Patents

Literature

272results about How to "Retention strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

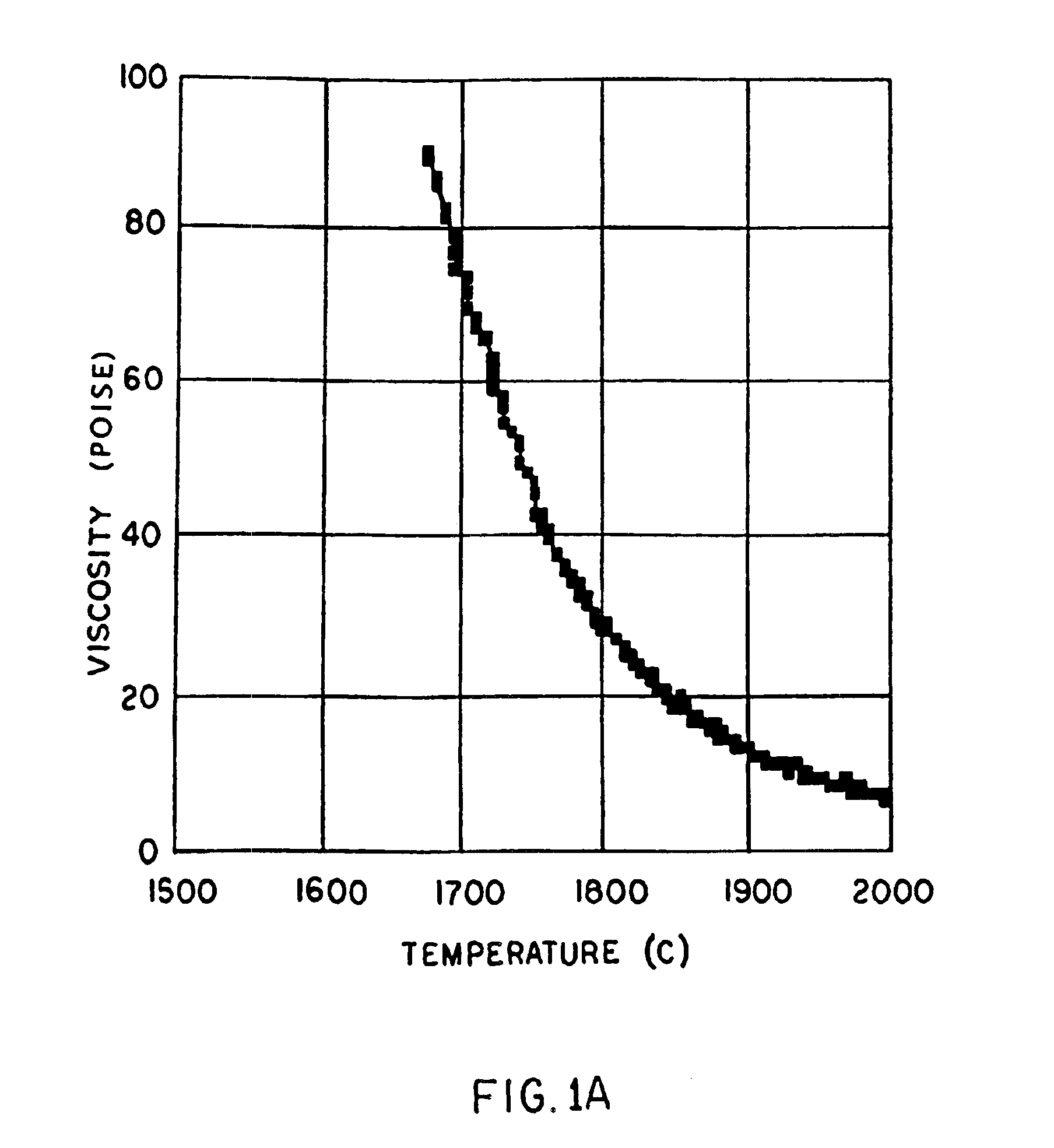

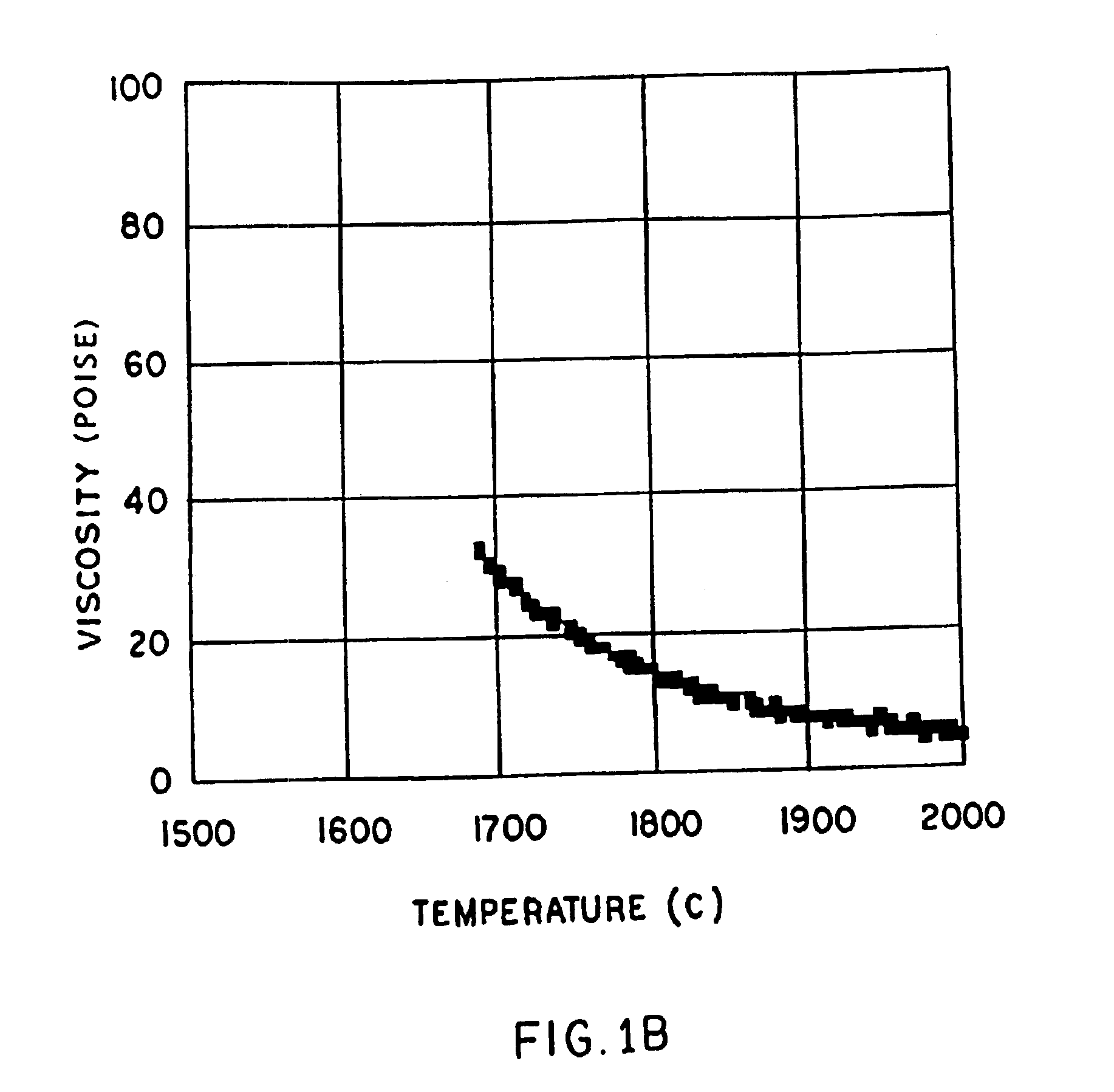

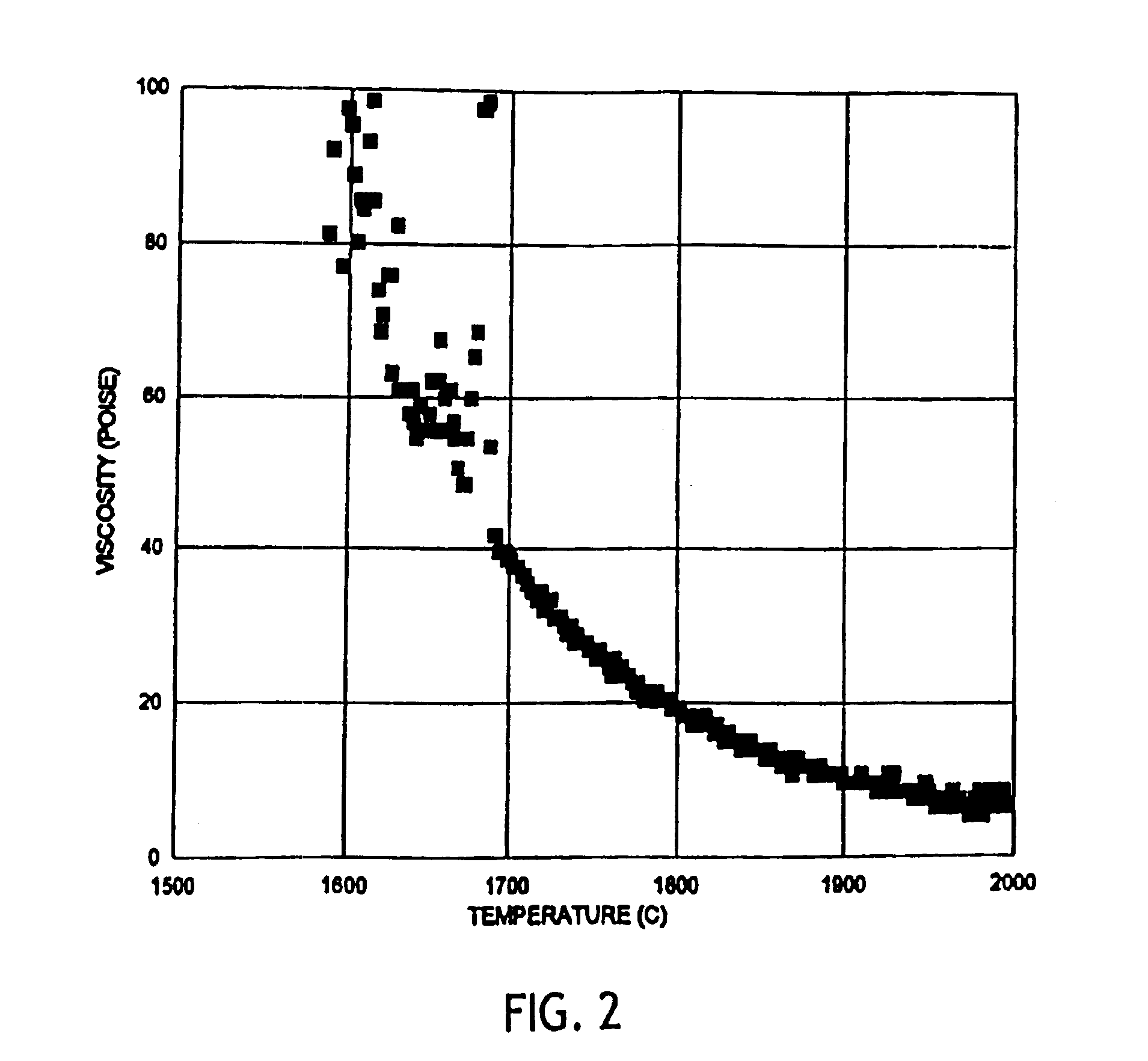

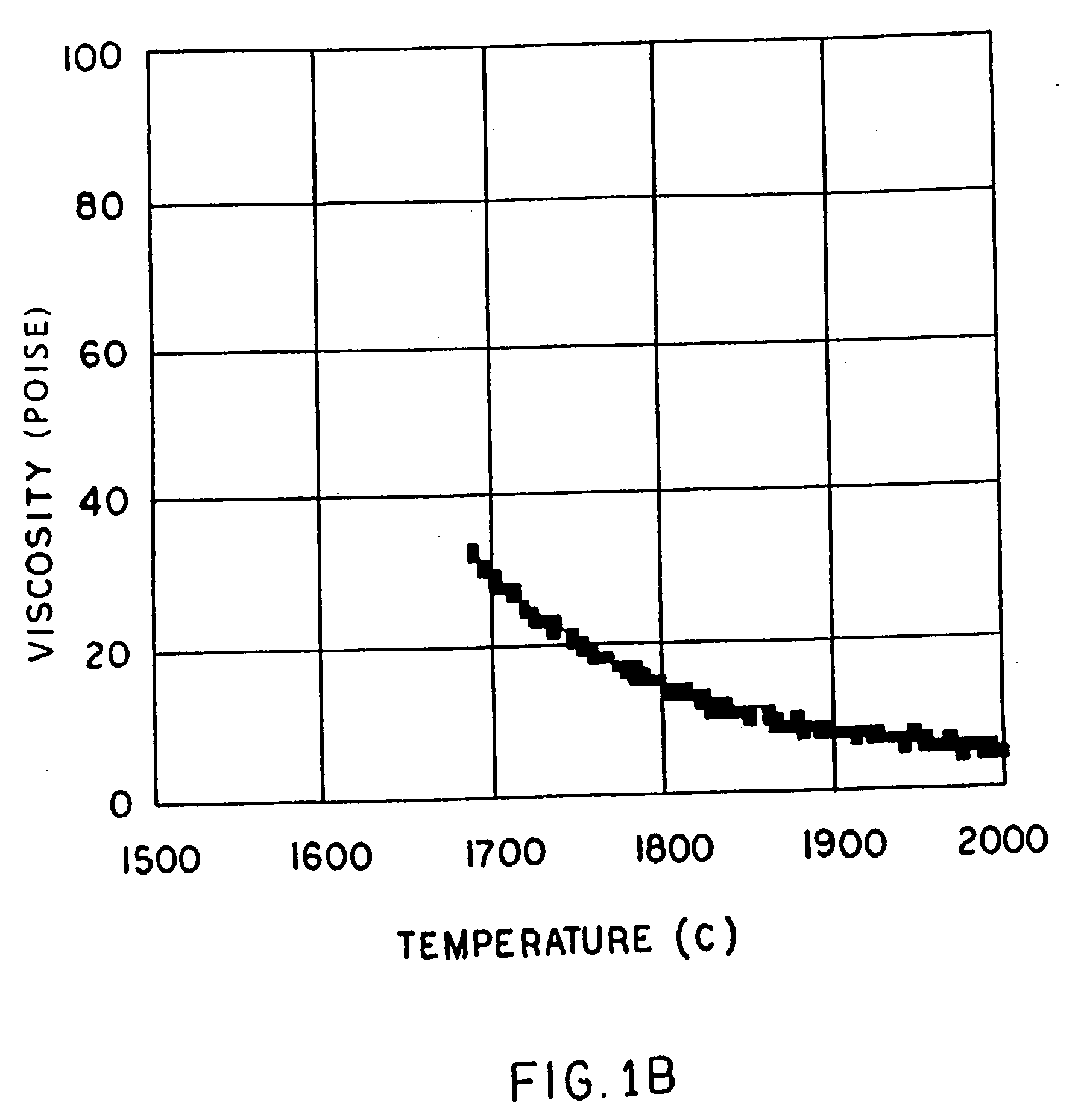

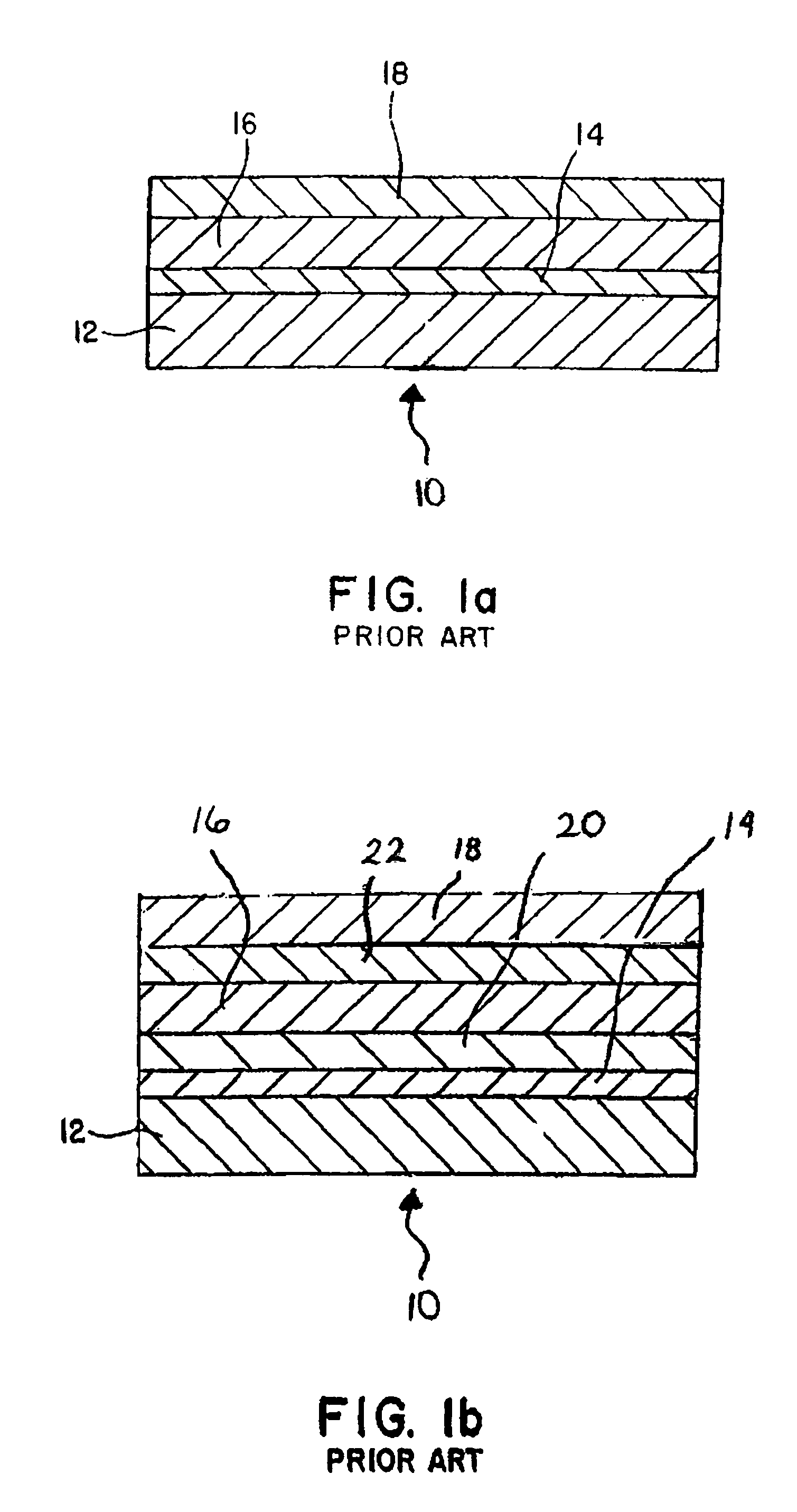

High temperature a resistant vitreous inorganic fiber

InactiveUS6953757B2Easy to manufactureLow shrinkageInorganic fibres/flakesInorganic material artificial filamentsFiberPhysiological fluid

A low shrinkage, high temperature resistant vitreous inorganic fiber having a use temperature up to at least 1330° C., which maintains mechanical integrity after exposure to the use temperature and which is non-durable in physiological fluids, is prepared by the method of forming a melt with ingredients including greater than 71.25 weight percent silica, 0 to about 20 weight percent magnesia, and about 5 to about 28.55 weight percent of calcia, 0 to about 5 weight percent zirconia, and optionally a viscosity modifier in an amount effective to render the product fiberizable; and producing fibers from the melt.

Owner:UNIFRAX I LLC

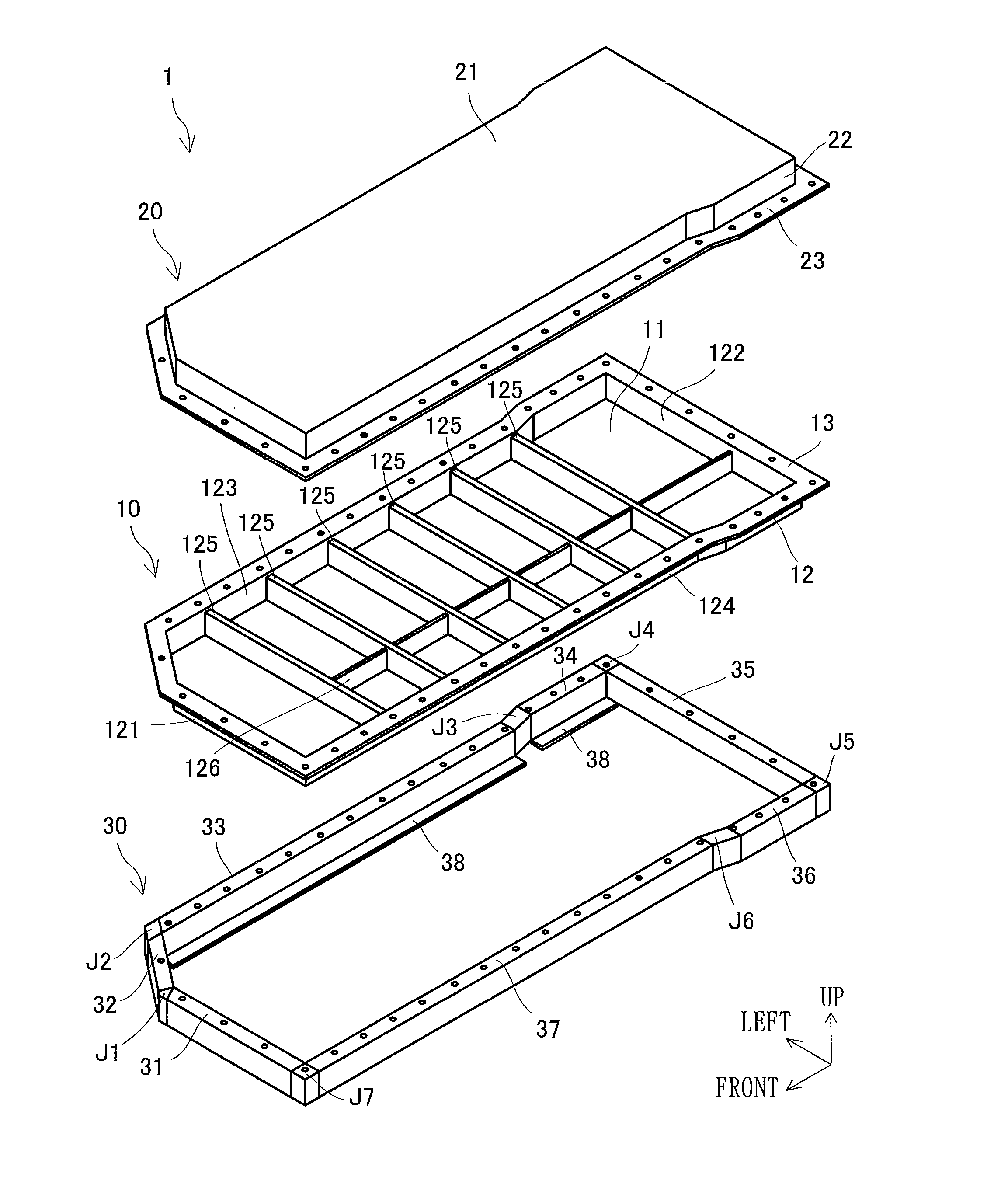

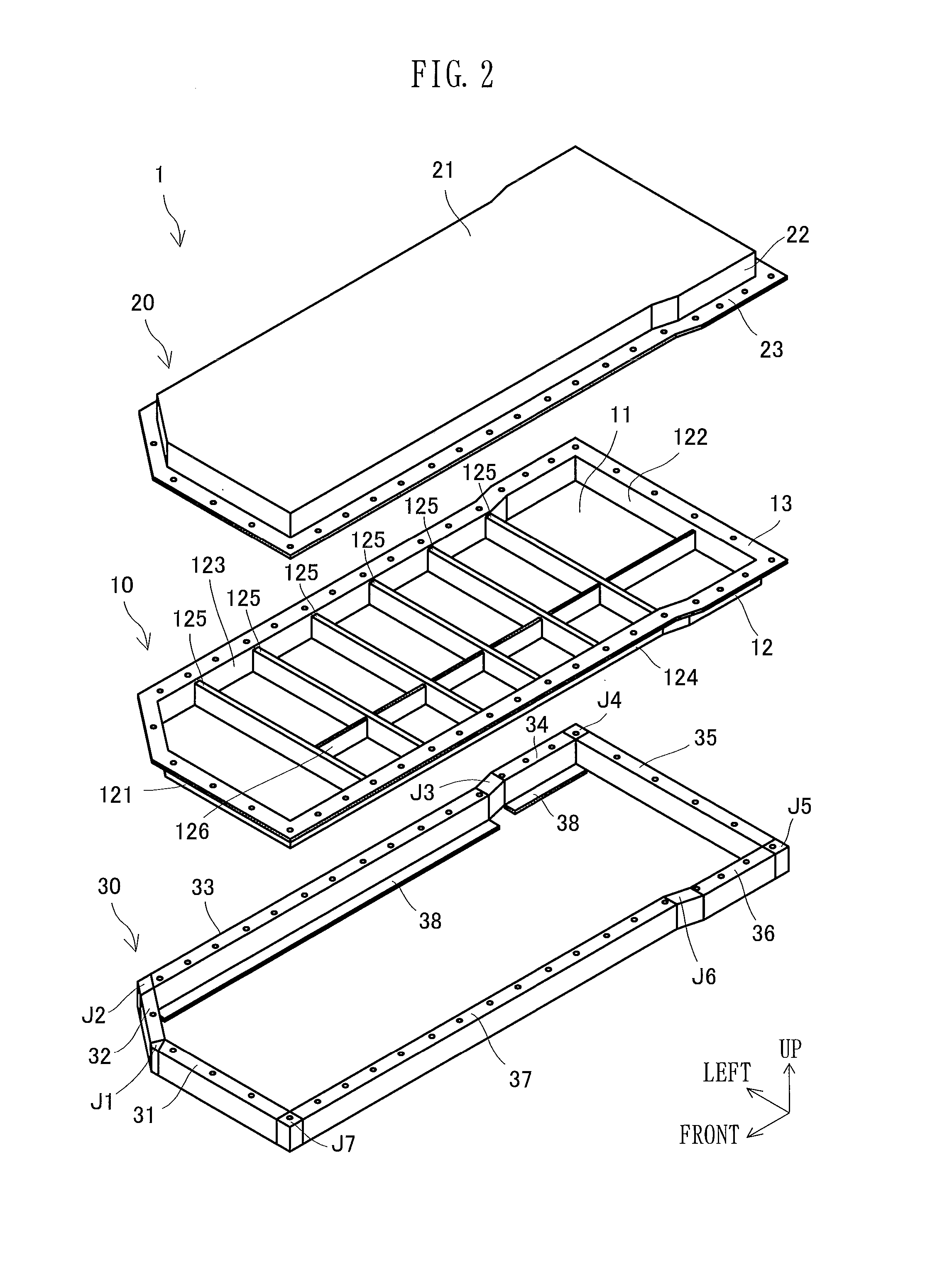

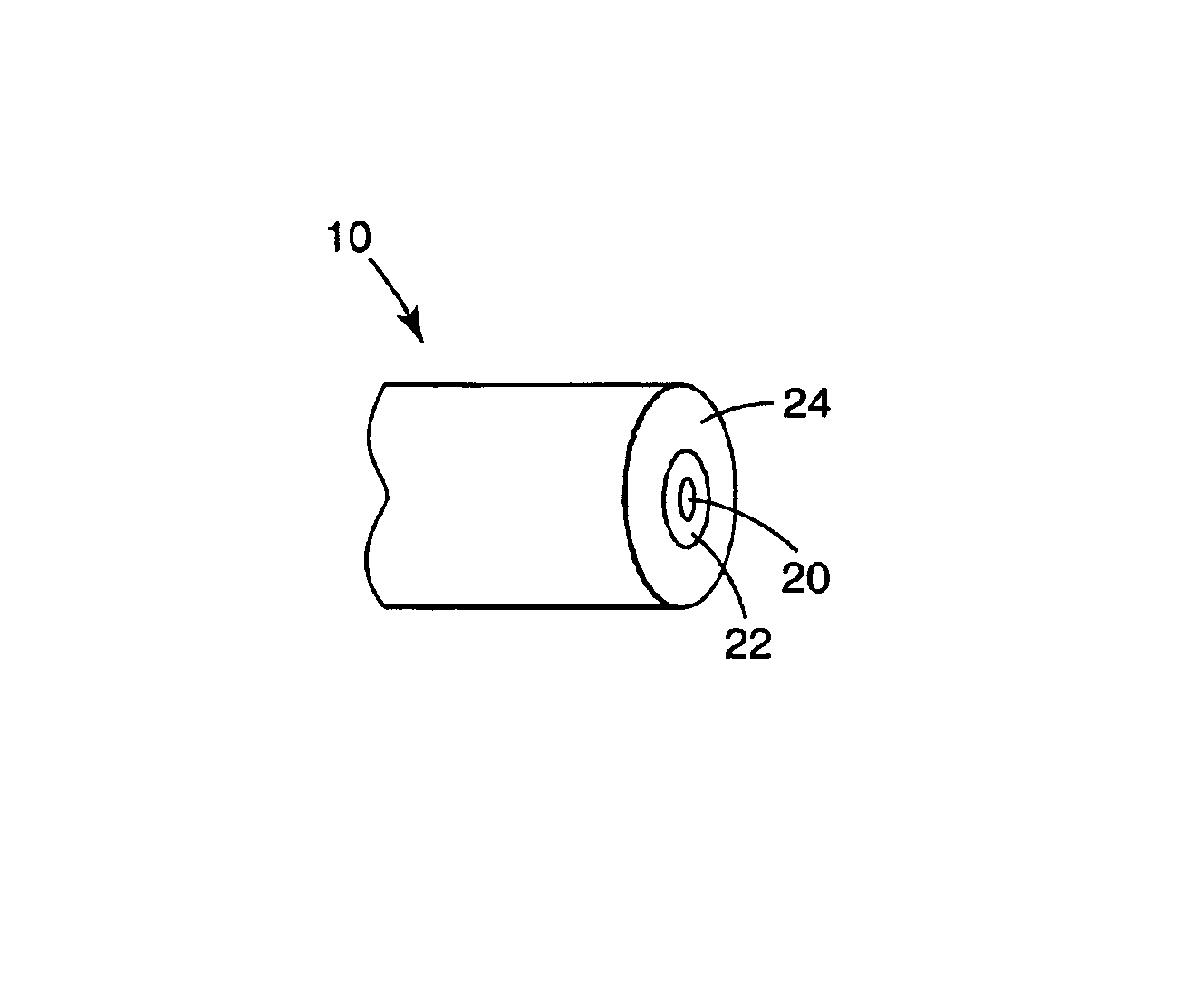

Battery case

ActiveUS20110143179A1Good effectRigidity be retainedSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringFlange

A battery case comprises: a battery tray formed from a resin, the battery tray having a bottom wall on which batteries are mounted, and a peripheral side wall which surrounds the periphery of the bottom wall; and a battery cover which covers the battery tray. A flange portion is provided on the upper surface of the peripheral side wall, and a metallic housing-shaped frame is provided beside the outer wall of the battery tray. The flange portion and the battery cover are fixed onto the upper surface of the metallic housing-shaped frame by fastening members.

Owner:MITSUBISHI MOTORS CORP

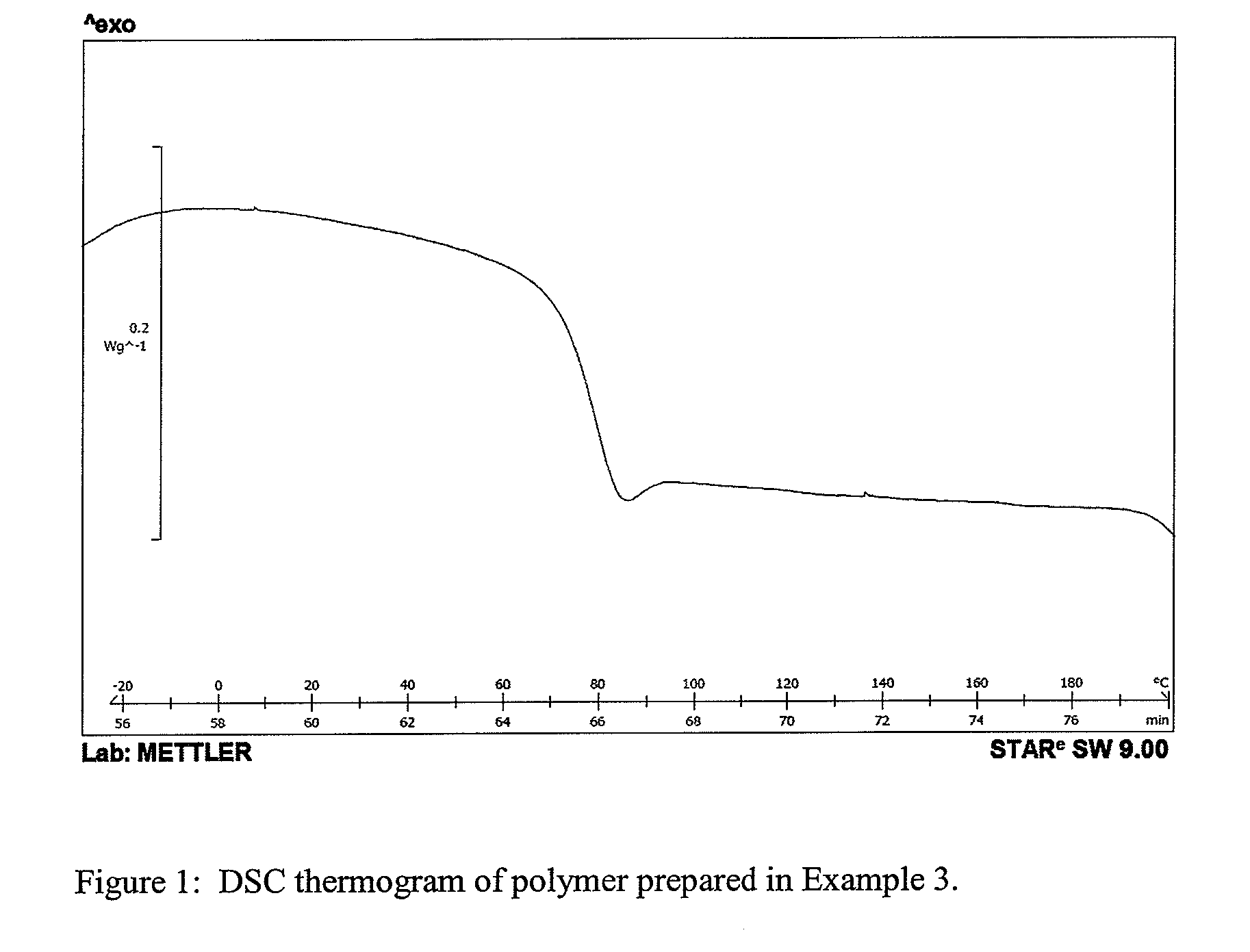

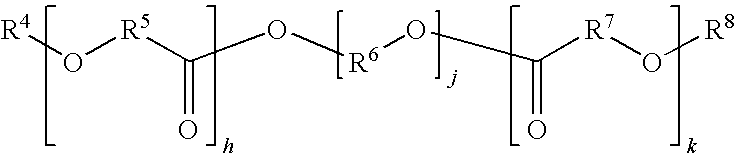

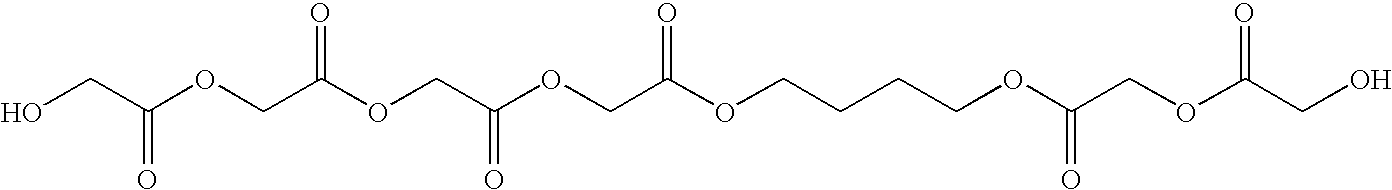

High modulus polyurethane and polyurethane/urea compositions

ActiveUS20090099600A1High modulusHigh strengthStentsAdditive manufacturing apparatusMedicineUltimate tensile strength

The present invention provides a polyurethane or polyurethane / urea composition which has a tensile strength greater than 10 MPa, a modulus of elasticity greater than 400 MPa and an elongation at break greater than 30% at a temperature of between 0° C. and 60° C. and at a relative humidity of between 0% and 100%.The invention further provides uses of the compositions of the invention in biomedical vascular stents, an orthopaedic implant, a drug delivery coating or in tissue engineering.

