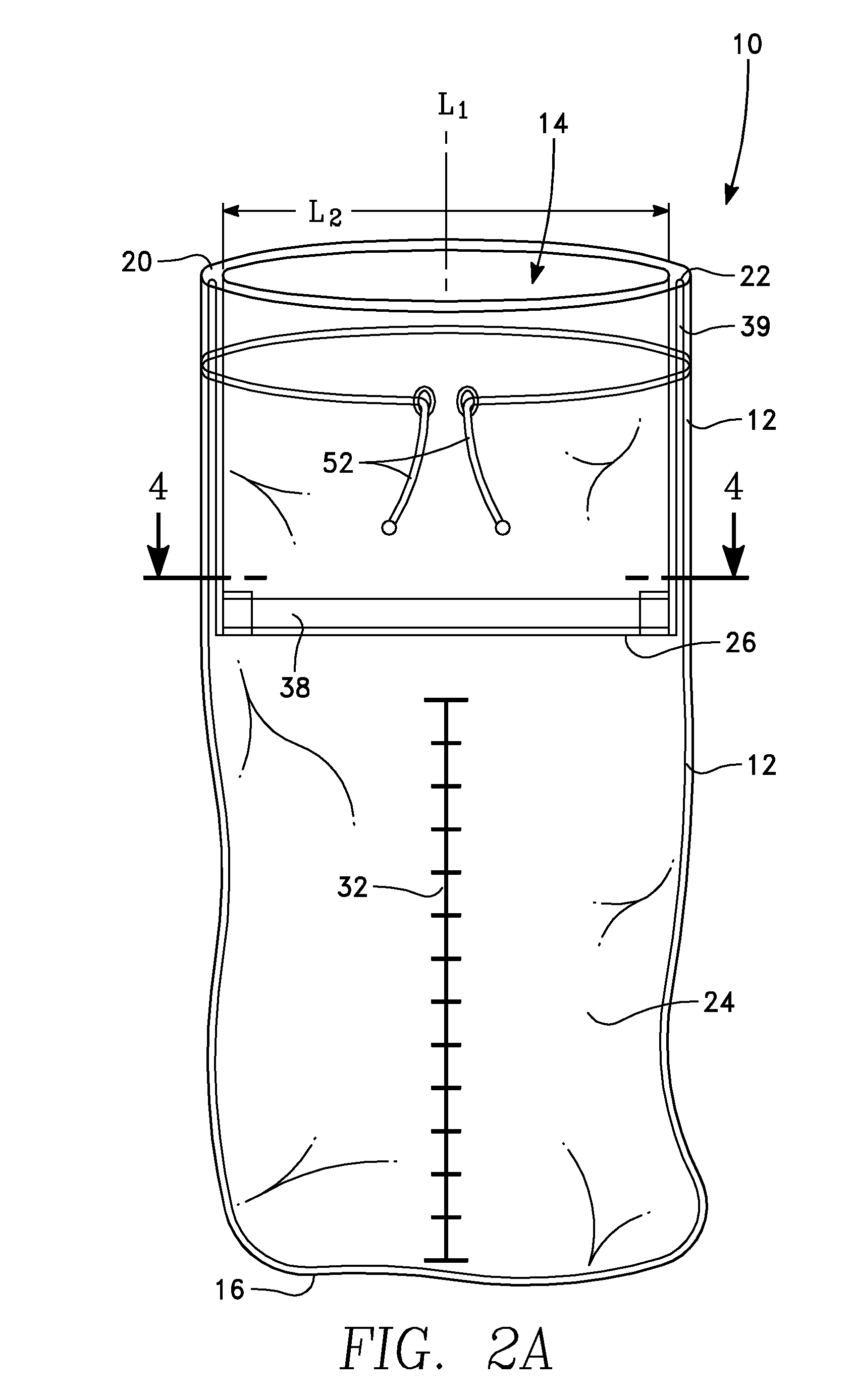

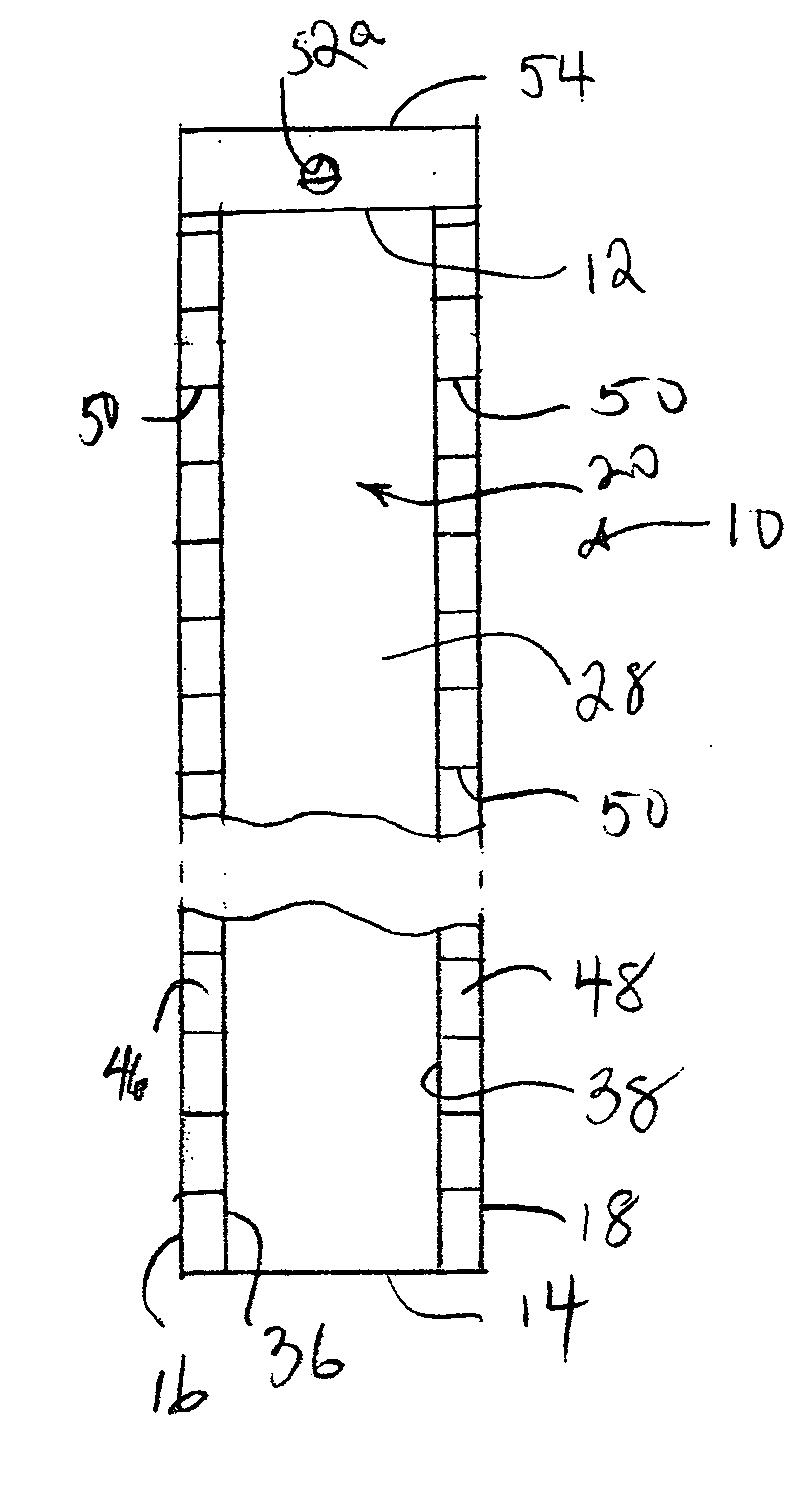

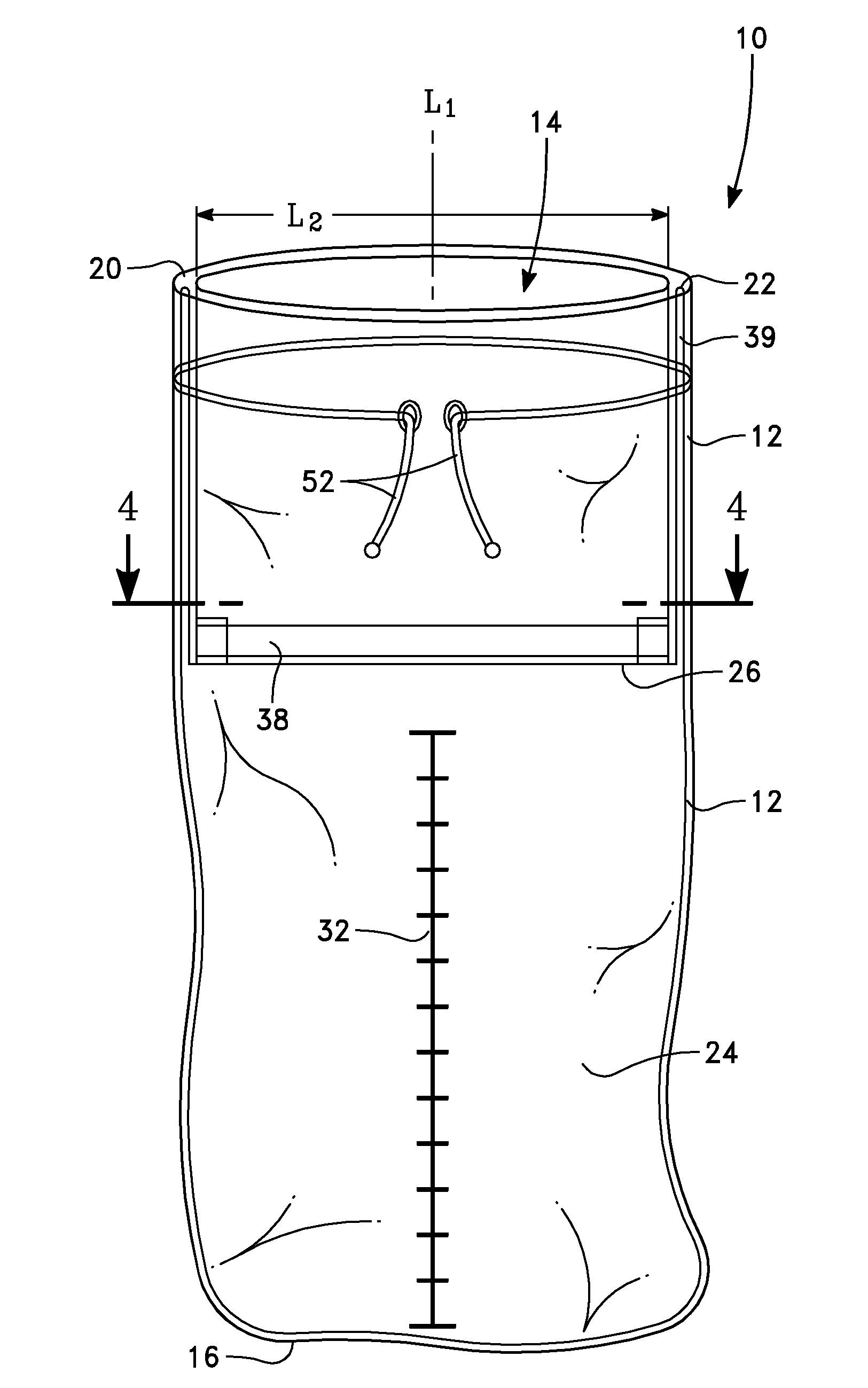

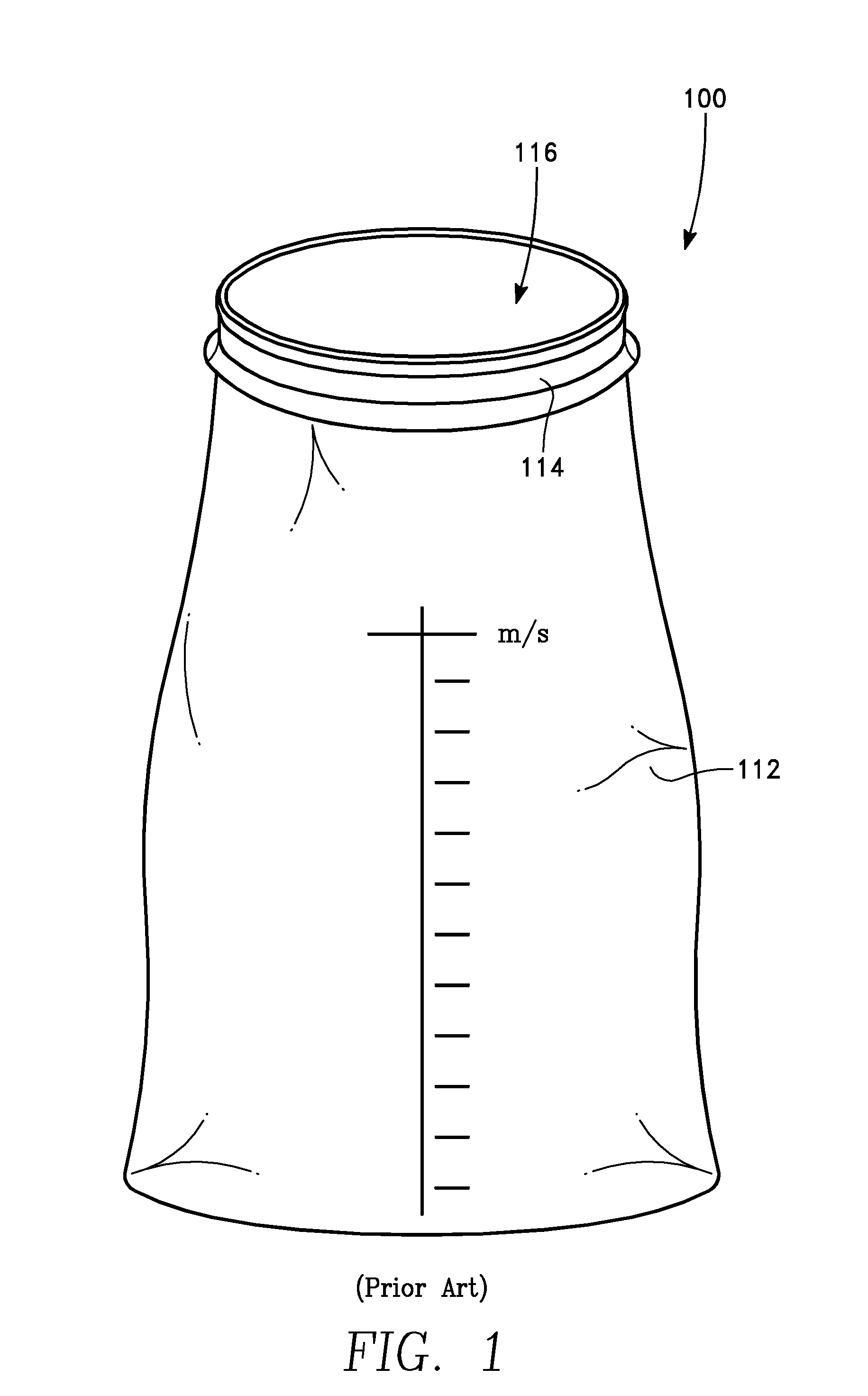

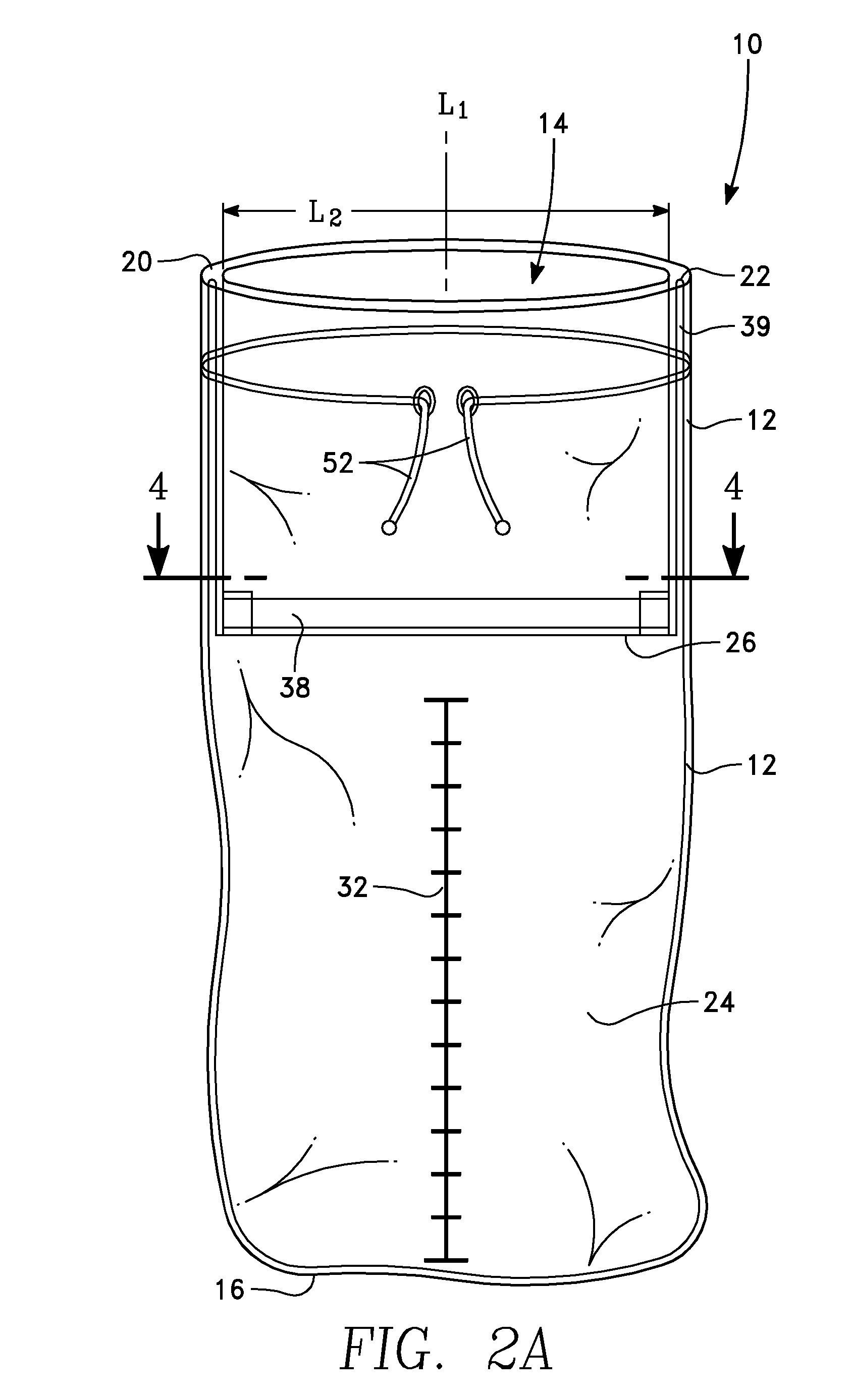

Sealable and Disposable Receptacle for Biologic Waste Products

ActiveUS20100278456A1Avoid wasting materialFacilitate responsible disposalFlexible coversWrappersHuman wasteWaste product

A portable and sealable waste disposal receptacle receives human waste material through an opening in an outer chamber. The waste passes through an inner chamber, which is suspended within the outer chamber, and passes through a one-way valve located at the bottom of the inner chamber into a lower chamber portion of the outer chamber. The one-way valve is fashioned from the bottom edges of the inner chamber, where a biasing strip is mounted in compression along one of the bottom edges, which causes the bottom edges of the inner chamber to be biased closed in sealing contact except when waste enters the inner chamber, the weight of which is sufficient to overcome the closing bias of the biasing strip, allowing the waste to flow into the lower chamber. Once the waste has cleared the inner chamber, the biasing member causes the bottom edges to come together in sealing contact, preventing the flow of waste back through the inner chamber.

