Patents

Literature

1090 results about "Filament winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

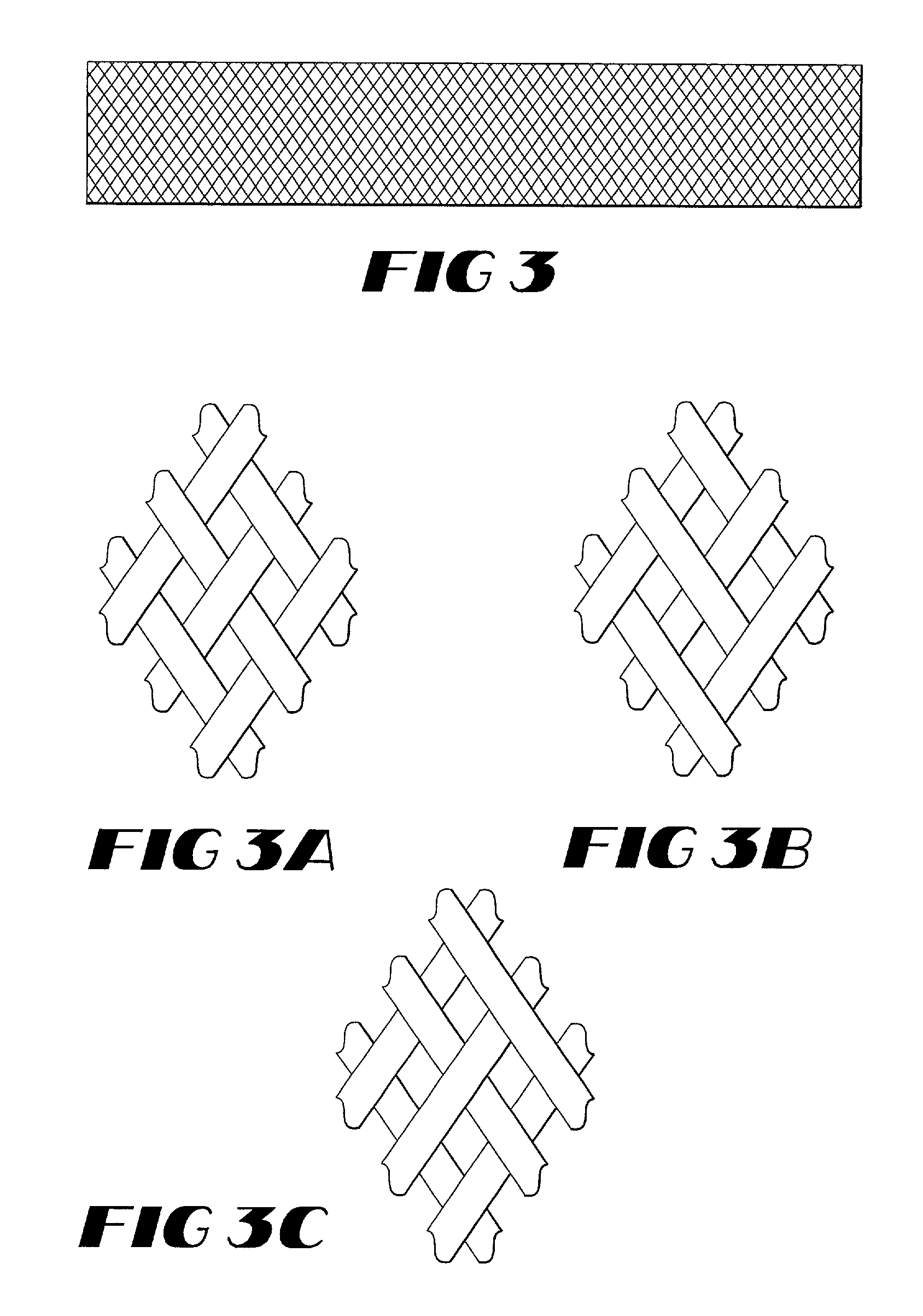

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle (Axis 1 or X: Spindle) while a delivery eye on a carriage (Axis 2 or Y: Horizontal) traverses horizontally in line with the axis of the rotating mandrel, laying down fibers in the desired pattern or angle. The most common filaments are glass or carbon and are impregnated in a bath with resin as they are wound onto the mandrel. Once the mandrel is completely covered to the desired thickness, the resin is cured. Depending on the resin system and its cure characteristics, often the rotating mandrel is placed in an oven or placed under radiant heaters until the part is cured. Once the resin has cured, the mandrel is removed or extracted, leaving the hollow final product. For some products such as gas bottles, the 'mandrel' is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored.

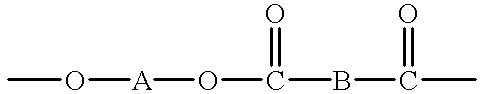

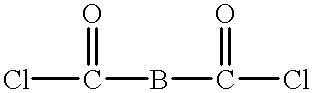

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

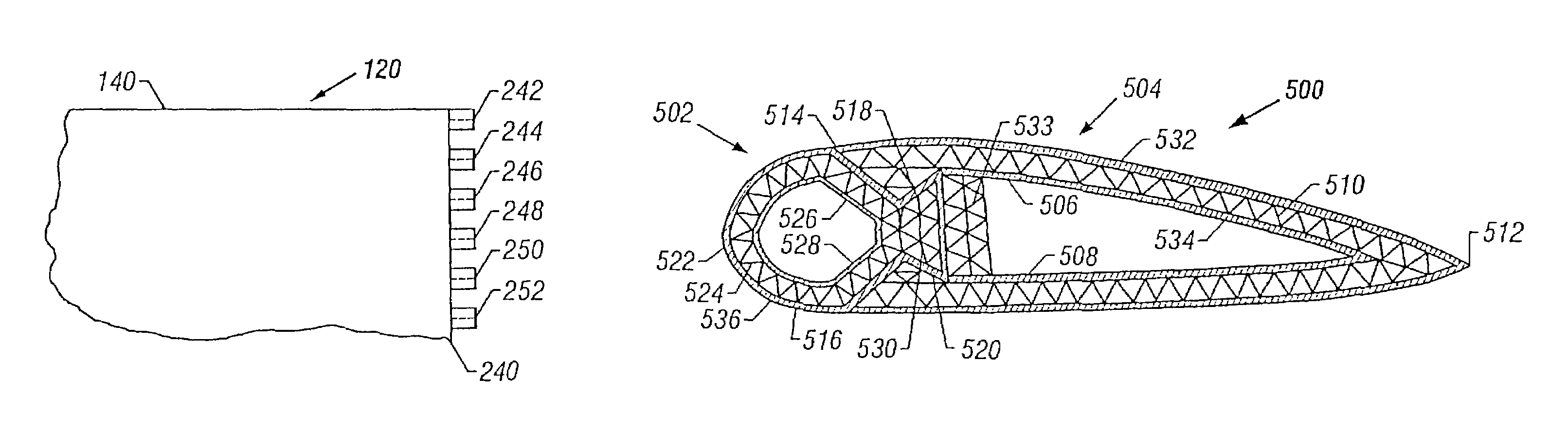

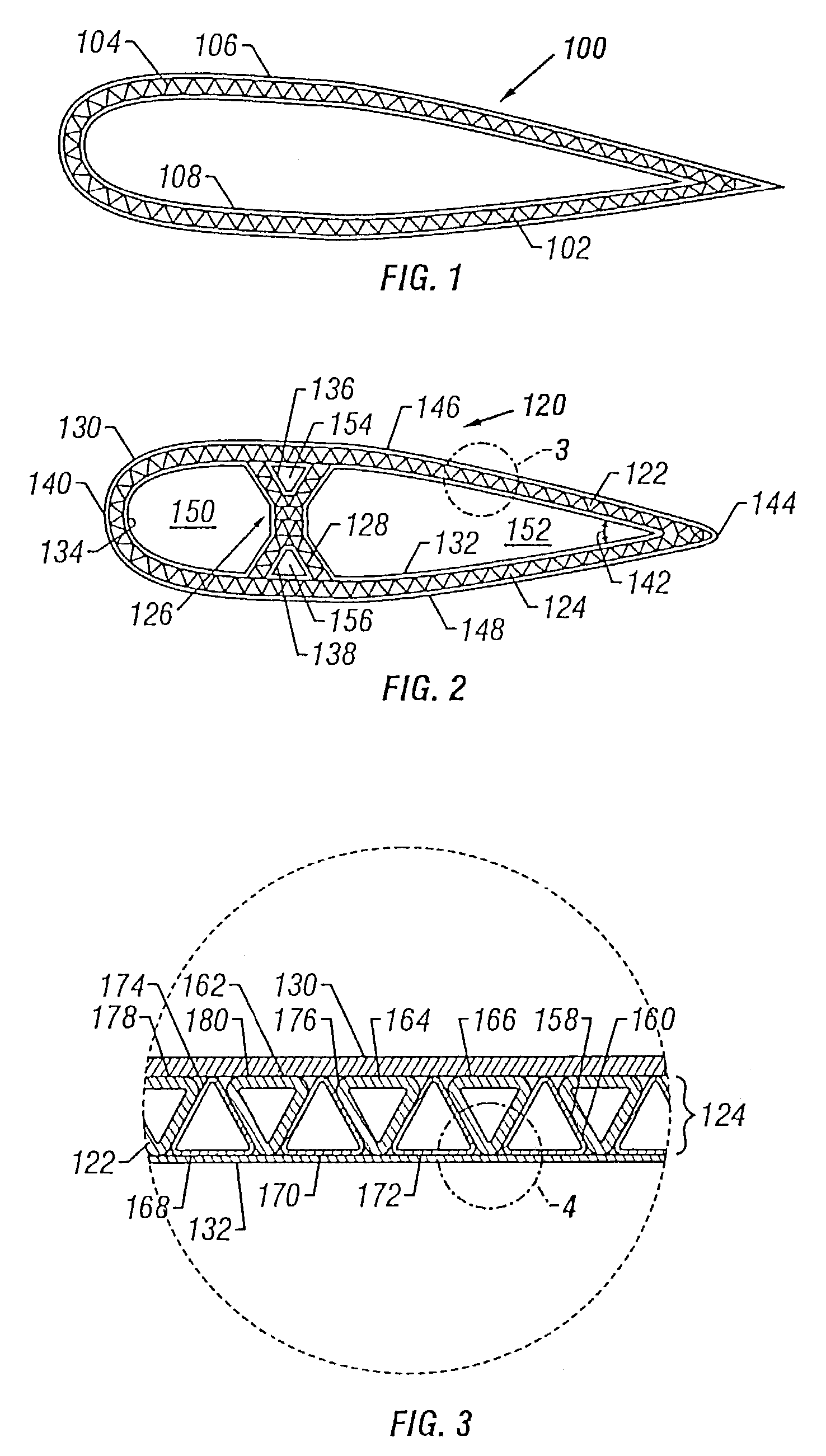

Tubular members integrated to form a structure

InactiveUS7063763B2Eliminate needEffective carryFuselage framesAircraft stabilisationMechanical engineeringFilament winding

Integrally stiffened and formed, load carrying structures comprising a plurality of elongated thin-walled tubes placed co-extensively in a complementary side-by-side fashion which together form a hollow structure having a desired external contour. Integral skins forming the external and internal surfaces of the structure cooperatively therewith. The structure can be formed with an underlying internal support member spanning the interior of the load carrying structure, thereby connecting opposite sides of the structure together. Also, each of the tubes are wound with fibers in controlled orientations generally paralleling the direction of the loads applied to the tubes to optimize the strength to weight ratio of the tubes.

Owner:CHAPMAN JR W CULLEN

Implantable textile prostheses having PTFE cold drawn yarns

The present invention provides an implantable prosthesis and more specifically, an implantable tubular textile prosthesis comprising a biocompatible fabric having inner and outer surfaces and first and second ends; the fabric having a textile construction comprising cold drawn PTFE yarns having a substantially uniform denier and high molecular orientation. Use of cold drawn PTFE yarns result in implantable prostheses that have excellent abrasion resistance, strength and lubricity properties. Useful textile constructions include weaves, knits, braids, filament windings, spun windings and combinations thereof. The prostheses of the present invention are lubricious and have characteristics that closely resemble the properties of a natural body lumen.

Owner:LIFESHIELD SCI

Process for filament winding

Filament winding process based on the mixing initiated polymerization of an at least two-component resin system, the system comprising an organic polyisocyanate and a polyfunctional active hydrogen composition as the principle isocyanate reactive species. The invention further provides improved composite articles produced by the filament winding process.

Owner:HUNTSMAN INT LLC

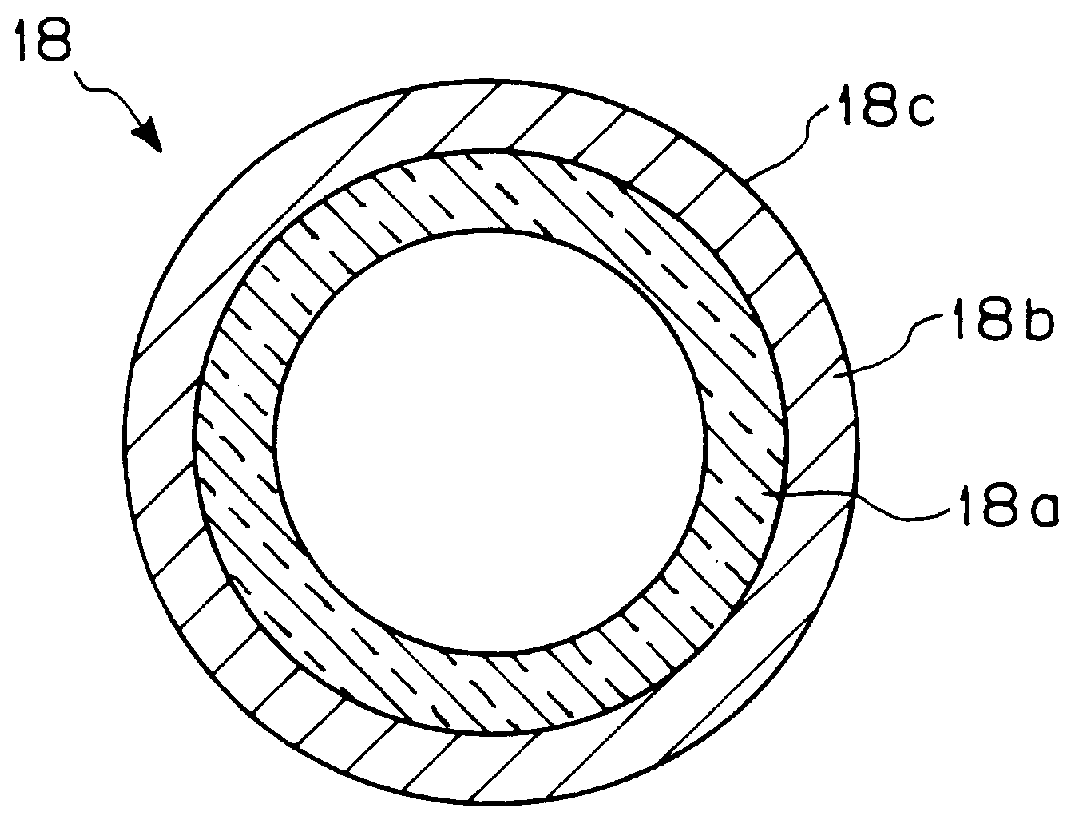

Fixing device for an image forming apparatus and fixing roller for the same

InactiveUS6122479AReduce power consumptionIncreased durabilityShaft and bearingsOhmic-resistance heating detailsElectricityImage formation

In a fixing device for an image forming apparatus, a heat roller includes a hollow cylindrical base, a heating layer formed of strip-like fibers implementing desired power consumption, and a parting layer provided on the outer periphery of the heating layer with the intermediary of an electrical insulating layer. The strip-like fibers of the heating layer are wound on the base and provided with a preselected resistance.

Owner:RICOH KK

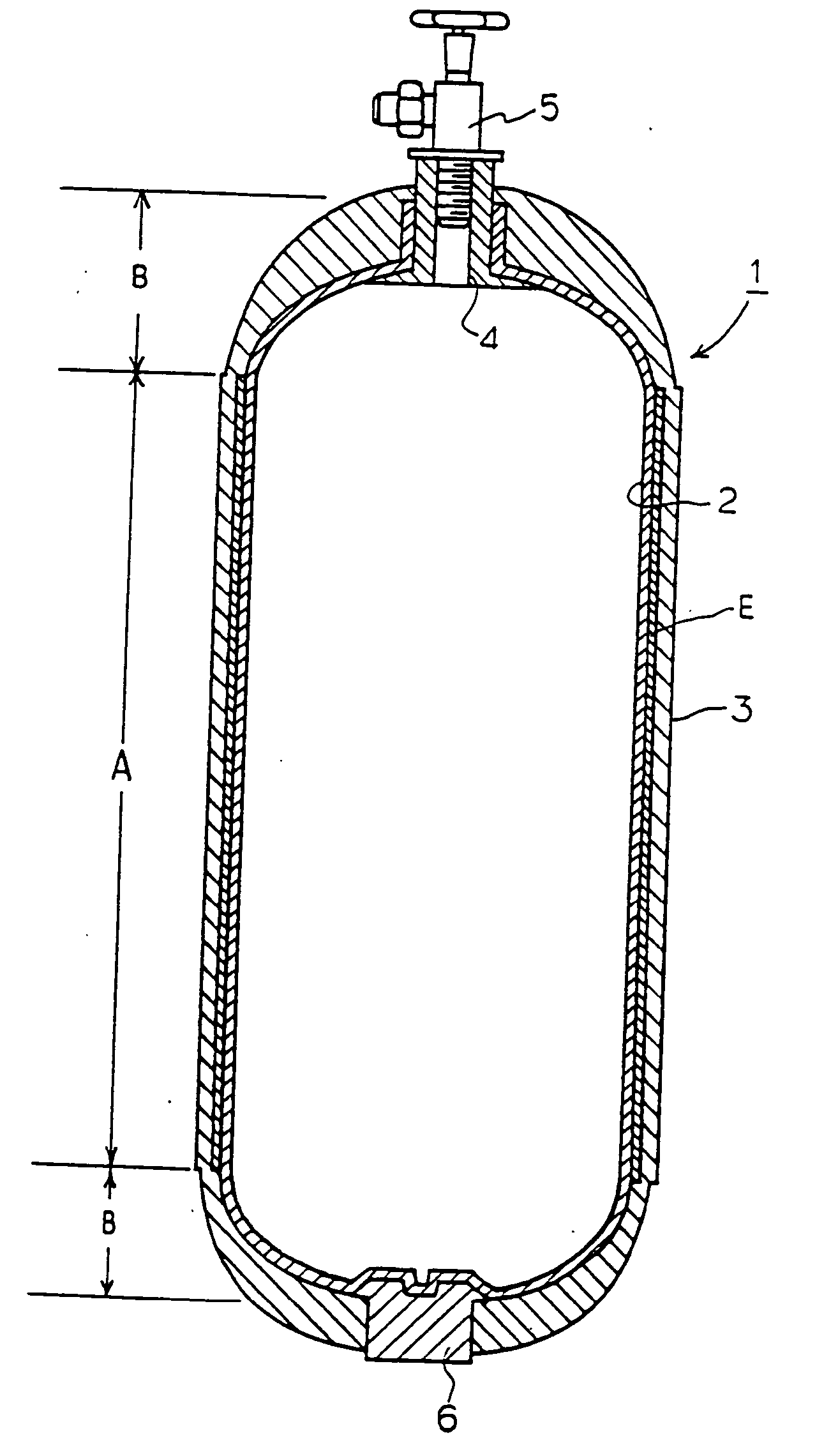

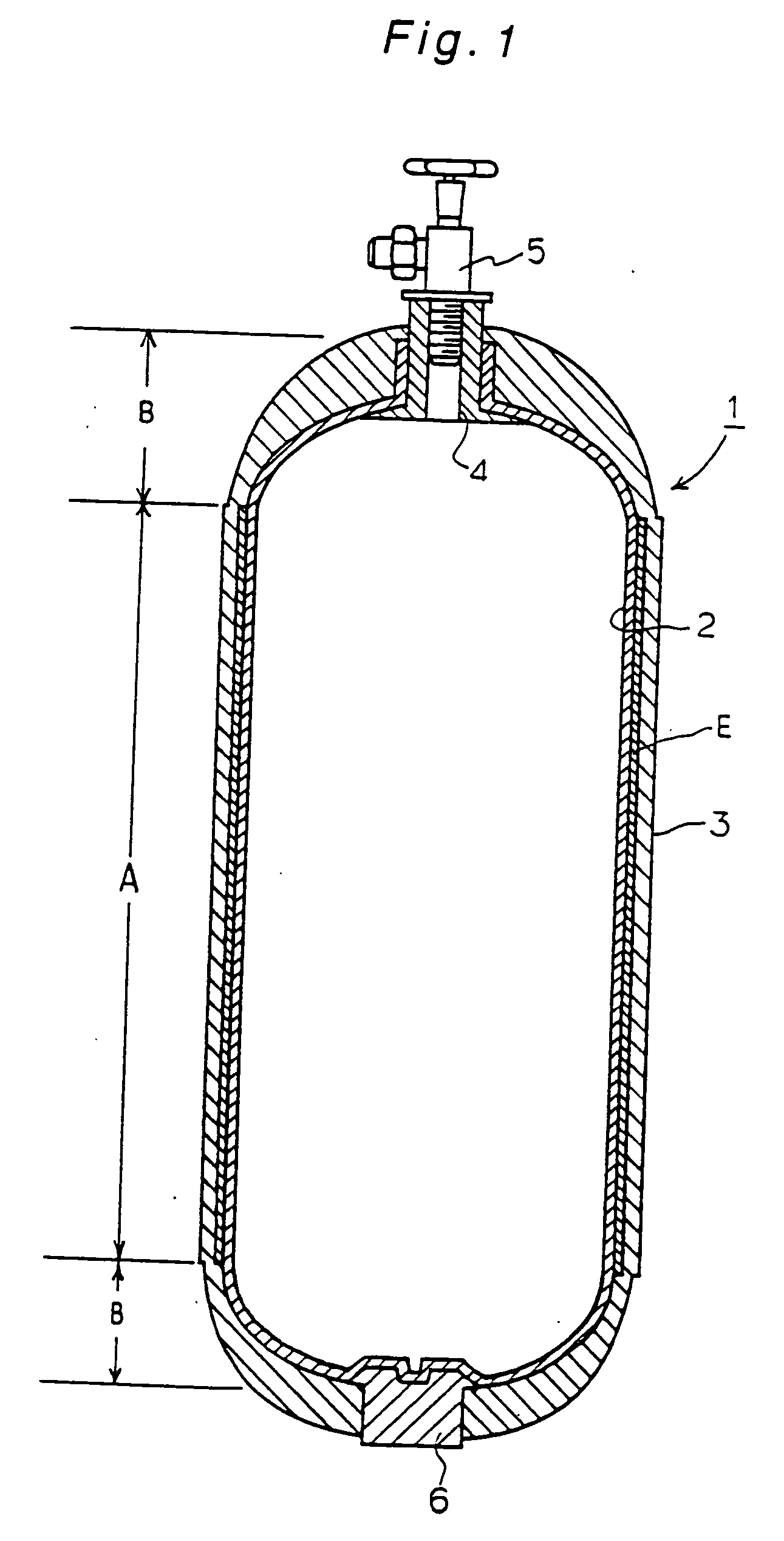

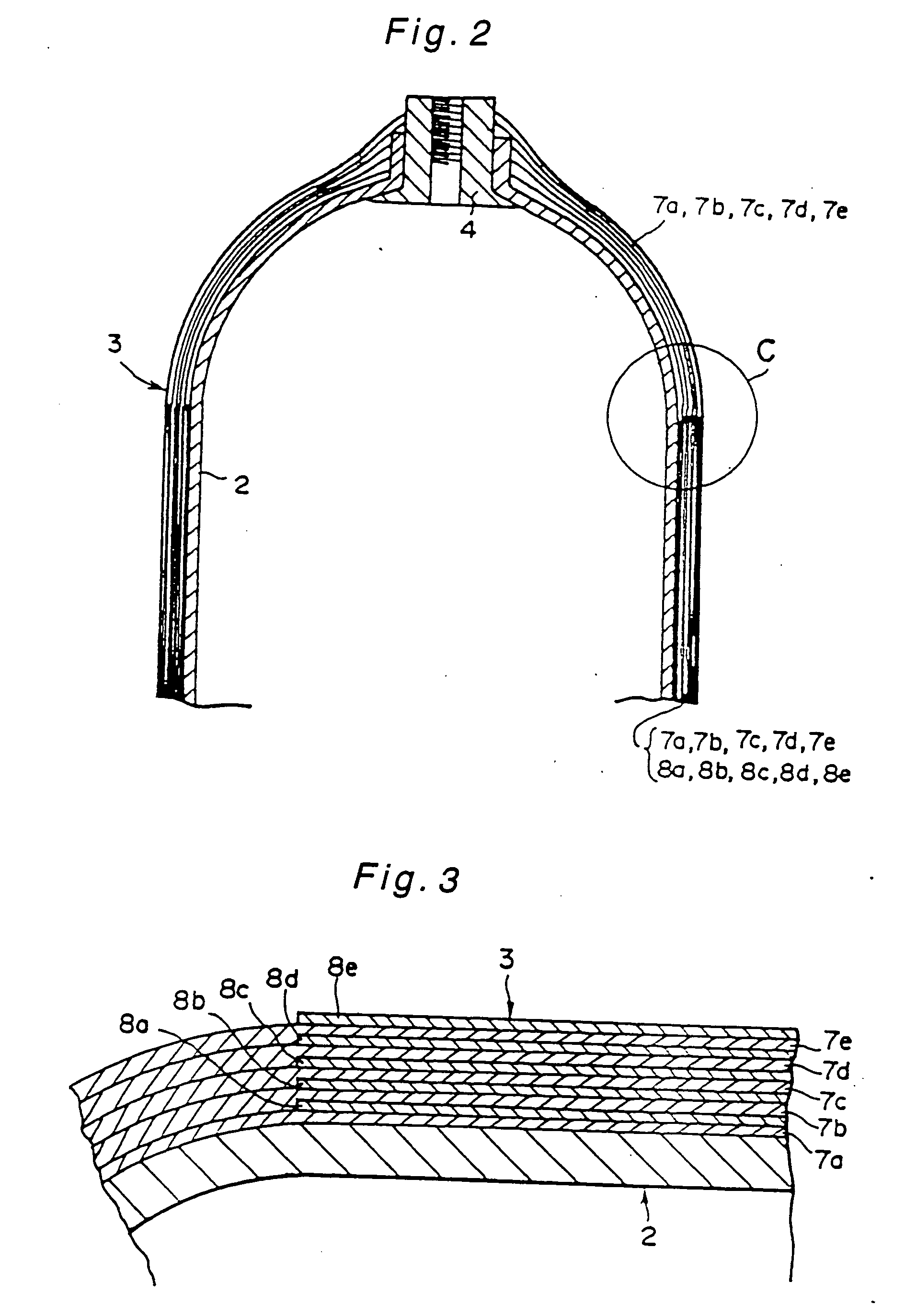

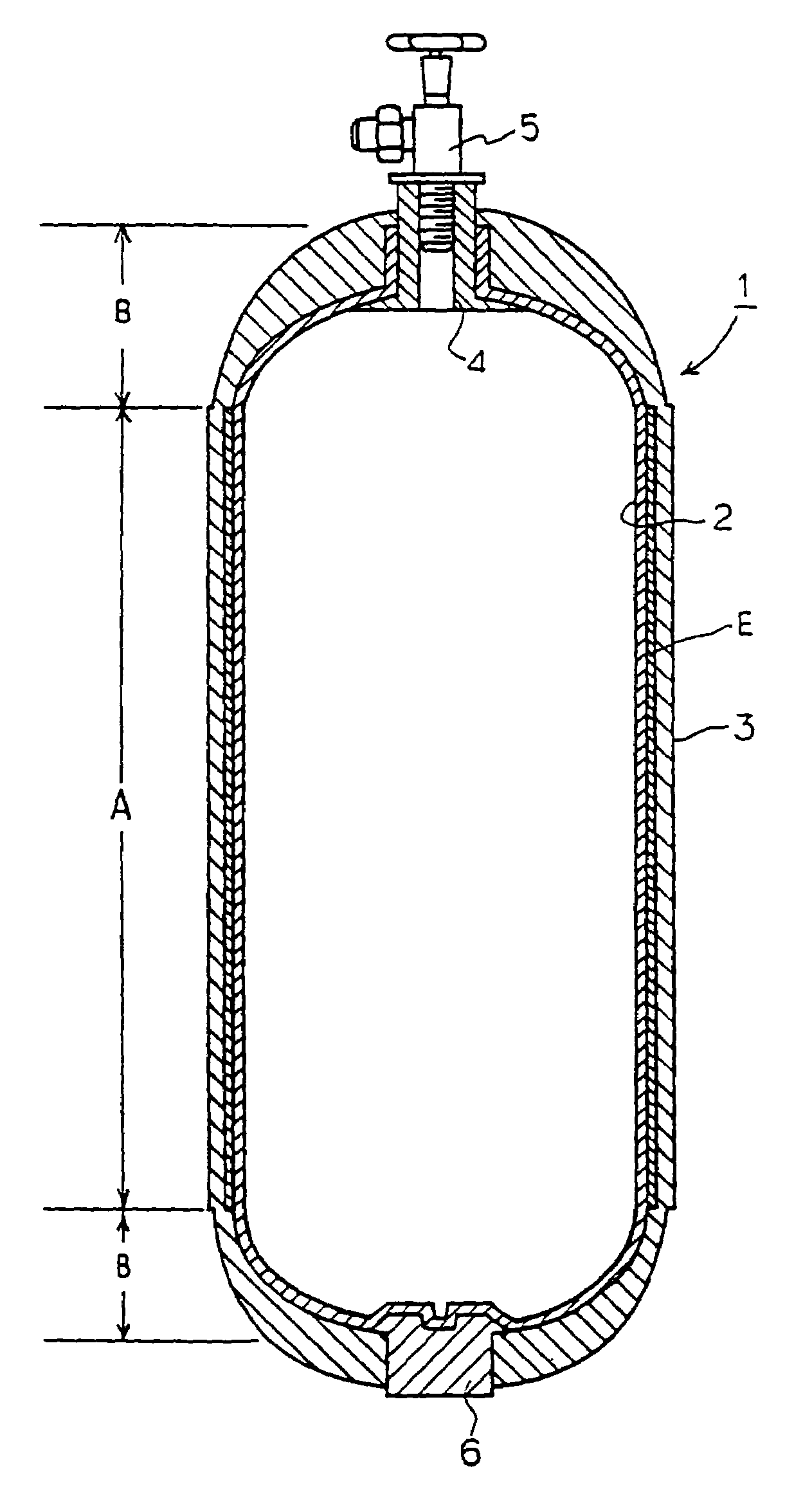

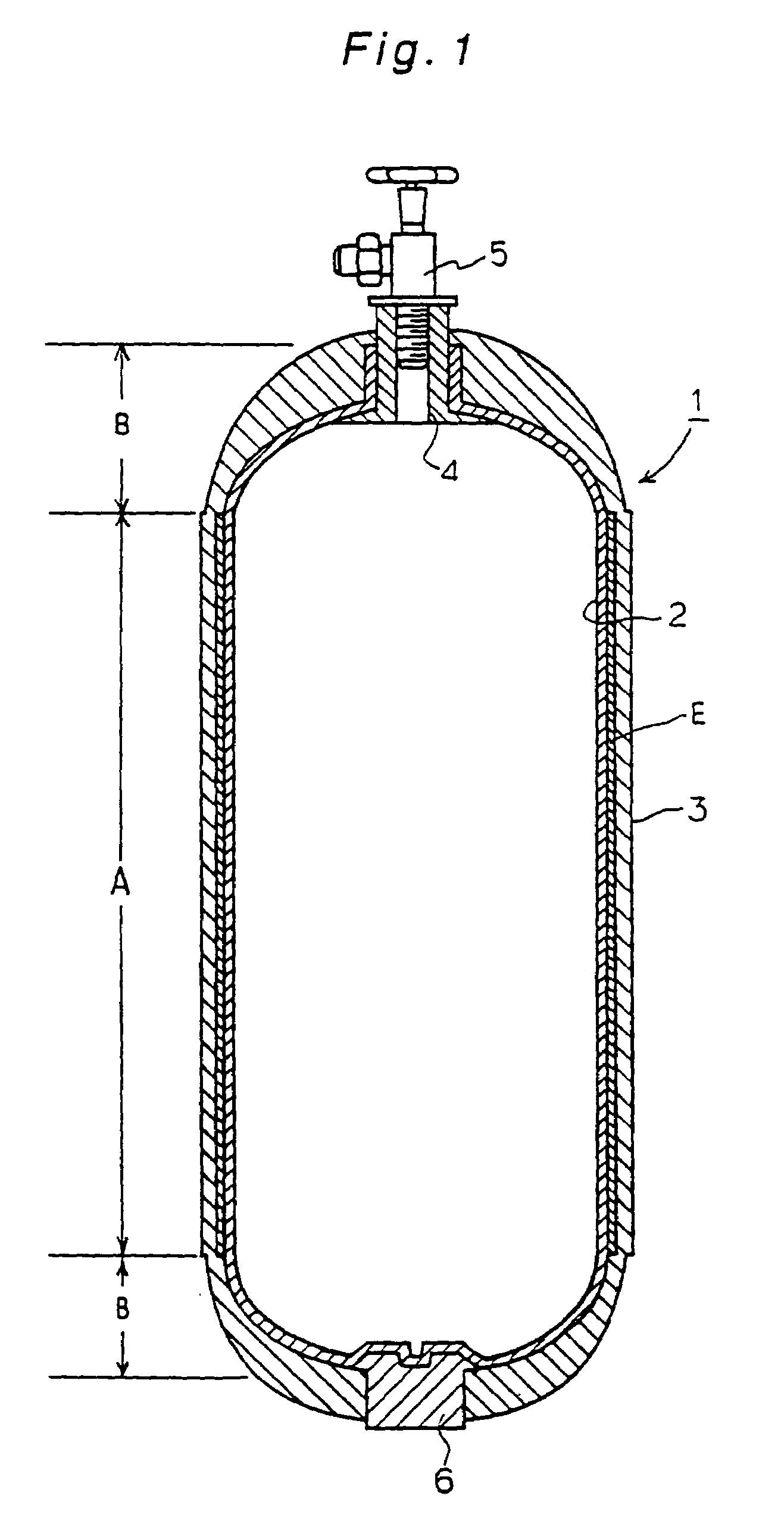

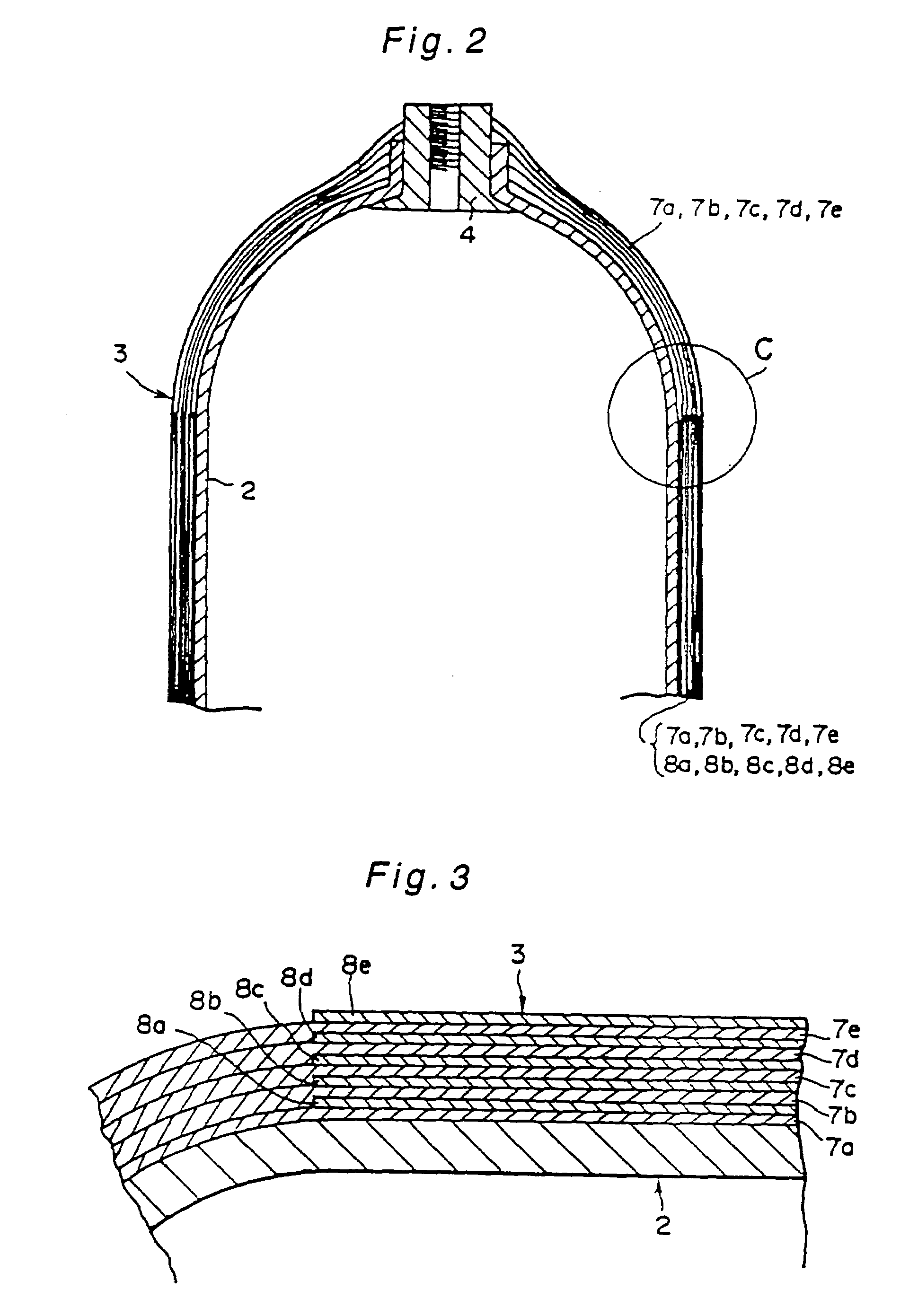

Pressure vessel and process for producing the same

InactiveUS20040206762A1Light weightIncrease pressureVessel mounting detailsVessel manufacturingInternal pressureEngineering