Owner:POLYNOVO BIOMATERIALS PTY LTD

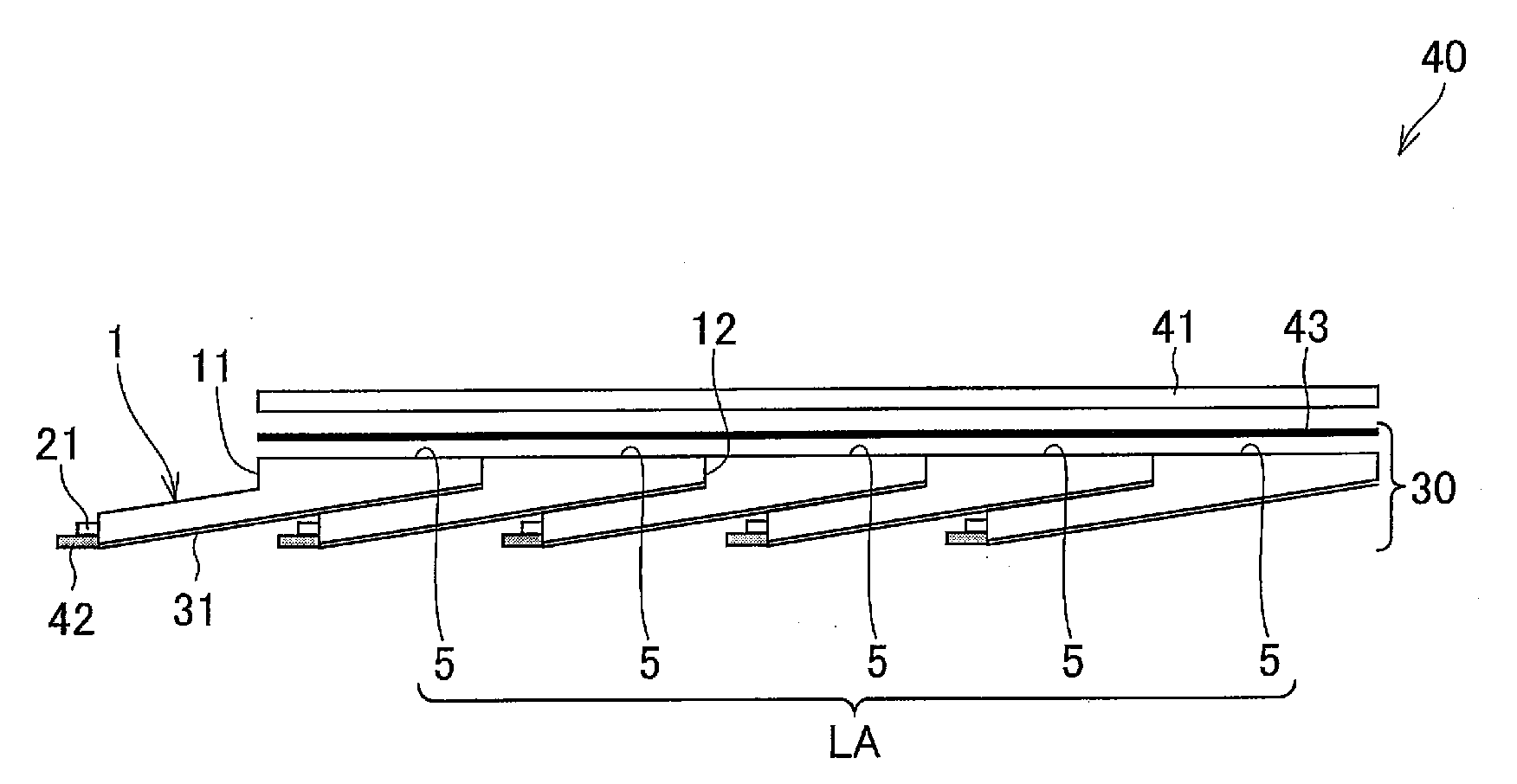

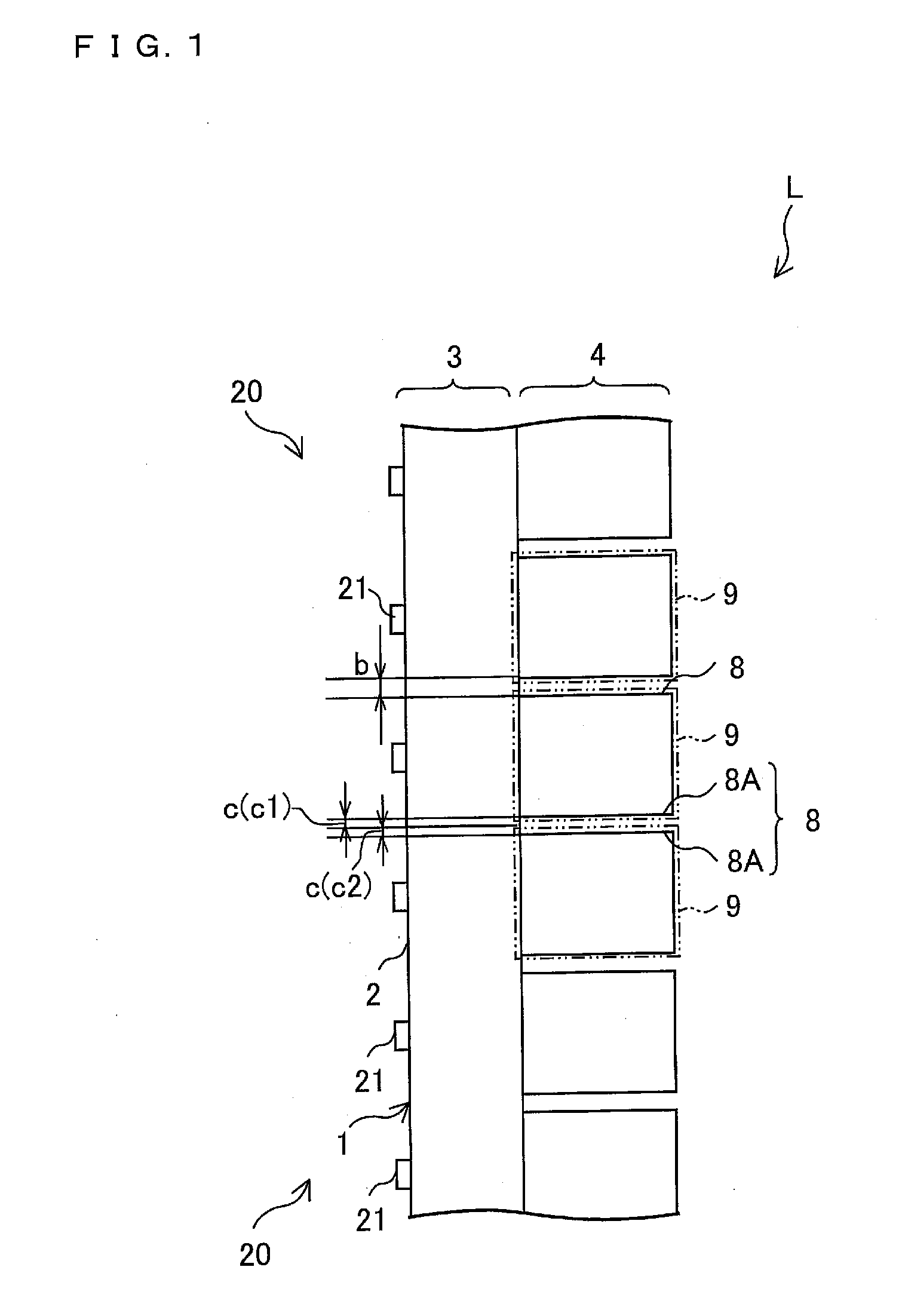

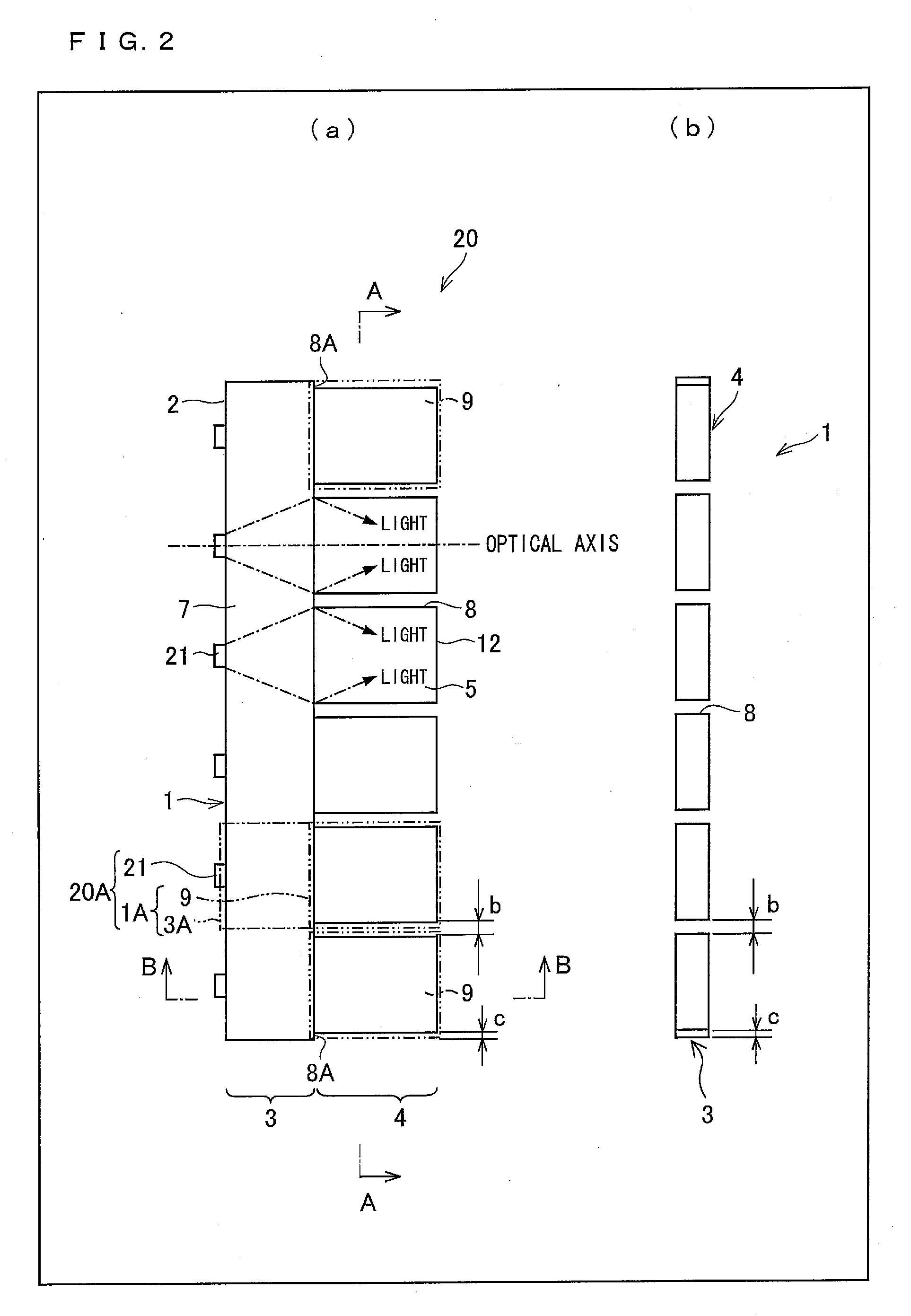

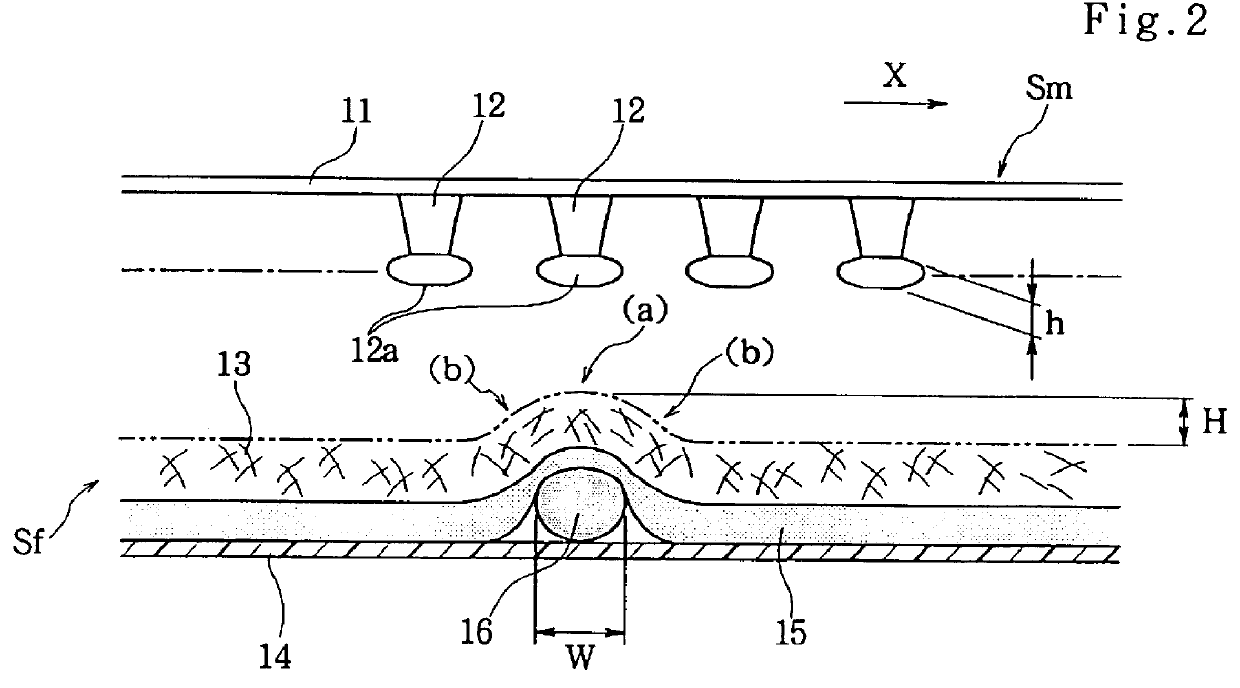

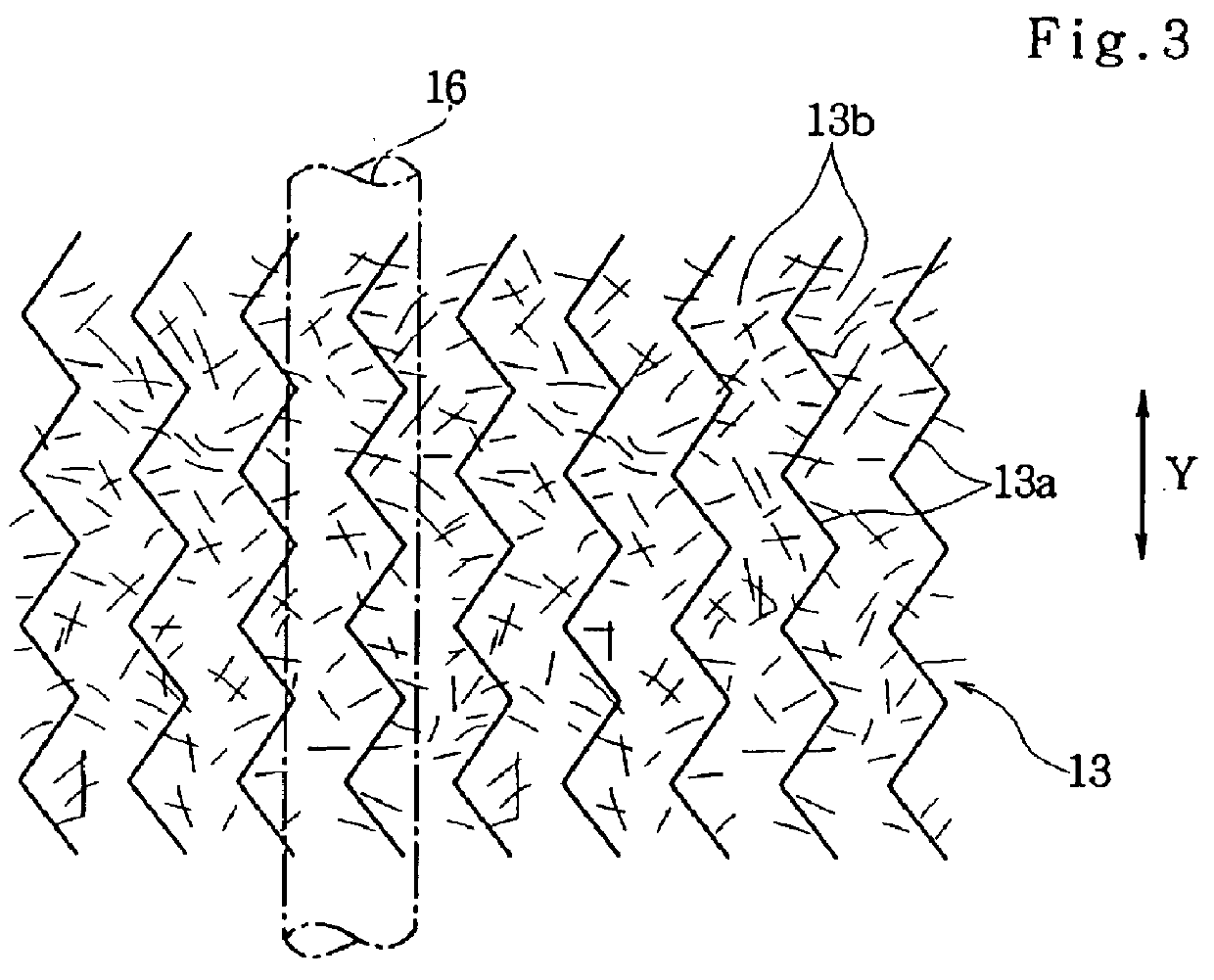

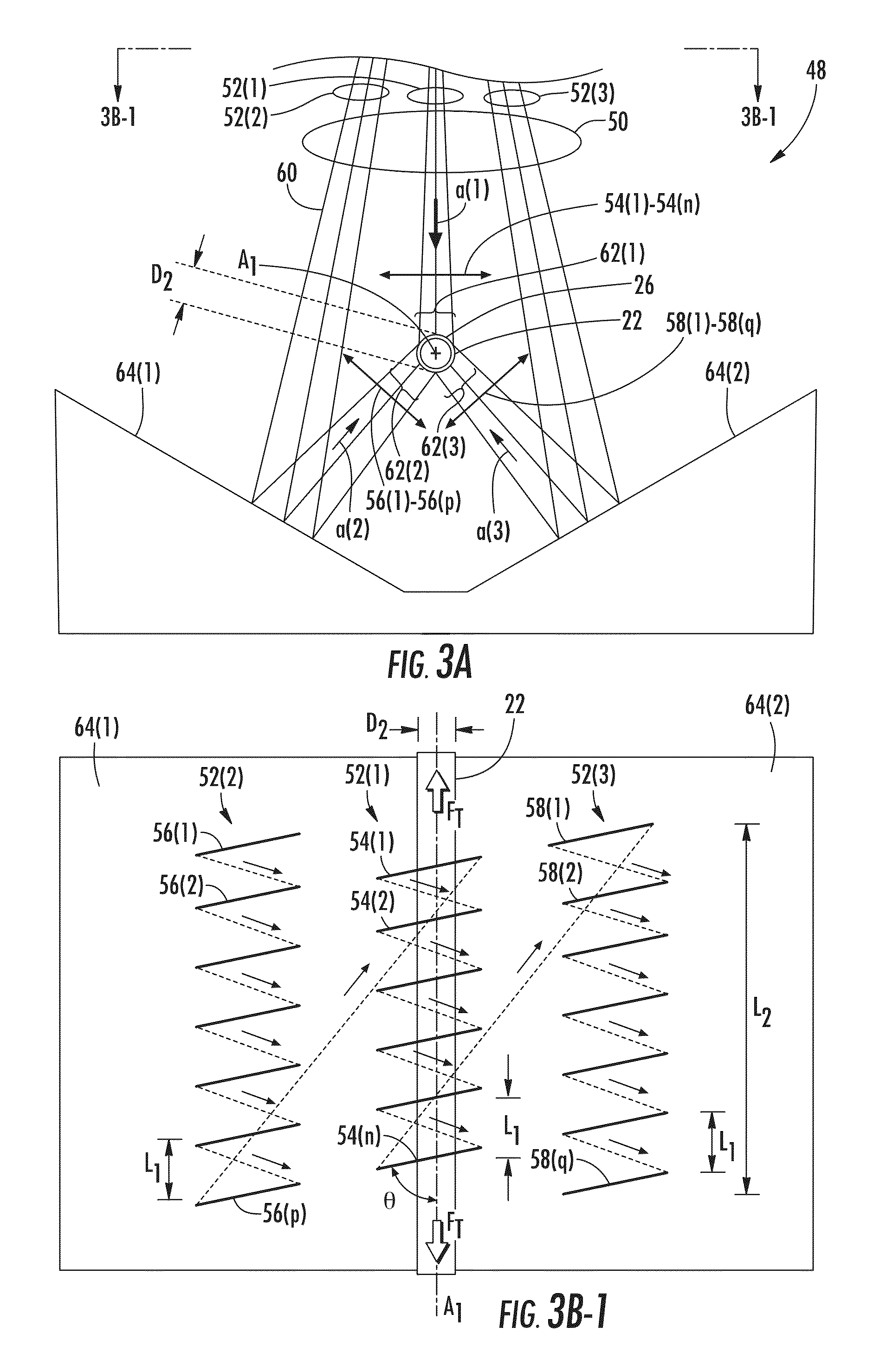

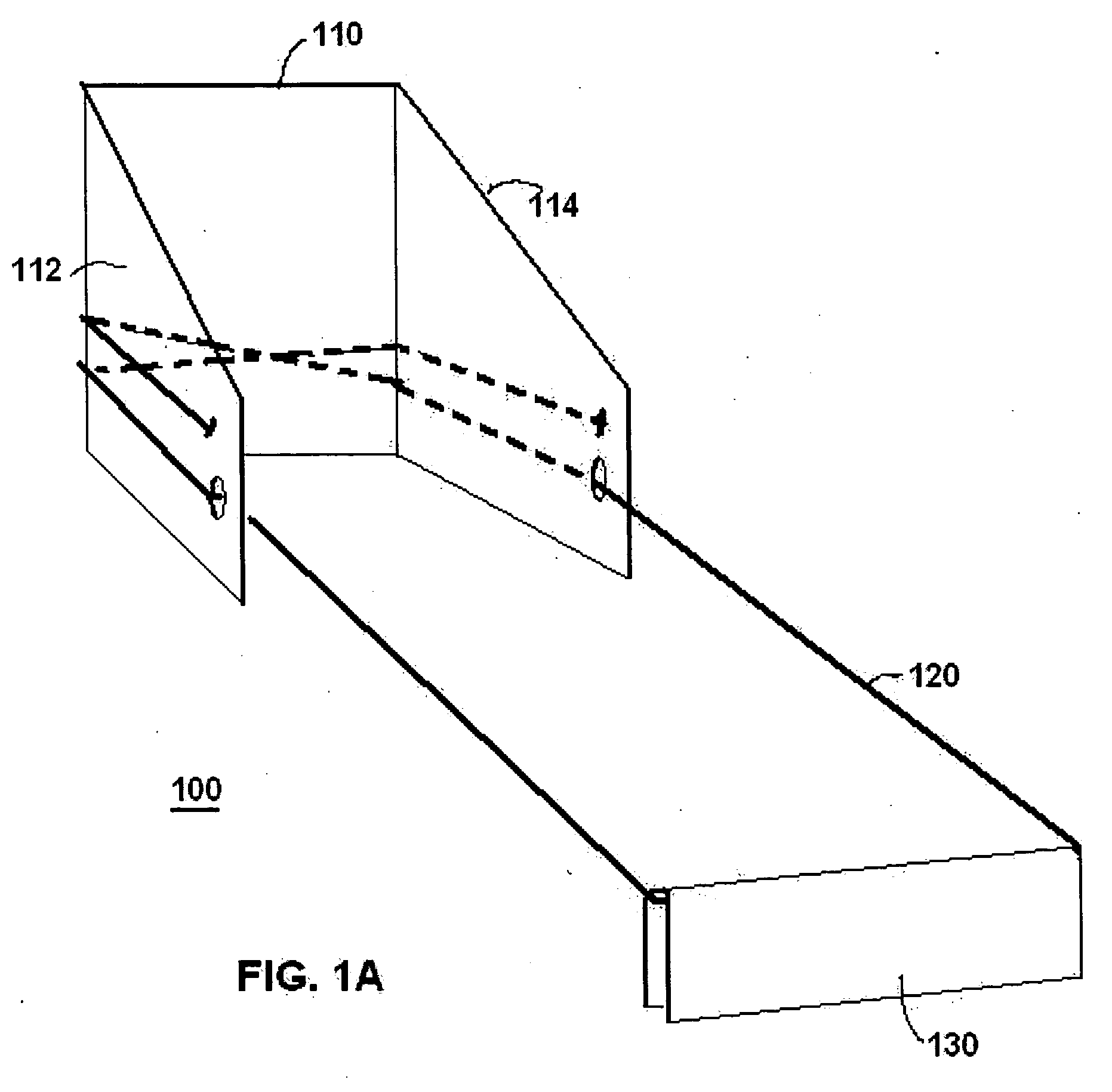

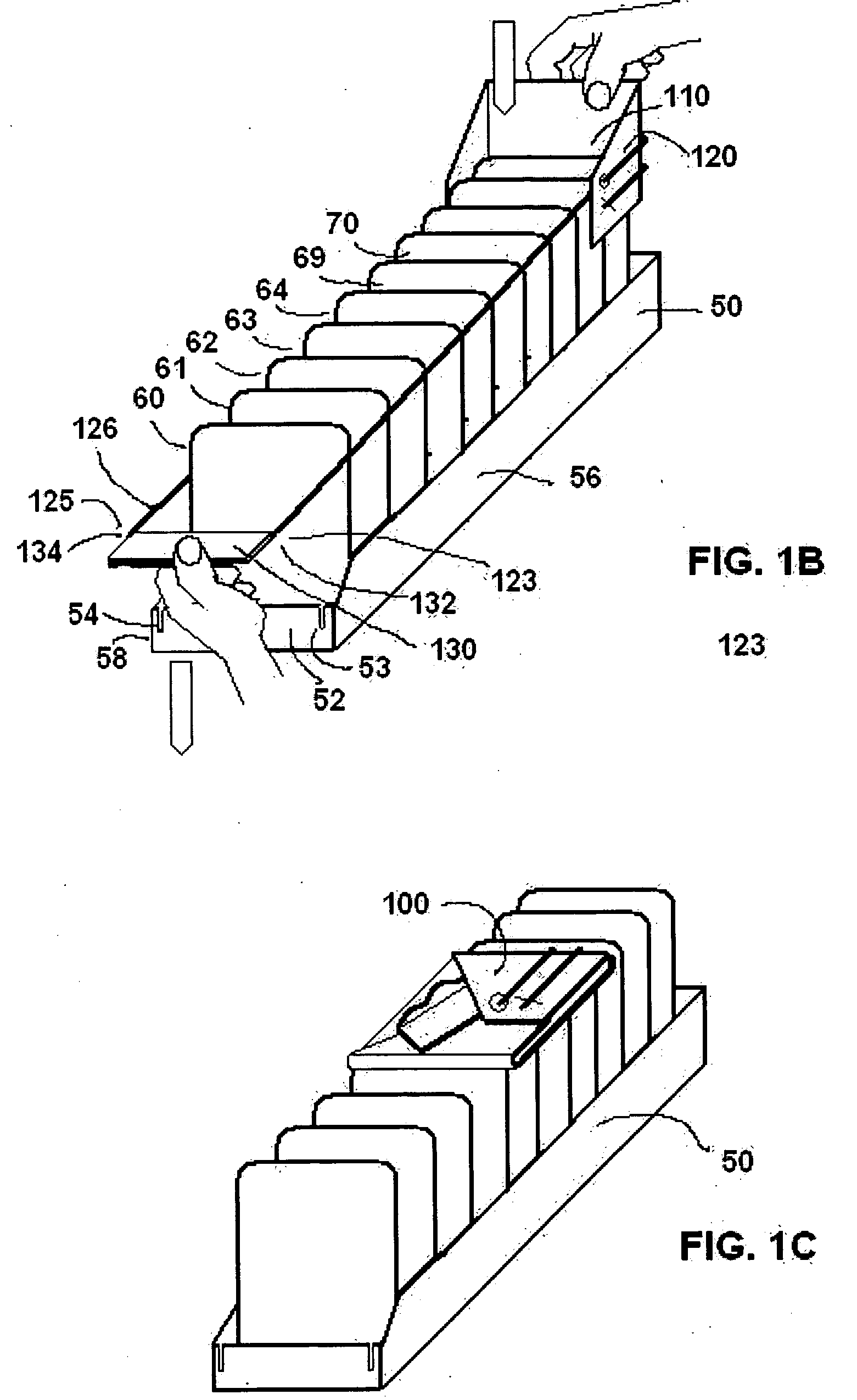

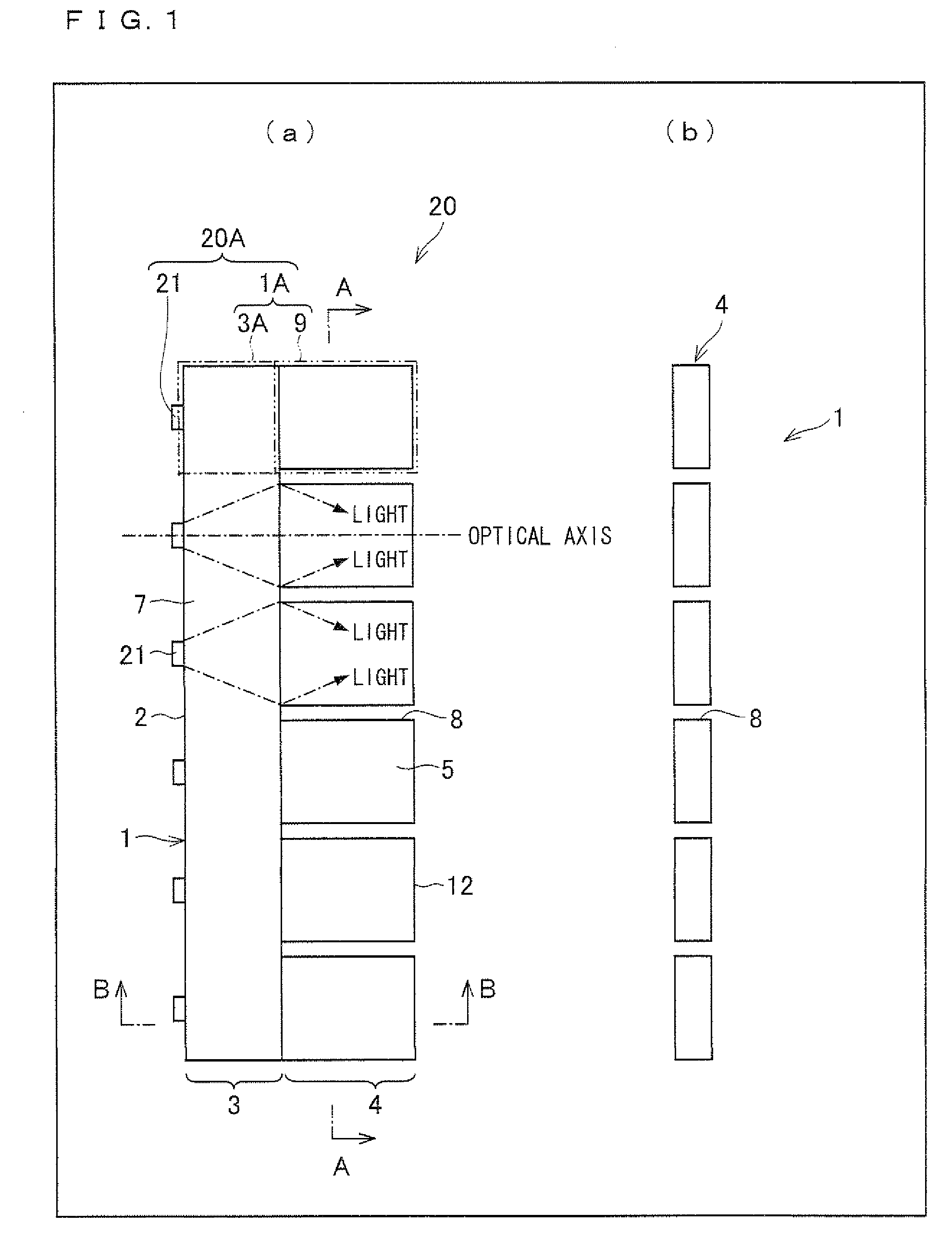

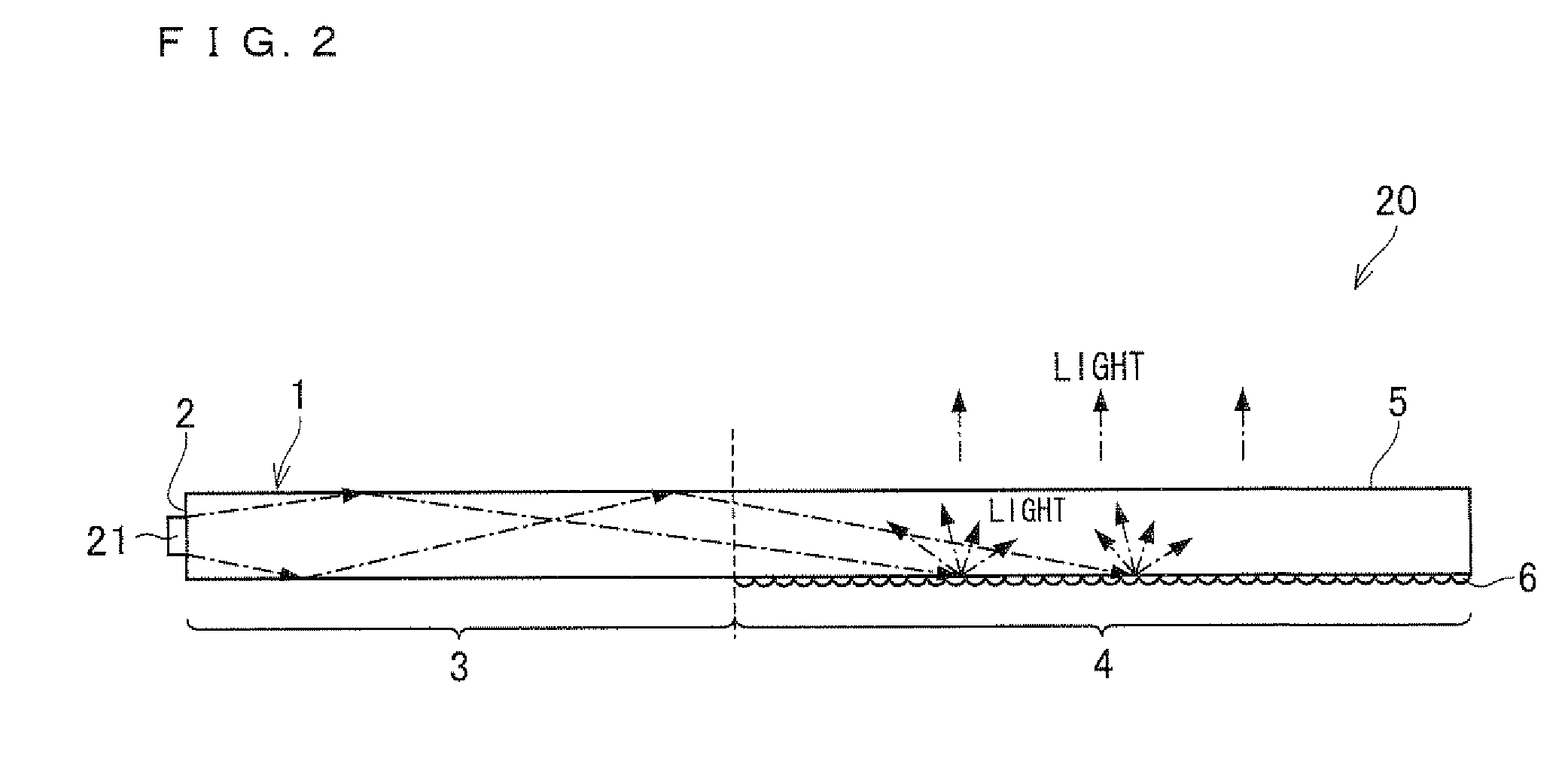

Illumination device, display device, and light guide plate

InactiveUS20110025730A1Reduce light leakageRetention strengthCathode-ray tube indicatorsPlanar/plate-like light guidesLight guideOptical axis

An illumination device (L) includes a plurality of light source units (20) each having a light guide plate (1) and a plurality of light sources (21). The light guide plate (1) has an illumination region (4) through which incident beams of light from the light sources (21) are emitted outward and a light guide region (3) through which the incident beams of light from the light sources (21) are guided toward the illumination region (4), with the light guide region (3) and the illumination region (4) laid side-by-side. The illumination region (4) is divided into a plurality of light-emitting sections (9) by slit sections (8), provided in such a way as to extend along directions of optical axes of the light sources (21), which restrict transmission of light. At least one of the light sources (21) is provided to each of the light-emitting sections (9) in such a way as to be placed side-by-side along the light guide region (3). The light source units (20) are provided in such a way as to be placed side-by-side along at least along a first direction along which the light-emitting sections (9) are arranged in the illumination region (4). There is also provided a slit section (8) in at least part of a space between light-emitting sections (9) between light source units (20) adjacent to each other along the first direction. This makes it possible to provide an illumination device (L) capable of retaining its strength as a combination of light guide blocks while reducing leakage of light into an adjacent area and capable of emitting uniform light.

