Patents

Literature

59results about How to "Small rolling angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

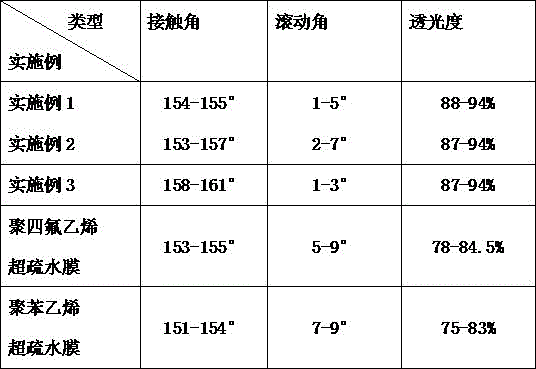

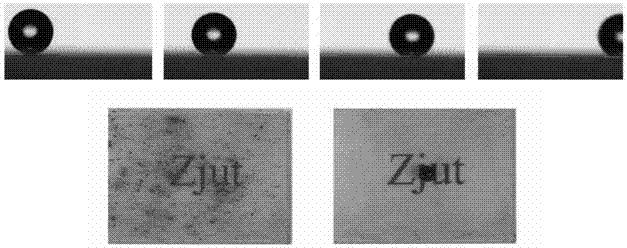

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496ALow costSimple equipment and preparation processPolyurea/polyurethane coatingsSurface energySelf-assembly

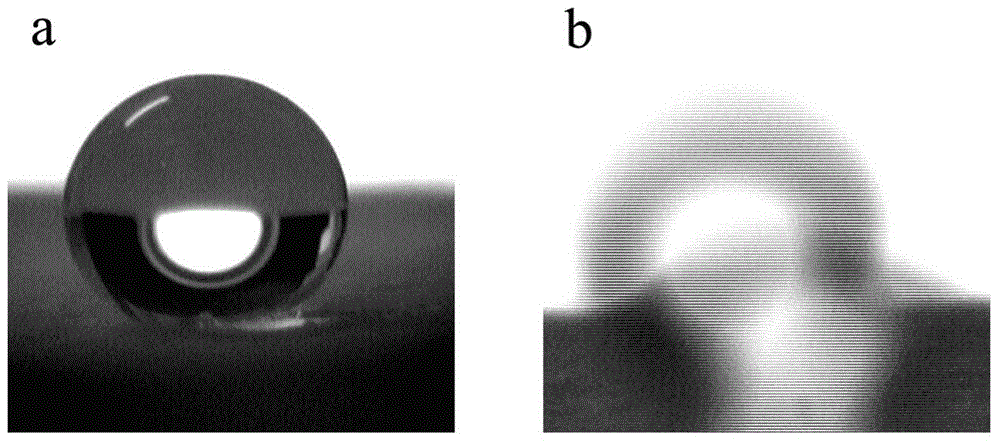

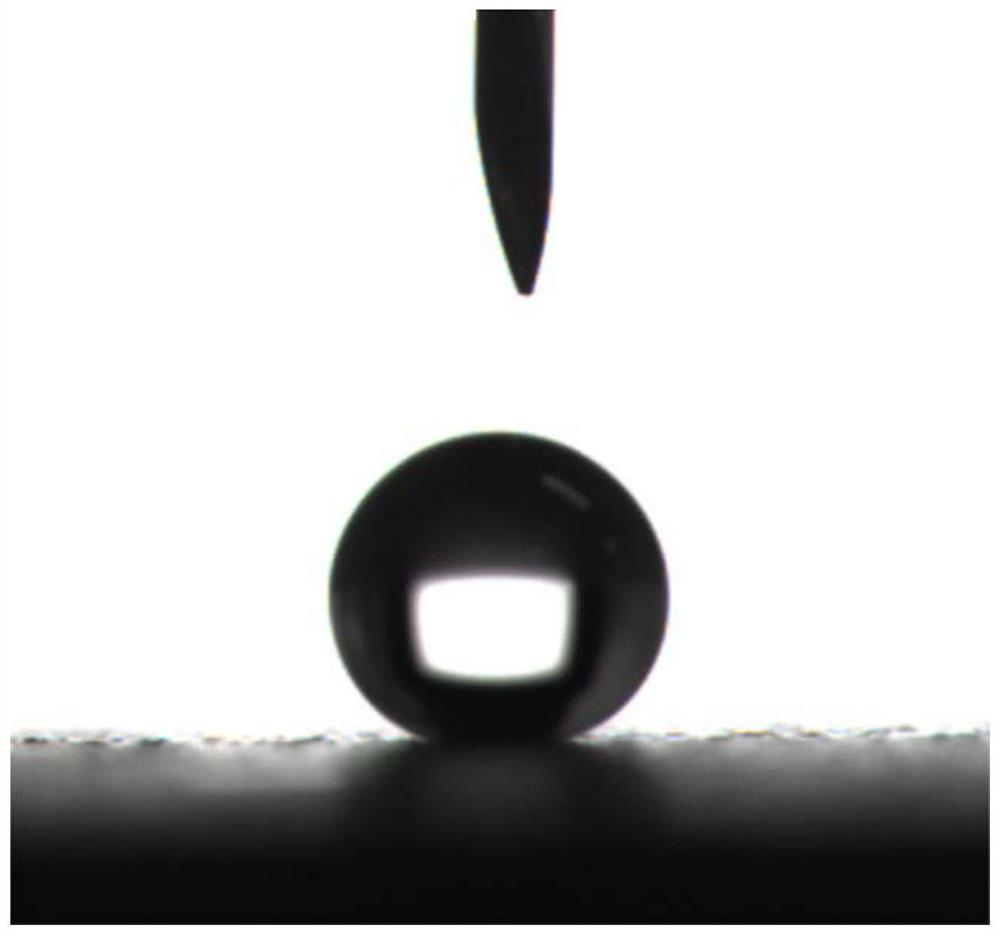

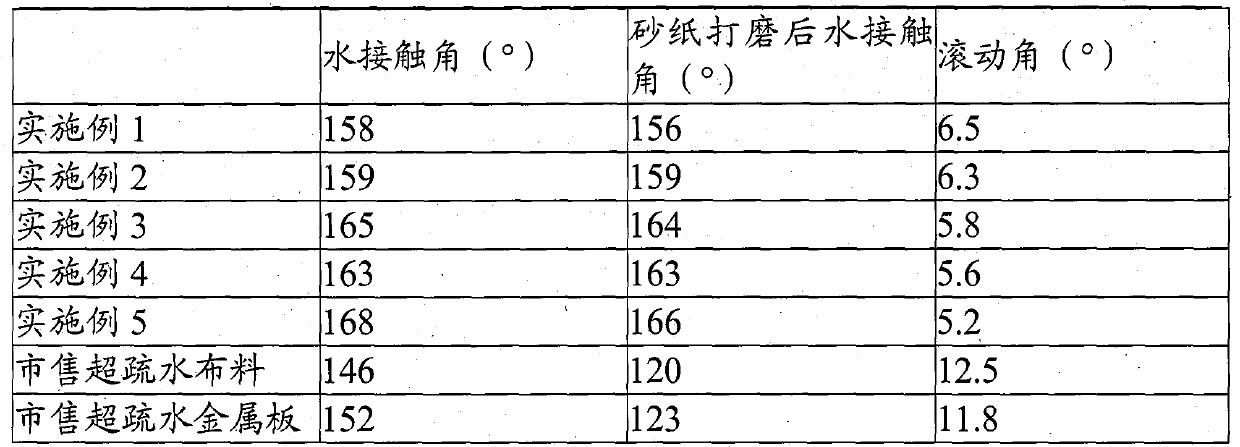

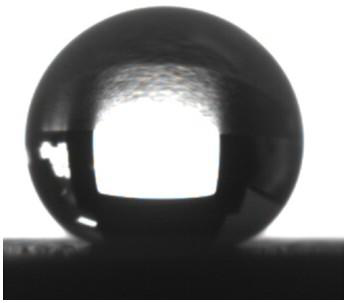

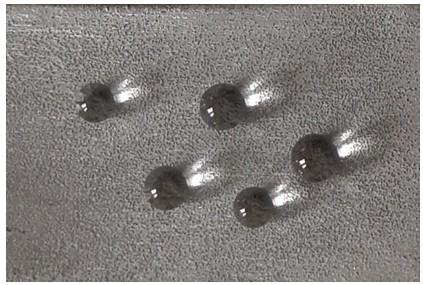

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and theprepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

