Patents

Literature

316results about How to "High degree of mechanical automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

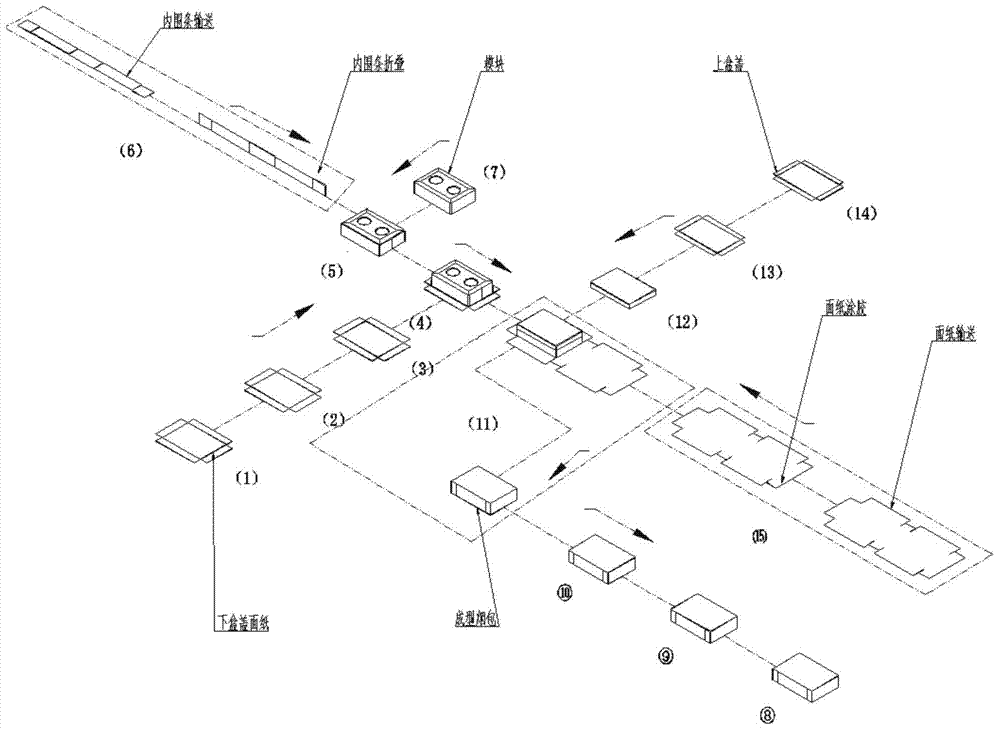

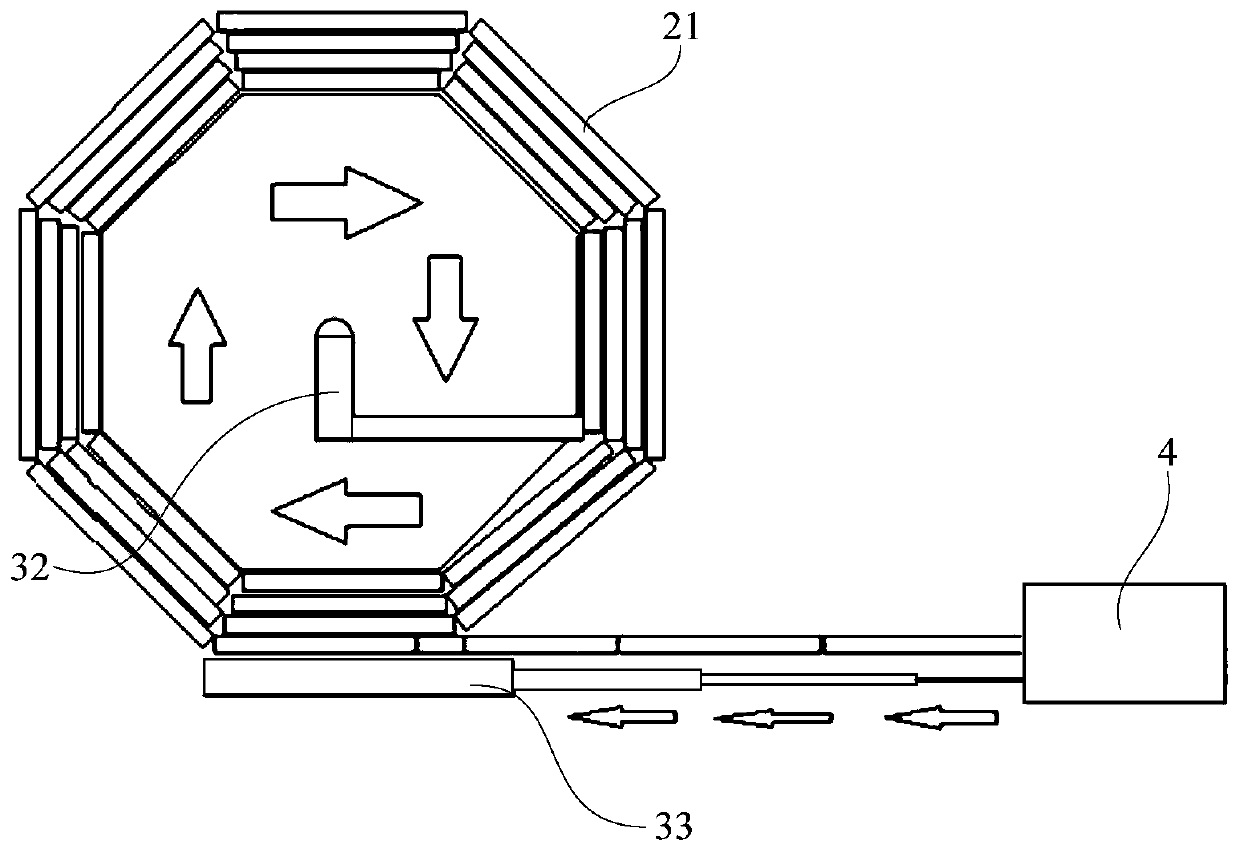

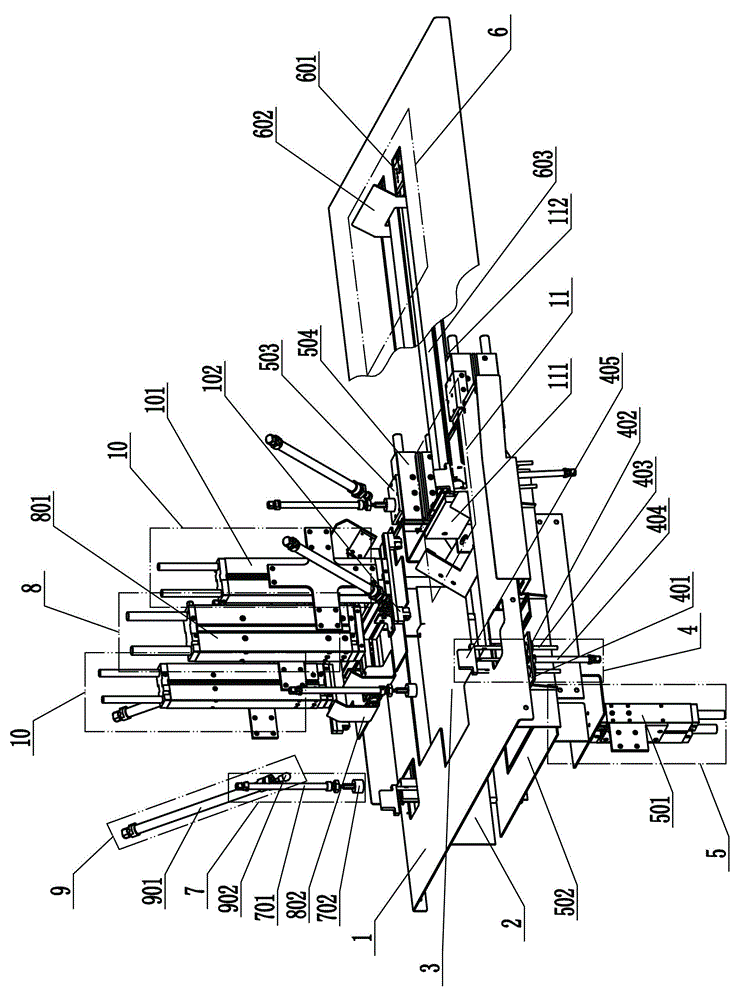

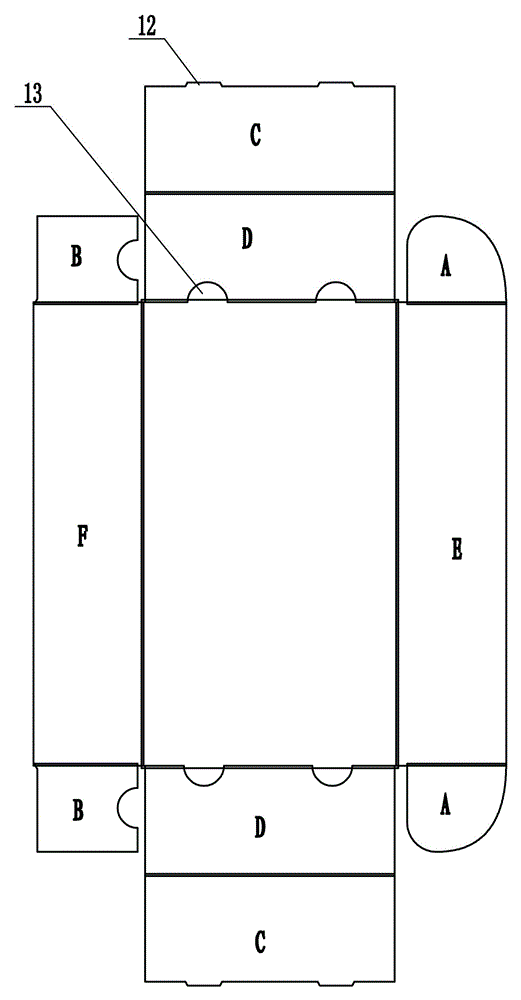

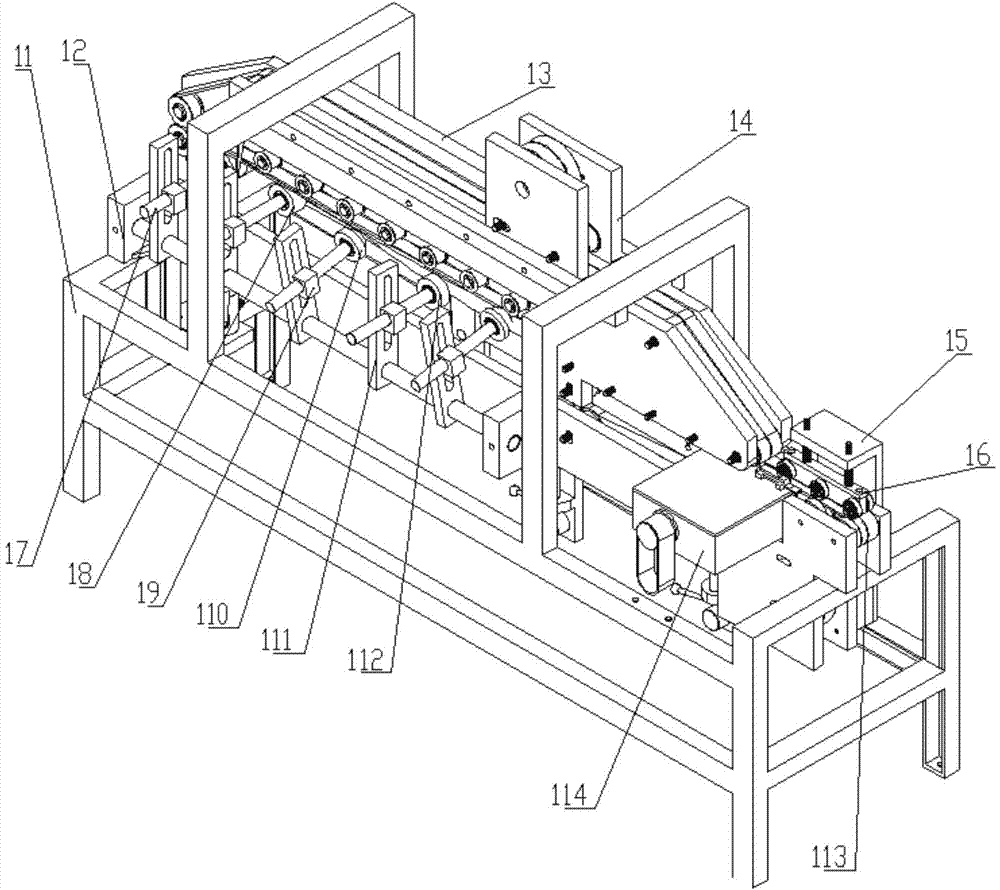

Carton forming machine and forming method implemented by same

ActiveCN103707553AIncrease productivityImprove product qualityContainer making machineryCartonEngineering

The invention relates to a carton forming machine and a forming method implemented by the same. The carton forming machine is characterized by comprising an upper cover forming device, a lower cover forming device, an inner surrounding strip forming device, a lower cover and inner surrounding strip combining mechanism, an integral forming device, a grooving device and a conveying device, an outlet of the upper cover forming device is connected with a first inlet which is perforated through the integral forming device, an outlet end of the lower cover forming device and an outlet end of the inner surrounding strip forming device are jointly connected to a second inlet of the integral forming device by the lower cover and inner surrounding strip combining mechanism, a third inlet of the integral forming device is connected with an outlet of a surface paper conveying device, and an outlet of the integral forming device is connected with the grooving device by the conveying device. The carton forming machine and the forming method have the main advantages that current manual operation is converted into mechanical operation, accordingly, the production efficiency can be greatly improved, the quality of products can be enhanced, the stability of the products can be guaranteed, and the production cost can be reduced.

Owner:世彩智能科技(上海)有限公司

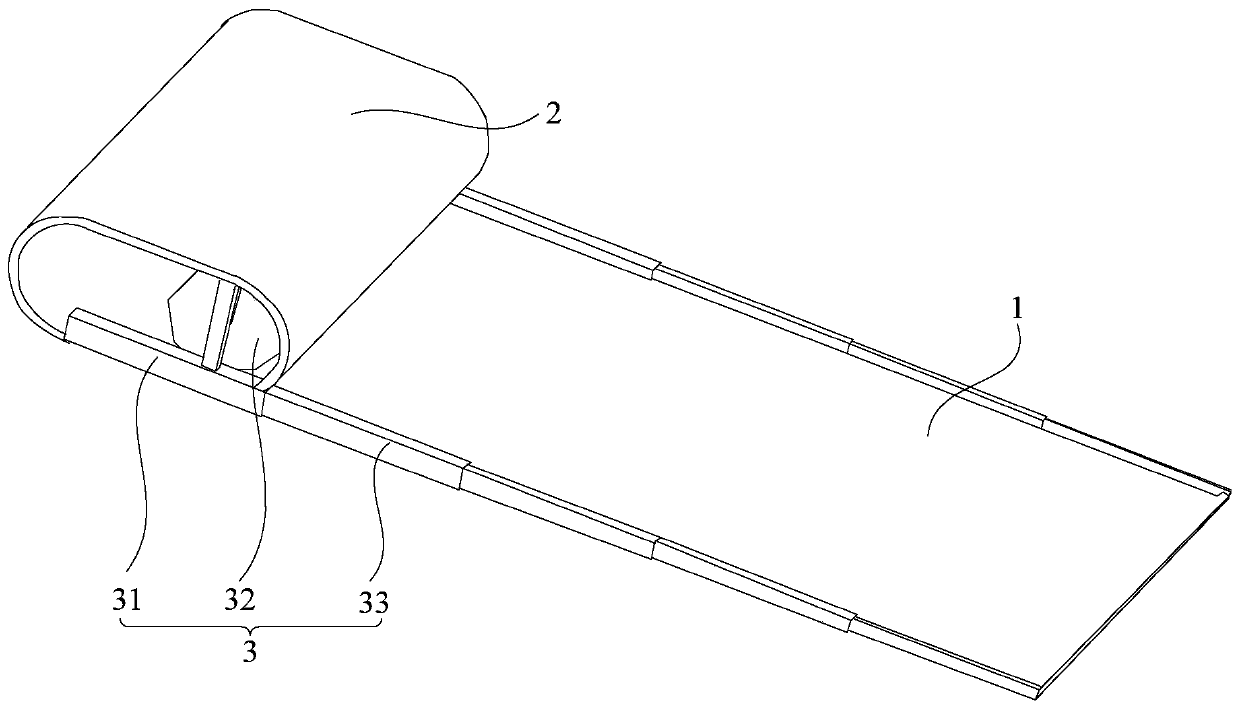

Rollable display device

InactiveCN110534024AHigh degree of mechanical automationIncrease flexibilityIdentification meansEngineeringFlexible display

The invention provides a rollable display device. The invention provides the rollable display device that comprises a flexible display panel, a supporting assembly and a driving assembly. The supporting assembly comprises a plurality of supporting pieces arranged side by side, the supporting pieces are connected with one another to form a rollable supporting face, the flexible display panel is supported on the supporting face, and the driving assembly is used for driving the supporting pieces to move so that the flexible display panel can be rolled or unfolded in the arrangement direction of the supporting pieces. The rollable display device can be automatically rolled and unfolded, and the mechanical automation degree is high.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

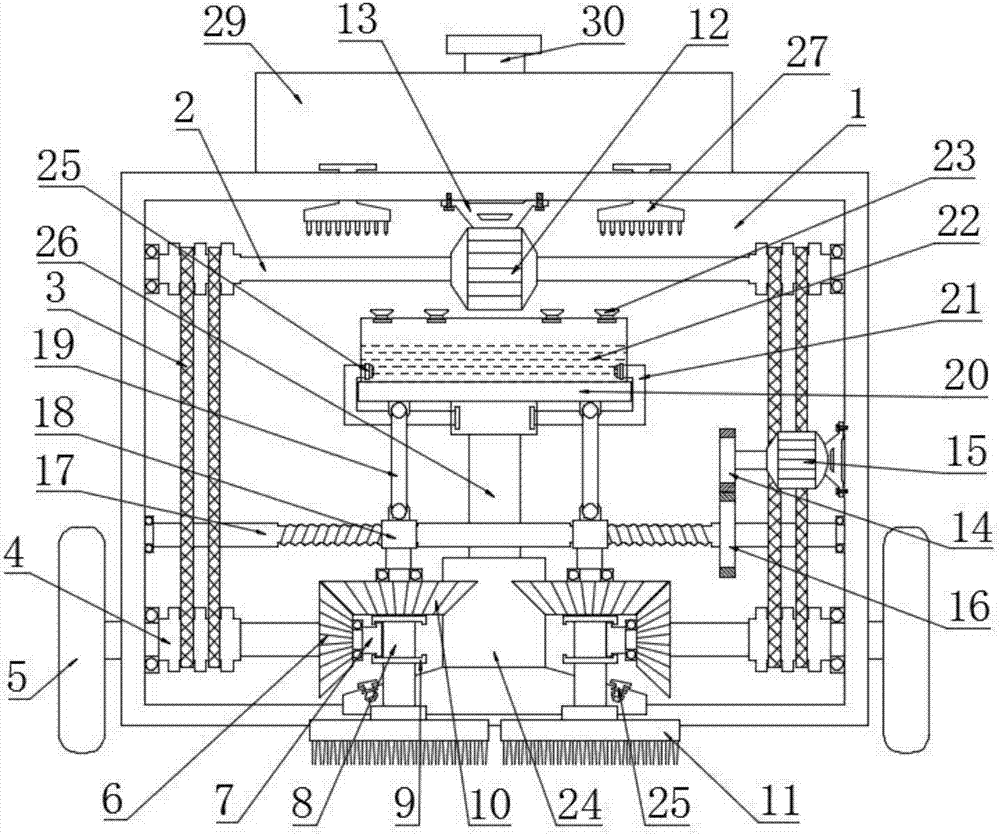

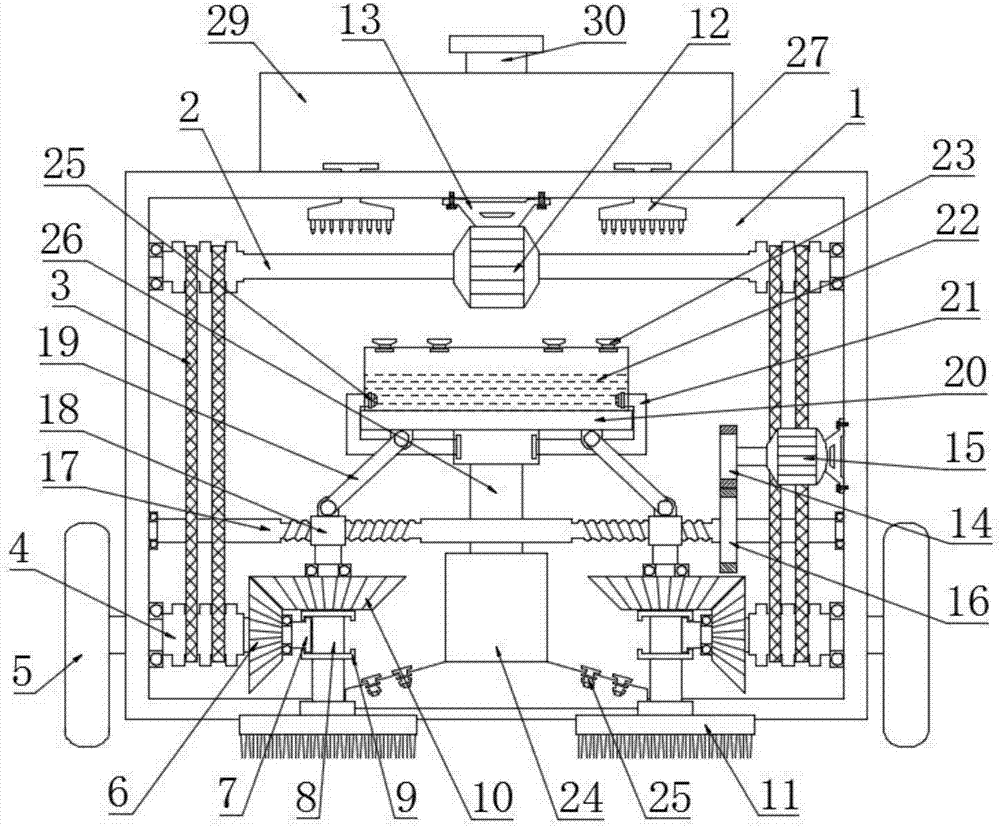

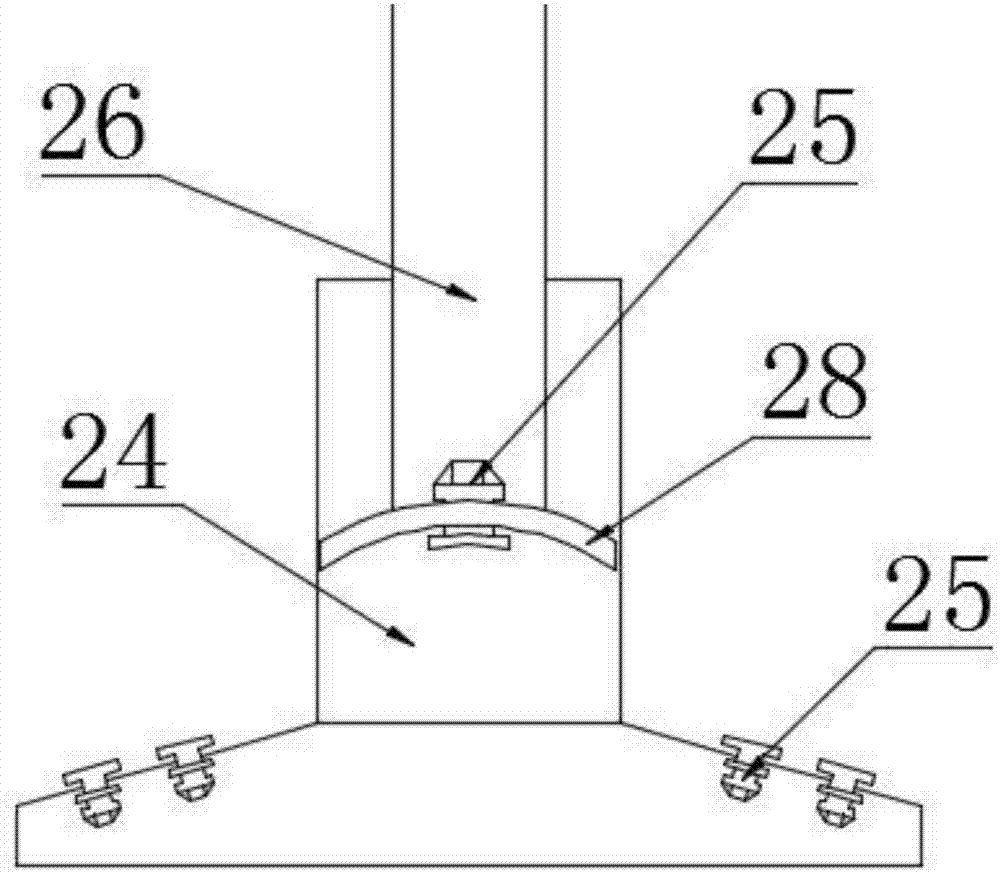

Municipal road cleaning device

InactiveCN107460842ALarge cleaning rangeReasonable structural designRoad cleaningDrive shaftEngineering

The invention discloses a municipal road cleaning device. A drive motor is arranged on the upper part of the device body, and the drive motor is rotatably connected to a drive shaft; the end of the drive shaft is rollingly connected to the upper end of a transmission belt; The two bevel gears are fixedly connected to the vertical support rod, and the lower part of the vertical support rod is fixedly connected to the cleaning brush; the middle part of the vertical support rod is fixedly connected to the limit slot; The bidirectional threaded rod is connected, and the bearing at the end of the bidirectional threaded rod rotates the side wall of the connecting device body; the right end of the bidirectional threaded rod is fixedly connected to the large gear, and the upper end of the large gear is engaged with the pinion. The device drives the cleaning brush to rotate and clean the ground through the telescopic driven shaft, and the two-way threaded rod drives the left and right reciprocating movement while rotating, so that the cleaning range is wider. The device has a reasonable structure design, greatly saves labor, and has a high degree of mechanical automation to improve work efficiency.

