Patents

Literature

42results about How to "Achieve superhydrophobicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

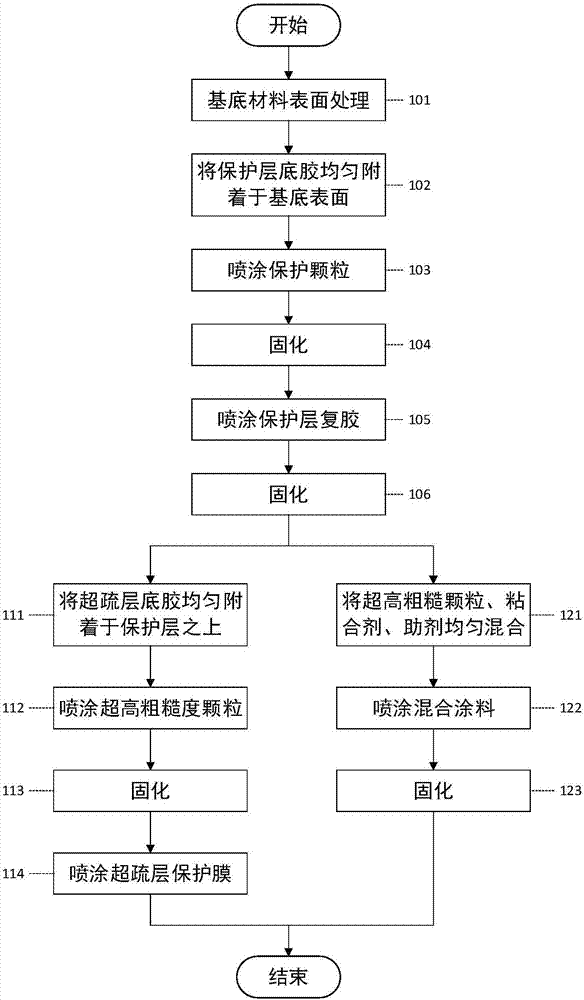

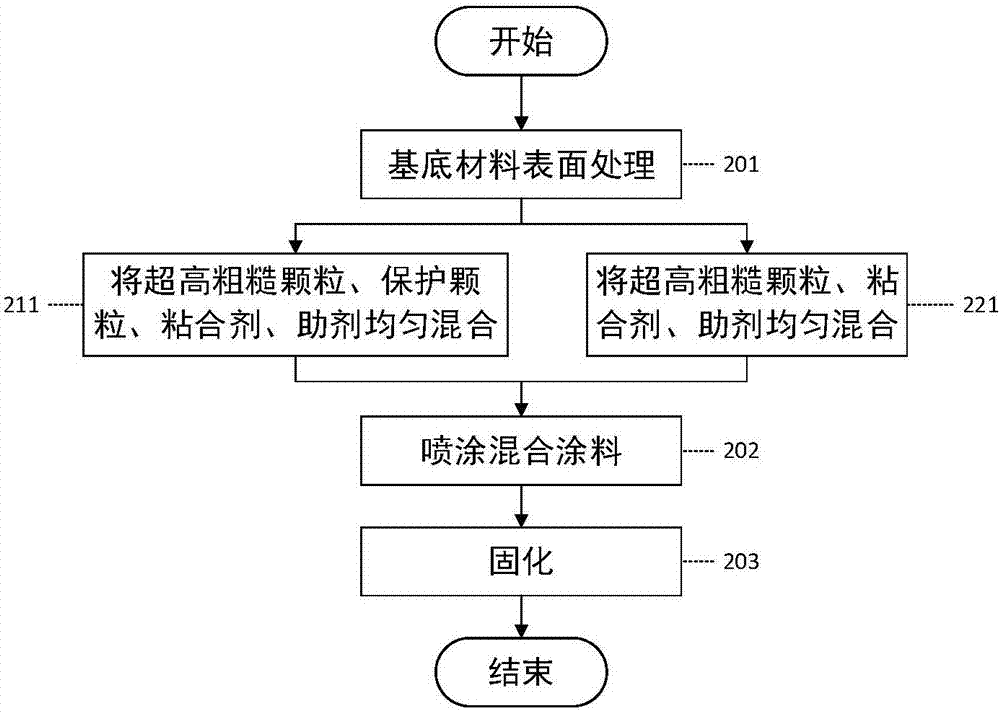

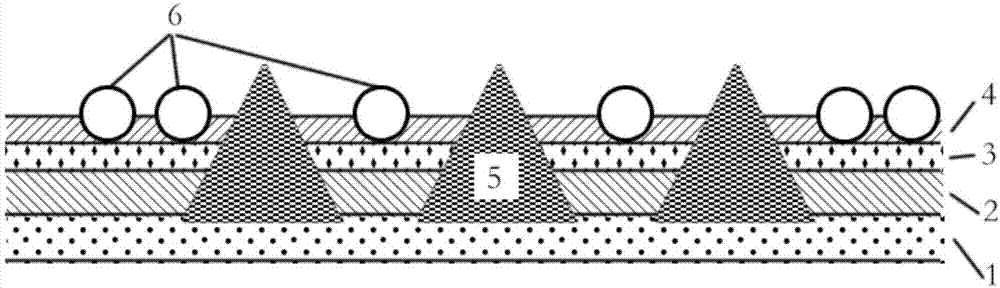

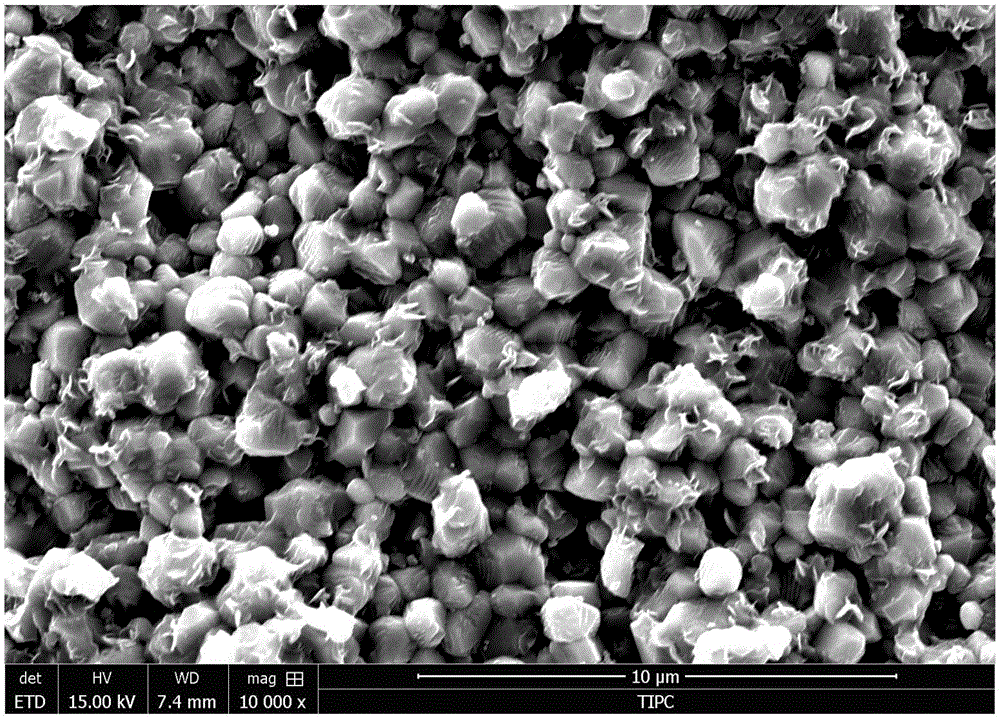

Coating prepared from particles with ultrahigh roughness

ActiveCN107254237AImprove performanceOvercome structurePretreated surfacesPolyurea/polyurethane coatingsSuperhydrophobic coatingLotus effect

The invention provides a superhydrophobic coating prepared from particles with ultrahigh roughness. The superhydrophobic coating is prepared from the following components: particles with protrusions or holes and unsmooth structures, protective particles, a bonding agent and an assistant, wherein the volume ratio of the particles with the protrusions or the holes and the unsmooth structures to the protective particles to the bonding agent is (0.1-7):(1-7):(1-10). A lotus effect technical theory is applied to obtain a super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic surface coating, further the performance of the coating is improved, and the defects of the conventional superhydrophobic coating that the structure is easy to damage, the service life is short and the like are overcome. The prepared coating has super hydrophobic properties (super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic properties), self-cleanness and excellent wear resistance; substrate materials suitable for the coating are glass, plastic, rubber, textiles, paper, metal, cement, ceramic materials or the materials covering other coatings.

Owner:HONGDA TECH BEIJING CO LTD

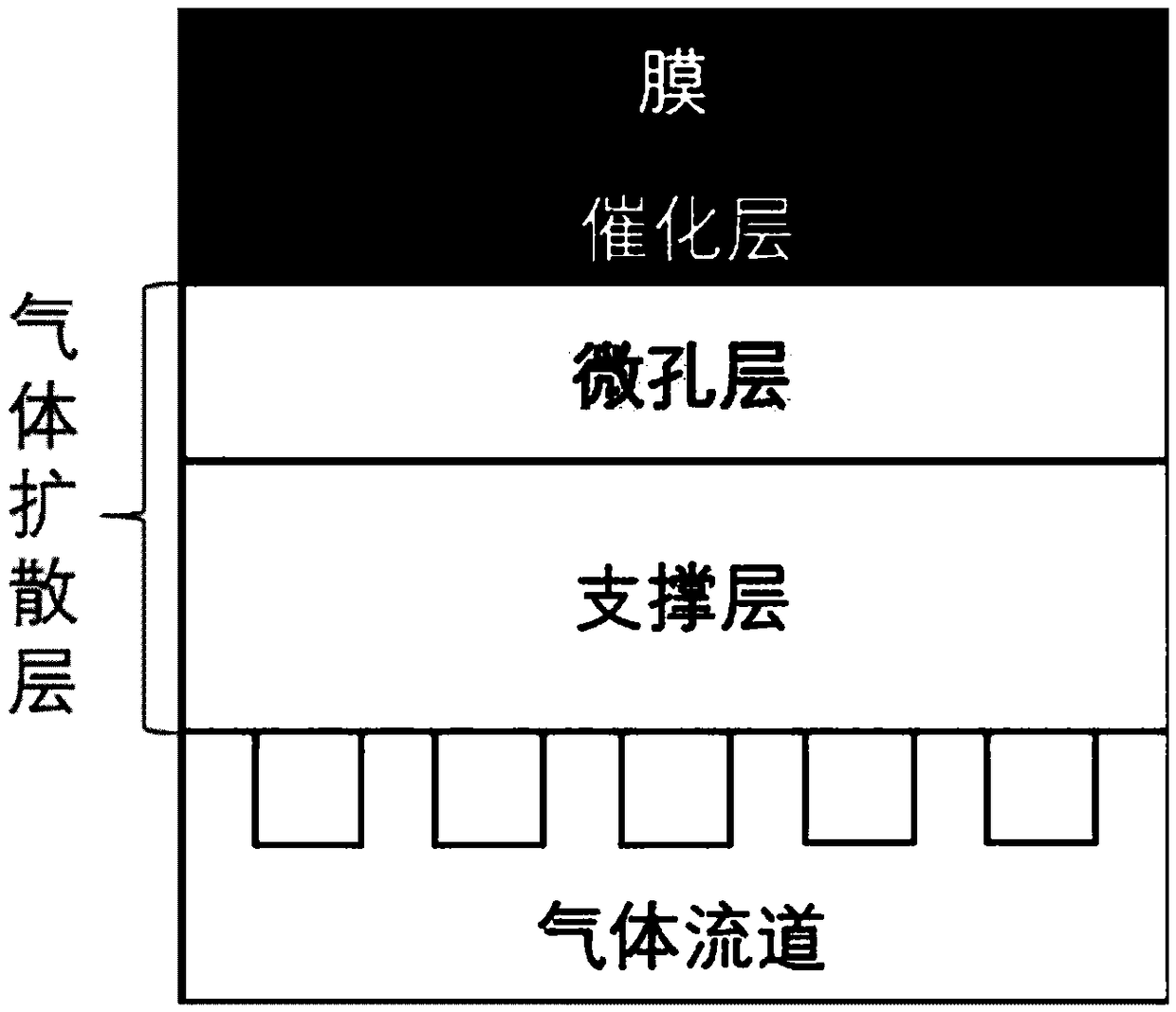

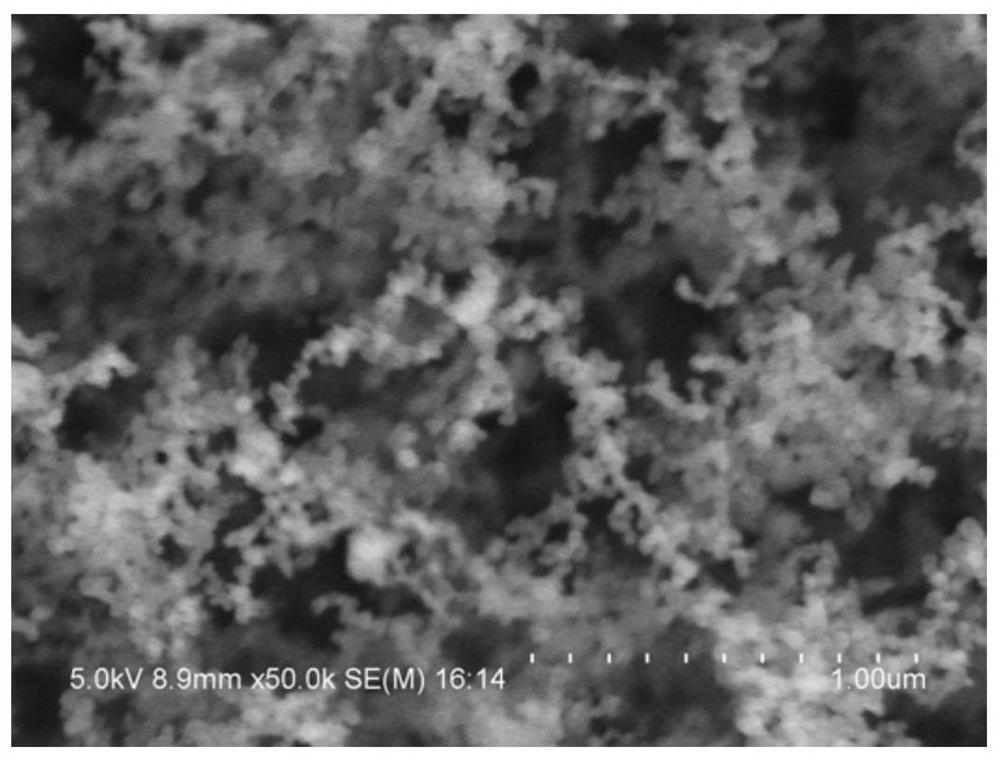

A microporous layer of a gas diffusion layer of a proton exchange membrane fuel cell and a preparation method thereof

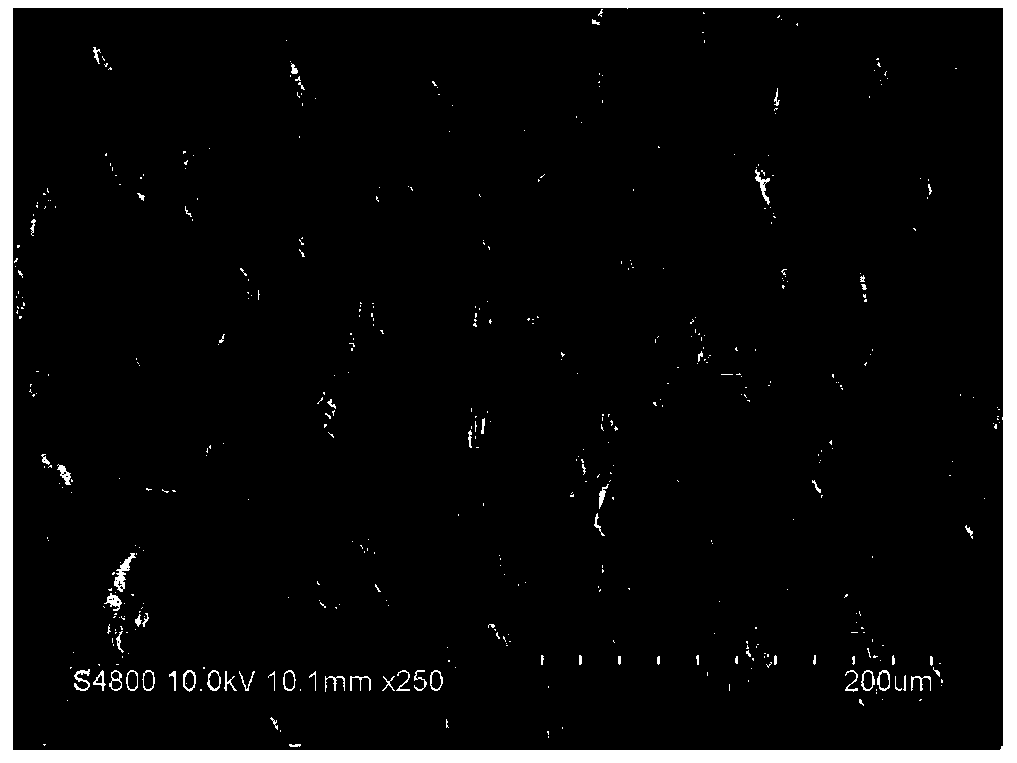

The invention relates to a proton exchange membrane fuel cell, in particular to a gas diffusion layer microporous layer of the proton exchange membrane fuel cell and a preparation method thereof. After hydrophobic treatment, the surface of the support layer is scraped or sprayed with organic solvent containing organic siloxane and carbon nanomaterials, and the micro-porous layer of the gas diffusion layer of the proton exchange membrane fuel cell is formed through the micro-nano structure of the interface of the micro-porous layer and the coating layer. Among them, the dosage ratio of organosiloxane and carbon nanomaterials is 10% wt%-100wt%. The invention has the characteristics of simple treatment process, mild experimental conditions, friendly chemical environment and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

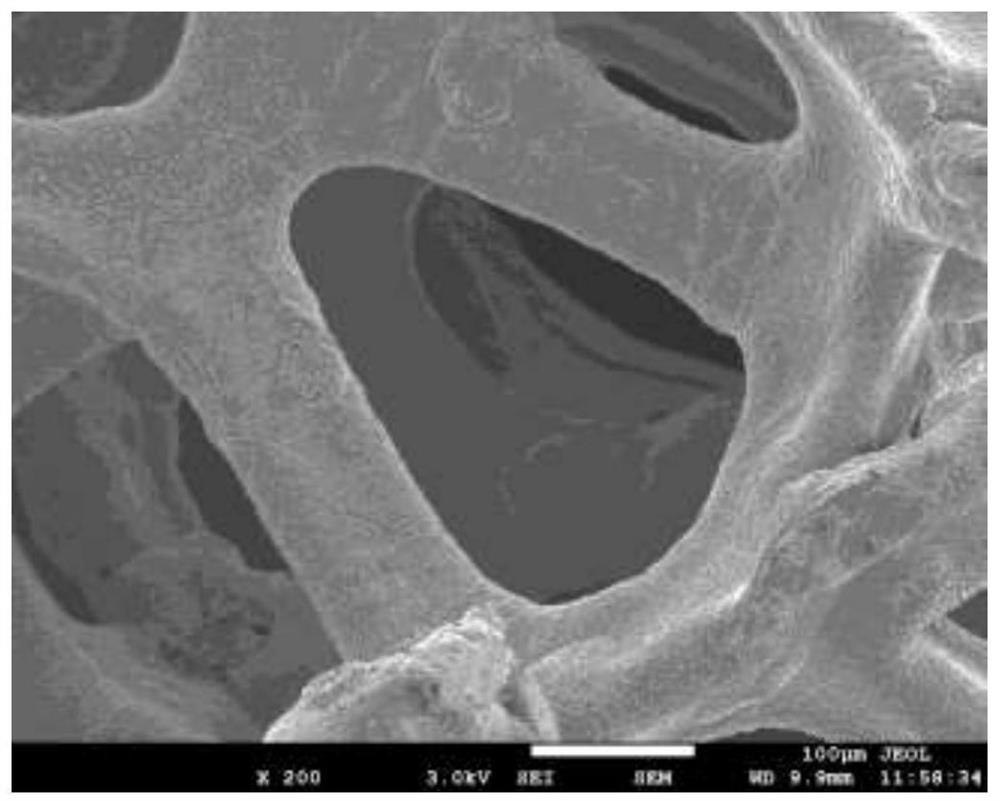

Preparation method of unilateral super-hydrophobic polyethersulfone membrane

InactiveCN106731904AAchieve superhydrophobicityNo breathability impactSemi-permeable membranesMembranesVacuum pumpingSilanes

The invention discloses a preparation method of a unilateral super-hydrophobic polyethersulfone membrane. The method comprises the following steps: dissolving polyethersulfone into a solvent; preparing a polyethersulfone membrane through a dry-wet method; preparing silicon dioxide sol gel through a sol-gel method; modifying the silicon dioxide sol gel by utilizing fluorine-containing silane to prepare fluorinated silicon dioxide sol gel filtrate; depositing fluorinated silicon dioxide sol gel to one side of the polyethersulfone membrane by adopting a vacuum pumping filtration method, so as to obtain the polyethersulfone membrane with a unilateral super-hydrophobic property. The method disclosed by the invention is mainly used for the field of separation of membranes with the unilateral super-hydrophobic property, and can be used for preparing nano materials of membrane-absorption, membrane-analysis and gas-liquid membrane contactor methods. The method is simple and easy to operate; the prepared membrane has a good membrane hydrophobic property and the preparation cost is greatly reduced.