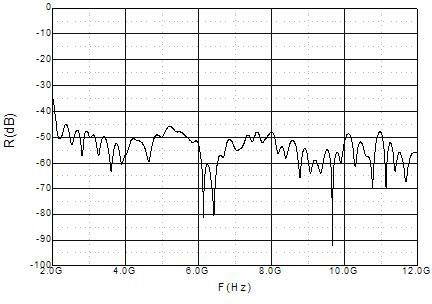

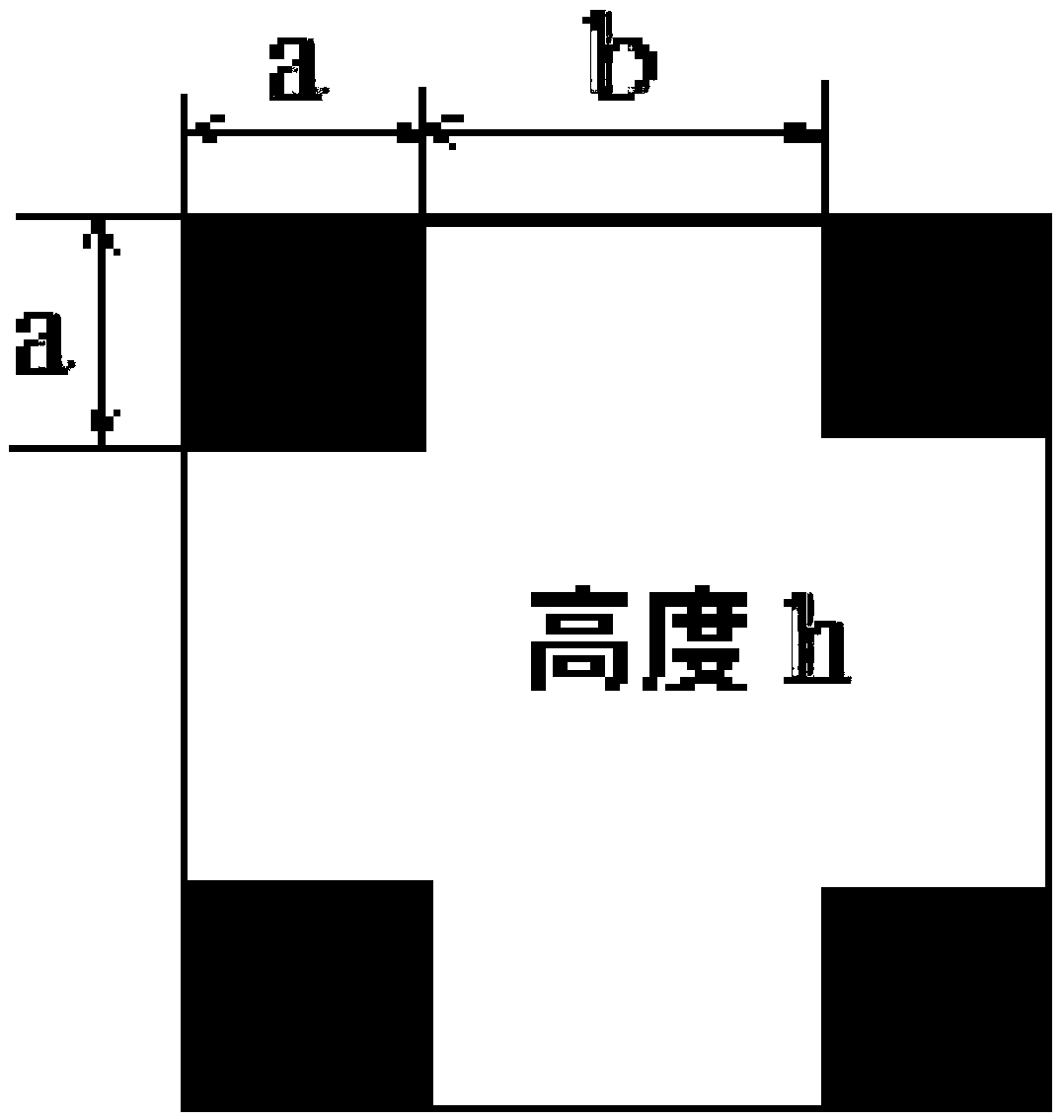

Self-cleaning microwave absorption paint and uses thereof

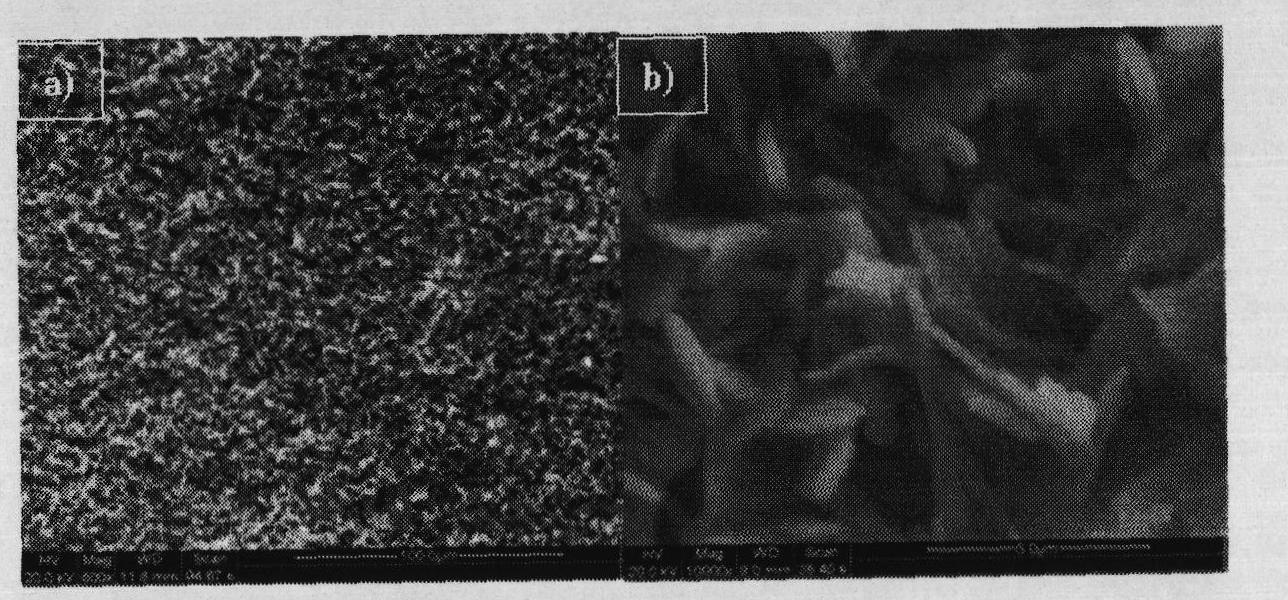

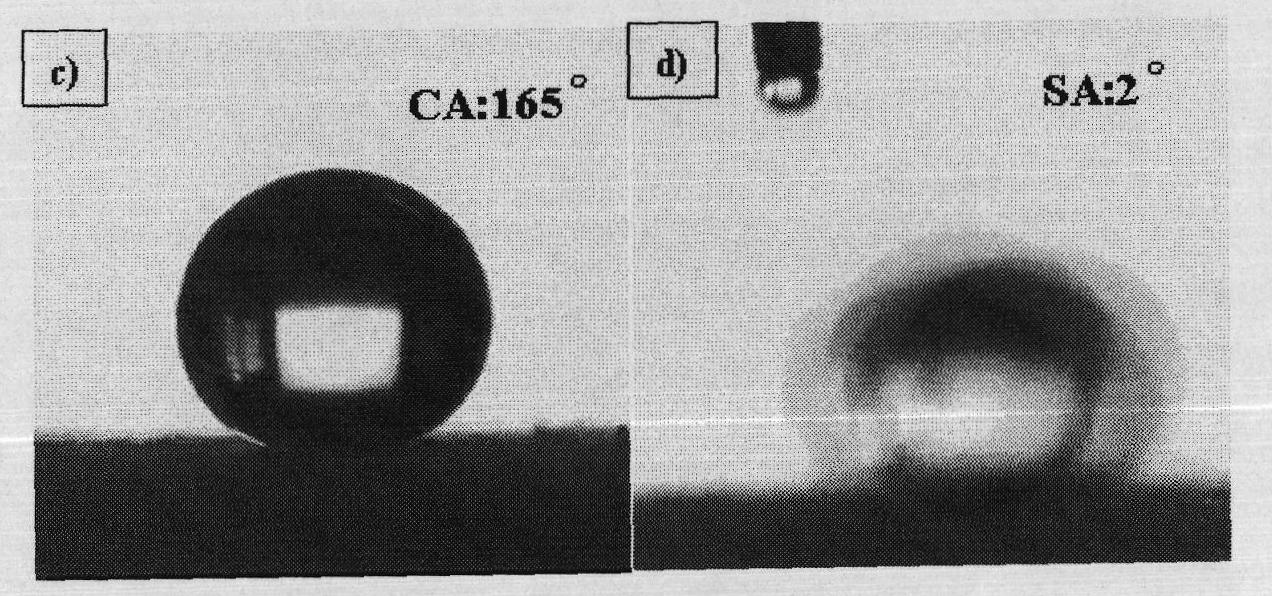

ActiveCN102229767AIncrease roughnessWear-resistantPolyurea/polyurethane coatingsRadiation-absorbing paintsMicrowaveOrganic solvent

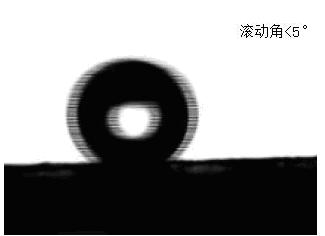

The invention relates to a self-cleaning microwave absorption paint and uses thereof. According to the invention, a urethane foam pyramidal material is coated with a layer of paint to form a micron-nano composite structure layer which has an angle of contact larger than 150 degrees and an angle of roll smaller than 5 degrees. The paint consists of a nano material, a micrometer material, a coupling agent, bonding resin, a base material, a curing agent, an auxiliary and an organic solvent. By means of the microwave absorption paint provided by the invention under a fireproof spraying mode, water beads can roll off a pyramidal surface rapidly with ashes contained in the water beads, thus achieving the effect of self cleaning, reducing the ashes in a microwave darkroom and accordingly meeting the special requirement of a cleaning-type dark room on maintaining high long-term cleanness. The self-cleaning microwave absorption paint provides a new way for implementing the cleaning-type dark room.

