Patents

Literature

176results about How to "Precise and reliable control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-conditioner refrigerant flow control method

InactiveCN103712309AOvercome technical problems that are prone to infinite loopsControl method has little effectSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringStreamflow

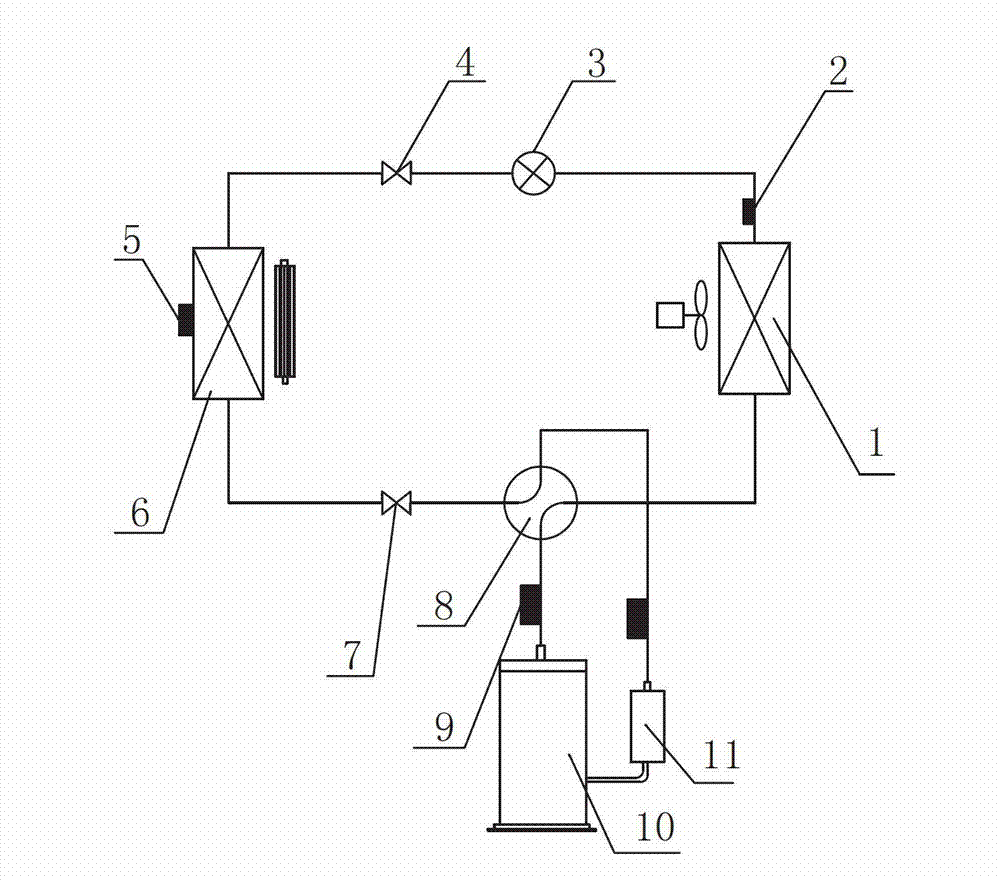

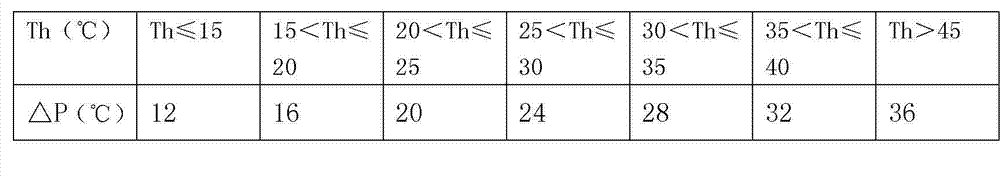

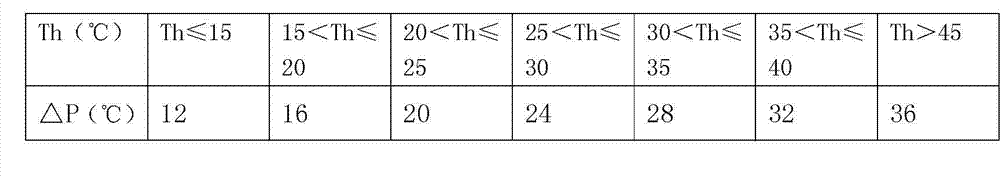

The invention discloses an air-conditioner refrigerant flow control method. The air-conditioner uses an electronic expansion valve as a throttling component. The air-conditioner refrigerant flow control method includes the steps of S1, determining a condensate depression delta T according to running modes of the air-conditioner, S2, determining a target condensate depression delta P according to running modes of the air-conditioner and environmental temperature, and S3, obtaining a condensate depression differential value SH according to the difference between the condensate depression delta T and the target condensate depression delta P, and regulating the openness of the electronic expansion valve according to the condensate depression differential value SH. The air-conditioner refrigerant flow control method has the advantages of accurate flow controlling and low cost.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Method for spraying adhesive

InactiveUS6037009APrecise and reliable controlConsistent levelSpraying apparatusCoatingsAdhesiveEngineering

Apparatus and methods are disclosed for spraying an adhesive in a selected pattern on a continuously moving web. The method includes the steps of: (a) supplying a predetermined volumetric flow of adhesive to a nozzle; (b) selectively operating the nozzle between an off position and an on position to spray the volumetric flow of the adhesive; (c) diverting the volumetric flow of the adhesive from the nozzle when the nozzle is operated in the off position; and (d) maintaining a back pressure at the nozzle when the nozzle is operated in the off position to provide a substantially instantaneous spray of the adhesive when the nozzle is operated from the off position to the on position.

Owner:KIMBERLY-CLARK WORLDWIDE INC

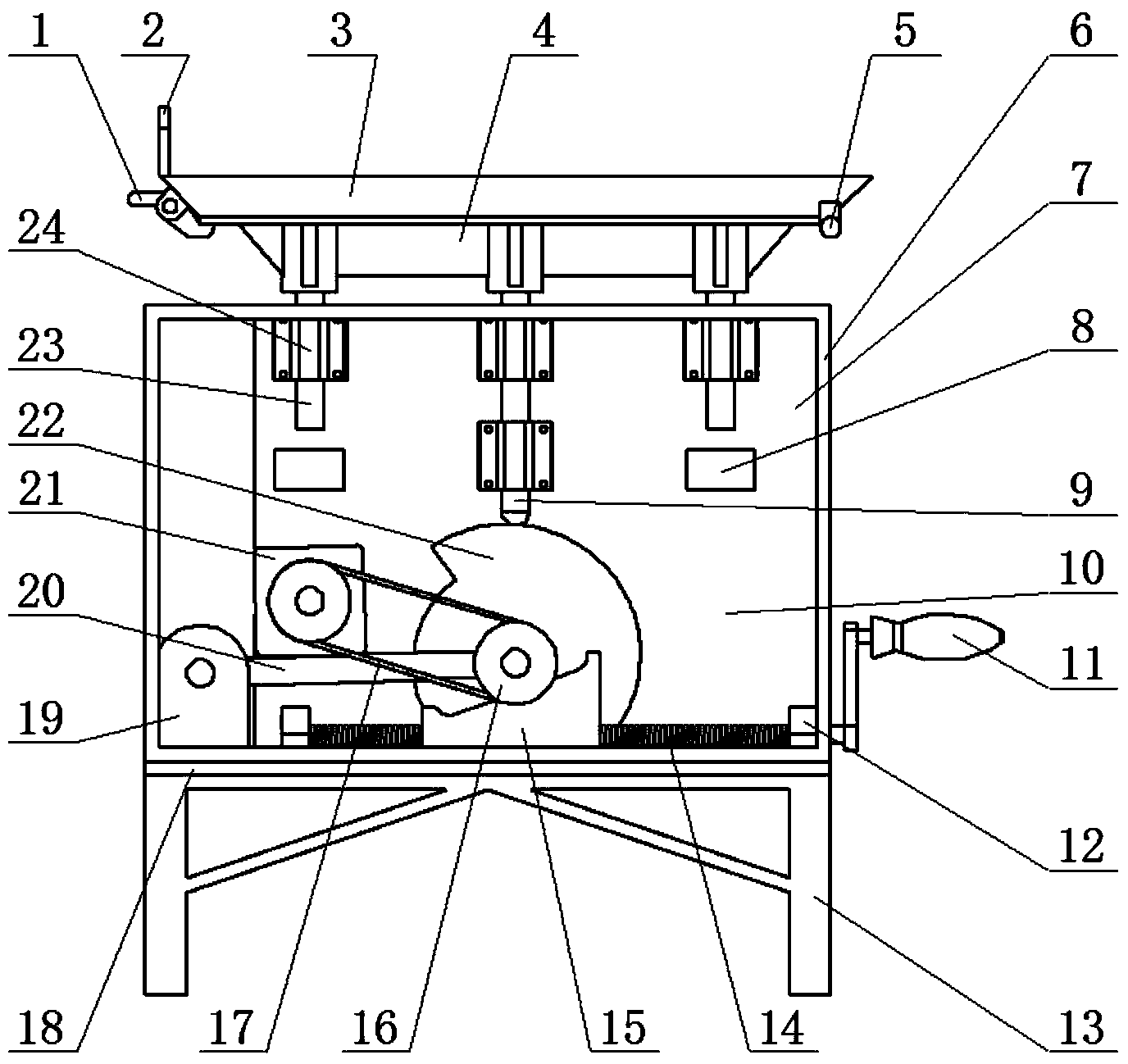

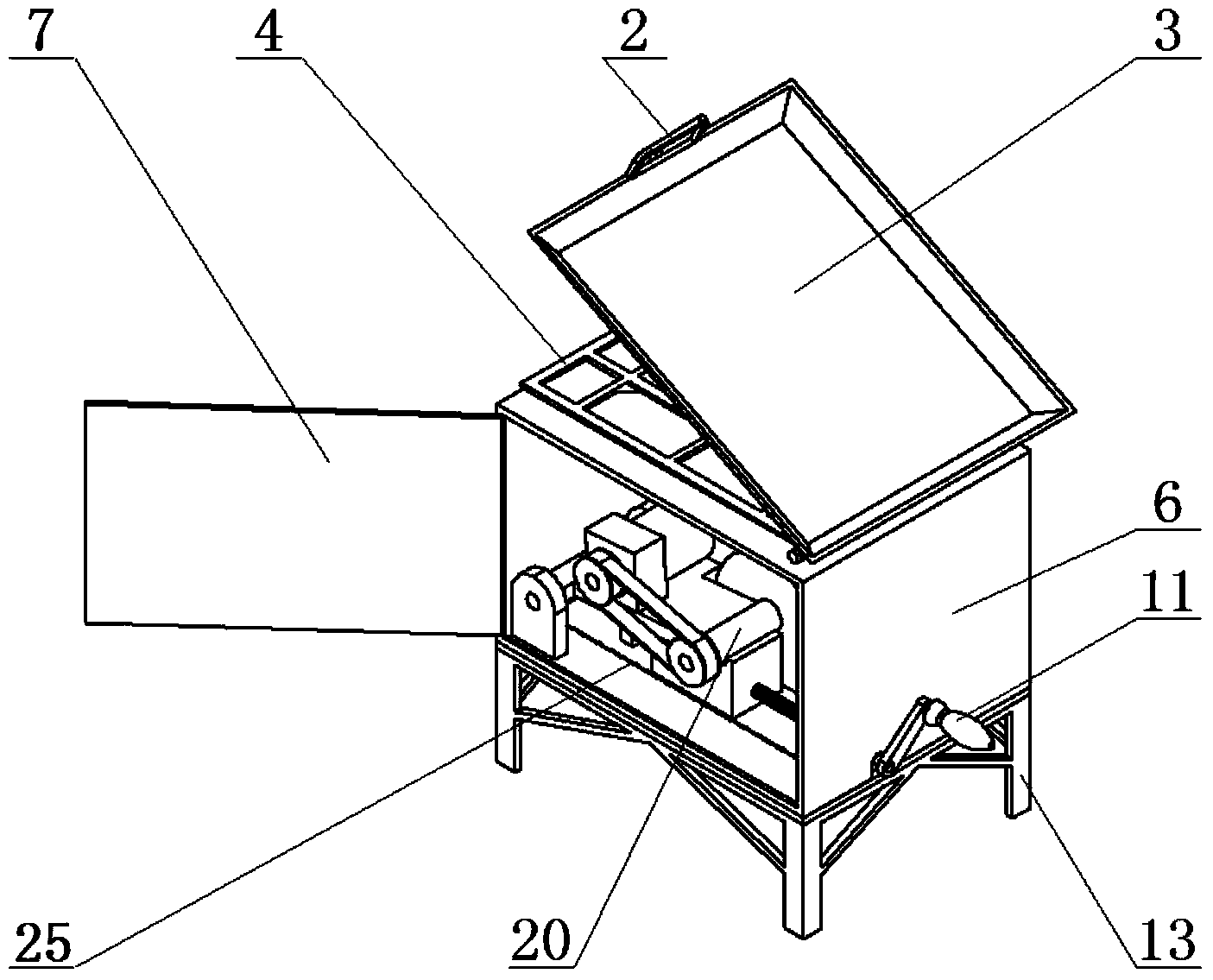

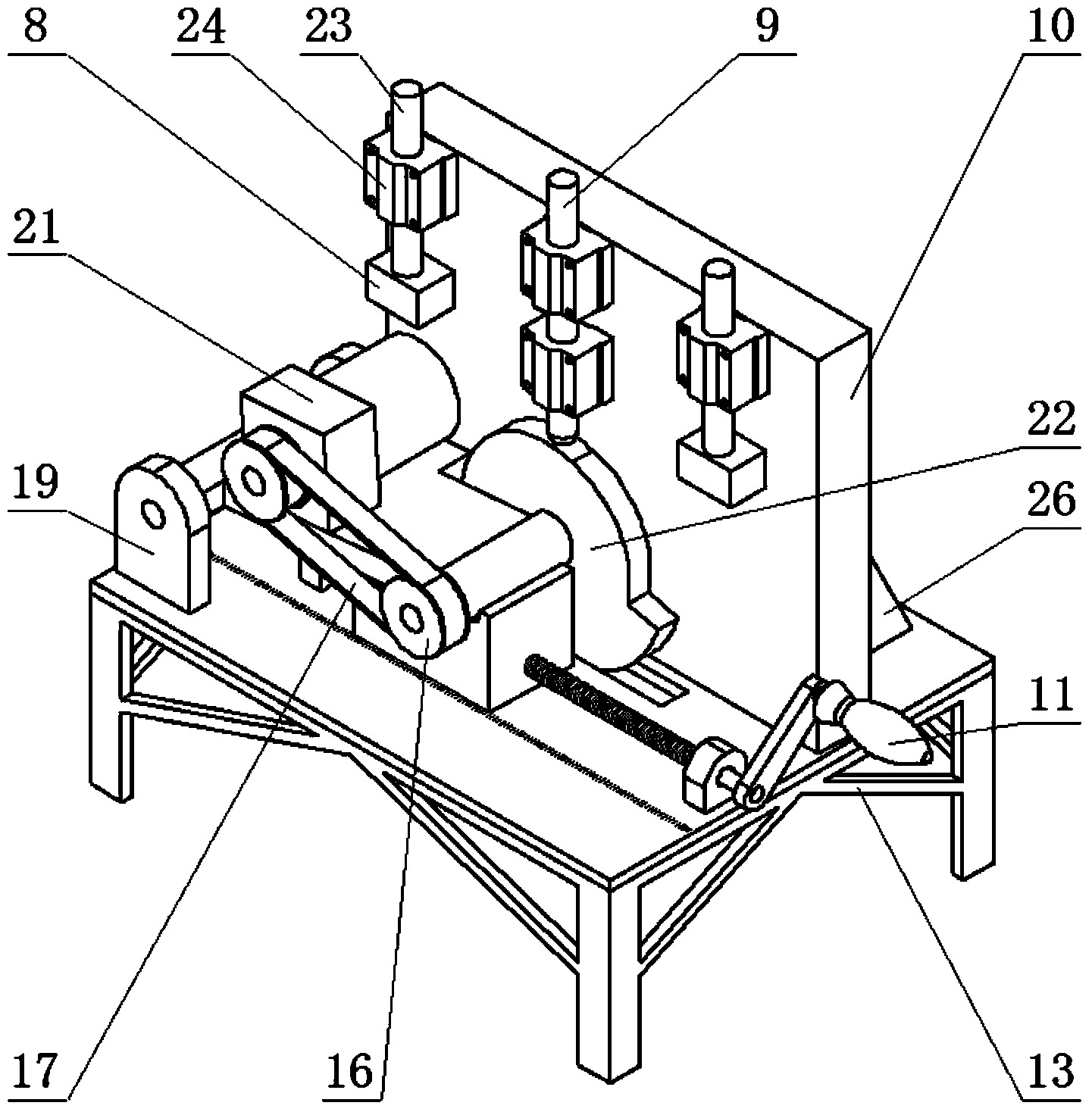

Automatic batching apparatus and batching method

ActiveCN104043376AReasonable structural designEasy to break awayMixer accessoriesEngineeringMechanical engineering

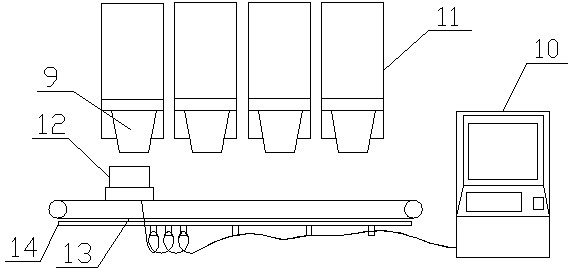

The invention provides an automatic batching apparatus and a batching method. The apparatus comprises a control cabinet, batching bins with blanking devices, a mobile weighing disc. The batching bins are provided with quantitative blanking devices, which are connected with the control cabinet; a plurality of batching bins are in linear arrangement; blanking ports of the batching bins are in a straight line, and a conveyor belt is arranged right below the blanking ports of the batching bins; the weighing disc comprises a weighing bucket and an electronic scale; and the electronic scale is placed on the conveyor belt, and is connected with the control cabinet through a circuit. The control cabinet conducts remote blanking control on blanking of batching bins and movement of the weighing disc. Compared with the current automatic blanking apparatus and blanking method, the apparatus and method provided by the invention save manpower and material source, realizes automatic operation, more precise and reliable dropping material control, and greatly improves the efficiency of material proportion.

Owner:TAIAN DEPU AUTOMATION EQUIP

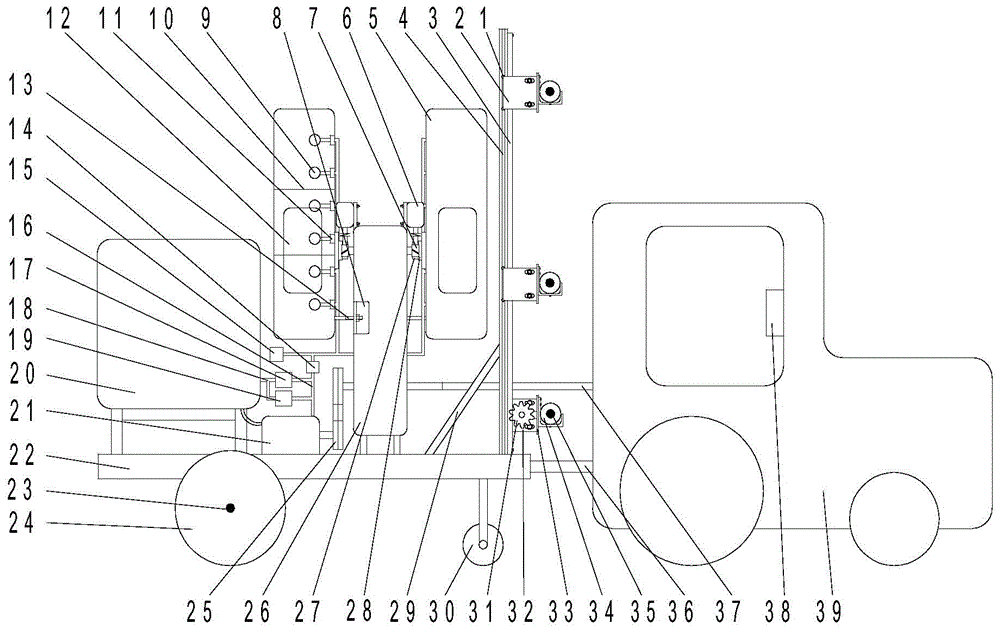

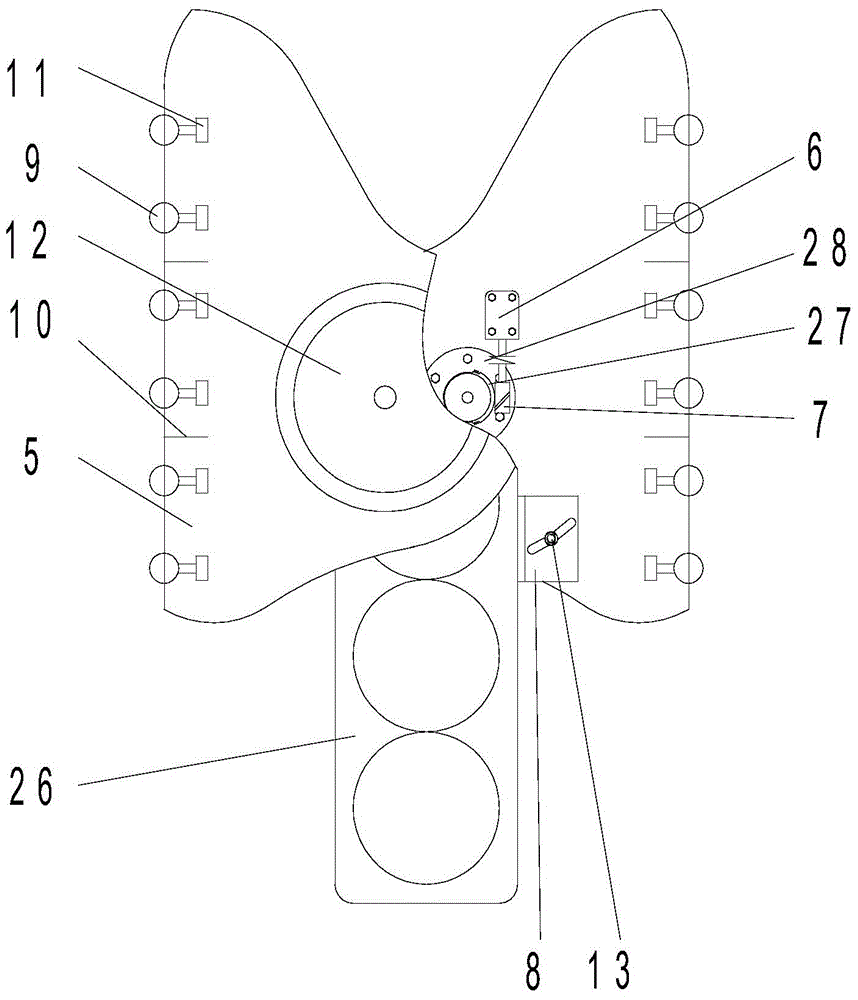

Self-adaptive orchard sprayer

ActiveCN104082268AUniform and stable sprayingIncrease profitInsect catchers and killersControl signalSprayer

A self-adaptive orchard sprayer comprises a traction chassis, wherein a pesticide application device and a plurality of movable ultrasonic detection devices are arranged at the front end above the traction chassis. Each ultrasonic detection device mainly comprises an ultrasonic sensor and a vertical moving device, and a detection signal of the ultrasonic sensor is output and connected to an embedded control platform. The pesticide application device mainly comprises a pesticide spraying device and a stepping motor rotation control device, wherein the pesticide spraying device are provided with electric ball valves, flow sensors, pressure sensors and solenoid valves, and detection and control signals of the electric ball valves, the flow sensors, the pressure sensors and the solenoid valves are connected to the embedded control platform which integrates signals of the sensors to control opening of the electric ball valves and actions of the solenoid valves. By means of the self-adaptive orchard sprayer, tree form information of control targets in an orchard can be collected automatically; according to the information, the ultrasonic sensors can be distributed automatically, and rotating angles of an air bellow are regulated automatically, or rotating angles of the air bellow can be regulated manually according to actual needs. Therefore, pesticide application efficiency is increased, pollution to the environment and personal injury to operators caused by pesticide application are reduced.

Owner:NORTHWEST A & F UNIV

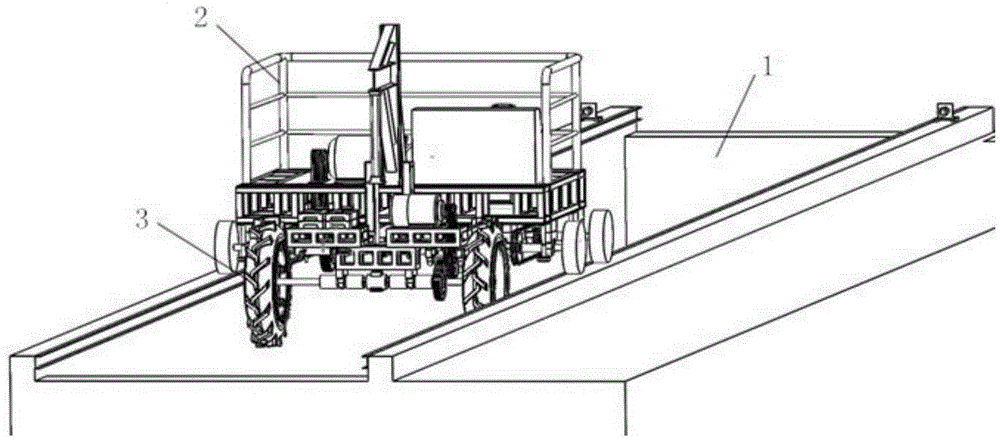

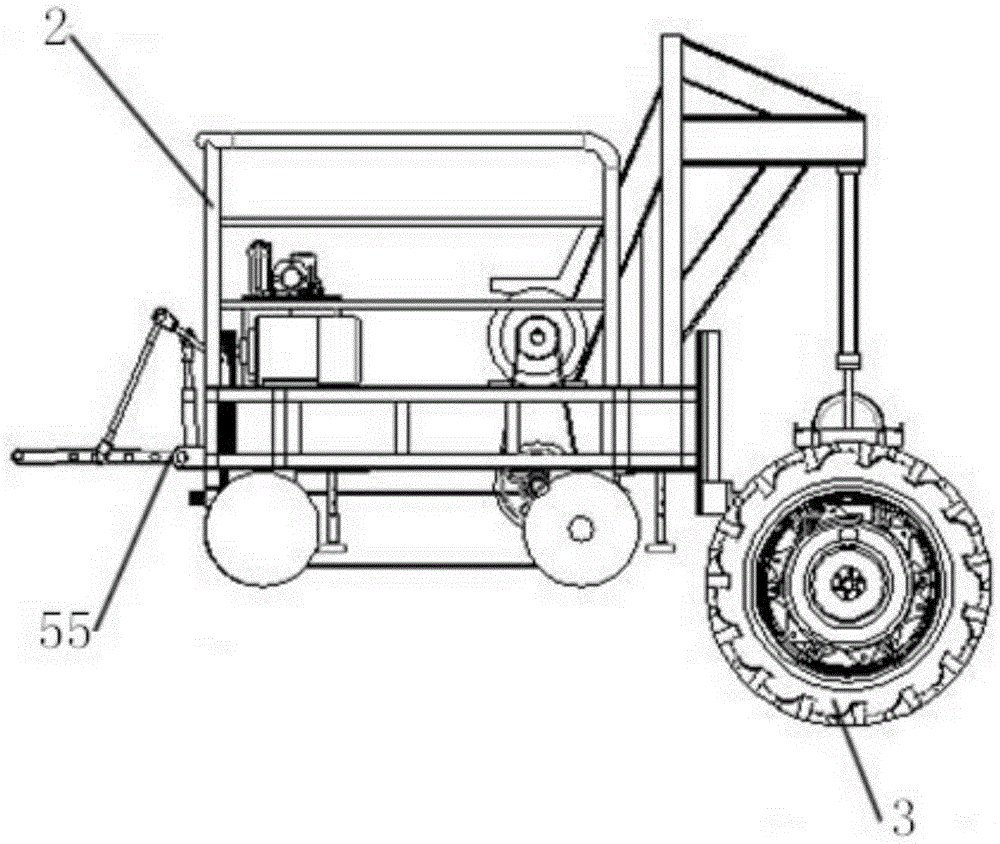

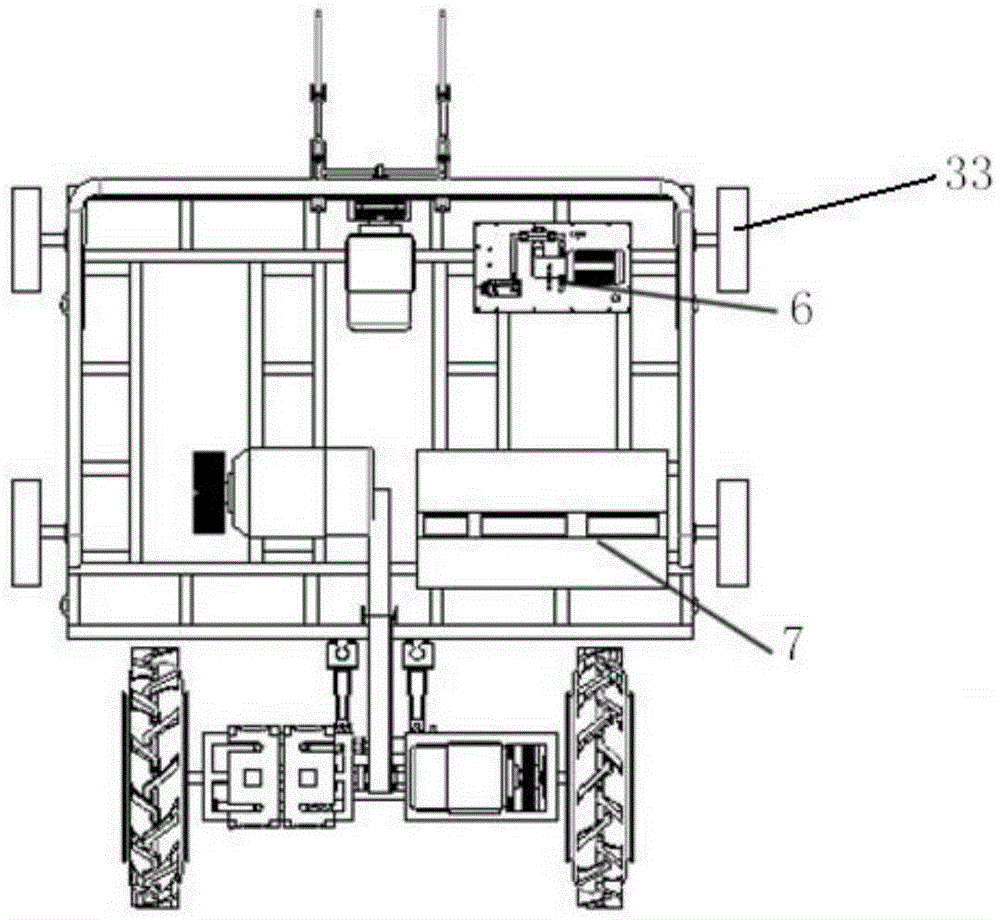

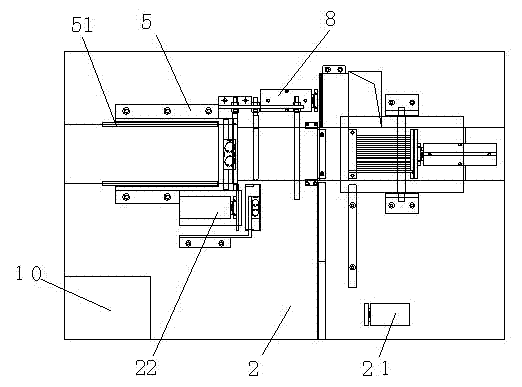

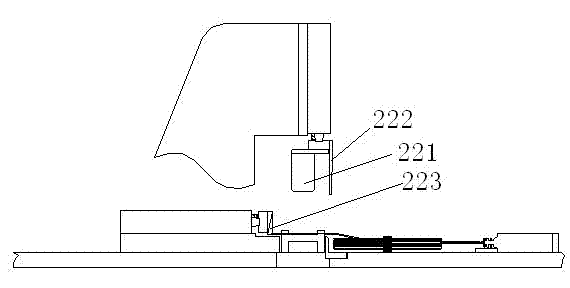

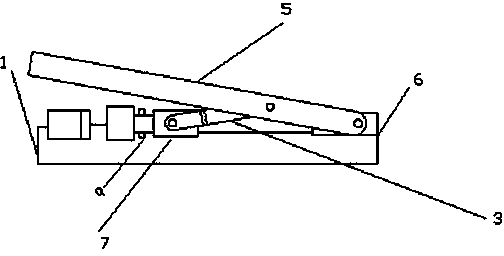

Soil bin test trolley

InactiveCN105388031AEasy to measureSolve the problem of vibration affecting measurement resultsMachine part testingVehicle tyre testingReciprocating motionData acquisition