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight,.but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability. The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

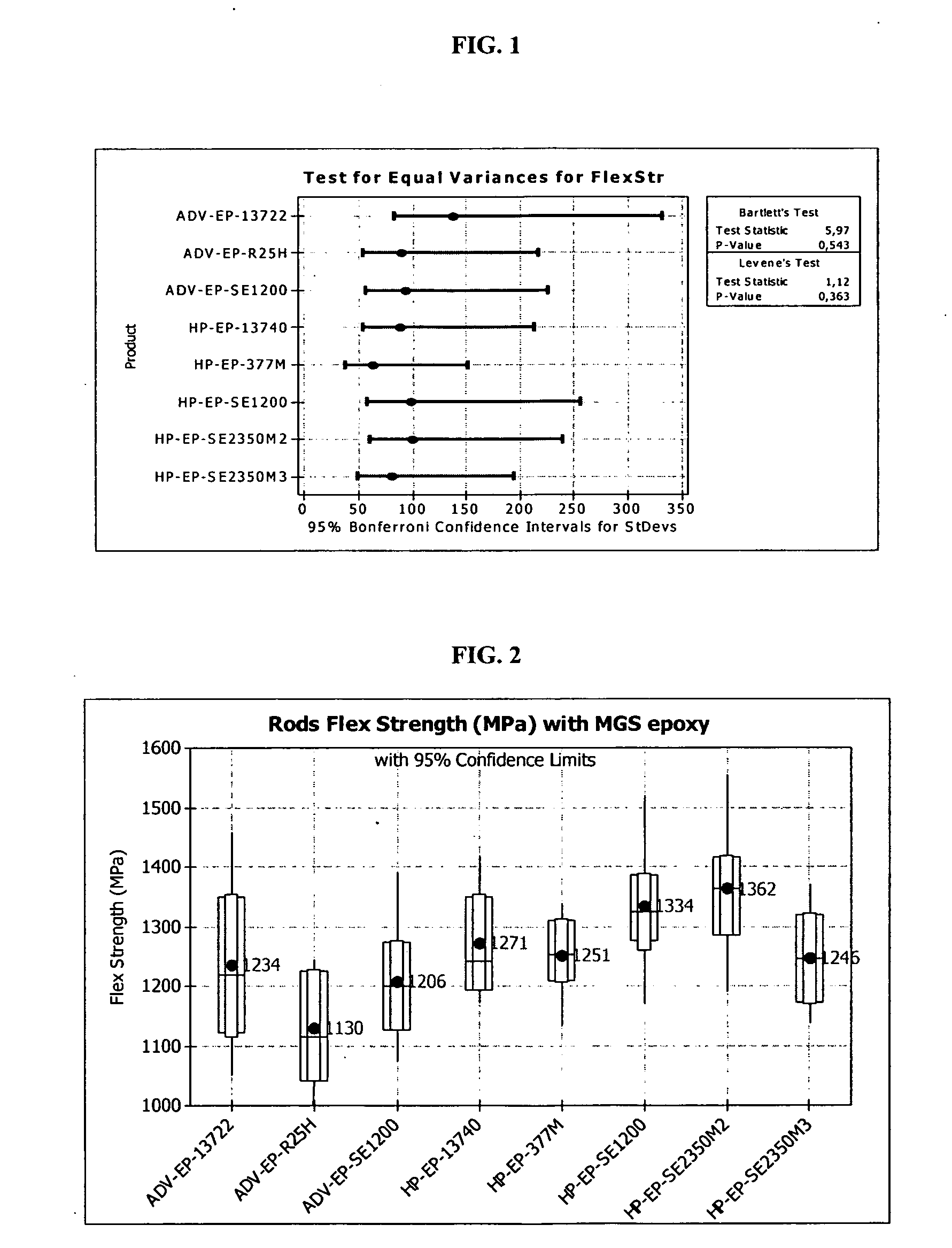

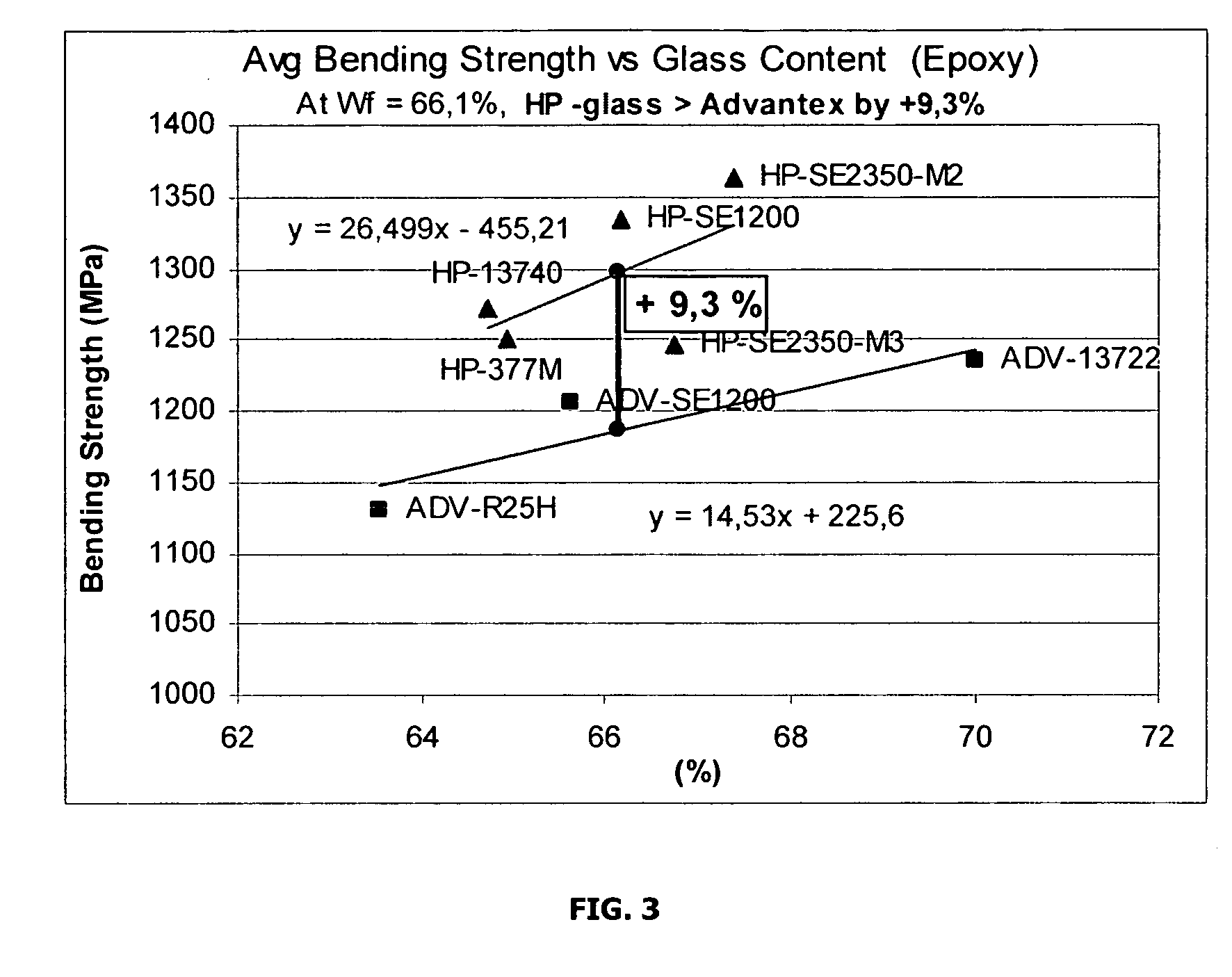

Sizing for high performance glass fibers and composite materials incorporating same

ActiveUS20060204763A1Reduces amount of boronProcess environmental protectionOther chemical processesFibre treatmentEpoxySilanes

A sizing composition containing an epoxy film former, a urethane film former, a silane package that includes an aminosilane coupling agent and an epoxy silane coupling agent, a cationic lubricant, a non-ionic lubricant, an antistatic agent, and at least one acid is provided. The epoxy resin emulsion includes a low molecular weight liquid epoxy resin and one or more surfactants. The epoxy resin preferably has an epoxy equivalent weight from 185-192. The sizing composition may optionally contain a methacryloxy silane. The sizing composition may be used to size glass fibers used in filament winding applications to form reinforced composite articles with improved mechanical properties, wet tensile properties, improved resistance to cracking, and improved processing characteristics.

Owner:OCV INTELLECTUAL CAPITAL LLC +1

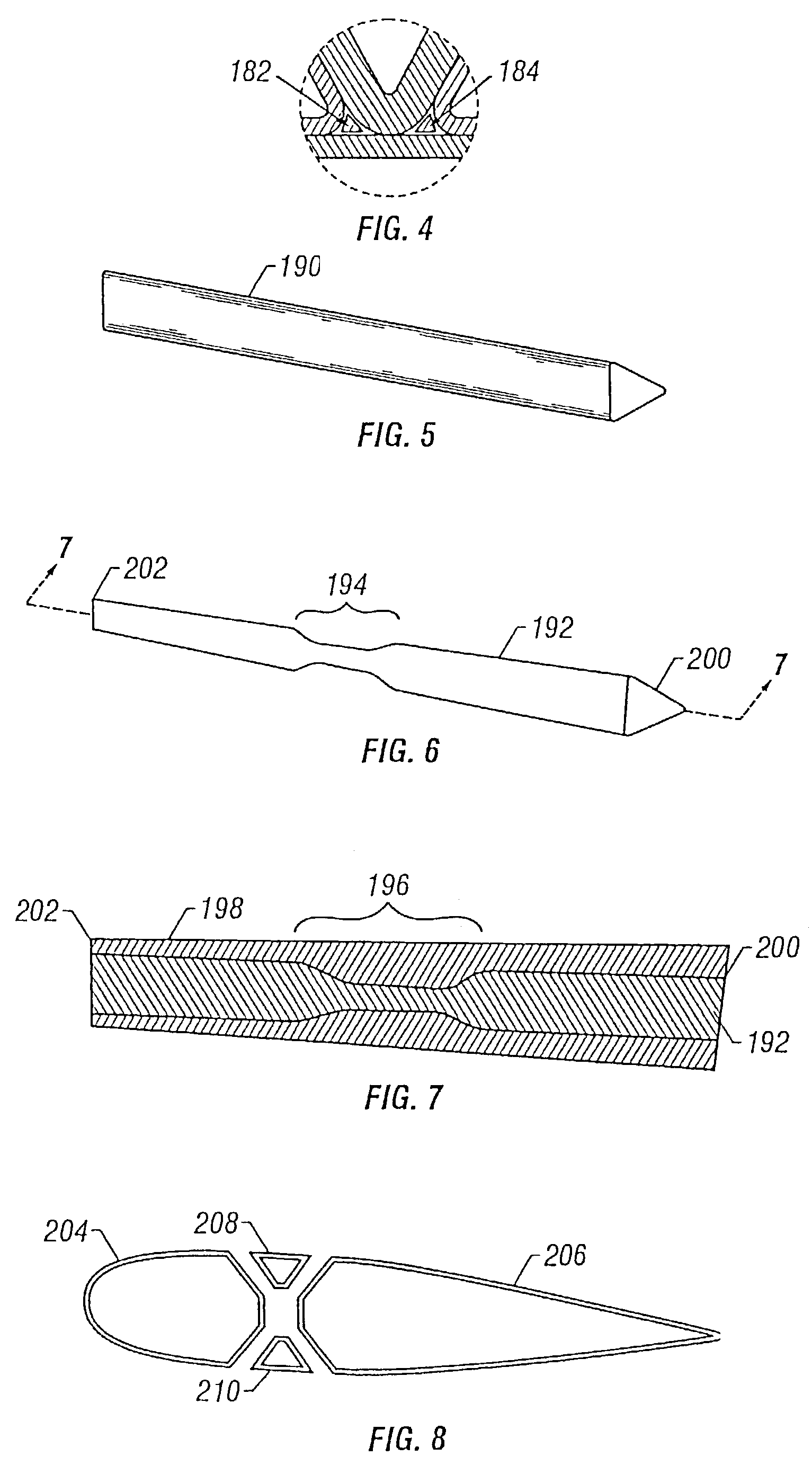

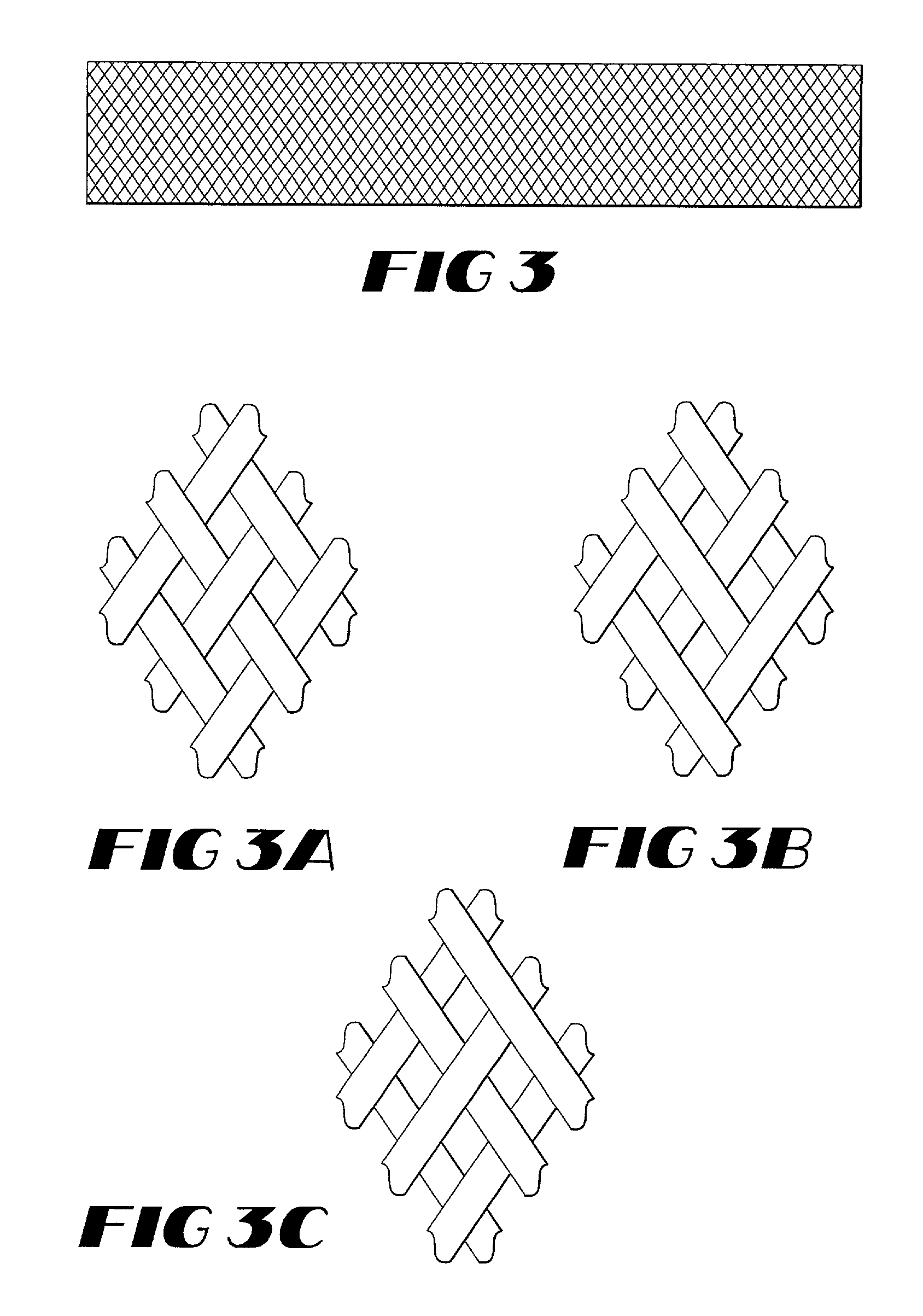

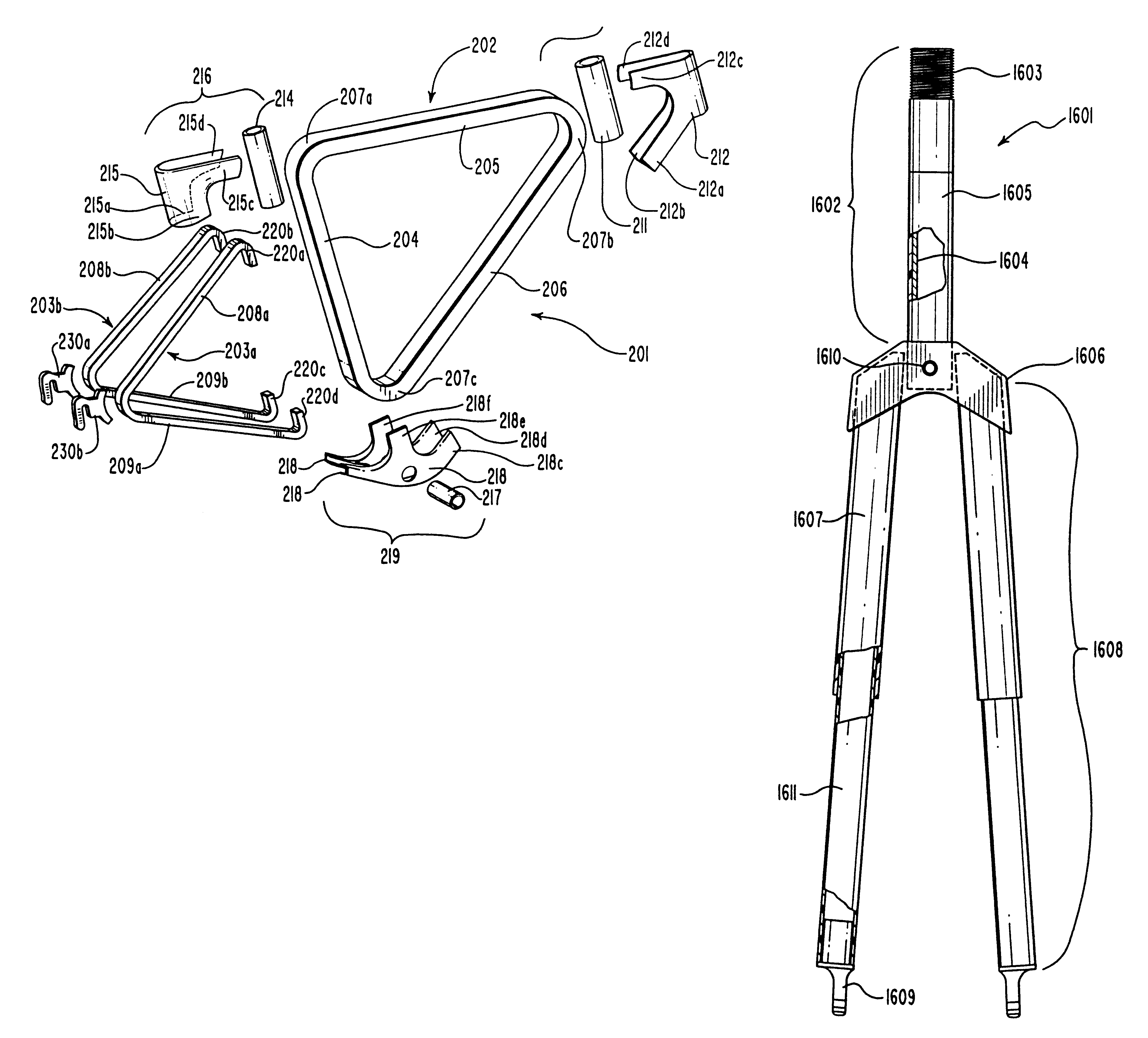

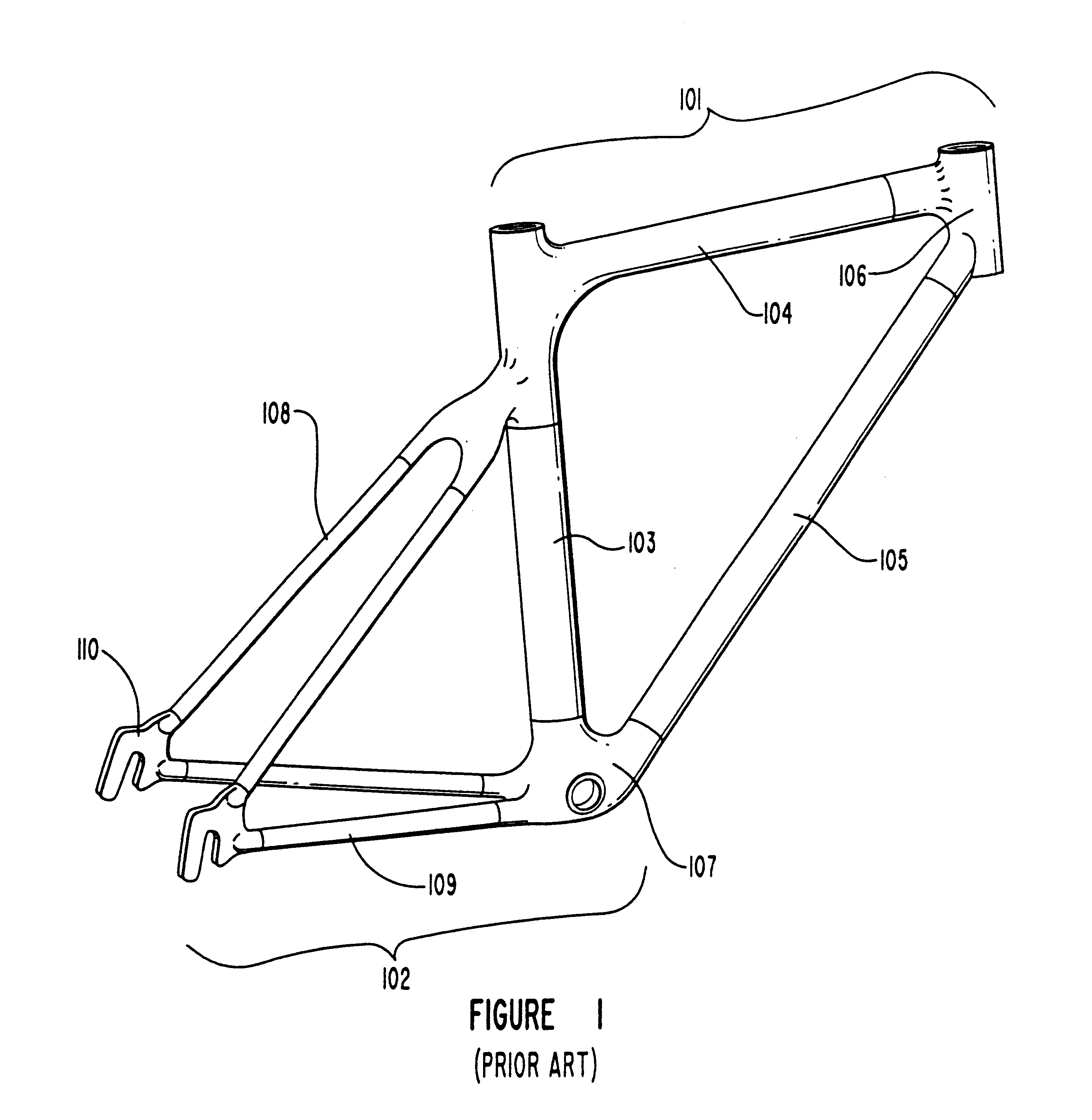

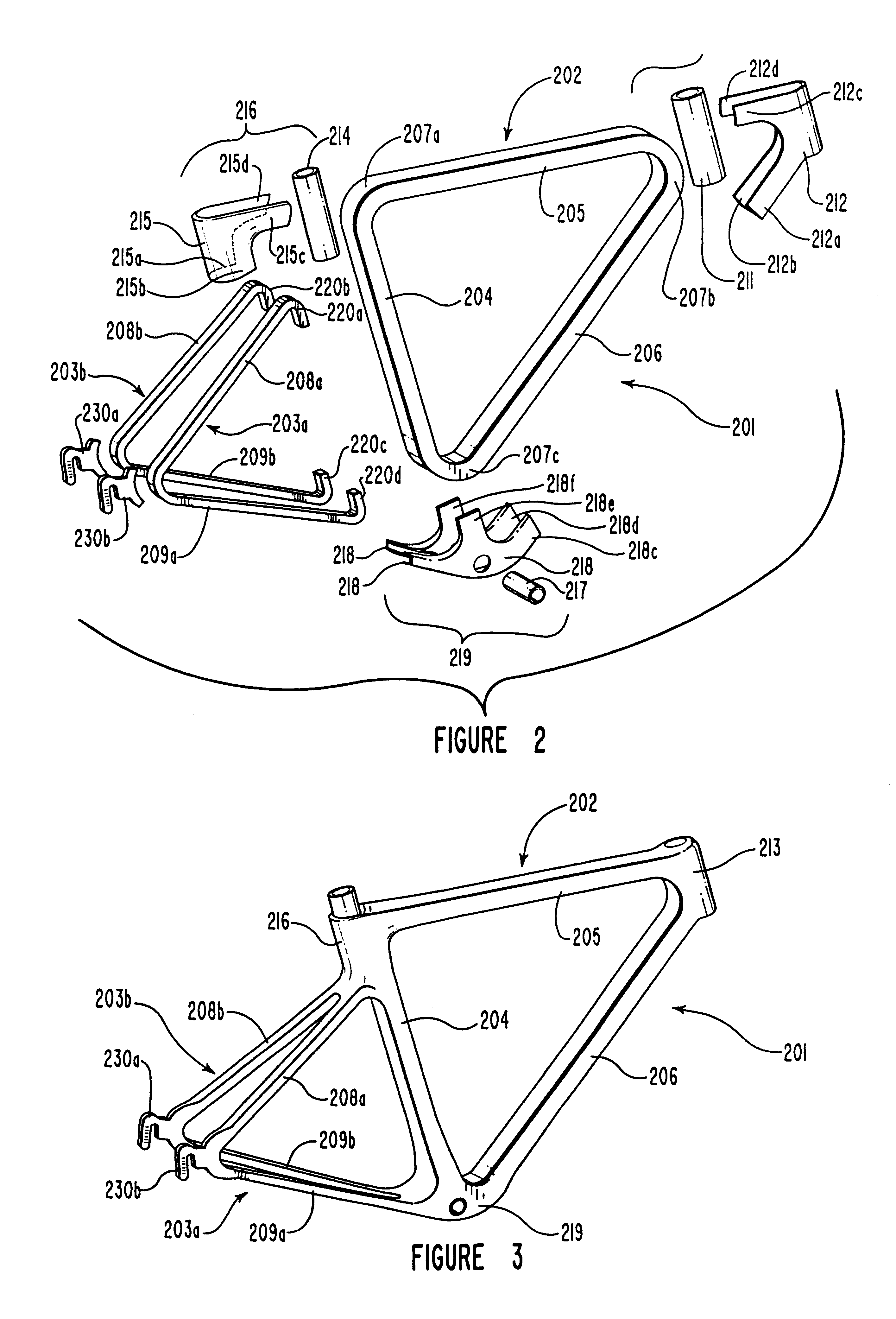

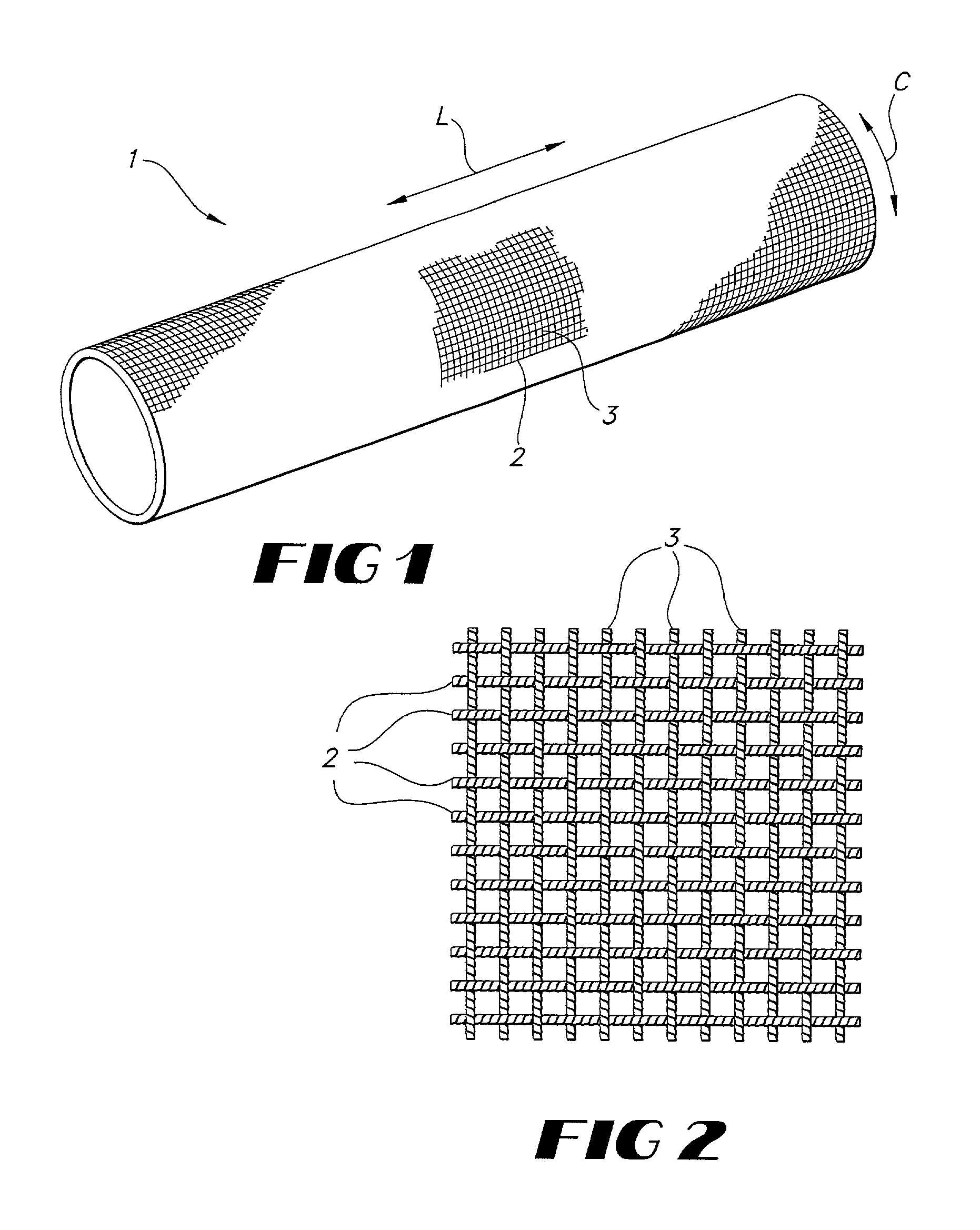

Net shape filament winding manufacturing process, articles made therefrom and composite bicycle fork and other components

InactiveUS6267399B1Manufactured quickly and inexpensivelyHigh strengthPassenger cyclesWheel based transmissionNet shapeFilament winding

A high production net shape filament winding manufacturing process and resulting products are disclosed. The manufacture of bicycle frame and their components from filament wound components which have been cut from a section of filament wound stock is disclosed. Also disclosed is a bicycle frame and its manufacturing process and a composite bicycle fork and components thereof.

Owner:ADVANCED COMPOSITES

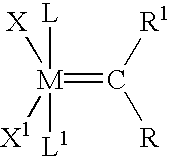

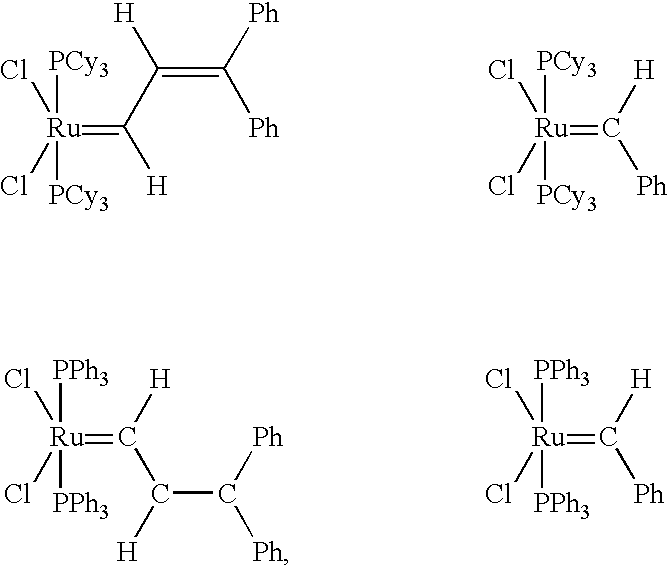

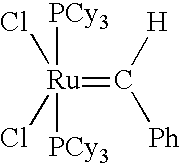

Pipe made from metathesis polymerized olefins

InactiveUS6410110B1Extended validity periodImprove responseLayered productsBottlesPolymer sciencePipe fitting

Thermosetting resin pipes and pipe fittings are provided which are prepared by polymerizing a cyclic olefin monomer in the presence of a ruthenium or osmium metathesis polymerization catalyst. These articles may be prepared by various methods, such as centrifugal casting. Reinforced articles may also be prepared by filament winding.

