Self-adaptive orchard sprayer

A self-adaptive, sprayer technology, applied in the field of sprayers and self-adaptive orchard sprayers, can solve the problems of inability to adapt to the target tree shape, manual adjustment by manpower, automatic adjustment of the spraying method, etc., and achieve good spraying effect. , compact structure, wide adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

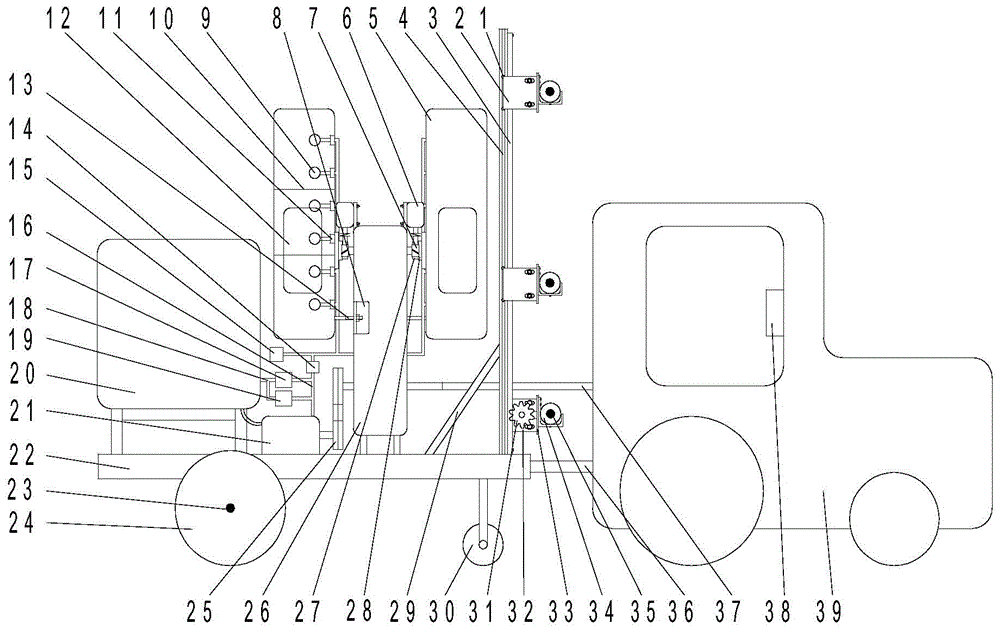

[0028] Such as figure 1 Shown is the concrete structure of a kind of self-adaptive orchard sprayer of the present invention, comprises traction chassis 22, and traction chassis 22 adopts wheeled structure, comprises the road wheel 24 of the rear, the guide wheel 30 of the front and traction frame 36, road wheel Speed sensor 23 is set on 24. The traction chassis 22 is connected to the tractor 39 through the traction frame 36 and the universal coupling 37, and is driven forward by the tractor 39. Major mechanisms such as an ultrasonic detection device, a drug application device, a vertical gear box 26 and an embedded control platform 38 are arranged on the traction chassis 22 .

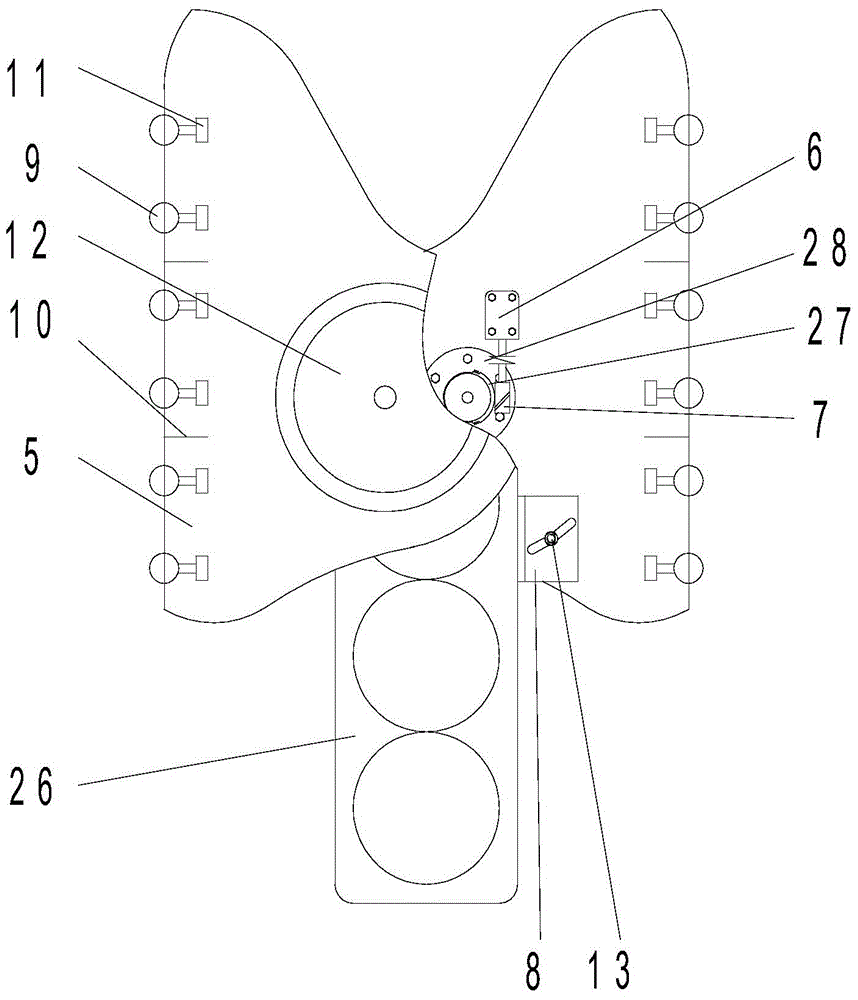

[0029] Wherein, the ultrasonic detecting device is arranged on both sides of the front end above the traction chassis 22, and includes a vertical moving device and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com