Owner:GILL ZORA SINGH +1

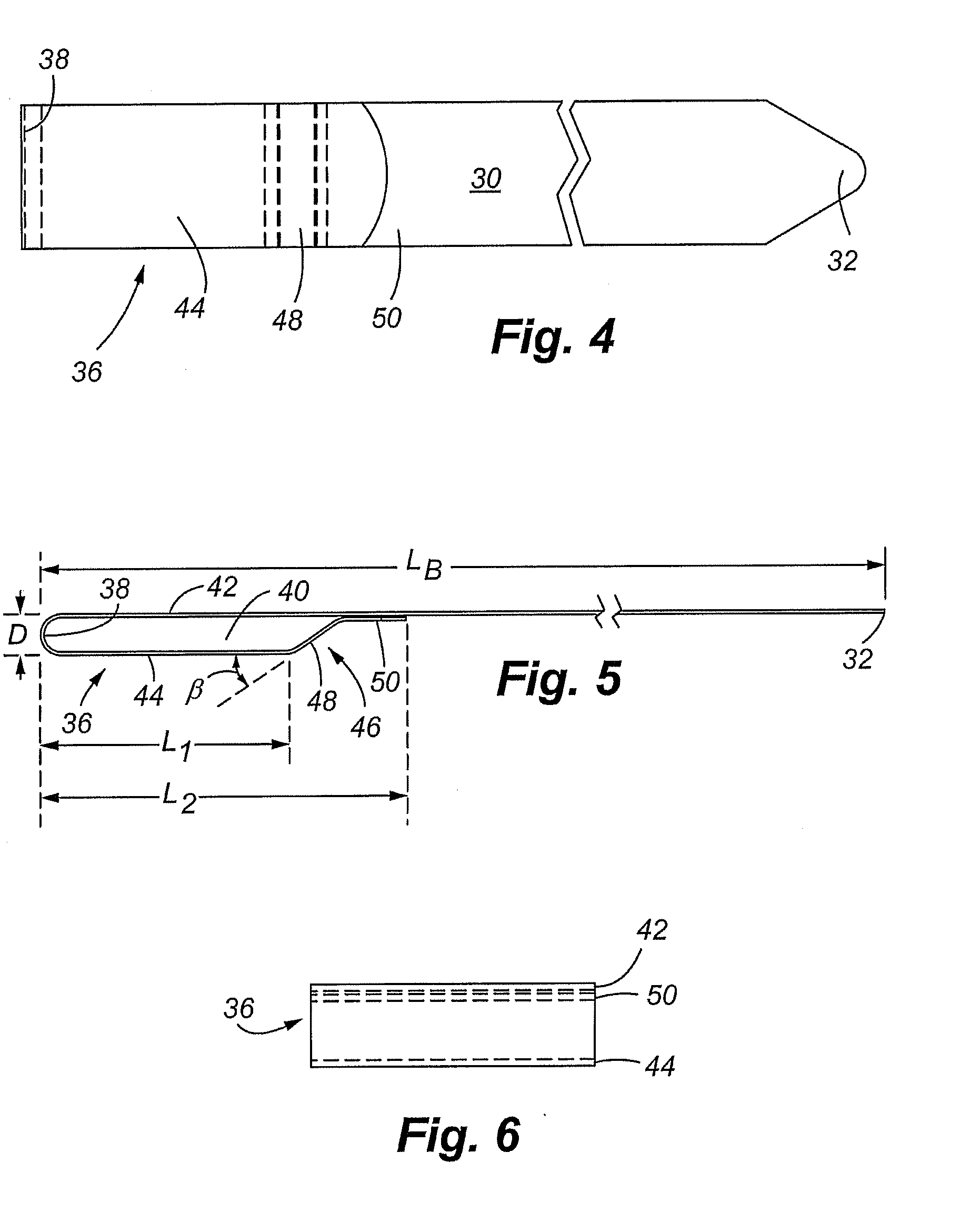

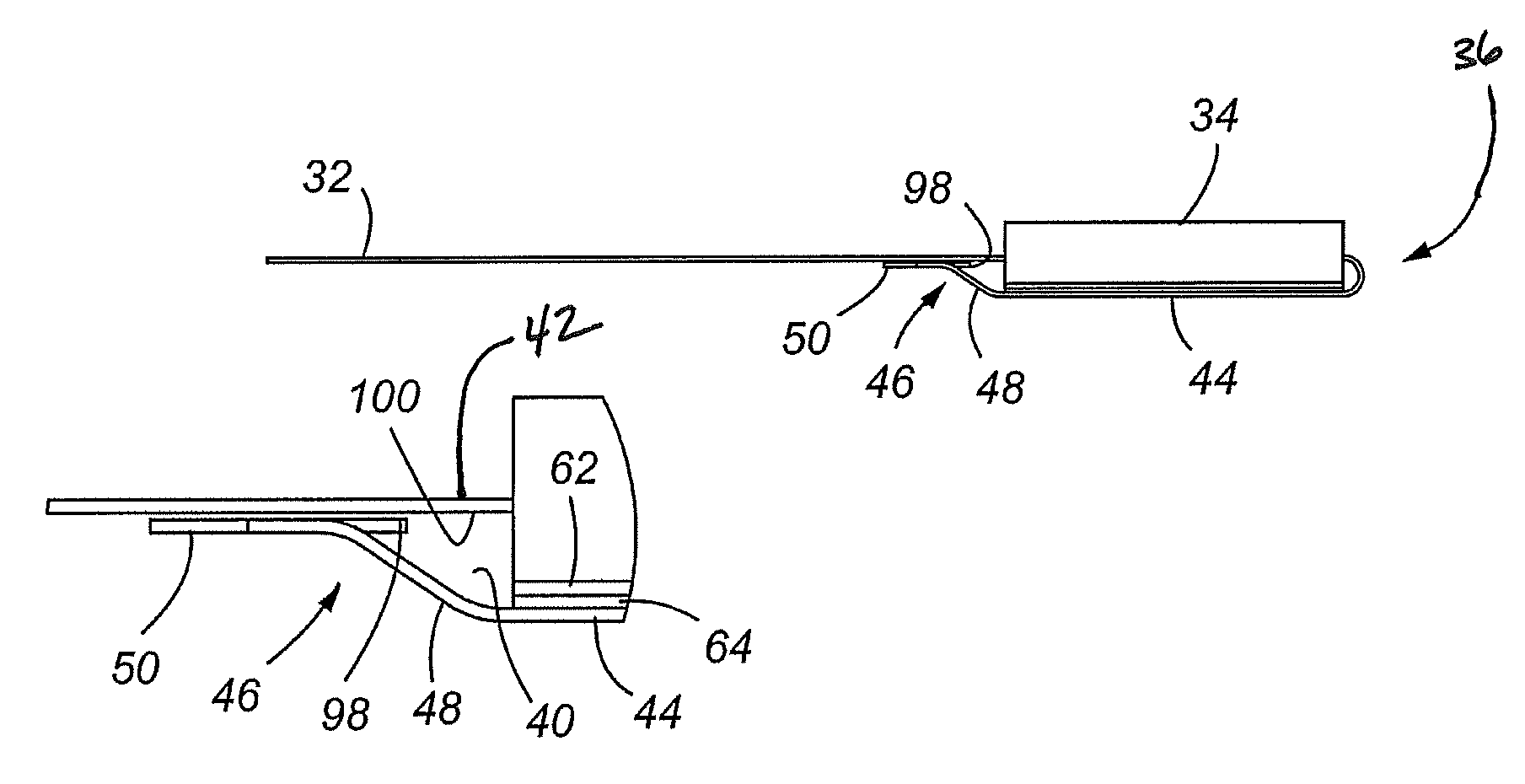

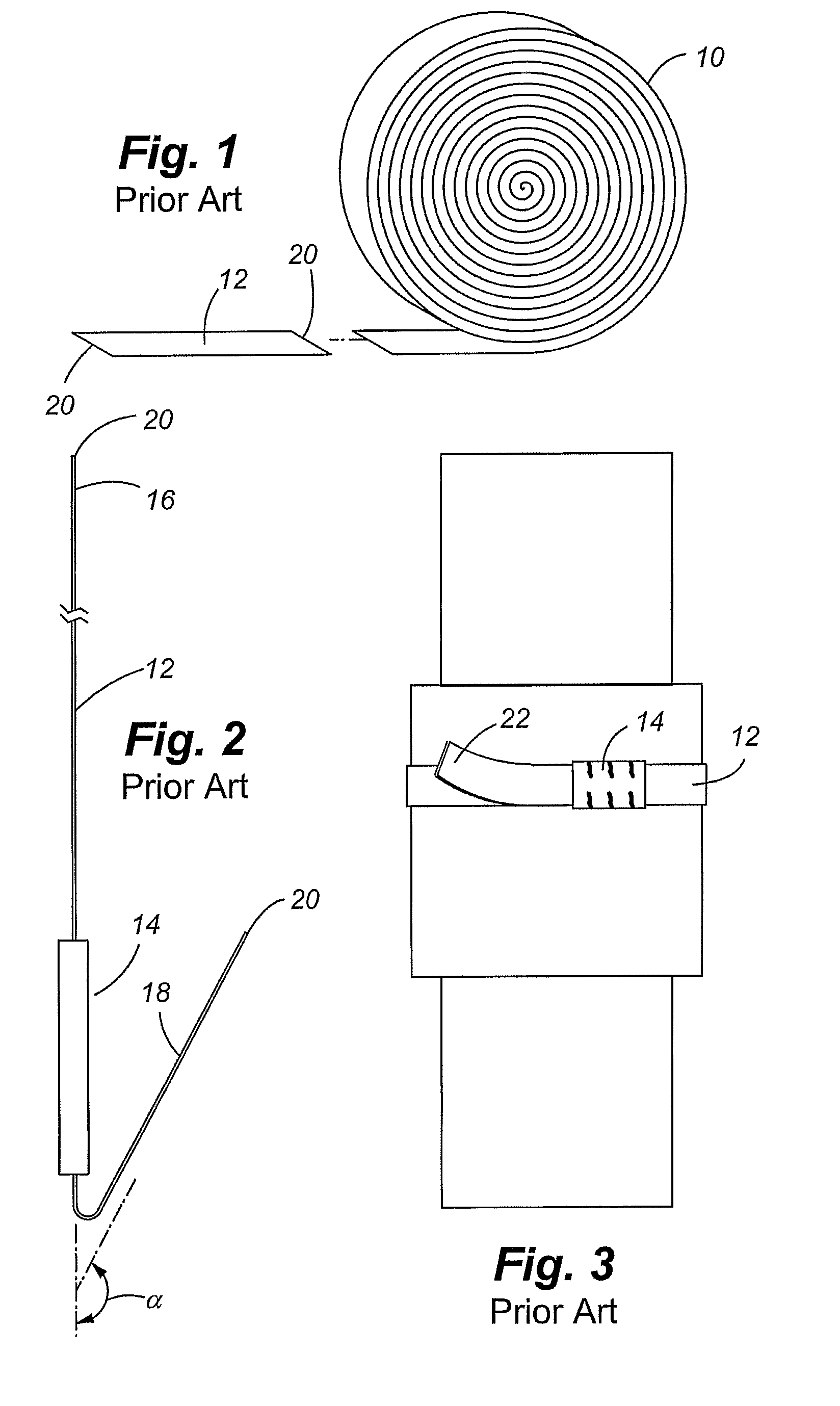

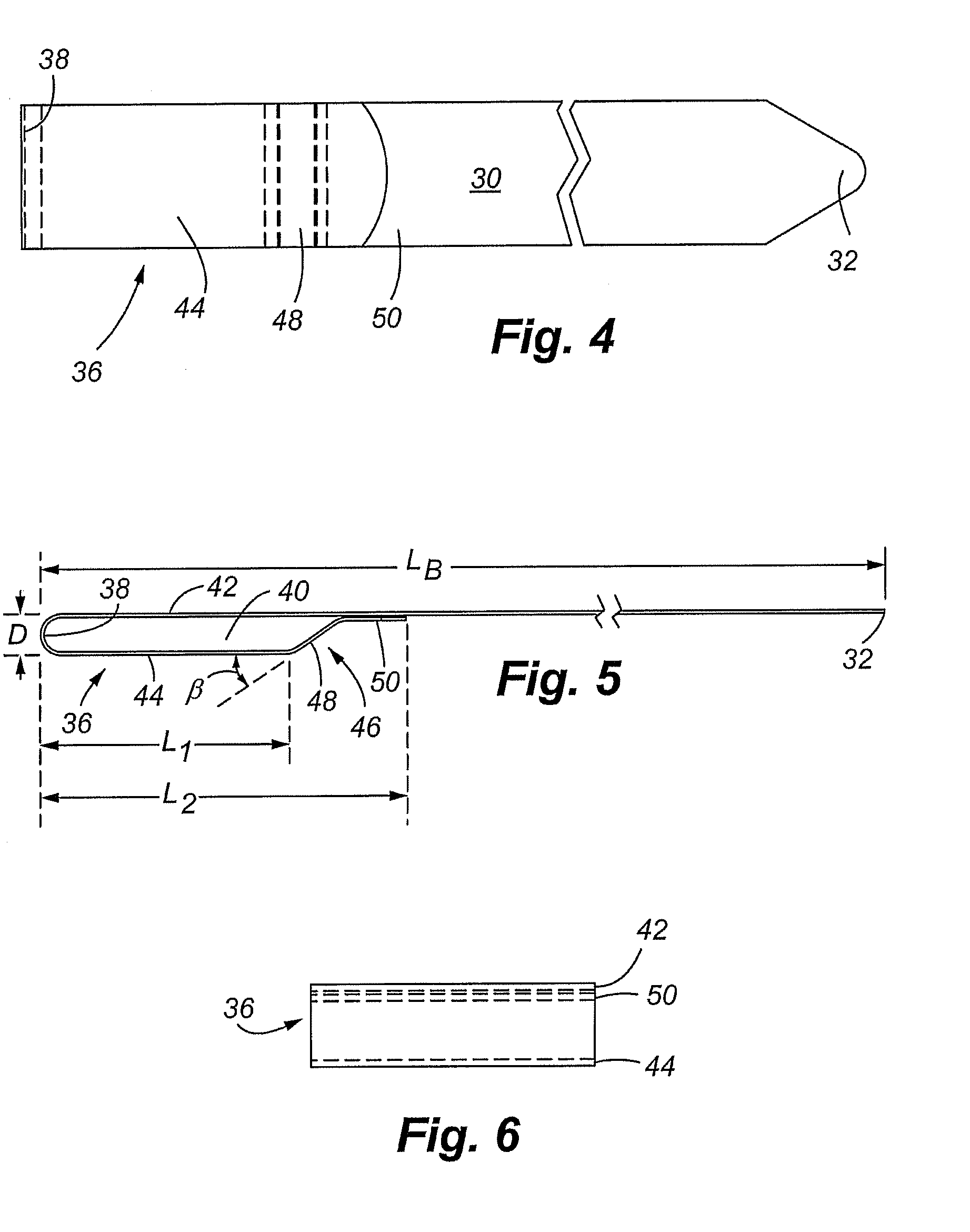

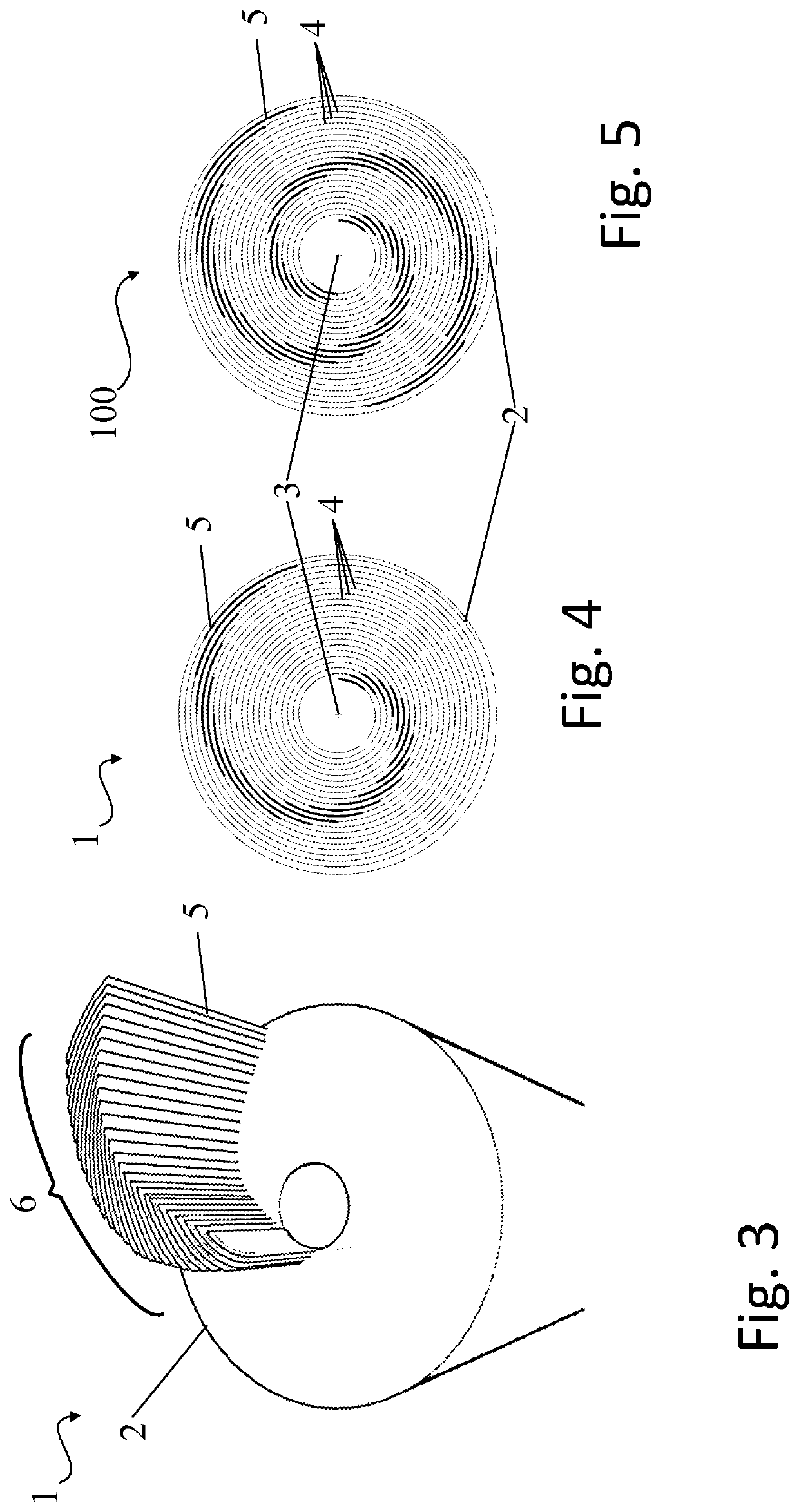

Free end band and seal

ActiveUS20060272133A1Avoid wasting materialReduce labor costsStaplesFlexible elementsClosed loopEngineering

A pre-cut and preformed free end band and seal of a predetermined length, and method of making and using the same is disclosed. The band is preformed with a substantially closed loop of band material to capture a seal to provide a preassembled band and seal wherein the seal is generally inhibited from being dislodged during packing, shipment, handling and installation. The band and seal are also formed in a manner to facilitate relative positioning of the band and seal as well as placement of a crimping tool relative to the band and seal for optimized crimping of the band and seal.

Owner:BAND IT IDEX

Free end band

A pre-cut and preformed free end band and seal of a predetermined length, and method of making and using the same is disclosed. The band is preformed with a substantially closed loop of band material to capture a seal to provide a preassembled band and seal wherein the seal is generally inhibited from being dislodged during packing, shipment, handling and installation. The band and seal are also formed in a manner to facilitate relative positioning of the band and seal as well as placement of a crimping tool relative to the band and seal for optimized crimping of the band and seal.

Owner:BAND IT IDEX

Free end band

A pre-cut and preformed free end band and seal of a predetermined length, and method of making and using the same is disclosed. The band is preformed with a substantially closed loop of band material to capture a seal to provide a preassembled band and seal wherein the seal is generally inhibited from being dislodged during packing, shipment, handling and installation. The band and seal are also formed in a manner to facilitate relative positioning of the band and seal as well as placement of a crimping tool relative to the band and seal for optimized crimping of the band and seal.

Owner:BAND IT IDEX

Print system for conferencing and print method thereof

ActiveUS8294937B2Eliminate riskAvoid wasting materialDigitally marking record carriersDigital computer detailsComputer scienceData science

A print system for conferencing includes a plurality of print apparatuses that are provided in a plurality of conference locations and interconnected via a network; a storage that registers in itself, data of conference material and information of prospective attendees from the respective conference locations; and a detector that detects the start of a conference. Each of the print apparatuses obtains and records the registered data of conference material and information of prospective attendees from the conference location where the print apparatus is provided, then prints as many copies of conference material as the number of the prospective attendees, if the start of a conference is detected.