Owner:A O SMITH +1

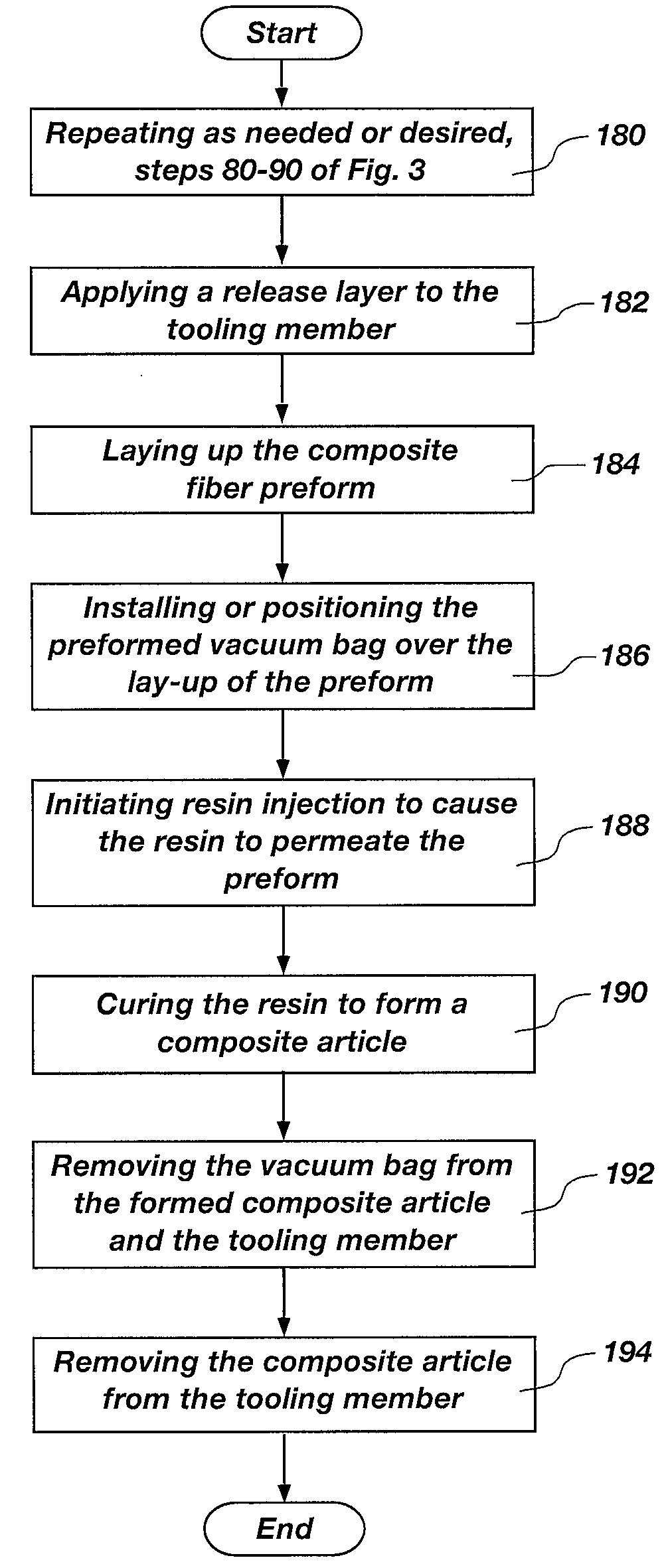

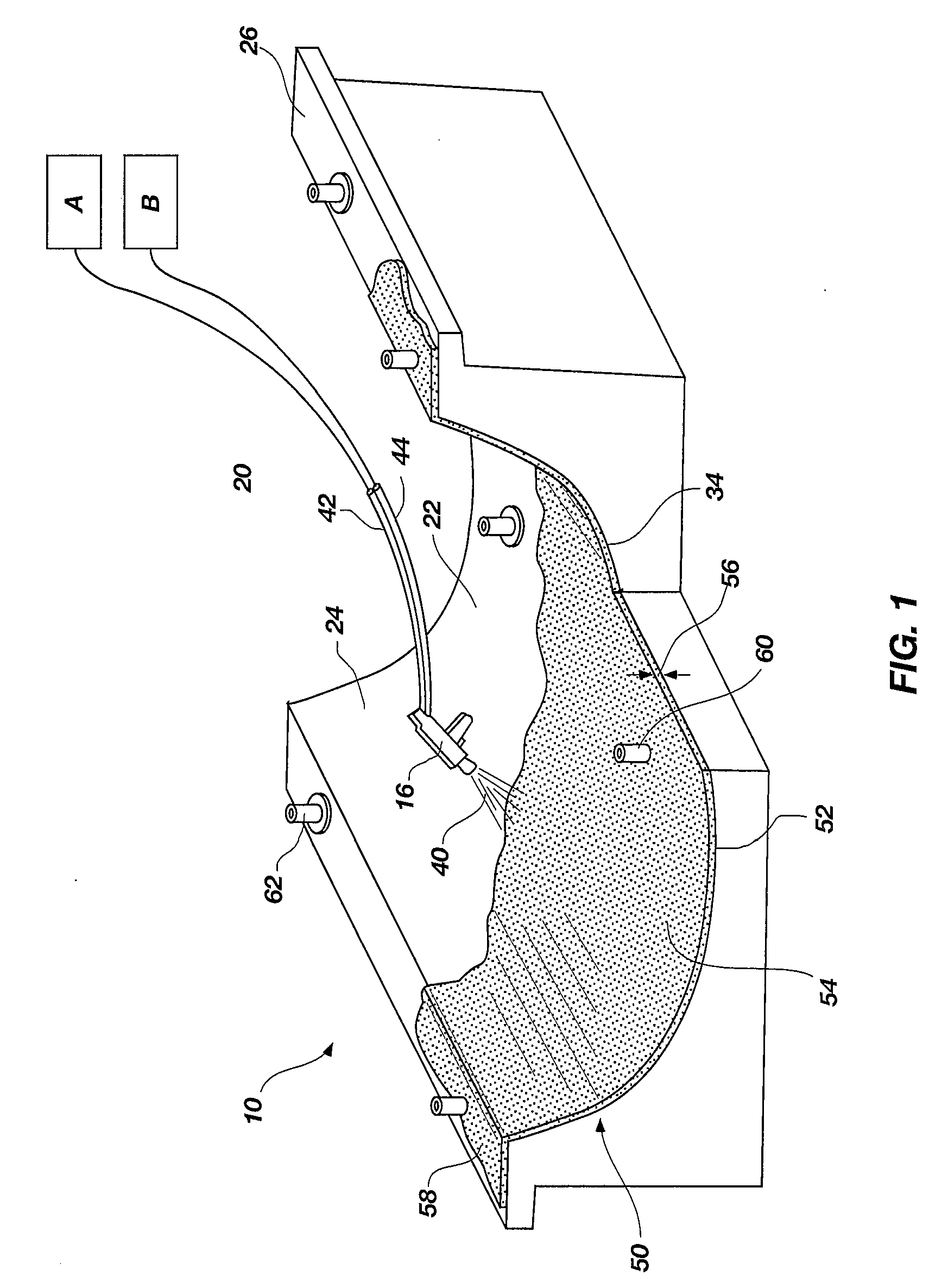

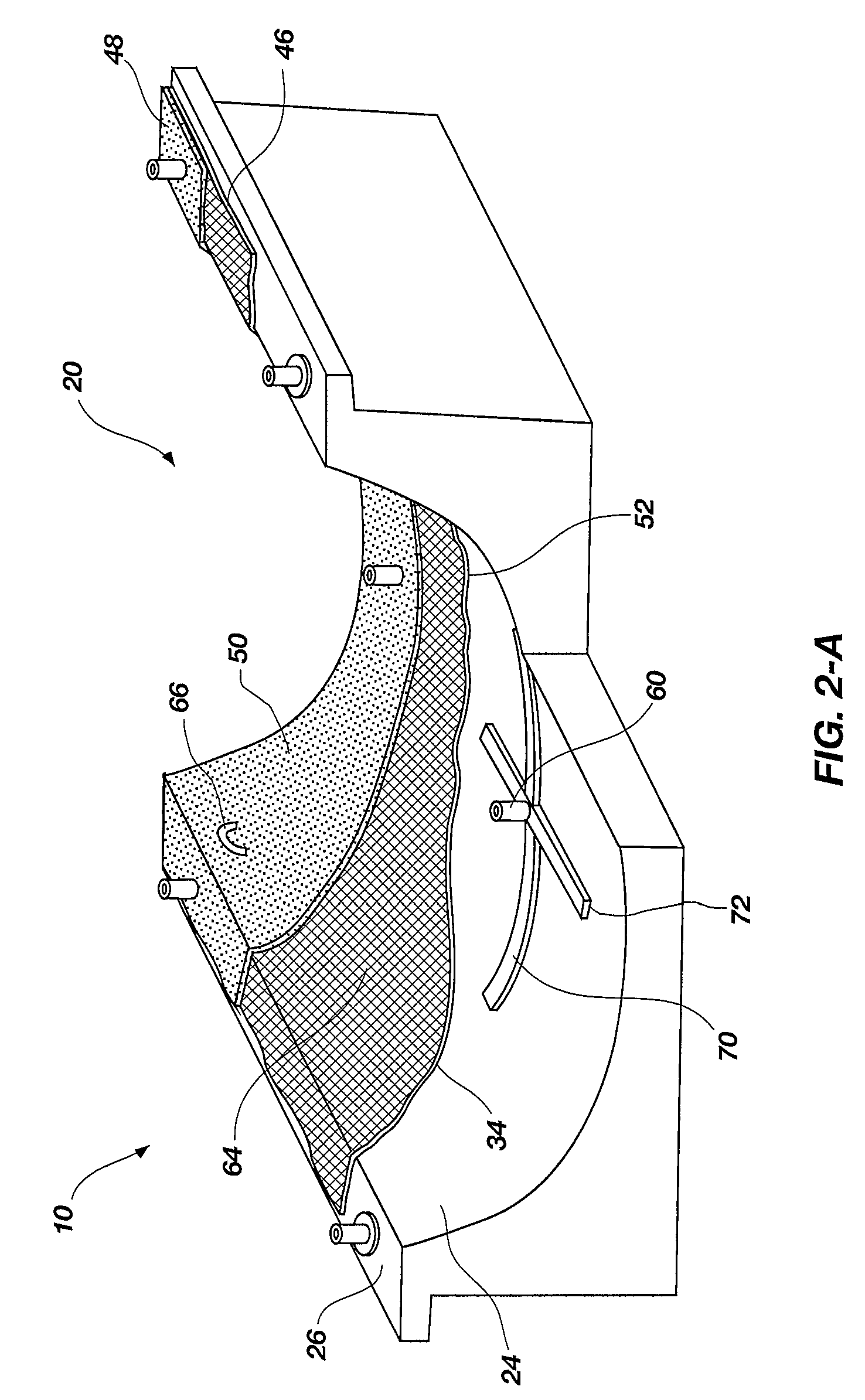

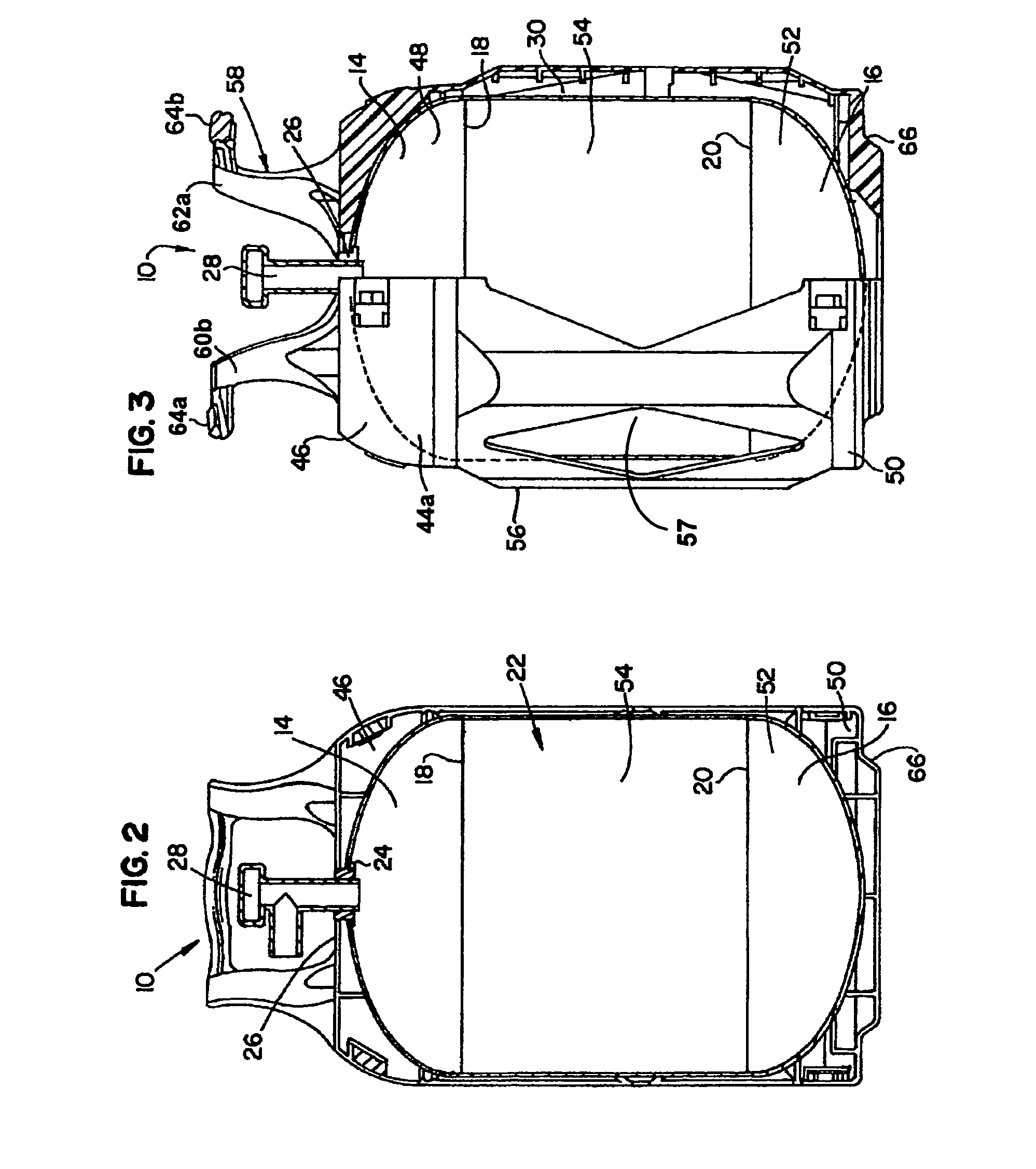

Multi-function vacuum bag for composite part manufacture

A multi-function vacuum bag for use in the manufacture of composites, wherein the vacuum bag may be configured to provide all-in-one capabilities, namely to function as the vacuum bag, a caul or caul sheet, release layer and / or a breather, as well as to provide other functions. Specifically, the multi-function vacuum bag allows a separate breather or breather material, a separate caul or caul layer, and a release or release layer all to be eliminated, if desired, as the multi-function vacuum bag is capable of performing the functions of each of these once formed. Furthermore, the multi-function vacuum bag may be used with various composite manufacturing process, such as VARTM or resin infusion processes, various vacuum bagging processes, filament winding processes, and others.

