Low-temperature camellia seed oil cold-pressing process

A technology of camellia oil and camellia seeds, which is applied in the direction of oil/fat production, fat production, etc., can solve the problems of affecting the peeling effect, unbalanced flow, etc., and achieves strong adaptability and continuous production capacity, high degree of mechanical automation, The effect of improving equipment operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

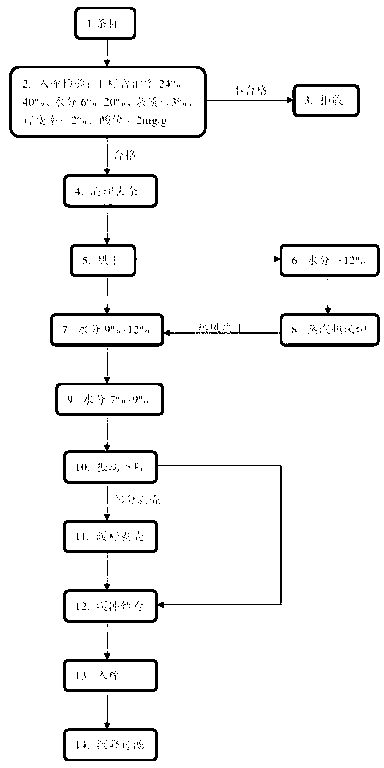

[0021] Camellia oleifera seed oil low-temperature cold pressing process, the main process is the inspection of camellia oleifera seeds, cleaning and removing impurities, drying to control moisture, vibration cutting, warm seed peeling, buffer temporary storage, pressing, sedimentation and filtration. The innovations of the present invention are firstly regulating moisture, secondly warming the seeds and shelling them; thirdly, buffering and temporarily storing, vibrating and dropping materials from the storage tank during pressing, and fourthly, pre-pressing and pre-pressing; the specific operation process is as follows:

[0022] 1. Warehousing inspection (2)

[0023] The warehousing indicators of Camellia oleifera seeds purchased in large quantities (1) are: the oil content of dry seeds is 24%-40%, the water content is 6%-20%, the impurities are less than 3%, the mildew rate is less than 2%, and the acid value is less than 2mg / g. Only those that are qualified can be put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com