Owner:KONICA MINOLTA BUSINESS TECH INC

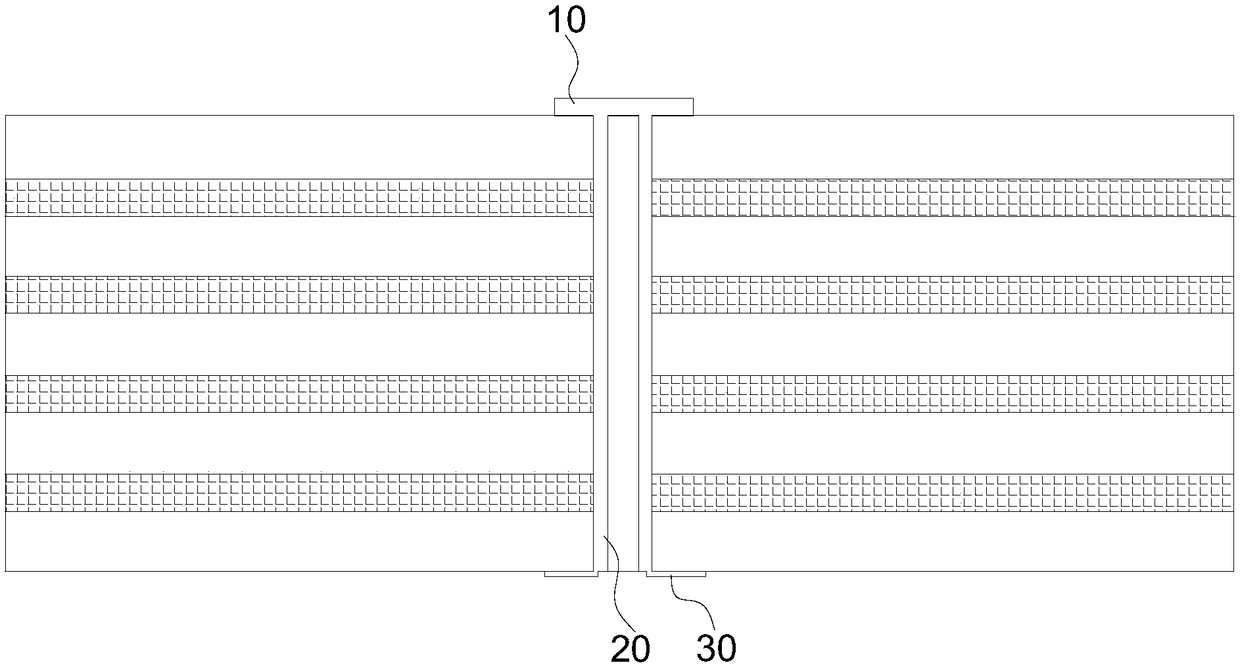

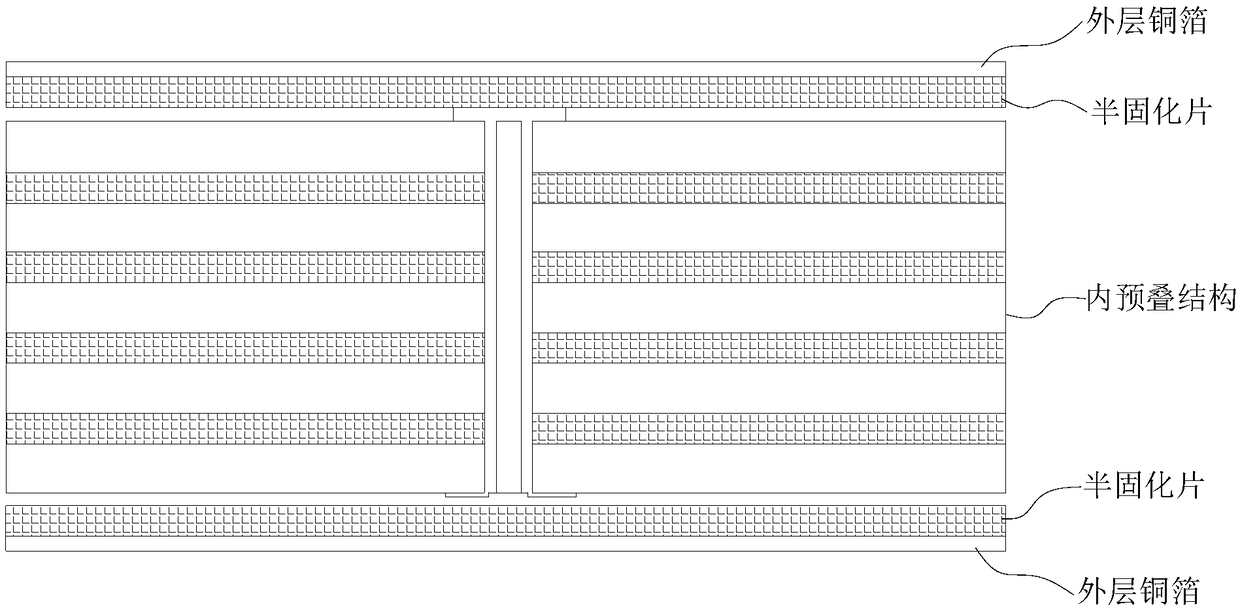

A rivet for improving the offset of a laminated layer and a method for riveting and positioning a PCB before lamination

InactiveCN109246930AIncrease productivityAvoid utilizationLaminating printed circuit boardsCircuit board tools positioningThick plateEngineering

The invention relates to the technical field of circuit board fabrication, in particular to a rivet for improving the offset of a laminated layer and a method for riveting and positioning a PCB beforelamination. By setting a rivet composed of a flowering section and a through section with a wall thickness not less than 0.65 mm, the rivet is used for positioning each core plate layer in the prestacking structure, the fixing force after riveting can be increased, and the deviation problem of the pressing layer can be solved. The rivet of the invention is used for riveting and fixing, and is suitable for the production and manufacture of the PCB medium-thick plate, communication substrate, thick copper power supply plate and other large-size backplates. The rivet has high alignment accuracy,can avoid the problem of internal short circuit scrap caused by deviation of the laminating layer, and can realize the compression positioning of this type of plate without using PIN-Lam positioningmethod, thereby significantly improving the production efficiency of this type of plate and avoiding the situation that PIN-Lam positioning method has the problems of low utilization rate of plate andwaste of materials.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