Owner:AMERICAN CONSULTING TECH

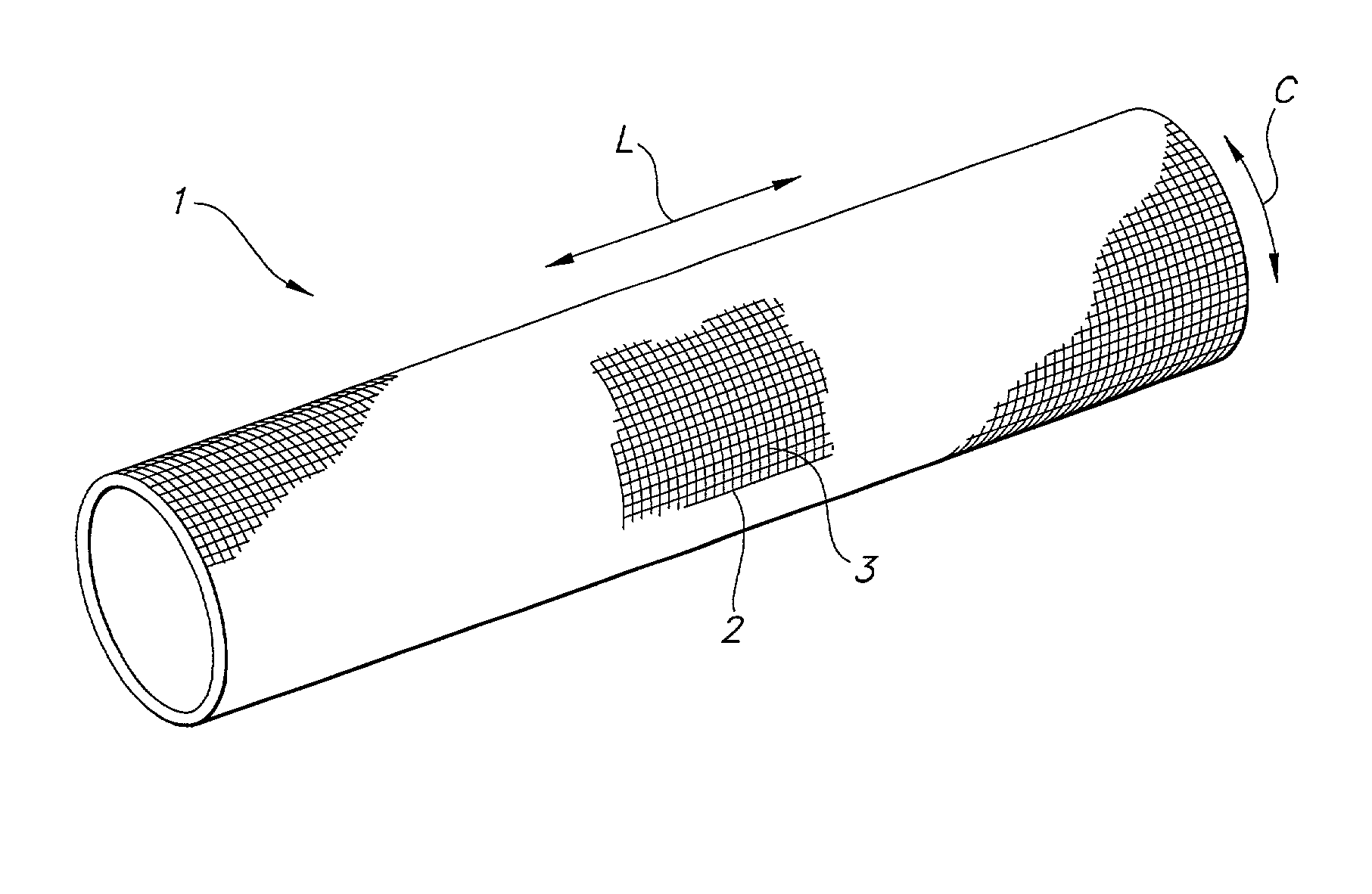

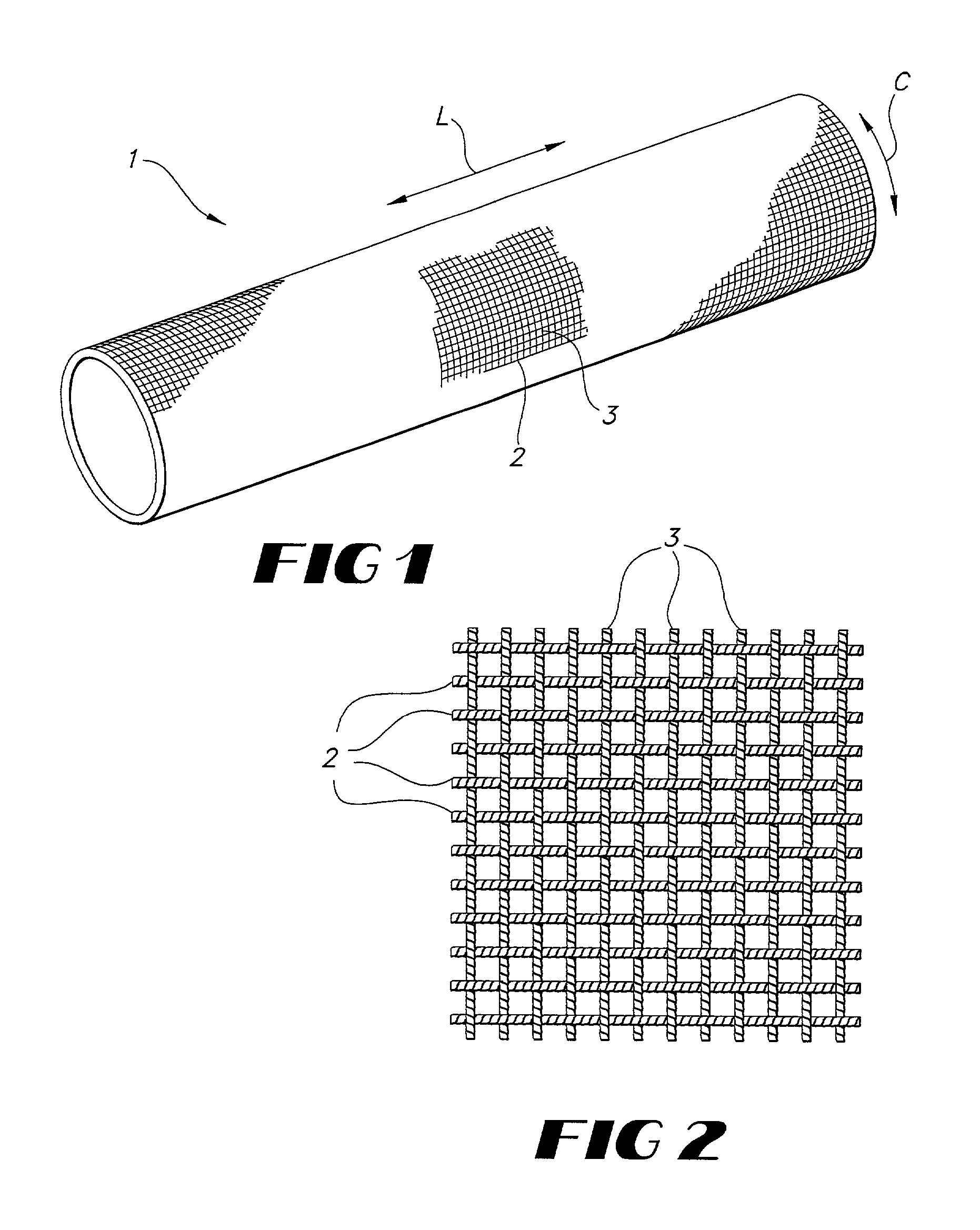

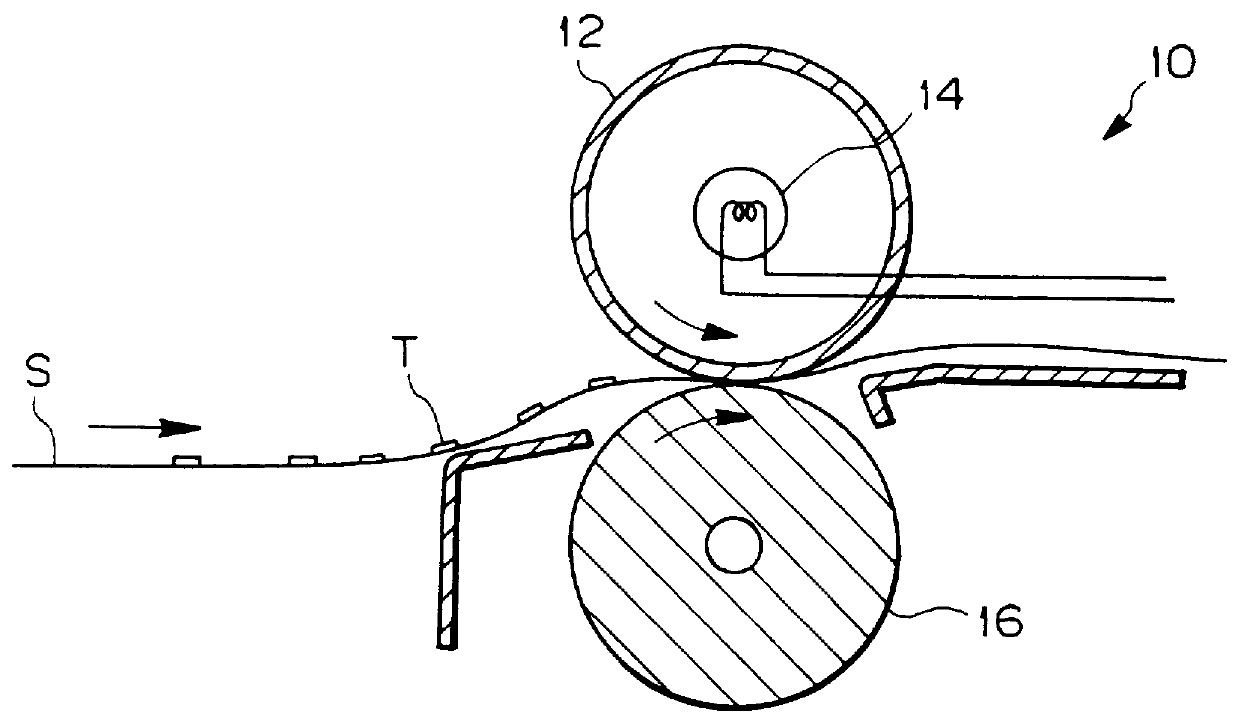

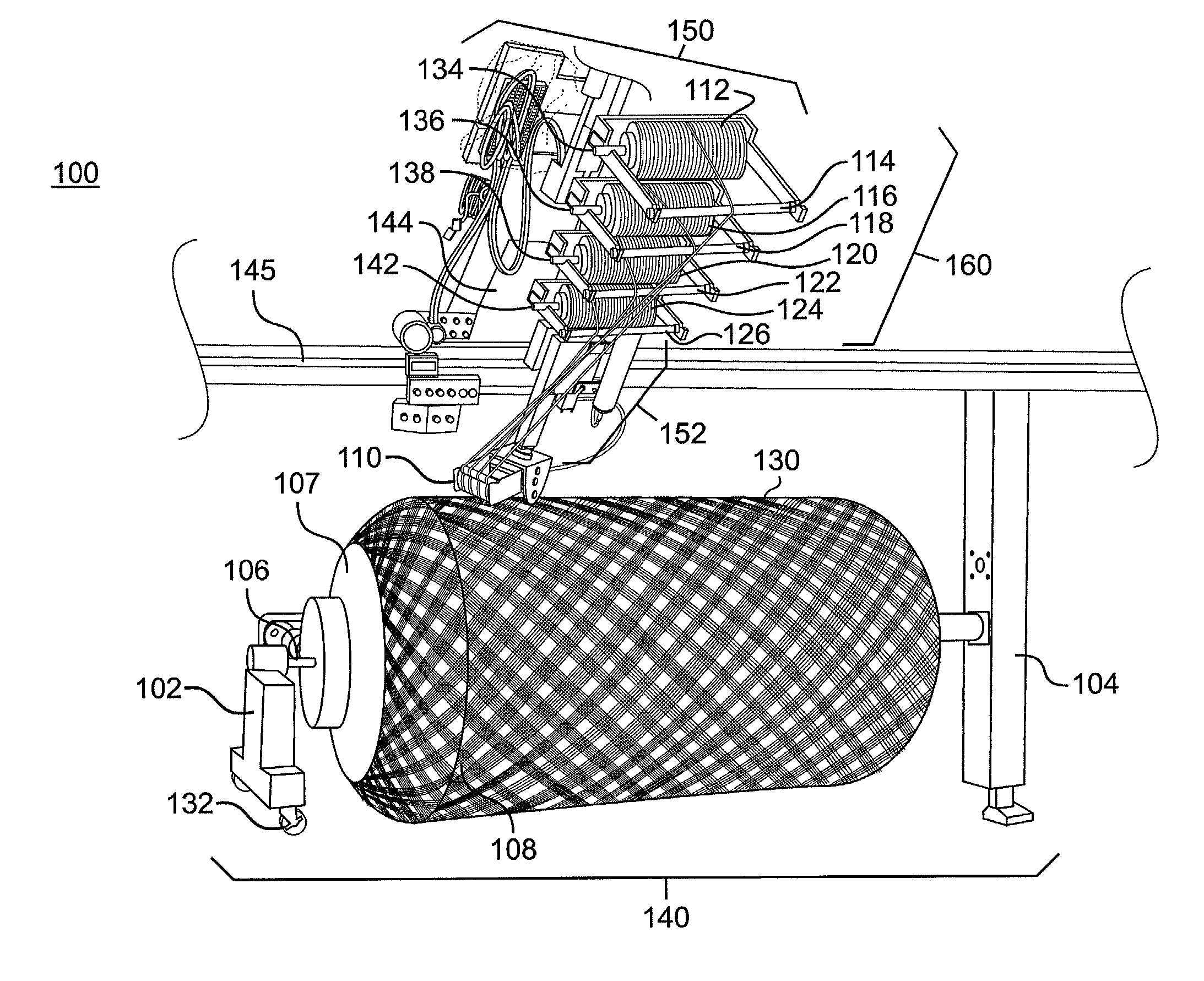

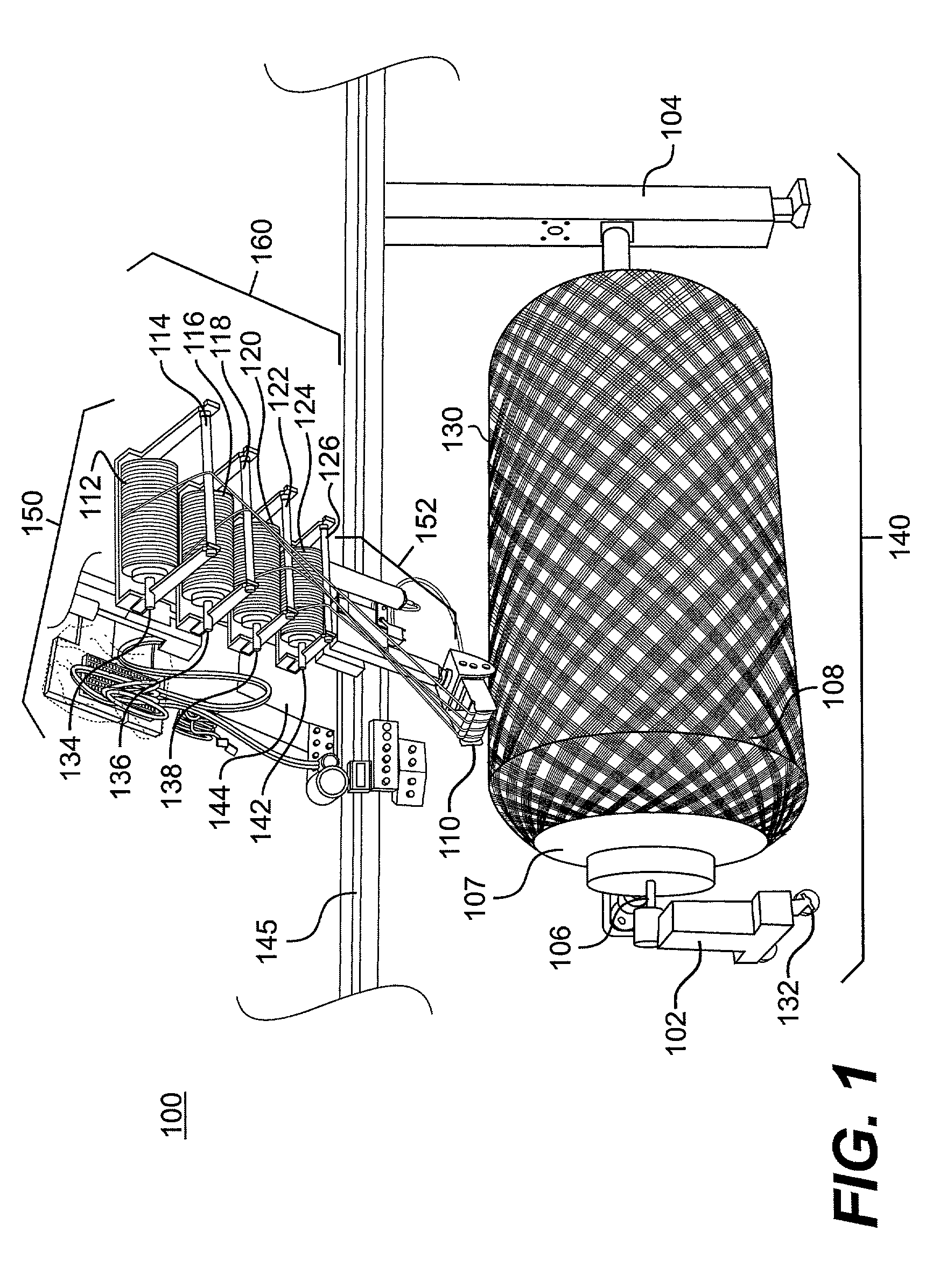

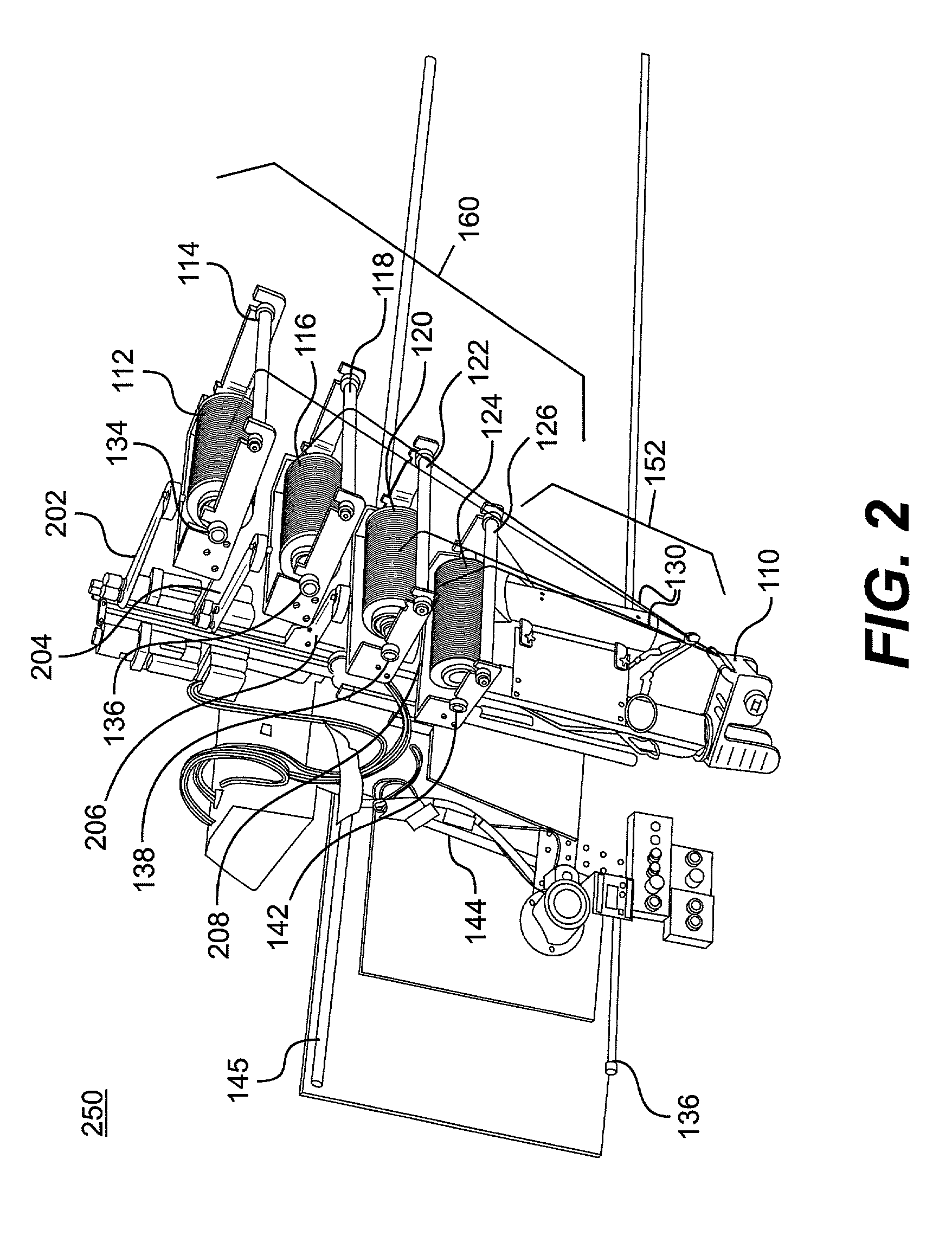

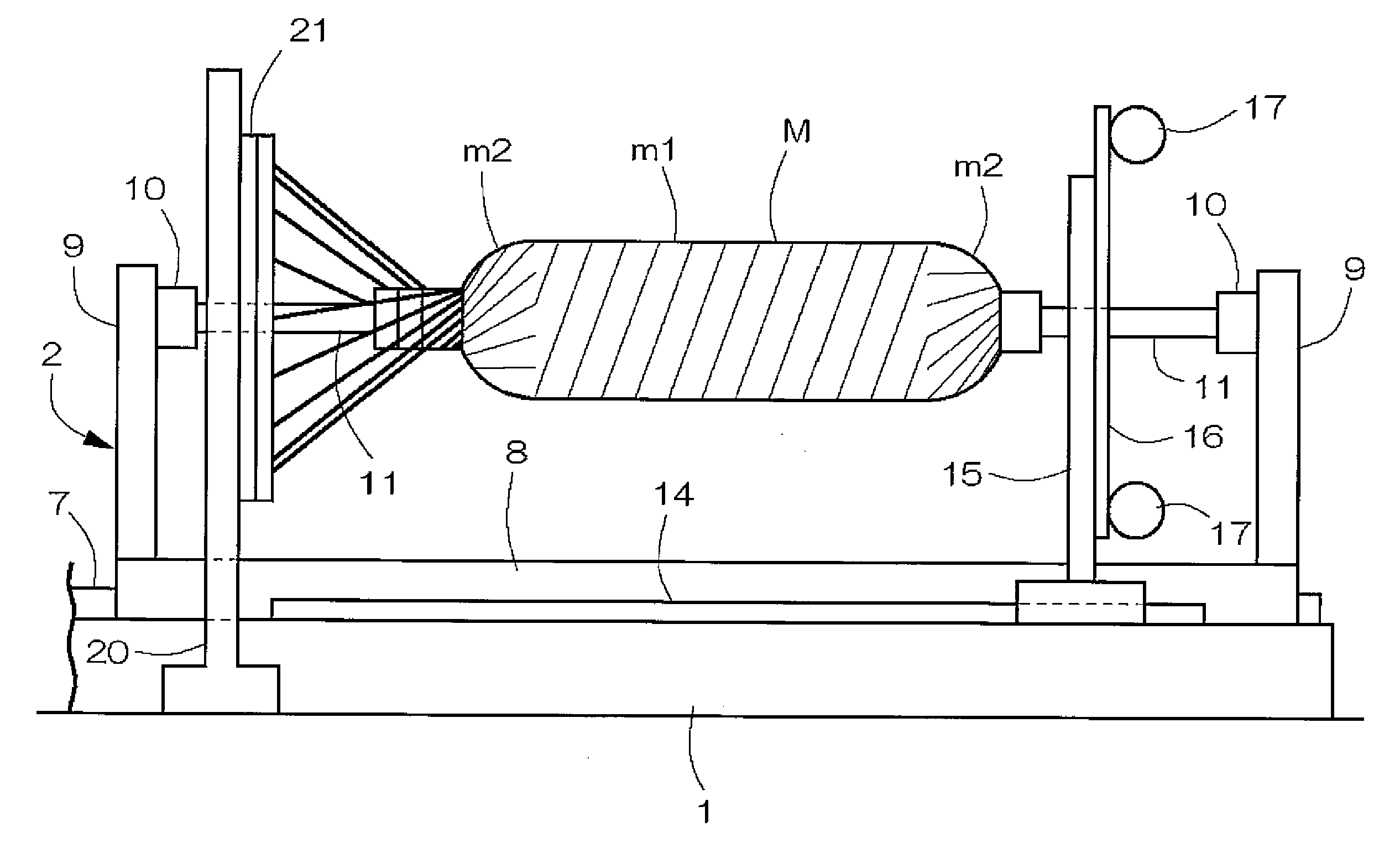

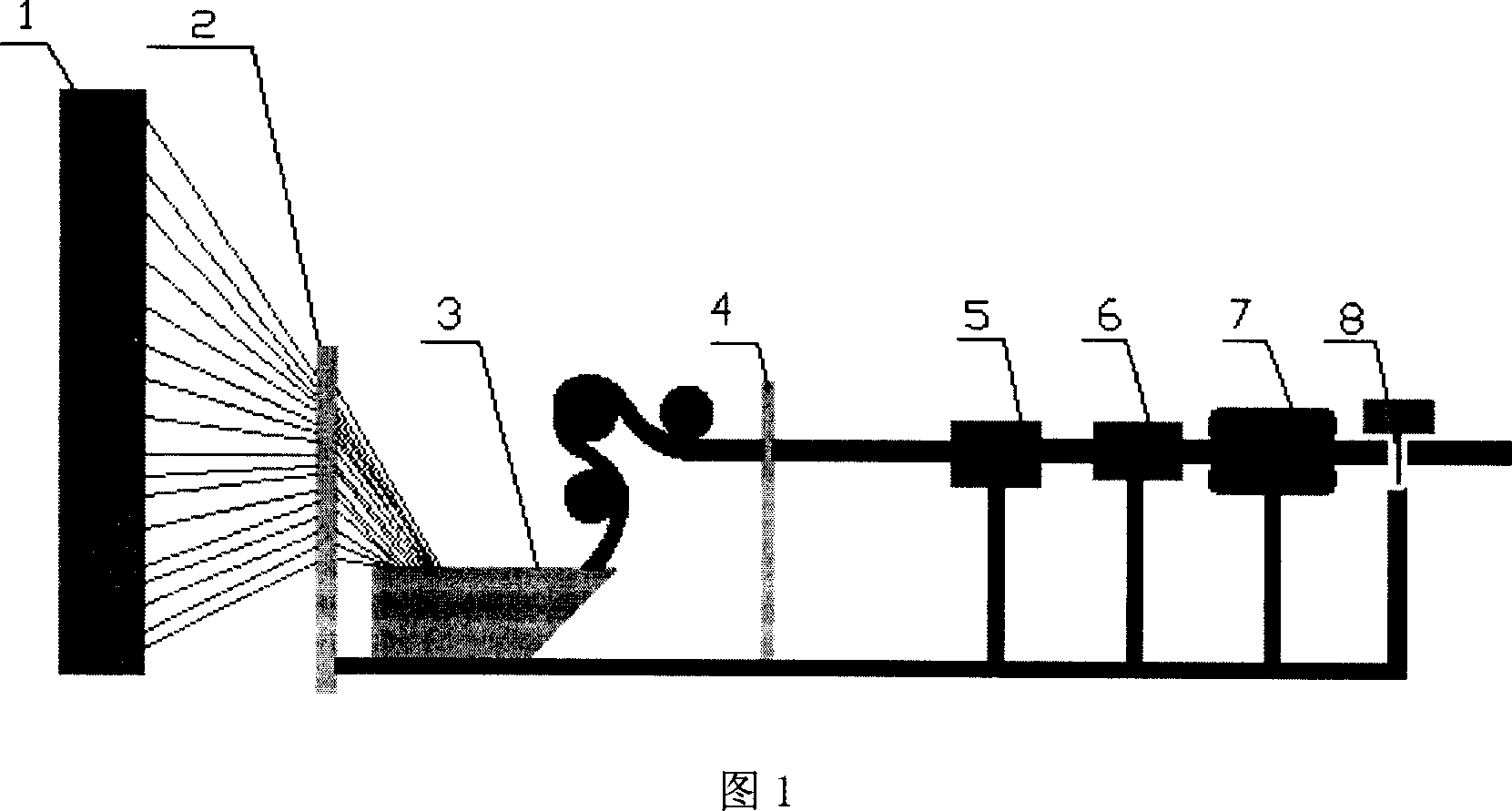

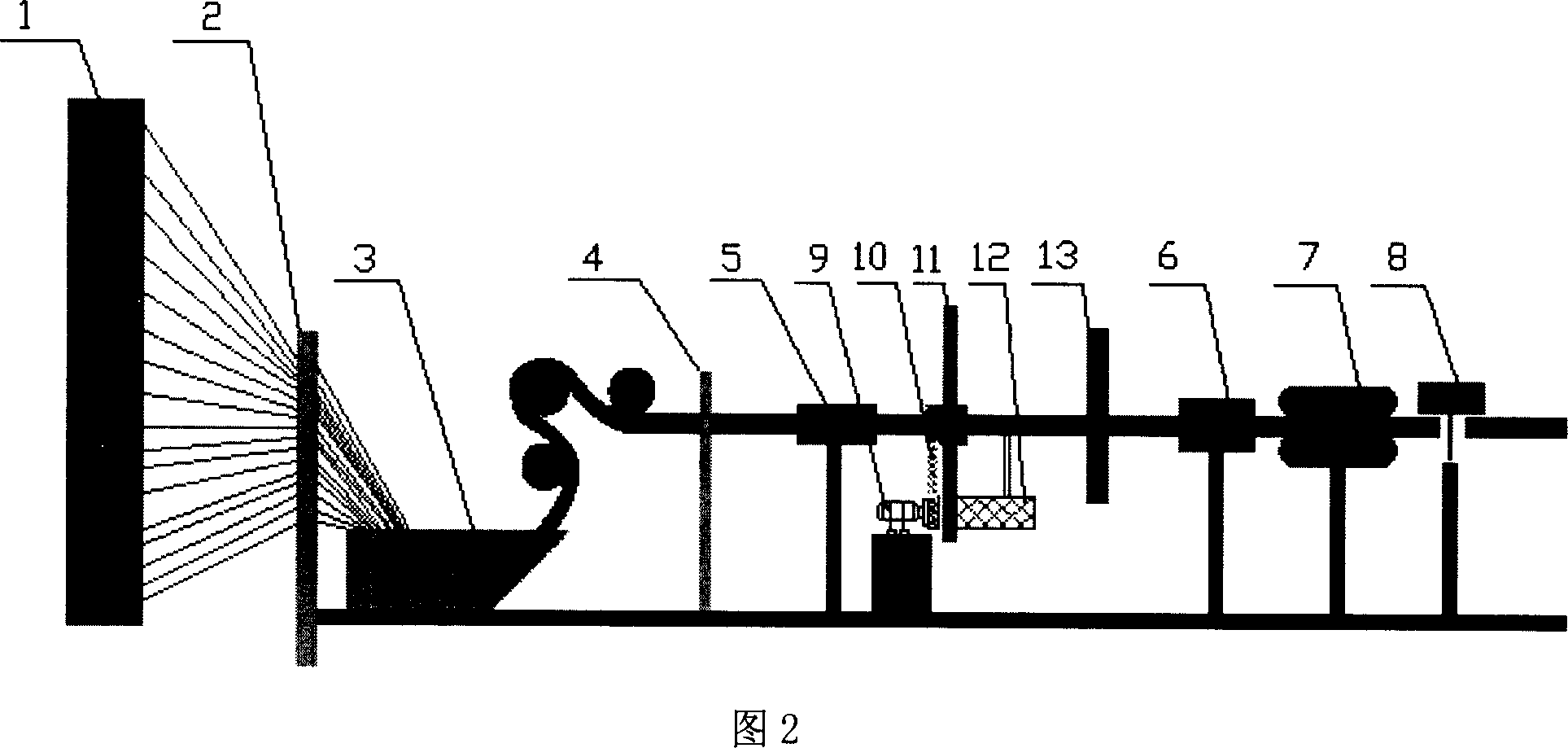

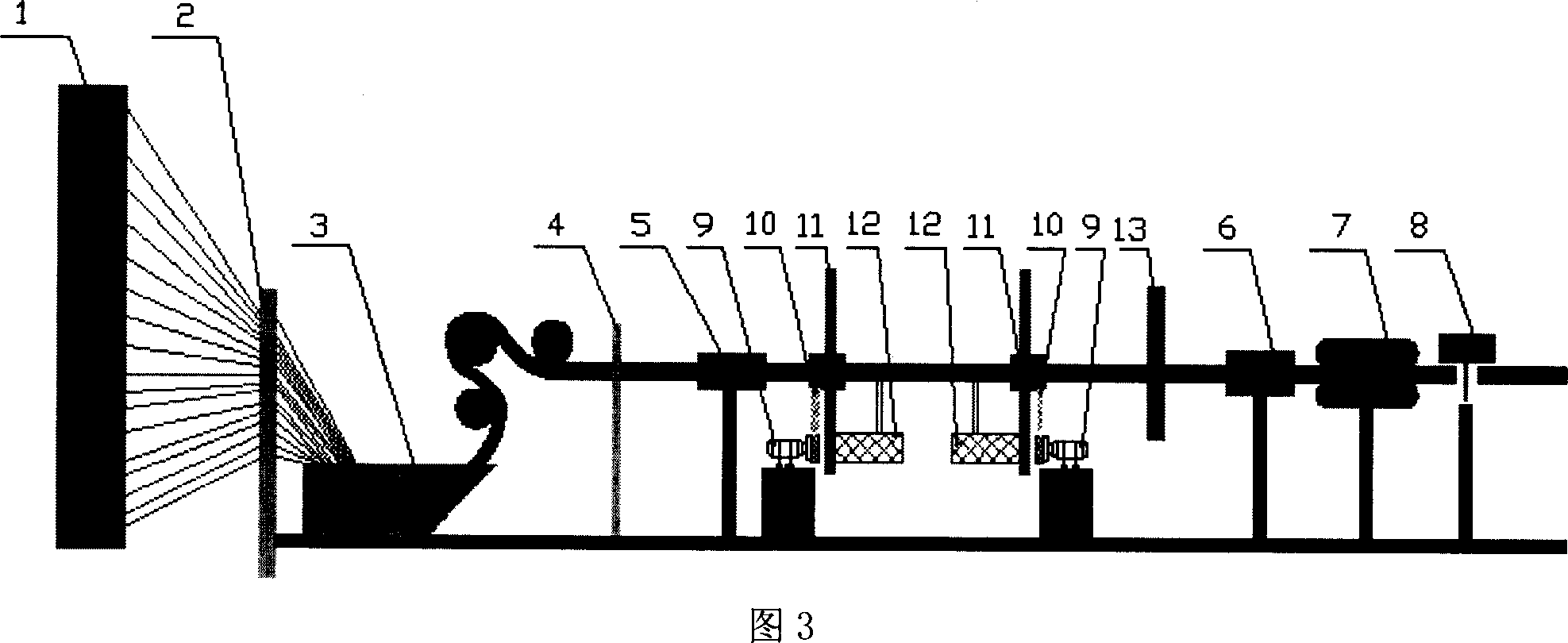

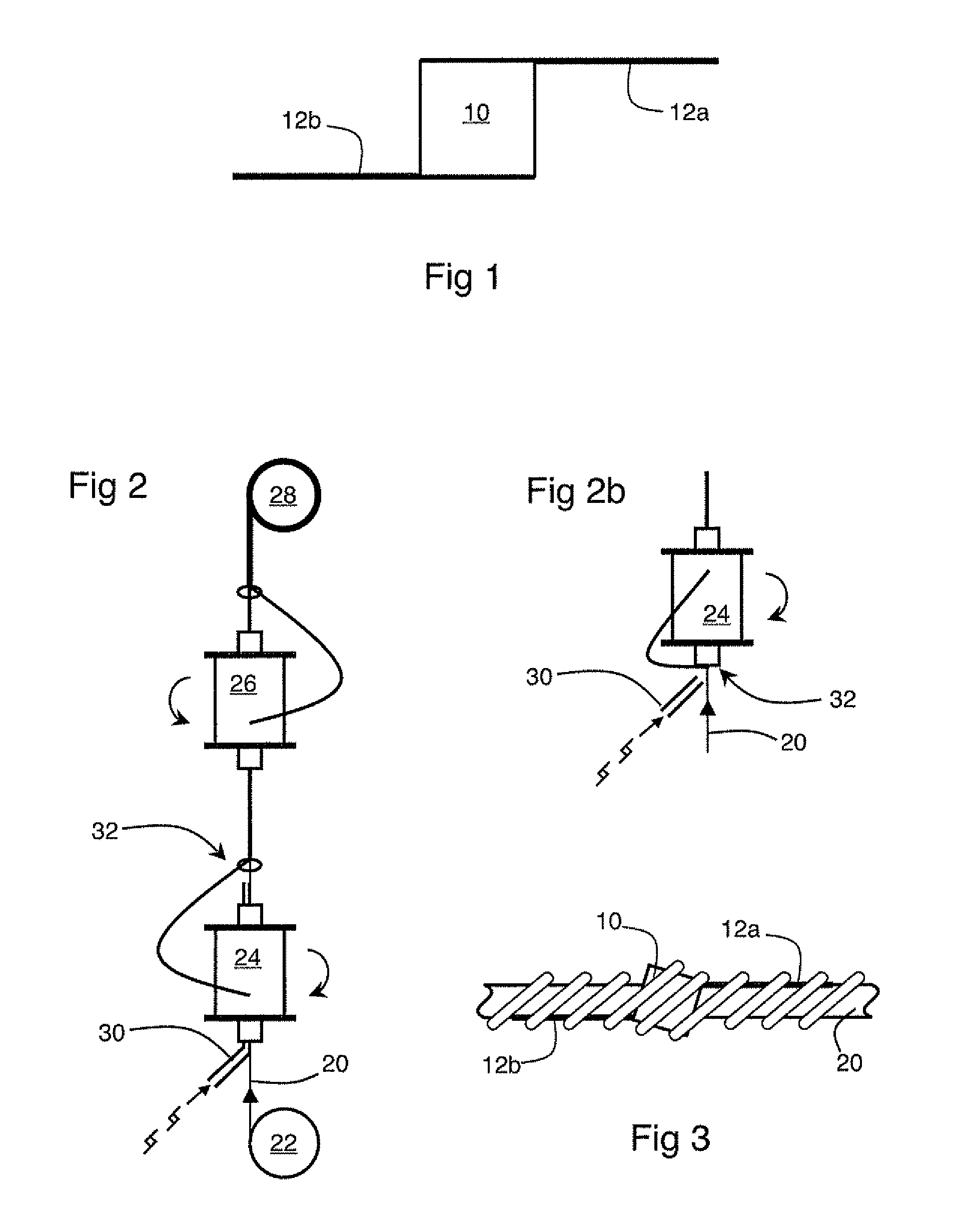

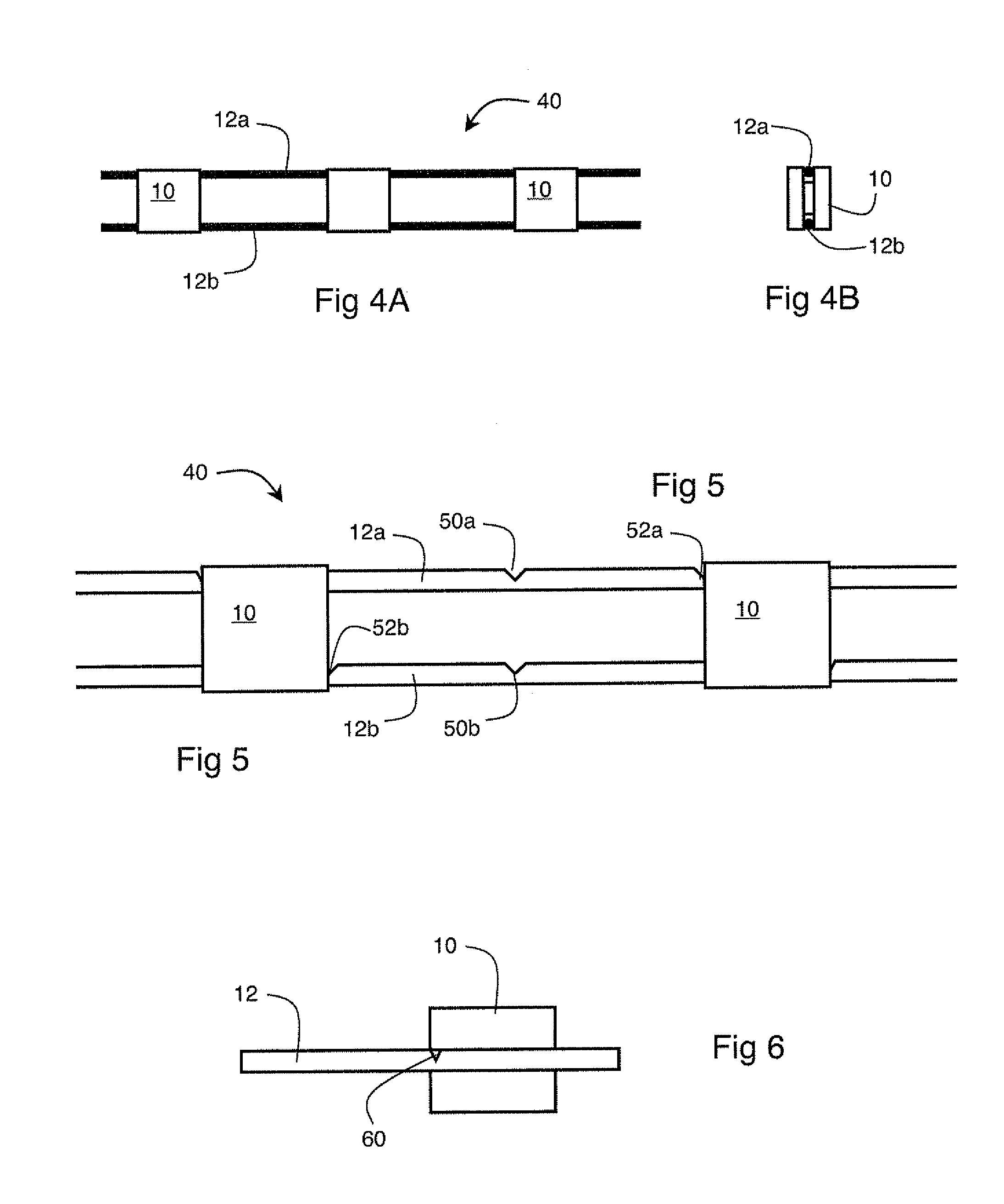

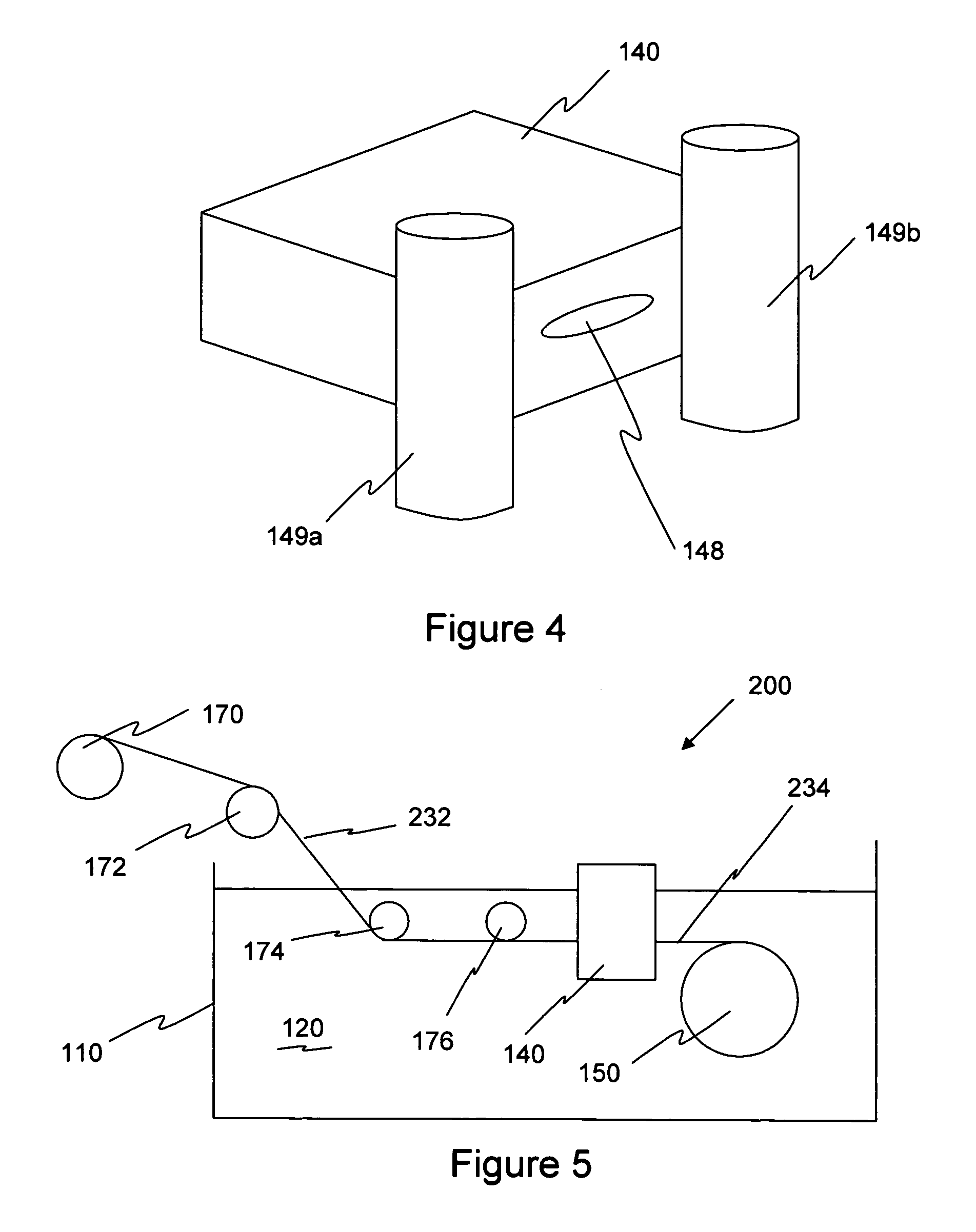

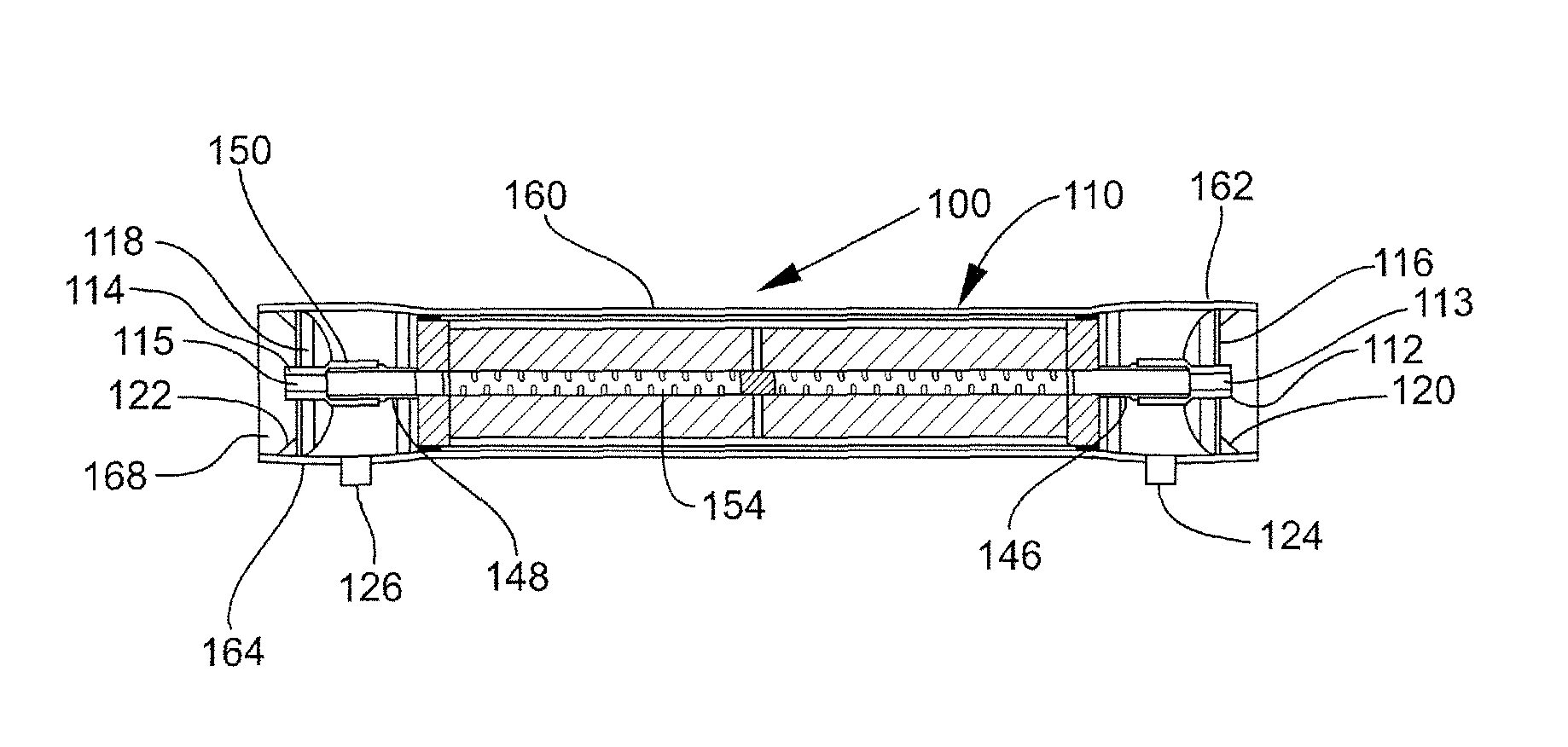

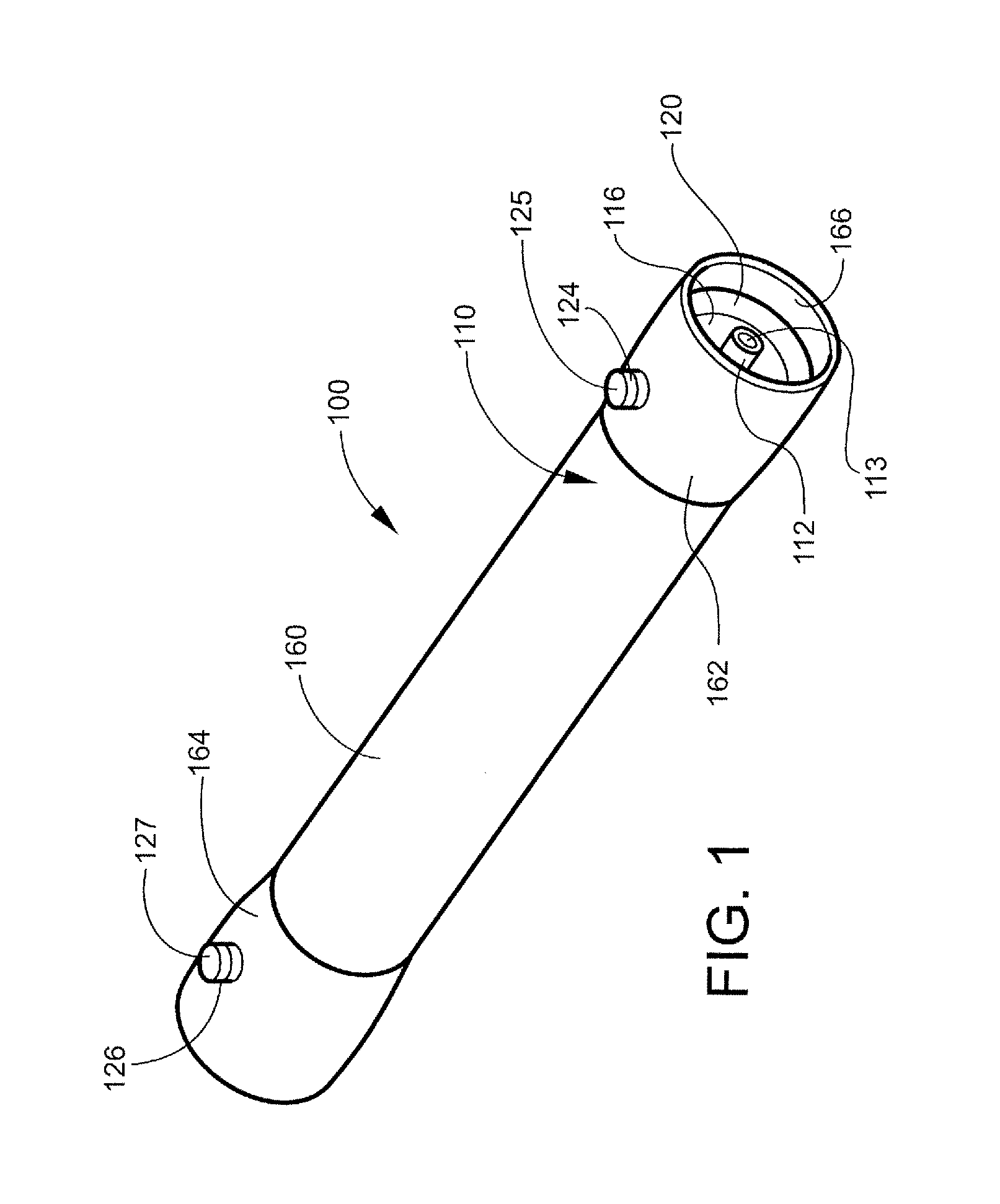

Filament winding apparatus and methods of winding filament

InactiveUS20030052212A1Thin and uniformThin and uniform skinFilament handlingDomestic articlesMechanical engineeringFilament winding

The present invention relates to apparatus and methods for winding filament to create a structure. In one embodiment, the invention includes the application of filament to a rotating mandrel to create a desired shape. The invention includes the filament winding of both simple and complex shapes.