Owner:卢杰

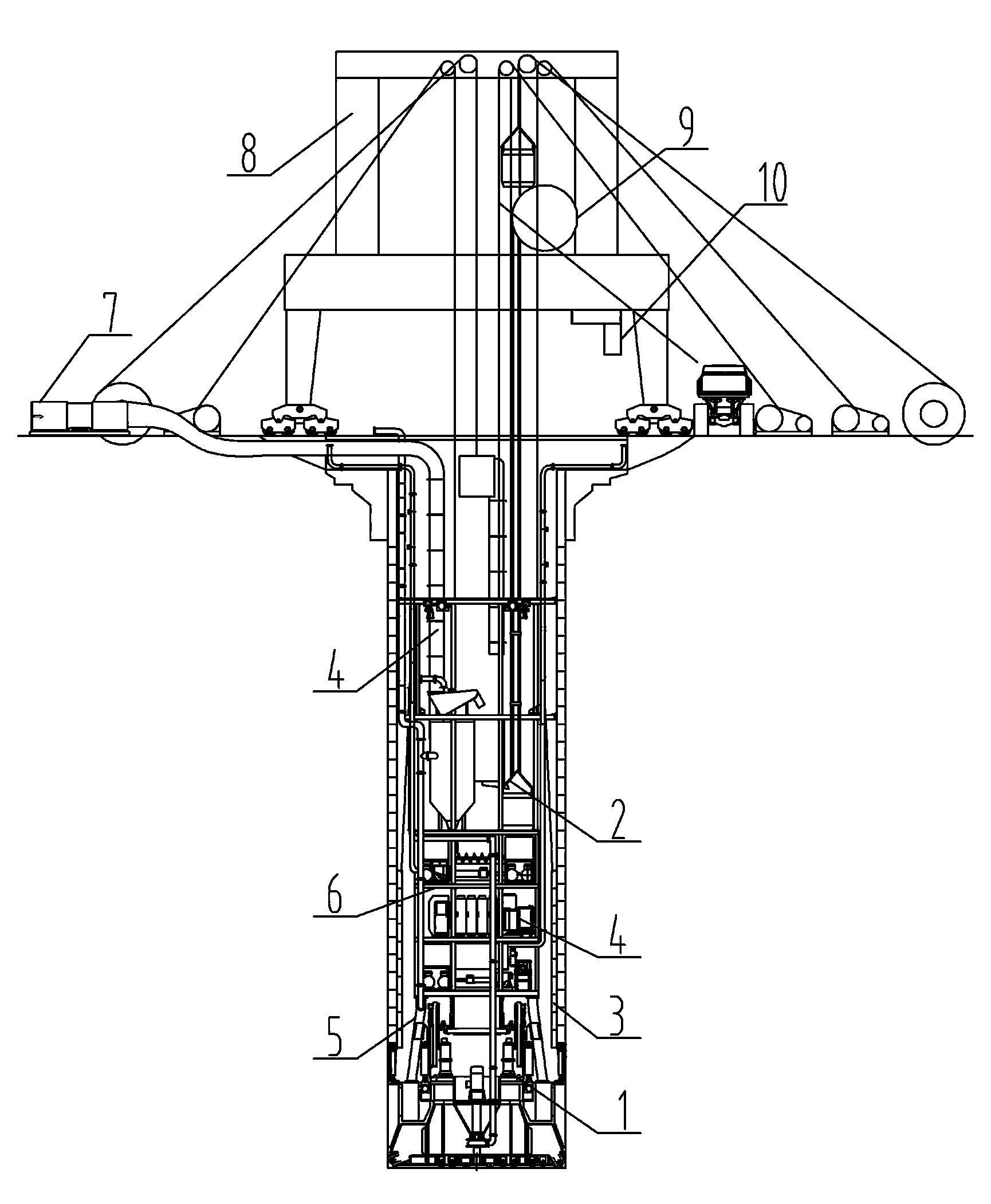

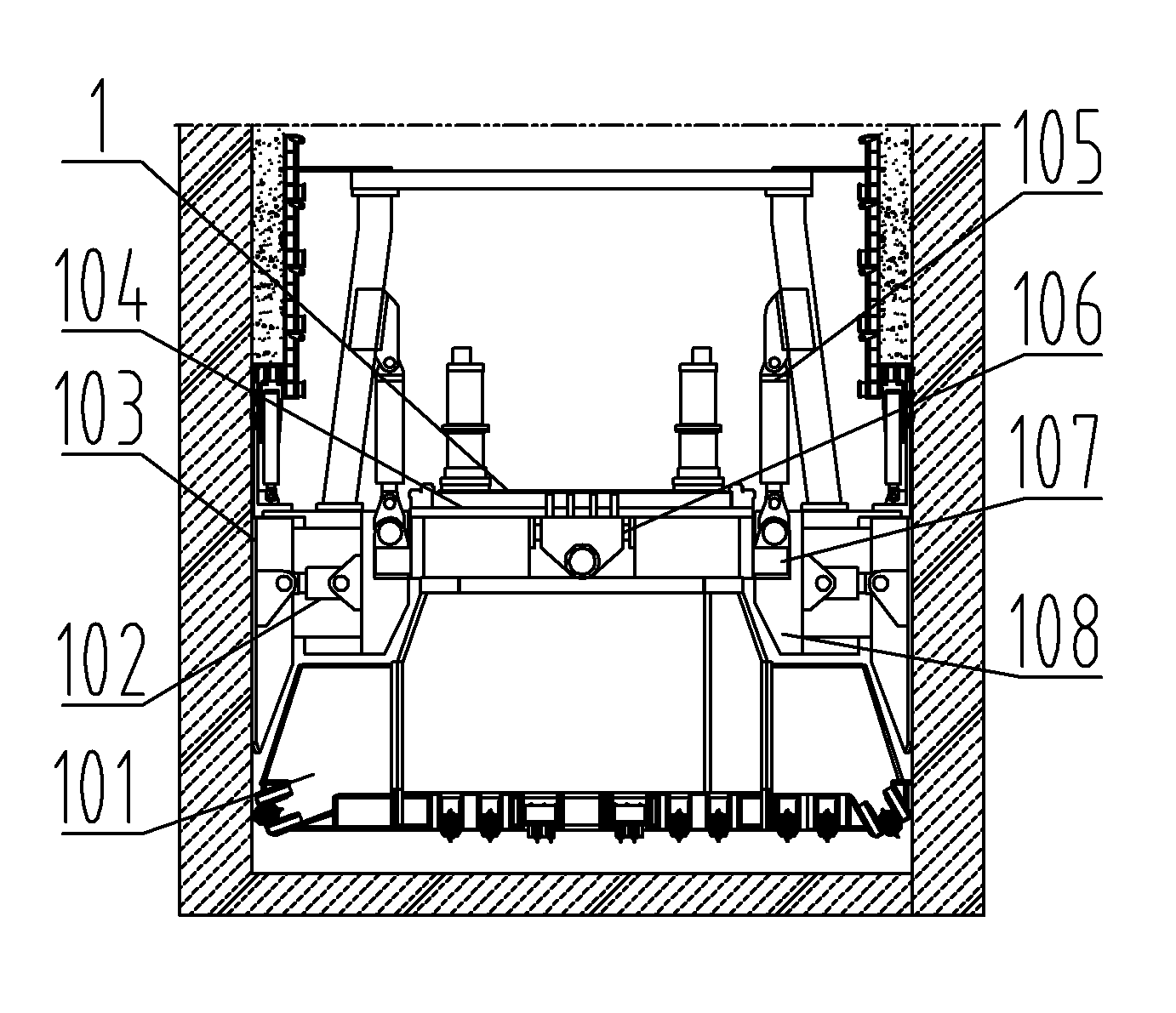

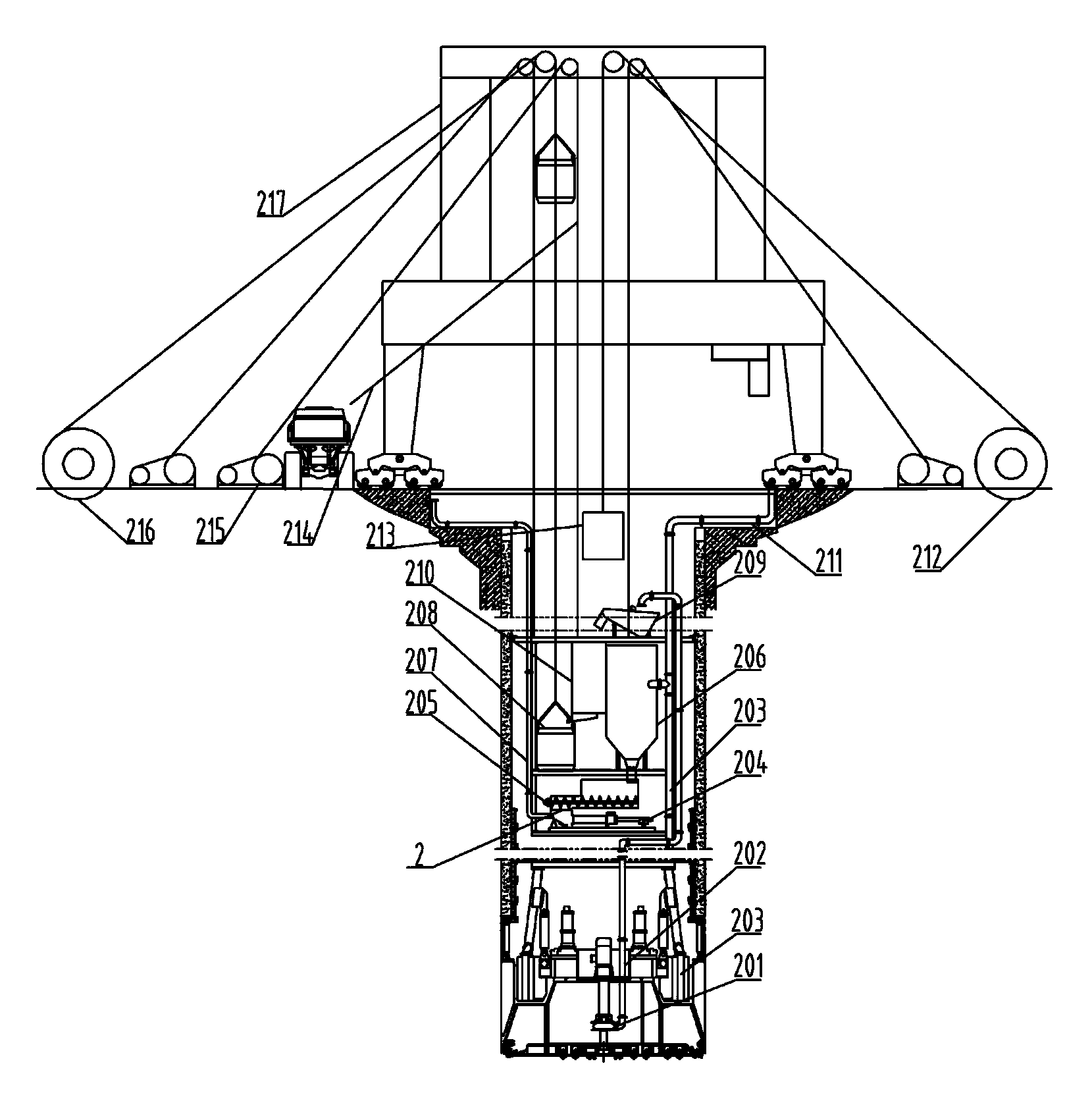

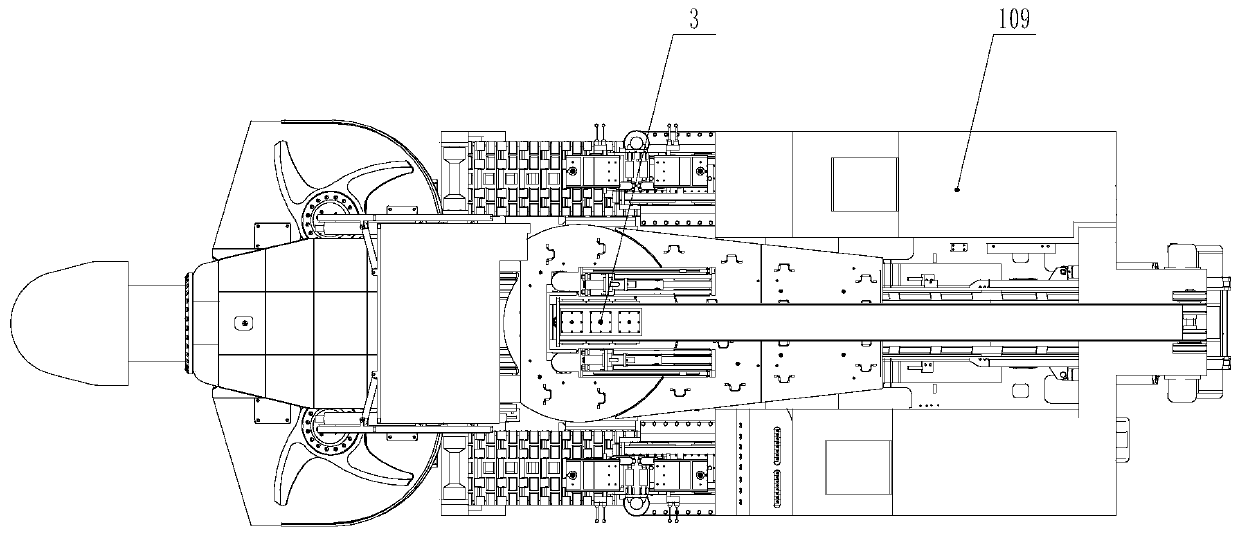

Full-fracture-surface vertical shaft drilling machine

ActiveCN103670420AEfficient constructionImprove construction efficiencyShaft sinkingShaft liningSlagControl engineering

The invention belongs to the technical field of mineral product machinery and discloses a full-fracture-surface vertical shaft drilling machine which comprises a device main girder, device platforms, a head frame, a tunneling system, a personnel and material conveying system, a shaft wall supporting and protecting system, a guaranteeing system and a manipulating chamber. The tunneling system is installed at the front end of the device main girder, the device platforms are installed at the rear end of the device main girder, the head frame is arranged on a shaft mouth, the manipulating chamber is arranged on the head frame, the personnel and material conveying system and the guaranteeing system are installed on the rear portion of the tunneling system, the shaft wall supporting and protecting system is arranged on the rear portion of the tunneling system and the periphery of the tunneling system, the personnel and material conveying system comprises a hoister, a first-level separation station, a slag storage cabin, a second-level separation station, a feeding mechanism and a conveying pump, the shaft wall supporting and protecting system comprises an auxiliary crane, a hoister, an underground concrete mixing tank, a concrete pump and an anchoring system, and the auxiliary crane, the hoister, the underground concrete mixing tank, the concrete pump and the anchoring system are installed on the device platforms respectively. The full-fracture-surface vertical shaft drilling machine solves the construction problems of large-scale vertical shafts such as coal mines, complete equipment of automation, mechanization and integration of the functions of shaft tunneling, slag tapping, supporting, protection, water discharging, ventilation and the like, the construction efficiency is improved, the construction cost is reduced, the construction safety is improved, and the application range is wide.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