The invention relates to a soil bin test trolley. The soil bin test trolley includes a soil bin system, a test tractor and a double-wheel test device; the front end of the test tractor is provided with the double-wheel test device; and the test tractor and the double-wheel test device perform reciprocating motion along the soil bin system. With the soil bin test trolley of the invention adopted, the stress-strain of a tire and mechanical parameters of agricultural implements such as a plough and a rotary cultivator under different experimental factors can be tested, and the problem of influence of the vibration of traction equipment on measurement results existing in an existing test system can be solved. The soil bin test trolley has the advantages of controllability of test conditions and environmental factors, convenient measurement of test data and parameters, high measurement precision, high test repeatability, high driving ability, accurate and reliable control, flexible and convenient test and coherent data acquisition.

Owner:NANJING AGRICULTURAL UNIVERSITY

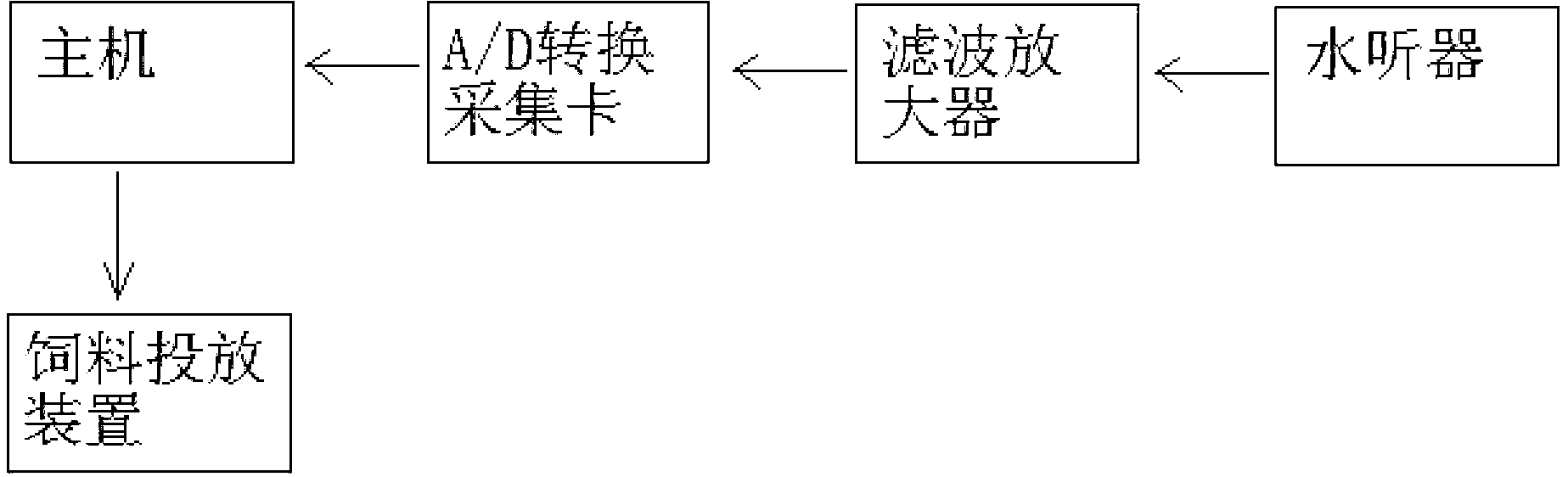

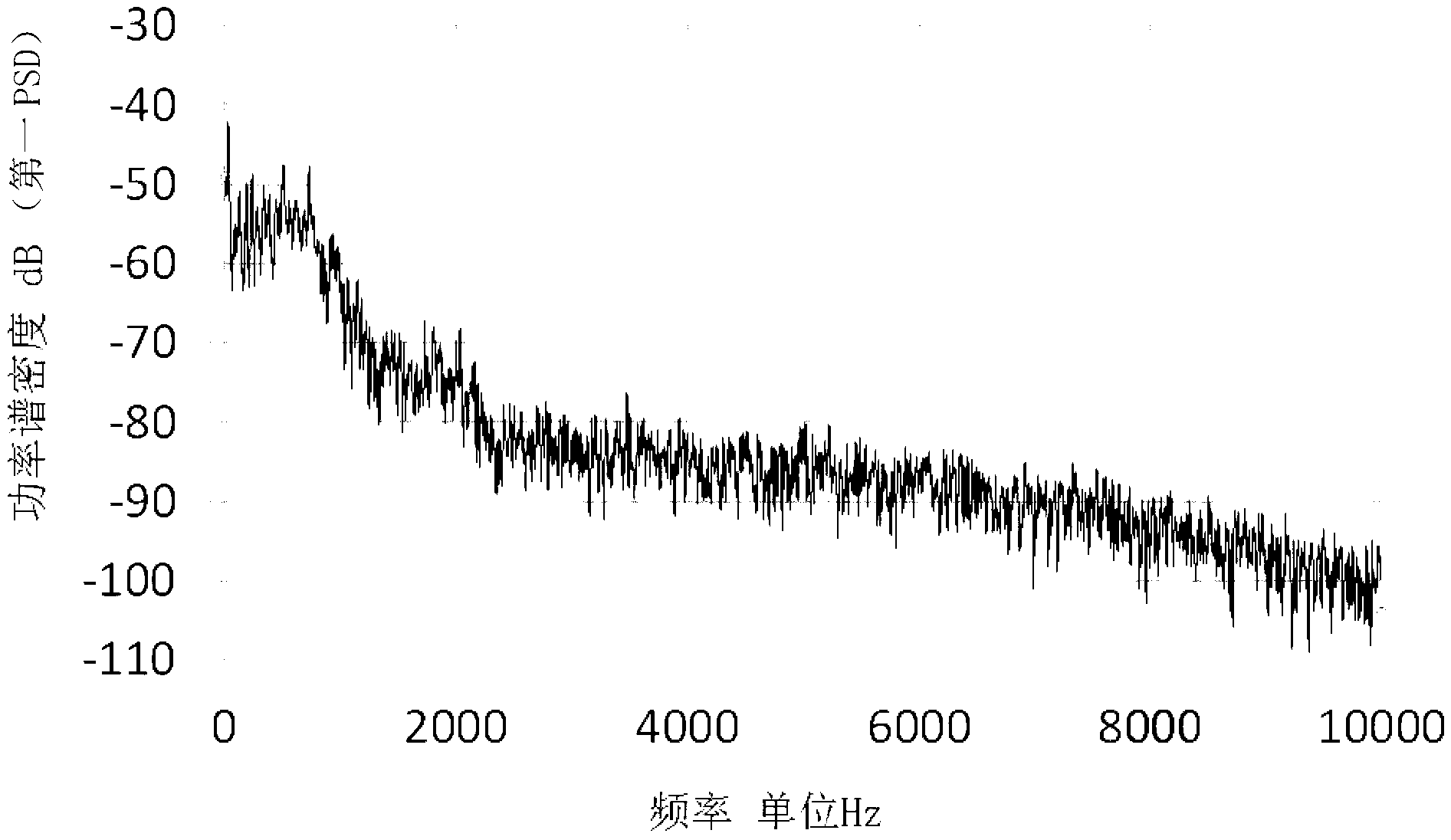

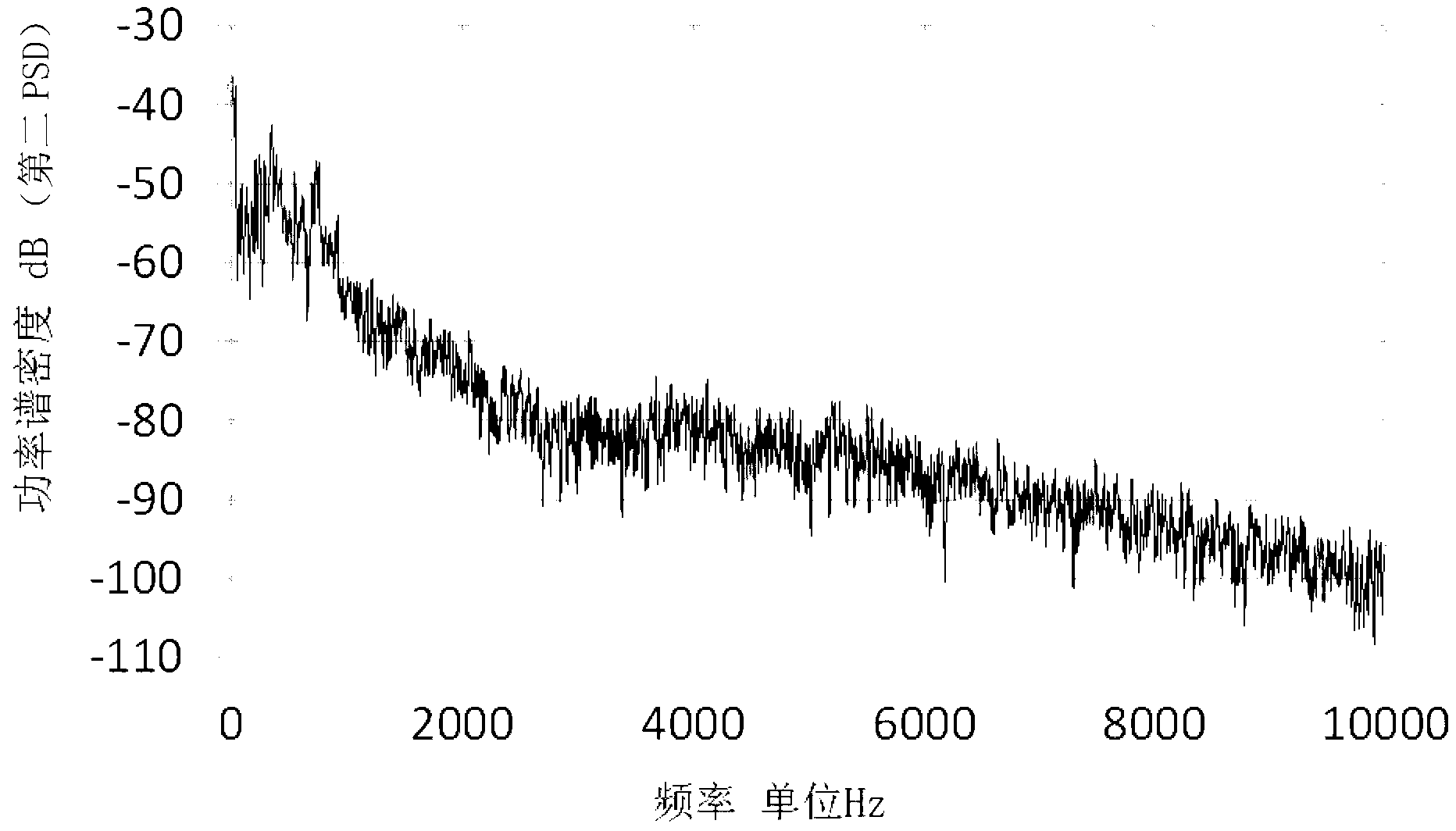

Pond culture sound control feeding method and device based on same

InactiveCN103070126APrecise and reliable controlImprove efficiencyPisciculture and aquariaZoologyBackground noise

The invention relates to a pond culture sound control feeding method. The pond culture sound control feeding method is characterized by comprising the following steps of 1) determining background noise of underwater environment of a feeding water area, and establishing background average PSD (Power Spectral Density) pn (m); 2) determining a sound signal of the feeding water area after feeding, and calculating sound PSD p (m) after feeding; 3) obtaining fish ingestion sound PSD after subtracting the sound PSD p (m) after feeding from the background noise average PSD pn (m) according to frequency; 4) calculating ingestion power in one moment through an integral formula as shown in the description, wherein ms refers to starting frequency, and me refers to cut-off frequency; and obtaining an ingestion power-time curve diagram; and 5) obtaining an ingestion power-time N-second average-line diagram, and respectively setting feeding ingestion quickening power, feeding ingestion power slow-down power and feeding ingestion stopping power according to ingestion power values on the ingestion power-time N-second average-line diagram.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

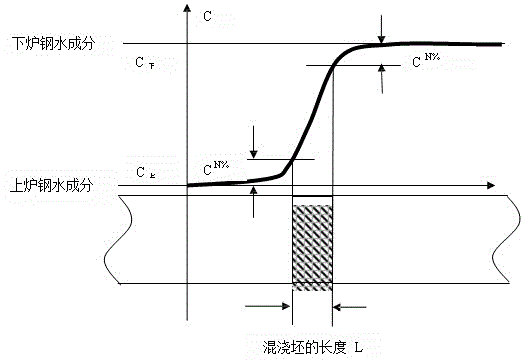

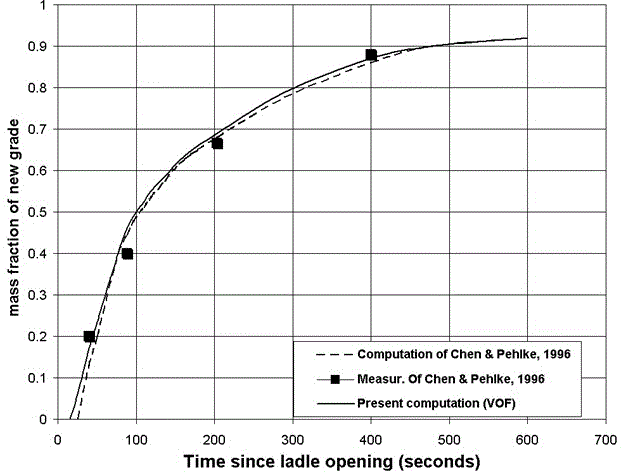

Control method for mixed casting of continuous-cast tundish

The invention provides a control method for mixed casting of a continuous-cast tundish. The control method comprises the following steps that (1) whether casting is conducted in a mixed casting mode or not is judged according to the judgment criterion based on the component difference between a prior furnace turn and a later furnace turn, a mixing section calculation mode starts to be used and the step (2) is conducted if yes, and treatment is conducted according to a normal casting mode if not; (2) the position and length of a mixing section are calculated; and (3) the initial position and the mixing length of the mixing section for mixed casting of the tundish are sent to a quality judgment model, optimized cutting of a plate blank is controlled by optimizing a cutting model, and comprehensive quality judgment of the plate blank is conducted. According to the control method for mixed casting of the continuous-cast tundish, the position of the mixing section between different furnace turns can be controlled more accurately and reliably, the precision of control over the mixing section is effectively improved, and the yield of molten steel is increased.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

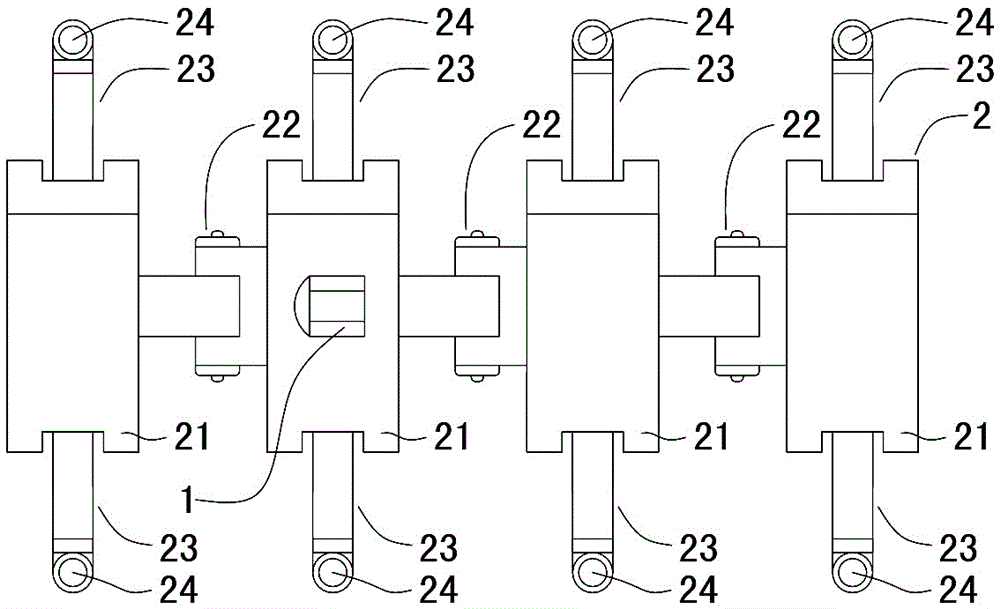

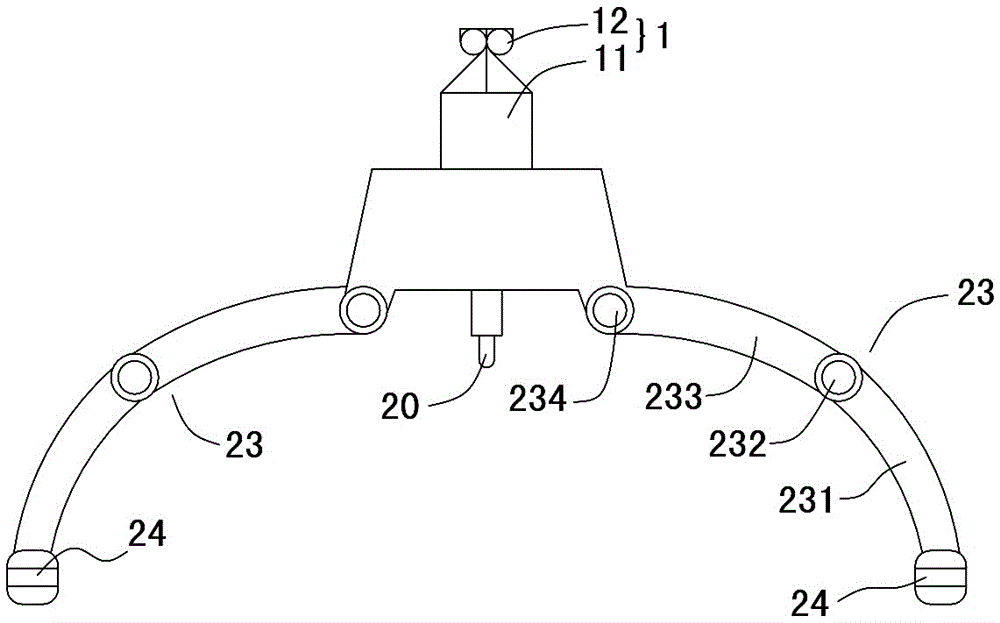

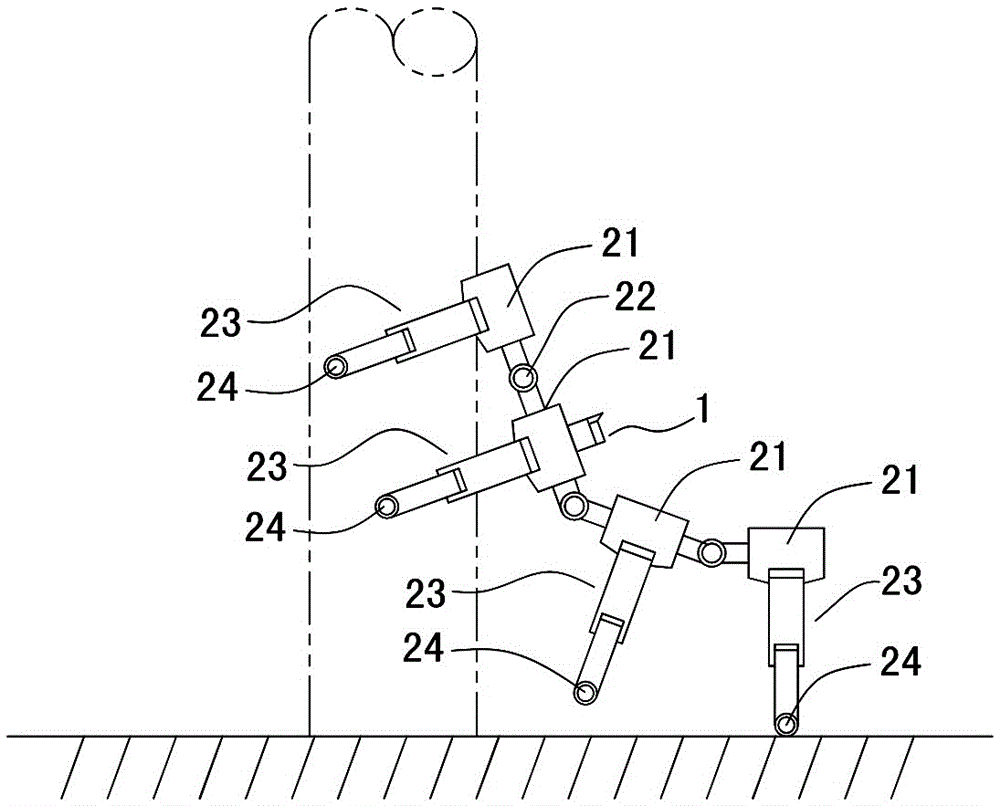

Transformer substation patrol and inspection robot with rod climbing function and drive method for transformer substation patrol and inspection robot

ActiveCN105730540AControl running statusCompact structureProgramme-controlled manipulatorVehiclesBody jointsTransformer

The invention discloses a transformer substation patrol and inspection robot with a rod climbing function and a drive method for the transformer substation patrol and inspection robot. The transformer substation patrol and inspection robot comprises a monitoring device, a drive control module and a climbing mechanism. The monitoring device and the drive control module are arranged on the climbing mechanism. The climbing mechanism comprises multiple sections of body units and body joints. The adjacent body units are connected through the body joints. A body joint motor is arranged between every two adjacent body units. Each body unit is provided with a pair of mechanical arms. The ends of each mechanical arm are provided with walking and rotating universal wheels and universal wheel drive mechanisms. The universal wheel drive mechanisms and the body joint motors are connected with the drive control module. The drive method includes the steps that the transformer substation patrol and inspection robot is driven to move on the ground, move up and down a rod column and climb / rotate / stop along the rod column. By the adoption of the robot and the method, the functions that the robot moves on the ground, moves up and down the rod column and climbs / rotates / stops along the rod column can be achieved, the structure is compact, the control accuracy is high, and the operating state of a power transformation device can be monitored in all directions without a dead zone.

