Patents

Literature

233 results about "Membrane contactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

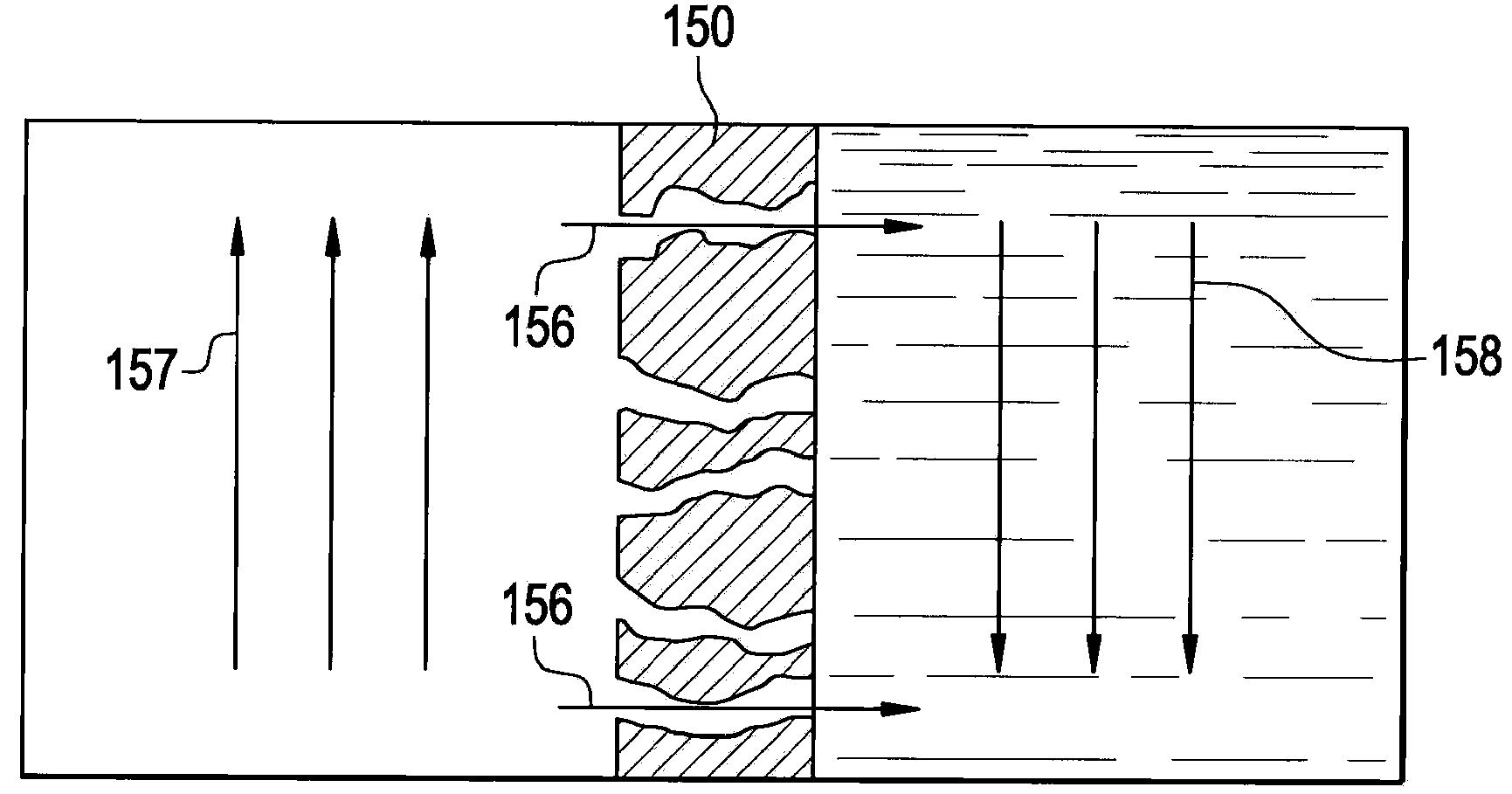

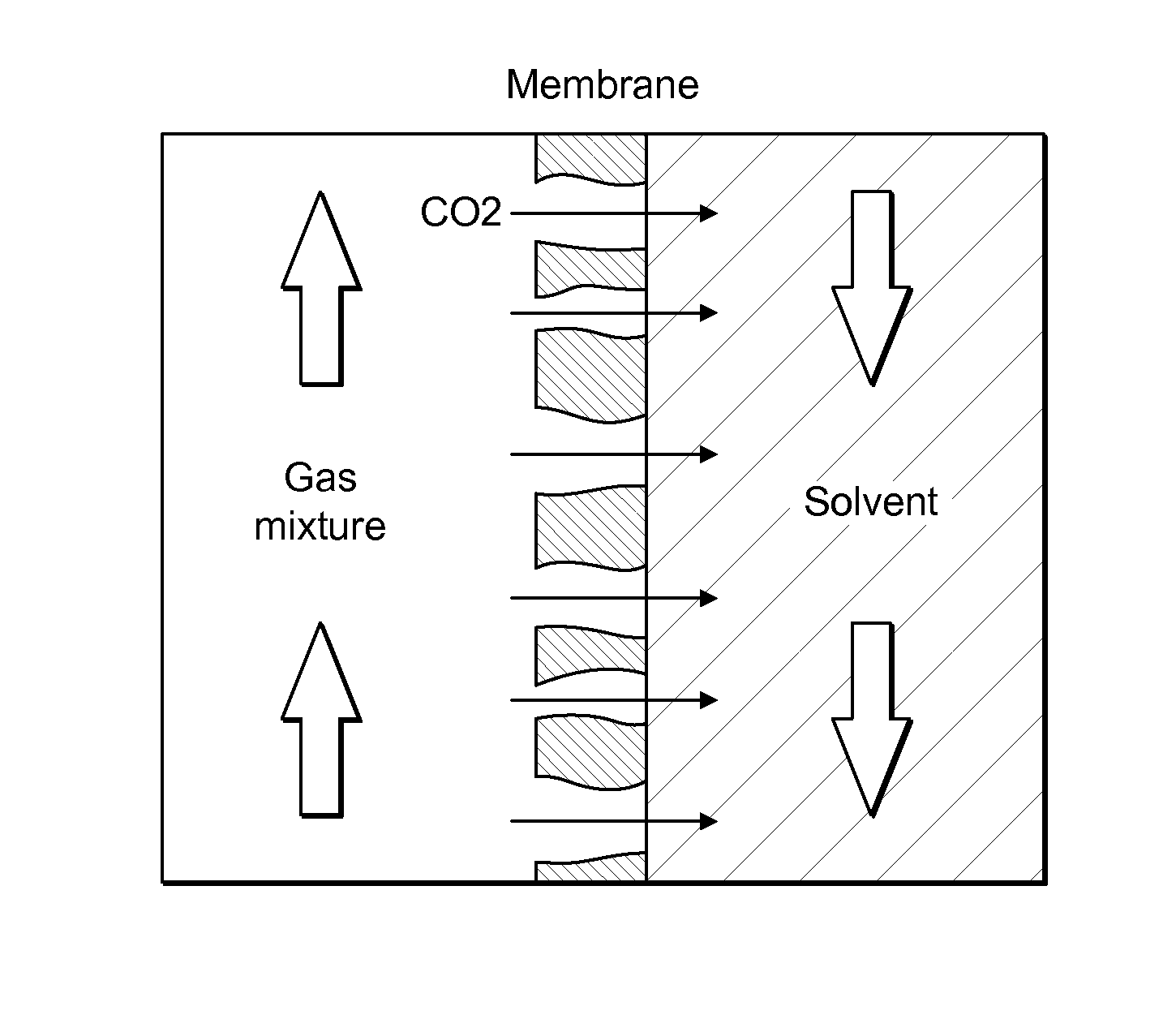

"Membrane contactors are devices that allow a gaseous phase and a liquid phase to come into direct contact with each other, for the purpose of mass transfer between the phases, without dispersing one phase into the other.

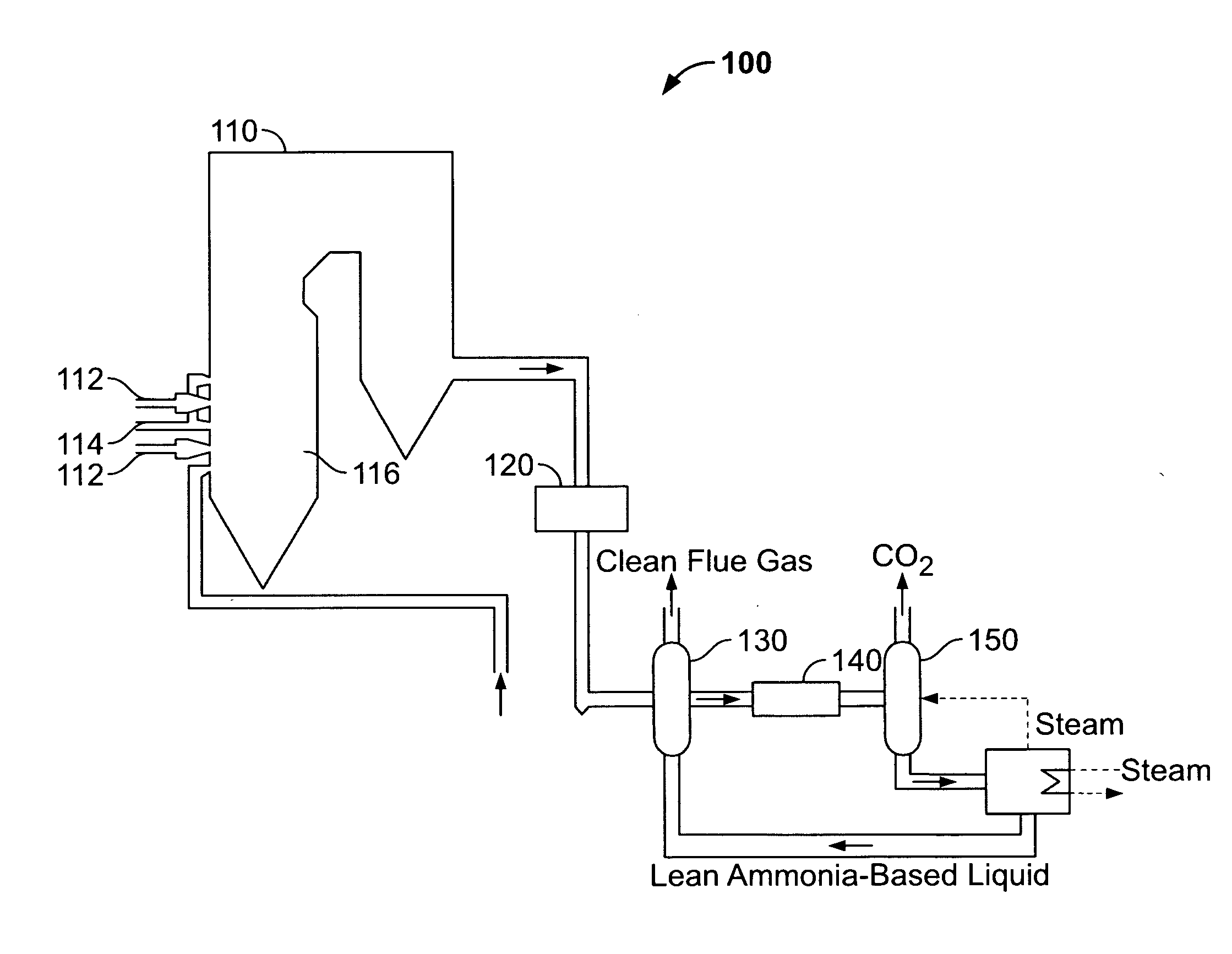

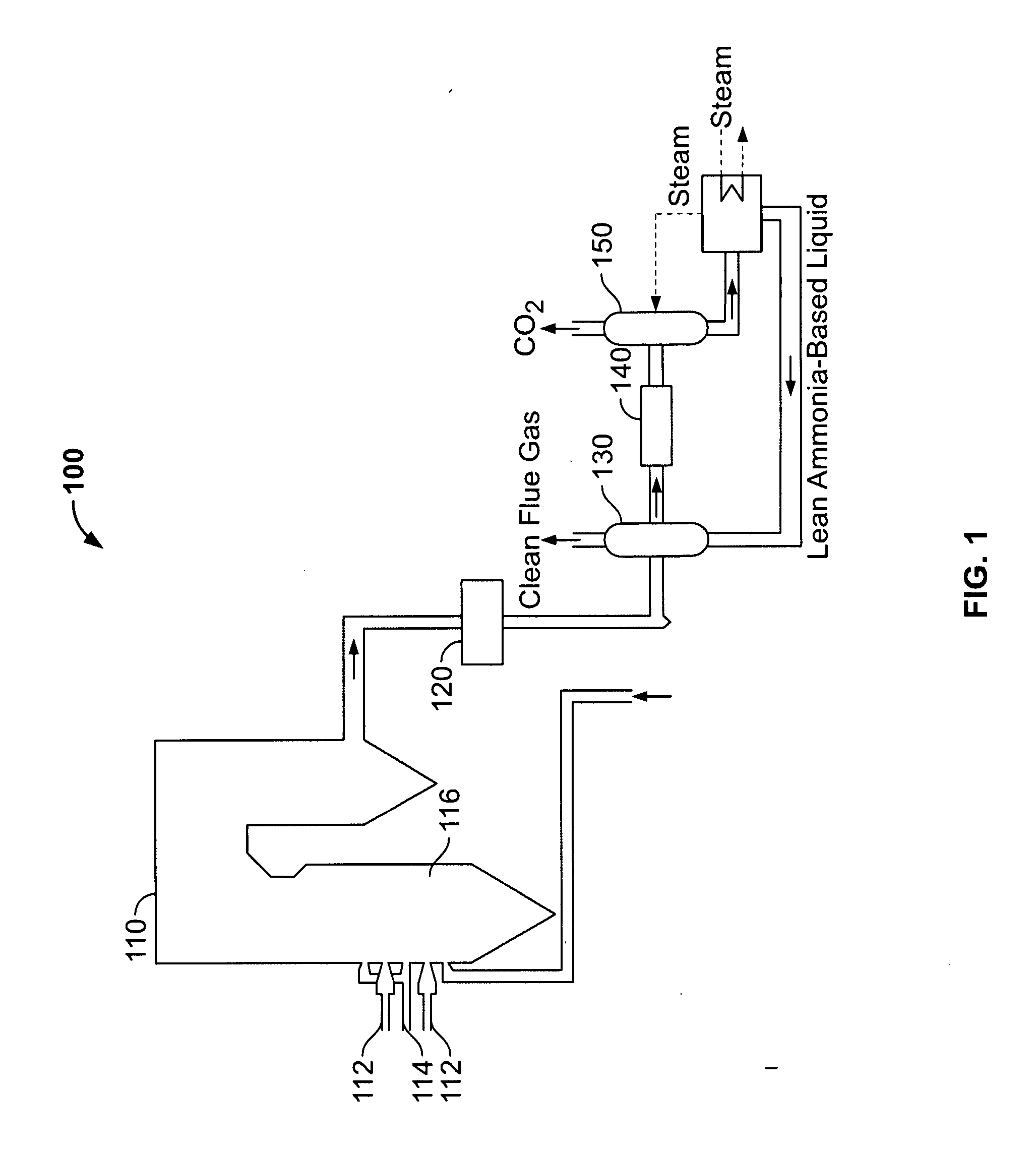

Methods and systems for reducing carbon dioxide in combustion flue gases

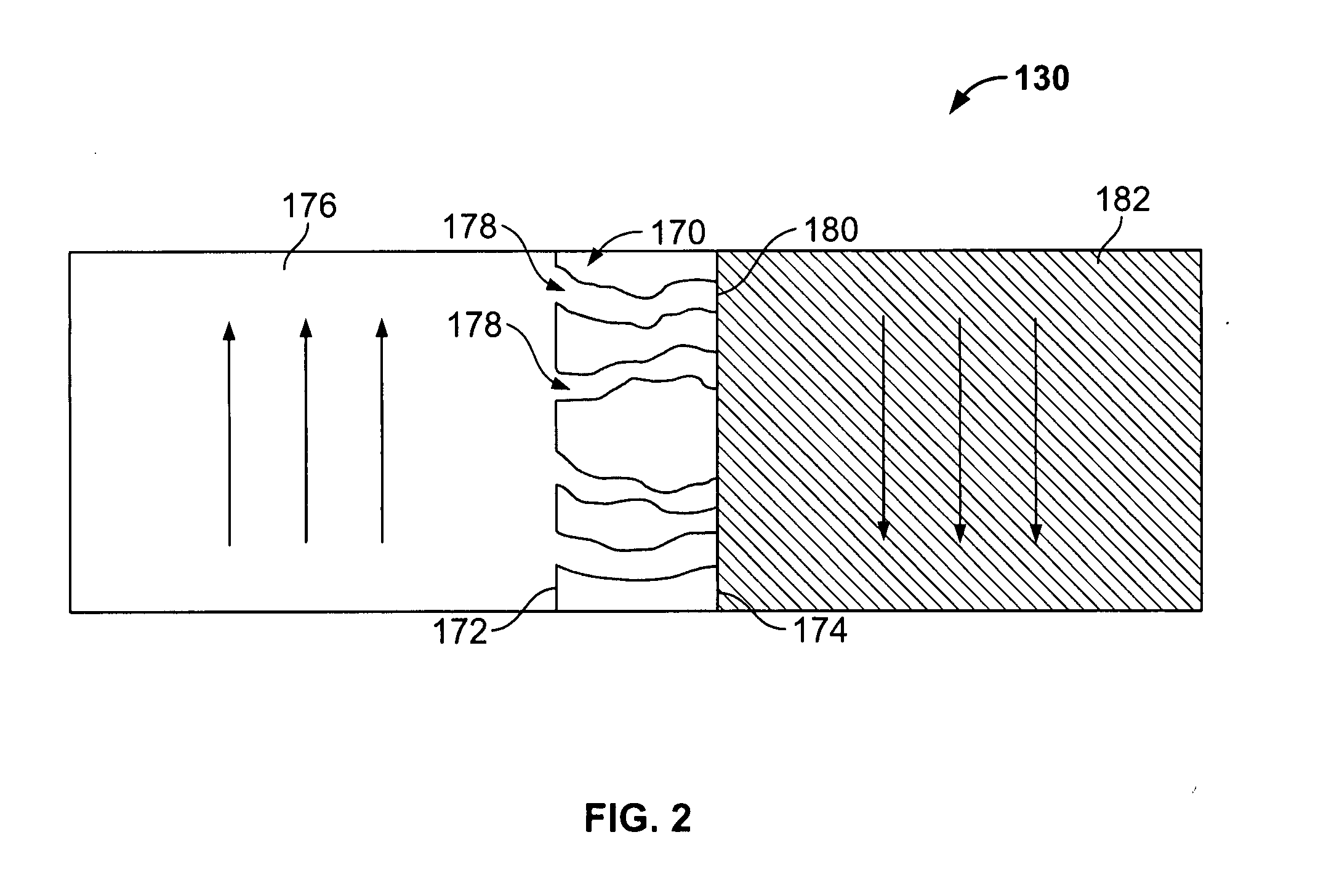

A method for processing flue-gas, in an exemplary embodiment, includes providing an absorber unit having a membrane contactor, channeling a combustion flue gas along a first surface of the membrane contactor, and channeling an ammonia-based liquid reagent along a second opposing surface of the membrane contactor. The method also includes partially separating the ammonia-based liquid from the flue gas such that the ammonia-based liquid and the flue gas contact at gas-liquid interface areas, defined by a plurality of pores of the membrane contactor, to separate CO2 from the flue gas by a chemical absorption of CO2 within the ammonia-based liquid to produce a CO2-rich ammonia-based liquid.