Owner:SHARP KK

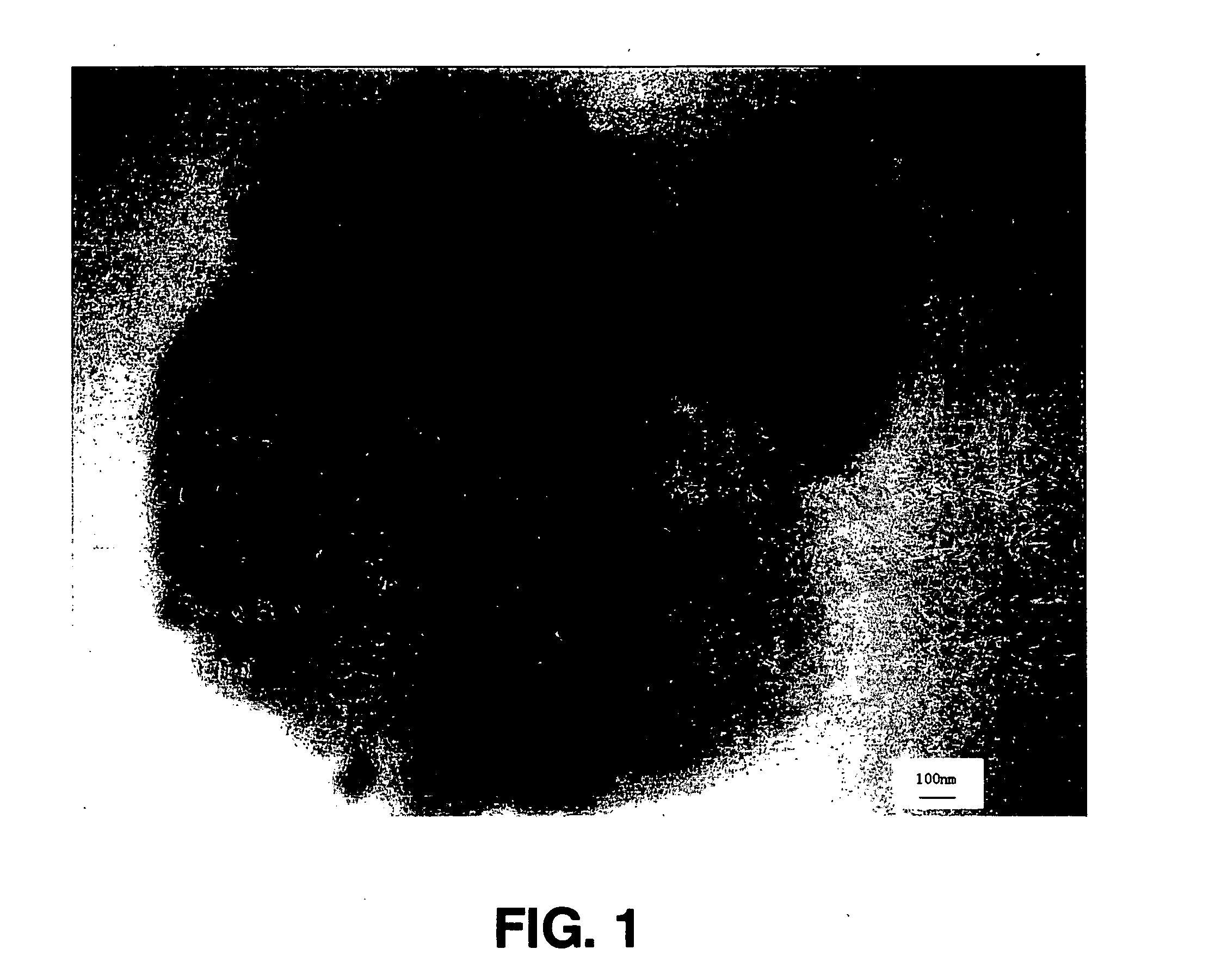

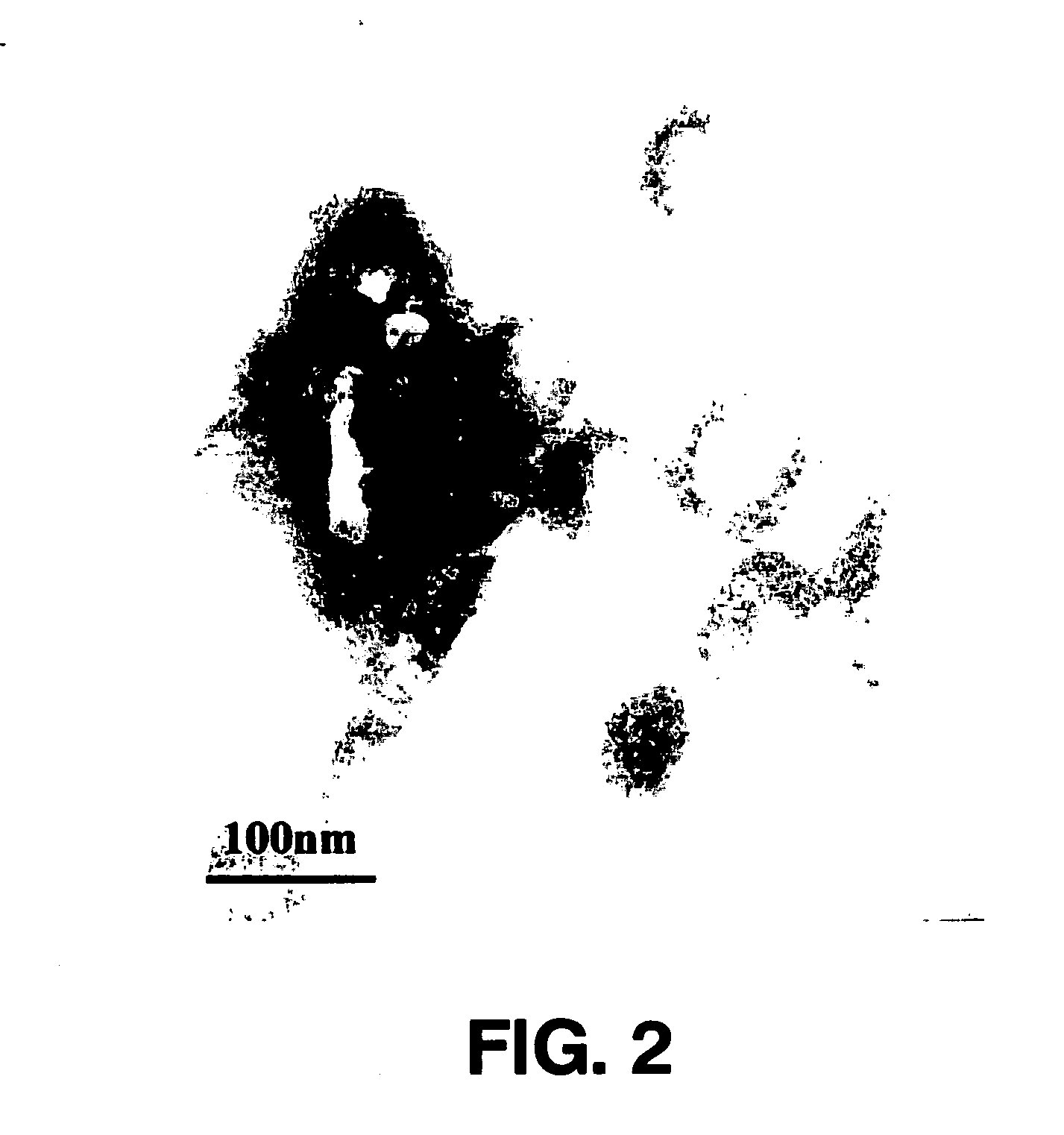

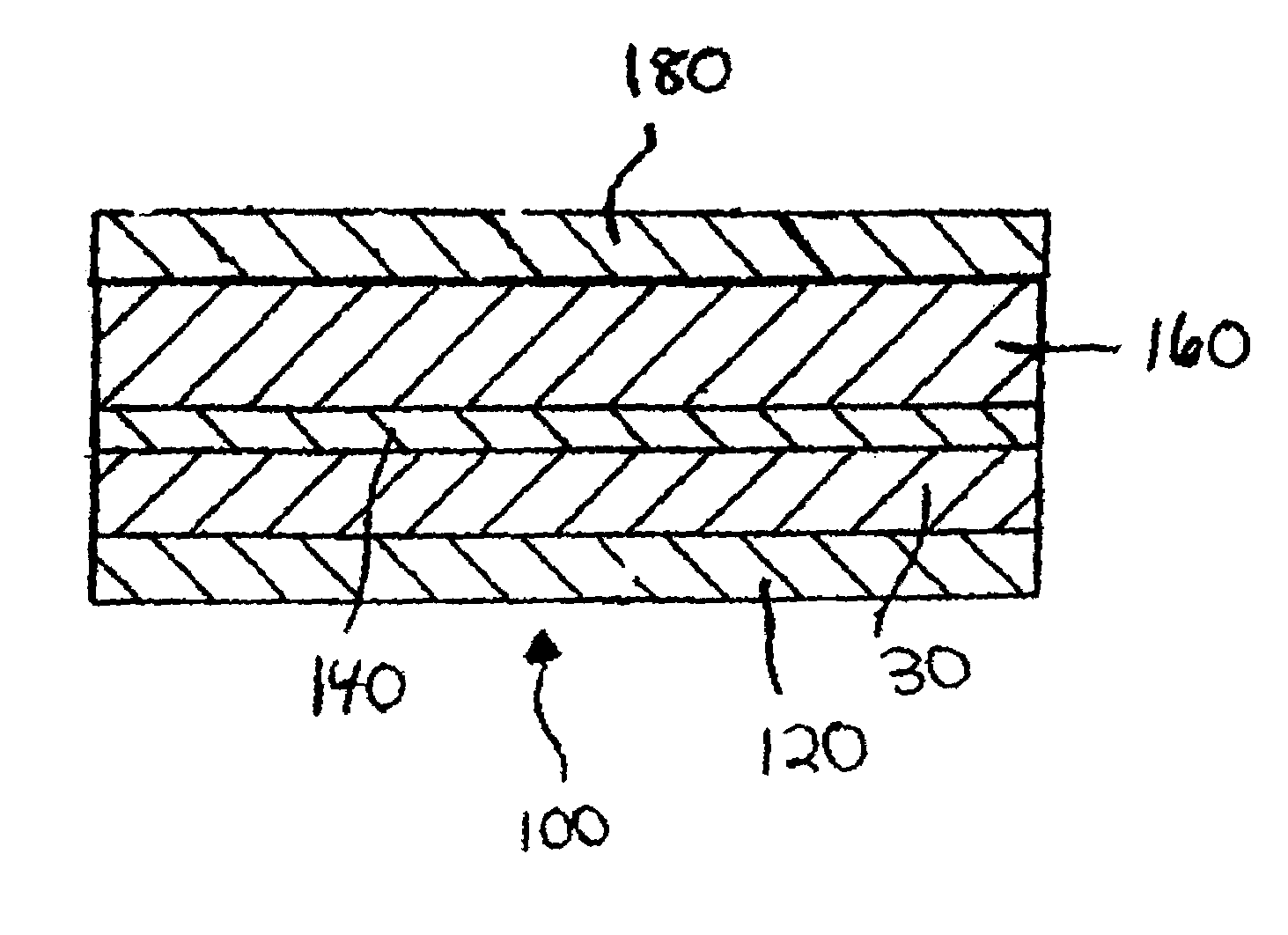

Metal matrix composite material

InactiveUS20100003536A1Reduce size of crystalIncreased strengthLayered productsThin material handlingNanometreMetal matrix composite

According to the present invention there is provided a metal matrix composite material and a method for the manufacture thereof, the material comprising an aluminium-based alloy matrix, the matrix comprising a microstructure composed of at least a first aluminium alloy phase and having a second phase of nanostructured quasicrystalline particles embedded therein and further including in said matrix fibrils of at least one other dissimilar material.

Owner:SMITH GEORGE DAVID WILLIAM +3

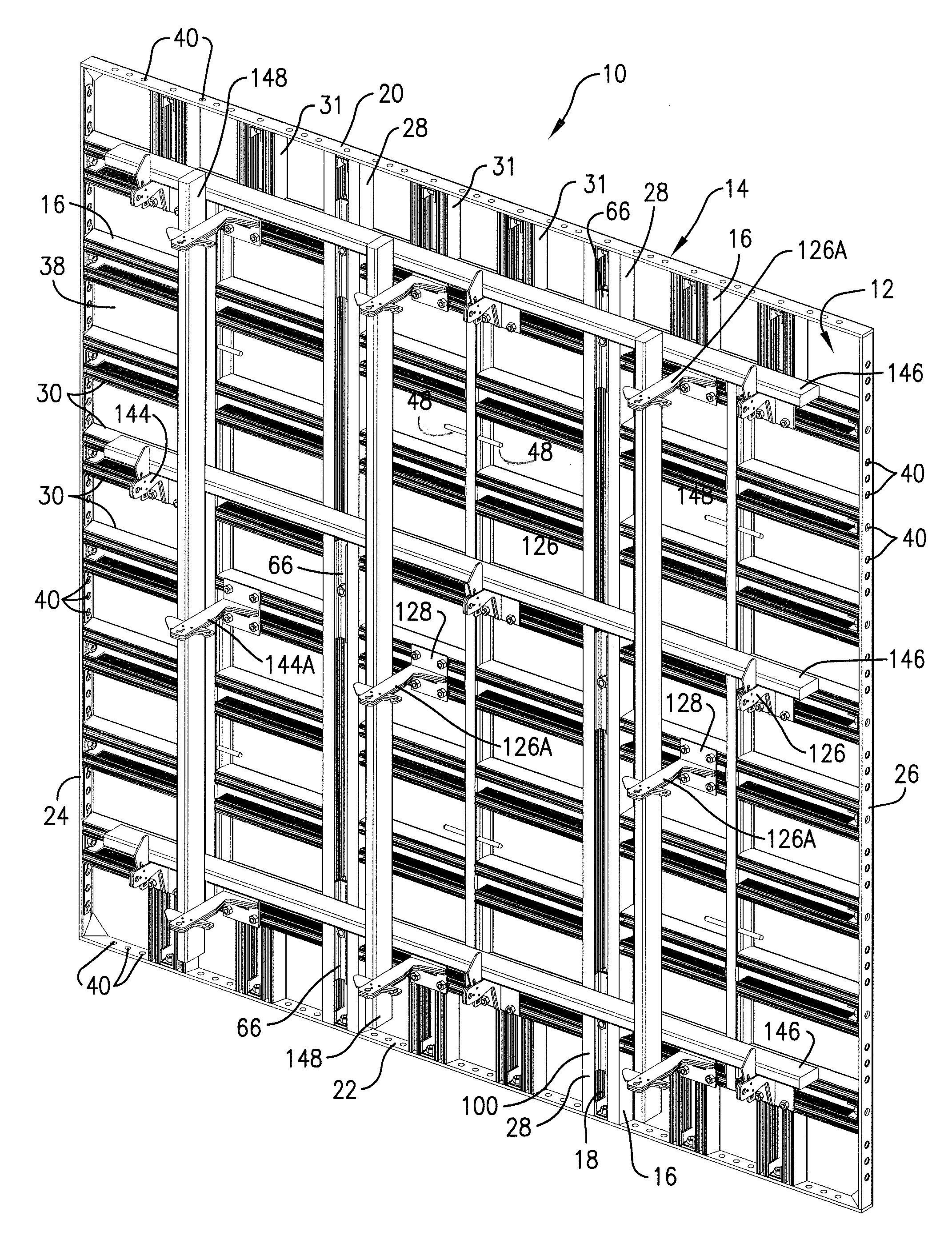

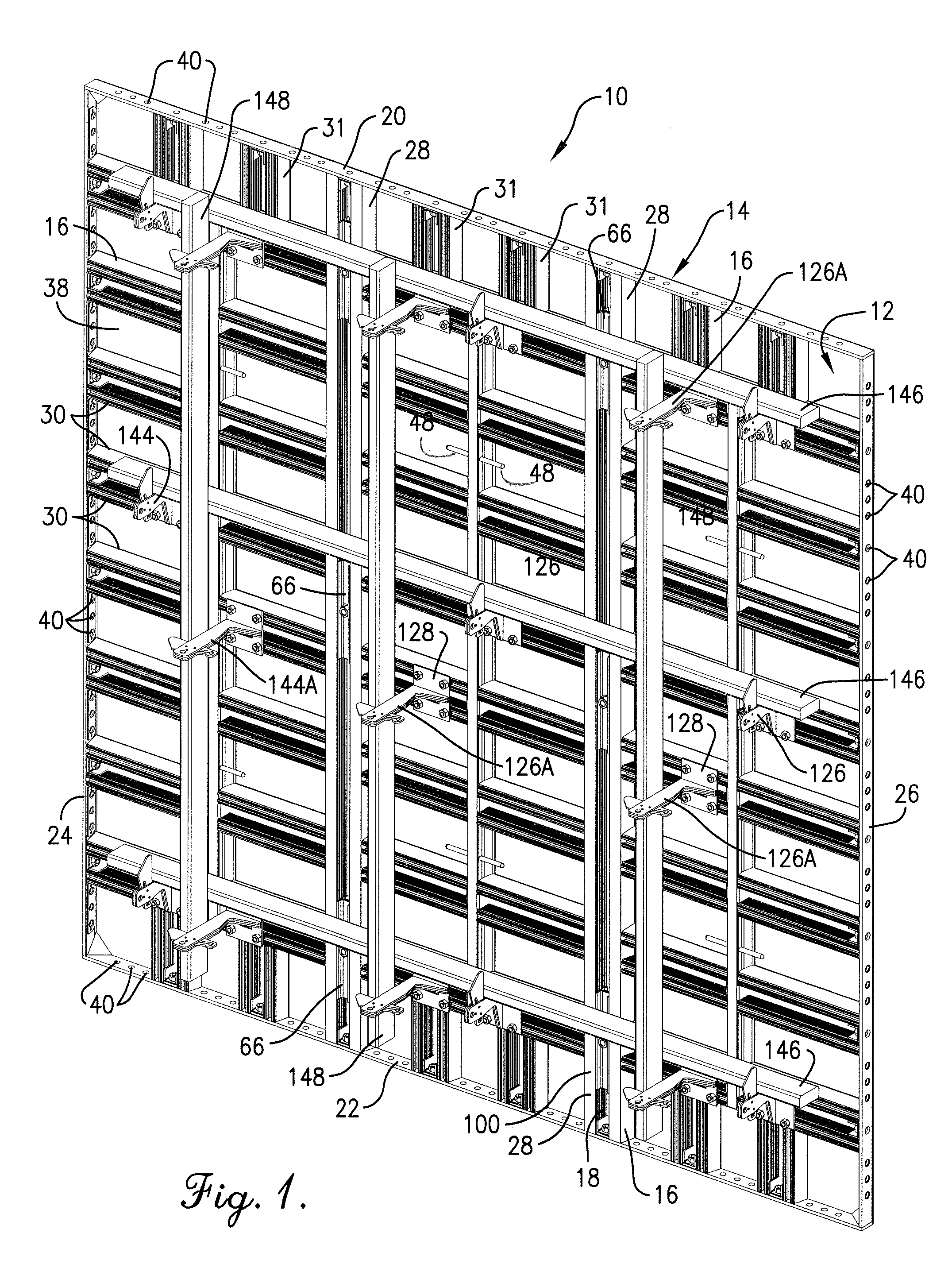

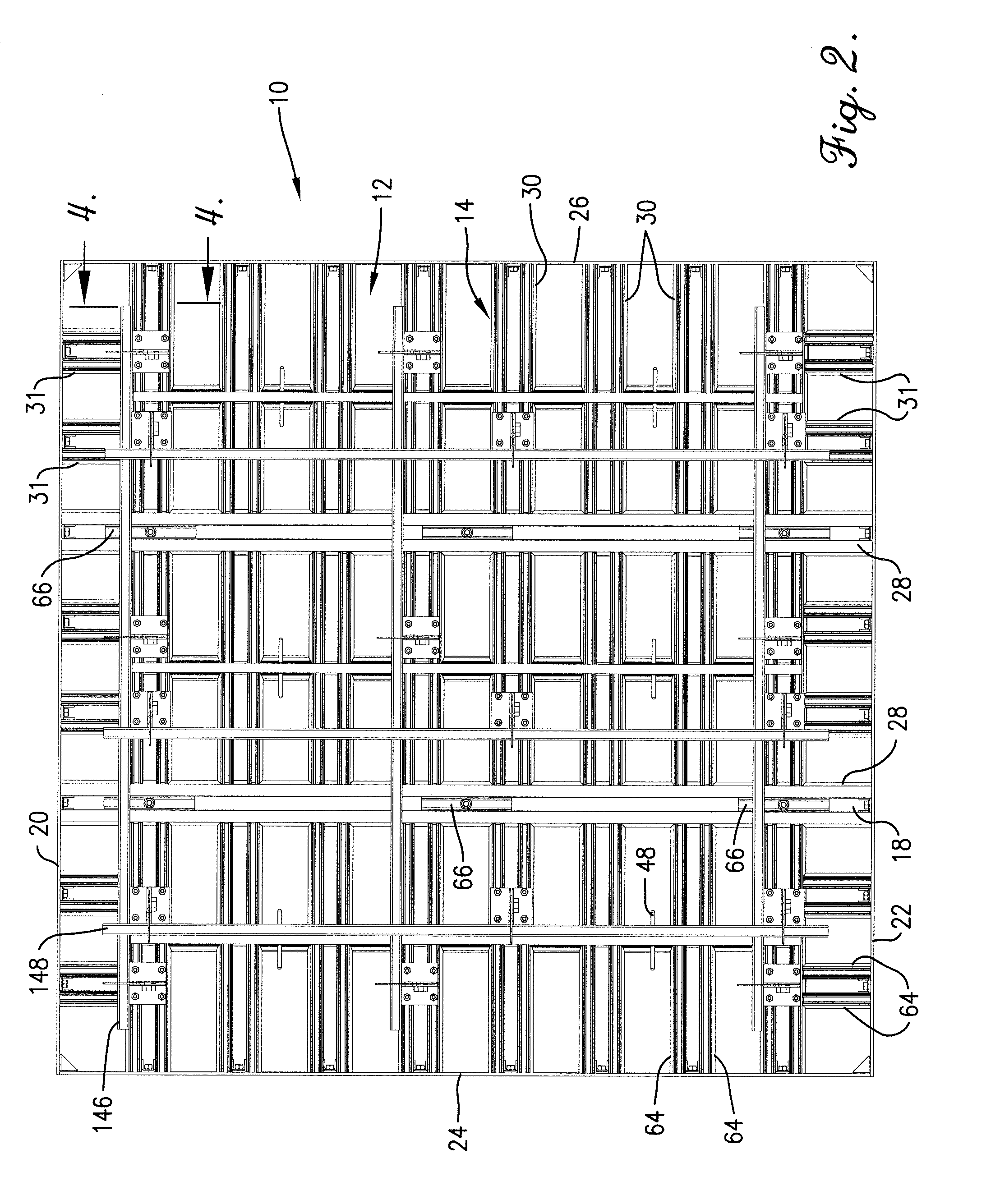

Lightweight Crane-Set Forming Panel

InactiveUS20080173788A1Easy to useReinforce against deflectionCeramic shaping apparatusForms/shuttering/falseworksEngineeringSurface plate

A forming panel is provided which is particularly useful as a large, crane-set forming panel for forming concrete walls. The forming panel includes a face plate and a frame, the frame including channels having a slot extending longitudinally therealong. The slot is adapted to receive a filler insert having a bushing which includes a flexible barrier having a brush-like element with a plurality of filaments extending into a passage configured to receive either a tie bar or a tie rod. The forming panel preferably includes a shiftably mounted bracket for supporting a waler, scaffold or strongback thereon, wherein the bracket includes an arm which may be pivoted to a position substantially parallel to the frame and its mounting plate for transport and / or storage. The face plate may be provided as a multilayered composite panel and the frame may include rails having grooves on the side opposite the face plate which receive flexible barriers for inhibiting the passage of fine particles of concrete therepast.

Owner:WESTERN FORMS

Composite powder, preparation and use thereof

ActiveUS20050031870A1Retains modulus propertyRetains strength propertyPigmenting treatmentSynthetic resin layered productsPolymer scienceInorganic particle

The present invention relates to a composite powder, preparation and use thereof. The composite powder according to the present invention is prepared by intimately mixing an irradiated or non-irradiated rubber latex with a slurry of inorganic particles in a ratio corresponding to that of rubber particles to inorganic particles in the composite powder according to the present invention, and then drying the resultant mixture. The composite powder according to the present invention comprises agglomerates composed of powdery rubber particles and inorganic particles, with inorganic particles being uniformly distributed either inside the agglomerats or both inside the agglomerates and on the surfaces thereof. The composite powder according to the present invention can be easily dispersed in plastic matrixes and thus can be compounded with plastics to produce toughened plastics and thermoplastic elastomers.