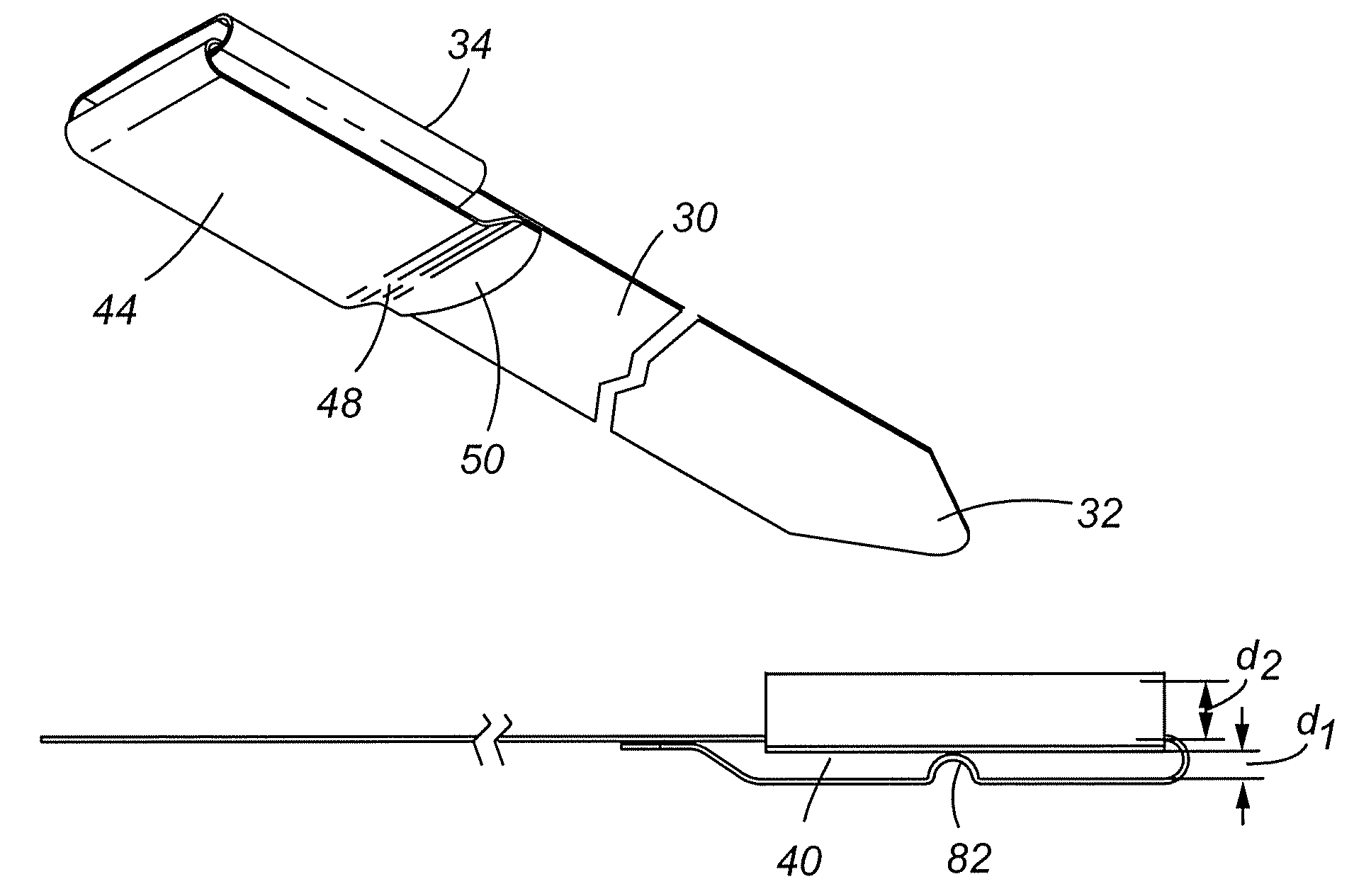

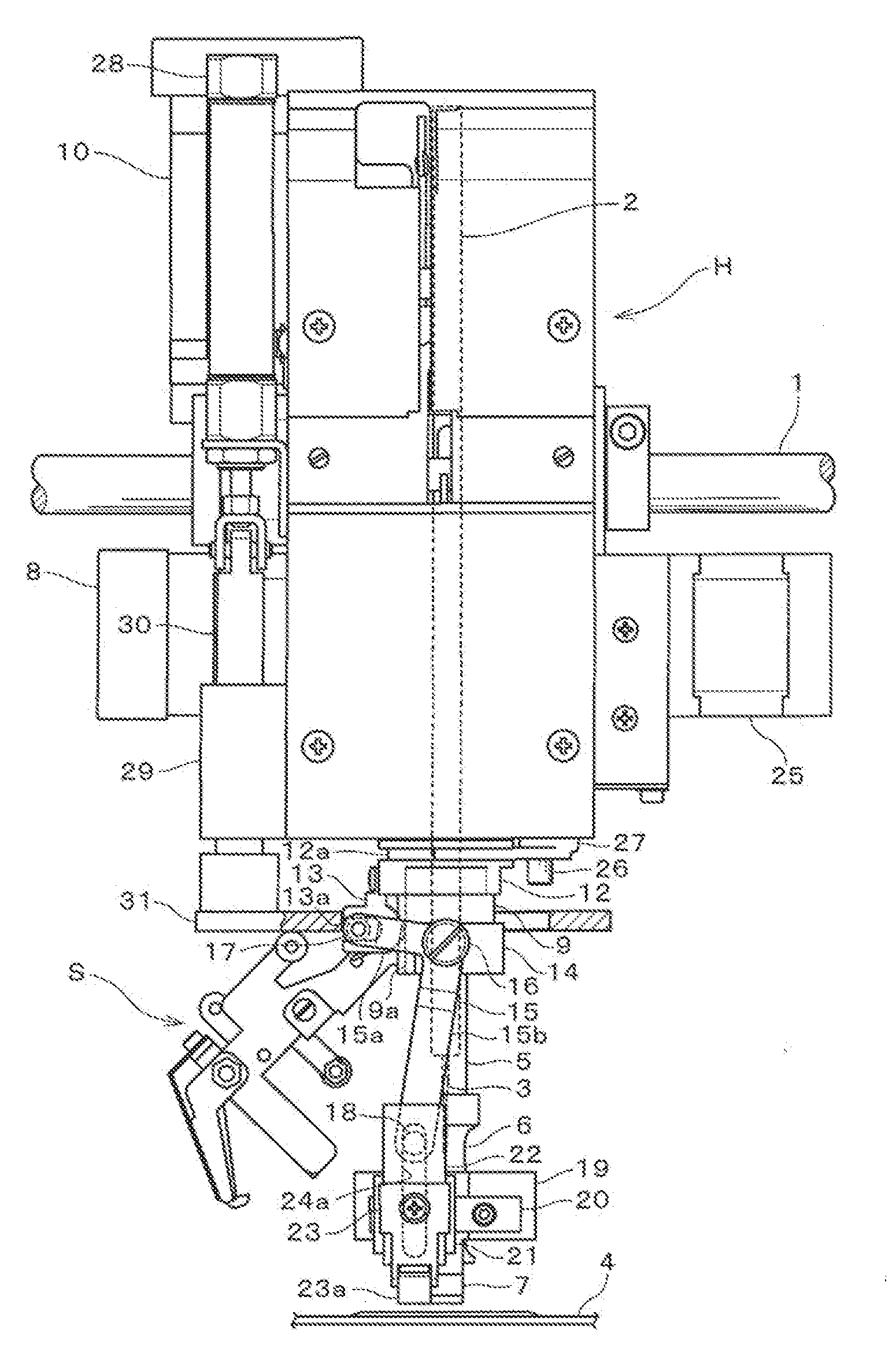

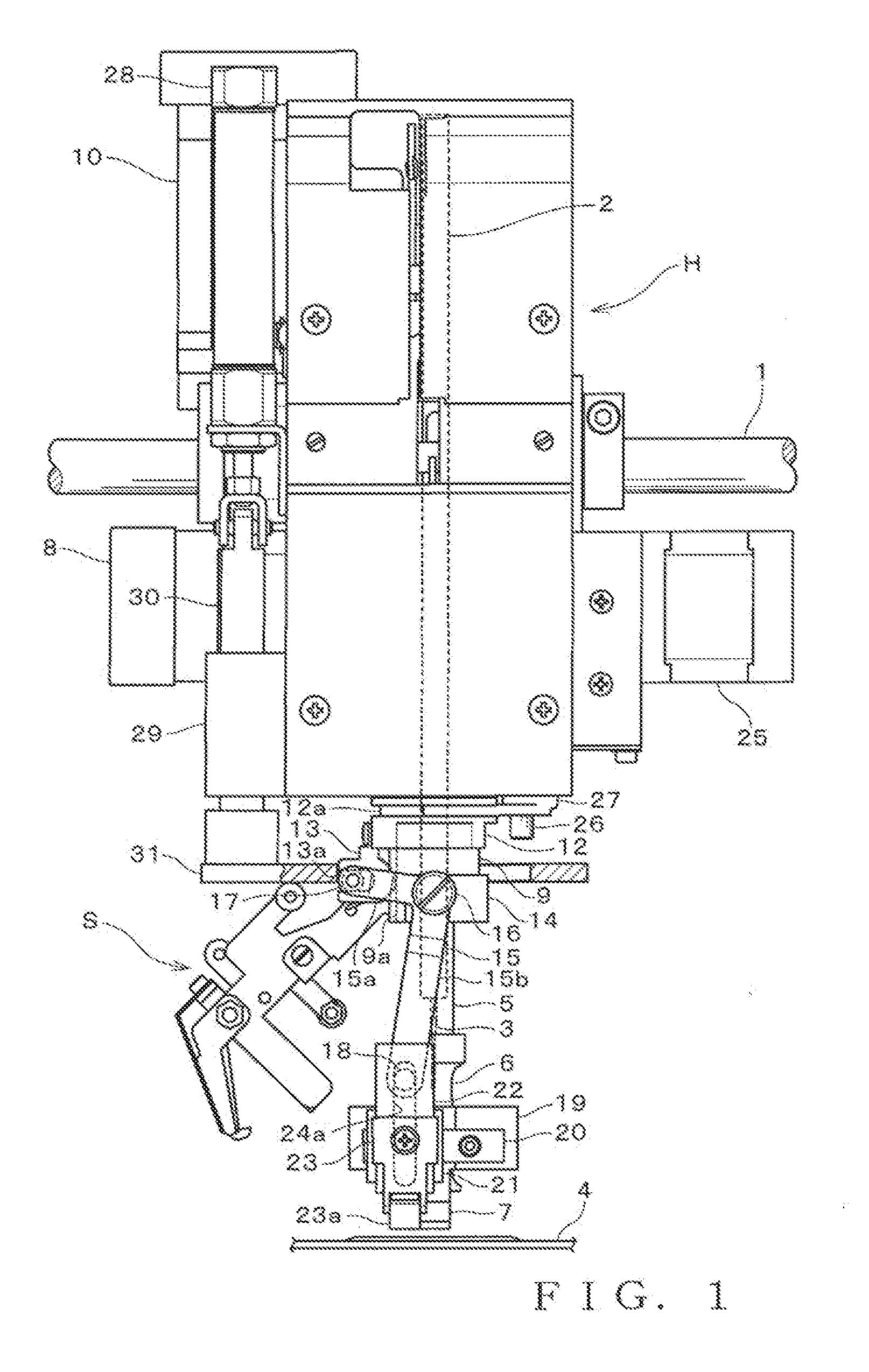

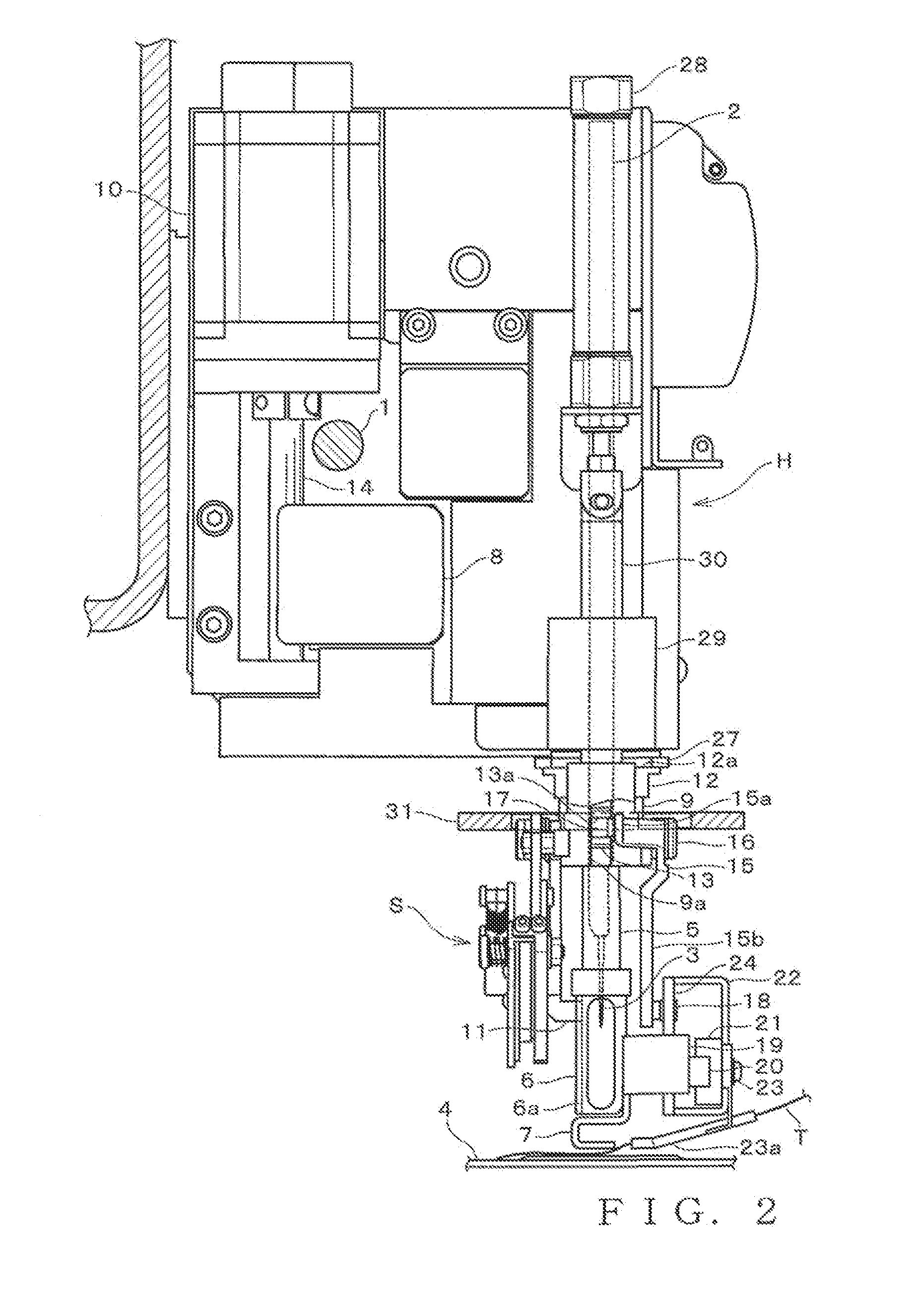

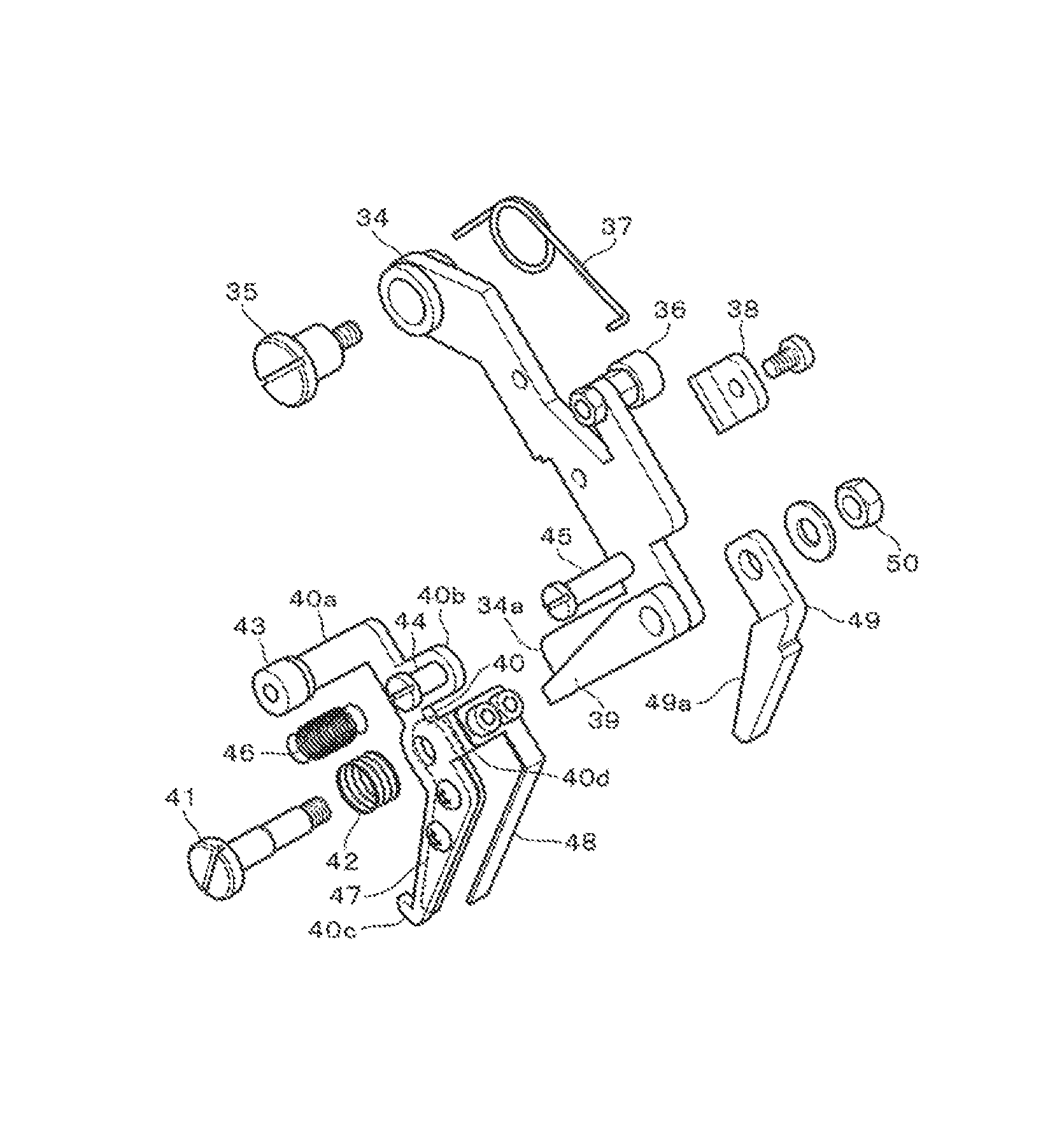

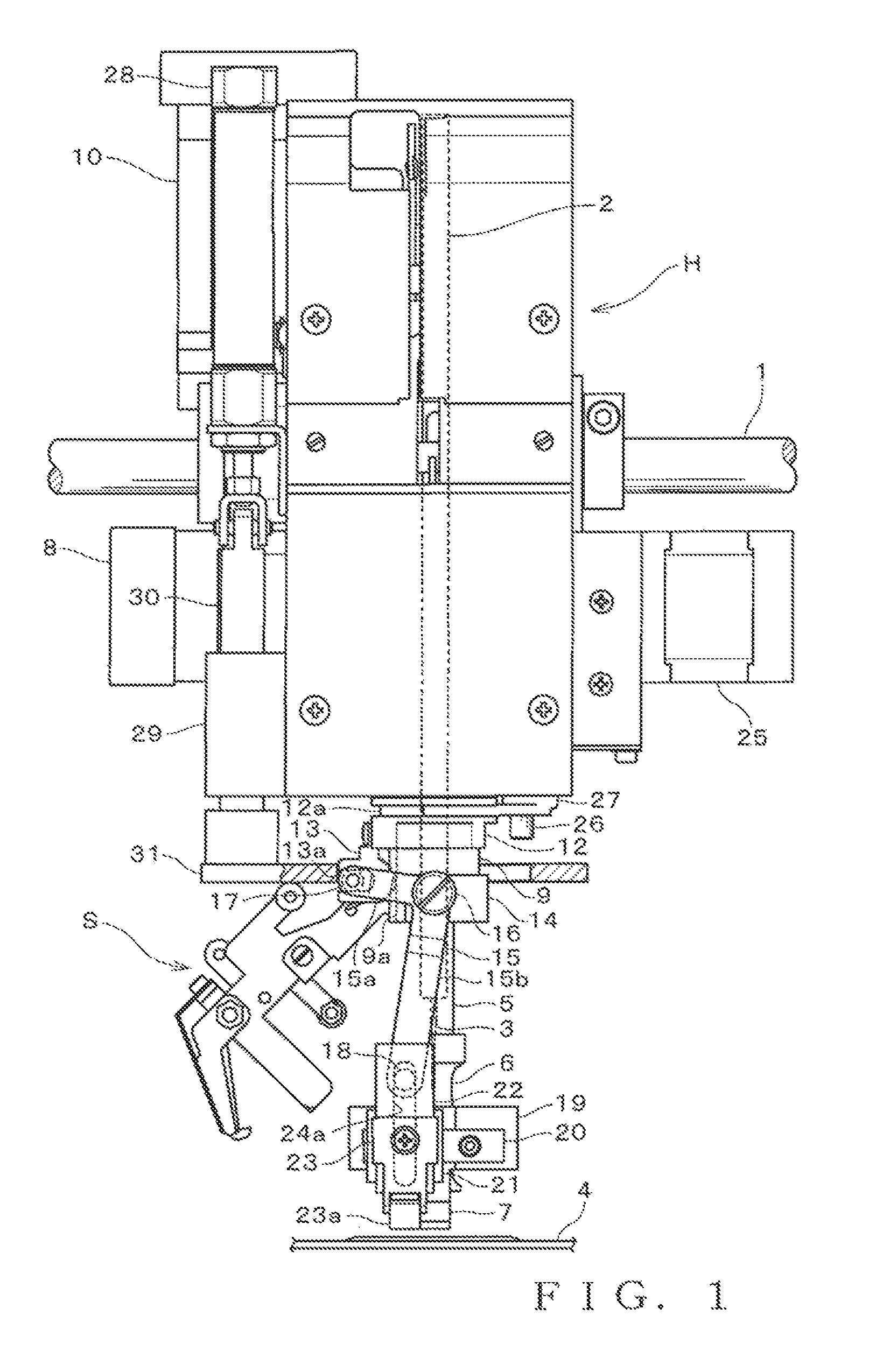

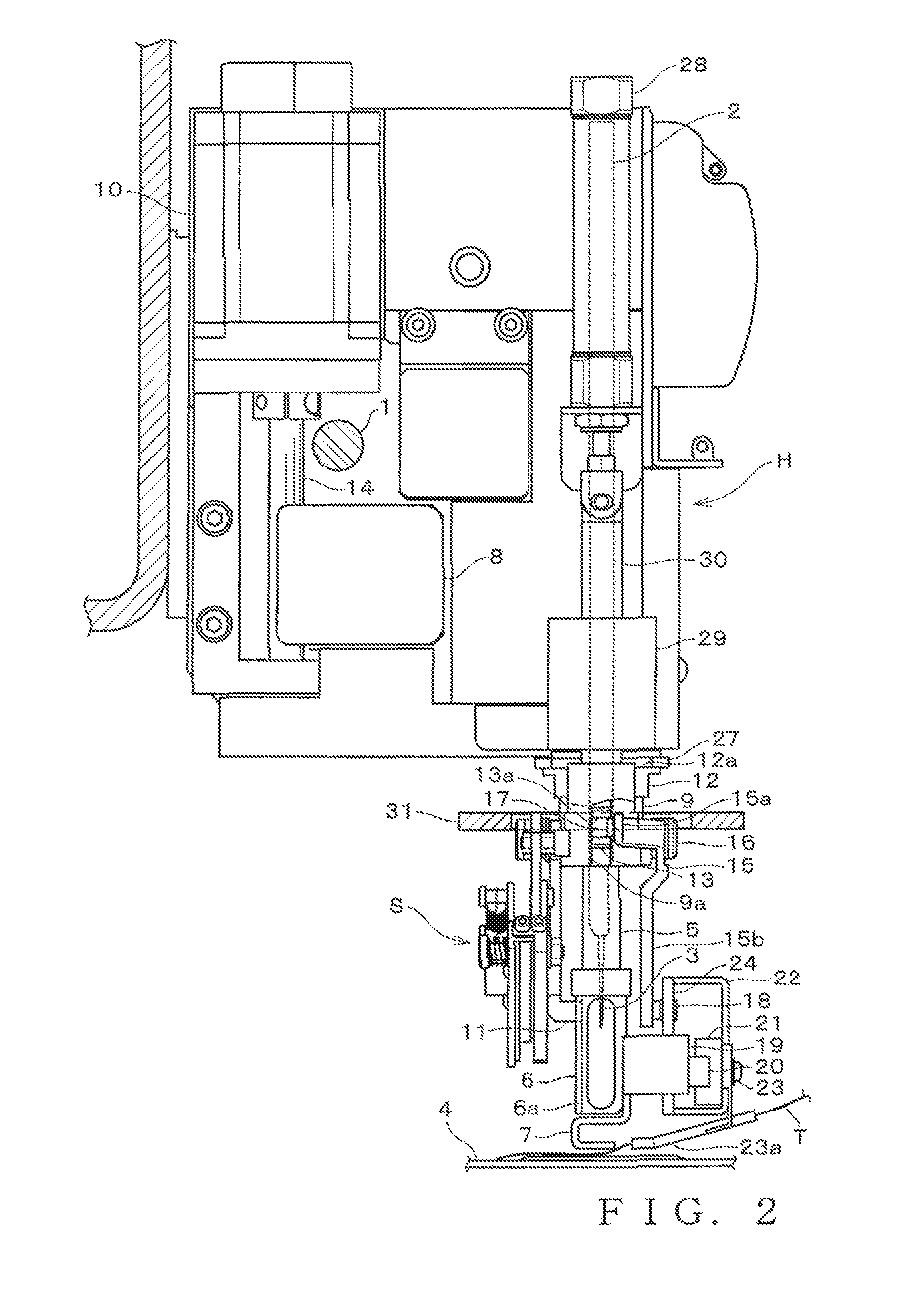

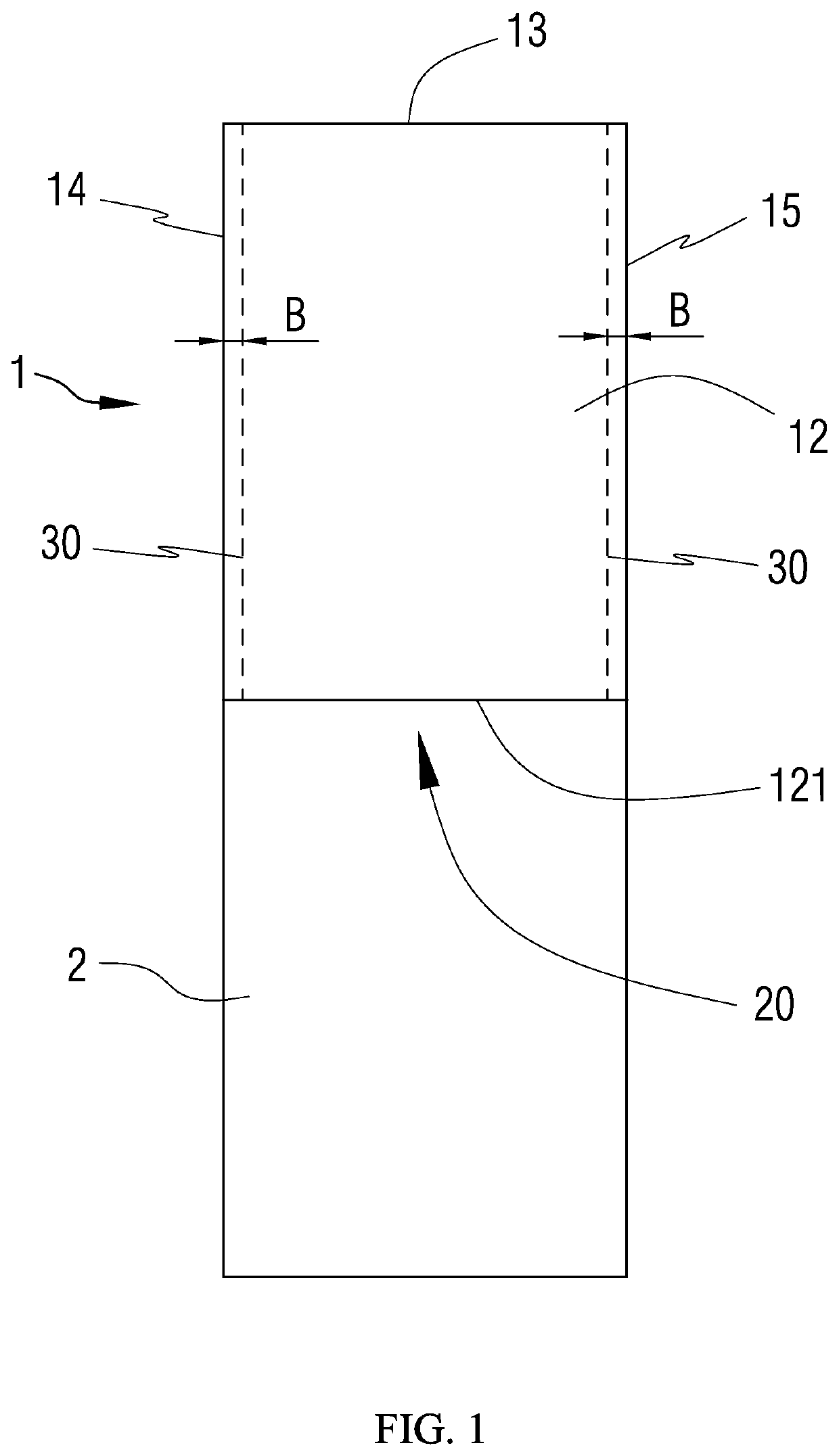

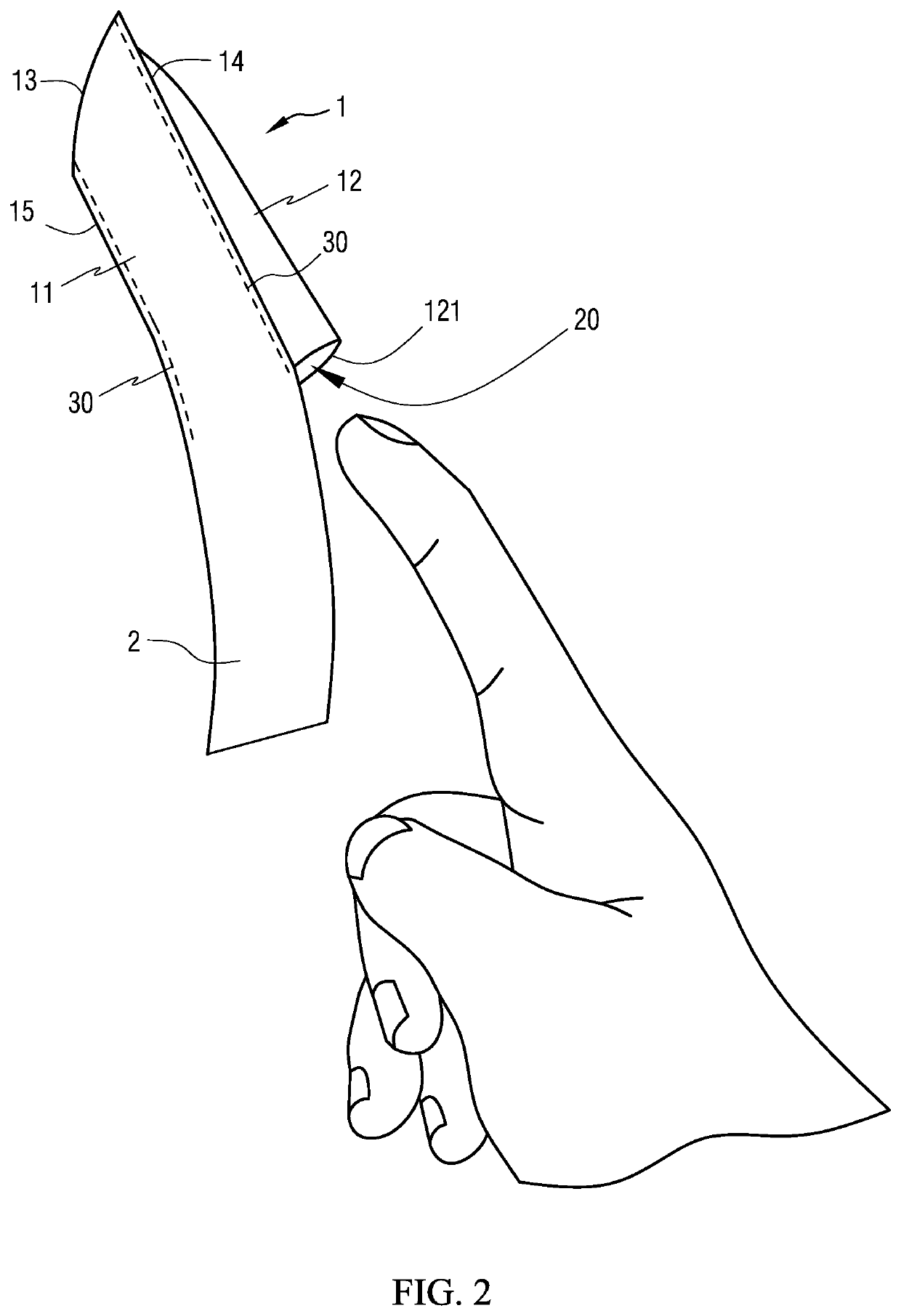

Sewing machine

ActiveUS20110253021A1Avoid wastingAvoid wasting materialWorkpiece carriersWork-feeding meansEngineeringSewing needle

A guide is mounted to a rotary member which is freely rotatable about the axis of a needle bar, and guides a sewing material to a needle drop position of the sewing needle. A cutter device is mounted to a side of the rotary member opposed to the guide in such a manner that the cutter device is rotatable together with the rotary member for cutting the sewing material, having been paid out from the guide, at a predetermined cutting position. A retention mechanism is incorporated in the cutter device for retaining an end portion of the sewing material, at a position closer to the guide than the predetermined cutting position and in interlocked relation to cutting, by the cutter device, of the sewing material. Thus, upon restart of sewing of the sewing material, the retention mechanism retains an end portion of the sewing material.

Owner:TOKAI IND SEWING MACH CO LTD

Cleaning box and method for cleaning pipe by utilizing the same

InactiveUS20070079464A1Prevent leakageEasy to cleanFouling preventionSuction cleanersEngineeringExhaust pipe

A cleaning box used to catch the waste materials from a vacuum pipe of a working machine is provided. The present invention is characterized in that the cleaning box includes a catch inlet and an air outlet wherein the catch inlet is connected to the vacuum pipe of the working machine, and the air outlet is connected to an exhaust pipe of an exhaust apparatus. That the cleaning box has high rigidity can prevent the cleaning box from breaking and the waste materials from leaking out of the cleaning box.