Owner:BHA ALTAIR

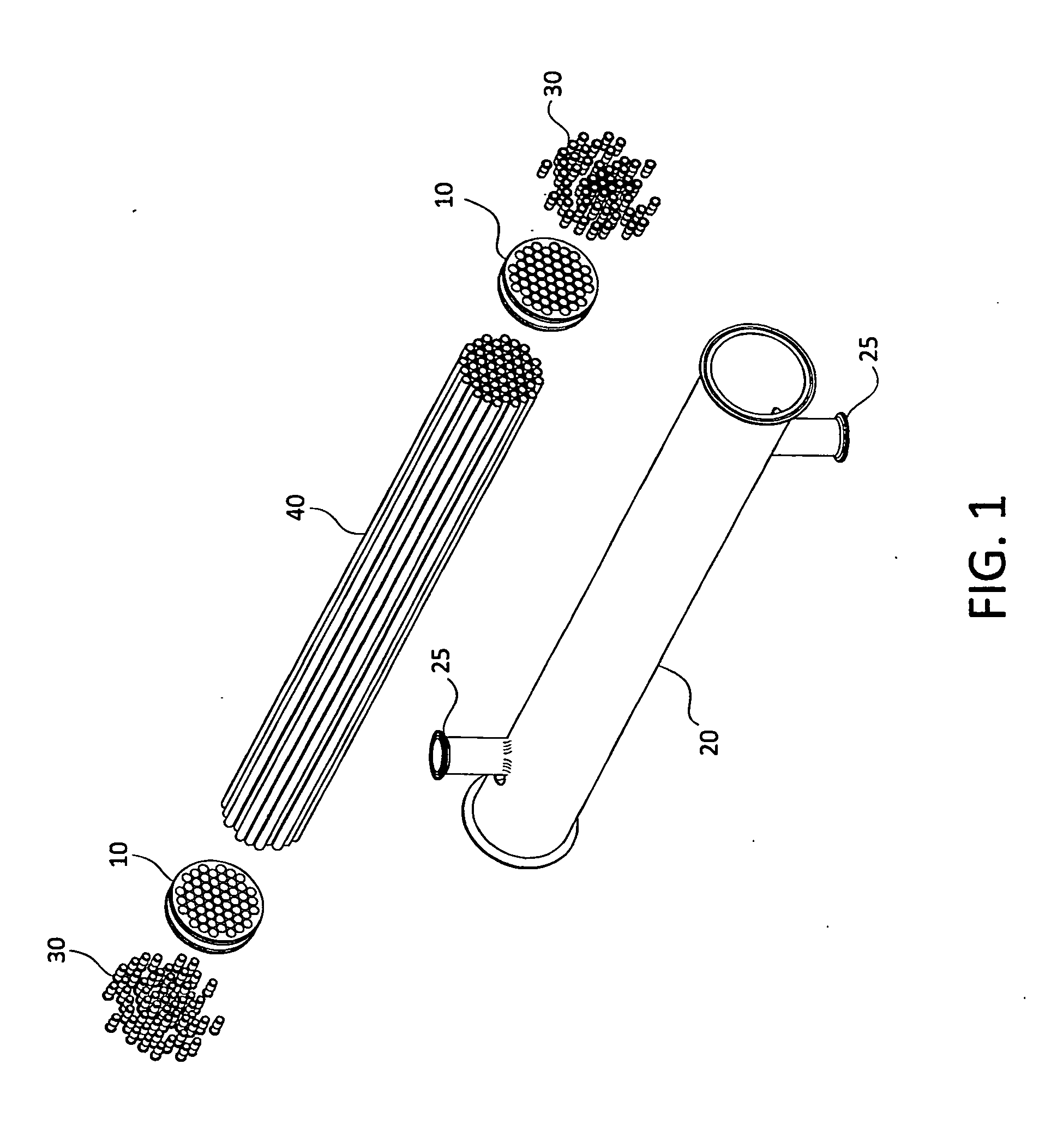

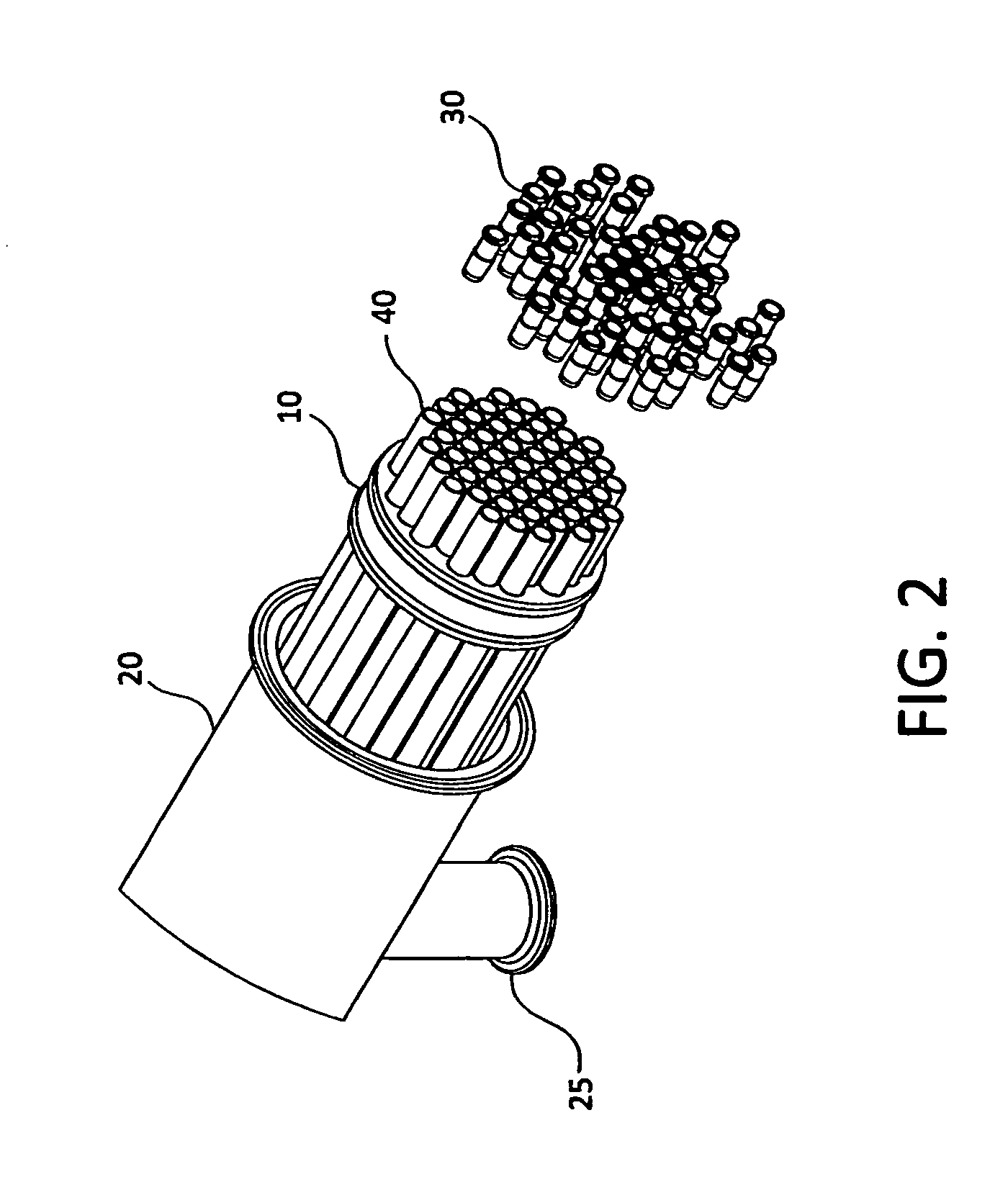

Membrane contactor and method of making the same

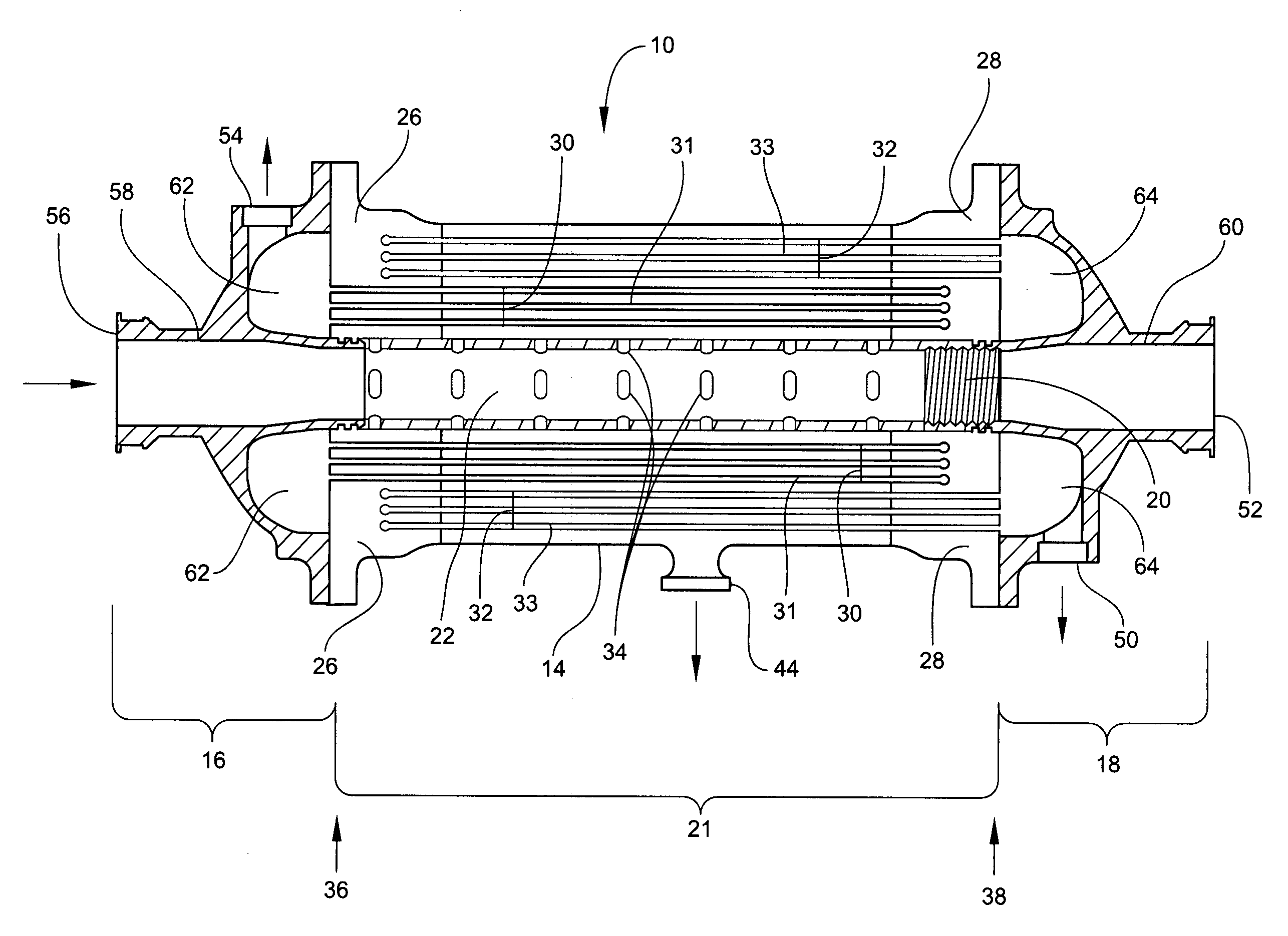

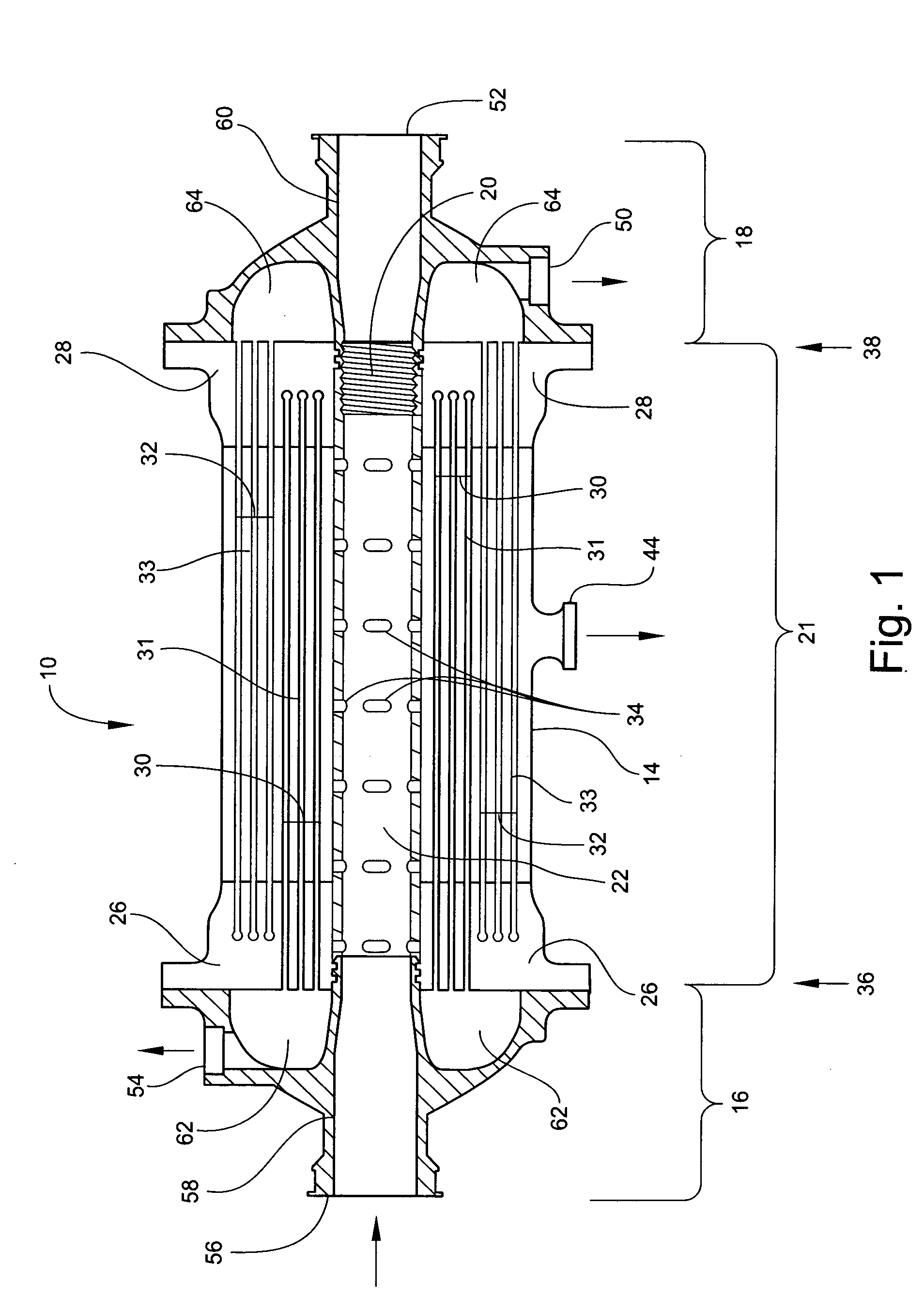

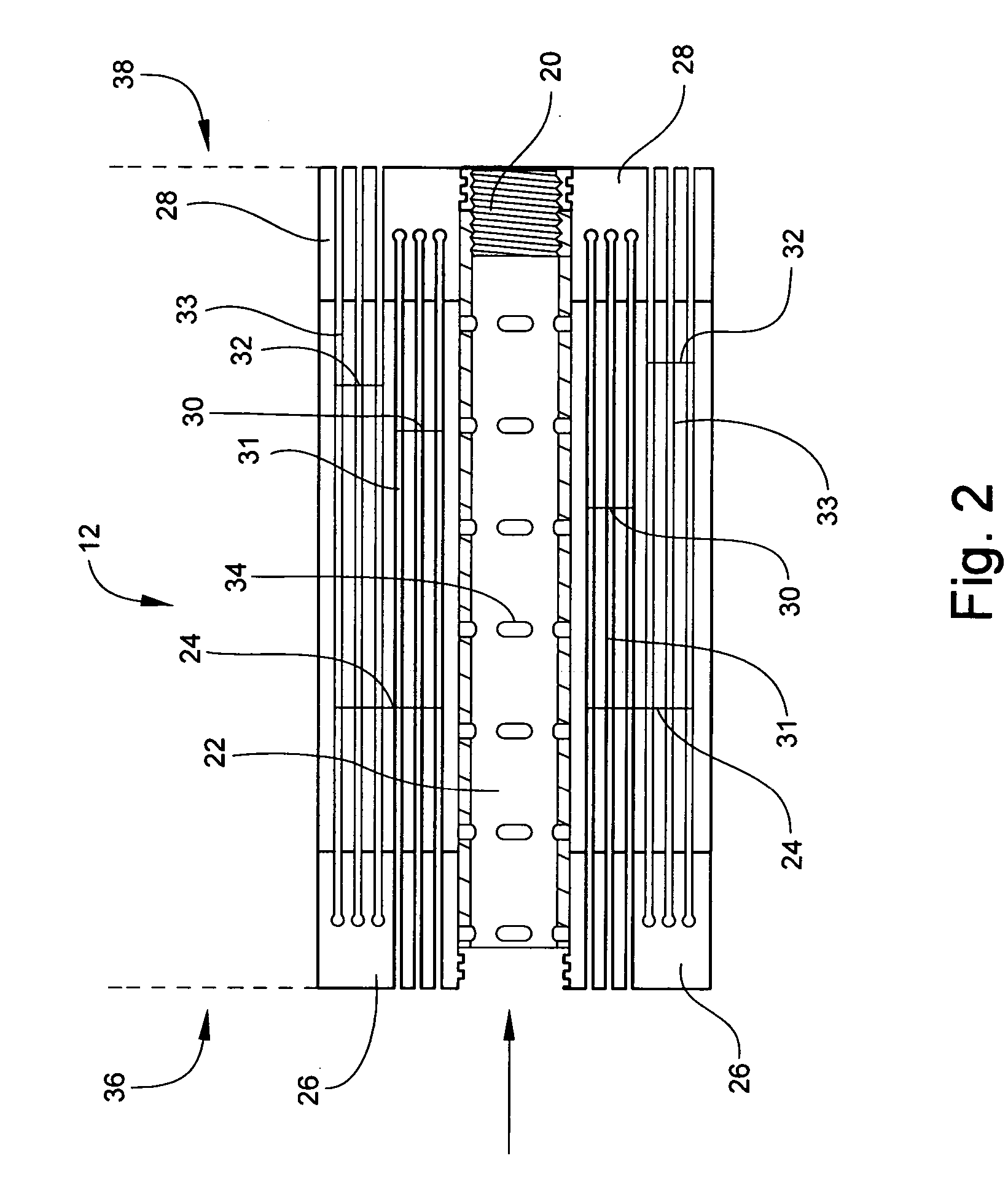

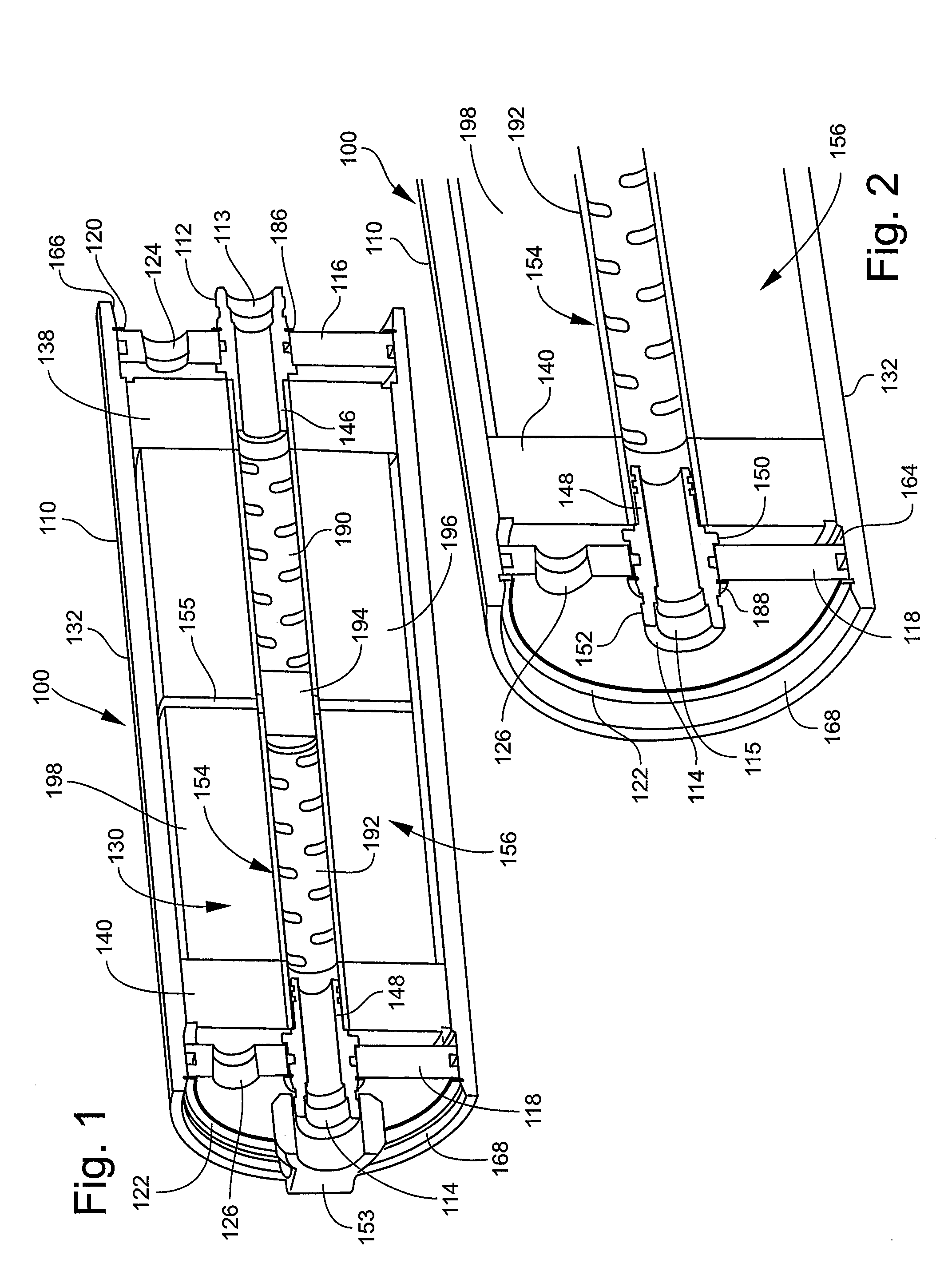

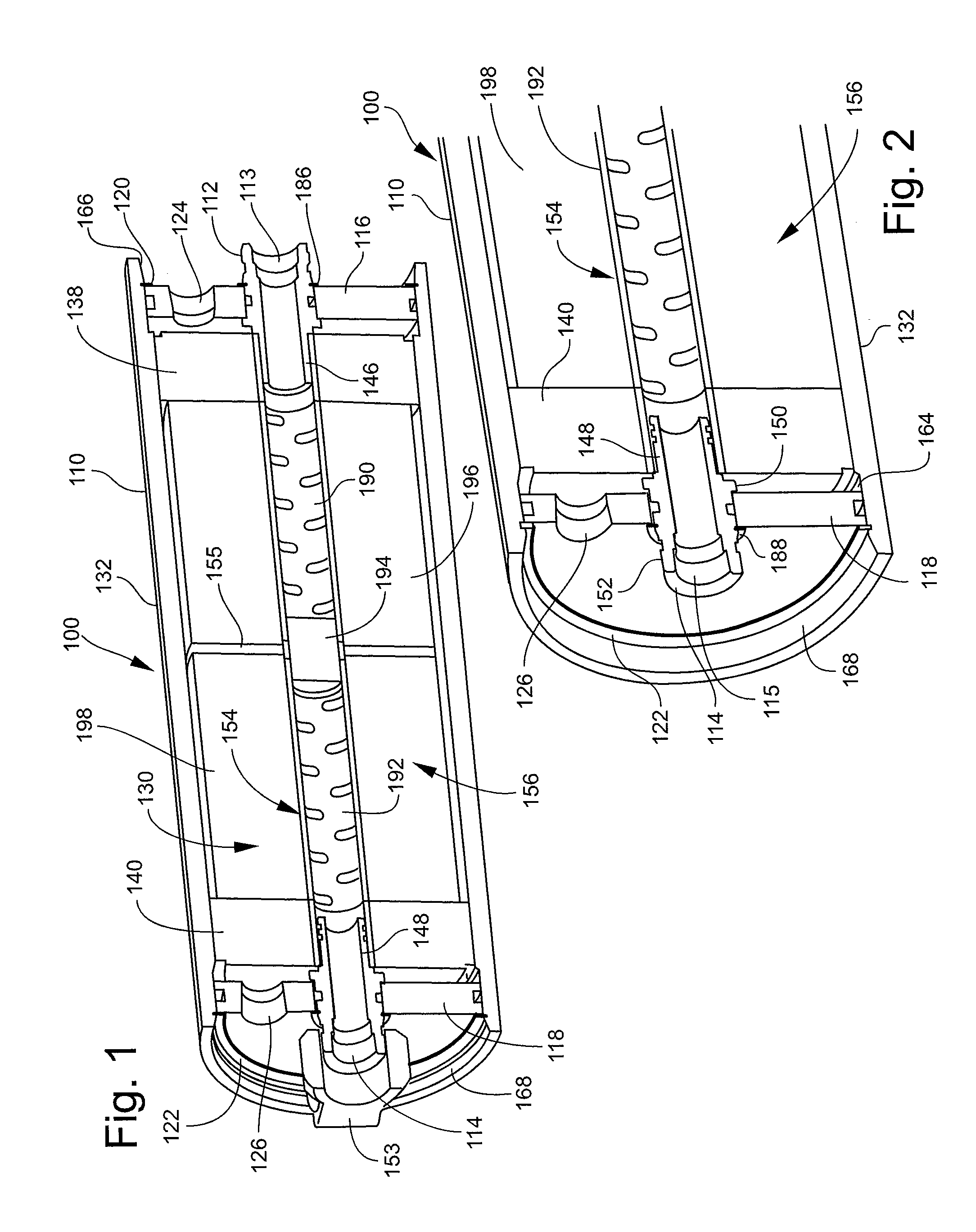

A hollow fiber membrane contactor includes a perforated center tube, a first mat comprising a first hollow fiber membrane, a second mat comprising a second hollow fiber membrane, a first tube sheet, a second tube sheet, a shell, and end caps. The first and second hollow fiber membranes are dissimilar. The first and second mats surround the center tube, and the first and second tube sheets affix the first and second mats to the center tube. The first hollow fiber membrane has a first lumen, and the second hollow fiber membrane has a second lumen. The first lumen may be open at the first tube sheet and closed at the second tube sheet while the second lumen may be open at the second tube sheet and closed at the first tube sheet. The shell surrounds the first and second mats, and it is sealed to the tube sheets. The end caps are affixed to the shell thereby defining headspaces therebetween the tube sheets and the end caps.

Owner:CELGARD LLC

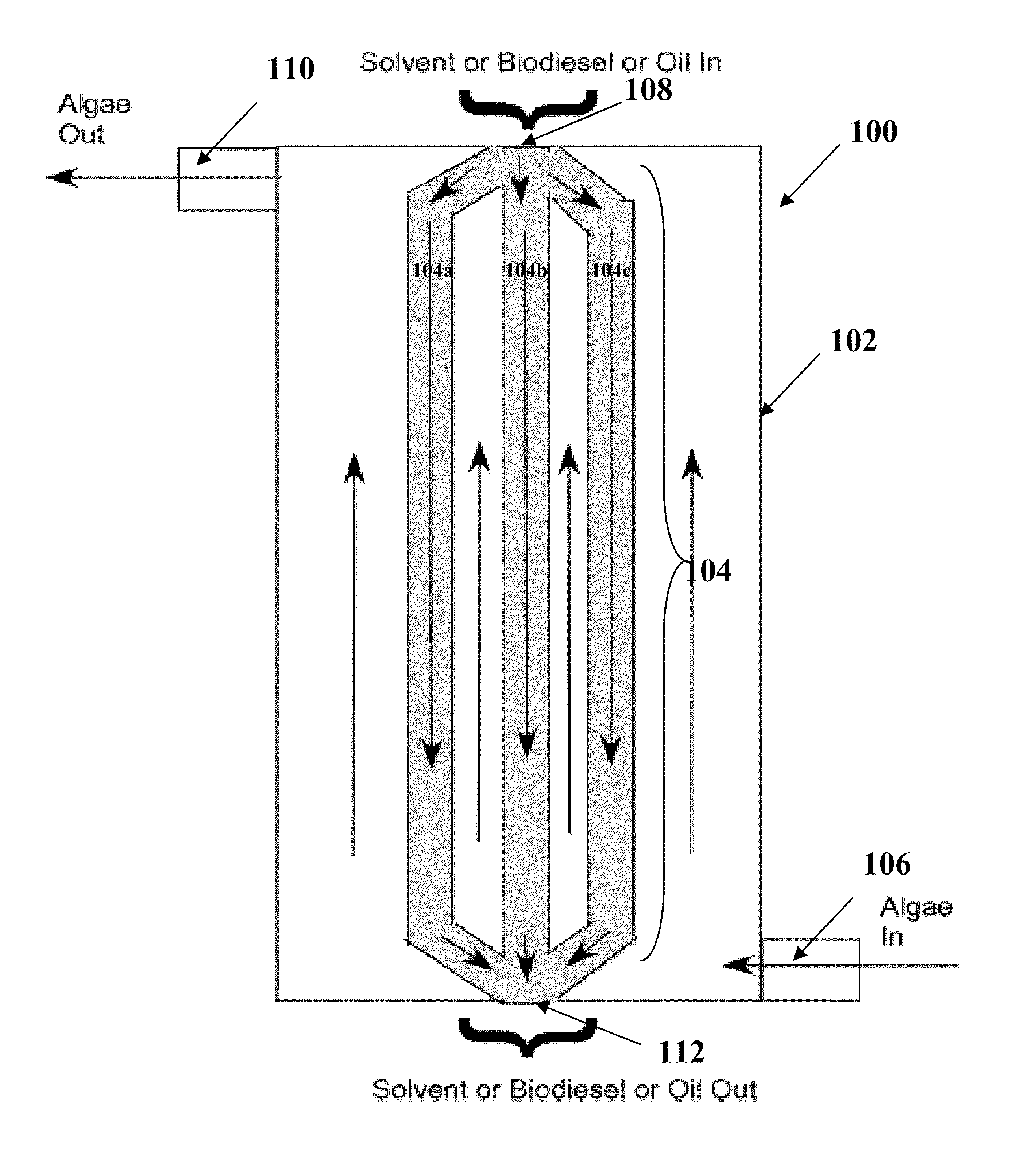

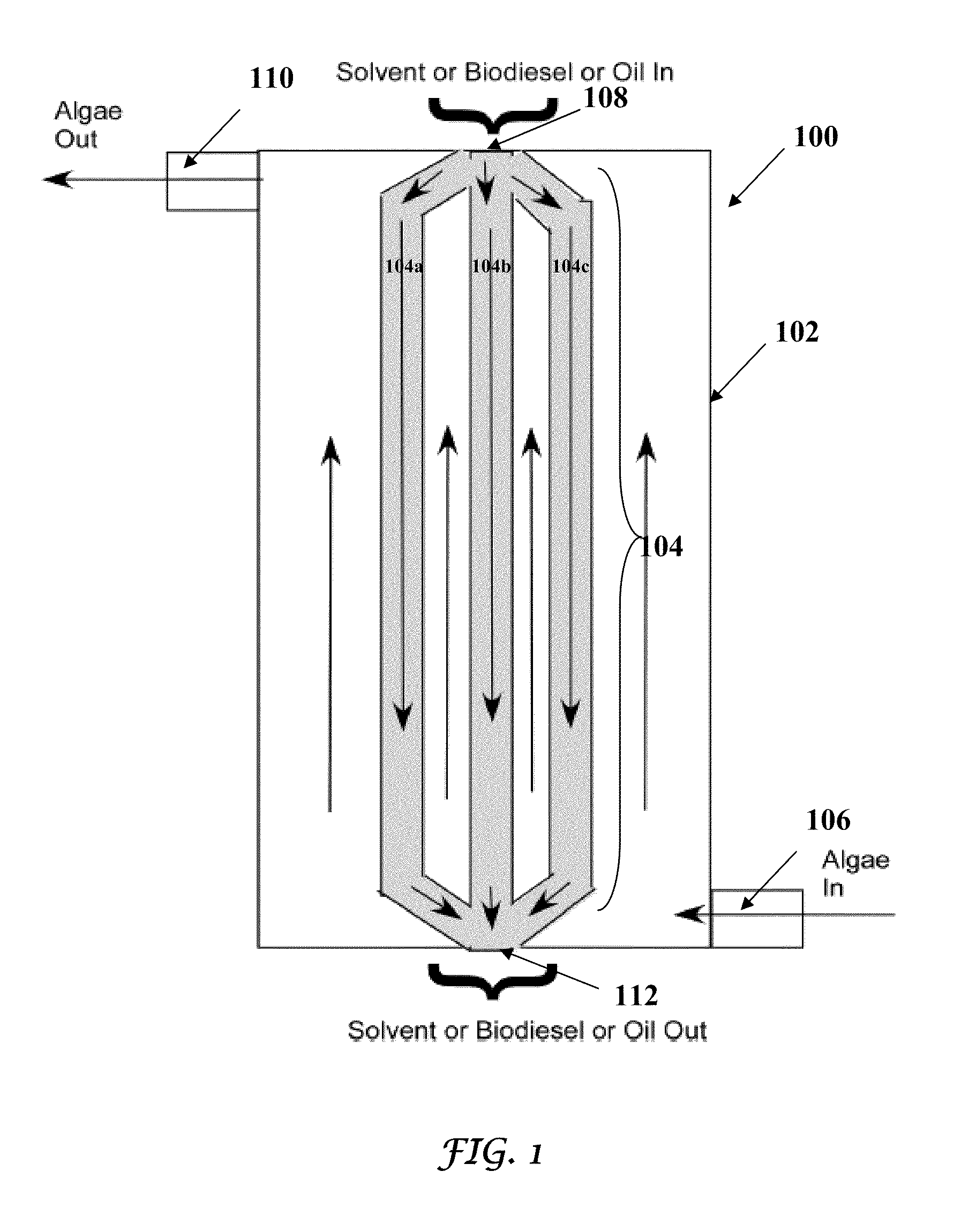

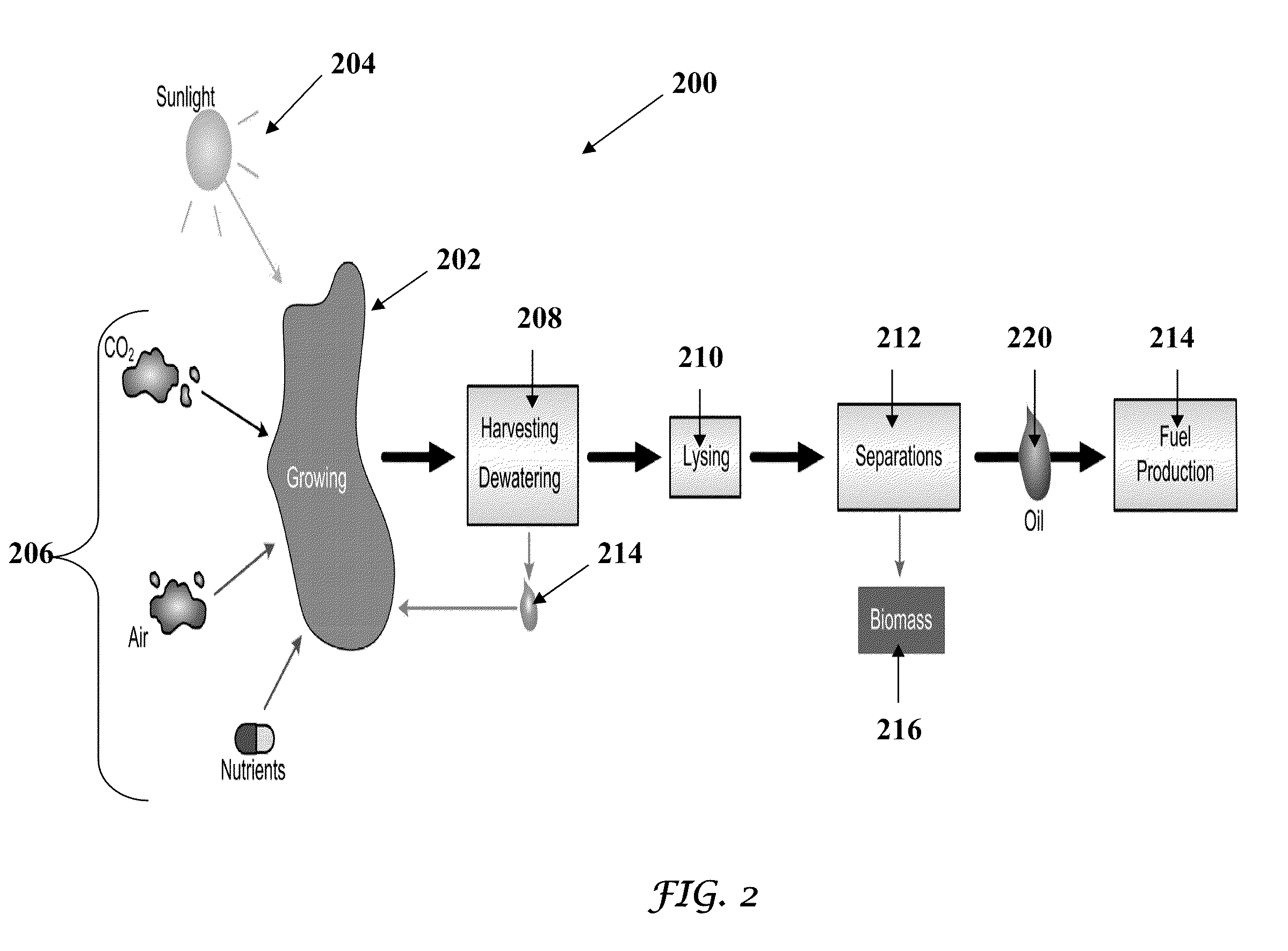

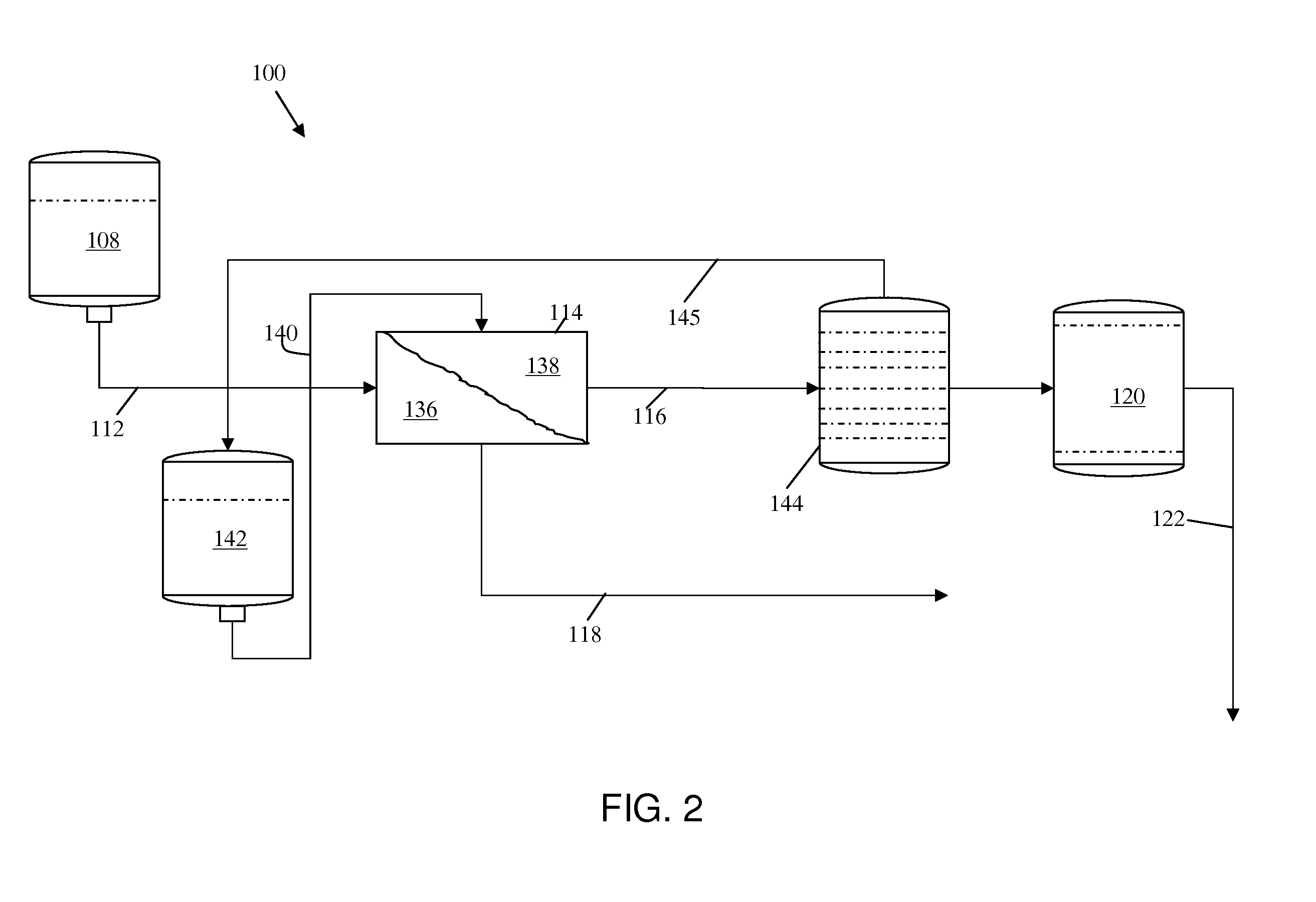

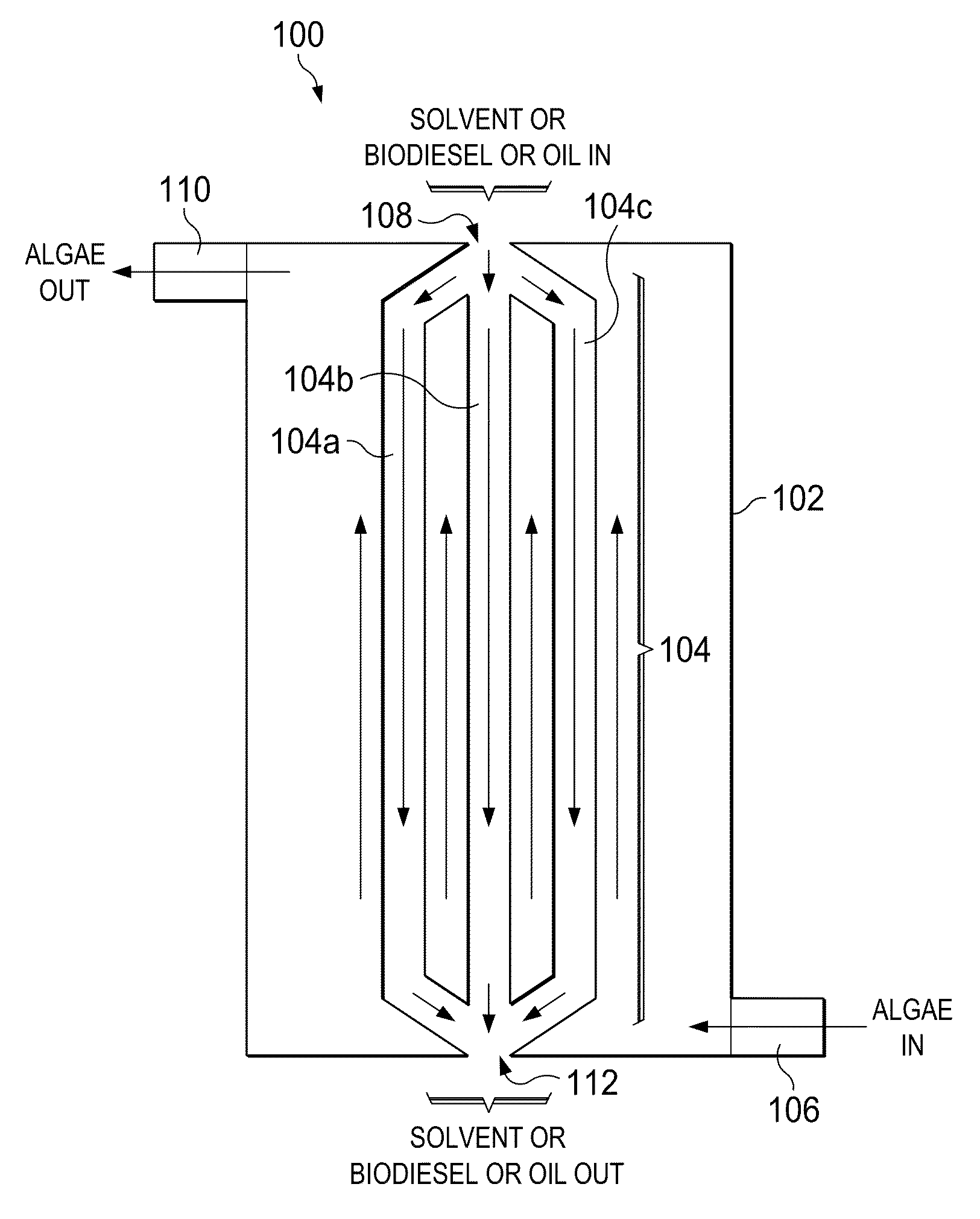

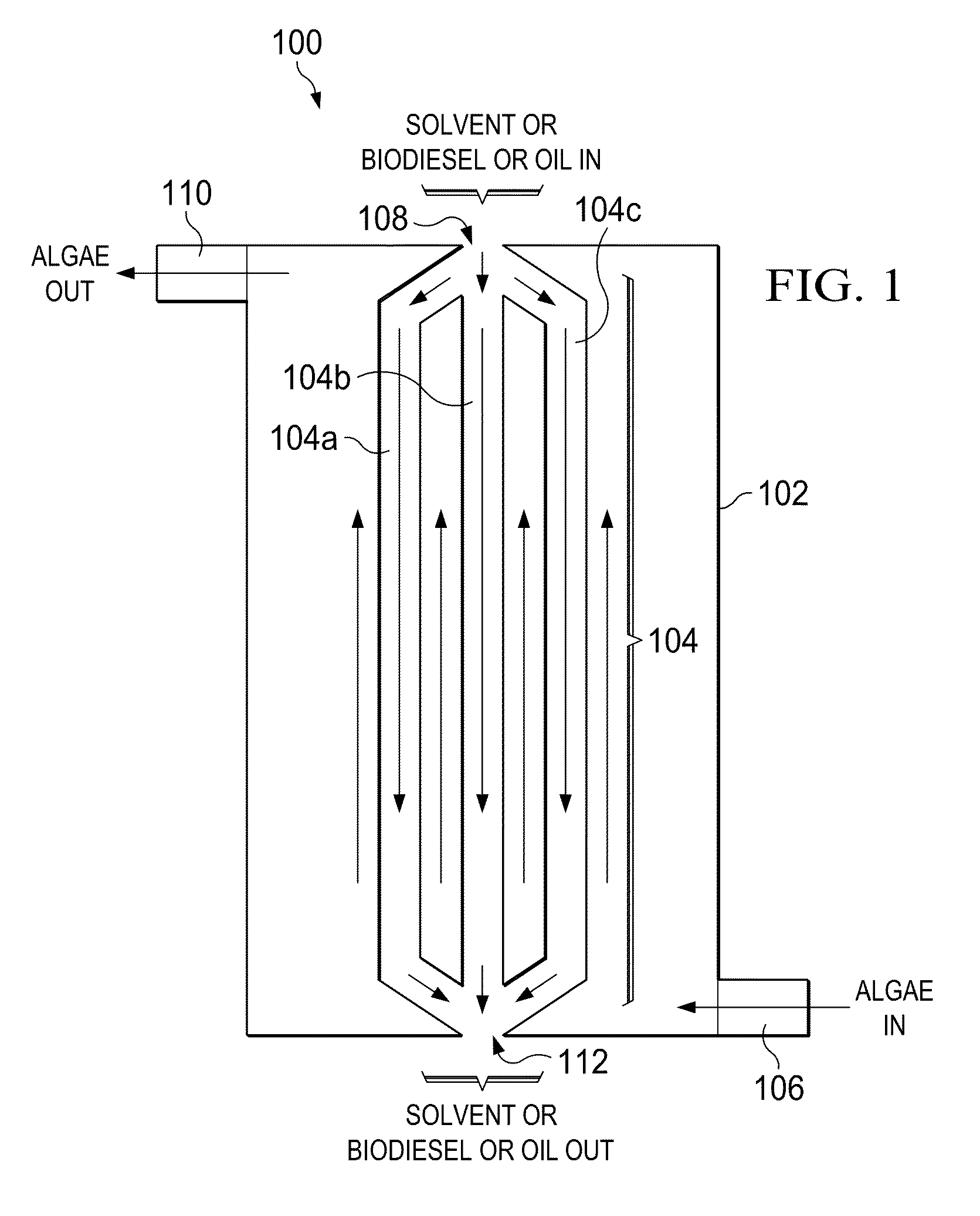

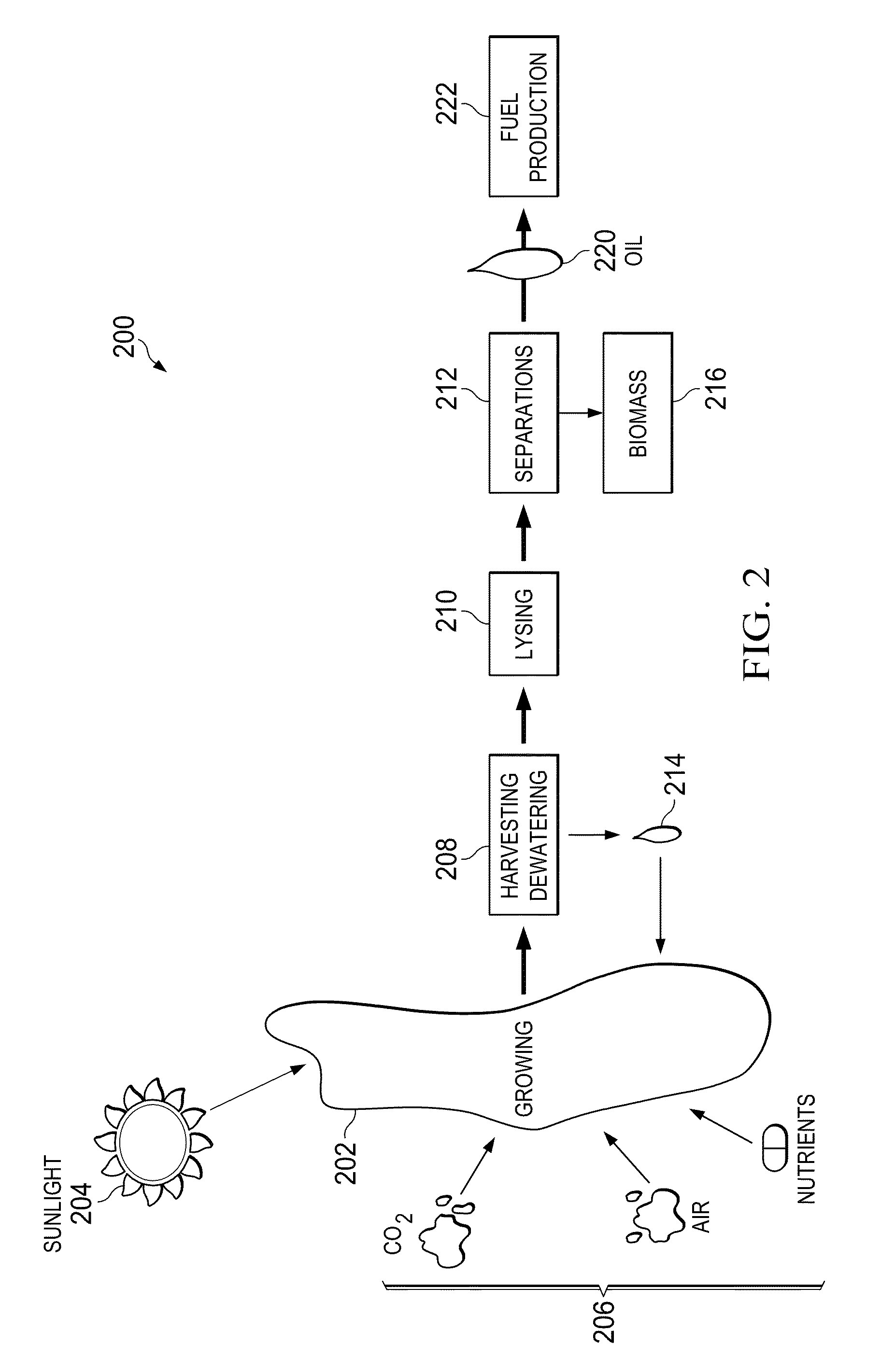

Non-Dispersive Process for Insoluble Oil Recovery From Aqueous Slurries

ActiveUS20110174734A1Efficient separationEliminate the problemFatty acid chemical modificationFatty acids production/refiningBiodieselBeta-Carotene

The development and application of a novel non-polar oil recovery process utilizing a non-dispersive solvent extraction method to coalesce and recover oil from a bio-cellular aqueous slurry is described herein. The process could apply to recovery of algal oil from a lysed algae slurry, recovery of Omega fatty acids from a bio-cellular aqueous feed, recovery of Beta-carotene from a bio-cellular aqueous feed and for the removal from produced water in oil production and similar type applications. The technique of the present invention utilizes a microporous hollow fiber (MHF) membrane contactor. The novel non-polar oil recovery process described herein can be coupled to a collecting fluid (a non-polar solvent such as heptane, a biodiesel mixture or the previously extracted oil) that is circulated through the hollow fiber membrane. In cases where the biodiesel mixture or the previously extracted oil is used the solvent recovery step (e.g. distillation) can be eliminated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Membrane desulfurization of liquid hydrocarbons using an extractive liquid membrane contactor system and method

InactiveUS20110000823A1Transfer rate is not hinderedEasy to transportWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionOrganosulfur compoundsLiquid hydrocarbons

The process of the present invention is directed to the desulfurization of a sulfur-containing hydrocarbon stream with a membrane contactor, where sulfur compounds are concentrated in a sulfur-rich stream on a permeate side of the membrane using an extractive liquid, and a sulfur-lean stream is recovered as a retentate. The sulfur-rich stream, which has a small volume relative to the original hydrocarbon stream, is conveyed to a recovery zone to recover extractive liquid, and the remaining hydrocarbon stream having an increased concentration of sulfur compounds is passed to a downstream desulfurization apparatus or system, such as a hydrotreating system, to recover the hydrocarbons associated with the organosulfur compounds.

