Electric razor with helical filament winding

a technology of electric razors and filaments, applied in the direction of metal working devices, etc., can solve the problems of not contributing to the lifting of hairs, wires, etc., and achieve the effect of preventing the migration of filaments along the roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

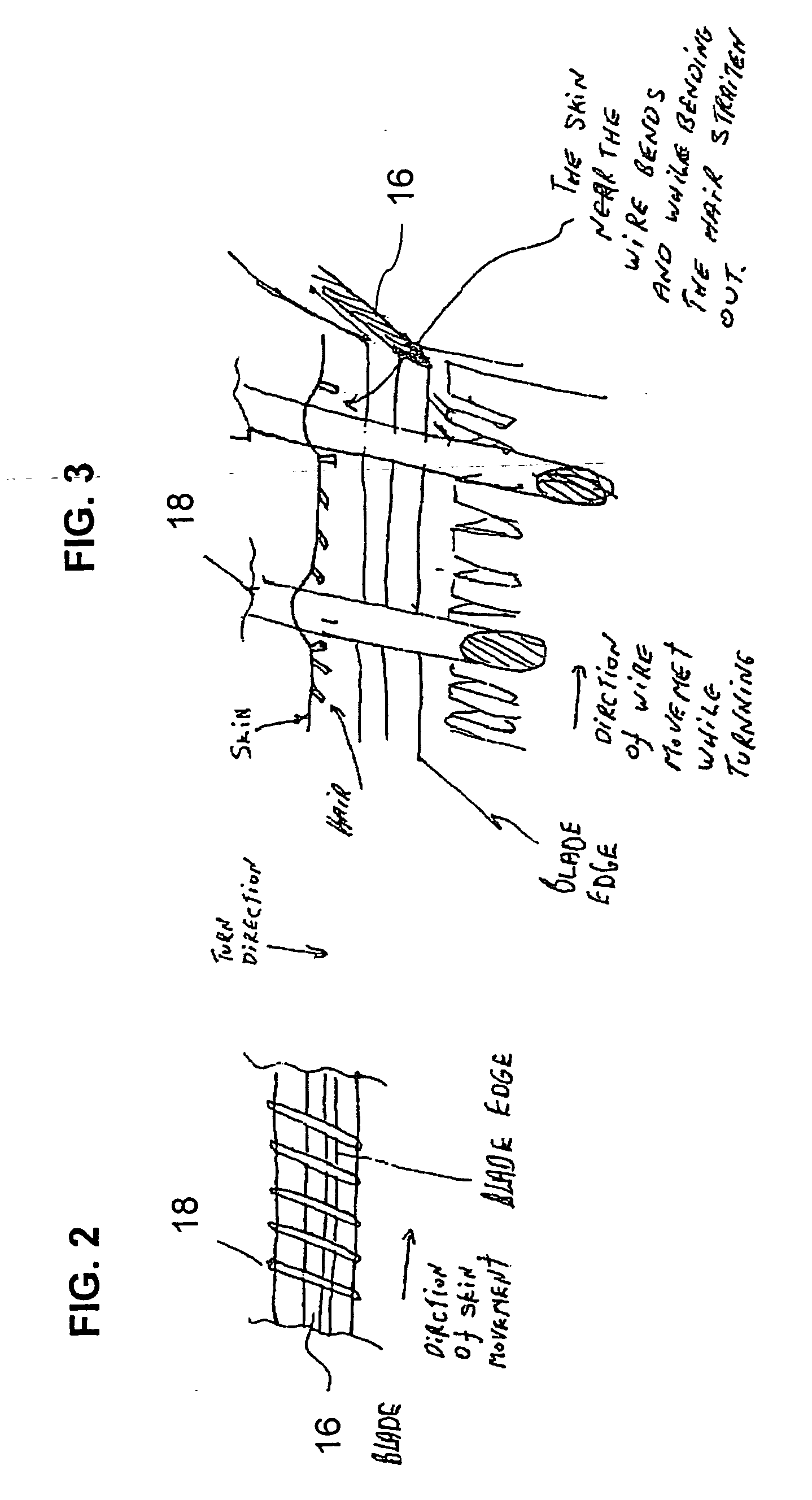

[0026] The present invention is an electric razor with exposed-blade rollers wherein the rollers are at least partially wound with a filament in a helical configuration.