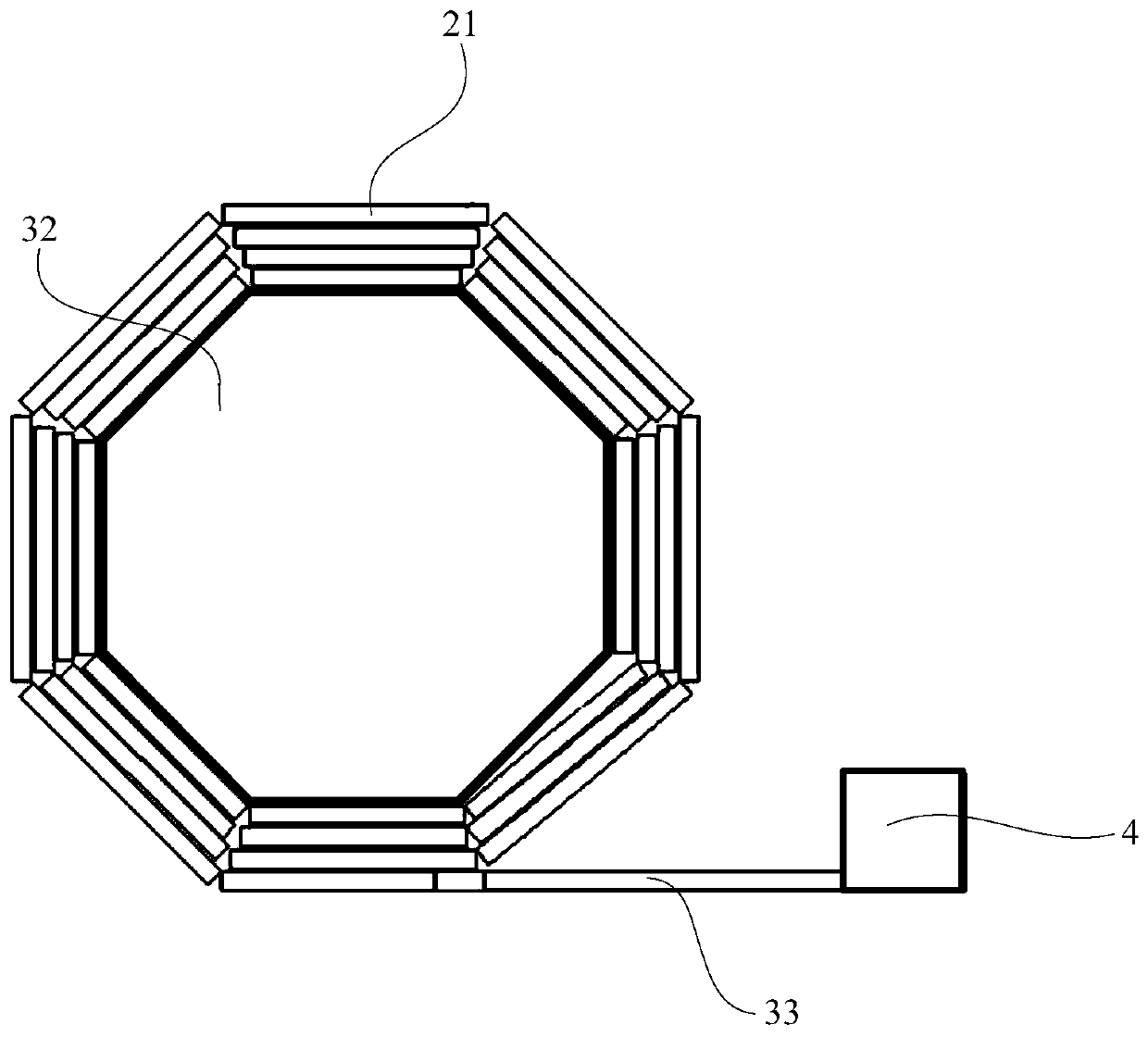

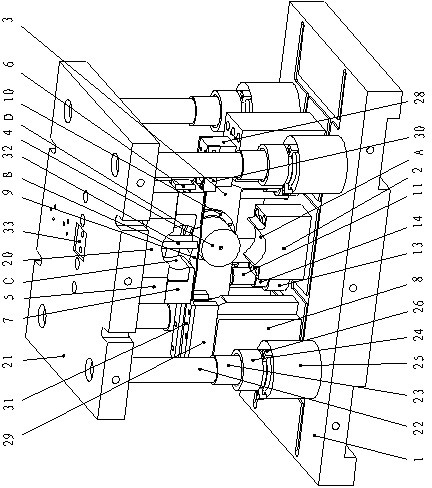

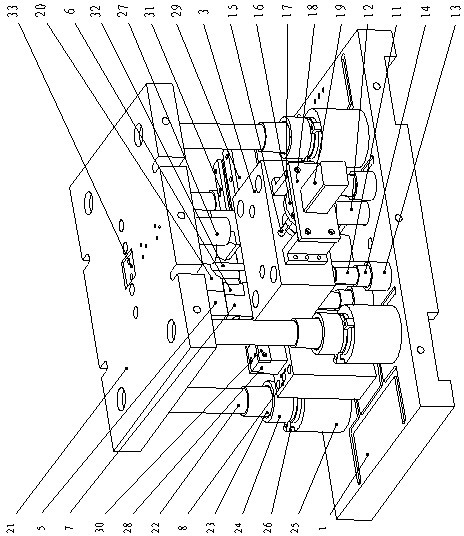

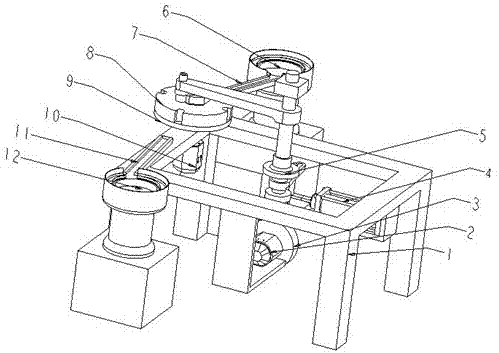

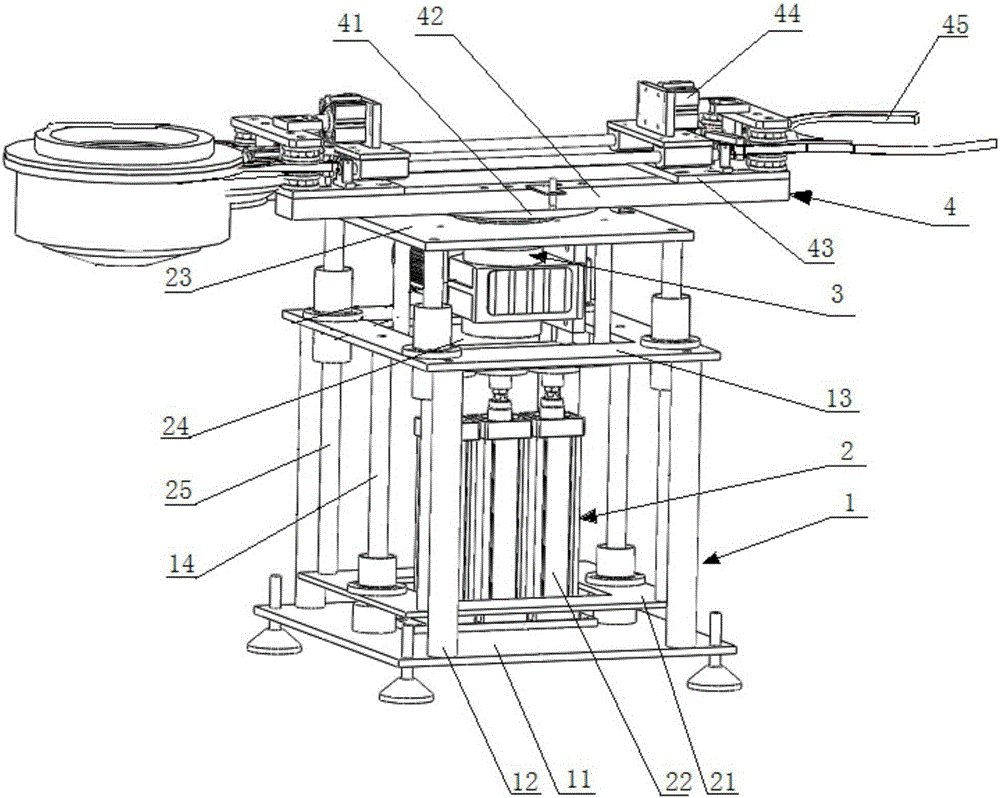

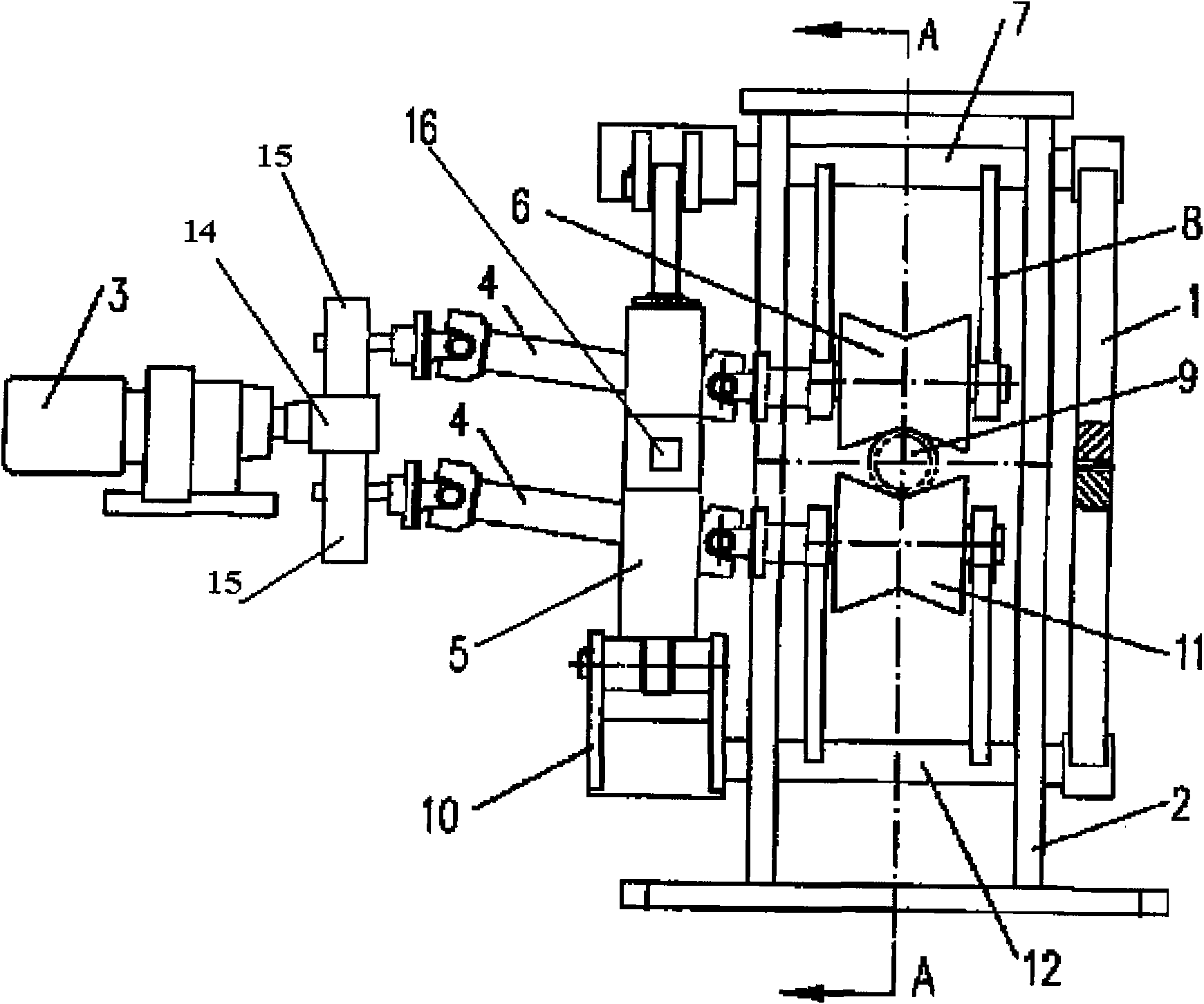

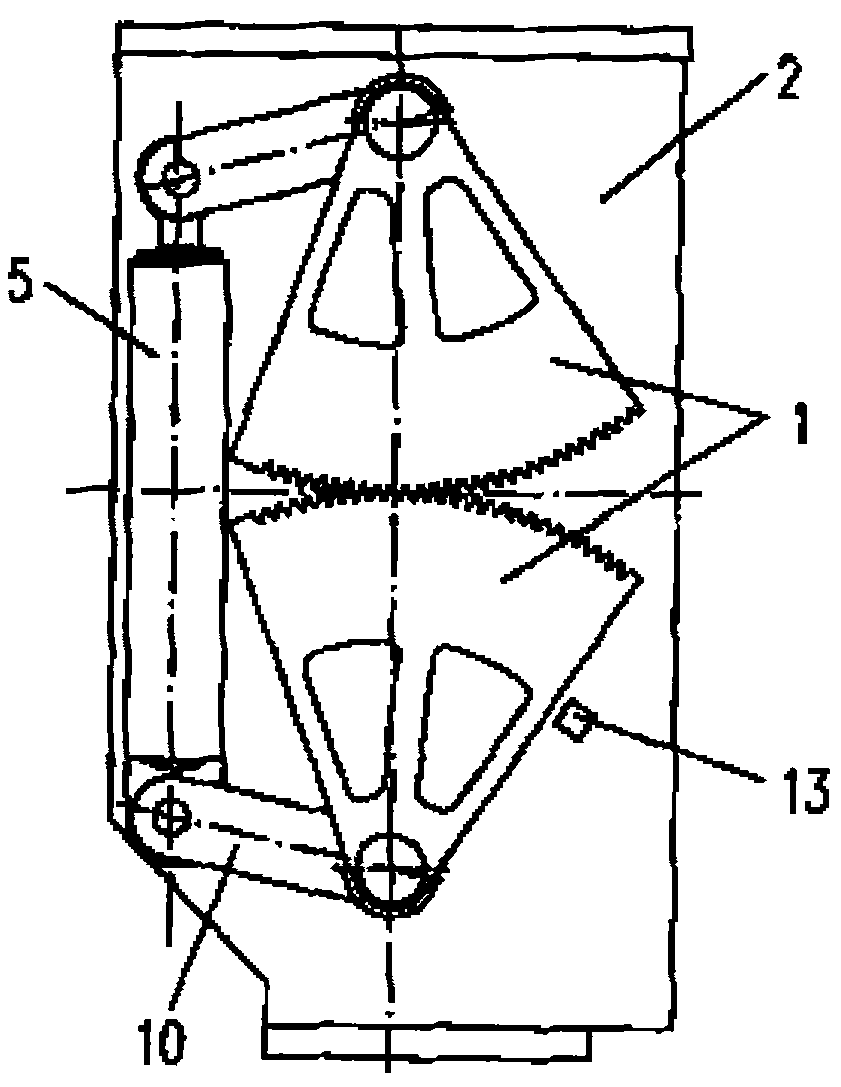

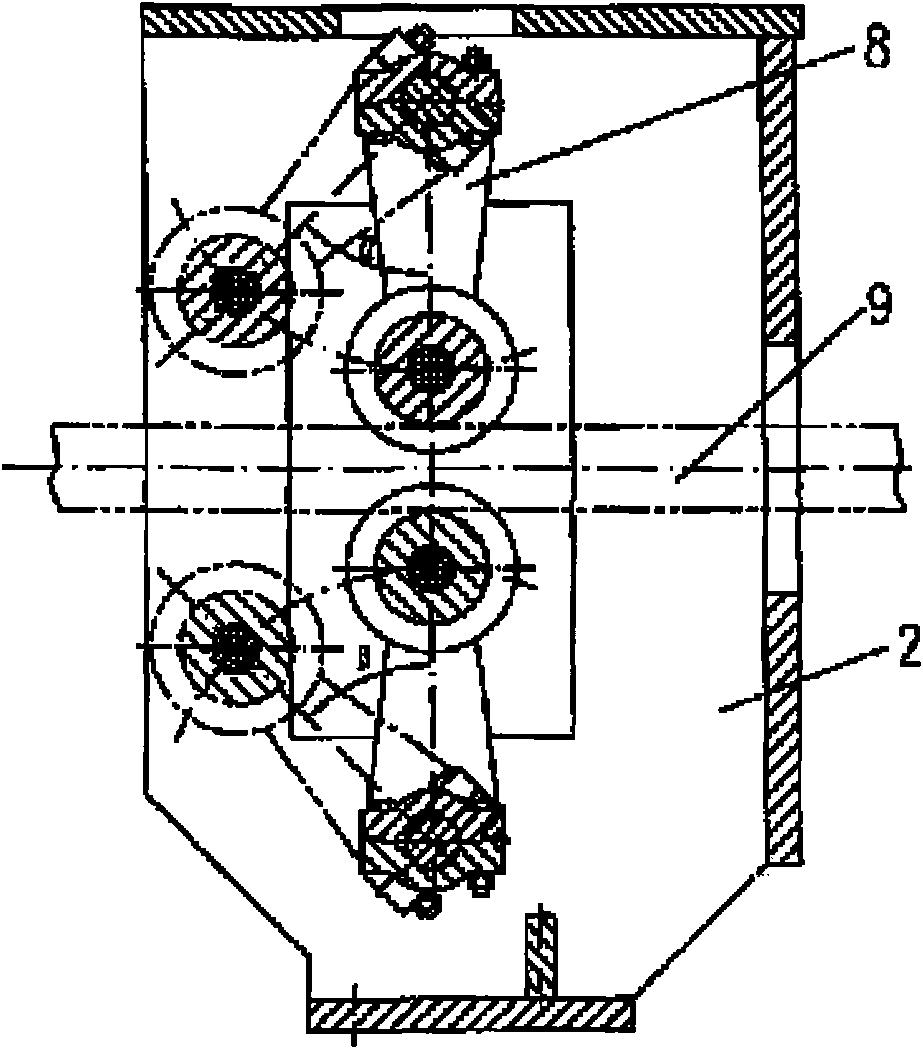

Disposable arc-rolling and forming die

The invention discloses a disposable arc-rolling and forming die, relating to the technical field of motor production. The disposable arc-rolling and forming die comprises a lower template (1) and a lower template accessory device, an upper template (21) and an upper template accessory device, and also comprises a movable plate device, a slideway device, a pressing device and a positioning device. The disposable arc-rolling and forming die can ensure that a plate cylinder motor shell is once coiled and formed, thus accumulated errors are avoided, collision and deformation of the products in machining and conveying processes are avoided, uniformity of sizes of final products is greatly improved, mechanical automation degree is increased, working efficiency is improved, yield and quality ofthe products are increased, and input of equipment resources and manpower resources is also reduced.

Owner:JIANGSU CHAOLI ELECTRIC

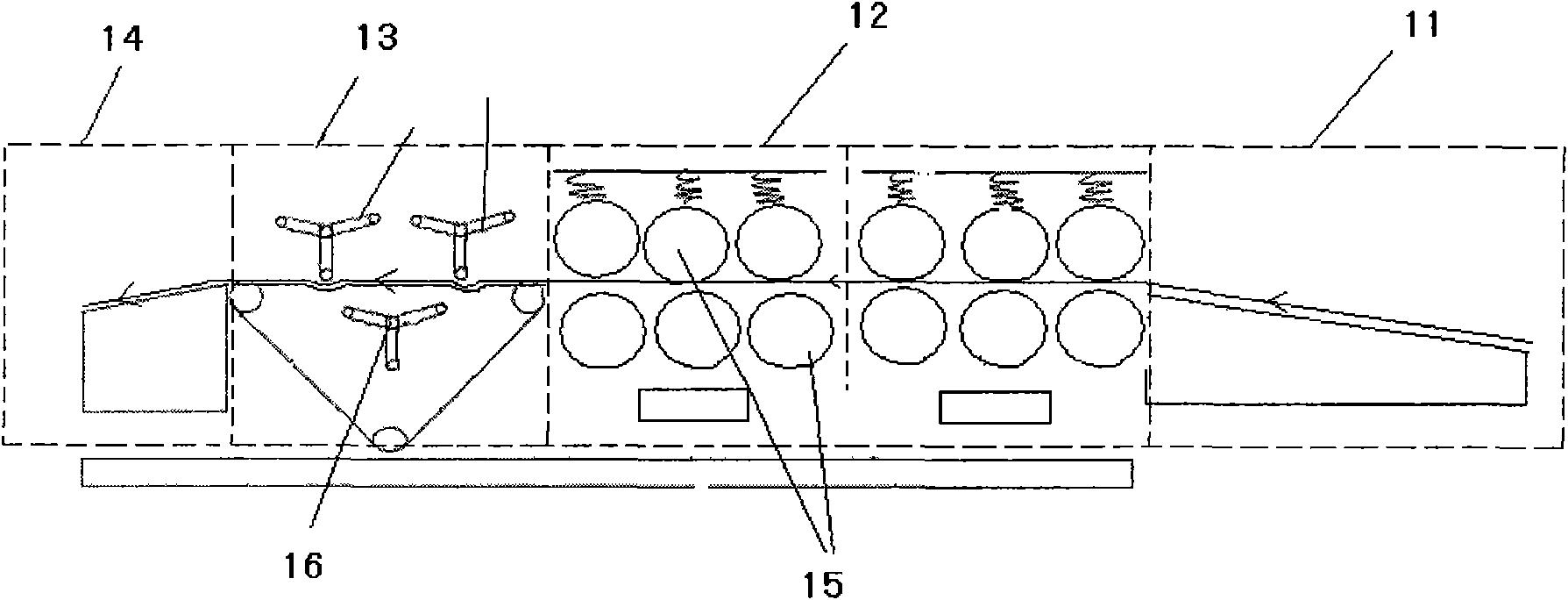

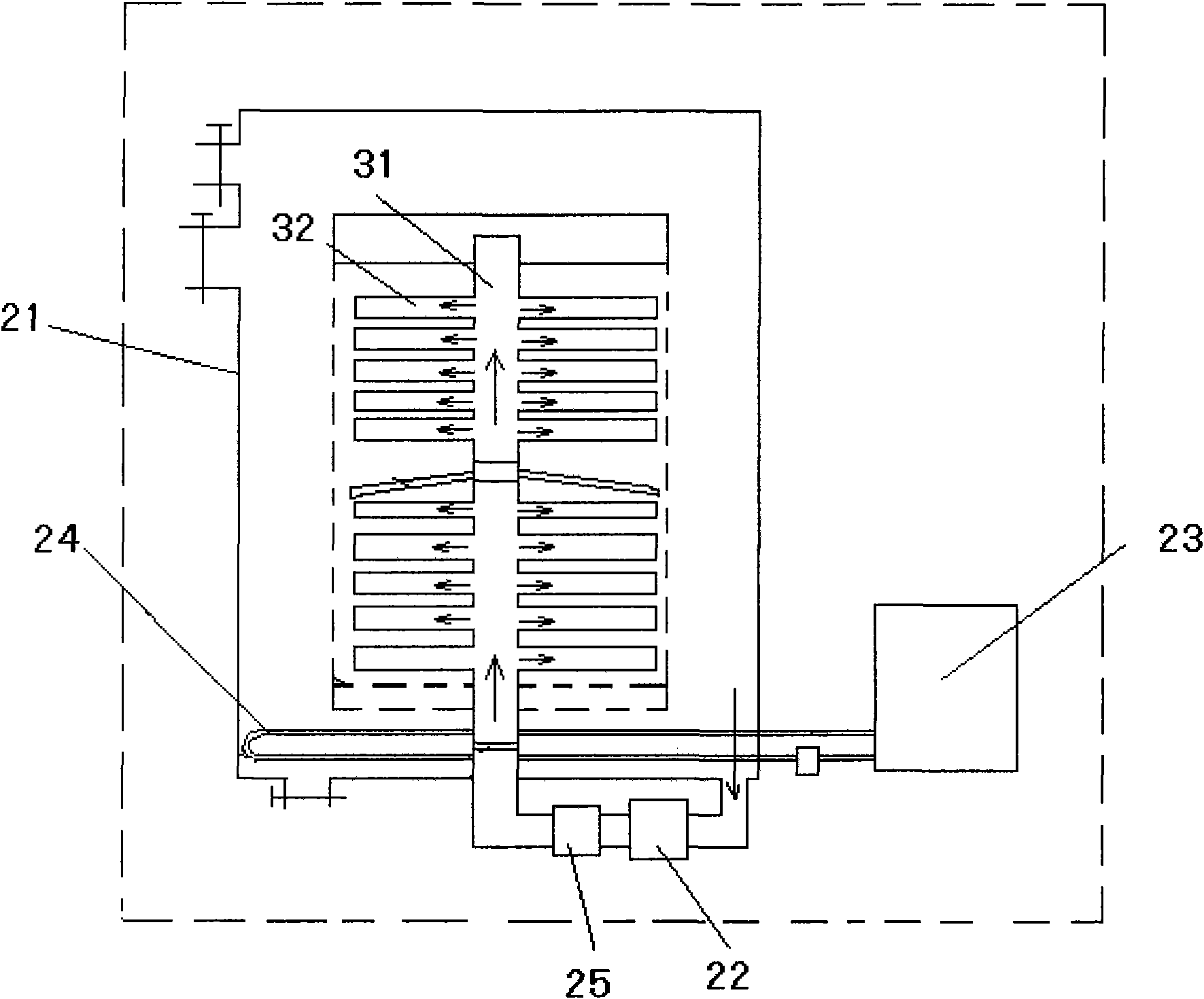

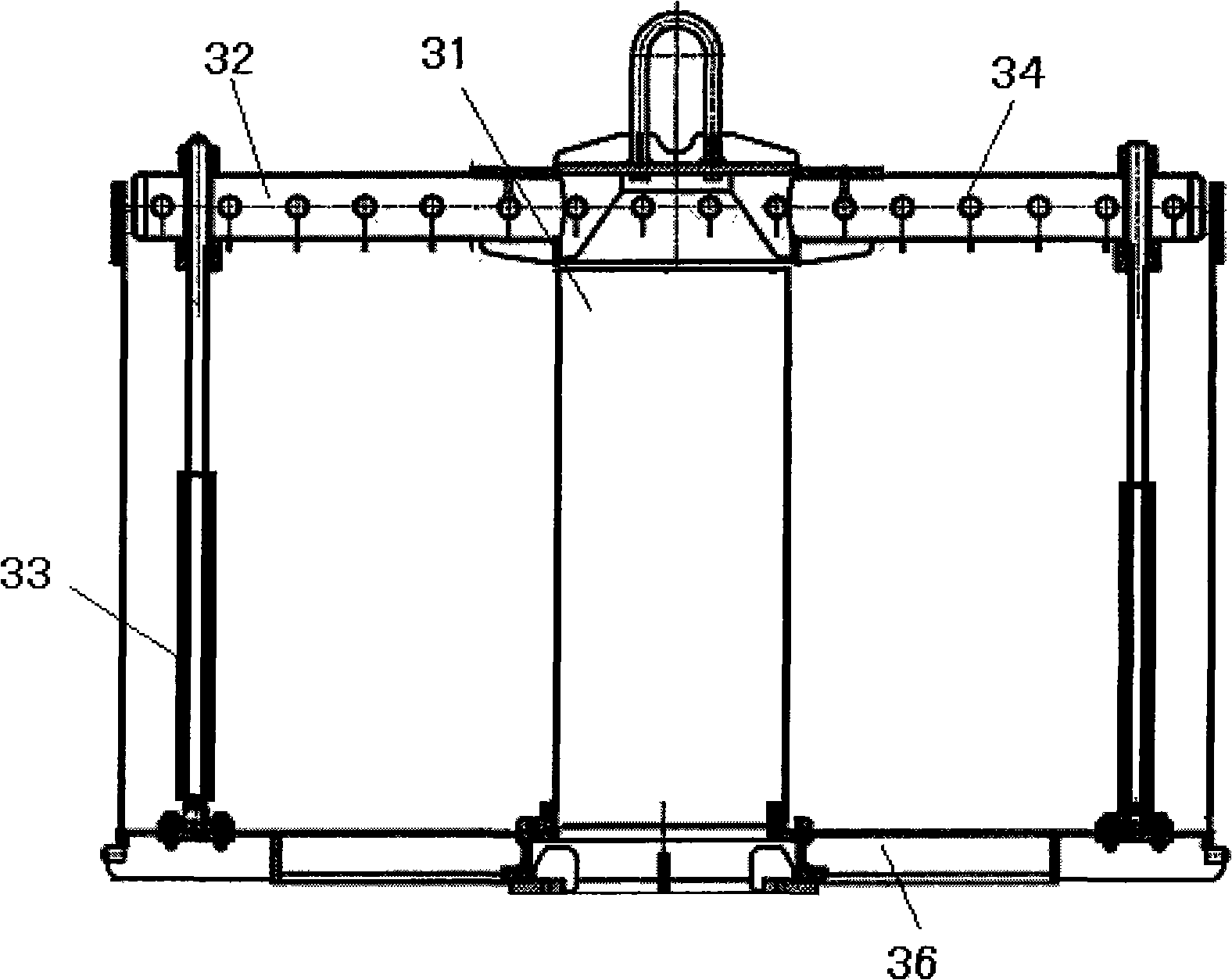

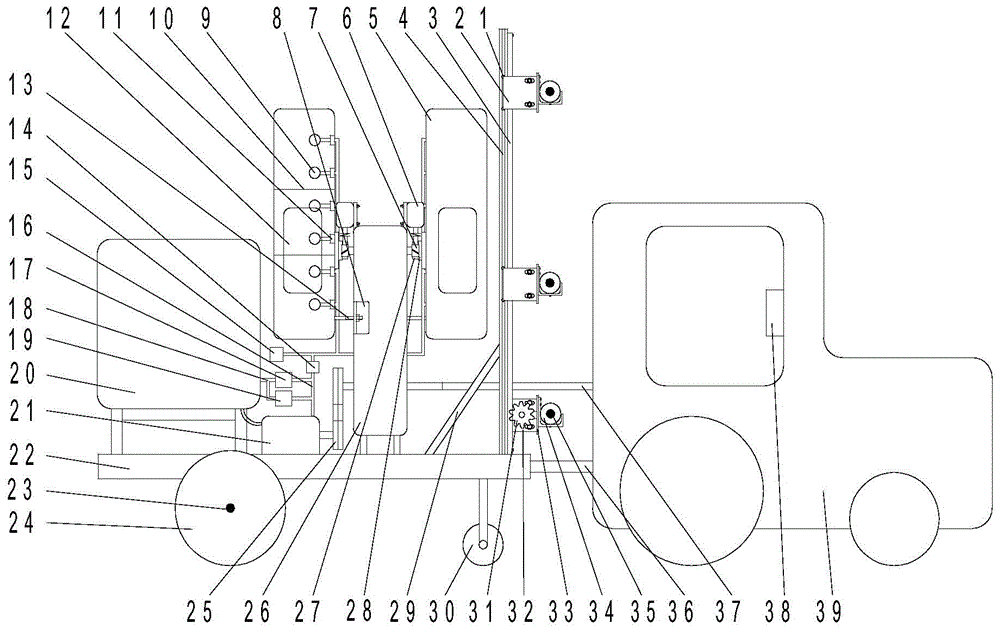

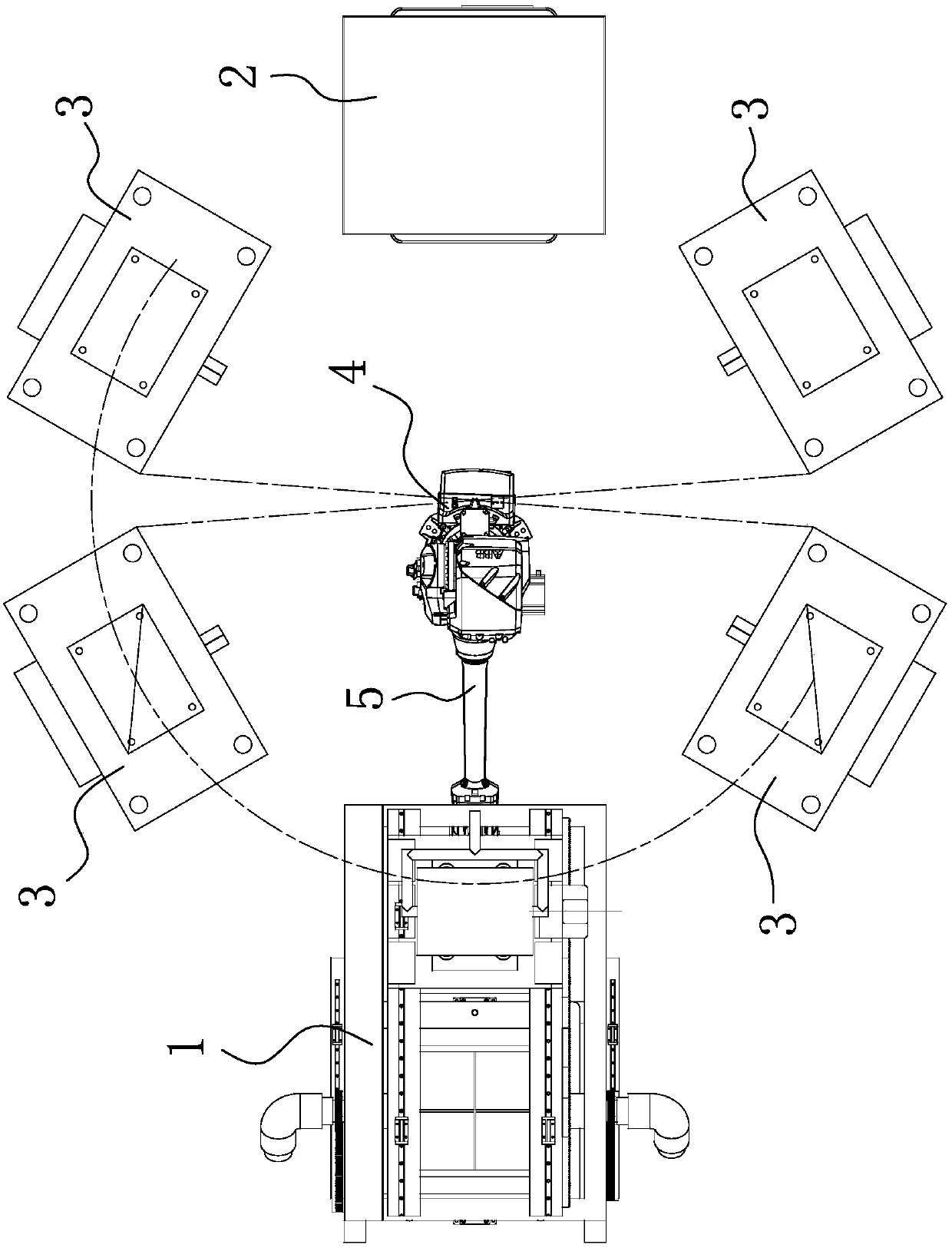

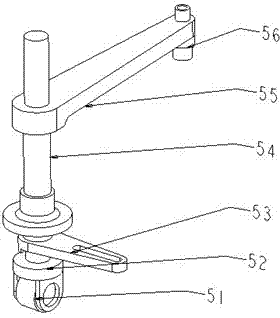

Self-adaptive orchard sprayer

ActiveCN104082268AUniform and stable sprayingIncrease profitInsect catchers and killersControl signalSprayer

A self-adaptive orchard sprayer comprises a traction chassis, wherein a pesticide application device and a plurality of movable ultrasonic detection devices are arranged at the front end above the traction chassis. Each ultrasonic detection device mainly comprises an ultrasonic sensor and a vertical moving device, and a detection signal of the ultrasonic sensor is output and connected to an embedded control platform. The pesticide application device mainly comprises a pesticide spraying device and a stepping motor rotation control device, wherein the pesticide spraying device are provided with electric ball valves, flow sensors, pressure sensors and solenoid valves, and detection and control signals of the electric ball valves, the flow sensors, the pressure sensors and the solenoid valves are connected to the embedded control platform which integrates signals of the sensors to control opening of the electric ball valves and actions of the solenoid valves. By means of the self-adaptive orchard sprayer, tree form information of control targets in an orchard can be collected automatically; according to the information, the ultrasonic sensors can be distributed automatically, and rotating angles of an air bellow are regulated automatically, or rotating angles of the air bellow can be regulated manually according to actual needs. Therefore, pesticide application efficiency is increased, pollution to the environment and personal injury to operators caused by pesticide application are reduced.