Owner:SAUDI ARABIAN OIL CO

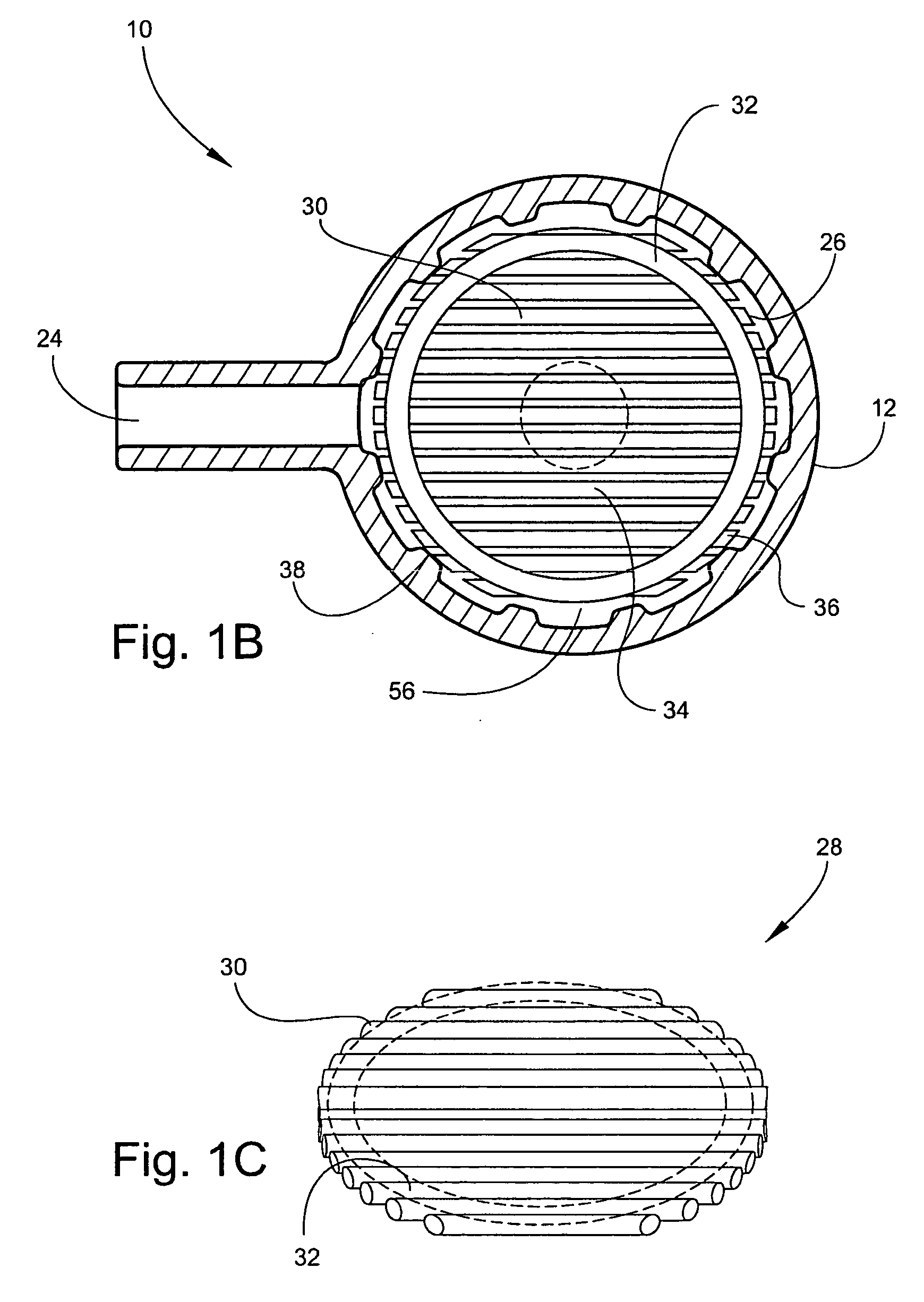

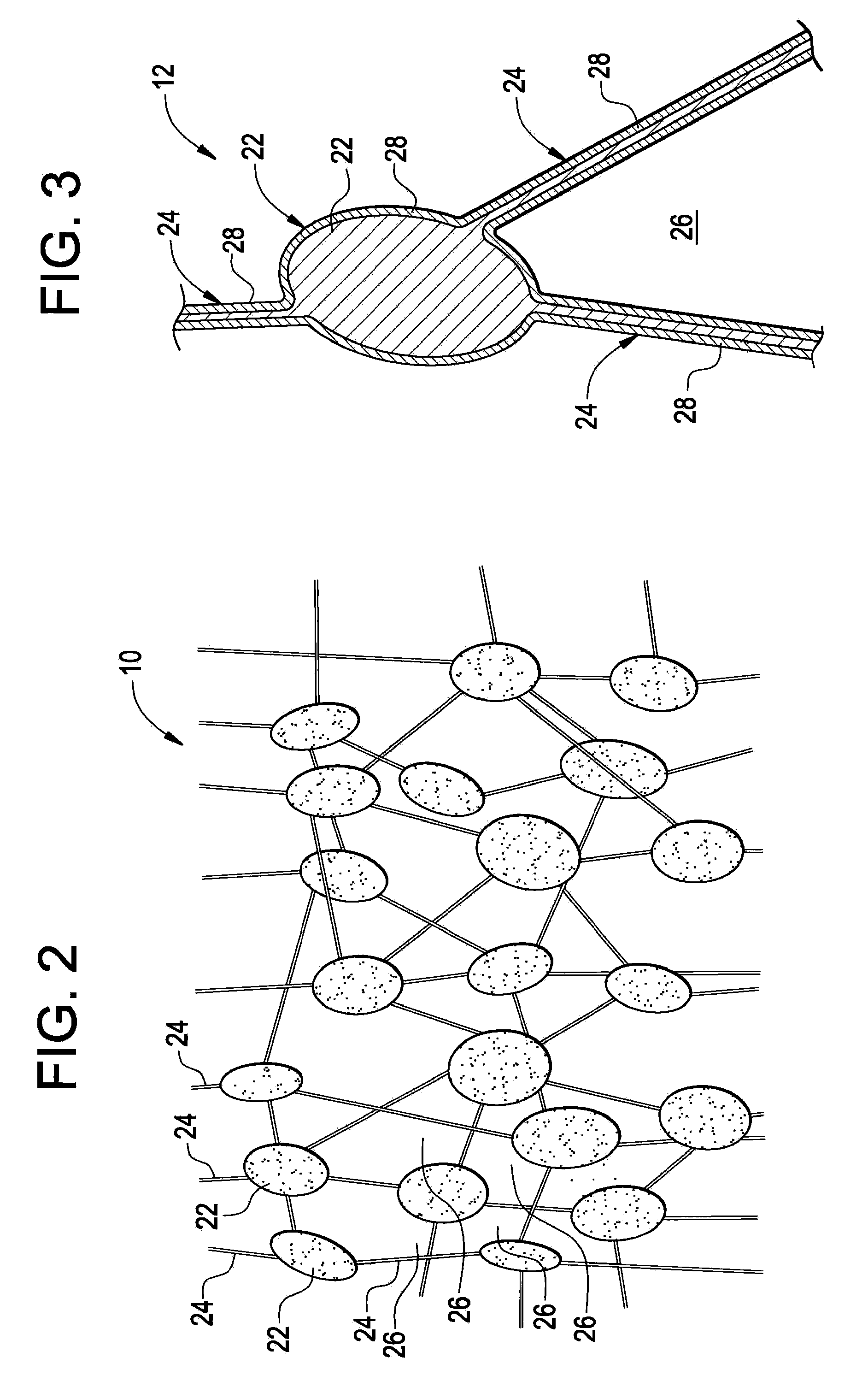

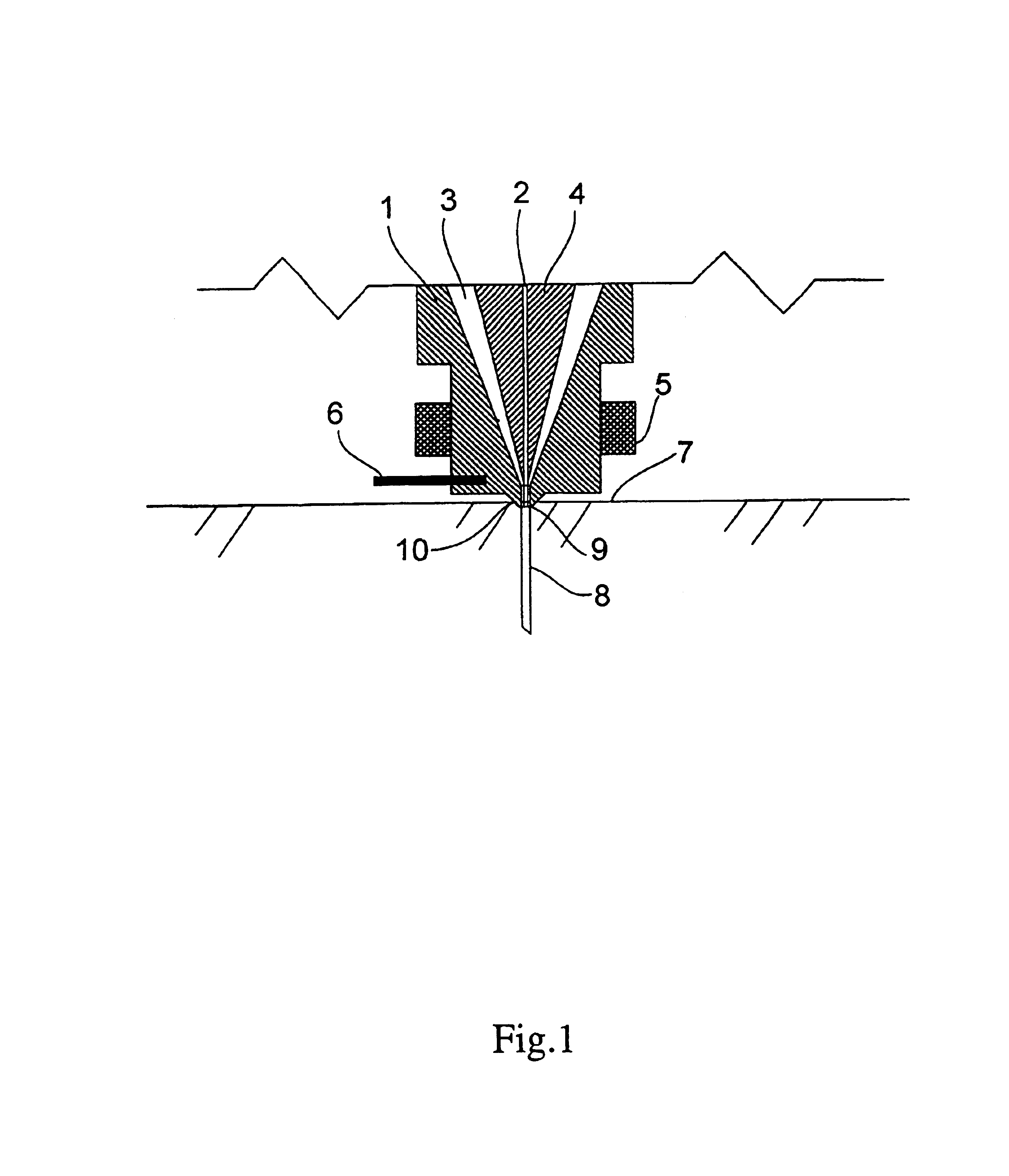

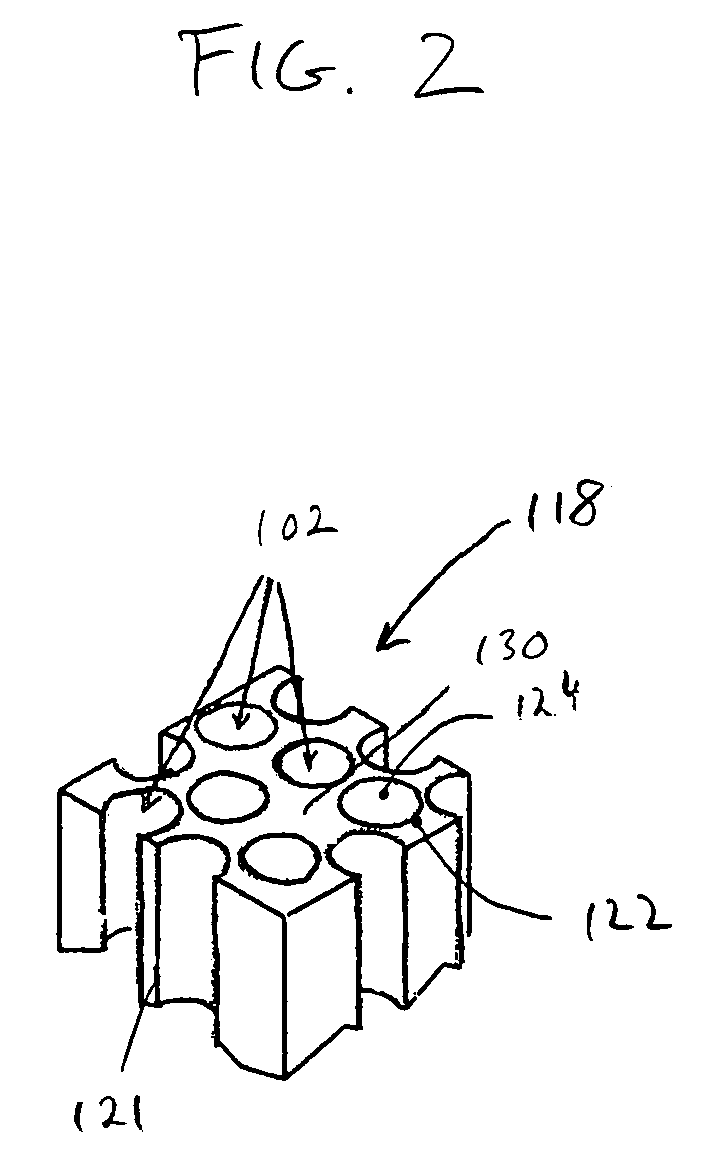

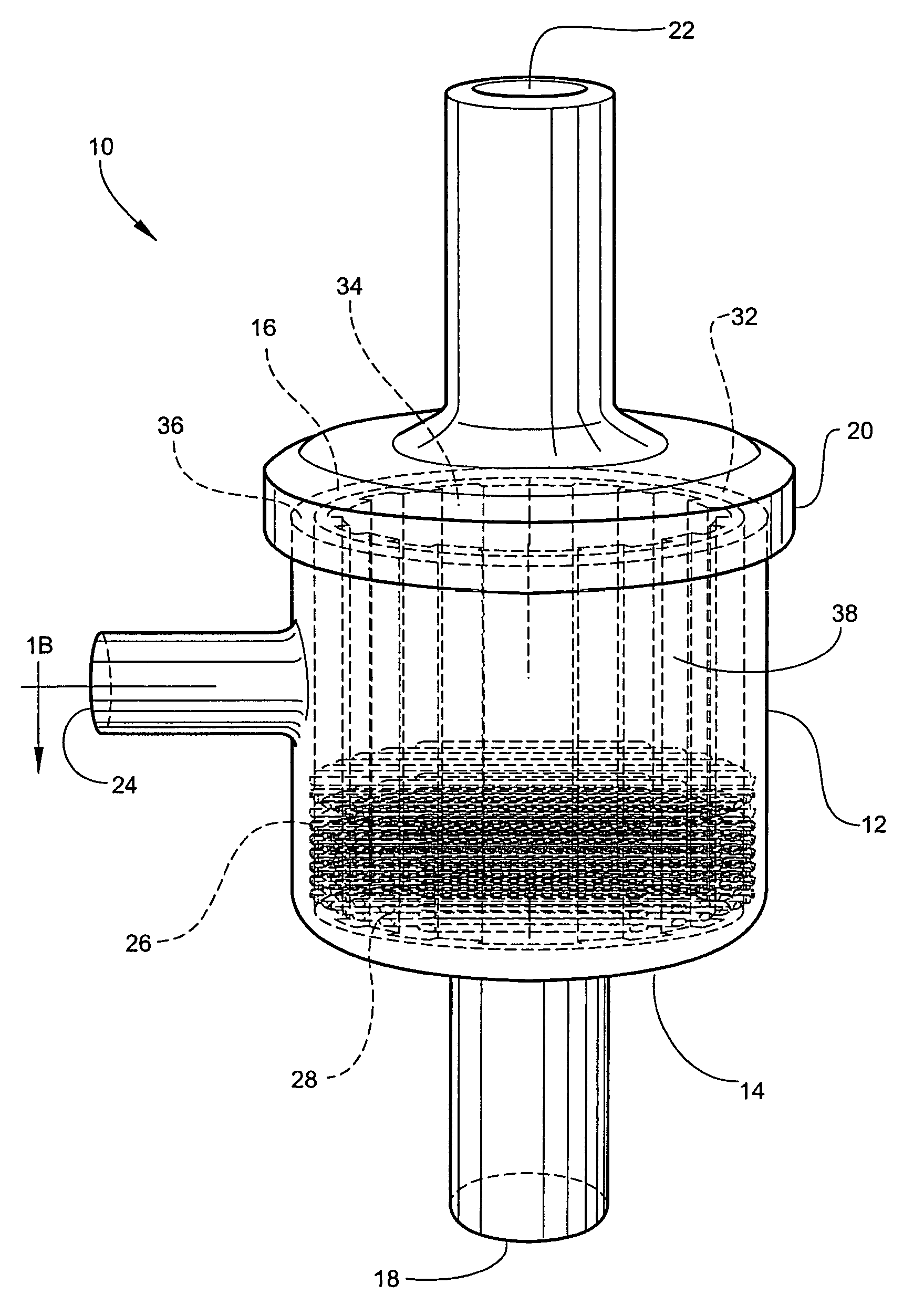

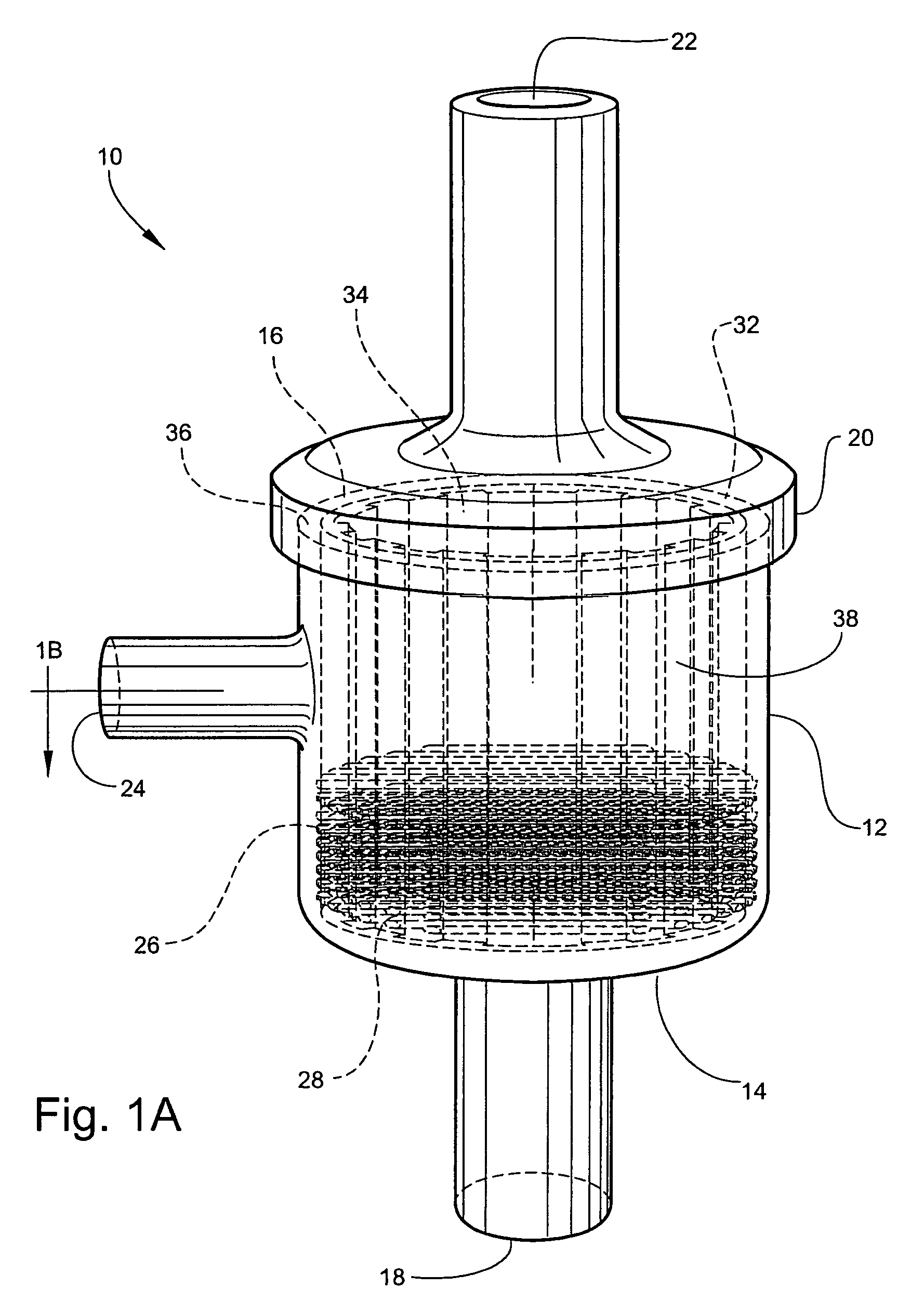

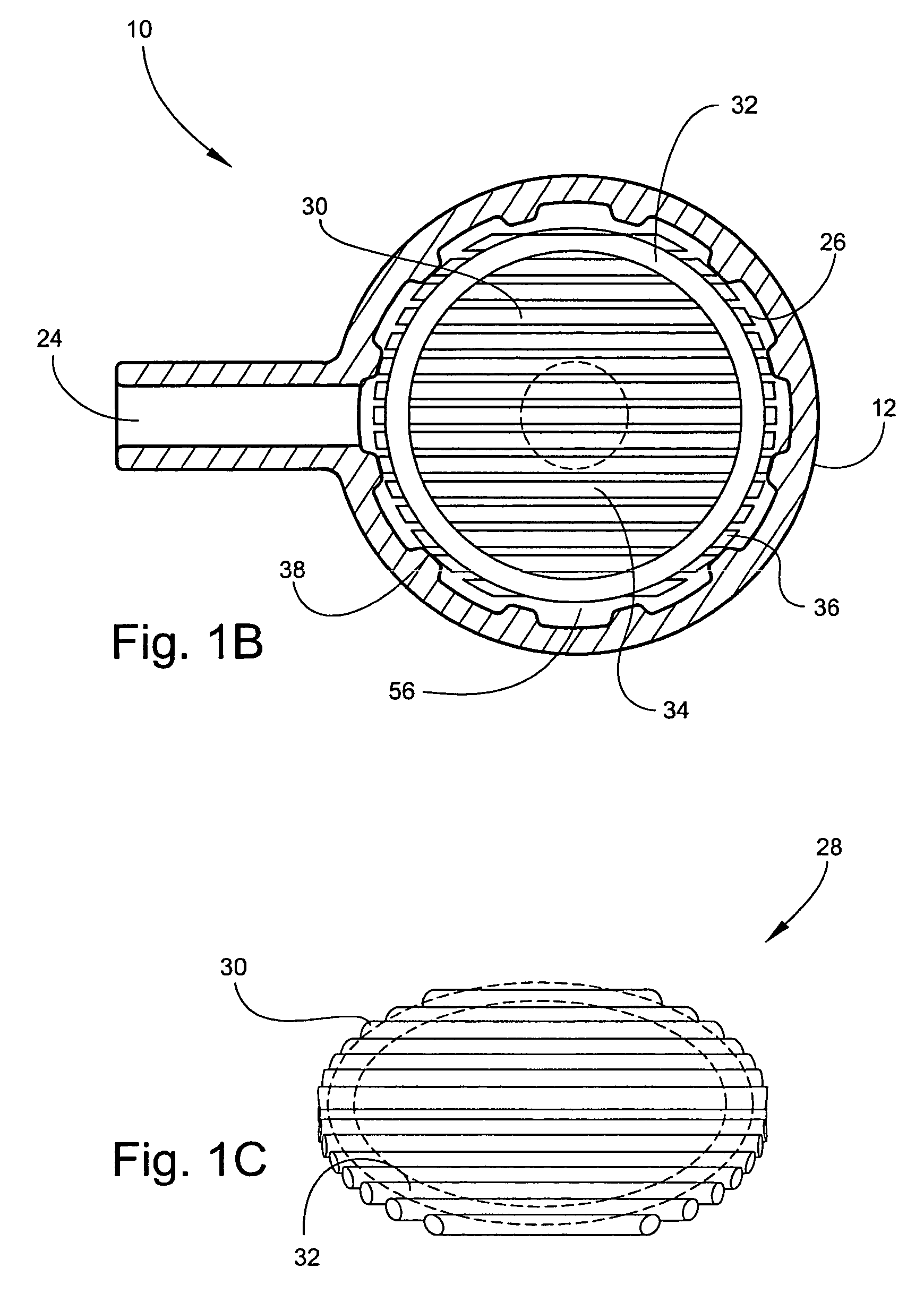

Membrane contactor

A membrane contactor includes a housing, a stack of membrane mats, and a cap. The housing has a closed end and an open end. The closed end includes an outlet port. The cap is united to the open end and includes an inlet port. A stack of membrane mats is within the housing stacked substantially perpendicular to the longitudinal axis of the housing. Each membrane mat has a plurality of hollow fiber members. A potting material bonds the membrane mats to each other and simultaneously bonds one end of the stack to the closed end and bonds the other end of the stack to the cap. The potting material forms an internal chamber and at least one external chamber within the housing. The hollow fiber members extend through the potting material from the internal chamber into the external chambers. The inlet port and the outlet port are in communication with the internal chamber. At least one side port is in communication with the external chambers.

Owner:3M INNOVATIVE PROPERTIES CO

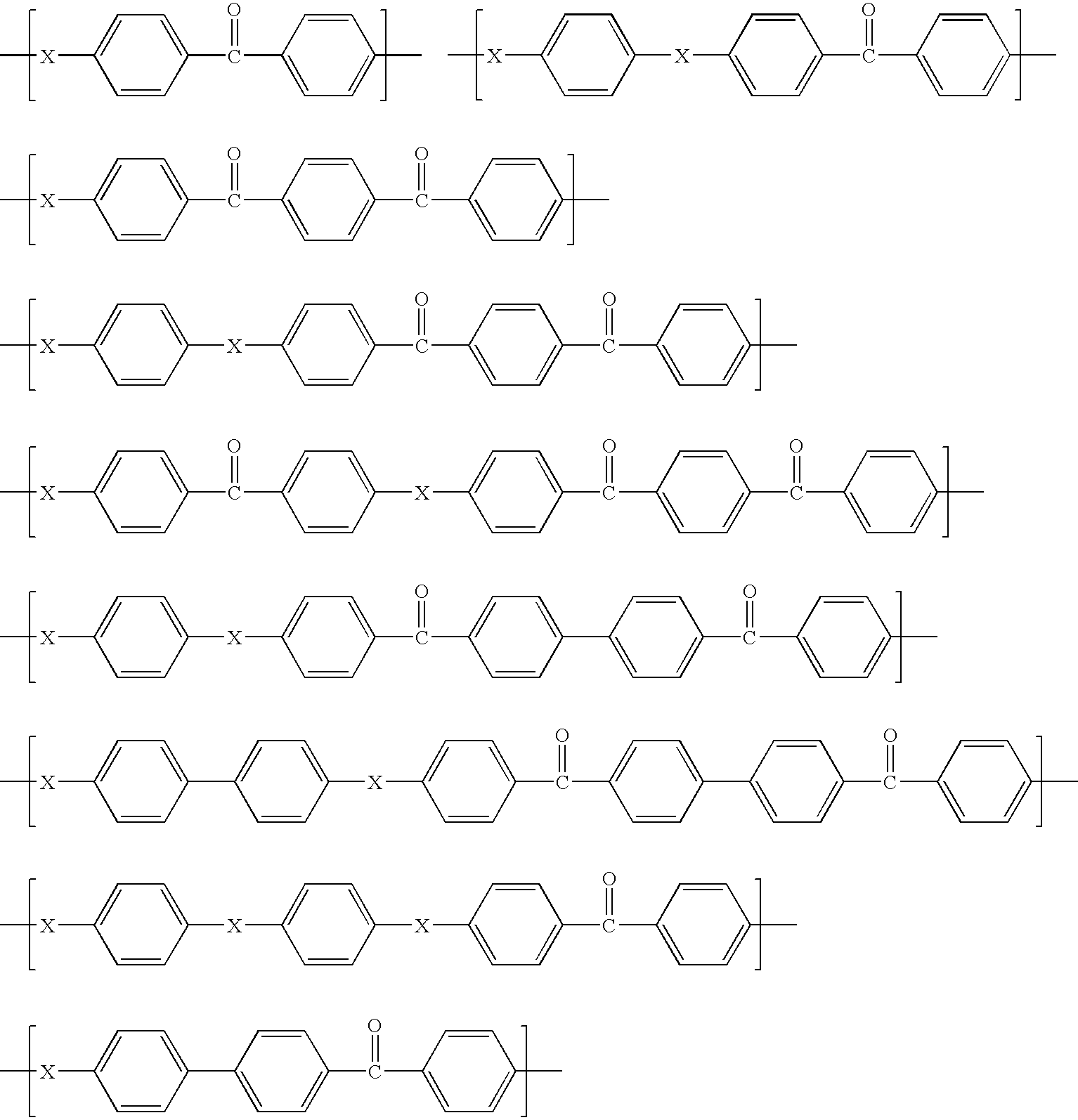

Composite Perfluorohydrocarbon Membranes, Their Preparation and Use

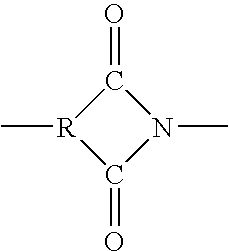

InactiveUS20070256969A1Improved uniform pore structureSimple and cost-effective and industrially feasibleSemi-permeable membranesMembranesArylNatural-gas processing

Composite porous hydrophobic membranes are prepared by forming a perfluorohydrocarbon layer on the surface of a preformed porous polymeric substrate. The substrate can be formed from poly(aryl ether ketone) and a perfluorohydrocarbon layer can be chemically grafted to the surface of the substrate. The membranes can be utilized for a broad range of fluid separations, such as microfiltration, nanofiltration, ultrafiltration as membrane contactors for membrane distillation and for degassing and dewatering of fluids. The membranes can further contain a dense ultra-thin perfluorohydrocarbon layer superimposed on the porous poly(aryl ether ketone) substrate and can be utilized as membrane contactors or as gas separation membranes for natural gas treatment and gas dehydration.