Owner:TOYOTA MOTOR CO LTD

Pressure vessel and process for producing the same

InactiveUS7032769B2Light weightIncrease pressureVessel mounting detailsVessel manufacturingInternal pressureEngineering

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight,.but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability.The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

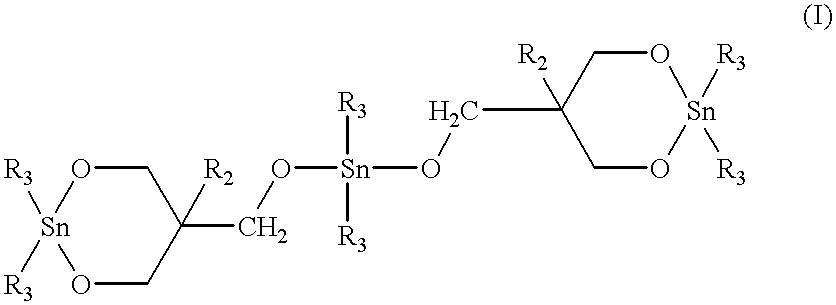

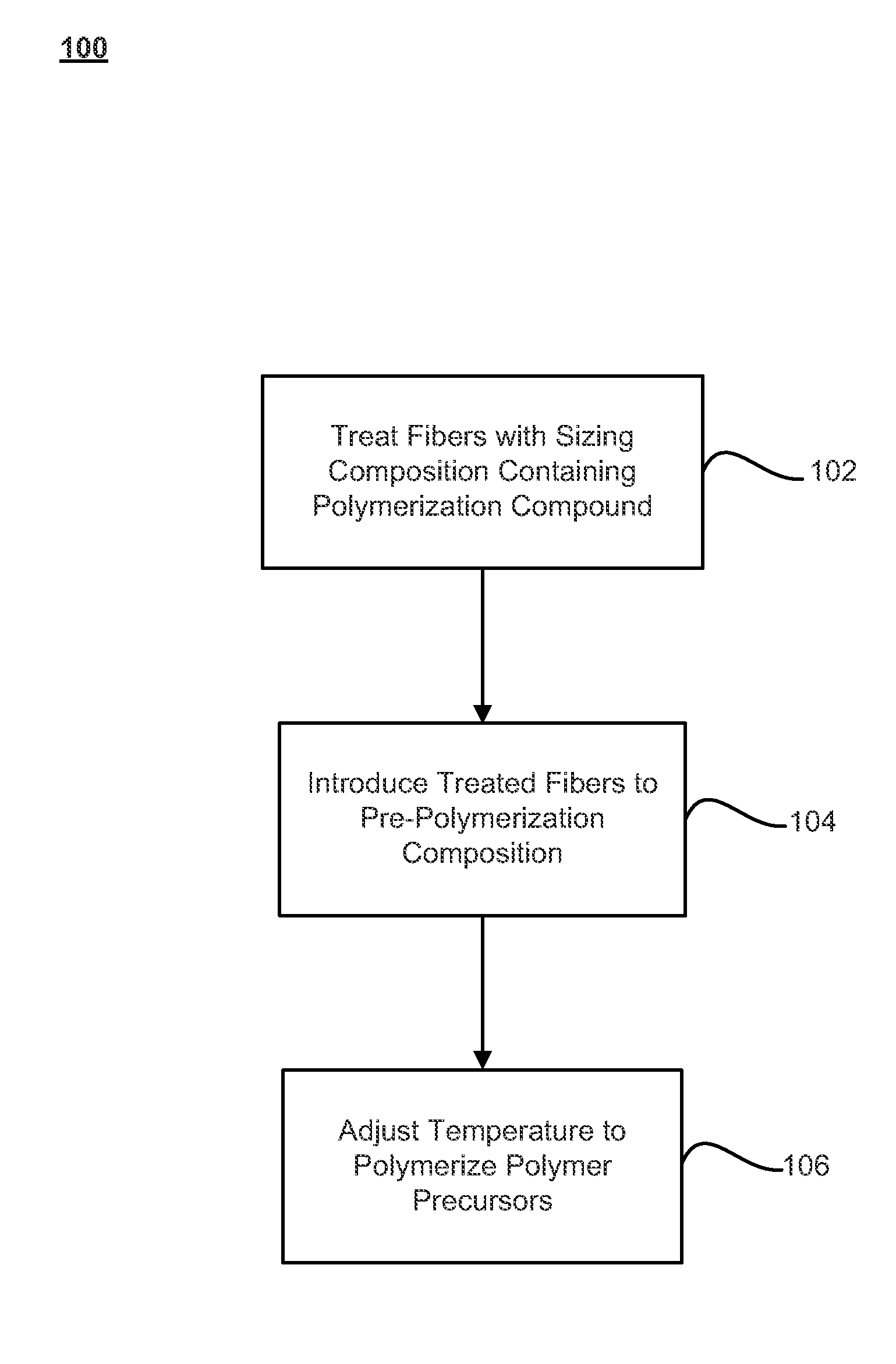

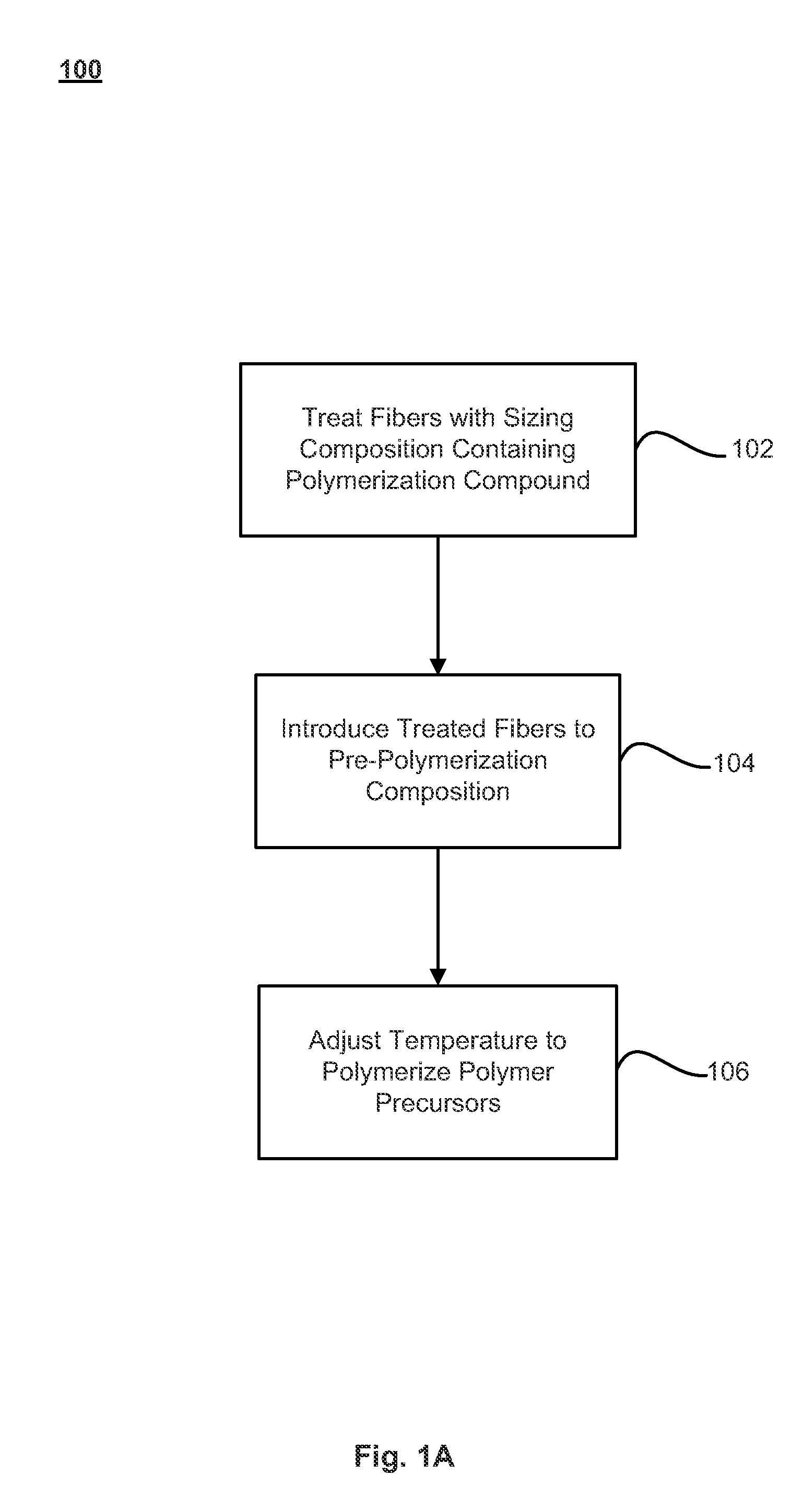

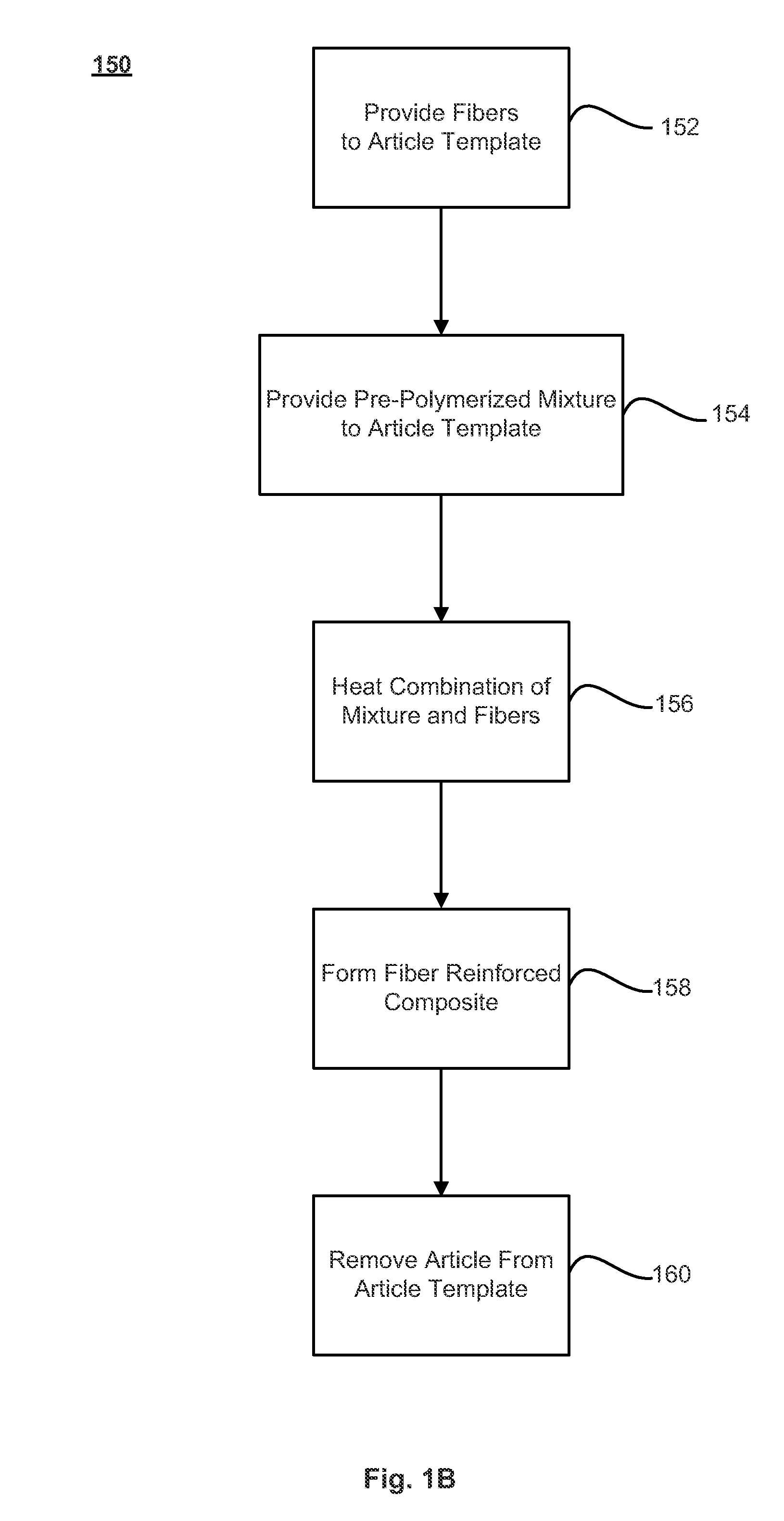

Fibers treated with polymerization compounds and fiber reinforced composites made therefrom

InactiveUS20110045275A1Group 4/14 element organic compoundsMolecular sieve catalystsFiber-reinforced compositePolymer chemistry

Methods of making fiber reinforced composite articles are described. The methods may include treating fibers with a sizing composition that includes a polymerization compound, and introducing the treated fibers to a pre-polymerized composition. The combination of the treated fibers and pre-polymerized composition may then undergo a temperature adjustment to a polymerization temperature at which the pre-polymerized composition polymerizes into a plastic around the fibers to form the fiber-reinforced composite article. Techniques for introducing the treated fibers to the pre-polymerized composition may include pultrusion, filament winding, reactive injection molding (RIM), structural reactive injection molding (SRIM), resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM), long fiber injection (LFI), sheet molding compound (SMC) molding, bulk molding compound (BMC) molding, a spray-up application, and / or a hand lay-up application, among other techniques.

