Novel twin-roller bar-stock transfer bed

A technology of double rollers and transfer machines, which is applied in metal processing and other directions, can solve the problems of poor adaptability to rhythmic assembly lines, high labor intensity of workers, and low production efficiency, so as to achieve a high degree of mechanical automation, reduce labor intensity, and provide production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

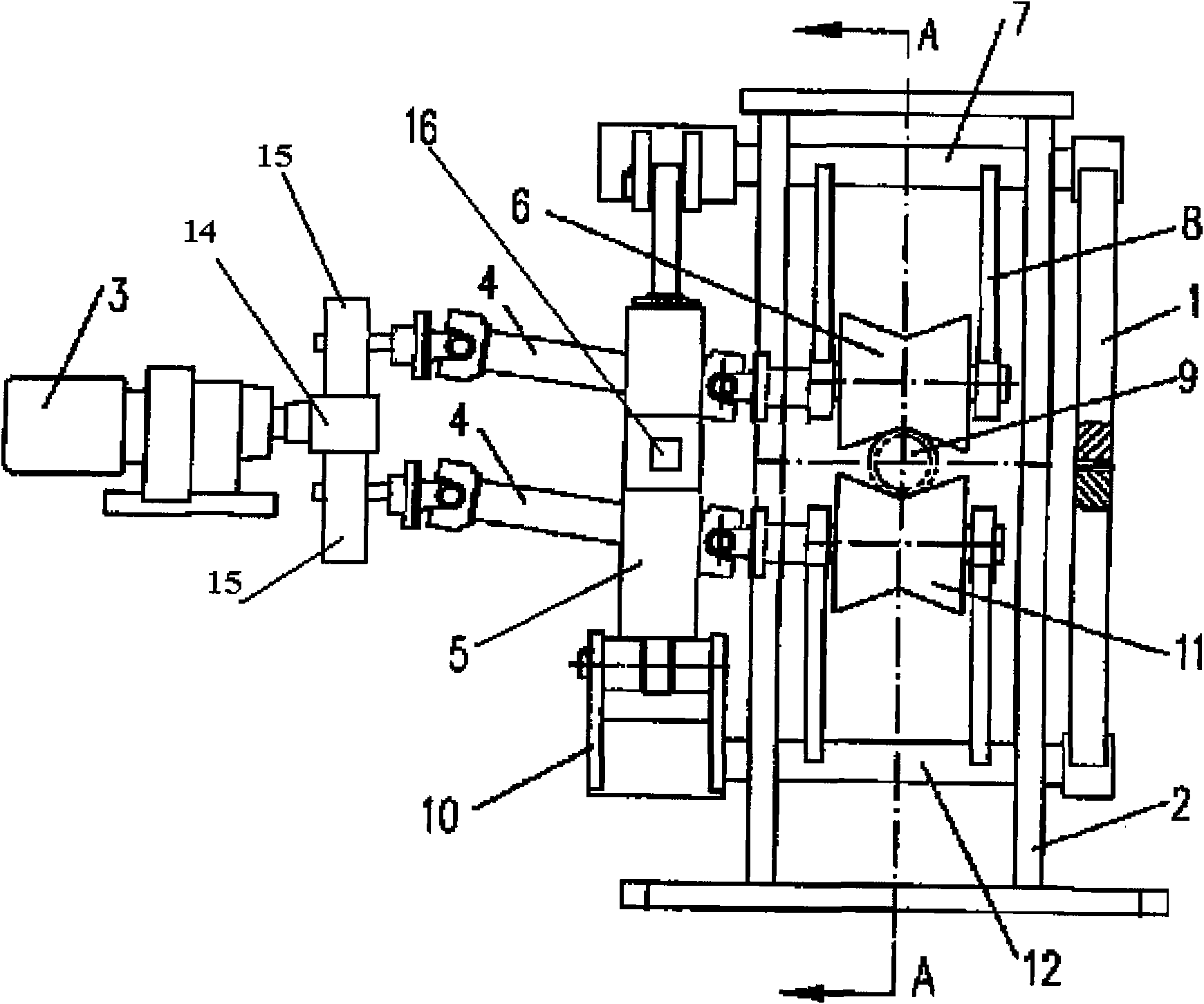

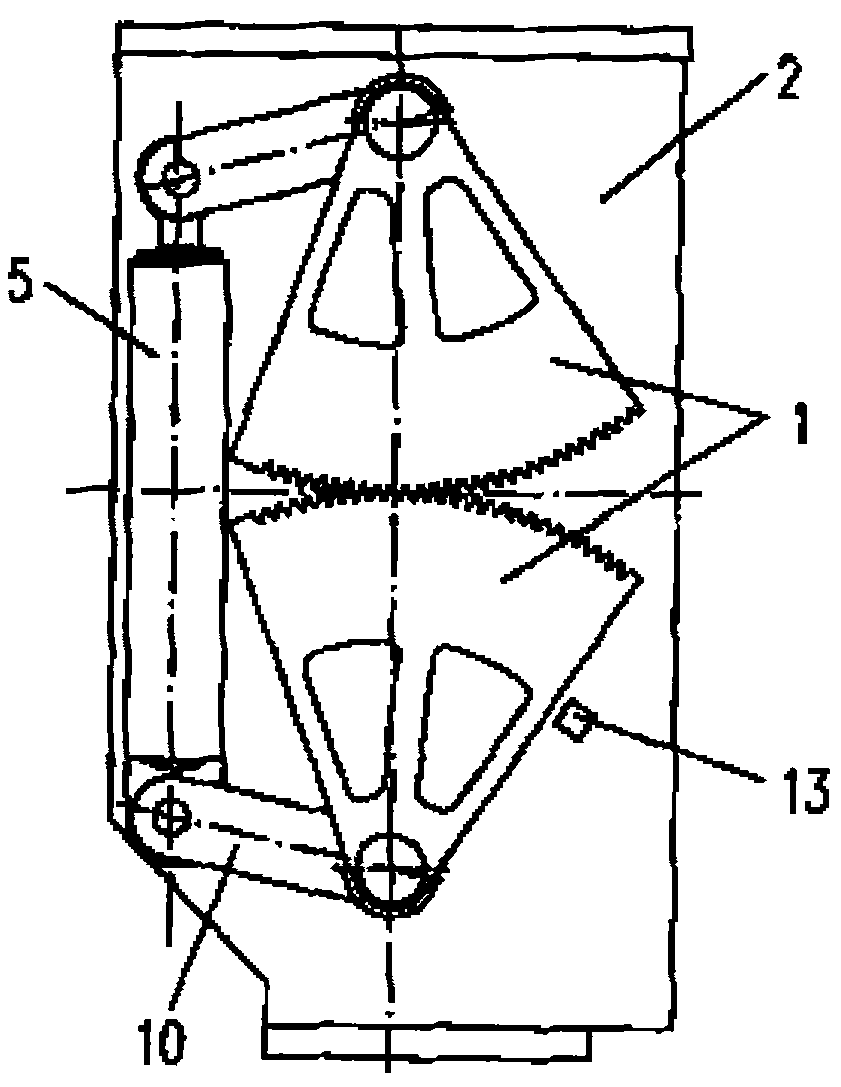

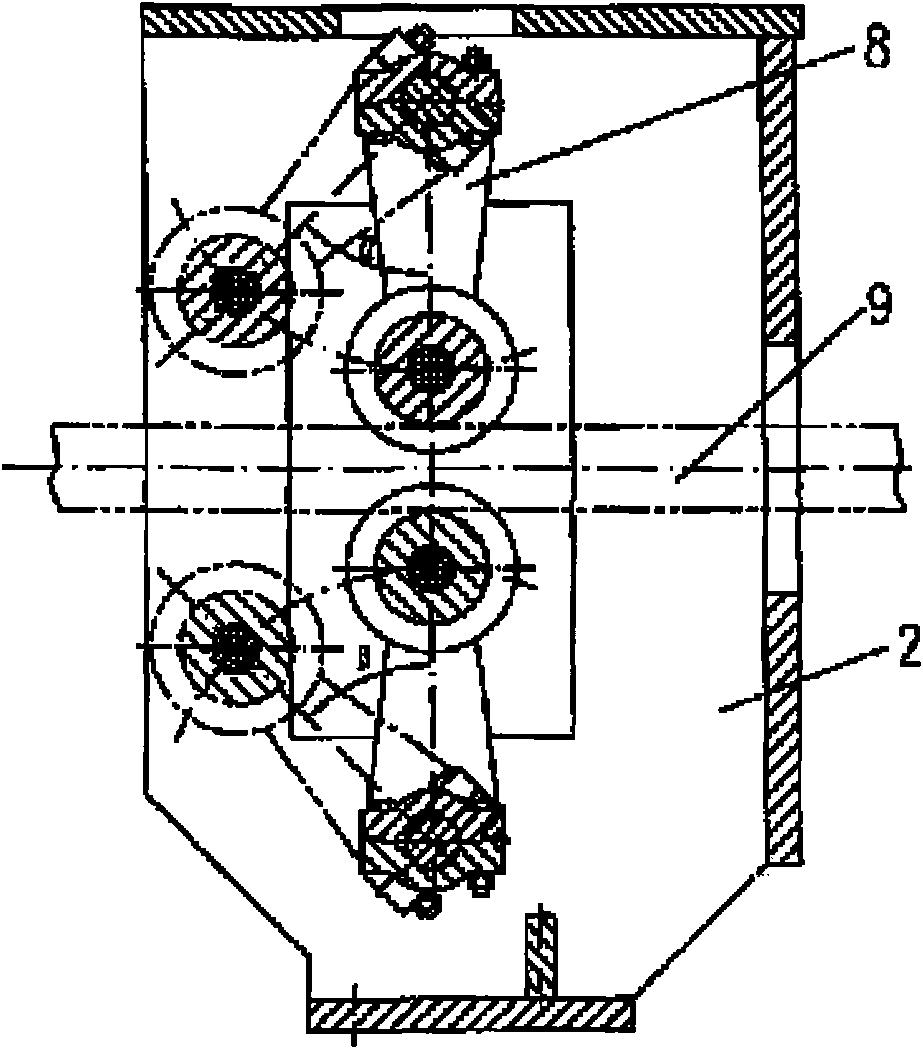

[0011] Upper synchronous shaft (7) and lower synchronous shaft (12) are installed on the frame (2); then upper swing arm (8) is installed respectively on upper synchronous shaft (7) and lower synchronous shaft (12); On the top of the swing arm (8), the upper roller (6) and the lower roller (11) are correctly installed. On one side of the frame (2), install sector gears (1) on the protruding ends of the upper synchronous shaft (7) and the lower synchronous shaft (12), and install an encoder on the top of the frame (2) Bracket (13), install the rotary encoder (16) on the top of the encoder bracket (13), and at the same time fix the input shaft of the rotary encoder (16) with the upper synchronous shaft (7), and ensure the rotation when fixing The axis of the input shaft of the encoder (16) is coaxial with the axial direction of the upper synchronous shaft (7). One end of a connecting rod (10) is hinged with the piston rod of the hydraulic cylinder (5), the other end is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com