[0027] The principles and operation of razors according to the present invention may be better understood with reference to the drawings and the accompanying description.

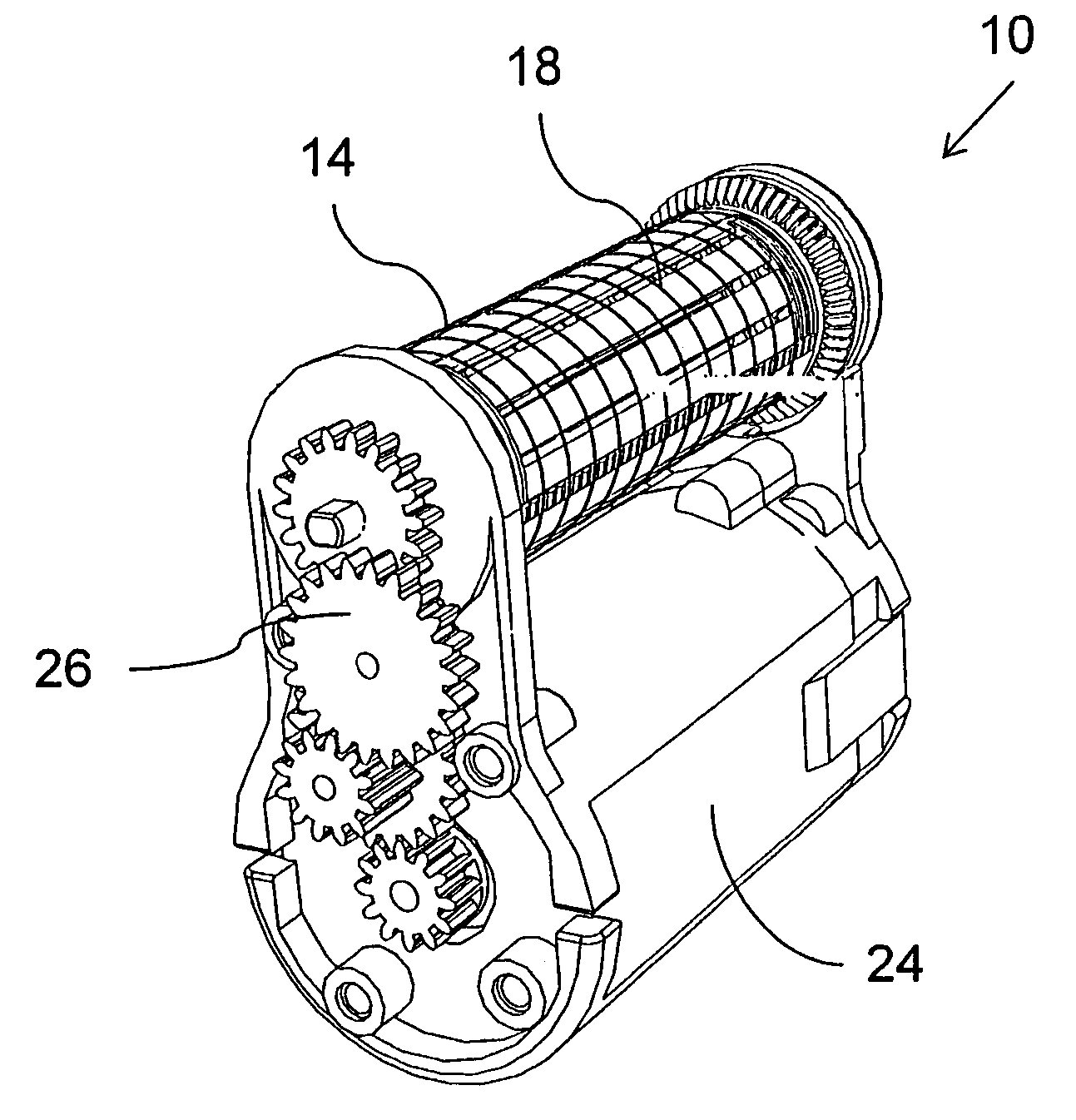

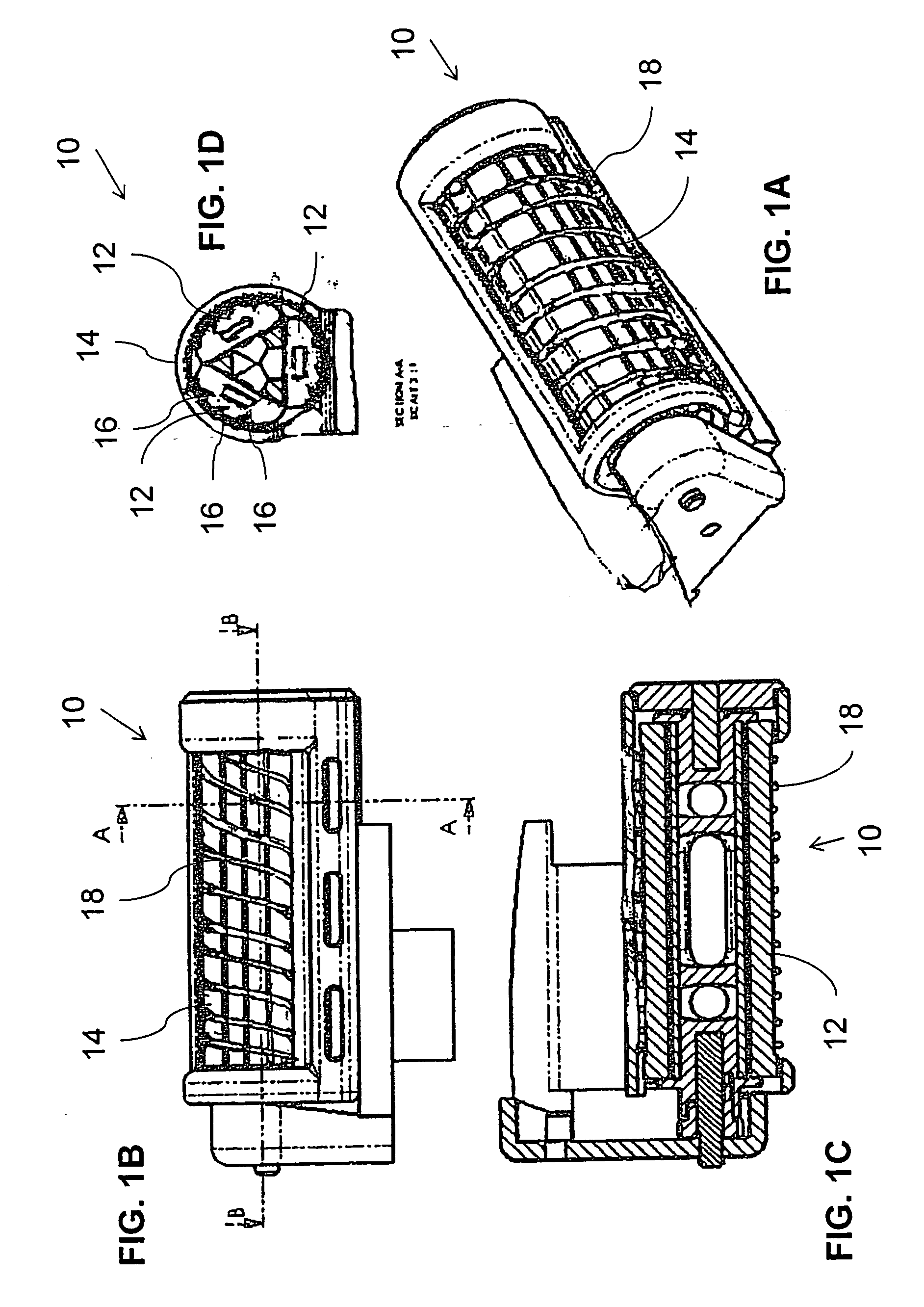

[0028] Referring now to the drawings, FIGS. 1A-1D show a particularly preferred option for implementing the one or more roller assemblies, generally designated 10, constructed and operative according to the teachings of the present invention. A particularly effective and cost efficient implementation employs a plurality of convexly curved multi-blade cartridges 12 mounted together to form a blade roller structure 14 approximating to a cylindrical overall form. Preferably, the convexly curved multi-blade cartridges 12 are implemented according to the teachings of one or both of U.S. Pat. Nos. 6,055,731 and 6,305,084, both of which are co-assigned wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com