Owner:TANGSHAN COLLEGE

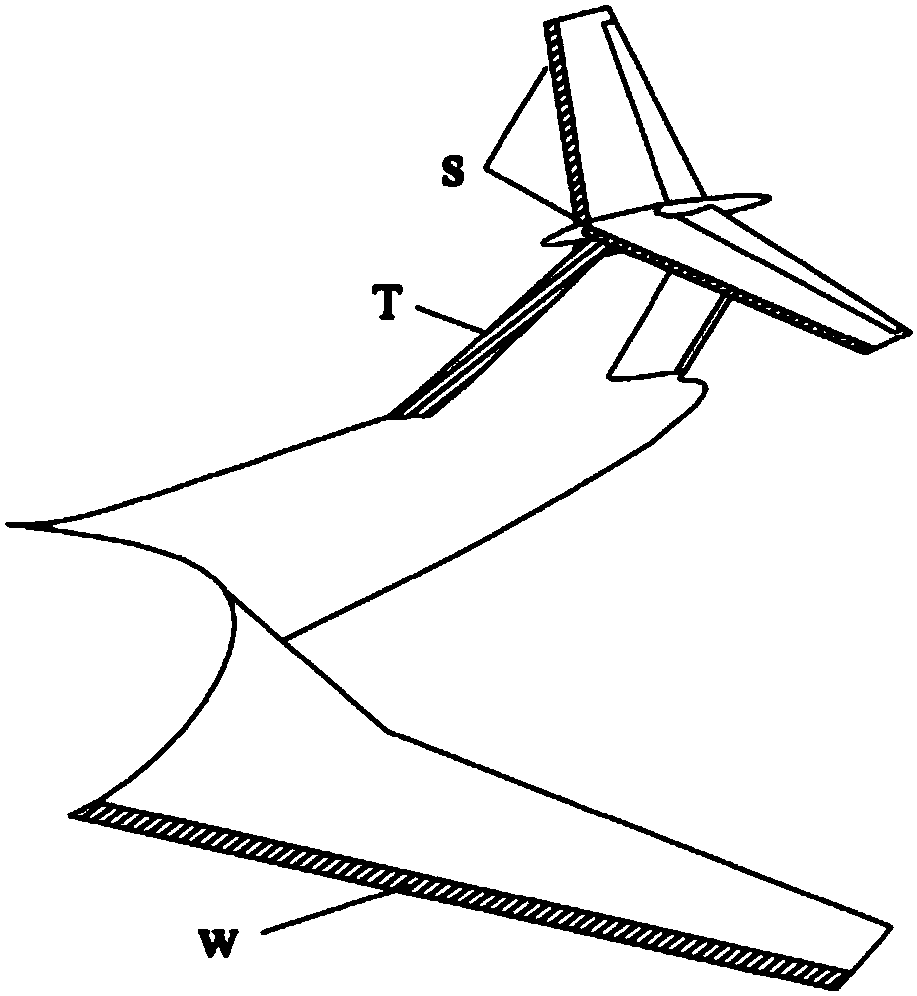

Novel micro-nano structure surface anti-deicing skin

InactiveCN108454816AAchieve superhydrophobicityExtended service lifeDe-icing equipmentsFuselage bulkheadsMicro nanoEngineering

The invention discloses a novel micro-nano structure surface anti-deicing skin, and belongs to the field of aircraft anti-deicing. The skin comprises a surface super-hydrophobic layer and an electricheating layer which are connected together, the surface super-hydrophobic layer is a polyimide PI layer with a micro-nano structure surface, and low-surface energy substances are modified on a micro-nano structure. According to the novel micro-nano structure surface anti-deicing skin, the surface super-hydrophobic layer is obtained by micromachining, compared with a traditional surface hydrophobictreatment mode, the service life is greatly prolonged, the novel micro-nano structure surface anti-deicing skin is a separate module and has good adaptability to the aircraft surface, the product isthin and has flexibility, the pasting and covering are easy, and the replacement is convenient after the surface is destroyed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

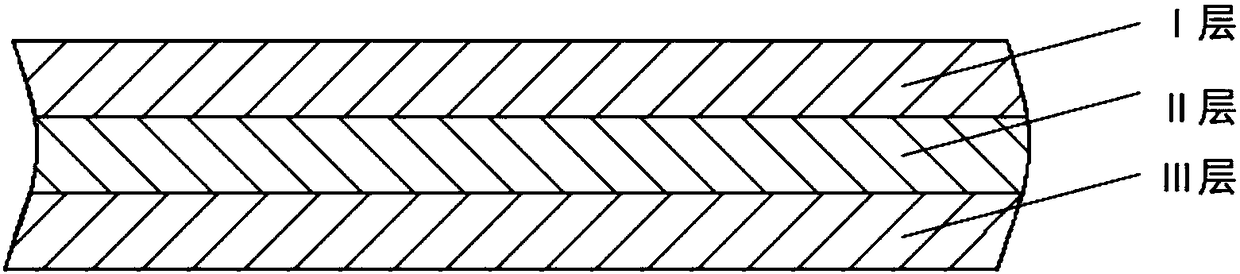

Preparation method of super-hydrophobic PVDF (polyvinylidene fluoride) membrane with micro-nano structure

InactiveCN108114610AImproves anti-wetting propertiesLow costSemi-permeable membranesMembranesWater bathsMicro nano

The invention discloses a preparation method of a super-hydrophobic PVDF (polyvinylidene fluoride) membrane with a micro-nano structure. The preparation method comprises the steps of: (1) preparing membrane casting liquid: putting hydrophobic inorganic nano particles in a polar aprotic solvent, adding a pore-foaming agent for stirring to form a suspension, adding PVDF powder into the suspension, performing uniform stirring in a thermostatic waterbath, standing and defoaming to form the membrane casting liquid, and (2) performing membrane casting liquid striking-up to form a nascent flat sheetmembrane or spinning to form a nascent hollow fiber membrane yarn, remaining in air, putting in an alcohol aqueous solution for phase inversion and performing water cleaning, soaking and drying. The surface and internal walls of pore channels of the membrane prepared have the micro-nano structures, so that super-hydrophobicity of the surface and the internal walls of pores of the membrane is achieved; the wettability resistance of the membrane is improved entirely; and the membrane is applicable to the fields of membrane distillation, support liquid membranes, permeation distillation, membraneabsorption and the like. In addition, the preparation method of the super-hydrophobic membrane is simple, flexible, low in cost and applicable to the preparation of flat sheet membranes and hollow fiber membranes.

Owner:TIANJIN POLYTECHNIC UNIV

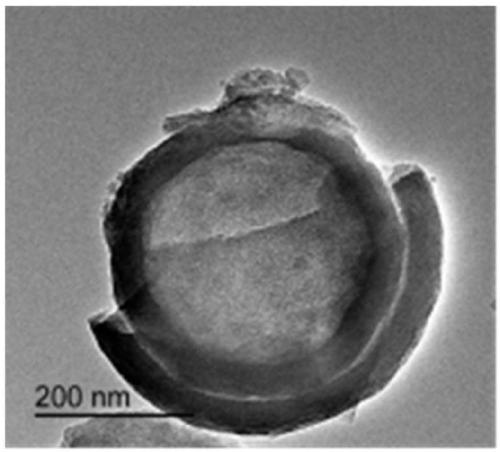

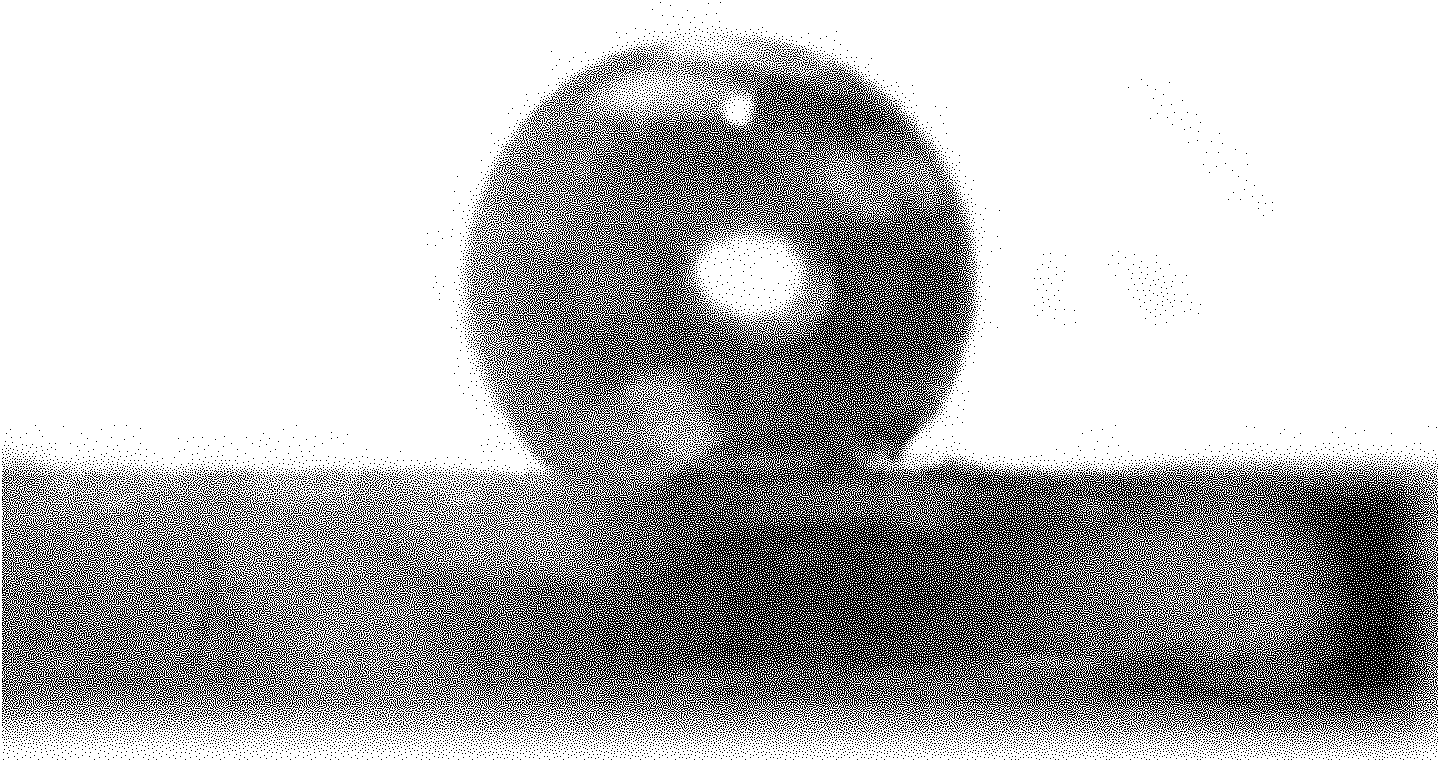

Method for constructing super-hydrophobic wear-resistant leather coating layer based on amphipathic hollow silicon dioxide Janus particles

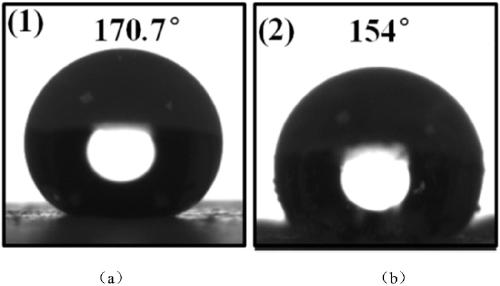

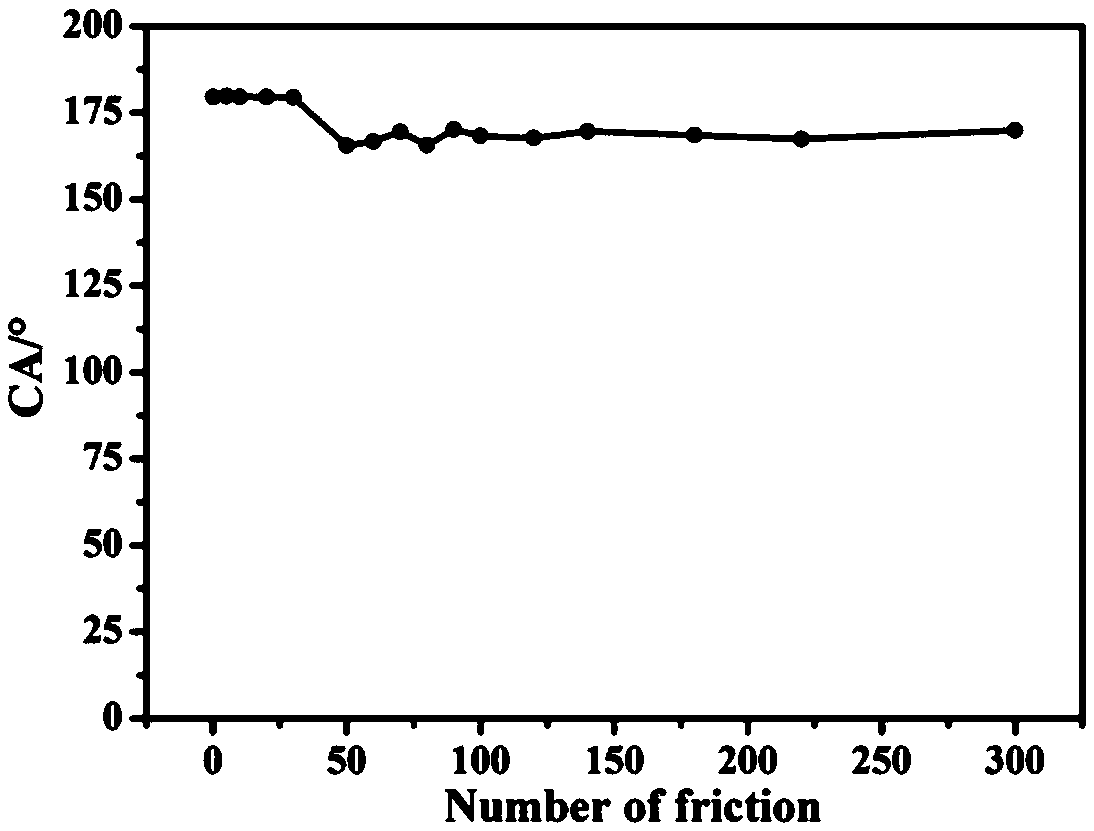

ActiveCN109233598ARegular shapeOptimal Control StructureSilicaPolyurea/polyurethane coatingsCoated surfaceJanus particles

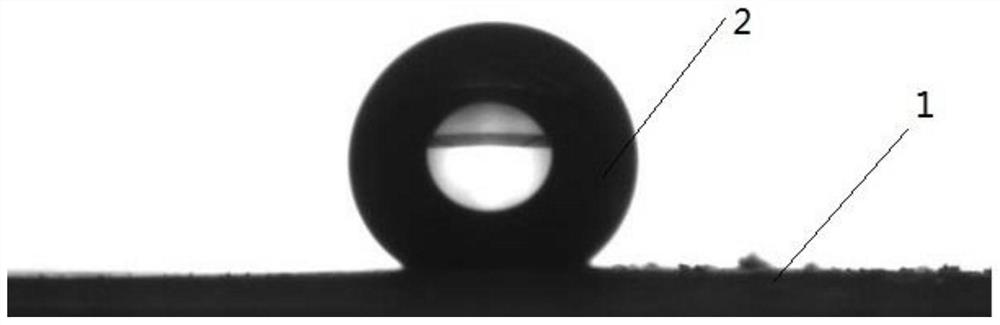

The invention relates to a method for constructing a super-hydrophobic wear-resistant leather coating layer based on amphipathic hollow silicon dioxide Janus particles. The method comprises the stepsof preparing reactive amphipathic hollow silicon dioxide Janus particles through the combination of a Pickering emulsion method and a click chemistry method, and generating chemical crosslinking between hydrophilic ends with reaction activity in the amphipathic hollow silicon dioxide Janus particles and a base material by virtue of a layer-layer coating method to enable hydrophobic ends to extendto the surface of a coating layer, so as to obtain the super-hydrophobic wear-resistant leather coating layer. A result shows that the water contact angle of the constructed super-hydrophobic wear-resistant leather coating layer is over 170 degrees, and the hydrophobic durability and wear resistance of the constructed super-hydrophobic wear-resistant leather coating layer are both relatively good.After a water drop is remained on the surface of the coating layer for 30 minutes, the contact angle is still over 150 degrees; and when the coating layer is seriously worn after a leather sample isrubbed for 300 times, the coating layer still has a super-hydrophobic effect.