Owner:CHINA PETROCHEMICAL CORP +1

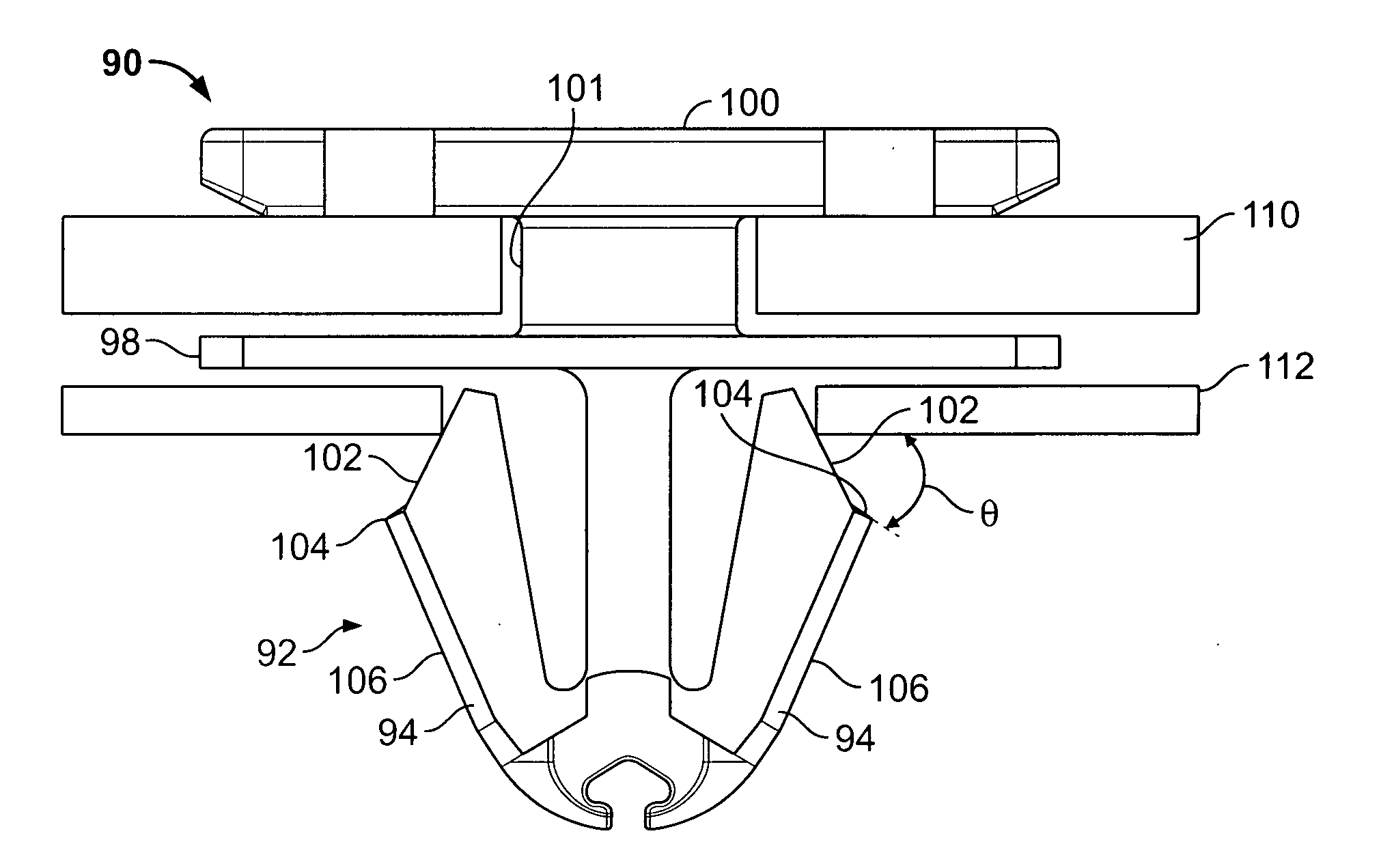

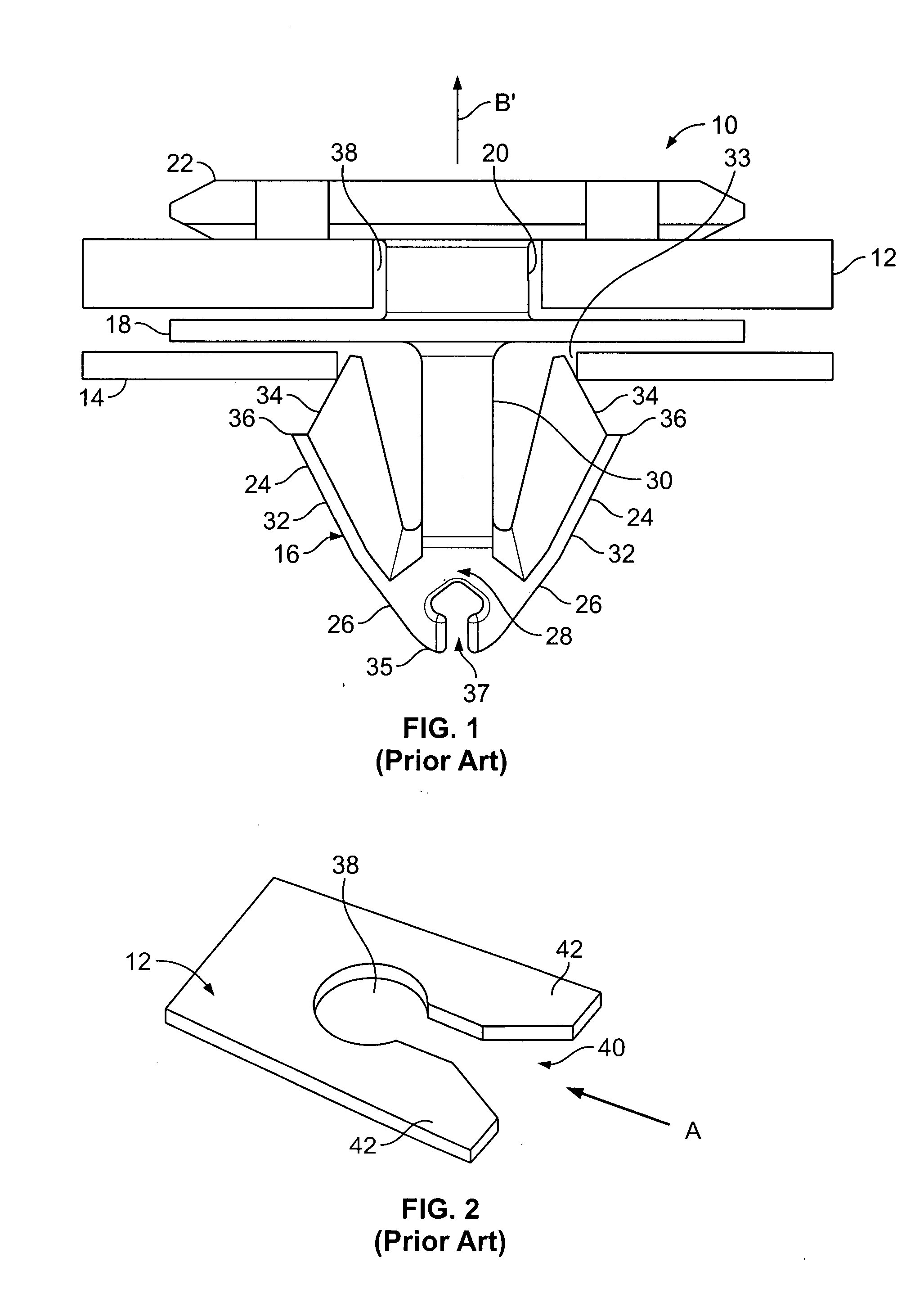

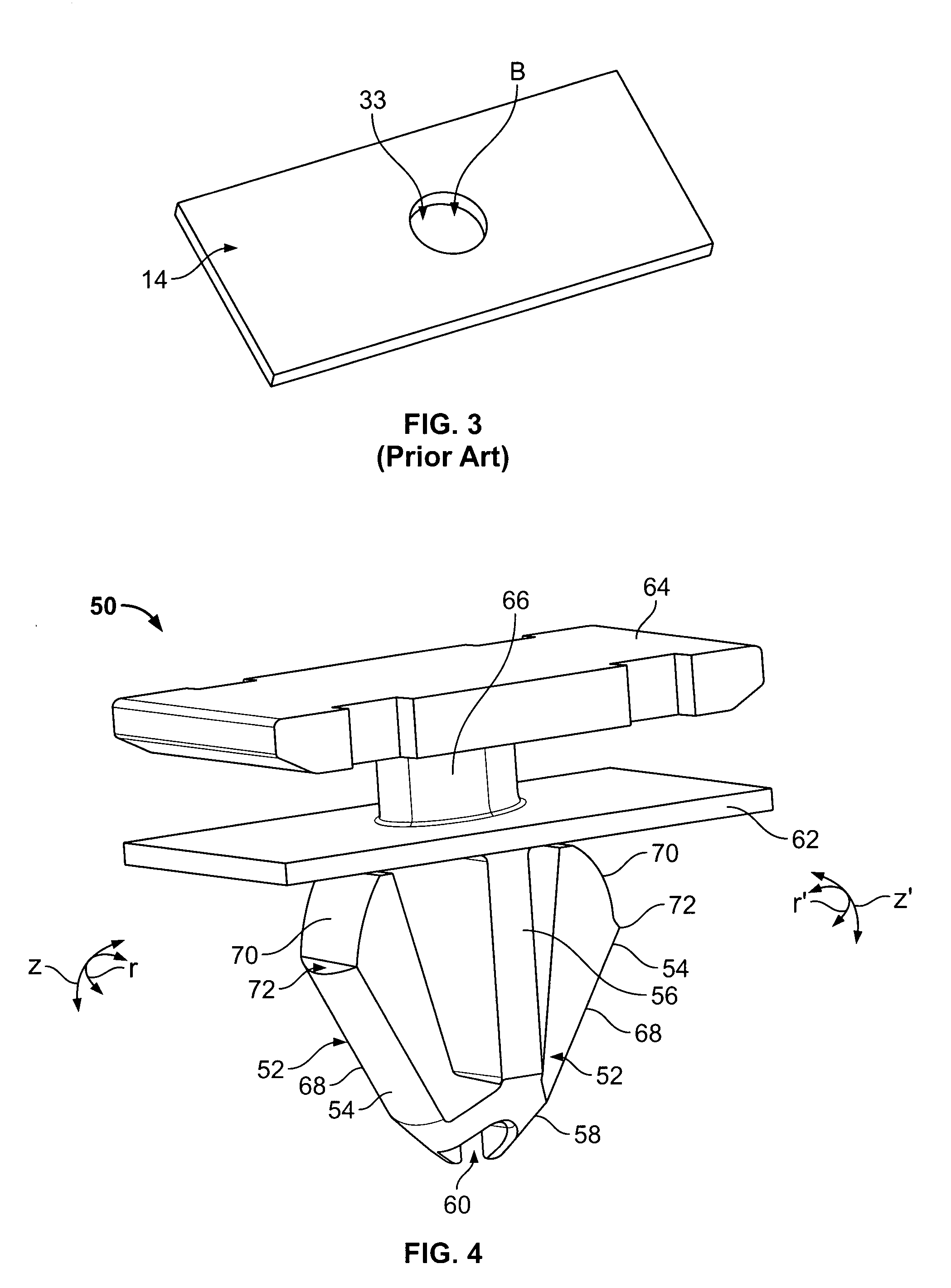

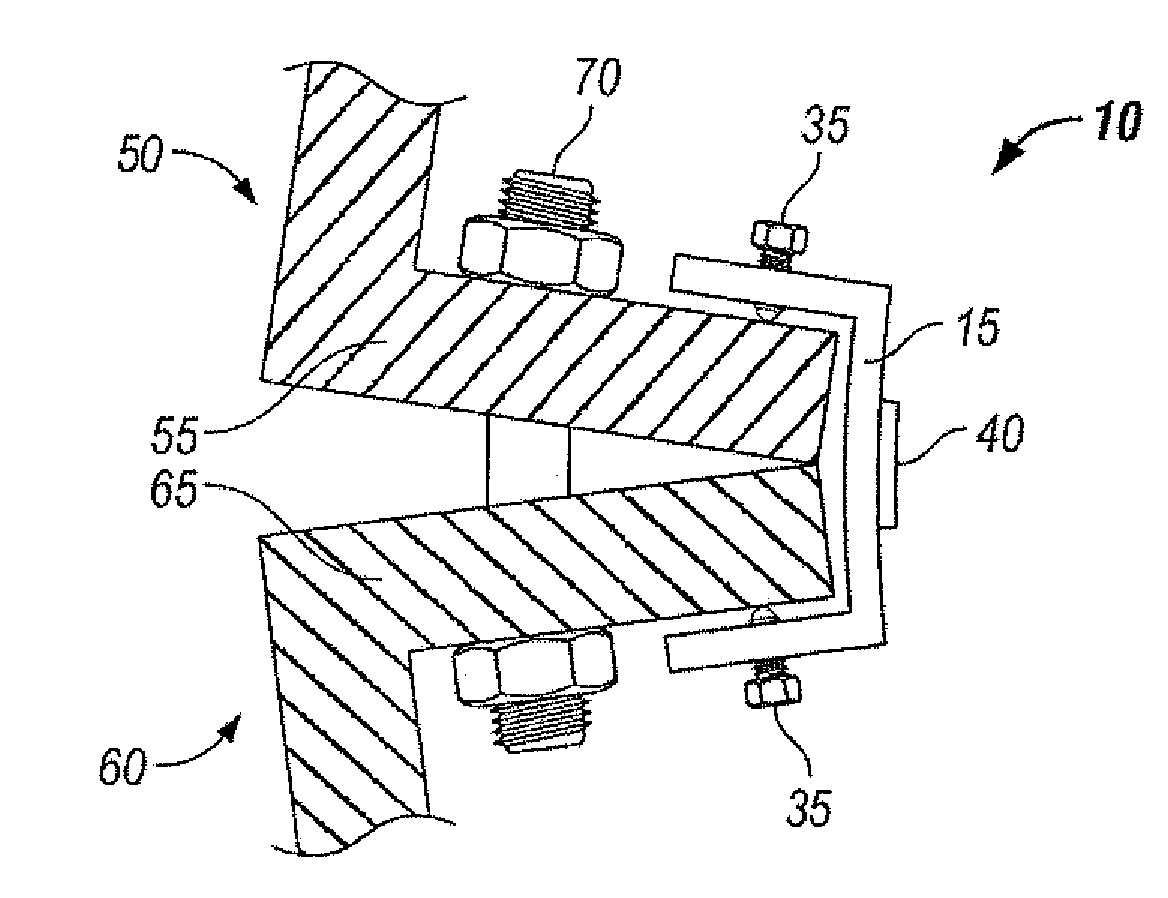

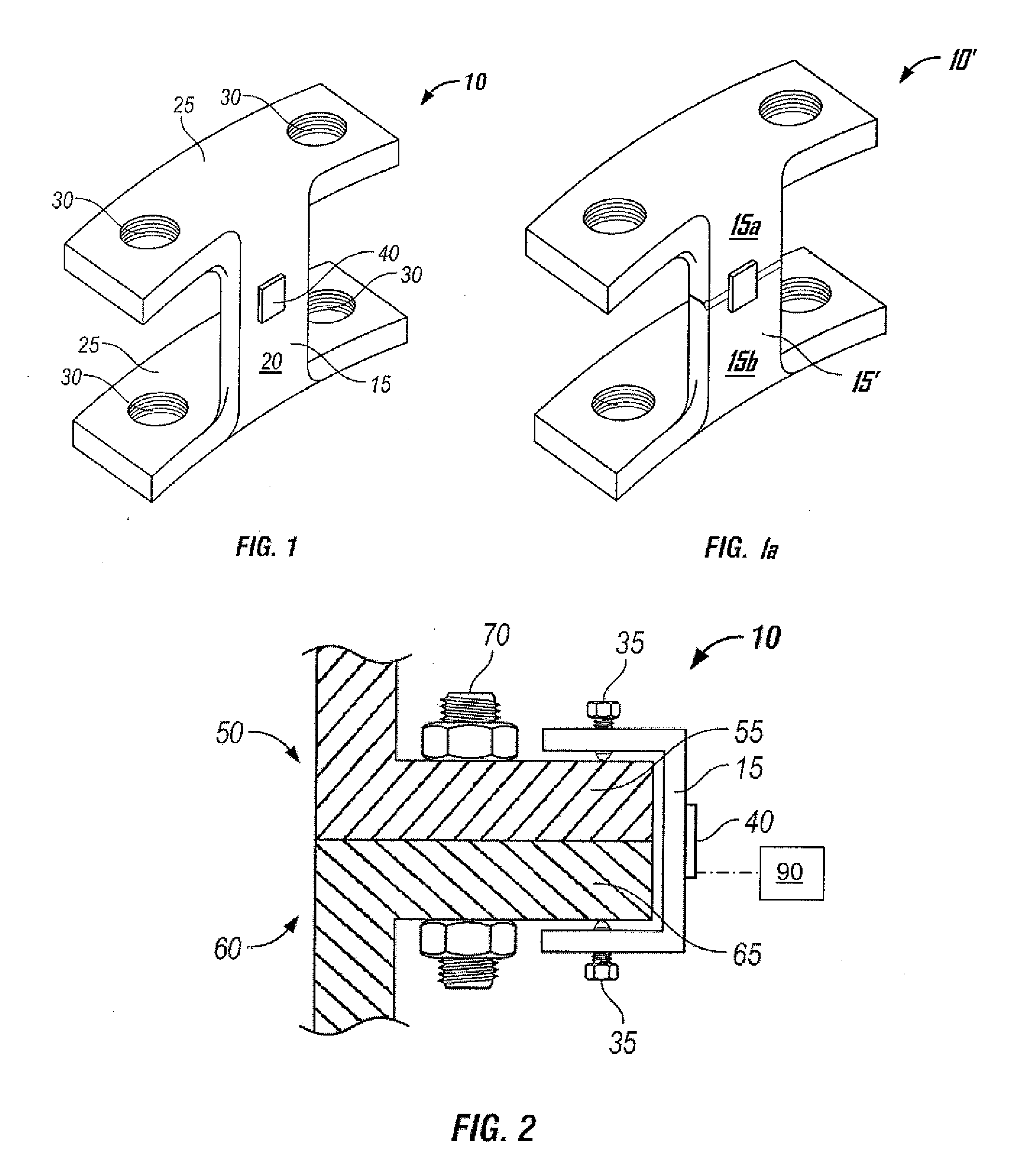

Fastener assembly

InactiveUS20080066266A1Low profileEasy to manipulateSnap fastenersClothes buttonsFastenerBiomedical engineering

A fastener assembly configured to secure a first panel with respect to a second panel includes a base having lateral wings connected to a central post. The lateral wings and the central post converge at a distal tip. Each of the lateral wings includes a first outer surface and a second outer surface, wherein the first outer surface is inwardly angled toward the distal tip. The fastener assembly also includes angled retaining ledges located between the first outer surface and the second outer surface. The angled retaining ledges are canted in a non-parallel fashion with respect to a plane of at least one of the first and second panels. The angled retaining ledges allow for safe and easy removal of the base from at least one of the first and second panels.

Owner:ILLINOIS TOOL WORKS INC

Water tree resistant cable

InactiveUS6869995B2Reduce sweatingImprove propertiesBiocidePlastic/resin/waxes insulatorsPolyethylene glycolMethyl group

A composition comprising:(i) polyethylene, and, based on 100 parts by weight of component (i),(ii) about 0.3 to about 0.6 part by weight of 4,4′-thiobis(2-methyl-6-t-butylphenol); 4,4′-thiobis(2-t-butyl-5-methylphenol); 2,2′-thiobis(6-t-butyl-4-methylphenol); or a mixture of said compounds, and(iii) about 0.4 to about 1 part by weight of a polyethylene glycol having a molecular weight in the range of about 1000 to about 100,000.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

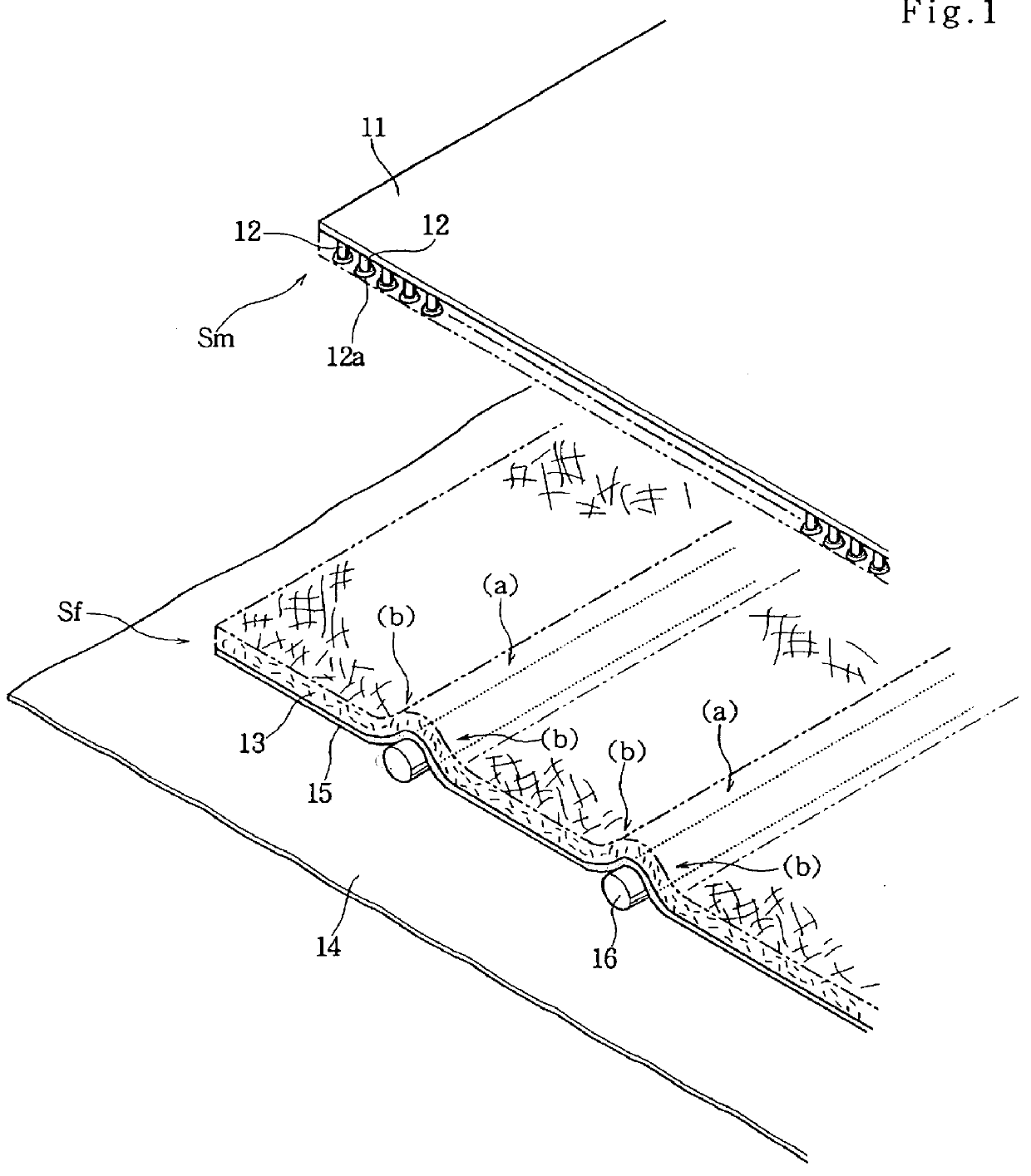

Retaining fastener and diaper using the fastener

InactiveUS6027485AHigh holding strengthOptimization rangeSnap fastenersGarmentsEngineeringUltimate tensile strength

Medium members such as thread are provided between woven fabric sheet such as warp knitting serving as the other sheet and base member, forming linear raised portions in the woven fabric sheet. The density of woven fabric sheet at the inclined portions to either side of these raised portions becomes coarse and the gaps between fine filaments on the woven fabric sheet spread, so that retaining heads of one sheet can easily enter and so that the fine filaments easily become hooked to the base portion of the retaining heads. Consequently, the retaining of the one sheet and the other sheet in strengthened, and the peeling strength is improved.

Owner:UNI CHARM CORP

Flame retardant polymer composites and method of fabrication

InactiveUS20050049355A1Quality improvementImprove mechanical propertiesMaterial nanotechnologyFibre treatmentCarbon nanofiberGraphite

A flame retardant composite and a method for its fabrication are disclosed. The flame retardant composite shows both improved mechanical properties and flame retardancy. The composite comprises a matrix material and carbon nanotubes, such as single walled nanotubes, multi-walled nanotubes or fishbone-like graphitic cylinders, exhibiting a hollow core. For example, the outer diameters of the carbon nanofibers may be in the range from 1.2 to 500 nm. For example, a carbon nanotube may be incorporated as a layer in or on the surface of the composite. The method of fabrication of the composite may include a step of de-agglomeration.

Owner:C POLYMERS +1

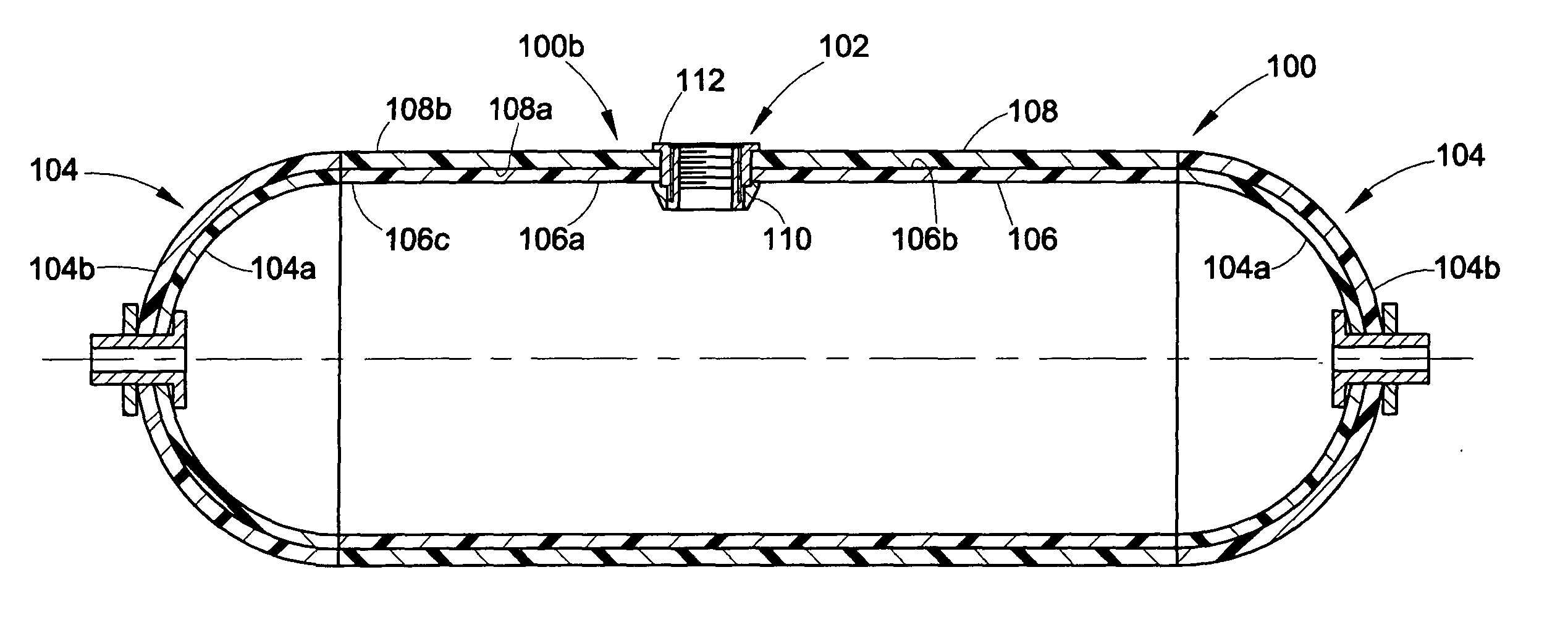

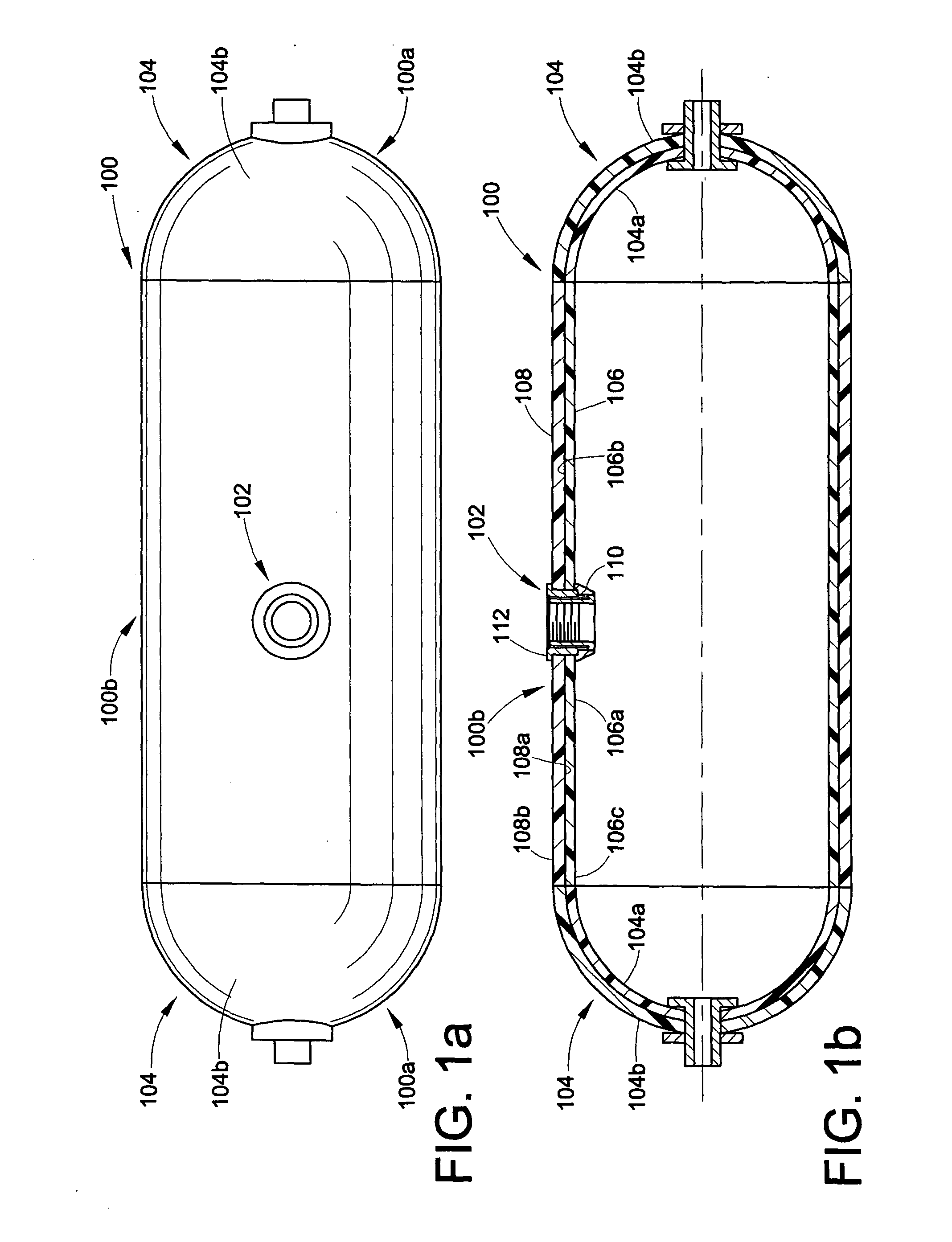

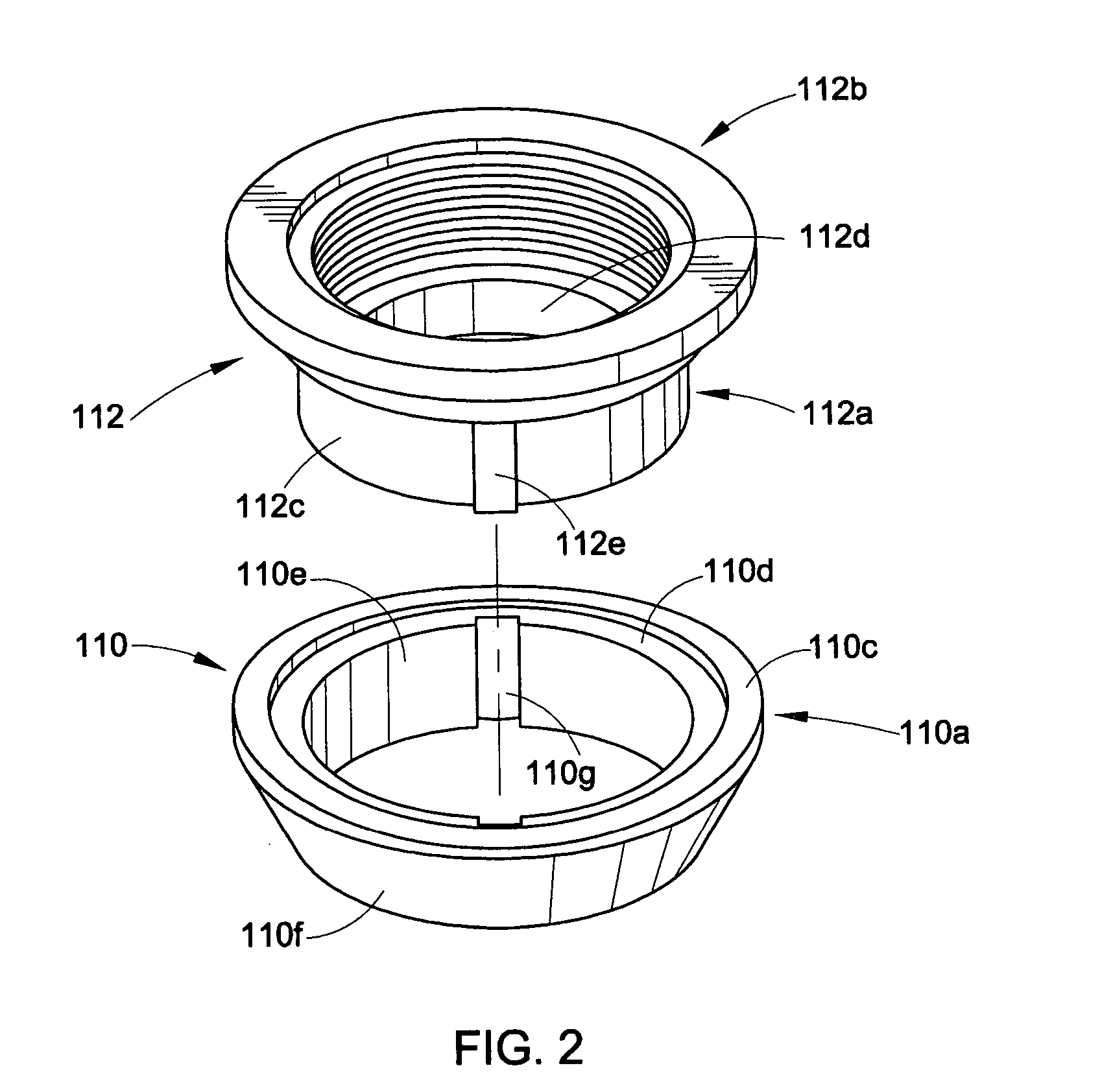

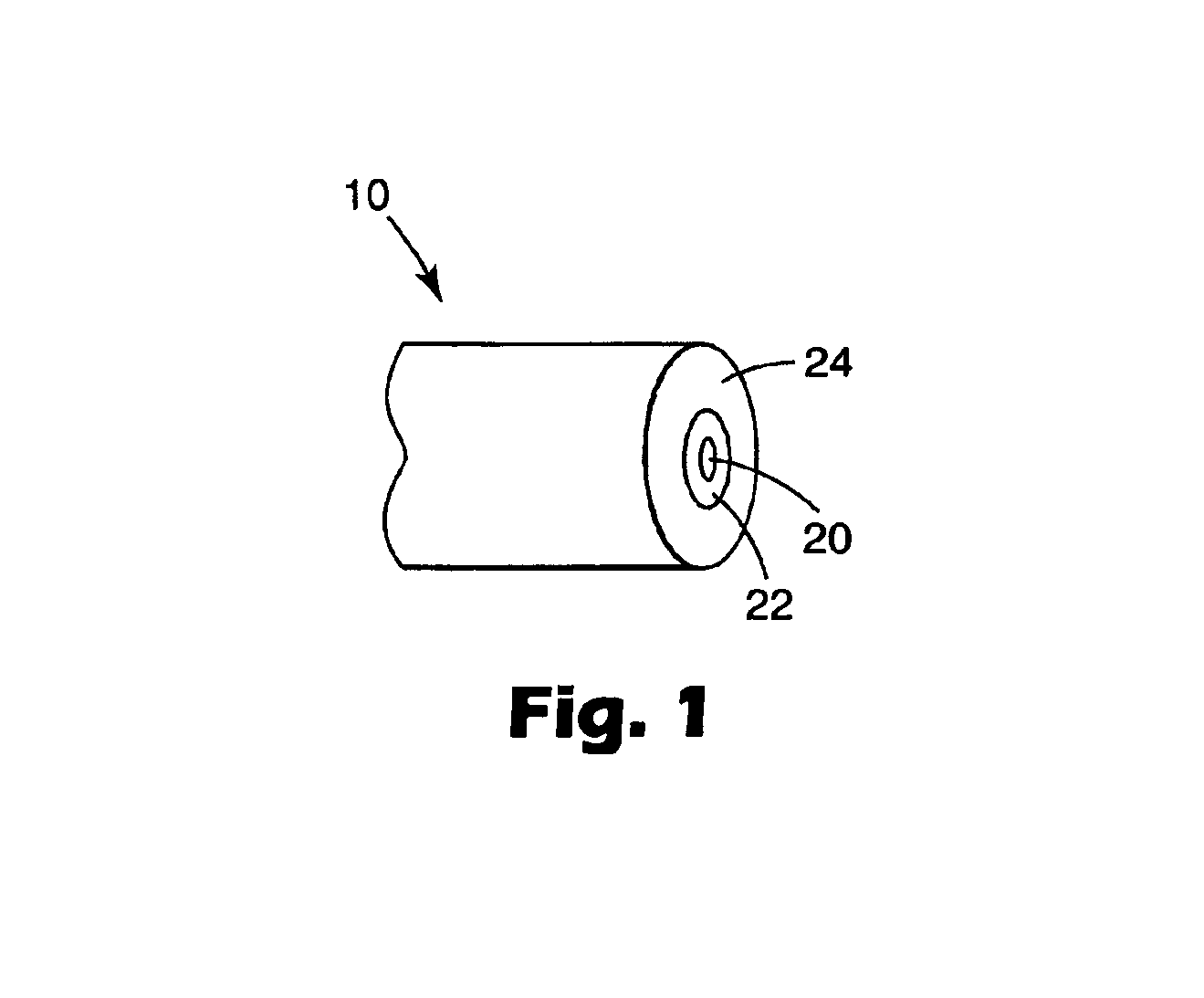

Filament-reinforced composite thermoplastic pressure vessel fitting assembly and method

ActiveUS20050006393A1Easy size adjustmentEasy to relocateCoatingsVessel mounting detailsPlastic materialsEngineering

A method of forming a fitting assembly in a filament-reinforced pressure vessel, and a pressure vessel having a fitting assembly secured therein. In the method, a first fitting portion is bonded to an inner surface of a thermoplastic liner in a fluid tight manner. A layer of commingled reinforcing filaments and plastic material is applied to an outer surface of the thermoplastic liner to form a vessel wall. A portion of the vessel wall adjacent to the opening bounded by the fluid-tight seal between the first fitting portion and the inner surface of the thermoplastic liner is removed. Then, a second fitting portion is bonded to the first fitting portion so as to define a port for access into the interior of the vessel.