Owner:STATE GRID CORP OF CHINA +3

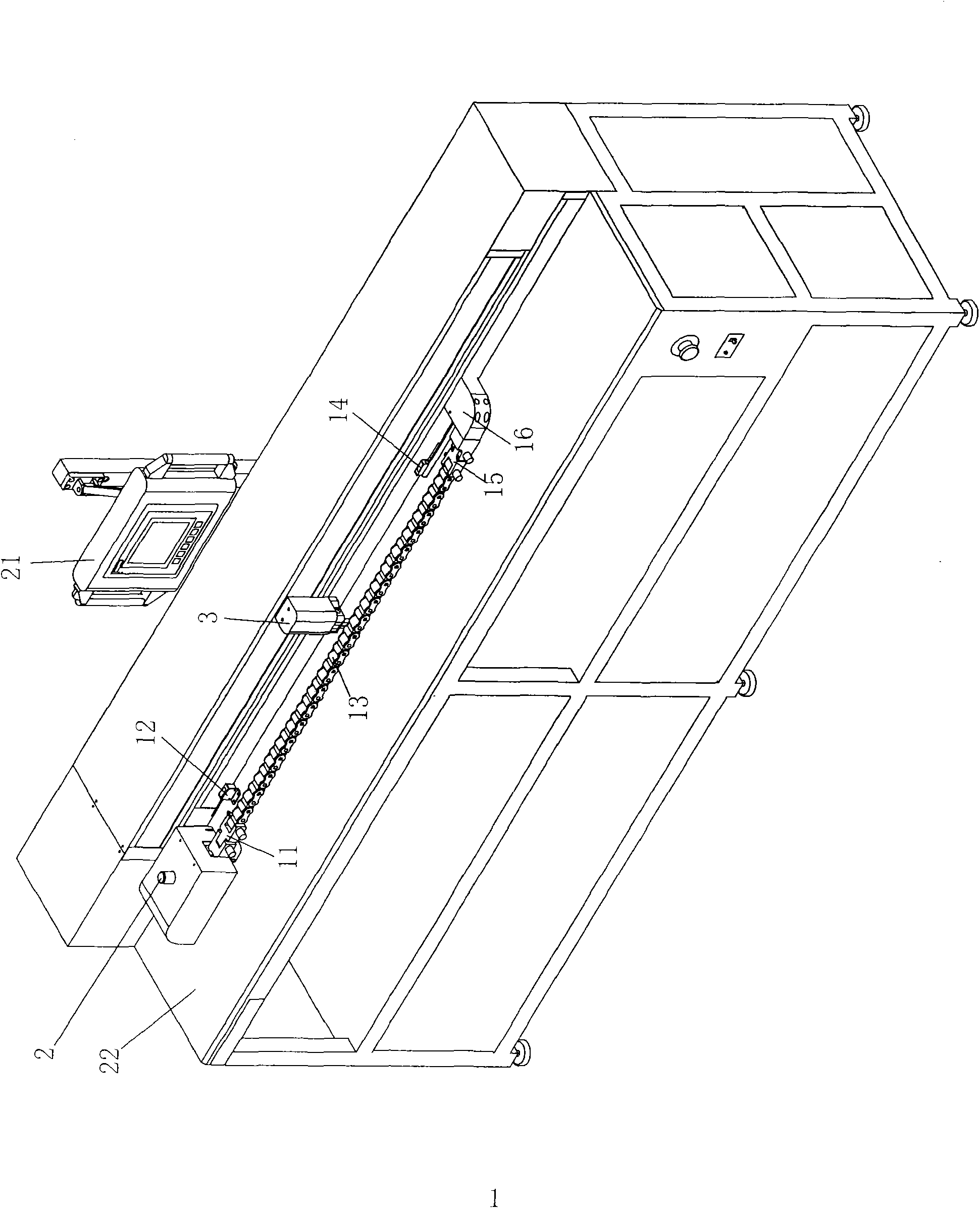

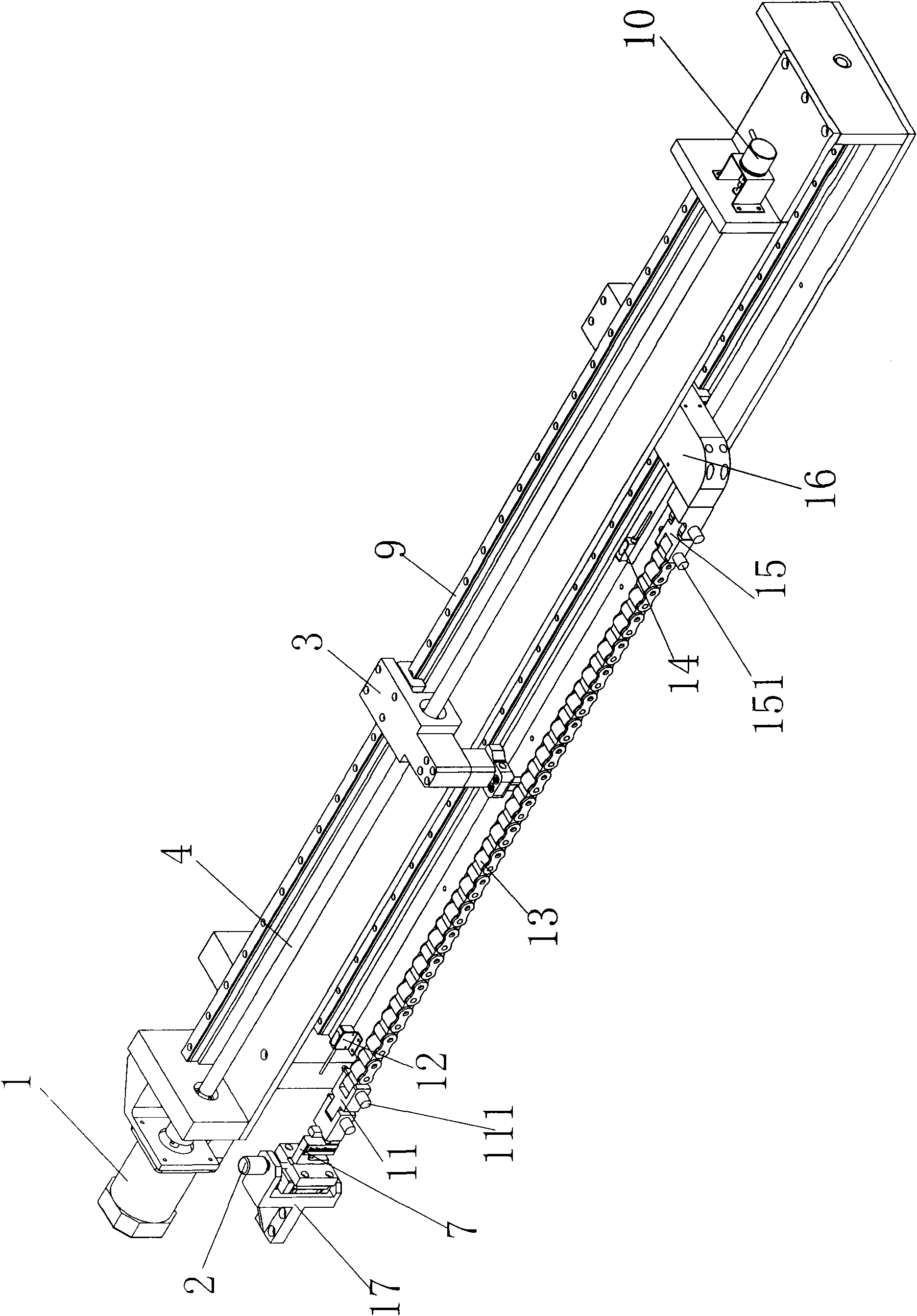

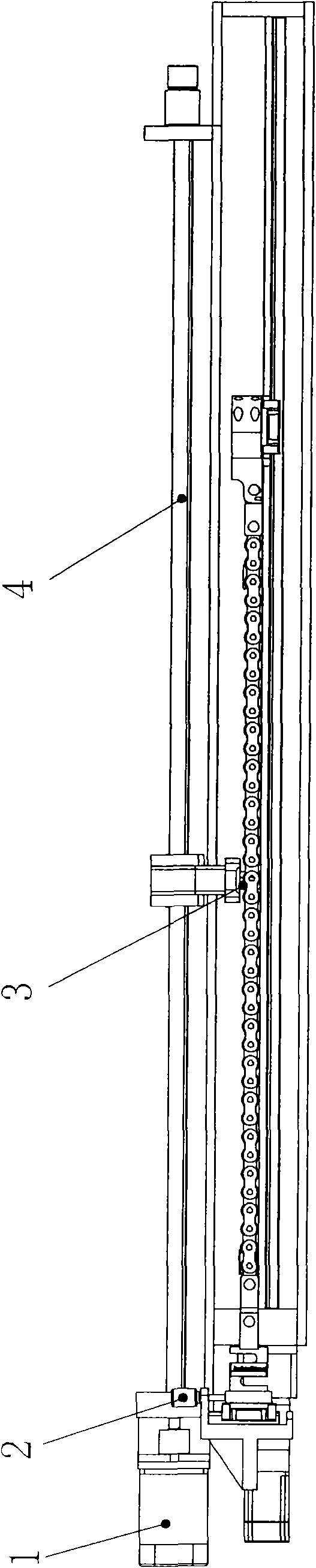

Chain length measuring instrument

InactiveCN101598532APrecise and reliable controlAutomatically display preset controlsUsing optical meansMetal chainsData displayMotor drive

The invention relates to a chain length measuring instrument, comprising a chain tension mechanism and a chain length measuring mechanism. The chain tension mechanism comprises a servo motor, wherein the servo motor drives a lead screw B to rotate to drive a movable gripper seat to move on a liner guide rail B and a liner guide rail C straight so as to tension the chain. The chain length measuring mechanism comprises a sensing head and an encoder, wherein the motor drives a lead screw A to rotate to drive a sensing head to move on a liner guide rail A straight so as to measure the chain length. The invention has the advantages that the tension force can be preset by a control panel, and the servo motor tensions the chain, therefore, the control is accurate and reliable. The motor drives the sensing head to measure the chain length, the encoder counts the number and transfers the number to the control panel so as to automatically display the chain length. Therefore, the invention has the advantages of high accuracy, default control and automatic data display, convenient reading, high efficiency, and the like.

Owner:GOTECH TESTING MACHINES DONGGUAN

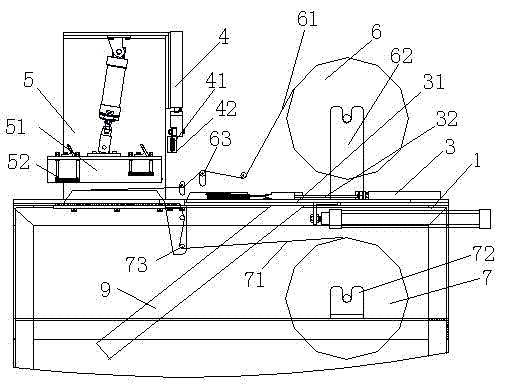

Automatic electric detonator packaging machine

ActiveCN102897334APrecise and reliable controlImprove intrinsic safetyPackaging by pressurising/gasifyingWrappingProgrammable logic controllerElectricity

The invention relates to an automatic electric detonator packaging machine which relates to an automatic packaging machine capable of automatically taking electric detonators out, reshaping the electric detonators and packing the electric detonators with a thermal sealing mode in the electric detonator production process. The automatic electric detonator packaging machine aims to solve the problems that in the prior art, the full-manual operation is low in efficiency and the safety can not be ensured. The technical scheme of the automatic electric detonator packaging machine is as follows: the operation of the automatic electric detonator packaging machine is entirely controlled by a PLC (programmable logic controller) control system, and comprises a mould conveying device, a pipe bagging device, a device for cutting two sealed ends, a side sealing device, a upper film feeding device and a lower film feeding device, wherein the mould conveying device, the pipe bagging device, the device for cutting two sealed ends and the side sealing device are positioned on a workbench according to the order of stations, the upper film feeding device is positioned above the workbench, and the lower film feeding device is positioned under the workbench. The automatic electric detonator packaging machine can prevent operators from directly contacting the dangerous electric detonators, enhances the internal safety, meets the automatic and isolate production requirements on the functions of the stations, and enhances the production efficiency. The automatic electric detonator packaging machine is mainly applied to the automatic packaging of the electric detonator and other objects of the similar structures.

Owner:YAHUA GROUP MIANYANG INDAL

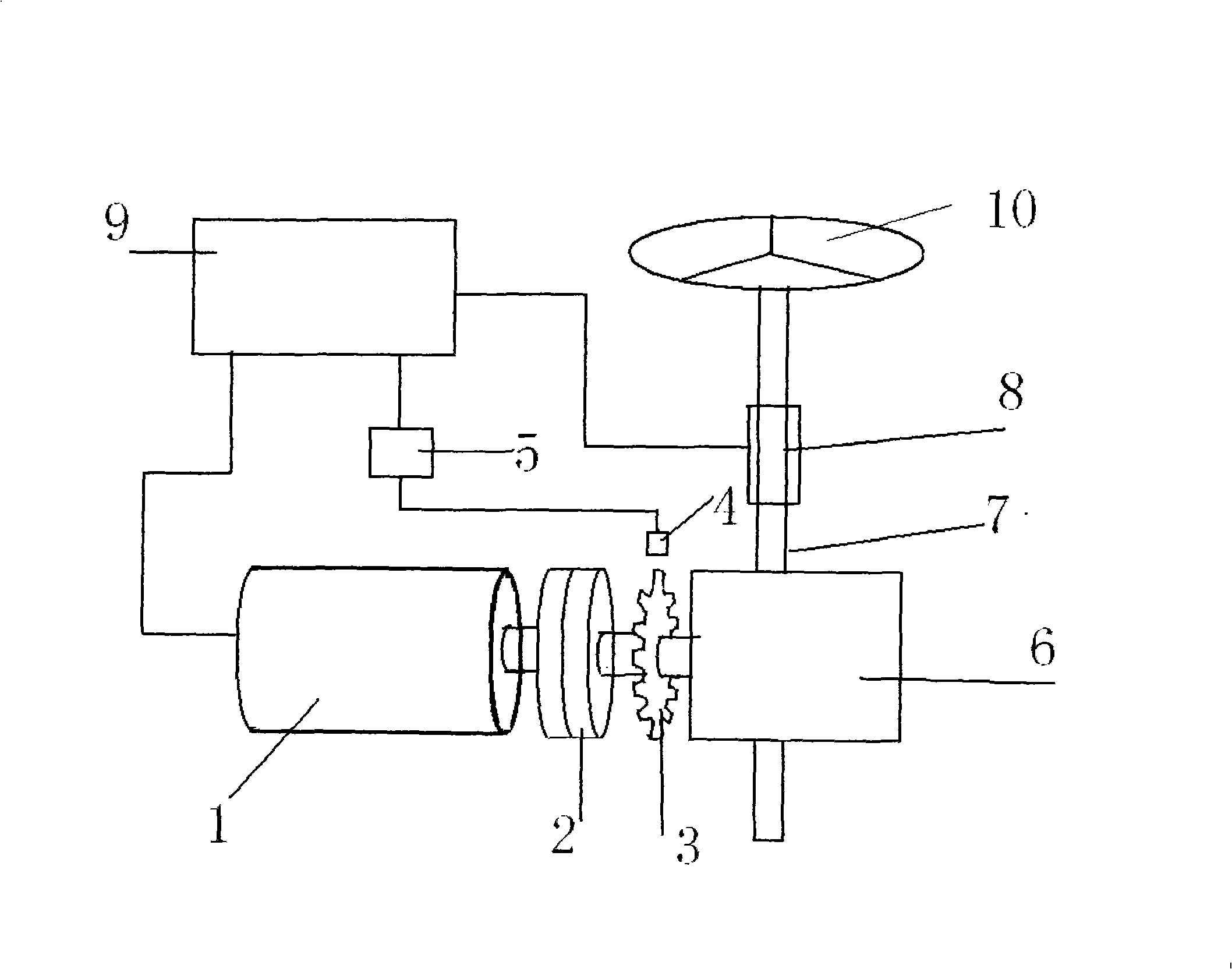

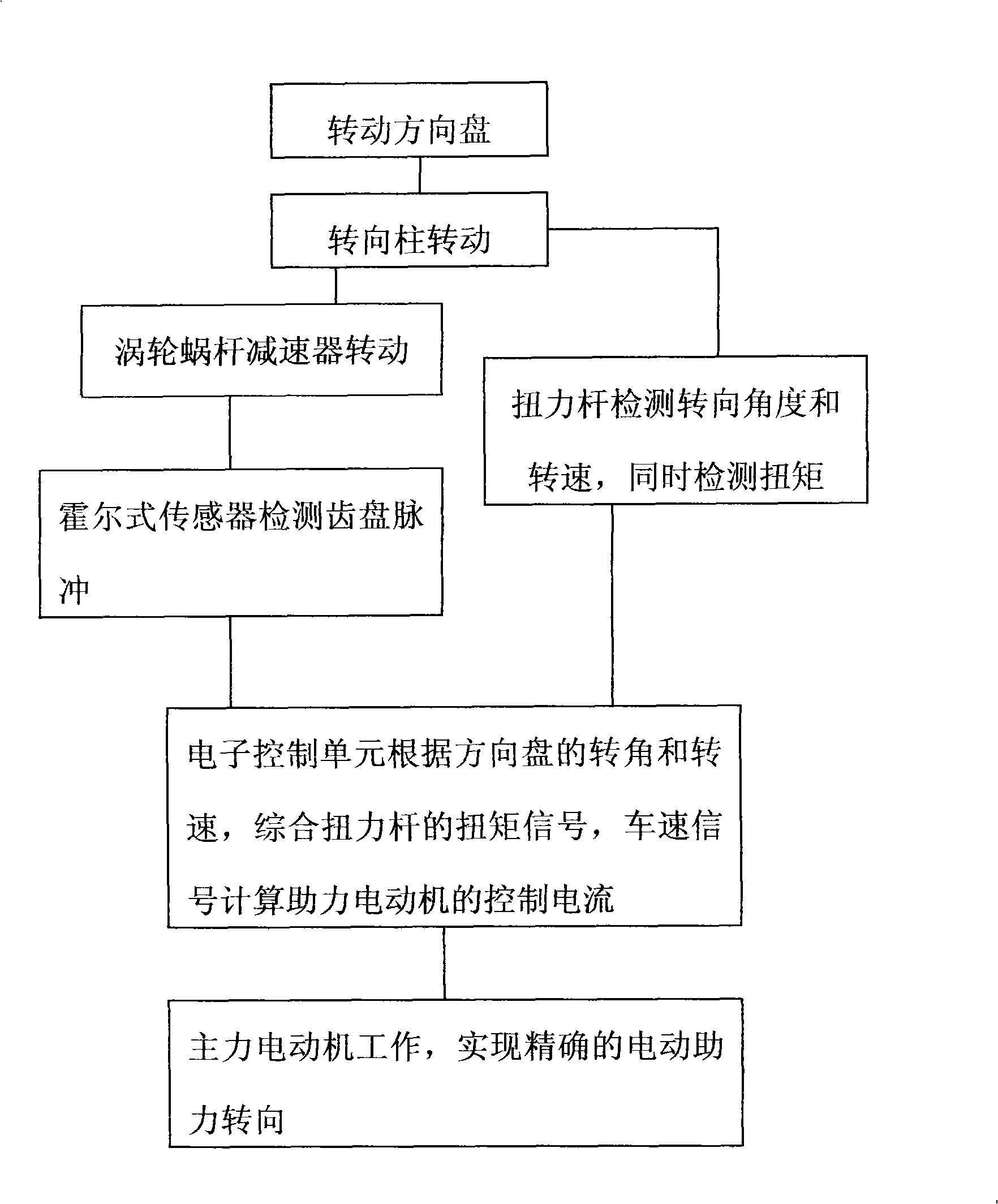

Control method for electric power-assisted steering device with steering wheel corner computation and compensation

InactiveCN101269669APrecise and reliable controlSteering linkagesAutomatic steering controlSteering wheelSquare waveform

The invention relates to a control method with a steering wheel cornering calculation and compensating electro motion power-assisted turning machine. A tooth clamp is driven by a steering wheel to rotate, a Hall type sensor can induce the change of magnetic flow passing through the tooth clamp to generate corresponding pulse signals, and the pulses can be changed into regular square waves after being treated via a deformation circuit and can be sent to an electric control unit for treatment. The rotary direction of the steering wheel can be analyzed by the electric control unit according to torsional moment signals, and simultaneously, the positive and negative square waves can be accumulated to calculate the rotary angel of the steering wheel. The square wave signals can be numbered to calculate the rotary speed of the steering wheel according to the cornering and rotary speed of the steering wheel, the torsional moment signals of the steering wheel, vehicle speed signals, etc. to calculate the control current of the power-assisted motor to achieve the control aim with exactness and reliability.

Owner:赵明翔

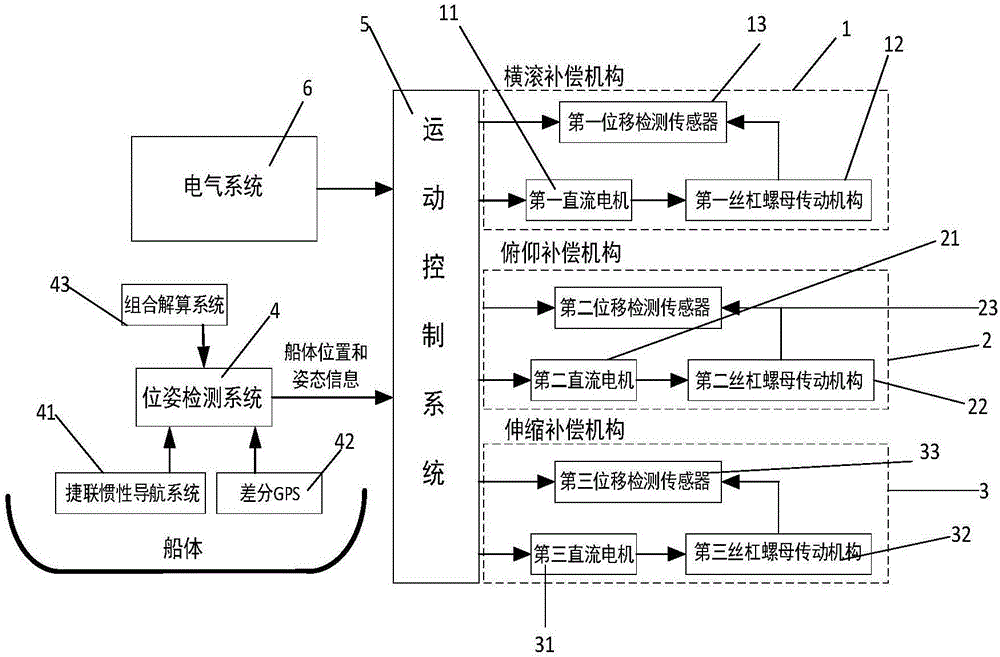

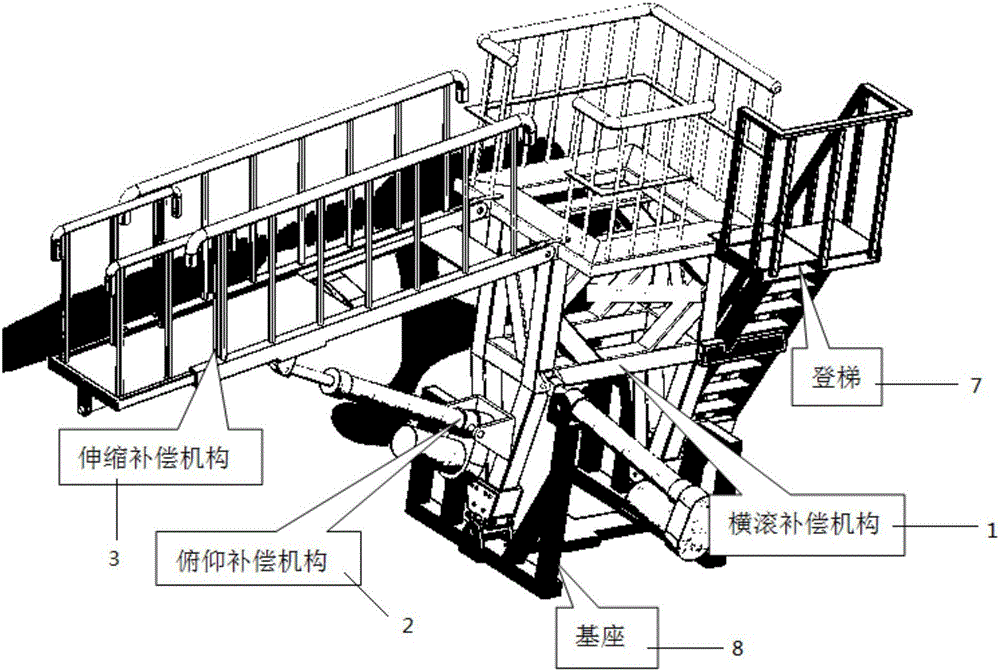

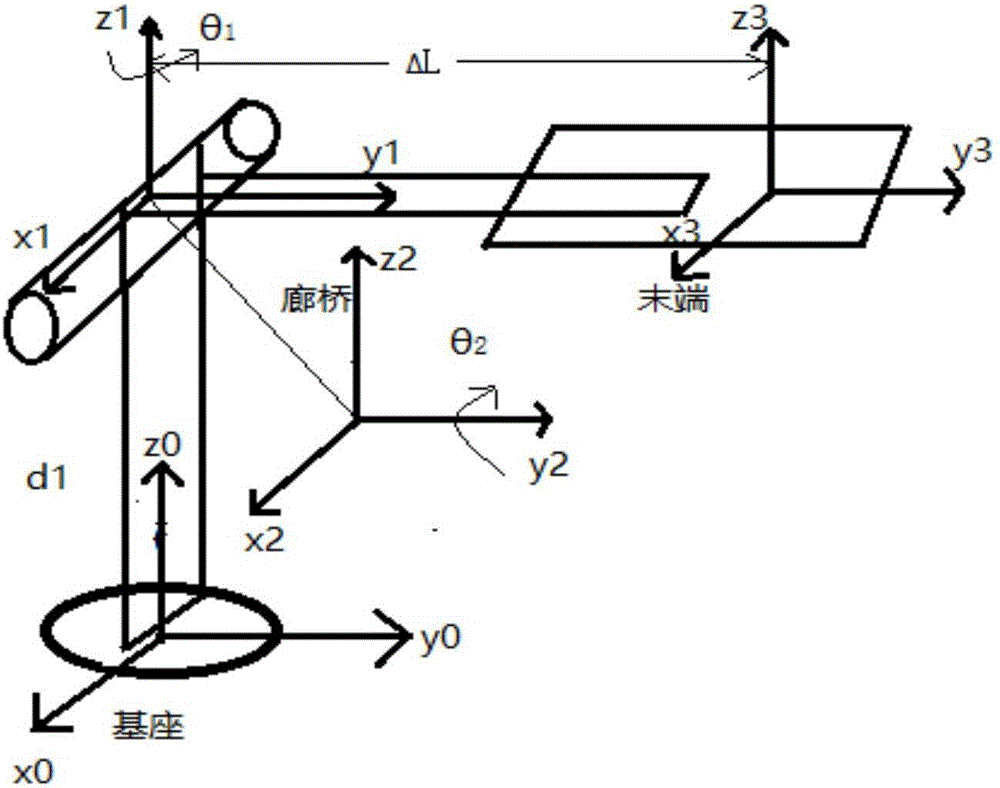

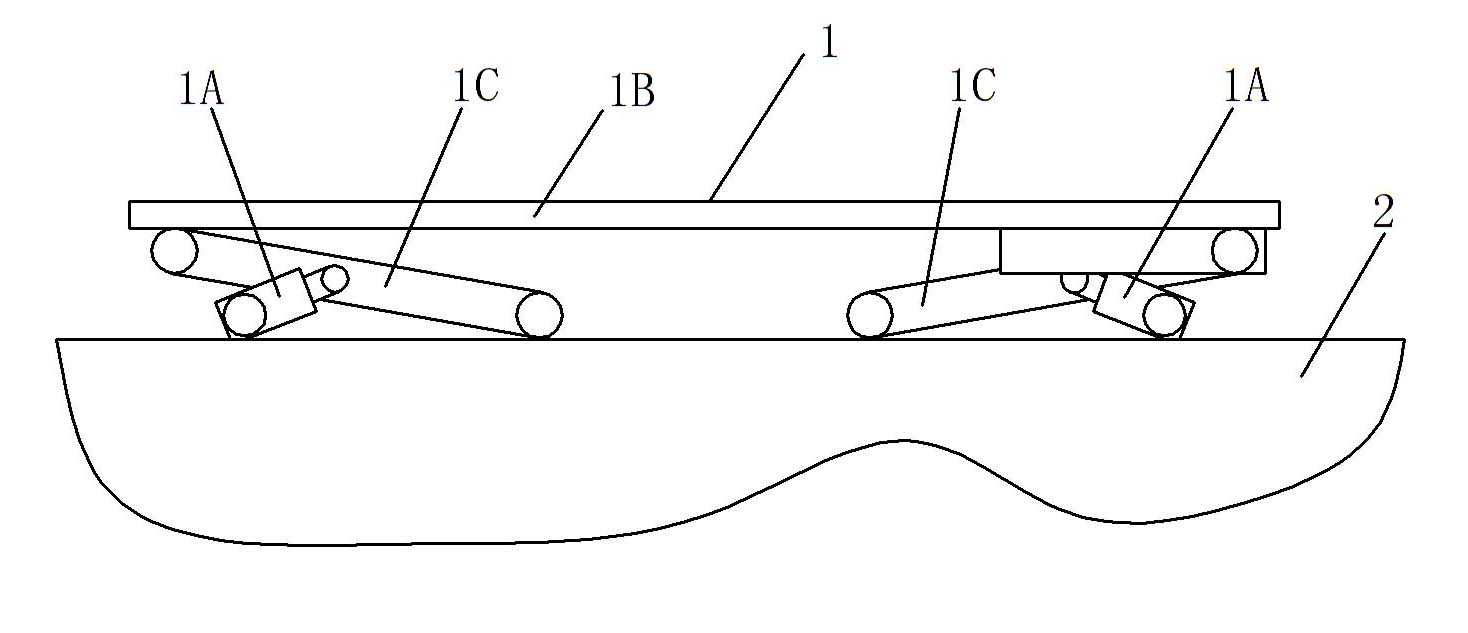

Electric ocean wave active compensation embarkation system and control method thereof

ActiveCN107434010AActive compensation real-time monitoringActive compensation real-time controlCargo handling apparatusShip vibration reductionControl systemEngineering

The invention relates to an electric ocean wave active compensation embarkation system and a control method thereof, and relates to the technical field of marine engineering. The system comprises a rolling compensation mechanism, a pitching compensation mechanism, a stretching and retracting compensation mechanism, a pose detecting system, a movement control system and an electrical system. The method comprises the following steps: connecting a base with a deck of a ship; placing the tail end of the system on a marine fan platform, wherein the pose and position of the ship can be changed due to the fact that the ship is affected by ocean waves; detecting the ship change position and a posture change parameter by using the pose detecting system; providing control information feedback to the movement control system; and controlling the rolling compensation mechanism, the pitching compensation mechanism and the stretching and retracting compensation mechanism to actively compensate the ocean waves in real time by using the movement control system according to parameters of the pose detecting system through model resolving and motion control calculation. The ocean waves are actively compensated, and therefore, maintenance staffs can safely and reliably walk on the marine fan platform.