Owner:SHAANXI UNIV OF SCI & TECH

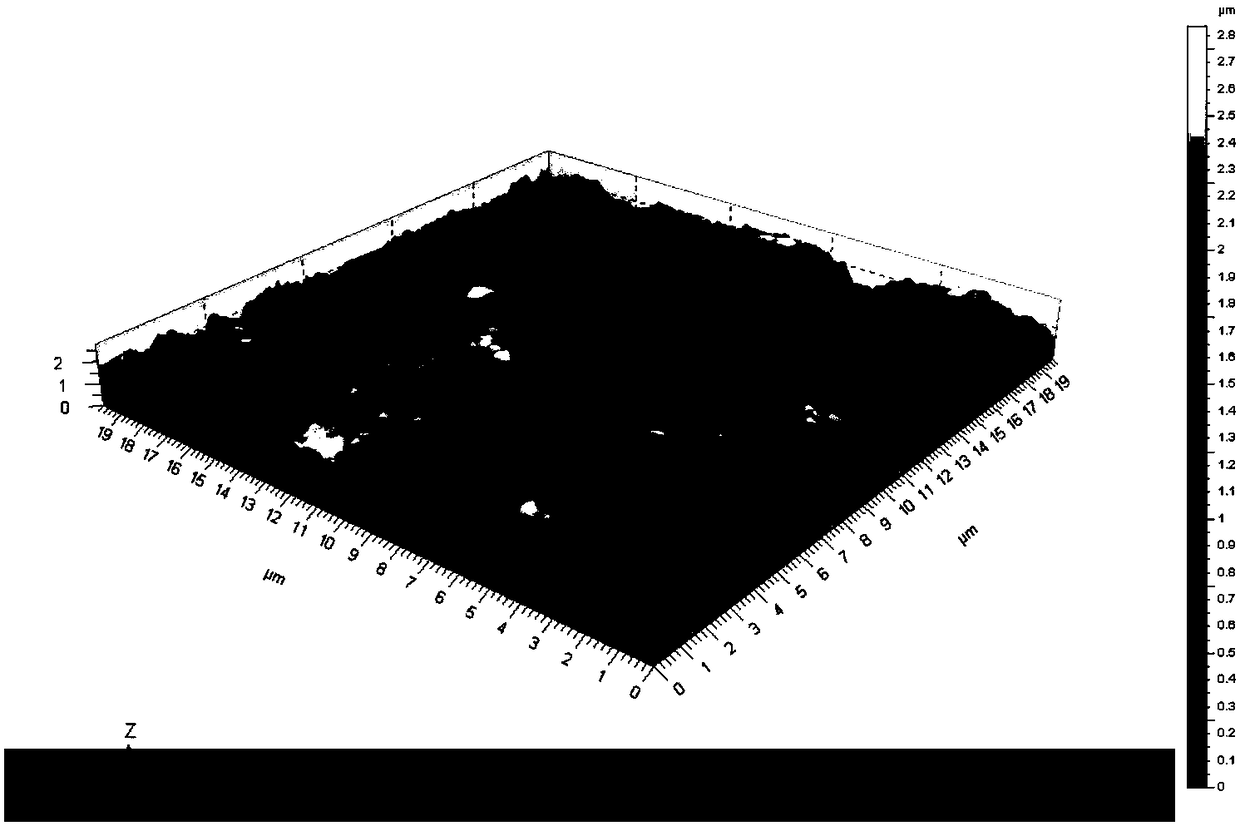

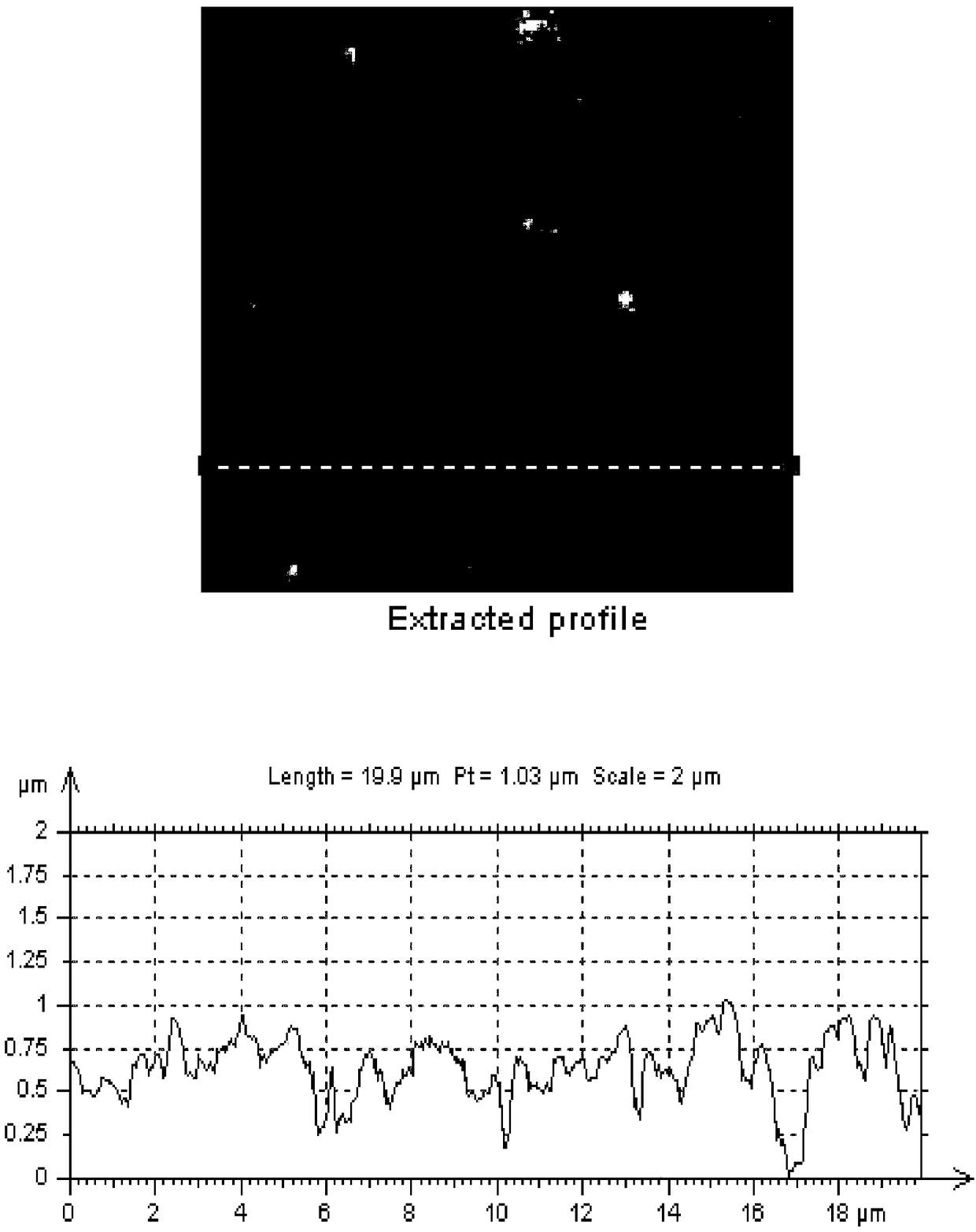

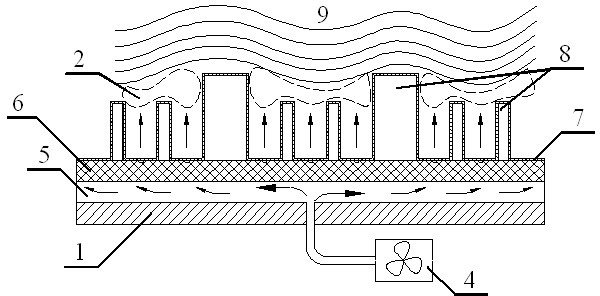

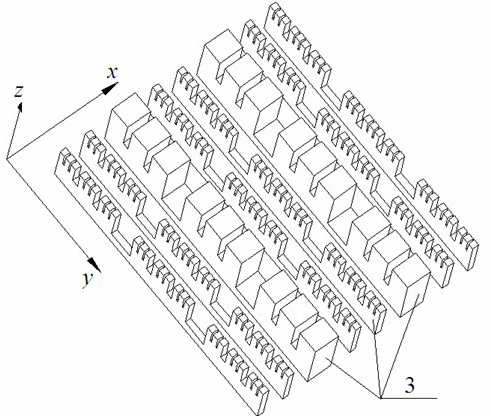

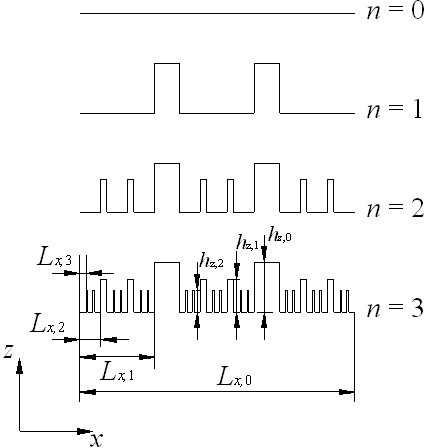

Rough surface for fractal structure

ActiveCN102424354AAchieve superhydrophobicityIndividual molecule manipulationSolid-state devicesRough surfaceMechanical engineering

The invention discloses a rough surface for a fractal structure. The rough surface comprises a substrate and is characterized in that: the substrate is provided with an uncondensable gas film layer; the uncondensable gas film layer consists of a compressed gas generator, a gas accommodating cavity and a porous core; the porous core is arranged on the surface of the substrate through a connecting piece; a gap between the substrate and the porous core forms the gas accommodating cavity; the outer surface of the porous core is provided with a rough structure; the rough structure is a series of micro fin structures with fractal characteristics, and at least two-stage concave-convex micro fins are distributed so as to form a superhydrophobic surface; and uncondensable gas generated by the uncondensable gas film layer maintains certain pressure and is soaked in pore spaces among the micro fin structures. The rough surface is combined with two flowing drag reduction technologies of the superhydrophobic surface and the gas film, so that the aims of high-efficient flow drag reduction and energy conservation can be fulfilled.

Owner:SOUTHEAST UNIV

Anti-condensation coating, radiation terminal with anti-condensation coating on surface, radiator and air-conditioning system

ActiveCN106833371AImprove stabilityExtend your lifeCondensate preventionLighting and heating apparatusInorganic particleGraphene coating

The invention provides an anti-condensation coating, a radiation terminal with the anti-condensation coating on surface, a radiator or an air-conditioning system. The anti-condensation coating comprises a functional material and an organic solvent, wherein the functional material comprises the following materials by weight percent: 40-79wt% of super-hydrophobic raw material, 1-10wt% of graphene and 20-50wt% of mixture of graphene coated inorganic particle and fluorine-containing organic particle. The mixture of graphene coated inorganic particle and fluorine-containing organic particle comprises a particle mixture in the grain size of 0.2-5 mu m and the graphene coating the particle mixture. The radiation terminal with the anti-condensation coating, the radiator and / or the air-conditioning system provided by the invention can be used for solving the problem of the prior art that air conditioning and heating are not matched and used with each other, so that the indoor heating radiator and the radiation terminal are difficult to dew in summer and the outdoor heat radiator is difficult to dew.

Owner:中安瑞材(北京)科技有限公司

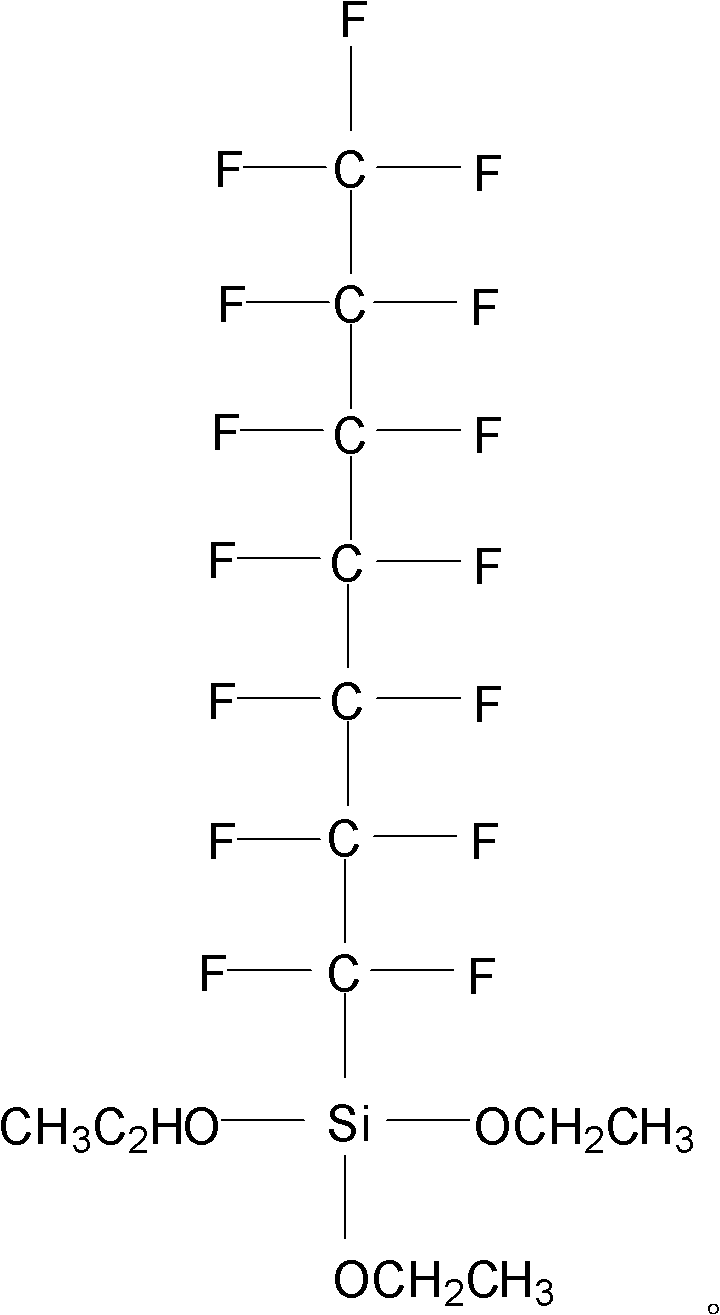

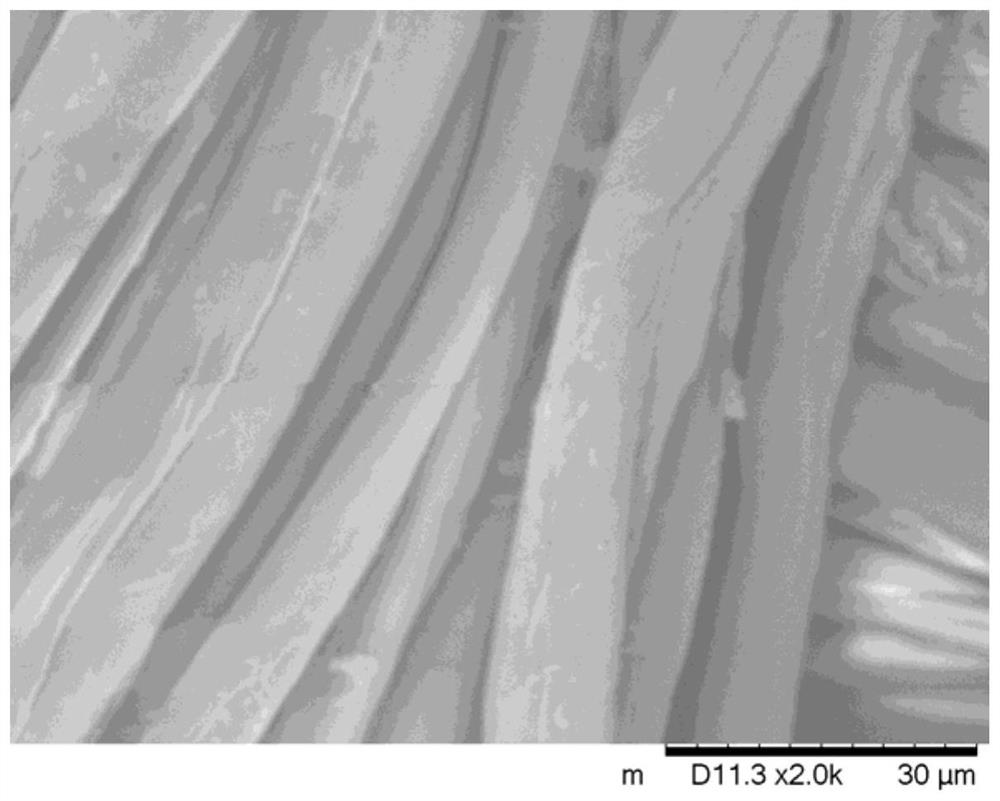

Preparation method for extra hydrophobic carbon fabric boat

InactiveCN102019996AAchieve superhydrophobicityWith invisibilityCarbon fibresVessel partsRough surfaceFiber

The present invention relates to a preparation method of fabric boats and provides a preparation method for preparing an extra hydrophobic carbon fabric boat with the surface covered with a thin layer of poly perfluoro alkyl siloxane. The method comprises the steps of: immersing carbon fabric into perfluoro siloxane solution and air drying it; repeating the former processes for twice to five times; drying it and wrapping the surface of the boat support body by processed carbon fabric. The invention realizes hydrophobicity of carbon fabric surface by coating hydrophobic substance (perfluoro alkyl siloxane) on the macroscopic and rough surface of carbon fabric itself. The carbon fiber fabric boat achieves the characteristics of light mass, small underwater driving resistance, large stealth carrying capacity and good corrosion resistance.

Owner:HARBIN INST OF TECH

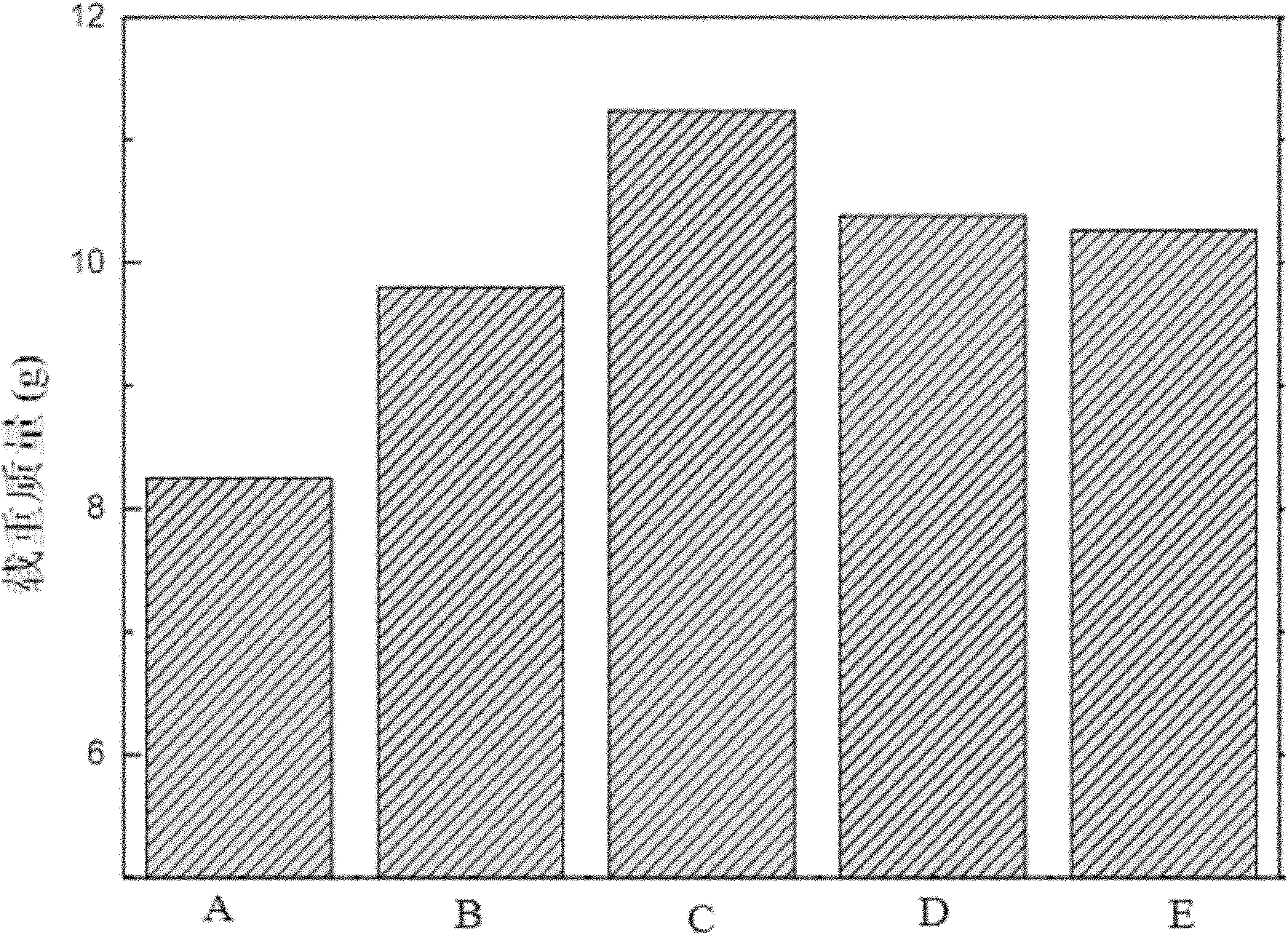

Preparation method for die plates with different roughness

InactiveCN107364057AAchieve superhydrophobicitySimple and fast operationLiquid surface applicatorsFlat articlesEpoxyRoom temperature

The invention provides a preparation method for die plates with different roughness. The preparation method comprises the following steps that 1, epoxy resin and a curing agent are mixedly prepared to serve as a base material, a glass plate or a metal plate serves as a base plane, the base plane is uniformly coated with the base material, and still standing is conducted for 1-5min; 2, the surface of the base material is uniformly paved with silicon carbide particles, and the base material is placed in an oven to be cured for 2-4 h at the temperature of 80 DEG C-110 DEG C; and 3, the base material is cooled to the room temperature after being taken out, and after an air gun is connected with an air pump, the silicon carbide particles which are not cured on the surface of the epoxy resin are blown off, so that the die plates rough in surface are obtained. The preparation method for the rough die plates is based on the theory of lotus leaf effect and can be used for preparing high molecular material films with uniform roughness, so that the high molecular material films have hydrophobicity.