Owner:南京南大波平电子信息有限公司 +1

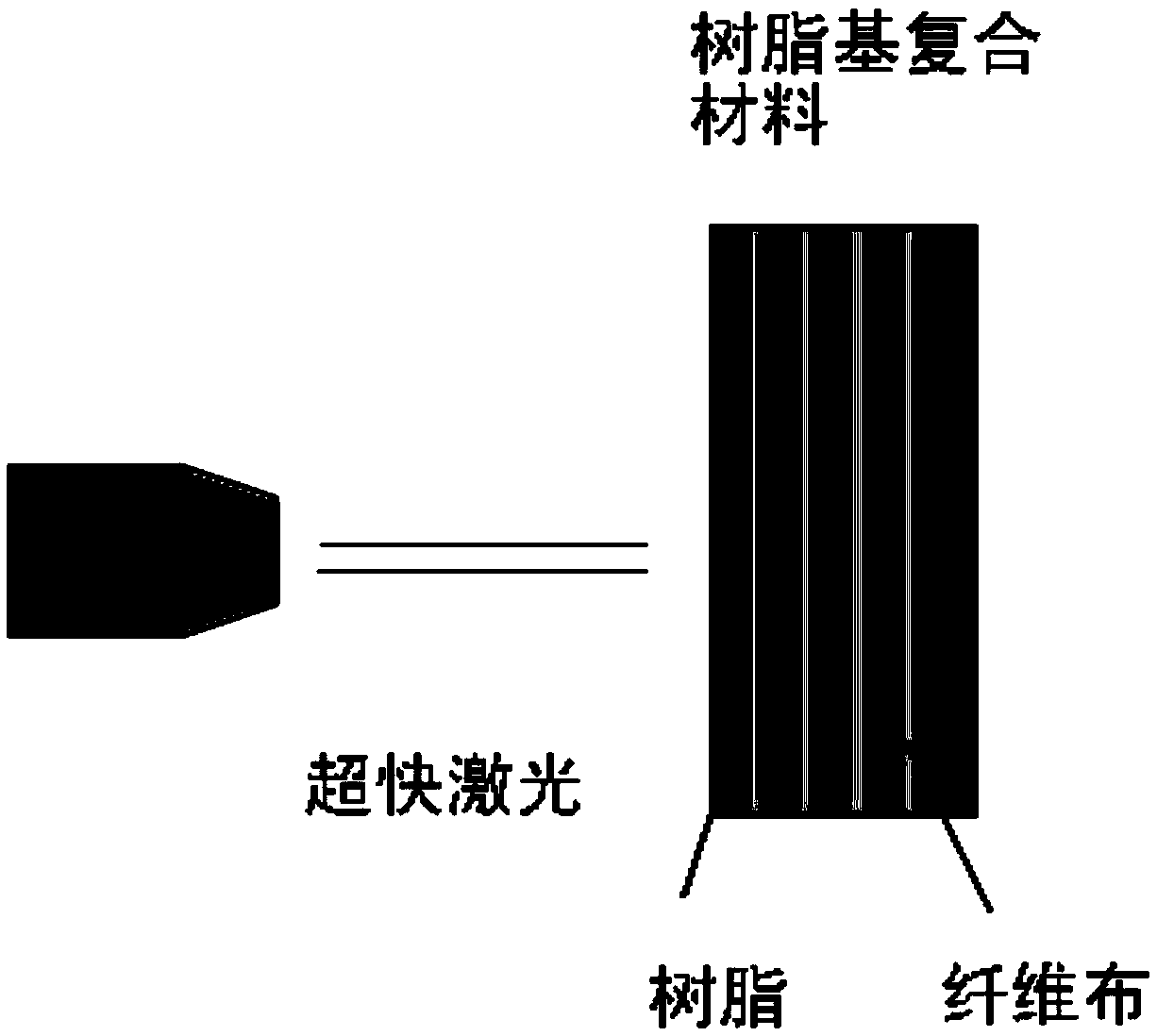

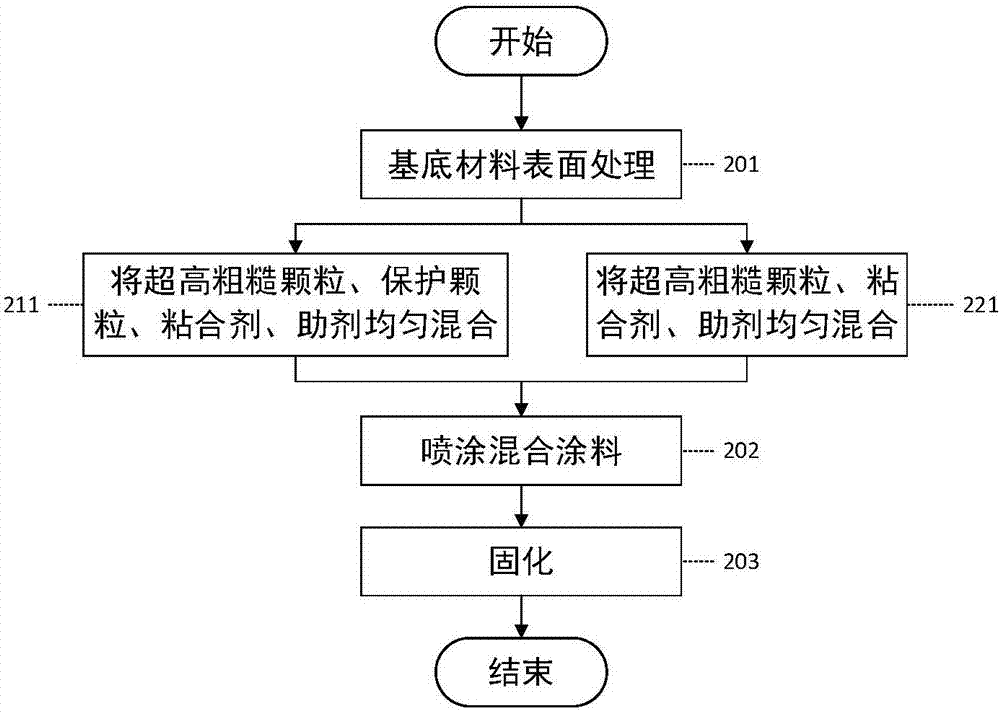

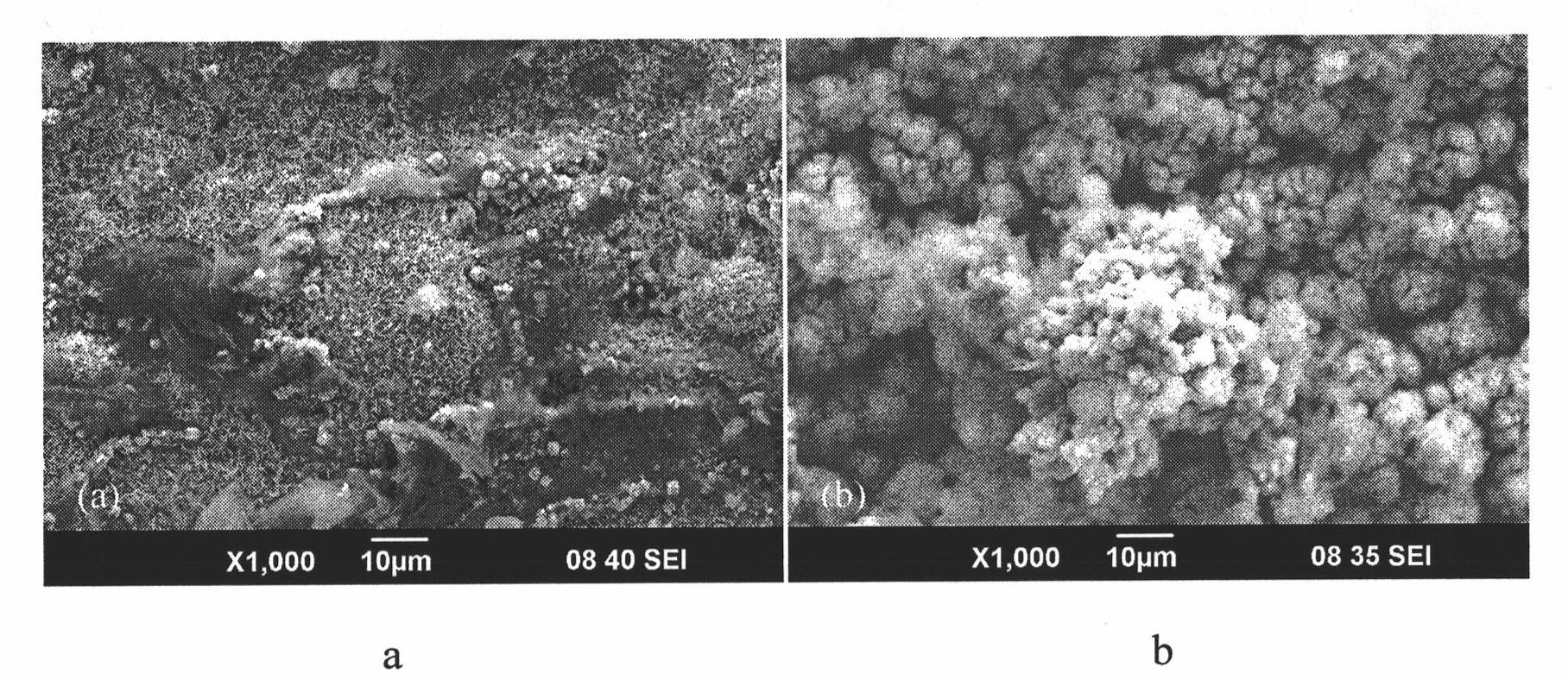

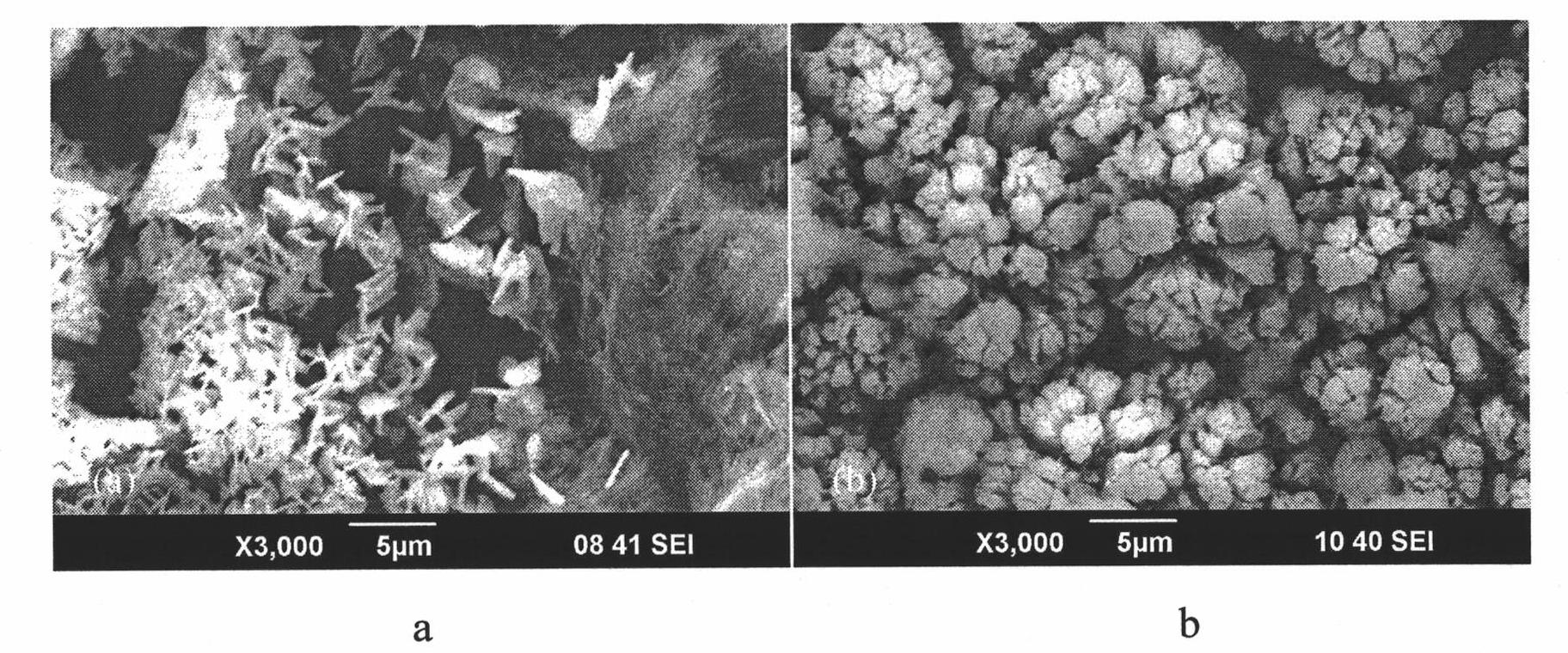

Resin matrix composite with super-hydrophobic bionic surface and preparation method of resin matrix composite

