High pressure gas cylinder made from carbon fiber composite material and manufacturing method thereof

A technology of composite materials and high-pressure gas cylinders, which is applied in the direction of pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of long manufacturing cycle, poor airtightness, and low strength, and achieve improvement The effect of efficiency, low cost and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

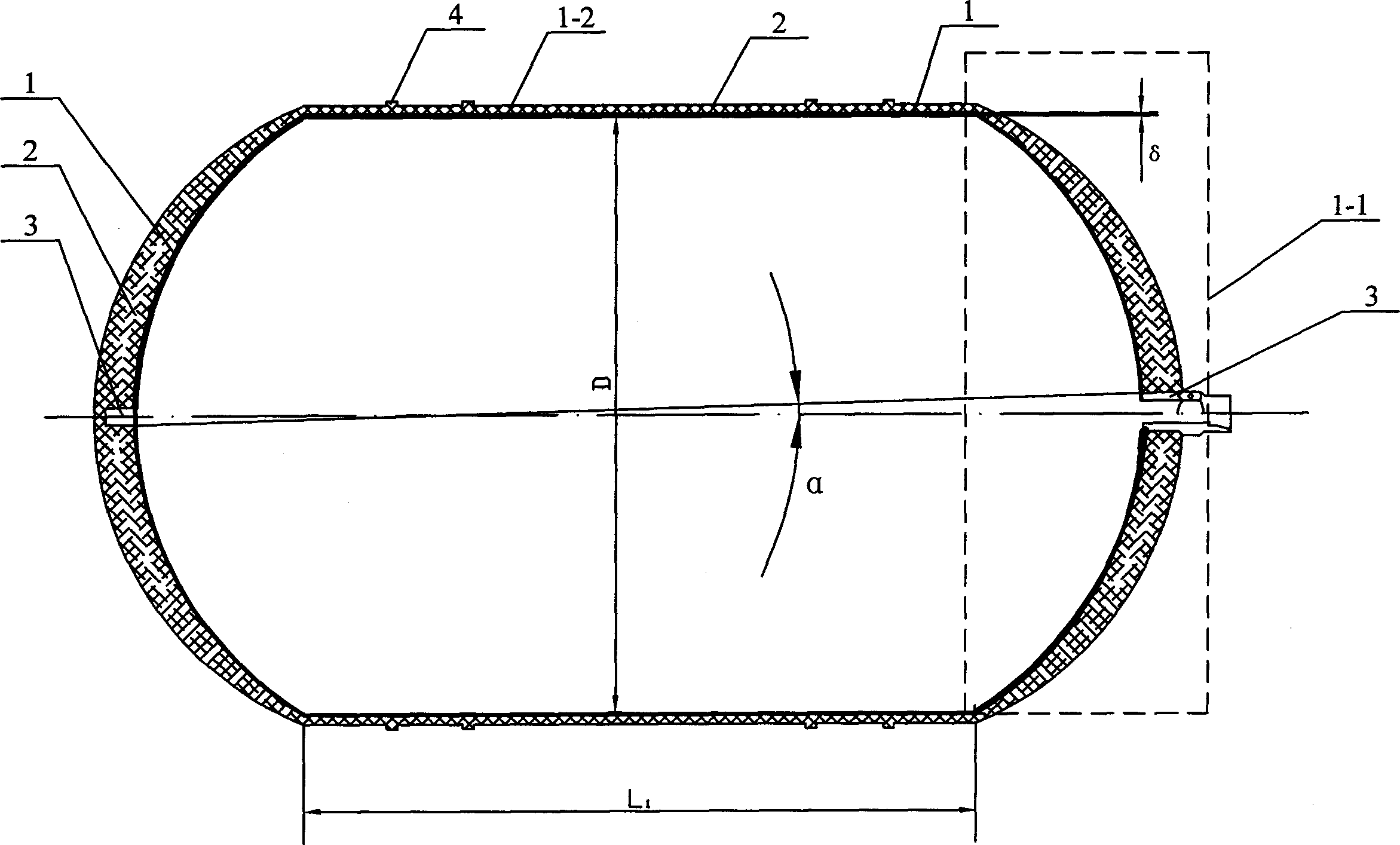

[0016] Embodiment 1: carbon fiber composite material high-pressure gas cylinder, which includes a metal liner 1 and a carbon fiber composite material layer 2 wound outside the metal liner 1, welded on the head 1-1 at both ends of the central axis of the metal liner 1 There is a terminal 3, and a circumferential rib 4 is wound outside the carbon fiber composite material layer 2, and the metal lining 1 is determined by the ratio F of the tensile yield strength and the modulus of elasticity TY / E is at least 0.6%, and the elongation at break is at least 5%. The thickness δ of the finished metal lining 1 is 0.5mm-1.8mm, which is far thinner than the existing titanium alloy lining, and also Thinner than the typical aluminum alloy lining, the thickness of the lining is thinner, and the efficiency of the high-pressure gas cylinder is greatly increased; the ratio of the thickness δ of the metal lining 1 to the diameter D is 2.8×10 -3 Below, 2.0×10 can be achieved after technical resea...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that it also includes a sixth step: cleaning and polishing. In the process of preparing the metal lining 1, the five steps described in the first embodiment can already achieve the purpose of obtaining a metal lining 1 with good performance. If the sixth step is added, that is, the cleaning and polishing process, the metal lining can be guaranteed The contact between the inner liner 1 and the outer wrapping layer is good. For example, in the preparation process, an adhesive can be coated on the outer surface of the metal inner lining 1, and then the composite material layer 2 is wound. The bonding between them is good, so that the high-pressure gas cylinder can achieve better performance. The cleaning and polishing process is as follows in sequence: (a) cleaning the surface of the lining 1 with a weak base with a concentration of 0.05% to 0.15% by mass for 5 to 10 minutes; (b) using a fine metal brush dipped in...

specific Embodiment approach 3

[0024] Specific embodiment three: The present invention requires that the material for preparing the metal lining 1 is the ratio F of the tensile yield strength and the modulus of elasticity TY / E is at least 0.6%, elongation is at least the titanium alloy of 5%, as long as all titanium alloys that can reach the above-mentioned properties can prepare the high-pressure cylinder required by the present invention. High-performance metals that meet this condition can be selected from titanium alloys containing alloying elements such as Al, Fe, Ta, Mo, Sn, Cr, Si, Zr and V. In actual operation, the more commonly used ones can achieve the above properties The titanium alloy materials are Ti-6V-2Sn, Ti-6Al-2Sn-4Zr-2Mo, Ti-6Al-2Cb-1Ta-0.8Mo, Ti-6Al-4V, Ti-13V-11Cr-3Al, Ti-8Al- 1Mo-1V, Ti-3Al-8V-6Cr-4Mo-4Cr, Ti-11Sn-5Zr-2Al-1Mo, Ti-5Al-2Sn-2Zr-4Mo-4Cr, Ti-10V-2Fe-3Al, Ti-6Al- 2Sn-4Zr-6Mo, Ti-15V-3Al-3Cr-3Sn, Ti-6Al-2Sn-2Zr-2Mo-2Cr-0.25Si or Ti-5Al-2.5Sn, the above materials are just e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com