Owner:TIANJIN POLYTECHNIC UNIV

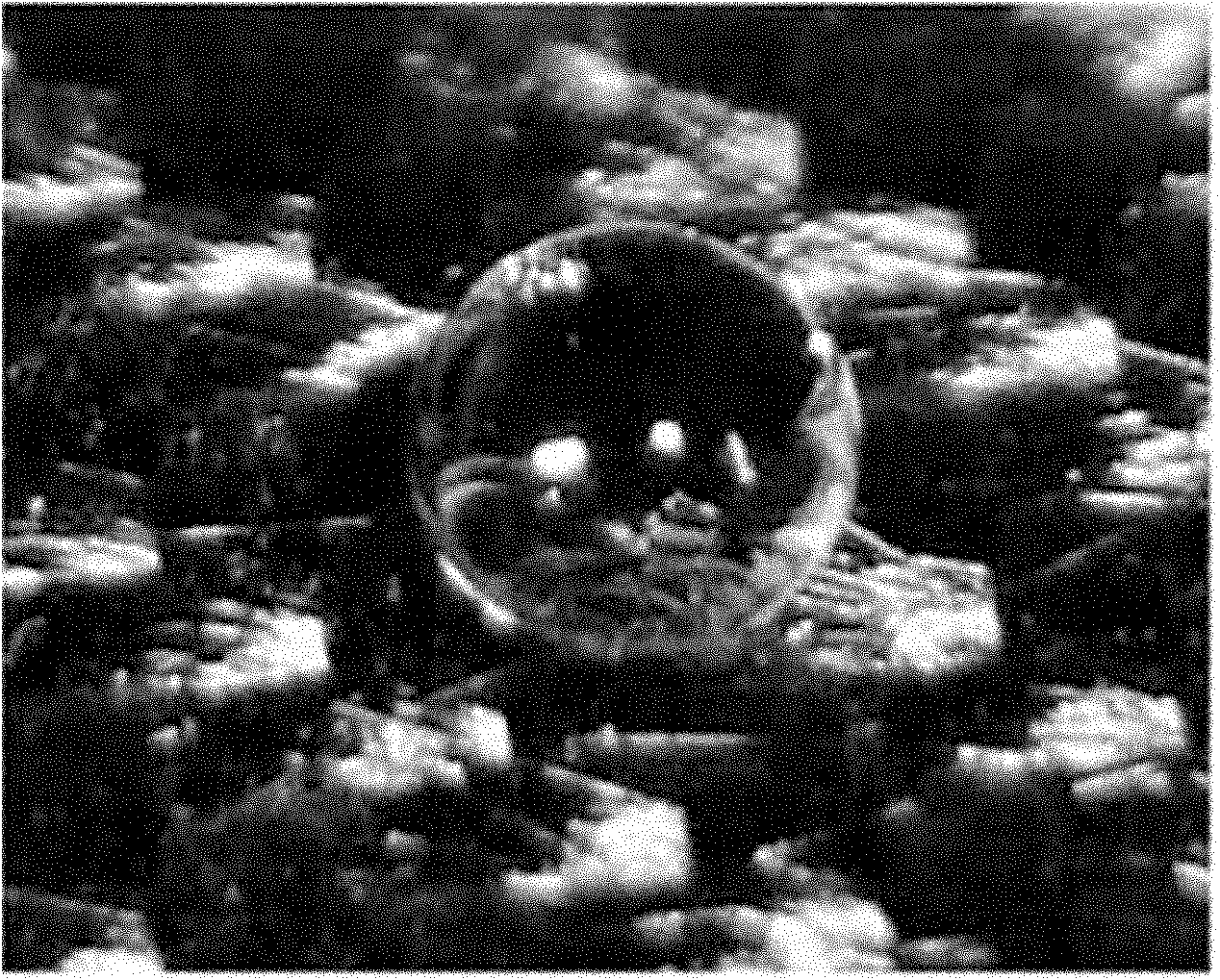

Method for preparing super-hydrophobic carbon fiber fabric

InactiveCN102094324AAchieve superhydrophobicitySmall underwater driving resistanceCarbon fibresFiberRough surface

The invention discloses a method for preparing a super-hydrophobic carbon fiber fabric and relates to a method for preparing a carbon fiber fabric. The invention aims to provide a method for preparing a superhy-drophobic carbon fiber fabric which is covered with a thin layer of polyperfluoralkylsiloxane on the surface. The method comprises the following steps of: soaking a carbon fiber fabric into a perfluoralkylsiloxane solution; and then airing, repeating 2 to 5 times and drying to obtain the super-hydrophobic carbon fiber fabric. The invention realizes the superhydrophobicity of the surface of the carbon fiber fabric by utilizing the method for coating a hydrophobic substance (perfluoralkylsiloxane) on the macroscopical rough surface of the carbon fiber fabric. The prepared super-hydrophobic carbon fiber fabric can be used as a main building material for manufacturing a small ship and a submarine and used as an outer-layer coating material for being coated on the outer surface of the ship and the submarine.

Owner:HARBIN INST OF TECH

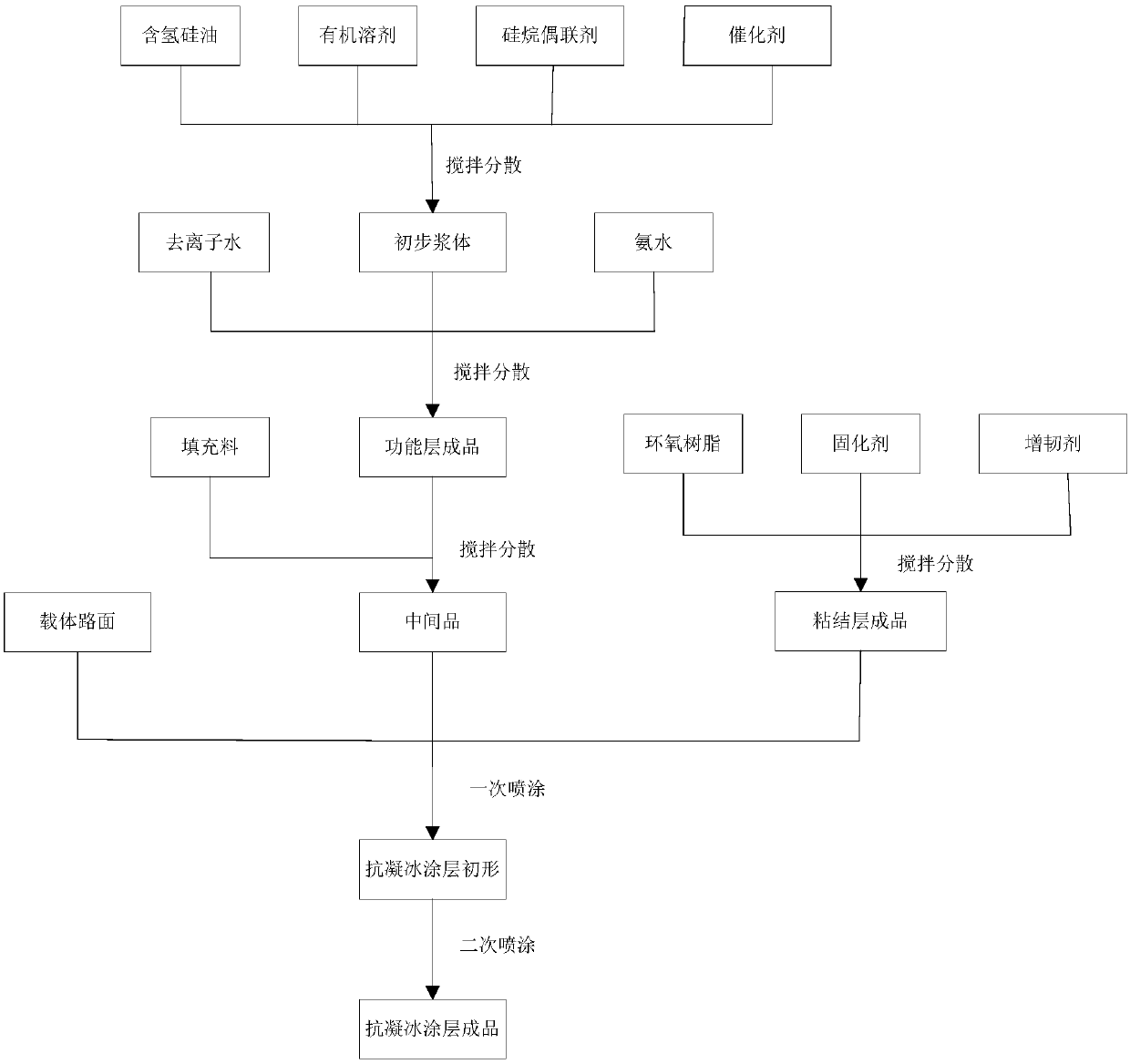

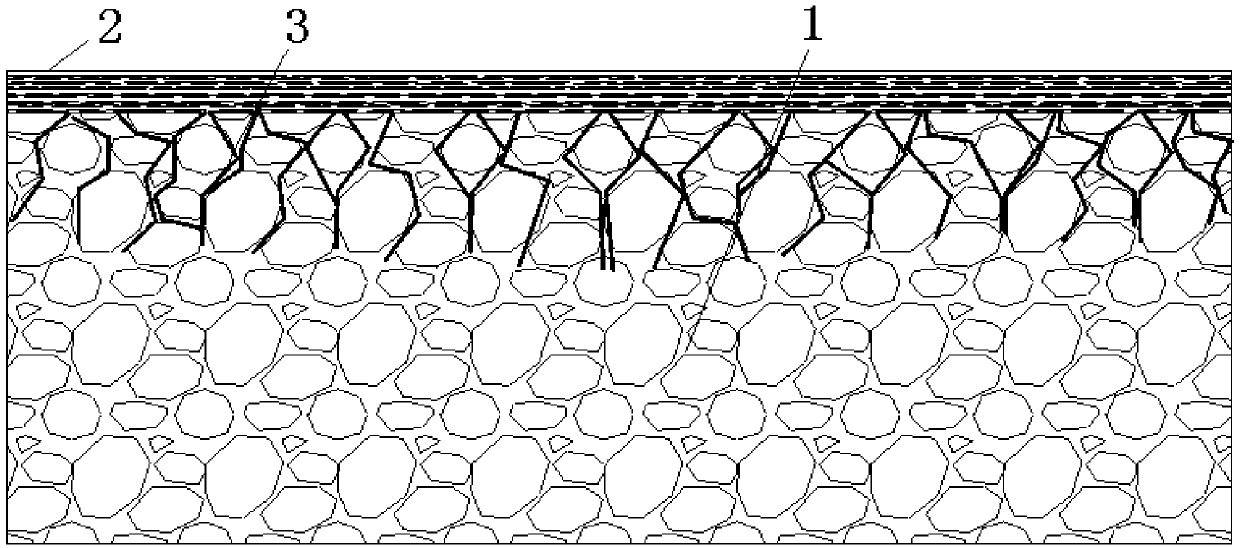

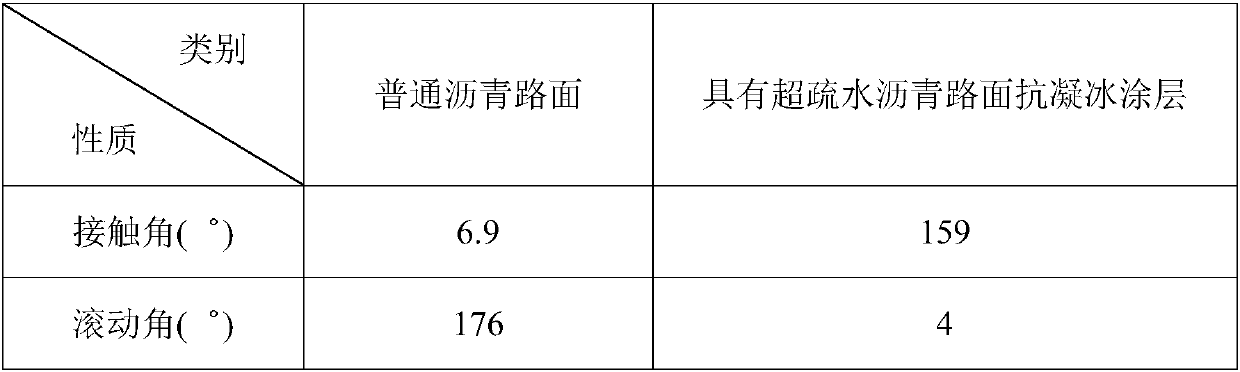

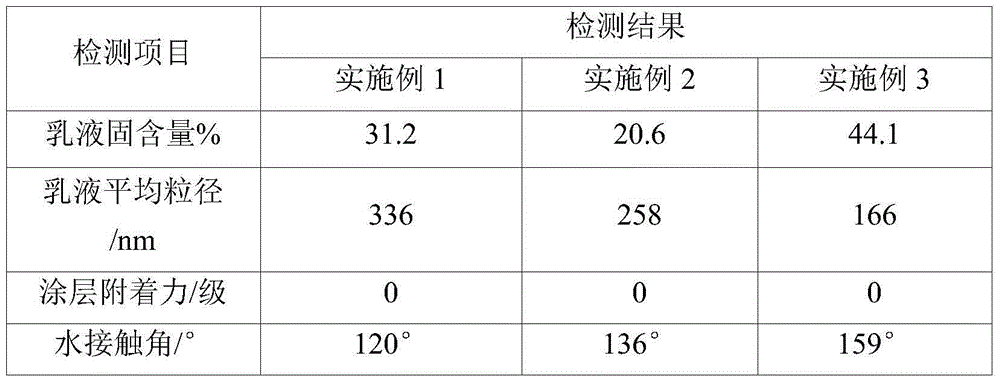

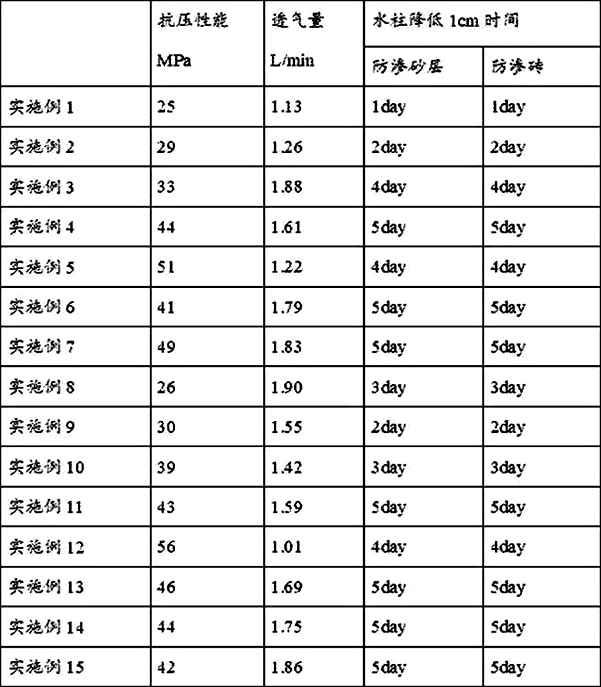

Super-hydrophobic asphalt pavement anti-freezing coating and preparing method thereof

ActiveCN109627974ASuperhydrophobicTo achieve the effect of anti-icingPaving detailsCoatingsEpoxySlurry

The invention belongs to the technical field of the design of asphalt concrete pavement coatings, and relates to a super-hydrophobic asphalt pavement anti-freezing coating and a preparing method thereof. The coating comprises an adhesive layer arranged on the surface of a carrier pavement, a functional layer arranged on the surface of the adhesive layer, and anti-wear filler dispersed in the functional layer. The functional layer is a low-surface-energy material. Slurry of the adhesive layer is formed by mixing epoxy resin 128, an amine curing agent and an epoxy toughening agent 277. Slurry ofthe functional layer is formed by mixing MHX-1107 hydrogen-containing silicone oil, gamma-aminopropyl triethoxysilane, dibutyltin dilaurate, absolute ethyl alcohol, ammonium hydroxide and deionized water. The anti-wear filler is evenly dispersed in the slurry of the functional layer. The performance of the super-hydrophobic asphalt pavement anti-freezing coating can completely meet the requirements for super hydrophobicity, freezing resistance, wear resistance, high friction coefficient and the like.