Owner:TADEPALLI RAJAPPA +3

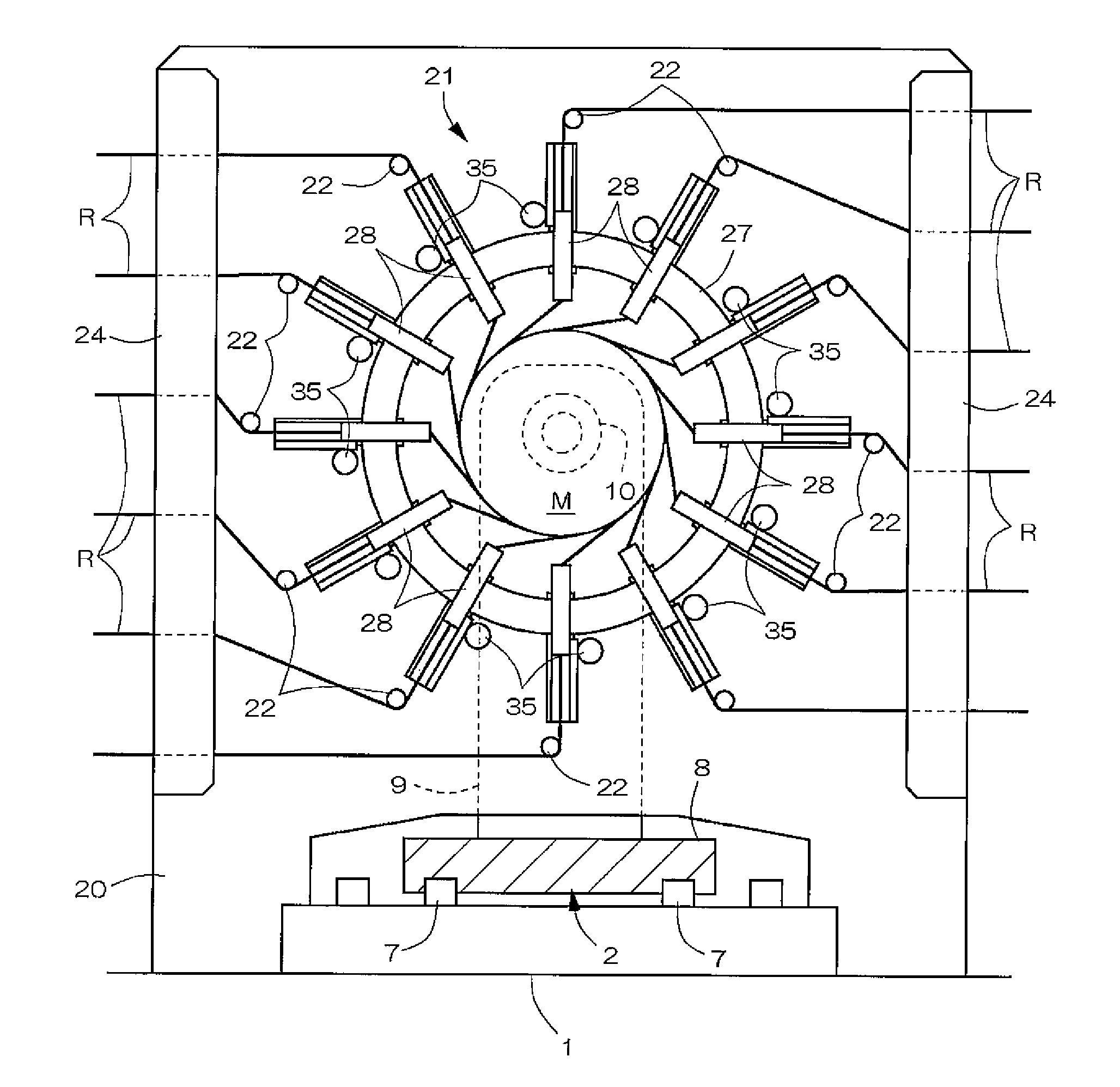

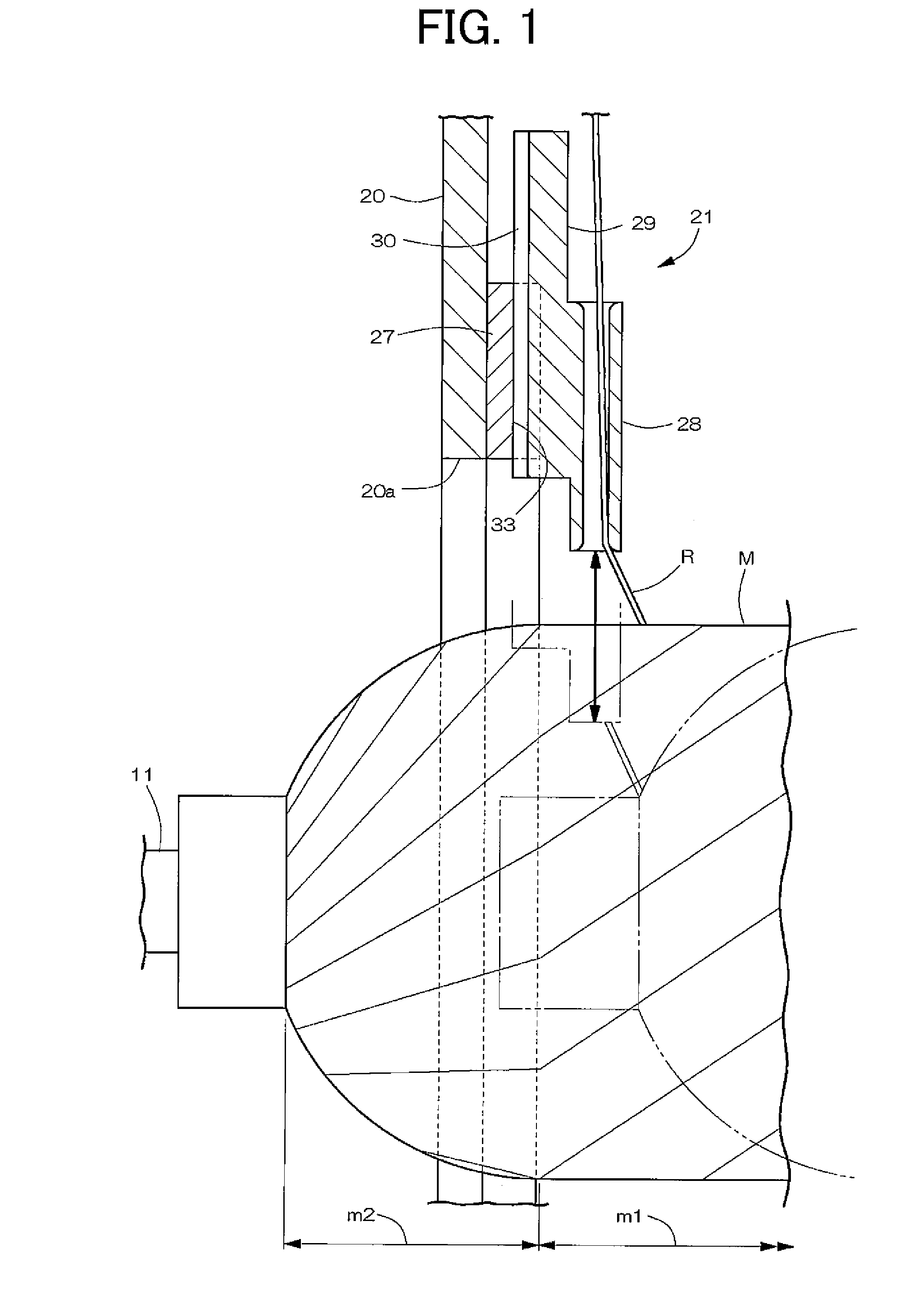

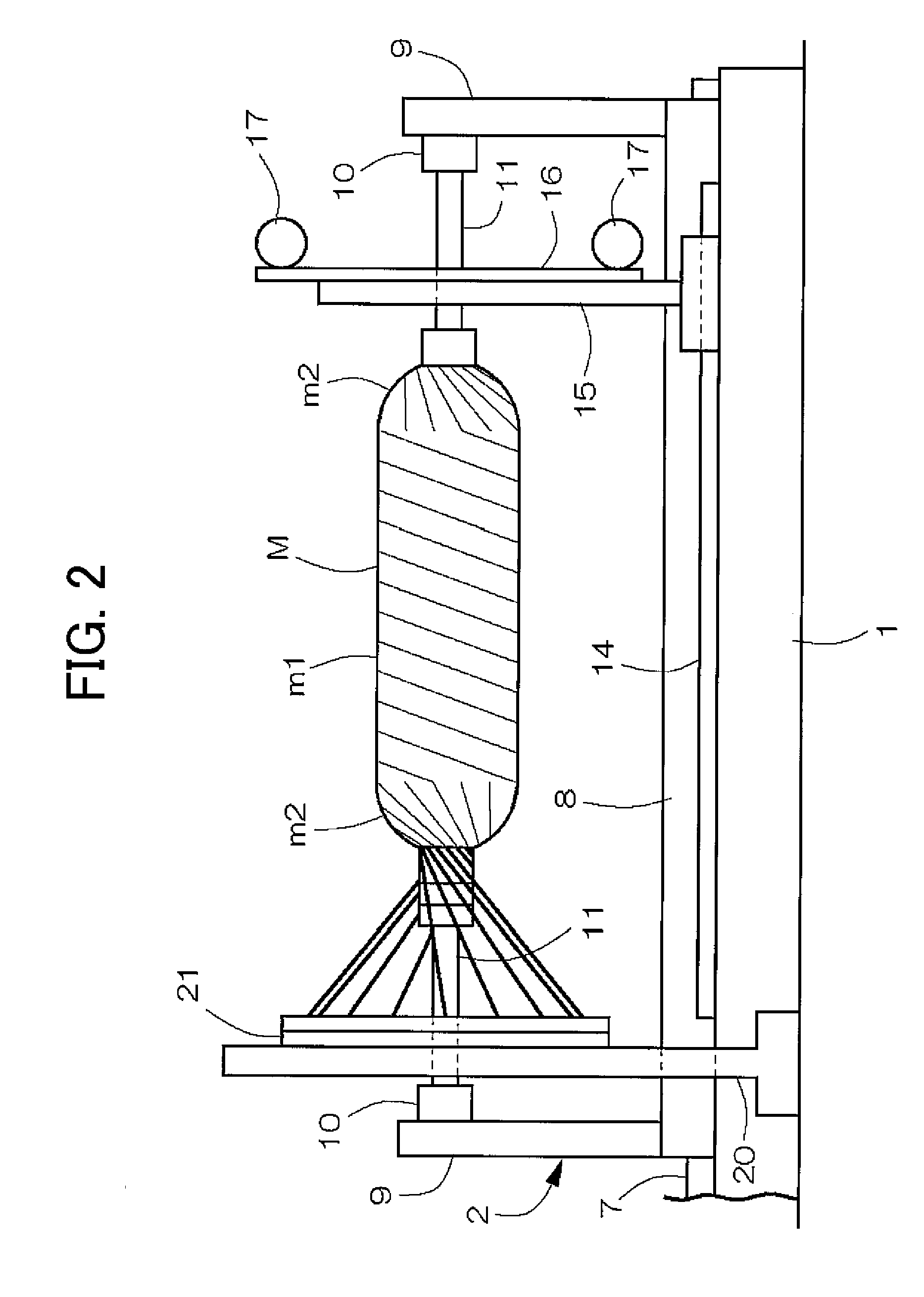

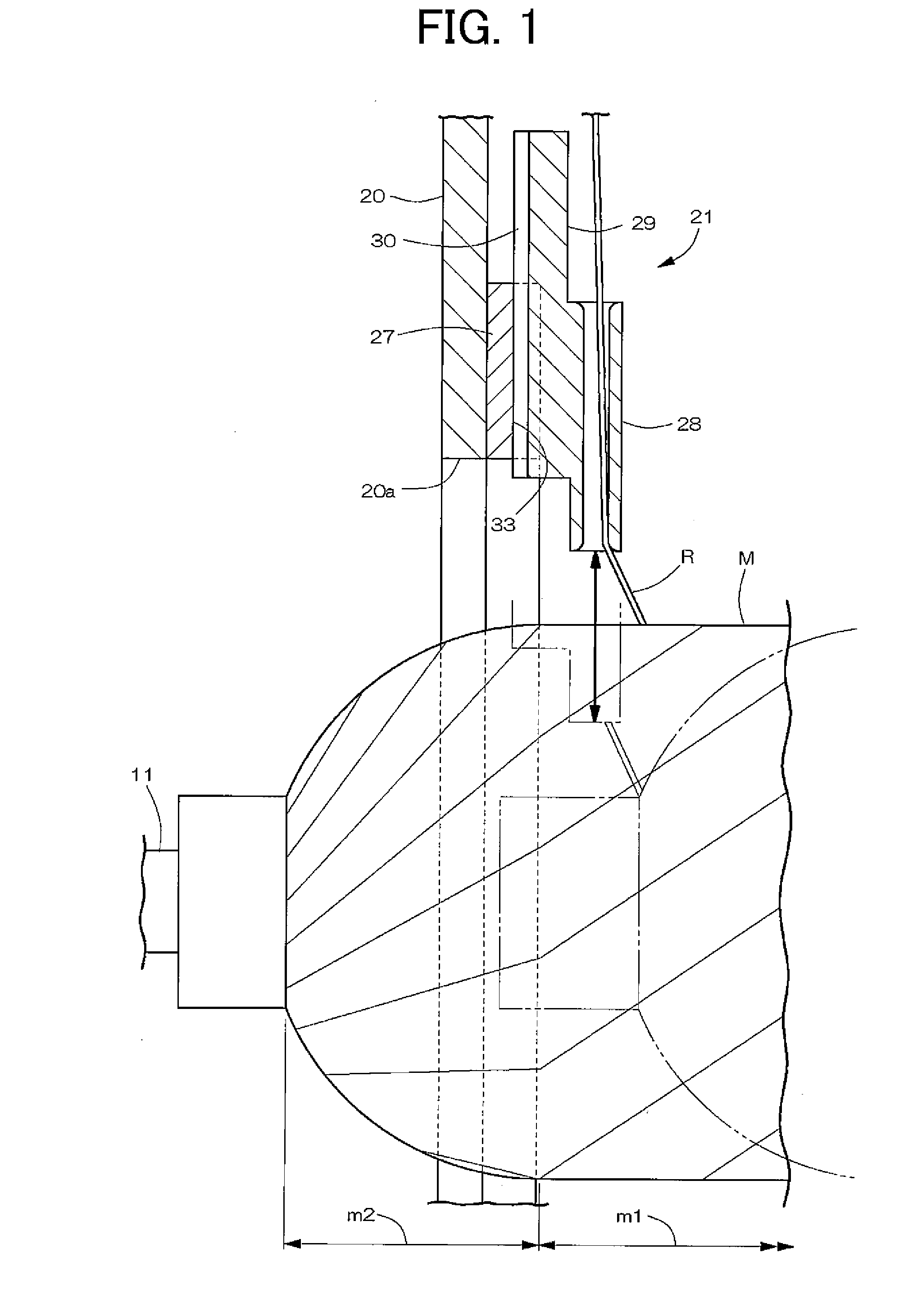

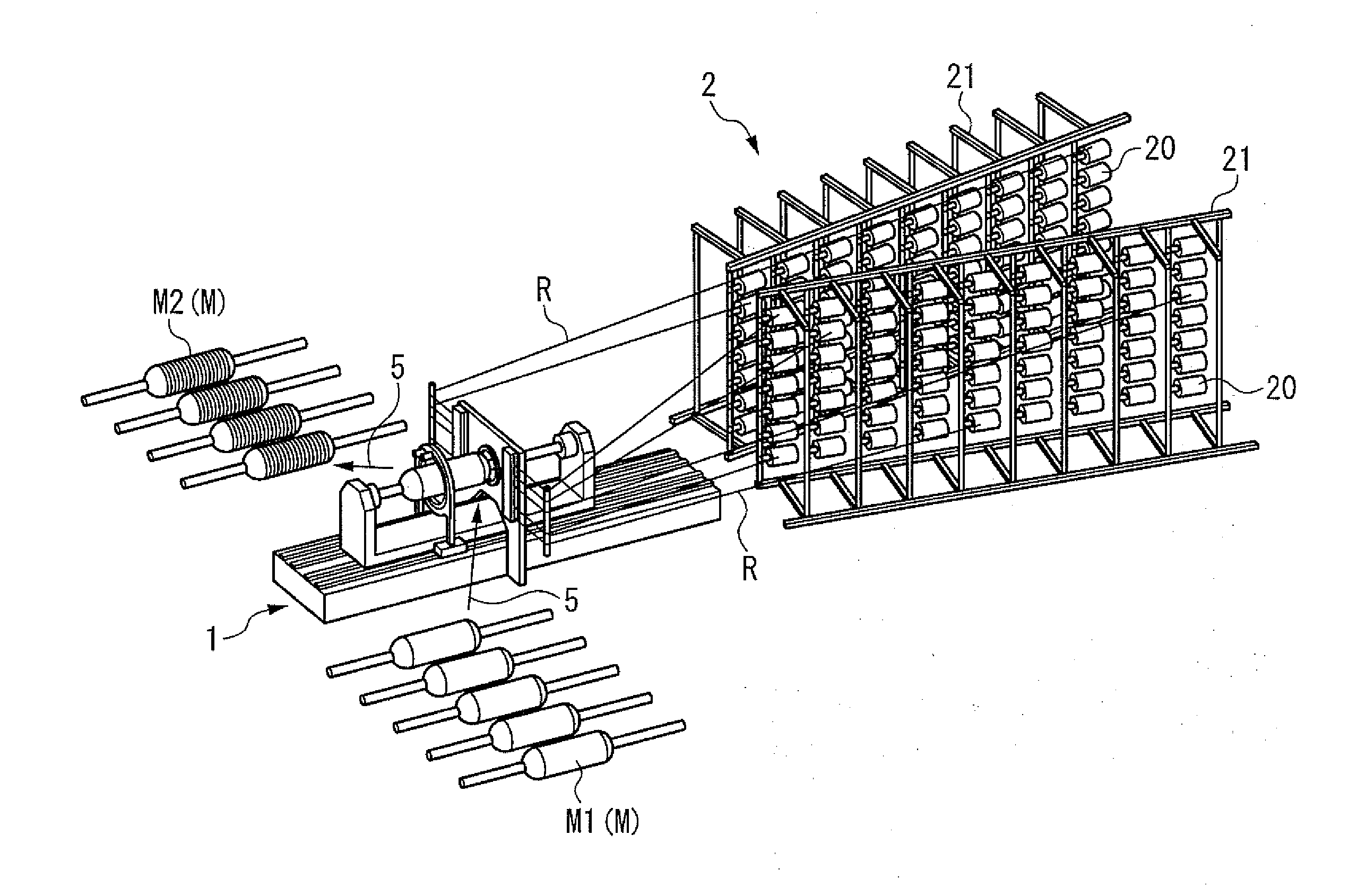

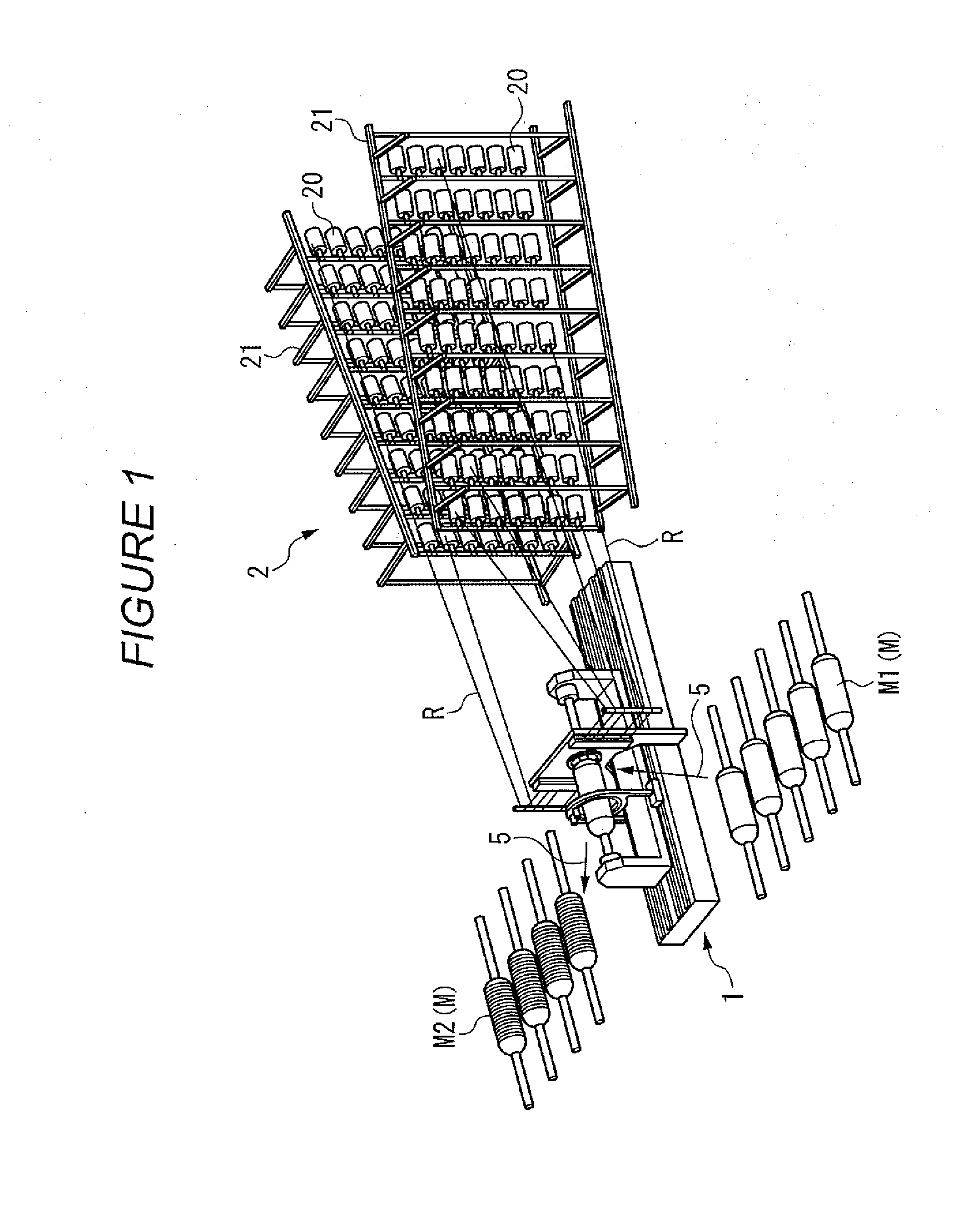

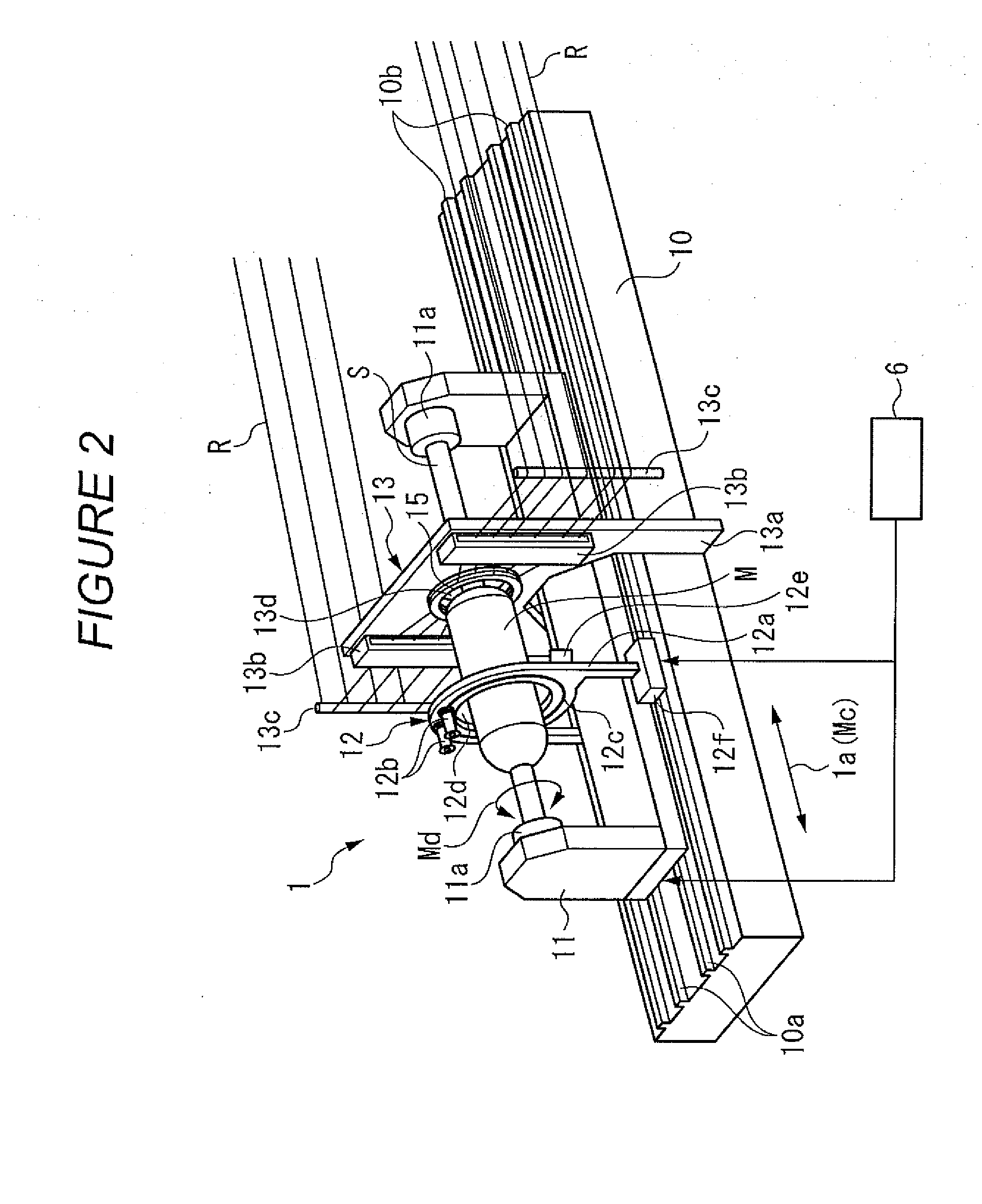

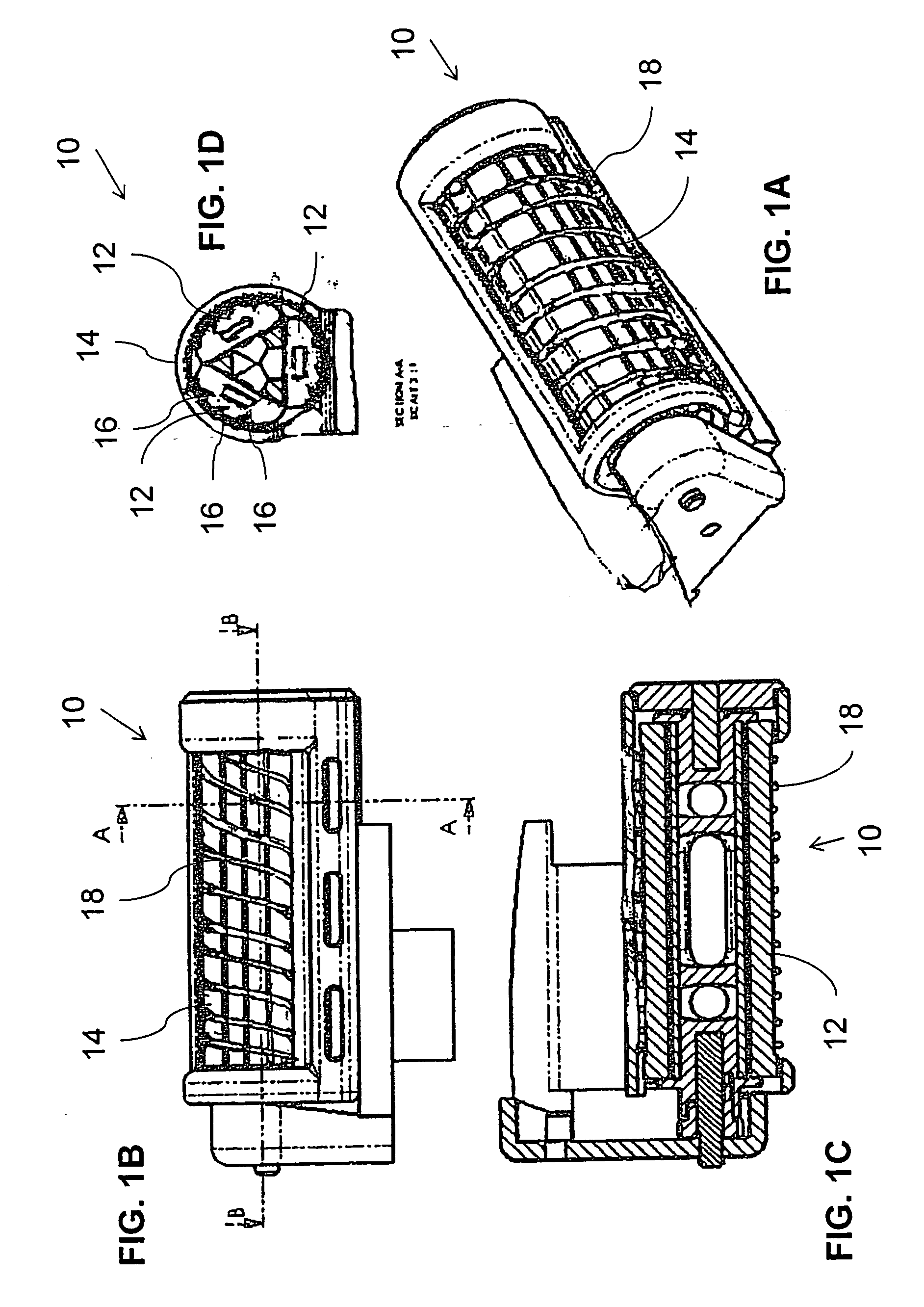

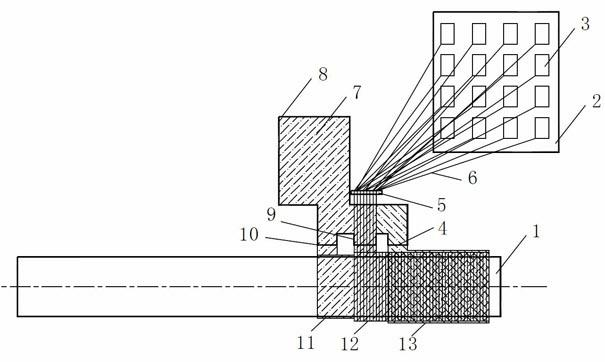

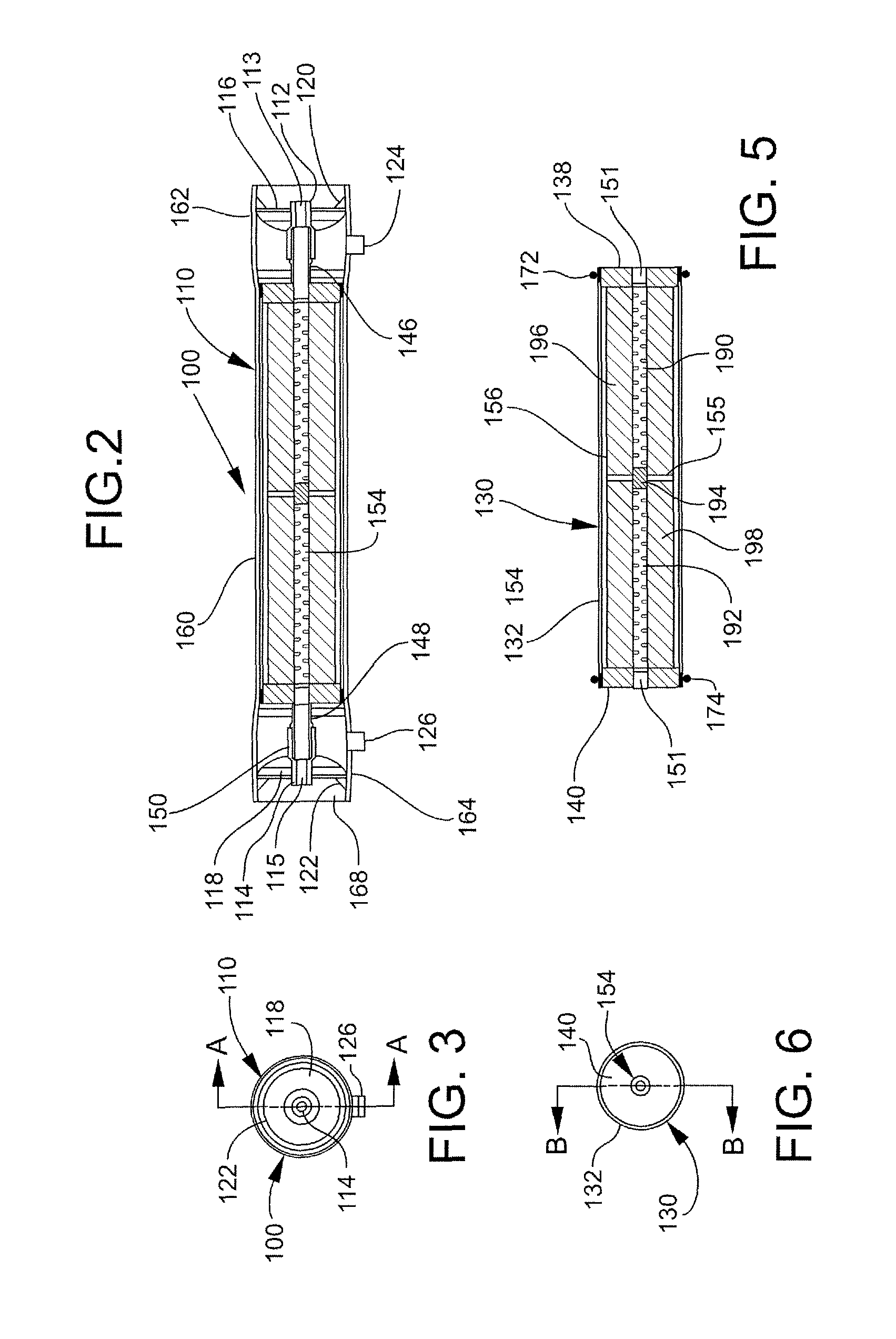

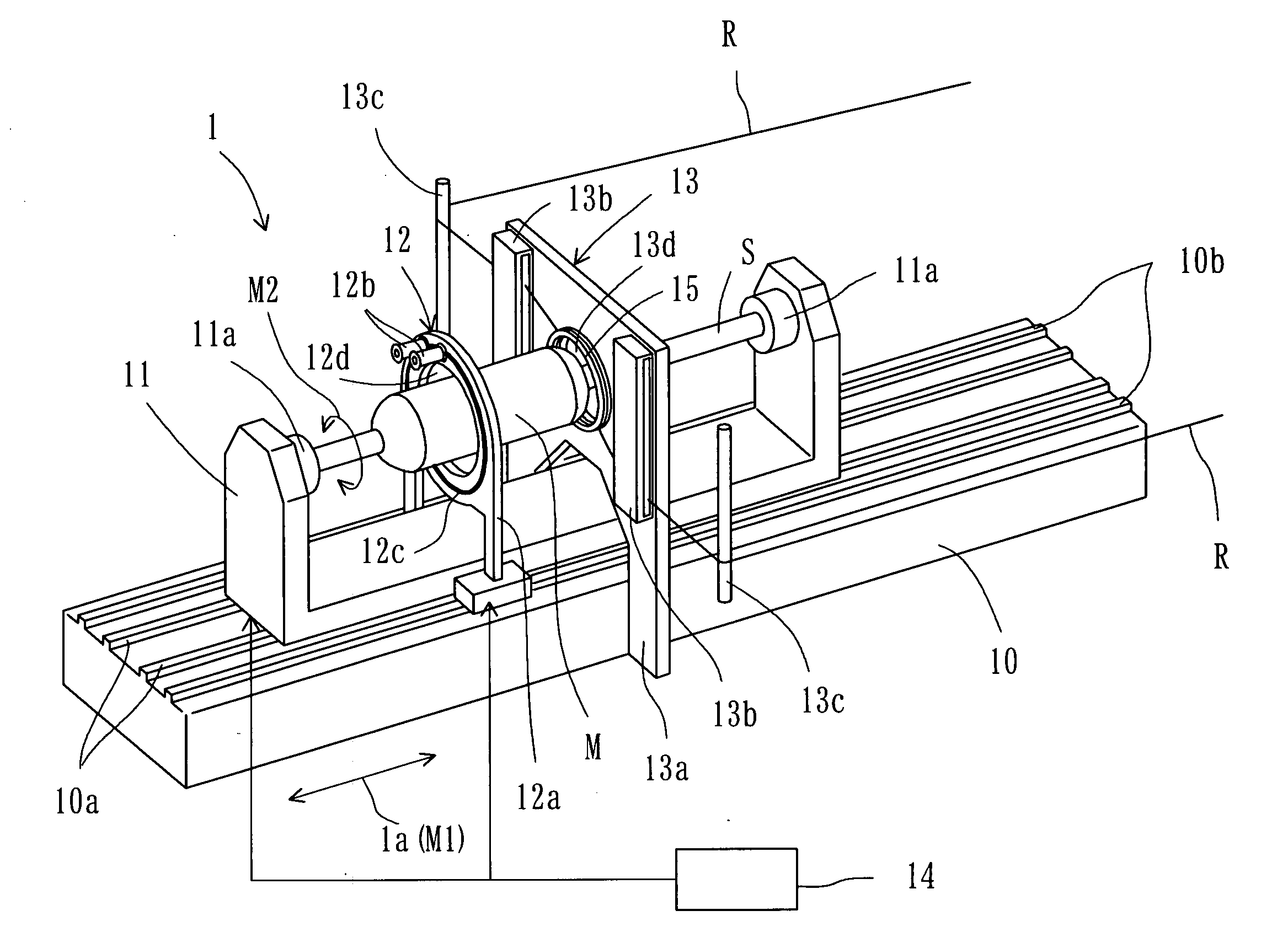

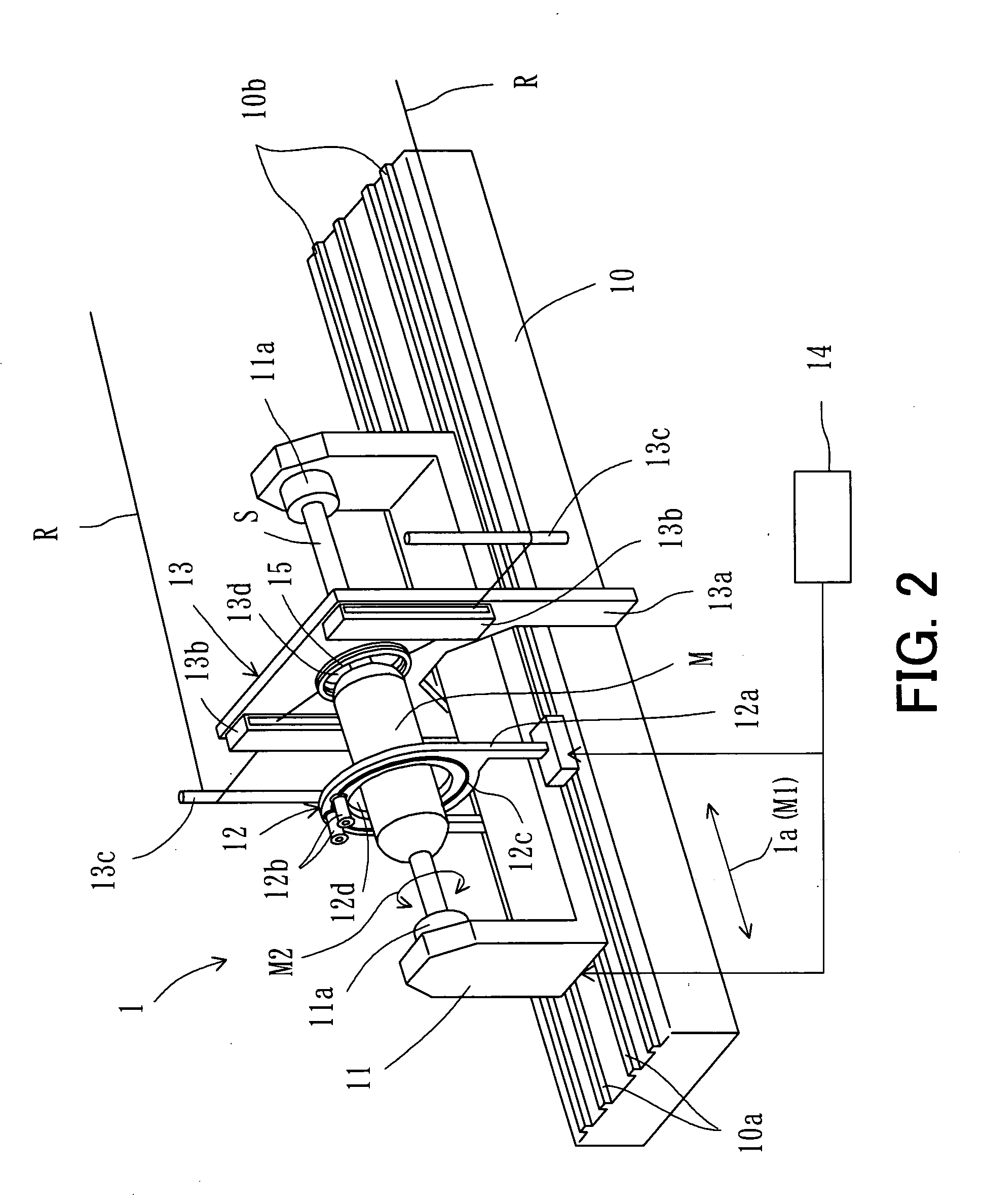

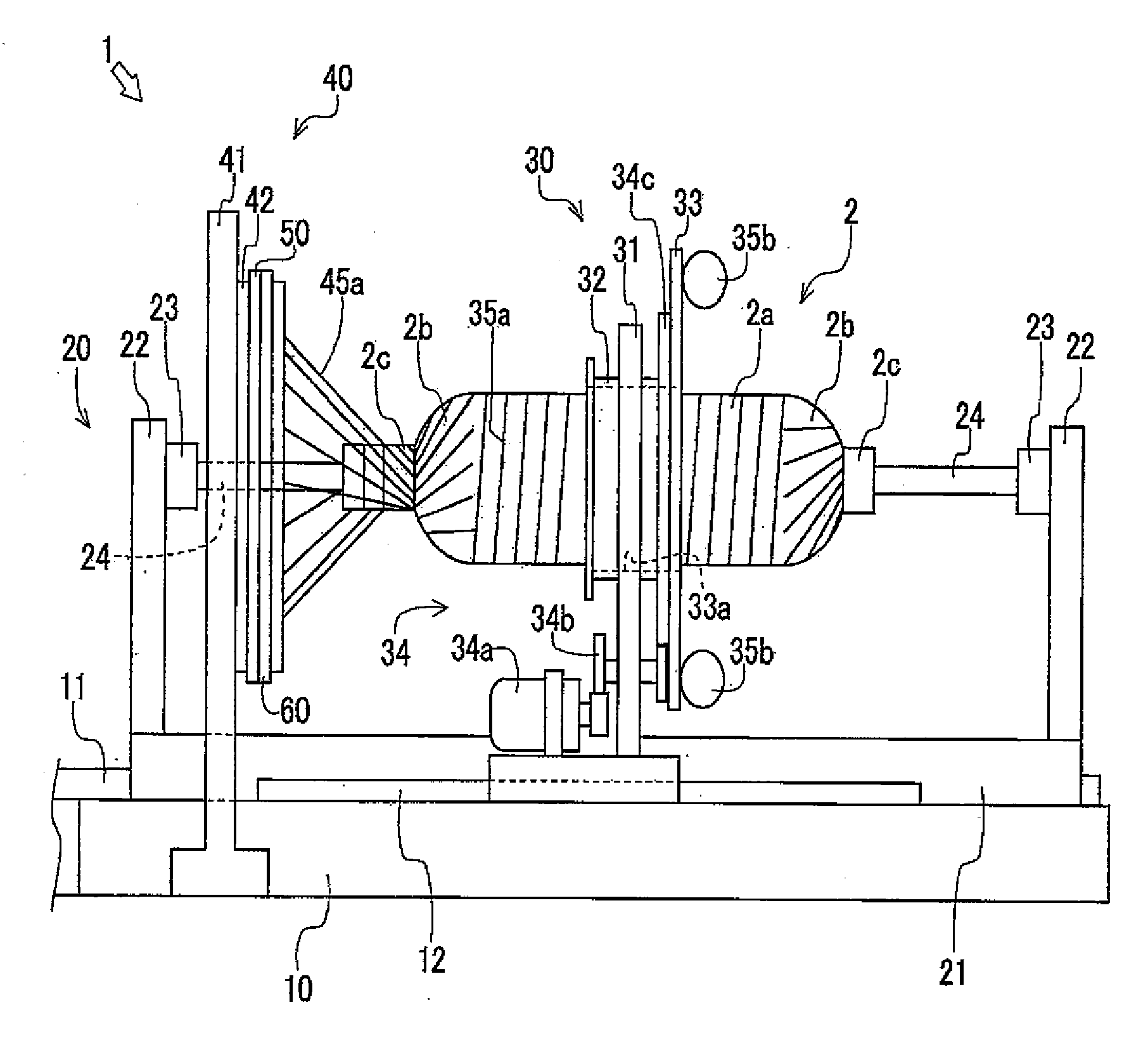

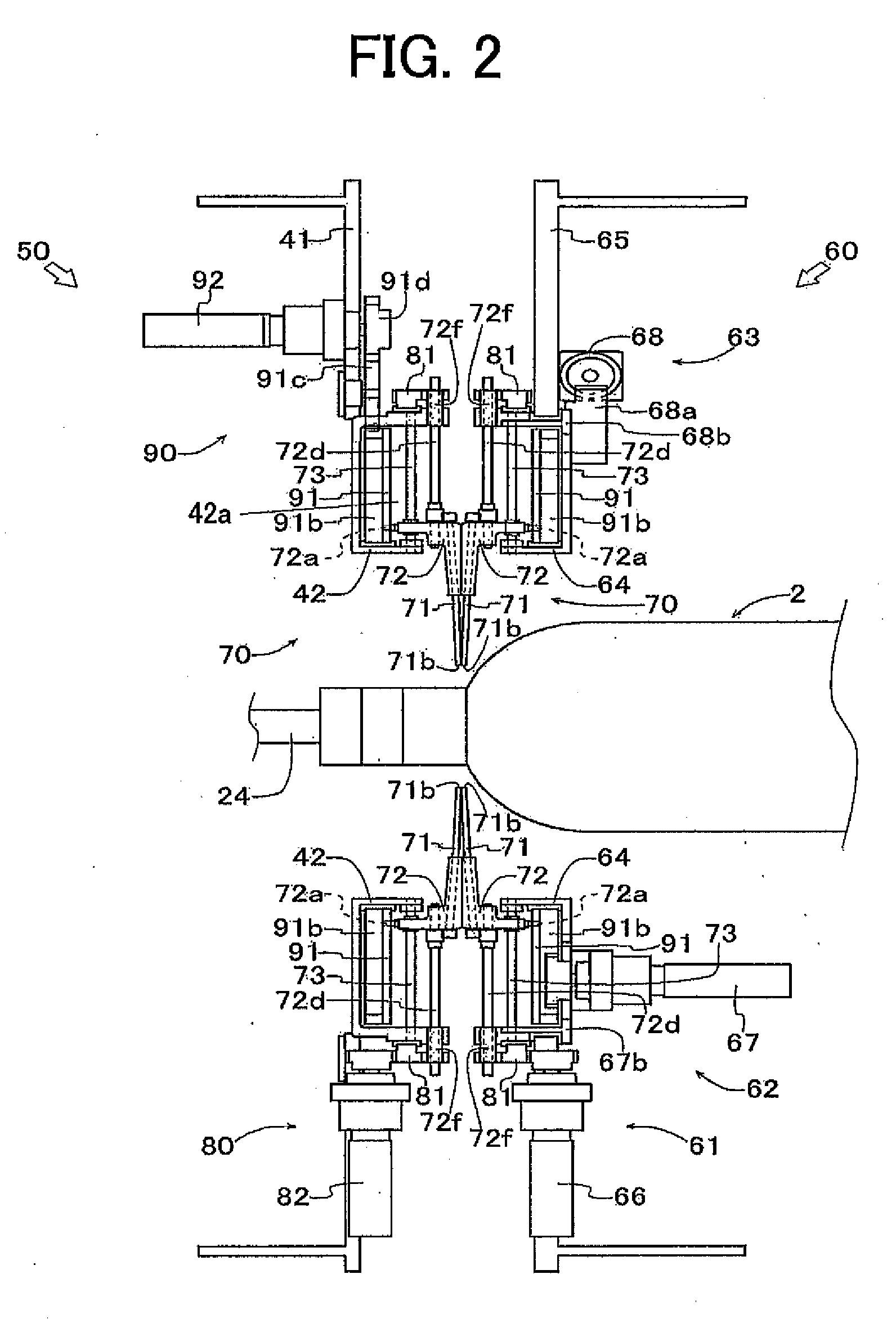

Filament winding apparatus

ActiveUS7815141B2Efficient executionWinding orderlyFilament handlingCoils manufactureFiber bundleReciprocating motion

A filament winding apparatus that efficiently and orderly winds a fiber bundle with respect to a mandrel in a short period of time. A supporting board supports the mandrel, and a helical winding head supplies and guides the fiber bundle towards the mandrel. The helical winding head includes a group of guide tubes radially arranged on a circumferential surface of a guide ring, and a tube operation mechanism that reciprocates the guide tube along a tube axis center direction. The guide tube is moved closer to a circumferential surface of the dome part when the guide tube is facing a dome part of the mandrel such that the distance between the winding position of the fiber bundle and the guide tube at the dome part can be reduced, and the fiber bundle is orderly wound according to an appropriate winding trajectory.

Owner:MURATA MASCH LTD

Manufacturing method for manual patch of heat insulating layer of filament winding engine shell

The invention discloses a manufacturing method for a manual patch of a heat insulating layer of a filament winding engine shell. By controlling the preparation environment of the manual patch, an appropriate adhesive is selected, a multilayer patching method is adopted to reduce the film thickness of a single-layer manual patch and patch size, then a fiber yarn is used for preloading pressure, and the heat insulating layer is repaired to increase the internal mass and shape structure size of the heat insulating layer after curing, thus manufacturing the manual patch. The manufacturing method solves the problems of high film hardness, poor self-adhesion and mutual viscosity, and high patching difficulty of an EPDM material, the thickness of the heat insulating layer meets the design requirements, and an EPDM anatomical layer is compact and smoothly passes engine ground test assessment for a few times.

Owner:航天科工火箭技术有限公司

Filament Winding Apparatus

ActiveUS20090127373A1Quality improvementReduce distanceFilament handlingCoils manufactureFiber bundleReciprocating motion

A filament winding apparatus that efficiently and orderly winds a fiber bundle with respect to a mandrel in a short period of time. A supporting board supports the mandrel, and a helical winding head supplies and guides the fiber bundle towards the mandrel. The helical winding head includes a group of guide tubes radially arranged on a circumferential surface of a guide ring, and a tube operation mechanism that reciprocates the guide tube along a tube axis center direction. The guide tube is moved closer to a circumferential surface of the dome part when the guide tube is facing a dome part of the mandrel such that the distance between the winding position of the fiber bundle and the guide tube at the dome part can be reduced, and the fiber bundle is orderly wound according to an appropriate winding trajectory.

Owner:MURATA MASCH LTD

Implantable textile prostheses having PTFE cold drawn yarns

InactiveUS7105021B2Highly oriented molecular structureUniform linear densitySurgeryCoatingsYarnUltimate tensile strength

The present invention provides an implantable prosthesis and more specifically, an implantable tubular textile prosthesis comprising a biocompatible fabric having inner and outer surfaces and first and second ends; the fabric having a textile construction comprising cold drawn PTFE yarns having a substantially uniform denier and high molecular orientation. Use of cold drawn PTFE yarns result in implantable prostheses that have excellent abrasion resistance, strength and lubricity properties. Useful textile constructions include weaves, knits, braids, filament windings, spun windings and combinations thereof. The prostheses of the present invention are lubricious and have characteristics that closely resemble the properties of a natural body lumen.

