Preparation method of glass fiber reinforced plastic cable protection tube

A technology of cable protection tubes and glass fiber reinforced plastics, which is applied to tubular objects, other household appliances, household appliances, etc., which can solve the problems of inconvenient installation and transportation, high cost and heavy weight of cable protection tubes, and achieve light weight and excellent electrical insulation The effect of high performance and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

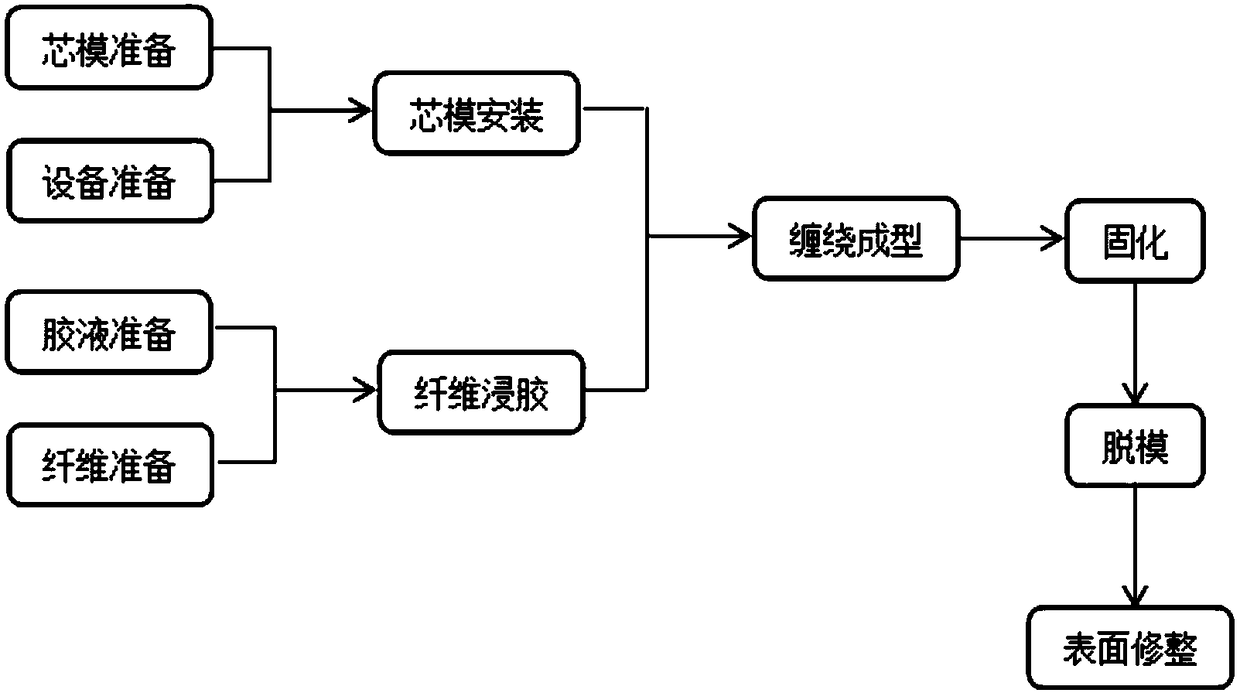

[0021] A preparation method for a glass fiber reinforced plastic cable protection tube, comprising the following steps:

[0022] The first step, the preparation of equipment, said equipment comprises winding machine and auxiliary equipment;

[0023] The second step is the preparation of the core mold. According to the cable protection tube, select the seamless steel pipe of the corresponding size as the blank of the core mold, use the cylindrical grinder to grind the surface of the core mold, and then use the polishing machine to polish the outer surface of the core mold. treatment, so that the roughness Ra of the surface of the mandrel reaches 1.6 μm, wipe the surface of the mandrel with absolute ethanol and dry it, apply a layer of release agent on the surface of the mandrel, and finally install the mandrel on the core of the winding machine on the module driver;

[0024] The third step is the preparation of materials. The materials required for preparation include glue and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com