Owner:CHANGAN UNIV

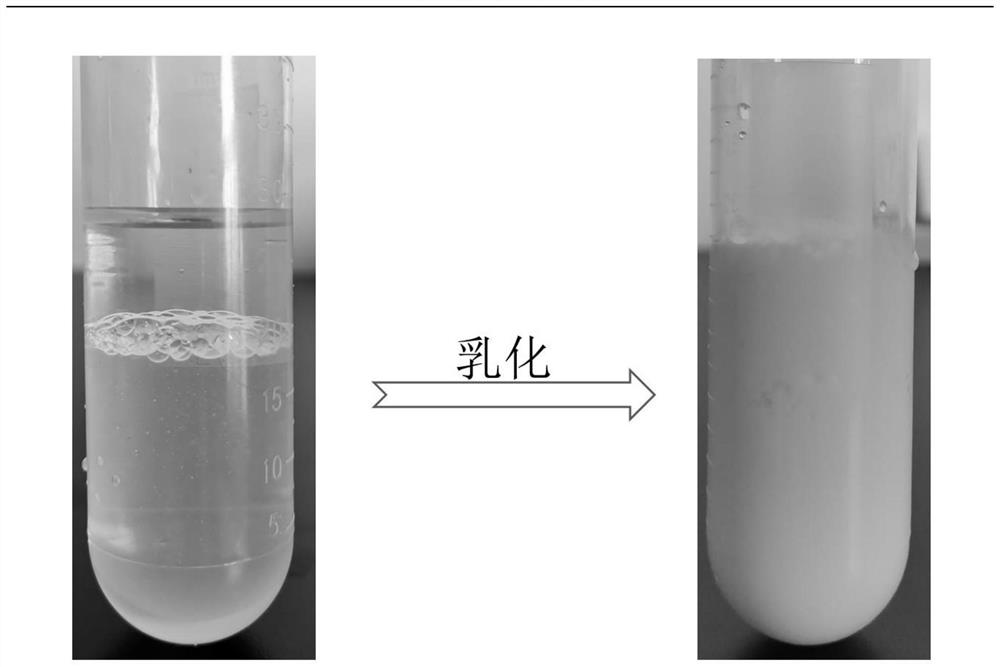

Anti-icing fluorocarbon emulsion and preparation method thereof

The invention discloses an anti-icing fluorocarbon emulsion. The anti-icing fluorocarbon emulsion is prepared from the following raw materials in percentage by weight: 10.00-50.00 percent of fluorinated monomer, 0.00-10.00 percent of modified monomer, 0.50-5.00 percent of inorganic nanometer particle, 0.00-2.00 percent of an initiator, 0.50-5.00 percent of an emulsifier, 0.00-20.00 percent of a cosolvent and the balance of water. The invention also discloses a preparation method of the anti-icing fluorocarbon emulsion. The anti-icing fluorocarbon emulsion is simple in production process and excellent in performance and is safe and environmentally friendly.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

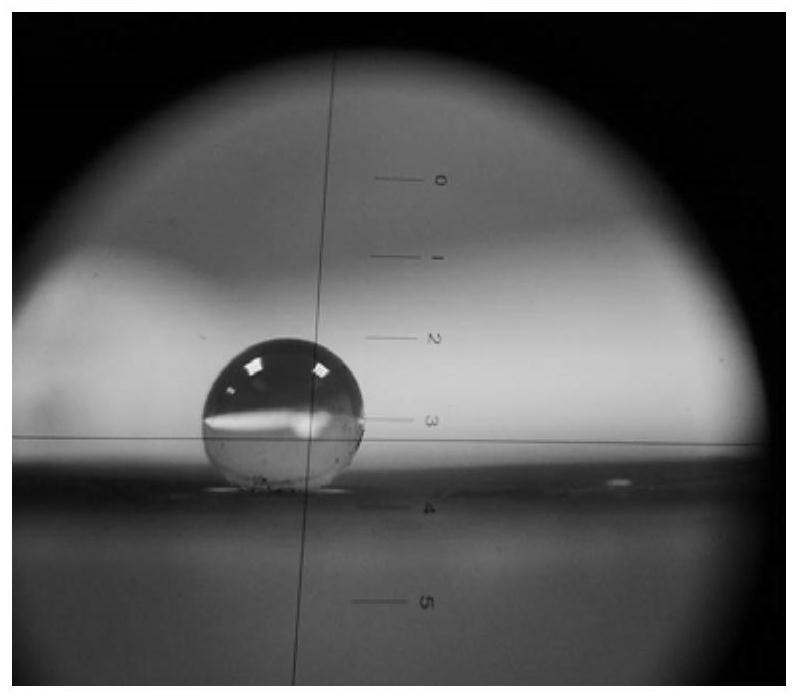

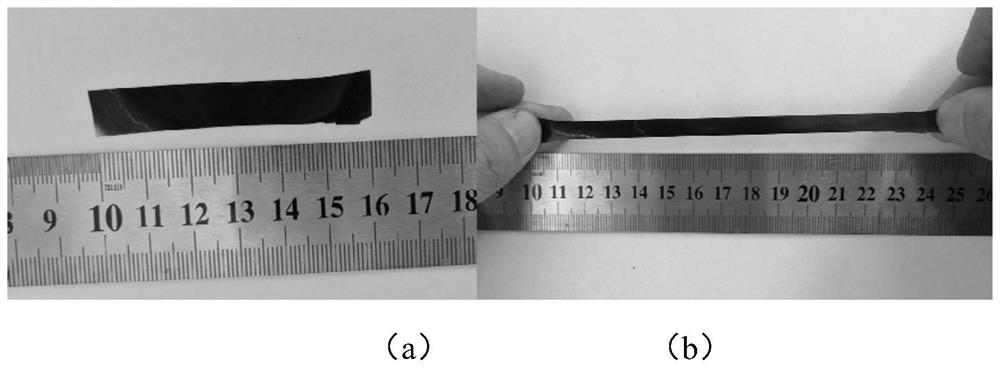

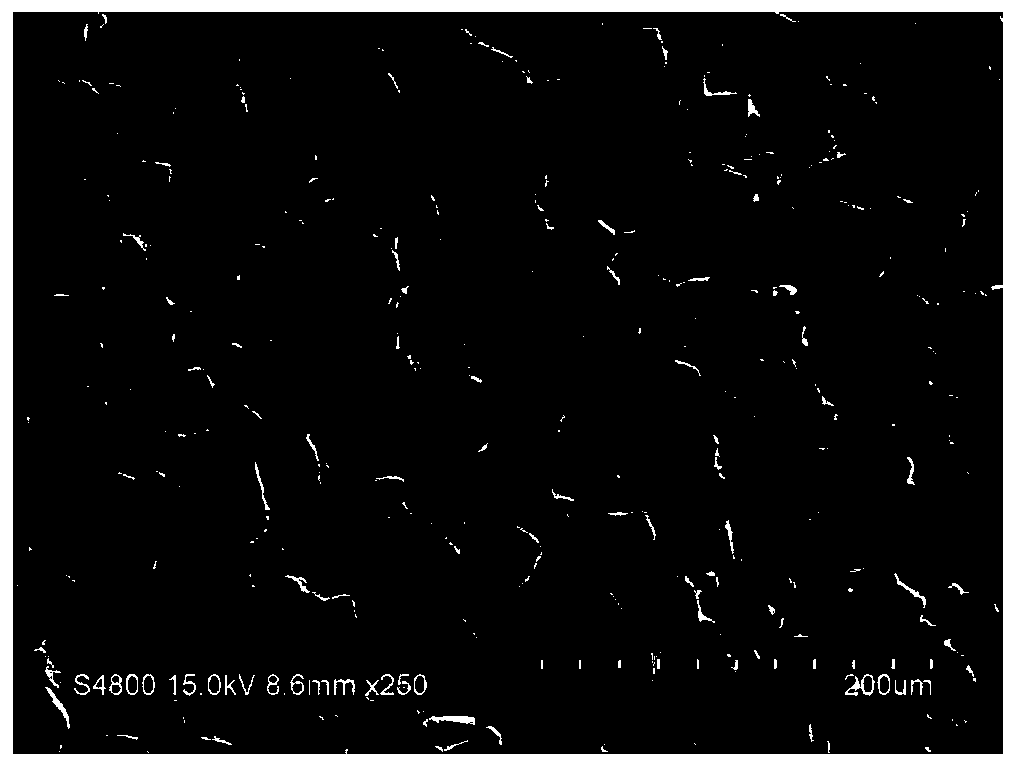

Stretchable super-hydrophobic surface material and preparation method thereof

The invention generally belongs to the technical field of self-cleaning, waterproof and stretchable devices, and provides a stretchable super-hydrophobic surface material which comprises a flexible film layer and a candle ash layer on at least one of the upper surface and the lower surface of the flexible film layer. The flexible thin film layer is a thin film layer formed by a thermosetting elastic polymer; the thickness of the flexible film layer ranges from 100 microns to 500 microns; and the thickness of the candle ash layer is 2-10 microns. The preparation method is simple (the candle soot layer is obtained by moving and baking on the burning candle flame), special equipment is not needed, the price is low, the environment is protected, the candle soot coating is prepared on the thermocuring rubber film, the rubber film is cured under the action of heat, and part of film molecules permeate among candle soot particles; the adhesion of the candle soot particles is enhanced, so the appearance of the candle soot layer cannot be damaged in the stretching process, and the film can still keep excellent super-hydrophobic performance in the stretching process.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Super-hydrophobic microcapsule polymer cement-based anticorrosive coating as well as preparation method and application thereof

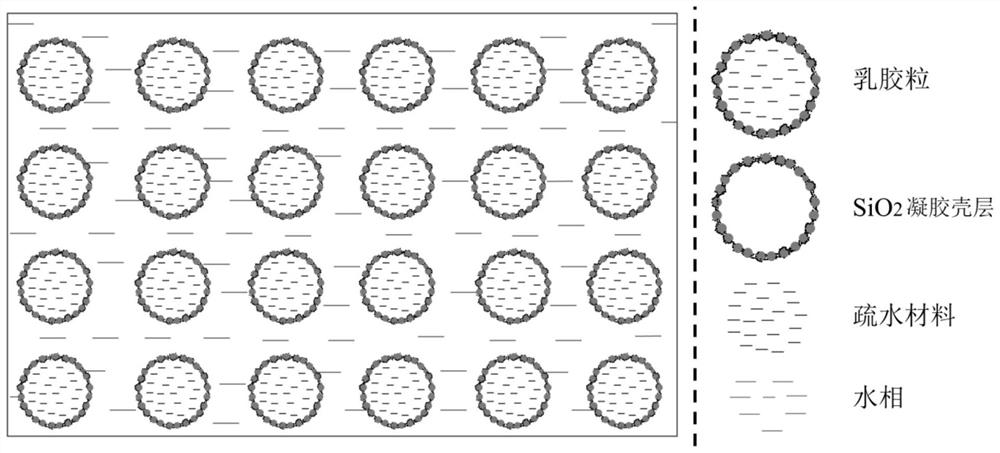

The invention relates to the field of cement anticorrosive coatings, in particular to a super-hydrophobic microcapsule polymer cement-based anticorrosive coating as well as a preparation method and application thereof. The coating is prepared from the following raw materials in parts by weight: 65-85 parts of cement, 65-70 parts of quartz sand, 0.5-1.0 part of a reinforcing agent, 0.17-0.32 part of a retarder, 45-55 parts of emulsion, 15-18 parts of water, 1.1-1.8 parts of a coalescing agent, 0.47-1.4 parts of a light stabilizer, 0.2-0.6 part of a preservative, 0.05-0.3 part of hydrophobic modified graphene oxide and 6-8 parts of a water-based microcapsule emulsion, wherein the water-based microcapsule emulsion is of a core-shell structure formed by taking a hydrophobic material as a coreand SiO2 gel as a shell layer. The anticorrosive paint provided by the invention avoids adverse effects on a cement hydration hardening process and a polymer film forming process, and effectively solves the problem of compatibility between a hydrophobic agent and emulsion as well as between the hydrophobic agent and cement.

Owner:UNIV OF JINAN

Bio-based super-hydrophobic coating as well as preparation method and application method thereof

ActiveCN110964390AAchieving superhydrophobicityGood compatibilityPriming paintsSuperhydrophobeOrganic chemistry

The invention relates to a bio-based super-hydrophobic coating and a preparation method and an application method thereof, the bio-based super-hydrophobic coating comprises a primer and a top coating,and the top coating is prepared from resin B, lotus leaf particles, a pigment, a thickener, an acid-base regulator and the like. According to the bio-based super-hydrophobic coating as well as the preparation method and the application method thereof, the resin B is used as a matrix, the lotus leaf particles belonging to pure organisms are crushed and ground through a specific process, a nano-micron dual structure of lotus leaves is reserved, and the lotus leaf particles are added into an environment-friendly coating matched with the the lotus leaf particles. The primer is firstly coated or sprayed on a surface to be hydrophobic to ensure adhesion, reduction of surface energy and adhesion of the coating due to addition of e thlotus leaf particles is avoided, then the top coating is coatedor sprayed on the surface to be hydrophobic, the water contact angle after coating is larger than 150 degrees, the synthesis process is simple, the cost is low, and the coating is green, environmentally friendly, safe and pollution-free and can be produced in batches. The super-hydrophobic self-cleaning coating can be widely applied to the surfaces of wall surfaces, cement, metal, glass and the like to realize super-hydrophobicity and self-cleaning.

Owner:SUZHOU WHOLENANO NEW MATERIAL TECH CO LTD

Super-hydrophobic fabric and preparation method and application thereof

ActiveCN109736080AAchieve superhydrophobicityShort reaction timePhysical treatmentLiquid separationChemical reactionStrong acids

The invention belongs to the scientific field of high molecular materials, in particular to a super-hydrophobic fabric and a preparation method and an application thereof. According to the method, thefabric is connected to vinyl blocked polydimethyl siloxane by using gamma-mercaptopropyl triethoxy silicon. The preparation method comprises the following steps: carrying out a reaction on hydrolysedgamma-mercaptopropyl triethoxy silicon and the fabric; and then carrying out a click chemical reaction on the gamma-mercaptopropyl triethoxy silicon and the vinyl blocked polydimethyl siloxane, wherein the fabric has a super-hydrophobic property. According to the method, strong acids and bases and toxic reagents are not used. The reaction is carried on mercapto in the gamma-mercaptopropyl triethoxy silicon and vinyl on the vinyl blocked polydimethyl siloxane, so that the reaction time is short, the course process is simple, and the preparation method is suitable for industrial production. Thecontact angle of waterdrops on the surface of the super-hydrophobic fabric in air is 151-156 degrees and the rolling angle is 5-8 degrees. The degrading rate of the super-hydrophobic fabric applied to oil-water separation reaches 99.95%, and the separating efficiency still can be kept over 99.9% if being recycled for many times.

Owner:中科检测技术服务(广州)股份有限公司 +2

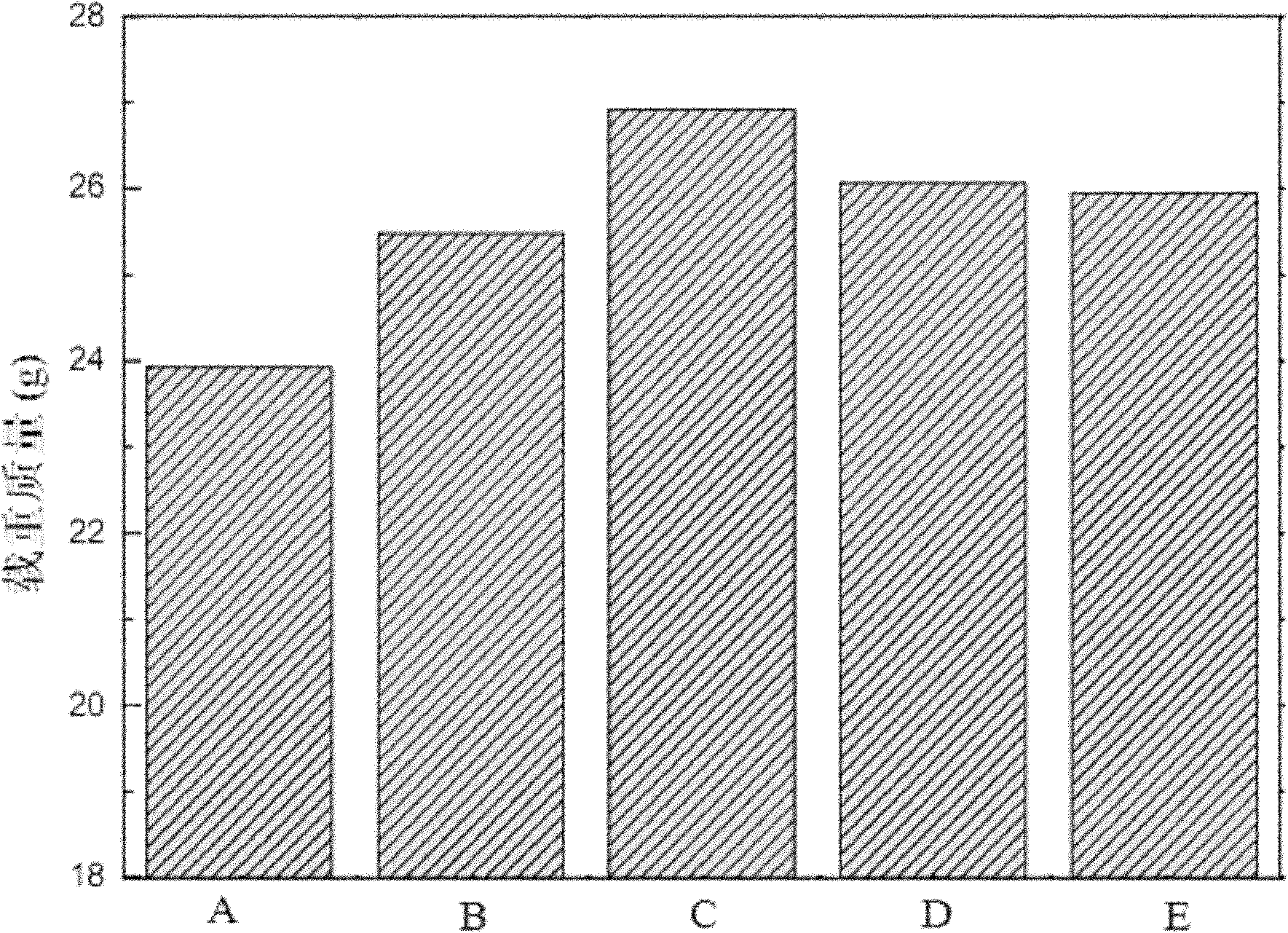

Coral sand breathable impermeable sand

InactiveCN112321261ASolve fresh water drinkingSolve the problem of vegetable and fruit sourcesGrowth substratesCulture mediaRosinAdhesive

The invention belongs to the field of composite materials, and particularly relates to coral sand breathable impermeable sand and a preparation method thereof. Coral sand is generated by long-term evolution of marine microorganisms, belongs to biochemical sedimentary rock, and is completely different from desert silica sand used for preparing breathable impermeable sand in the prior art, and a precedent for successfully preparing the breathable impermeable material from the coral sand does not exist in the prior art. According to the invention, coral sand particles, a filler, a laminating agent and an adhesive are mixed according to a specific ratio, and the particle size of the coral sand particles is limited to be 50 to 200 meshes, so that the coral sand breathable impermeable sand withbreathable impermeable effects is obtained. And the filler can be selected from one or more of cement, styrene-acrylic emulsion, silicone acrylic emulsion, kaolin and rosin. The most preferable filleris a mixed filler of kaolin and rosin, and when the filler is selected, the air permeability and the water resistance of the obtained coral sand breathable impermeable sand can be optimal.

Owner:BEIJING RECHSAND SCI & TECH GRP

Super-hydrophobic heat-resistant coating for aluminum alloy and preparation method of super-hydrophobic heat-resistant coating

InactiveCN114395326AAchieve superhydrophobicityAchieve heat resistanceMolten spray coatingPretreated surfacesThioureaCarboxylic acid

The invention discloses a super-hydrophobic heat-resistant coating for an aluminum alloy and a preparation method of the super-hydrophobic heat-resistant coating, and relates to the technical field of coatings. The heat-resistant coating is formed on the surface of the aluminum alloy through the spraying pretreatment process and the second-time spraying treatment in sequence, the heat-resistant coating and the aluminum alloy form a firm cross-linked interpenetrating network structure, the heat resistance of the coating is improved, and the phenomenon that the service life of the aluminum alloy is shortened in a high-temperature environment is reduced; and then third spraying treatment is conducted, a corrosion inhibitor serves as an inner core solution, stearic acid serves as a shell solution, a super-hydrophobic coating is formed through coaxial electrostatic spraying, the corrosion inhibitor is prepared from isoquinocarboxylic acid, dipropylene triamine and p-methoxyphenyl thiourea, the surface of the aluminum alloy is isolated from an environment medium, and corrosion of an acid medium and chloride ions is inhibited. The prepared super-hydrophobic heat-resistant coating for the aluminum alloy has the heat-resistant, super-hydrophobic and corrosion-resistant effects.