Owner:HARBIN ENG UNIV +2

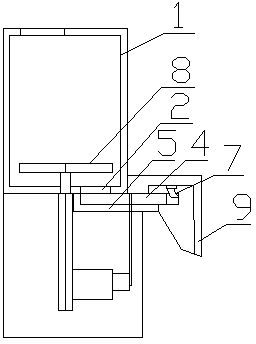

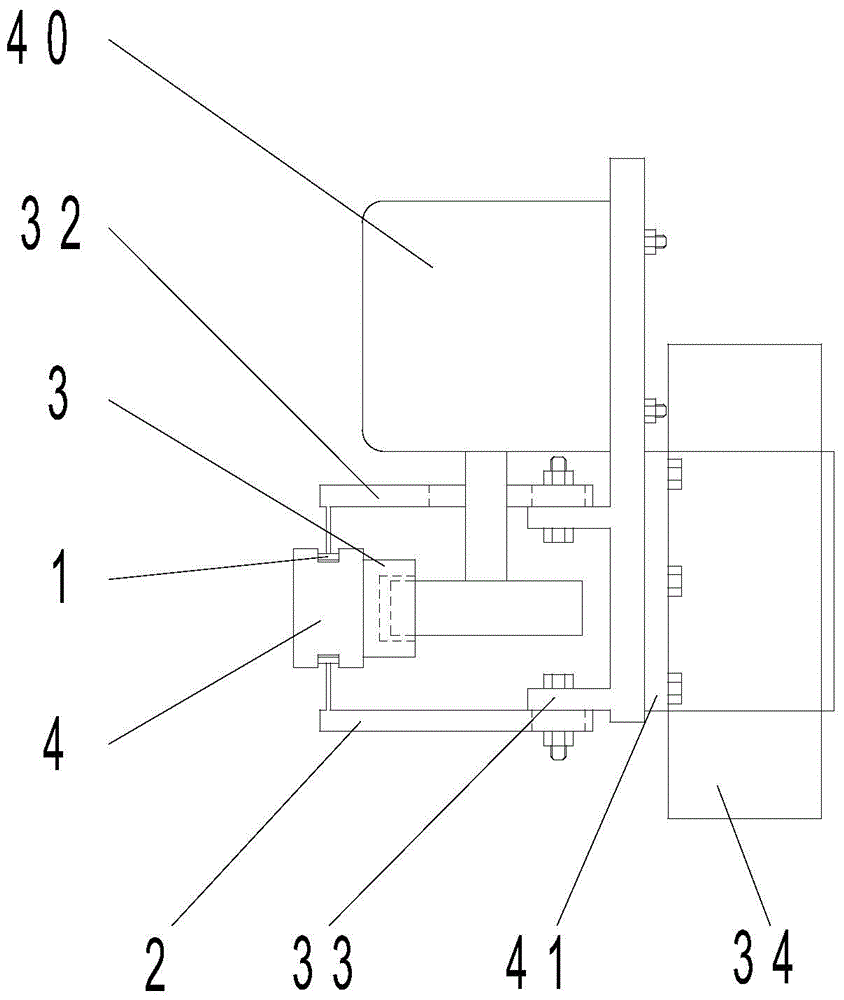

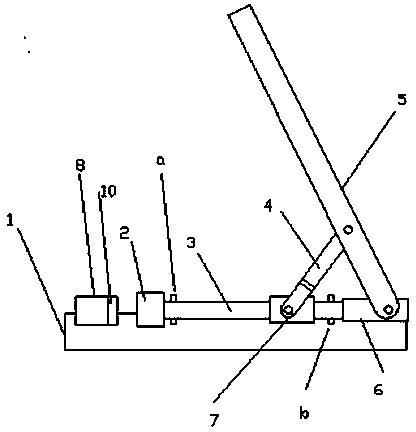

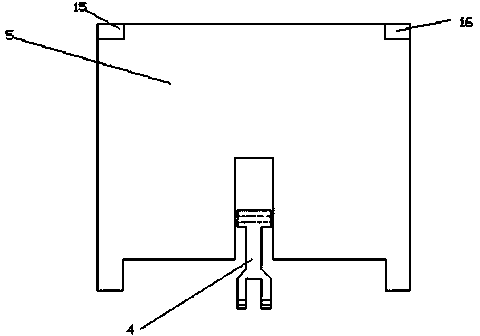

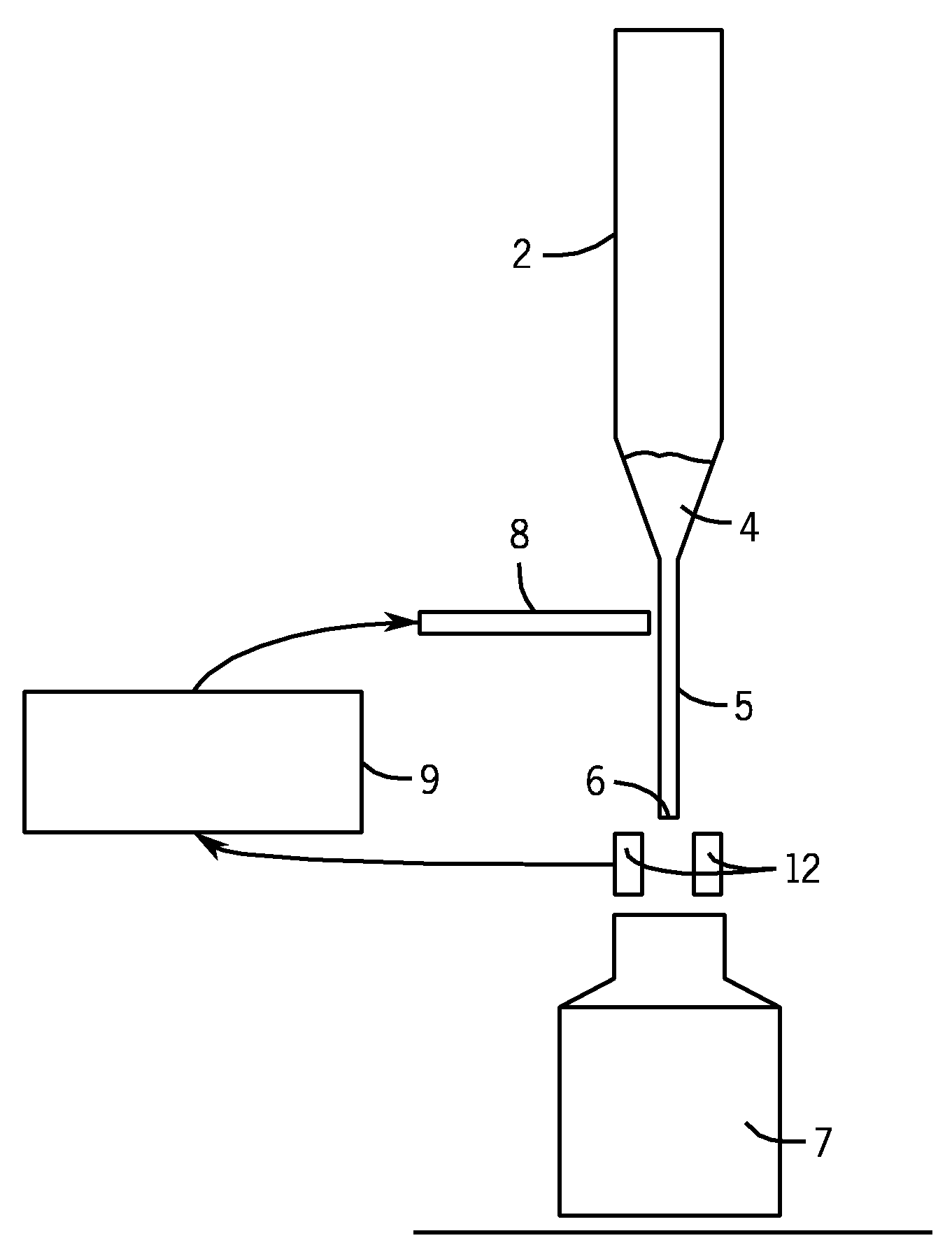

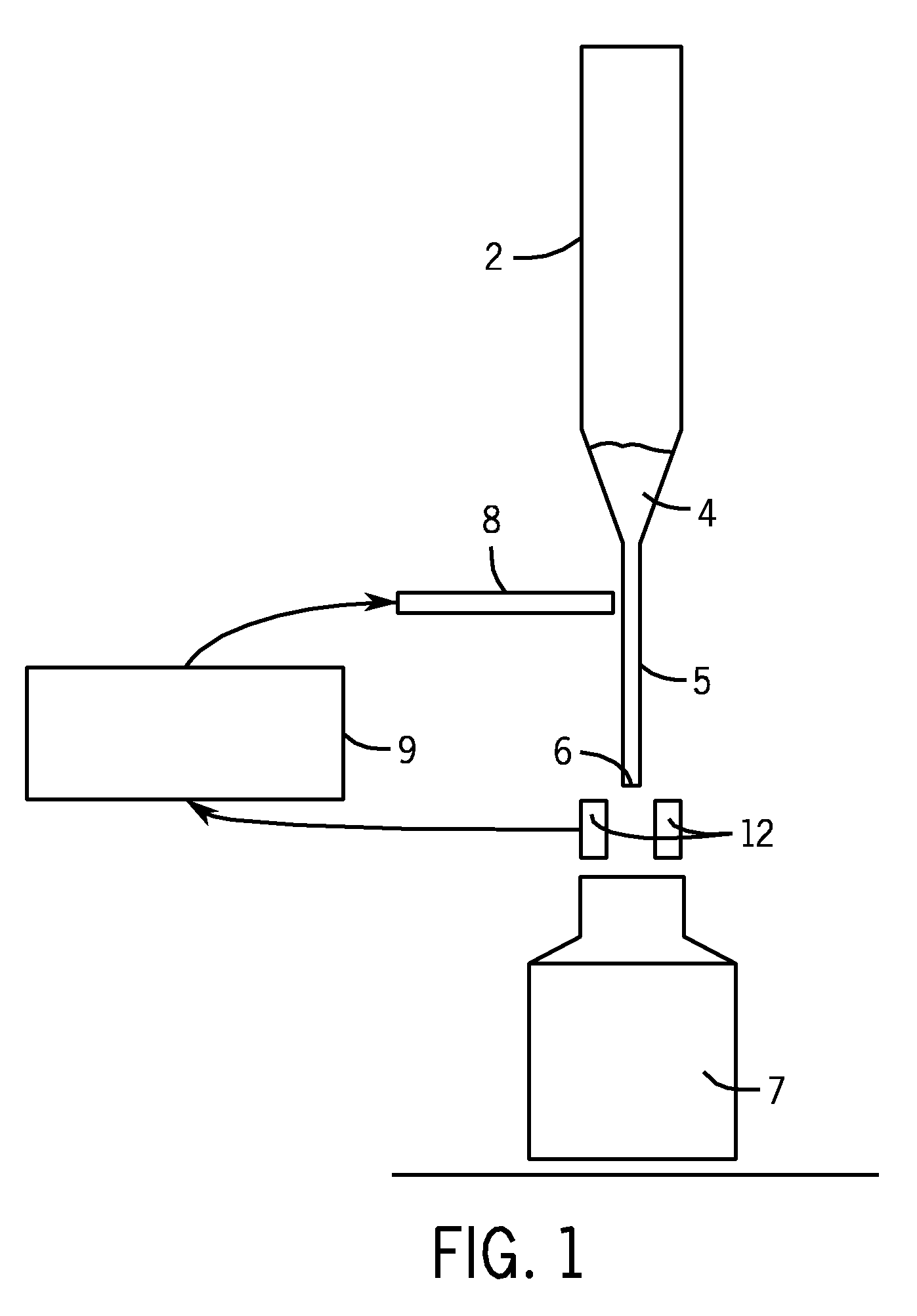

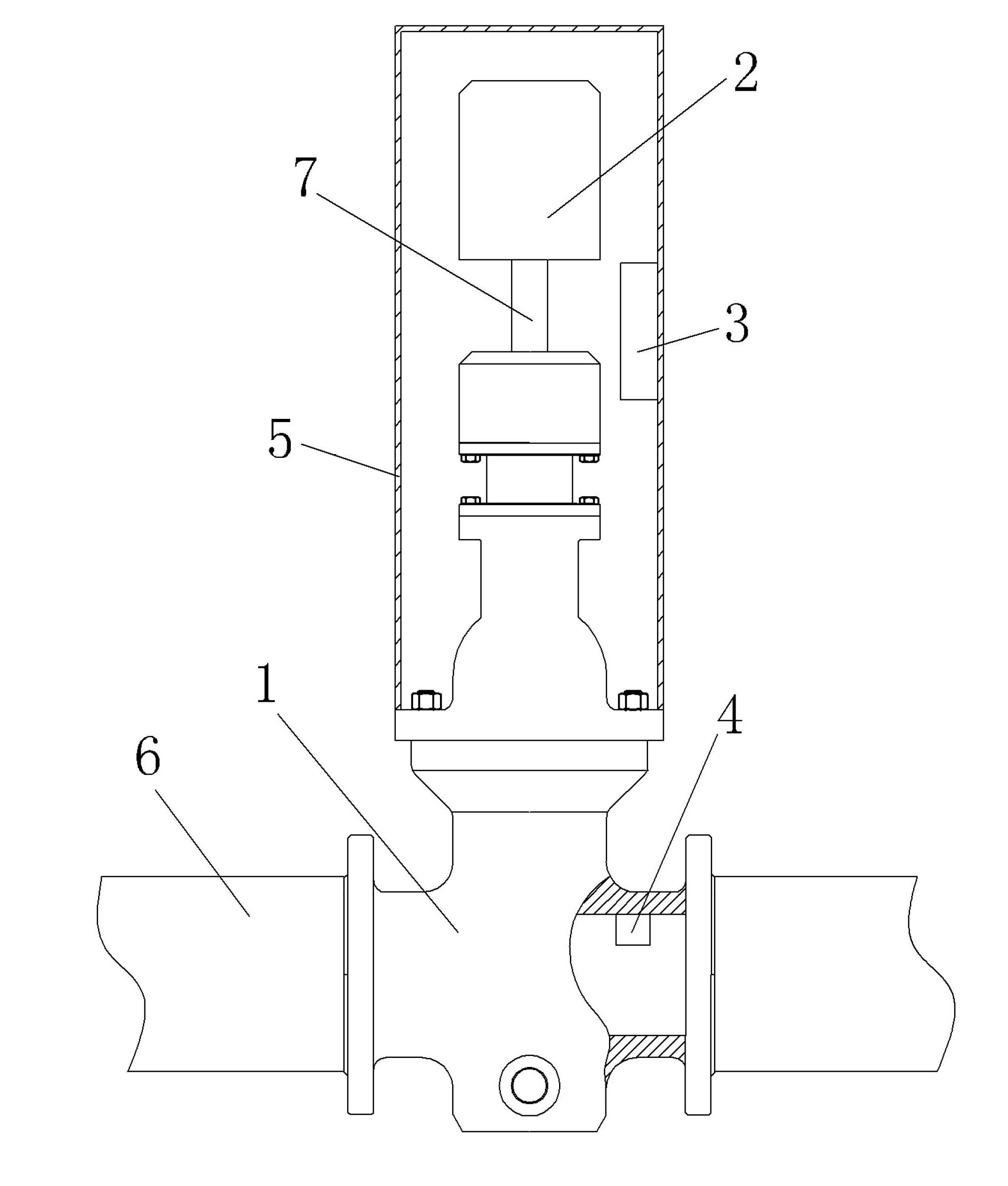

Closed-loop controlled remote control parking lock

The invention provides a closed-loop controlled remote control parking lock, comprising a mounting seat (1); a controller (10), a motor (2), a screw rod (3) and a bottom rod (6) are arranged on the mounting seat (1), wherein a detachable storage battery (8) is configured on the controller (10); two ends of the screw rod (3) are respectively provided with a screw nut position sensor a and a screw nut position sensor b; a screw cap (7) is further sleeved at the outer peripheral face of the screw rod (3); the screw cap reciprocates on the screw rod (3) along with the forward and backward rotating of the screw rod (3); a wireless signal receiving module (15) and a car departing sensor module (16) are respectively mounted at two sides of the upper end of the bottom rod (6); the remote control parking lock also comprises a support rod (4) of which one end is connected with the screw cap (7) in a clamping manner; the other end of the support rod is hinged to a movable panel (5).

Owner:郭树满

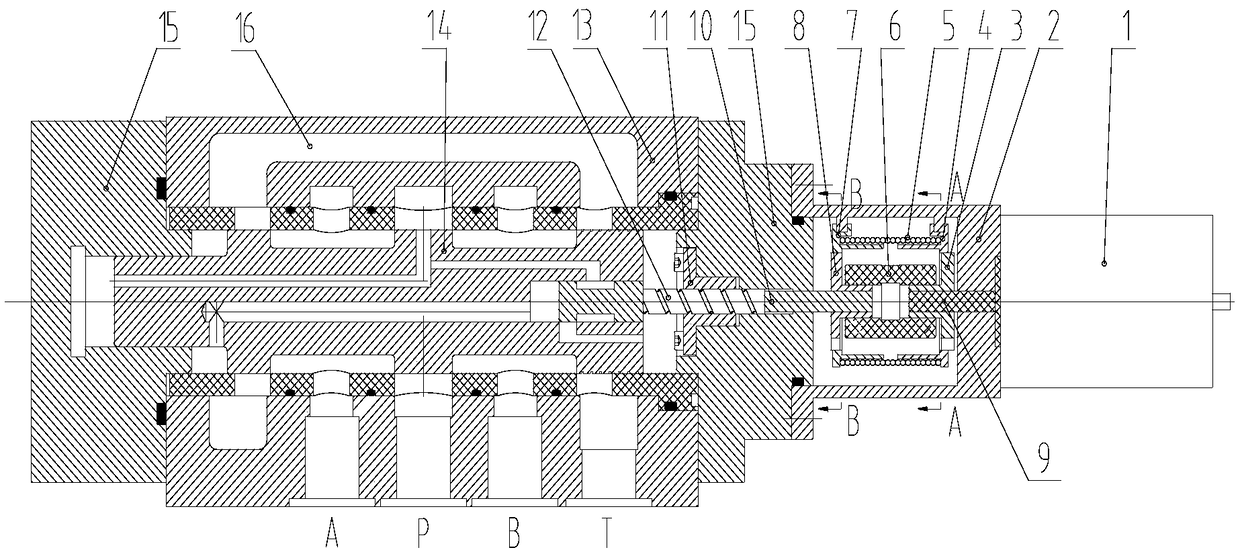

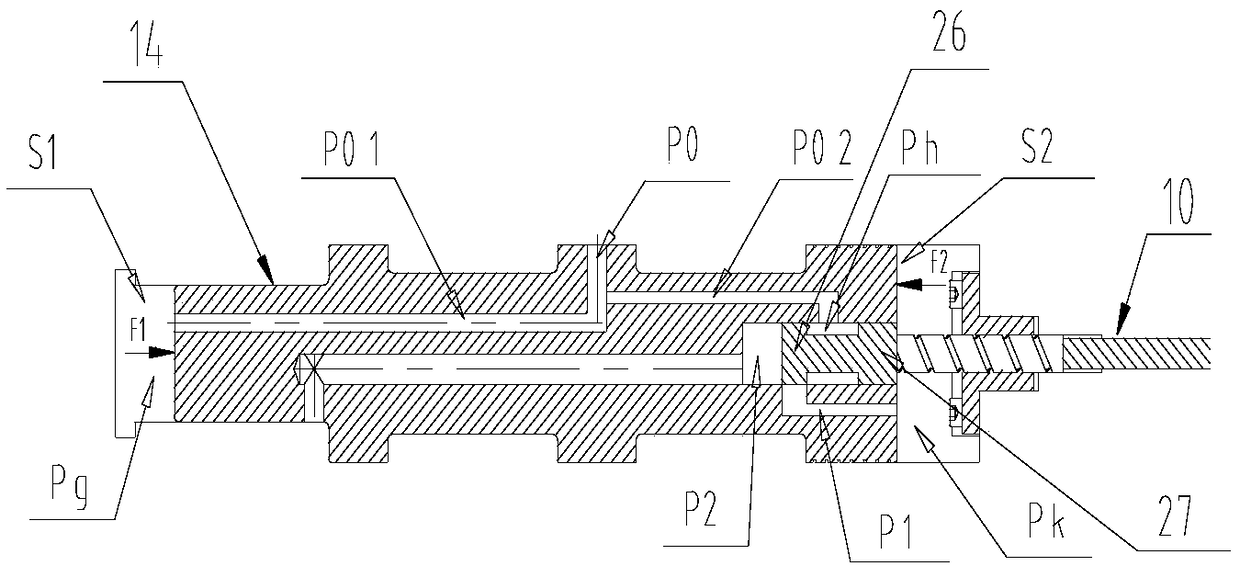

Indirect control type digital servo valve

PendingCN108757621ASimple structureImplementation driveServomotor componentsDifferential pressureEngineering

The invention provides an indirect control type digital servo valve. According to the technical scheme, digital quantity control is adopted, the driving force of a valve element is large, the valve element is not prone to jamming, the anti-pollution capability of the servo valve is improved, the control of a main valve element can be realized without arranging a sensor, so that the control loop issimplified. In order to achieve the aim, the indirect control type servo valve comprises a valve body, the main valve element and a pilot valve element, the main valve element is provided with an oilinlet passage, an oil return passage and a control oil passage, the area of the axial two ends of the main valve element is unequal, the valve body is provided with a control oil cavity communicatingwith the control oil passage at the end, which is large in area, of the main valve element, and is provided with a high-pressure oil cavity communicating with high-pressure oil at the end, which is small in area, of the main valve element, one end of the pilot valve element extends into the main valve element in an axial direction so as to enable the control oil passage and the oil inlet passageor the oil return passage to communicate through axial movement, so that the two ends of the main valve element form the differential pressure for axial movement, then the working positions of the valve are switched, and the continuous adjustment of the flow is realized.

Owner:三河沃达液压控制系统有限公司

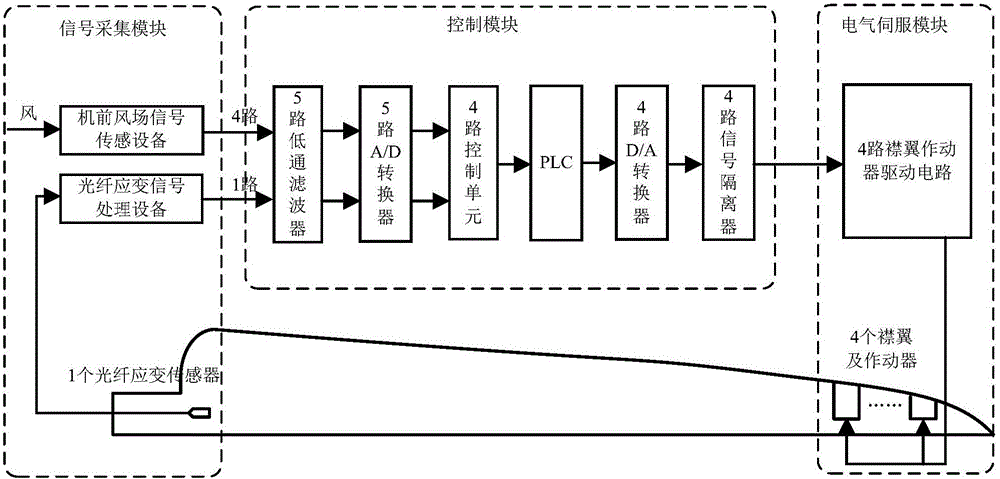

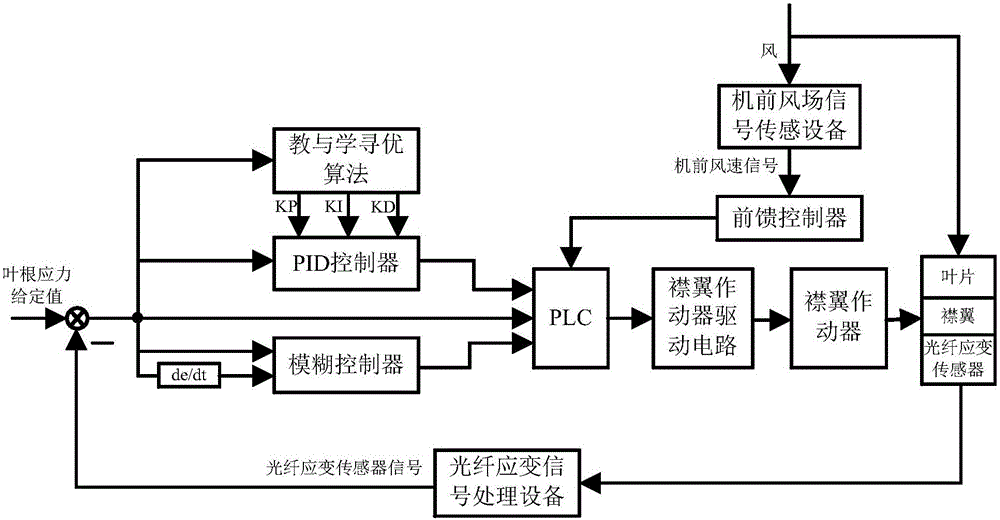

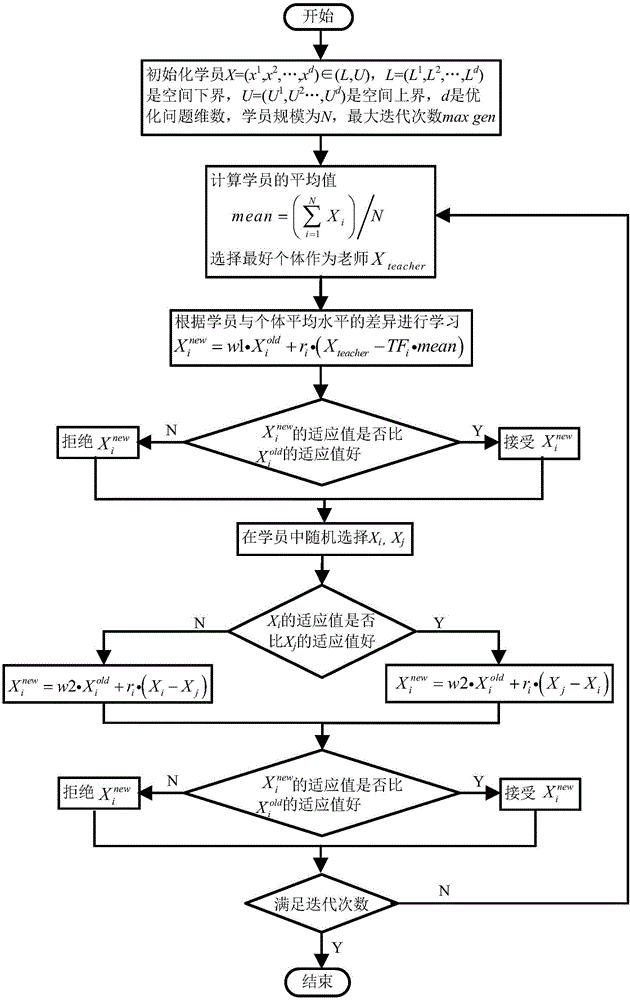

Active load reducing control system and method for large wind turbine blade

InactiveCN105888971AReduce strainReduce use costWind motor controlMachines/enginesControl systemTurbine blade

The invention relates to an active load reducing control system and method for a large wind turbine blade. An optical fiber strain sensor measures a stress value of the root portion of the blade and transmits the stress value to a control unit; the control unit comprises a PID controller performing parameter optimization through a teaching and learning algorithm and a fuzzy controller for processing a strain force signal of the root portion of the blade; a flap swing angle is subjected to switching control through the fuzzy controller and the PID controller, and beneficial effects of fuzzy control and PID control are synthesized; meanwhile, a machine front wind field signal sensing device measures the front air speed of a wind turbine and transmits the front air speed to the control unit; a feedforward controller in the control unit calculates control quantities needed by uniform loads caused by reducing stochastic wind or turbulent wind by monitoring the change of the machine front air speed in real time; and the control unit couples the two parts of control quantities, and control over the flap swing angle is completed. The active load reducing control system and method for the large wind turbine blade effectively reduce the strain force of the root portion of the blade, the service life of the blade is prolonged, and the using cost of a wind turbine unit is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

