Method for increasing transverse strength of fiber reinforced resin pultrusion section bar and product thereof

A technology of fiber-reinforced resin and pultrusion profiles, which is applied in the field of fiber-reinforced resin pultrusion profiles, and can solve problems such as powerlessness and weak transverse strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

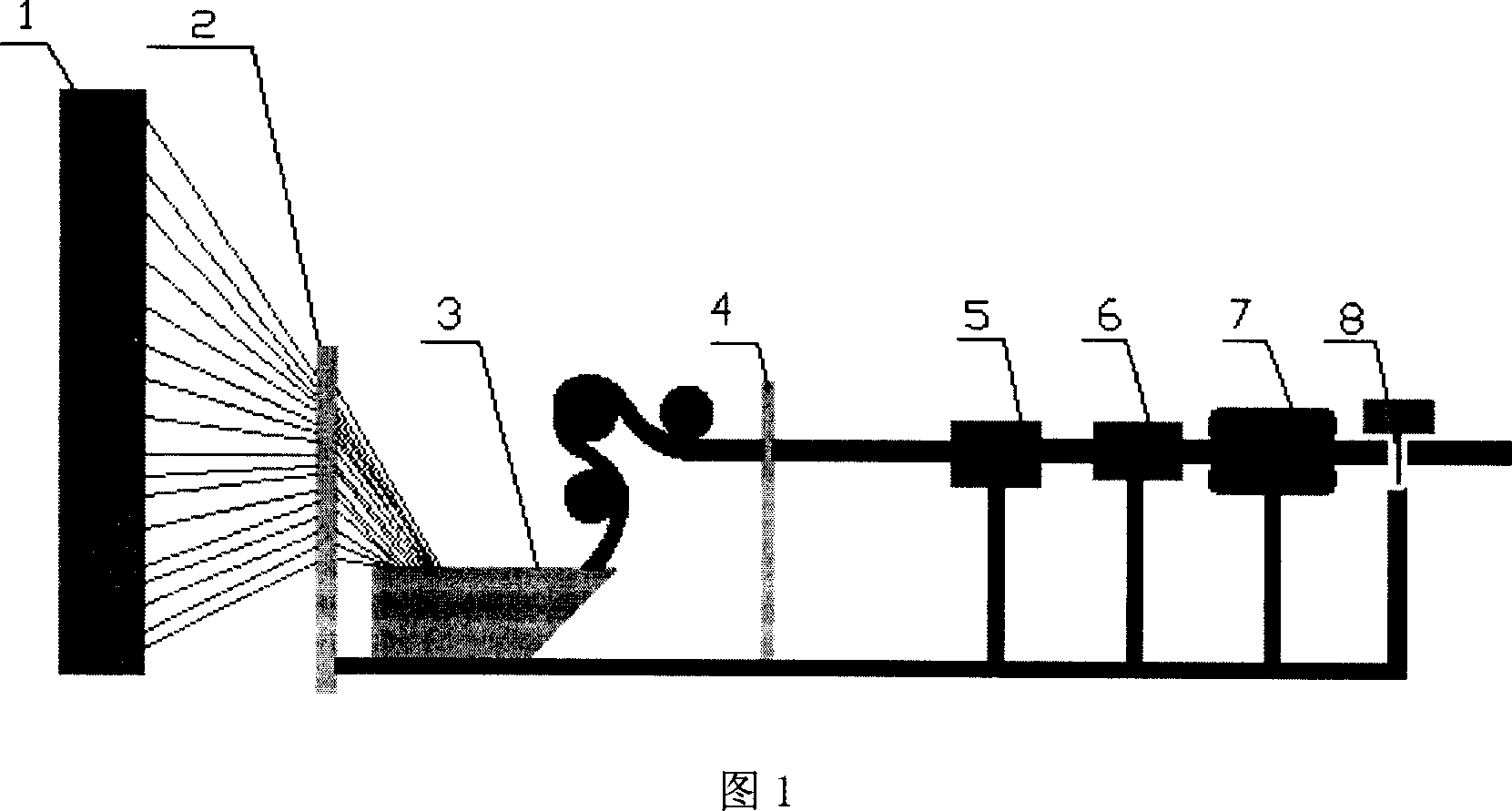

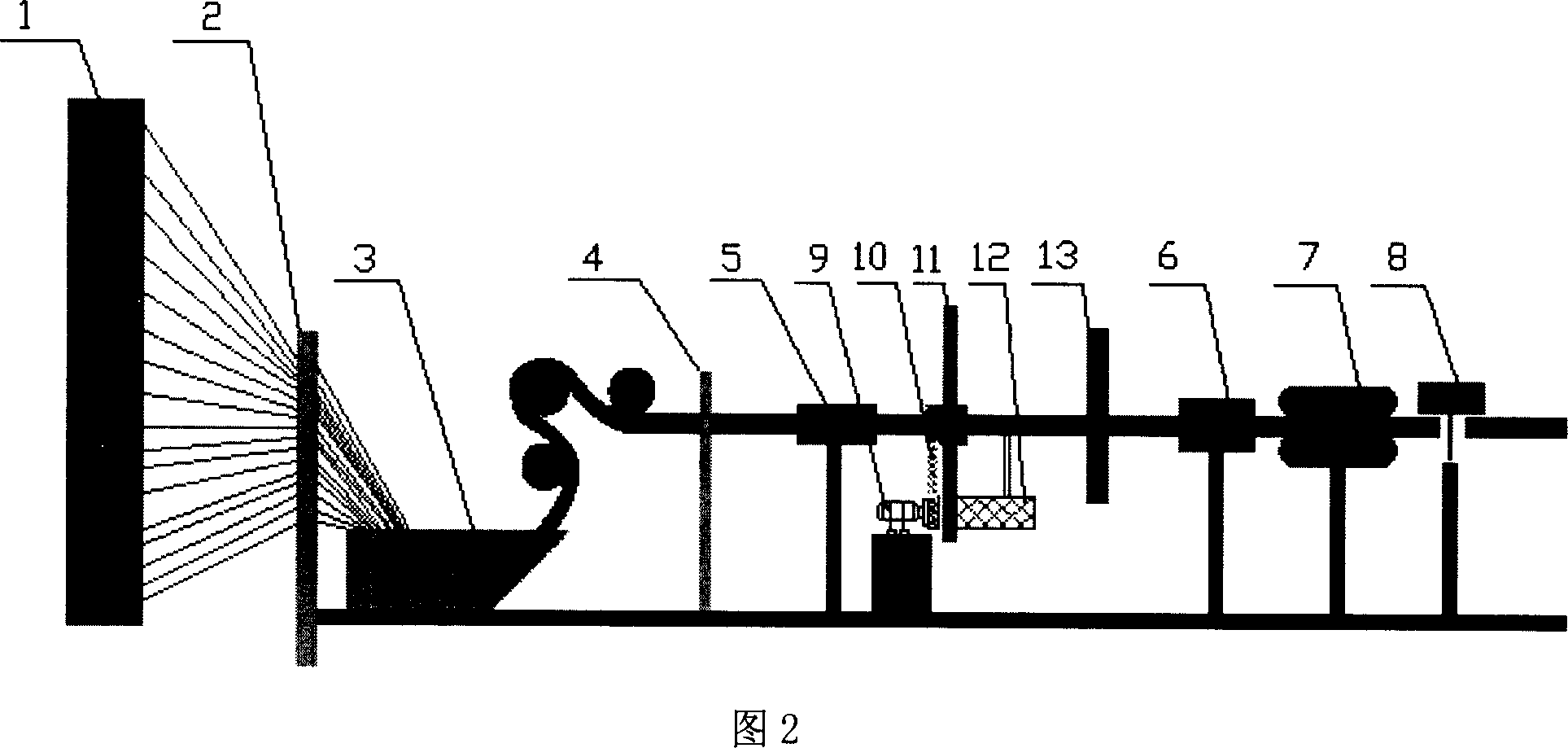

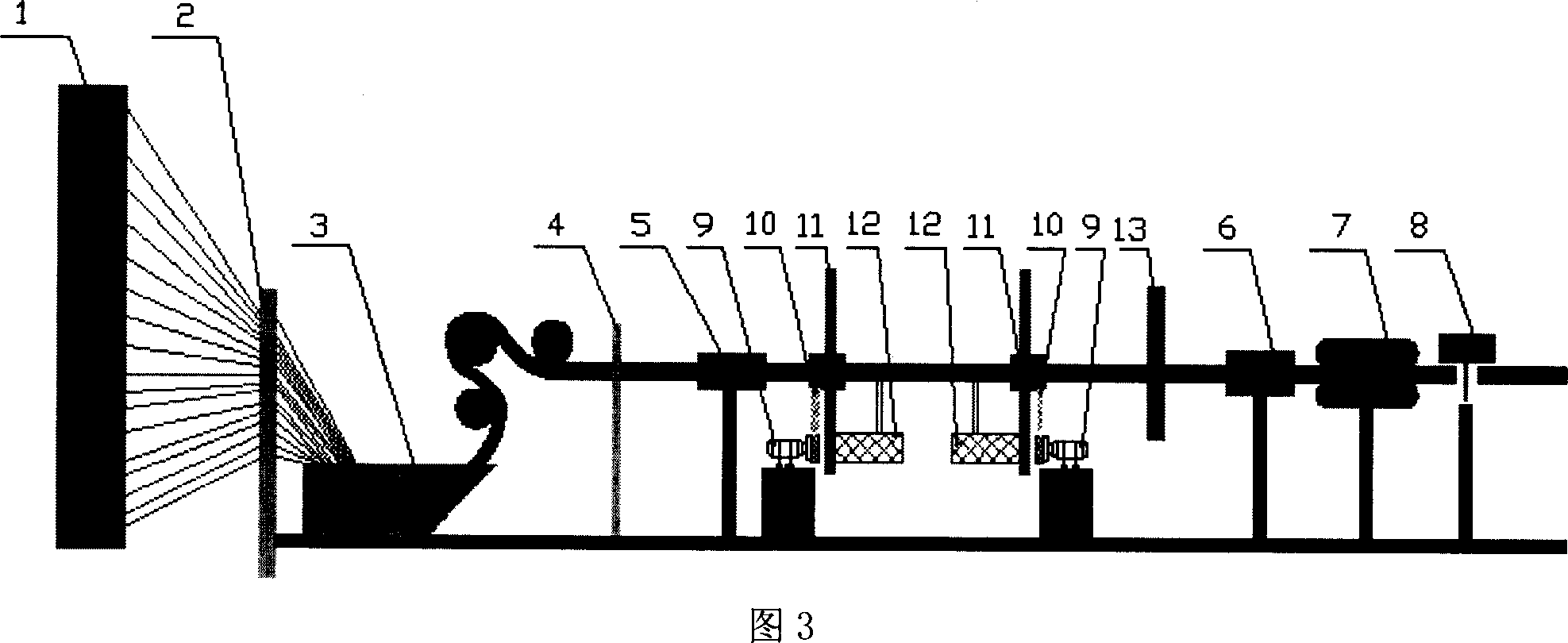

[0013] Describe molding process of the present invention in detail below in conjunction with accompanying drawing:

[0014] In the figure, 1 is a fiber creel, 2 is a material guide, 3 is a resin tank, 4 is a bundler, 5 is a preforming device, 6 is a heating and curing device, 7 is a traction device, 8 is a cutting device, and 9 is a motor , 10 is a gear transmission device, 11 is a turret, 12 is a horizontal winding fiber creel, and 13 is a scraper coating device.

[0015] In Fig. 1, the fiber bundles on the fiber creel 1 are first impregnated with resin in the resin tank 3 through the material guide 2, and then passed through the bundler 4 to align the fibers, and then the fiber bundles are preformed by the preforming device 5, so that The FRP pultrusion profile is preliminarily formed, then solidified at a high temperature in the heating and curing device 6, then passed through the traction device 7, and finally cut into a suitable length at the cutting device 8.

[0016] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com