Owner:严平

A nano-tio2/ptfe hybrid fluorocarbon coating applied to insulator anti-pollution flashover and preparation method thereof

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Preparation method of super-hydrophobic foam iron surface and application of super-hydrophobic foam iron in oily wastewater treatment

ActiveCN112981400AThe process steps are simpleAchieve superhydrophobicityFatty/oily/floating substances removal devicesGeneral water supply conservationHexamethylenetetramineHydrophobic surfaces

The invention discloses a preparation method and process of a super-hydrophobic foam iron surface. The preparation method comprises the following steps of (1) pre-treating foam iron to be treated, sequentially putting the foam iron to be treated into absolute ethyl alcohol, diluted hydrochloric acid and deionized water, and respectively carrying out ultrasonic cleaning for 10 minutes; (2) putting the pretreated foam iron into an aqueous solution of ferric salt and hexamethylenetetramine, carrying out hydrothermal reaction, then naturally cooling to room temperature, taking out the foam iron, and drying; and (3) carrying out precise atmosphere heat treatment on the dried foam iron, and obtaining the foam iron with the super-hydrophobic surface. After the foam iron with the super-hydrophobic surface is stored in a room temperature environment for two years, the contact angle between the surface and water can still reach 150 degrees or above, and the rolling angle is smaller than 10 degrees. According to the method, surface super-hydrophobicity can be achieved without modification of low-surface-energy organic matter fluorosilane and the like, the method is simple, effective and environmentally friendly, the hydrophobic layer is firmly combined with a rough micro-nano structure on the surface of the foam iron, falling is not likely to happen, mechanical stability is good, and practical application of the super-hydrophobic surface is facilitated.

Owner:ZHOUKOU NORMAL UNIV

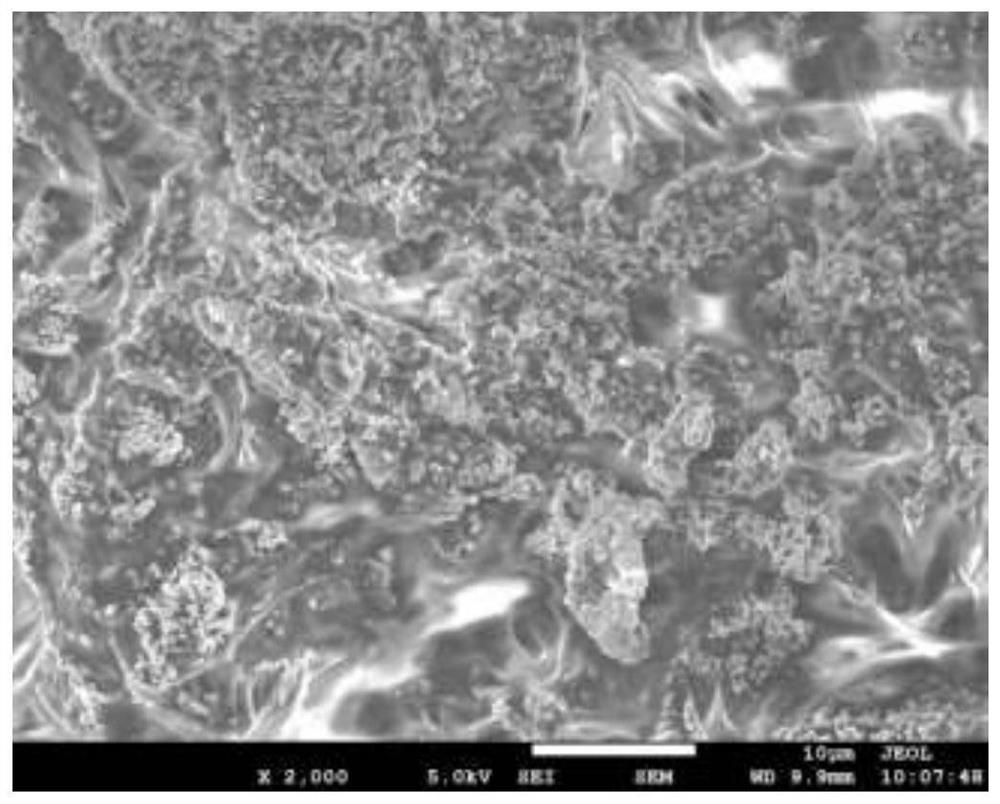

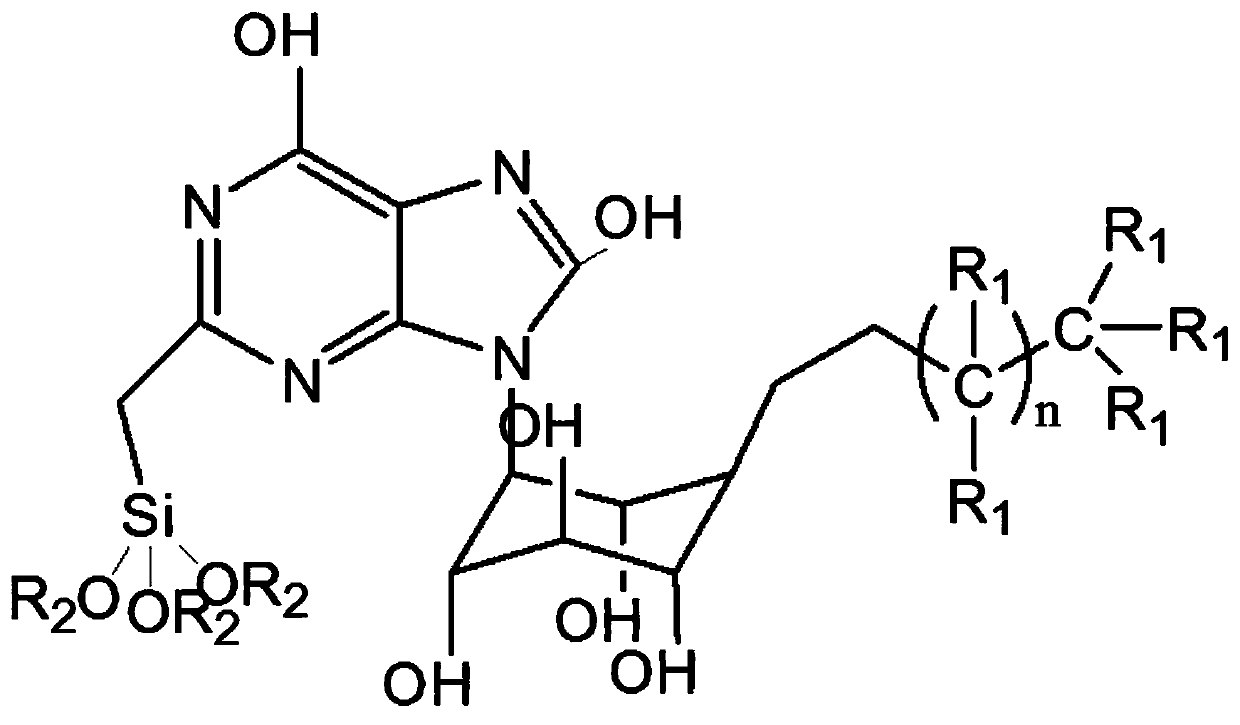

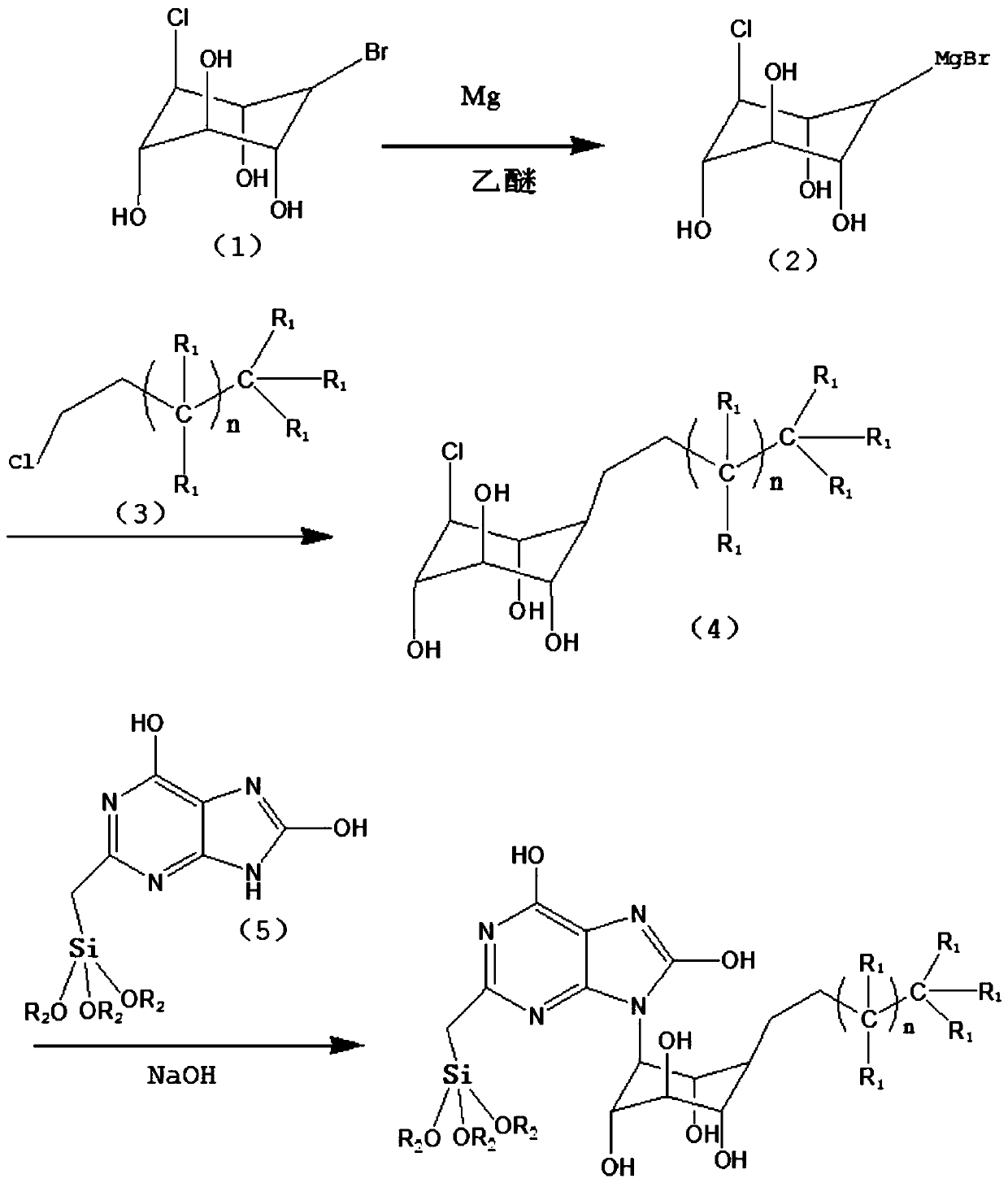

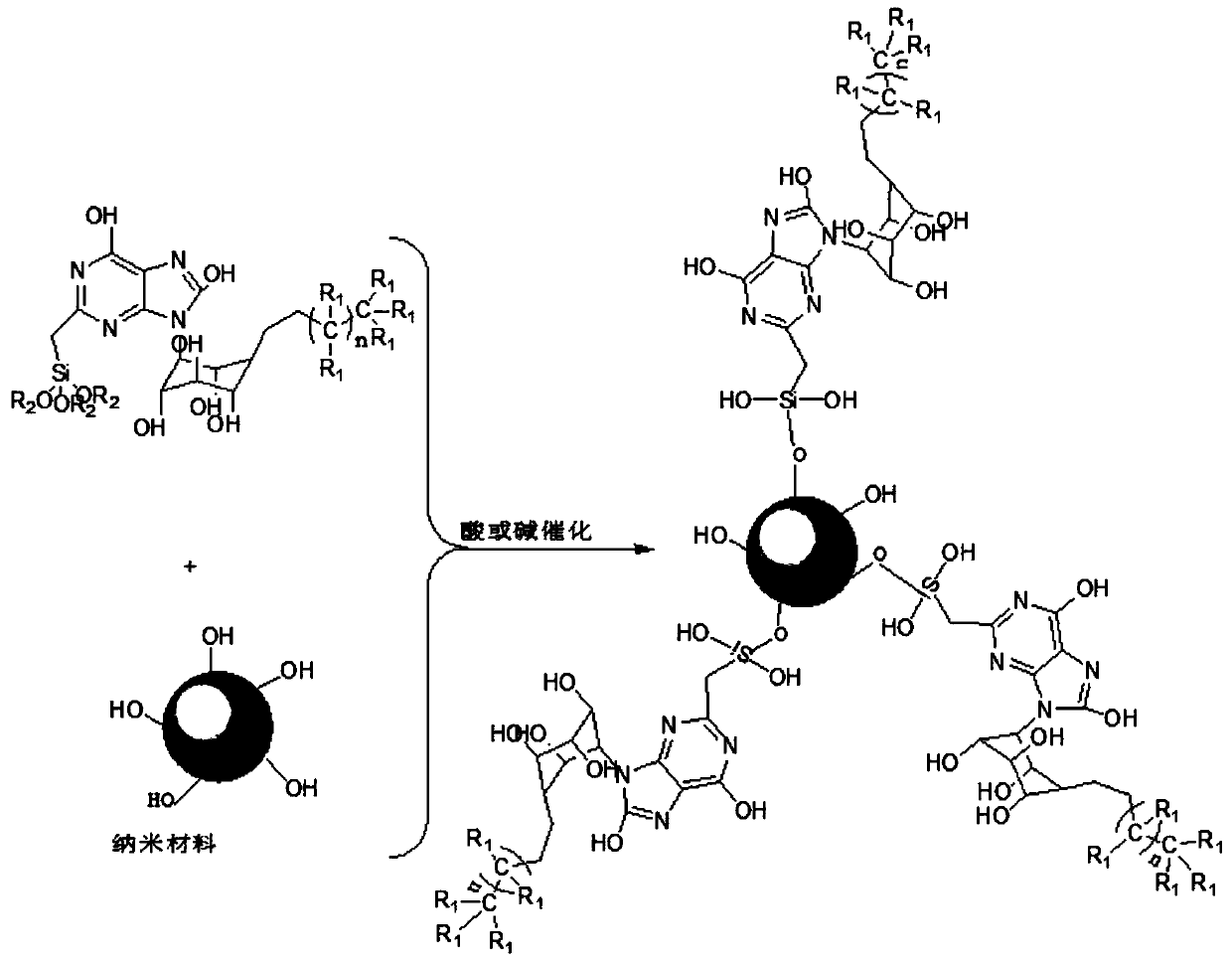

Multi-functional-group purine compound, super-hydrophobic material for car paint and preparation method thereof

InactiveCN110305130AModified stabilizationImprove stabilityOrganic chemistry methodsCoatingsPurineHydroxy compound

The invention relates to the field of super-hydrophobic materials, in particular to a multi-functional-group purine compound, a super-hydrophobic material for car paint and a preparation method thereof. By using the multi-functional-group purine compound to modify a nano material, adhesiveness of a super-hydrophobic nano material during application can be improved greatly; the compound has purinegroups, so that durability of the super-hydrophobic material can be improved; silicyl of the compound is in condensation with hydroxyl of a nano material under catalysis of acid or alkali to form a hydrophobic material, so that according to the above property, the compound can be used to modify a nano oxide material to obtain the super-hydrophobic material, and adhesiveness and durability of the super-hydrophobic material are improved. In addition, hydroxyl can also be formed after silicyl is hydrolyzed, and silicyl can also be in condensation with hydroxyl of a substrate material face, so that firmness of the compound adhered on glass is further improved.