Owner:ENPRESS

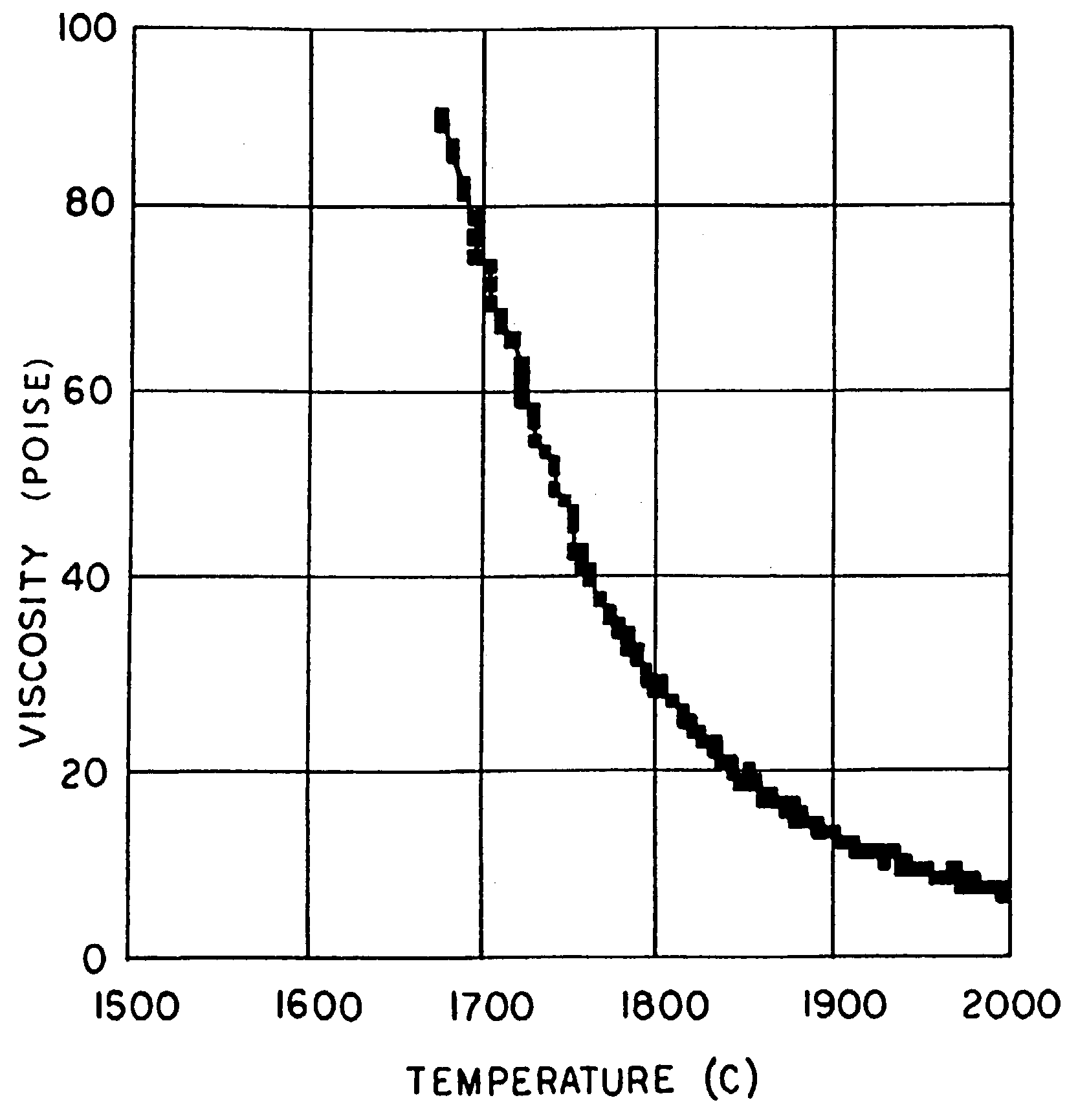

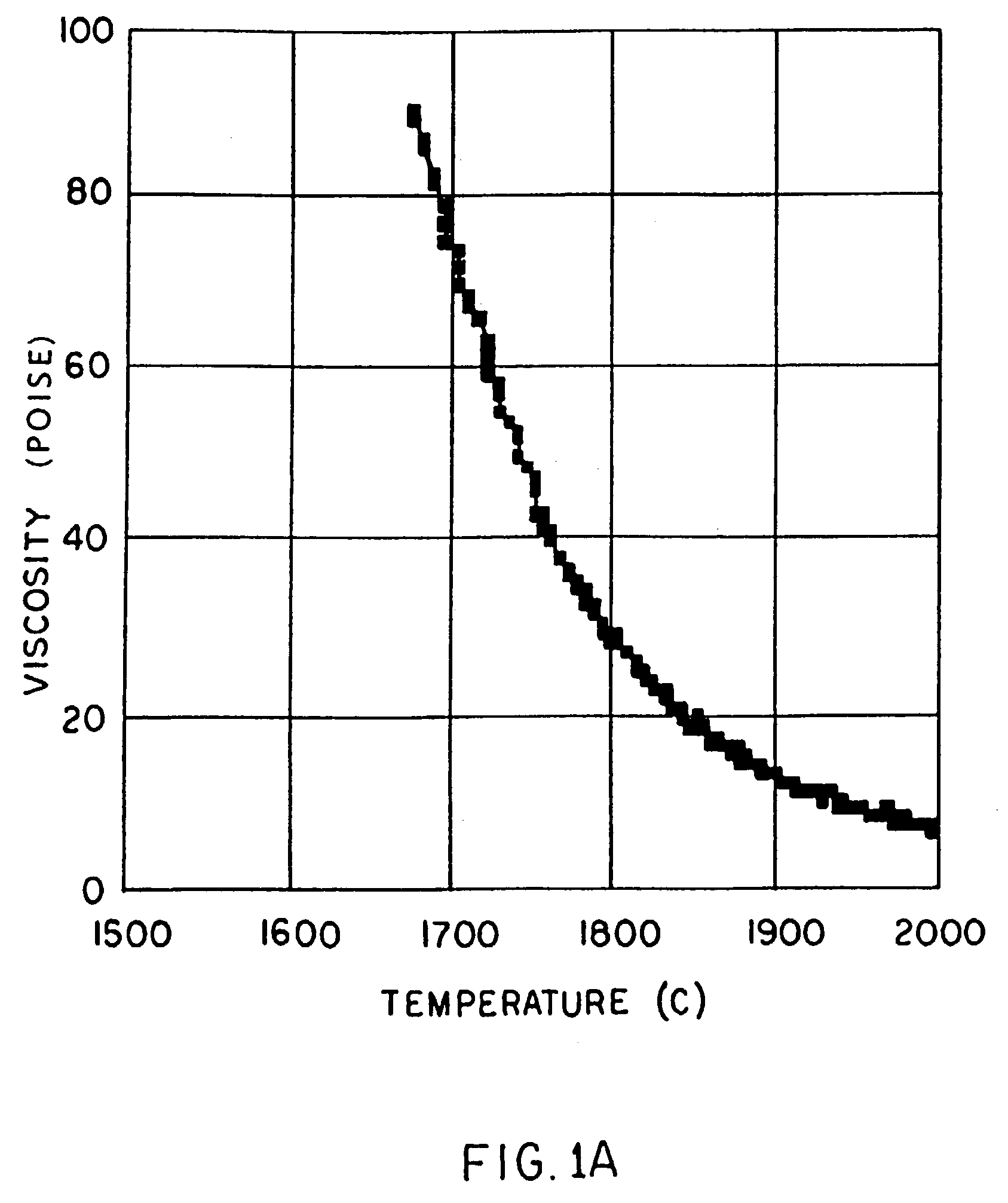

High temperature resistant vitreous inorganic fiber

InactiveUS20030162019A1Non-durableImprove shrinkage resistanceInorganic fibres/flakesInorganic material artificial filamentsFiberPhysiological fluid

A low shrinkage, high temperature resistant vitreous inorganic fiber having a use temperature up to at least 1330° C., which maintains mechanical integrity after exposure to the use temperature and which is non-durable in physiological fluids, is prepared by the method of forming a melt with ingredients including greater than 71.25 weight percent silica, 0 to about 20 weight percent magnesia, and about 5 to about 28.55 weight percent of calcia, 0 to about 5 weight percent zirconia, and optionally a viscosity modifier in an amount effective to render the product fiberizable; and producing fibers from the melt.

Owner:UNIFRAX I LLC

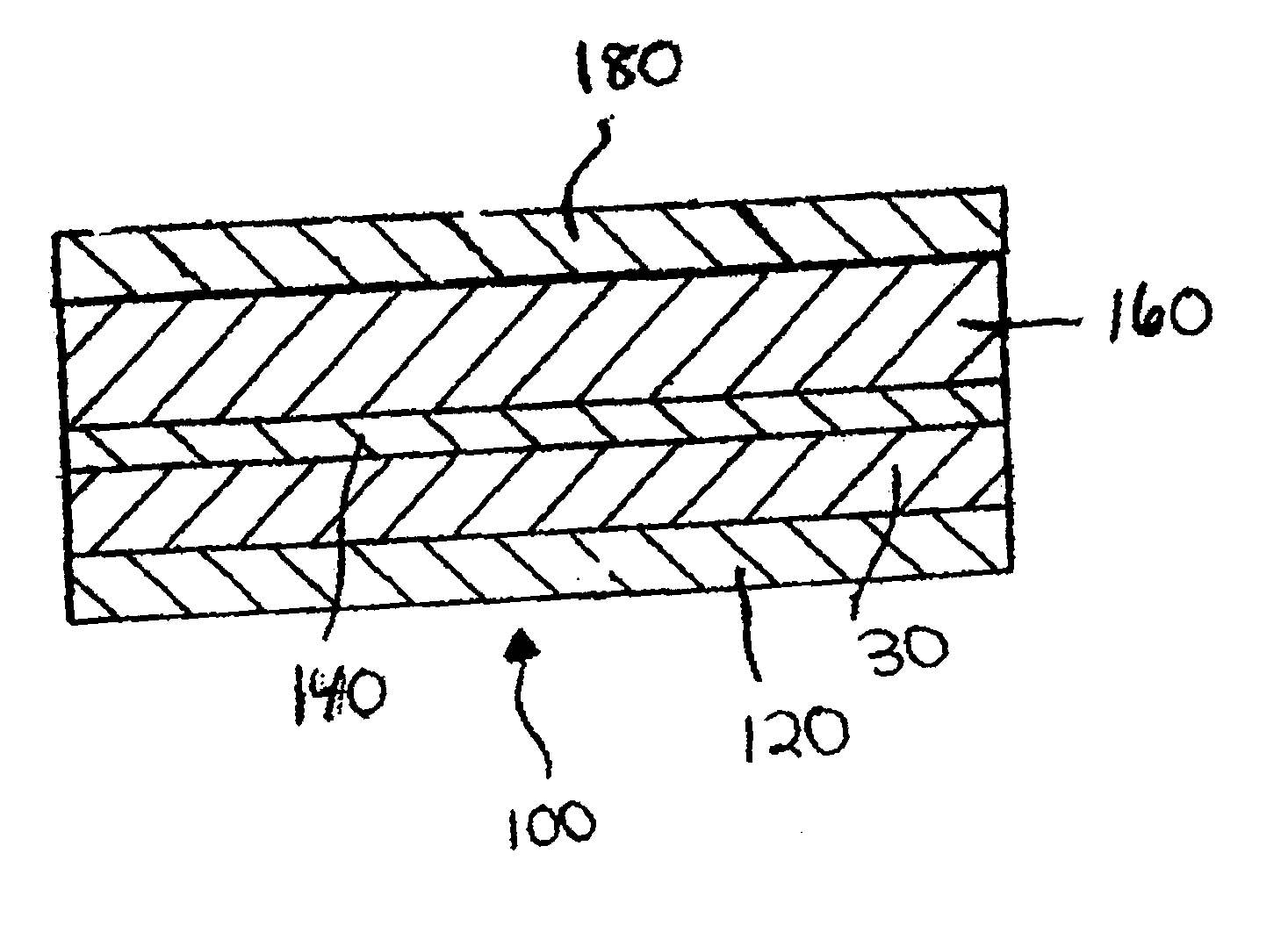

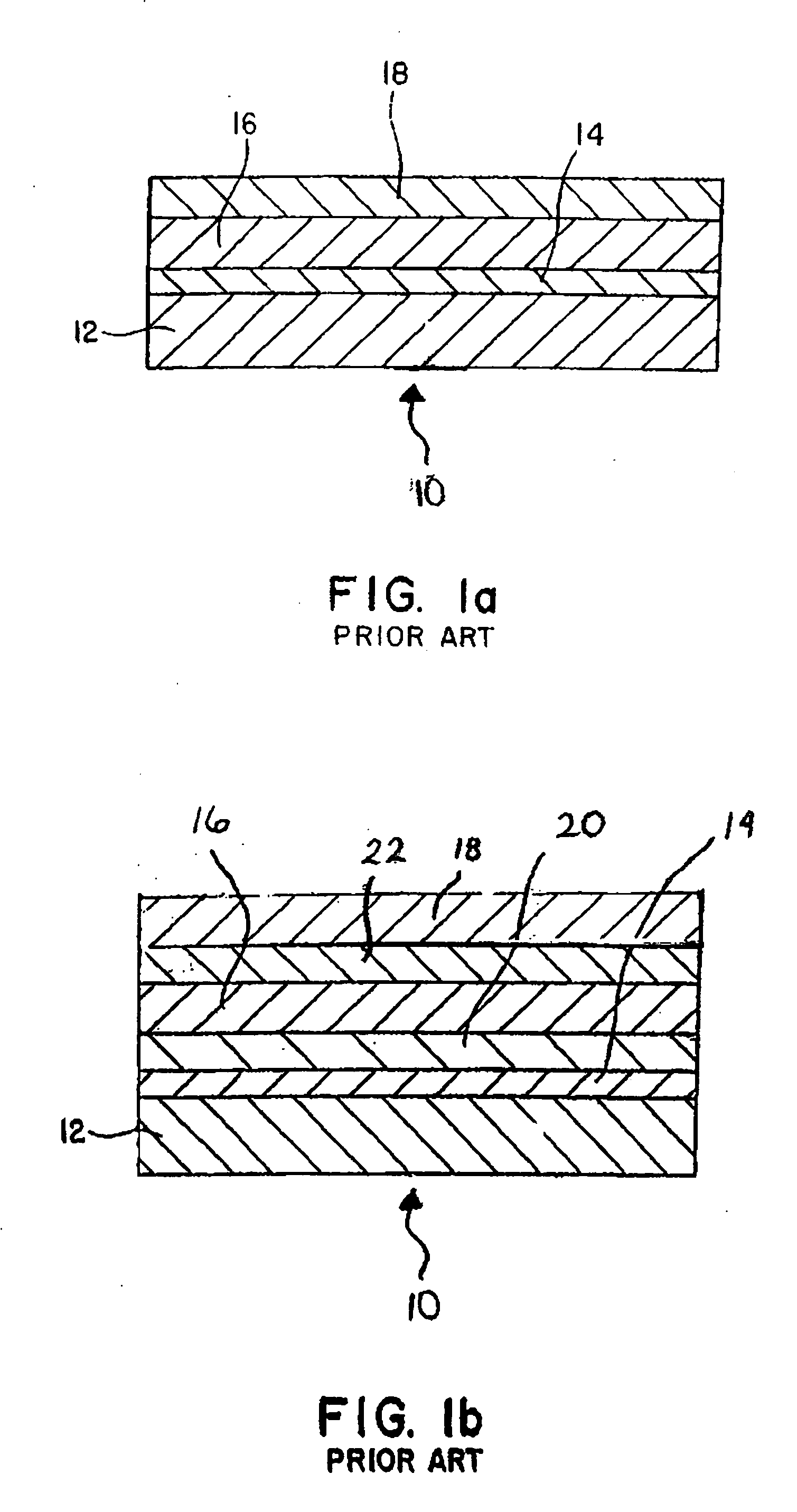

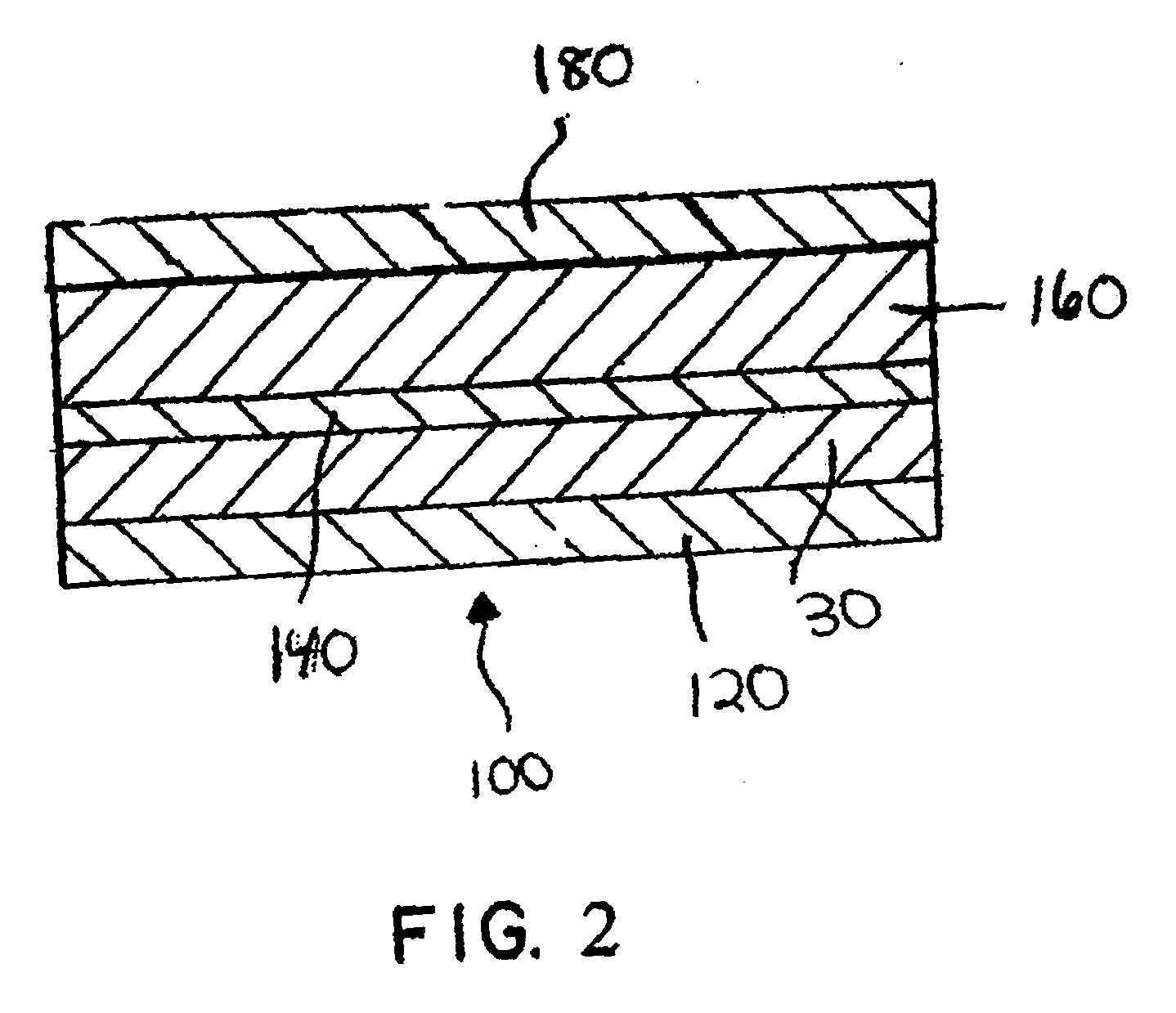

Coating system for silicon based substrates

ActiveUS20070014996A1Reduction in substrate strengthReduces stored elastic strain energyLiquid surface applicatorsMolten spray coatingCoating systemOxygen

Owner:RAYTHEON TECH CORP

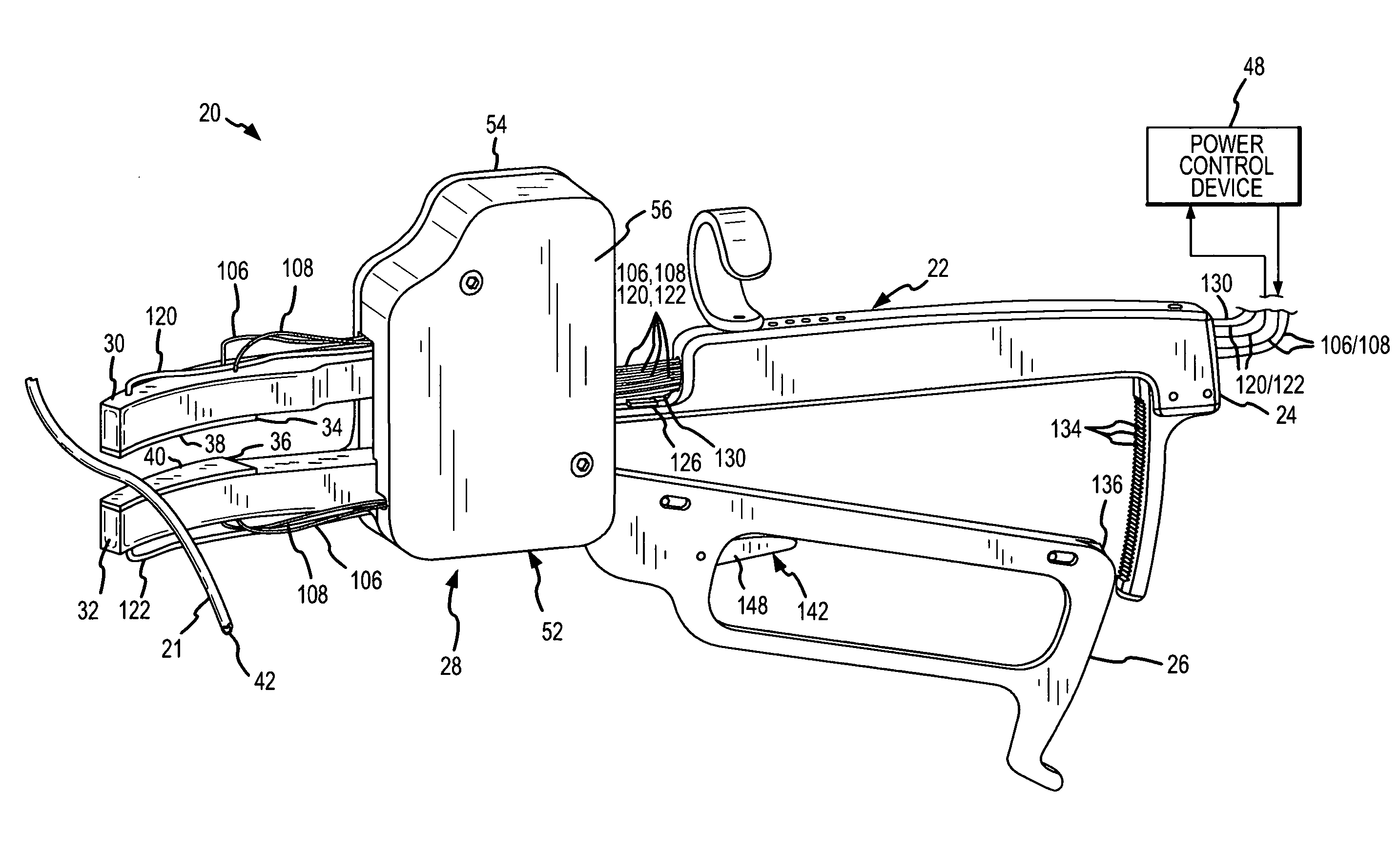

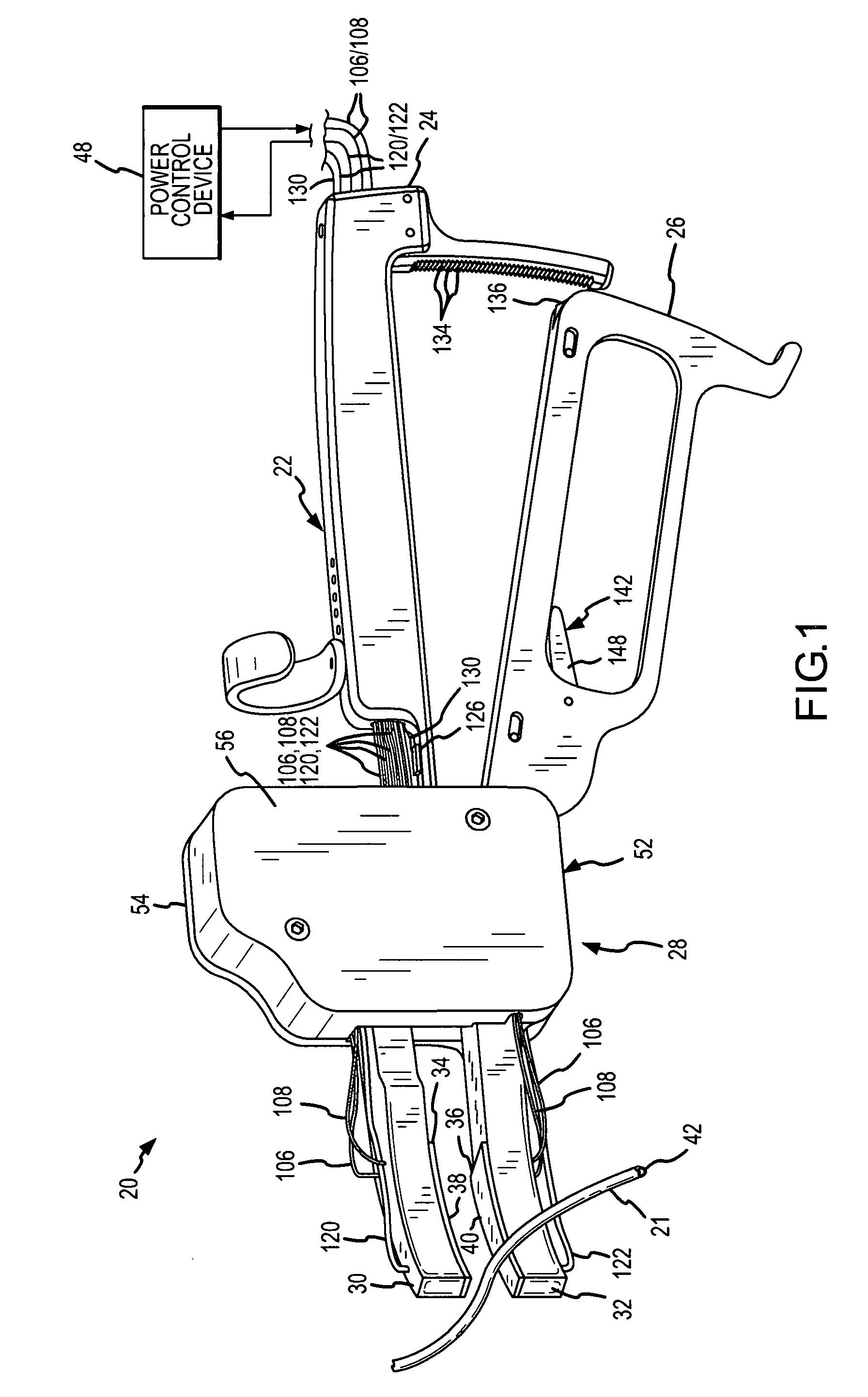

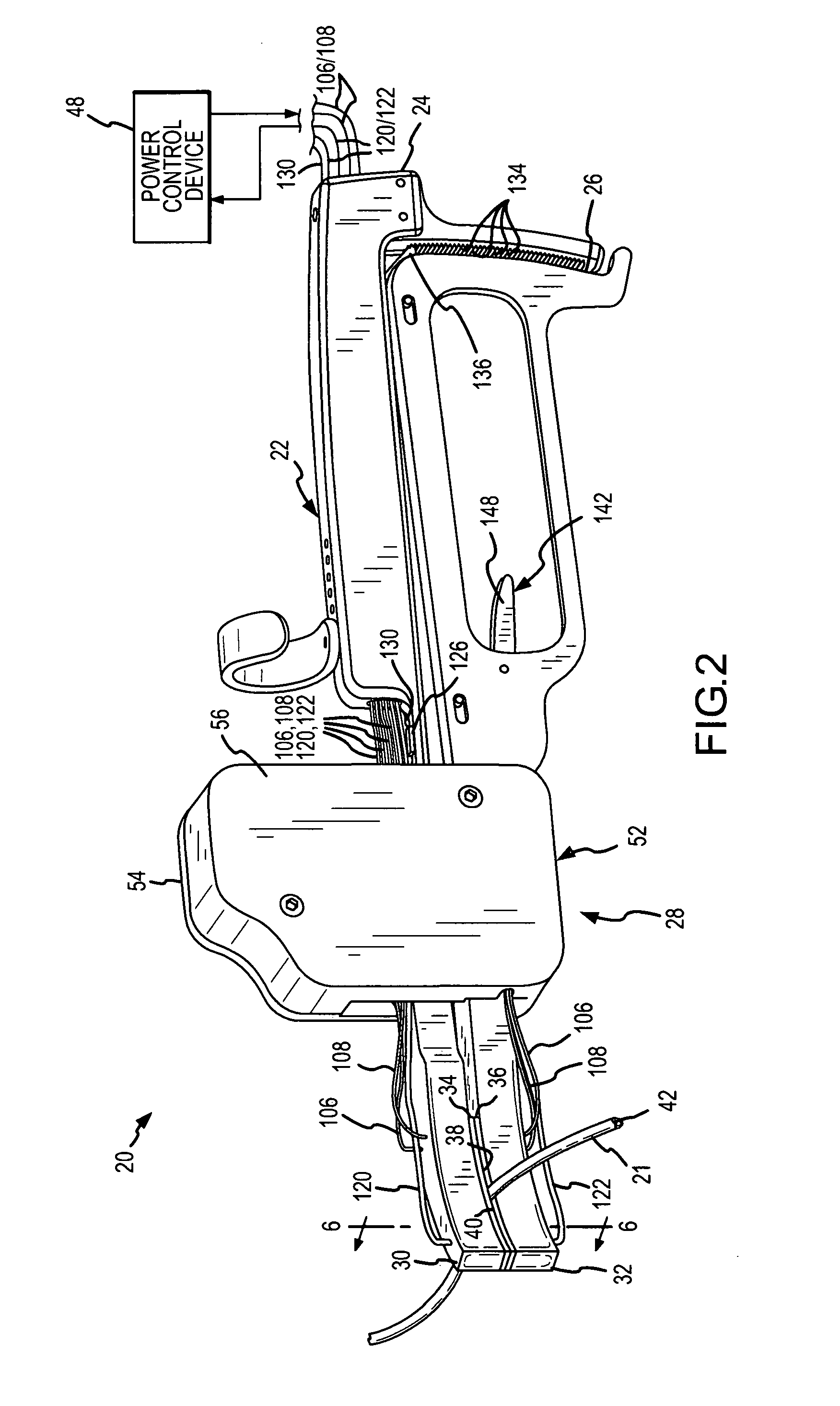

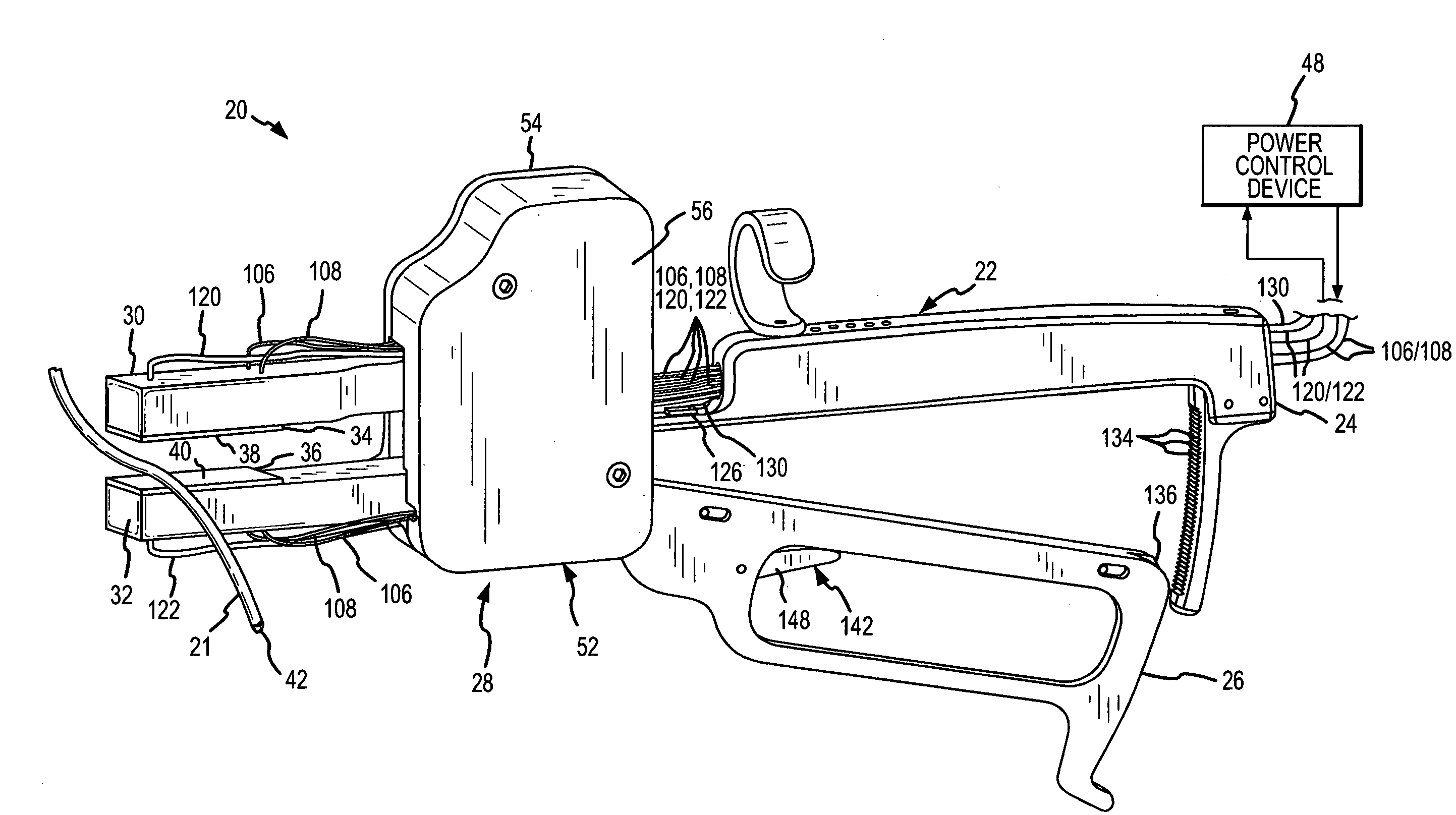

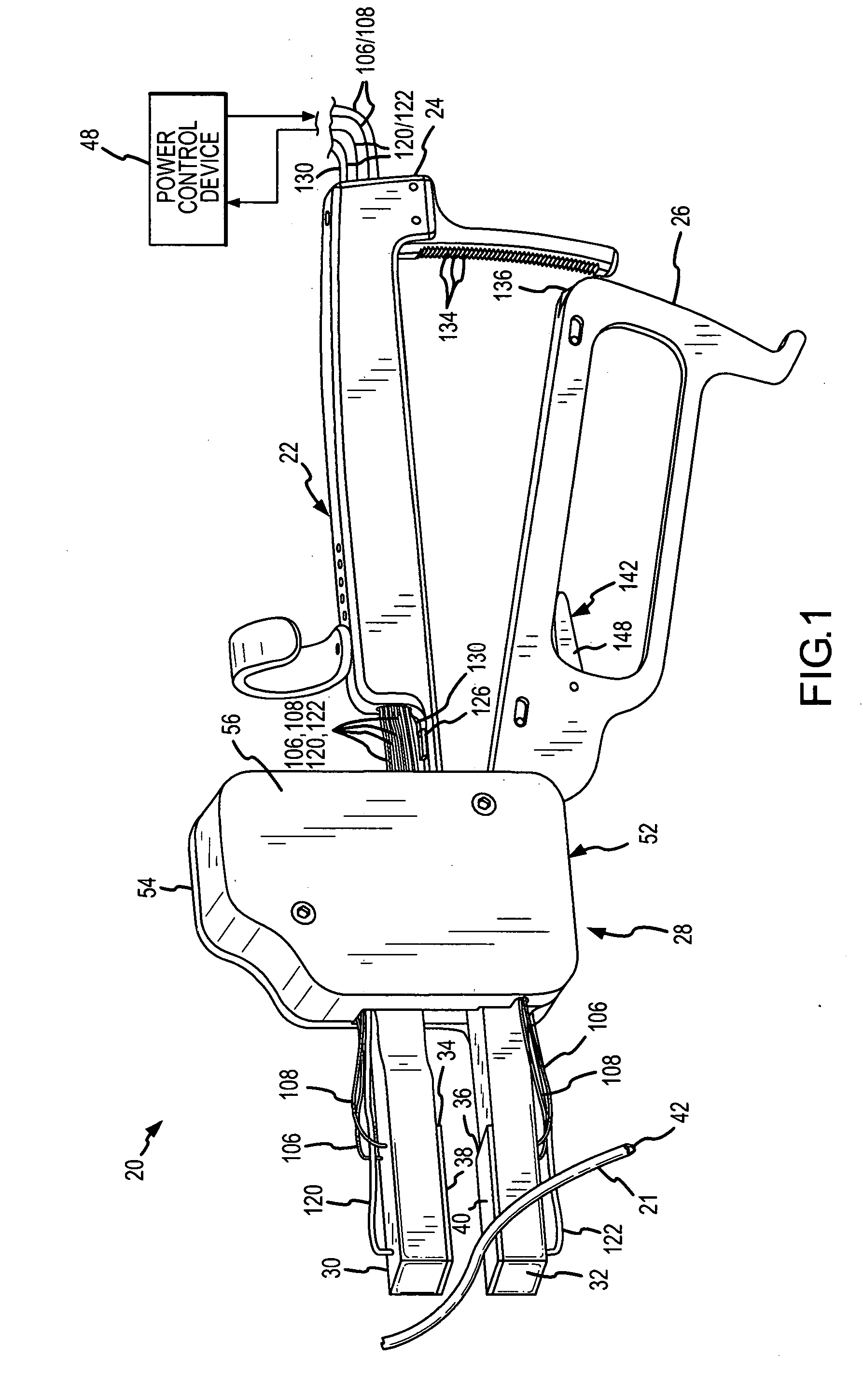

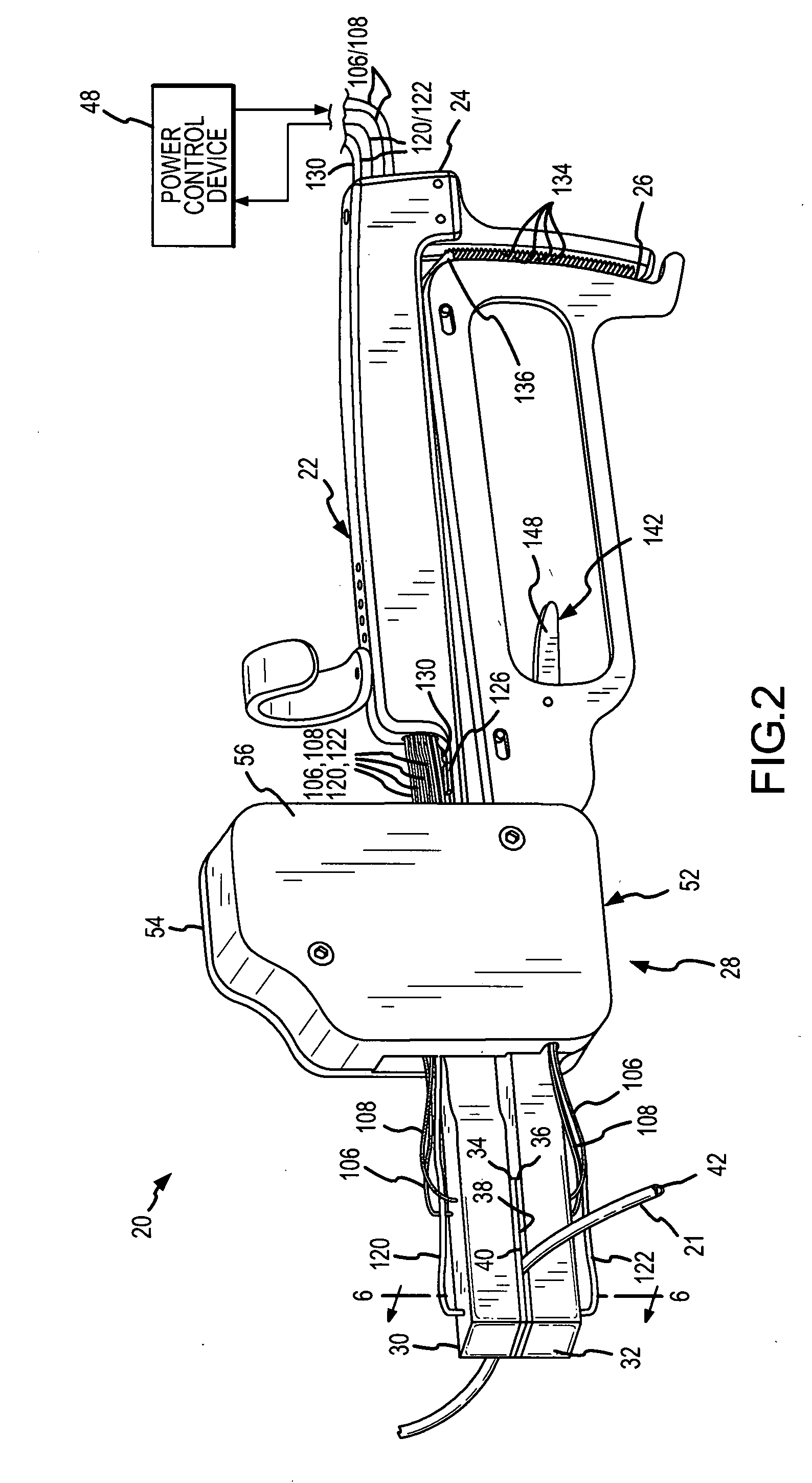

Apparatus and method for rapid reliable electrothermal tissue fusion and simultaneous cutting

InactiveUS20080188844A1Reliable sealGood integritySurgical instruments for heatingSurgical forcepsElectric heatingThermal energy

Pieces of tissue are fused together and simultaneously cut by compressing the pieces together at an interface, delivering an impulse of electrical power which is converted into sufficient thermal energy to fuse the pieces together at the interface and simultaneously cut the fused tissue pieces along a well-defined linear path. The impulse, and the fusion and the simultaneous cutting, occur within a preferable time of 1.5-2.0 seconds but no greater than 4.0 seconds. The temperature of the thermal energy is regulated between 220° C.-320° C. The force applied on the tissue pieces is sufficient to fuse the tissue at the interface followed by further compression to cut the fused tissue along the linear path as a result of the thermal energy and a zero distance gap between jaws which compress the tissue pieces. The jaws have smooth working surfaces with an Ra of 0.15 or less microns up to 0.40 microns.