Owner:NORTHWEST A & F UNIV

Carton folding machine

ActiveCN105128399ARealize folding box formingAchieve interconnectionBox making operationsPaper-makingMolding machineCarton

The invention provides a carton folding machine. The carton folding machine comprises a bottom board, a bracket, a paperboard feeding mechanism, a supporting mechanism, a compressing mechanism, an edge leftwards and rightwards folding mechanism, a forming mechanism, a carton push-out mechanism, an edge forwards and backwards folding mechanism and an edge forwards and backwards pressing mechanism, wherein the bracket is used for supporting the bottom of the bottom board which is provided with a forming cavity. The carton folding machine is provided with the forming cavity of the same structure as a formed package carton, the paperboard with folding lines is placed in the forming cavity, and then the bottom board of the package carton is downwards pressed to the bottom of the forming cavity and moves downwards so as to drive side boards of the package carton to be erected, so that the package carton is formed in a folded manner. According to the carton folding machine, the package carton is formed in the folded manner based on the stamping principle, and a new method is provided for folded molding of the package carton.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

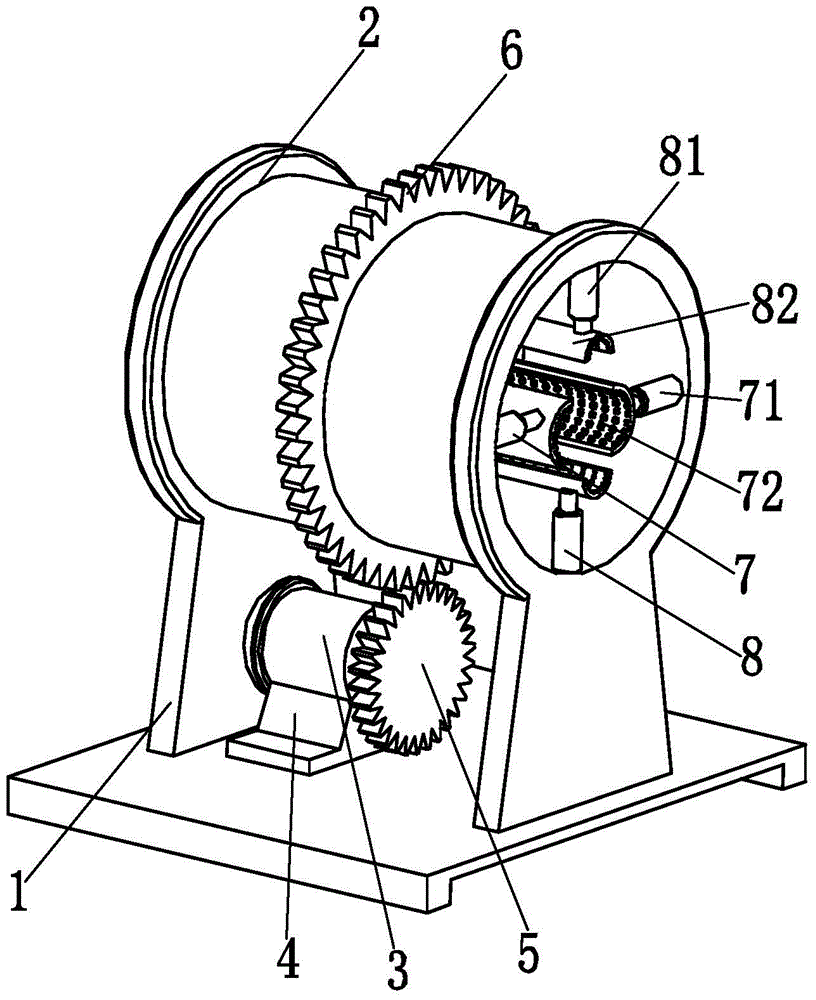

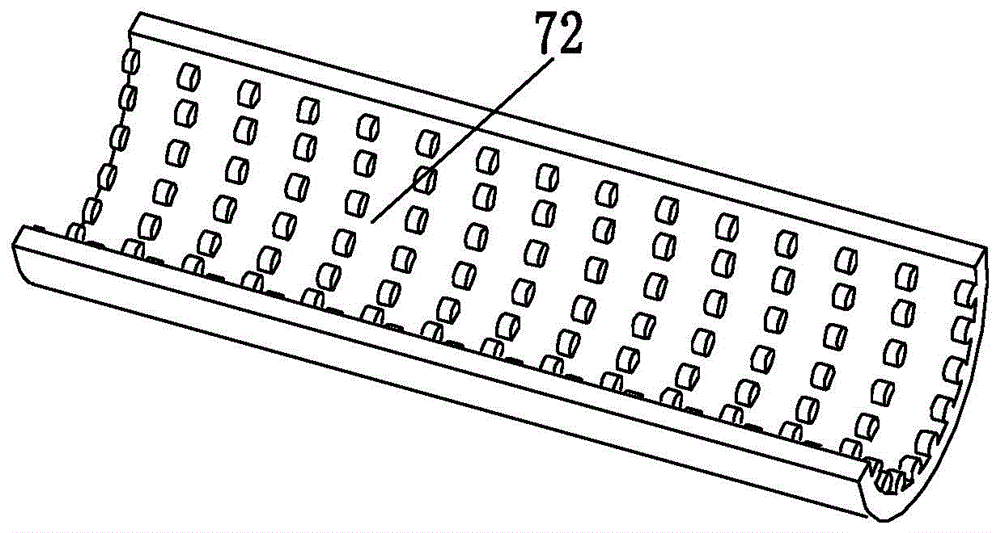

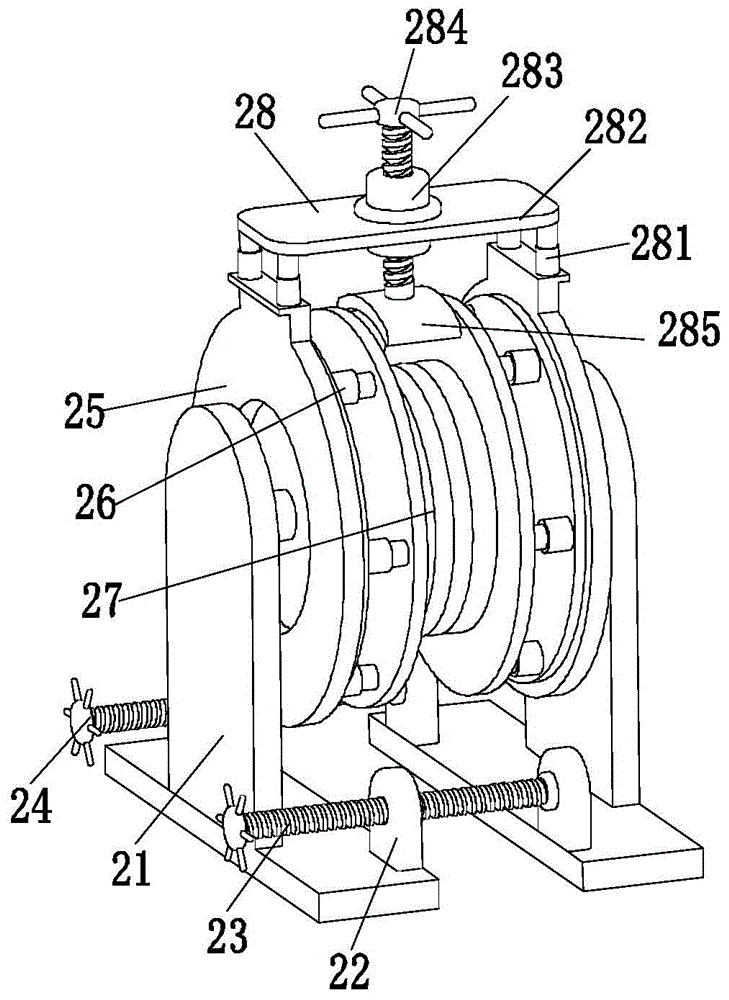

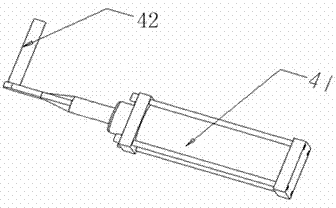

Diameter-variable steel wire rope derusting device

ActiveCN104907913ACompact structureEasy to operateGrinding machinesArchitectural engineeringAutomation

The invention relates to a diameter-variable steel wire rope derusting device which comprises two derusting supports, a derusting roller, a motor, a motor base, a driving gear, a driven gear, two large-diameter derusting mechanisms and two small-diameter derusting mechanisms. Rings are positioned at the upper ends of the derusting supports, the two ends of the derusting roller are installed in the rings at the upper ends of the two derusting supports respectively through bearings, the motor is located under the derusting roller, the driving gear is connected with a motor spindle through a key, the middle of the driven gear is provided with an installing sleeve ring, and the installing sleeve ring at the middle of the driven gear is fixed at the middle of the derusting roller. The driven gear is meshed with the driving gear; and the two large-diameter derusting mechanisms and the two small-diameter derusting mechanisms are located in the derusting roller. The diameter-variable steel wire rope derusting device can perform surface derusting treatment on steel wire ropes of different diameters, is quick in derusting speed, wide in applied range and high in mechanical automation degree and saves plenty of manpower.

Owner:江苏锐金钢丝绳索具有限公司

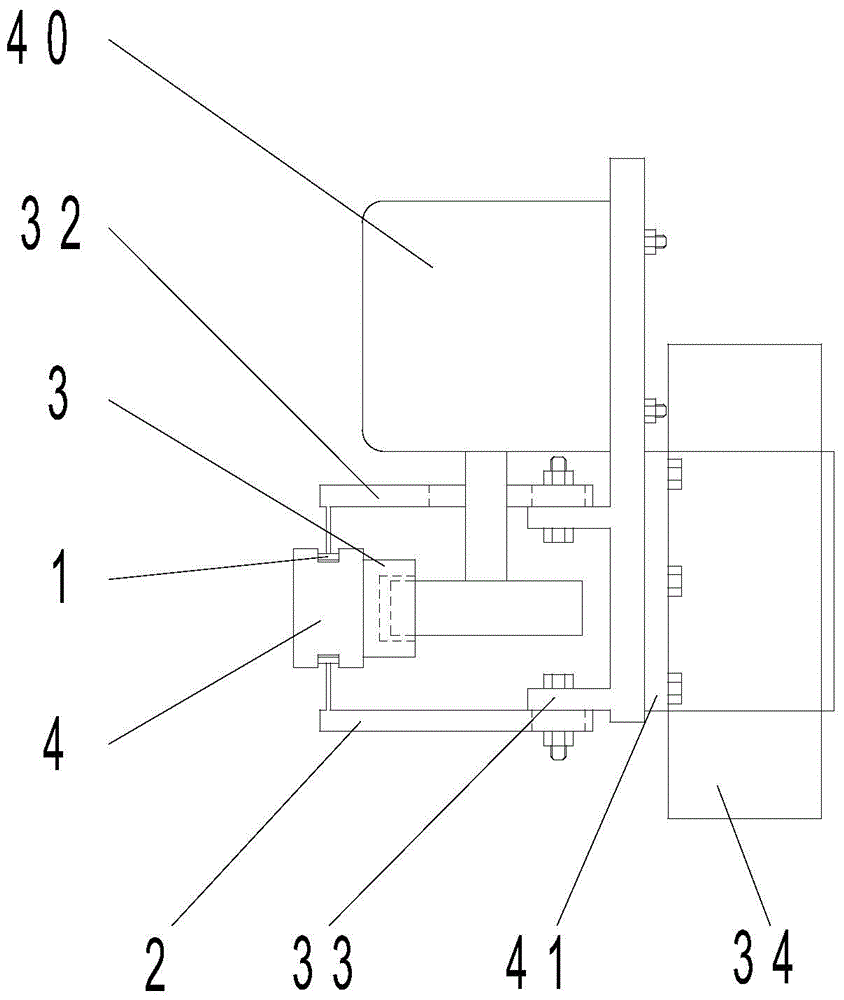

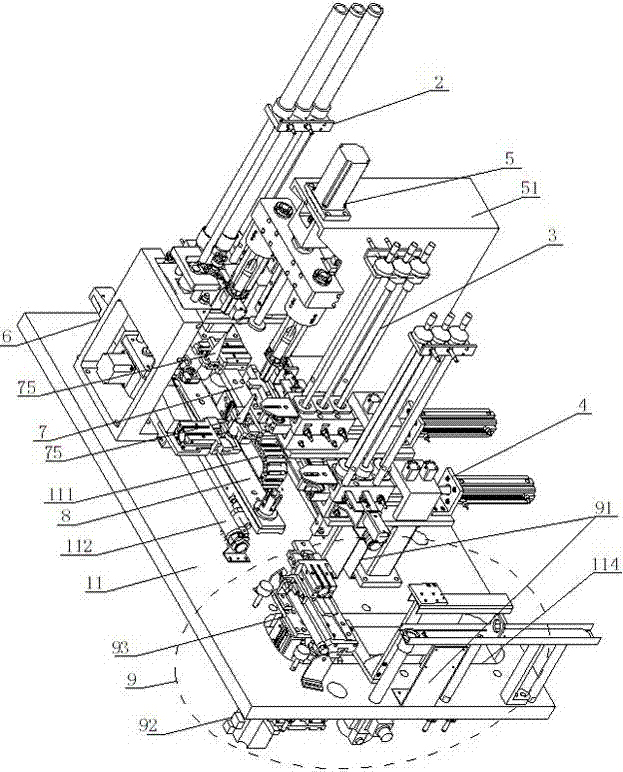

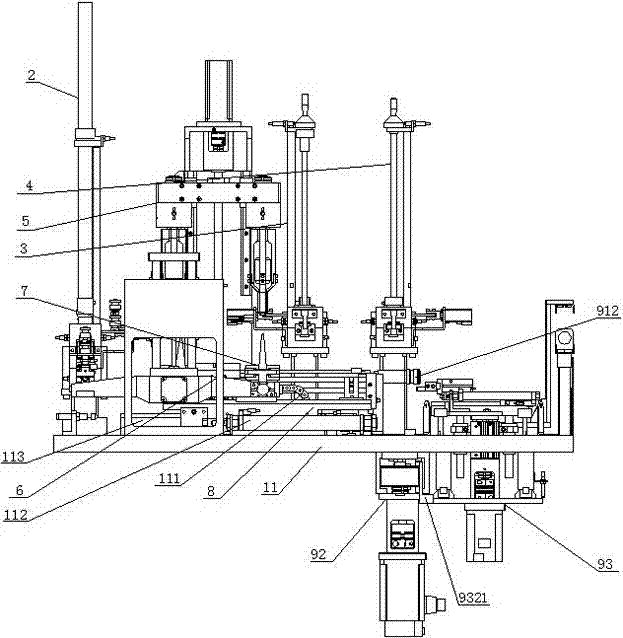

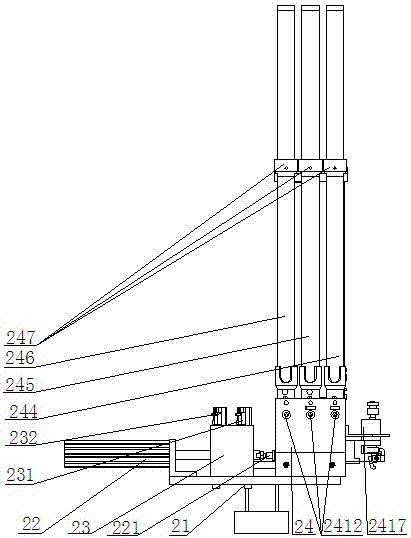

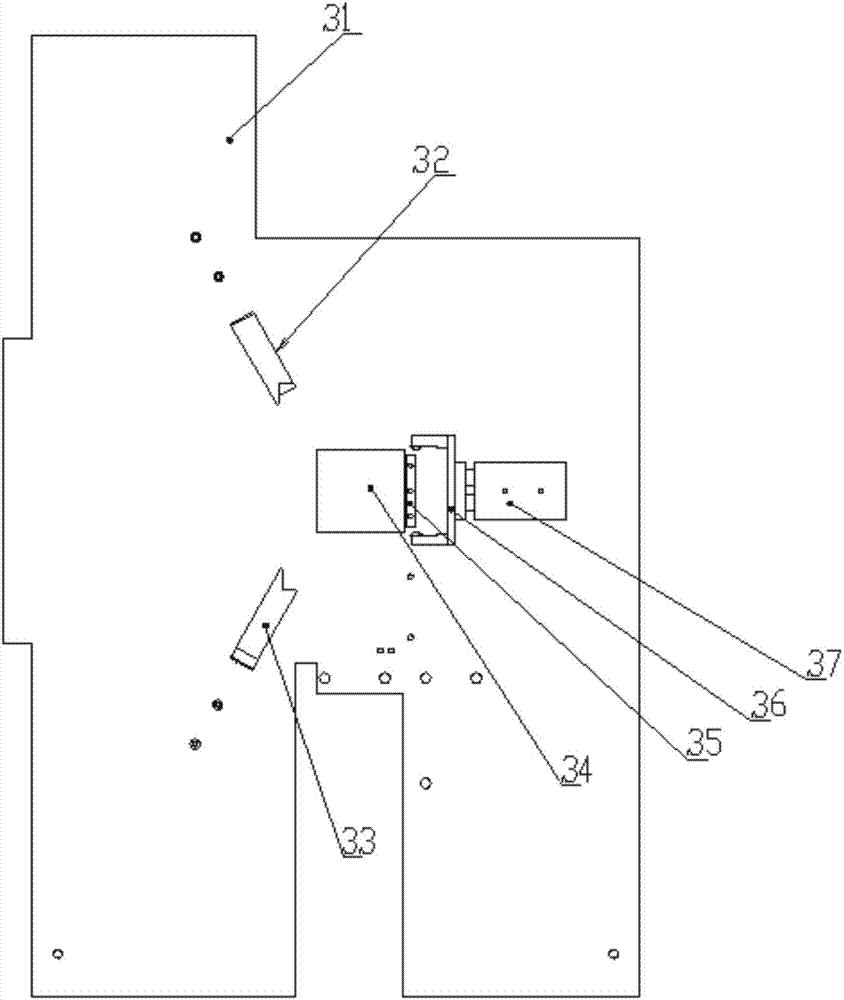

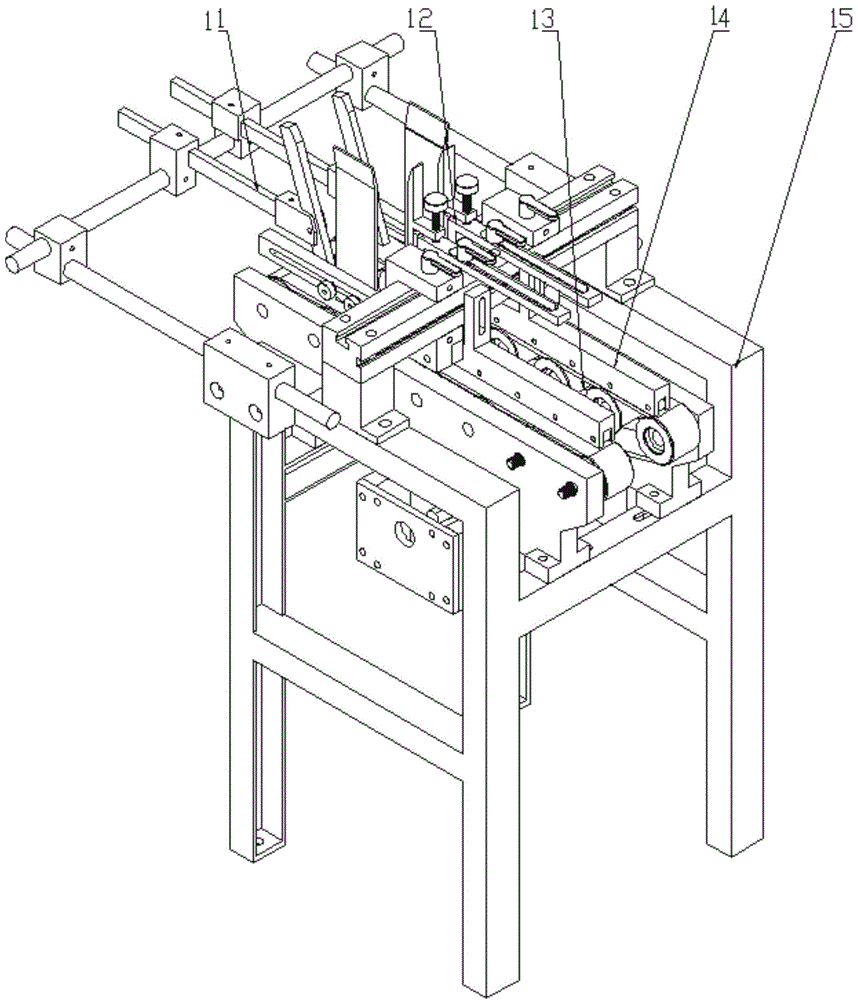

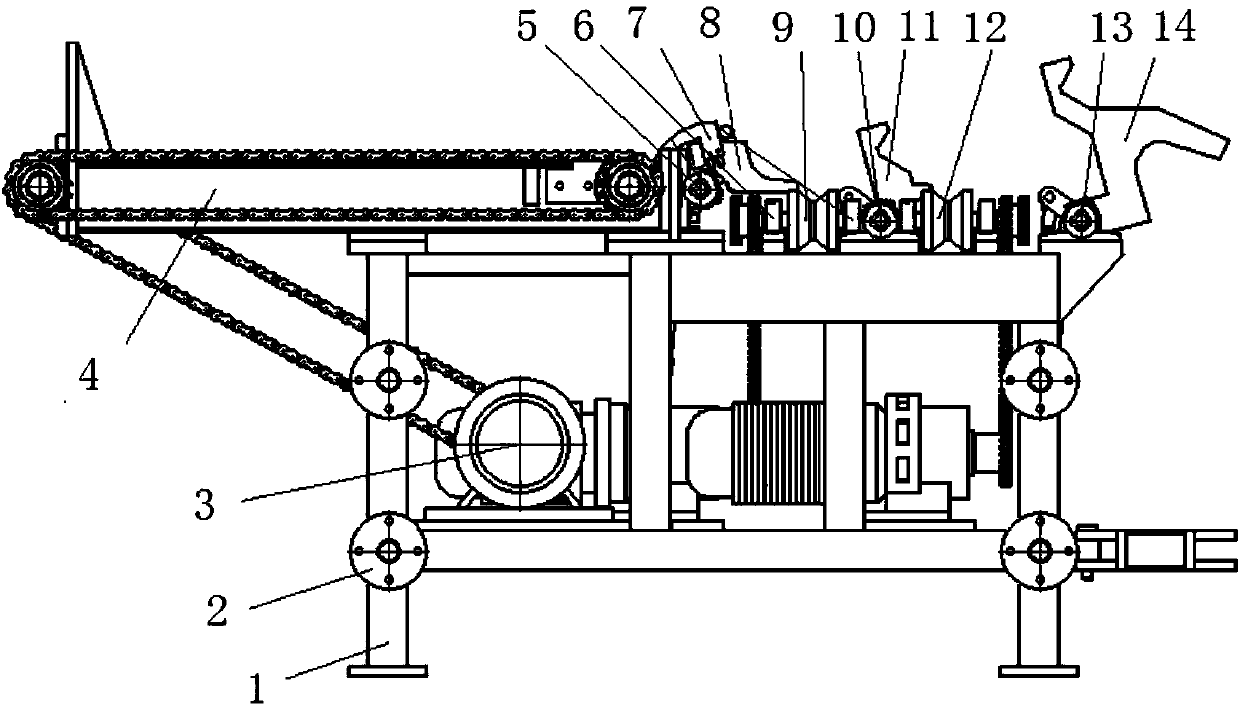

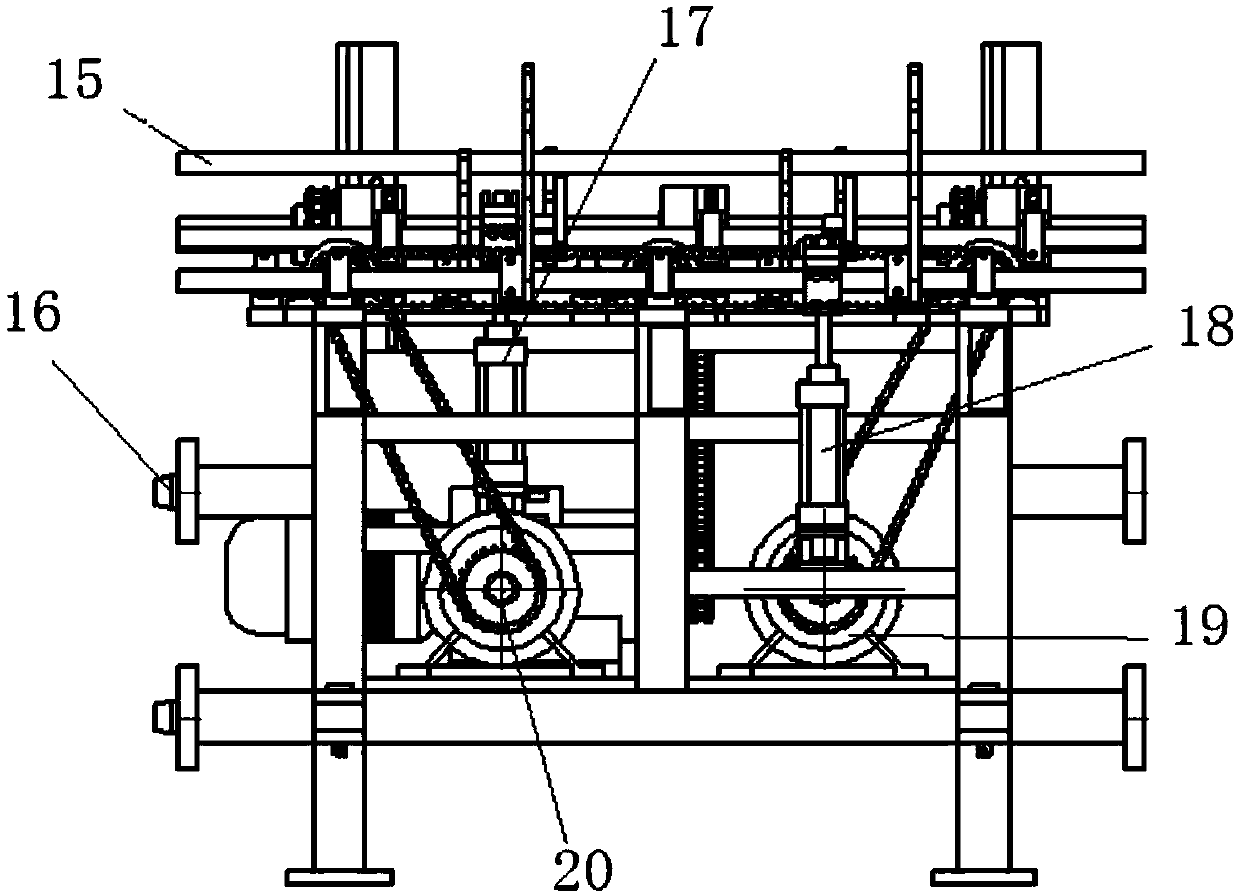

Automobile brake wheel cylinder cup assembly line

The invention relates to an automobile brake wheel cylinder cup assembly line which comprises a rack and a bottom plate, wherein the bottom plate is fixed on the rack. The automobile brake wheel cylinder cup assembly line is characterized by further comprising a piston discharging mechanism arranged on the bottom plate, a cup discharging mechanism, a dustproof cover discharging mechanism, a press fitting mechanism, a conical rod manipulator mechanism, an overturning manipulator mechanism and a working platform component. The piston discharging mechanism, the press fitting mechanism, the cup discharging mechanism and the dustproof discharging mechanism are sequentially fixed on the bottom plate, and the conical rod manipulator mechanism, the working platform component and the overturning manipulator mechanism are sequentially arranged in a matching mode and matched with the discharging mechanisms and the press fitting mechanism. The automobile brake wheel cylinder cup assembly line is reasonable in structural design, high in mechanical automation, reduces repetitive operation of operators, and improves production efficiency and quality of workpieces.