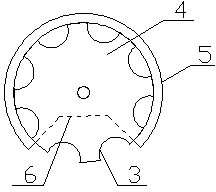

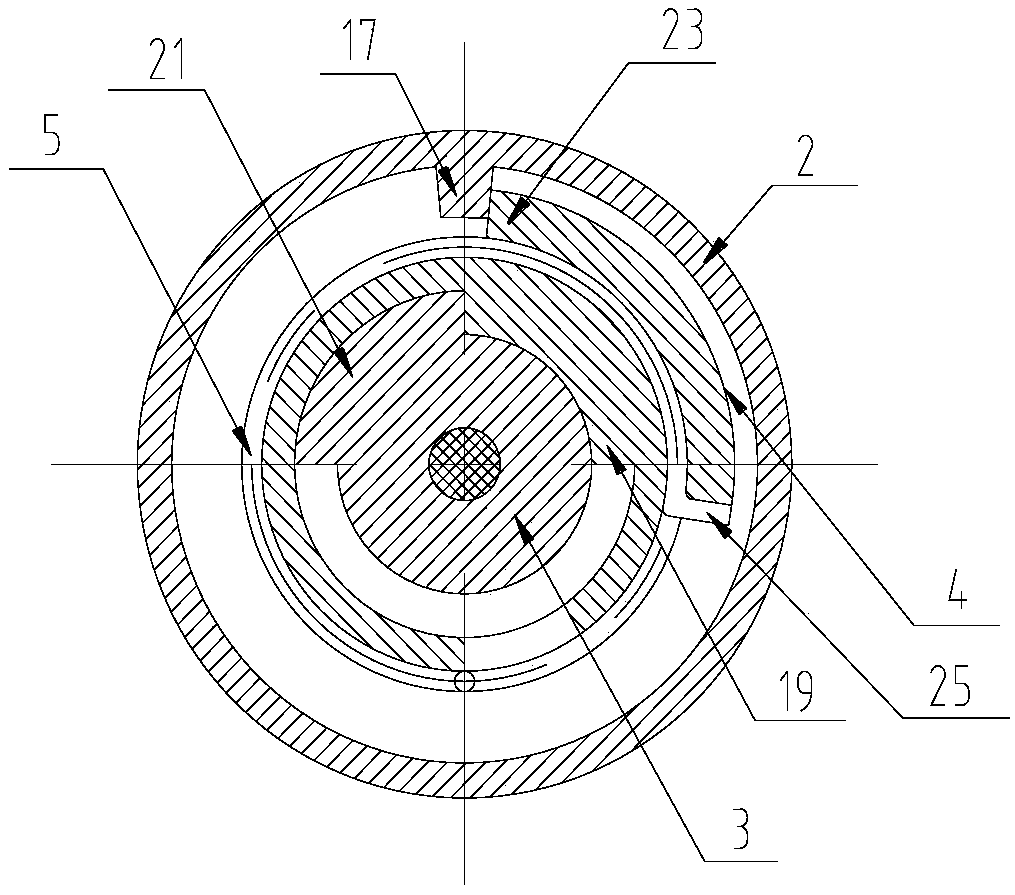

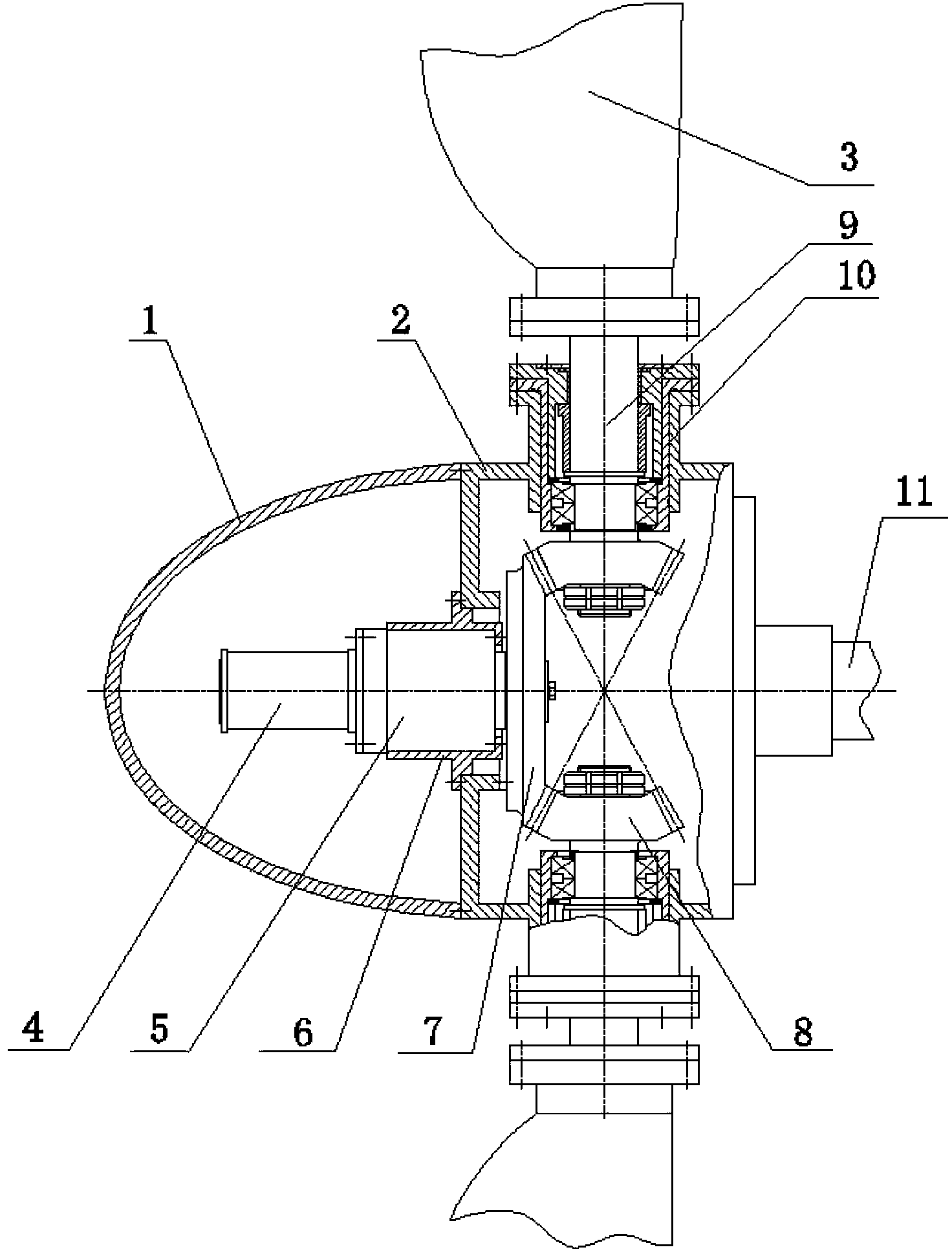

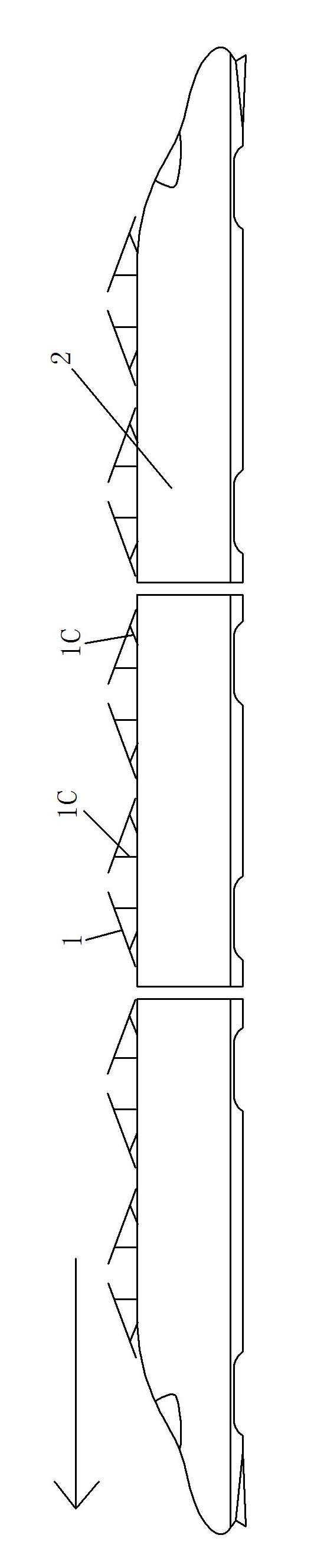

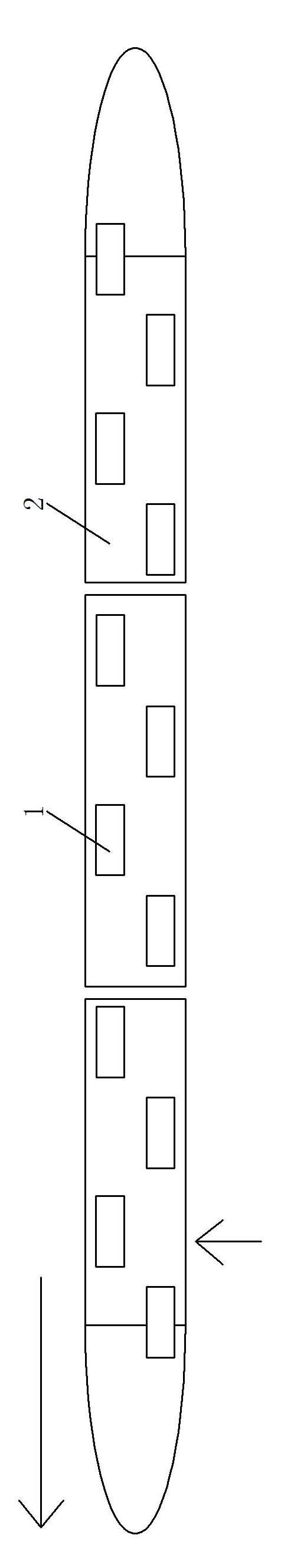

Variable-pitch mechanism of tidal current energy electricity generation water turbine

InactiveCN103397980AReduce positive shockReduce volumeHydro energy generationMachines/enginesWater turbineReduction drive

The invention discloses a variable-pitch mechanism of a tidal current energy electricity generation water turbine. The variable-pitch mechanism comprises a variable-pitch hub, a bevel gear wheel, bevel pinions, a blade shaft and blades; one end of the variable-pitch hub is connected with a speed reducer and a drive motor in sequence, and the speed reducer and the drive motor are arranged in an outer cover; the other end of the speed reducer is connected with the bevel gear wheel, and the bevel gear wheel is meshed with at least two of the bevel pinions; the blade shaft is arranged on the variable-pitch hub and can rotate by means of the rotation of the bevel pinions; the blades are arranged on the blade shaft. The variable-pitch mechanism of the tidal current energy electricity generation water turbine has the advantages that the drive motor and the speed reducer are installed at the front end of the variable-pitch hub, therefore, the structural size of the variable-pitch hub is effectively reduced, and the structure is compact; moreover, the outer cover of the water turbine adopts a streamlined design, therefore, the impact of water flow in the forward direction is effectively reduced, and the water turbine is safe and reliable; the mechanism of the drive motor and the speed reducer is adopted, therefore, accurate and reliable control over pitch angles is realized, large torque can be output, and synchronous pitch variation is facilitated.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Crosswind hazard inhibition method of train and device thereof

The invention discloses a crosswind hazard inhibition method of a train and a device thereof. The method comprises the following steps of: A. establishing a crosswind security database; B. measuring the running speed of a train by a speed monitoring device arranged on the train, and measuring the current wind speed and wind direction by a wind measurement device arranged on a railway line or an on-board wind measurement device; C. installing wing plates with regulable angles of attack at both sides of the top of the body of the train, wherein the actuators of the wing plates are connected with an on-board control computer; and D. the on-board control computer calls the crosswind security database to calculate and judge according to the measured running speed of the train and the measured wind speed and wind direction and outputs a corresponding command to control the actuators to actuate to regulate the angles of attack of the wing plates so as to inhibit the influence of the crosswind on the train. The method can change the balance characteristic of the train in the running process under the crosswind action, thereby ensuring the safety, the stability and the high-speed running of the train, and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

Frequency and amplitude adjustable mud sample vibration device

ActiveCN103852363AMeet regulatory control requirementsPrecise and reliable controlPreparing sample for investigationMechanical vibrations separationCamFrequency modulation

The invention relates to a frequency and amplitude adjustable mud sample vibration device which at least comprises a vibrating mechanism and a material loading and unloading mechanism. The sample vibration device also comprises an amplitude modulation mechanism and a frequency modulation unit, wherein the amplitude modulation mechanism comprises an amplitude modulation swing board, an amplitude modulation wedge block, an amplitude modulation handle, a lead screw, a lead screw support, an amplitude modulation support and an amplitude modulation scale; the frequency modulation unit is a stepping motor used for frequency modulation; the stepping motor is arranged on the amplitude modulation swing board; the vibrating mechanism comprises a belt, a belt pulley, a start vibration cam, an ejector rod, an impact rod and an impact block; the belt pulley is coaxial with the start vibration cam; the belt pulley is connected with the stepping motor through the belt; the belt pulley is embedded at one end of a sleeve on the right side of the amplitude modulation swing board; the middle of the sleeve is arranged on a wedge surface of the amplitude modulation wedge block; the material loading and unloading mechanism is positioned on the top of the whole device and at least comprises a material disc and a material disc bracket connected with the ejector rod and the impact rod. The dynamic characteristics of soil and dynamic load conditions needed by soil sample manufacturing are fully considered, and frequency modulation and amplitude modulation of mud sample vibration and vibration frequency control can be realized.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

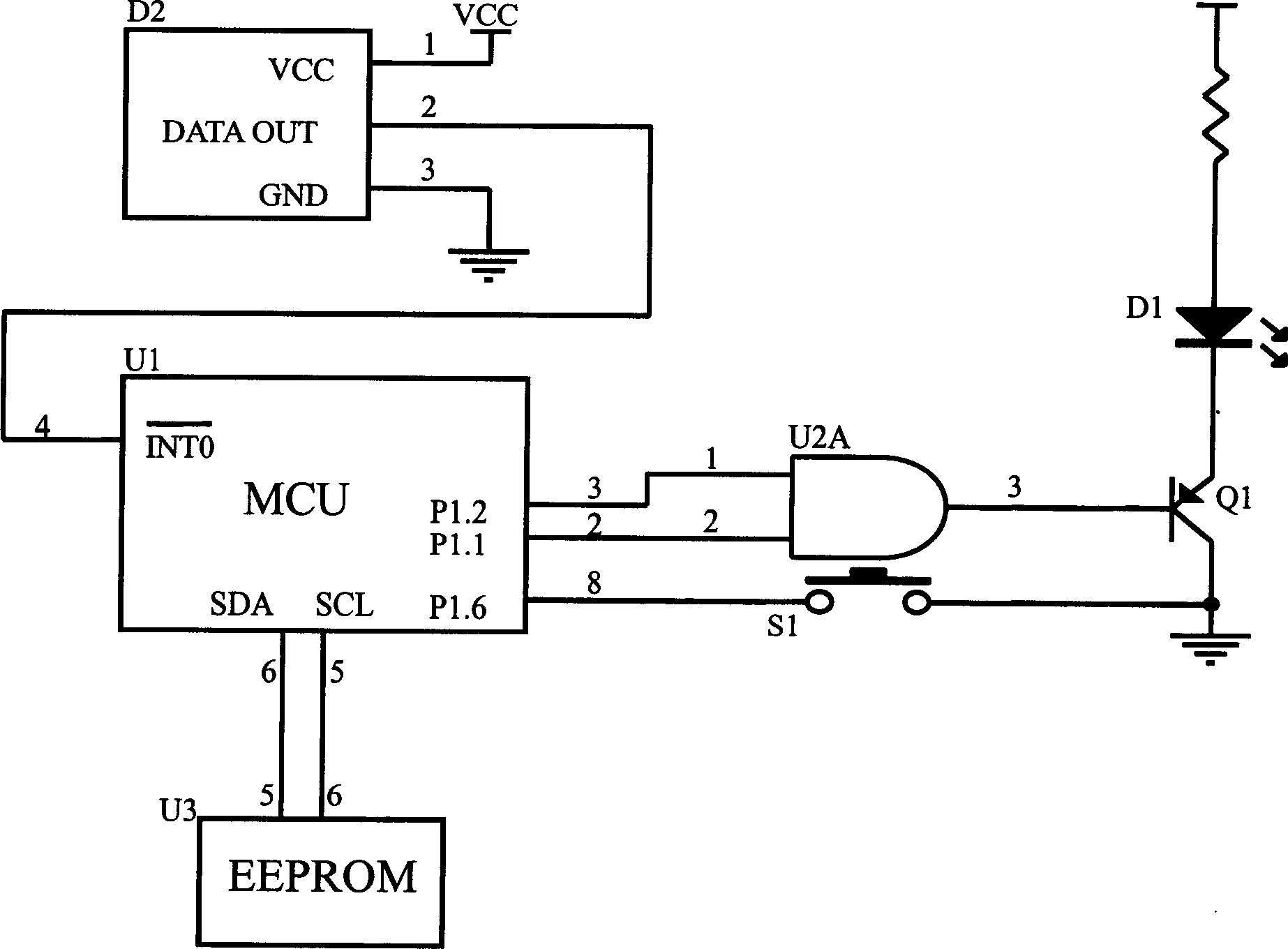

Programmable infrared remote control method and its circuit

InactiveCN1822067APrecise and reliable controlNon-electrical signal transmission systemsInfraredUser needs

This invention discloses a programmable infrared remote control method and its circuit, in which, a master electric appliance sends an infrared remote control signal received and processed to a MCU chip from an outer interrupt port of the MCU chip for decoding process to get the remote control codes and stores them into the EEPROM chip in terms of designed code number, when a user needs to remote control another appliance, it can read a related remote control code, an idle I / O port of the MUC chip simulates the level time sequence signals of the code and the other port generates infrared carrier signals cooperated by a timer then to send the modulated remote control signal to an infrared emission tube to be emitted, therefore, the master appliance can control other appliances accurately and reliably.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Device and Method for the Quantity-Controlled Filling of Containers with Powdered Substances

InactiveUS20090056826A1Extended reaction timeImprove reliabilityVolume/mass flow measurementVolume measurement and fluid deliveryQuantitative determinationEngineering

A device for the controlled filling of containers with powdered substance includes a supply vessel with a narrow exit opening for temporarily holding the powdered substance and for discharging a predetermined quantity of the powdered substance into a container located underneath the supply vessel, a vibrator means is connected to the supply vessel for effecting the discharge of the powdered substance. A sensor for determining the quantity of powdered substance discharged from the supply vessel into the container, and a control unit, which converts the data acquired by the sensor into control commands for the vibrator means is included. The sensor includes a capacitive sensor for the quantitative determination of the quantity of powdered substance falling there through during the filling process and is located between the supply vessel and the container.

Owner:UHLMANN VISIOTEC +1

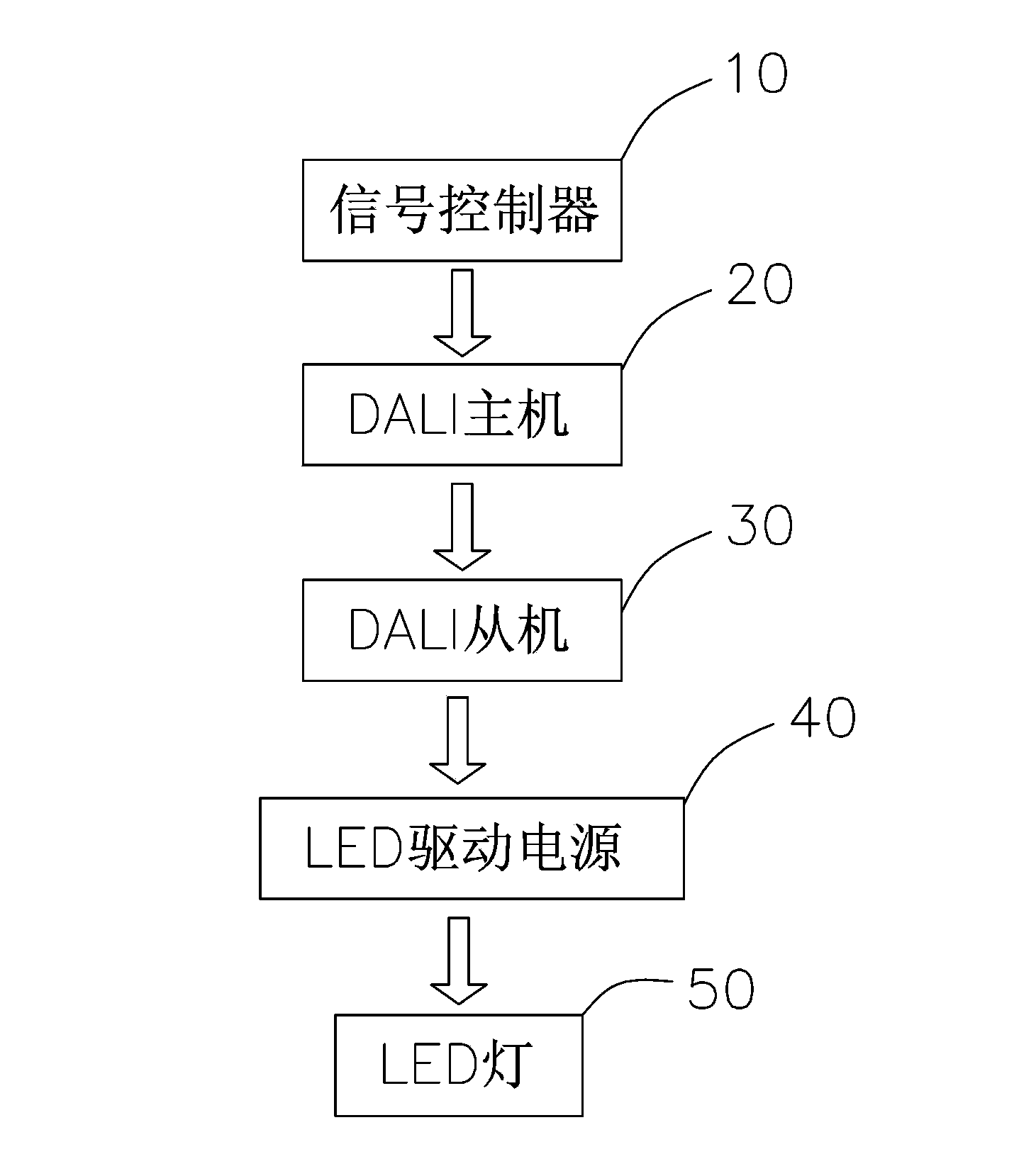

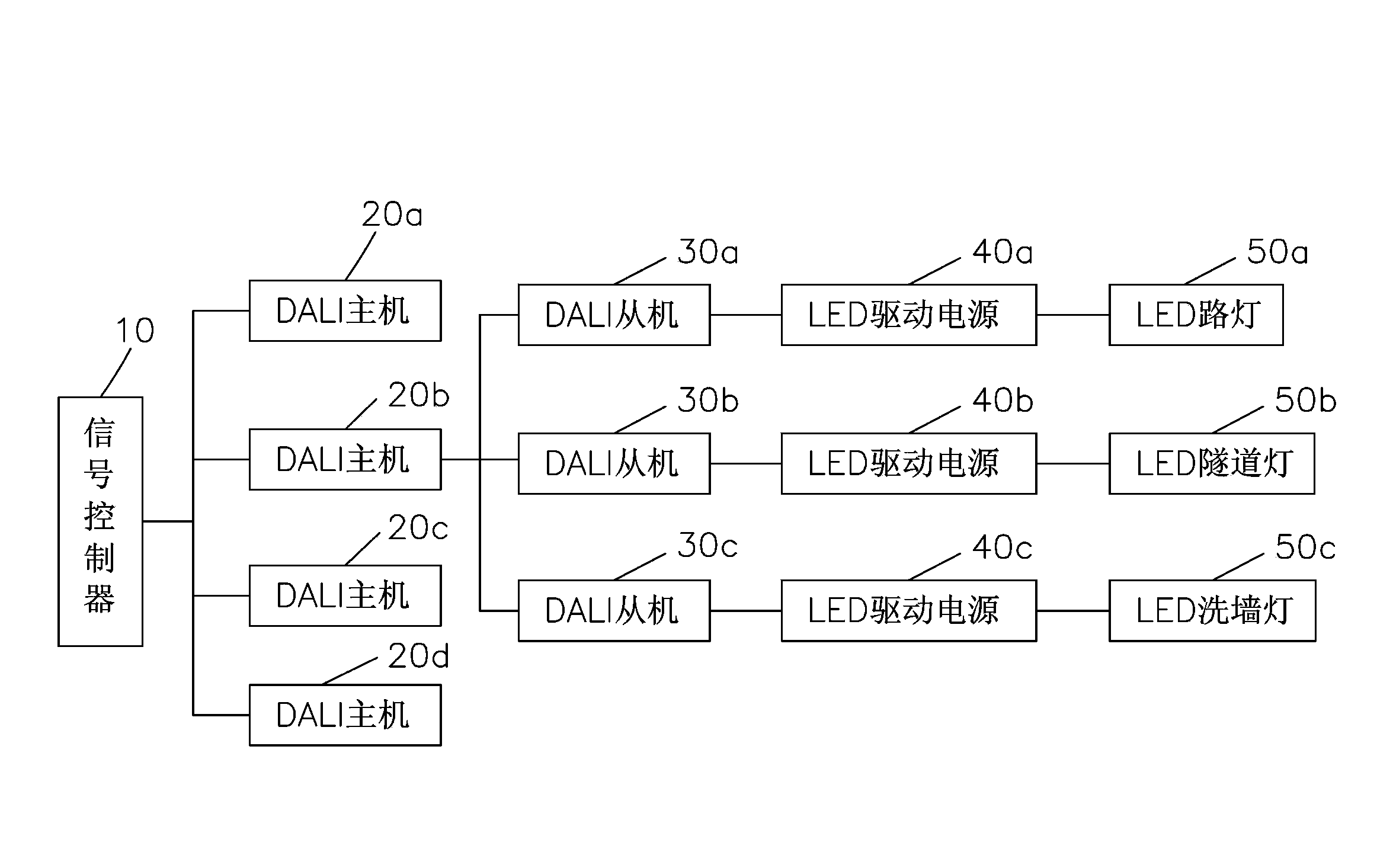

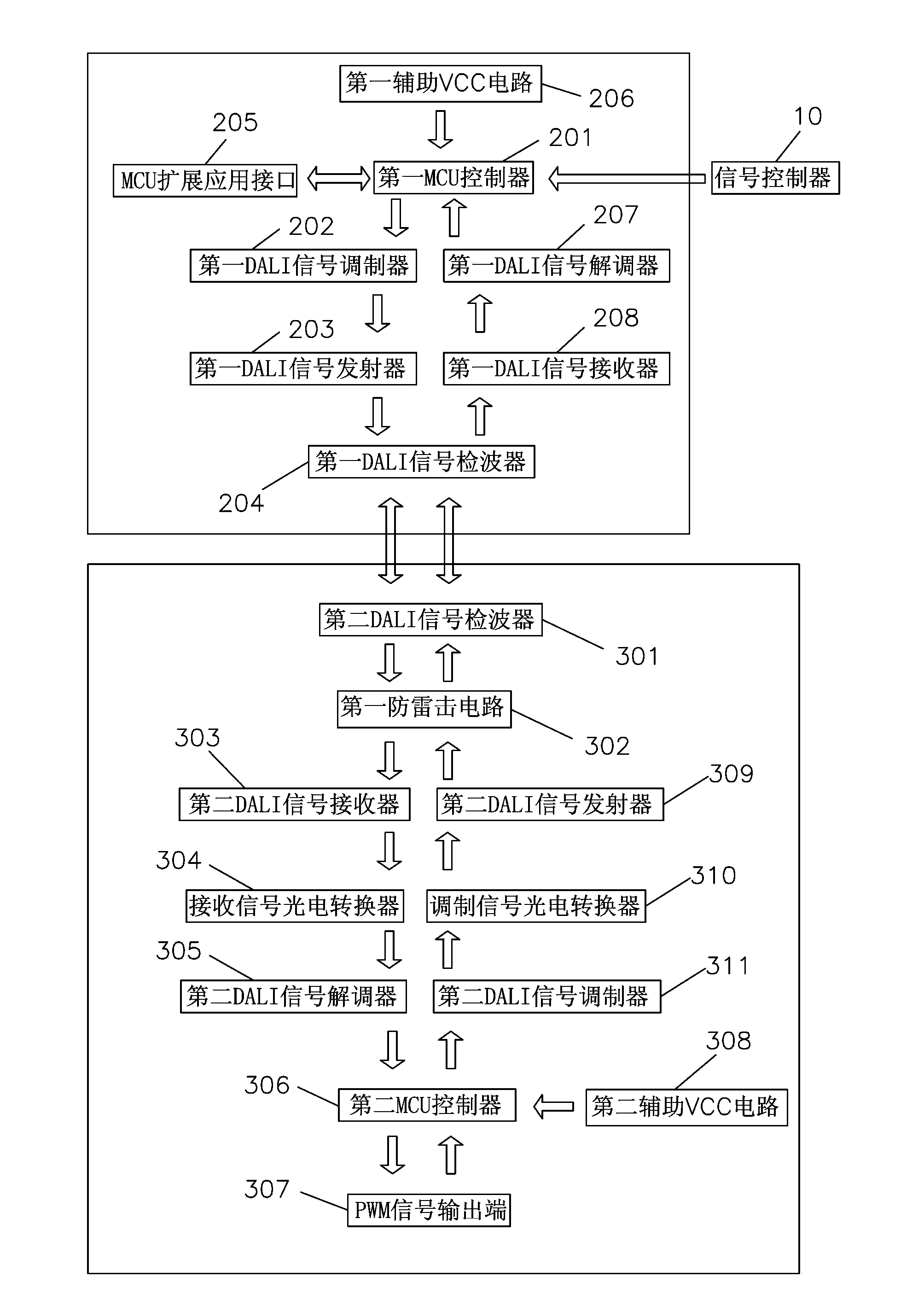

Intelligent light-regulating LED power supply device based on DALI

InactiveCN103781227ACompact designPrecise and reliable controlElectric light circuit arrangementEnergy saving control techniquesIntelligent lightingControl signal

The invention discloses an intelligent light-regulating LED power supply device based on a DALI, and relates to the technical field of LED light regulation. The device comprises a signal controller, a DALI host machine, a DALI slave machine, an LED driving power supply and an LED lamp connected onto the LED driving power supply. The DALI host machine is used for receiving control information sent by the signal controller and sending the information after processing the information. The DALI slave machine is sued for receiving a signal sent by the DALI host machine and decoding so that the LED driving power supply is controlled and thus brightness of the LED lamp is controlled. Beneficial effects of the device are that: the device is accurate and reliable in control; the DALI is a digital signal which is different from an analog signal, non-disturbance control can be realized by the digital signal without distortion of the control signal due to long-distance voltage drop so that a DALI digital signal control line is not interfered even the DALI digital signal control line and a strong electric line are laid in the same line pipe, and thus the device is accurate and reliable in light regulation.