Owner:POROGEN

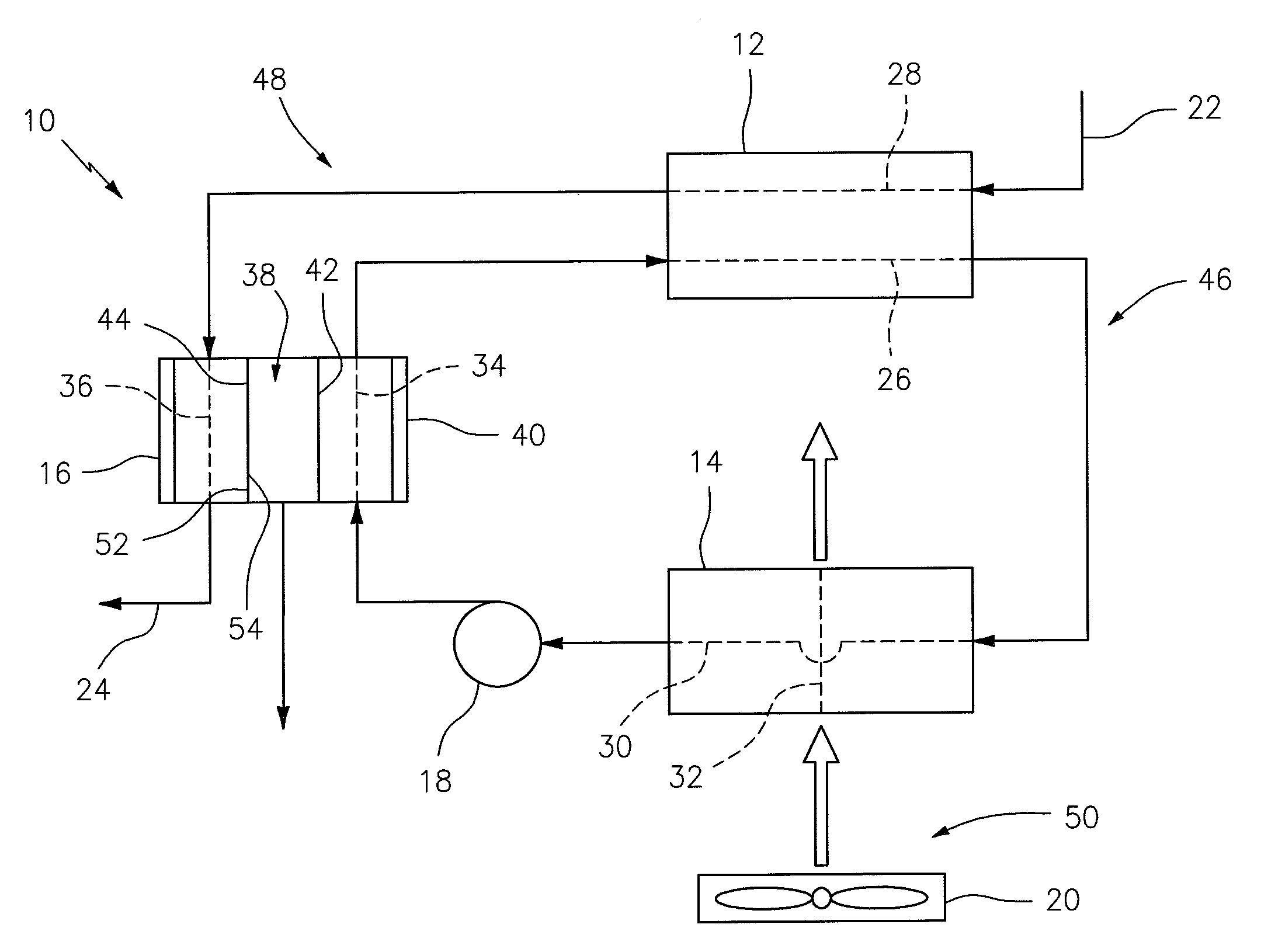

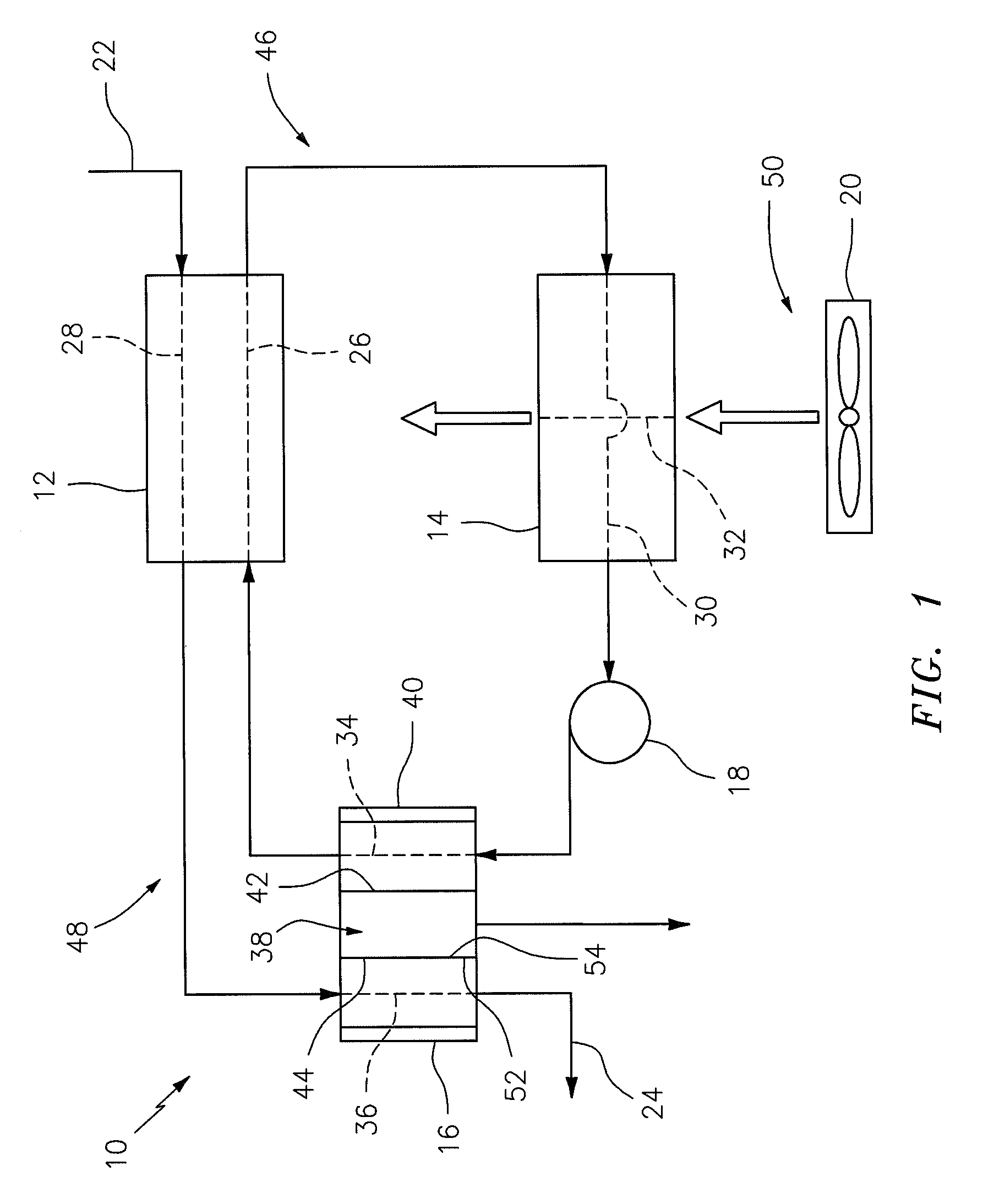

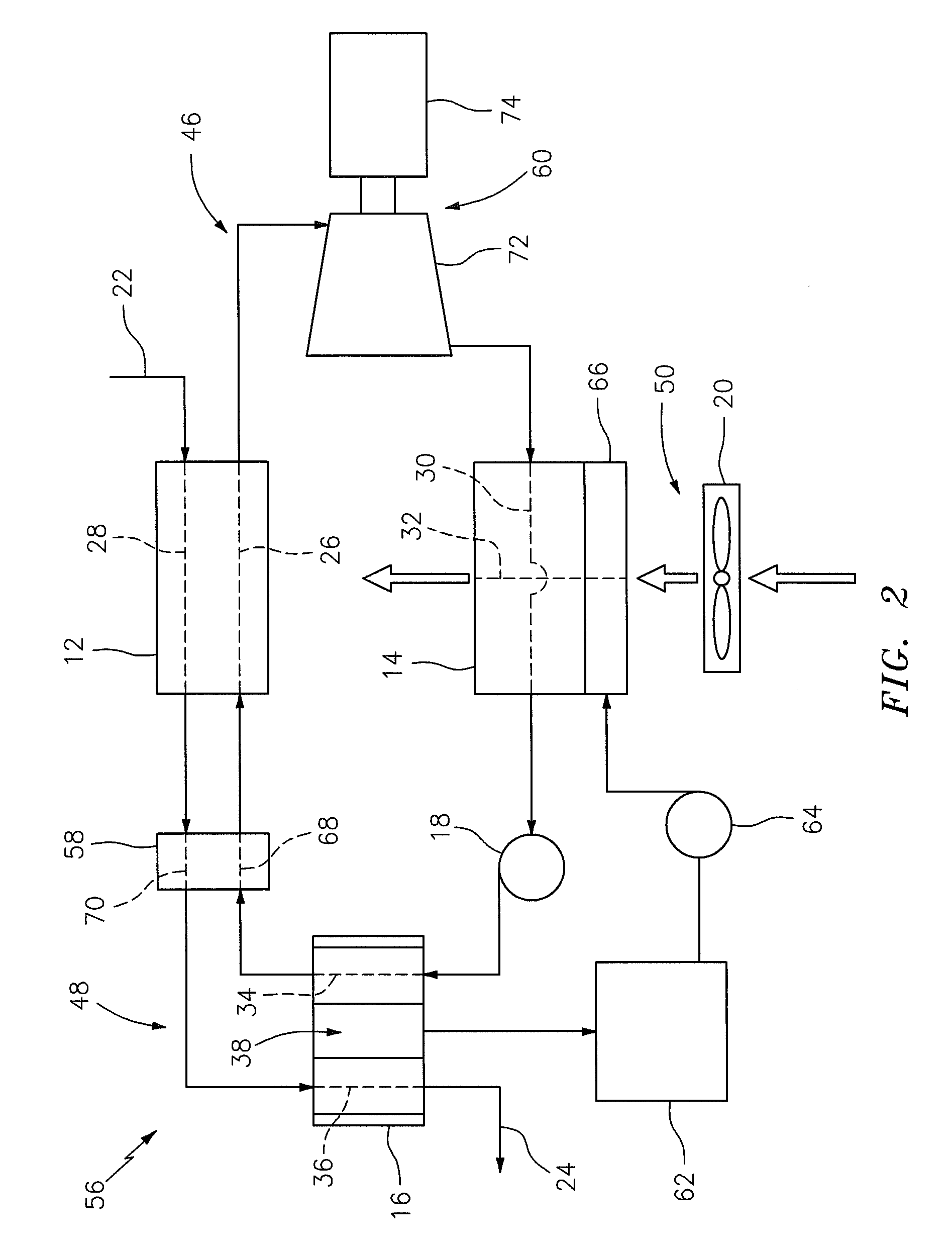

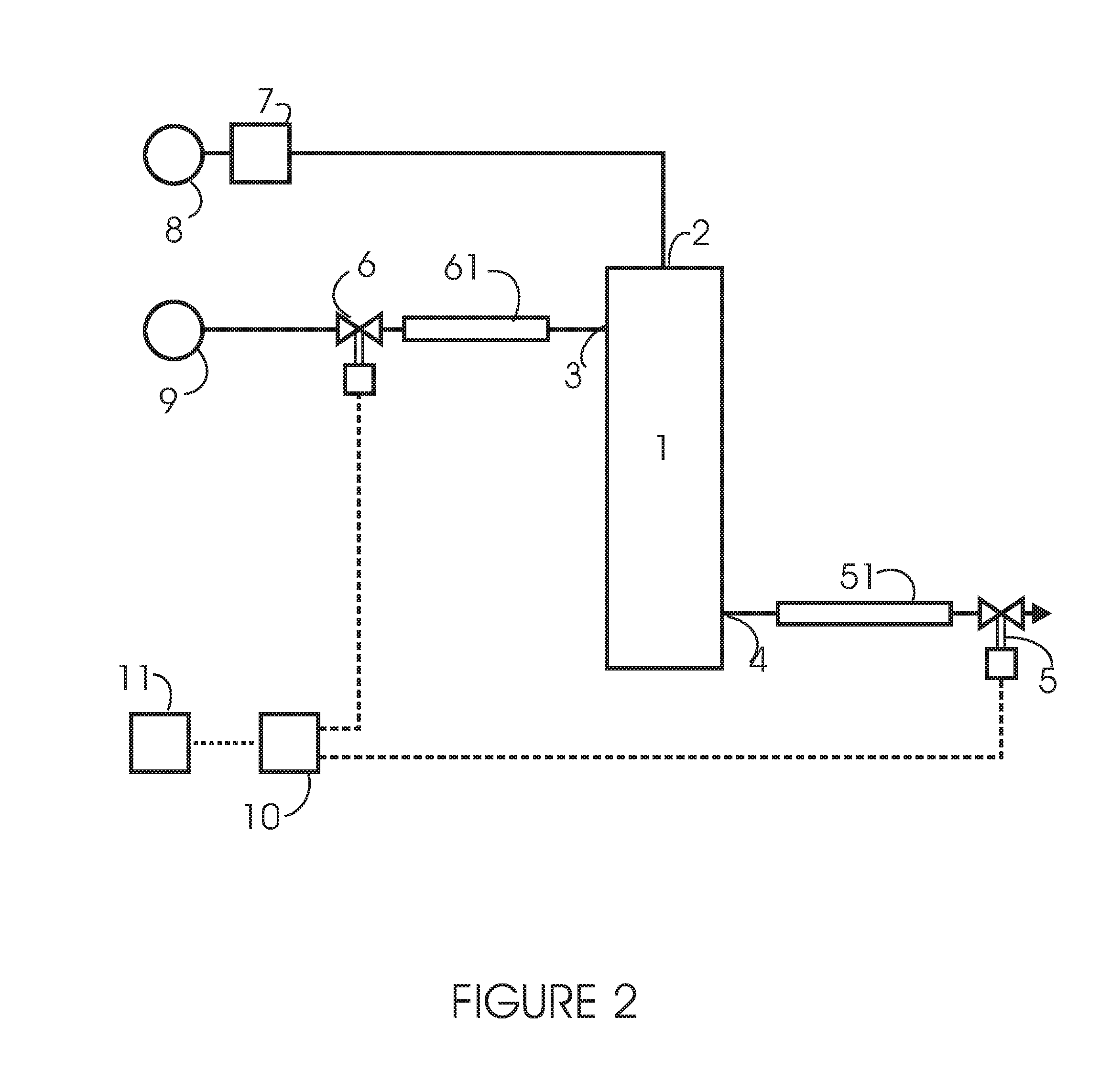

Heat exchange system configured with a membrane contactor

A heat exchange system may include a first heat exchange circuit and a second heat exchange circuit. The first heat exchange circuit may circulate a first working fluid sequentially through a first heat exchanger, a second heat exchanger and a membrane contactor. The second heat exchange circuit may direct a second working fluid sequentially through the first heat exchanger and the membrane contactor, where the second working fluid includes solute and solvent. The first heat exchanger and the membrane contactor may transfer heat energy from the second working fluid to the first working fluid, and the second heat exchanger may transfer heat energy from the first working fluid to a third working fluid. The membrane contactor may extract a portion of the solvent from the second working fluid.

Owner:RTX CORP

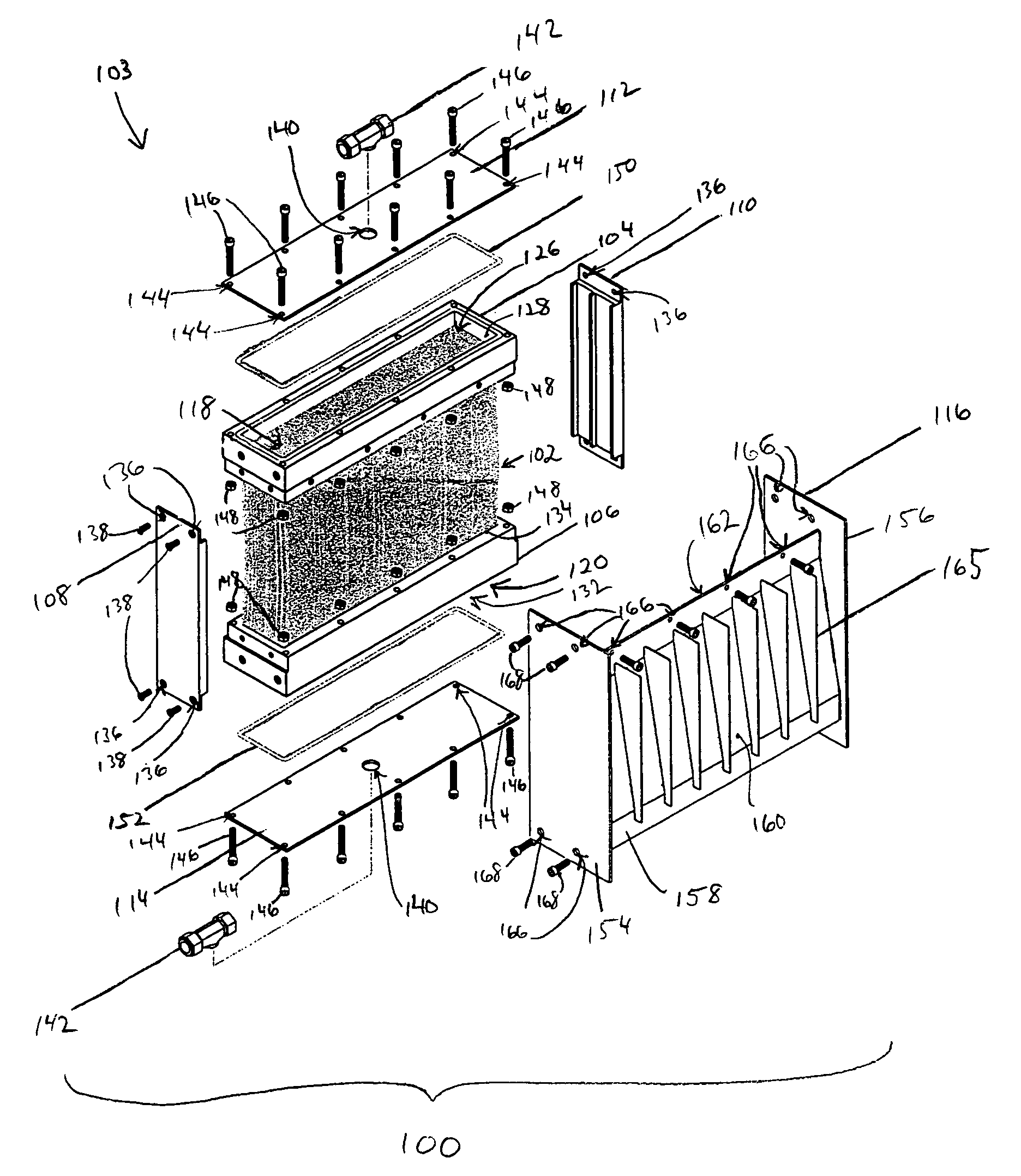

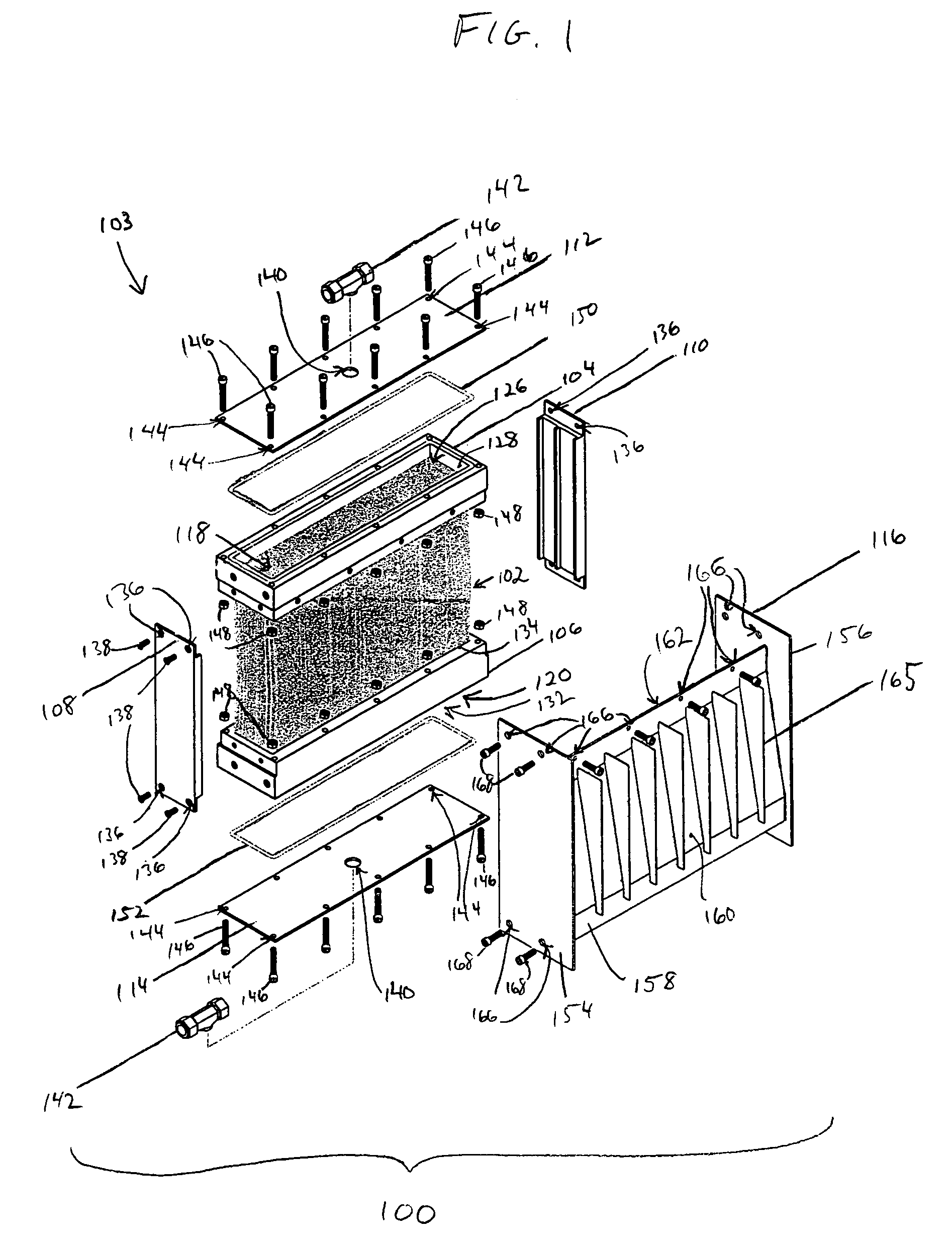

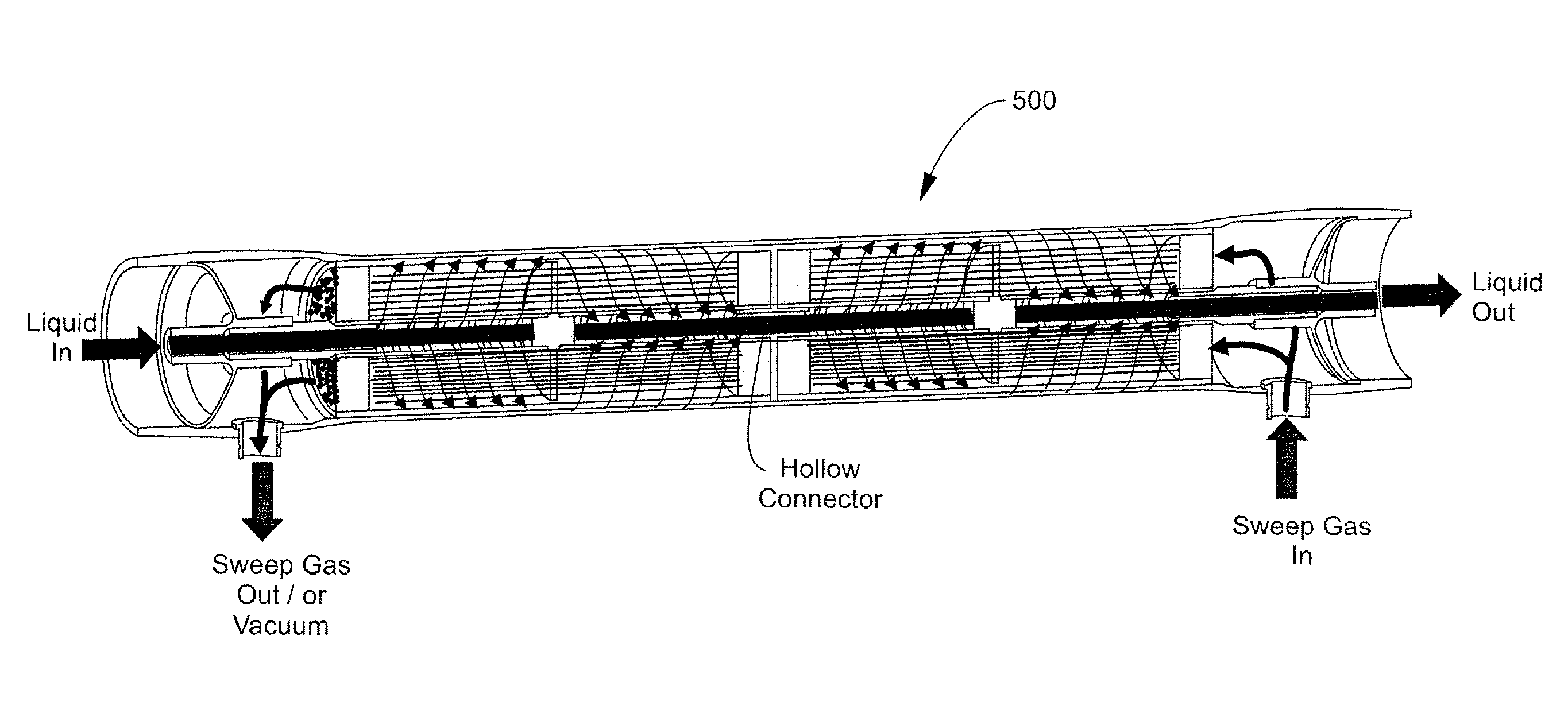

High pressure liquid degassing membrane contactors and methods of manufacturing and use

In accordance with at least selected embodiments of the present invention, an improved liquid degassing membrane contactor or module includes a high pressure housing and at least one degassing cartridge therein. It may be preferred that the high pressure housing is a standard, ASME certified, reverse osmosis (RO) or water purification pressure housing or vessel (made of, for example, polypropylene, polycarbonate, stainless steel, corrosion resistant filament wound fiberglass reinforced epoxy tubing, with pressure ratings of, for example, 150, 250, 300, 400, or 600 psi, and with, for example 4 or 6 ports, and an end cap at each end) and that the degassing cartridge is a self-contained, hollow-fiber membrane cartridge adapted to fit in the RO high pressure housing.

Owner:3M INNOVATIVE PROPERTIES CO

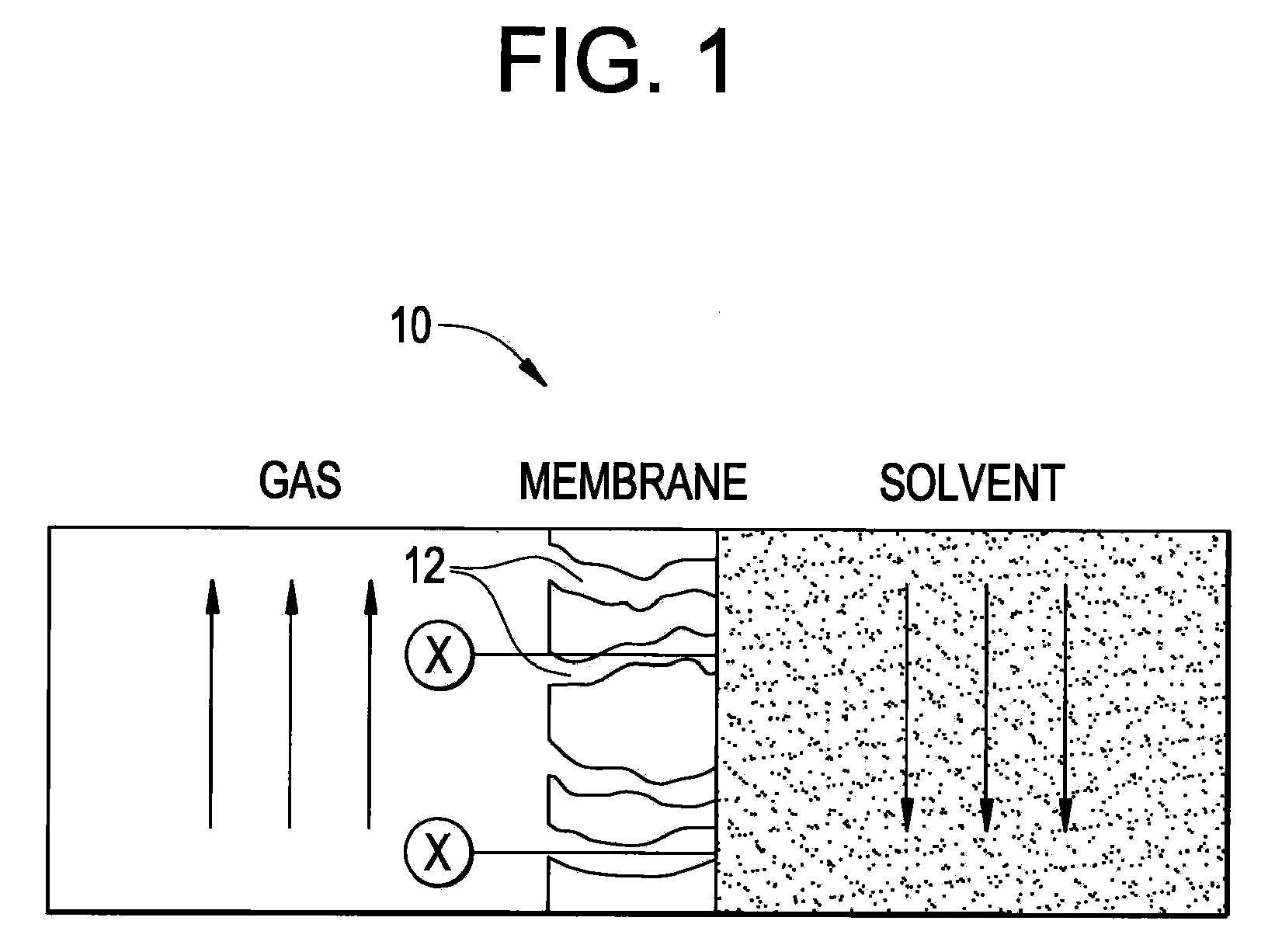

Membrane contactor systems for gas-liquid contact

A membrane contactor system for removing a component from a gas, comprising a housing defining a gas flow path; a microporous membrane positioned in the housing to allow the gas to flow across the membrane, wherein the membrane comprises a structure of nodes connected by fibrils in which surfaces of the structure of nodes and fibrils define a plurality of interconnecting pores extending through the microporous membrane, wherein the plurality of interconnecting pores are configured to allow the component to diffuse therethrough; and an oleophobic coating disposed on the microporous membrane to form a coated membrane and configured to provide oleophobicity to the coated membrane without blocking the plurality of interconnecting pores.

Owner:GENERAL ELECTRIC CO

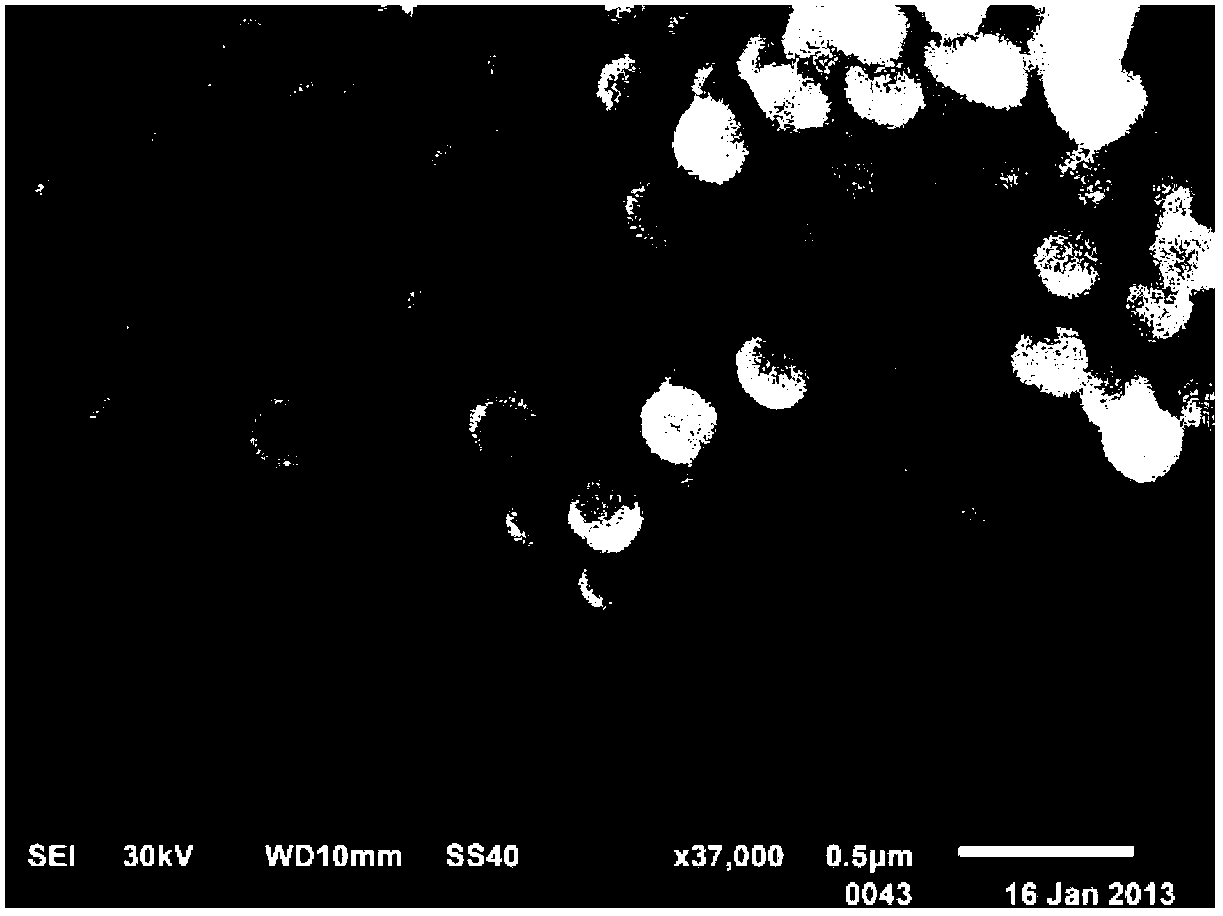

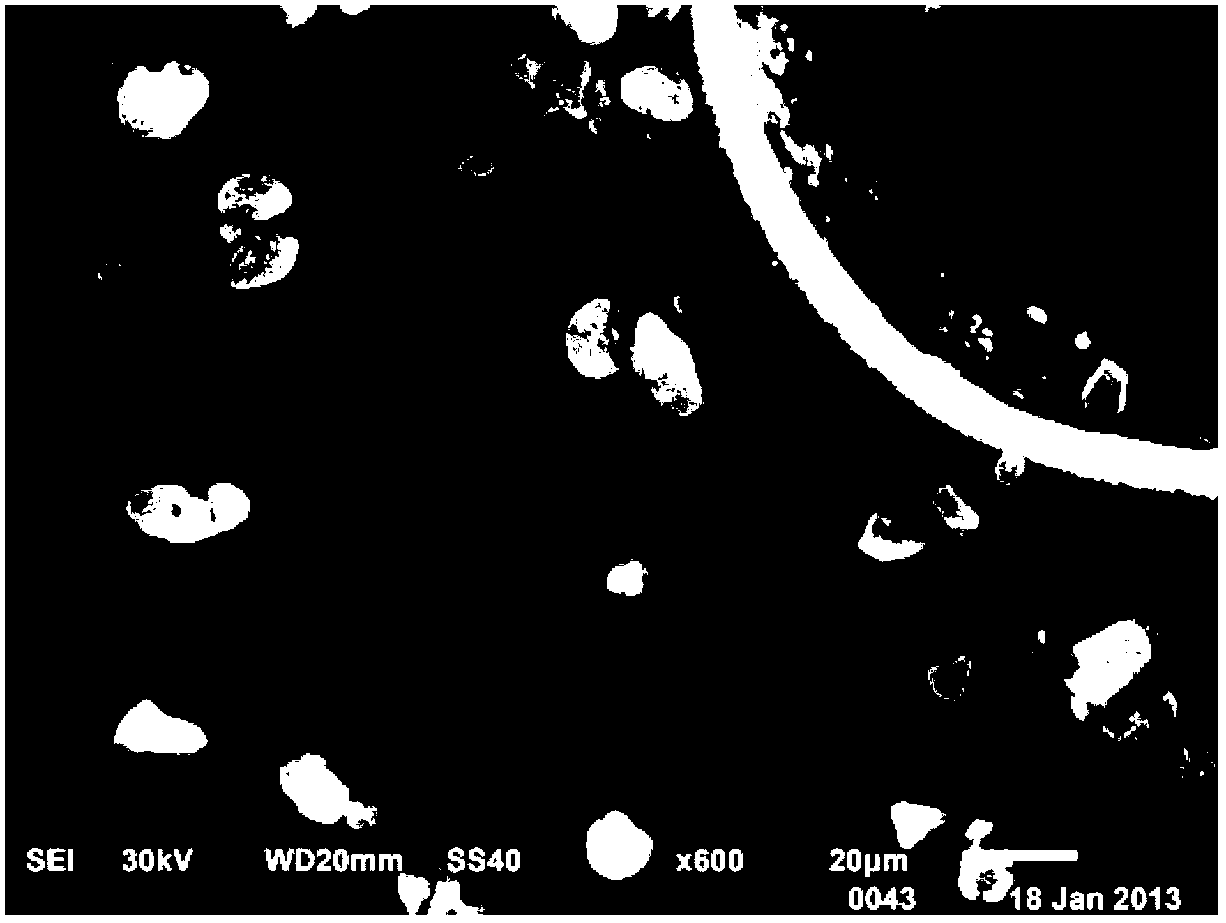

Self sealing membrane contactor with PTFE tubular membranes

ActiveUS20130075321A1Reliably and rapidly seal and isolateResilienceMembranesSemi-permeable membranesEpoxyAdhesive

A tubular membrane module and its method of manufacture are disclosed wherein tubular membranes form an interference self-sealing fit with hard tube sheets with the aid of a hard hollow mandrel inserted at the end of the tubular membranes. The tubular membranes are comprised of porous, compressible PTFE and / or fluorocopolymers. The self-sealing method described herein requires no heat treatment, allows for ease of manufacture without destruction of the tubular membranes and without the processing complexity of utilizing any additional potting agent, extrusion, or chemical cross-linking of any polymeric adhesives. The self sealing PTFE tubular membranes have superb chemical resistance and temperature resistance, and through the benefits of this invention, offer higher pull-out resistance than typically observed with potting materials such as polyurethane and epoxy. In addition, the self-sealing method is reversible and non-destructive (whereas chemical potting and sealing methods using heat are not), as one can easily remove one or more damaged tubes and replace them.