Owner:HANGZHOU GAOPIN AUTOMATION EQUIP

Wollastonite modified thermoplastic resin composite material and product preparation method thereof

The invention relates to a wollastonite modified thermoplastic resin composite material which comprises the following raw materials in percentage by weight: 50 to 70 percent of wollastonite, 25 to 40 percent of polypropylene, 3 to 6 percent of maleic anhydride modified polypropylene, 1 to 3 percent of titanium dioxide and 1 to 2 percent of anti-oxidant. The invention also provides a method for preparing sanitary ware, hardware of the sanitary ware, outdoor products, exterior wall decorative pipes, practical decoration of public landscape and other products with the wollastonite modified thermoplastic resin composite material. The method has the advantages of easily available raw materials, no need of high energy consumption and long-termed firing during the preparation process, greatly reduced energy consumption, high mechanical automation degree, reduced labor intensity and high yield, and the products fully meet the requirements of industrial and large-scale production.

Owner:SHANGHAI HUDA INVESTMENT & DEV CO LTD +1

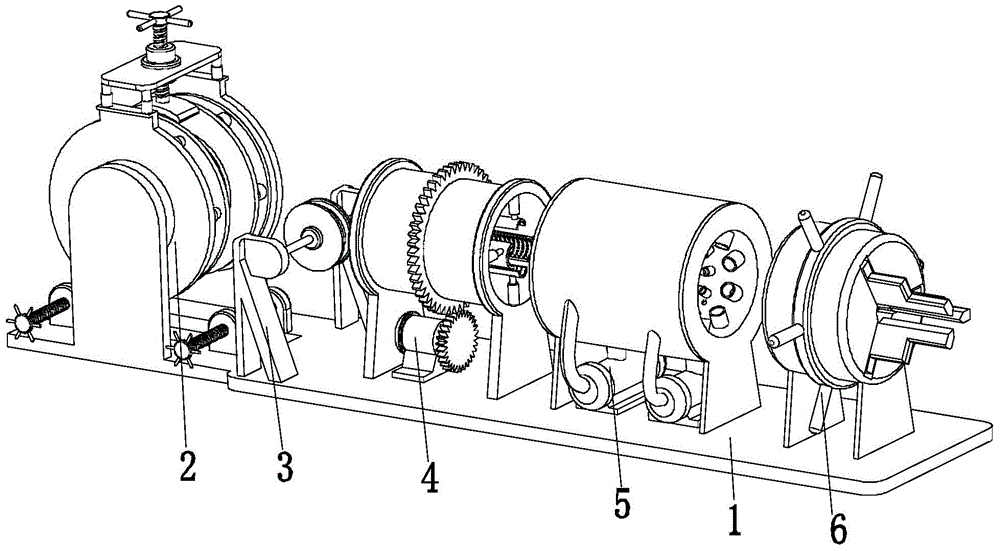

Treatment equipment for hoisting steel wire ropes of rope grab buckets

InactiveCN104909221ACompact layoutSmall footprintEdge grinding machinesPolishing machinesEngineeringLubrication

The invention relates to treatment equipment for hoisting steel wire ropes of rope grab buckets. The treatment equipment comprises a base, a rotary conveying device, a tensioning device, a derusting device, a lubricating device and a cutoff device. The rotary conveying device, the tensioning device, the derusting device, the lubricating device and the cutoff device are linearly arranged on the base which is in a rectangular flat plate structure. The rotary conveying device is positioned on the left side of the base, the tensioning device is mounted in front of the rotary conveying device, and the lubricating device is positioned between the derusting device and the cutoff device and fixedly connected with the base. The treatment equipment for the hoisting steel wire ropes of the rope grab buckets has the advantages that rotary pay-off and take-up, surface derusting, lubrication, air drying and fixed-length cutoff of the steel wire ropes can be completed, and compact layout, small space occupancy, high mechanical automation level and manpower saving are realized.

Owner:涂春生

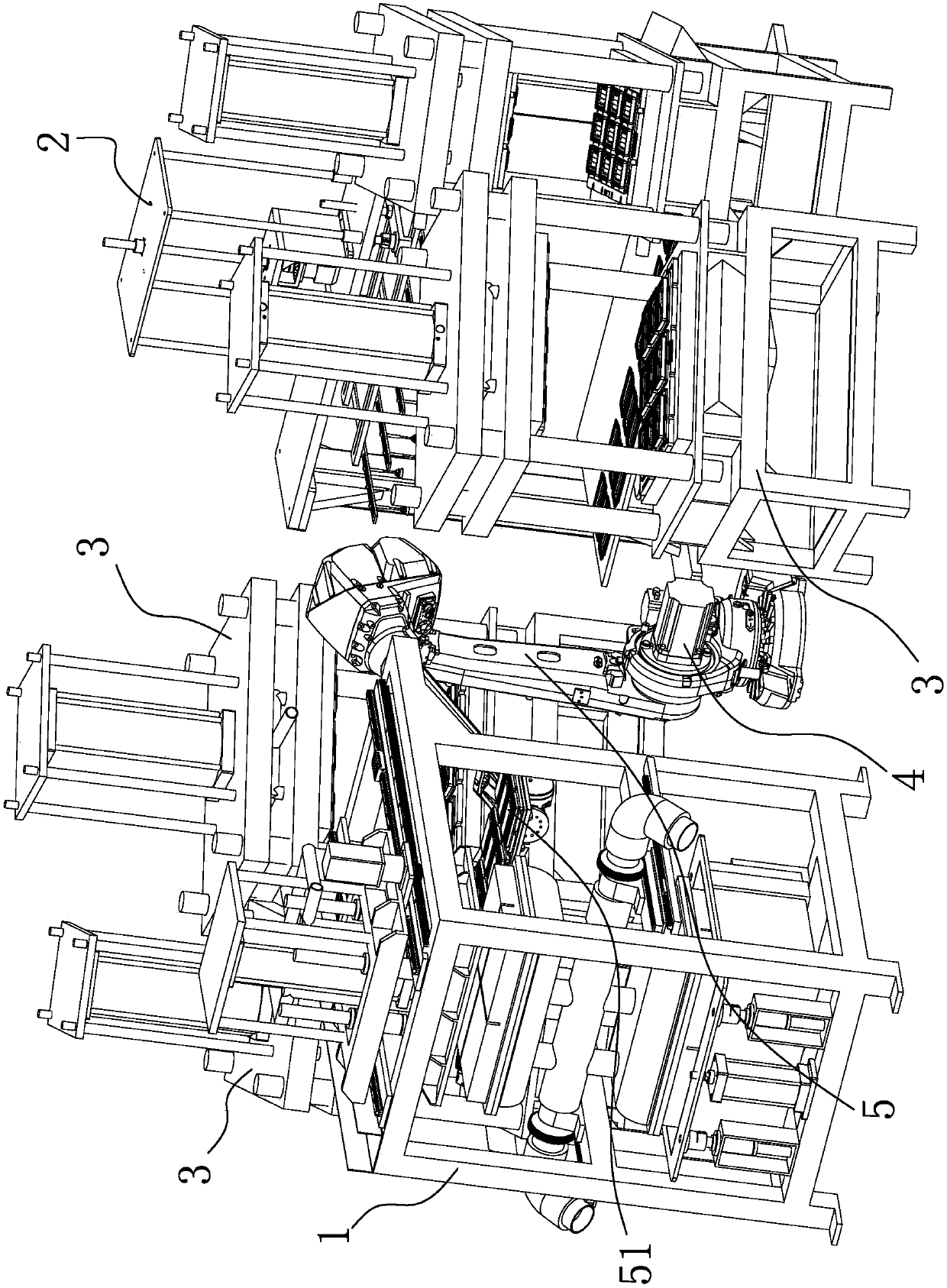

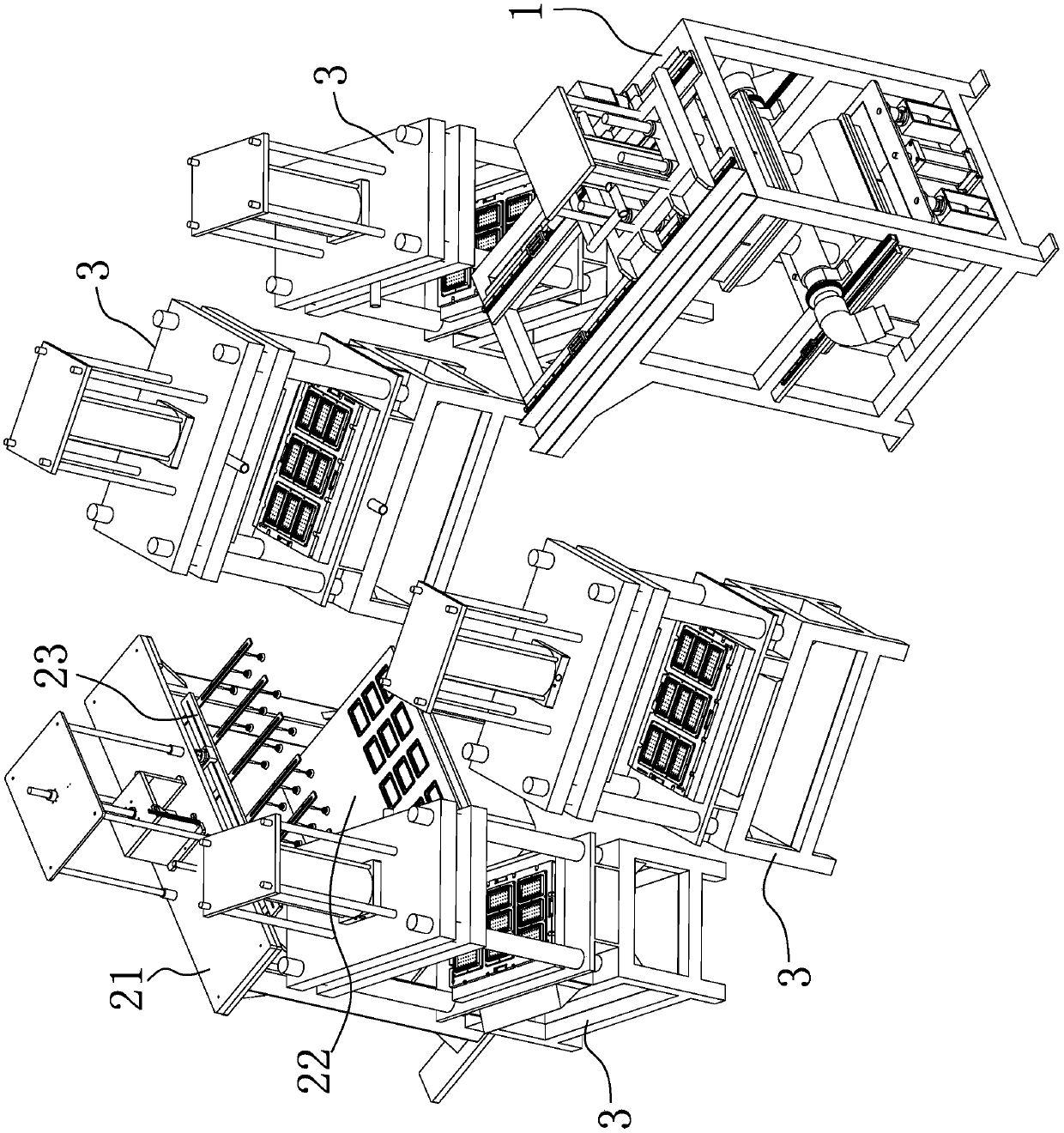

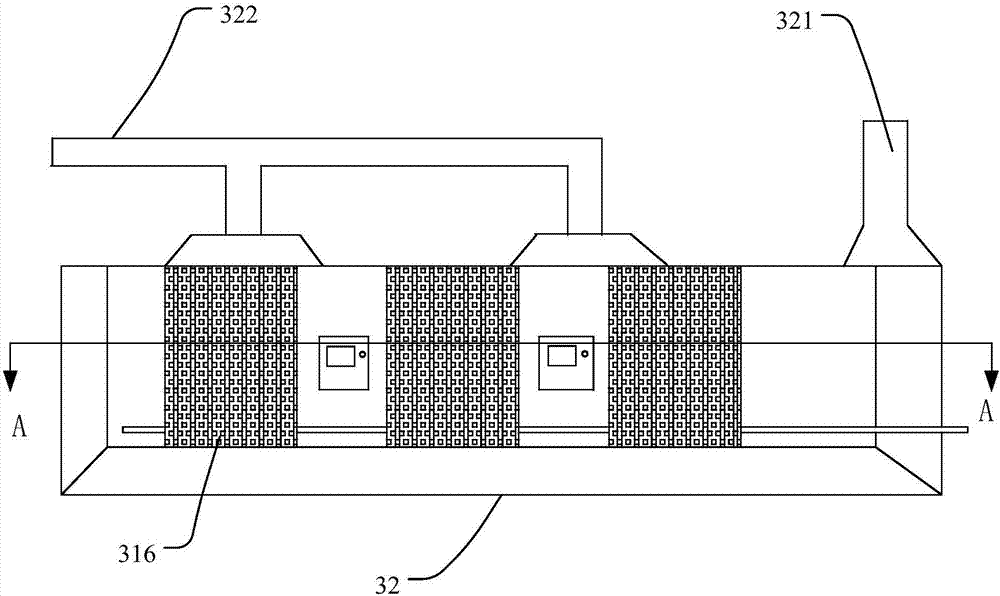

Flexible production line for producing paper pulp molded products

PendingCN107915044ASimple structureEasy to manufactureStacking articlesTextiles and paperMolded pulpProcess engineering

The invention belongs to the technical field of machines and particularly relates to a flexible production line for producing paper pulp molded products. Through the flexible production line, the problems that design is not reasonable and the like in the prior art are solved. The flexible production line for producing the paper pulp molded products comprises at least one product molding device, atleast one product stacking device and a plurality of hot-pressing sizing devices. The production line further comprises a transfer device. A mechanical arm is connected to the transfer device. At least one suction cup is connected to the mechanical arm; the mechanical arm drives the suction cups to transfer paper pulp molded products molded by the product molding device every time to the productstacking device one by one; the product stacking device stacks the paper pulp molded products received every time. The flexible production line has the advantages that the production efficiency can beimproved, and the cost is lower.

Owner:ZHEJIANG SHURCON MFG

Oyster rope releaser

InactiveCN101816292AHigh off-rope efficiencyReduce labor intensityClimate change adaptationPisciculture and aquariaOysterEngineering

The invention relates to an oyster rope releaser. The oyster rope releaser comprises a bracket and at least one oyster separating component which is fixedly connected with the bracket and is characterized by further comprising a horizontal frame, a power and driving device, a rope dragging device, a rope hook-releasing control device and a power electric control device, wherein the rope dragging device comprises a dragging box, a dragging body, a rope hook-releasing drive component, a stopping component and at least one rope hook fastener; and the rope hook-releasing control device comprises a limit component and a rope hook-releasing control component. In the oyster rope releaser, the oyster rope is hooked on the rope hook fastener; the rope attached with the oyster is placed on the oyster separating component; the oyster is separated from the rope due to the dragging of the rope hook fastener and the position limit of the oyster separating component; and the rope hook fastener is deflected when reaching the dragging travel limiting position so that the rope is separated from the hook. The oyster rope releaser has the advantages of reasonable design, high mechanical automation degree, low labor intensity and high efficiency of the separation of the oyster from the rope.

Owner:李汉忠

Energy-conserving, environment-friendly and recyclable thermosetting resin composite material and application thereof

The invention discloses an energy-conserving, environment-friendly and recyclable thermosetting resin composite material and an application thereof. The material comprises the following raw materials in percentage by weight: 20 to 75 percent of filler, 18 to 60 percent of unsaturated resin substrate, 6 to 18 percent of modified additive and 1 to 1.5 percent of pigment. According to the material and the application thereof, an injection process is adopted, high mechanical automation degree, low labor intensity and high yield are ensured; the material is not required to be burnt at high temperature for a long time, so that the energy consumption is greatly lowered; the composite material is high in toughness, strong in strength, resistant to impact, anticorrosive, environment-friendly, flame-retardant, free of radiation and heavy metal and recyclable, and can be used for manufacturing roofs, wall surfaces and grounds in bathrooms, kitchens and other rooms as well as shells of products such as bathroom cabinet panels, bathroom cabinets, tables, tea tables, switch socket panels, hand dryers and hair dryers, patterned panels, which have different artistic effects and impressions such as recesses and bumps, stripes and waves, and are attractive in appearance, high in artistic quality and strong in stereoscopic impression, and various artistic effects of wood grains, marble veins, leather grains and metallic texture can be achieved.

Owner:SHANGHAI HUDA INVESTMENT & DEV +1

Compressive handling equipment and process for organic solid waste

InactiveCN106862246ARealize resource utilizationWay out no problemSolid waste disposalPulp and paper industryIntegrated processing

The invention discloses compressive handling equipment and process for organic solid waste. The equipment comprises multiple material storage bins, a first mixer, a material compounding device, a fermentation box and a screening device. The multiple material storage bins are connected with a feeding opening of the first mixer and used for storing waste materials to be handled in a classified manner. A discharging opening of the first mixer is connected with the material compounding device. The discharging end of the material compounding device is connected with the feeding end of the fermentation box. The discharging end of the fermentation box is connected with the discharging end of the screening device. The material compounding device receives multiple types of waste materials. The multiple types of waste materials comprise waste materials from the first mixer. After all the types of received waste materials are added in proportion through the material compounding device, the waste materials are conveyed to the fermentation box for fermentation, and waste materials obtained after the fermentation effect is completed are conveyed to the screening device for screening treatment. By means of the equipment and process, automated and efficient operation of all links in the organic solid waste handling process can be achieved; the waste fermentation process is effectively monitored and adjusted in time; and handling efficiency and the handling effect are greatly improved.

Owner:北京华清博雅环保工程有限公司

Paper tube cutting machine

InactiveCN104626233AImprove work efficiencyHigh degree of mechanical automationMetal working apparatusAutomationUltimate tensile strength

The invention provides a paper tube cutting machine. The paper tube cutting machine comprises a supporting seat, a rotation shaft, a first motor, cutters and fixing pieces, wherein the rotation shaft is located below one end of the supporting seat and connected with the first motor, and each cutter is fixedly connected with the corresponding fixing piece and located above the rotation shaft. The paper tube cutting machine is characterized by further comprising lifting air cylinders, a fixing shaft and a fixing frame, wherein the lower end of each lifting air cylinder is fixedly connected with the fixing shaft, the upper end of each lifting air cylinder is fixedly connected with the fixing frame, the fixing pieces are fixed to the fixing shaft, and the number of the cutters is two to six. The paper tube cutting machine has the advantages that the fixing pieces are driven to move up and down through the lifting air cylinder, the moving mode of the fixing pieces is linear, and the paper tube cutting machine is high in working efficiency, avoids useless work, achieves cutting of multiple sections each time, is high in machinery automation degree, is high in production efficiency, relieves the labor intensity for workers, guarantees cutting quality of paper tubes, and is simple in structure and easy to implement.

Owner:TIANJIN SHENGLI HONGDA TECH BUSINESS INCUBATOR

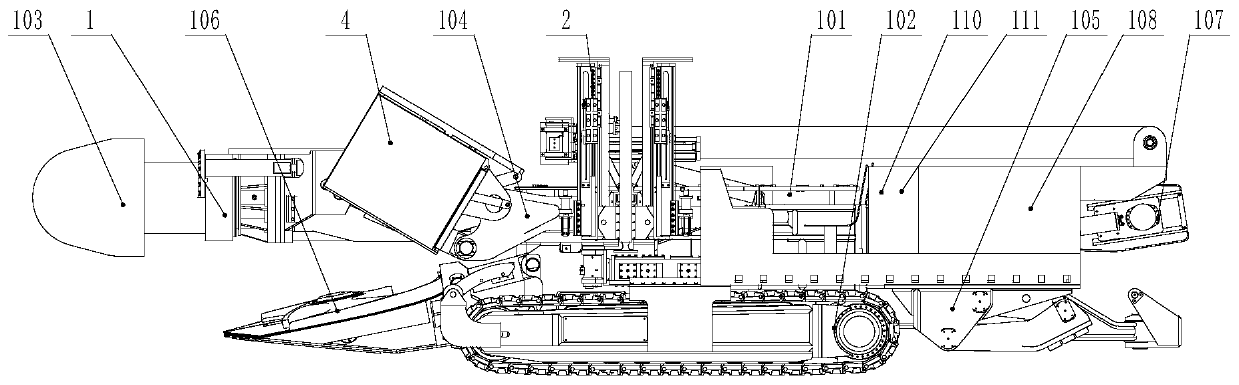

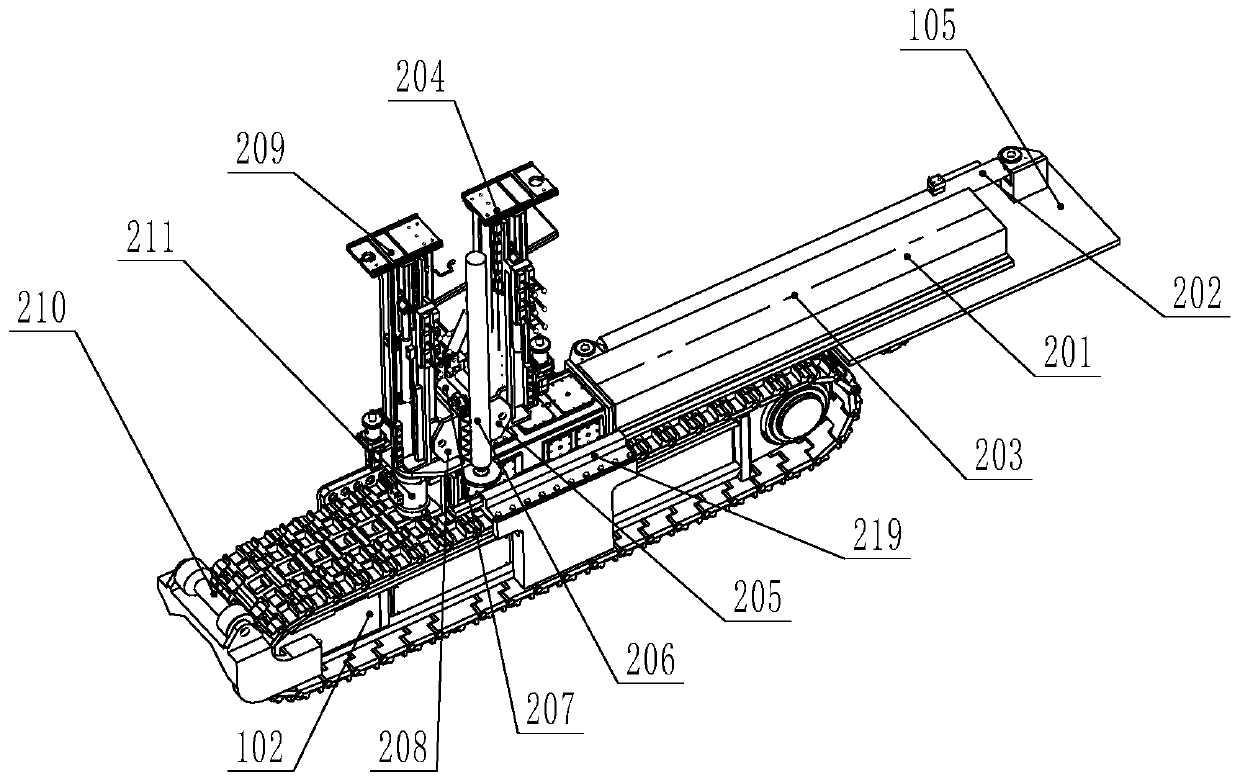

Digging and anchoring integrated six-arm digging and anchoring machine integrating

ActiveCN109736798AAchieve integrated effectMeet support requirementsSlitting machinesTunnelsEngineeringElectric control

The invention provides a digging and anchoring integrated six-arm digging and anchoring machine, comprising a heading machine and an anchor rod machine which are connected; the anchor rod machine comprises top anchor units, an side anchor unit and a working platform unit; the heading machine comprises a rack body, a walking part, a cutting part, a rotary body, a rear supporting body, a loading mechanism, a conveyor, an electric control system, a hydraulic system, a spraying system and a cooling system; the number of the top anchor units is two; the two top anchor units are symmetrically arranged on the left side and the right side of the rack body, and are located behind the rotation center of the rotary body and each set of top anchor unit is provided with two top anchor drilling machines; the side anchor unit is movably arranged on the rack body and located behind the cutting part, and is provided with two side anchor drilling machines, and the working platform unit is connected withthe cutting part and located above the cutting part. The empty jacking and side anchor time is reduced, the safety of workers is guaranteed, and the mechanical automation degree is improved.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

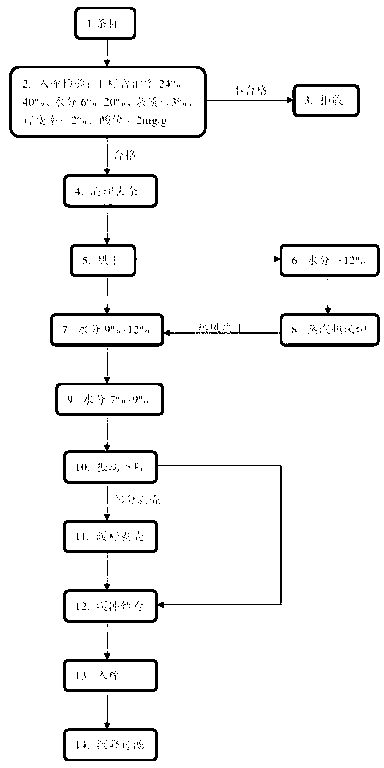

Low-temperature camellia seed oil cold-pressing process

InactiveCN103320214ASolve the problem of high benevolenceHigh degree of mechanical automationFatty-oils/fats productionEngineeringResidual oil

The invention relates to a low-temperature camellia seed oil cold-pressing process. The process comprises the main steps: warehousing and checking camellia seeds, cleaning and removing impurities, drying and controlling moisture, vibrating and discharging, warming the seeds and shelling, buffering and temporarily storing, pressing, settling and filtering. The process is characterized in that 1, the moisture is controlled, and the steps of flat-plate drying, storage bin ventilating, steam hot-blast stove moisture drying and cooling and storing are combined; 2, seed warming and shelling are carried out; 3, buffering and temporary storing are carried out, the seeds drop from the storage tank by vibrating during pressing; and 4,pre-pressing and pre-squeezing are carried out. The process is high in mechanical automation degree, the camellia seeds in different moisture contents can be dried and subjected to quality guarantee, and packaging and pouring after drying are not required when the seeds are stored for a long time after drying or are continuously squeezed after drying. Meanwhile, the problem that the kernel rate in the shells is extremely high after shelling is solved, the quality in the total process is well controlled, the process is simple and convenient to operate, and the oil extraction rate and the camellia seed oil quality are improved. The manual packaging and discharging cost is saved by 40 RMB for each ton of camellia seeds. The yield of the camellia seed oil in a two-screw unit is increased from the original 15 tons per day to over 30 tons per day, and the residual oil is reduced from the original 10-12 percent to 7-9 percent.