Owner:SHENZHEN MEIKAI ELECTRONICS

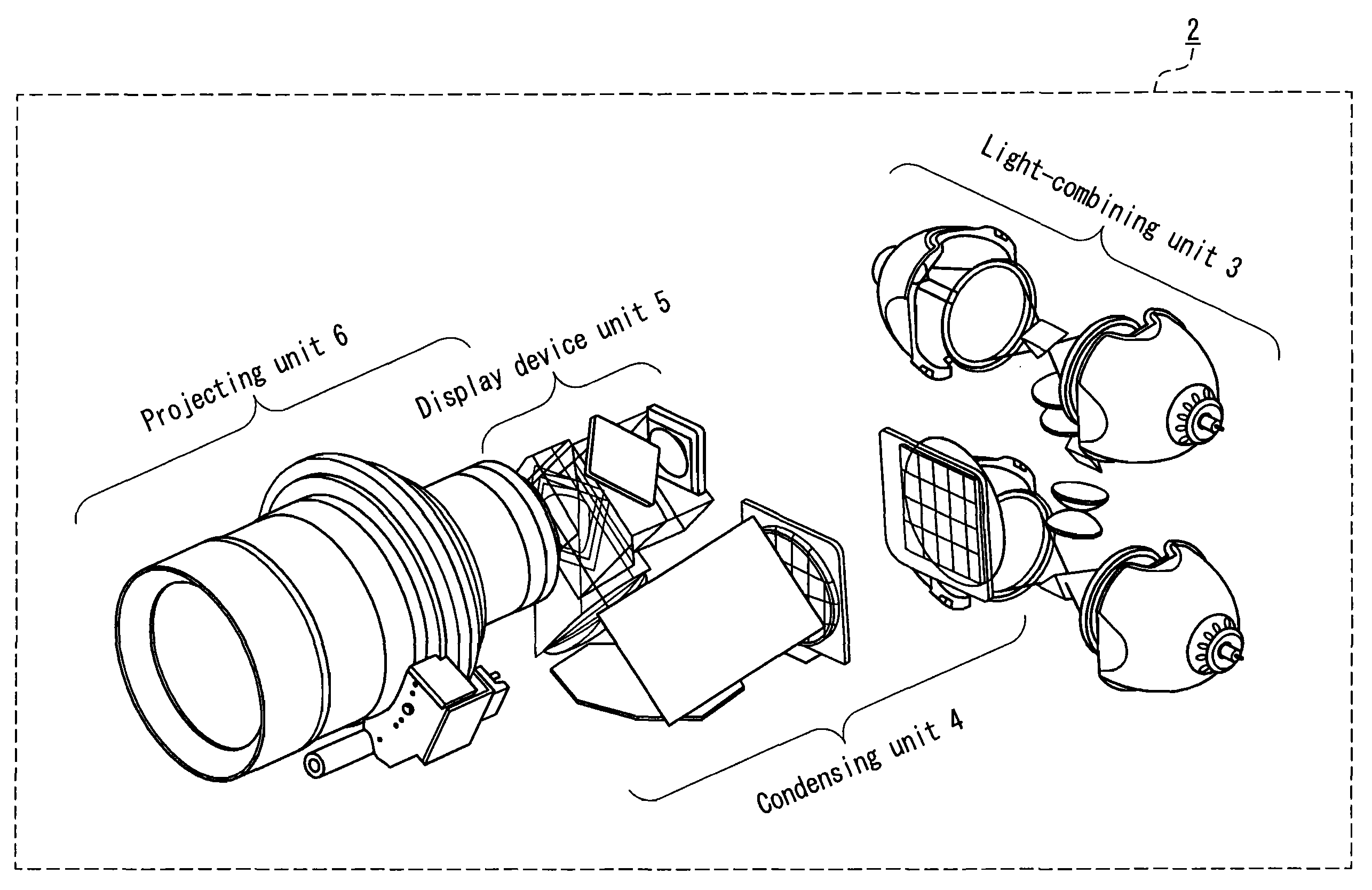

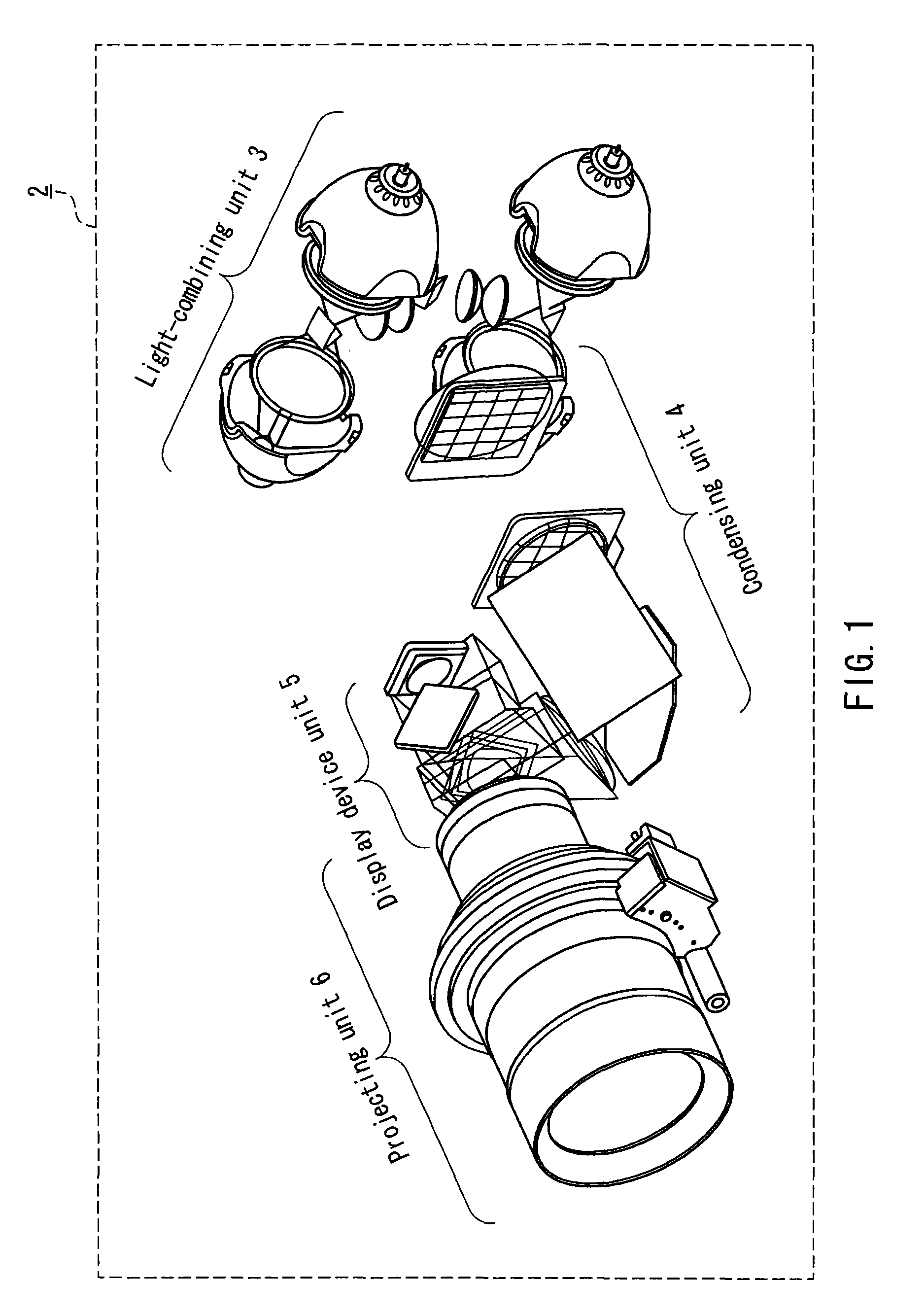

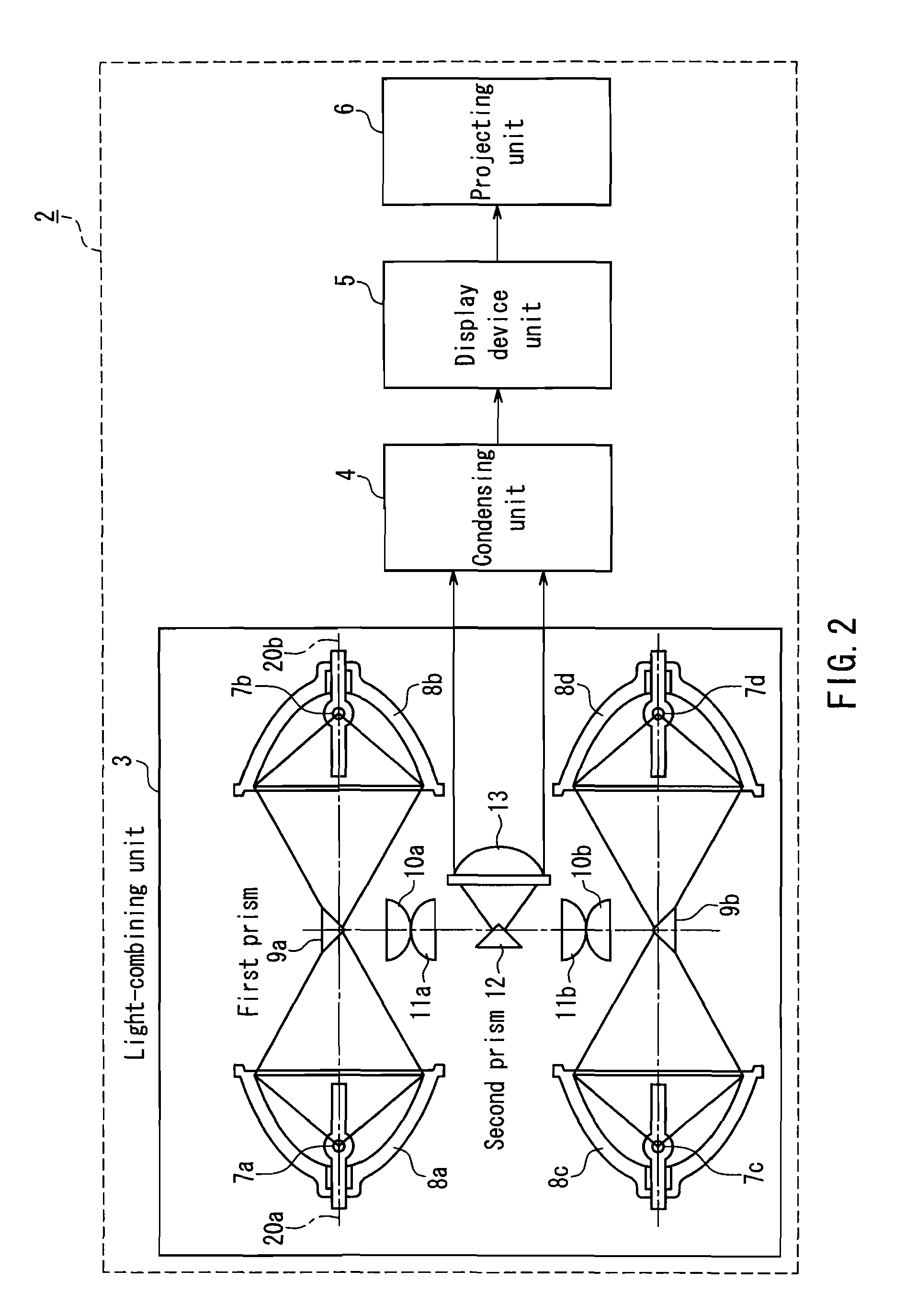

Projection type display apparatus

ActiveUS20100026965A1Prevent of light sourcePrevent and brightness degradationPhotometry using reference valueProjectorsInformation controlDisplay device

A projection type display apparatus includes a plurality of light sources 7a-7d, a display device unit 5, a light-combining unit 3 that combines output light from the plural light sources, a condensing unit 4 that propagates output light from the light-combining unit to the display device unit, and a projecting unit 6 that projects an image by the use of output light from the display device unit. In the projection type display apparatus, cooling units having fans 21a-21d are disposed respectively on the plural light sources, and a controlling unit 31 is provided to control the cooling units. Information regarding the lighting state of the plural light sources is inputted into the controlling unit, and the controlling unit controls a rotation rate of the fans of the cooling units with reference to the information. Concerning a case of temperature management of a plurality of light sources used, an accurate and reliable control is performed; problems such as whitening of the light sources, degradation of life property, blacking, brightness degradation and the like are suppressed, thereby high quality and high reliability are obtained.

Owner:PANASONIC CORP

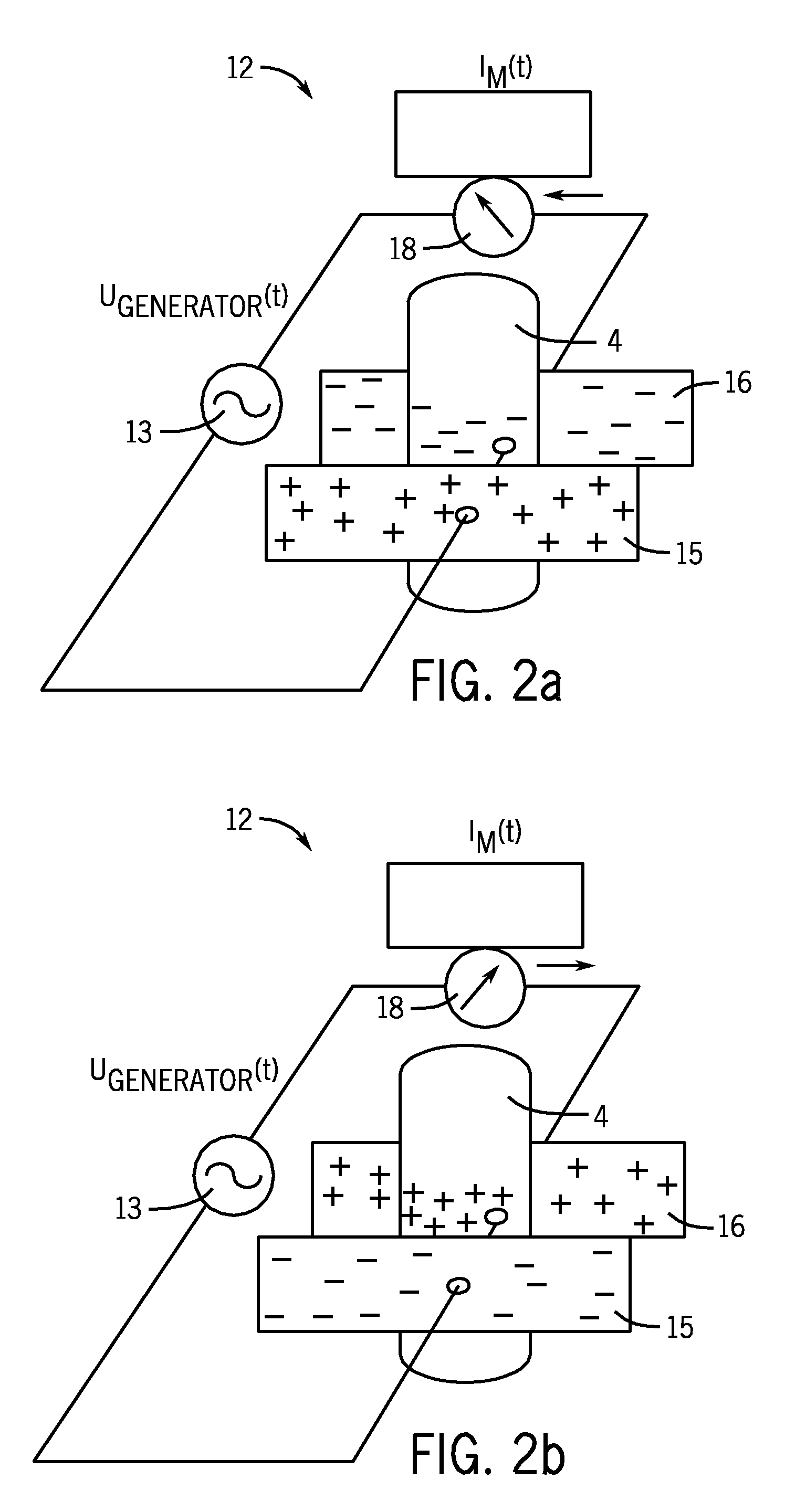

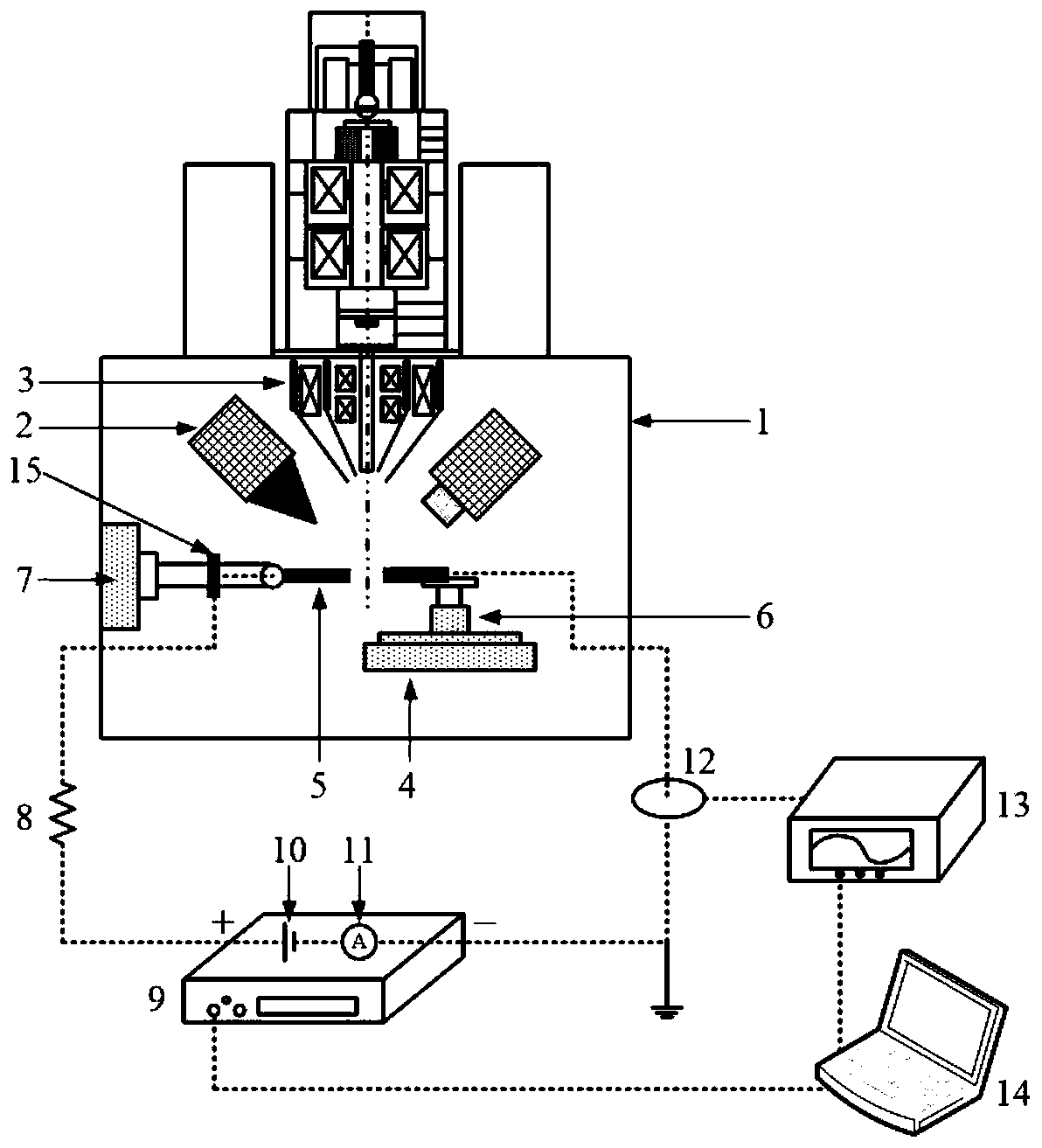

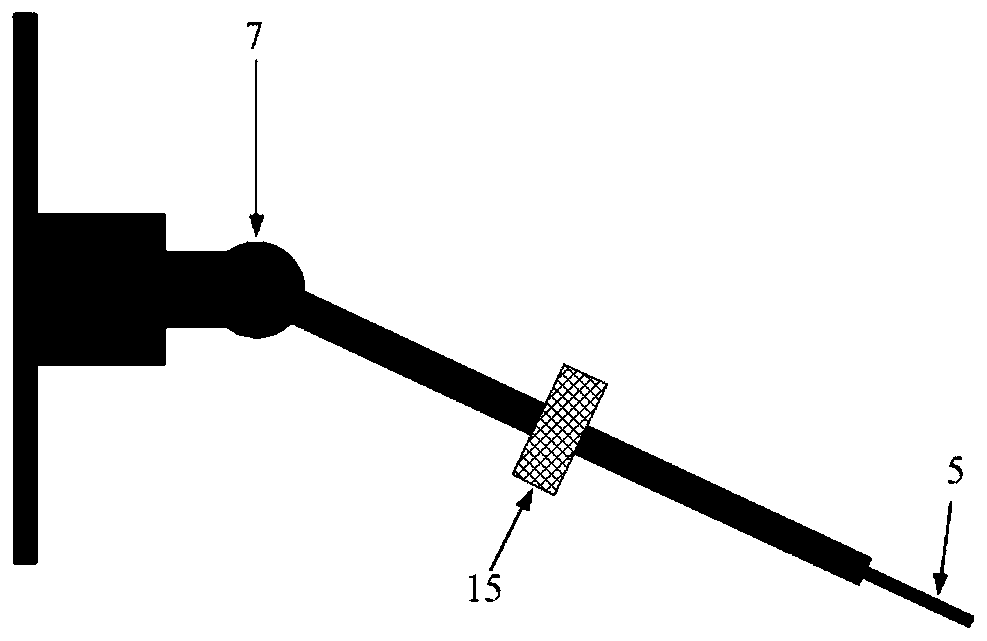

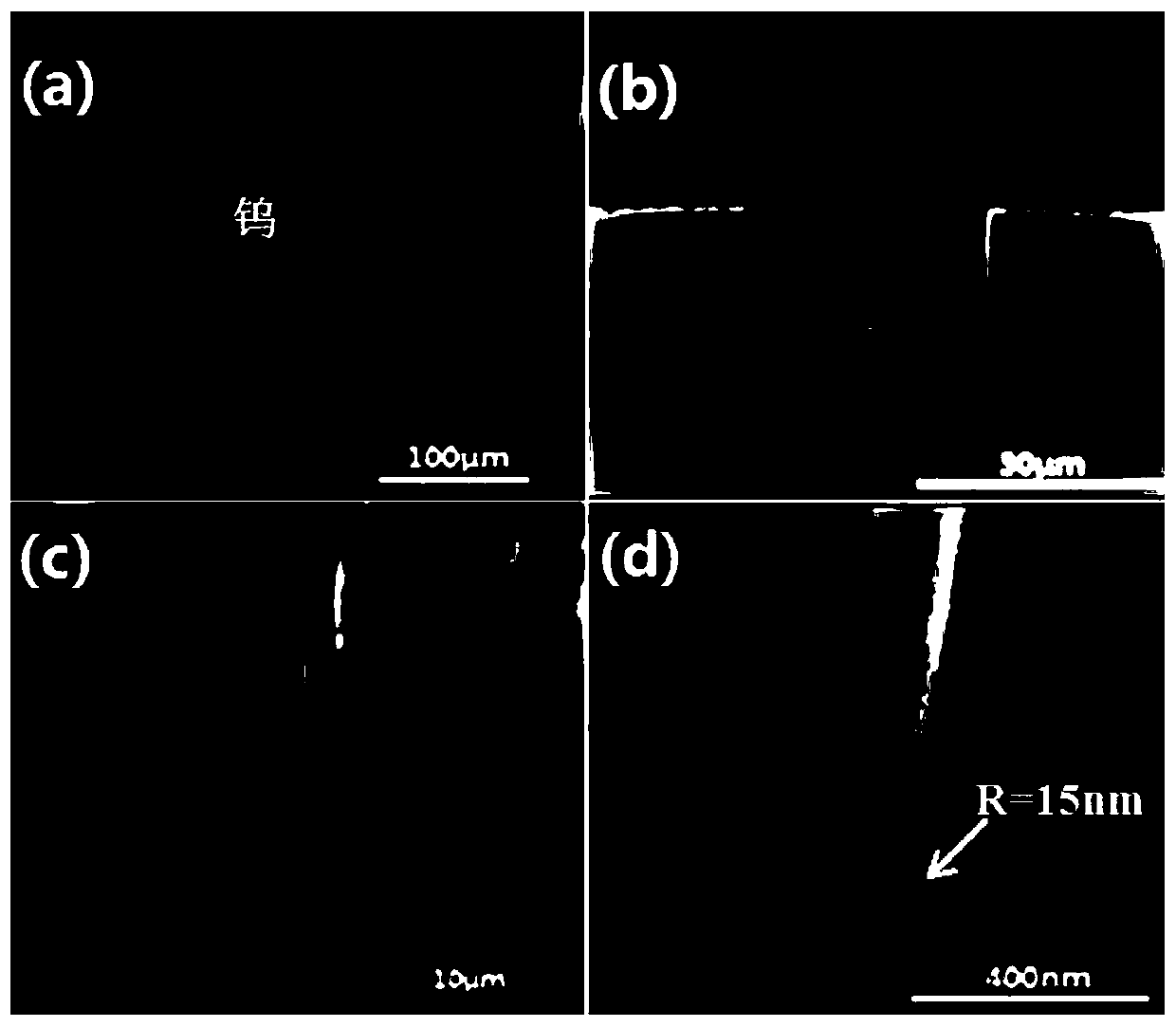

Nano-vacuum gap breakdown characteristic experimental device and method based on FIB-SEM two-beam system

InactiveCN109765466ARealize regulationRealize functionTesting dielectric strengthMicro nanoScanning electron microscope

The invention discloses a nano-vacuum gap breakdown characteristic experimental device and method based on an FIB-SEM two-beam system. The nano-vacuum gap breakdown characteristic experimental deviceincludes the FIB-SEM two-beam system. The FIB-SEM two-beam system is composed of a focused ion beam and a scanning electron microscope, a micro-nano scale electrode system is arranged in an experimental cavity of the FIB-SEM two-beam system, the micro-nano scale electrode system includes a test electrode, a nanometer manipulator and a five-axis sample table, the nanometer manipulator and the five-axis sample table are connected to a high-voltage voltage source and a weak current measurement unit in a voltage and current test circuit correspondingly through current limiting resistance, a pulsecurrent sensor passes through a test loop and is connected with an oscilloscope, and the oscilloscope and the voltage and current test circuit are connected with a computer to record test data. According to the nano-vacuum gap breakdown characteristic experimental device and method based on the FIB-SEM two-beam system, in-situ processing of a micro-nano-scale metal electrode, real-time regulationof vacuum gaps from 20 nm to 1 [mu]m, and corresponding functions of high-voltage testing and weak current measurement can be realized, and great significance for studying intrinsic rules of dischargebreakdown in the nano-scale vacuum gaps are achieved.