Owner:UNITED MICROELECTRONICS CORP

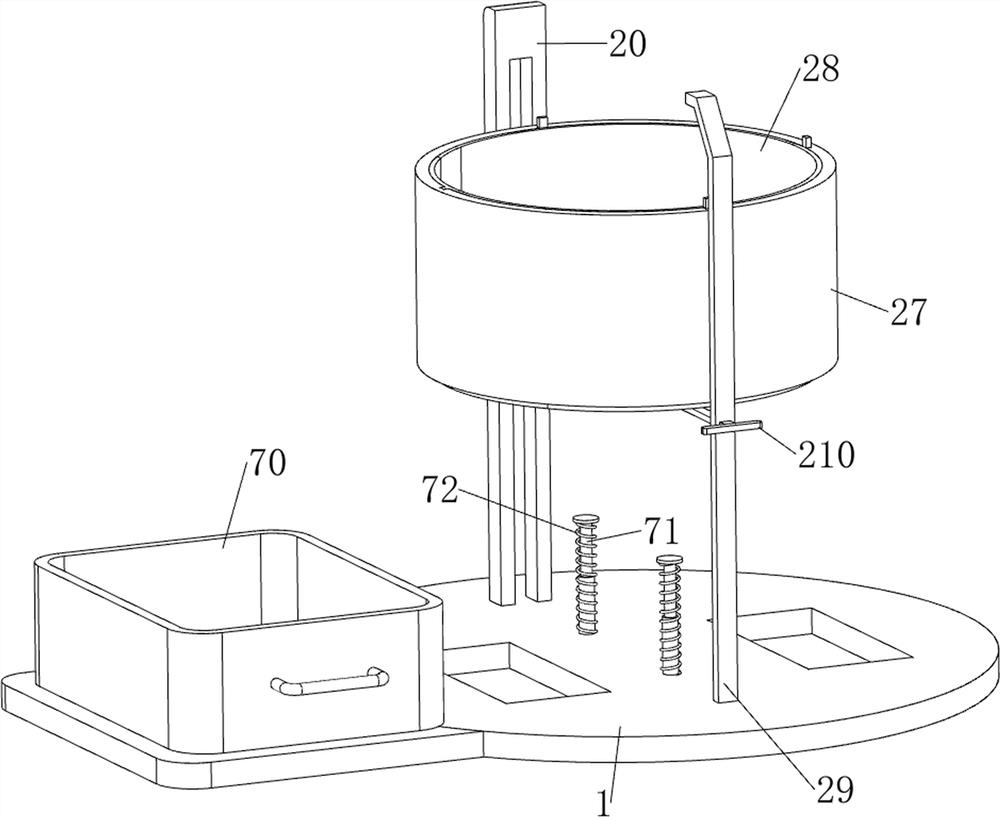

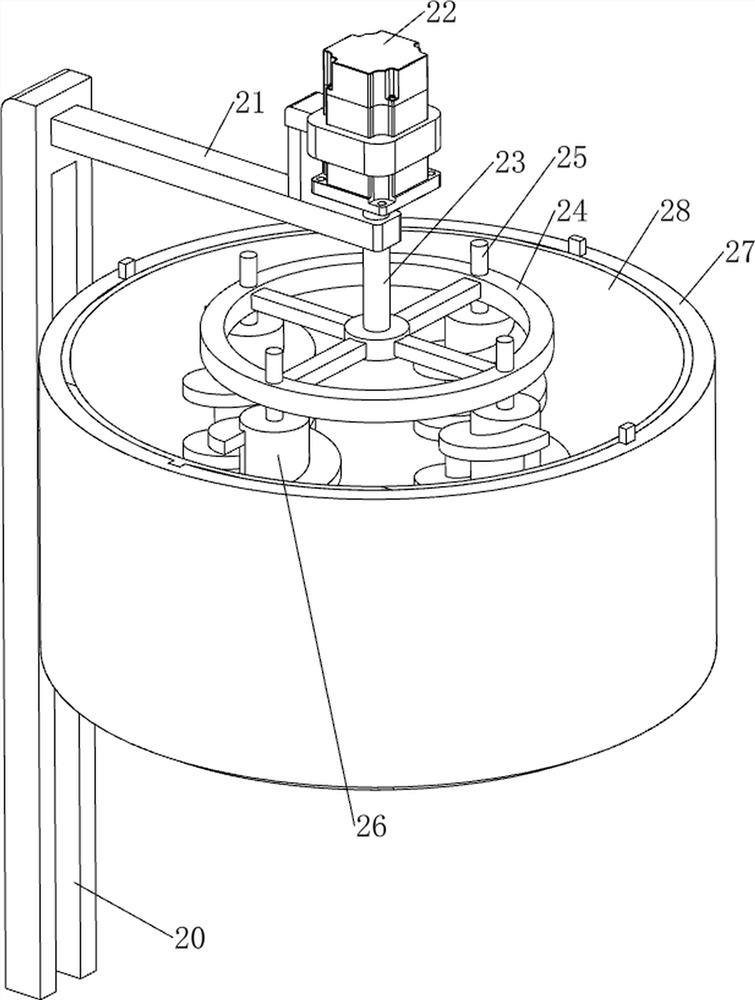

Household flour stirring device

PendingCN113080728AAvoid wasting materialPlay a buffer roleKitchen equipmentProcess engineeringEnvironmental geology

Owner:李彬

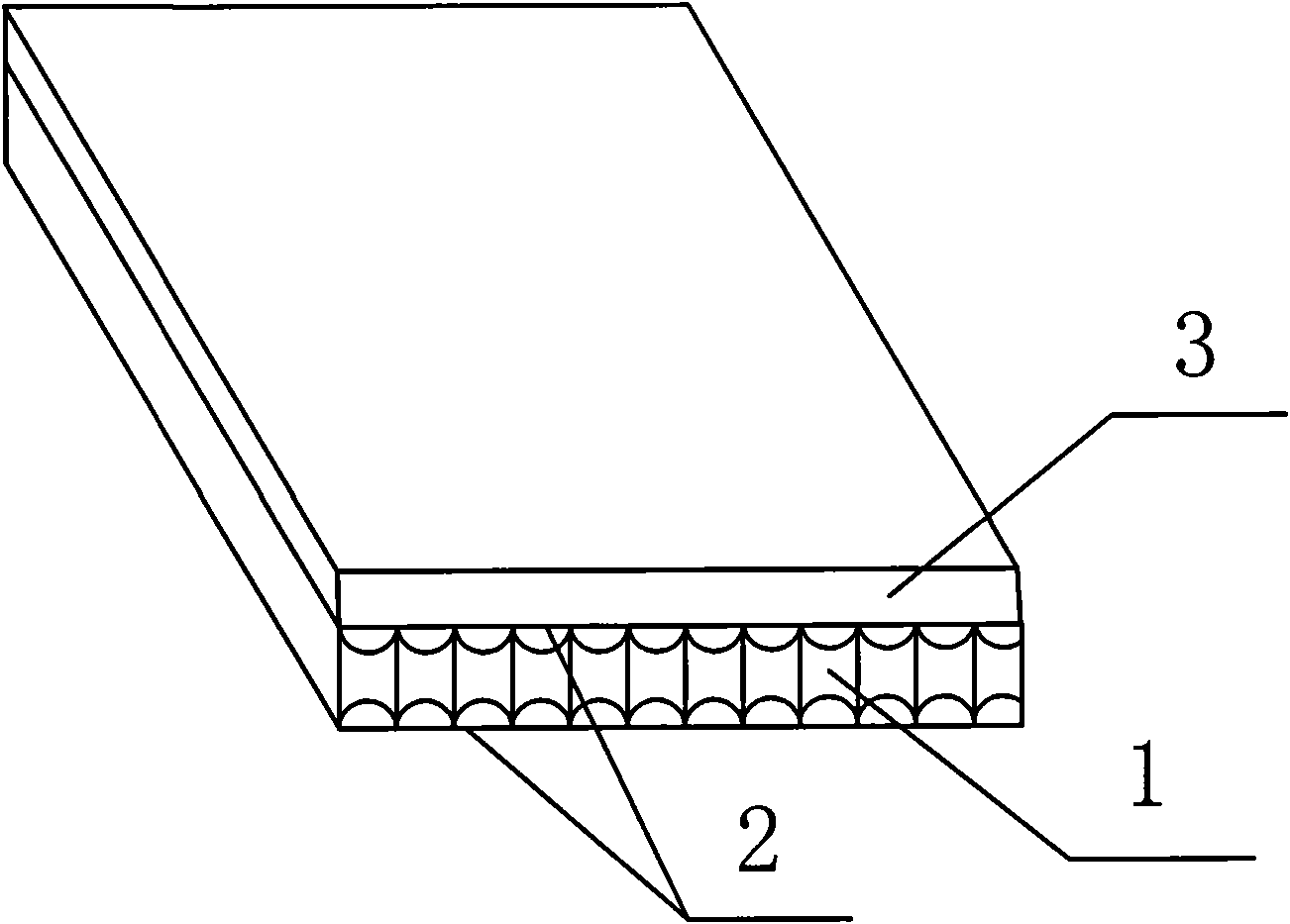

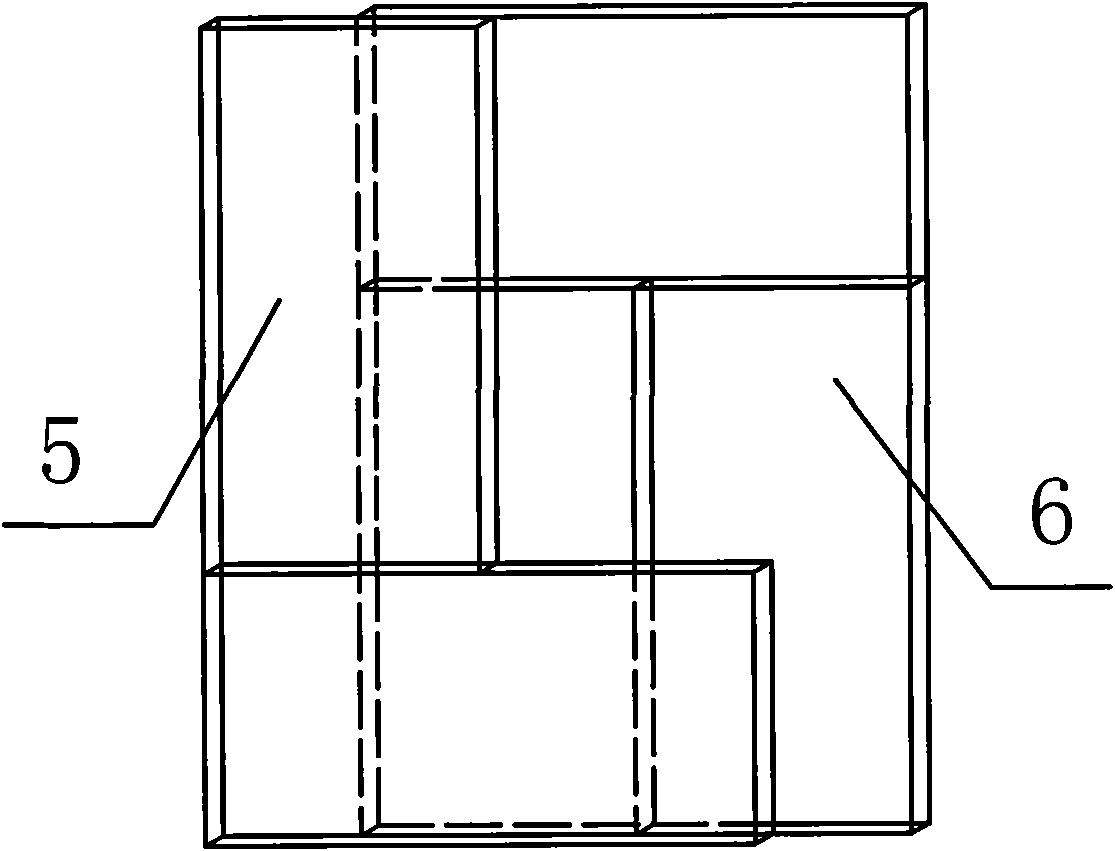

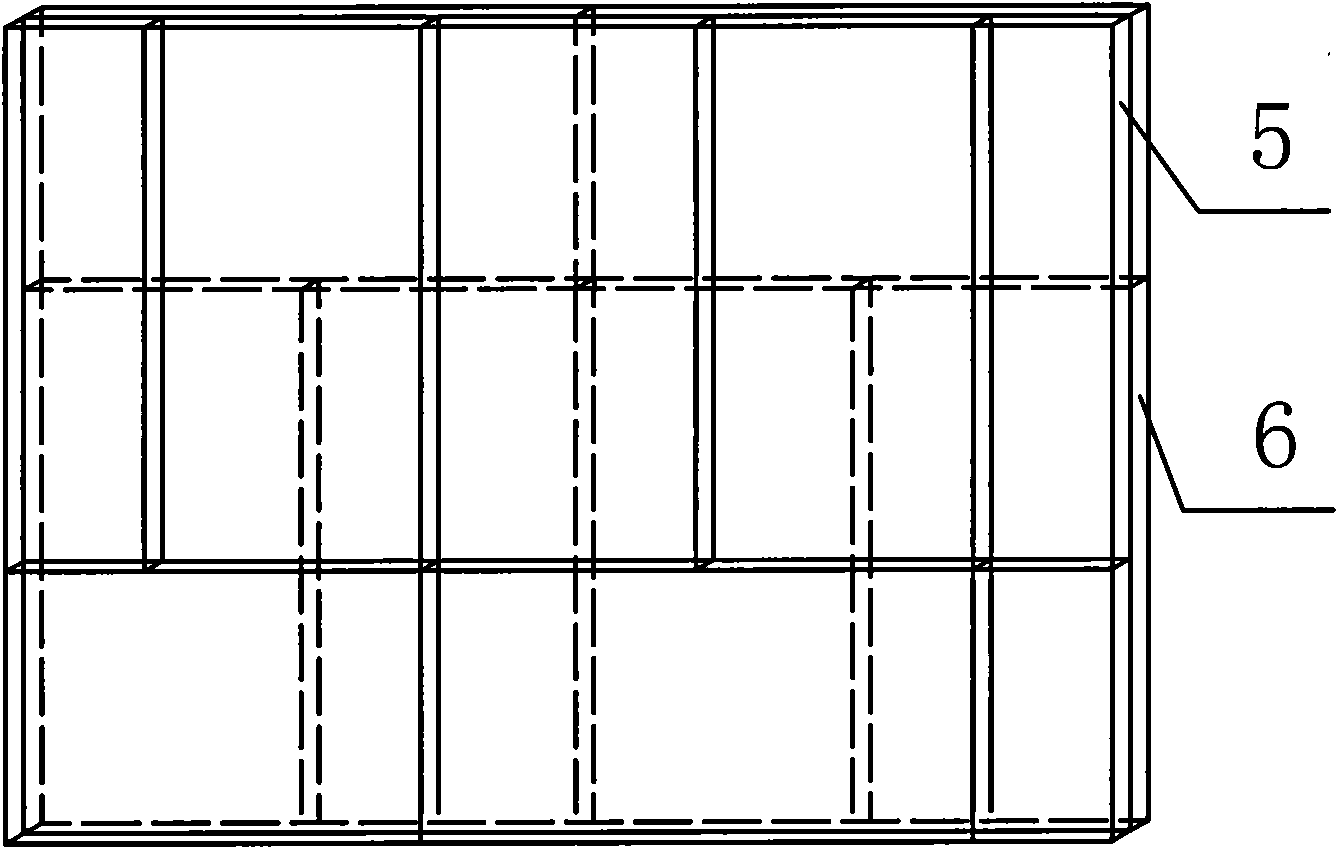

Installation method for wall constructed by honeycomb veneer

The invention relates to an installation method for the wall constructed by honeycomb veneers. When in construction, the honeycomb wall is designed in a way that the honeycomb veneers at two sides arestaggerly spliced so as to combine into a whole. Compared with the prior integral wallboard, the walls are connected with no need of a keel, and only honeycomb veneers are staggered and spliced; without the keel, the internal layers of the walls completely take the honeycomb paper as the sandwich core, and the sound insulation and thermal insulation effects are better because the keel is no longer utilized for partition. When being impacted by an external force, the stressed member is the integral wall instead of the single wall or the prior connecting keel, thereby improving the integral bearing capacity of the wall; and therefore, the problem that the material is wasted because the prior large forming board is needed to be cut when different internal partition walls are installed is also avoided.

Owner:贾丽萍

Sewing machine

ActiveUS8844453B2Avoid wastingAvoid wasting materialWorkpiece carriersWork-feeding meansEngineeringSewing needle

A guide is mounted to a rotary member which is freely rotatable about the axis of a needle bar, and guides a sewing material to a needle drop position of the sewing needle. A cutter device is mounted to a side of the rotary member opposed to the guide in such a manner that the cutter device is rotatable together with the rotary member for cutting the sewing material, having been paid out from the guide, at a predetermined cutting position. A retention mechanism is incorporated in the cutter device for retaining an end portion of the sewing material, at a position closer to the guide than the predetermined cutting position and in interlocked relation to cutting, by the cutter device, of the sewing material. Thus, upon restart of sewing of the sewing material, the retention mechanism retains an end portion of the sewing material.

Owner:TOKAI IND SEWING MACH CO LTD

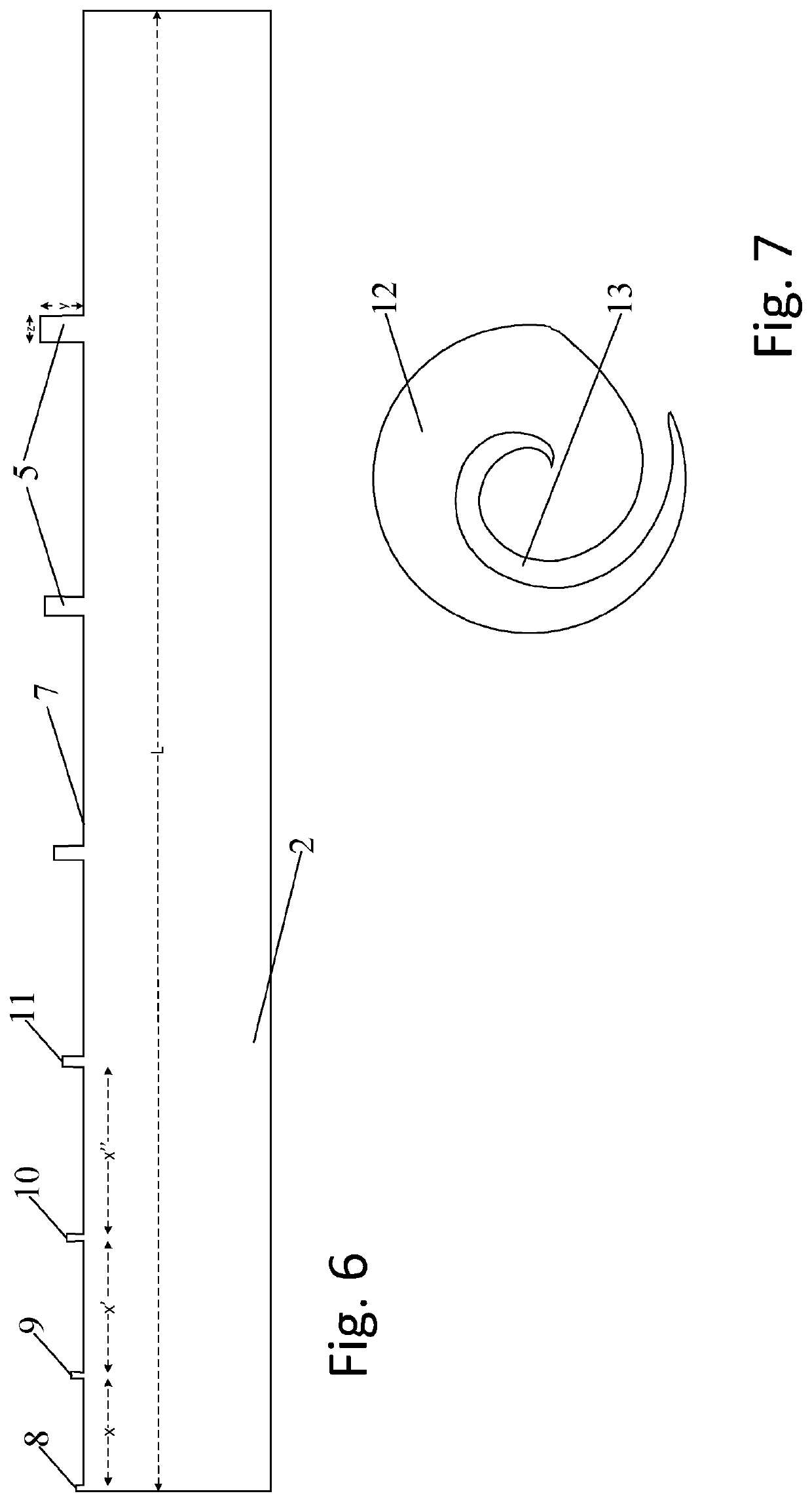

Laser engraving device for plastic spectacle frame

InactiveCN108067738AAvoid wasting materialReduce use costLaser beam welding apparatusMoving partsEngineering

The invention discloses a laser engraving device for a plastic spectacle frame. The laser engraving device is characterized in that a first driving device (5) is arranged at the left end of a cross beam (4), and the cross beam (4) is internally provided with a first screw rod connected with the first driving device (5); the first screw rod is movably connected with a longitudinal moving part (6),and the longitudinal moving part (6) is controlled to move left and right through the first driving device (5); a second driving device (7) is arranged at the top end of the longitudinal moving part(6), and the longitudinal moving part (6) is internally provided with a second screw rod connected with the second driving device (7); the second screw rod is movably connected with a moving seat (8),a laser engraving part (9) is fixed on the moving seat (8), and the laser engraving part (9) is controlled to move up and down through the second driving device (7); and a material clamping seat (12)arranged on a workbench (2) is driven to move forwards and backwards by a third driving device (10). The laser engraving device is simple in structure and convenient and rapid to operate.