Owner:重庆多次元新材料科技有限公司

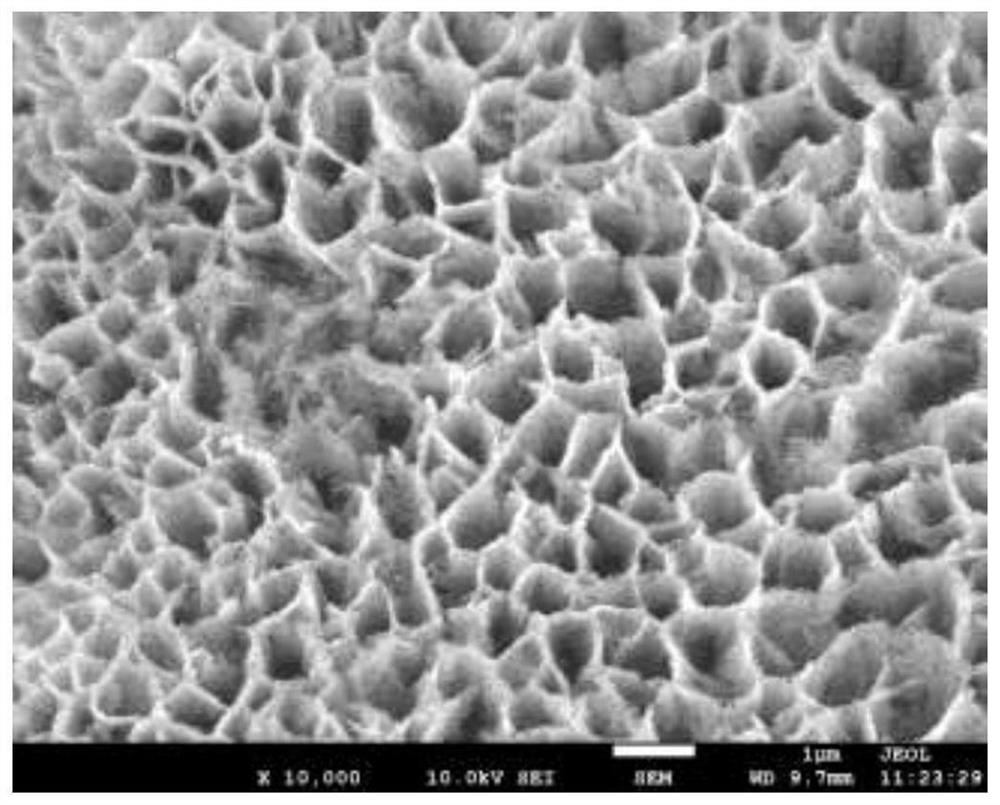

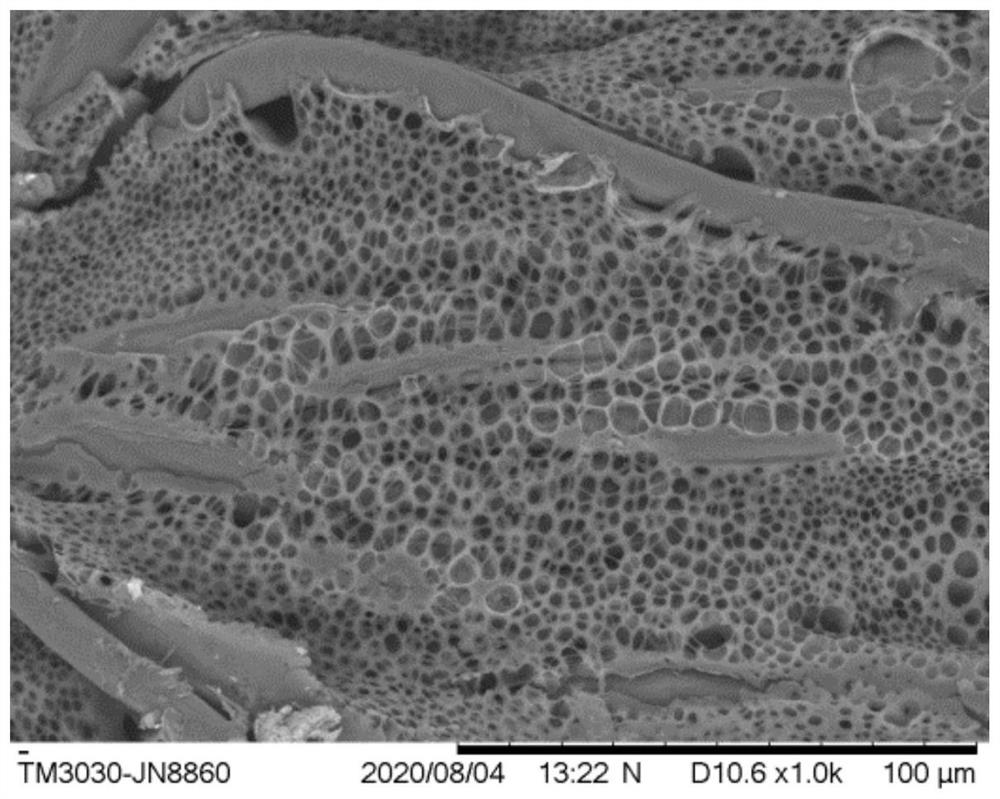

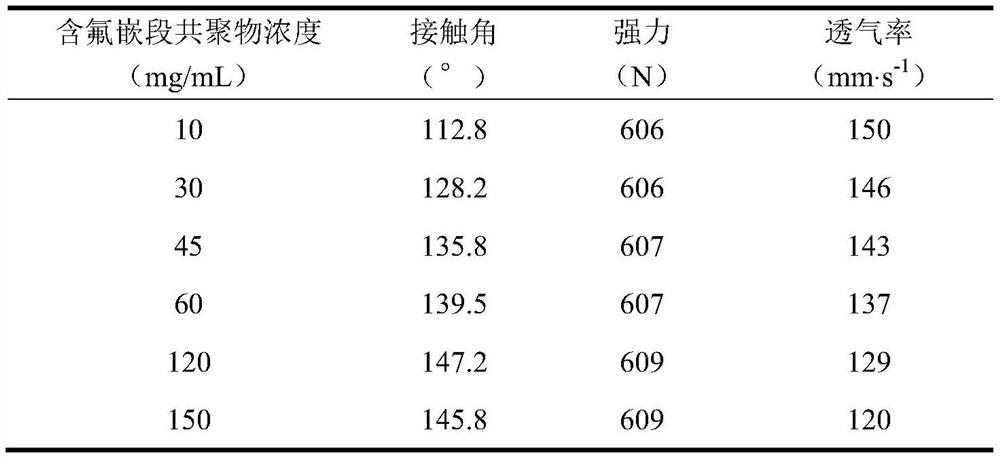

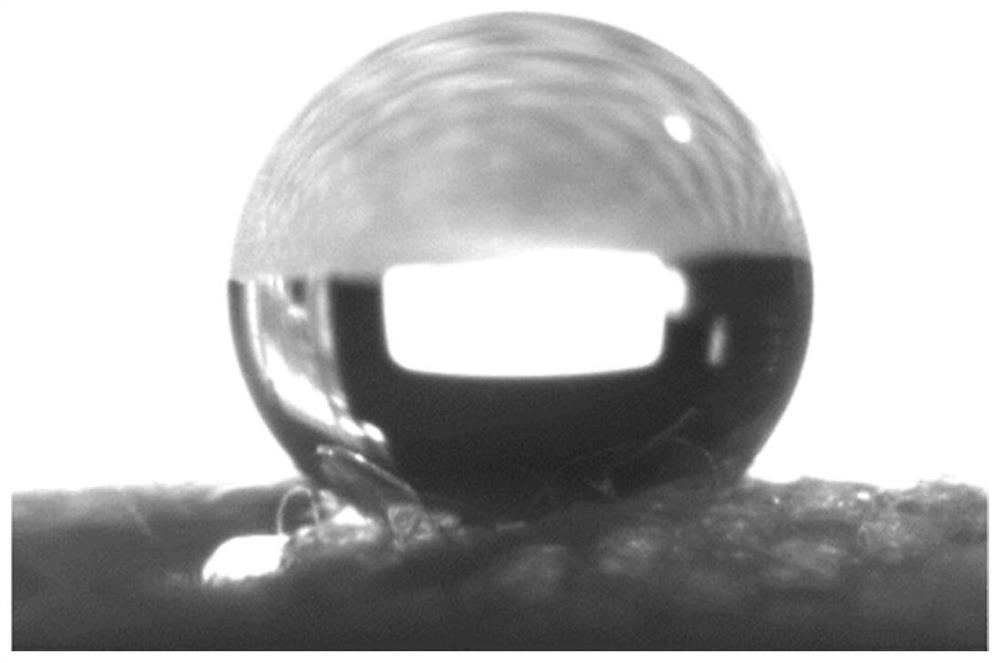

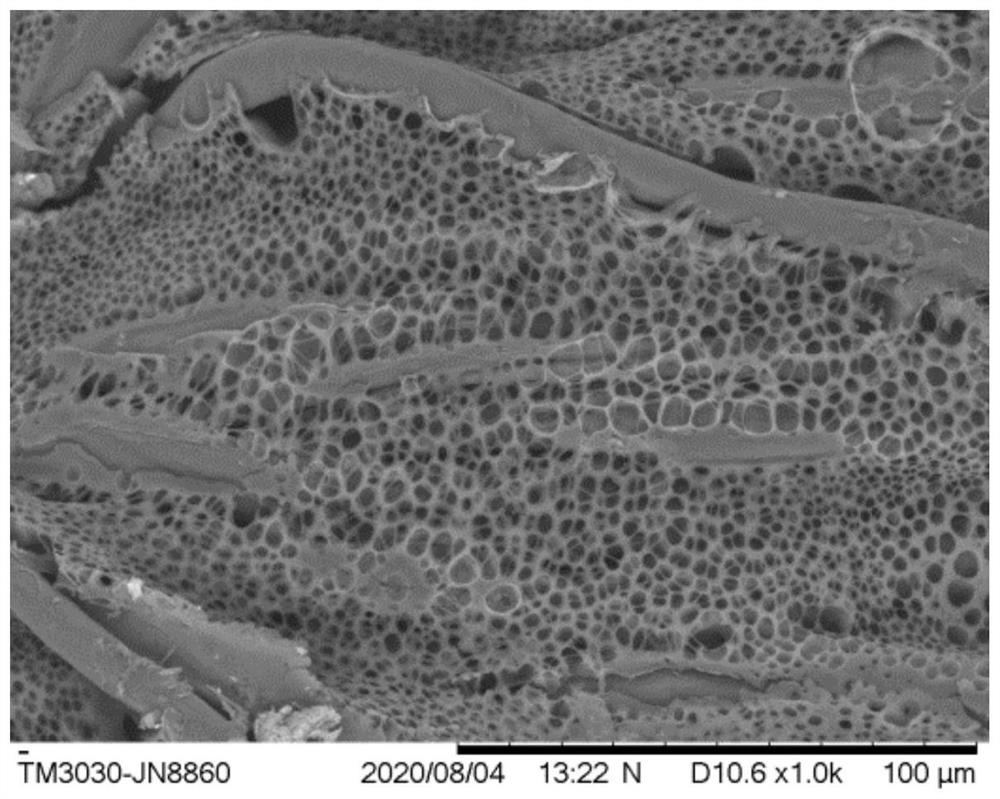

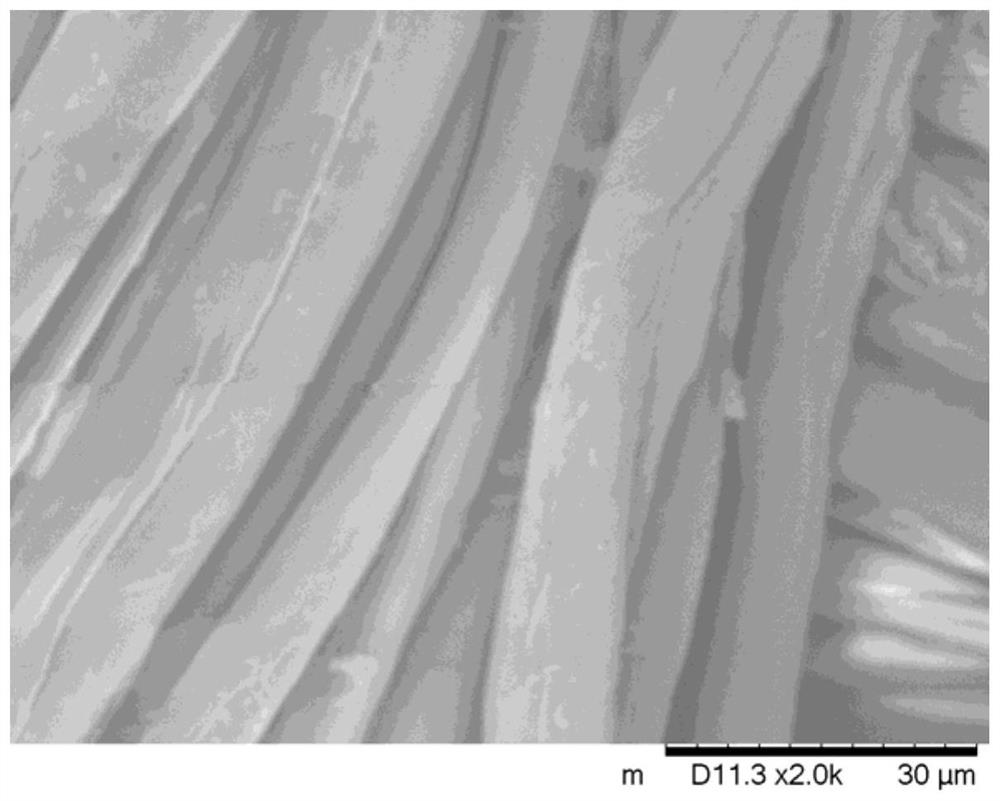

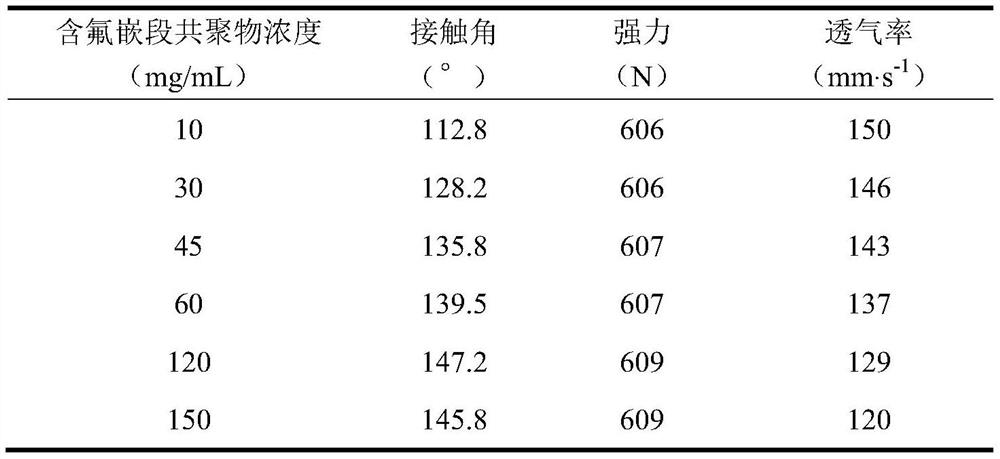

Preparation method of hydrophobic textile with porous surface structure

ActiveCN112695533ATo achieve the effect of hydrophobicPrevent coalescenceLiquid repellent fibresVegetal fibresPolymer scienceHydrophobe

The invention discloses a preparation method of a hydrophobic textile with a porous surface structure, and belongs to the technical field of textile finishing. According to the method, a hydrophobic or amphiphilic block copolymer is used as a film forming matter; volatile trichloromethane or dichloromethane is used as a solvent; and the fabric is soaked in a solution for a certain period of time, and then under the conditions of certain concentration and atmosphere humidity, the surface of the fabric is of a micro-nano-scale porous structure. The concentration of the block copolymer, the ambient humidity, the solvent, the type of the block copolymer and the like play an important role in formation of porous morphology on the surface of the fabric. The obtained fabric with the hydrophobic property is easy to adjust in surface appearance and good in hydrophobic property, the strength is not affected, and the fabric has potential application in the fields of self-cleaning, oil-water separation, filter membranes and the like.

Owner:JIANGNAN UNIV

Template for duplicating hydrophobic coating

The invention discloses a template for duplicating a hydrophobic coating. The template is prepared with a method comprising the step as follows: firstly, a template material is prepared, and raw materials of the template comprise 40-70 parts of silicone resin, 0.01-10 parts of a leveling agent, 0.01-10 parts of a defoaming agent, 0.01-5 parts of a catalyst and 20-50 parts of a solvent. After the silicone resin is dissolved in a solvent in proportion, the defoaming agent, the leveling agent and the catalyst are added and stirred uniformly, heat preservation is performed at the temperature of 40-100 DEG C for 1-8 h, and the template material for duplicating the hydrophobic coating is obtained; and then the surface of the template material is etched: soluble salt is inlaid in the surface layer of the template material in a repeated spraying mode, salt particles are etched, a multi-stage coarse structure is formed on the surface of a matrix simply and rapidly, and the template for duplicating the hydrophobic coating is prepared. The template adopts a simple process, has low production cost, is green and environmentally friendly, and can be recycled.

Owner:EAST CHINA UNIV OF SCI & TECH

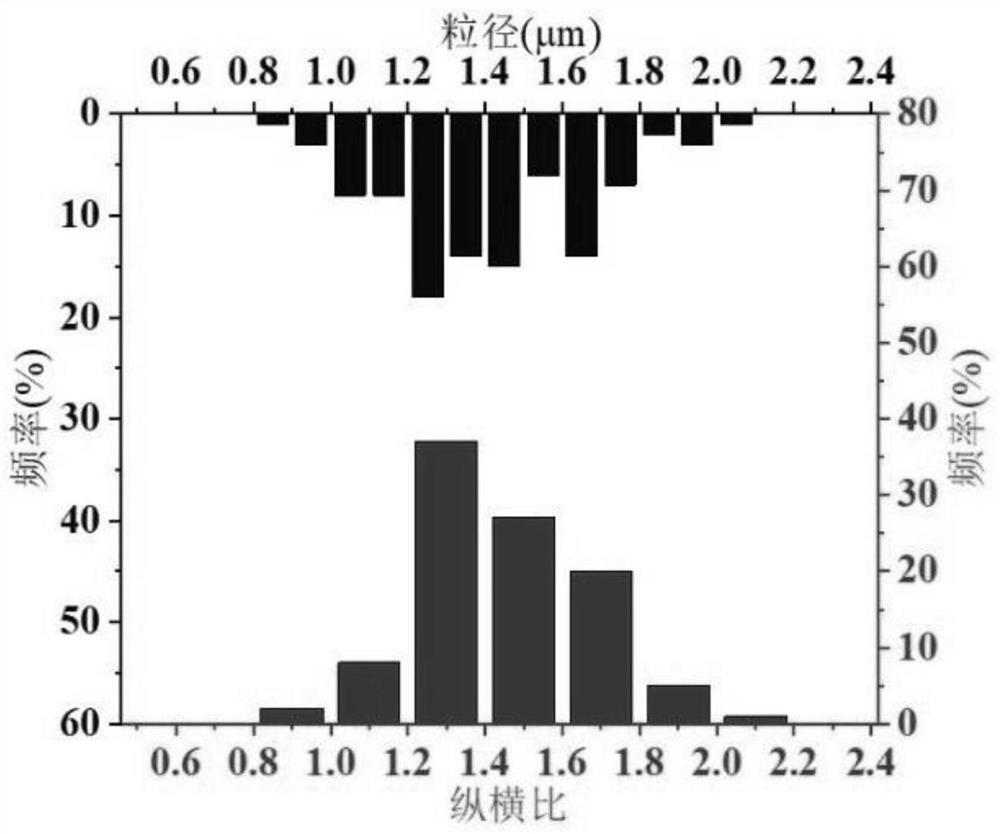

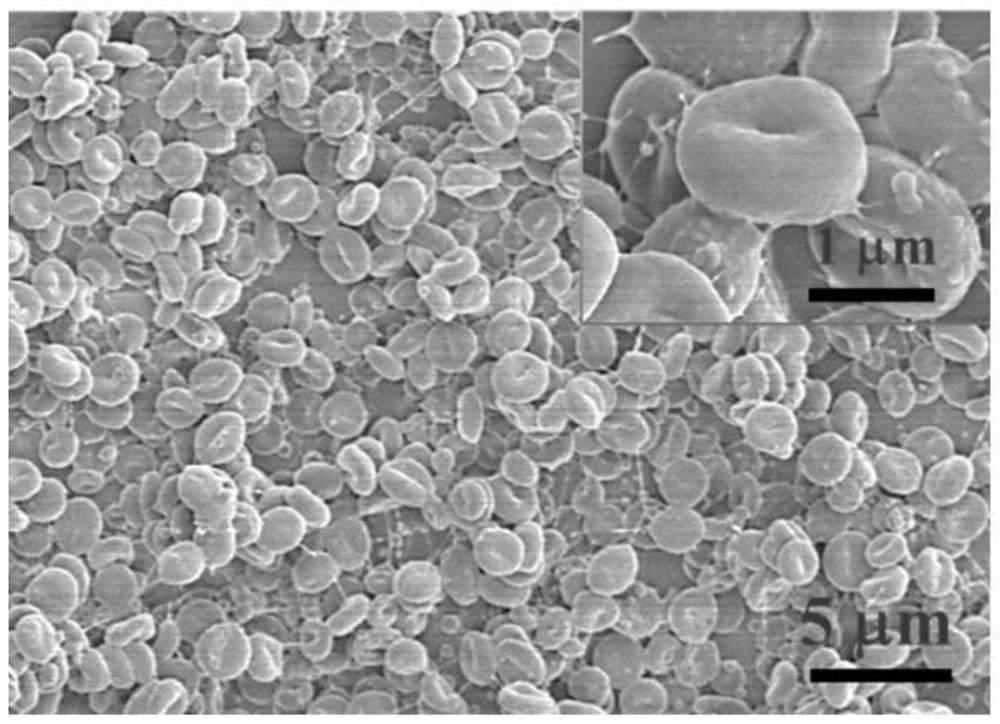

High-adhesion quasi-super-hydrophobic material and preparation method thereof

InactiveCN113638263AImprove adhesionAchieve superhydrophobicityWater-repelling agents additionPaper coatingPolymer scienceChemical composition

The invention discloses a high-adhesion quasi-super-hydrophobic material and a preparation method thereof. The preparation method comprises the following steps that polyurethane is dissolved in N, N-dimethylformamide, and an electronic injection solution with the viscosity range value ranging from 15 mPas to 25 mPas and the conductivity range value ranging from 6.40 s / cm to 10.71 s / cm is obtained; and the electronic injection solution is sprayed on the surface of a base material by adopting an electrostatic spraying method, so that polyurethane microspheres are attached to the surface of the base material, thereby obtaining the high-adhesion quasi-super-hydrophobic material. According to the high-adhesion quasi-super-hydrophobic material and the preparation method thereof, the preparation method is simple, complex equipment is not needed in the preparation process, the prepared high-adhesion quasi-super-hydrophobic material achieves super-hydrophobic or quasi-super-hydrophobic performance, and meanwhile, due to the special chemical composition of polyurethane, the high-adhesion quasi-super-hydrophobic material has high adhesion.