Owner:HUNAN REALPARK TEA SEED OIL

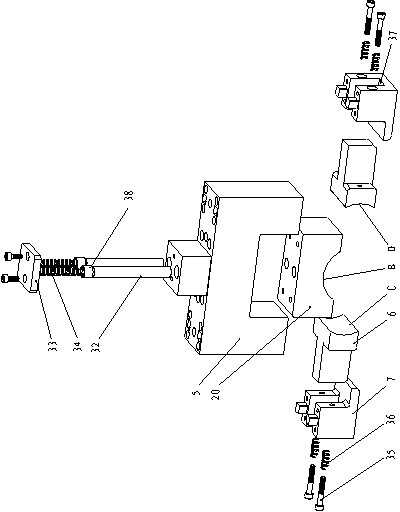

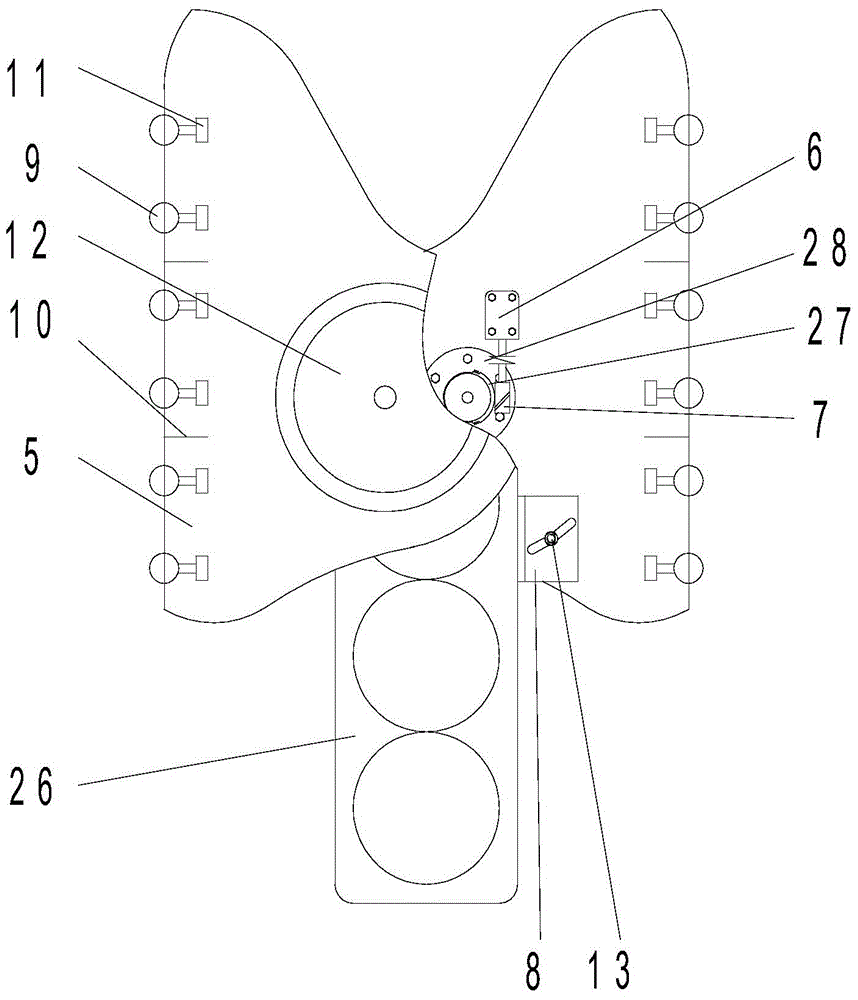

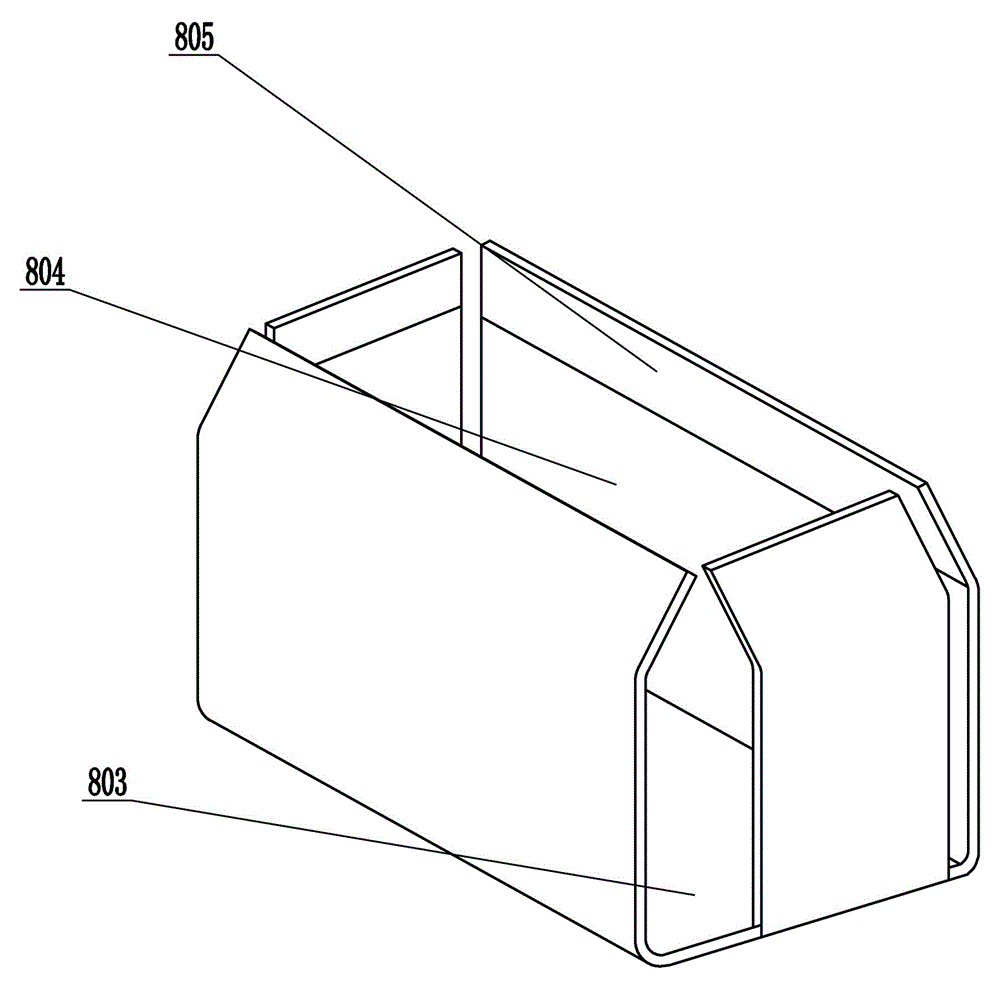

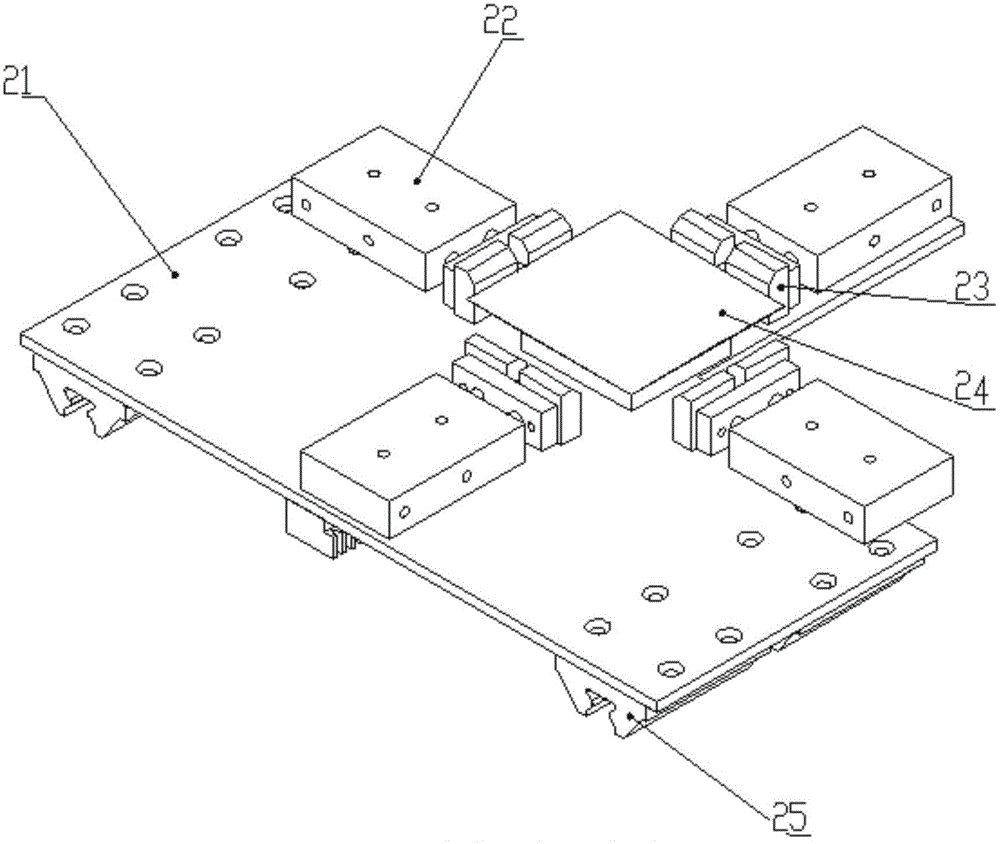

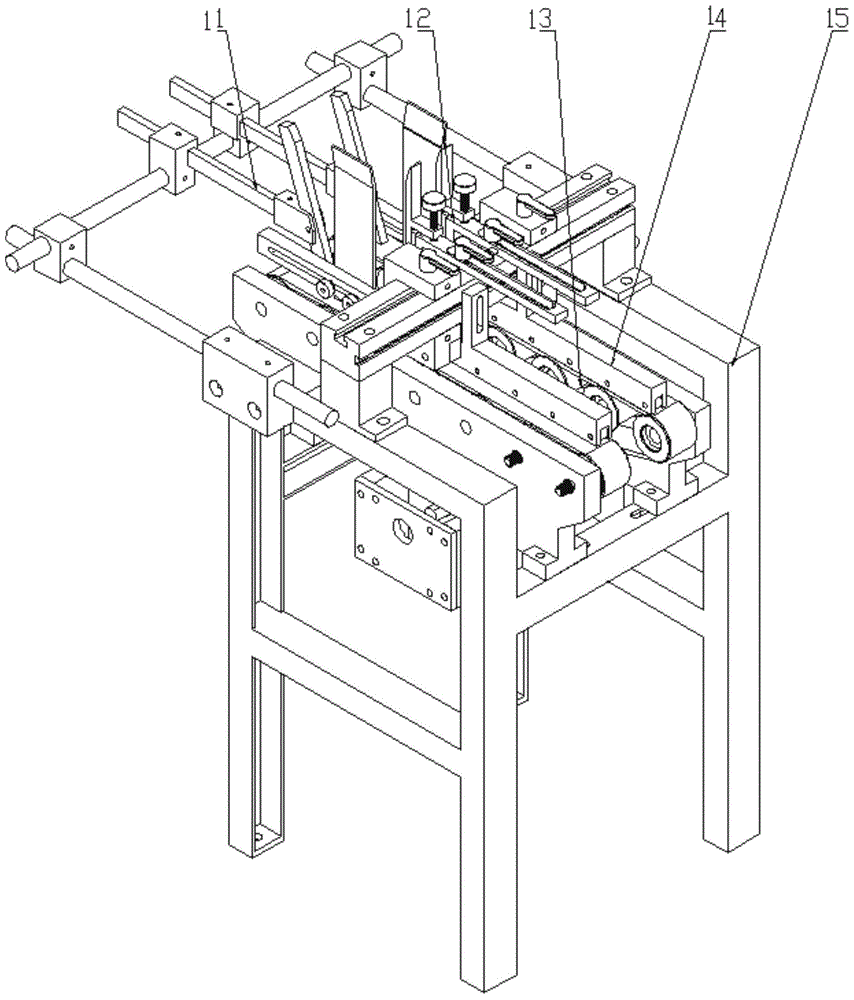

Inner foxing forming device for carton forming and forming method thereof

ActiveCN103692693AIncrease productivityImprove product qualityBox making operationsPaper-makingCartonEngineering

The invention relates to the technical field of carton forming, in particular to an inner foxing forming device for carton forming and a forming method thereof. The inner foxing forming device comprises a paper feeding mechanism, a conveying and folding mechanism, a turning mechanism and a forming mechanism; the outlet of the paper feeding mechanism is connected with the inlet of the conveying and folding mechanism; the outlet of the conveying and folding mechanism is connected with the inlet of the turning mechanism; the outlet of the turning mechanism is connected with an inner foxing forming mechanism. The biggest advantage of the device is that currently manual operation is converted into mechanical operation, so that the production efficiency is greatly improved; meanwhile, the product quality can be improved, the product stability is ensured, and the production cost is reduced; the product is a pioneer product in China, and has a certain leading advantages in the international market.

Owner:世彩智能科技(上海)有限公司

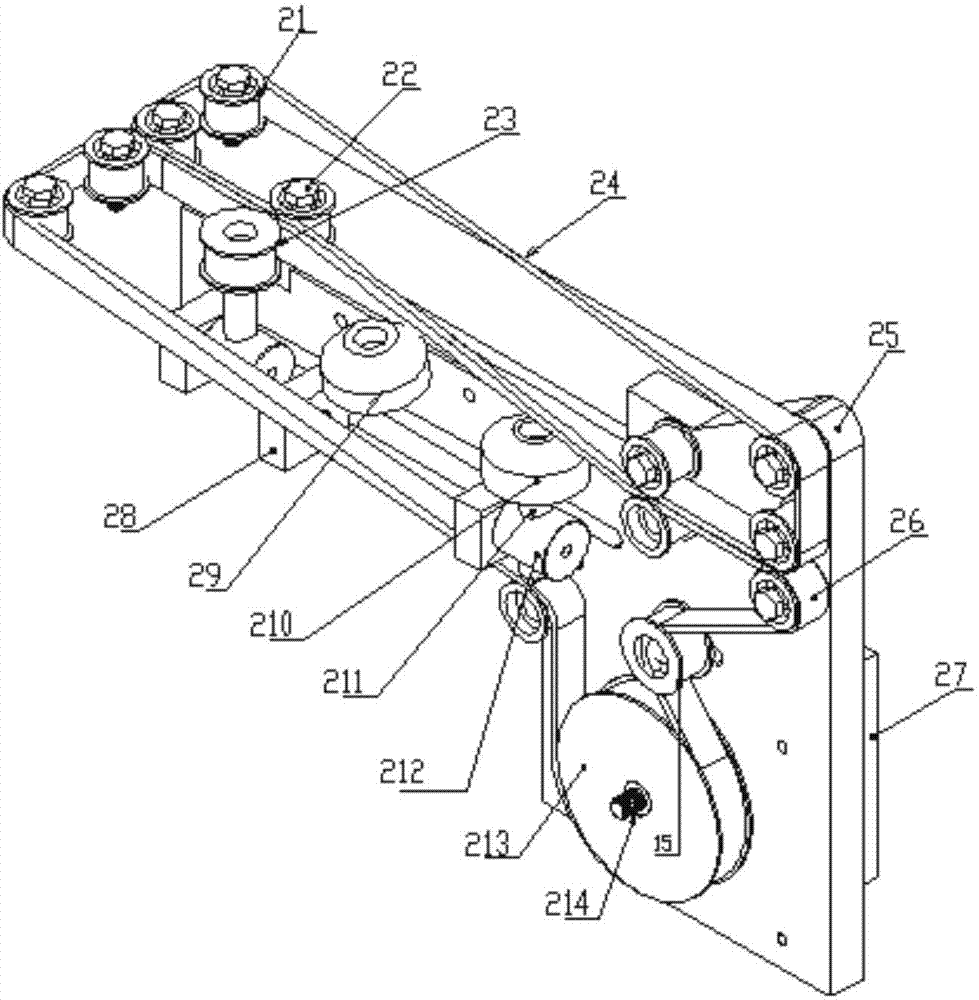

Automatic ring buckling device for cathodes of button cells

InactiveCN103050717AHigh degree of mechanical automationLow costFinal product manufacturePrimary cellsButton batteryEngineering

The invention discloses an automatic ring buckling device for cathodes of button cells. The device comprises a bracket, a pole shell feeding device and a sealing ring feeding device fixed on the bracket. The device is characterized by further comprising a loading isolation mechanism driven by an upper stepper motor, and a pole shell transporting device driven by a lower stepper motor, wherein the loading isolation mechanism and the pole shell transporting device are both fixed on the bracket; the loading isolation mechanism consists of a turntable, a turntable base and the upper stepper motor; and the pole shell transporting device comprises a cam mechanism for controlling the up-down movement thereof, a cylinder body for controlling the left-right oscillation thereof and a sucker for taking and placing materials. The device adopts the automated machine method to replace the manual operation so as to efficiently finish the matching operation between cell pole shells and sealing rings.

Owner:HEBEI UNIV OF TECH

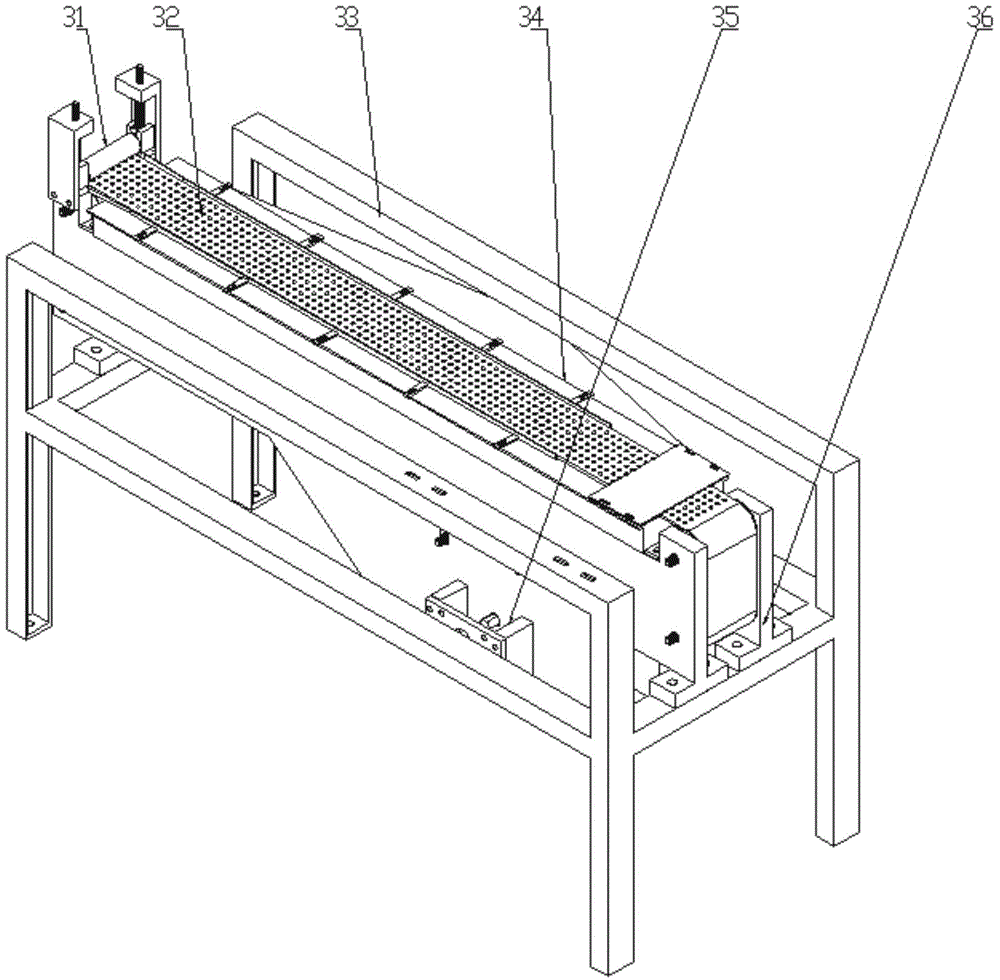

Upper box cover molding device for paper box molding and molding method thereof

ActiveCN103552280AIncrease productivityImprove product qualityPaper-makingBox making operationsProduction lineInternational market

The invention relates to the technical field of paper box molding, in particular to an upper box cover molding device for paper box molding and a molding method thereof. The upper box cover molding device is characterized by being composed of a paper feeding mechanism, a conveying mechanism, an edgefold molding mechanism and a grabbing mechanism, wherein the outlet end of the paper feeding mechanism is connected to the inlet end of the conveying mechanism; the outlet end of the conveying mechanism is connected to the inlet end of the edgefold molding mechanism; the outlet end of the edgefold molding mechanism is connected to a next production line by virtue of the grabbing mechanism; the edgefold molding mechanism is further provided with a pressure head mechanism. The upper box cover molding device has the greatest advantages of replacing manual operation with mechanical operation, greatly improving the production efficiency, meanwhile improving the product quality, ensuring the product stability and lowering the production cost. The upper box cover molding device is a national initiative product and has certain primacy in the international market.

Owner:世彩智能科技(上海)有限公司

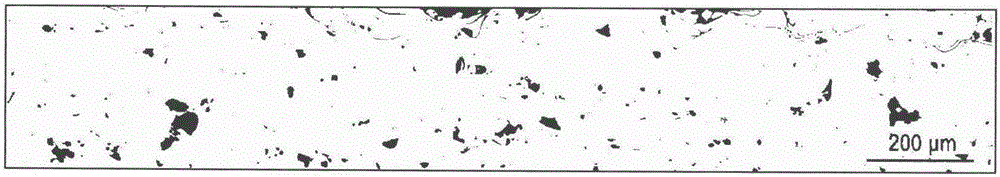

Plasma transfer arc spraying method for strengthening inner wall of cylinder sleeve of heavy truck

The invention relates to a plasma transfer arc spraying method for strengthening the inner wall of a cylinder sleeve of a heavy truck. The plasma transfer arc spraying method for strengthening the inner wall of the cylinder sleeve of the heavy truck comprises the steps that the inner wall of the cylinder sleeve is cleaned, and brown fused alumina is used for sand blasting for roughening treatment; an iron-based cored wire is sprayed to the inner wall of the cylinder sleeve of the truck through plasma transfer arc spraying, so that an abrasion-resistant and corrosion-resistant coating is obtained, wherein the iron-based cored wire is provided with stainless steel skin, and a core is formed by using FeCrBSi or FeCrBSi as a metal base material and adding other materials as compound phases; and the obtained coating is honed through a diamond honing stick. By adoption of the plasma transfer arc spraying method for strengthening the inner wall of the cylinder sleeve of the heavy truck, the defects that frictional power consumption is high, abrasion and corrosion occur easily, the fuel efficiency is low, and tail gas combustion is incomplete are overcome; and the friction coefficient between a piston ring and the inner wall of the cylinder sleeve is decreased, fuel is saved, and the service cycle of an engine is remarkably prolonged.

Owner:YANGZHOU UNIV

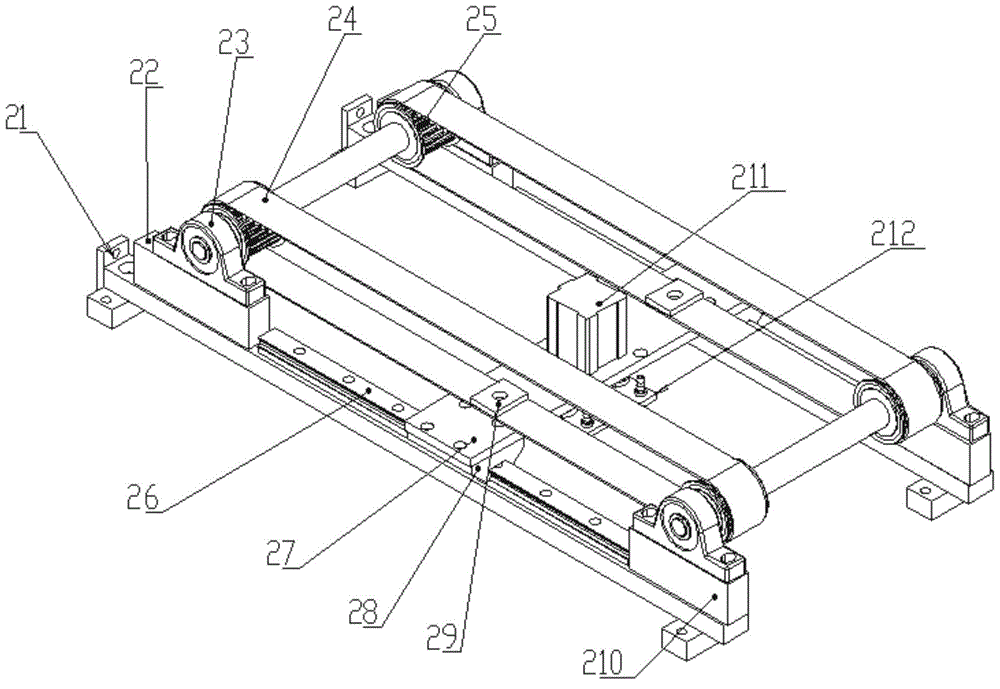

Lower box cover molding device for paper box molding and molding method thereof

ActiveCN103552281AIncrease productivityImprove product qualityPaper-makingBox making operationsMoulding deviceInternational market

The invention relates to the technical field of paper box molding, in particular to a lower box cover molding device for paper box molding and a molding method thereof. The lower box cover molding device is characterized by being composed of a paper feeding mechanism, a conveying and gluing mechanism, a grabbing mechanism and an edgefold molding mechanism, wherein the outlet end of the paper feeding mechanism is connected to the inlet end of the conveying and gluing mechanism; the outlet end of the conveying and gluing mechanism is connected to a first inlet end of the edgefold molding mechanism by virtue of the grabbing mechanism; a second inlet end of the edgefold molding mechanism is connected with the outlet of an inner foxing molding device by virtue of a lower box cover and inner foxing combination mechanism; the outlet end of the edgefold molding mechanism is connected to a next production line by virtue of the lower box cover and inner foxing combination mechanism. The lower box cover molding device has the greatest advantages of replacing manual operation with mechanical operation, greatly improving the production efficiency, meanwhile improving the product quality, ensuring the product stability and lowering the production cost. The lower box cover molding device is a national initiative product and thus has certain primacy in the international market.