Owner:CONMED CORP

Coating system for silicon based substrates

ActiveUS7374818B2Reduced strengthReduces stored elastic strain energyLiquid surface applicatorsElectric shock equipmentsCoating systemOxygen

Owner:RTX CORP

Polyamide resin composition

InactiveUS6515058B1Low elongationImproving releasabilityWater/sewage treatment by flocculation/precipitationPolyamideCarboxylic acid

Polyamide resin pellets which comprise: 100 parts by weight of a polyamide resin; from 0.01 to 1.0 part by weight of lubricant A, which comprises at least one ester of a higher aliphatic carboxylic acid with a higher alcohol; and from 0.01 to 1.0 part by weight of lubricant B. which comprises at least one higher aliphatic carboxylic acid metal salt, wherein lubricant A is present inside the pellets. Also disclosed are the polyamide resin pellets further comprising lubricant C, which comprises a higher aliphatic carboxylic acid amide.

Owner:ASAHI KASEI KK

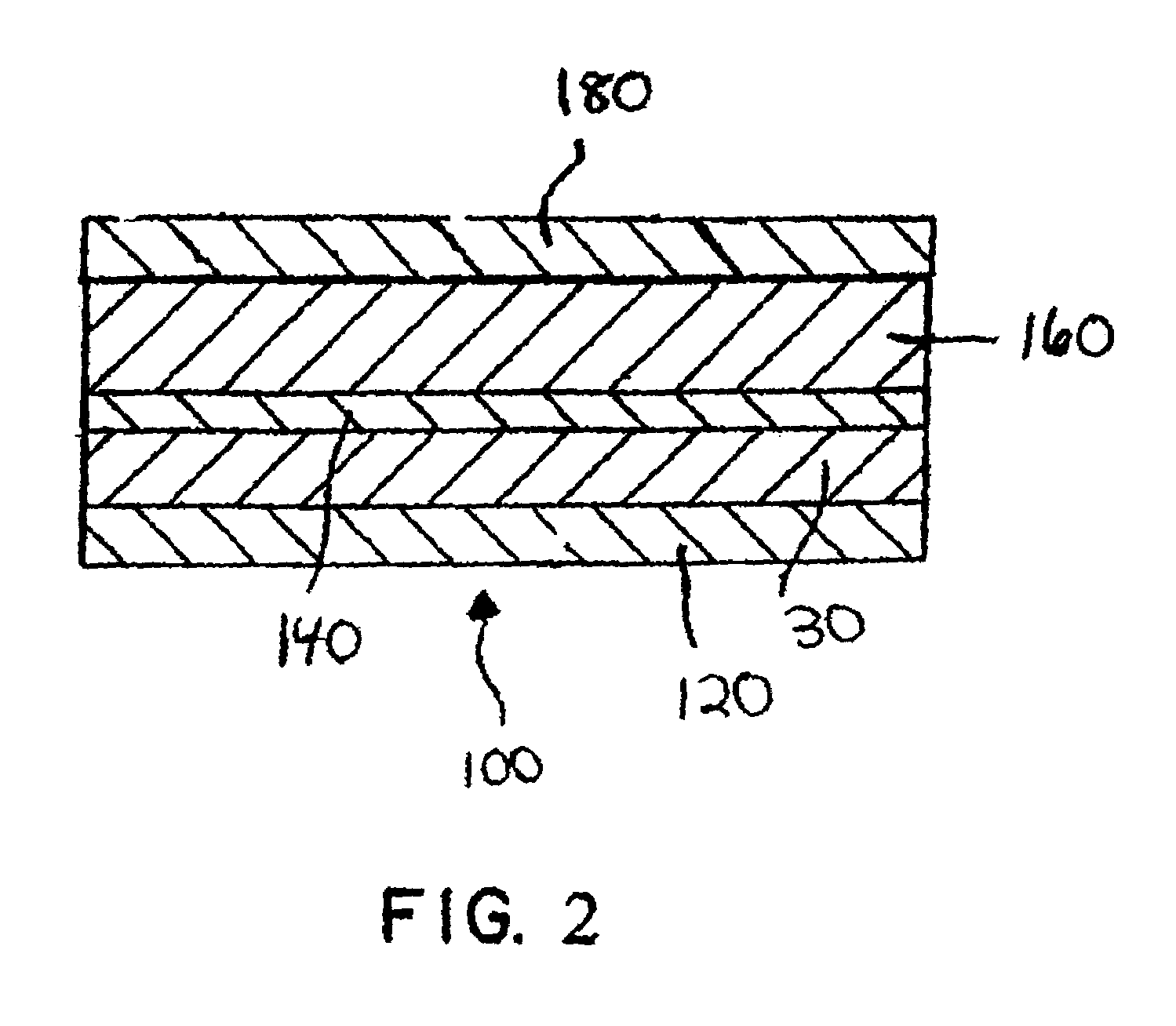

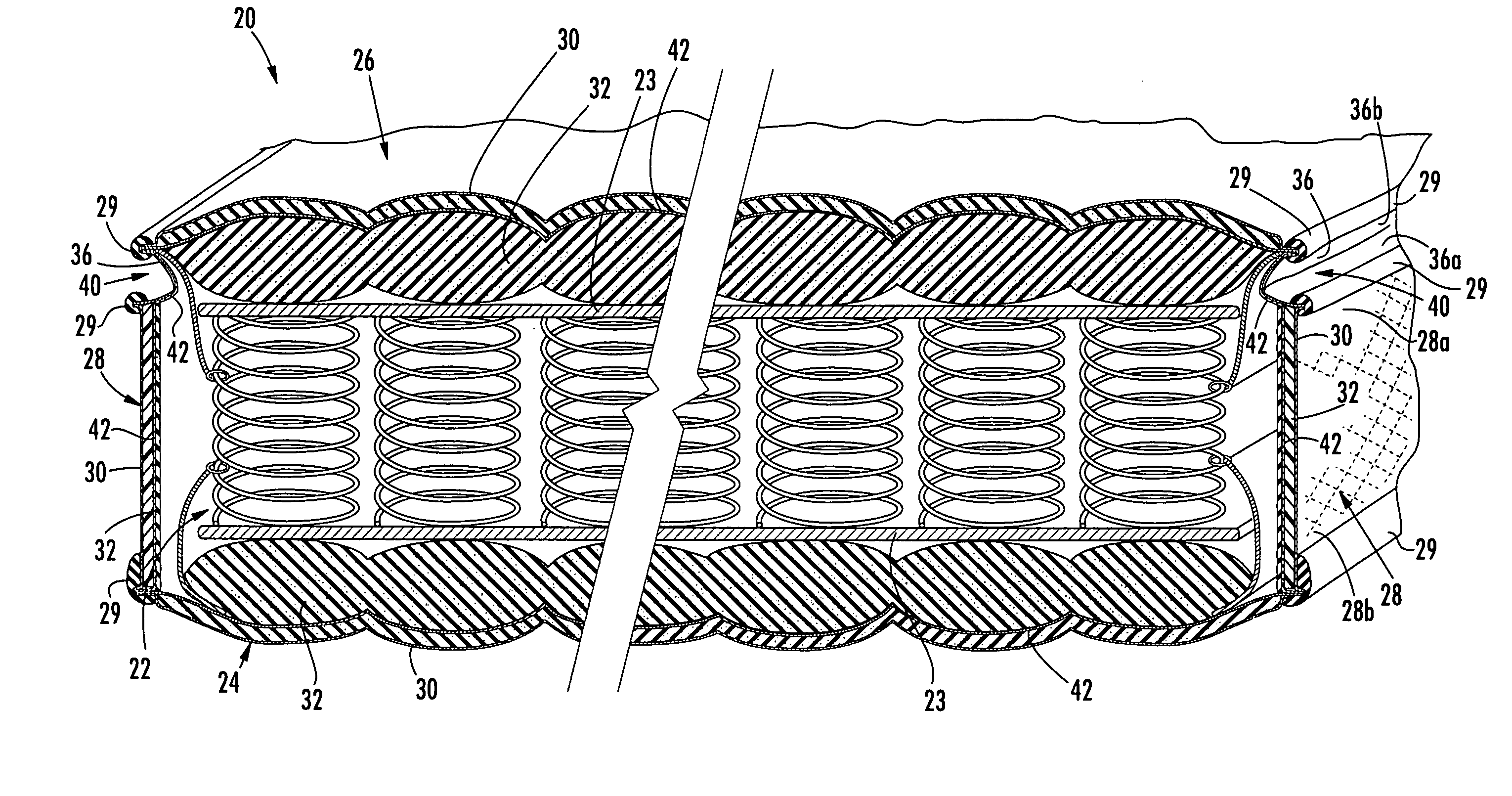

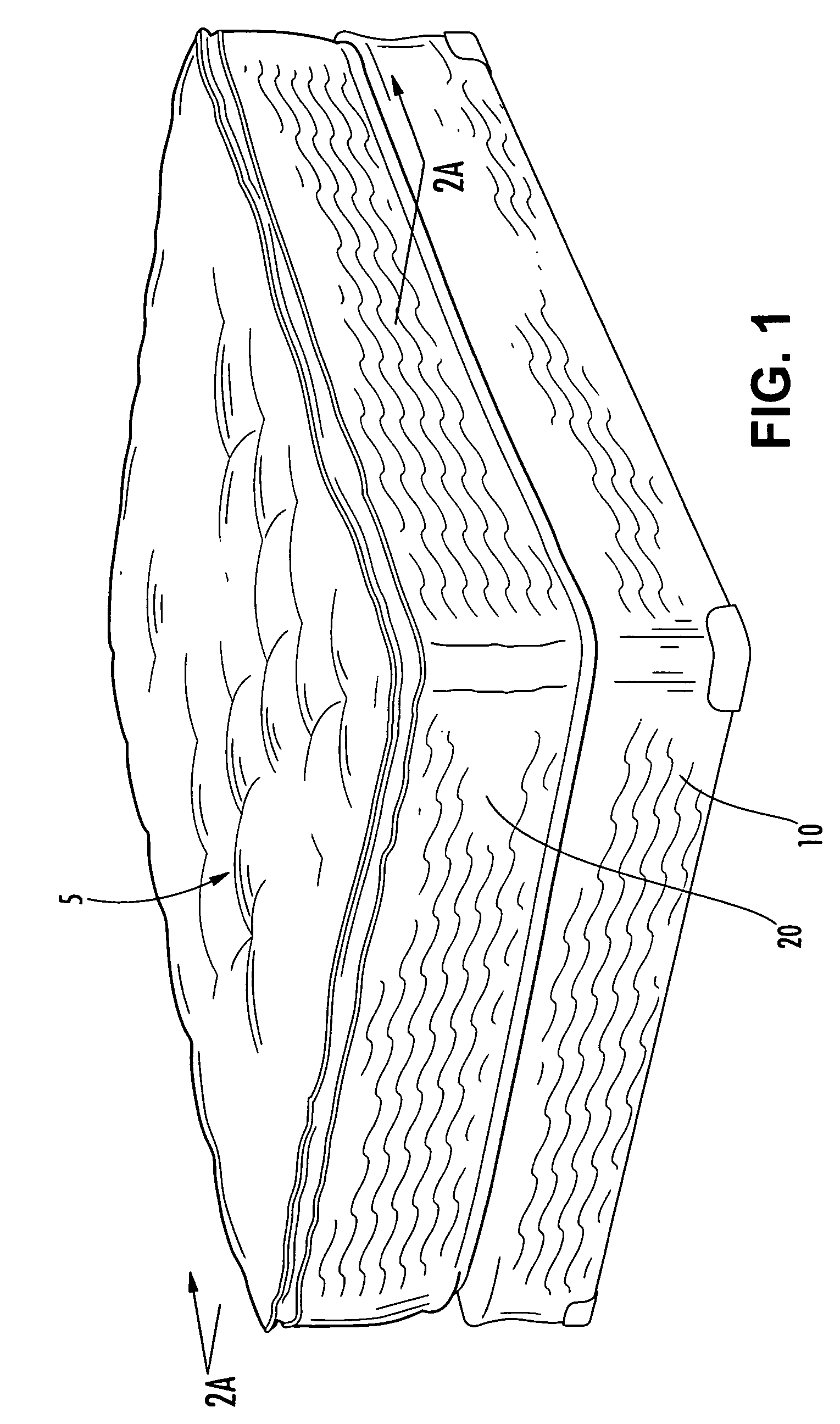

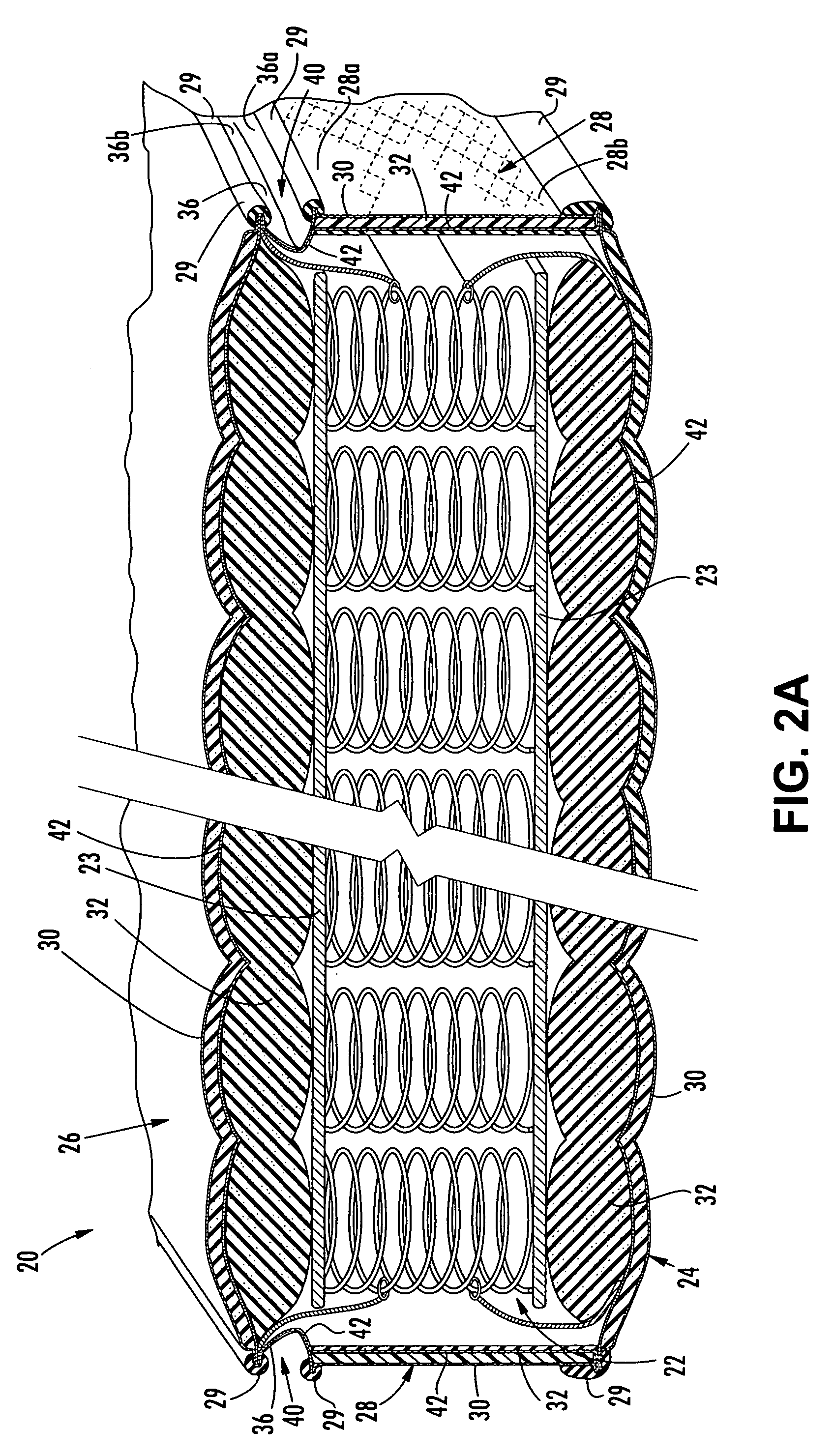

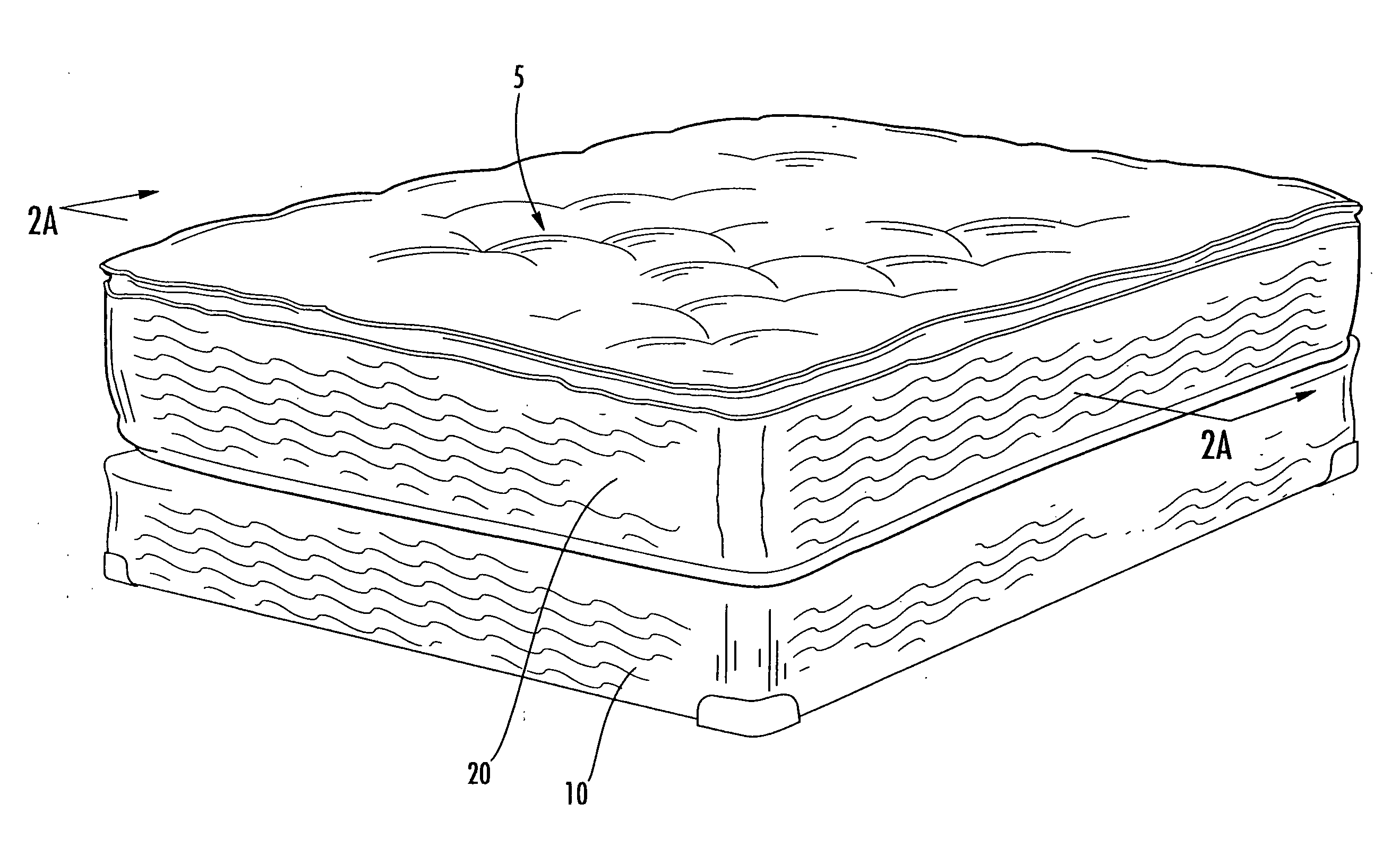

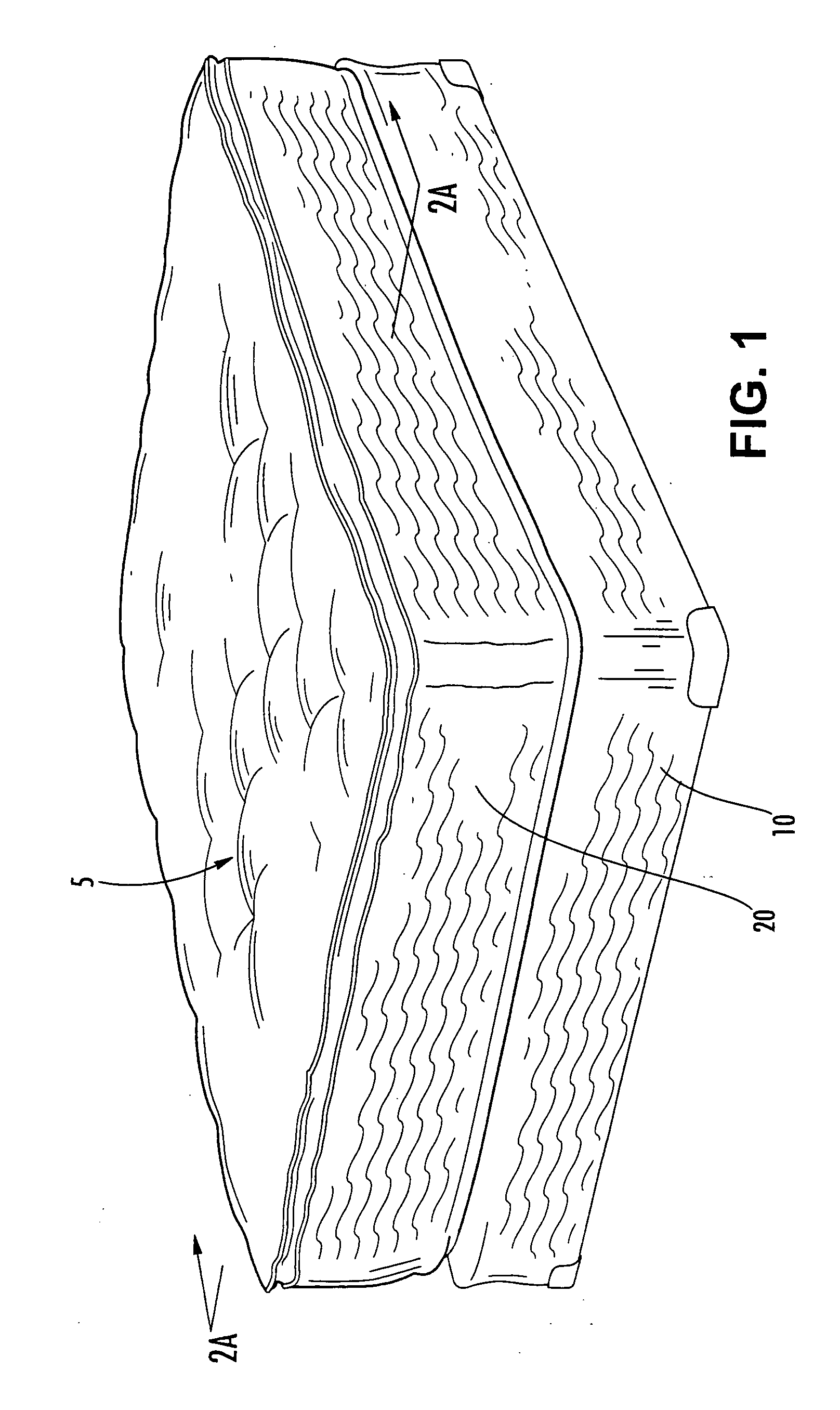

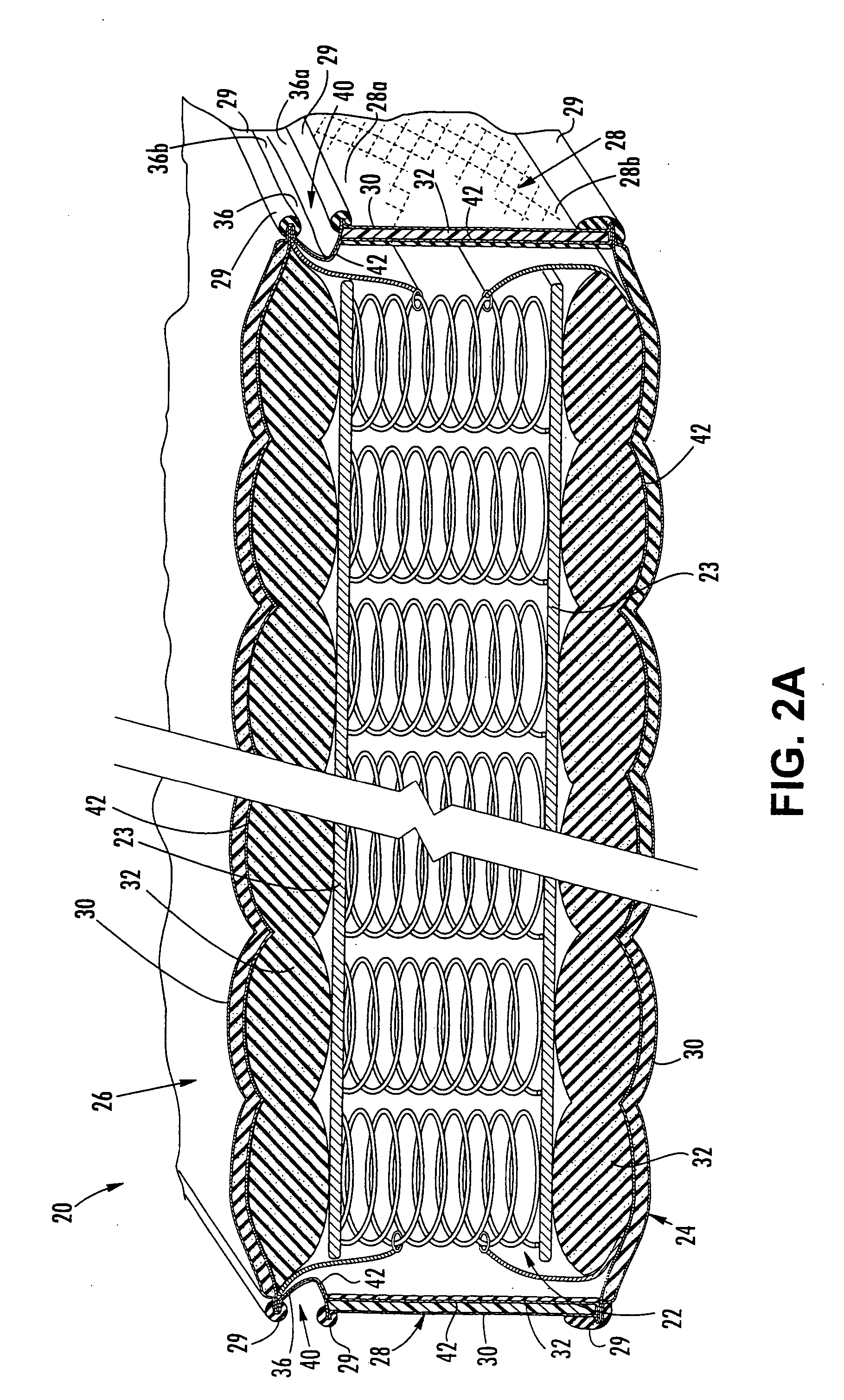

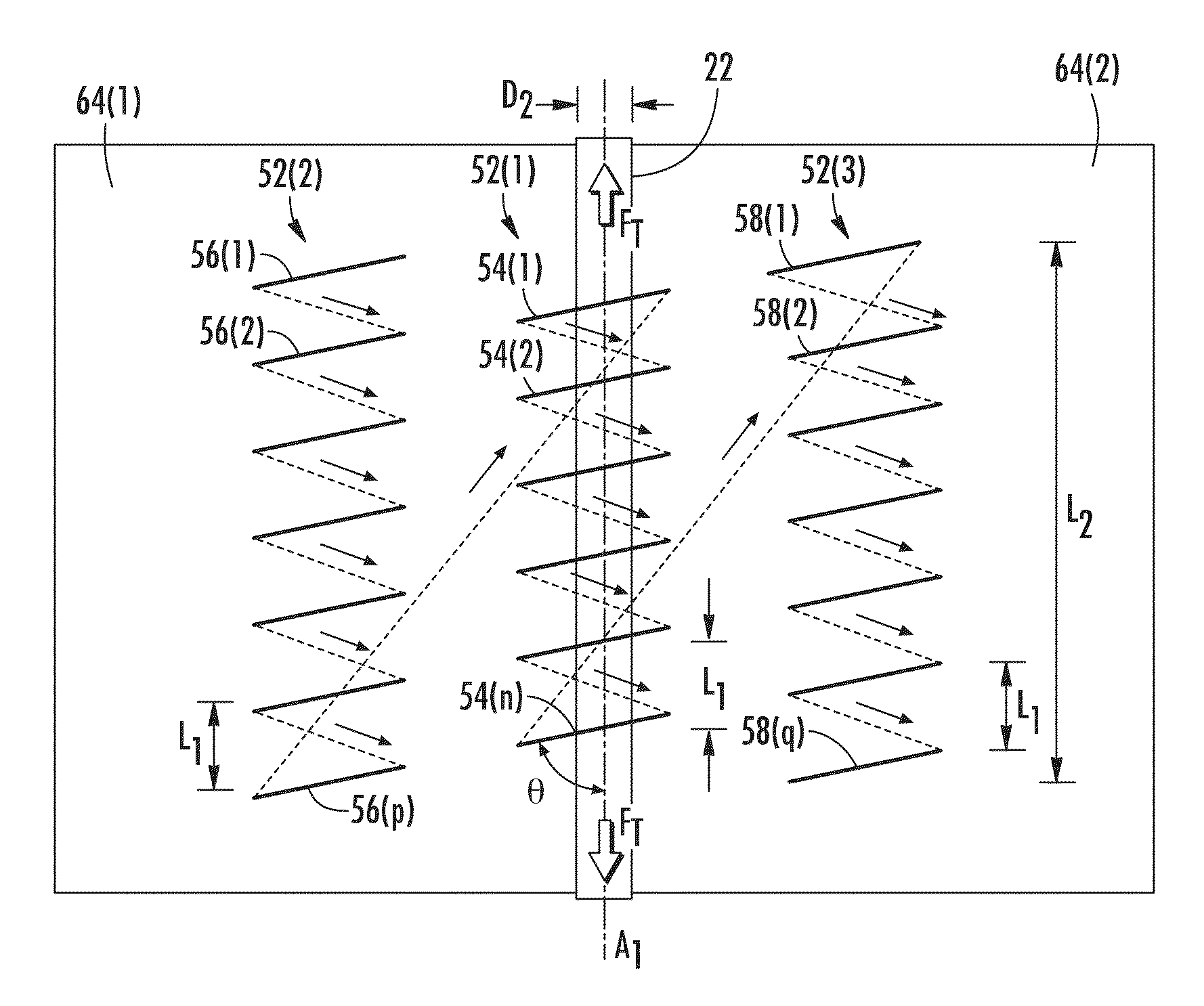

Heat and flame-resistant materials and upholstered articles incorporating same

ActiveUS7150059B2Improve performanceAvoid burnsStuffed mattressesSynthetic resin layered productsCombustionConus californicus

A mattress, foundation, or other upholstered sleep product or article includes a core and barrier material surrounding the core. The barrier material includes flame and heat-resistant material that is configured to prevent combustion of the core when the upholstered article is impinged with a gas flame according to California Technical Bulletin 603 of the State of California Department of Consumer Affairs. The barrier material may include an intumescent material that is configured to swell and char in the presence of a flame so as to form a barrier to the flame and to heat generated by the flame.

Owner:ADVANCED MICRO DEVICES INC +1

Apparatus and method for rapid reliable electrothermal tissue fusion

InactiveUS20080187989A1Improve integrityEffective and reliable and consistent sealBioreactor/fermenter combinationsBiological substance pretreatmentsThermal energyElectric energy

Pieces of tissue are fused together by compressing the pieces together at an interface, delivering an impulse of electrical power which is converted into sufficient thermal energy to fuse the pieces together at the interface. The impulse and the fusion occur within a preferable time of 0.5-2.0 seconds but no greater than 4.0 seconds. The temperature of the thermal energy is regulated between 150° C.-200° C. The tissue pieces are compressed to a thickness of 0.05-0.10 mm. Jaws which compress the tissue and transfer the energy have smooth working surfaces with an Ra of 0.15 or less microns to 0.40 microns.