Owner:LIFESHIELD SCI

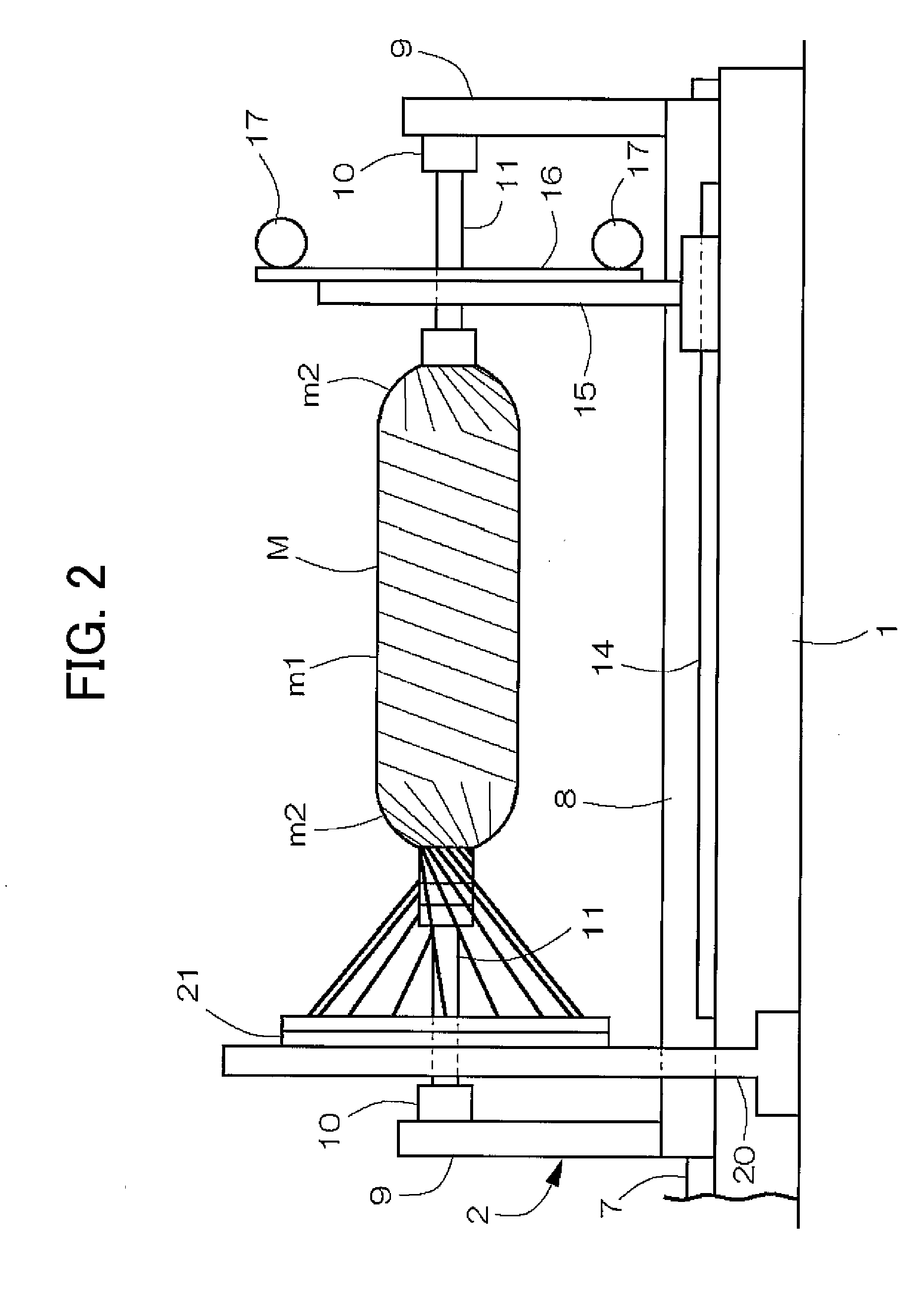

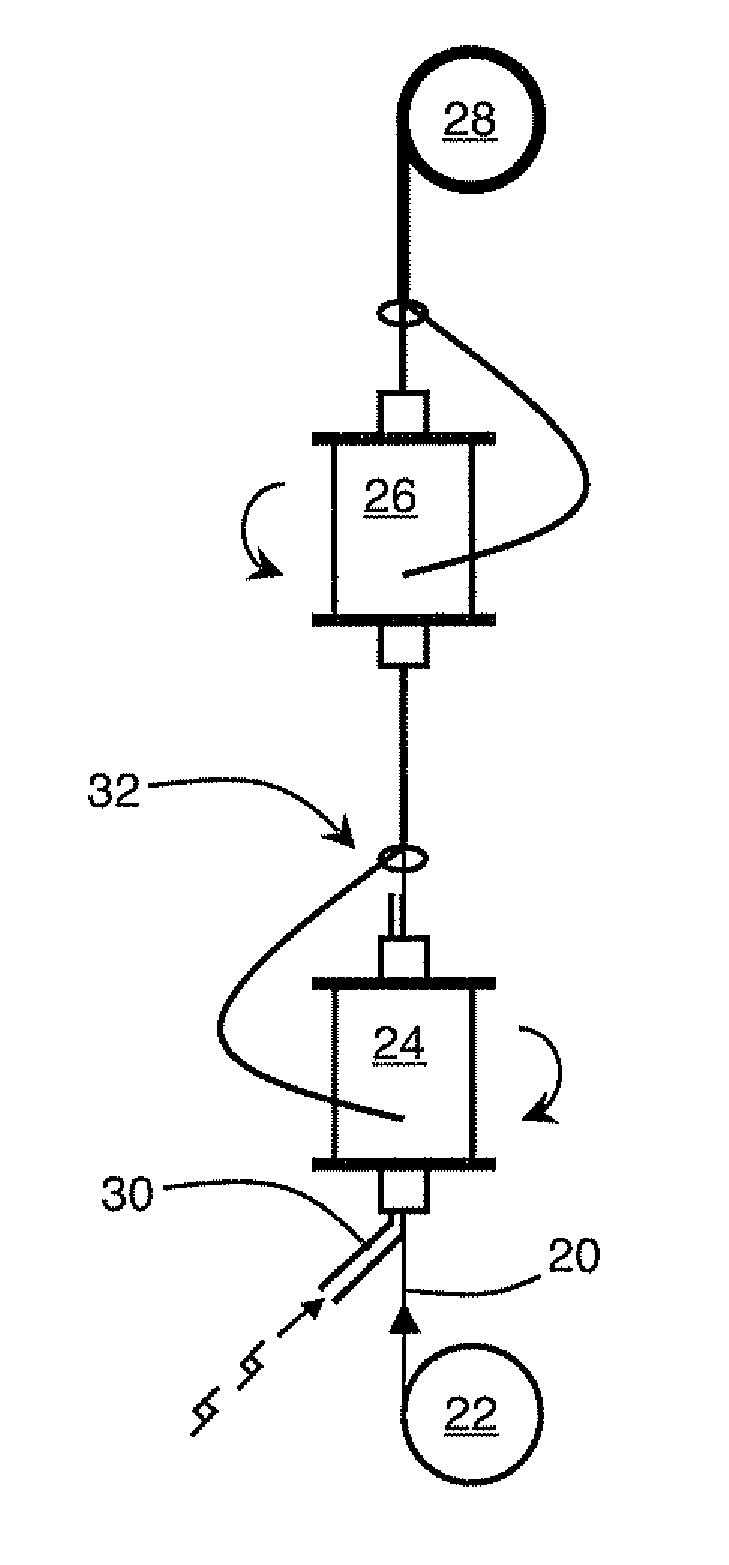

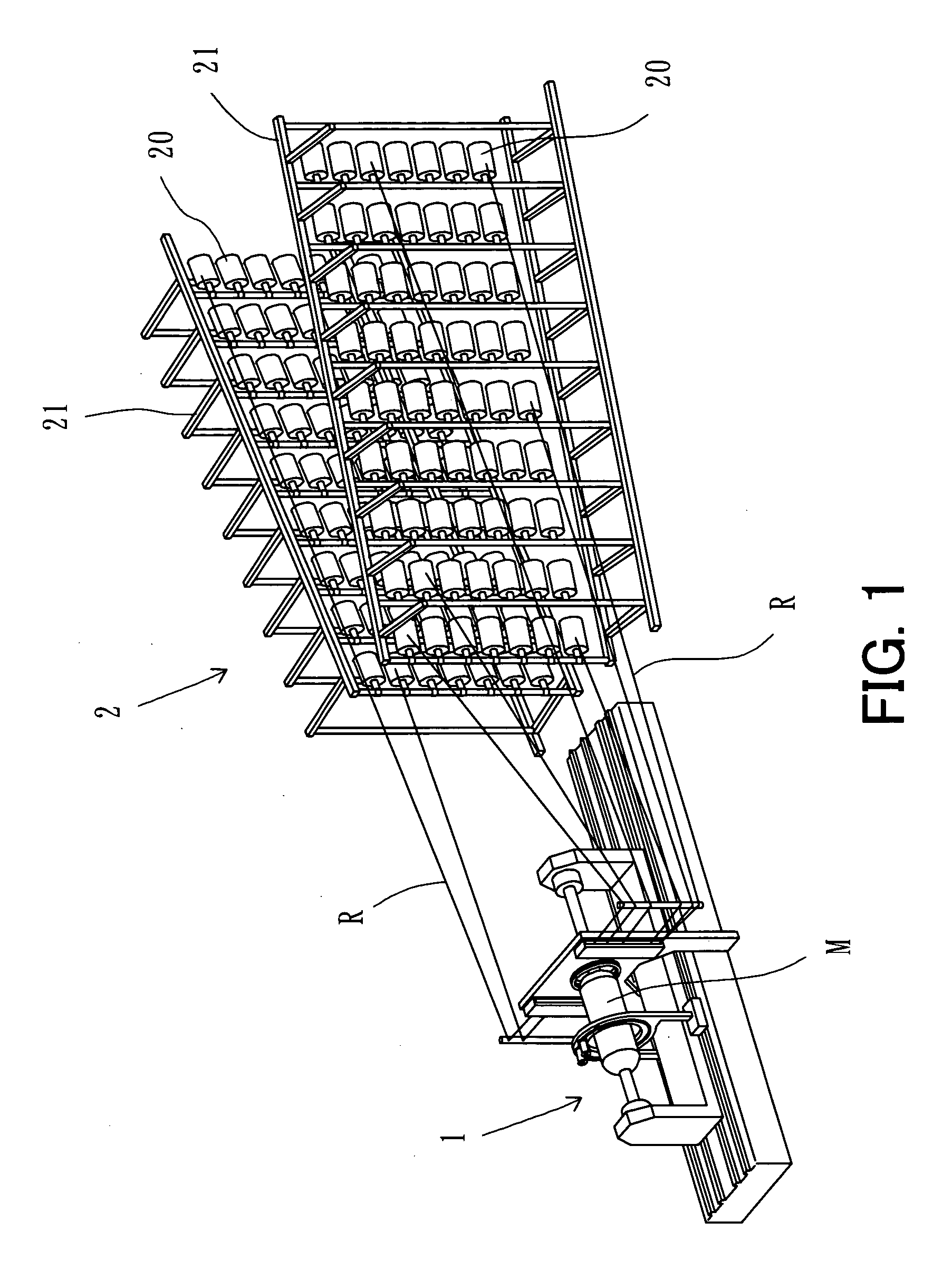

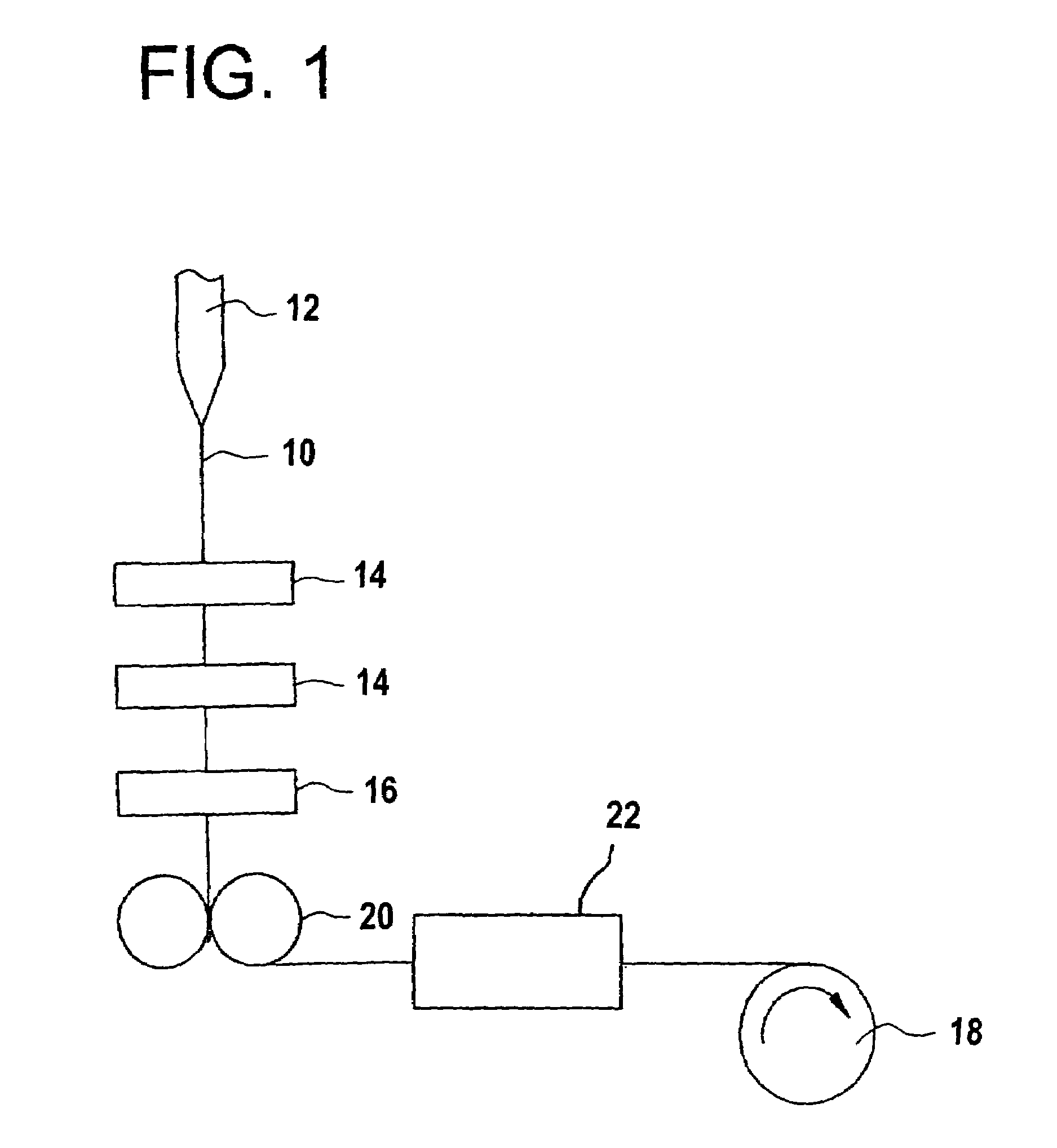

Filament Winding Automated System

ActiveUS20090038759A1Increase productionLow costFilament handlingDomestic articlesFiber bundleEngineering

The present invention makes it possible to increase production efficiency while reducing costs. A filament winding automated system according to the present invention includes a winding device winding a fiber bundle R paid out from a head portion 12, 13, around a mandrel M1, an installing device 5 installing the mandrel around M1 which no fiber bundle has been wound yet, at a winding position, a discharging device 5 discharging the mandrel around which the fiber bundle has already been wound, from the winding position, a delivery device 3 holding and delivering the fiber bundle R from the mandrel around which the fiber bundle has already been wound to a mandrel M1 around which no fiber bundle has been wound yet, and a cutting device cutting the fiber bundle R, and after winding is completed, the delivery device 3 holds the fiber bundle R paid out from the head portion 12, 13, the cutting device cuts and separates the fiber bundle R from the mandrel around which the fiber bundle has already been wound, the discharging device 5 discharges the mandrel around which the fiber bundle has already been wound, the installing device installs the mandrel M1 around which no fiber bundle has been wound yet, and the winding device starts winding the fiber bundle R held by the delivery device 3, around the mandrel M1 around which no fiber bundle has been wound yet.

Owner:MURATA MASCH LTD

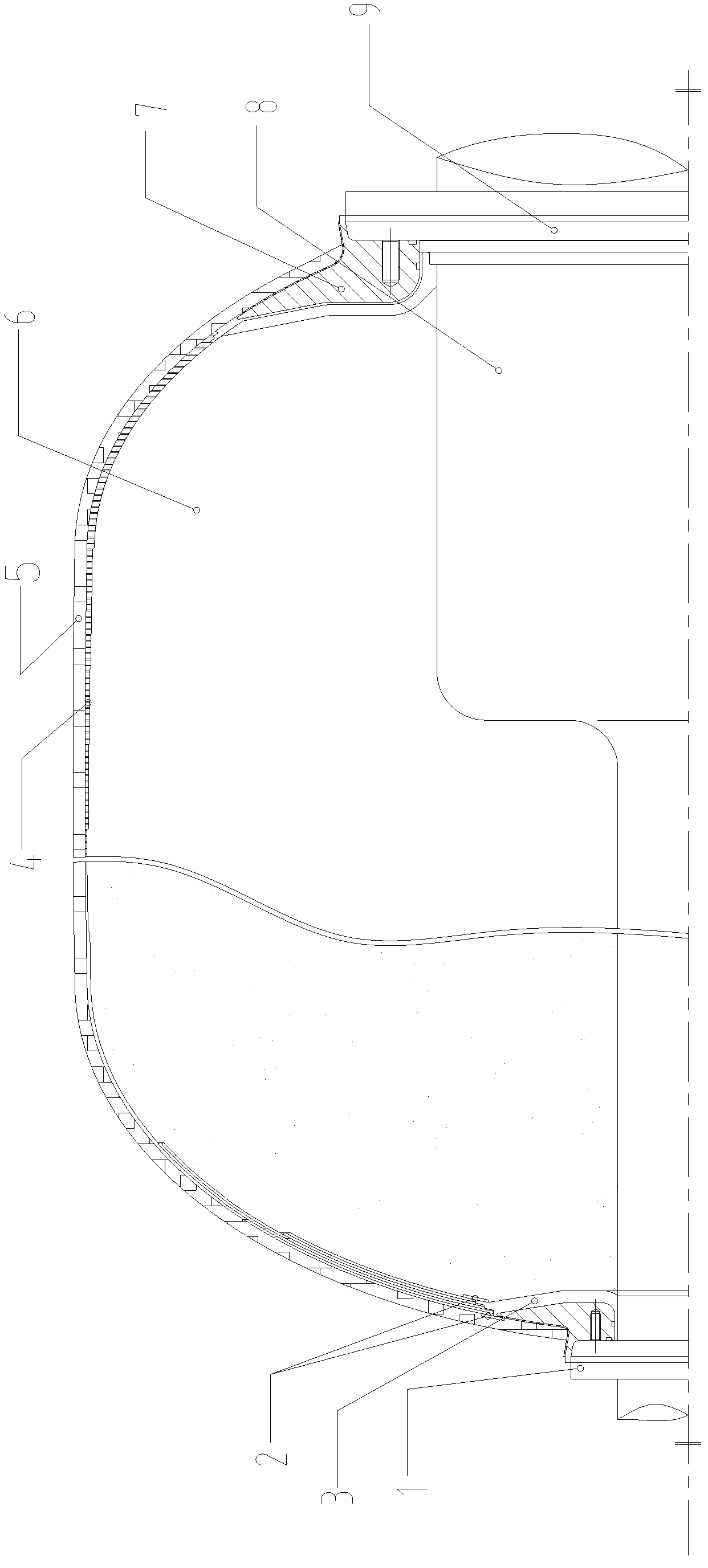

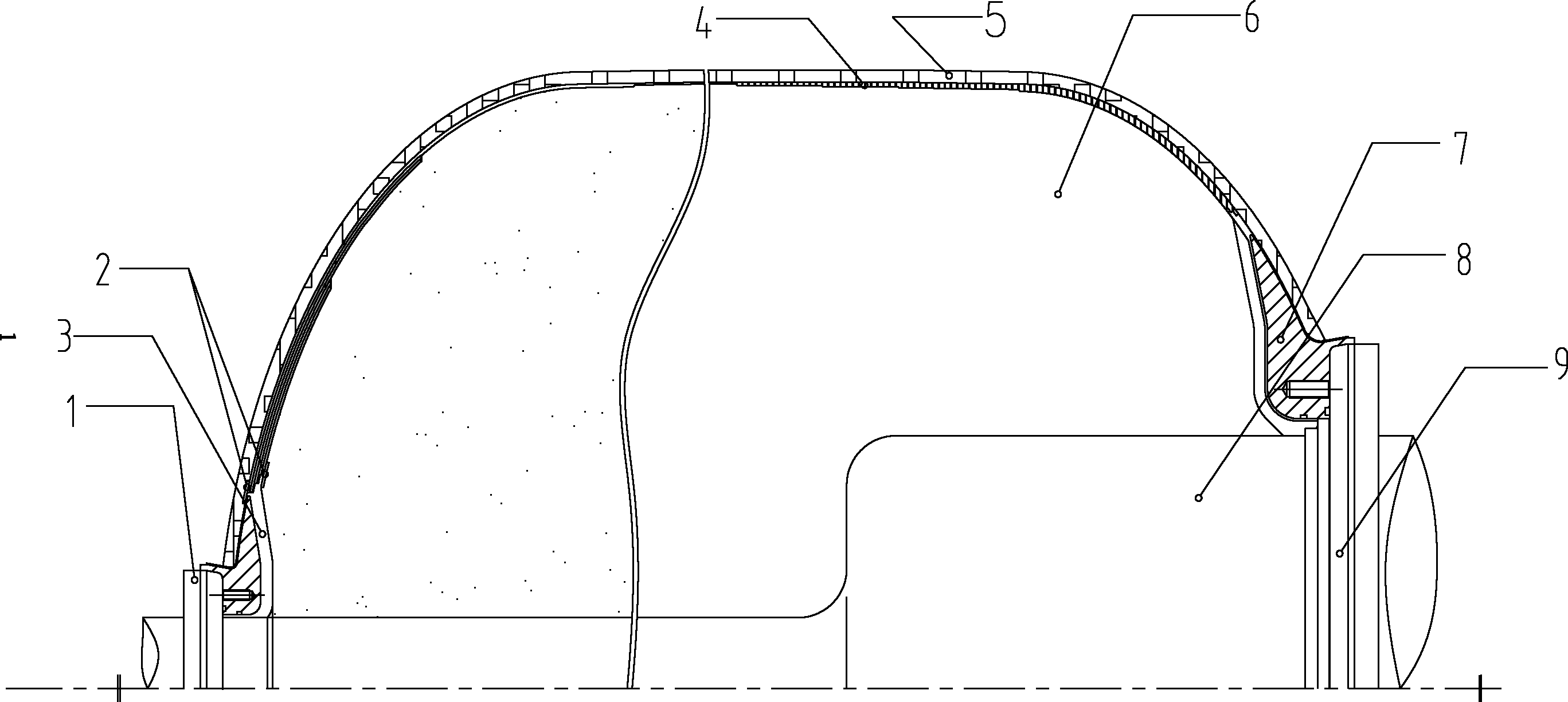

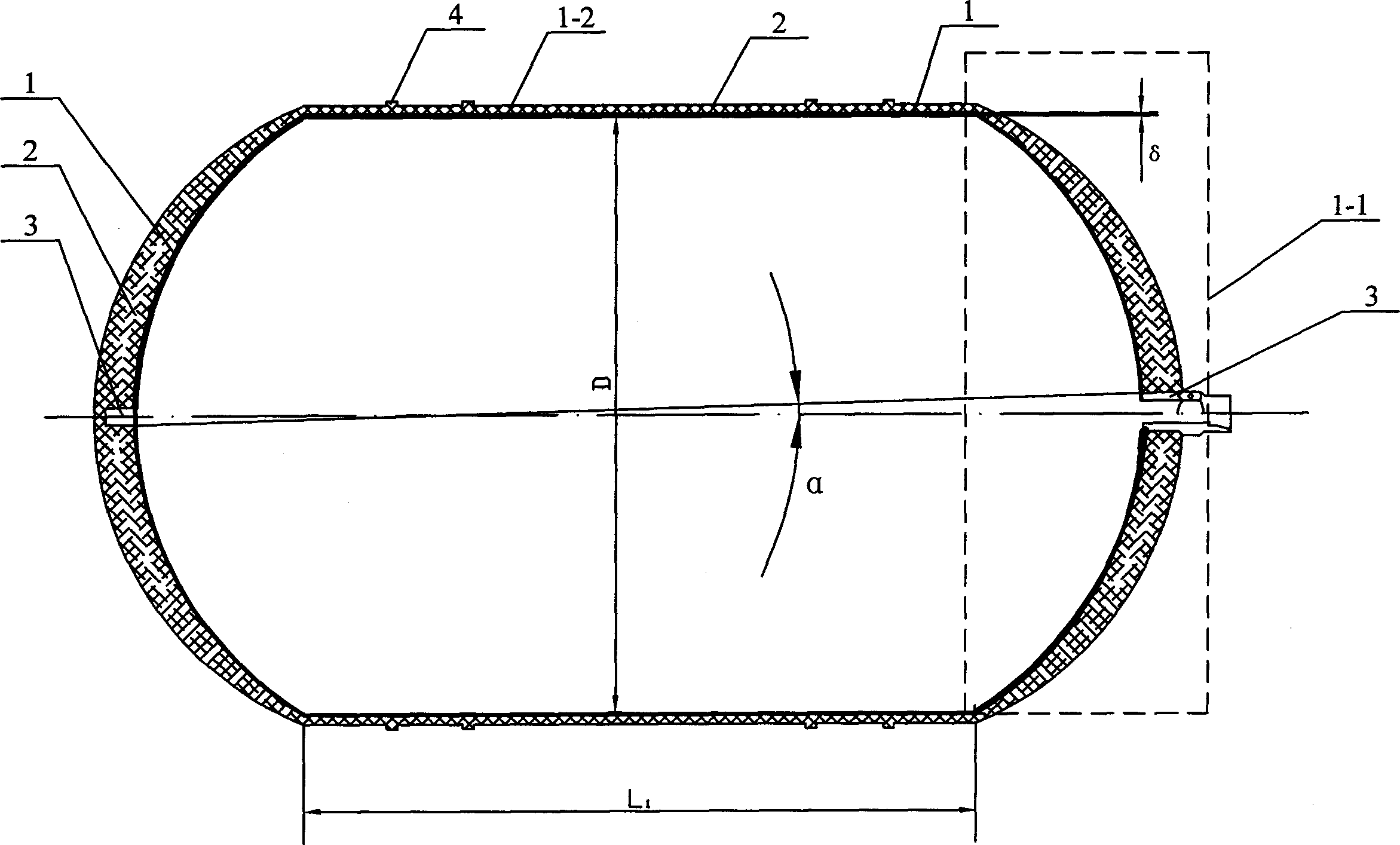

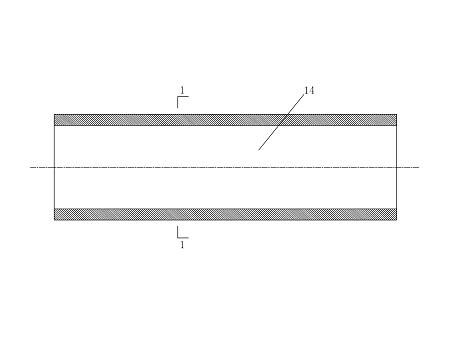

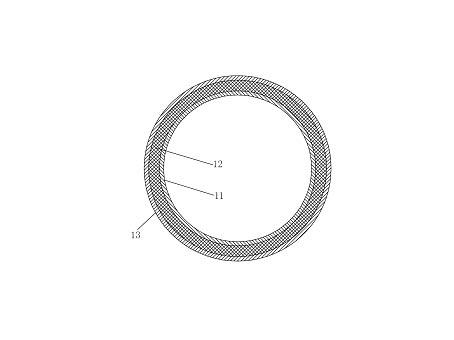

High pressure gas cylinder made from carbon fiber composite material and manufacturing method thereof

InactiveCN1734154AHigh PV/W characteristic valueImprove efficiencyPressure vesselsGas cylinderHigh pressure

This invention relates to a high-pressure gas jar for the carbon fiber compound material and it's making method, wherein it uses a fiber wrapped compound material. The capability of the carbon fiber compound material as follows: the metal liner is made of the titanium alloy, wherein the proportion between its stretching bending strength and its elasticity FTY / E is at least 0.6%, its stretch rate is at least 5%, and the shape of its closing head (1-1) is the three point circle. And the metal liner (1) is made by the following steps: spinning and stretching the closing head (1-1), crystallization annealing processing, end welding and integral welding; and the carbon fiber compound material layer (2) is the carbon fiber layer or the epoxy wrapping layer. The made method includes the following steps: fiber drying, glue confecting, glue immersing, wrapping, and solidified forming. Using this method can make the light weight, well gas sealing capability, high strength carbon fiber compound high-pressure gas jar.

Owner:HARBIN INST OF TECH

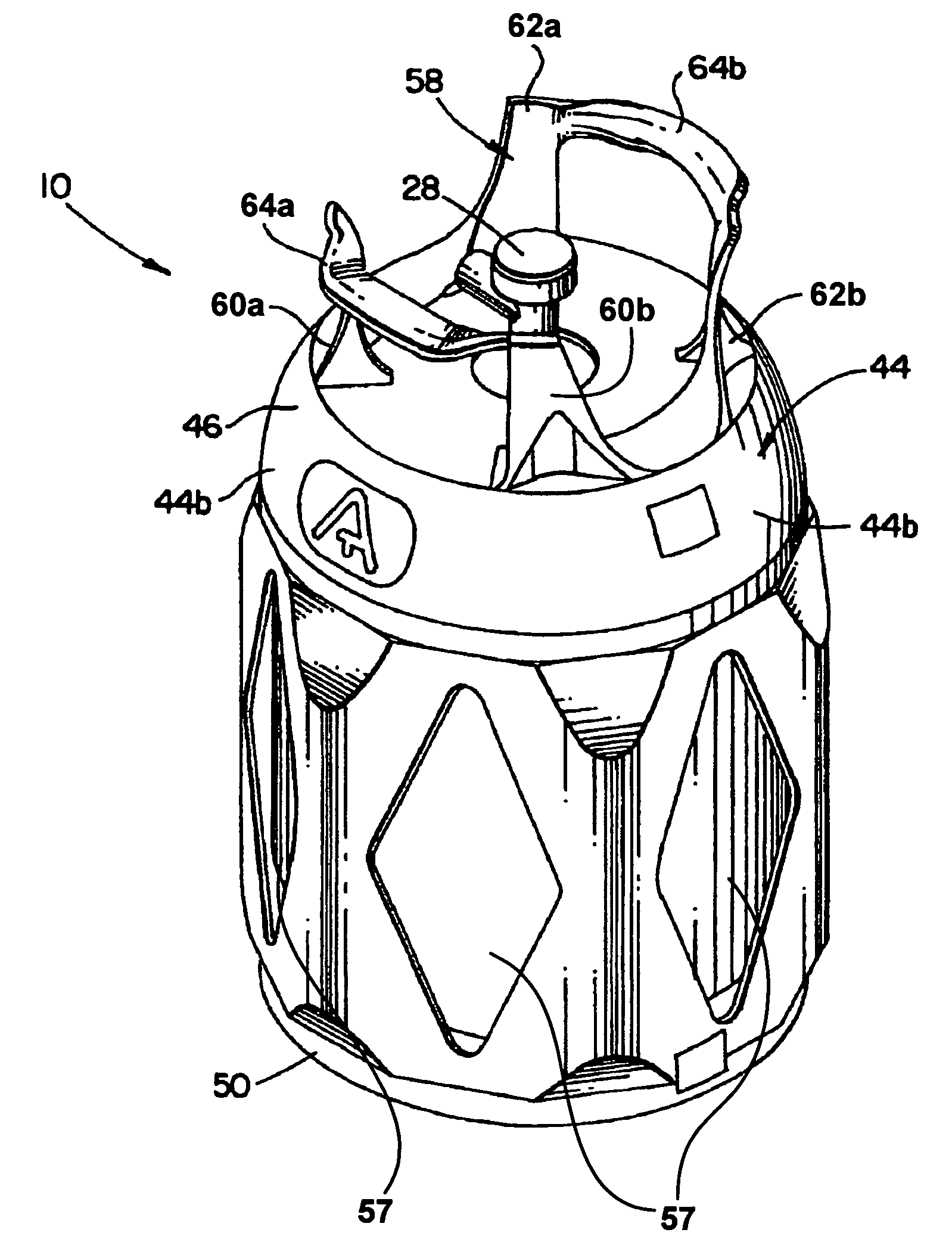

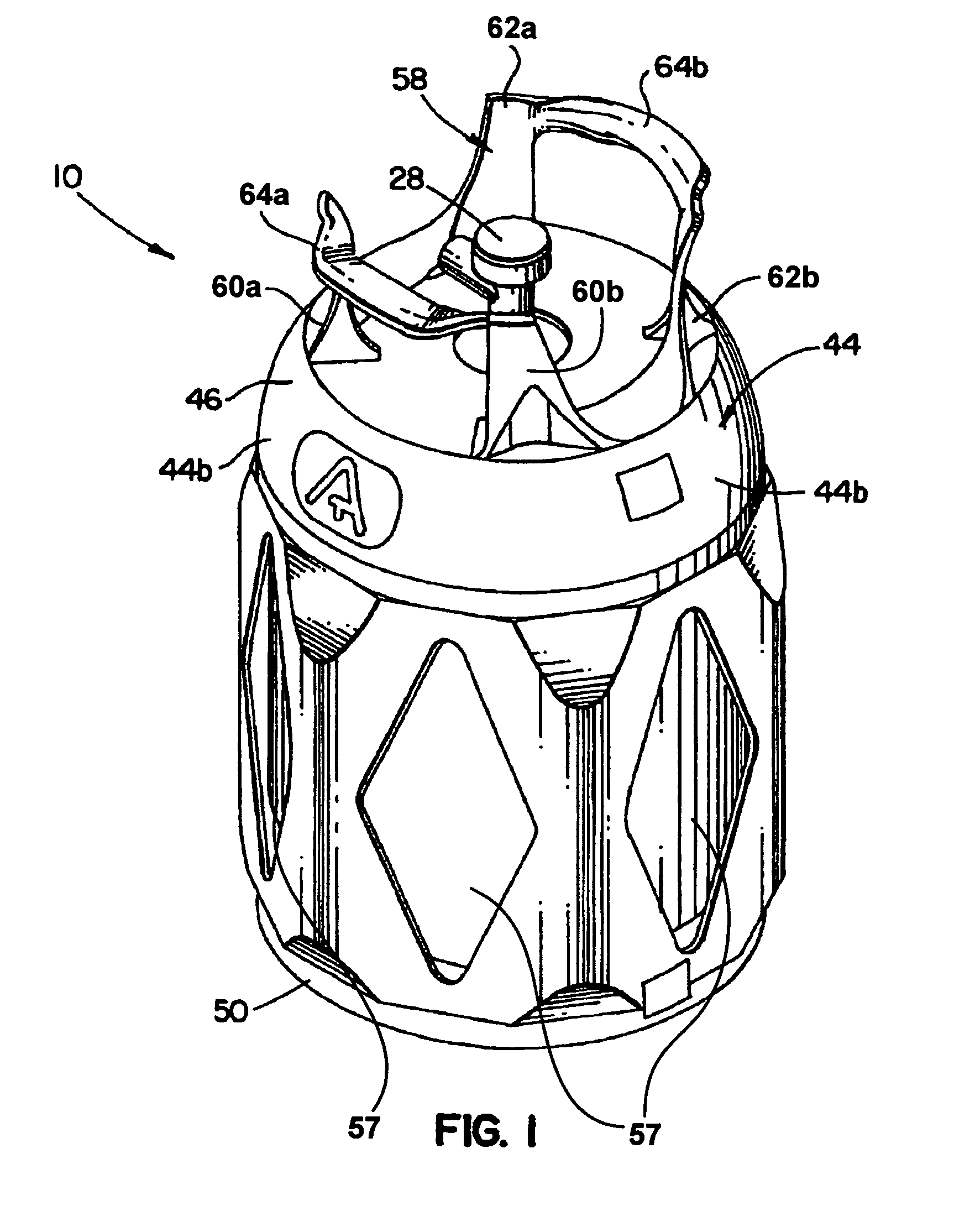

Hybrid pressure vessel with separable jacket

ActiveUS7255245B2Low costMeet actual needsContainer filling methodsGas handling applicationsVisual inspectionEngineering

A pressure vessel with a protective jacket disposed thereon, wherein the vessel is formed of a metal liner surrounded by a layer of thermoplastic composite filament winding and a protective jacket disposed thereon that facilitates stacking and portability of the vessel, while also providing sufficiently sized openings for visual inspection of the composite layer integrity.

Owner:AMTROL LICENSING INC

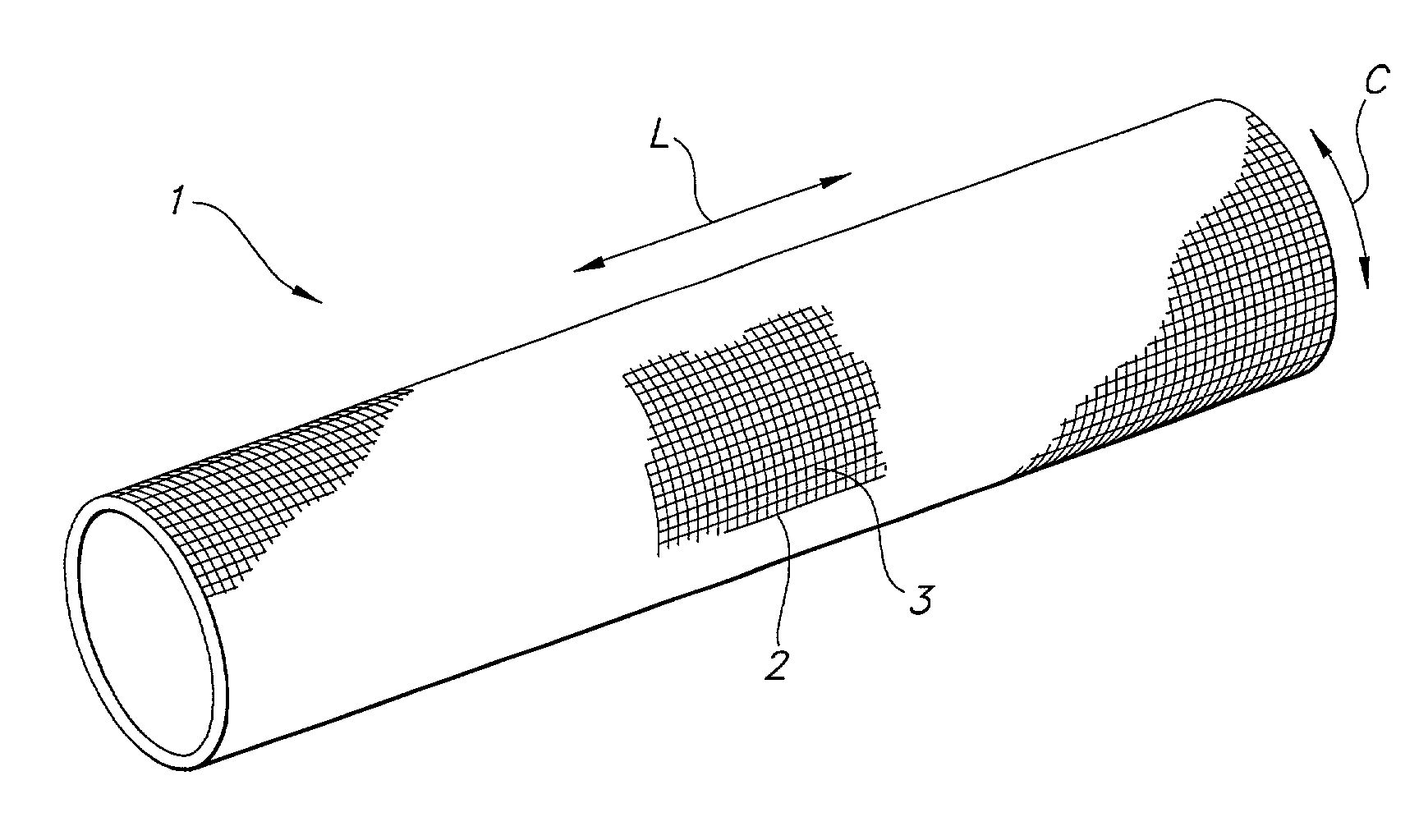

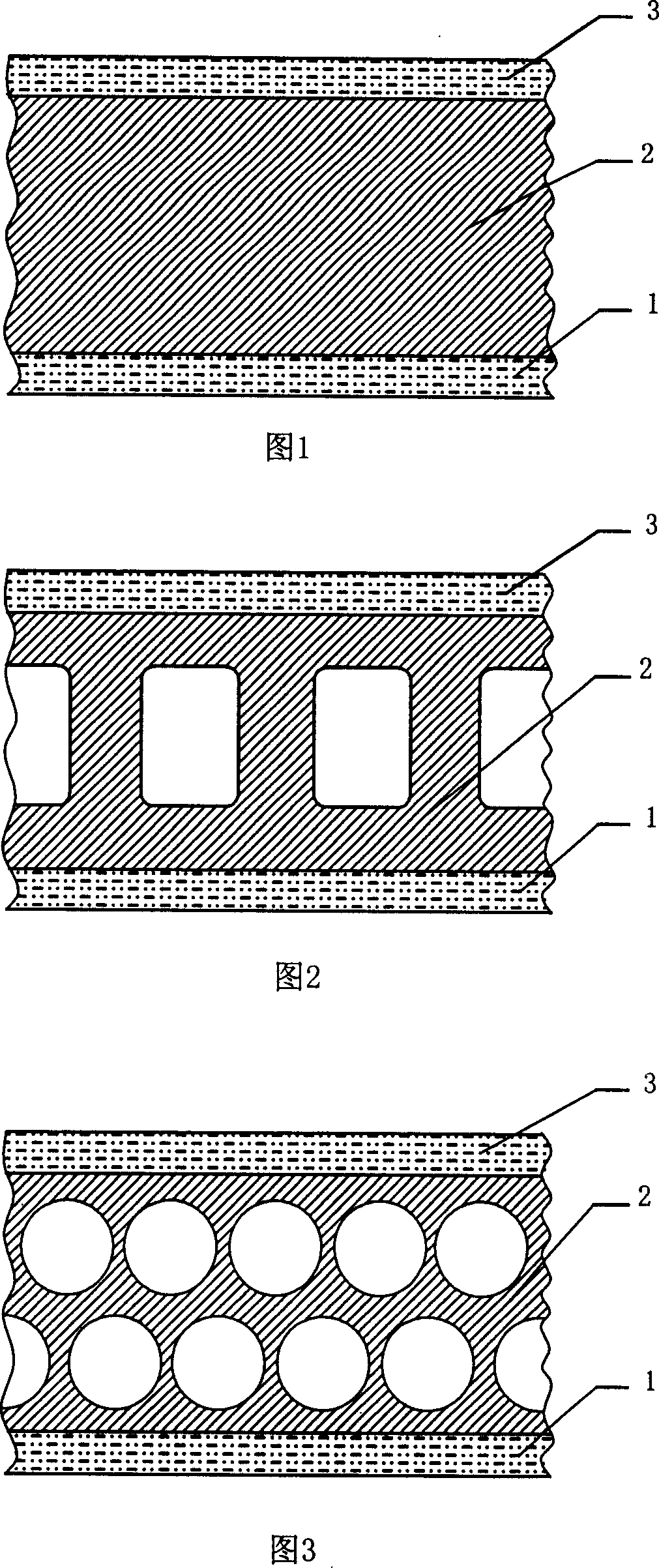

Fiber wrapped pipeline made from composite material

InactiveCN101004230ARetention strengthLow intensityRigid pipesPlastic pipeworkUltimate tensile strength

The present invention relates to a fiber-winded composite material pipe for water supply and drainage. It is characterized by that its pipe wall is divided into three layers, including internal winded layer, intermediate winded layer and external winded layer. Its intermediate winded layer is made up by using thermoplastic composite material, its internal winded layer and external winded layer are made up by using filament and / or continuous fiber reinforced thermoplastic or thermosetting composite material.