Owner:世彩智能科技(上海)有限公司

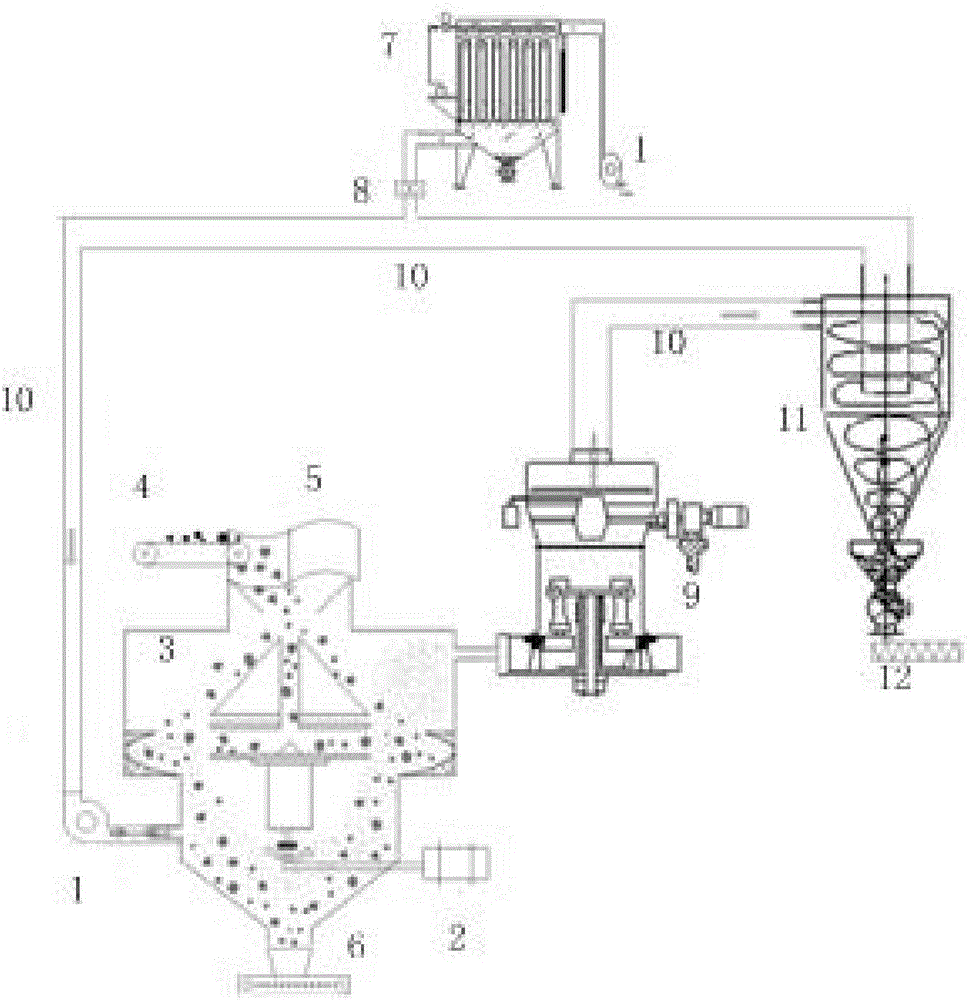

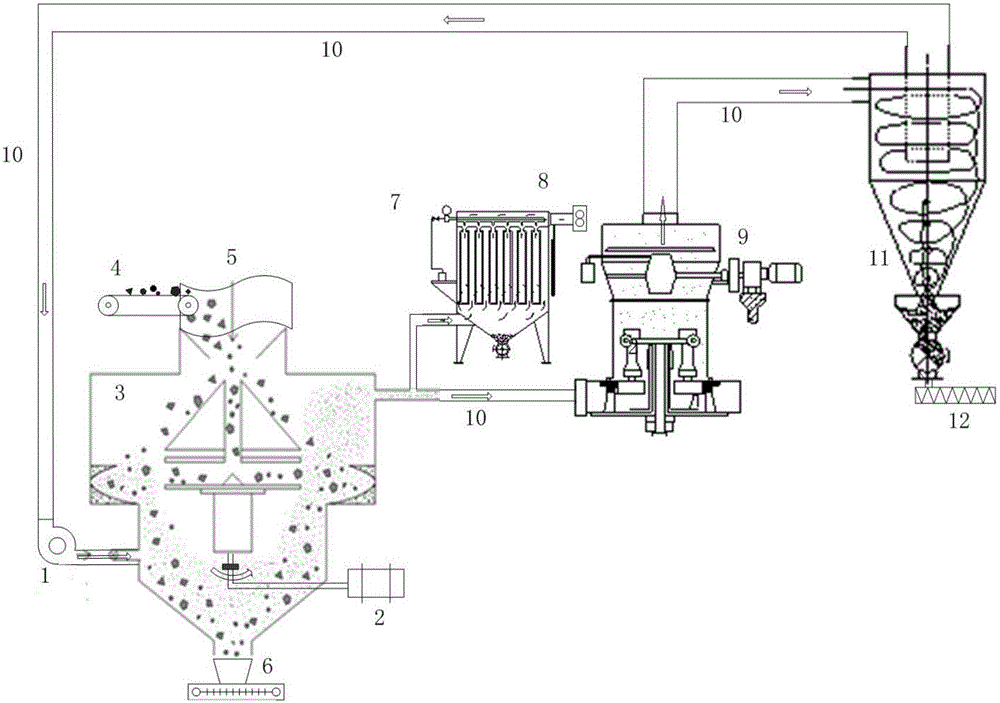

Environment-friendly recycled aggregate reinforcement and powder production integrated system

PendingCN106582999AReduce lossHigh degree of mechanical automationSolid waste managementGrain treatmentsEngineeringDust emission

The invention discloses an environment-friendly recycled aggregate reinforcement and powder production integrated system. The system comprises a particular shaping reinforcement equipment system, a powder production system and an adjusting system; the particle shaping reinforcement equipment system includes particle shaping reinforcement equipment, a motor, a fan, a belt conveyor, a lock wind buckle bag, a lock wind counterweight valve, a matched wind pipe and a matched bracket; the powder production system includes a refitted Raymond mill, a cyclone cylinder, a matched wind pipe, a matched bracket and a dust collecting and wind pressure adjusting system; and the adjusting system includes a pressure filter bag dust collector, a pressure division valve and a matched bracket. The system effectively integrates waste concrete recycled aggregate crushing, shaping reinforcement, powder production and dust collecting processes as a whole to prepare recycled aggregates and recycled micro powder for recycled concrete, and effectively reduces the dust emission.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

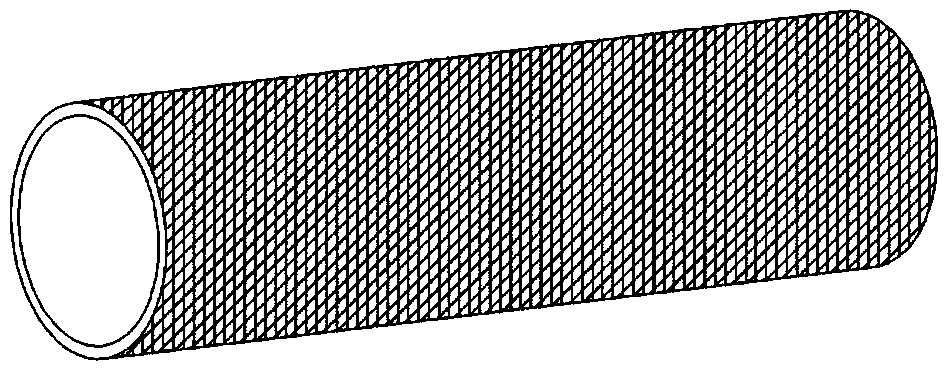

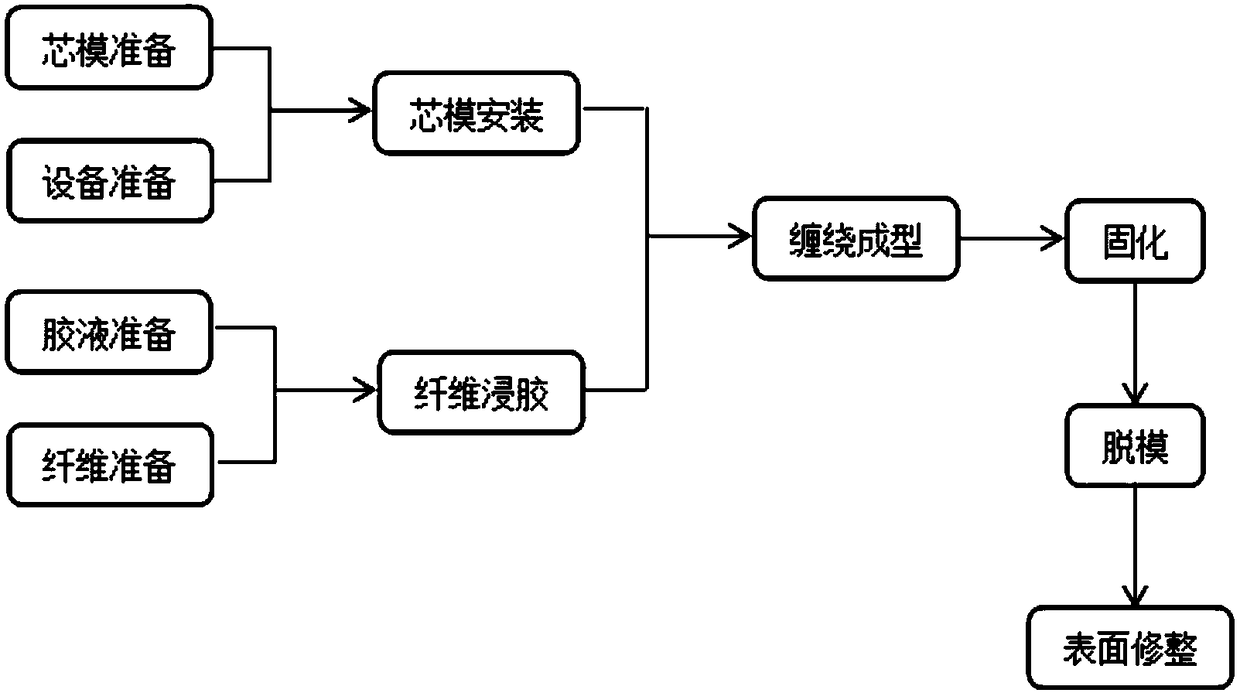

Preparation method of glass fiber reinforced plastic cable protection tube

The invention discloses a preparation method of a glass fiber reinforced plastic cable protection tube. The preparation method comprises preparation of equipment, preparation of a core mold, preparation of glue solution, preparation of fibers, winding forming, curing, demoulding, surface finishing and the like. According to the glass fiber reinforced plastic cable protection tube, alkali-free glass fiber is adopted as a reinforcing material, epoxy resin is used as a matrix, and the raw material cost is low; the glass fiber reinforced plastic cable protection tube is prepared by fiber winding,so that the mechanical automation degree is high, and the production efficiency is high; and compared with a metal steel tube, the prepared glass fiber reinforced plastic cable protection tube is light in weight, high in strength, good in toughness, excellent in corrosion resistance and electrical insulation performance, and long in service life, and can be safely applied to a power transmission line and telecommunication line dense area.

Owner:SHAOXING UNIV YUANPEI COLLEGE

Automatic switching device for stations

InactiveCN105347032AAutomatic conversion fastGuaranteed continuityConveyor partsEconomic benefitsEngineering

The invention discloses an automatic switching device for stations. The device comprises a worktable on which a lifting mechanism is arranged, wherein a manipulator, which can move up and down along the worktable and can also rotate along the horizontal direction in a reciprocating manner, is arranged on the worktable; a rotating mechanism for controlling the manipulator to rotate is arranged on the worktable; the manipulator comprises a rack assembly which is transversely arranged, and carrying mechanisms which are symmetrically arranged at two ends of the rack assembly. The device is simple in structure; the lifting mechanism and the rotating mechanism are arranged to control the manipulator to move up and down and rotate in the reciprocating manner, so as to quickly automatically switch the stations, and the transmission is stable, and as a result, the production efficiency can be effectively improved, and the economic benefits are obvious.

Owner:GUANGXI BEILIU ZHIYU CERAMIC AUTOMATION EQUIPCO

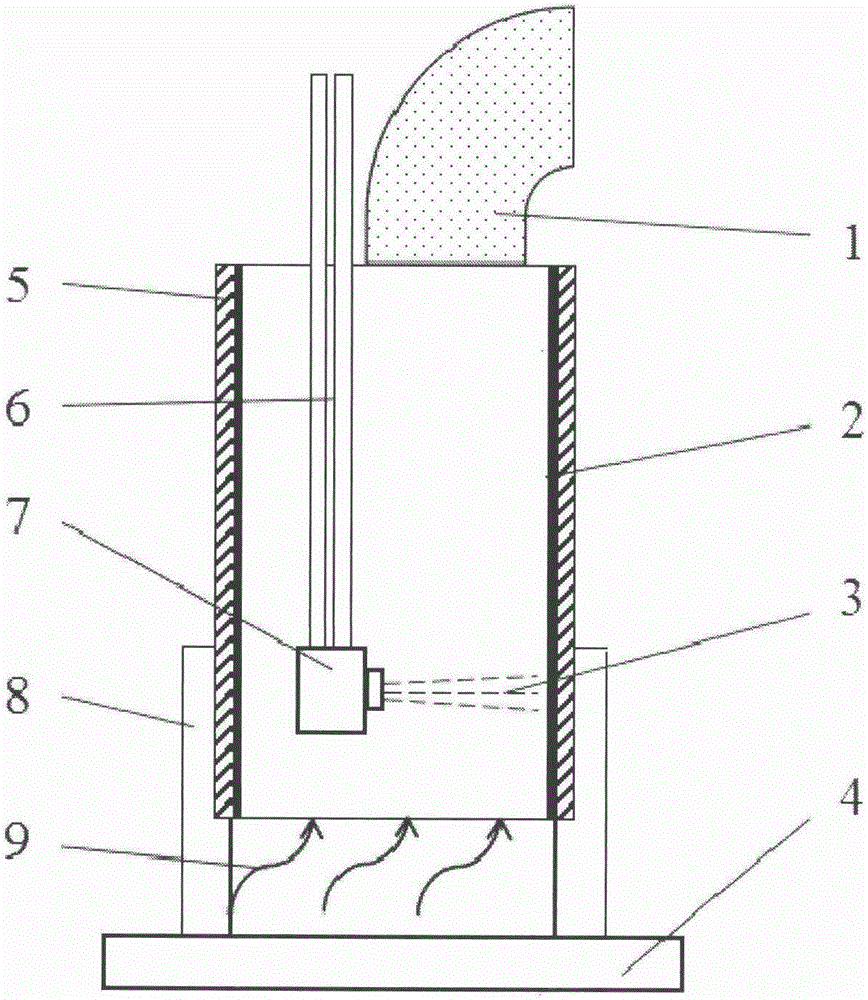

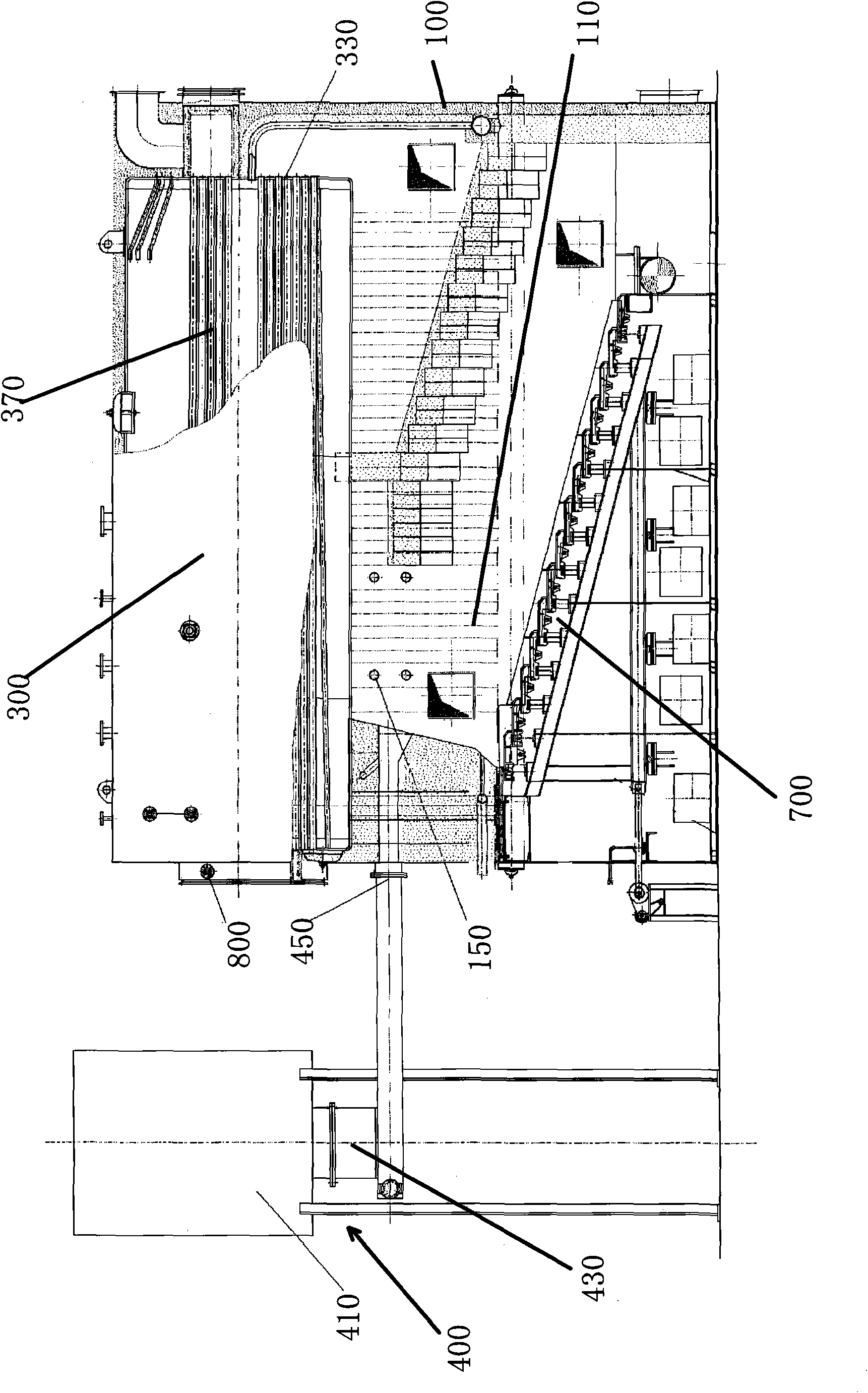

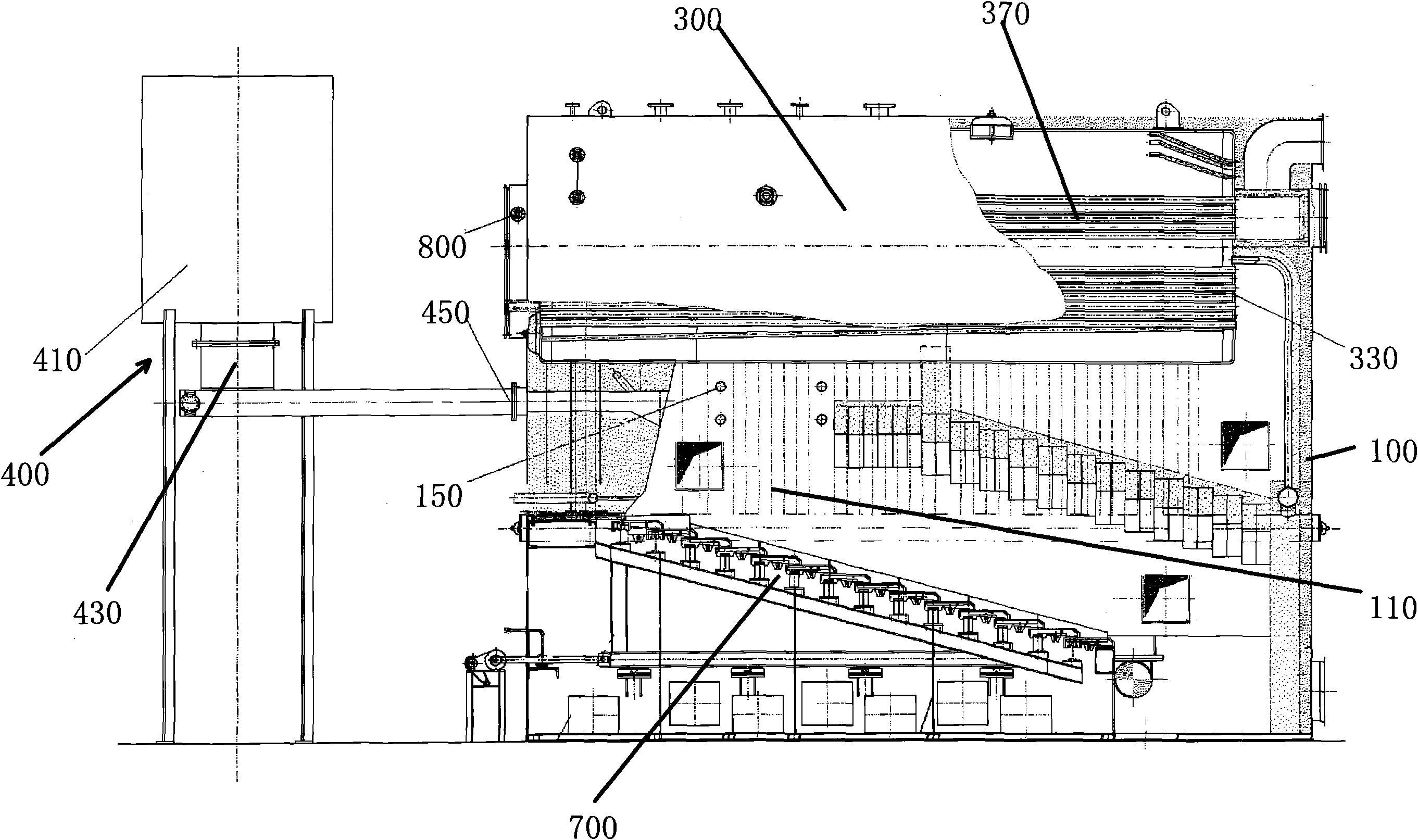

Steam boiler capable of burning biomass

InactiveCN101881433AHigh heat resistanceBig spaceTravelling grateAir/fuel supply for combustionCombustionHearth

The invention discloses a steam boiler capable of burning biomass, comprising a boiler body, a loading system and a vapour-water pipe system, wherein the boiler body is provided with a hearth in which the biomass fuel burns so as to release heat and a heat exchange device positioned above the hearth; the loading system is connected with the boiler body so as to convey the biomass fuel to the hearth for burning; the vapour-water pipe system is connected with the heat exchange device so as to exchange heat generated by the burning of the biomass; the hearth is internally provided with a reciprocal grate which downward slopes relatively to the level in an angle of inclination of 5-25 degrees from the end of the hearth close to the loading system to the far end far away from the loading system so as to enable the biomass fuel falling on the fire grate to be pushed and extruded and to roll relatively to the fire grate. In the invention, the fire grate moves relatively to fuel, the fuel is constantly extruded in the process of being pushed so as to damage coke and ash shells; and the fuel rolls slowly, thereby enabling the material layer to be loosened and facilitating full combustion.

