Absorption liquid regeneration method and special-purpose absorption liquid regeneration device

A liquid absorption and desorption technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

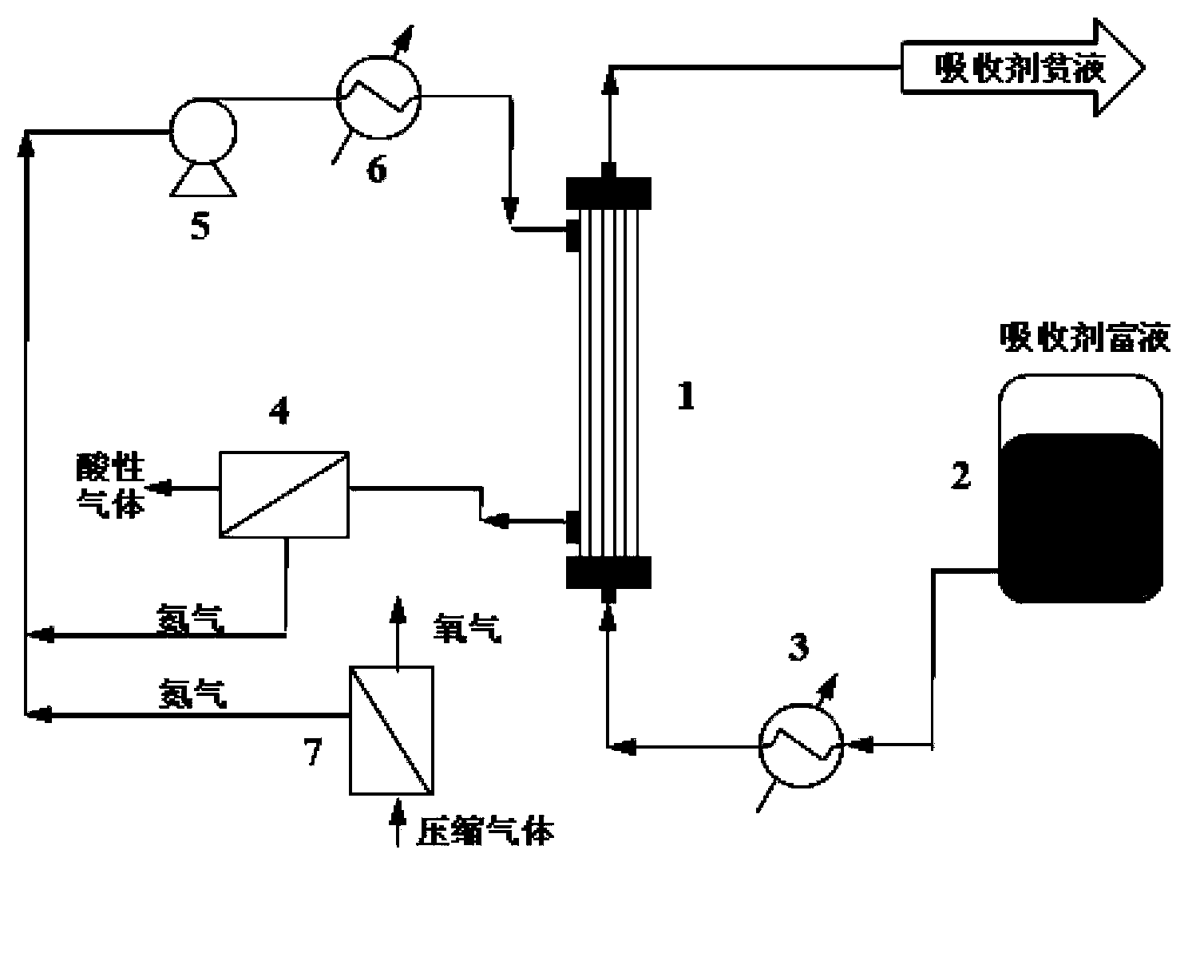

Image

Examples

Embodiment 1

[0026] The MDEA solution coming out of the membrane contactor contains CO 2 The concentration of the gas is 3.3wt%, the flow rate is 250L / h, the pressure is 6.0MPa, the temperature is 40°C, and after heating to 70°C, it enters the tube side of the membrane contactor for regeneration from bottom to top; the flow rate is 500m 3 / h purge nitrogen, the concentration is lower than 0.08%, pressurized to 6.0MPa, enters the heater to heat to 90 ℃, and then enters the shell side of the membrane contactor from top to bottom to contact with the rich liquid of MDEA absorbent in reverse, MDEA absorbent The rich liquid releases acid gas under the thermal effect, which is carried out from the shell side by the purge gas, and the concentration of acid gas in the MDEA absorbent at the outlet of the membrane contactor is reduced to 0.18wt%.

[0027] After the sweep gas comes out of the membrane contactor, it contains CO 2 gas, at a concentration of 1%, into CO 2 Separation membrane for CO 2 ...

Embodiment 2

[0029] The DEA solution from the absorption tower contains CO 2 The concentration of the gas is 2.6wt%, the flow rate is 100L / h, the pressure is 0.15MPa, the temperature is 45°C, and after heating to 100°C, it enters the tube side of the membrane contactor for regeneration from bottom to top; the flow rate is 360m 3 / h purge nitrogen, the volume fraction is less than 0.09%, pressurized to 0.12MPa, enters the heater to heat to 100°C, and then enters the shell side of the membrane contactor from top to bottom to contact with the DEA absorbent rich liquid in reverse, and the DEA absorbs The agent-rich solution releases acid gas under the thermal effect, and is carried out from the shell side by the purge gas, and the concentration of acid gas in the DEA absorbent at the outlet of the membrane contactor is reduced to 0.5wt%.

[0030] After the sweep gas comes out of the membrane contactor, it contains CO 2 gas, at a concentration of 0.5%, into CO 2 Separation membrane for CO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com