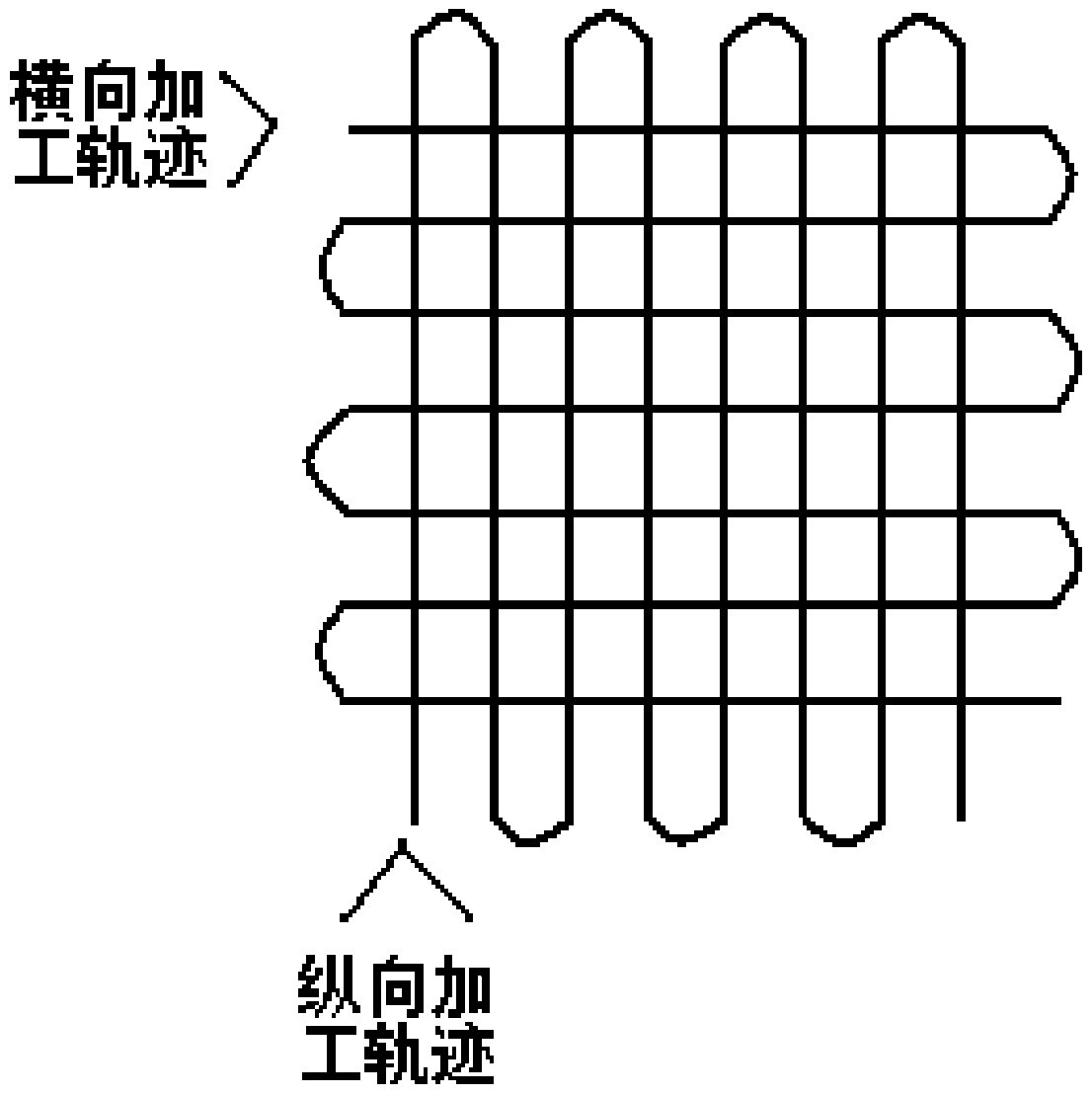

ActiveCN105504324AImprove environmental adaptabilityAvoid heat damageCoatingsMicrostructureResin matrix

The invention provides a resin matrix composite with a super-hydrophobic bionic surface and a preparation method of the resin matrix composite. The method comprises steps as follows: the surface of a matrix of the resin matrix composite is polished until the surface turns white; the matrix of the resin matrix composite is processed through ultrafast laser, and a microstructure is formed on the surface; a first coating is sprayed on the microstructure surface of the matrix of the resin matrix composite through a pneumatic type paint spray gun to form a bonding layer, a second coating containing nanosilicon dioxide particles is sprayed to form a surface hydrophobic function layer, and the resin matrix composite with the super-hydrophobic bionic surface is obtained. The preparation method is simple to operate and facilitates production, the prepared resin matrix composite with the super-hydrophobic bionic surface can allow water drops to freely slip off, and the real self-cleaning super-hydrophobic function is realized.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

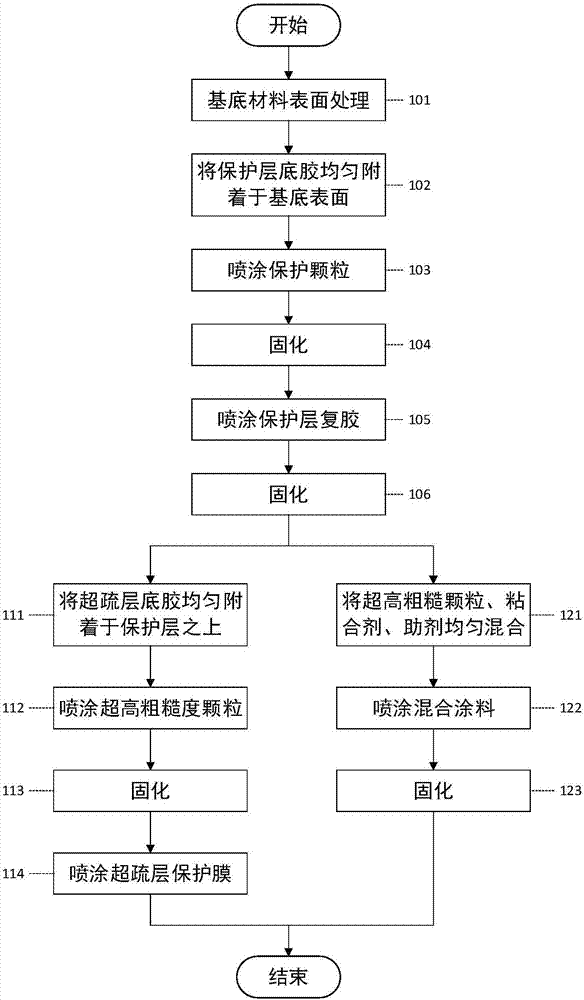

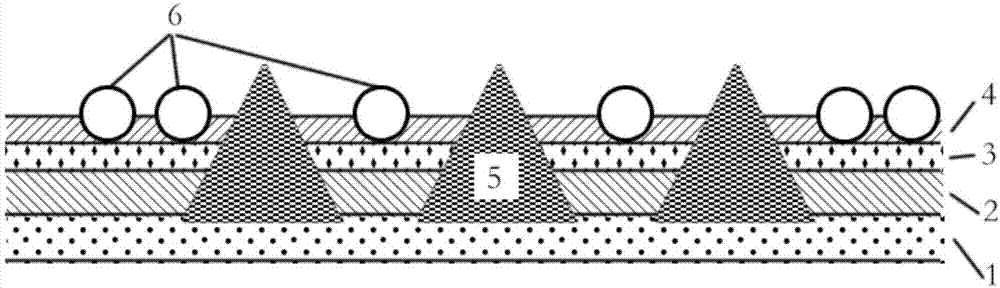

Coating prepared from particles with ultrahigh roughness

ActiveCN107254237AImprove performanceOvercome structurePretreated surfacesPolyurea/polyurethane coatingsSuperhydrophobic coatingLotus effect

The invention provides a superhydrophobic coating prepared from particles with ultrahigh roughness. The superhydrophobic coating is prepared from the following components: particles with protrusions or holes and unsmooth structures, protective particles, a bonding agent and an assistant, wherein the volume ratio of the particles with the protrusions or the holes and the unsmooth structures to the protective particles to the bonding agent is (0.1-7):(1-7):(1-10). A lotus effect technical theory is applied to obtain a super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic surface coating, further the performance of the coating is improved, and the defects of the conventional superhydrophobic coating that the structure is easy to damage, the service life is short and the like are overcome. The prepared coating has super hydrophobic properties (super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic properties), self-cleanness and excellent wear resistance; substrate materials suitable for the coating are glass, plastic, rubber, textiles, paper, metal, cement, ceramic materials or the materials covering other coatings.