Owner:GUANGZHOU DEVOTION THERMAL TECH

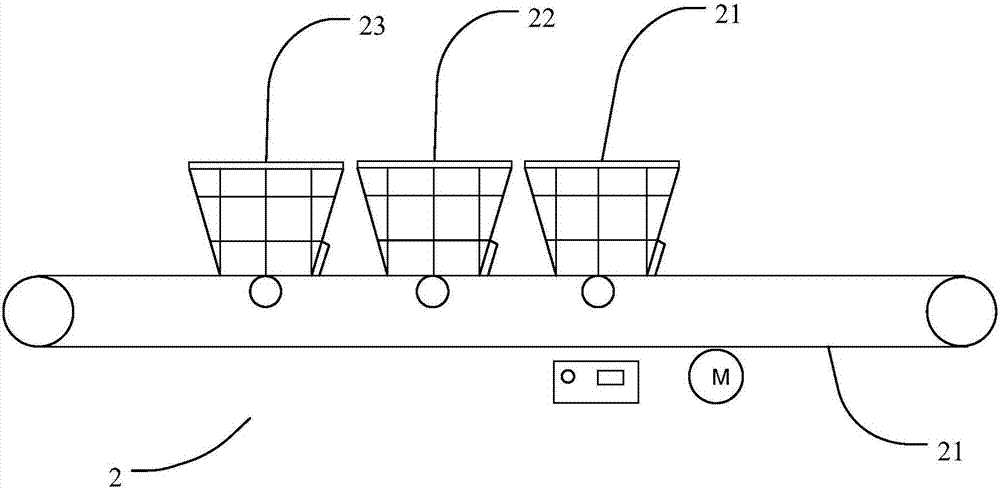

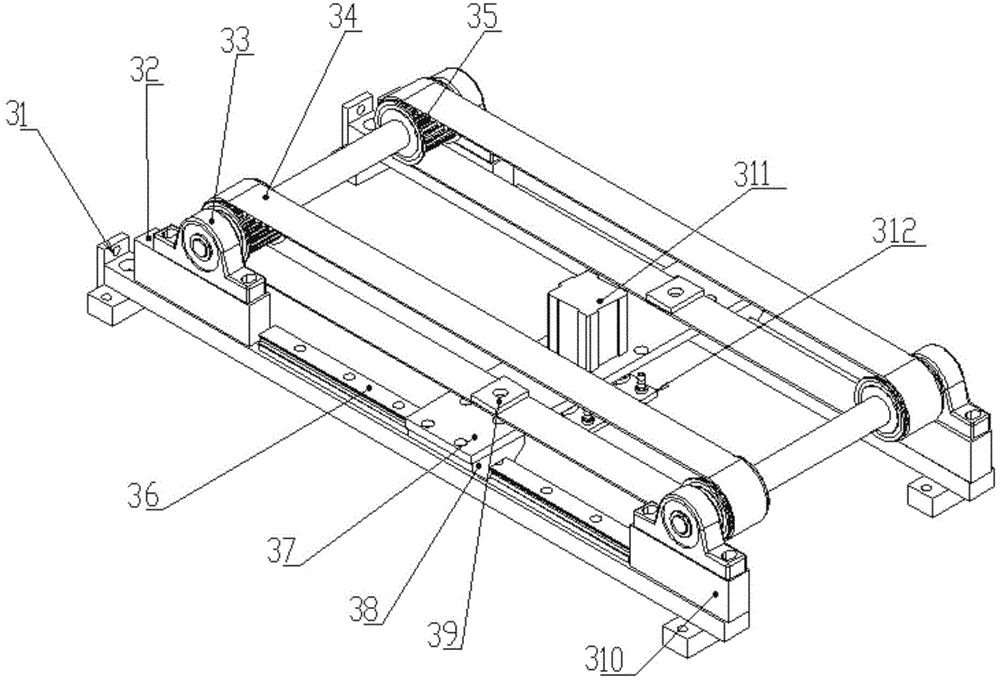

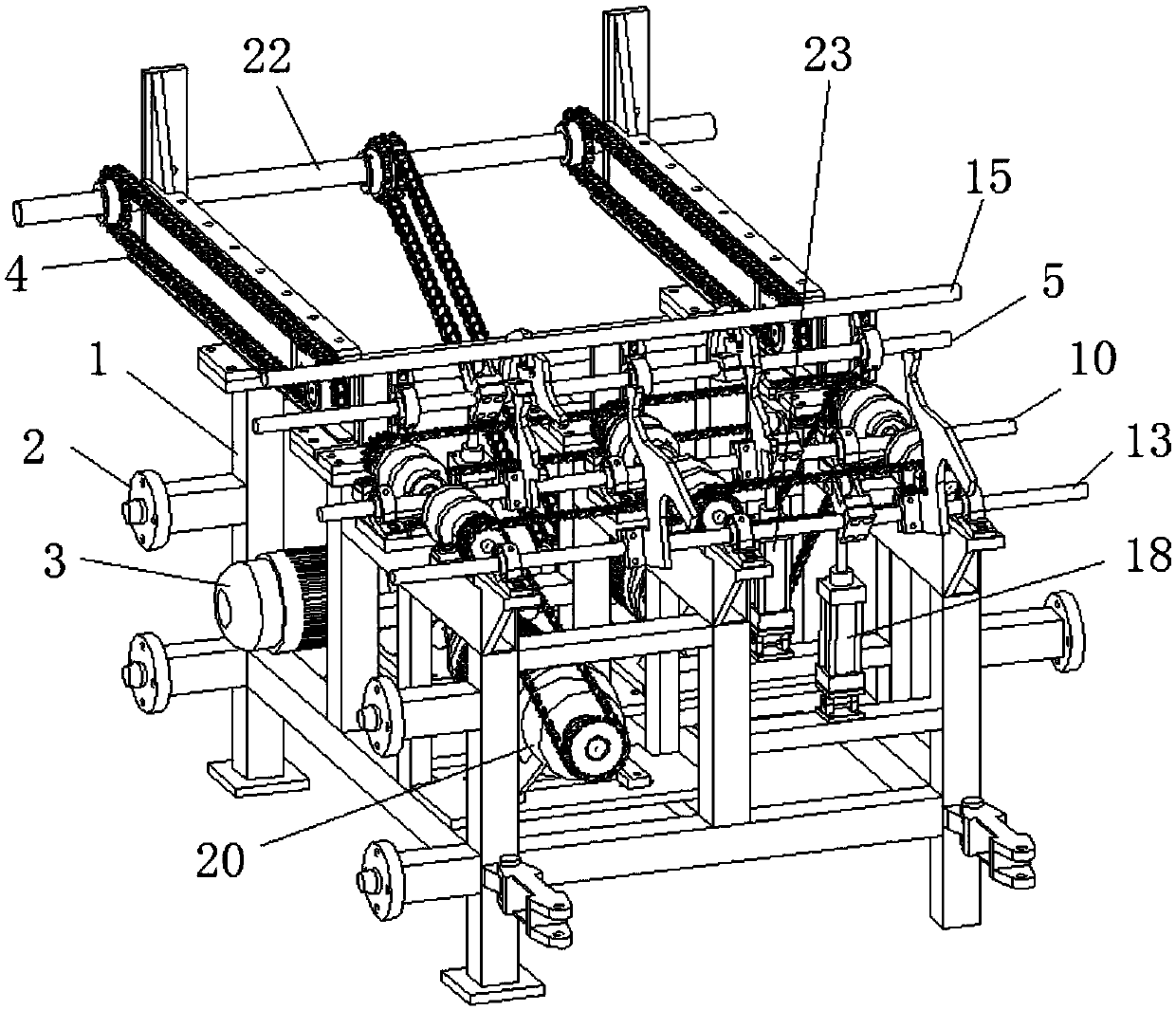

Modular arranging and conveying device of reinforcing steel bar end processing production line

PendingCN107651429ARealize isolated deliveryHigh degree of mechanical automationConveyor partsProduction lineRebar

The invention discloses a modular arranging and conveying device of a reinforcing steel bar end processing production line, belongs to the technical field of reinforcing steel bar processing equipment, and is used for arrangement and conveyance of ribbed reinforcing steel bar end processing production lines. According to the technical scheme, the modular arranging and conveying device comprises one or more standard arranging and conveying modules; each standard arranging and conveying module comprises a rack, a reinforcing steel bar storing and dispersing mechanism, a single reinforcing steelbar taking-out and turning-over mechanism, a front roller conveying mechanism, an inter-station turning-over and shifting mechanism, a back roller conveying mechanism and a discharging and turning-over mechanism, and the mechanisms are sequentially mounted on the rack; and when the standard arranging and conveying modules are connected, the mechanisms are correspondingly connected. With the modular arranging and conveying device, field operations such as storage, automatic dispersion, single separation, inter-station conveyance, collection after processing and the like of multiple reinforcingsteel bars can be realized, the device can be matched with different reinforcing steel bar end processing devices, different connection technology requirements can be met, and the mechanical and automatic degree and the processing quality of the processing production line can be improved.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

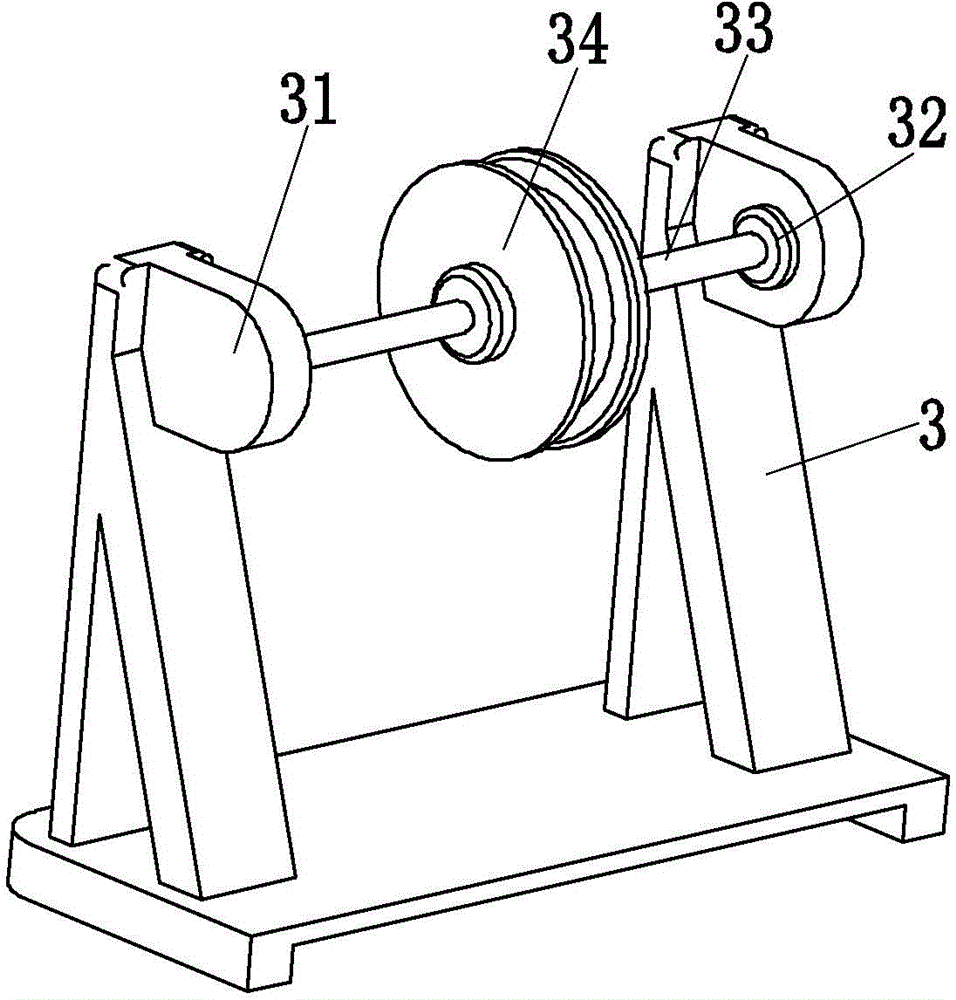

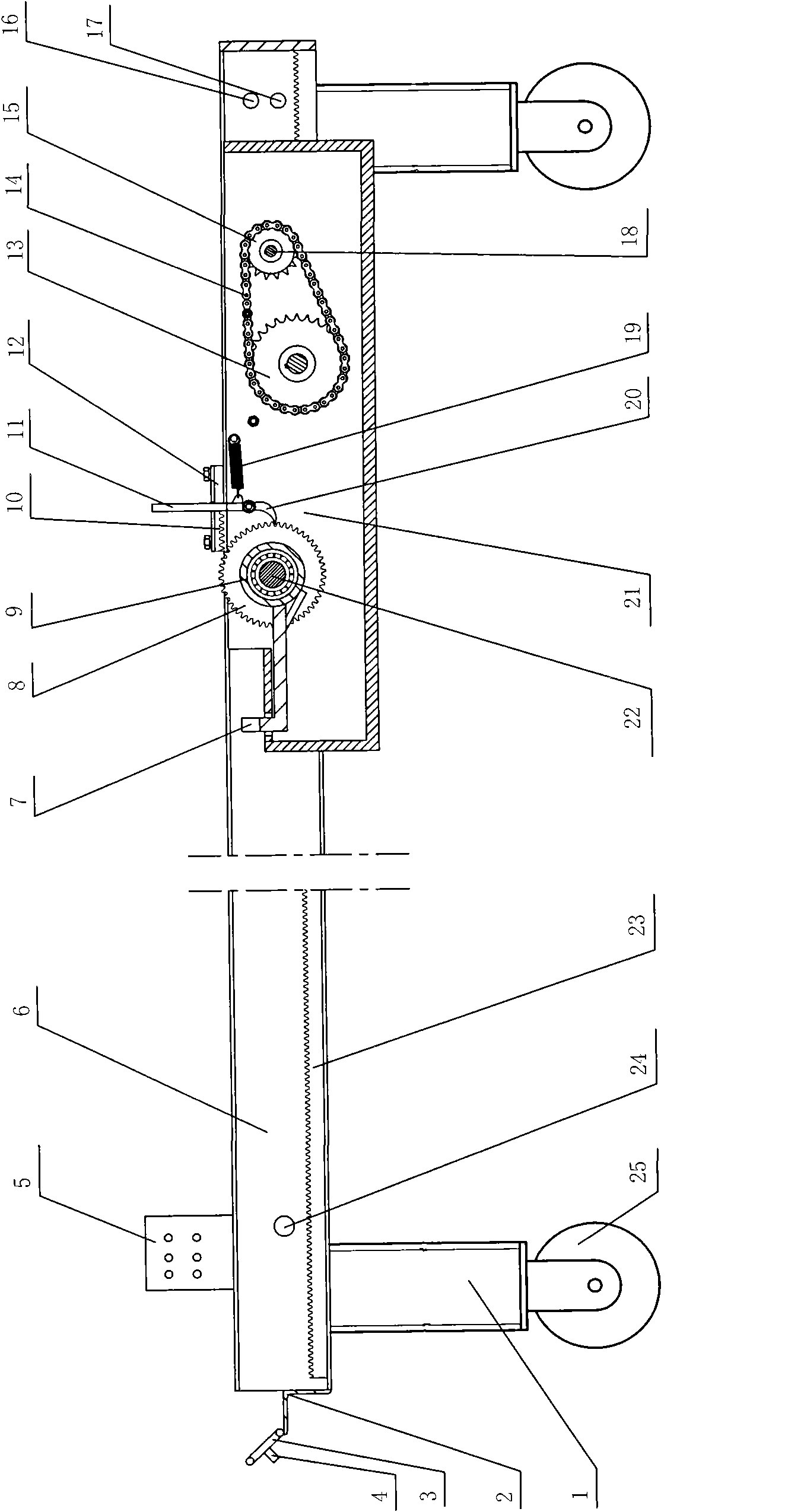

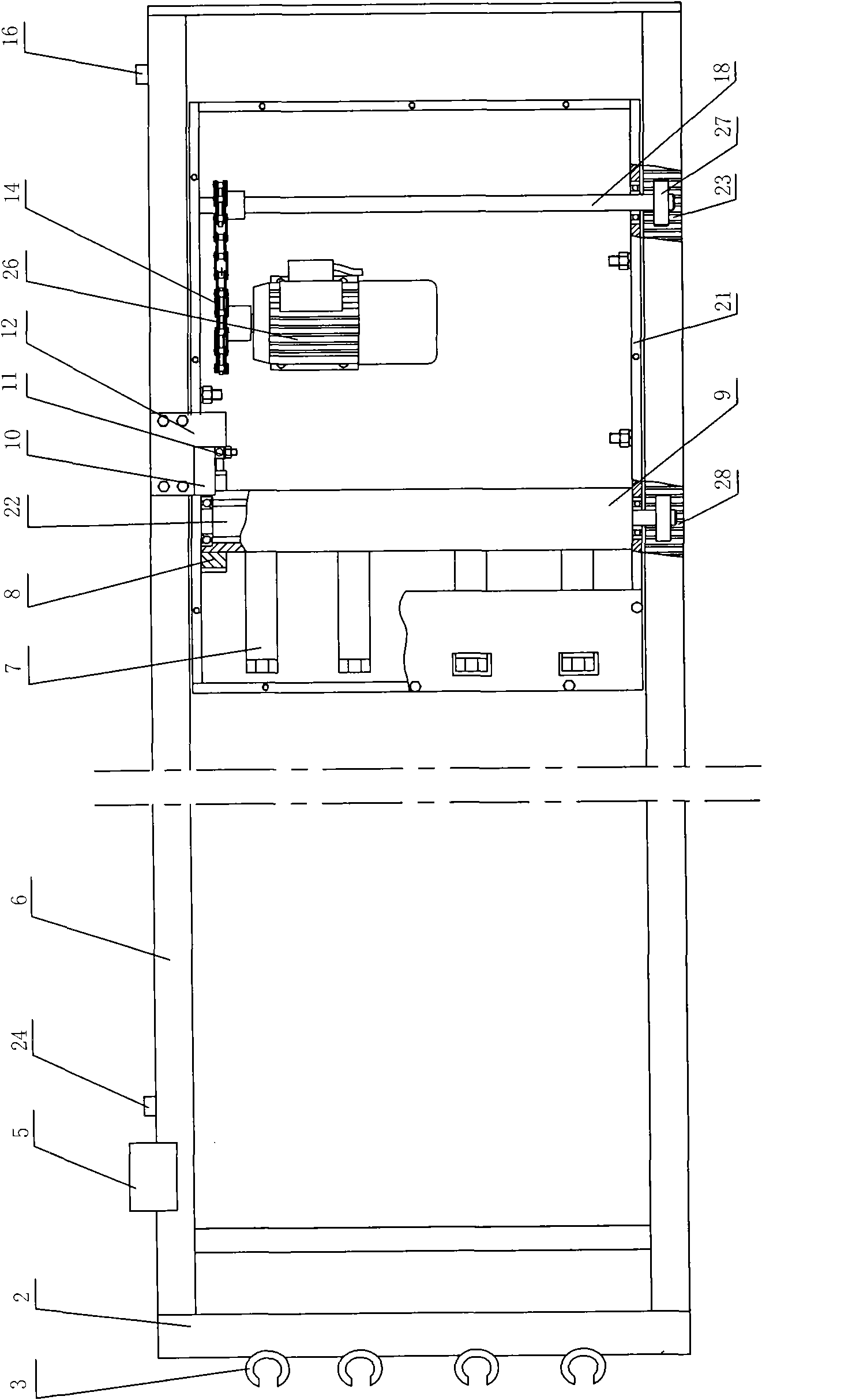

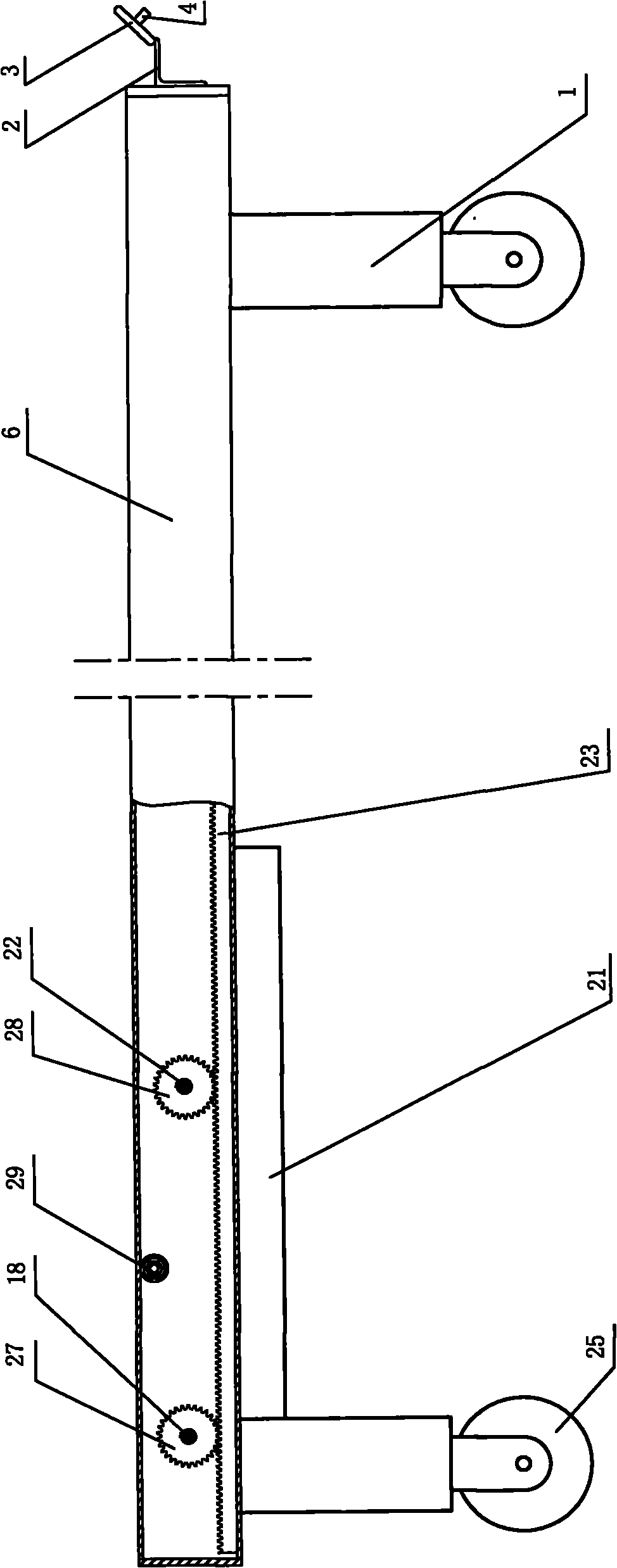

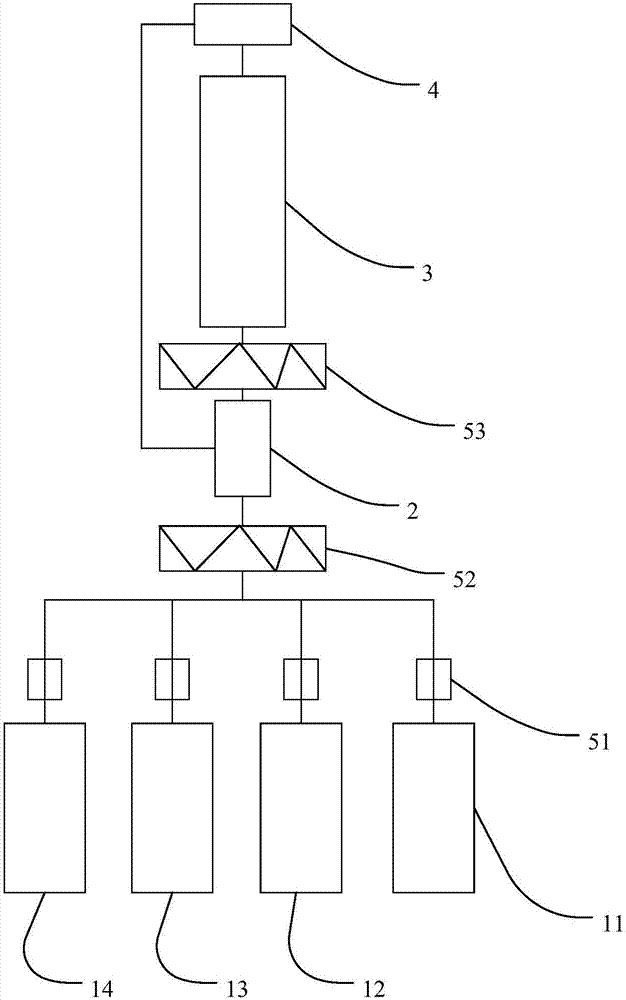

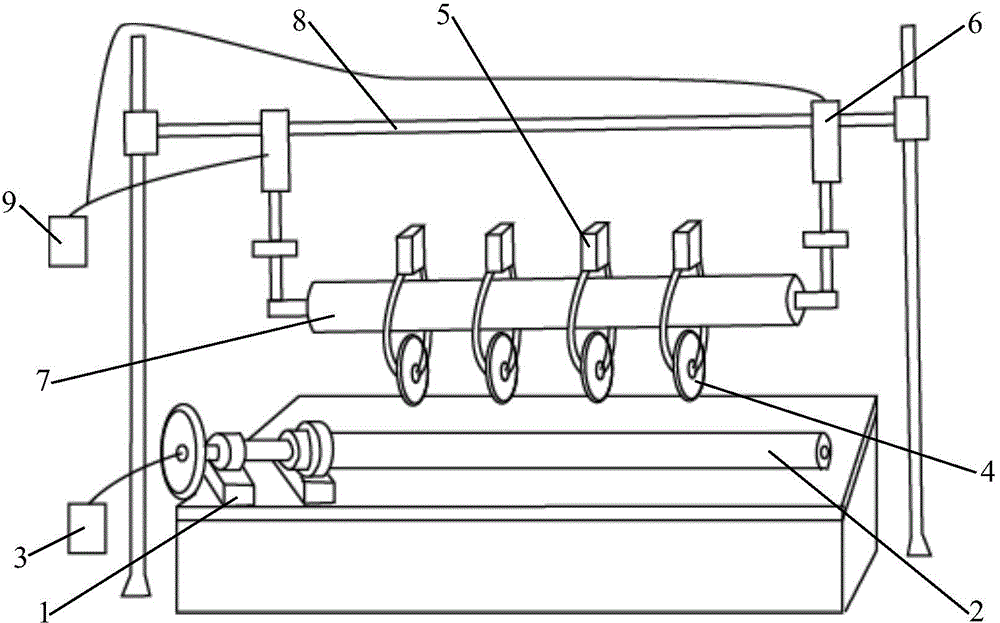

Novel twin-roller bar-stock transfer bed

InactiveCN101837555AReduce labor intensityReliable driveMetal working apparatusGear wheelControl theory

The invention discloses a novel twin-roller bar-stock transfer bed. An upper synchronizing shaft and a lower synchronizing shaft are arranged on a machine frame; a swinging arm is arranged on the upper synchronizing shaft and the lower synchronizing shaft respectively; and an upper roller and a lower roller are correctly arranged on the swinging arms. On one side of the machine frame, the head parts of extended ends of the upper synchronizing shaft and the lower synchronizing shaft are provided with a sector gear respectively; the top end of the machine frame is provided with an encoder bracket; a rotary encoder is arranged on the encoder bracket; and simultaneously, an input shaft of the rotary encoder is fixed with the upper synchronizing shaft, and the axis line of the input shaft of the rotary encoder is ensured to be kept the same as that of the axial direction of the upper synchronizing shaft when the input shaft of the rotary encoder is fixed with the upper synchronizing shaft. A driving gear is arranged and fixed on an output shaft of a speed reduction motor.

Owner:白淑荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com