Combination method and device of caustic sludge desulfuration and dephenolization neutralization and tail gas desulphurization processing

A combined method and combined device technology, which is applied in the fields of desulfurization of oil desulfurization alkali slag, neutralization and tail gas desulfurization, and dephenolization. It can solve the problems of equipment and pipeline corrosion, insufficient oxidation capacity, and inability to directly discharge, etc., and achieve the best results Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

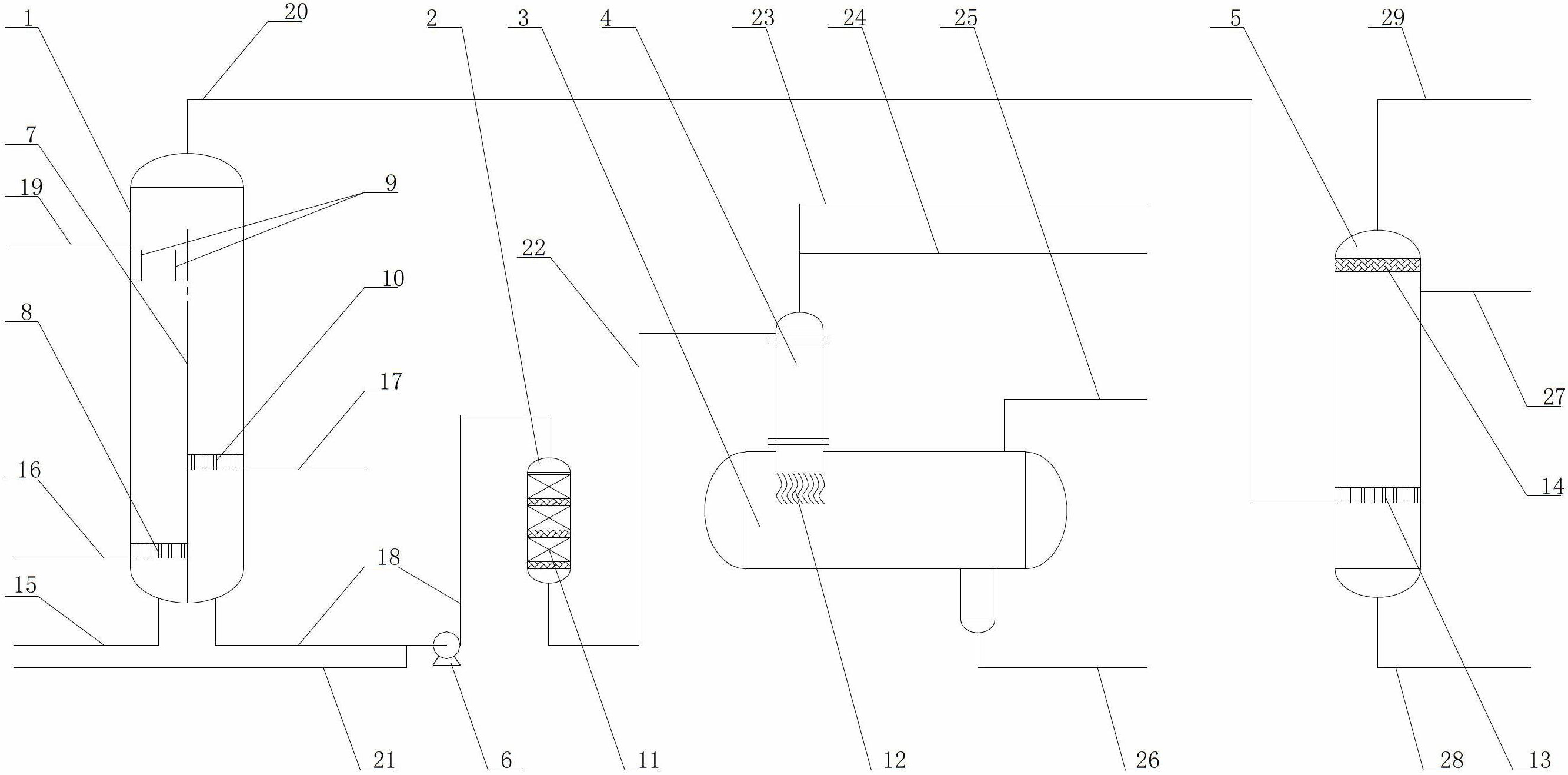

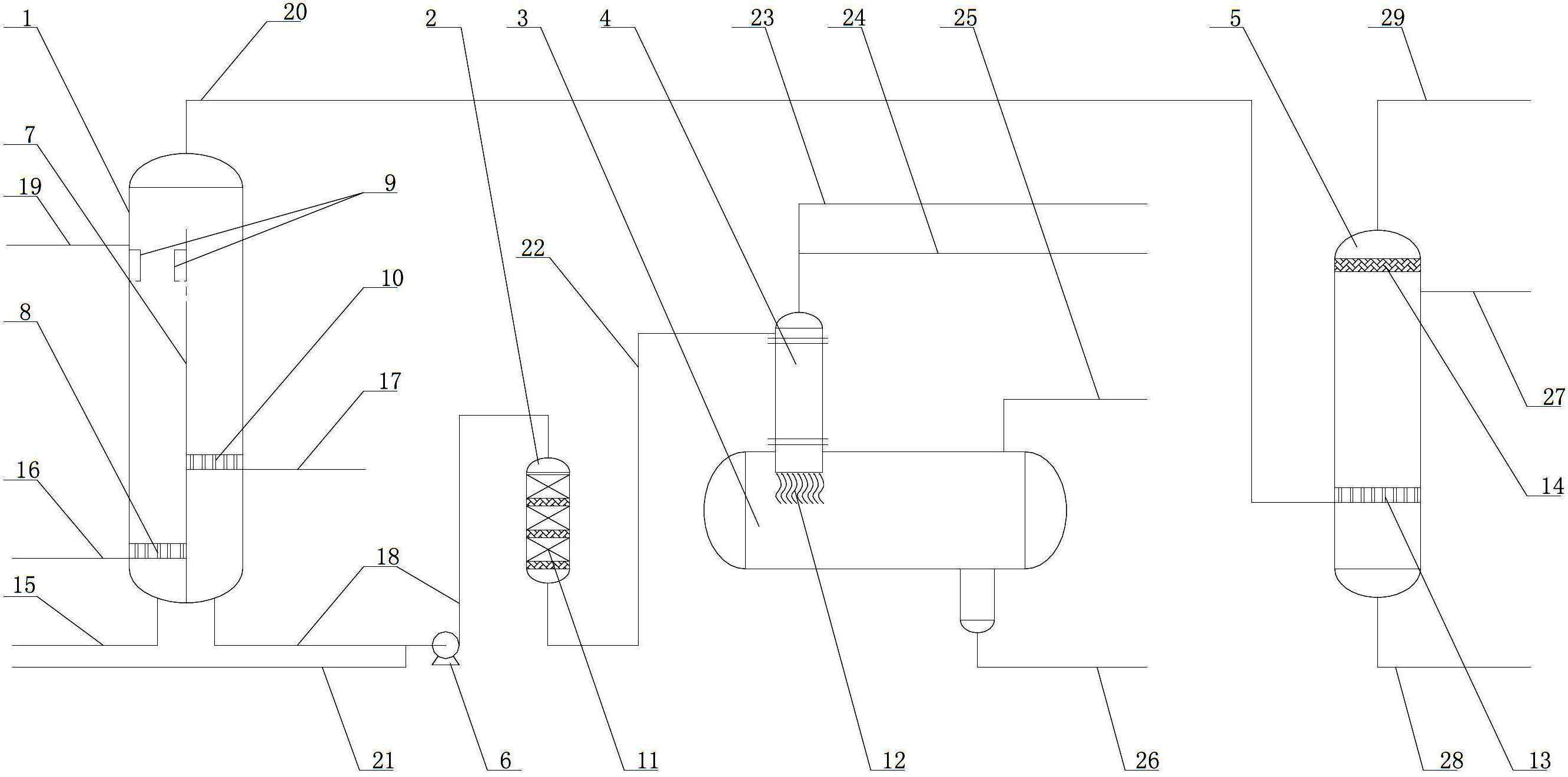

[0048] A Sinopec company adopts the combination method of the present invention to build a set of gasoline desulfurization pre-alkali washing alkali slag industrial device: alkali slag processing capacity: 400Kg / h; alkali slag composition: sodium hydroxide concentration 6-10%wt, sodium sulfide and Sodium mercaptide concentration 5-6.5%wt, sodium phenate content 3-5%wt, COD23-300,000 mg / L; main equipment specifications: alkali slag oxidation desulfurization tower Φ1400×9000, alkali slag filter Φ600×1200, fiber liquid Membrane contactor Φ400×4000, alkali slag carbonization separation tank Φ2000×7000, tail gas adsorption desulfurization tank Φ800×3100; process operation parameters: alkali slag preheating temperature 25-30 ℃, adding solid catalyst 1Kg per day, oxidation air flow 100-130Nm3 / h, fresh water flow rate 400-800Kg / h, gasoline flow rate 5000-8000Kg / h, carbon dioxide flow rate 25-40 Nm3 / h; device operation results: disulfide content in tail gas <200mg / m3 (calculated as dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com