Owner:MARKEL CORPORATION

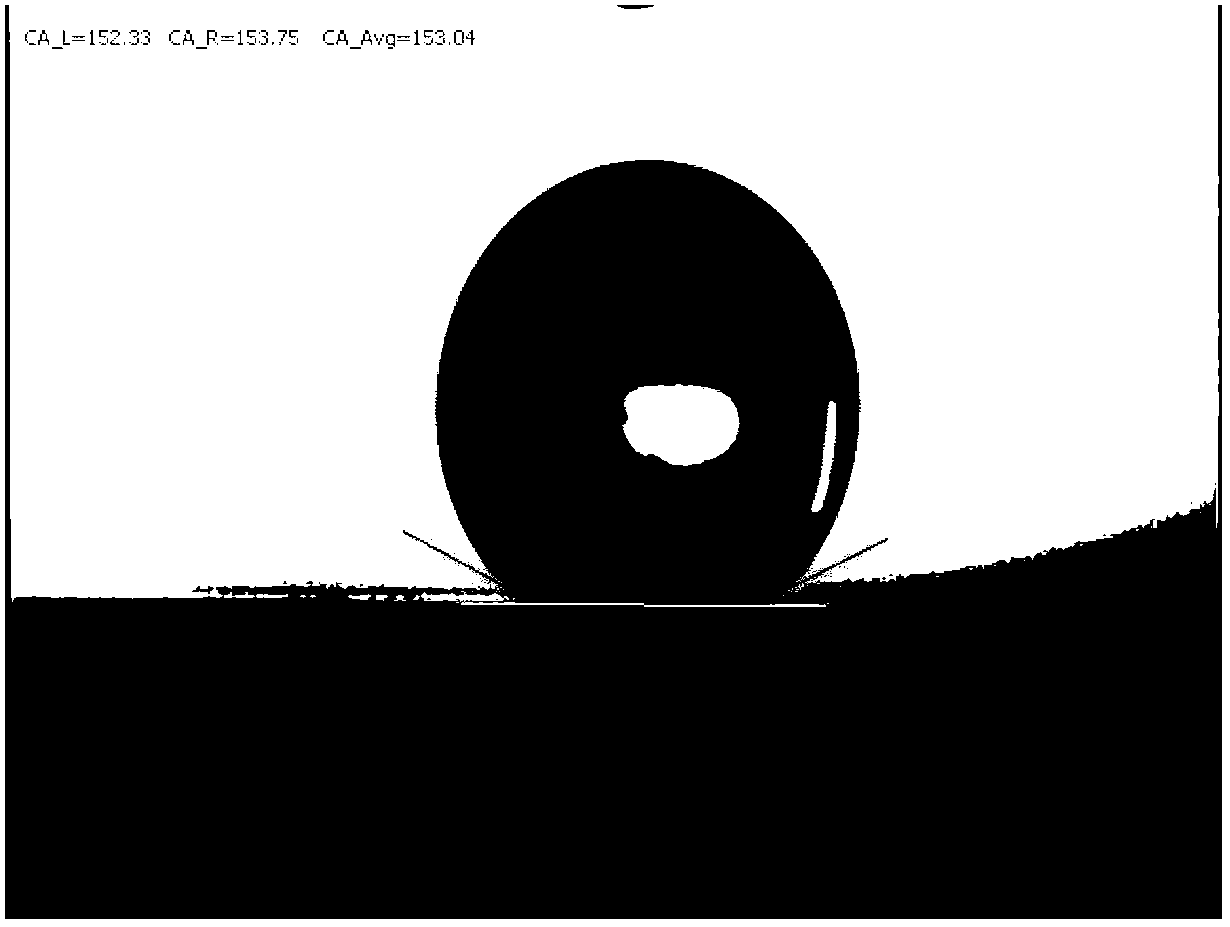

Method for preparing super-hydrophobic membrane for removing dissolved gas in water

InactiveCN103285746AReduce mass transfer resistanceImprove mechanical propertiesSemi-permeable membranesWater/sewage treatment by degassingSolubilityHydrophobic polymer

The invention discloses a novel method for preparing a super-hydrophobic membrane for removing dissolved gas in water. Based on a self-cleaning bionic principle, coupling agent modified inorganic nanoparticles with low surface energy and hydrophobic polymer PVDF (Polyvinylidene Fluoride) are blended to obtain a super-hydrophobic flat membrane with good mechanical properties by a phase inversion method. The surface of the super-hydrophobic membrane has a water contact angle of 154+ / -1 degrees and a rolling angle of 4+ / -1 degrees, so that the has super-hydrophobic membrane good super-hydrophobicity and self-cleaning properties, the mass transfer resistance of the wetted membrane can be obviously reduced, and the separation efficiency of a membrane contactor is improved.

Owner:SHANDONG ZHONGYU ENVIRONMENTAL PROTECTION TECH +1

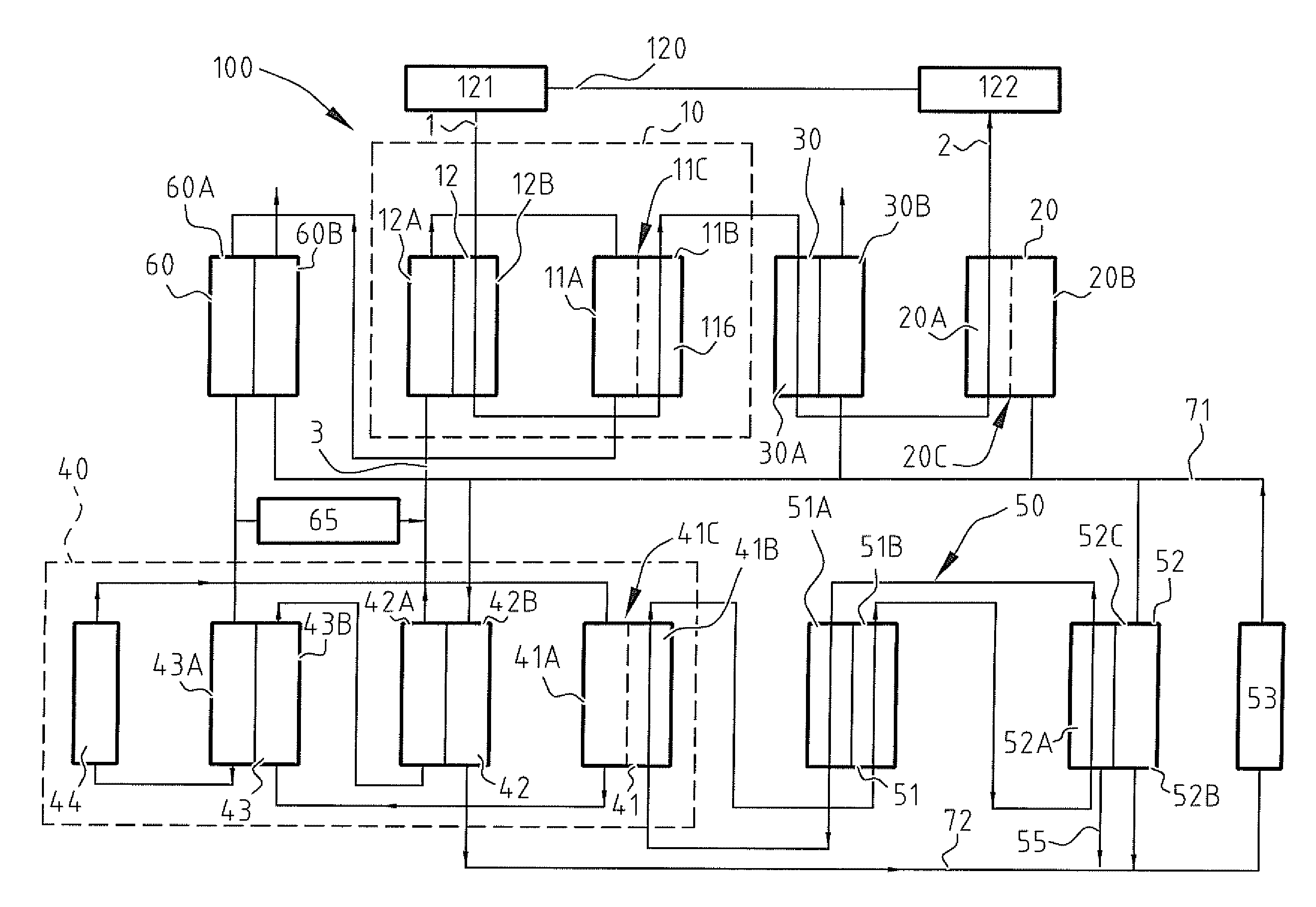

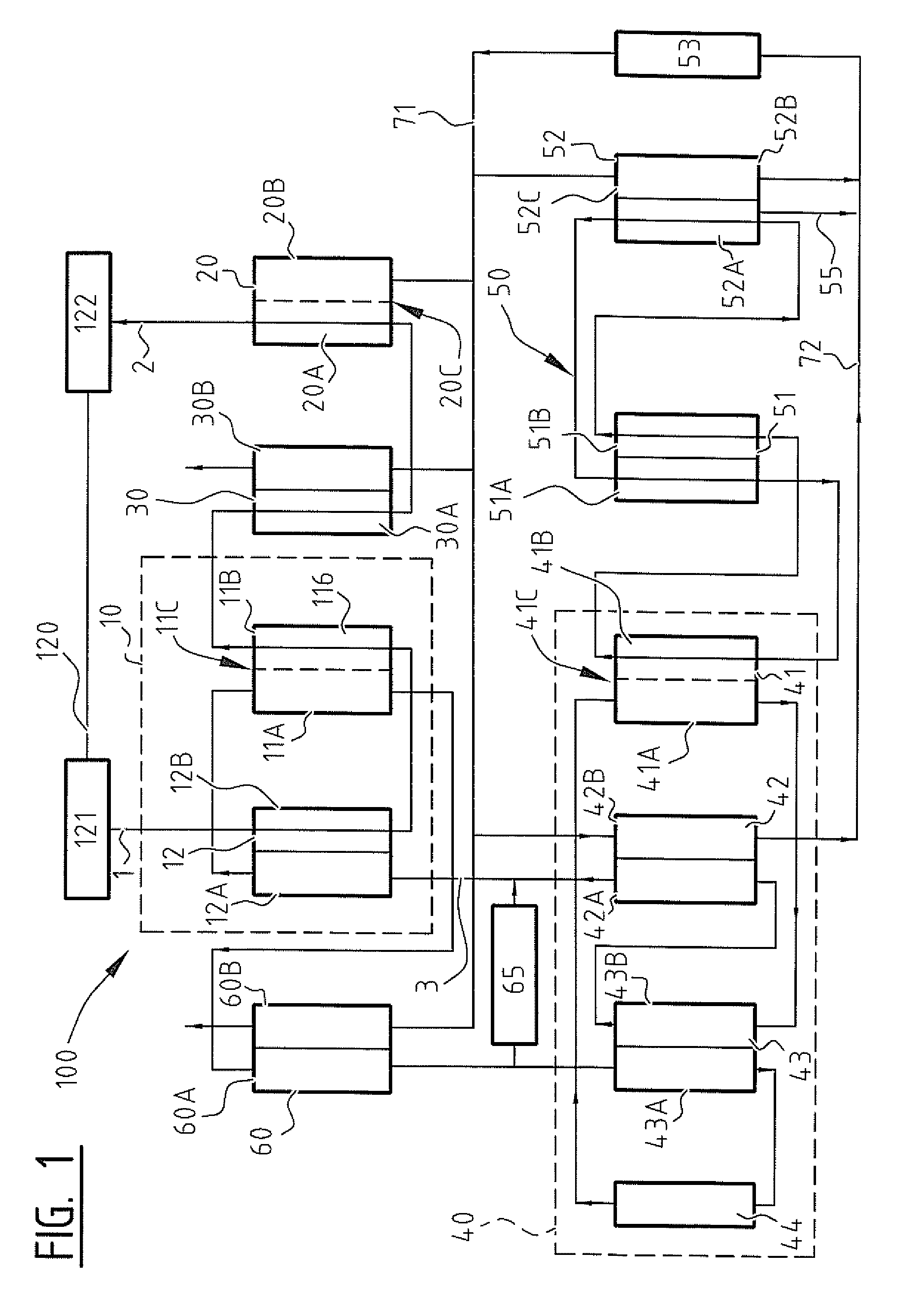

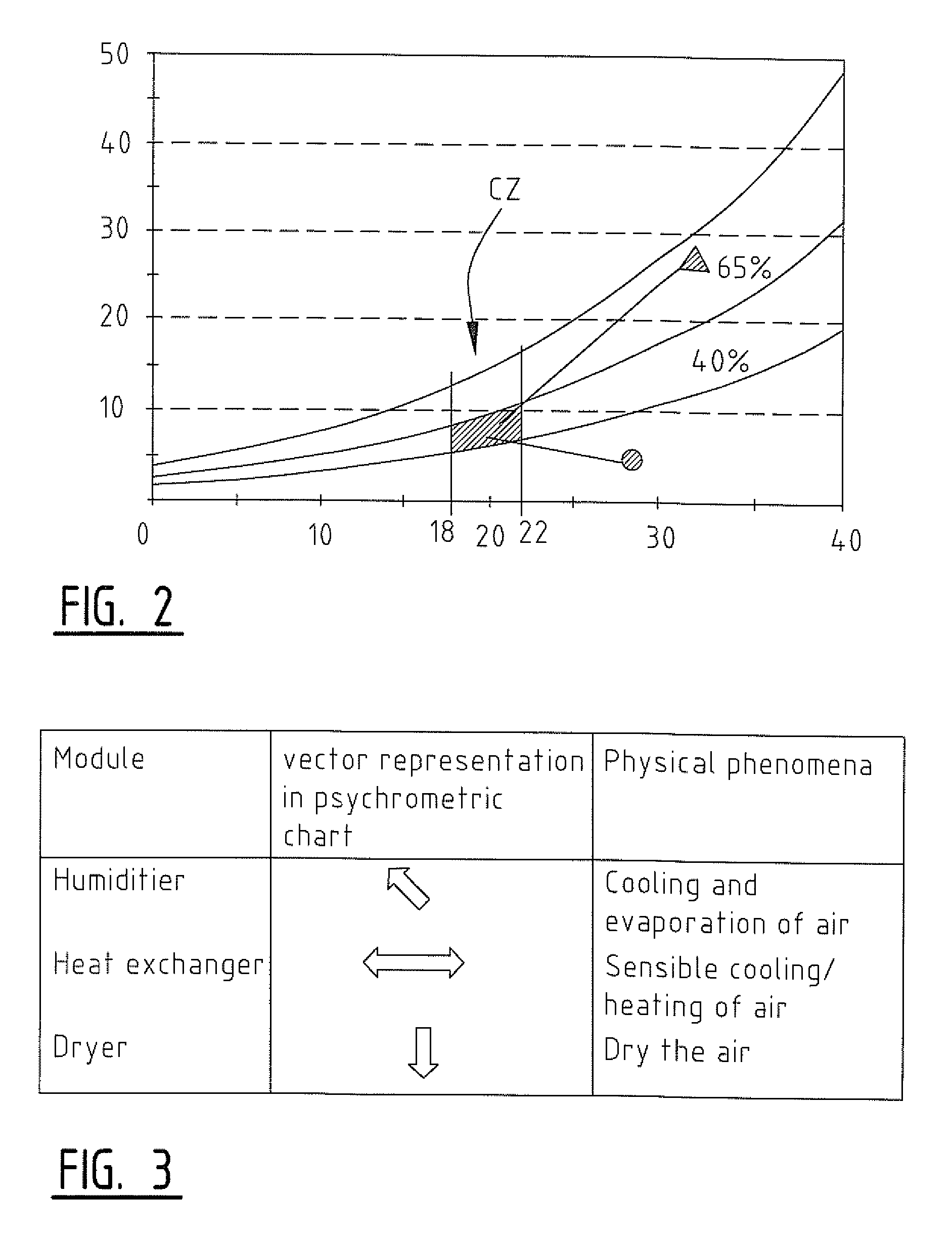

Air-conditioning system and use thereof

InactiveUS9188349B2Simple processMeet the requirementsLighting and heating apparatusDispersed particle separationDesiccantEngineering

The air-conditioning system comprises a dryer (10) comprising a membrane contactor (11) provided with a first channel (11b) for air flow and a second channel (11a) for desiccant flow, which channels are separated through a membrane (11c). The air conditioning system further comprises a humidifier (20) comprising a membrane contactor. The air flow passes in operation the dryer (10) and the humidifier (30) between an inlet (121) and an outlet (122). The dryer (10) comprises a series connection of a heat exchanger (12) and the membrane contactor (11), which heat exchanger couples air flow from the inlet (121) with desiccant flow from a regenerator (40) and in which membrane contactor (11) the thus heat-exchanged air flow and the heat-exchanged desiccant flow are coupled for drying of the airflow.

Owner:2NDAIR

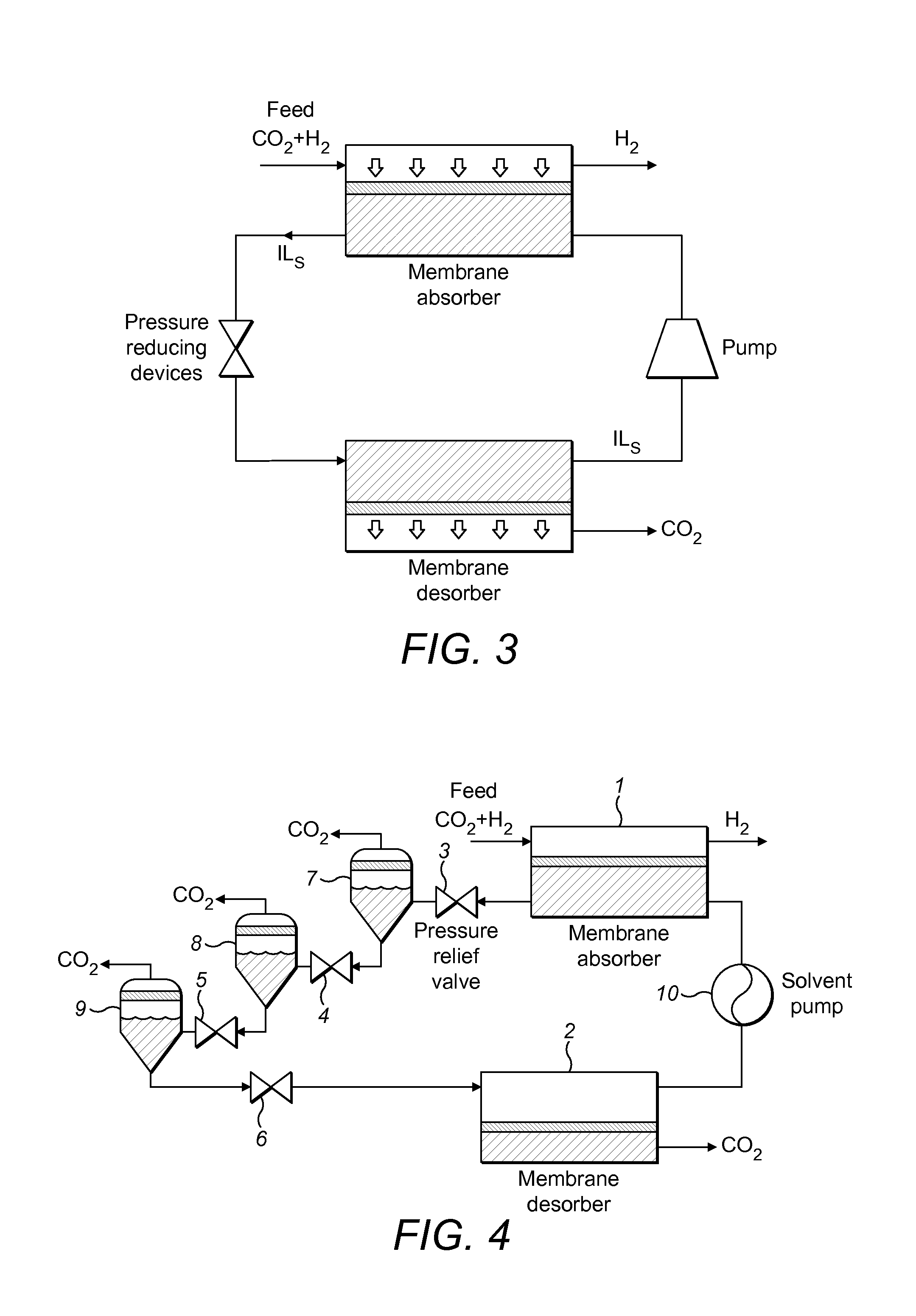

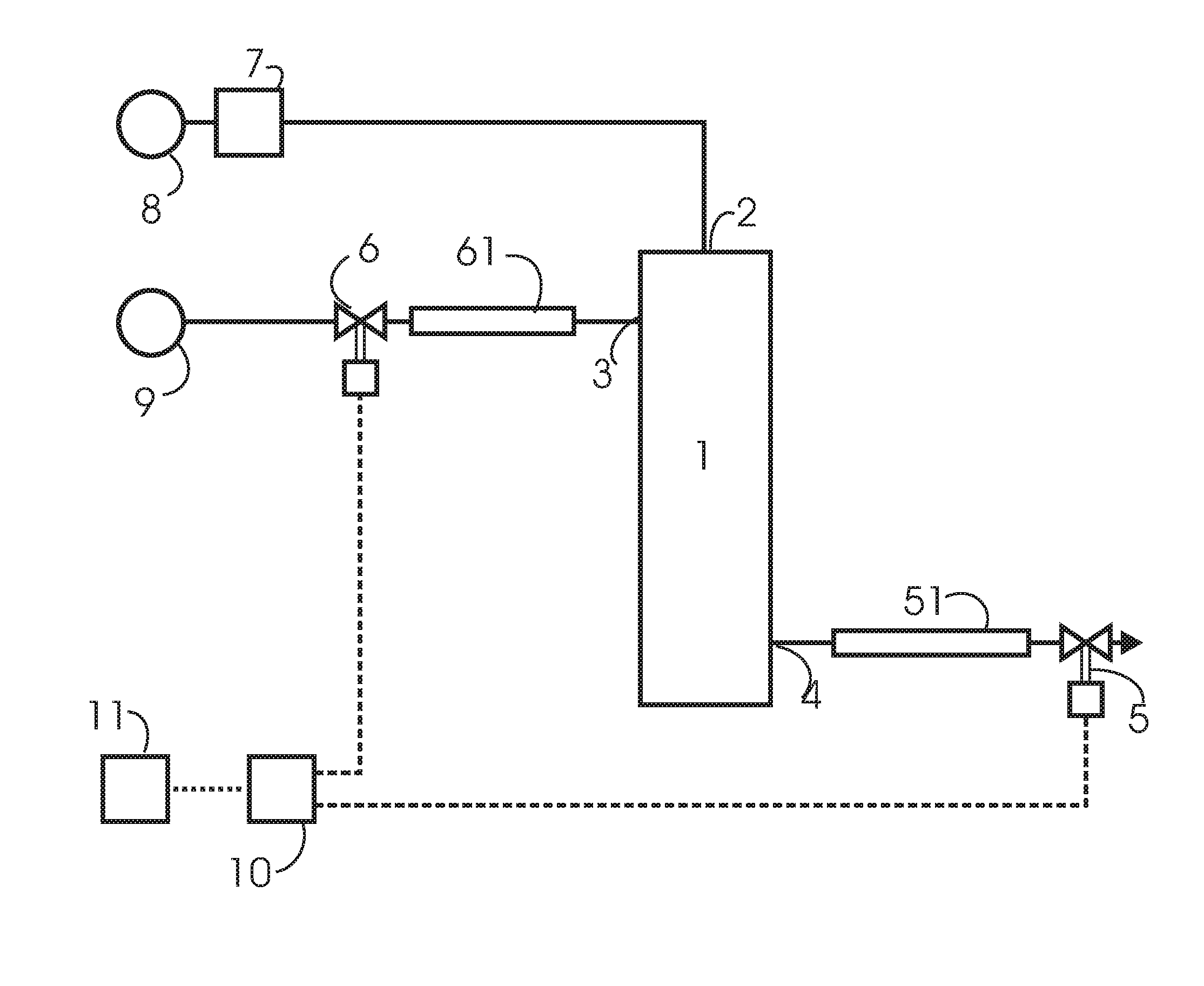

Closed cycle continuous membrane ionic liquids absorption/desorption process for co2 capture

InactiveUS20160206993A1Reduce corrosionHigh calorific valueSemi-permeable membranesGas treatmentDesorptionProduct gas

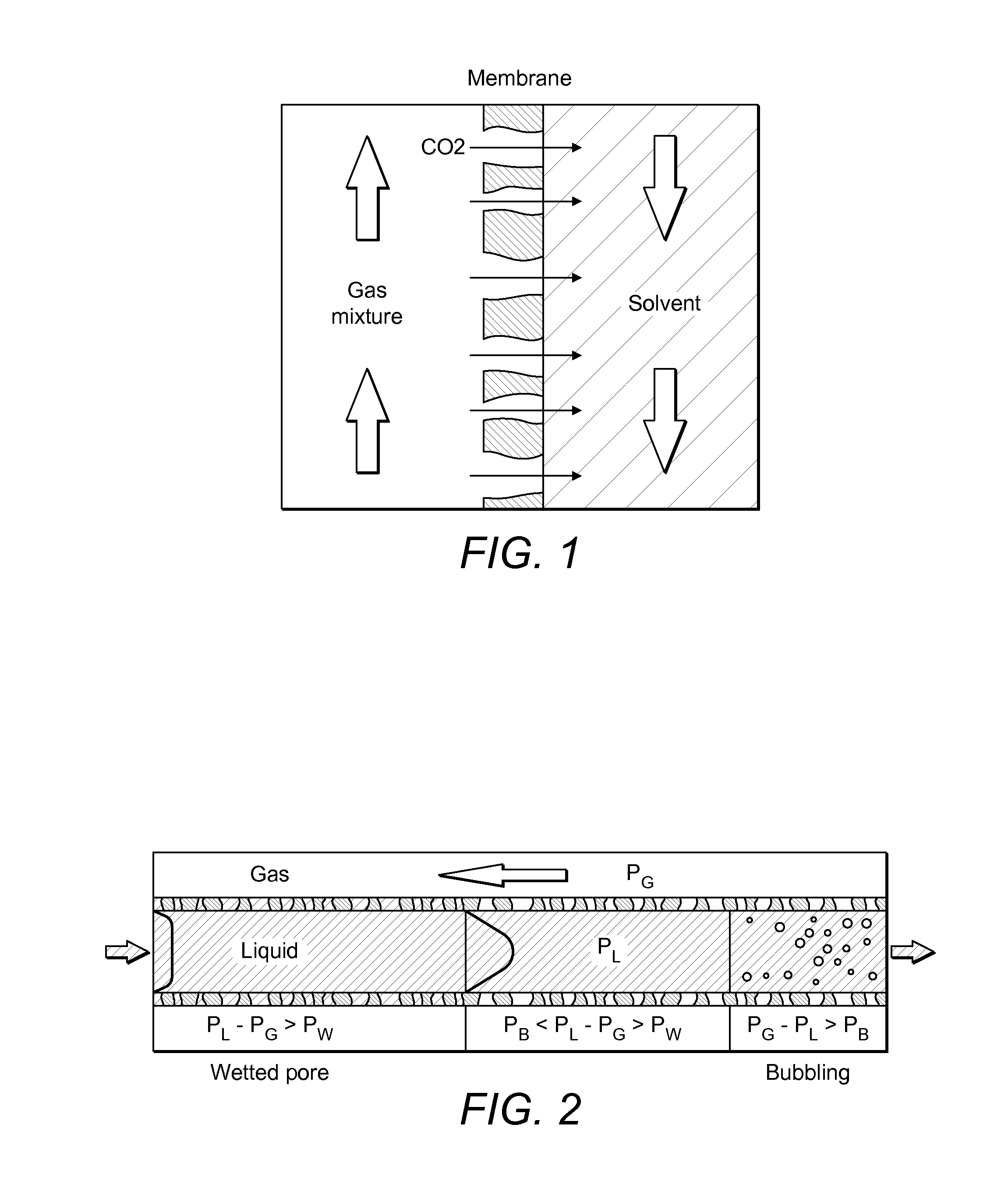

A process for separating at least one gas (e.g. at least one of CO2, H2S and / or NH3) from a mixed gaseous feed stream, said process comprising (i) Passing said mixed gaseous feed stream through a first membrane contactor comprising a first membrane and a liquid absorbent at a first pressure, such that the liquid absorbent absorbs the at least one gas from the mixed gaseous feed stream to form a rich liquid absorbent; (ii) Feeding said rich liquid absorbent to a second membrane contactor comprising a second membrane at a second pressure; (iii) Desorbing said at least one gas (e.g. at least one of CO2, H2S and / or NH3) from the rich liquid absorbent in the second membrane contactor; and (vi) Recirculating all or at least a part of the liquid absorbent from the second membrane contactor back to the first membrane.

Owner:DENG LIYUAN

Membrane contactors and systems for membrane distillation or ammonia removal and related methods

New, improved, or modified membrane contactors, modules, systems, and / or methods for membrane distillation and / or ammonia removal, and / or methods of manufacture, use, and / or the like. In accordance with at least selected embodiments, particular possibly preferred membrane contactors, modules, systems, and / or methods for membrane distillation and / or ammonia removal, and / or to particular possibly preferred membrane contactors, modules, systems, and / or methods for membrane distillation and / or ammonia removal, involving membrane contactors adapted for membrane distillation, for ammonia removal, or for both membrane distillation and for ammonia removal, as well as for other membrane contactor systems, methods or processes such as degassing, gasifying, separation, filtration, and / or the like.

Owner:3M INNOVATIVE PROPERTIES CO

Producing or Dispensing Liquid Products

InactiveUS20140220207A1Avoid disadvantagesImprove the level ofLighting and heating apparatusMixing methodsLiquid productHollow fibre

A liquid product is dispensed via a membrane contactor. The contactor employs a plurality of gas-permeable hollow fibres. The contactor has a gas port communicating with the interior of the fibres and input and output ports for liquid communicating with space within the contactor surrounding the fibres. A gas comprising carbon dioxide or nitrous oxide is dissolved in the liquid in the contactor. The gas at a controlled pressure is supplied to the gas port. The liquid is supplied at a higher pressure than the gas to the input port for liquid from a supply of such liquid via a first valve having a first valve inlet port communicating with the supply of liquid and a first valve outlet port communicating with the inlet port for liquid. Liquid with the gas dissolved therein is dispensed from the outlet port for liquid via a dispense tap to ambient. The dispensing liquid step includes a start dispense step in which dispensing commences and a stop dispense step in which dispensing is stopped. The first valve is opened with the dispensing tap in the start dispense step, and is closed in the stop dispense step. Pressure build-up is relieved in liquid in communication with the space within the contactor surrounding the fibres after closure of the first valve and while maintaining the first valve closed. The balance between gas pressure and liquid pressure during the systems' standby periods protects the membranes from flooding.

Owner:HEADMASTER

Method for cleaning hollow fiber gas-liquid membrane contactor

InactiveCN101259379ALow operating costSmall footprintSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a method used for washing a hollow fibre gas-liquid membrane contactor in the technical field of environment protection. Pressure gas enters one side of the hollow fibre and enters the other side thereof through a membrane hole to form a gas-liquid mixed phase onflow with the cleaning solution floating in the other side to impact and wash out the pollutants stuck on a membrane wall, thus leading the pollutants to loosen and shed. The pollutants in the membrane hole can be purged to shed by the pressure gas and be carried away along with the gas-liquid mixed phase onflow. By effectively combining a physical washing method with a chemical method and utilizing the gas-liquid mixed phase onflow formed by the pressure gas and the cleaning solution to wash the hollow fibre membrane, the invention can leave out or reduce the usage of chemical cleaning agents and lower the erosion to the membrane caused by chemical cleaning agents, thus the service life of the membrane is prolonged, the cost of technology is reduced, furthermore, no secondary pollution is caused.

