Environment-friendly recycled aggregate reinforcement and powder production integrated system

A technology of recycled aggregate and integrated system, applied in the direction of climate sustainability, sustainable waste treatment, grain treatment, etc. The degree of automation, efficient recovery, and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

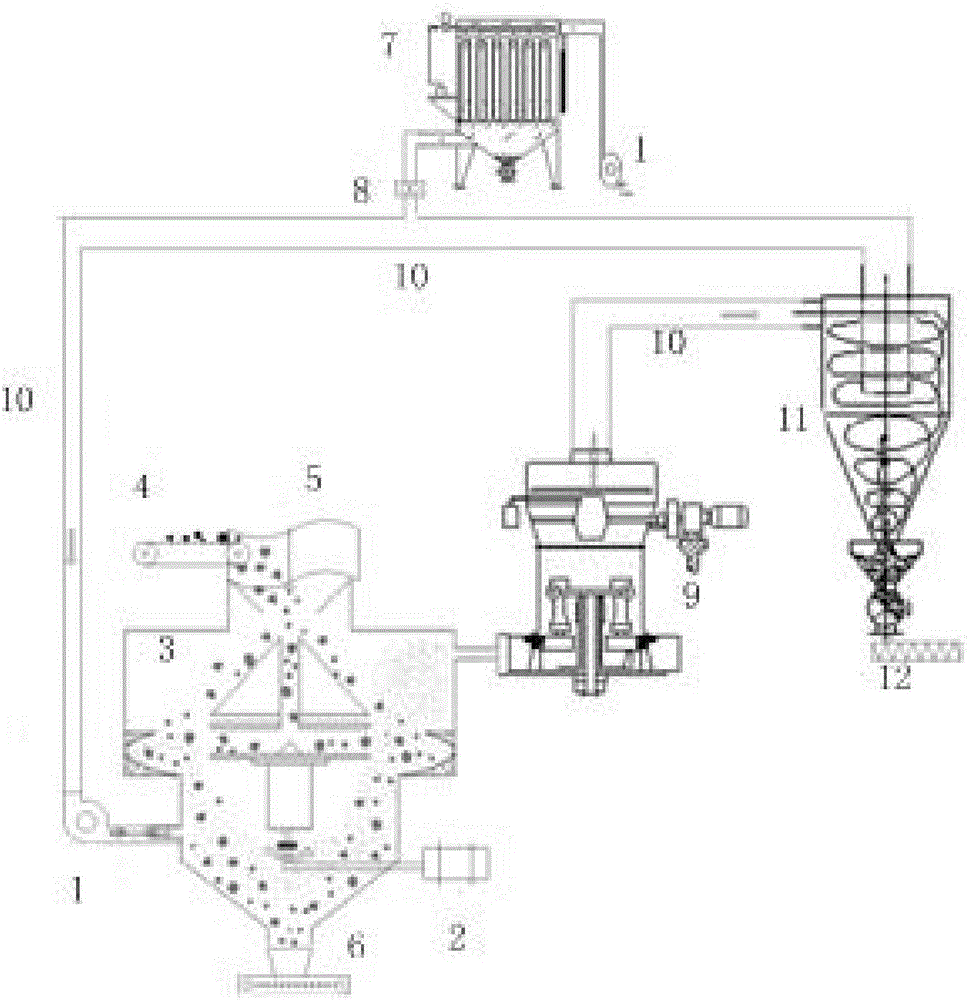

[0024] Such as figure 1 As shown, the environment-friendly recycled aggregate strengthening and pulverizing system of the present invention includes a fan 1, a motor 2, a refitted particle shaping and strengthening equipment 3, a belt conveyor 4, an air lock bag 5, an air lock counterweight valve and a blower Plate conveyor 6, filter bag dust collector 7, pressure divider valve 8, modified Raymond mill 9, supporting air duct 10, cyclone cylinder 11, air lock counterweight valve and screw conveyor 12. After integration, a complete set of process steps covering waste concrete crushing, screening, pulverizing and dust collection is obtained, as follows:

[0025] 1) Under the condition that the motor 2 drives the spreader and the fan 1 blows air, the waste concrete blocks enter the particle shaping and strengthening equipment 3 with the feeding port of the air lock bag 5 through the belt conveyor 4, and the blocks are centrifuged By controlling the air volume and wind speed per u...

Embodiment 2

[0029] The difference from Example 1 is that the cyclone 11 is two cyclones 11 of the same specification connected in parallel, and the supporting air ducts 10 of the two cyclones 11 are respectively connected to the modified particle shaping and strengthening equipment 3 and the filter bag dust collector 7 . All the other are the same as in Example 1.

Embodiment 3

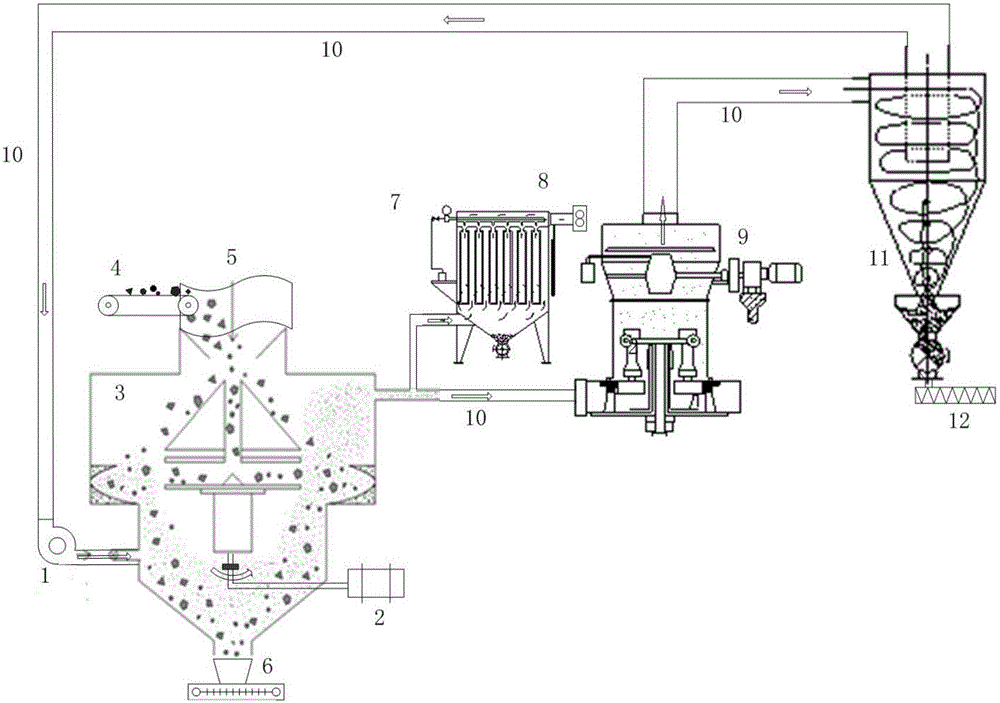

[0031] The difference from Example 1 is that the feed inlet of the refitted Raymond mill 9 is completely sealed, and the air inlet of the bag filter 7 is only connected to the air outlet of the fan 1 and the cyclone 11 by the supporting air duct 10, forming a whole series series system. Specific as attached figure 2 . All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com