Owner:HONGDA TECH BEIJING CO LTD

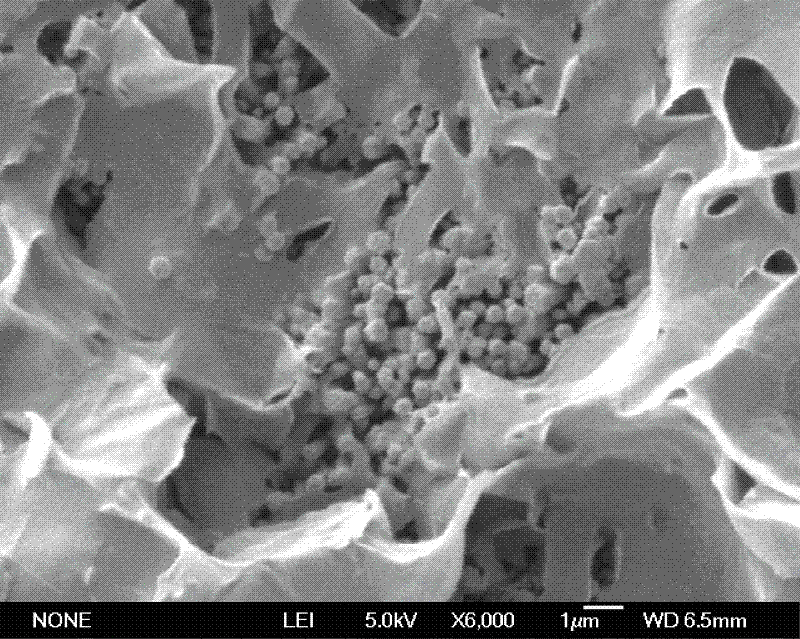

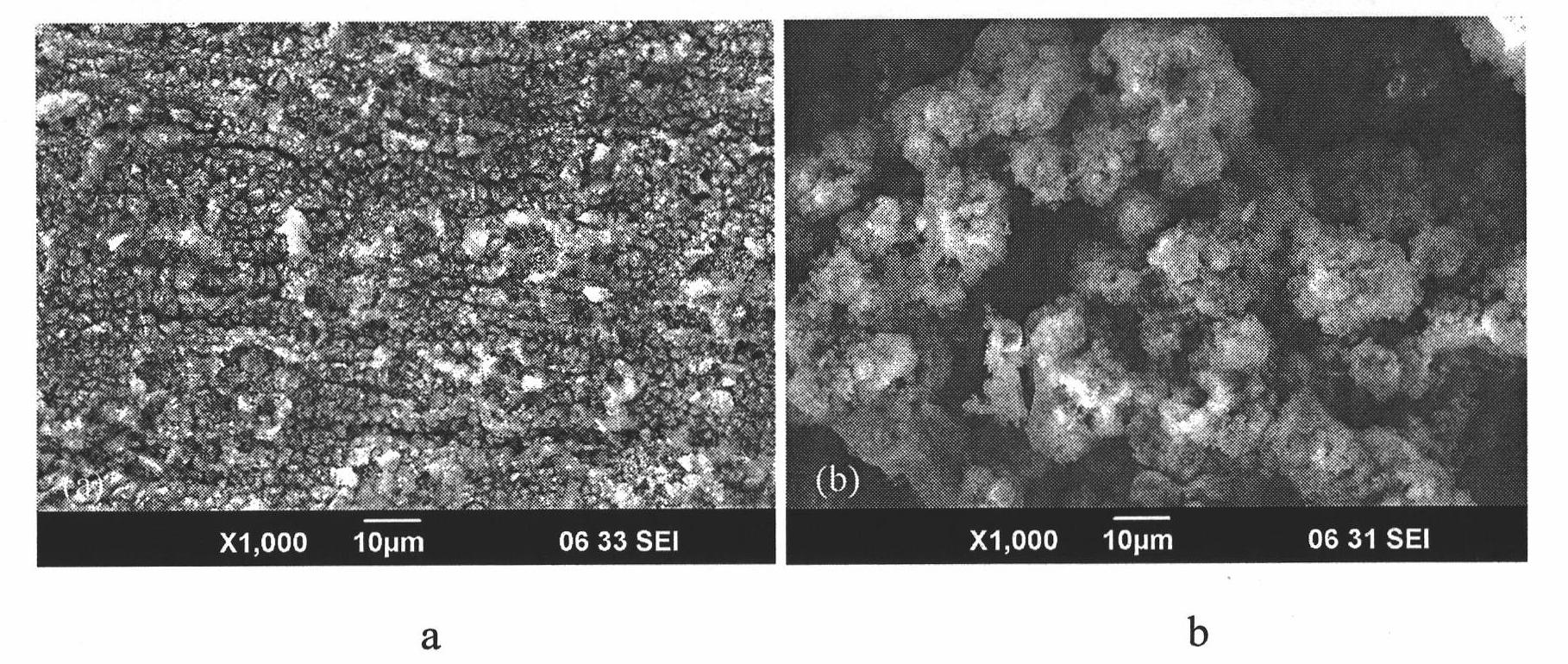

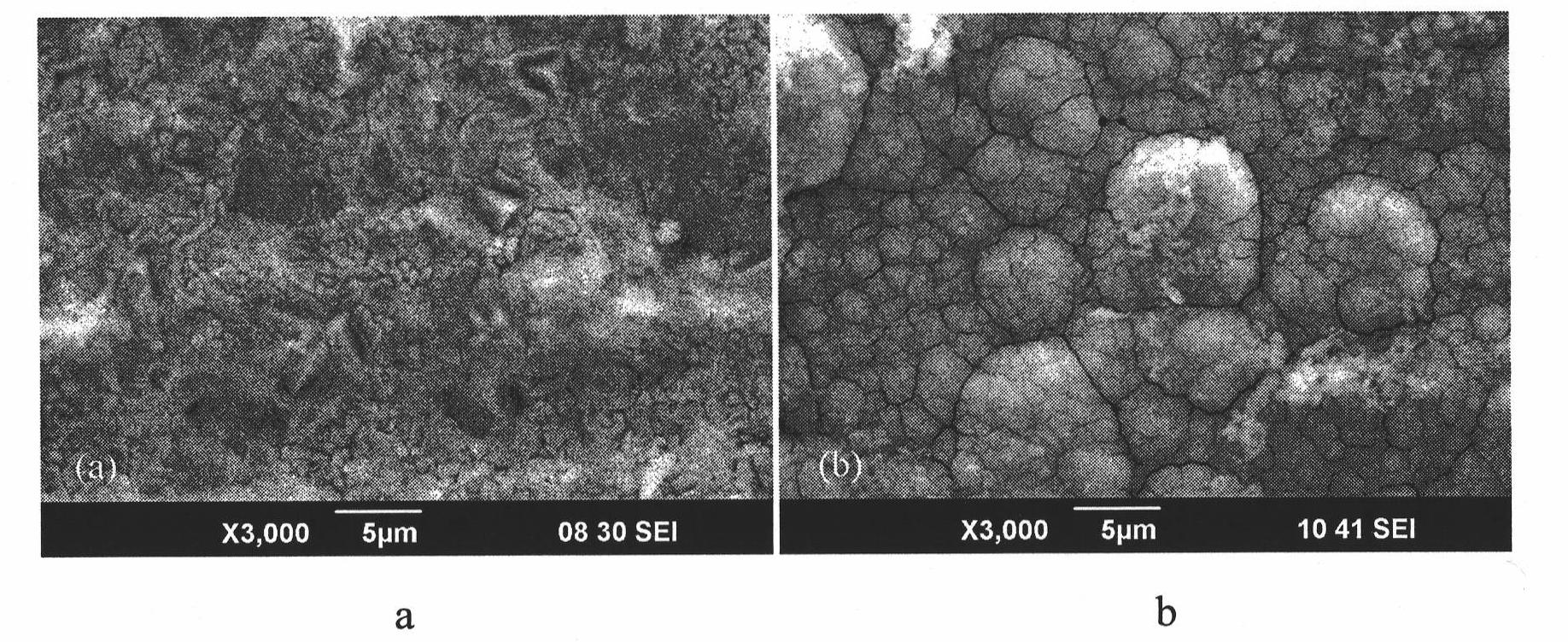

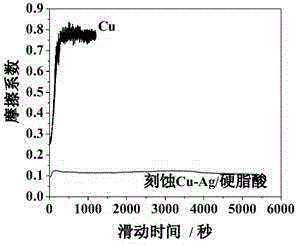

Copper based super-hydrophobic surface with low friction coefficient and preparation method thereof

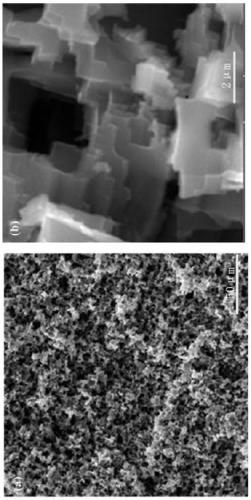

ActiveCN103469215AIncreased static contact angleReduce coefficient of frictionLiquid/solution decomposition chemical coatingMicron scaleEtching

The invention relates to a copper based super-hydrophobic surface with a low friction coefficient and a preparation method thereof. The copper based super-hydrophobic surface with a low friction coefficient is characterized in that chemical etching is performed on the surface of a copper based material to form a coarse structure with a micron-scale pit structure and submicron / nano-scale metal silver particles, and then a product is obtained through surface chemical modification. The copper based super-hydrophobic surface with low friction coefficient has a contact angle of more than 150 degrees to water, is low in friction coefficient, can be stably maintained, and has good super-hydrophobic properties and low friction coefficient.

Owner:XUCHANG UNIV

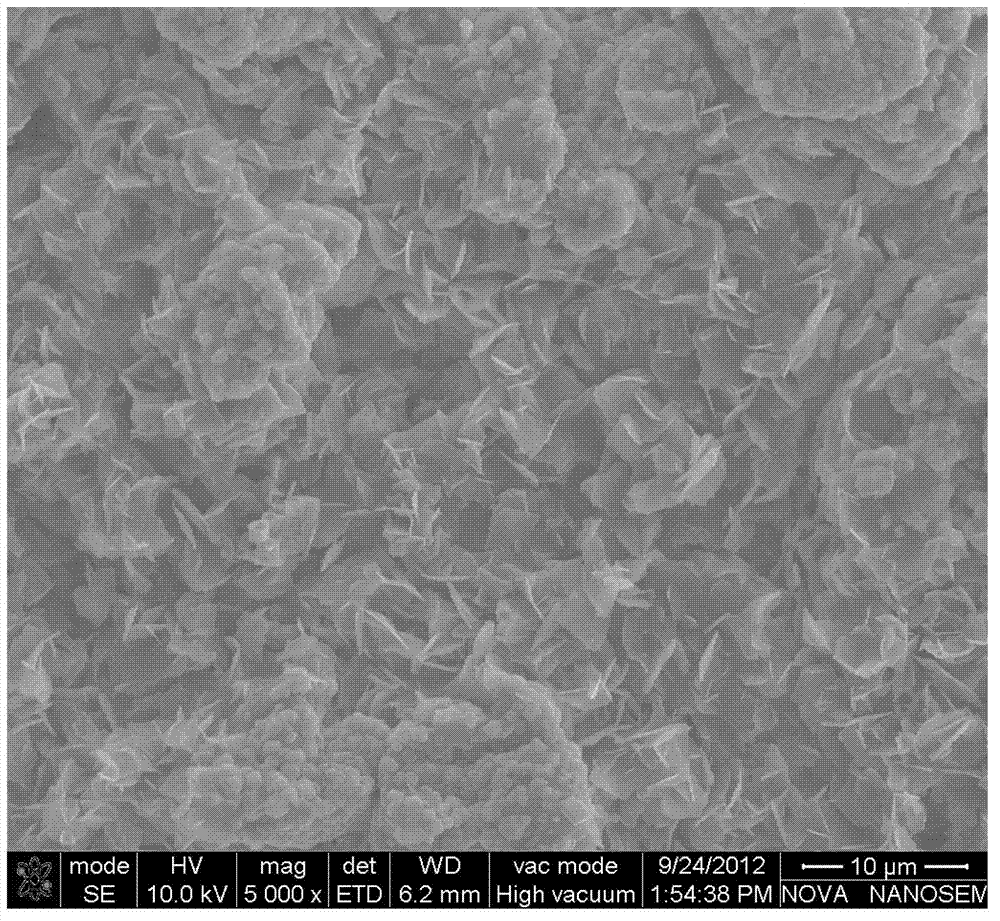

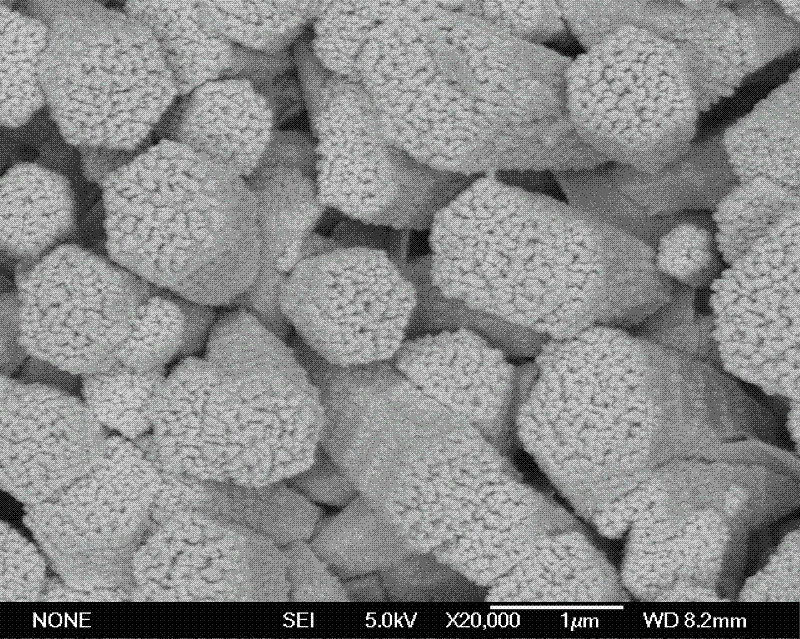

Preparation method of rubber-based composite material with super-hydrophobic surface

