Method of controlling rigidity of long span cable-stayed bridge of railway through stay cable

A cable-stayed bridge and long-span technology, applied in the direction of instruments, geometric CAD, calculation, etc., can solve problems such as difficult control of stiffness, achieve the effects of reducing project investment costs, saving construction material consumption, and increasing project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] This embodiment is applied to control the stiffness of a domestic railway long-span cable-stayed bridge with a span of 432m.

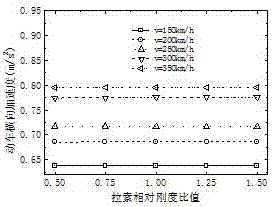

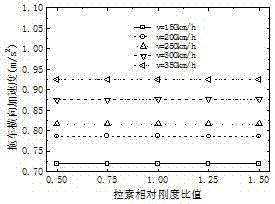

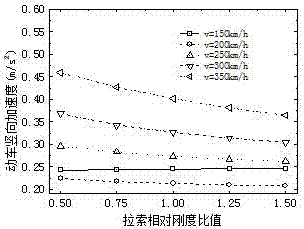

[0066] The method of controlling the stiffness of long-span railway bridges through cable-stayed cables establishes a dynamic analysis model, including the long-span railway bridge model and the vehicle model. The vehicle-bridge coupled vibration model is used, and the vehicle-rail contact surface is used as the boundary. The bridge system is decomposed into independent vehicles and bridge subsystems. The bridge structure scientific research and analysis software BANSYS is used for analysis. During the analysis, the vehicle response and bridge response are analyzed. The vehicle model is CRH2 train, and the train formation is 2× (train + trailer +train+train+train+train+trailer+train), a total of 16 sections, and the trains and trailers are arranged crosswise.

[0067] The bridge model is a railway long-span cable-stayed bridge whose main bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com