Owner:江苏裕昌光学眼镜有限公司

Short-cut control method for materials

InactiveCN106176051AAvoid wastingAvoid wasting materialAbsorbent padsBaby linensAutomatic controlProgrammable logic controller

The invention relates to the field of manufacture of hygienic products and provides a short-cut control method for materials. The method comprises the following steps: (1) a PLC (programmable logic controller) is arranged between a material short-cut mechanism and a host controlling the material short-cut mechanism, that is, the host controls the material short-cut mechanism to cut the materials through the PLC; (2) the material short-cut mechanism starting speed is set on the PLC, that is, start and stop for the material short-cut are controlled by modifying the product length cut by the material short-cut mechanism on a program running by the PLC; (3) a detector for detecting the running state of a glue application mechanism is arranged at the glue application mechanism, the running information, detected by the detector in real time, of the glue application mechanism is sent to the PLC, and the PLC controls running of the material short-cut mechanism automatically according to the running state of the glue application mechanism. The method solves the problems of material waste, cleaning inconvenience, labor consumption and the like of the conventional material short-cut mechanism.

Owner:QUANZHOU HANWEI MACHINERY MFG

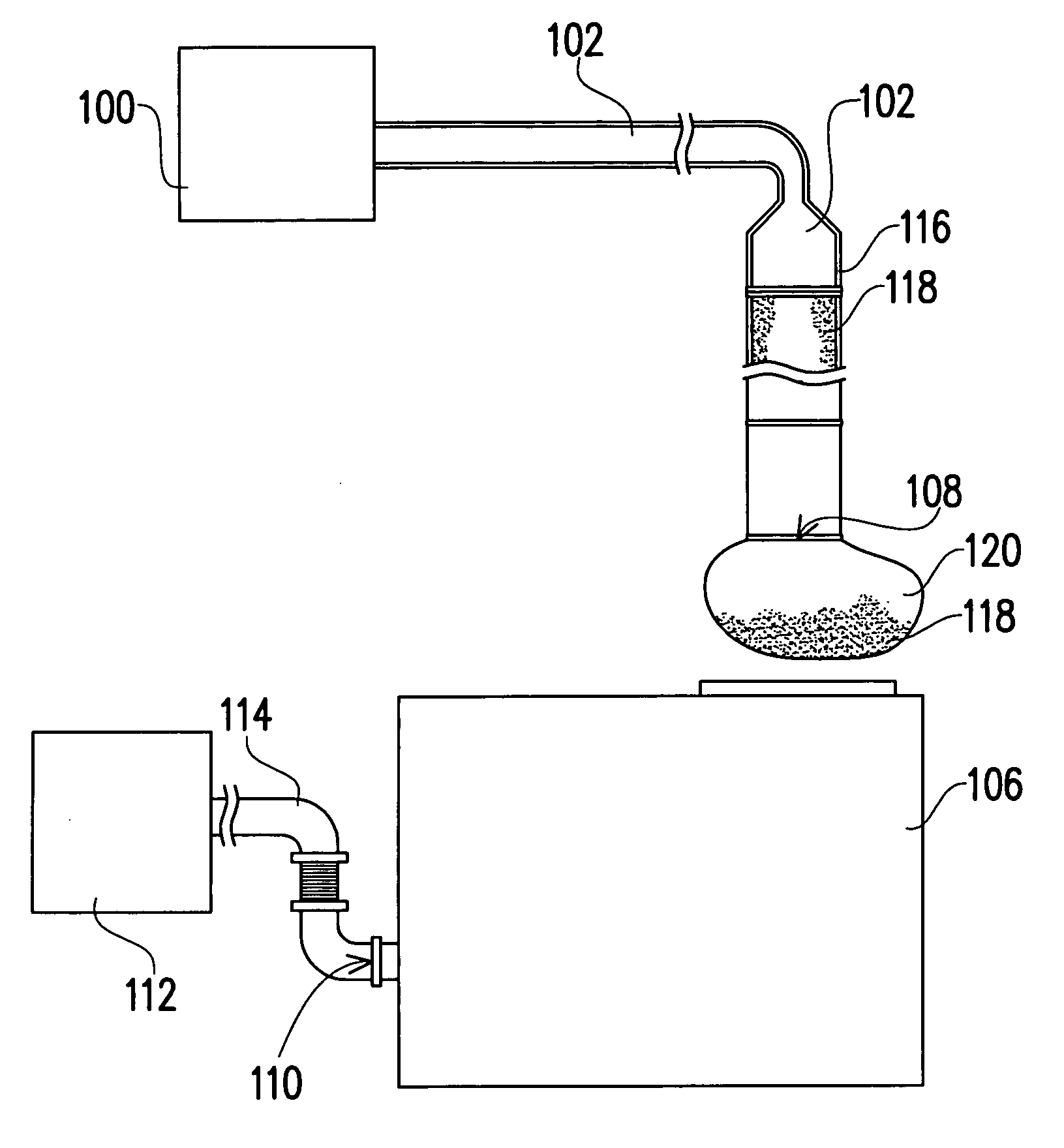

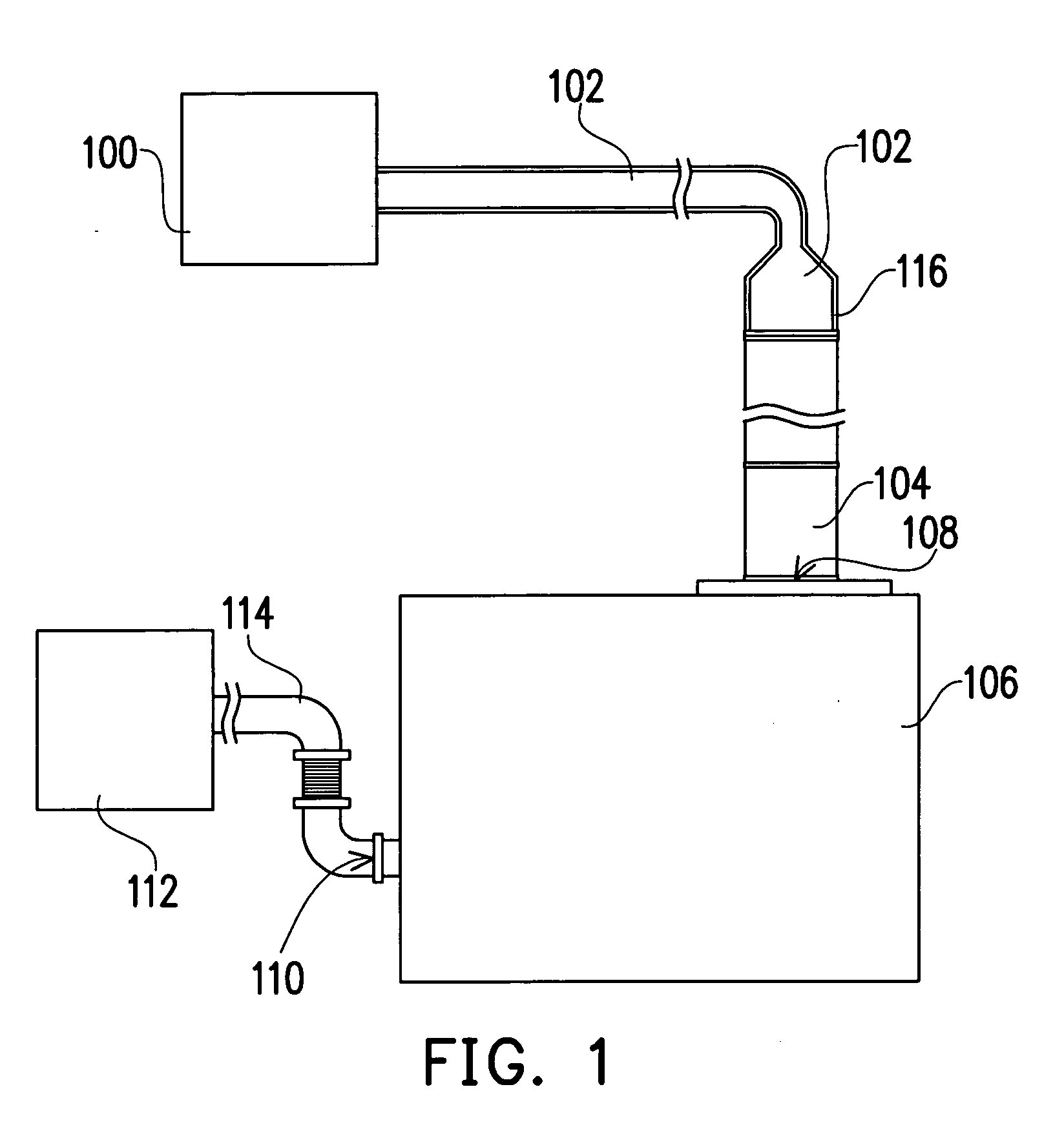

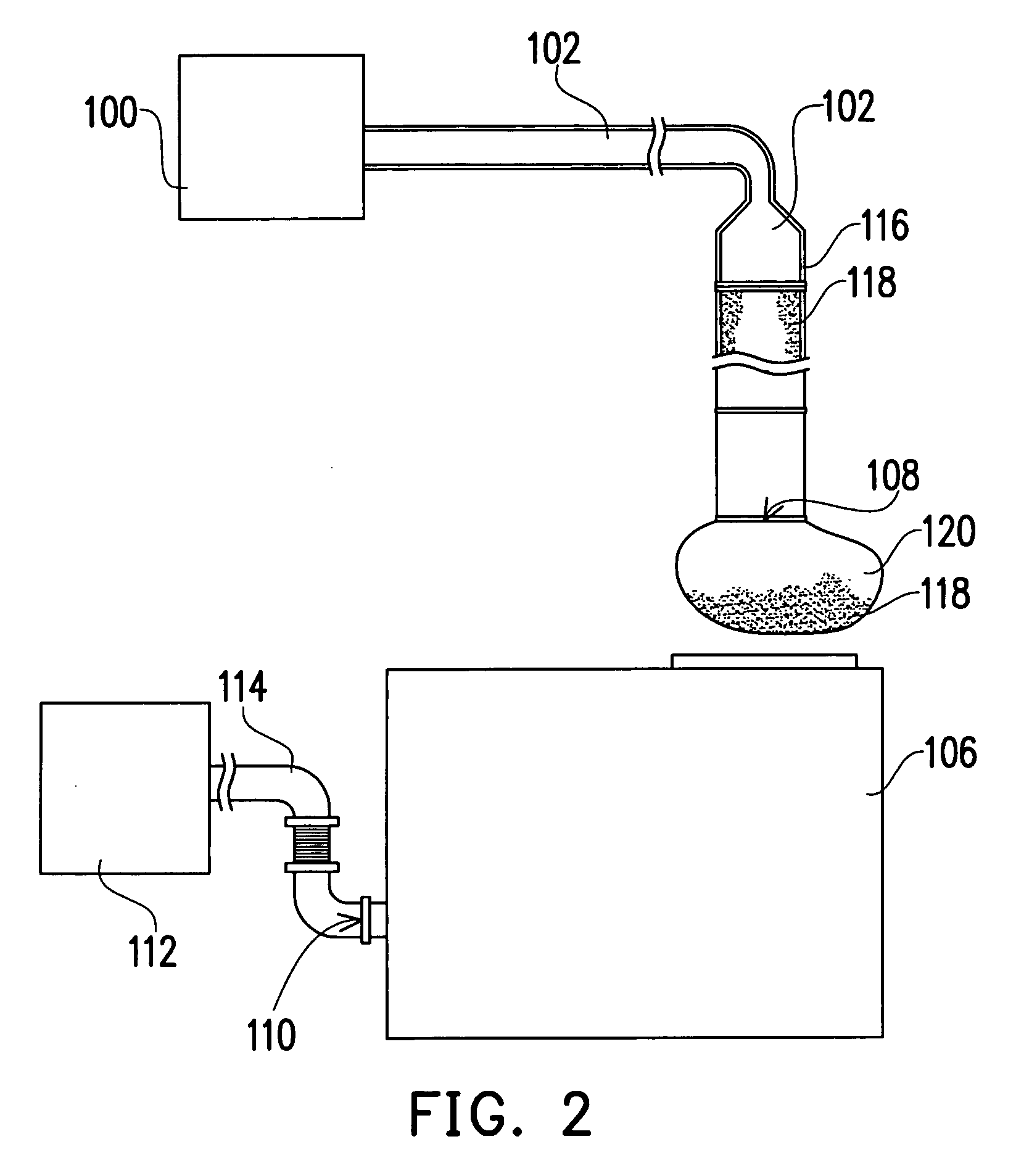

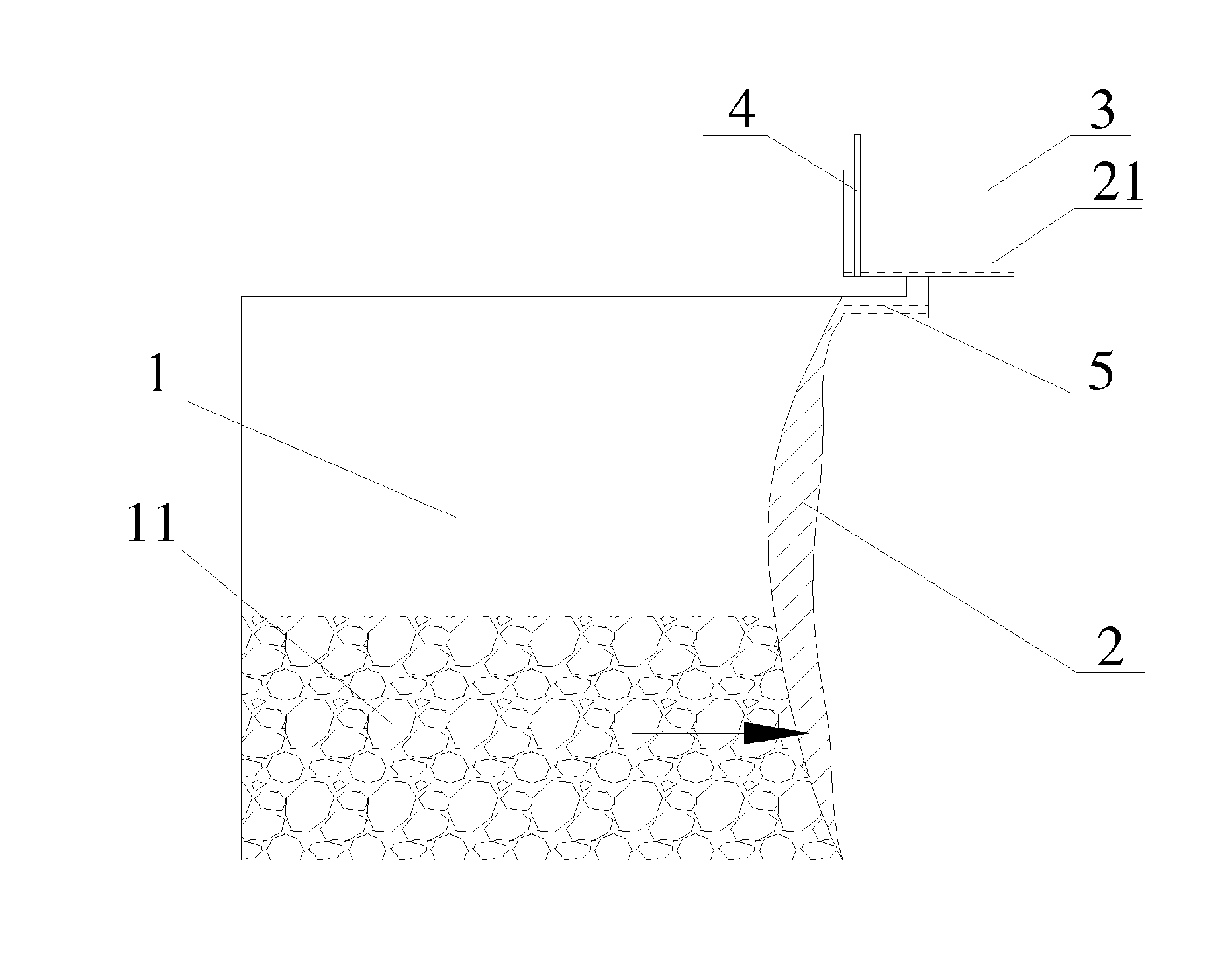

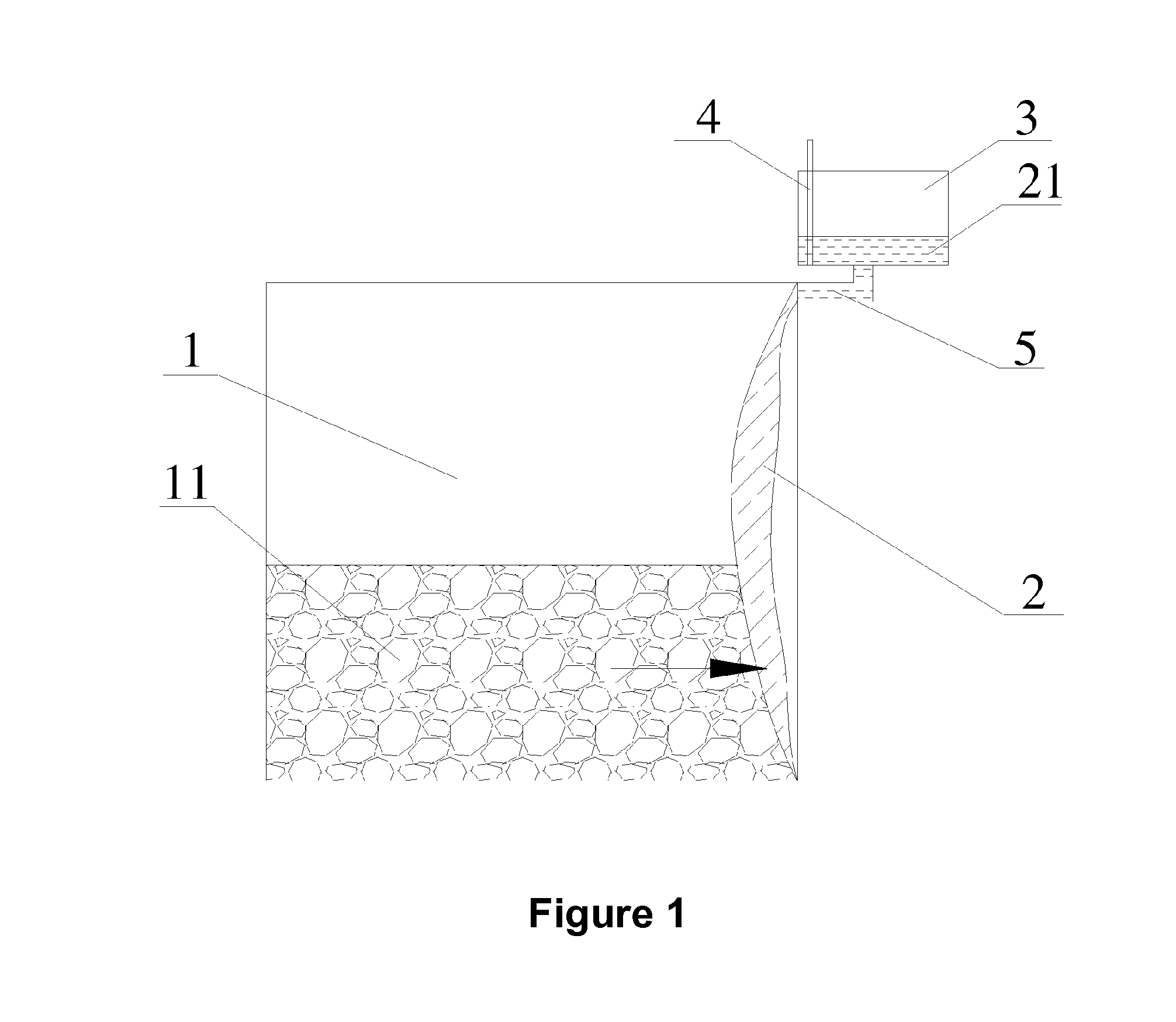

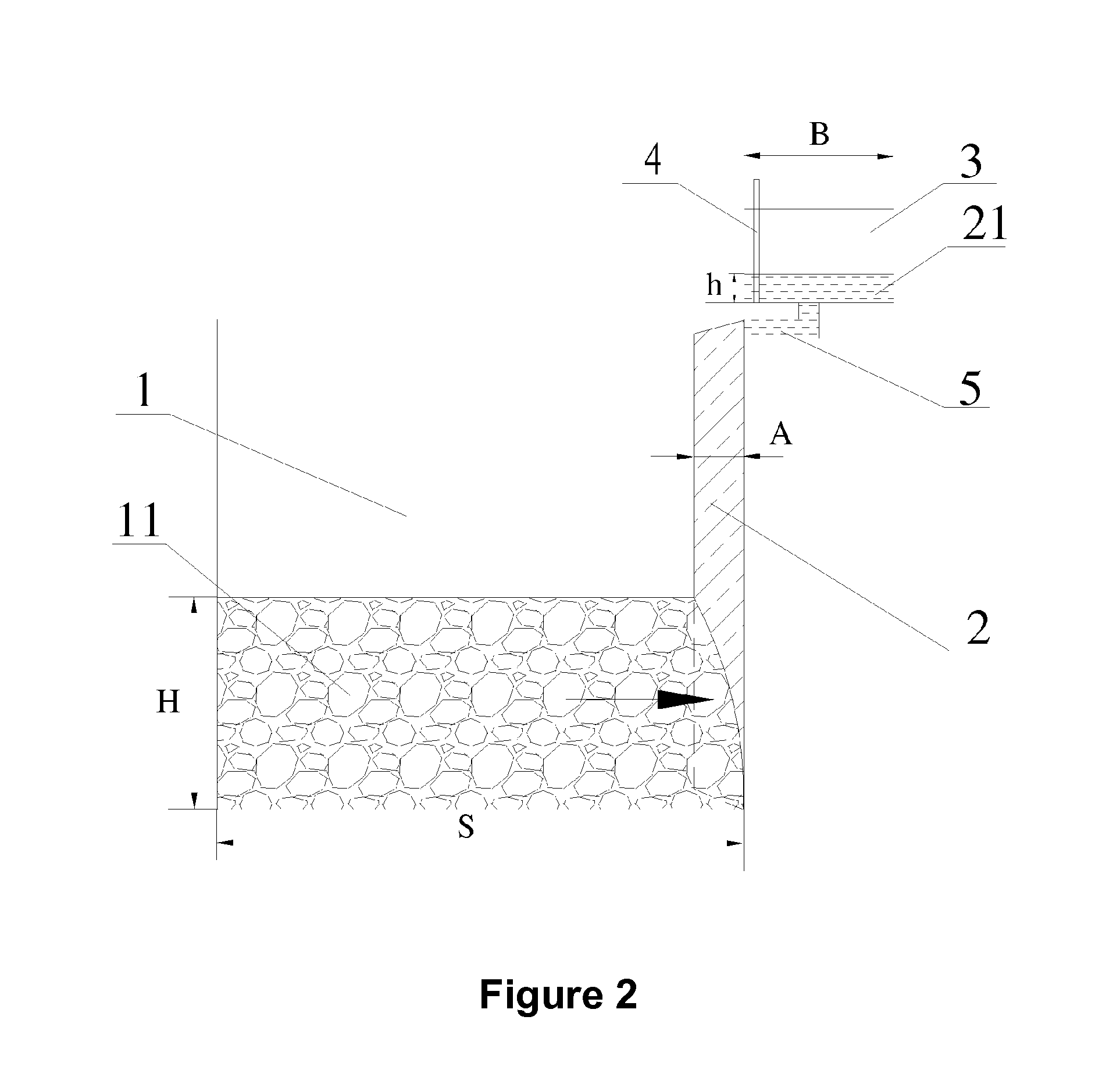

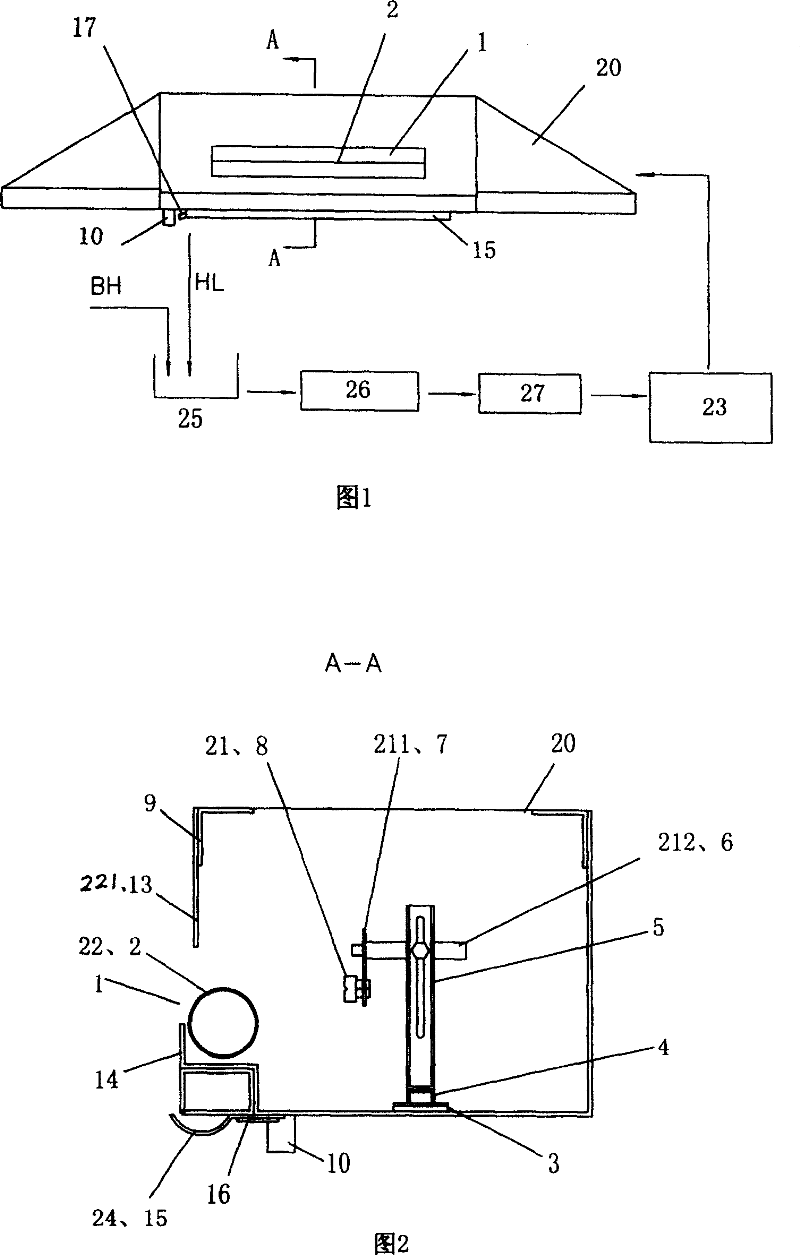

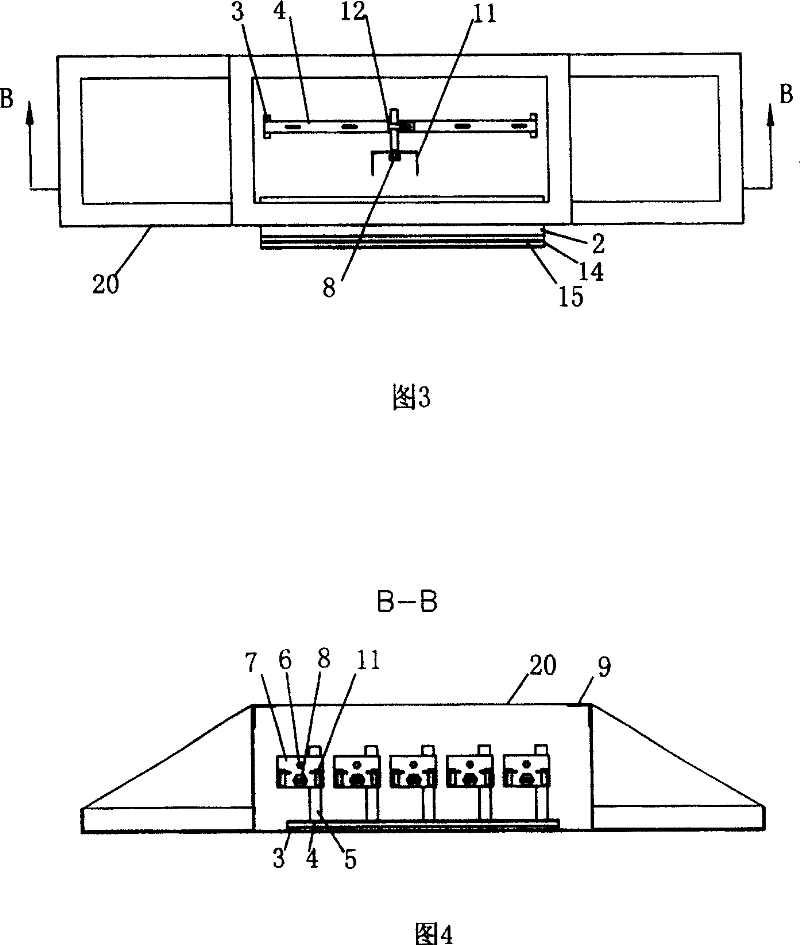

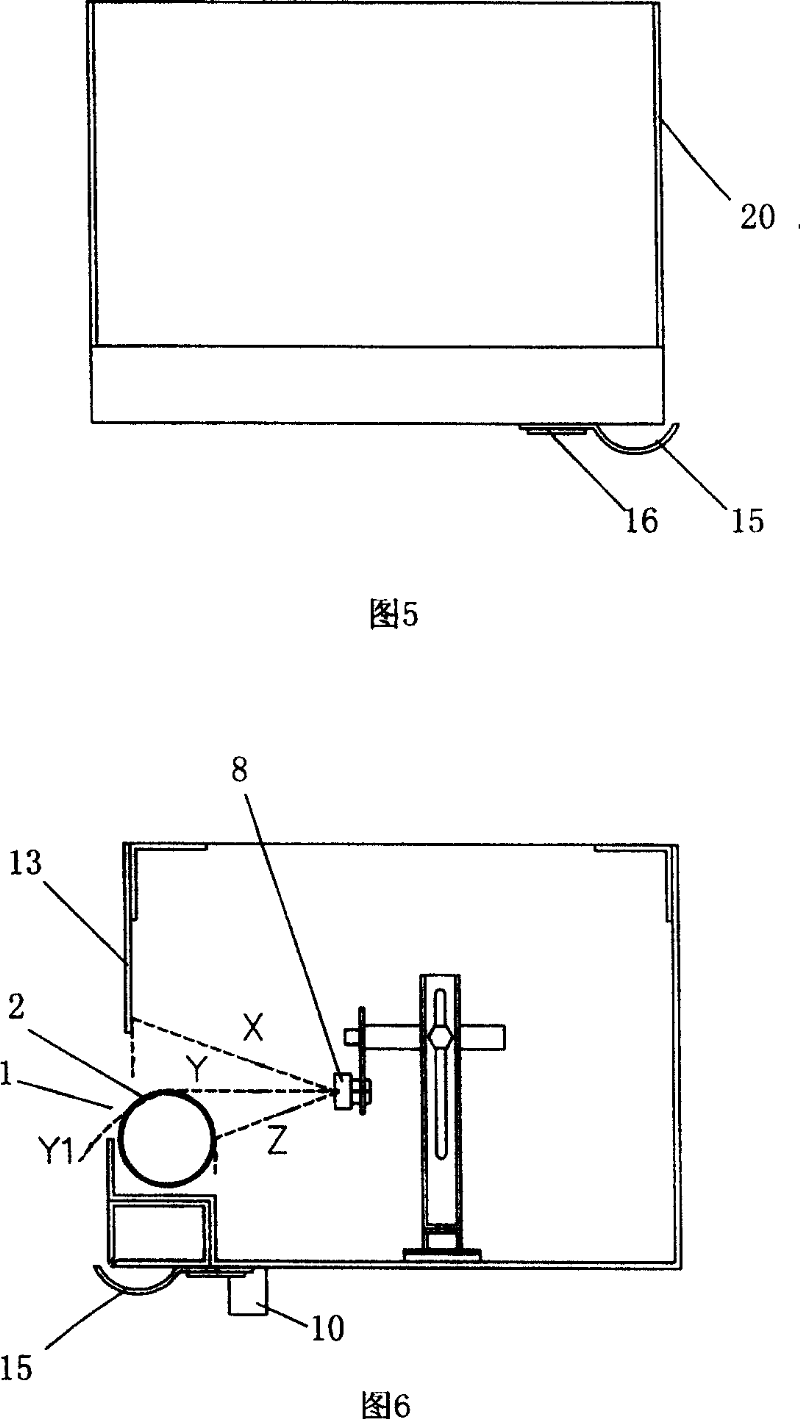

Detecting device and pumping equipment for concrete

InactiveUS20140314585A1Control speedAvoid wasting materialPump controlContainer/cavity capacity measurementEngineeringConcrete pump

A detecting device for detecting the volume of a material in a material container and a concrete pumping apparatus comprising the above detecting device are disclosed. The detecting device comprises a soft container full of a medium; a medium container in communication with the soft container; a volume detecting sensor for detecting the volume of the medium in the medium container; the soft container is provided within the material container and immersed in the material of the material container, and under the extrusion of the material, the medium in the soft container enters the medium container, the volume detecting sensor detects the volume of the medium in the medium container; and the volume of the material can be calculated according to a preset relationship between the volume of the medium in the medium container and the volume of the material in the material container.

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP CO LTD & SANY HEAVY IND

Tennis training device and tennis training system

The present invention involves a cleaning sleeve for cleaning the oral cavity, suitable to be applied over a finger or a tool to clean the inside of the oral cavity. The cleaning sleeve has a flat-layered structure comprising a sleeve portion formed by laminated sheet-like fabrics and a grip portion formed by a single-layer sheet-like fabric, wherein the sleeve portion comprises a working layer and a sleeve layer; the working layer and the sleeve layer form a head at the top, of the cleaning sleeve; and the grip portion is integrally extended from the Working layer. The cleaning sleeve is formed by ultrasonically bonding the two sides of a piece of folded degradable nonwoven fabric.

Owner:HANGZHOU JADE CLOVE SCI & TECH CO LTD

Method of preventing exposure of asbestos-containing material, method of treating asbestos-containing waste material, method of melt treating asbestos-containing waste material, asbestos-containing waste material treated article, and asbestos-containing melt treated article