Owner:SHANGHAI JIAO TONG UNIV

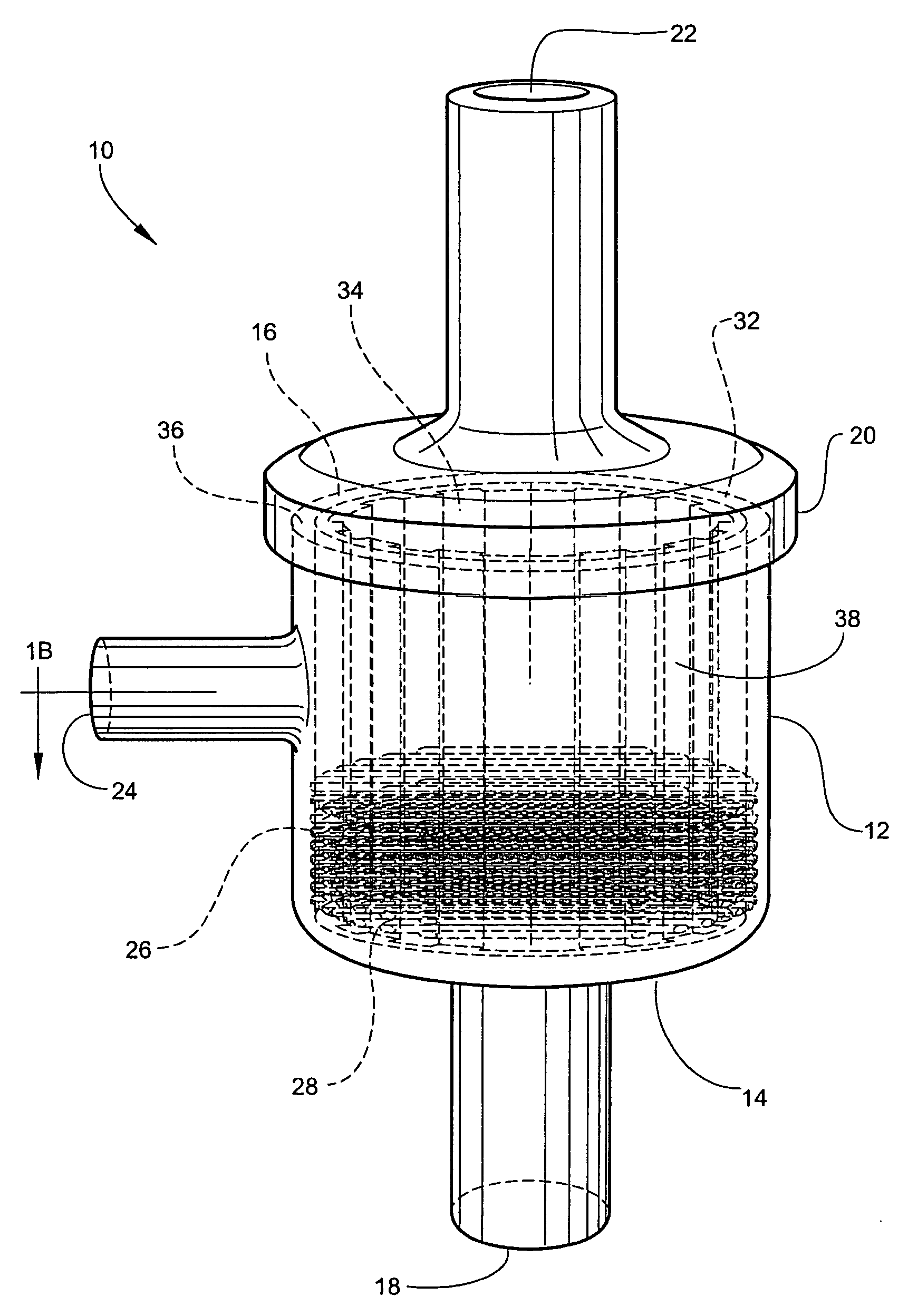

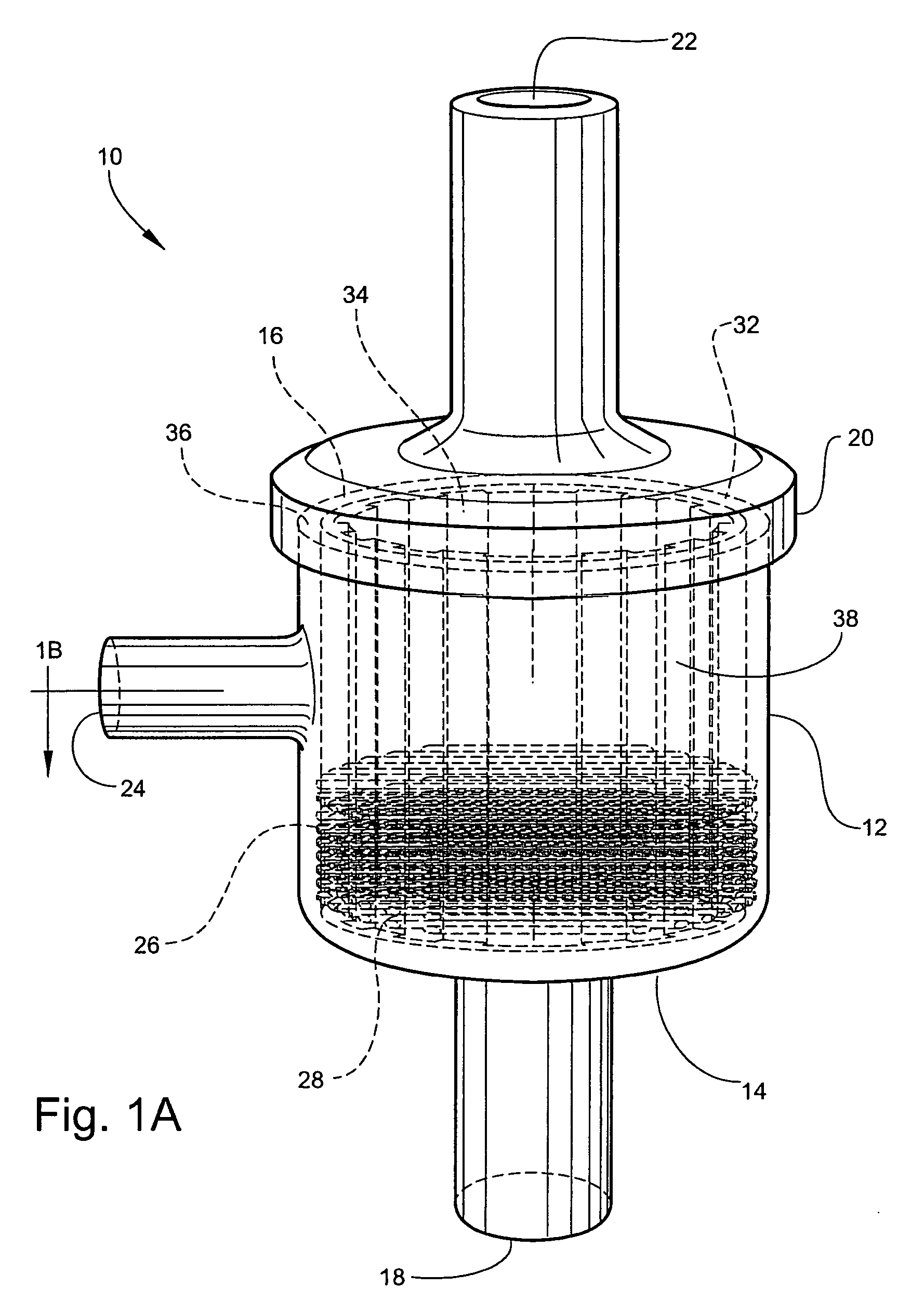

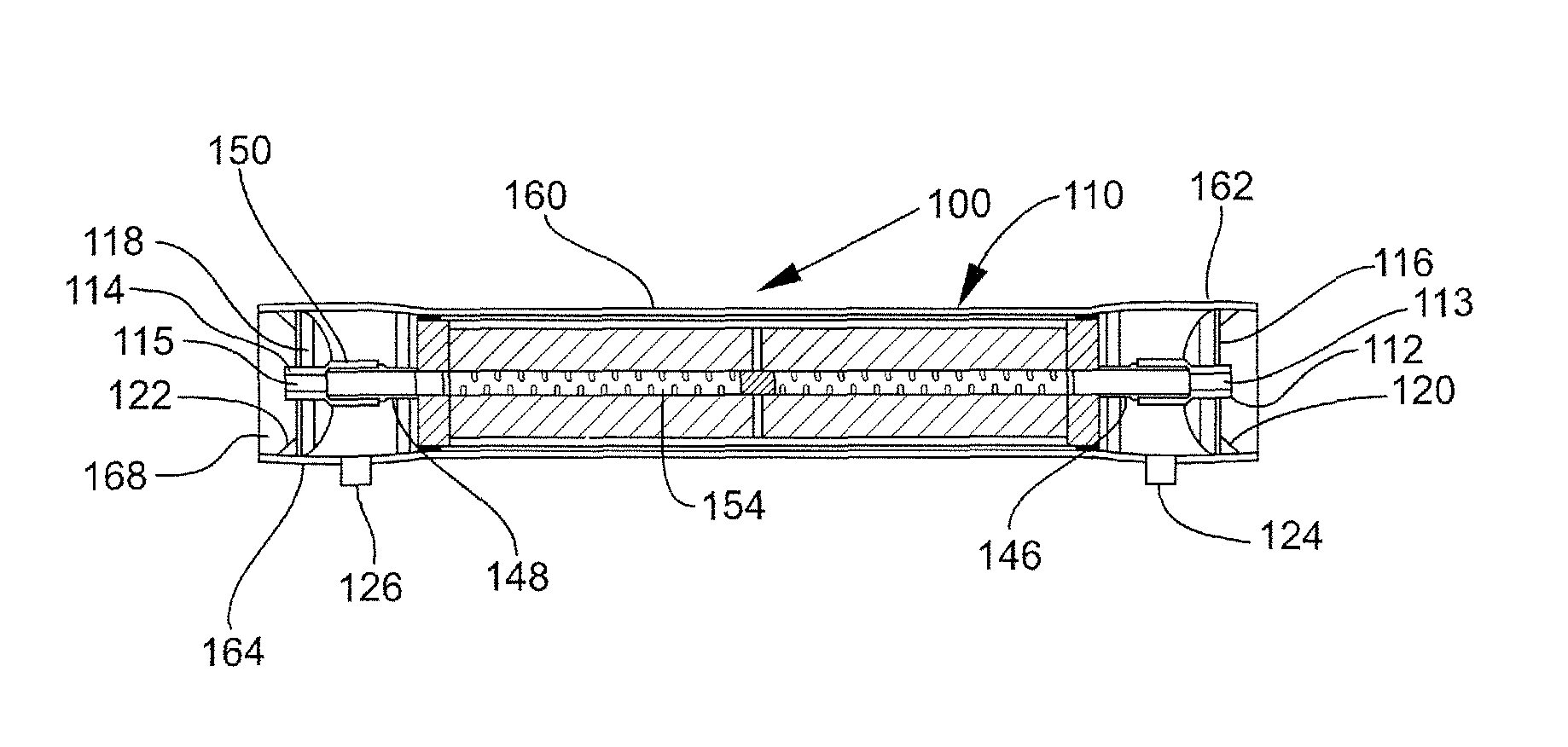

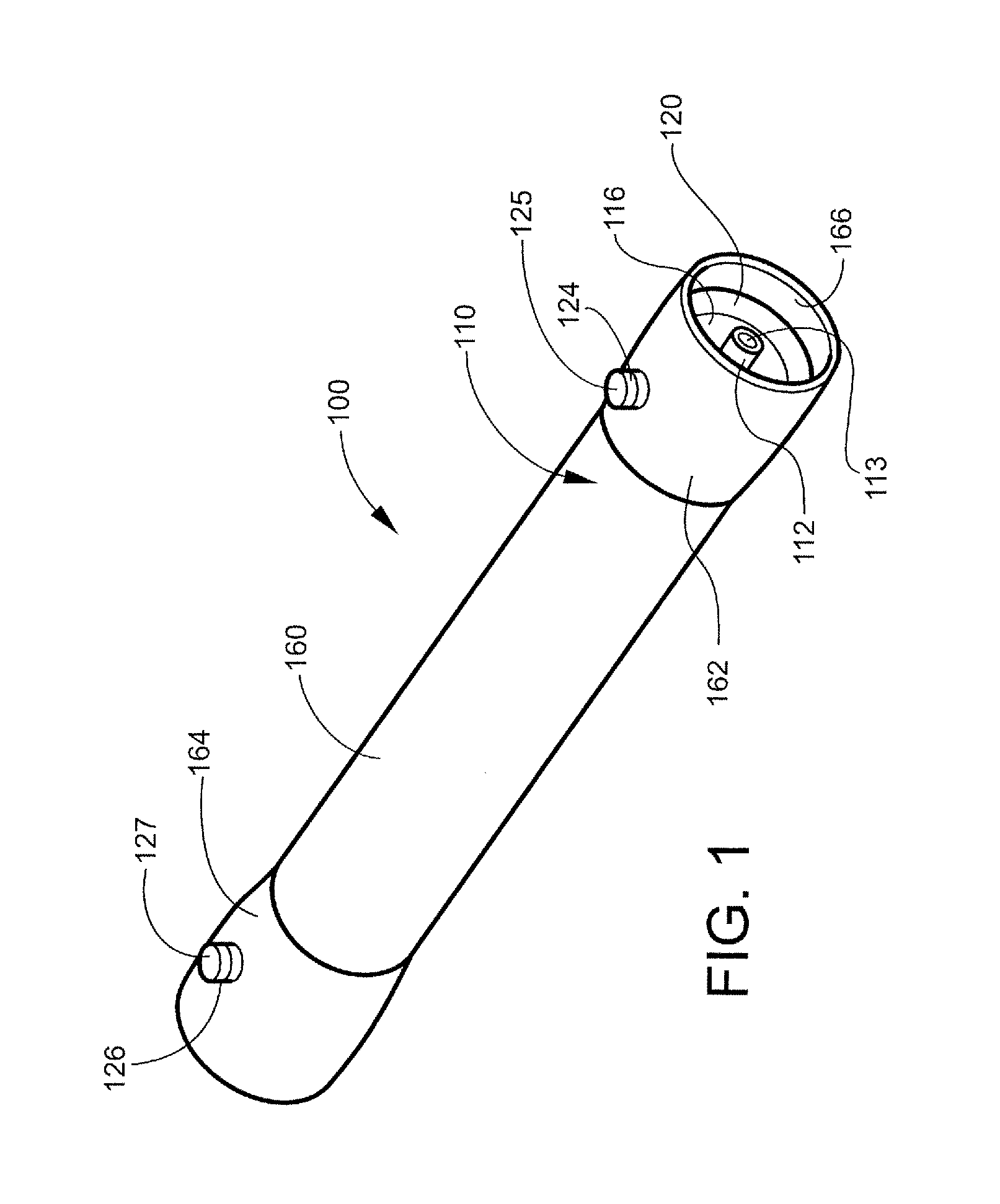

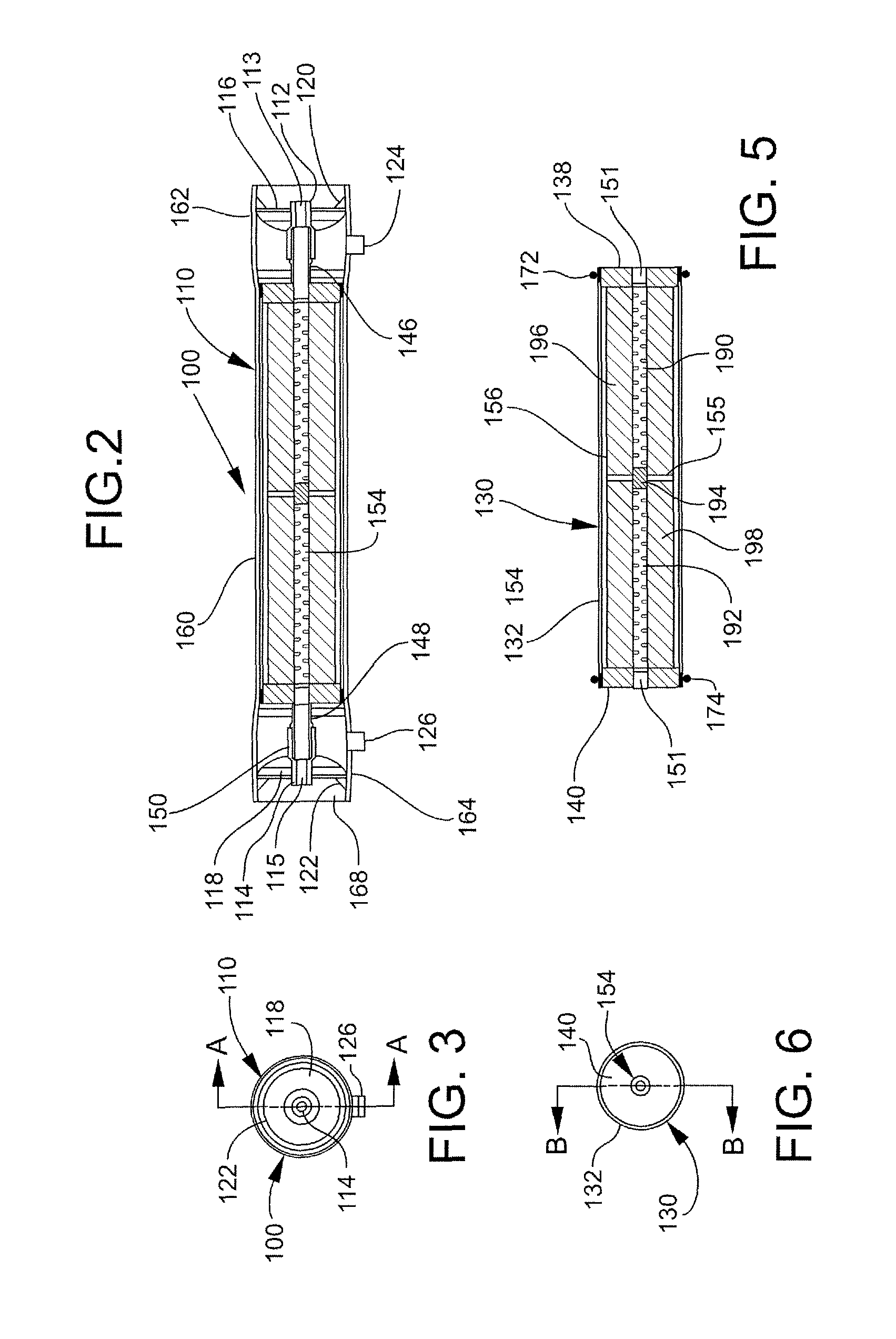

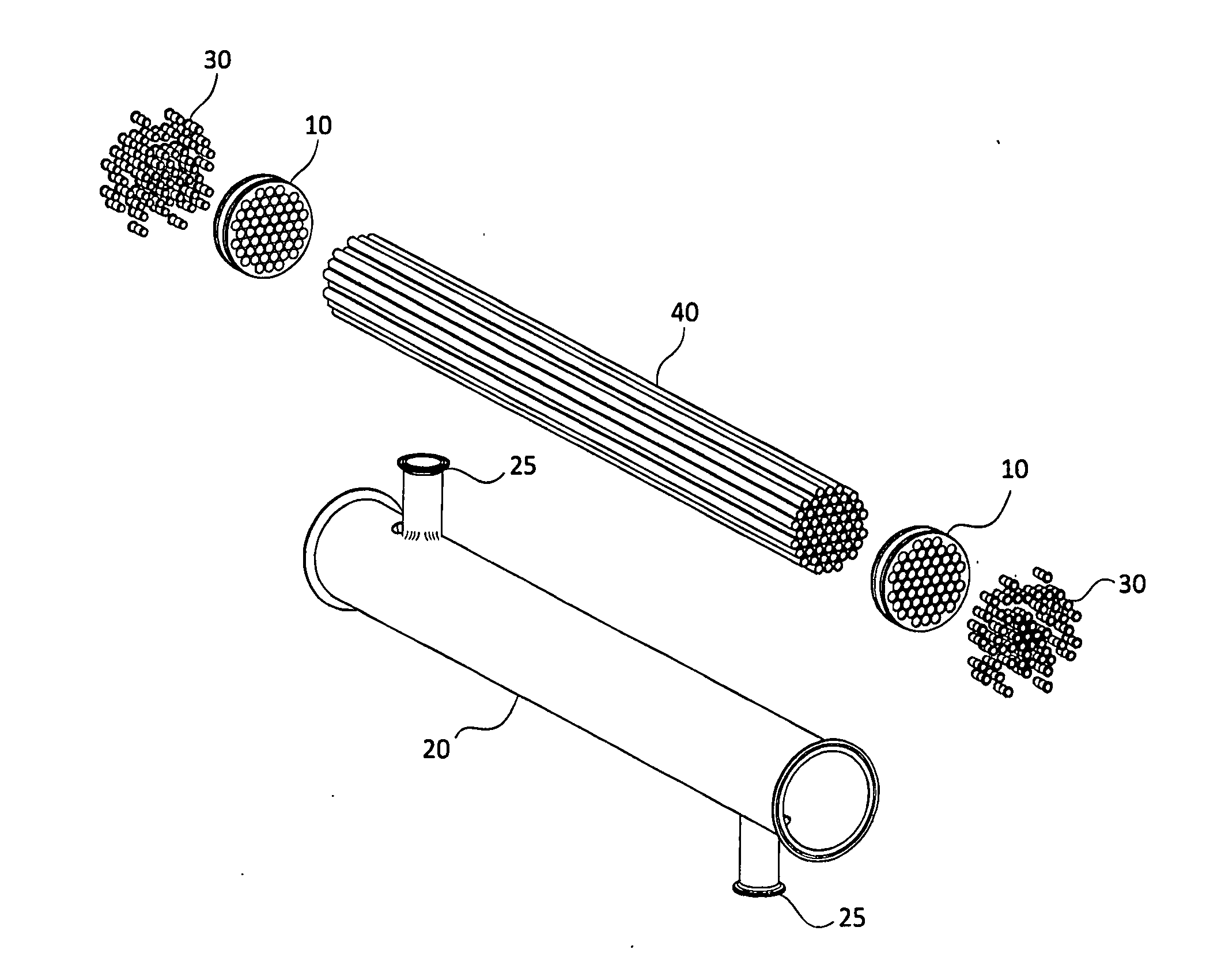

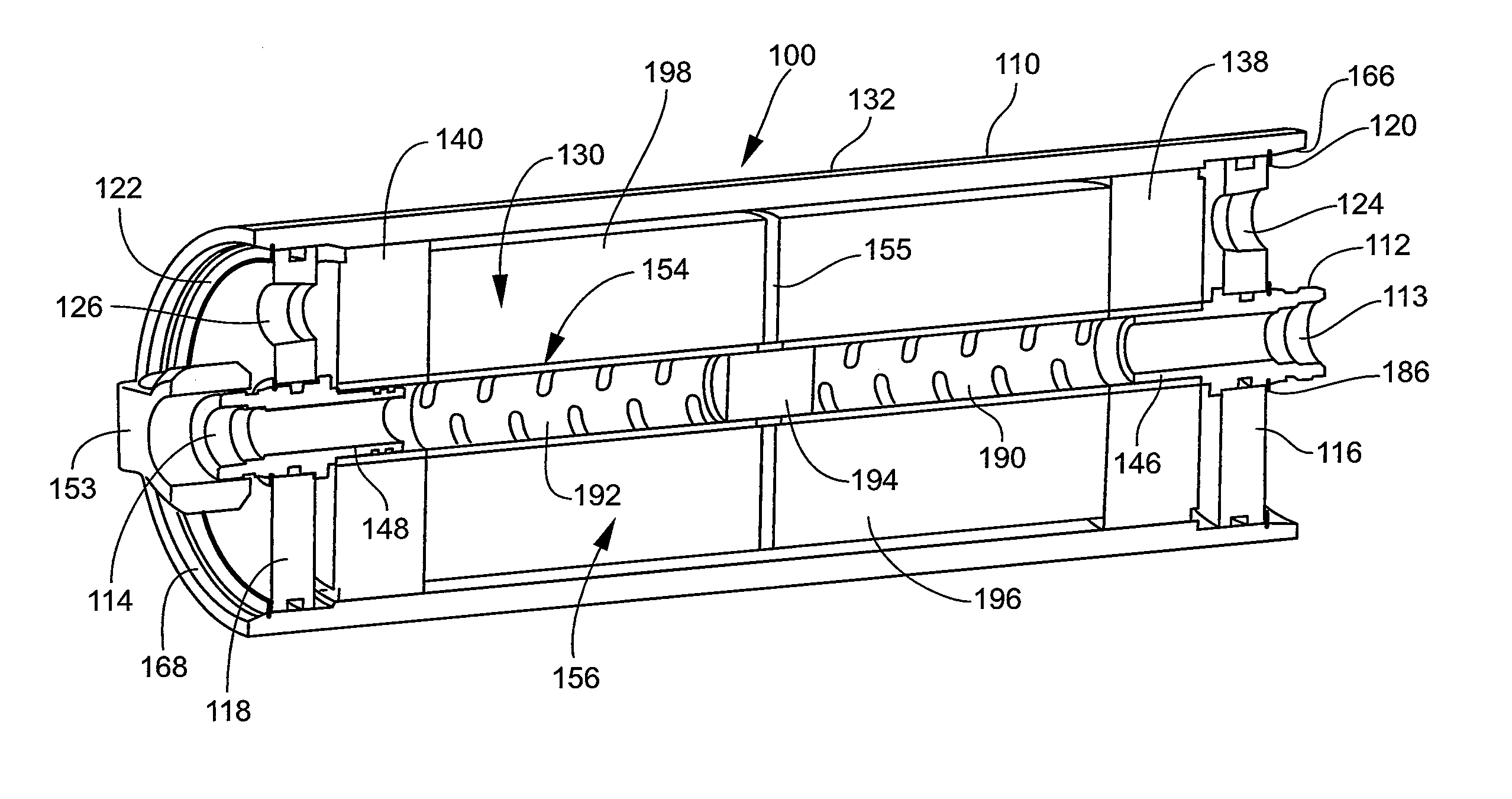

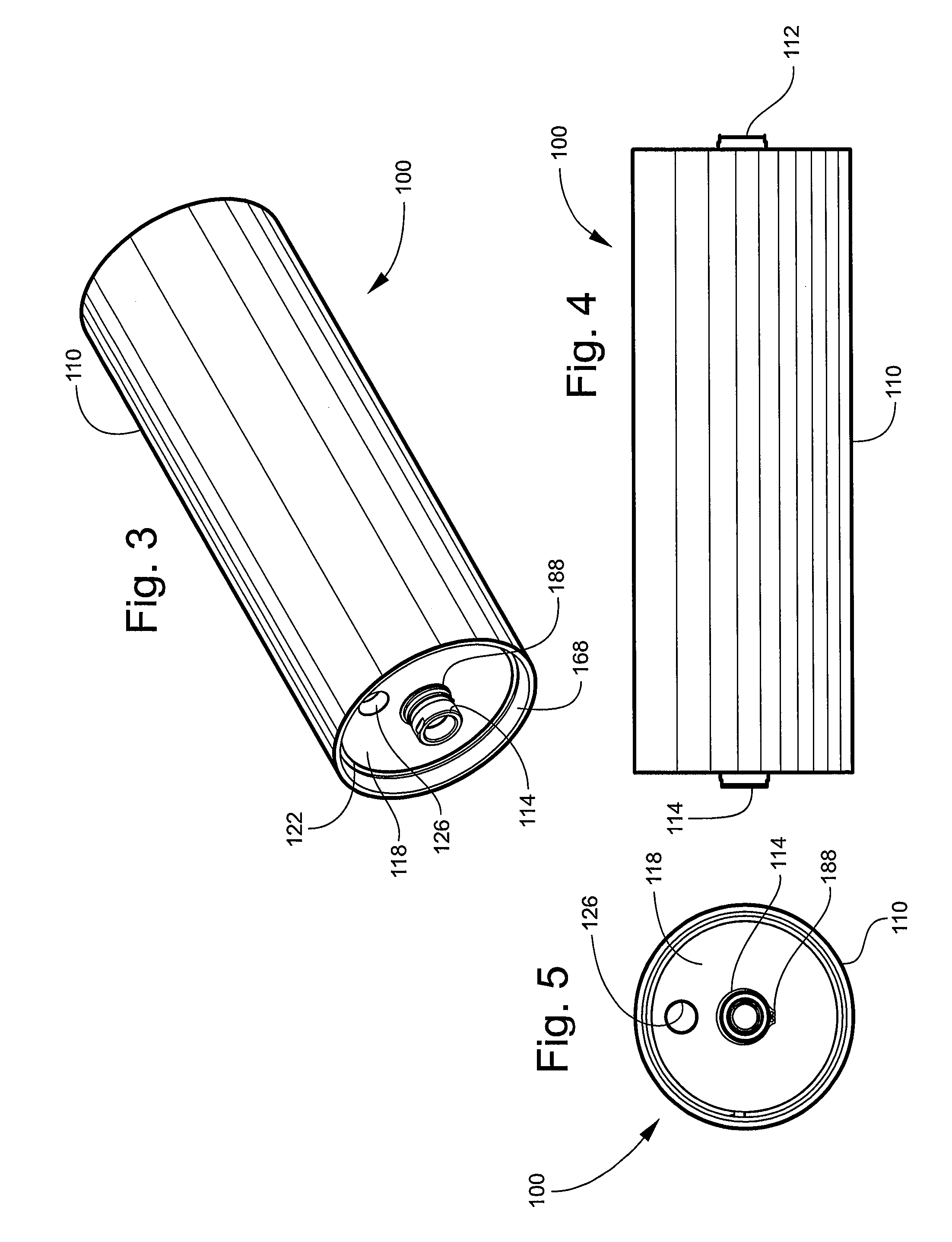

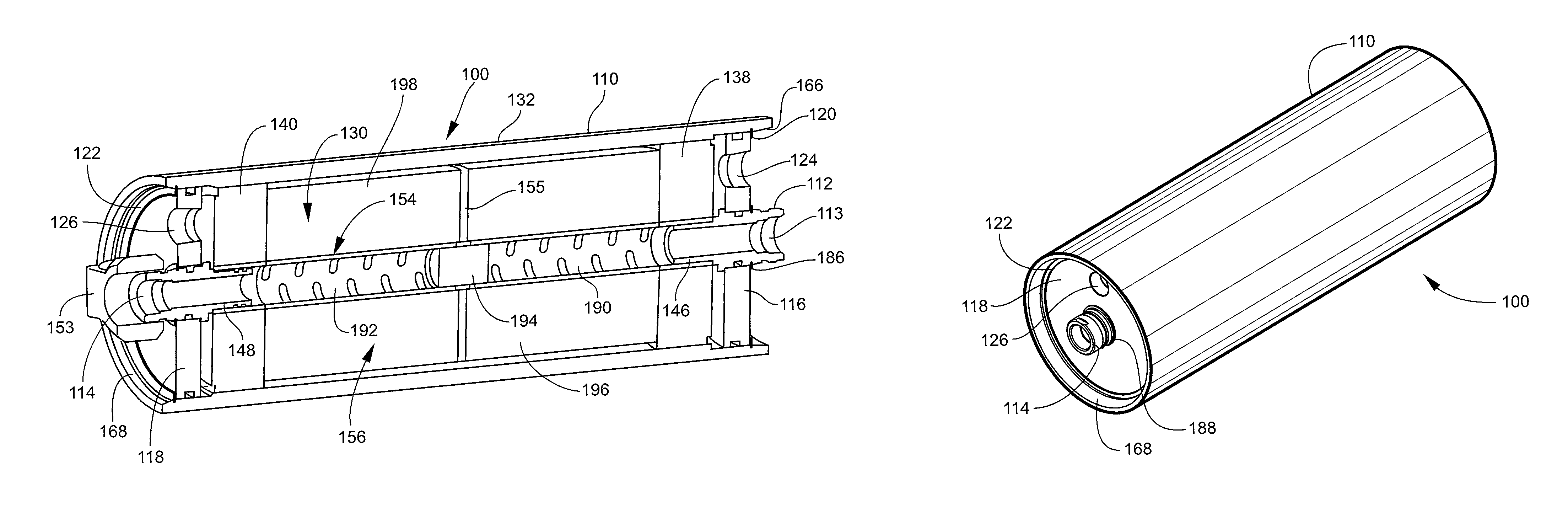

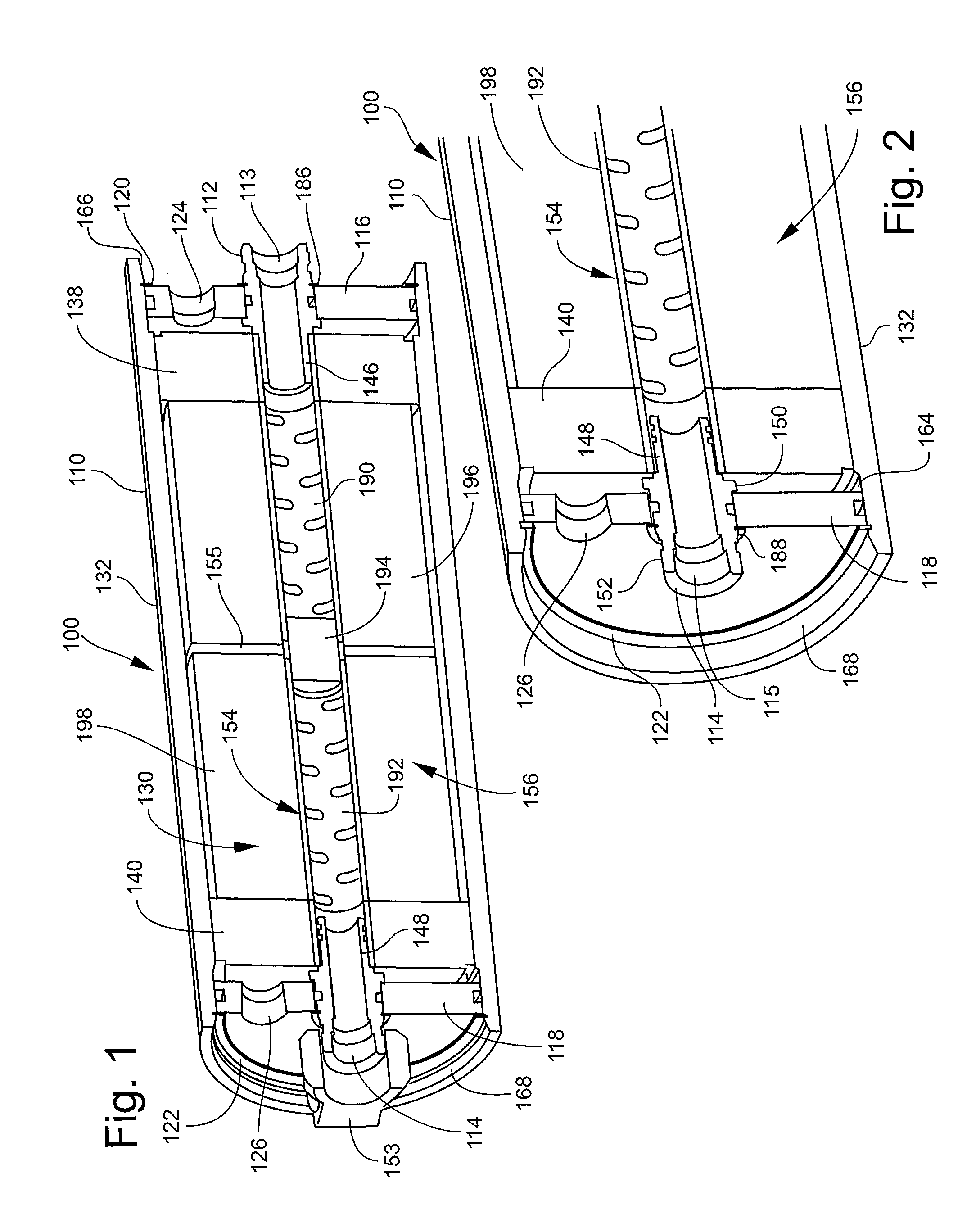

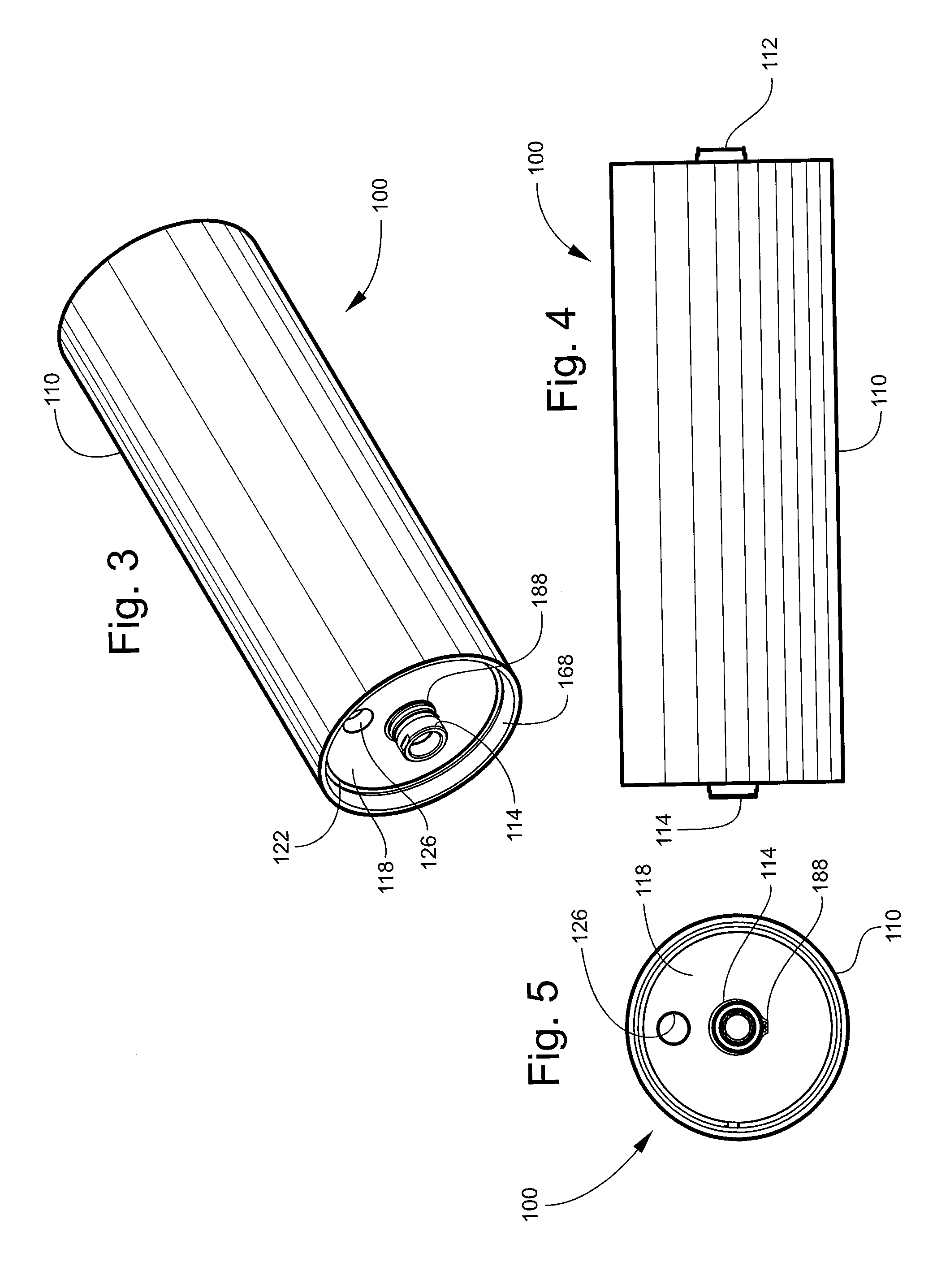

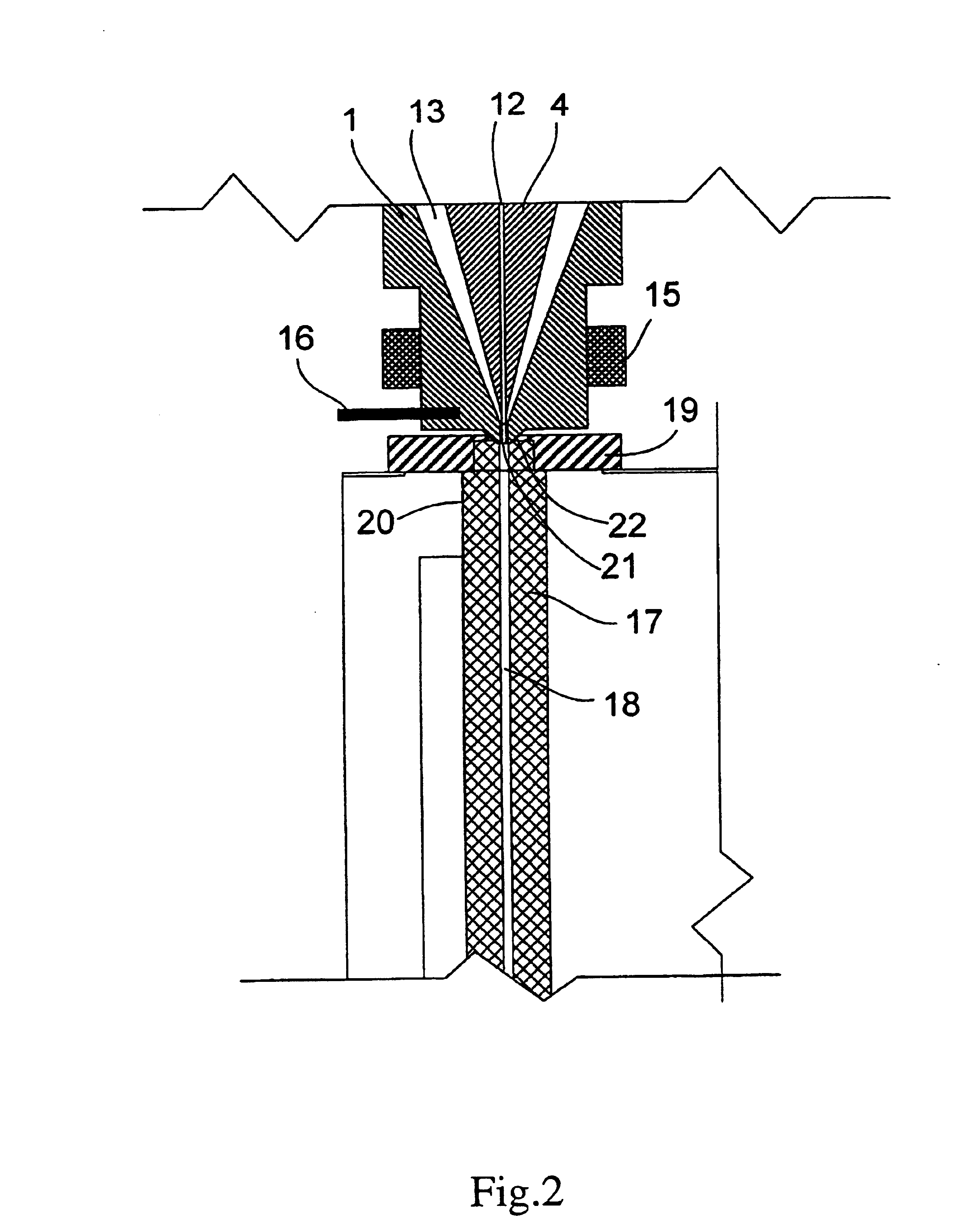

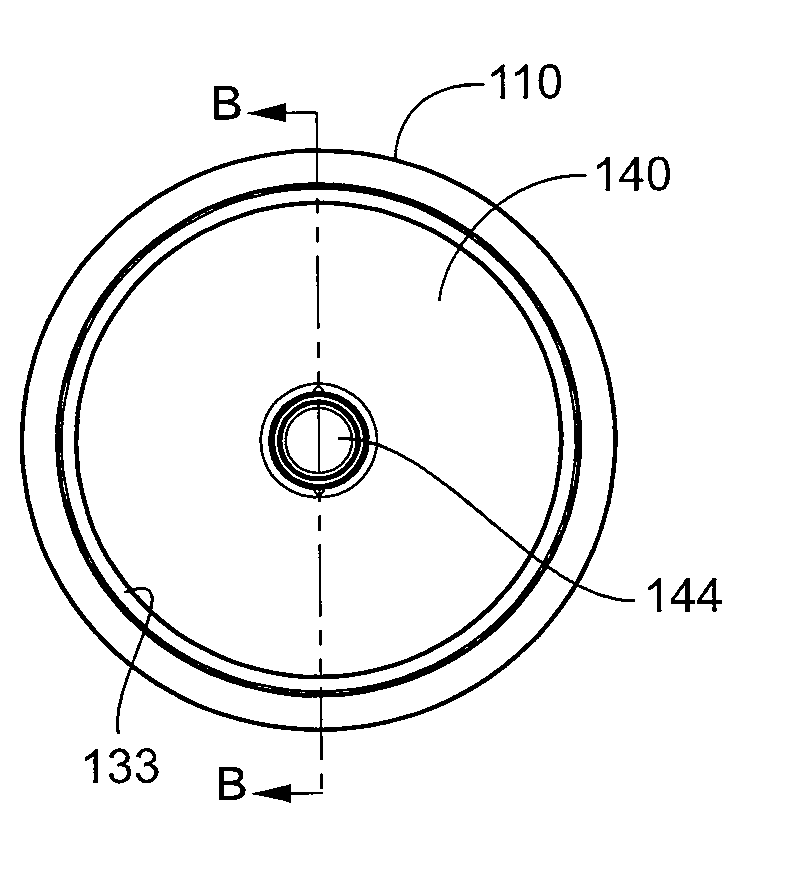

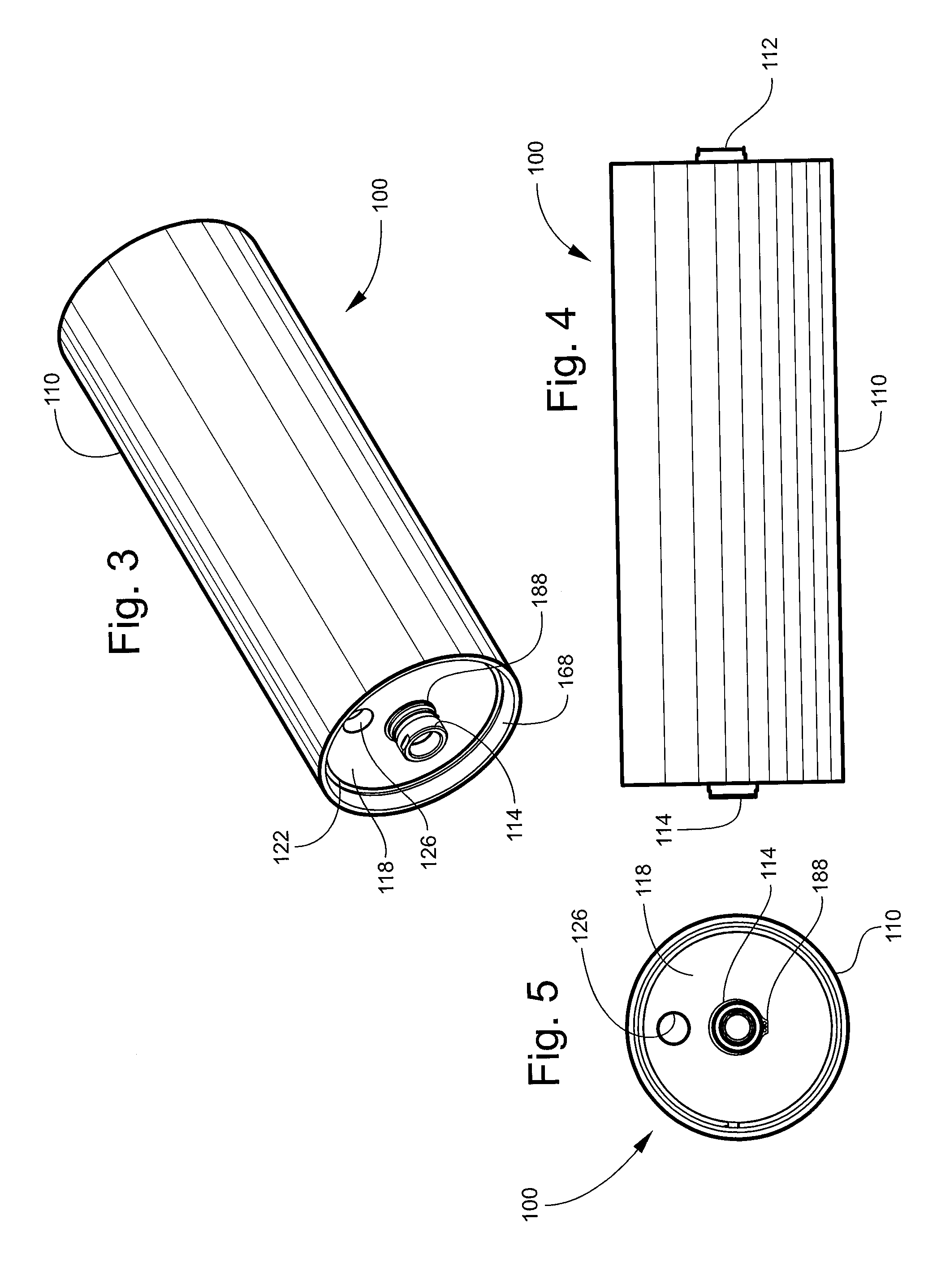

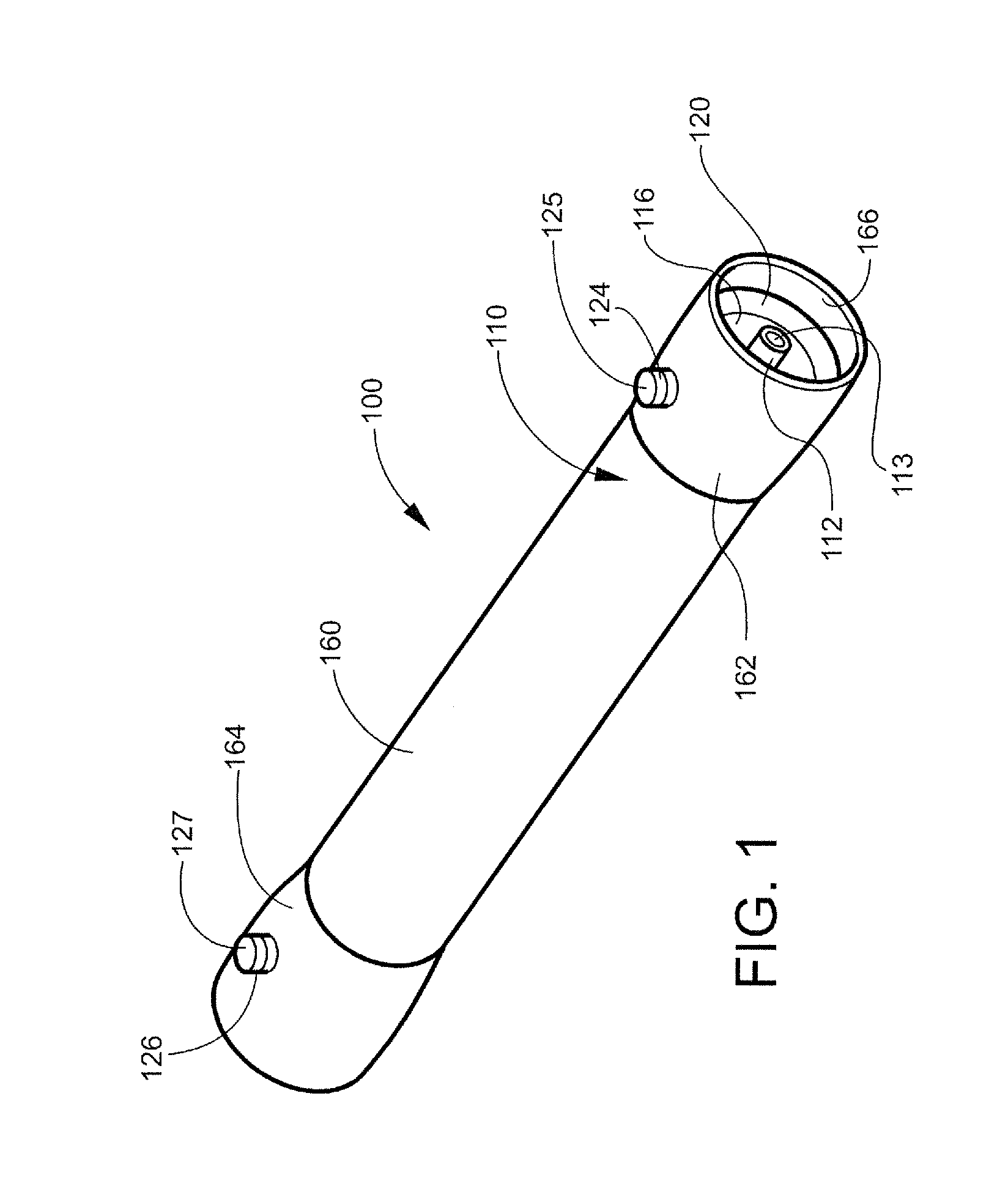

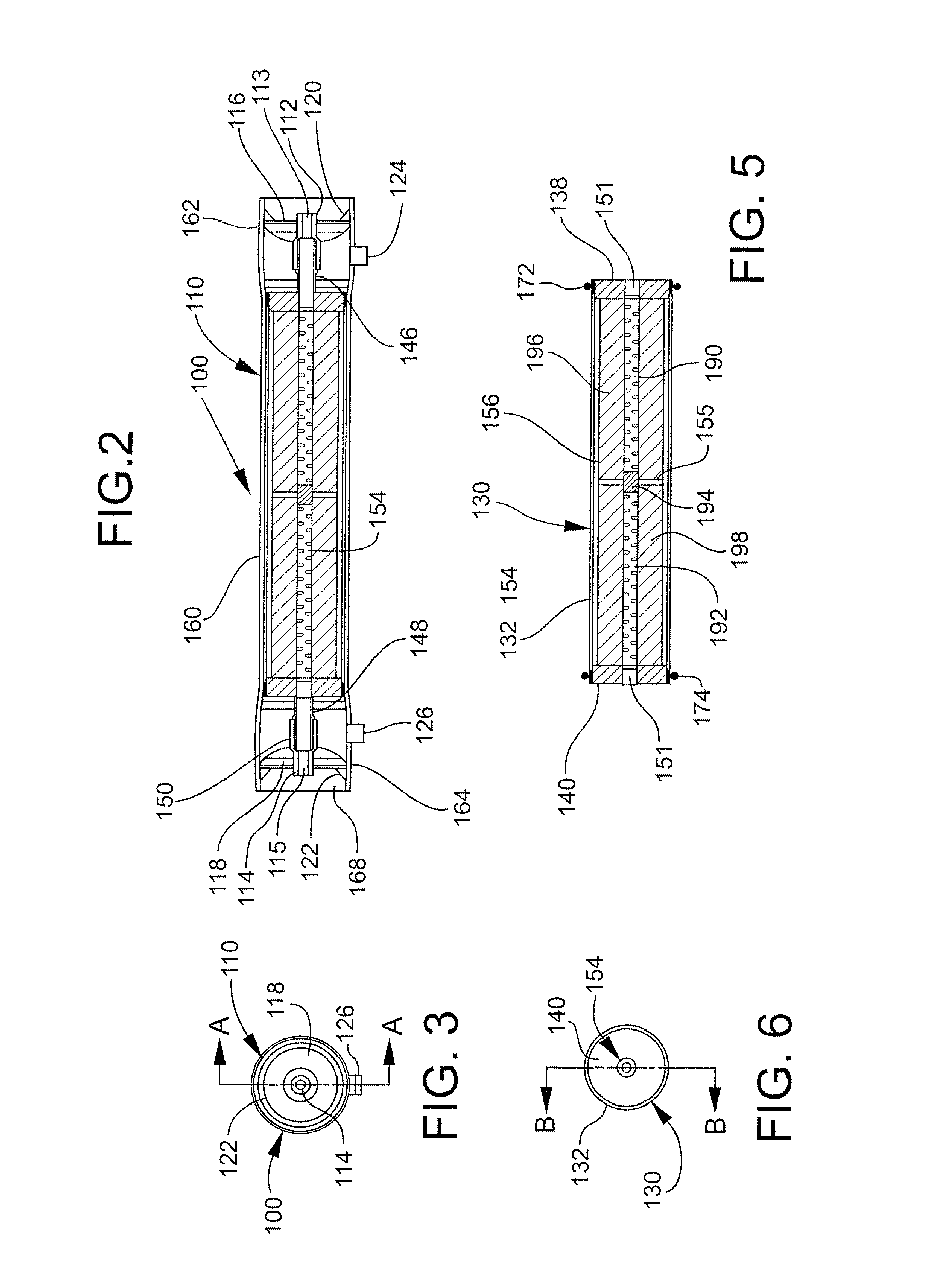

Liquid degassing membrane contactors, components, systems and related methods

ActiveUS8449659B2Emission reductionImprove efficiencyMembranesSemi-permeable membranesEngineeringBiomedical engineering

The present invention is directed to contactors, modules, components, systems, and / or methods of manufacture, and / or methods of use including degassing liquids. The contactor or module is integrally potted, has planar, disc shaped end caps, and a cylindrical housing or shell receiving and supporting a membrane structure. Each of the planar disc shaped end caps has a central opening therein adapted to receive a liquid end port or nozzle and is held in place in the housing or shell by at least one retaining element. The integrally potted membrane structure is preferably potted in place in the housing or shell by an inverted potting process involving the use of a removable plunger or plug to recess the potting.