The invention discloses a preparation method of a rubber-based composite material with the super-hydrophobic surface. The preparation method comprises the following steps: firstly placing an aluminum sheet into chemical corrosive liquid to corrode for 2-120 minutes, washing the corroded aluminum sheet by deionized water, drying for standby; placing a mixed rubber compound onto the corroded aluminum sheet, then using a press vulcanizer to vulcanize or tablet the sheet; separating the cooled aluminum sheet from the rubber; brush coating an ethanol solution of a low surface energy substance on the rough surface of the separated rubber-based composite material, taking reaction for 1-36 hours at the temperature of 40-200 DEG C, and at last obtaining the rubber-based composite material with the micro-nano coarse structure super-hydrophobic surface. The surface water contact angle of the super-hydrophobic rubber-based composite material is more than 150 degrees; the rolling angle is smaller than 8 degrees; the super-hydrophobic rubber-based composite material has excellent comprehensive properties such as high elasticity, high abrasion resistance and high strength, is simple in preparation technology and beneficial to large-scale production and application.

Owner:SOUTH CHINA UNIV OF TECH

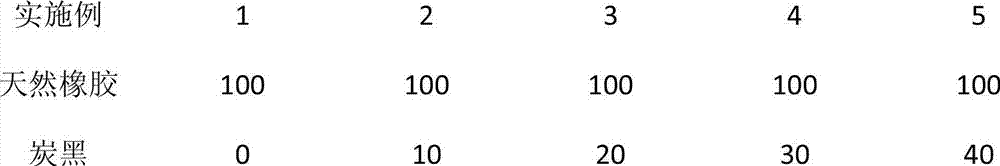

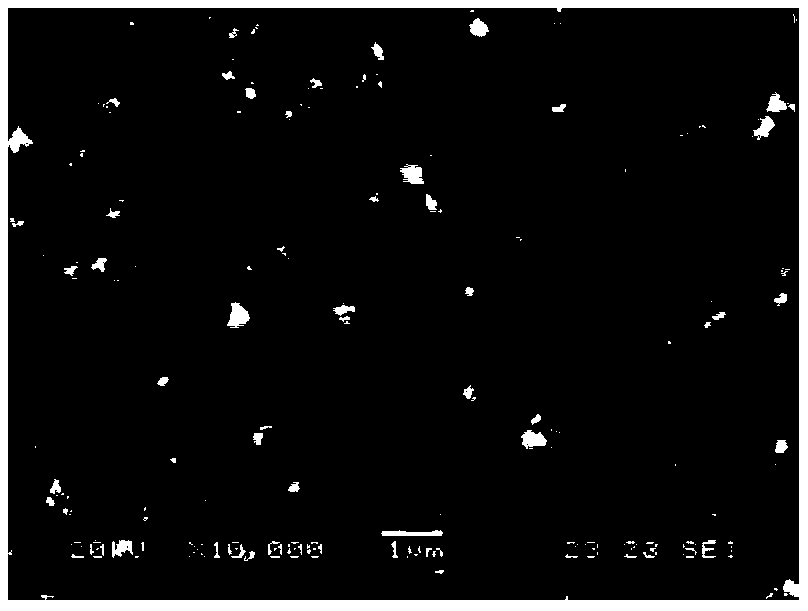

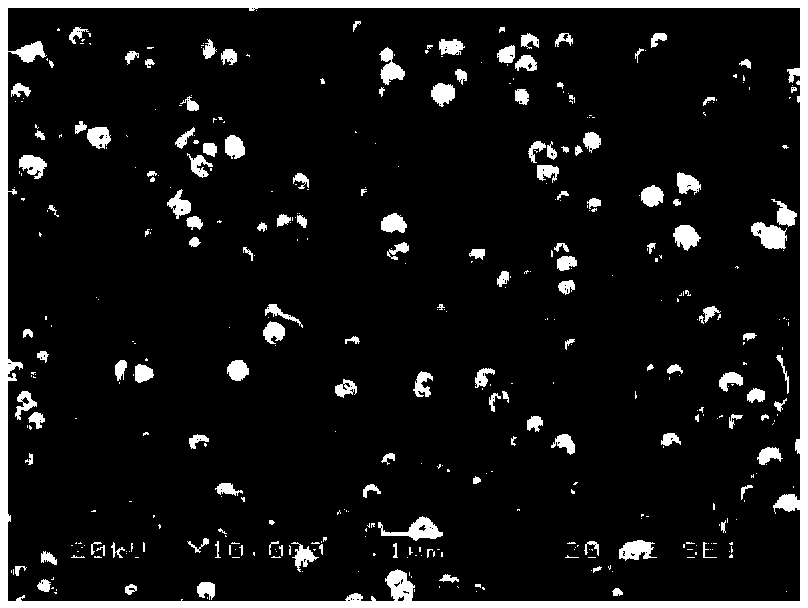

Method for preparing super hydrophobic film on surface of zinc substrate

InactiveCN102407220ASimple methodLow costPretreated surfacesMetallic material coating processesPolymer scienceHydroxystearic Acid

The invention provides a method for preparing a super hydrophobic film on the surface of a zinc substrate, which belongs to the technical field of a functional material. The method comprises the following steps of: ultrasonically washing a zinc sheet substrate, blow-drying by nitrogen gas, oxidizing by formamide water solution, and forming a rod-like nanometer zinc oxide array on the surface of a zinc sheet; and modifying by low surface energy substances, namely, stearic acid, 12-hydroxystearic acid and normal dodecyl mercaptan, and forming the super hydrophobic film with high static contact angle and low roll angle on the surface of the zinc sheet substrate. The super hydrophobic film may not be changed after being placed in the air for long time due to better stability and can be used for preventing water, resisting frost, preventing snow and resisting metal corrosion due to better acid and alkali resistance.

Owner:NORTHWEST NORMAL UNIVERSITY

Nano super-hydrophobic coating and production technology thereof

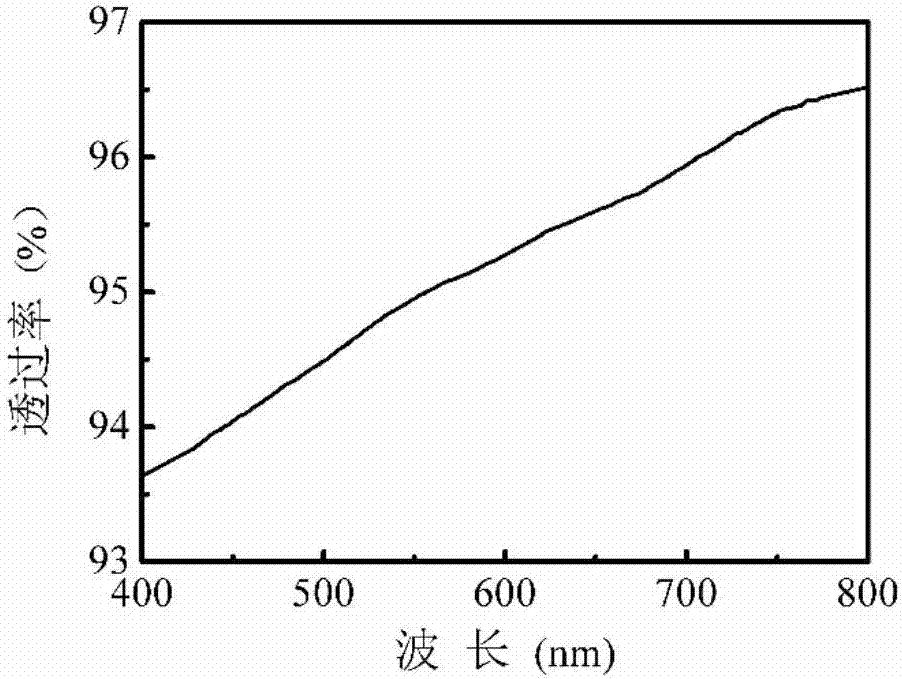

InactiveCN106497406AIncrease contact angleSmall rolling angleAntifouling/underwater paintsPaints with biocidesN dimethylformamideSilicon dioxide

The invention discloses a nano super-hydrophobic coating which comprises the following materials in parts by mass: 50-3650 parts of nano silicon dioxide, 20-120 parts of hexamethyl-disilazane, 350-600 parts of a solvent, 200-450 parts of organic silicon resin and 5-25 parts of a curing agent, wherein the curing agent is aliphatic polyamine; and the solvent is one or a combination of some of absolute ethyl alcohol, normal propyl alcohol, isopropanol, acetone, tetrahydrofuran, N,N-dimethyl acetamide or N,N-dimethylformamide, methylbenzene and dimethylbenzene. The production technology comprises the steps: S1, preparing a filling solution, S2, preparing a super-hydrophobic solution, and S3, preparing the super-hydrophobic coating. The raw materials adopted by the coating are simple and easy to obtain; a preparation process is easy; the production cost is low; the prepared super-hydrophobic coating has the advantages of large contact angle, small roll angle, high light transmittance and the like, is long in service life and strong in adhesion and has wide application prospects.