Owner:CONMED CORP

Heat and flame-resistant materials and upholstered articles incorporating same

InactiveUS20050227558A1Improve performanceAvoid burnsStuffed mattressesSynthetic resin layered productsCombustionEngineering

A mattress, foundation, or other upholstered sleep product or article includes a core and barrier material surrounding the core. The barrier material includes flame and heat-resistant material that is configured to prevent combustion of the core when the upholstered article is impinged with a gas flame according to California Technical Bulletin 603 of the State of California Department of Consumer Affairs. The barrier material may include an intumescent material that is configured to swell and char in the presence of a flame so as to form a barrier to the flame and to heat generated by the flame.

Owner:PRECISION FABRICS GROUP

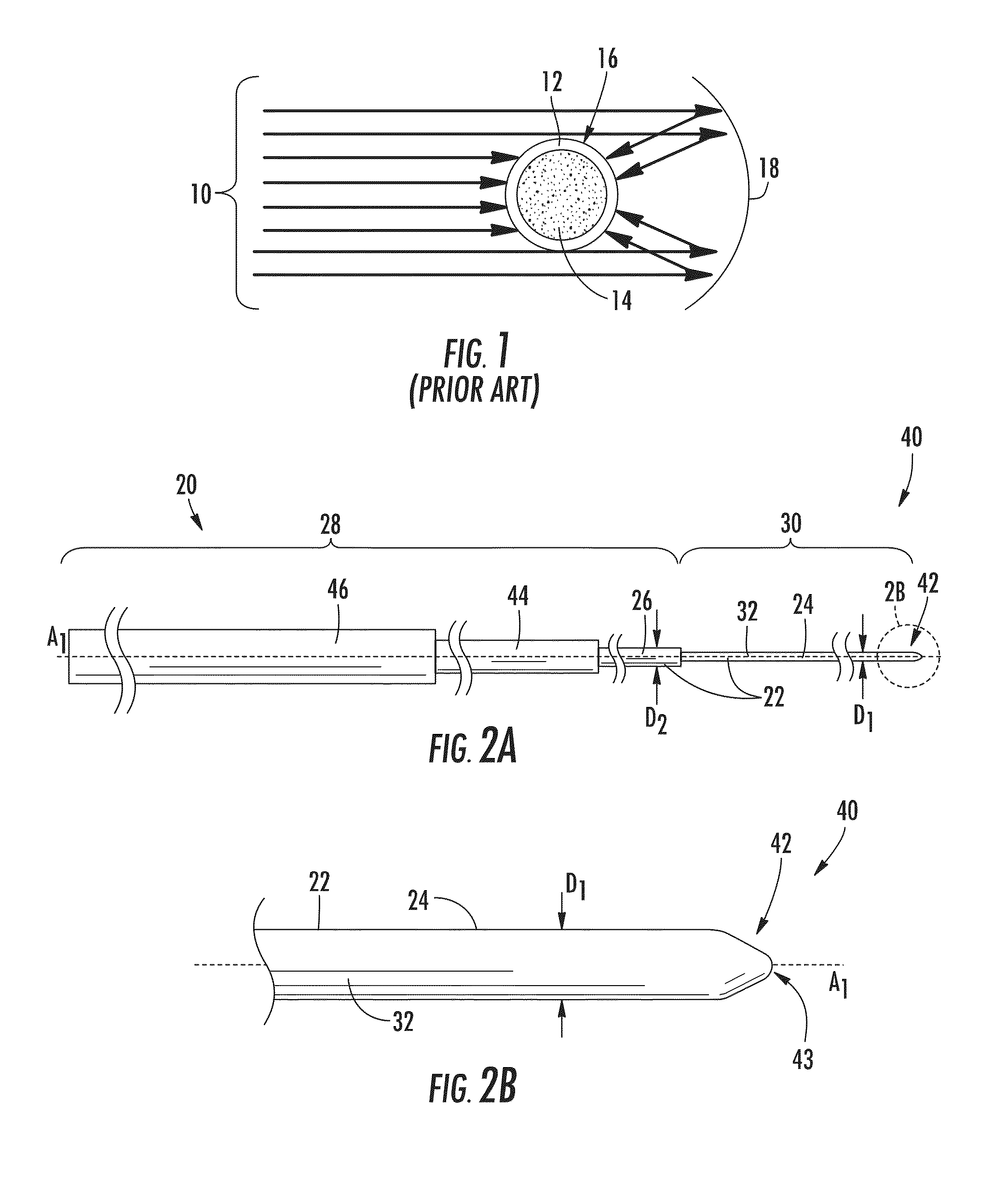

Coating removal systems for optical fibers

ActiveUS8755654B1Efficient removalReliable communicationCoupling light guidesWelding/soldering/cutting articlesGlass fiberLight beam

Coating removal systems for optical fibers are disclosed. An optical fiber includes a glass fiber, having a cladding and core, surrounded by a protective coating. By removing the coating at an end portion of the optical fiber, the end portion may be precisely positioned and secured in a connector to enable reliable optical communications. A laser beam may remove the protective coating while the optical fiber is under tension. In this manner, the coating may be efficiently removed while retaining tensile strength of the optical fiber.

Owner:CORNING OPTICAL COMM LLC

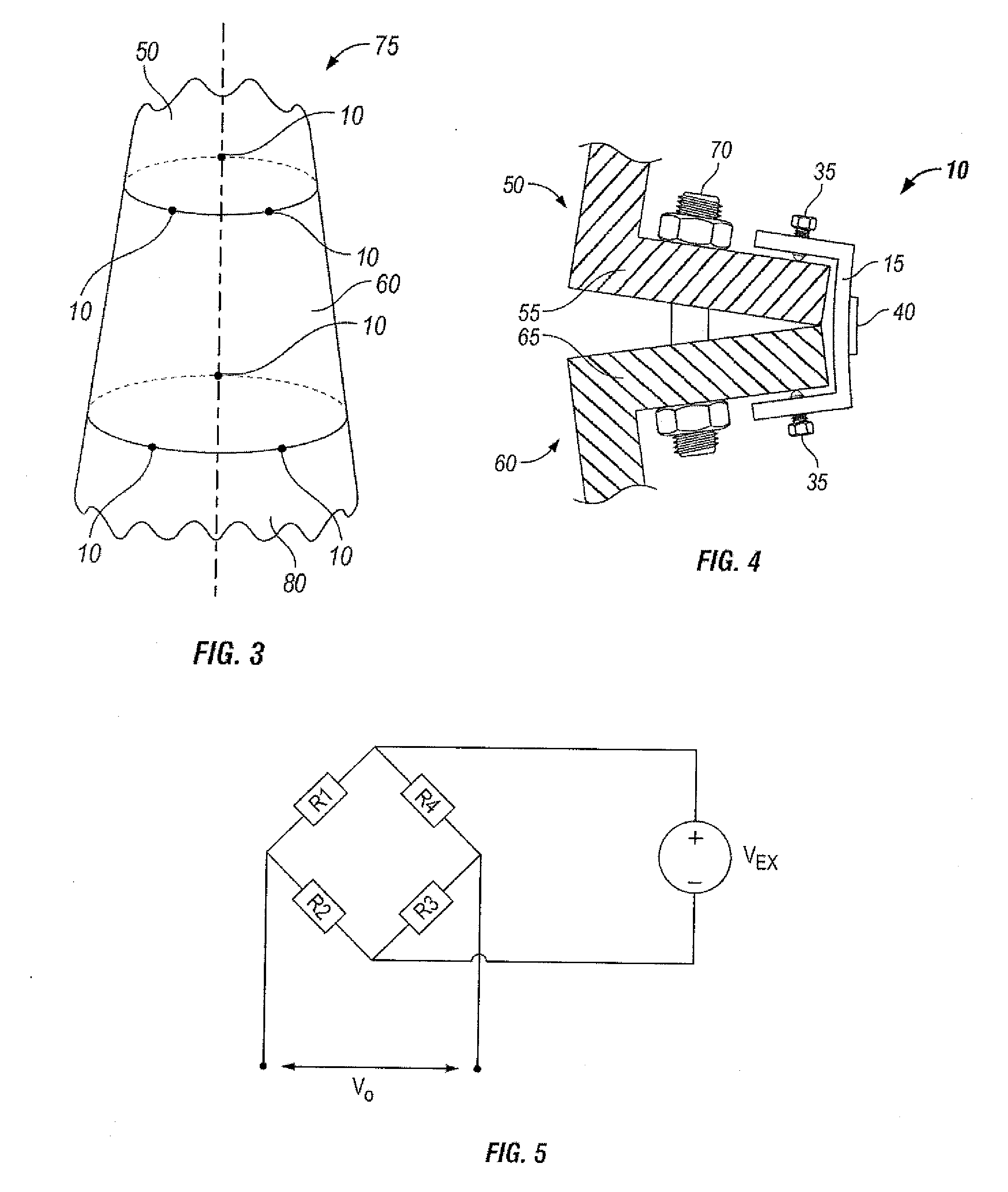

Wind Turbine Tower Monitoring Device

InactiveUS20100126115A1Non invasiveImprove installation speedEngine fuctionsForce measurementRelative motionTower

A wind turbine installation monitoring device, for detecting relative movement between two adjacent components of a wind turbine installation is provided. The device comprises a deformable member together with a securing device. The securing device is configured to enable the device to be connectable to a wind turbine installation, in use. The deformable member is located across an interface between the adjacent components of a wind turbine installation. Further, a detection device is provided and configured to detect deflection of the deformable member and thereby to detect relative movement between the two components.

Owner:VESTAS WIND SYST AS

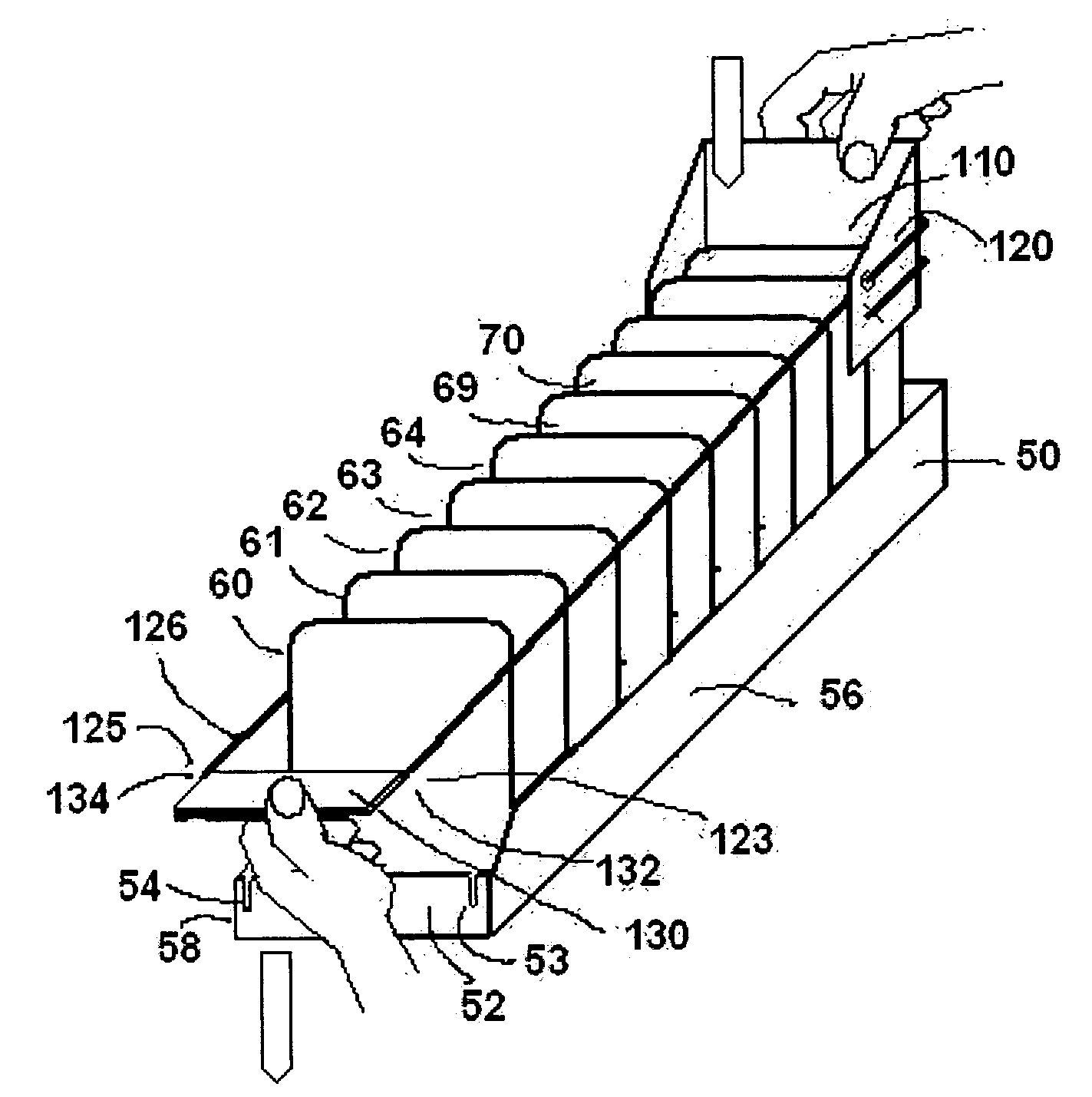

Method and apparatus for in-carton display and fronting of merchandise items

An elastic alignment mechanism utilizes cloth elastic strips to pull a rear engagement element toward the front of a display carton. As items are removed from the carton, remaining items are pulled forward. In one embodiment, the items may rest on the bottom of the carton, and the products are pulled by a rear engagement member, such as plastic or cardboard, which is pulled by elastic strips which are secured to the front of the carton. In one embodiment, the mechanism includes a reusable support base, and the elastic strip is provided below the row of items. The strip may be wound around one or more sheaves to decrease the required working range of the elastic. In one embodiment, cardboard support ribs are built into the bottom of the carton, so that the elastic strip may be provided below the items which are supported on the ribs.

Owner:CLOSE JAMES GARTH

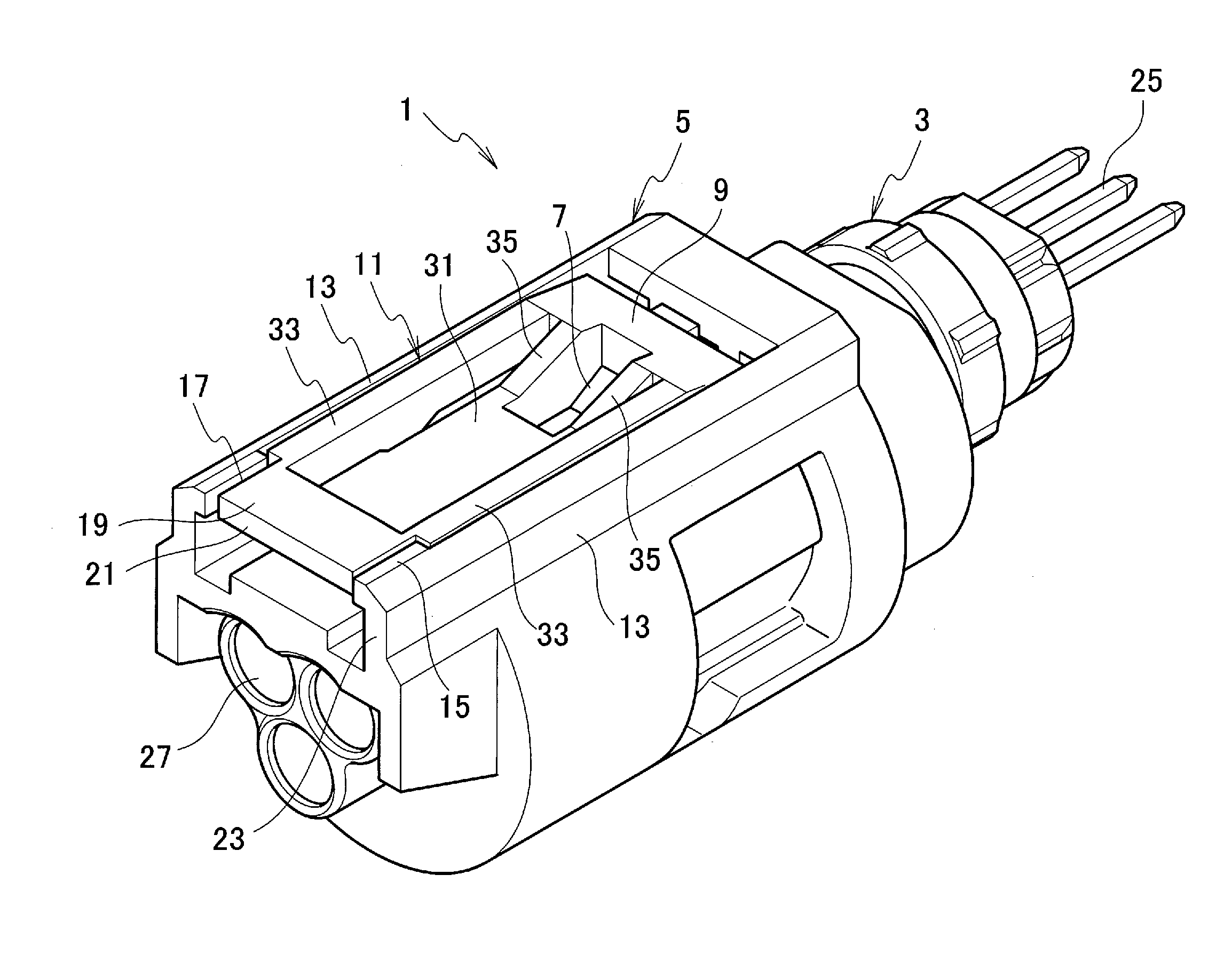

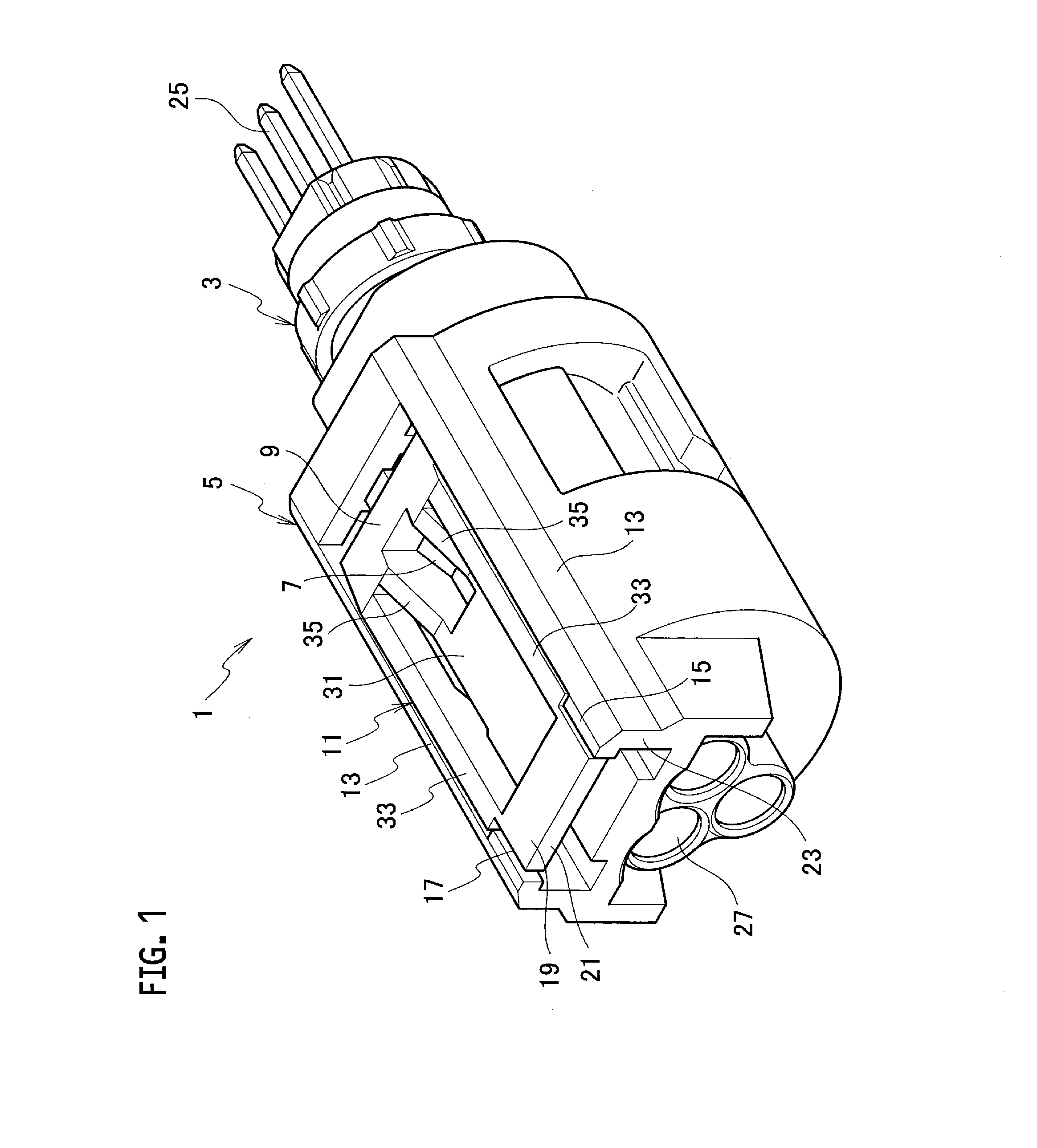

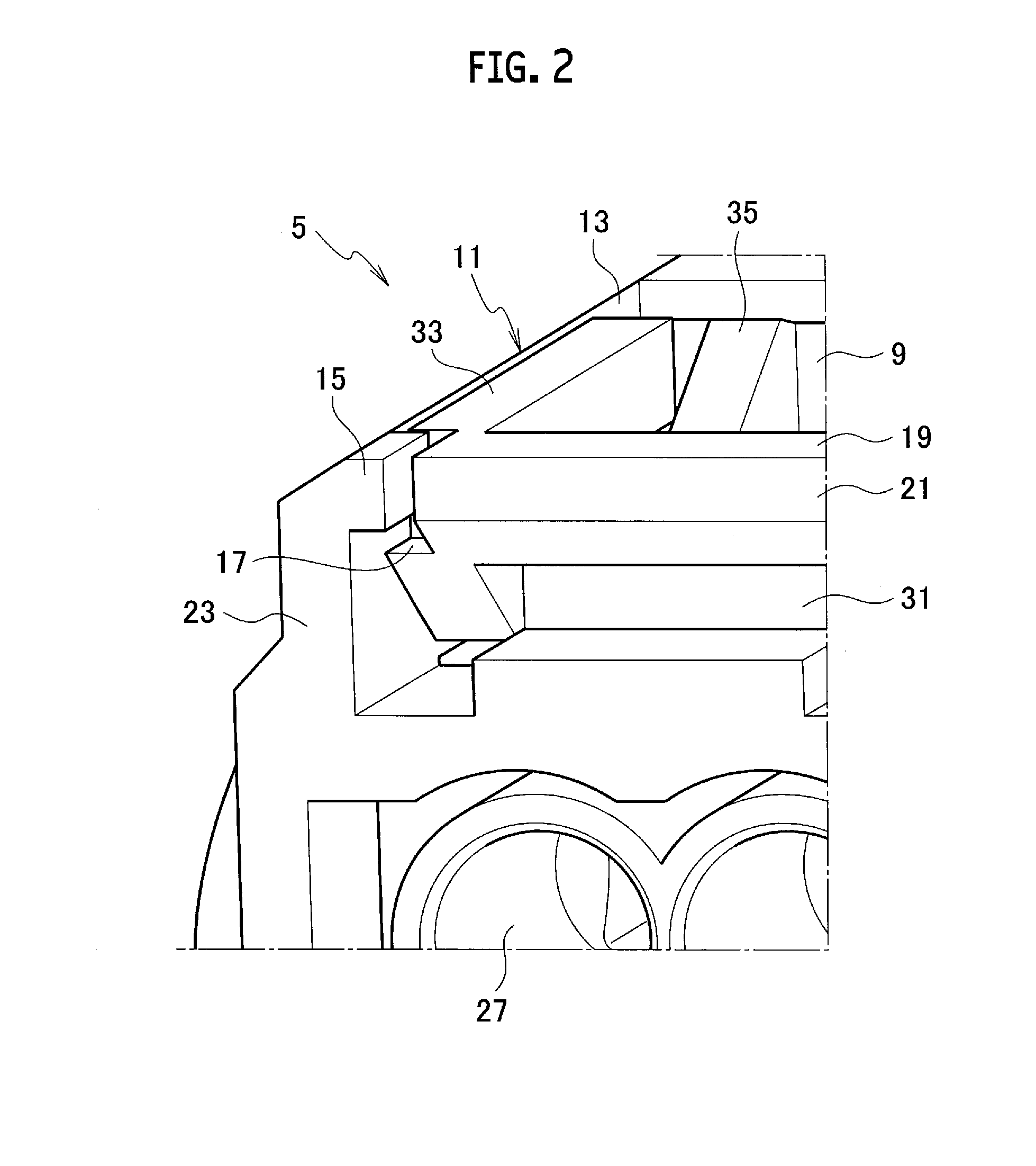

connector

ActiveUS20160164224A1InterferenceAvoid interferenceCoupling device detailsEngineeringMechanical engineering

A connector includes a housing capable of fitting with a mating housing, a locking arm swingably disposed on the housing and having a locking portion capable of locking with a locked portion of the mating housing, and locking arm protective walls disposed on the housing and arranged on both sides in a width direction of the locking arm. An engaging protrusion is disposed on each of the locking arm protective walls so as to protrude toward a side of the locking arm. An engaging recess portion is disposed on the locking arm. The engaging recess portion is positioned on a surface facing each of the locking arm protective walls, engages with the engaging protrusion, and regulates displacement toward one side of a swinging direction of the locking arm.

Owner:YAZAKI CORP

Small diameter, high strength optical fiber

InactiveUS6895156B2High strengthShorten the timeGlass optical fibreOptical fibre with multilayer core/claddingSilicon dioxideUltimate tensile strength

A coated optical fiber, preferably a GGP optical fiber includes an optical fiber core, and a silica cladding over the optical fiber core, to provide a silica clad core. A permanent polymeric coating forms on the silica cladding during ultraviolet radiation of a photocurable composition containing a non-hydrolyzable photoinitiator. The coated optical fiber has a diameter from about 120 microns to about 160 microns and a relative frequency distribution of at least about 85% for dynamic fatigue measurements between about 49.2×103 kg / cm2 (700 kpsi) and about 63.3×103 kg / cm2 (900 kpsi).

Owner:3M INNOVATIVE PROPERTIES CO

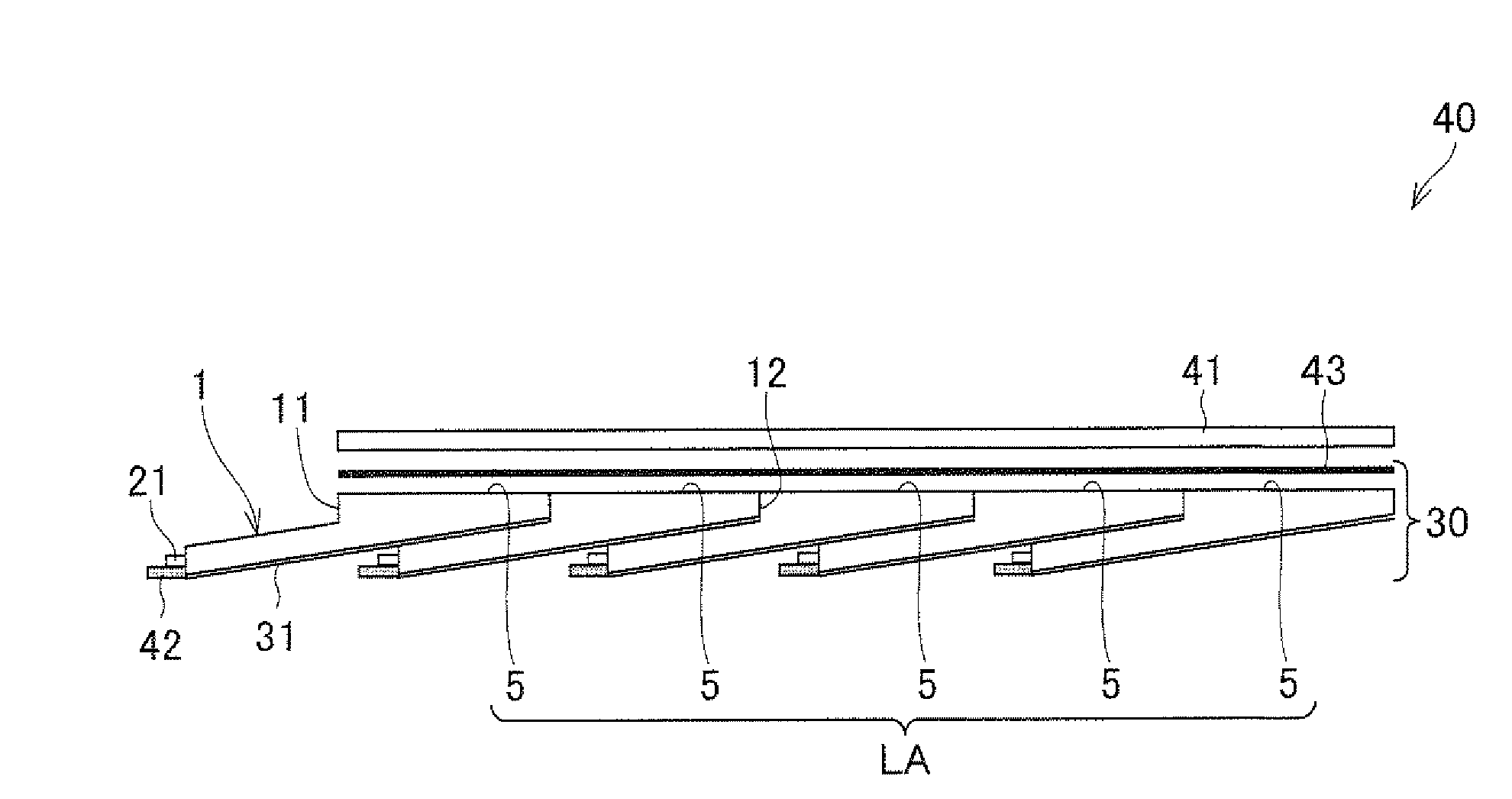

Illumination device, display device, and light guide plate

ActiveUS20100214281A1Reduce light leakageBright enoughCathode-ray tube indicatorsPlanar/plate-like light guidesOptical axisLight guide

An illumination device (30) includes a plurality of light source units (BLU) each having a light guide plate (1) and a plurality of light sources (21). The light guide plate (1) has an illumination region (4) through which incident beams of light from the light sources (21) are emitted outward and a light guide region (3) through which the incident beams of light from the light sources (21) are guided toward the illumination region (4), with the light guide region (3) and the illumination region (4) laid side-by-side. The illumination region (4) is divided into a plurality of light-emitting sections by slit sections (8), provided in such a way as to extend along directions of optical axes of the light sources (21), which restrict transmission of light. At least one of the light sources (21) is provided to each of the light-emitting sections in such a way as to be placed side-by-side along the light guide region (3). Light source units (20) adjacent to each other along the directions of the optical axes of the light sources (21) are disposed so that the illumination region (4) of one of the light source units (BLU) covers at least a part of the light guide region (3) of the other light source unit (BLU). This makes it possible to retain the strength of the illumination device as a combination of light guide blocks while reducing leakage of light into an adjacent area.