Owner:XI AN JIAOTONG UNIV

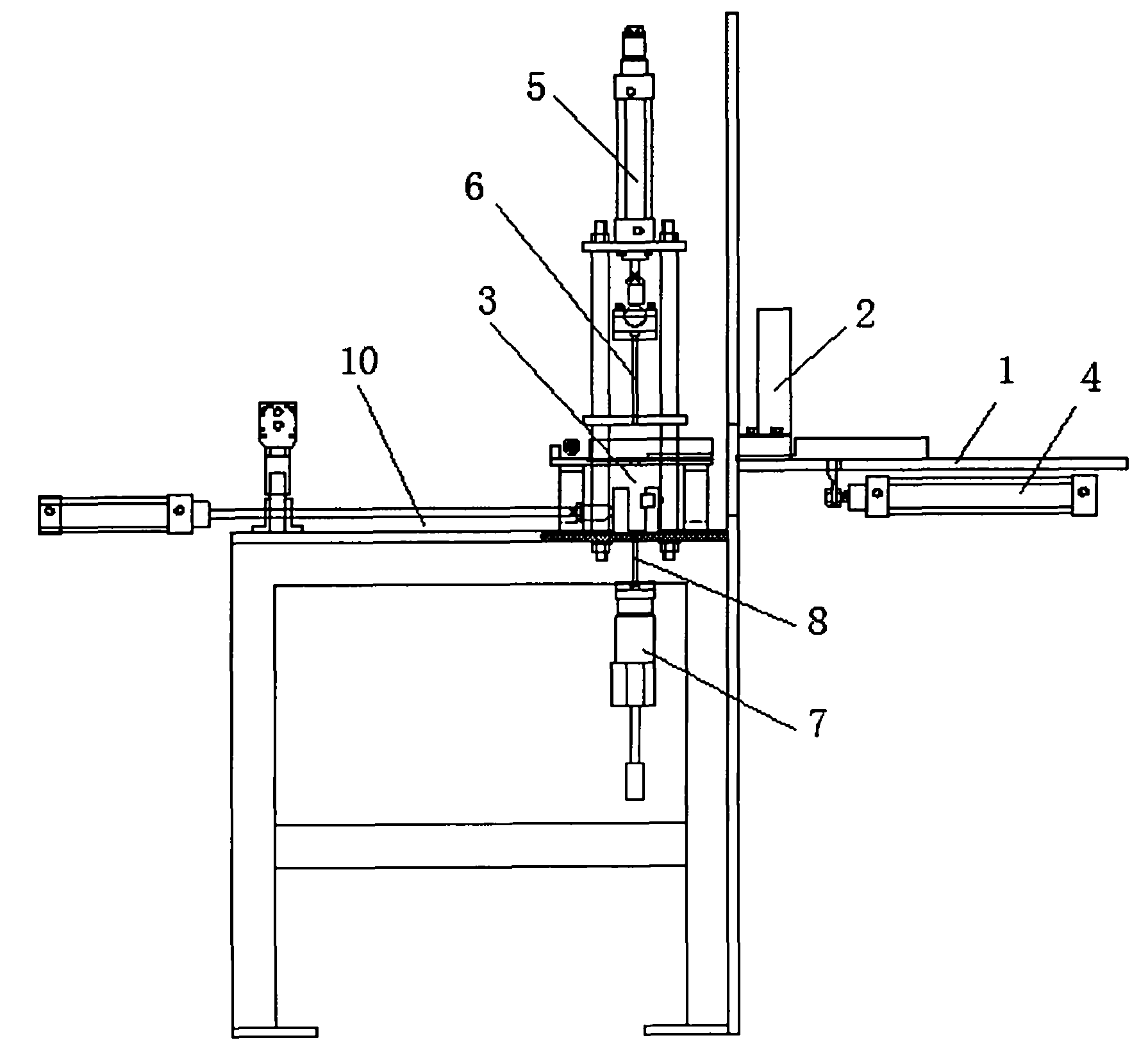

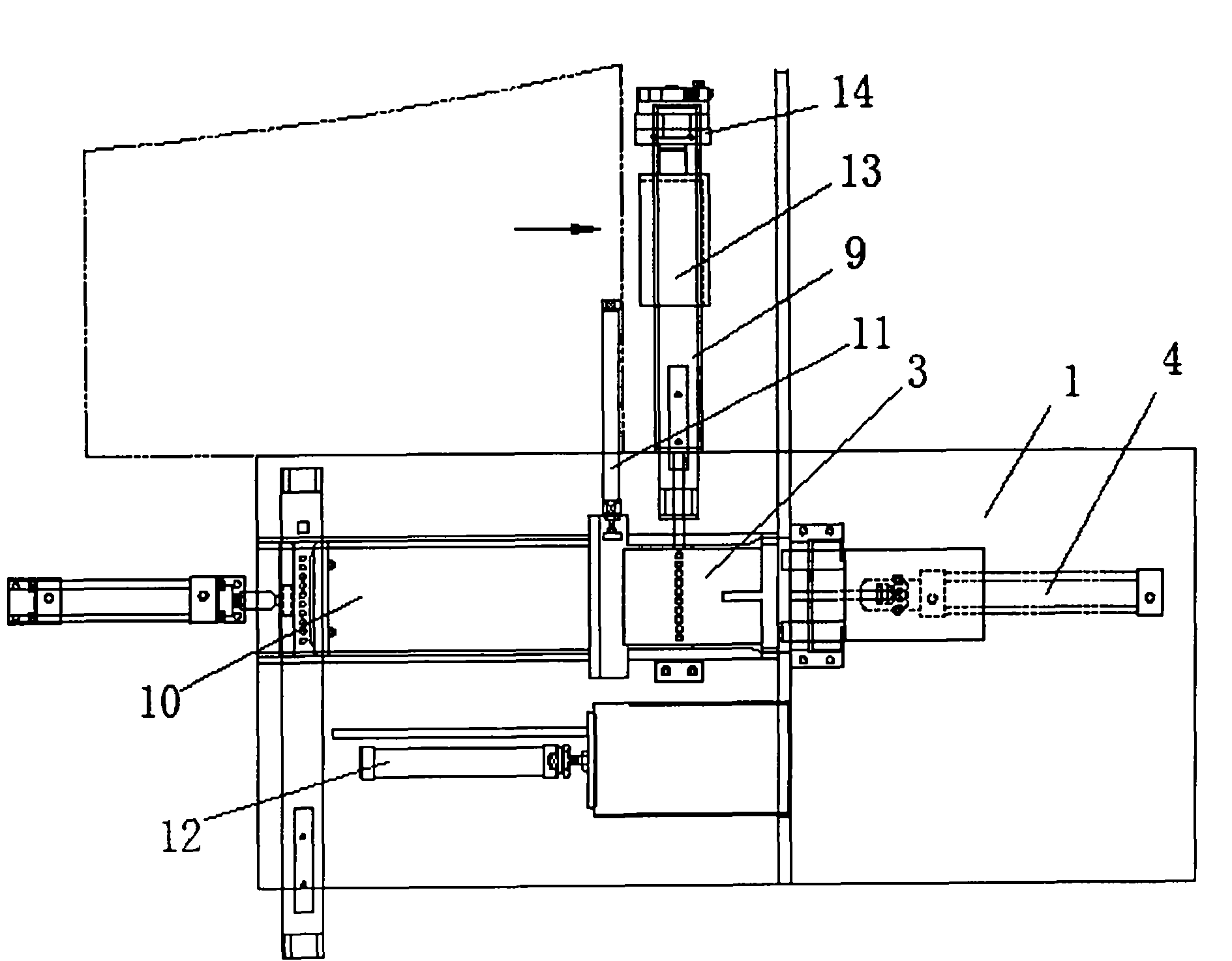

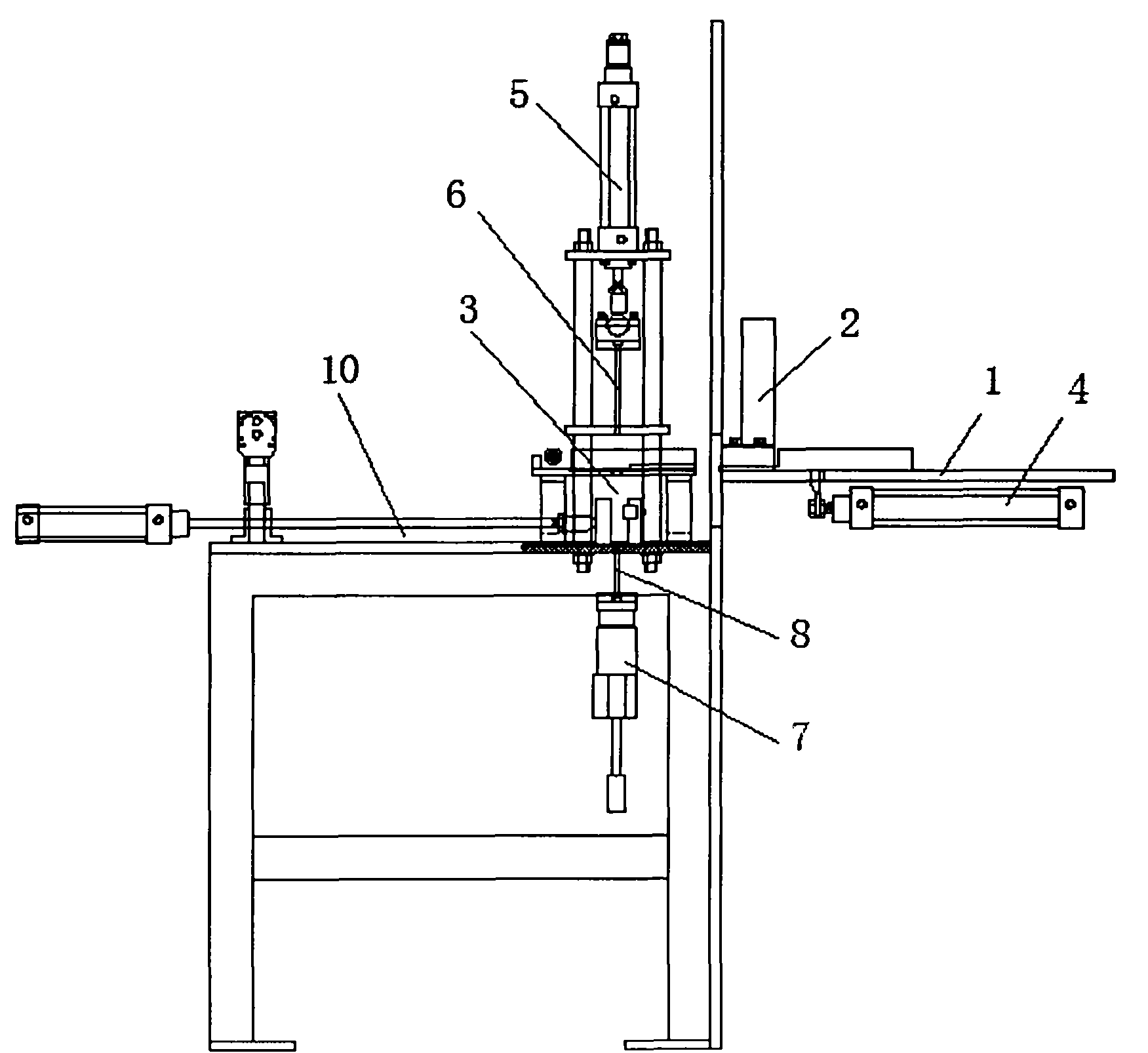

Automatic lead removing press

The invention discloses an automatic lead removing press, and relates to a detonator lead delay body assembly device. In order to solve the problems that the efficiency of manually assembling and pressing a delay body is low and the safety cannot be guaranteed, the invention provides the automatic lead removing press capable of effectively realizing safe operation of human-machine separation and greatly improving the production efficiency. In odor to achieve the purposes, the invention adopts the technical scheme that: the automatic lead removing press comprises a lead core die delivery cylinder for pushing a lead core connecting die on an outer mesa into a pressing station; a lead pressing punch strip controlled by a lead pressing cylinder is arranged above the pressing station, and a pipe jacking punch strip controlled by a pipe jacking cylinder is arranged below the pressing station, wherein the lead pressing punch strip and the pipe jacking punch strip can move up and down; and the lateral surface of the pressing station is provided with a die delivery cylinder for delivering a detonator die into the pressing station. The automatic lead removing press is mainly applied to automatic assembly of the detonator lead delay body.

Owner:YAHUA GROUP MIANYANG INDAL

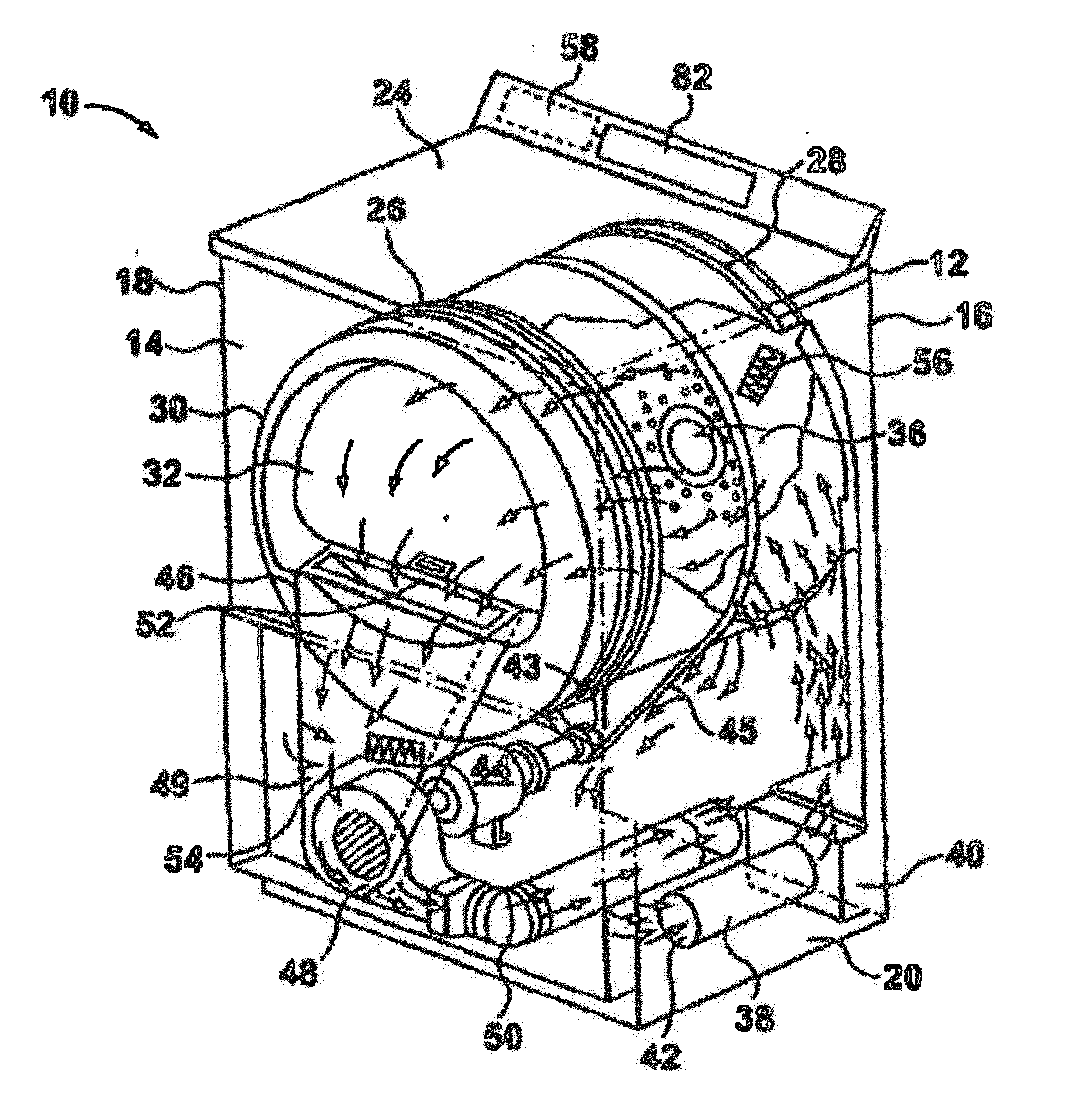

Energy saver cycle

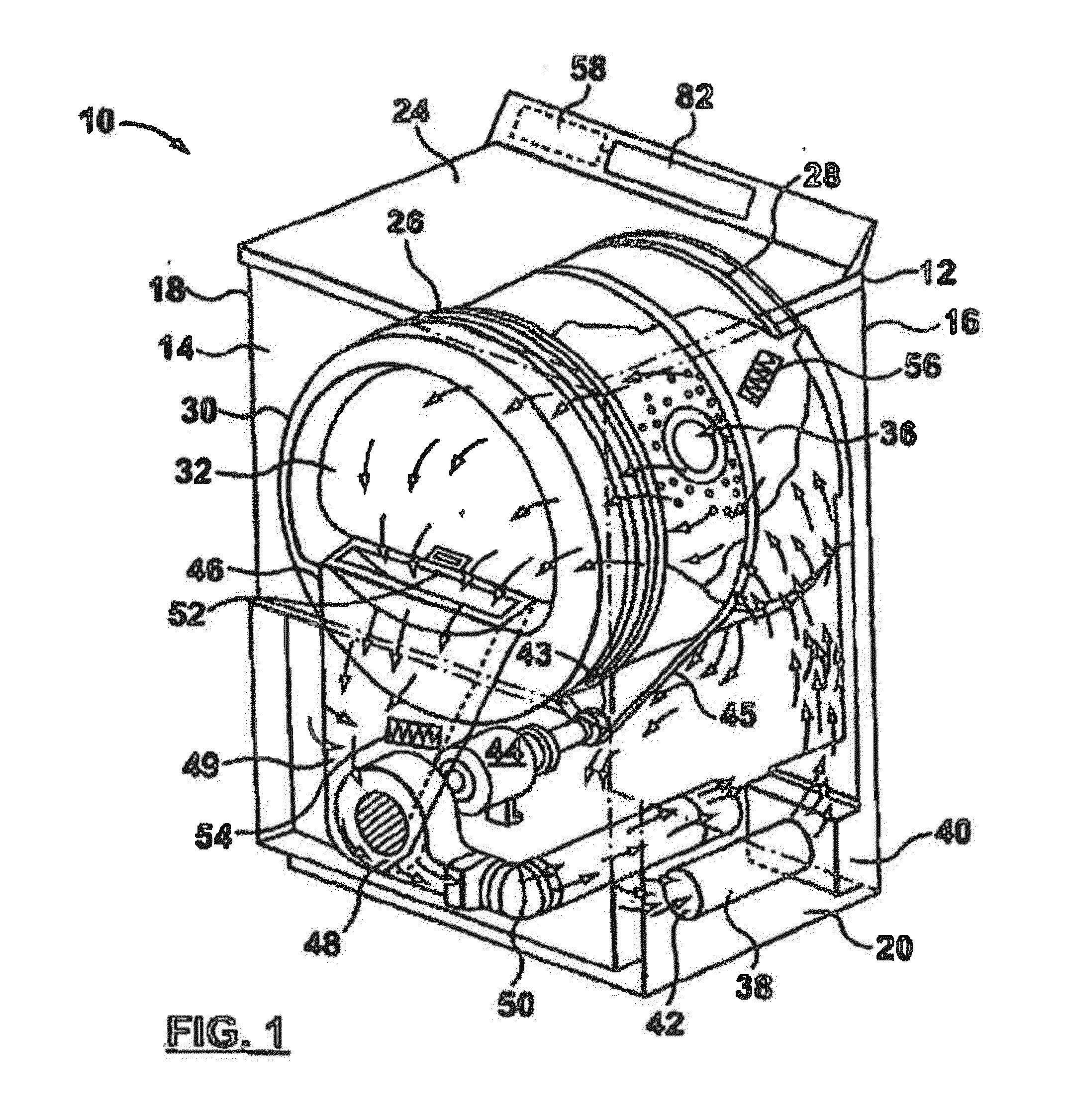

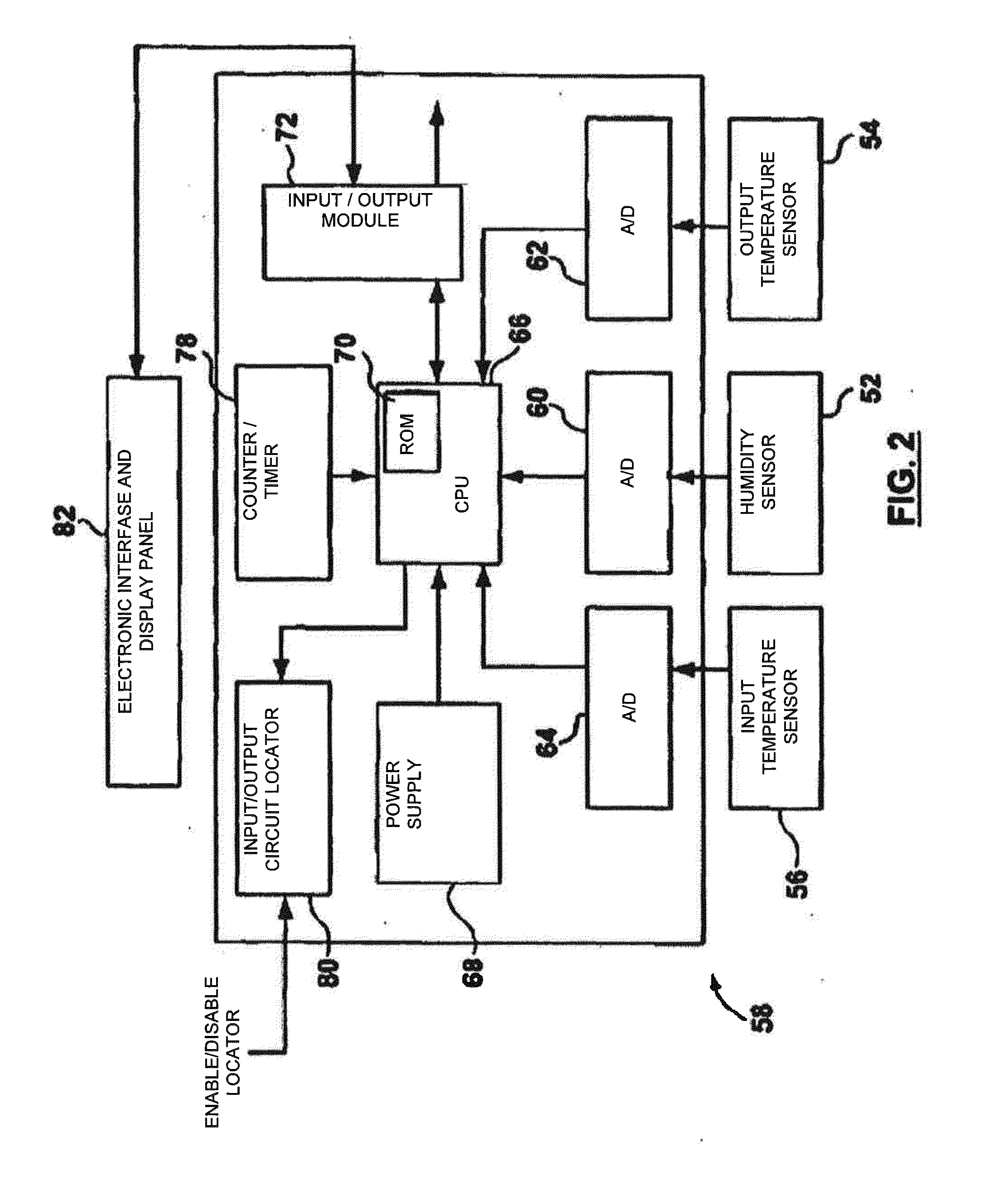

InactiveUS20160208428A1Energy saveLong operationDrying solid materials with heatTextiles and paperProcess engineeringElectricity

Embodiments are related to a drying procedure and a household appliance for drying textile items, and more particularly to a dryer using controls based on a processor in order to control the drying operation making an efficient use of the heat source (electrical or gas), evaluating various parameters as temperature, time and humidity level in predetermined ranges.

Owner:MABE SA DE CV

Pipeline remote monitoring valve

InactiveCN102661423AEasy to installFree from destructionOperating means/releasing devices for valvesEqualizing valvesElectricityEngineering

A pipeline remote monitoring valve comprises a valve body mounted in a pipeline and a valve rod arranged on the valve body. The pipeline remote monitoring valve is characterized in that: the valve rod is connected with a driving mechanism, a sensor is mounted in the valve body, and the sensor and the driving mechanism are all electrically connected with a GPRS (General Pocket Radio Service) wireless data transmission unit. The monitoring valve can realize the remote monitoring of the pipeline transmission and remotely control the automatic and timely opening and closing of the valve, so that the waste of fluid resources is avoided, and the pollution to the environment is also avoided; meanwhile, no damage is caused to the pipeline, the service life of the pipeline is long, and the operation is more reliable.

Owner:四川川力智能阀业有限公司

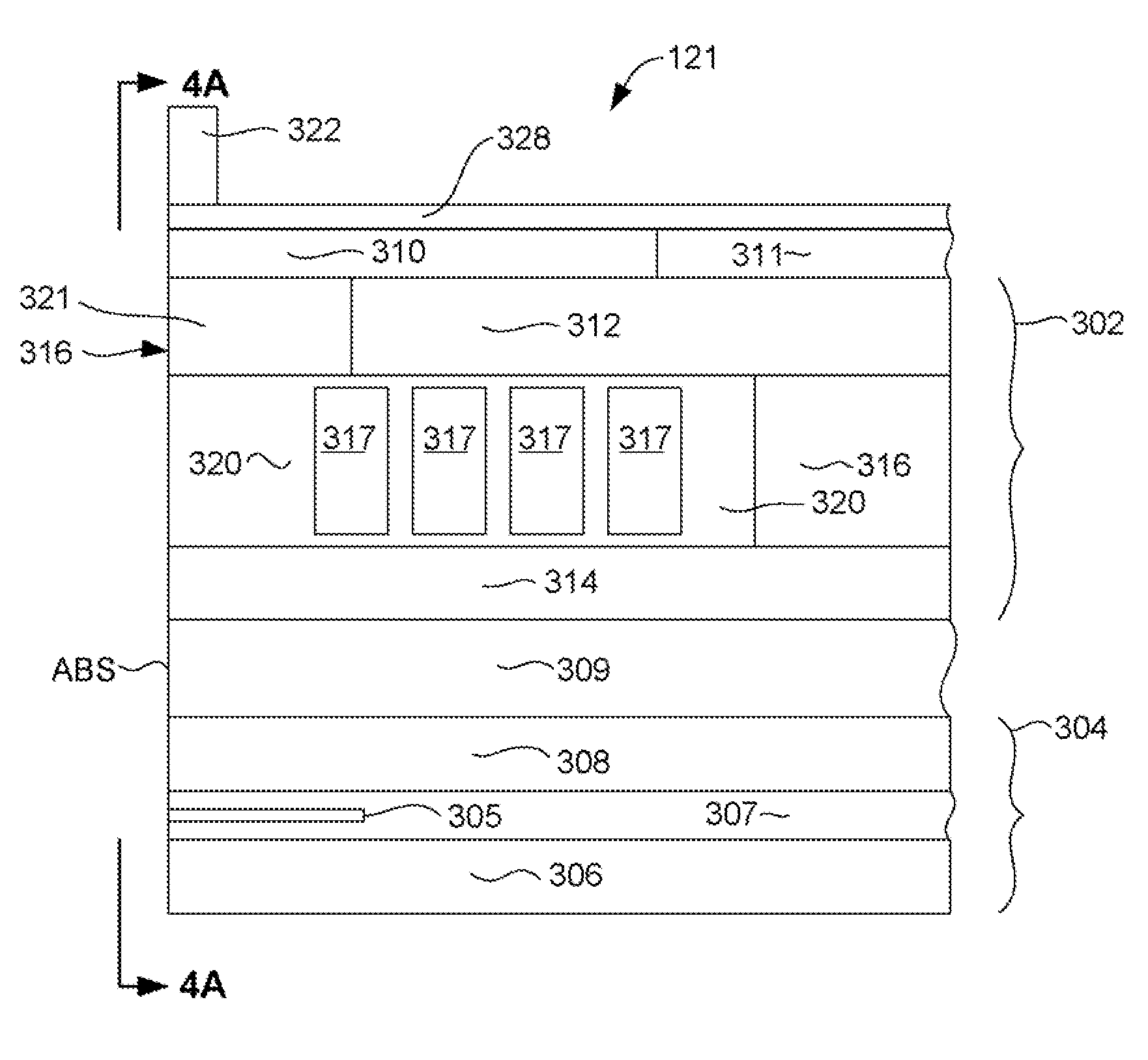

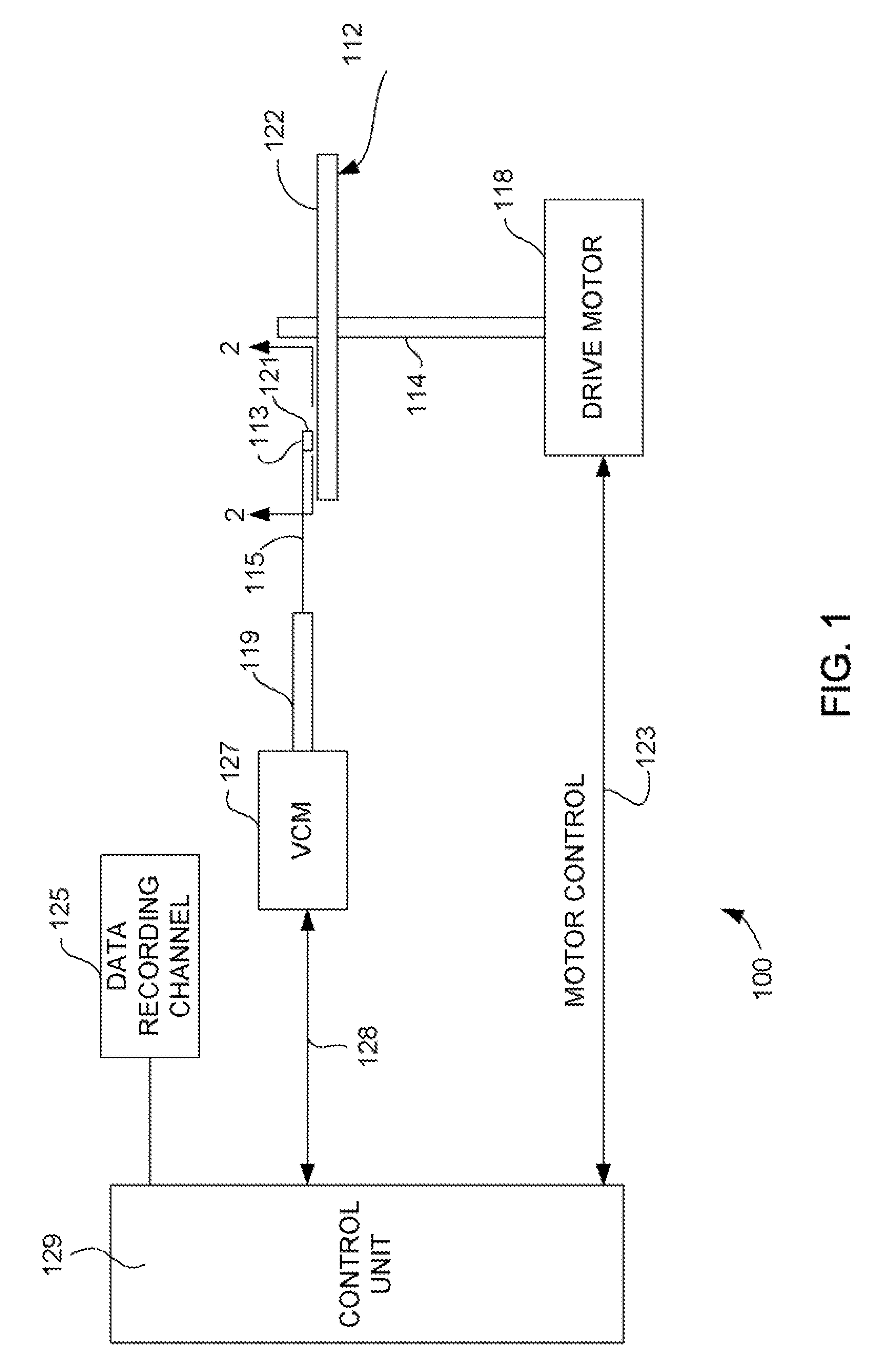

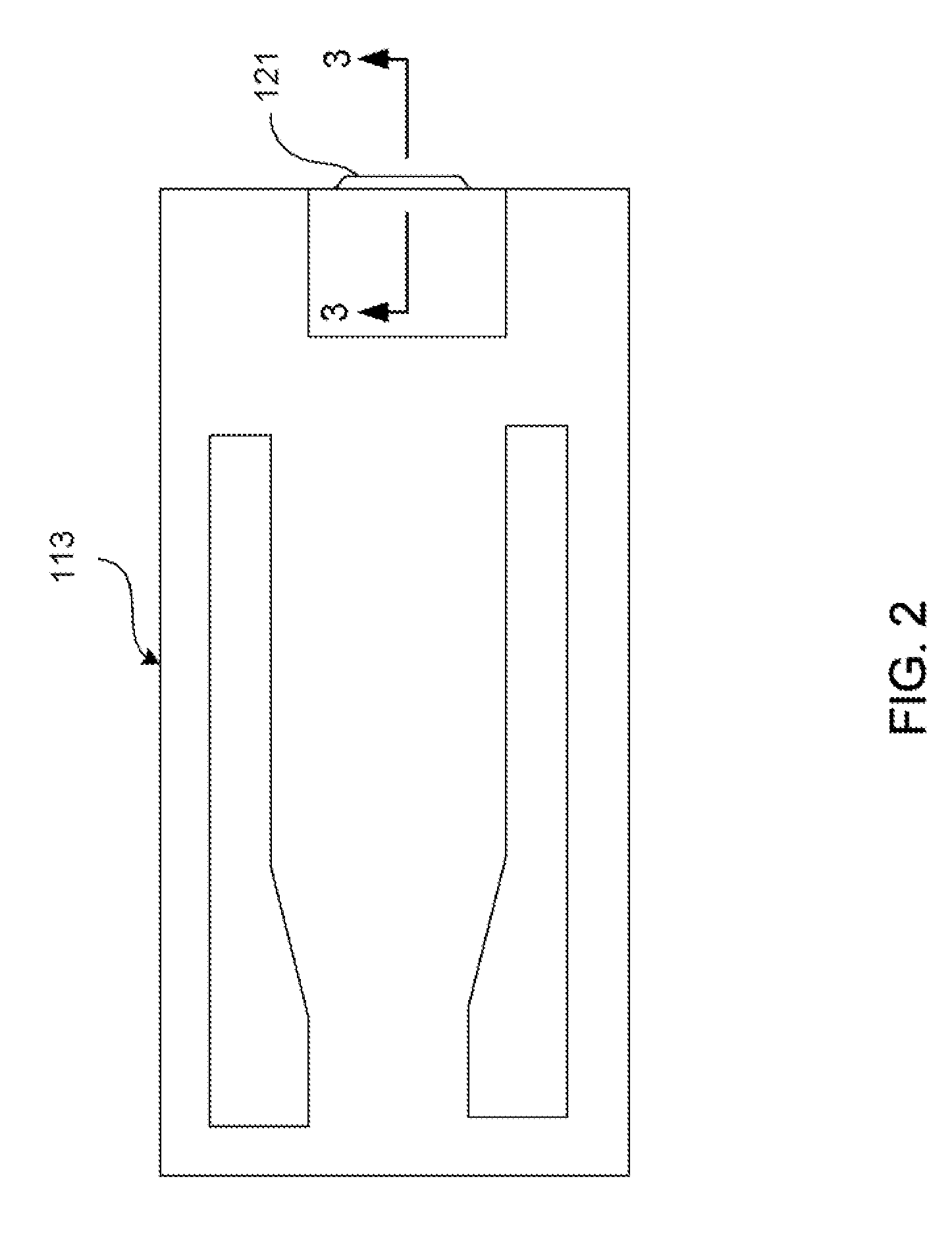

Method of manufacturing a perpendicular magnetic write head having a wrap-around trailing shield and a concave trailing edge main pole