Owner:SUZHOU LAVENNANO TECH INC

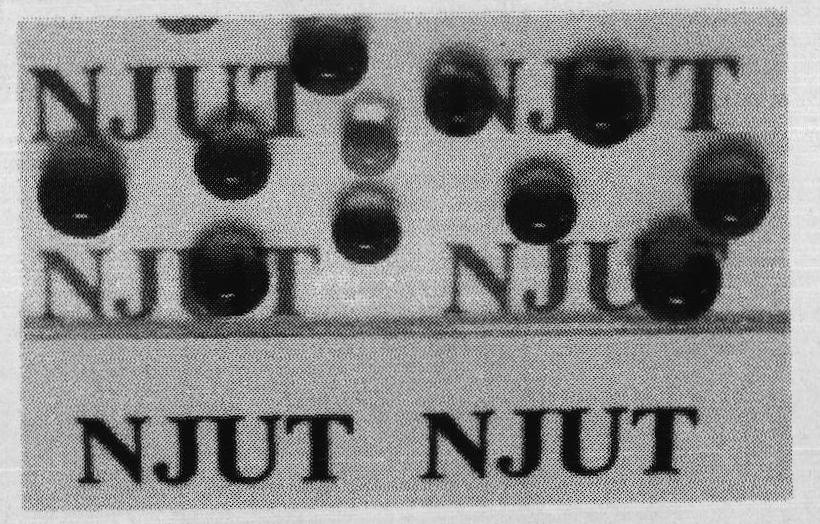

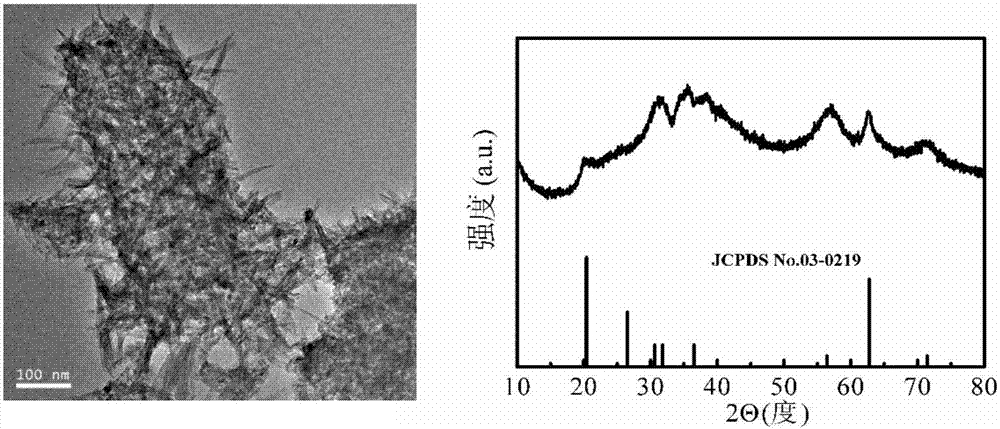

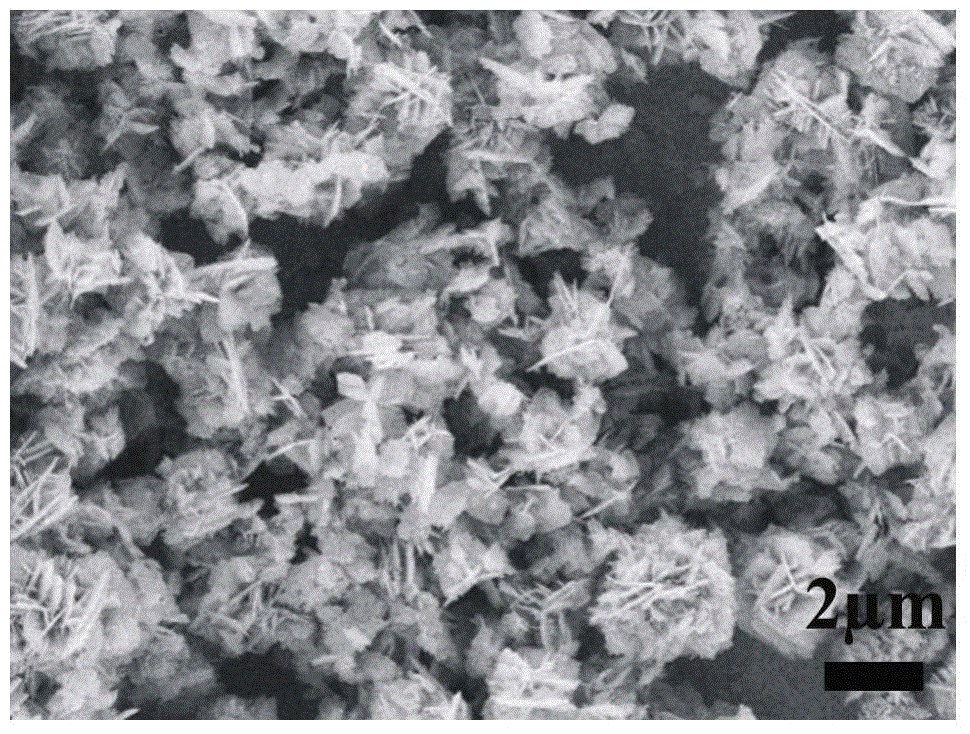

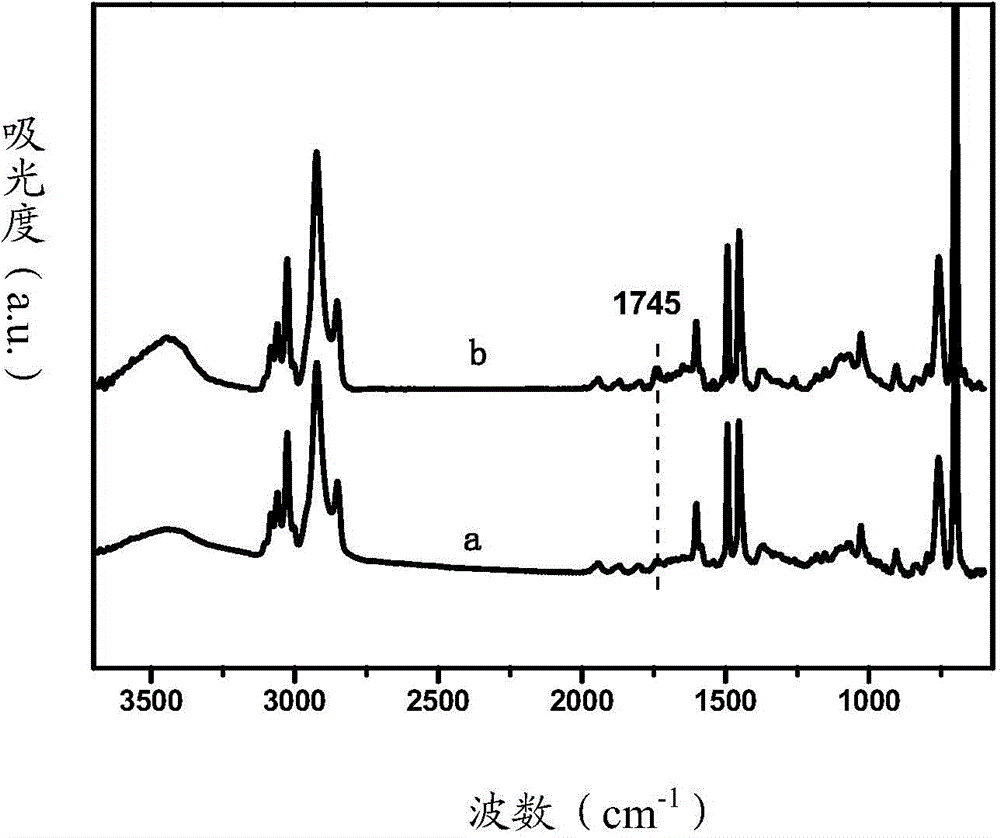

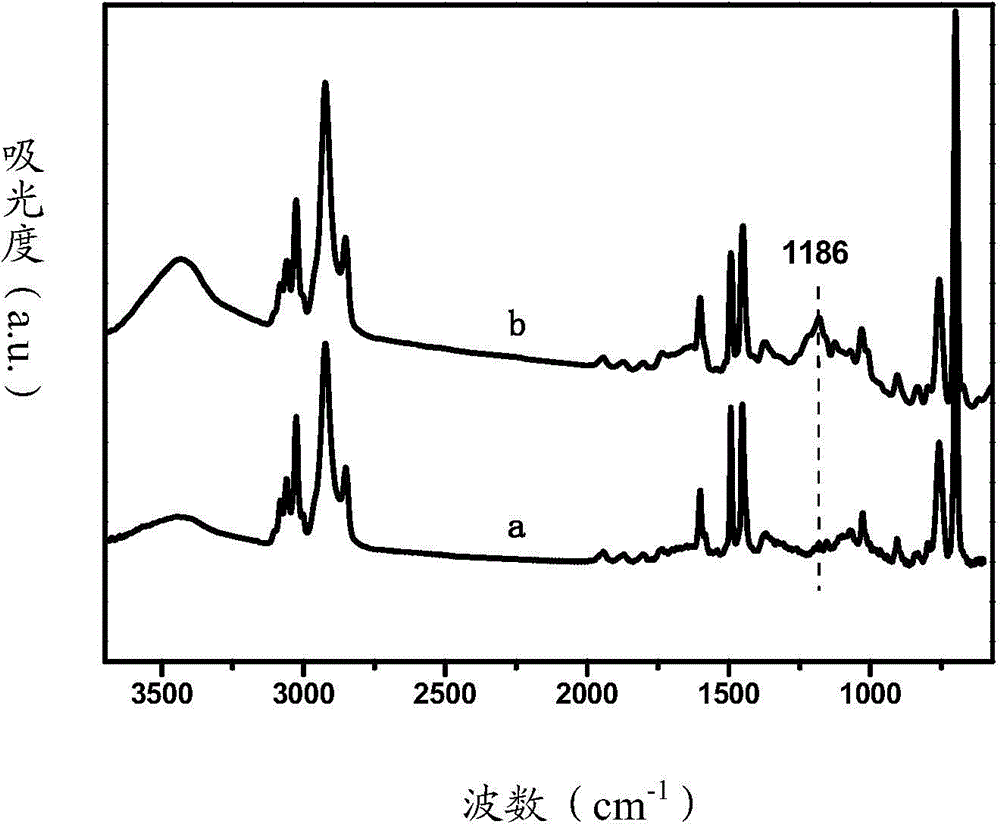

Graphene oxide/copper silicate composite powder, preparation method of composite powder and application thereof in super-hydrophobic coating