Owner:SHARP KK

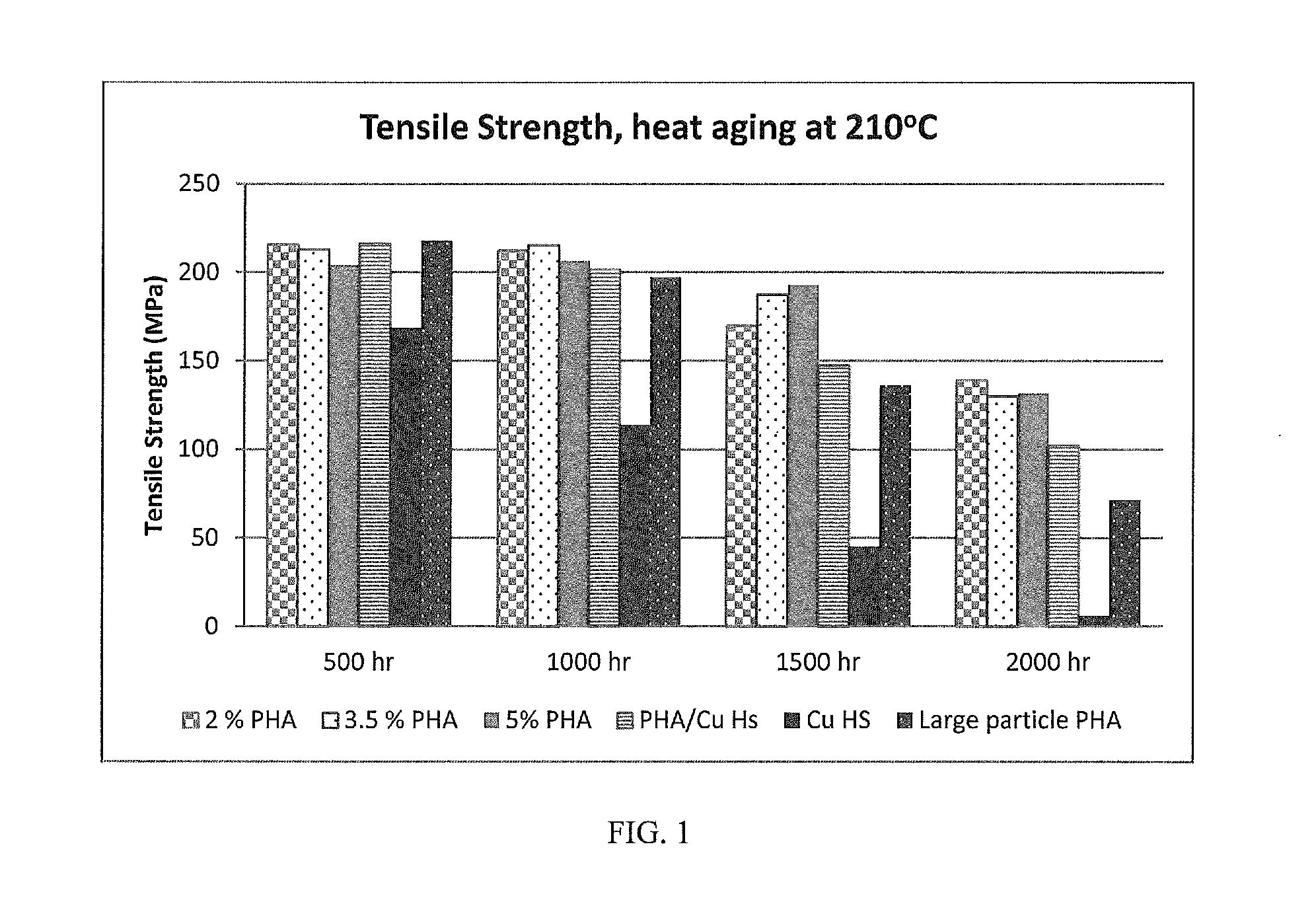

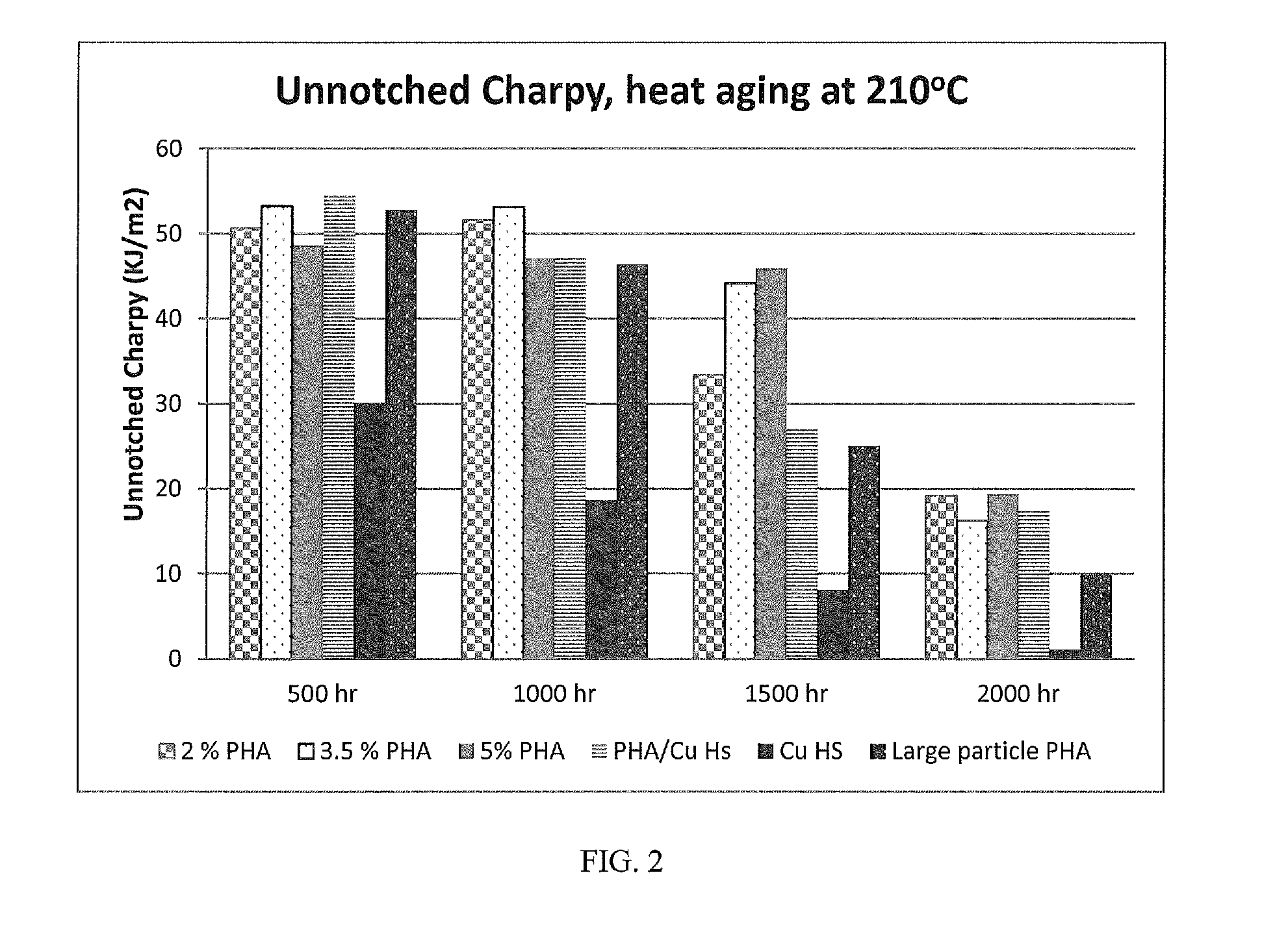

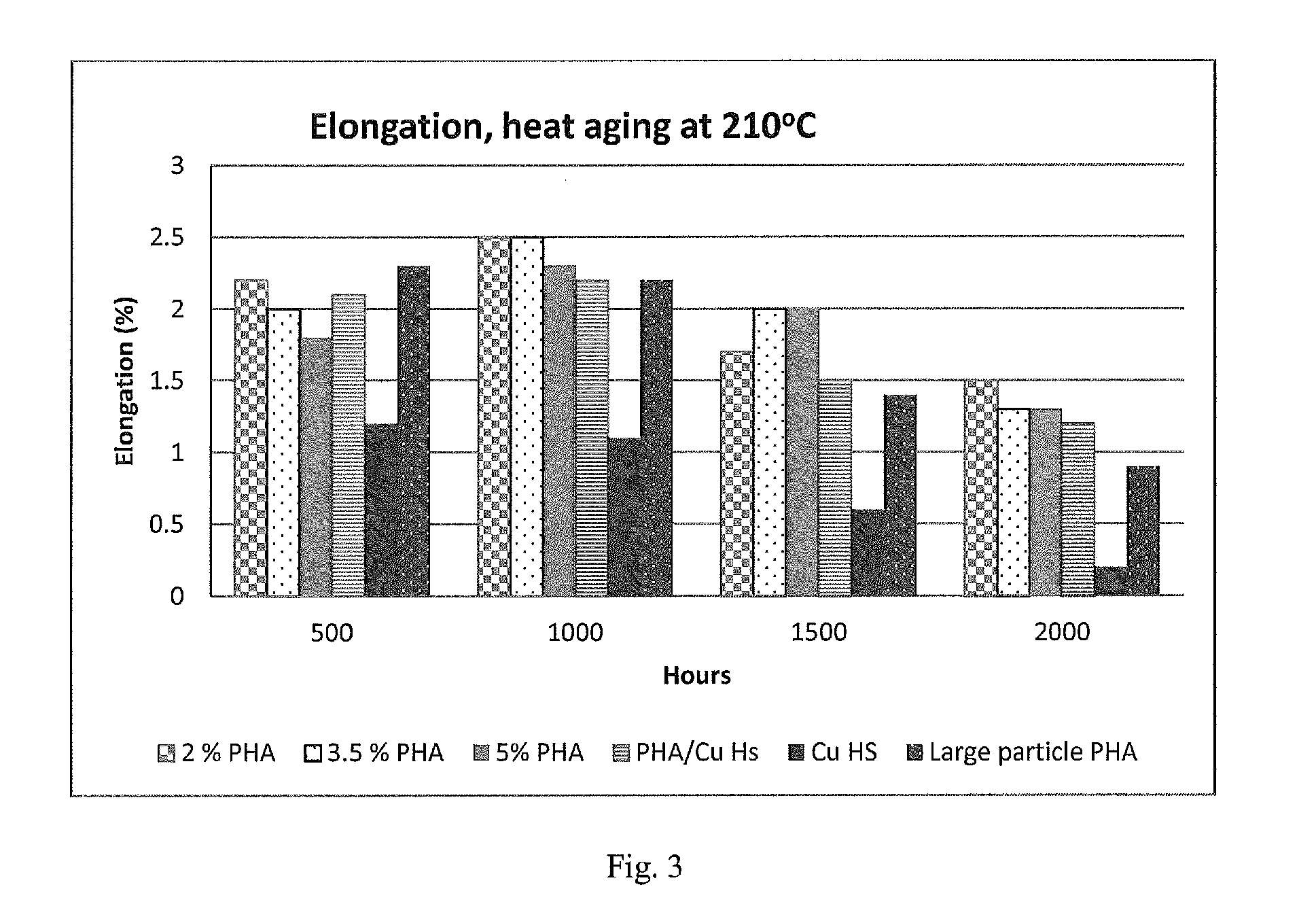

Compositions of polyhydric alcohols and polyamides

ActiveUS20130228728A1Improve aging stability performanceRetention strengthFireproof paintsSpecial tyresPolyolAlcohol

The present invention relates to a thermoplastic composition that provides improved thermal aging stability along with durability. The thermoplastic composition comprises a polyamide resin, and a polyhydric alcohol, wherein a majority of the polyhydric alcohol particles have a particle size that is less than about 70 microns. It has been found that a combination of a polyamide resin and a polyhydric alcohol with this particle size produces a superior product demonstrating greater thermal stability and durability than the polyamide resin alone.

Owner:RADICI PLASTICS USA INC

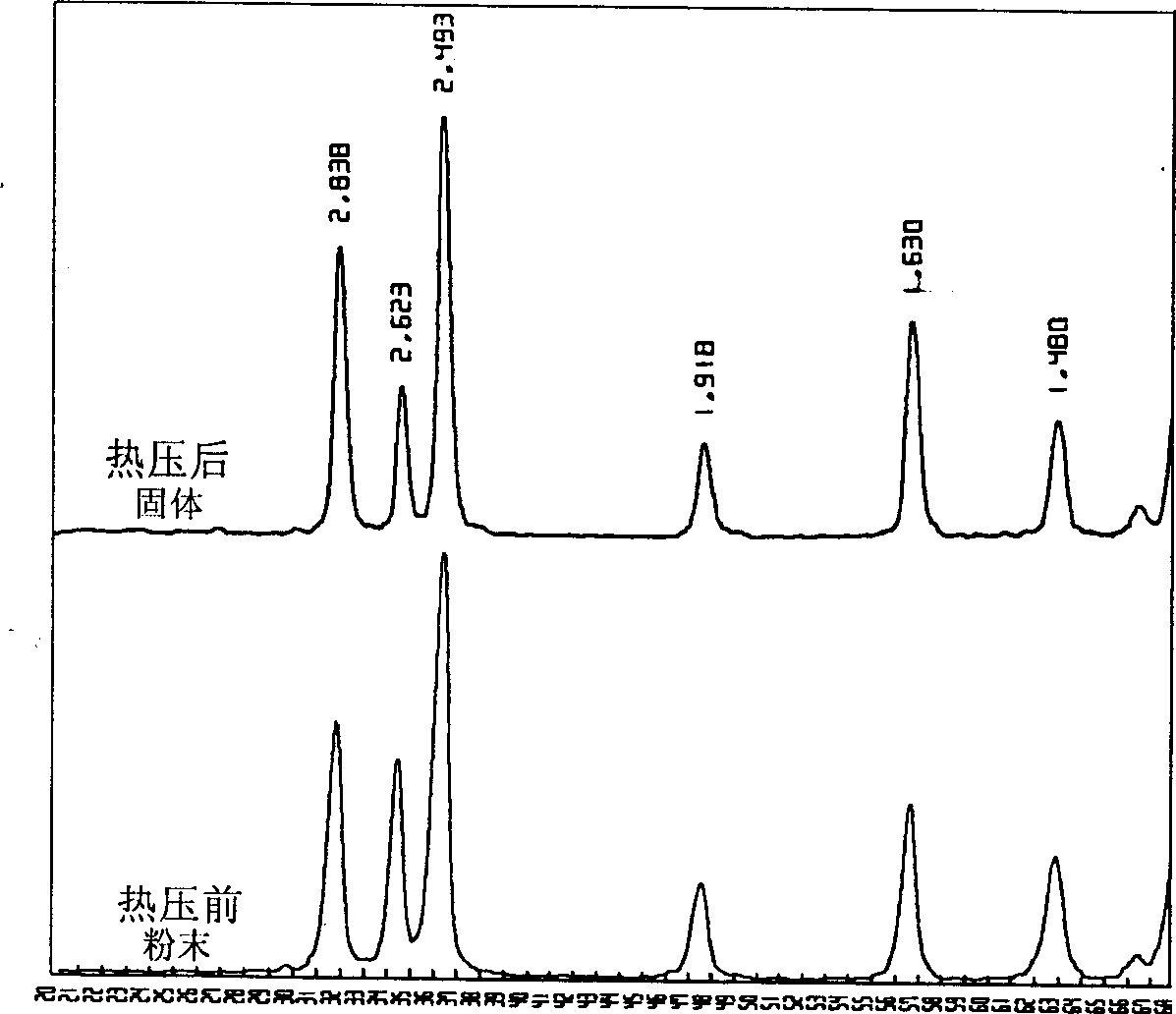

Method for preparing porous nano solid by using hot pressing technique through controllable vaporized solvent

InactiveCN1431169AWide range of usesGood mechanical strength and pore size uniformityCeramicwareSolventPorous solids

A process for preparing nano-class porous solid includes proportionally mixing nano powder with pore-forming agent, heating to 80-500 deg.c under 50-1000 MPa, holding the temp and pressure for 0.5-12hr to forming pores by gasifying and firm pore wall, and cooling. Its advantages are high uniformity of pore diameters and high mechanical strength.

Owner:SHANDONG UNIV

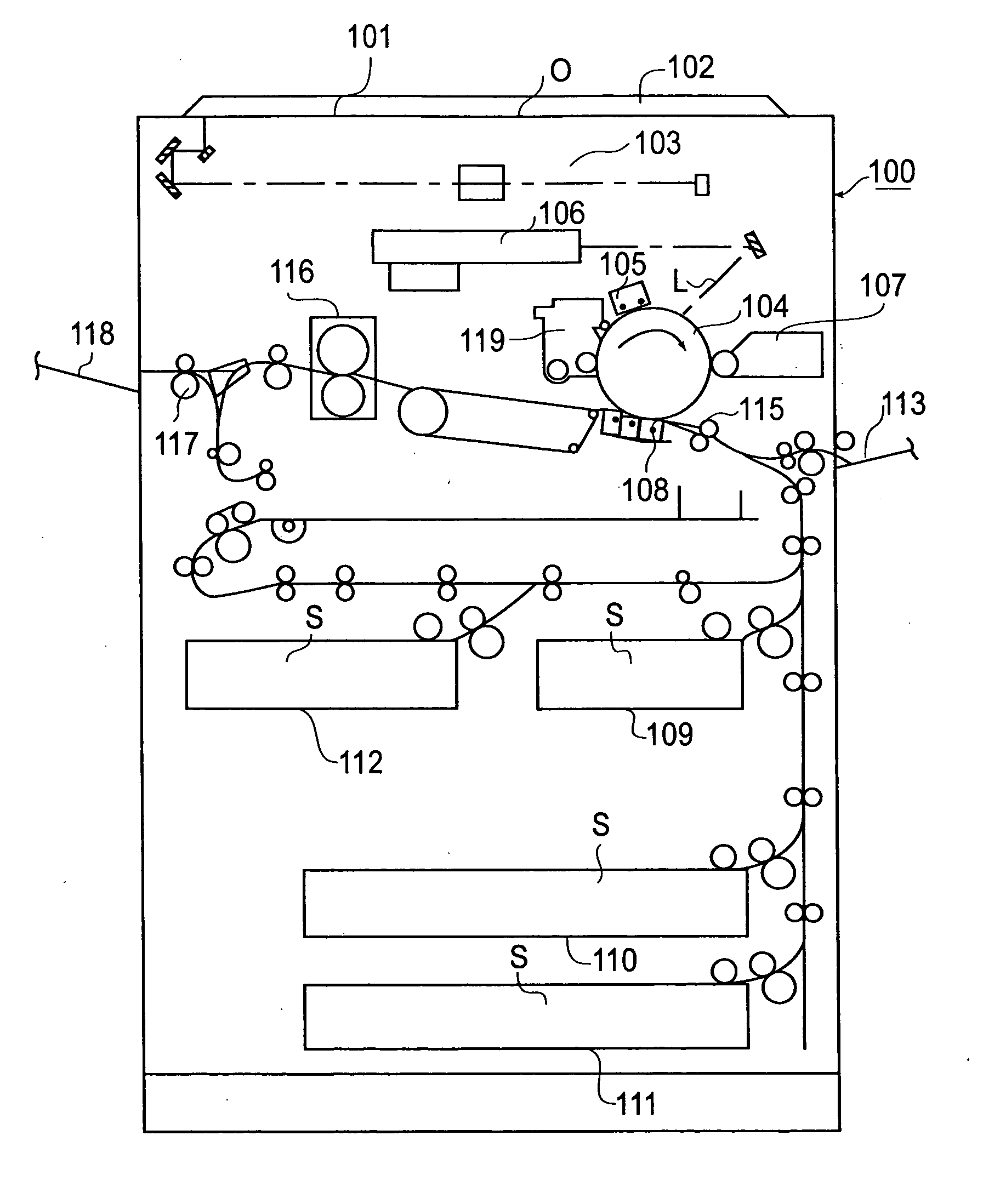

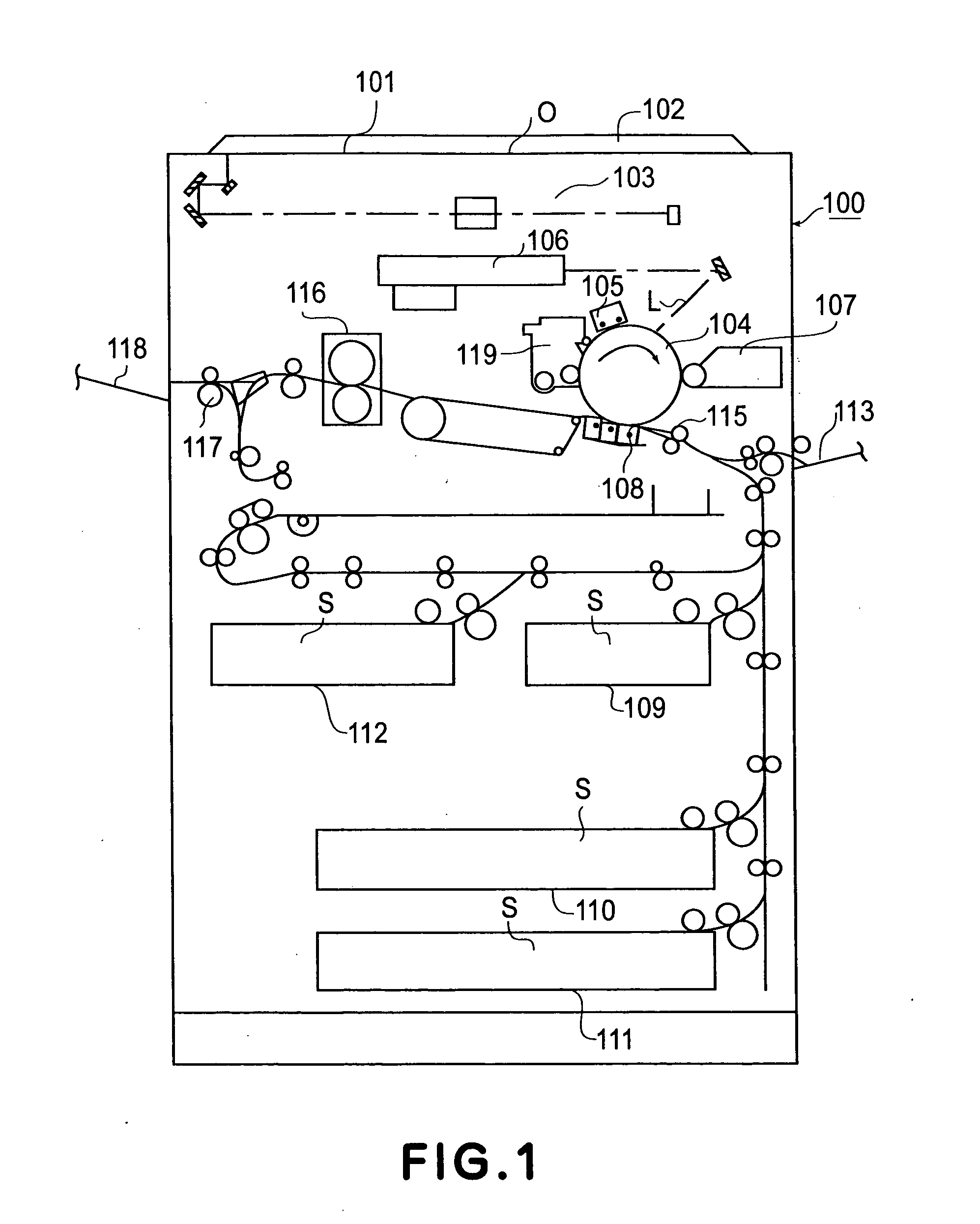

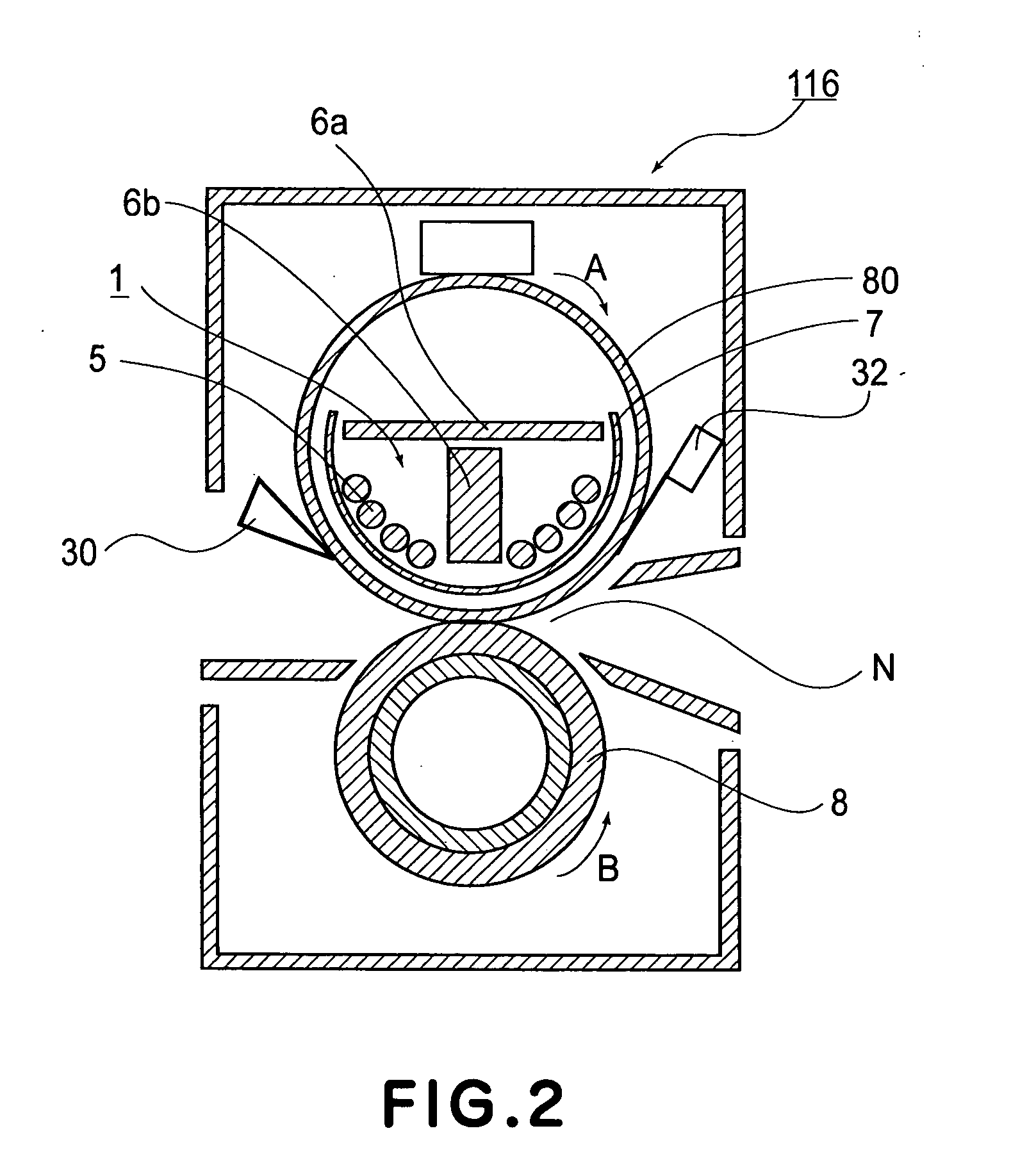

Image heating apparatus

InactiveUS20060086722A1InhibitionRetention strengthFurnaces without endless coreElectrographic process apparatusEngineeringMagnetic flux

A fixation apparatus having a good fixability in its longitudinal direction and an image forming apparatus are provided. The fixation apparatus includes an electromagnetic induction heating member which is a hollow rotation member, and a magnetic flux generation member for causing the electromagnetic induction heating member to generate heat by generating magnetic flux in the electromagnetic induction heating member. The fixation apparatus fixes a toner image on a recording material by imparting heat energy by heat generation of the electromagnetic induction heating member to the recording material to be conveyed. The electromagnetic induction heating member has a different thickness in the longitudinal direction thereof and a uniform diameter at a surface facing the magnetic flux generation means in the longitudinal direction.

Owner:CANON KK

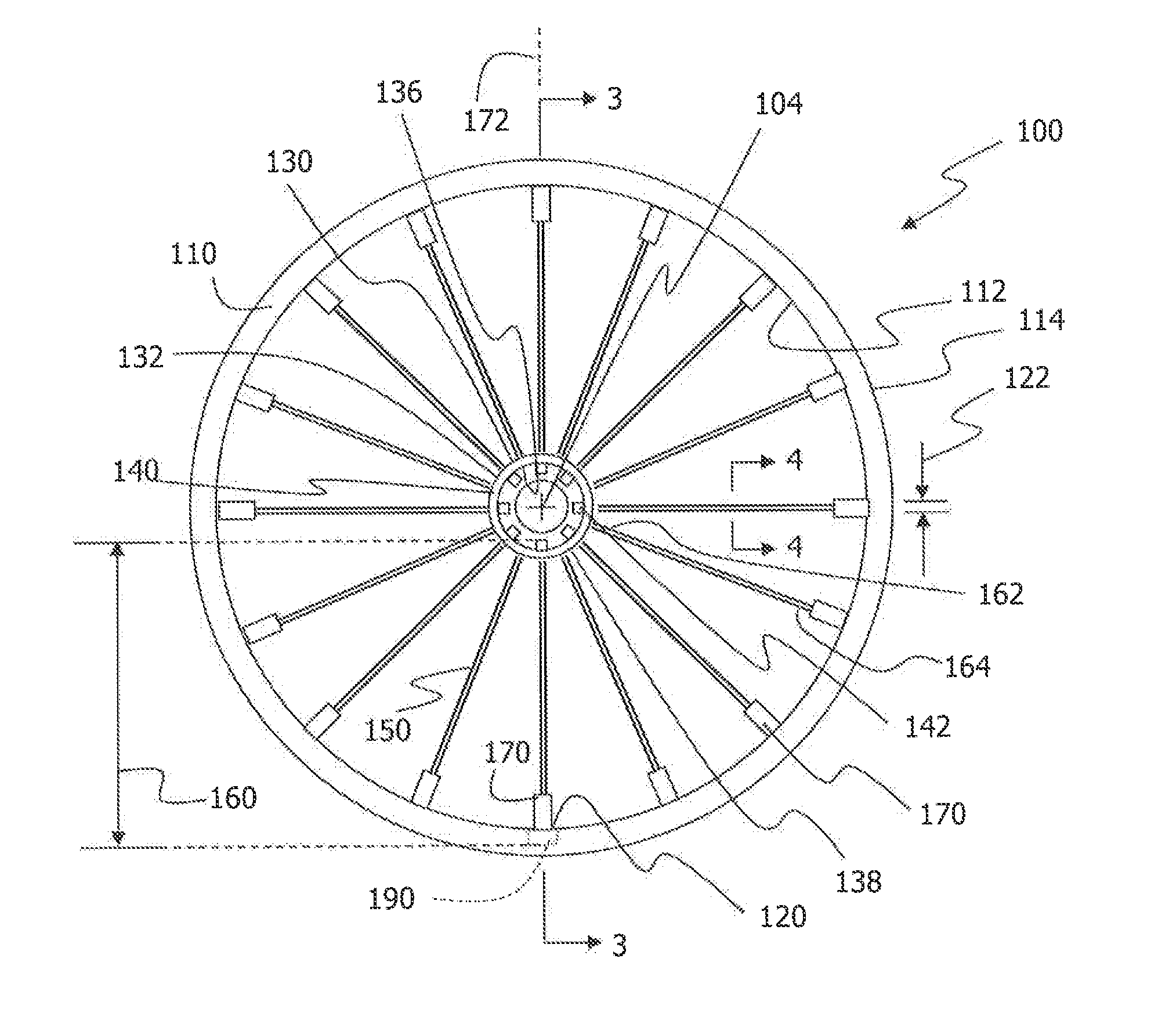

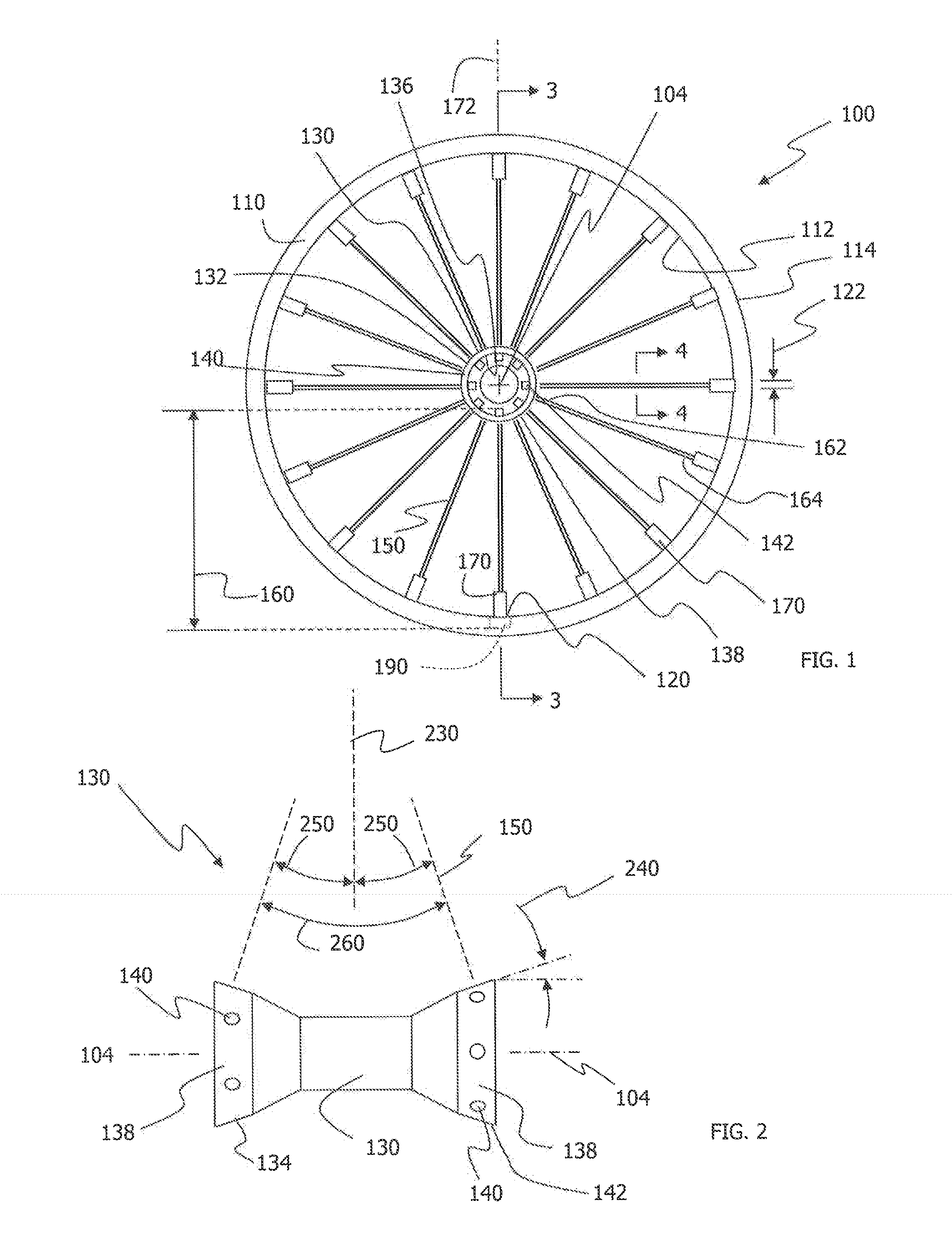

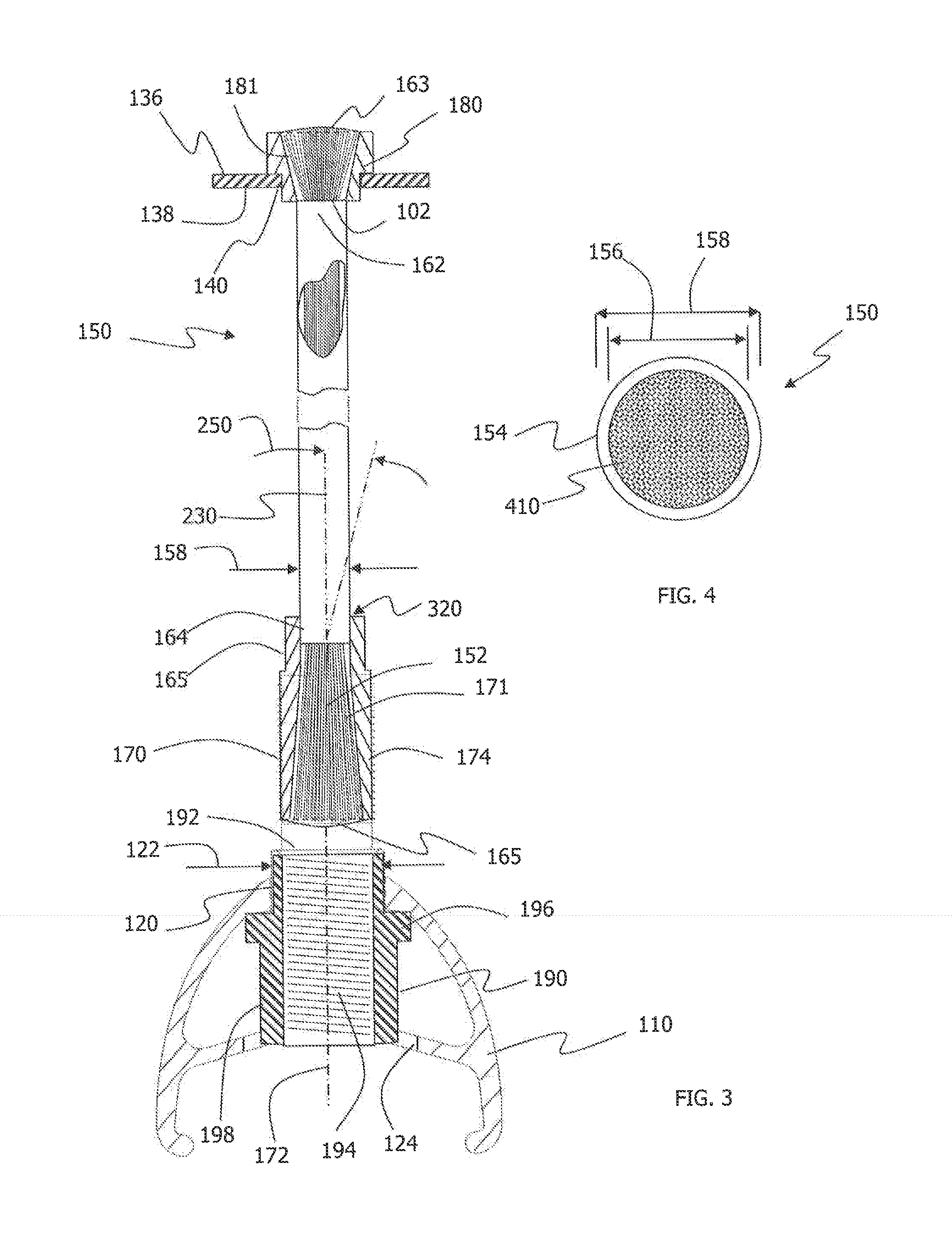

Wheel With High Strength Flexible Spokes

ActiveUS20130320749A1Light weightRetaining integrityRimsNon-metallic wheel bodyPliabilityEngineering

A wheel with high strength flexible spokes of the present invention, including a rim and hub, and spokes between the rim and hub made of fibrous material that causes the spokes to be both lighter in weight and stronger than comparable steel spokes. The spokes are also flexible and resilient such that they can bend while retaining their integrity and strength. The wheel includes a nipple within the rim that receives the high strength spoke and allows for flexibility in adapting the spoke to wheels having differing shapes and sizes.

Owner:SPINERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com