InactiveUS7506431B2Precise and reliable controlImprove performanceElectrical transducersManufacture head surfaceEngineeringTrailing edge

A method for manufacturing a magnetic write head for perpendicular magnetic recording. The method allows the write head to be formed with a write pole having a concave trailing edge. The method further allows the amount of concavity of the trailing edge to be accurately and carefully controlled both within a wafer and between wafers. A write pole is formed using a mask that includes a hard mask, a RIEable layer and an endpoint detection layer. A layer of non-magnetic material (ALD layer) is deposited, and then, an ion milling process is used to remove a portion of the ALD layer disposed over the write pole and mask. A reactive ion etch process is performed to remove the RIEable layer leaving the ALD layer to form non-magnetic side walls with upper portions that extend above the write pole. Another ion milling is then performed, preferably at an angle relative to normal, such that shadowing from the upper portions of the non-magnetic side walls causes the ion milling to form the write pole with a concave trailing edge.

Owner:WESTERN DIGITAL TECH INC

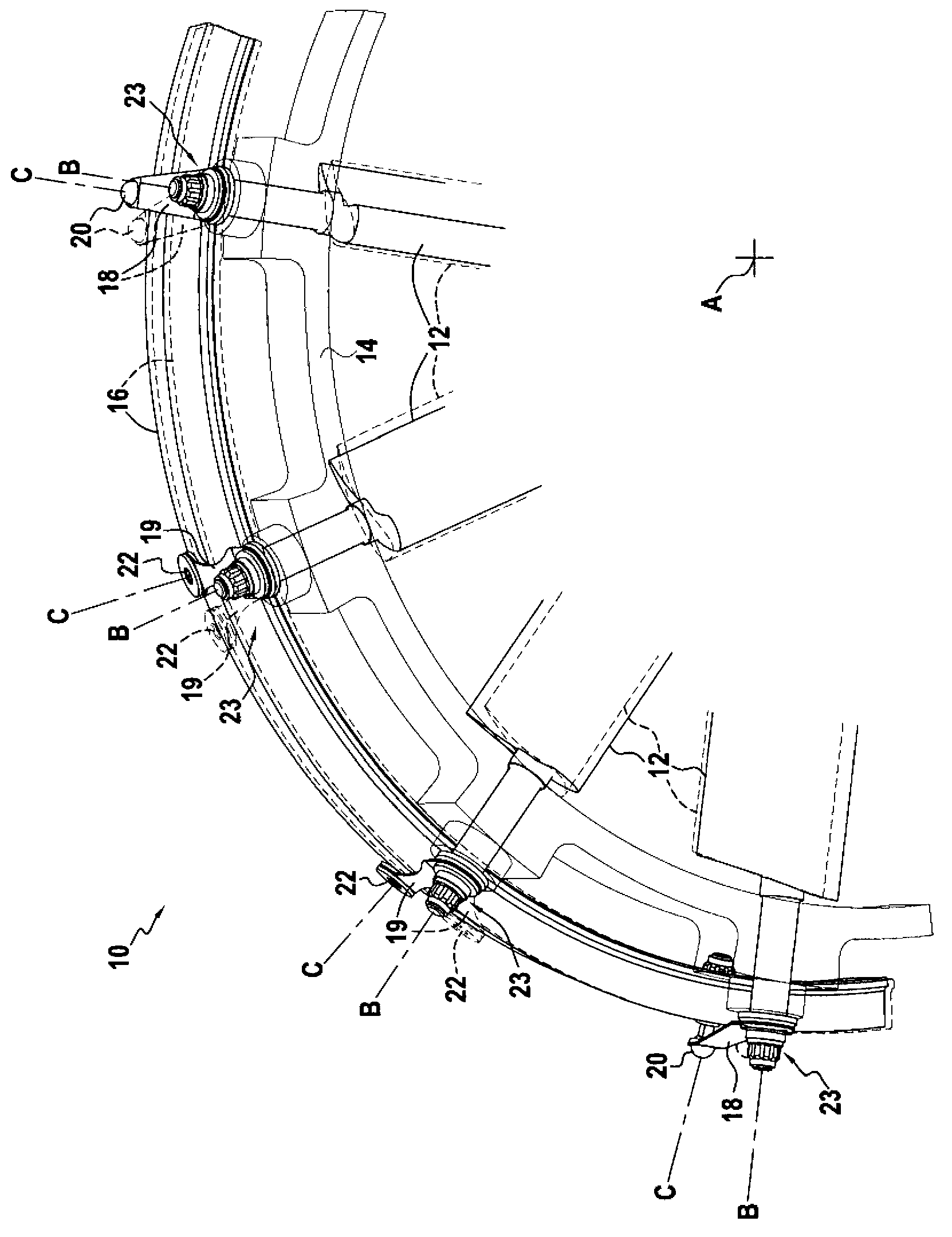

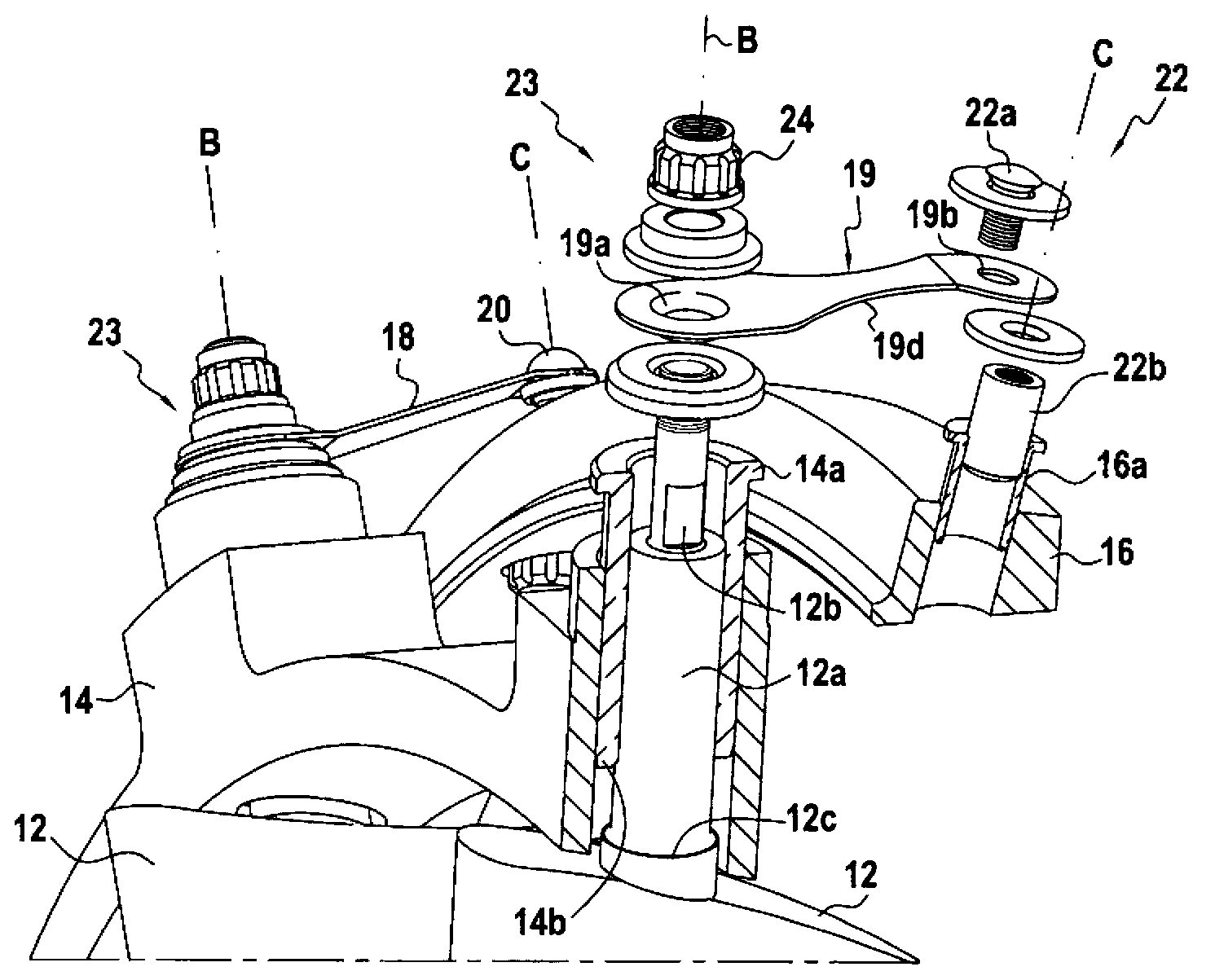

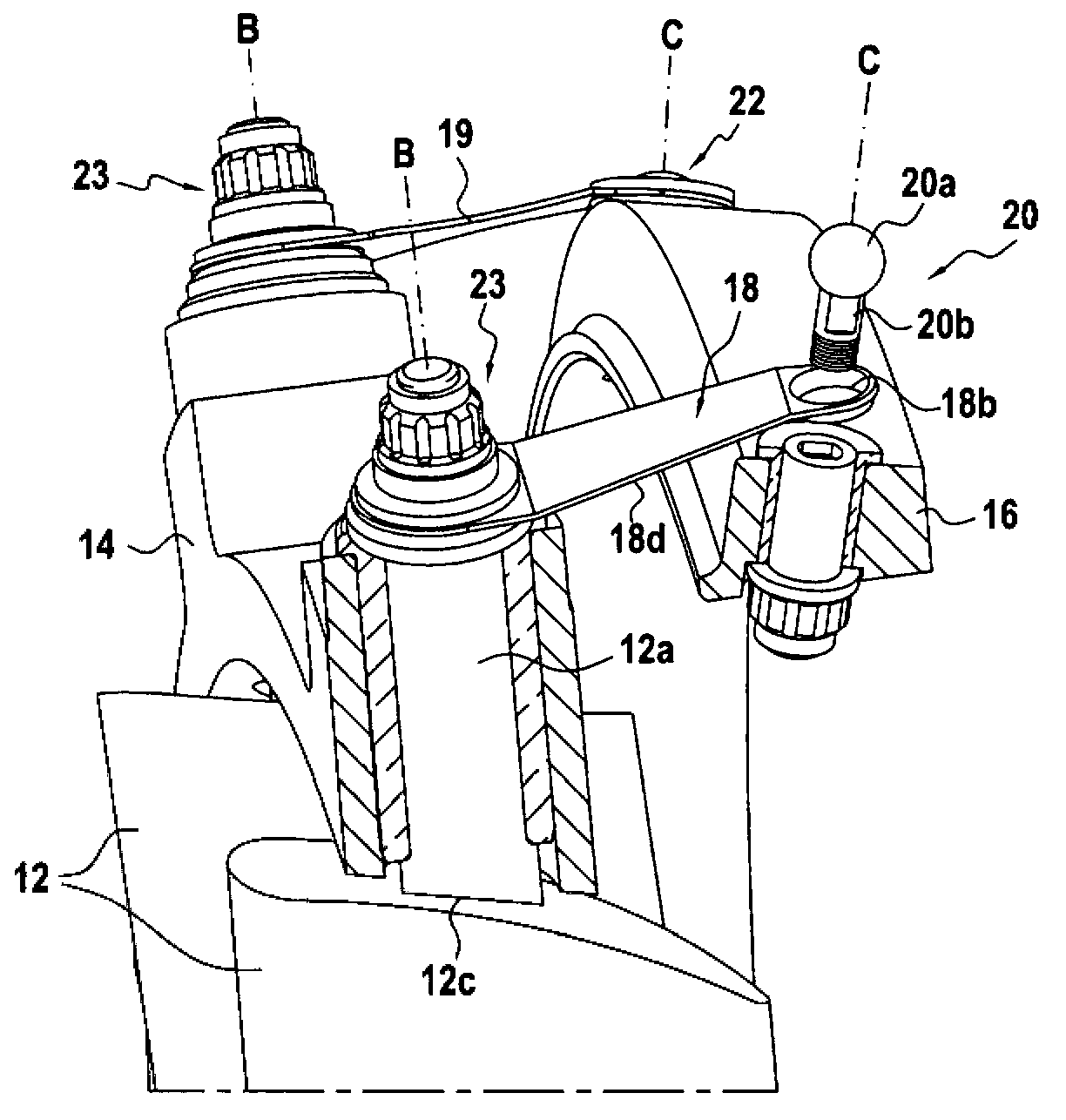

Device for controlling pivoting blades of a turbine engine

ActiveCN103189602APrecise and reliable controlReduce movementInternal combustion piston enginesPump componentsTurbine

Owner:TURBOMECA SA

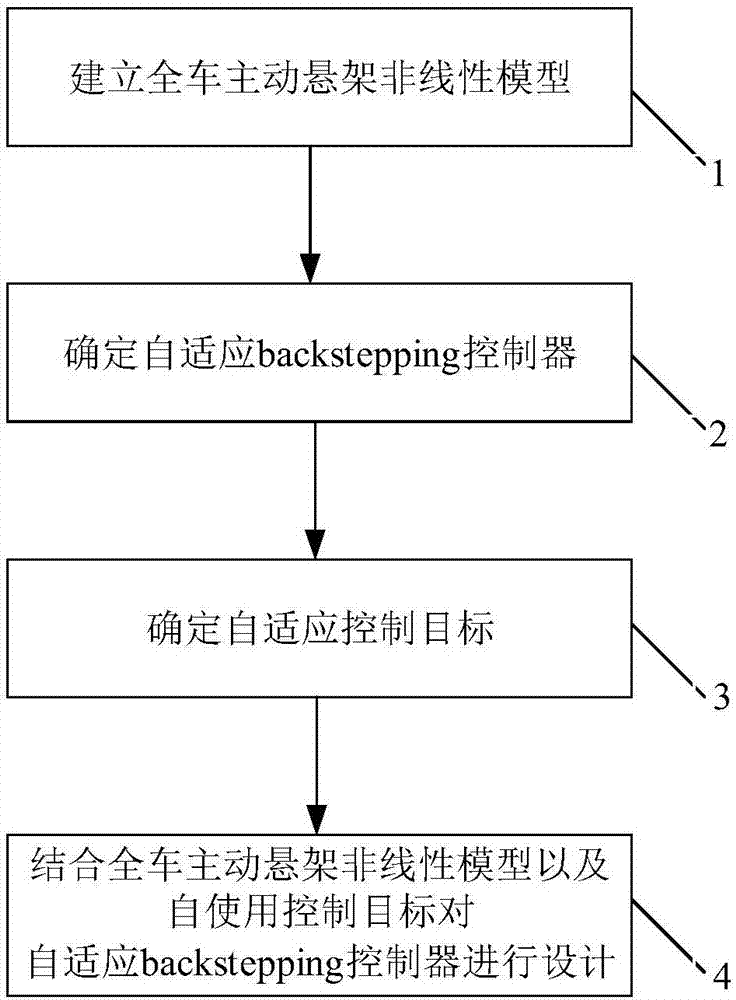

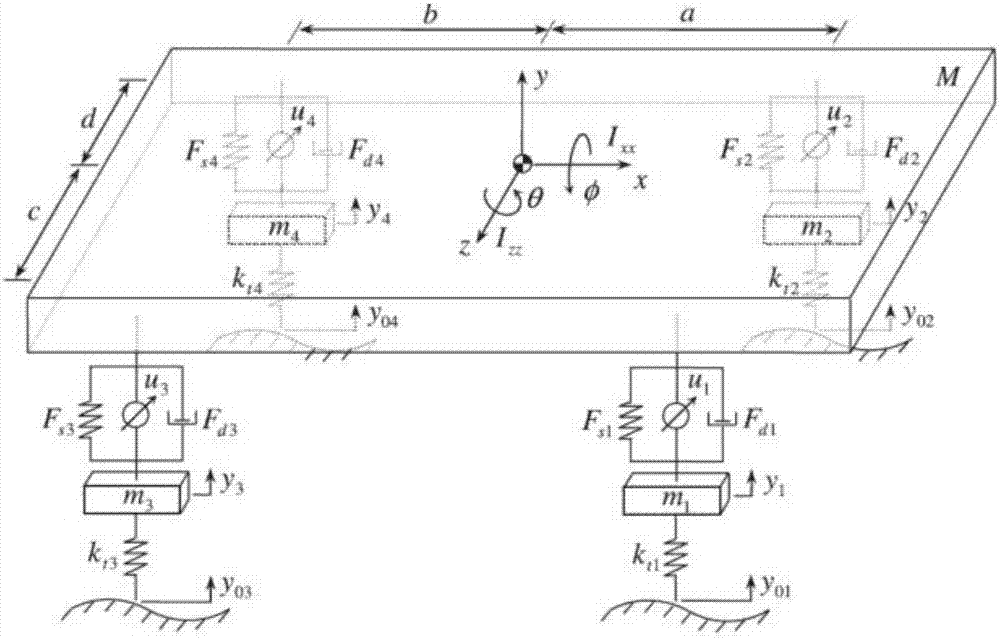

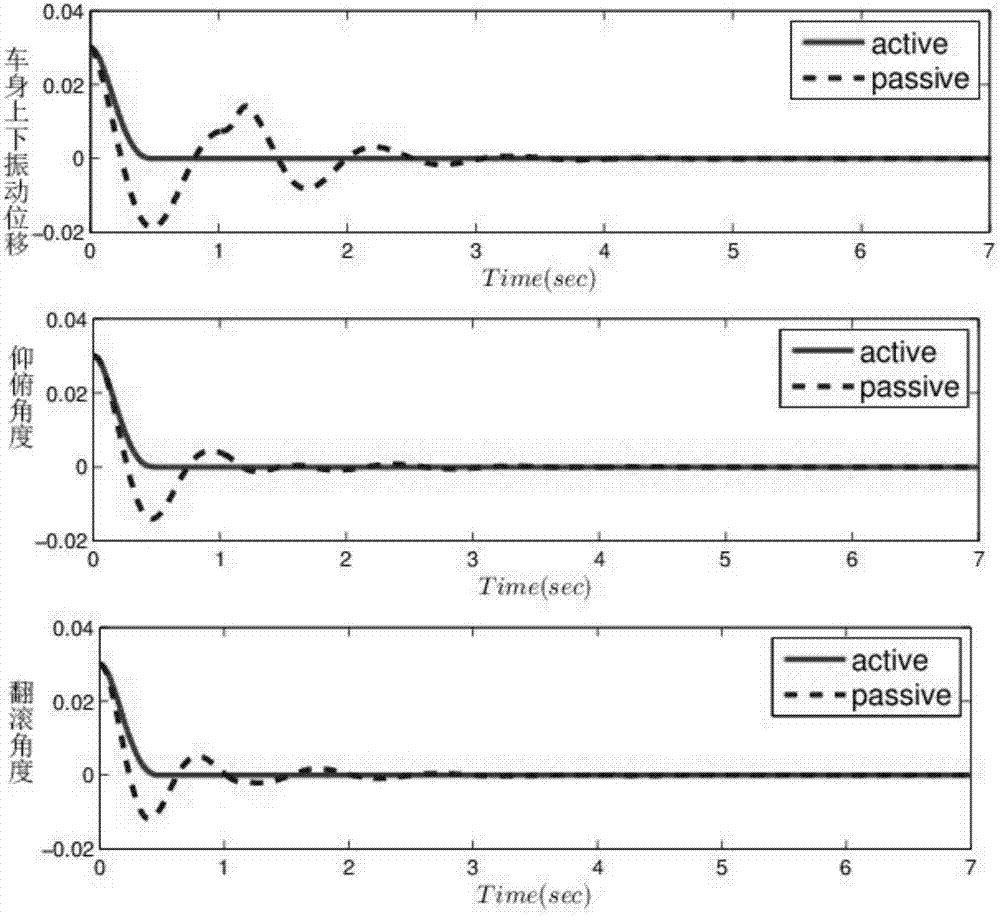

Designing method of self-adaption backstepping controller of full vehicle active suspension system

InactiveCN107220416AFully establishedPrecise and reliable controlGeometric CADDesign optimisation/simulationActuator saturationVehicle driving

The invention relates to a designing method of a self-adaption backstepping controller of a full vehicle active suspension system. The method comprises the following steps of 1, building a full vehicle active suspension non-linear model; 2, determining the self-adaption backstepping controller, wherein the self-adaption backstepping controller comprises a front right suspension controller, a front left suspension controller, a rear right suspension controller and a rear left suspension controller and all the controllers are connected to actuators corresponding to suspensions respectively; 3, determining a self-adaption control target; 4, determining a control law of the self-adaption backstepping controller by combining the full vehicle active suspension non-linear model and the self-adaption control target. Compared with the prior art, according to the designing method of the self-adaption backstepping controller of the full vehicle active suspension system, the driving comfort of vehicles is improved, meanwhile the vehicle driving safety, the suspension travel, the actuator saturation phenomenon and the like can all be satisfied, and the controllers of the design perform control more precisely and more reliably.

Owner:TONGJI UNIV

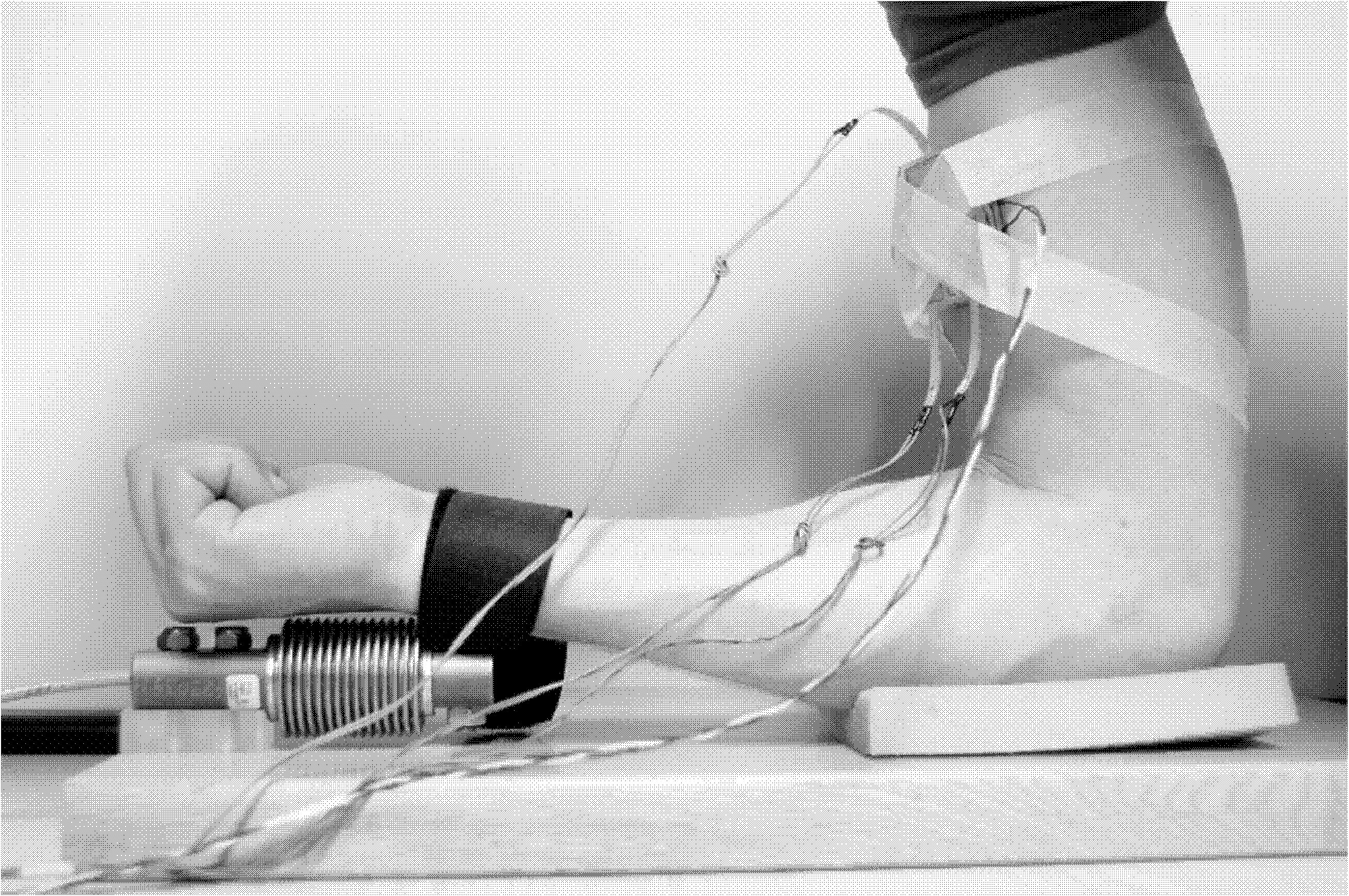

Measurement of bio-signals

InactiveCN102170825AAccurate measurementPrecise and reliable controlElectromyographyAuscultation instrumentsMuscle contractionContact force

Apparatus for measuring a bio-signal associated with contraction of a muscle in a human or animal body. The apparatus has a sensor for placement in contact with the body for measuring said muscle contraction signal. It also includes means for measuring a contact force and / or relative movement between the sensor and the body.

Owner:NORWEGIAN UNIVERSITY OF SCIENCE AND TECHNOLOGY (NTNU)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com