Owner:SUZHOU UNIV

A kind of superhydrophobic fabric and its preparation method and application

ActiveCN109736080BAchieve superhydrophobicityShort reaction timePhysical treatmentLiquid separationSuperhydrophobePolymer science

The invention belongs to the field of polymer material science, and particularly relates to a super-hydrophobic fabric and a preparation method and application thereof. The method uses γ-mercaptopropyl trimethoxy silicon to connect the fabric and vinyl terminated polydimethylsiloxane, first reacting the hydrolyzed γ-mercaptopropyl trimethoxy silicon with the fabric, and then γ-mercaptopropyl trimethoxy silicon Propyltrimethoxysilicon reacts with vinyl-terminated polydimethylsiloxane through click chemistry, resulting in the superhydrophobicity of the fabric. The method does not use strong acid, strong base and toxic reagents, utilizes the mercapto group in γ-mercaptopropyl trimethoxysilicon to react with the vinyl group on the vinyl-terminated polydimethylsiloxane, the reaction time is short, and the process is simple , suitable for industrial production. When the obtained superhydrophobic fabric is in the air, the contact angle of water droplets on its surface is 151-156°, and the rolling angle is 5-8°. When it is used for oil-water separation, the separation rate is as high as 99.95%, and the separation efficiency can still be maintained above 99.9% after repeated use.

Owner:中科检测技术服务(广州)股份有限公司 +2

Preparation method of hydrophobic textile with porous surface structure

ActiveCN112695533BTo achieve the effect of hydrophobicPrevent coalescenceLiquid repellent fibresVegetal fibresMicro nanoPolymer science

The invention discloses a method for preparing a hydrophobic textile with a porous surface structure, belonging to the technical field of textile finishing. The method uses a hydrophobic or amphiphilic block copolymer as a film-forming substance, uses volatile trichloromethane or dichloromethane as a solvent, immerses the fabric in the solution for a certain period of time, and then immerses the fabric in a certain concentration and atmospheric humidity. Under these conditions, the surface of the fabric presents a micro-nano porous structure. The concentration of block copolymer, atmospheric humidity, solvent, and type of block copolymer played an important role in the formation of the porous morphology of the fabric surface. The surface morphology of the hydrophobic fabric obtained by the invention is easy to adjust, the hydrophobicity is good, the strength is not affected, and the fabric has potential applications in the fields of self-cleaning, oil-water separation, filter membranes and the like.

Owner:JIANGNAN UNIV

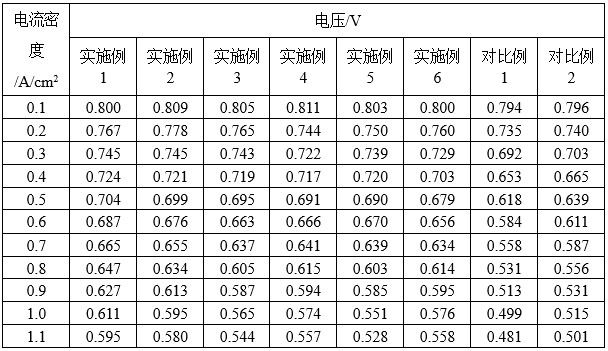

Fuel cell membrane electrode gas diffusion layer and its microporous layer preparation method and application

ActiveCN112724724BSmall expansion coefficientNo residual stressFinal product manufacturePretreated surfacesPolymer scienceFuel cells

The invention discloses a fuel cell membrane electrode gas diffusion layer and a preparation method and application thereof, belonging to the field of fuel cells. The gas diffusion layer includes a support layer and a microporous layer; the preparation method of the microporous layer includes the following steps: dissolving organosiloxane, active monomer, photoinitiator, coupling agent and carbon material in a predetermined ratio In an organic solvent, stirring and dispersing to form a uniformly mixed slurry; coating the slurry on one side of the hydrophobically treated support layer until the loading amount of the carbon material is 0.5-3.0 mg / cm 2 , to obtain a support layer with slurry; placing the support layer with slurry in an ultraviolet curing box for curing, forming a microporous layer on the support layer. The invention prepares a uniform slurry by organosiloxane, active monomer, photoinitiator, coupling agent and carbon material, and adopts ultraviolet light curing technology to quickly cure the microporous layer of the gas diffusion layer. The process is simple and fast, and energy is saved. , to facilitate production.

Owner:YOUON TECH CO LTD +1

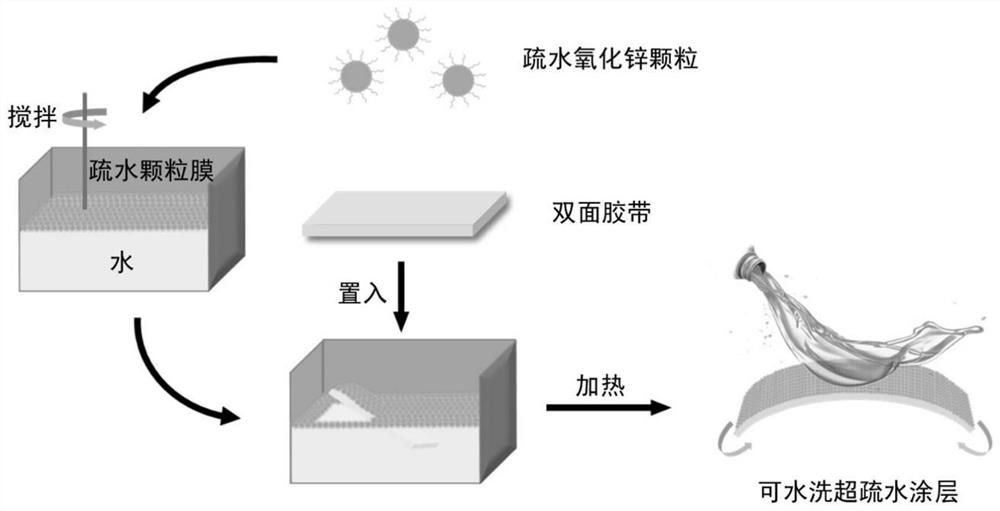

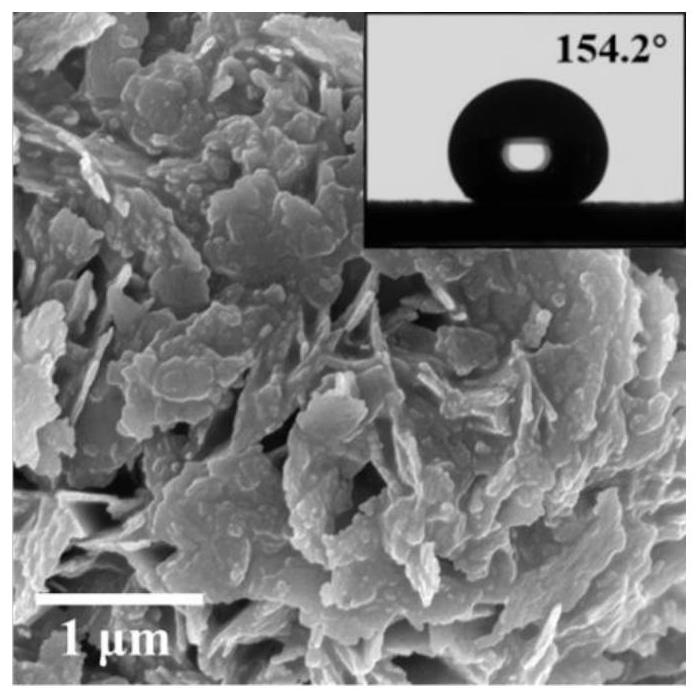

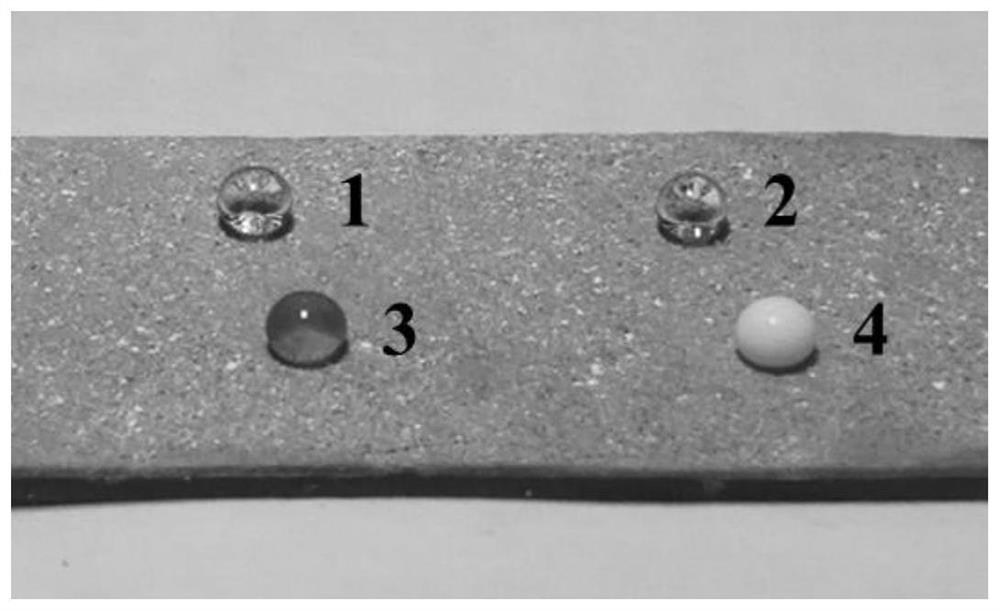

Washable antibacterial super-hydrophobic coating as well as preparation method and application thereof

ActiveCN114226211AImprove antibacterial propertiesGood underwater stabilityLiquid surface applicatorsAntifouling/underwater paintsFood industryTextile printer

The invention discloses a washable antibacterial super-hydrophobic coating and a preparation method and application thereof.According to the method, hydrophobic interaction is utilized, after hydrophobic nano-particles form a compact hydrophobic particle film on the water surface, a drainage sedimentation technology is changed into a printing technology, namely, a base plate with a double-face bonding layer is vertically placed into water, then the base plate is rotated to the horizontal angle to be slowly lifted, and the base plate is subjected to water washing; and the particle film is attached to the double-sided bonding layer, heating is carried out to enhance the bonding force of the particle film and the double-sided bonding layer, and the super-hydrophobic coating is obtained. The preparation method takes water as a medium, does not need to use an organic solvent, and has the characteristics of simple process and environmental protection; the printing process can greatly simplify the process flow, reduce the production cost and is suitable for large-area preparation. The prepared super-hydrophobic coating has the advantages of good antibacterial performance, good super-hydrophobic performance, good underwater stability, washability, good flexibility and the like, has high practical value and good application prospects, and can be applied to the fields of medical treatment and public health, food industry, antifouling, environmental protection and the like.

Owner:NAT UNIV OF DEFENSE TECH

Super-hydrophobic sponge ball as well as preparation method and application thereof

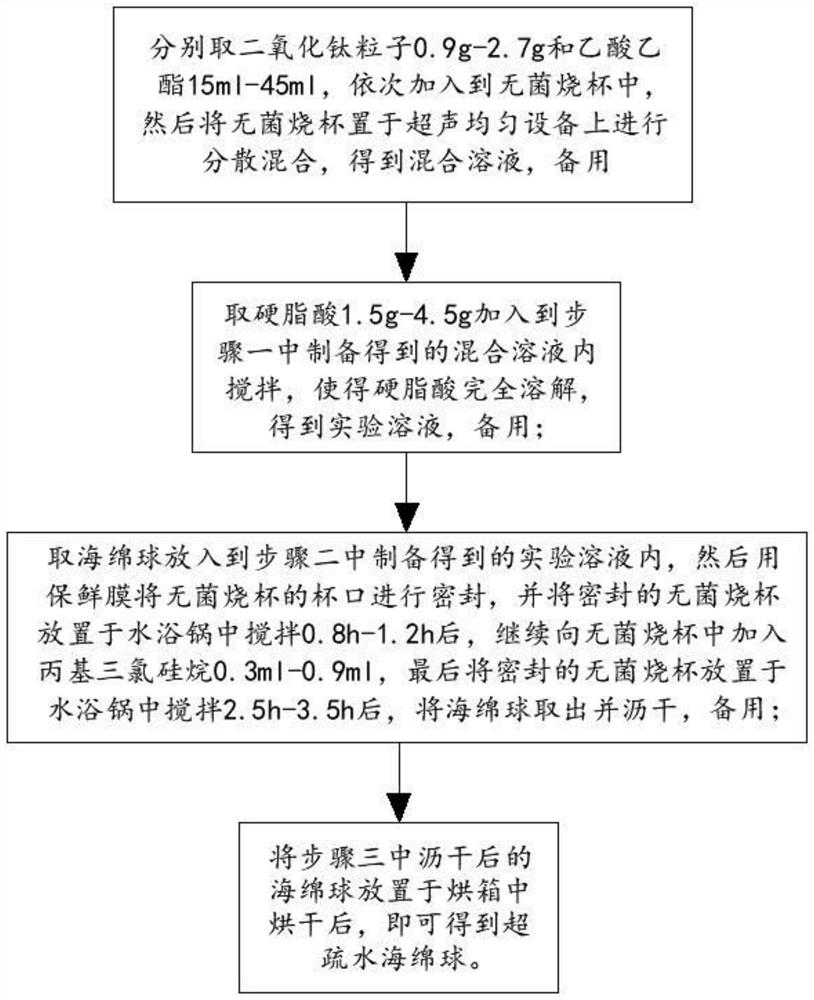

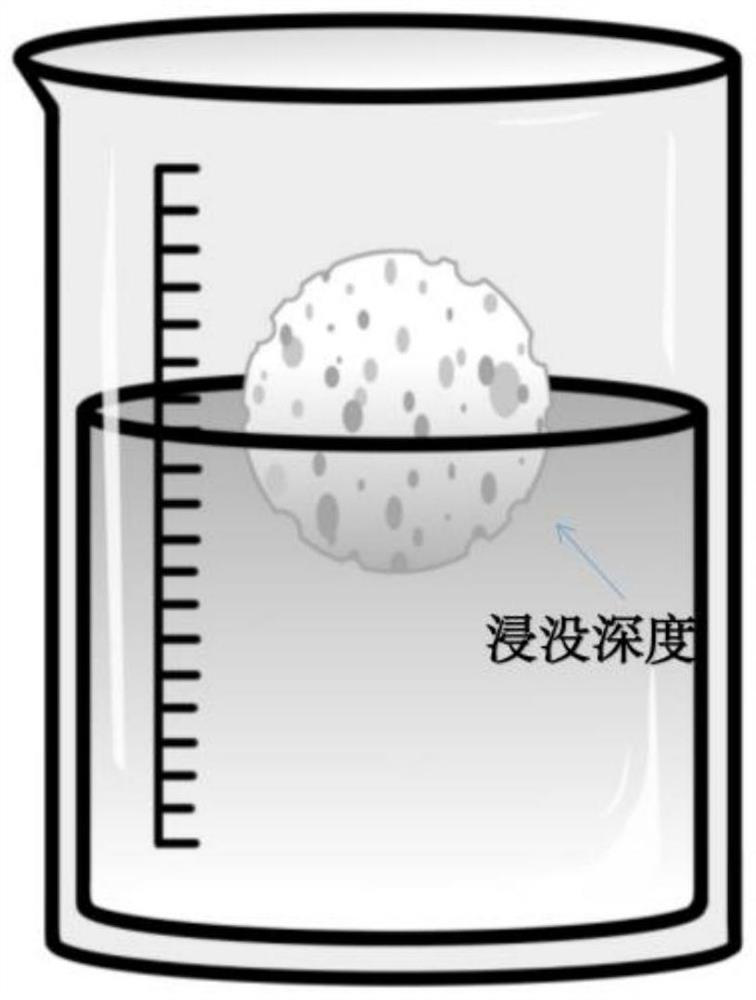

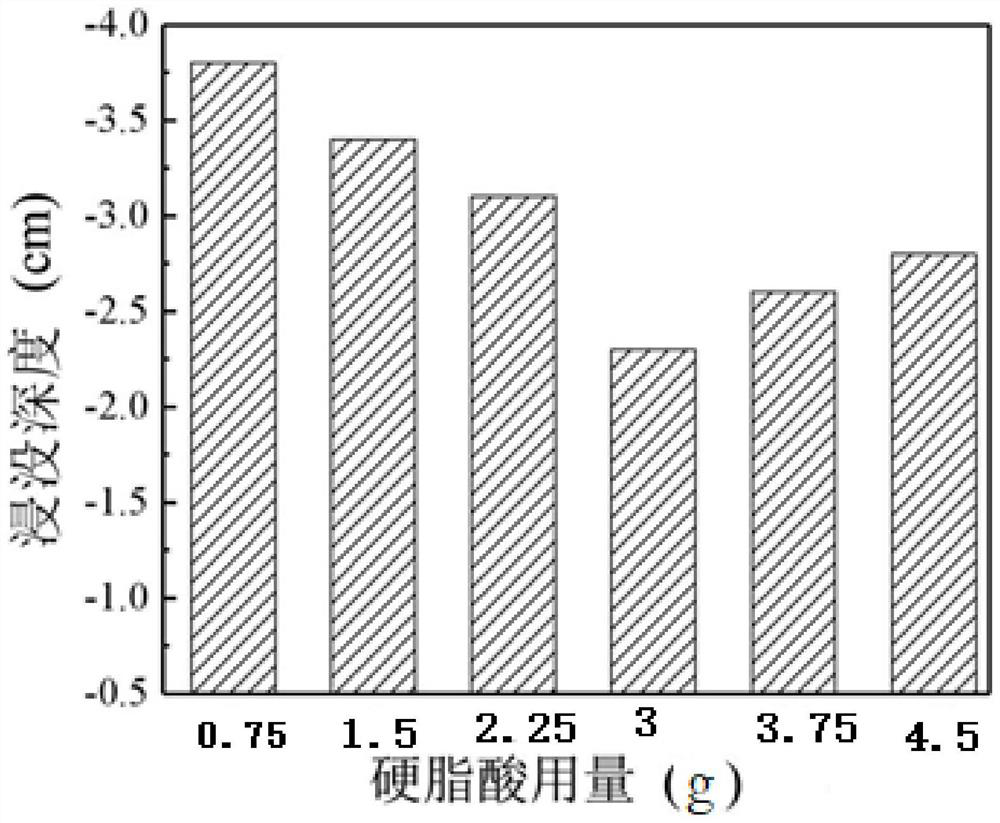

PendingCN114289001AHigh selectivitySelective oil absorptionOther chemical processesWater contaminantsOil separationMechanical stability

The invention relates to a preparation method of a super-hydrophobic sponge ball. The preparation method comprises the following steps: 1, respectively adding titanium dioxide particles and ethyl acetate into a beaker in sequence, dispersing and mixing; 2, adding stearic acid into the mixture obtained in the step 1, and stirring until the stearic acid is completely dissolved; 3, a sponge ball is taken and placed in the step 2, then a preservative film is used for sealing and stirring a beaker opening, propyl trichlorosilane continues to be added into the beaker for sealing and stirring, and the sponge ball is taken out and drained; and step 4, drying the drained sponge balls to obtain the super-hydrophobic sponge balls. The sponge ball obtained by the preparation method provided by the invention has excellent chemical stability and mechanical stability, can adapt to various different types of water-oil separation, and is wide in application environment; the preparation method is simple, convenient and low in cost, and has conditions and basis for realizing large-scale industrial production; the method plays an extremely positive and important role in construction of the sponge city.

Owner:ZHUHAI TAIRAN TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com