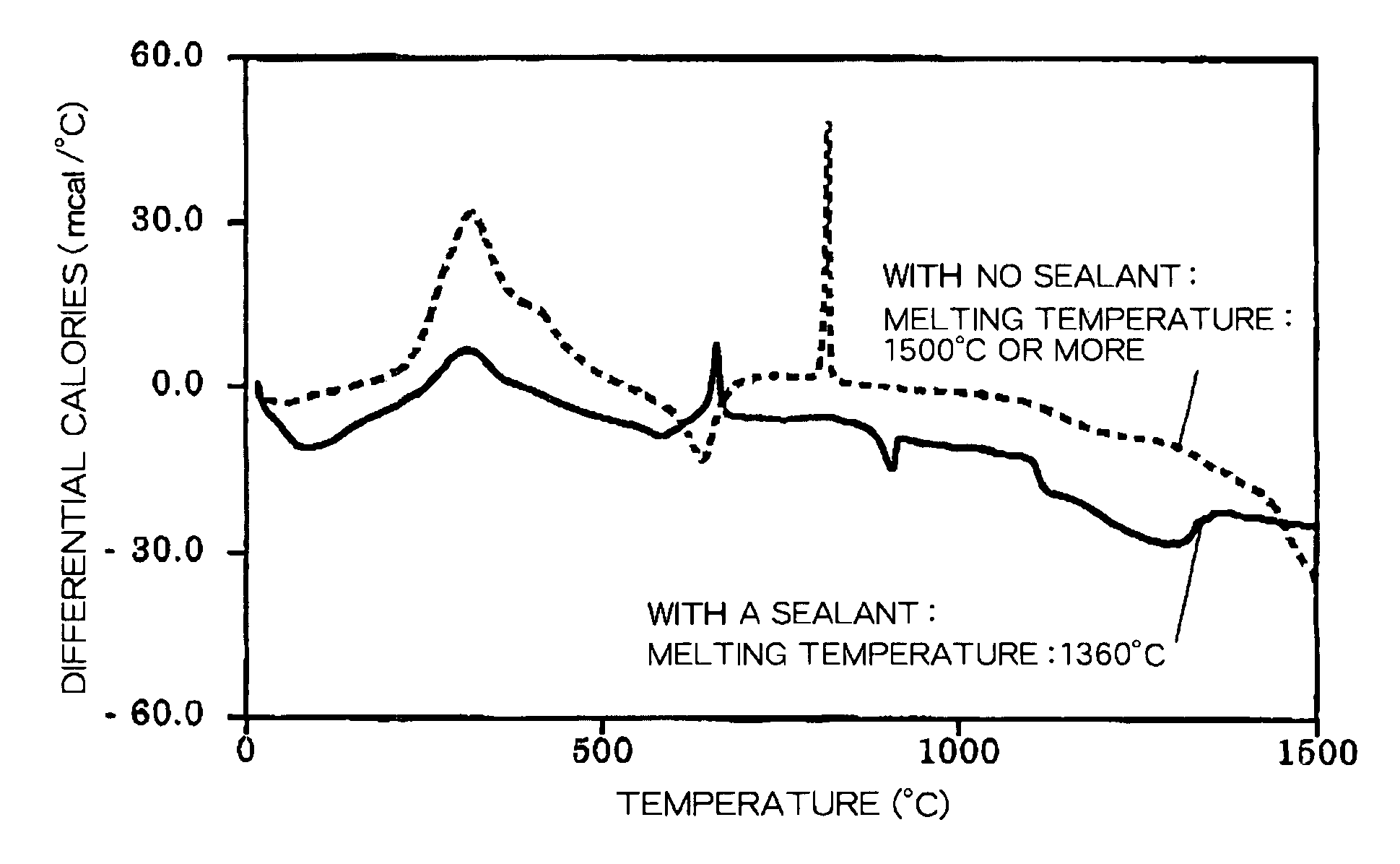

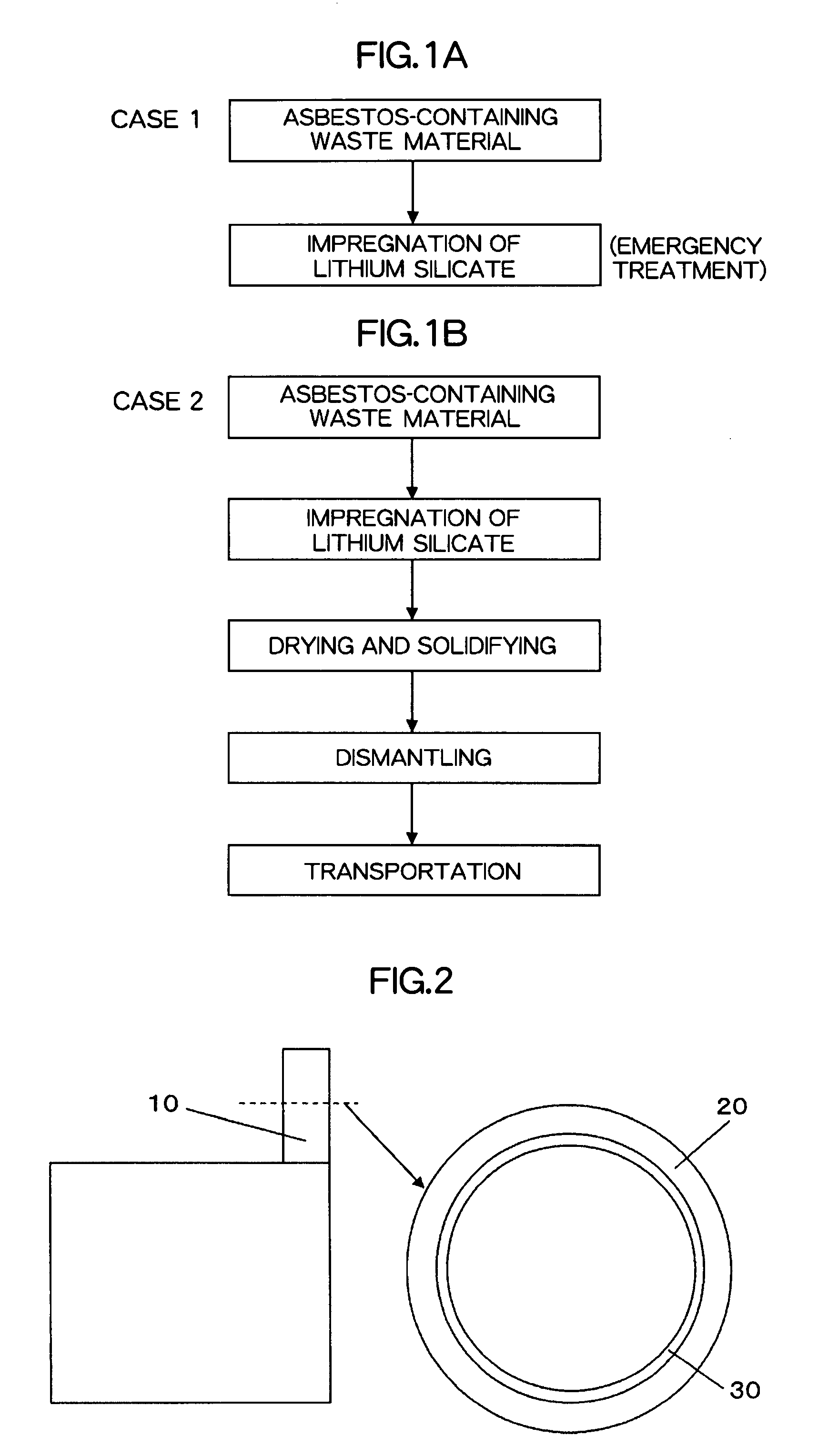

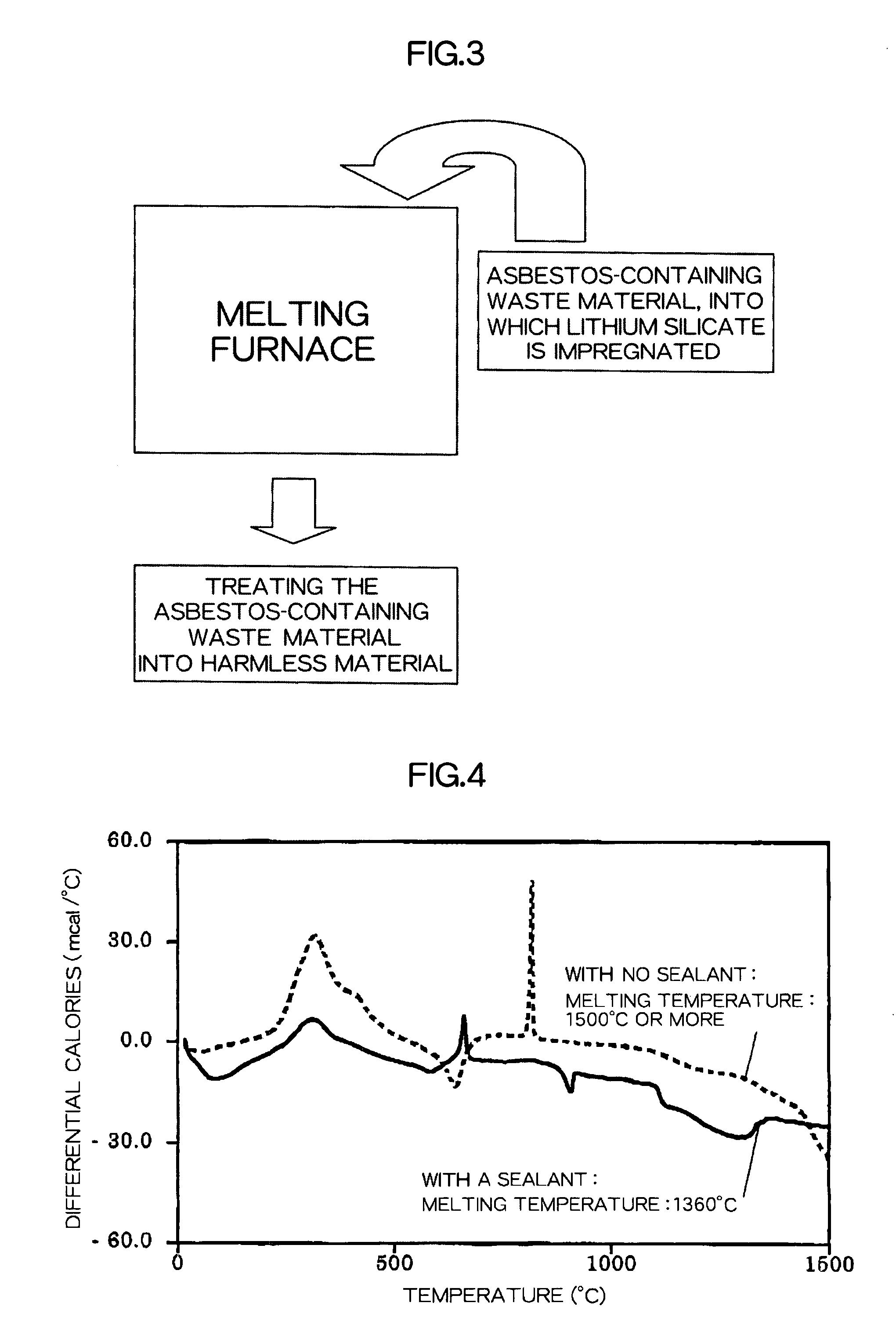

The present invention relates to a series of techniques for treating a waste material of an asbestos-containing material, from emergency treatment, dismantling, or transportation of an already constructed asbestos-containing material to a heating and melting treatment of the dismantled asbestos-containing waste material. The preset invention provides a method of preventing the exposure of the fibrous dust of the asbestos involving melting an asbestos-containing waste material, into which lithium silicate is impregnated in a melting furnace for treating an asbestos-containing material into harmless. The lithium silicate impregnated into the asbestos-containing waste material forms a gel within the range of temperatures of 500 to 1,100° C., and the formed gel adheres onto the surfaces of asbestos fibers, thereby preventing the exposure of the fibrous dust of the asbestos. Moreover, the melting temperature of asbestos can be reduced to about 1,360° C.

Owner:NICHIAS CORP

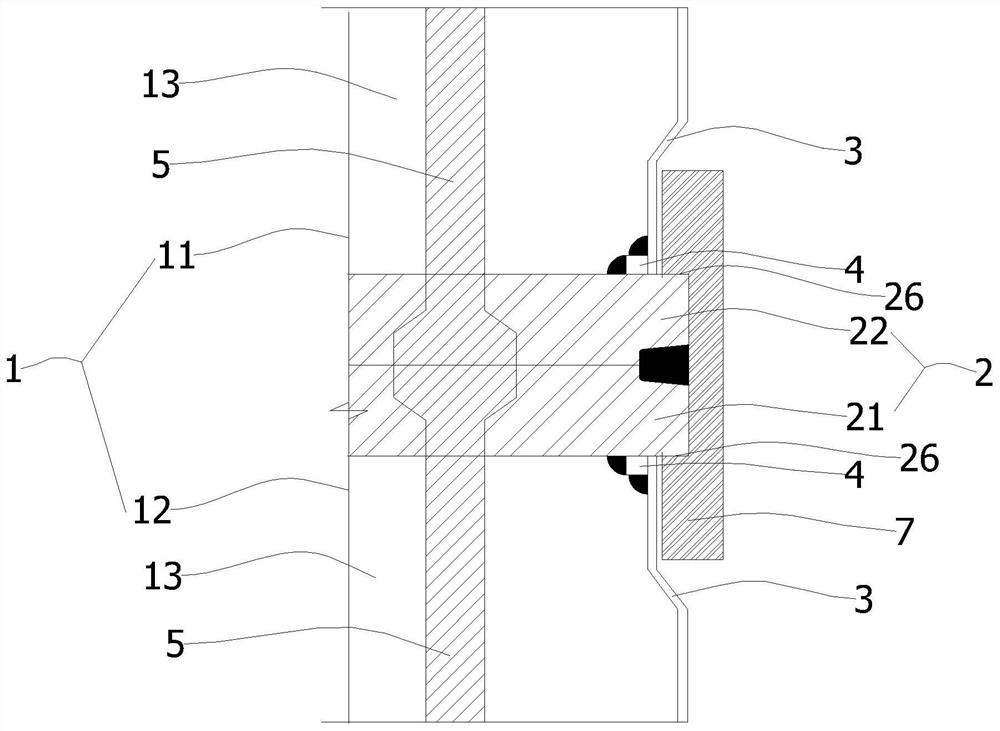

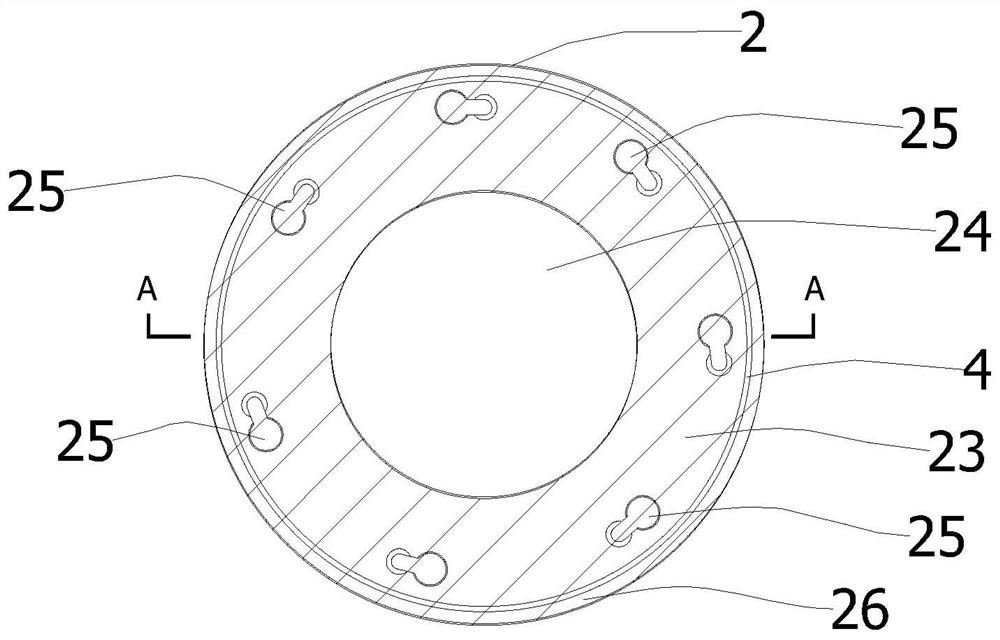

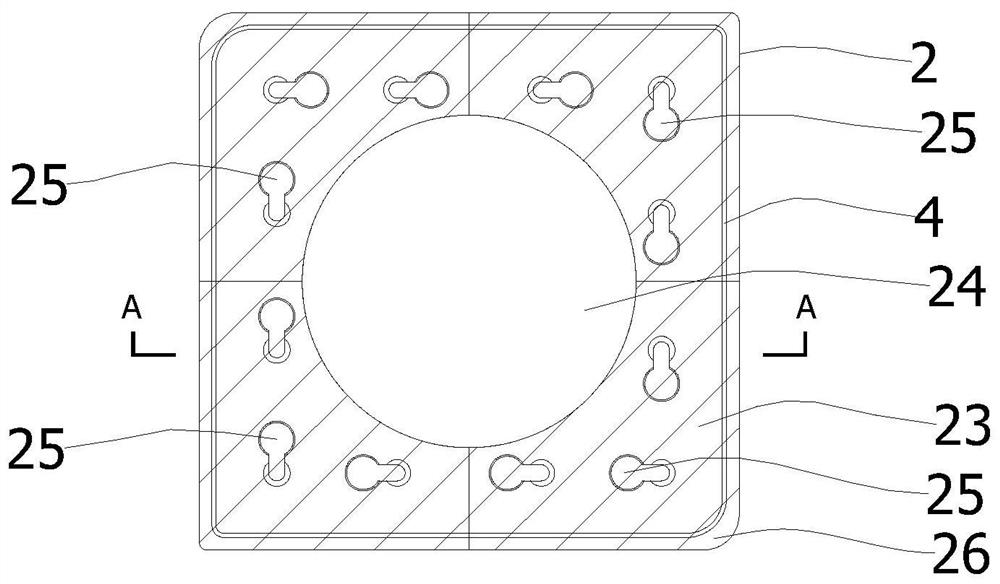

Concrete precast pile and connecting structure of concrete precast pile

PendingCN112240023AAvoid wasting materialReduce manufacturing costBulkheads/pilesStructural engineeringArchitectural engineering

The invention relates to a concrete precast pile and a connecting structure of the concrete precast pile. The concrete precast pile comprises a pile body, an end plate, an apron board and a connectingpart. The end plate is arranged at the end of the pile body, the connecting part is arranged on the end plate, the apron board is arranged on the outer surface of the pile body, one end of the apronboard is fixedly connected with the end plate, one face of the connecting part is fixedly connected with the inner side face of the apron board, and the other face of the connecting part is fixedly connected with the end plate. The connecting part plays a role in sealing, slurry is prevented from leaking from a gap where the apron board and the end plate are connected in the pile manufacturing process, material waste is avoided, the production cost is saved, environmental protection is achieved, and the stability of the concrete precast pile is improved.

Owner:FUJIAN ZHONGTUO CONSTR MATERIAL CO LTD

Spring rod preassembling structure, stamping cutter head and processing jig

ActiveCN106001225AAvoid wasting materialReduce manufacturing costMetal-working feeding devicesPositioning devicesMagnetEngineering

The invention belongs to the technical field of spring rod processing equipment, and particularly relates to a spring rod preassembling structure, a stamping cutter head and a processing jig. The spring rod pre-mounting structure comprises a preassembling baseplate and a linear slide rail, wherein a slide rail stopping block is arranged at one end of the linear slide rail, a front end positioning seat is arranged at the other end of the linear slide rail, and a back end positioning seat is arranged between the slide rail stopping block and the front end positioning seat; front placing grooves are formed in the front end positioning seat, a front spring cover plate is rotationally arranged on one side of the front end positioning seat, a cavity is arranged on the other side, away from the back end positioning seat, of the front spring cover plate, stopping parts are arranged on the groove walls of the front placing grooves and near the cavity, and a stopping block cover plate is rotationally arranged on one side of the cavity; back placing grooves are formed in the back end positioning seat, an accommodating groove communicated with the back placing grooves is also formed in the back end positioning seat, bearing grooves are correspondingly formed in the side wall of the accommodating groove, and a back end spring cover plate is rotationally arranged at the side part of the back end positioning seat; a magnet is arranged on each of the front end positioning seat and the back end positioning seat, and a connecting structure is also arranged between the front end positioning seat and the back end positioning seat. The problem that the conventional spring preassembling structure can only realize one-end stamping is solved.

Owner:QINGDAO GOERTEK

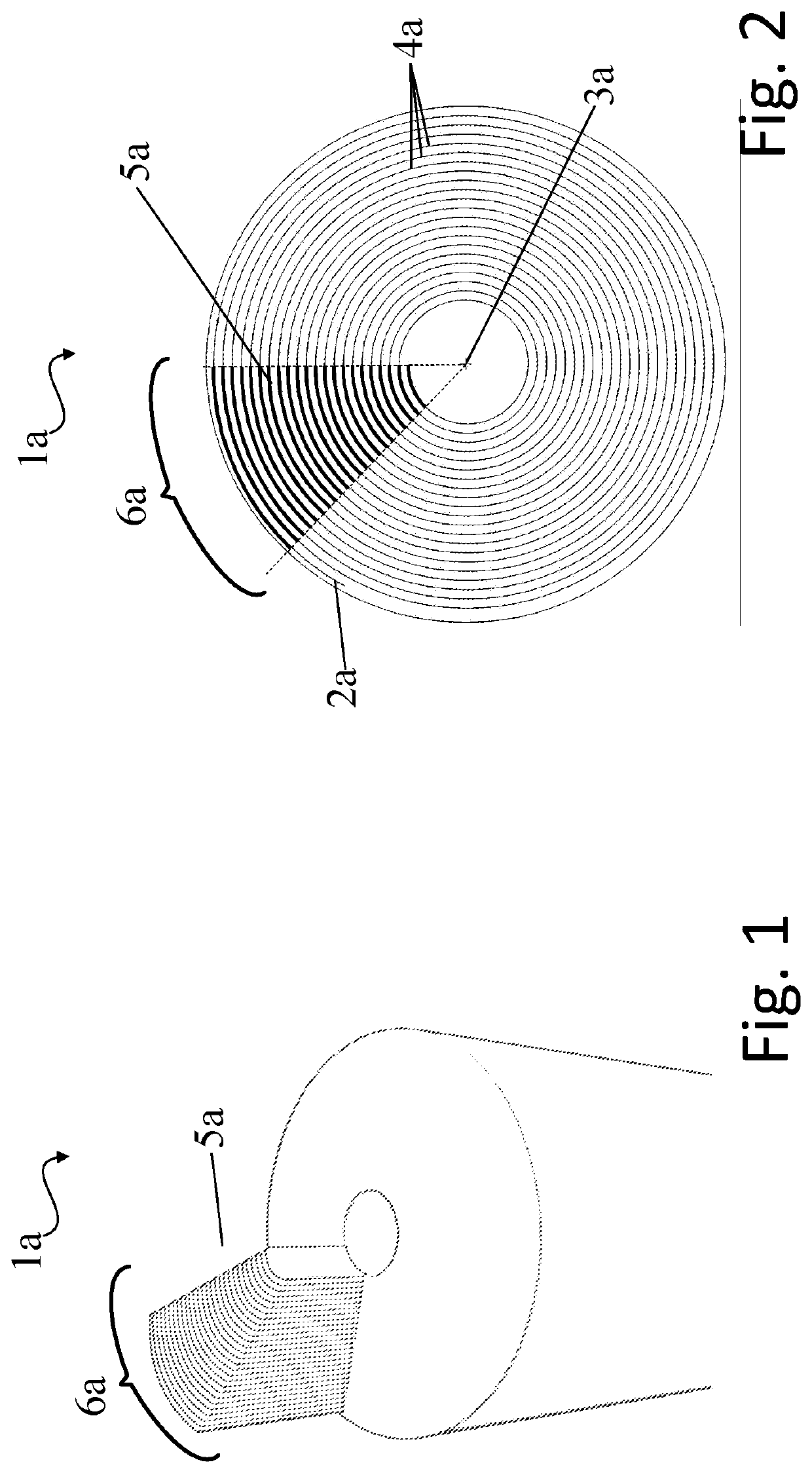

Energy storage device

InactiveUS20200144581A1Improve heat transferIncrease in numberCell seperators/membranes/diaphragms/spacersFinal product manufacturePhysicsChemistry

An electrochemical storage device comprising a container, a sheet of cathode material, a sheet of anode material and a separator material. The electrode sheets being wound in the container about a winding axis to provide a cylindrical electrochemical cell assembly having a curved sidewall and two end faces. At least one of the sheets of the anode or cathode material has a plurality of tabs that extend from one end face of the cylindrical electrochemical cell assembly. The tabs are arranged on said end face in a spiral about the winding axis.

Owner:DYSON TECH LTD

Spraying device

The invention discloses the sprayer unit used for chemical adjuvant spraying in paper industry. The sprayer unit comprises spraying chest, spraying head, spraying head regulating mechanism, spraying guide mechanism, spraying content control mechanism and coagulation liquid reflux mechanism. The spraying head regulating mechanism comprises regulation segment and instalment segment, and the spraying head fixed in spraying chest is connected with regulation segment through instalment segment. The spraying guide mechanism comprises preposition guide tube and baffle installed on the exit of spraying chest. The preposition guide tube fixed on the two side walls of spraying chest is between spraying head and baffle. The external surface of preposition guide tube is downward bent camber, useful for spraying. The unit has the advantages of good spraying effect, downward spraying and reclaiming condensation liquid.

Owner:ZHEJIANG HUAZHANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com