Spraying device

A spray device and spray head technology, applied in spray devices, spray devices, etc., can solve problems such as inability to spray downward, droplet size change, droplet drift, etc., to ensure spray quality, improve use function, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

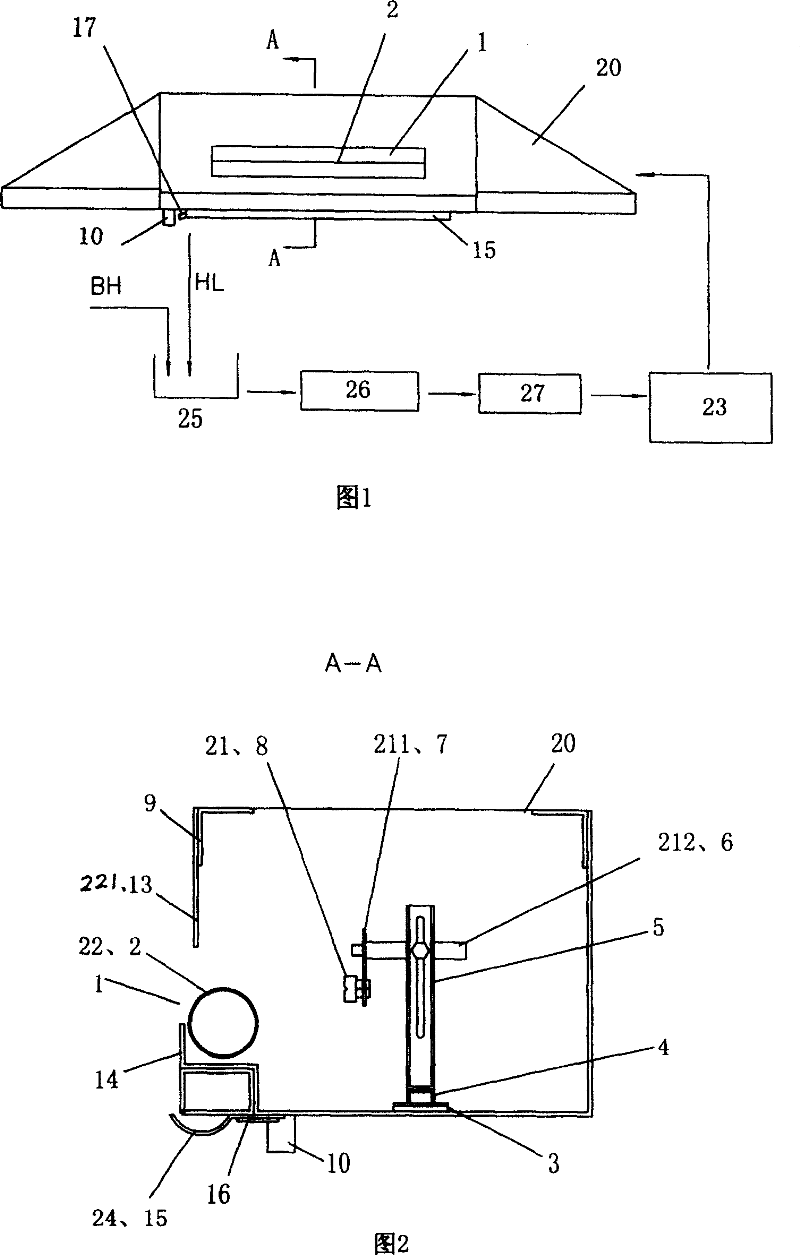

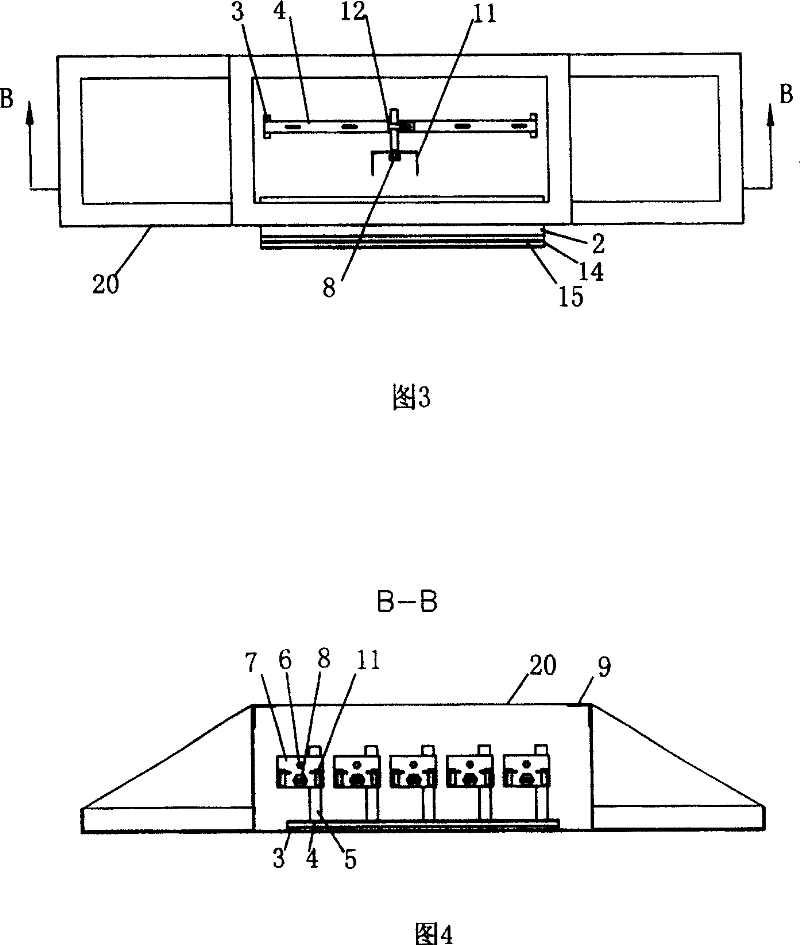

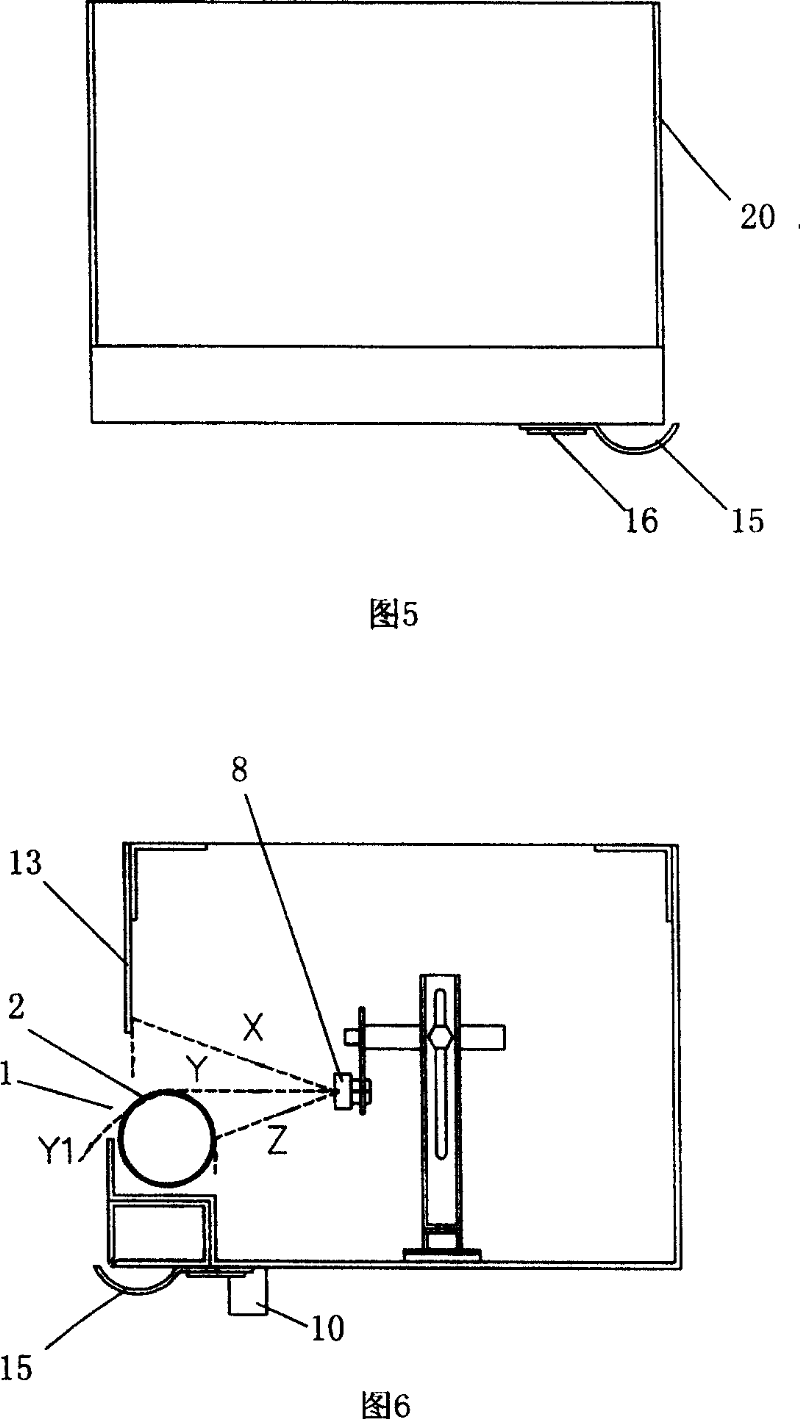

[0021] The spray device of the embodiment includes a spray box 20 , a spray head 8 , a spray head adjustment mechanism 21 , a spray guide mechanism 22 , a spray volume control mechanism and a condensate return mechanism 24 . The spray head adjustment mechanism 21 and the spray guide mechanism 22 are installed in the spray box 20, the condensate return mechanism 24 is installed at the bottom of the spray box 20, the spray head 8 is installed on the spray head adjustment mechanism 21, and the spray guide mechanism 22 is located at the spray head 8 In the front, the spray volume control mechanism is connected with the spray head 8. When in use, refer to Figure 1 for the system connection of the spray device. The integrated water tank 25 for storing the spray liquid is placed under the reflux liquid outlet 10 and the condensate outlet 17 of the spray tank 20, the hydraulic pump 27 is connected to the integrated water tank 25 through the liquid filter 26, and the hydraulic pump 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com