Owner:3M INNOVATIVE PROPERTIES CO

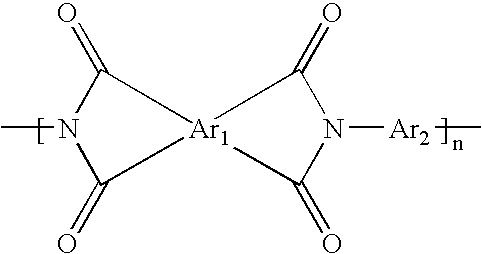

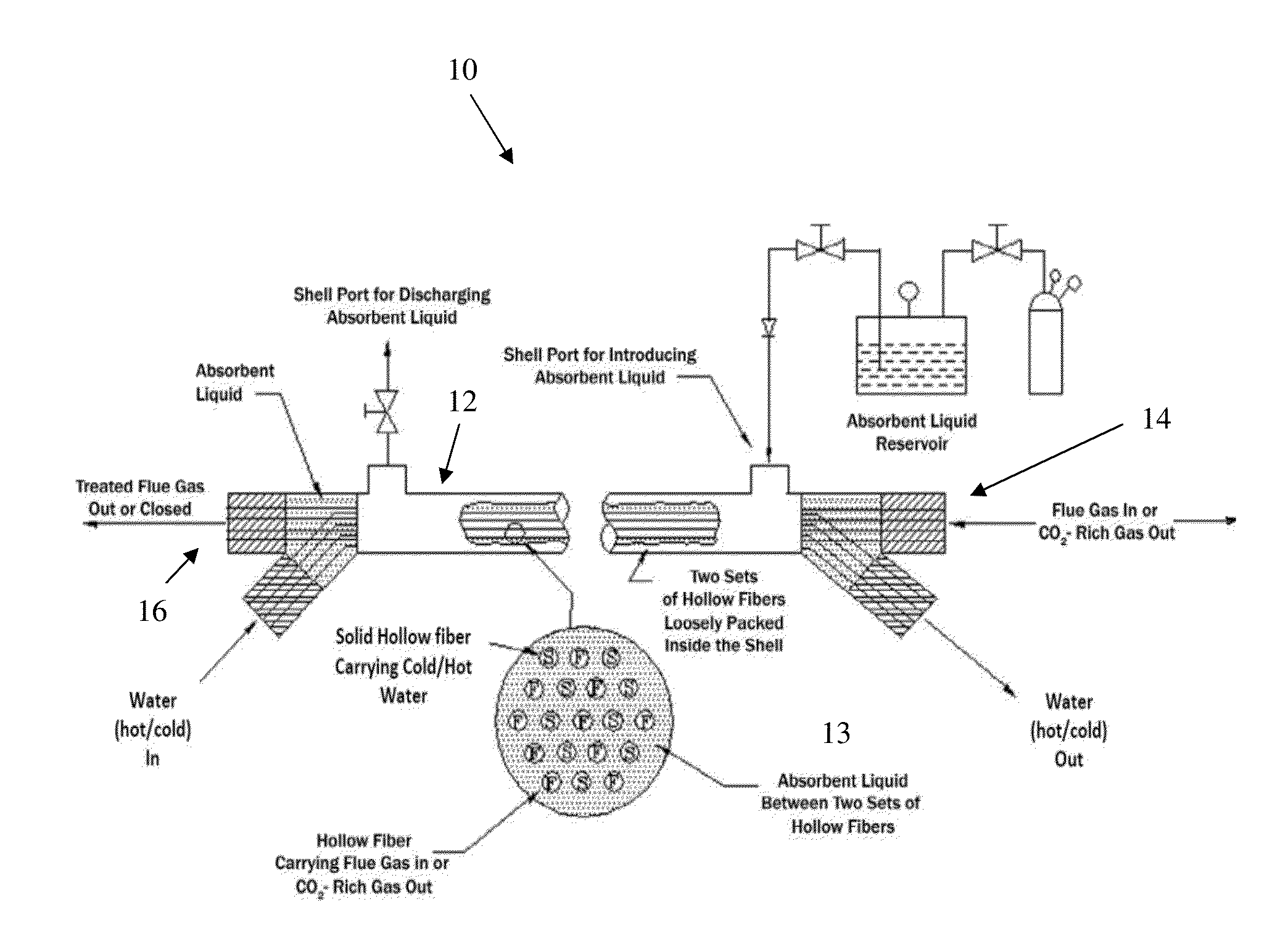

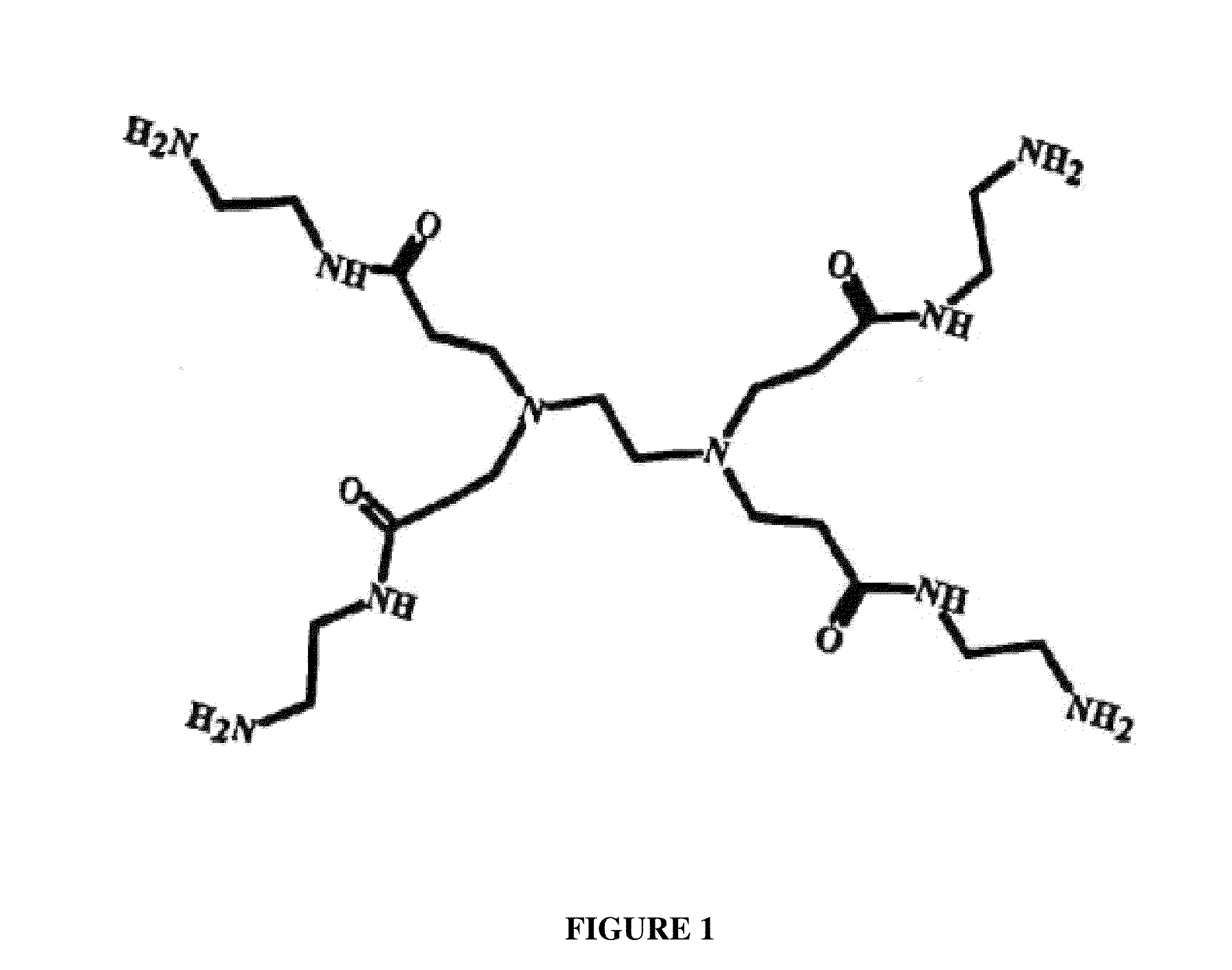

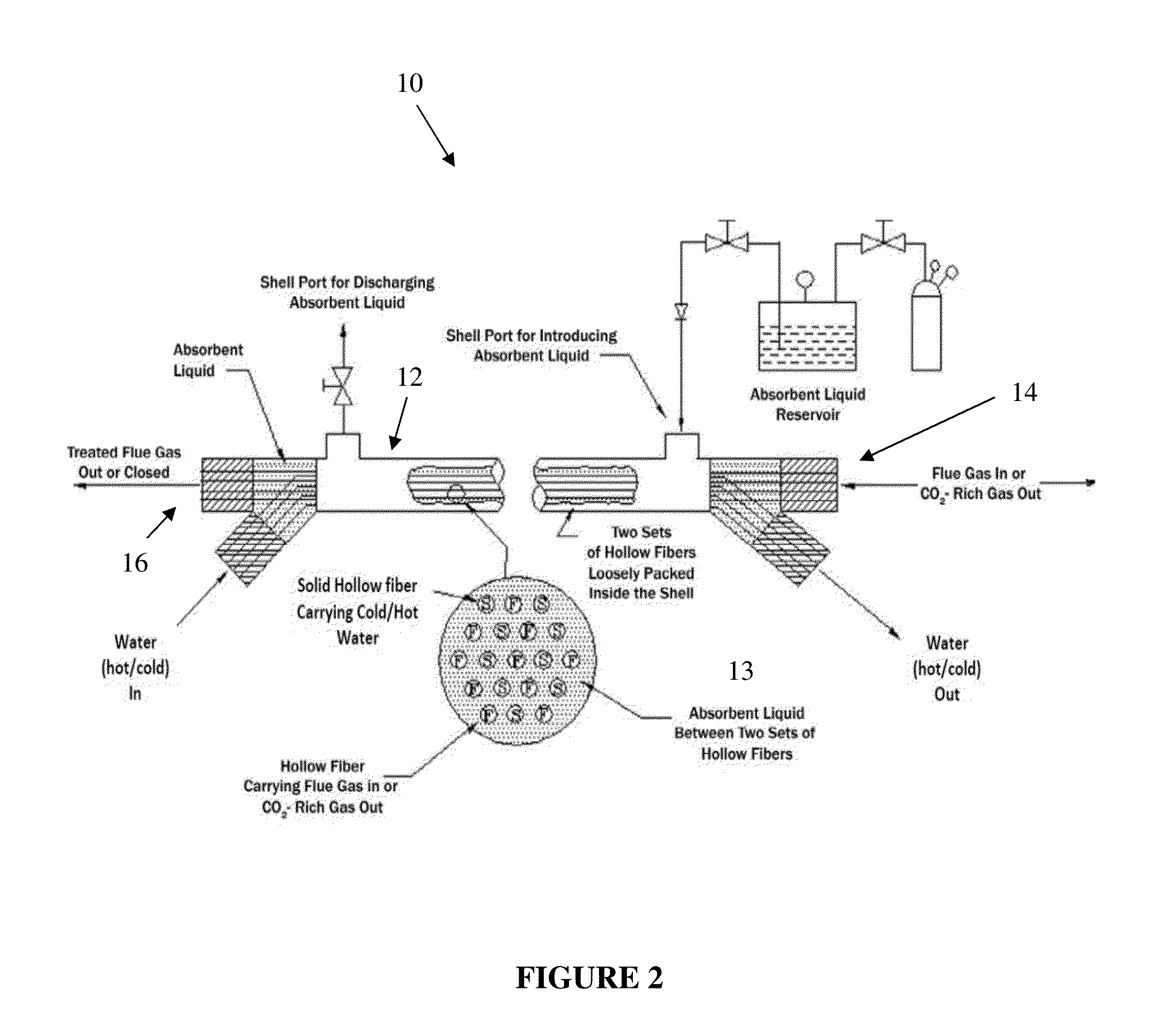

Systems and Methods for CO2 Removal From Flue Gas By Temperature Swing Absorption

The present disclosure provides improved systems, assemblies and methods to remove and recover CO2 from emissions. More particularly, the present disclosure provides improved membrane contactors configured to remove CO2 from flue gas by temperature swing absorption. In exemplary embodiments, the present disclosure provides a novel hollow fiber membrane contactor that integrates absorption and stripping using a nonvolatile reactive absorbent (e.g., 80% polyamidoamine (PAMAM) dendrimer generation 0, and 20% of an ionic liquid (IL)). Equilibrium CO2 absorption in the nonvolatile viscous mixed absorbent is as high as 6.37 mmolCO2 / g absorbent in the presence of moisture at 50° C. A novel membrane contactor is provided for CO2 absorption and stripping via a process identified as temperature swing membrane absorption (TSMAB). The contactor integrates non-dispersive gas absorption and hot water-based CO2 stripping in one device / assembly containing two sets of commingled hollow fibers.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

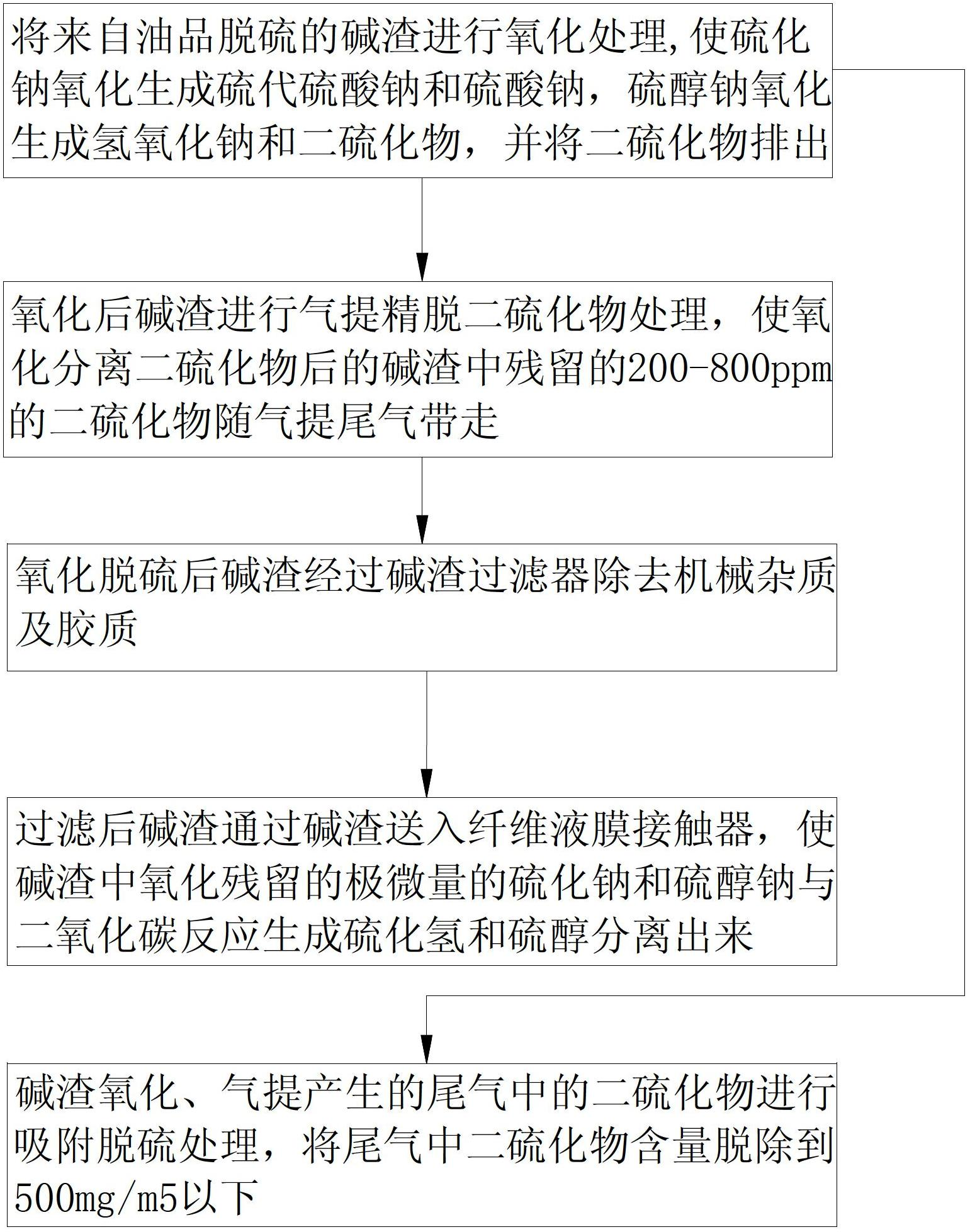

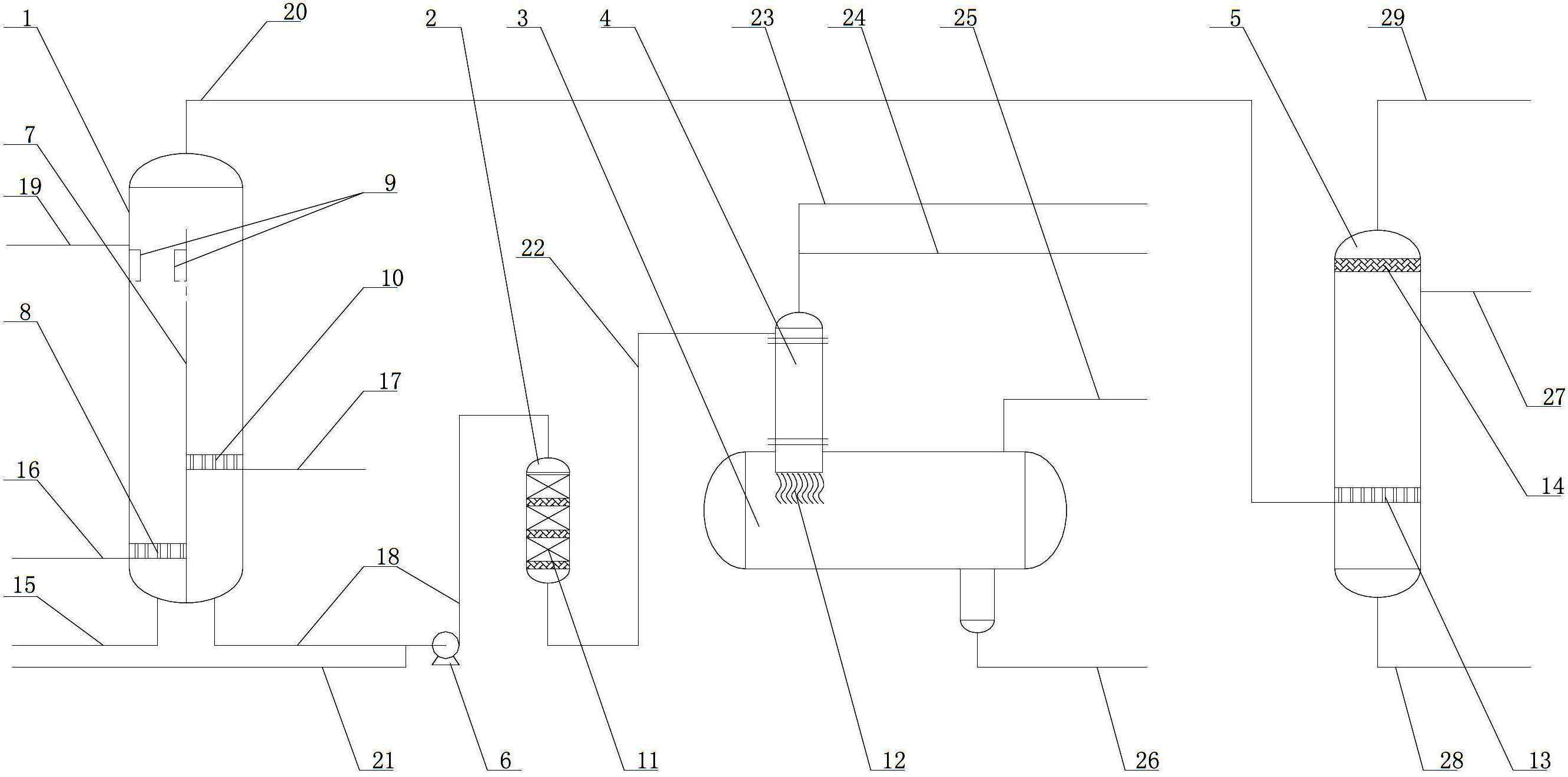

Combination method and device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing

The invention relates to a combination method and a device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing. The device comprises a caustic sludge oxidation desulfurization tower, a caustic sludge filter, a carbonization precipitation tank, a fiber liquid membrane contactor and a tail gas adsorption desulfurization tank, the top of the caustic sludge oxidation desulfurization tower is connected with a tail gas adsorption desulfurization tank through a tail gas discharging pipe one, the bottom of the caustic sludge oxidation desulfurization tower is connected with the caustic sludge filter through a caustic sludge discharging pipe, the caustic sludge filter is connected with the fiber liquid membrane contactor through a caustic sludge feeding pipe two, and the bottom of the fiber liquid membrane contactor is fixed on the carbonization precipitation tank through a flange; and the method includes subjecting the caustic sludge to oxidation treatment, air stripping fine taking off disulphide treatment and removing mechanical impurities ad colloids, separating hydrogen sulfide and mercaptan and adsorption desulfurization treatment successively. The combination method and the device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing have the advantages that disulphide of sodium sulphide and mercaptan sodium can be separated and recycled, and the tail gas after desulfuration can meet the relevant state standard requirements of direct discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

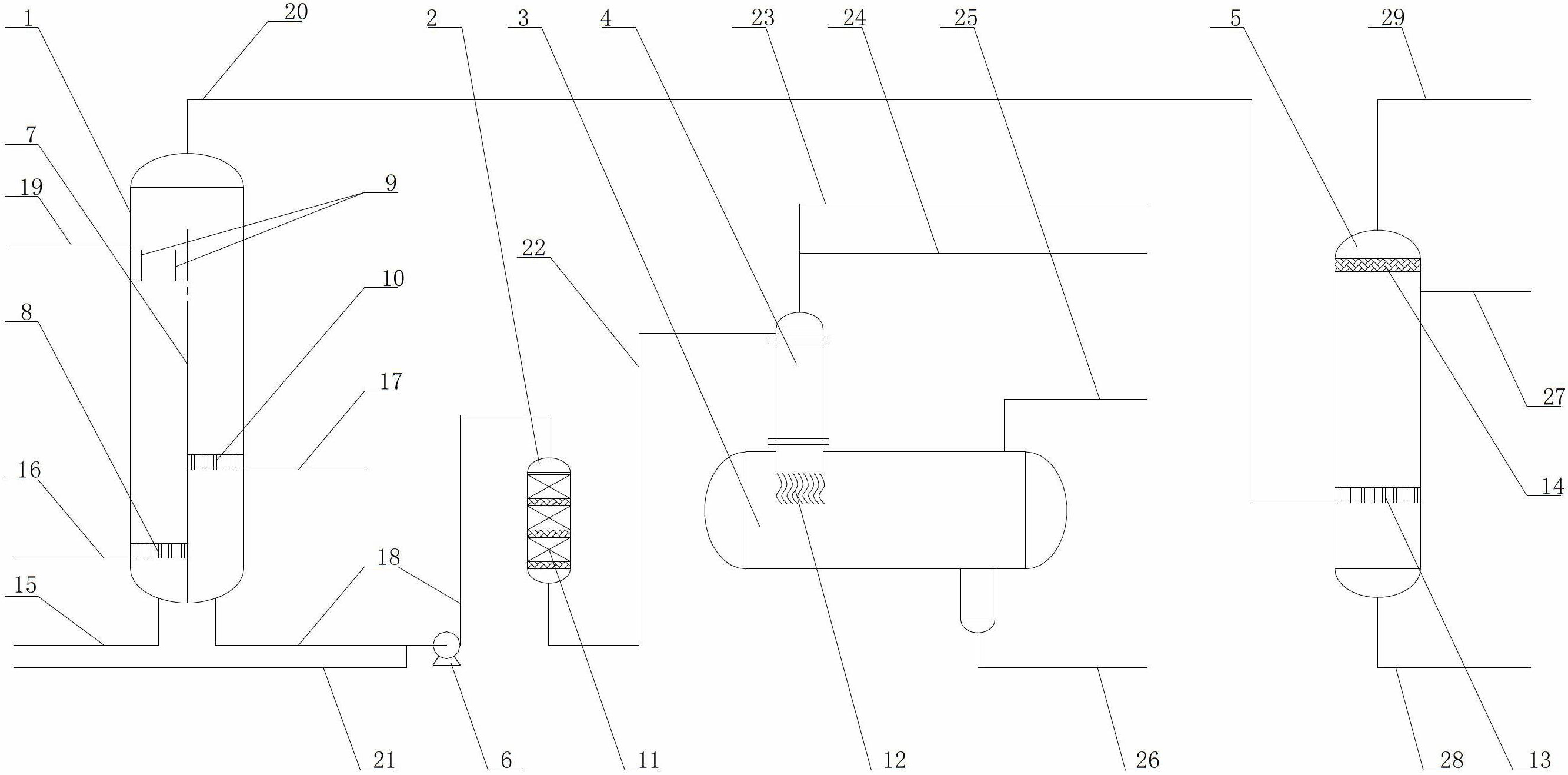

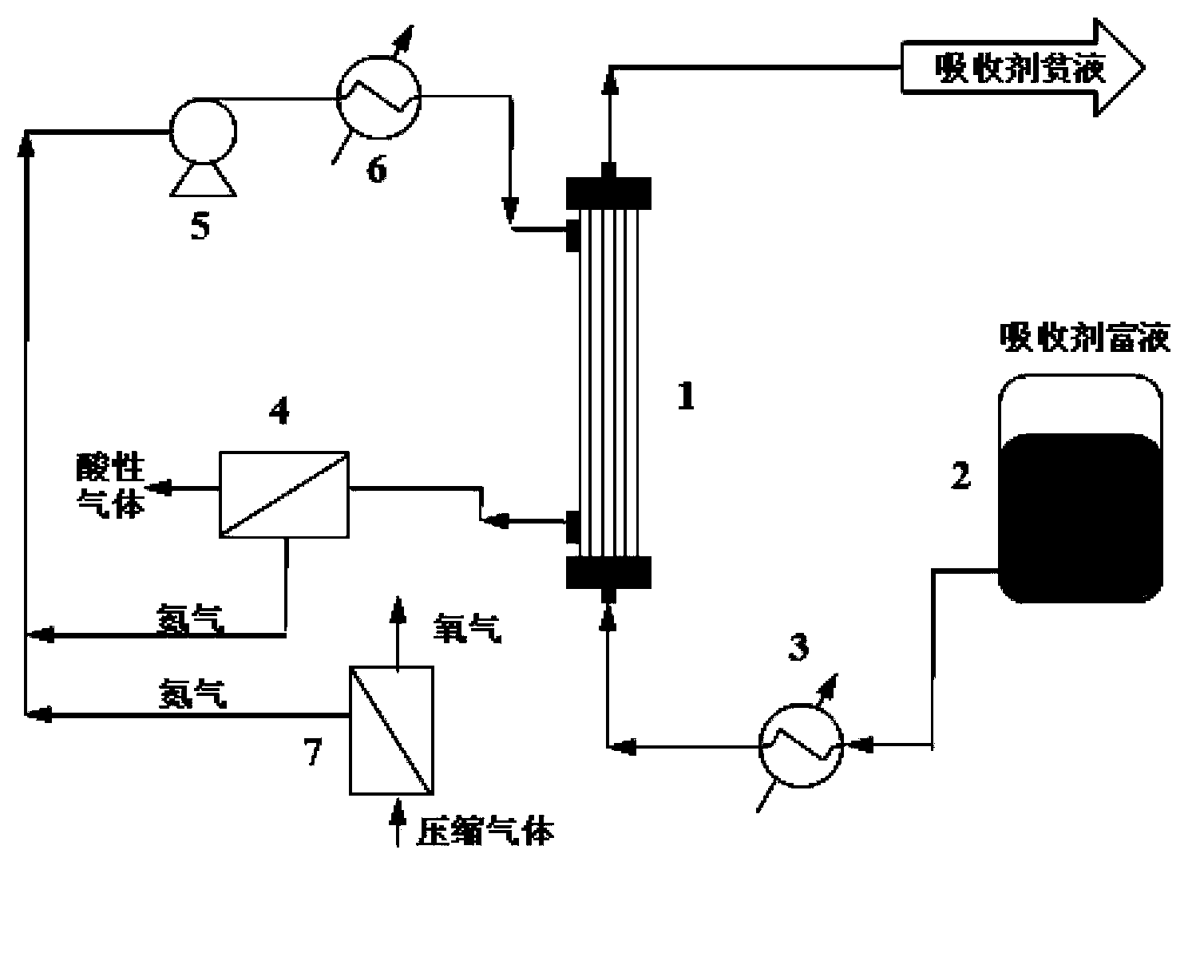

Absorption liquid regeneration method and special-purpose absorption liquid regeneration device

The invention discloses an absorption liquid regeneration method and a special-purpose absorption liquid regeneration device, the absorption liquid regeneration method comprises the following processes: an acidic-gas-containing absorption liquid is sent into a tube side or a shell side of a membrane contactor for desorption regeneration, nitrogen is used for purging of the tube side or the shell side of the membrane contactor; after the purging, the nitrogen contains an acidic gas, the nitrogen containing the acidic gas enters a membrane separation device using an acid gas separation membrane for acid gas separating, and the separated nitrogen is led into the tube side or the shell side of the membrane contactor, and is used for purging of the acid gas in the membrane contactor, so that the nitrogen can be recycled; in addition, the nitrogen is separated from a compression gas by using a membrane separation device with an oxygen and nitrogen separation membrane, and is used for supplement of nitrogen loss during operation process. According to the method, a membrane contactor is used for absorption liquid regeneration, the mass transfer area is improved, the absorption liquid regeneration temperature is reduced, and by recycling of purging nitrogen, the absorption liquid regeneration energy consumption is effectively reduced. The absorption liquid regeneration method has the advantages of being simple in equipment and easy to operate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

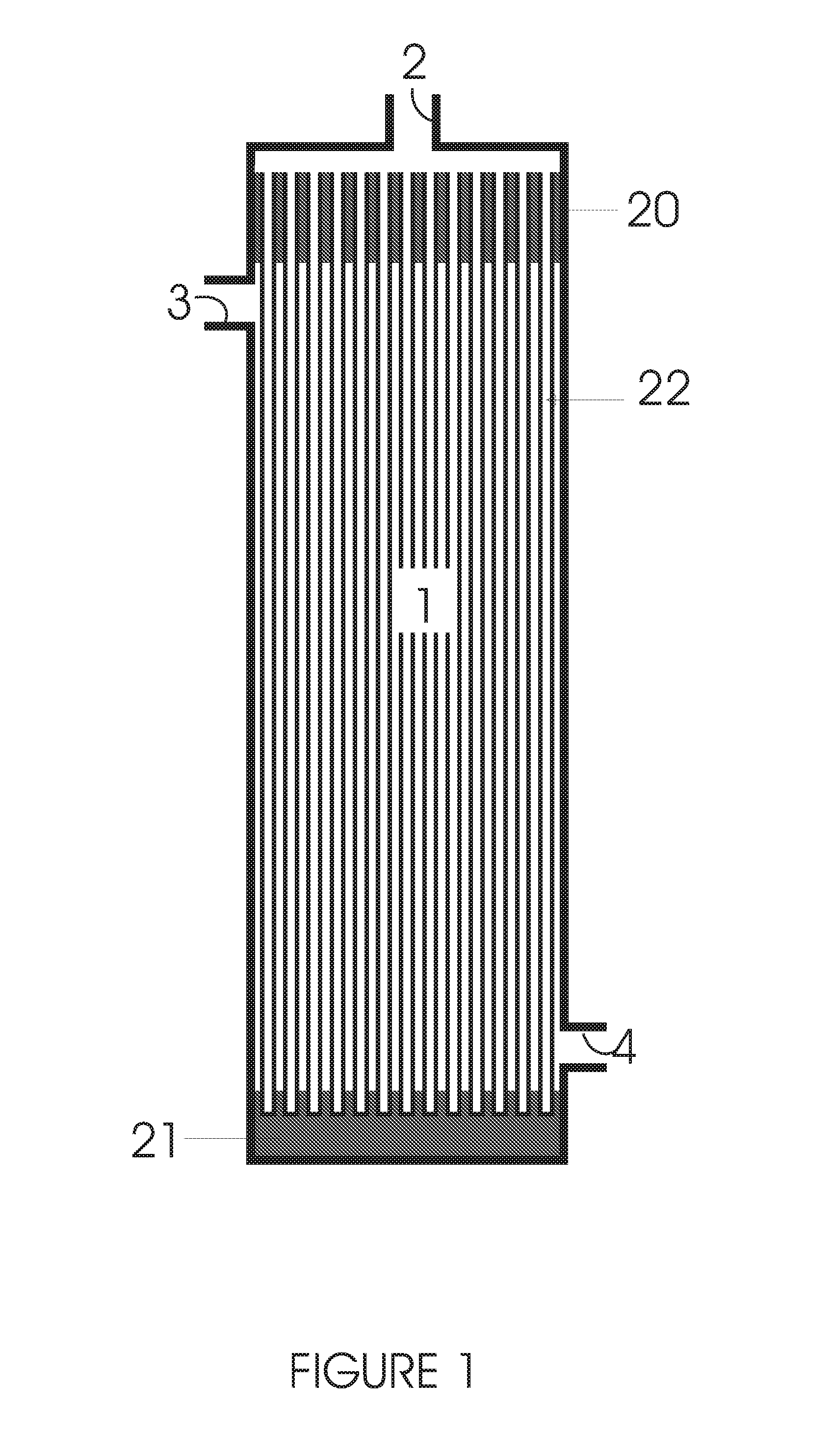

Hollow fiber membrane contactor, air dehumidification system and air humidification system for air humidity control

InactiveCN104190262AImprove heat transfer effectImprove efficiencySemi-permeable membranesLighting and heating apparatusThermodynamicsMechanical engineering

The invention provides a hollow fiber membrane contactor and a humidification / dehumidification system using the hollow fiber membrane contactor. Compared with the prior art, the membrane contactor comprises a membrane fiber tube of which the cross section takes the shape of an ellipse, the flowing direction of first fluid which flows in a shell is parallel to a short axis of the ellipse, mathematical calculation and data simulation show that by adopting the design, the nusselt number is greatly increased when air transversely sweeps the membrane fiber tube in the membrane contactor, although the average resistance coefficient is increased to certain extent, comprehensive heat conduction factors are greatly improved, the heat exchange capability of the membrane contactor is greatly improved under the condition of identical membrane contact areas, and the steam conduction efficiency can be greatly improved under the condition of membranes of equal areas in the humidification / dehumidification system, so that the efficiency of the humidification / dehumidification system is improved.

Owner:DONGGUAN UNIV OF TECH

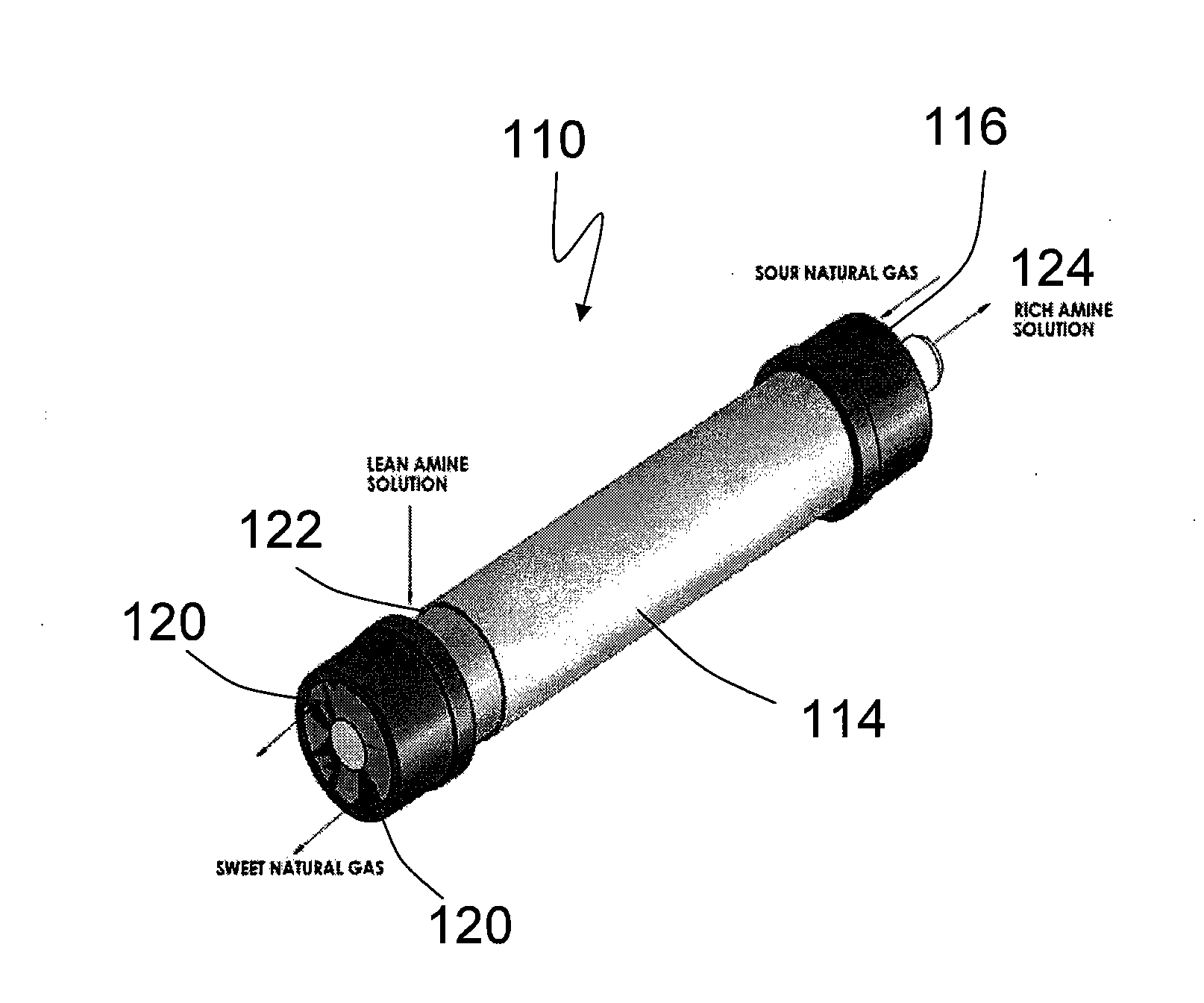

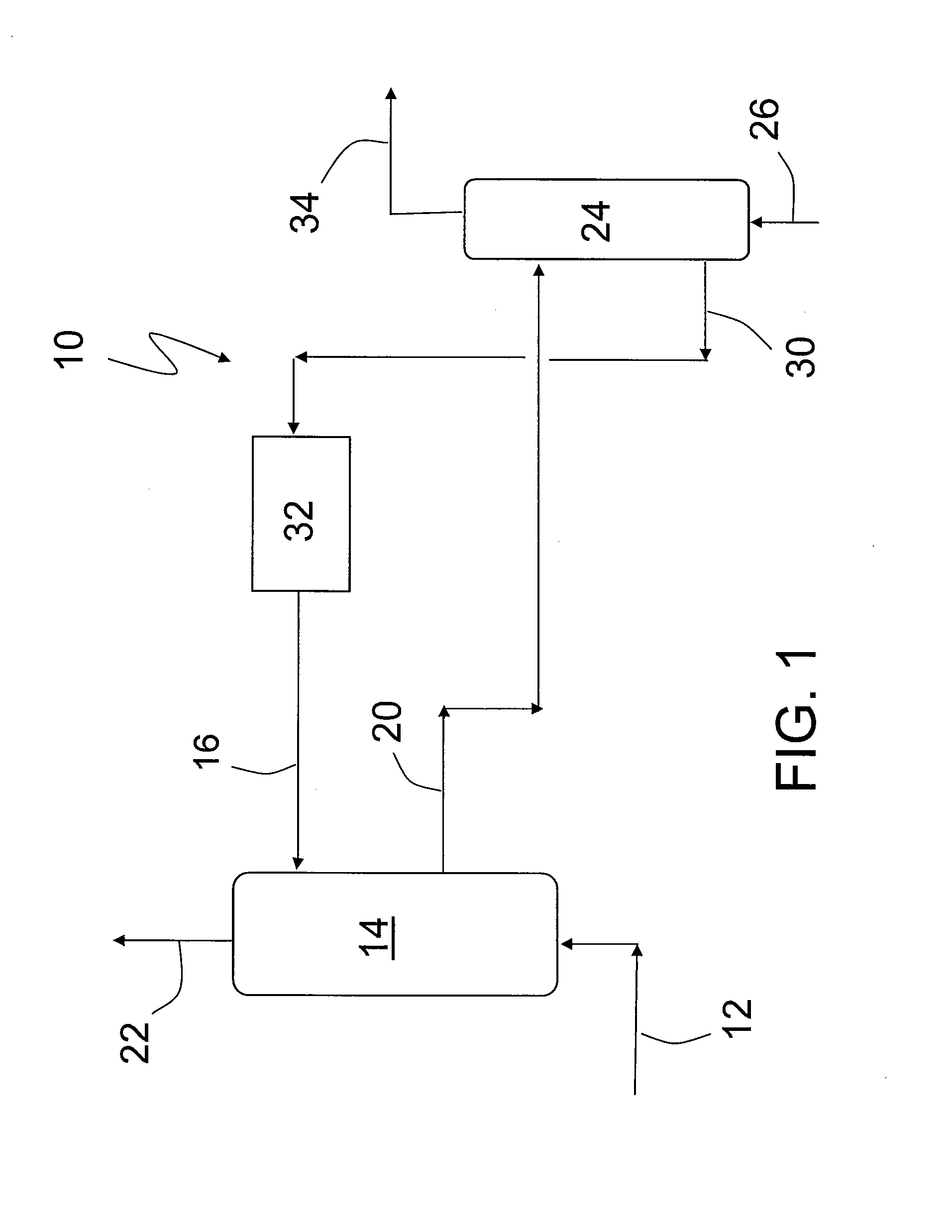

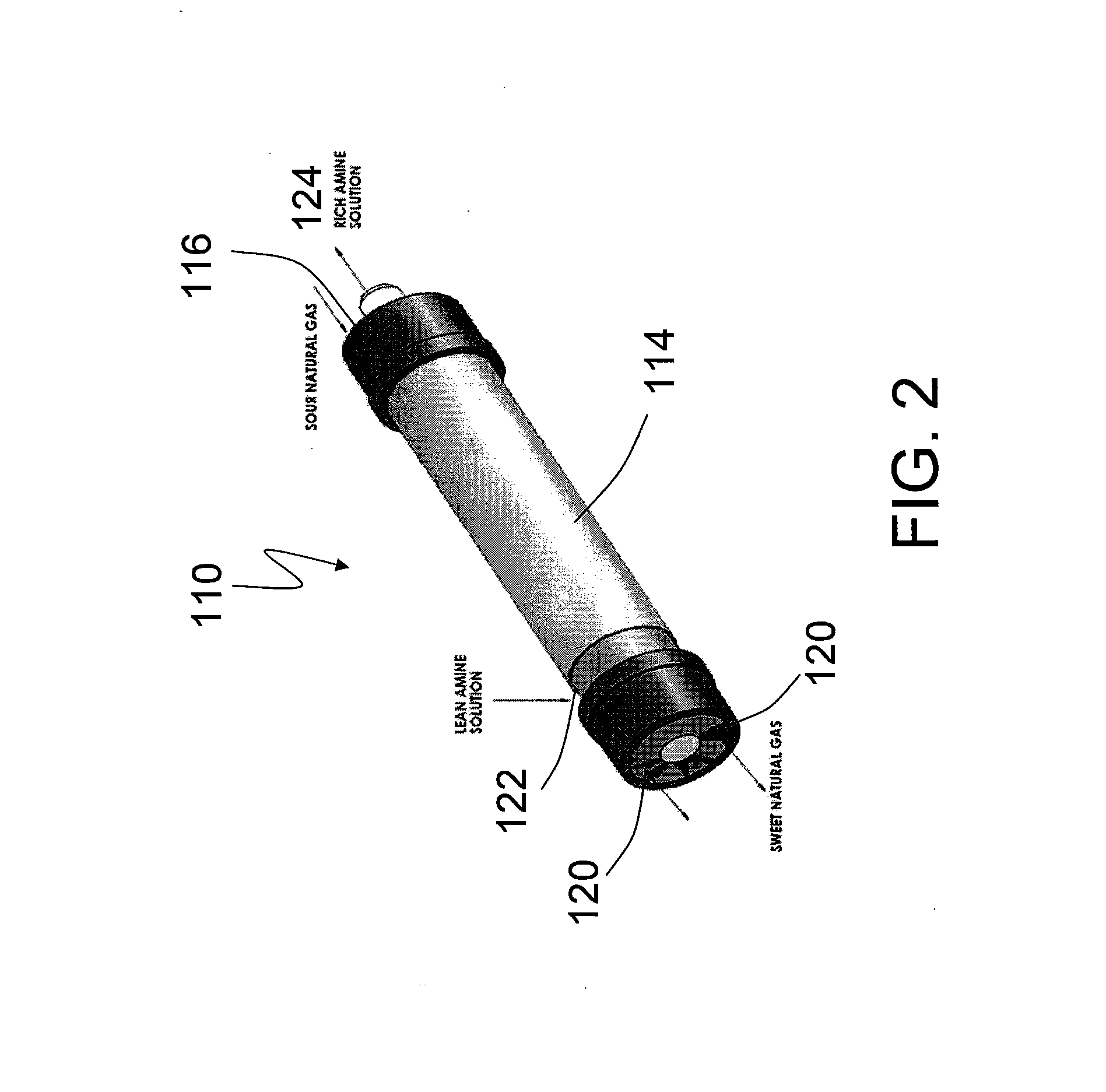

Sweetening of natural gas

An exemplary embodiment can be a process for sweetening natural gas to liquefied natural gas specifications. The process can include providing a membrane contactor having a lumen side and a shell side. A feed natural gas is introduced to the lumen side of the membrane contactor. An absorption solvent is introduced to the shell side of the membrane contactor. CO2 and H2S are removed with the absorption solvent from the feed natural gas resulting in a sweetened natural gas containing less than 50 ppmv CO2 and less than 4 ppmv H2S. Corresponding or associated systems for such sweetening of natural gas are also provided.

Owner:GAS TECH INST

Skinned hollow fiber membrane and method of manufacture

InactiveUS6921482B1Not prevent solvent evaporationPrevents formation of skinSemi-permeable membranesMembranesFiberHollow fibre membrane

Hollow fiber membranes having a skinned surface on one diameter, and a porous surface on the opposite diameter arm produced from perfluorinated thermoplastic polymers by extruding a heated solution of the polymer having a lower critical solution temperature directly into a cooling bath to form the porous membrane by liquid-liquid phase separation. Extrusion can be conducted either vertically or horizontally. The hollow fiber membranes are useful as ultrafiltration membranes and as membrane contactors.

Owner:ENTEGRIS INC +1

Liquid degassing membrane contactors, components, systems and related methods

ActiveUS20120247337A1Emission reductionImprove efficiencyMembranesSemi-permeable membranesBiomedical engineeringMembrane contactor

The present invention is directed to contactors, modules, components, systems, and / or methods of manufacture, and / or methods of use including degassing liquids. The contactor or module is integrally potted, has planar, disc shaped end caps, and a cylindrical housing or shell receiving and supporting a membrane structure. Each of the planar disc shaped end caps has a central opening therein adapted to receive a liquid end port or nozzle and is held in place in the housing or shell by at least one retaining element. The integrally potted membrane structure is preferably potted in place in the housing or shell by an inverted potting process involving the use of a removable plunger or plug to recess the potting.

Owner:3M INNOVATIVE PROPERTIES CO

Membrane contactor apparatus including a module having hollow fiber membranes

Owner:GEOSCI SUPPORT SERVICES

Non-dispersive process for insoluble oil recovery from aqueous slurries

ActiveUS8486267B2Easy to practiceComplete separation of the immiscible liquids is extremelyFatty oils/acids recovery from wasteFatty acid chemical modificationRecovery methodBiodiesel

The development and application of a novel non-polar oil recovery process utilizing a non-dispersive solvent extraction method to coalesce and recover oil from a bio-cellular aqueous slurry is described herein. The process could apply to recovery of algal oil from a lysed algae slurry, recovery of Omega fatty acids from a bio-cellular aqueous feed, recovery of Beta-carotene from a bio-cellular aqueous feed and for the removal from produced water in oil production and similar type applications. The technique of the present invention utilizes a microporous hollow fiber (MHF) membrane contactor. The novel non-polar oil recovery process described herein can be coupled to a collecting fluid (a non-polar solvent such as heptane, a biodiesel mixture or the previously extracted oil) that is circulated through the hollow fiber membrane. In cases where the biodiesel mixture or the previously extracted oil is used the solvent recovery step (e.g. distillation) can be eliminated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

High pressure liquid degassing membrane contactors and methods of manufacturing and use

ActiveUS20120137879A1Fast displacementCost-effectiveMembranesSemi-permeable membranesEpoxyGlass fiber

In accordance with at least selected embodiments of the present invention, an improved liquid degassing membrane contactor or module includes a high pressure housing and at least one degassing cartridge therein. It may be preferred that the high pressure housing is a standard, ASME certified, reverse osmosis (RO) or water purification pressure housing or vessel (made of, for example, polypropylene, polycarbonate, stainless steel, corrosion resistant filament wound fiberglass reinforced epoxy tubing, with pressure ratings of for example, 150, 250, 300, 400, or 600 psi, and with, for example 4 or 6 ports, and an end cap at each end) and that the degassing cartridge is a self-contained, hollow-fiber membrane cartridge adapted to fit in the RO high pressure housing.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of unilateral super-hydrophobic polyethersulfone membrane

InactiveCN106731904AAchieve superhydrophobicityNo breathability impactSemi-permeable membranesMembranesVacuum pumpingSilanes

The invention discloses a preparation method of a unilateral super-hydrophobic polyethersulfone membrane. The method comprises the following steps: dissolving polyethersulfone into a solvent; preparing a polyethersulfone membrane through a dry-wet method; preparing silicon dioxide sol gel through a sol-gel method; modifying the silicon dioxide sol gel by utilizing fluorine-containing silane to prepare fluorinated silicon dioxide sol gel filtrate; depositing fluorinated silicon dioxide sol gel to one side of the polyethersulfone membrane by adopting a vacuum pumping filtration method, so as to obtain the polyethersulfone membrane with a unilateral super-hydrophobic property. The method disclosed by the invention is mainly used for the field of separation of membranes with the unilateral super-hydrophobic property, and can be used for preparing nano materials of membrane-absorption, membrane-analysis and gas-liquid membrane contactor methods. The method is simple and easy to operate; the prepared membrane has a good membrane hydrophobic property and the preparation cost is greatly reduced.

Owner:TANGSHAN COLLEGE

Continuously-super-hydrophobic hollow fiber membrane and preparation method thereof

ActiveCN103831018AImprove hydrophobicityHydrophobic persistenceSemi-permeable membranesPolymer scienceEmulsion

The invention discloses a continuously-super-hydrophobic hollow fiber membrane and a preparation method thereof. The hollow fiber membrane and the preparation method are characterized in that: the hollow fiber membrane is prepared by a coating-sintering method; and the preparation method includes 1) a step of preparing hollow braided tube, namely, a step of weaving fiber twisted with filaments by utilization of a two-dimensional weaving technology to obtain a hollow braided tube substrate; 2) a step of preparing a coating liquid, namely, a step of uniformly mixing an aqueous solution of fibre-forming polymer with low decomposition temperature and a concentrated dispersive emulsion of fluorine-containing polymer to obtain the coating liquid, wherein the aqueous solution of fibre-forming polymer is adopted as a membrane forming carrier and the concentrated dispersive emulsion is adopted as dispersoid; 3) a step of preparing a primary hollow fiber membrane, namely a step of uniformly coating the external surface of the hollow braided tube with the coating liquid by adoption of a skin / core composite spinning technology to obtain the primary hollow fiber membrane; and 4) a step of sintering, namely, a step of sintering the primary hollow fiber membrane at 200-300 DEG C for 1-2 min to obtain the hollow fiber membrane. The hollow fiber membrane is high in strength and good in porous performance. The continuous super-hydrophobic property of the hollow fiber membrane is particularly suitable for processes of membrane contactors, such as membrane distillation and membrane absorption.

Owner:江苏膜芮环保科技有限公司

Membrane contactor

A membrane contactor includes a housing, a stack of membrane mats, and a cap. The housing has a closed end and an open end. The closed end includes an outlet port. The cap is united to the open end and includes an inlet port. A stack of membrane mats is within the housing stacked substantially perpendicular to the longitudinal axis of the housing. Each membrane mat has a plurality of hollow fiber members. A potting material bonds the membrane mats to each other and simultaneously bonds one end of the stack to the closed end and bonds the other end of the stack to the cap. The potting material forms an internal chamber and at least one external chamber within the housing. The hollow fiber members extend through the potting material from the internal chamber into the external chambers. The inlet port and the outlet port are in communication with the internal chamber. At least one side port is in communication with the external chambers.

Owner:3M INNOVATIVE PROPERTIES CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com