Owner:曾建祥

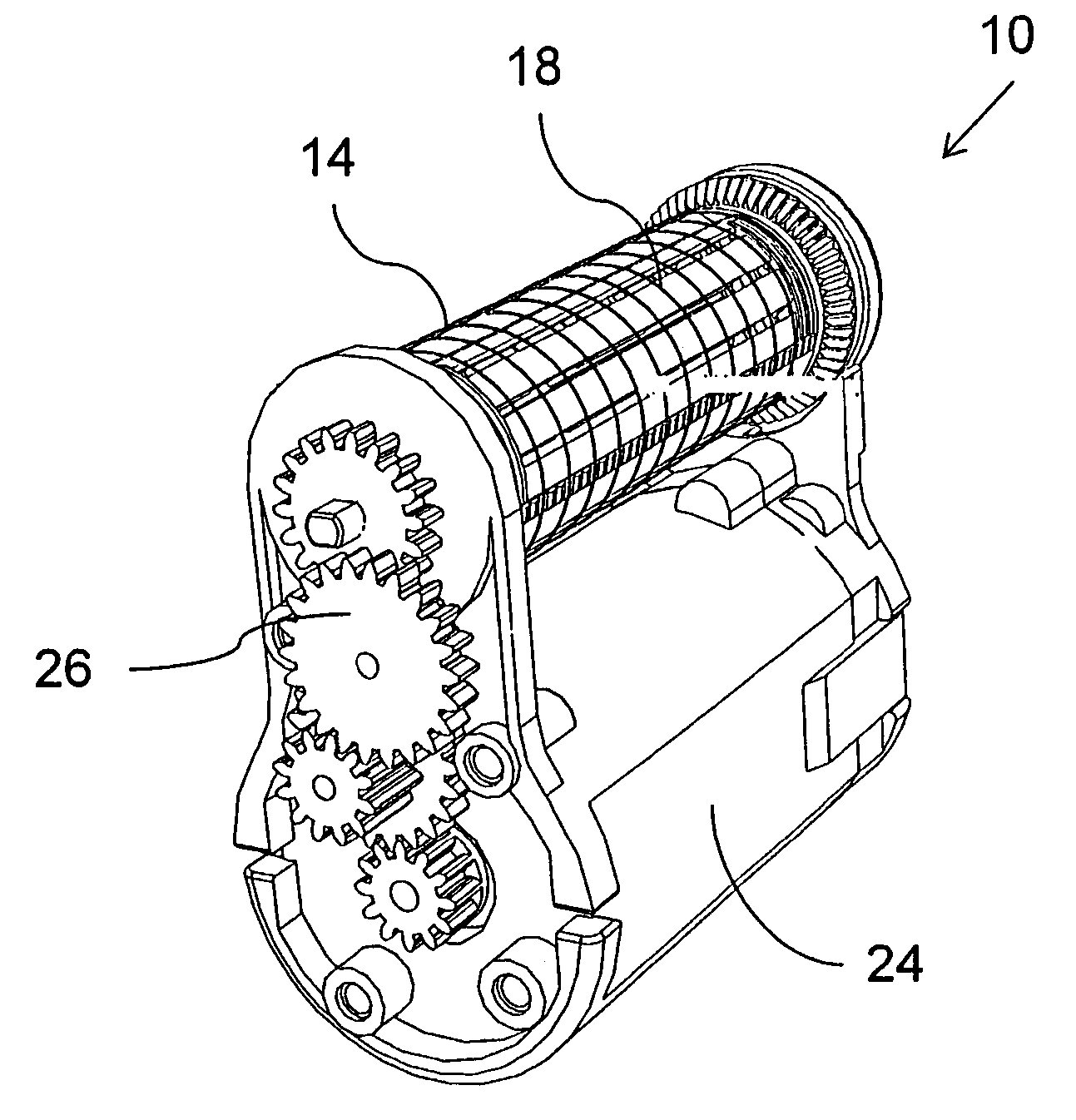

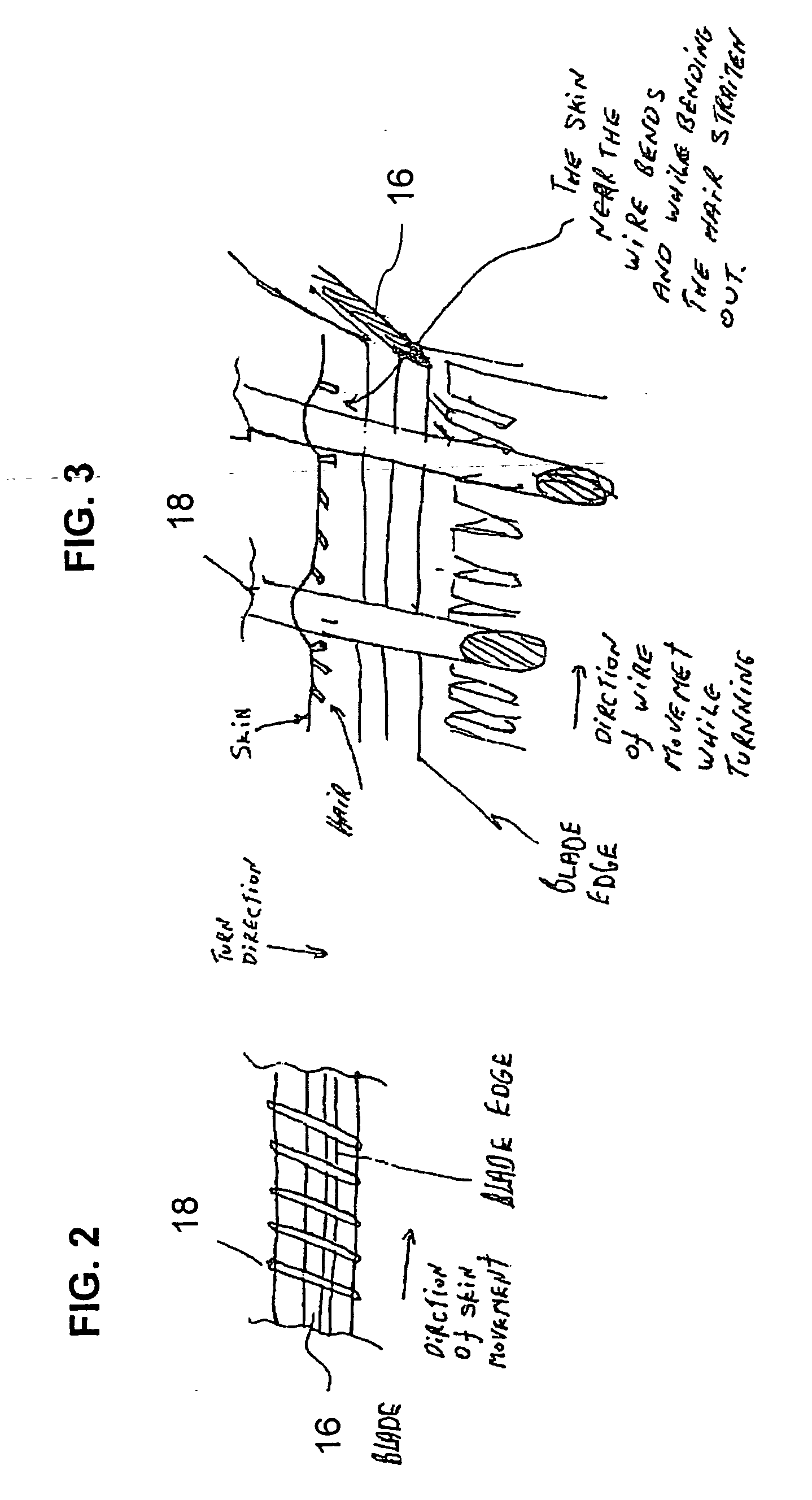

Electric razor with helical filament winding

A roller assembly for an electric razor includes a generally cylindrical roller driven by a drive arrangement to rotate about a central axis. The roller supports a number of blades, each having a cutting edge externally exposed and extending parallel to the central axis. Each blade moves across the skin of a user so as to slice through hair projecting from the skin of the user. The roller assembly further includes at least one filament wond in a helical path around the roller such that a gap between adjacent portions of the filament along the cutting edges is no more than about 8 millimeters.

Owner:WHEEL TECH LTD

Continuous filament wound and reinforced thermoplastic pipe and manufacturing process thereof

The invention relates to a pipeline structure used for transporting different media such as solid, liquid and gases and a manufacturing process thereof. A continuous filament wound and reinforced thermoplastic pipe is characterized in that a tubular pipeline liner layer, a pipeline structural layer and a pipeline outer protective layer are wound to manufacture a whole structure; the pipeline structural layer is positioned between the pipeline liner layer and the pipeline outer protective layer; the pipeline liner layer and the pipeline outer protective layer are made of thermoplastic plastics; and the pipeline structural layer is made of continuous filaments. The pipeline provided by the invention has better strength, rigidity, shock resistance, fracture toughness, temperature and corrosion resistance, seepage resistance and the like than the traditional thermoplastic or thermosetting pipelines, can be widely applied in the fields such as water supply and sewerage works, petrochemical industry, coal gas and natural gas transportation, seawater desalination and nuclear power and can be suitable for special environments and requirements such as heavy calibre, high rigidity, high strength and high corrosivity.

Owner:CHANGSHA XINSHI PIPELINE

Method for increasing transverse strength of fiber reinforced resin pultrusion section bar and product thereof

InactiveCN1919587AHigh tensile strengthHigh compressive strengthCompressive strengthFiber orientation

The invention discloses a transverse direction strength improving method of fiber reinforced resin pultrusion, which comprises the following steps: distributing fiber, gumming, premoulding, heating, solidifying, drawing, cutting, premoulding, heating, solidifying, increasing transverse fiber, connecting with premoulding material tightly. The invention improves drawing-proof strength, pressure-proof, bending-proof strength and cutting-proof strength of FRP, which increases bond force between FRP section bar and other materials.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

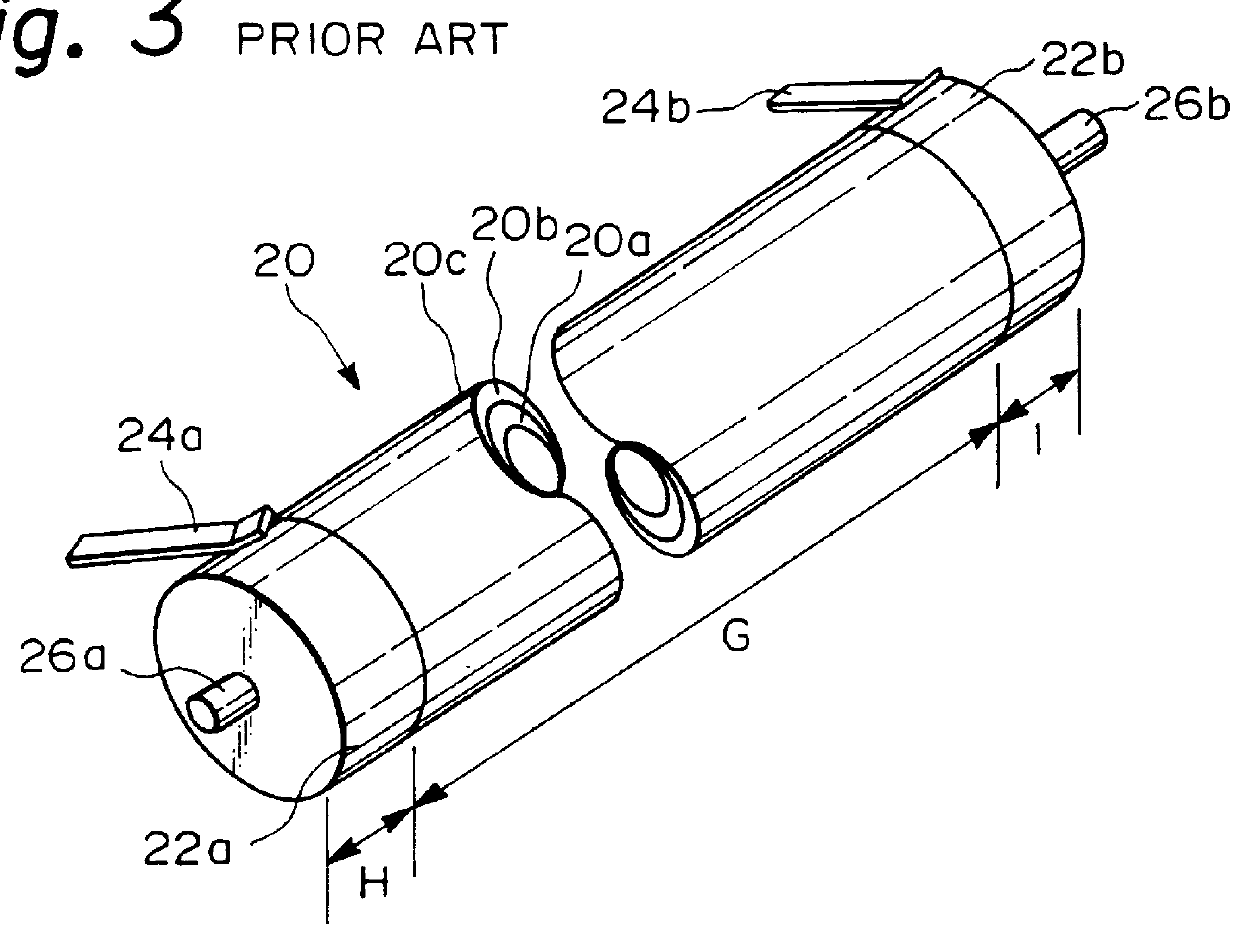

Inclusion of chip elements in a sheathed wire

ActiveUS20130092742A1Small sizeEasy to takeWave amplification devicesSolid-state devicesFilament windingElectrical and Electronics engineering

A method for forming a sheathed wire includes the steps of axially advancing a core through a sheathing zone; wrapping a sheathing fiber around the core in the sheathing zone; and providing, in the sheathing zone, a series of microelectronic chip elements each provided with a wire section, in such a way that the sheathing fiber that wraps around the core also wraps around a chip element and the wire section thereof to form a sheathed wire incorporating spaced-apart chip elements.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

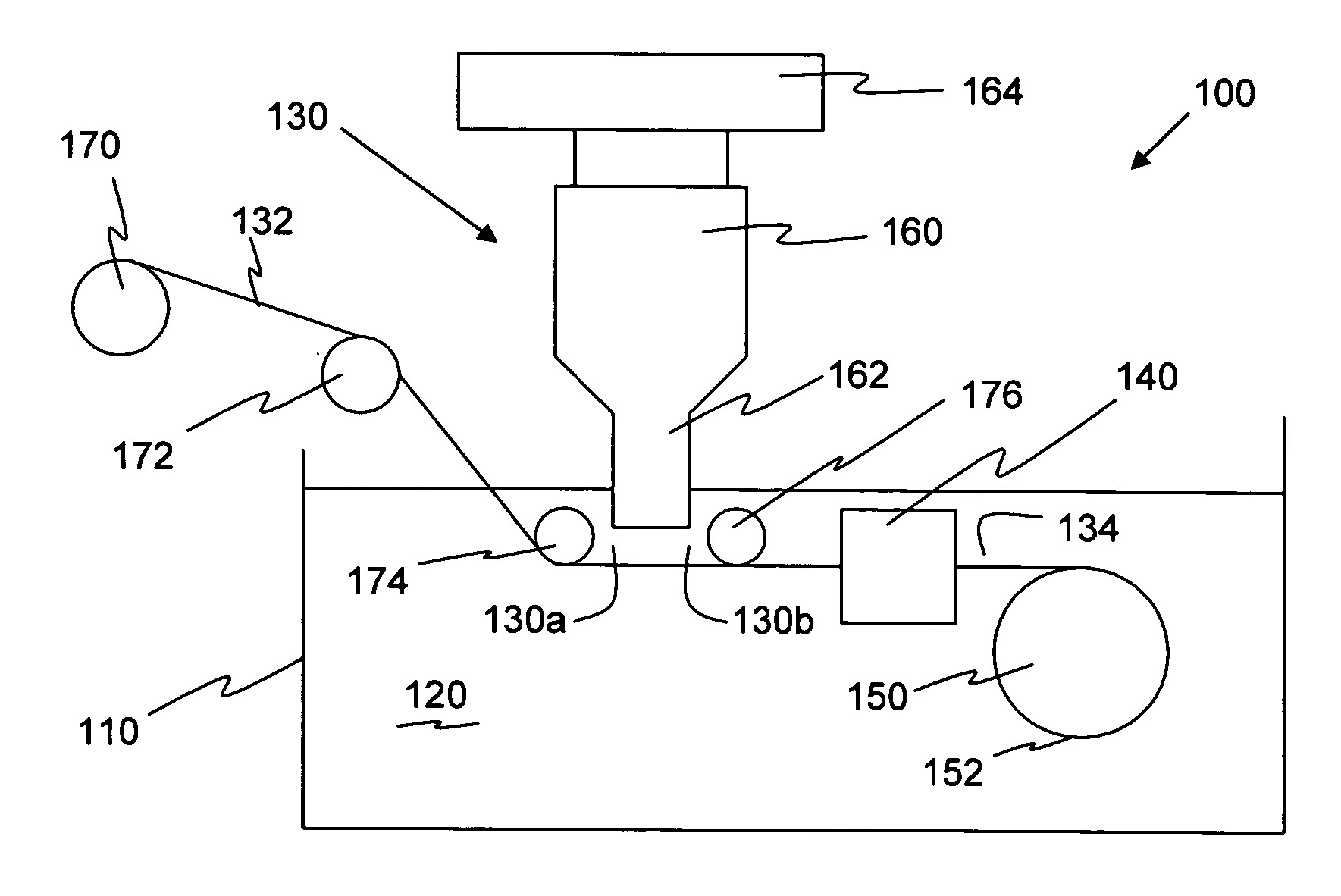

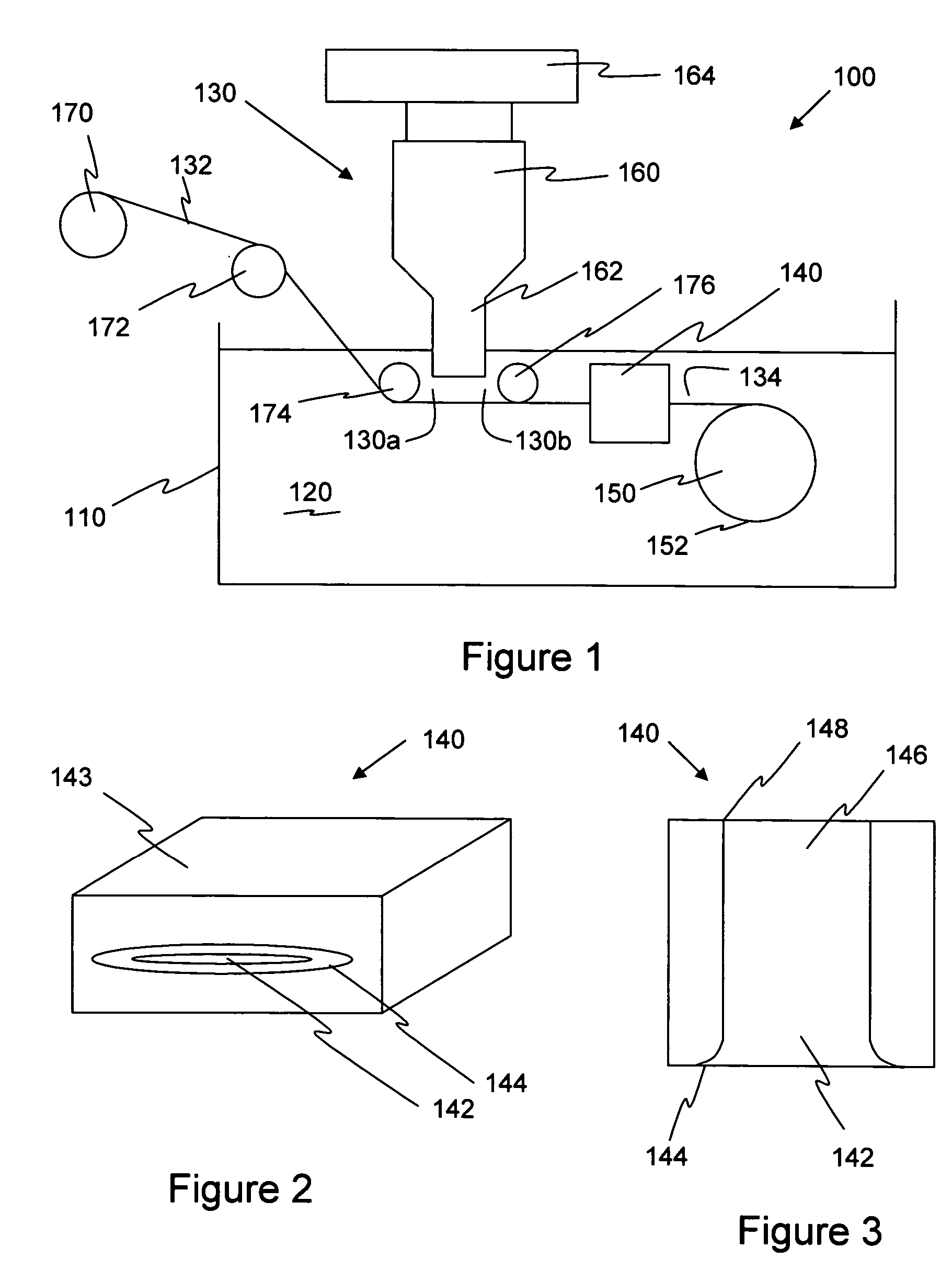

Filament winding for metal matrix composites

A wet filament winding method and apparatus for producing a consolidated metal matrix composite is described. The methods are directed to winding a softened metal infiltrated fiber bundle and layering the resulting softened metal infiltrated fiber bundle onto a rotating mandrel in a prescribed pattern on the surface of the mandrel to form a consolidated metal matrix composite. Upon cooling, the matrix metal solidifies and the resulting consolidated metal matrix composite may be removed from the mandrel. The consolidated metal matrix composites may be produced in a variety of shapes, such as cylinder, a tapered cylinder, a sphere, an ovoid, a cube, a rectangular solid, a polygonal solid, and panels.

Owner:TOUCHSTONE RES LAB

High pressure liquid degassing membrane contactors and methods of manufacturing and use

In accordance with at least selected embodiments of the present invention, an improved liquid degassing membrane contactor or module includes a high pressure housing and at least one degassing cartridge therein. It may be preferred that the high pressure housing is a standard, ASME certified, reverse osmosis (RO) or water purification pressure housing or vessel (made of, for example, polypropylene, polycarbonate, stainless steel, corrosion resistant filament wound fiberglass reinforced epoxy tubing, with pressure ratings of, for example, 150, 250, 300, 400, or 600 psi, and with, for example 4 or 6 ports, and an end cap at each end) and that the degassing cartridge is a self-contained, hollow-fiber membrane cartridge adapted to fit in the RO high pressure housing.

Owner:3M INNOVATIVE PROPERTIES CO

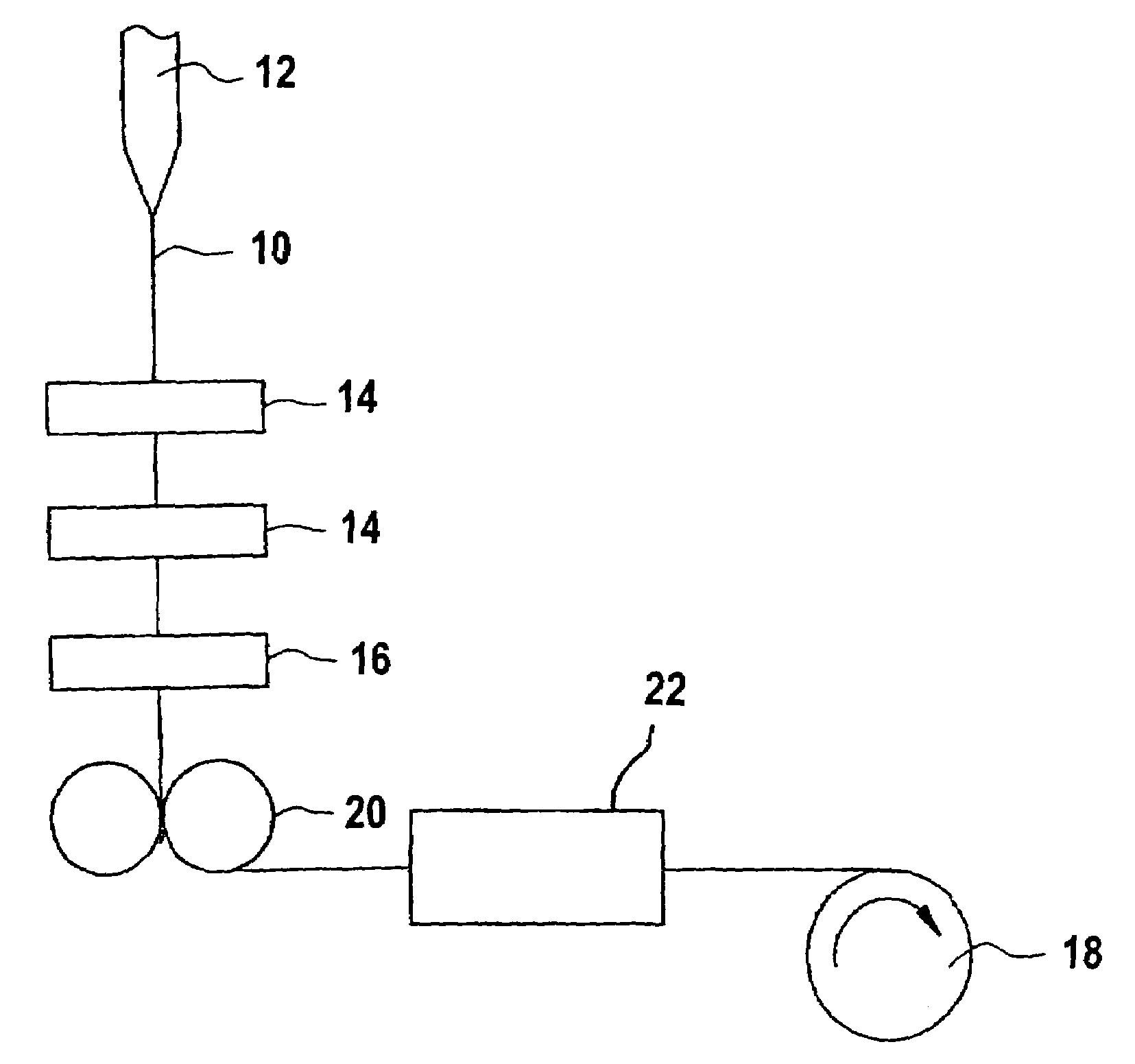

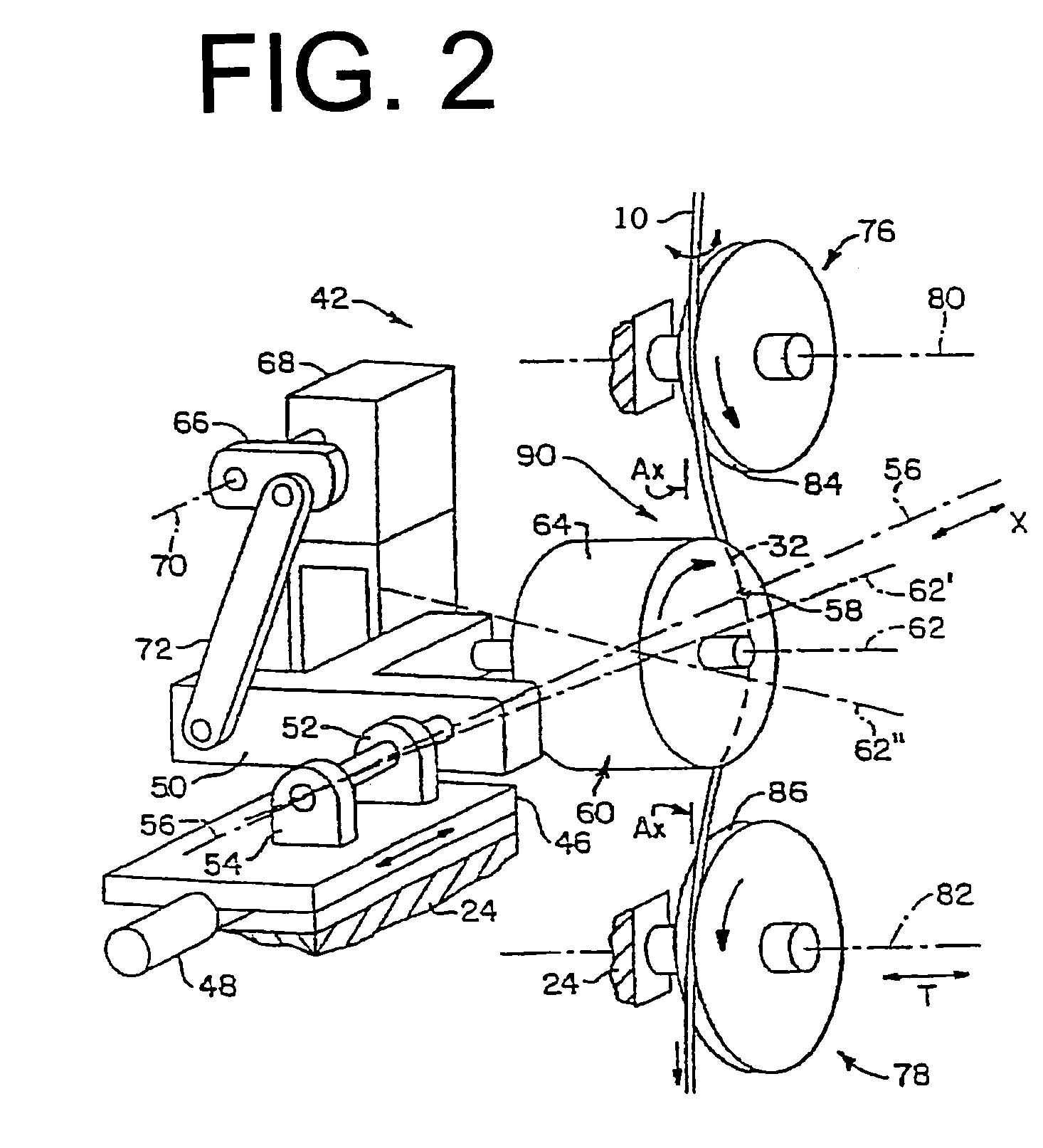

Filament winding method and apparatus

ActiveUS20080197229A1Shorten production timeEasy to carryFilament handlingCoils manufactureFiber bundleConductor Coil

Helical winding is reliably carried out in a plurality of patterns at different angles in a short period of time. A filament winding apparatus for winding fiber bundles onto the surface of a mandrel includes a helical winding head for use in helical winding of the fiber bundles onto the mandrel. The helical winding head includes at least two guide arrays, each including a plurality of guide portions disposed along a circumferential direction of the mandrel, and a repositioning mechanism capable of repositioning the guide portions by rotating each guide array relative to another.

Owner:MURATA MASCH LTD

Method of imparting twist to optical fiber

InactiveUS7317855B2Increases magnitudeLow PMDCladded optical fibreGlass fibre drawing apparatusGlass fiberEngineering

Owner:CORNING INC

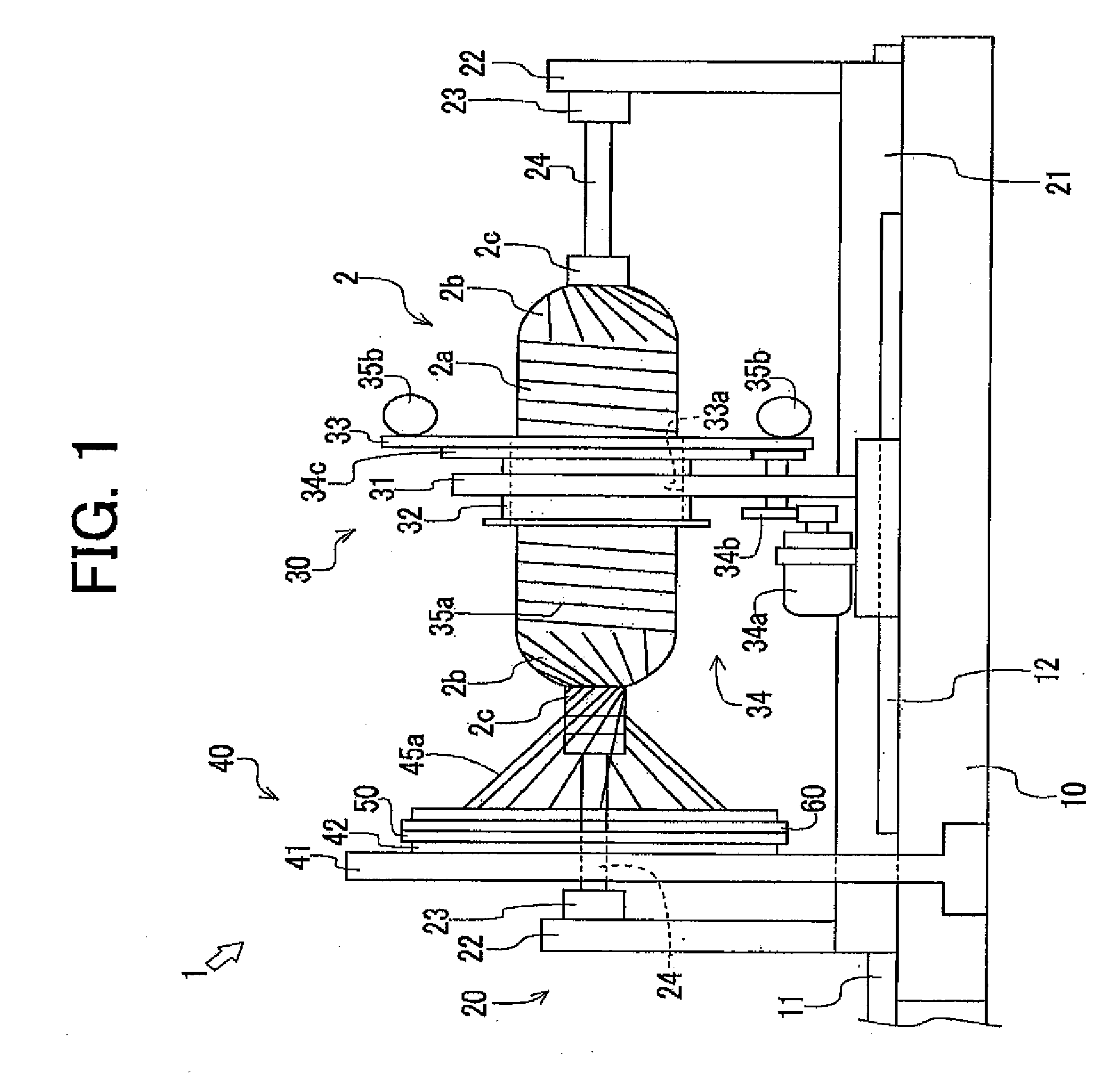

Filament Winding Apparatus

ActiveUS20100032510A1Reduce volatilityReduce variationFilament handlingCoils manufactureFiber bundleEngineering

A filament winding apparatus reduces fluctuations in a winding operation by bringing a plurality of guide portions that guide fiber bundles to a liner close to the liner in a winding unit. Each of the guide portions is a tubular member having a guide hole penetrated from a base end to a leading end portion. The leading end portion has a smaller thickness width. Each of the guide portions guides a second fiber bundle to the liner by passing the second fiber bundle from a side of the base end portion to a side of the leading end portion of the guide hole. By rotating each of the guide portions about an axis of the guide portion, and by sliding the guide portions in the radius direction of the liner, the guide portions can be brought close to the liner.

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com