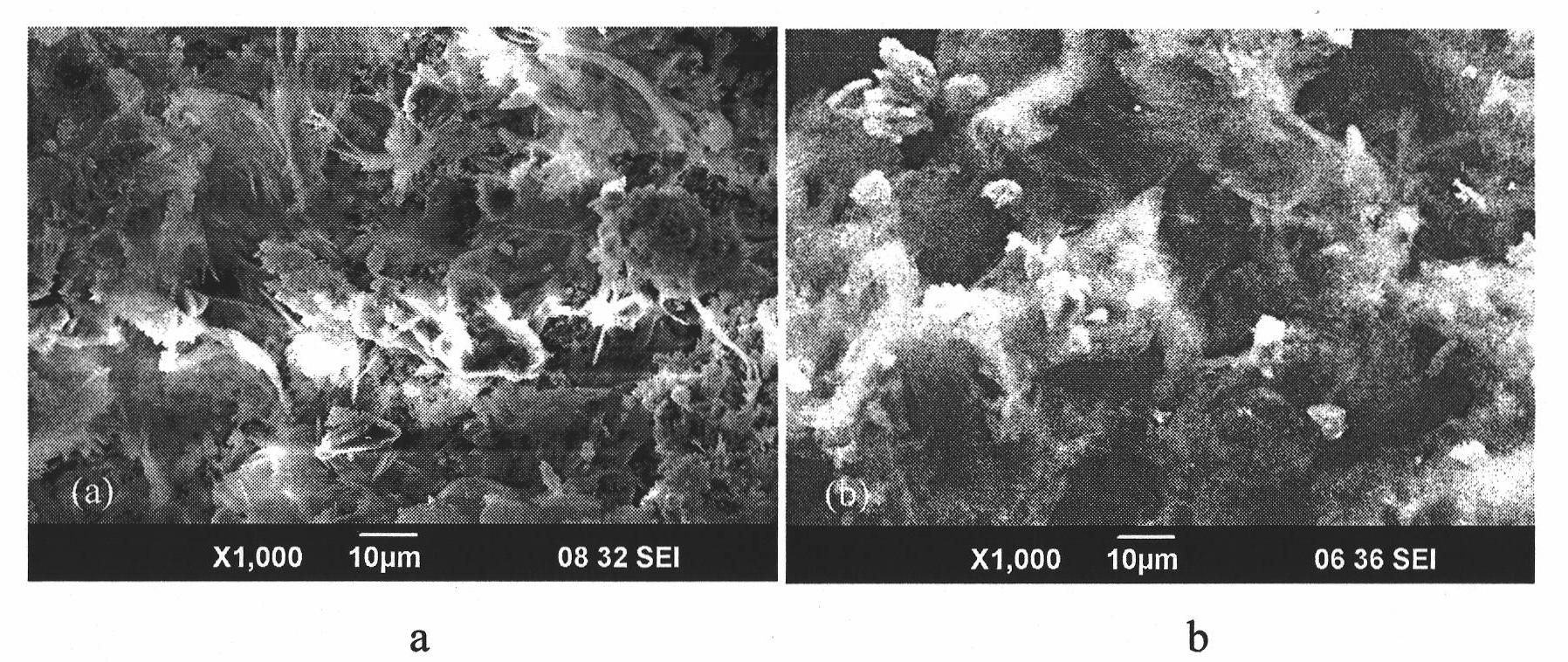

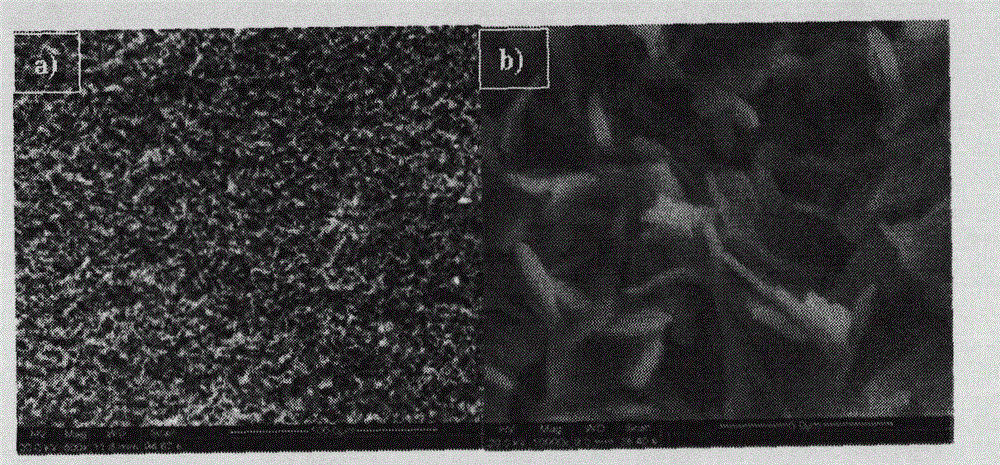

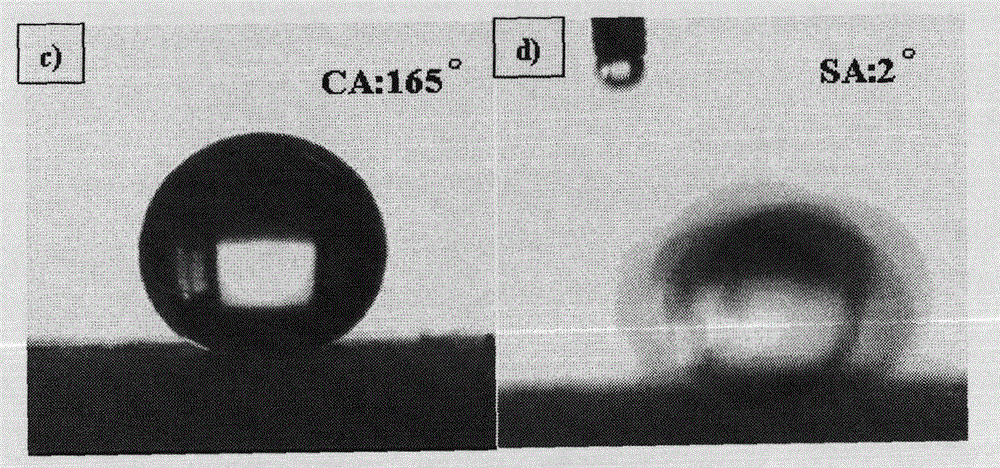

InactiveCN107128937ASimple processMild reaction conditionsMaterial nanotechnologyCarbon compoundsMicro nanoUltraviolet lights

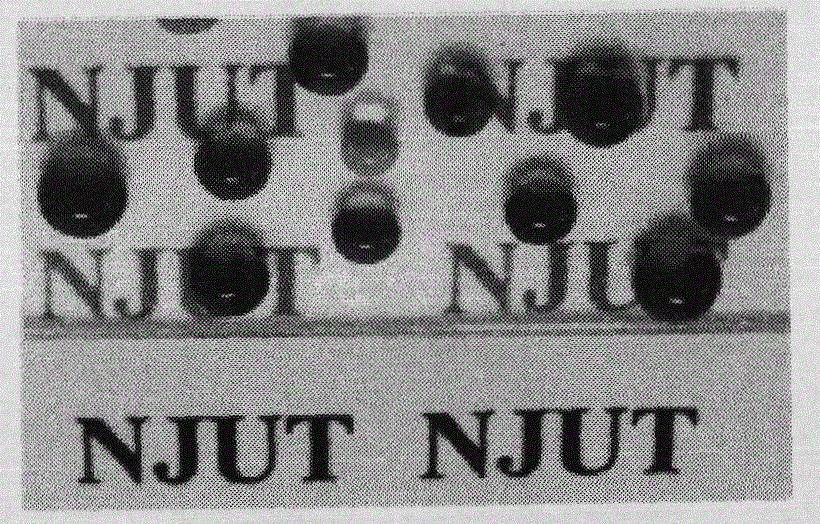

The invention discloses graphene oxide / copper silicate composite powder, a preparation method of the composite powder and application thereof in a super-hydrophobic coating. The graphene oxide / copper silicate composite powder with a micro-nano structure on the surface comprises a core formed by flake graphene oxide and a shell layer formed by needle-like nano copper silicate, wherein the needle-like nano copper silicate is arranged on the surface of the core in an array form. The super-hydrophobic coating is prepared by the following steps: coating the surface of a base material with the graphene oxide / copper silicate composite powder with the micro-nano structure on the surface, drying, and performing fluoroalkyl silane low-surface energy treatment, thereby obtaining the product. The preparation method disclosed by the invention is mild in reaction conditions, easy to realize and excellent in process repeatability; the prepared high-transparency, self-cleaning and anticorrosive super-hydrophobic coating has a static water drop contact angle of not less than 150 degrees; the slide angle does not exceed 1 degree; and the light transmissivity is not lower than 90% in a visible-ultraviolet light wave range. The product has excellent corrosion resistance and is expected to be widely applied to the fields of automobiles, spaceflight, solar cells, articles of daily use and the like.

Owner:ZHEJIANG UNIV OF TECH

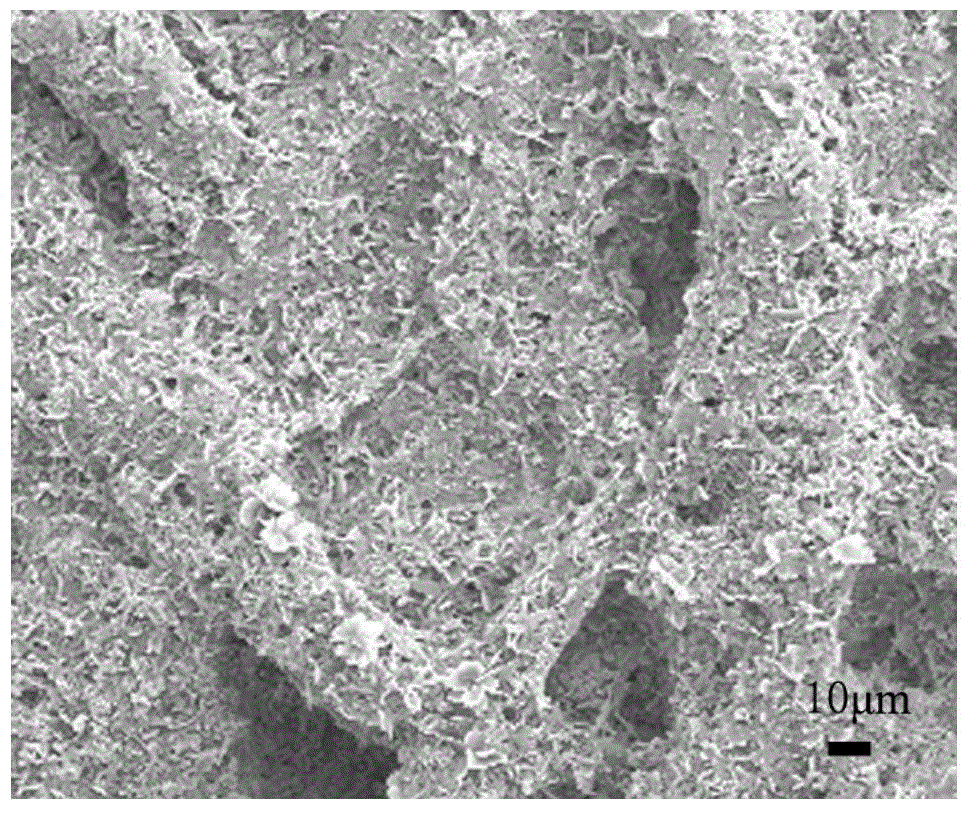

Universal preparation method for self-cleaning superhydrophobic paper

ActiveCN104532664ALow costSimple preparation processNon-macromolecular organic additionFiltration separationTolueneStearic acid

The invention discloses a universal preparation method for self-cleaning superhydrophobic paper, and is characterized in that the universal preparation method comprises the steps: dipping ordinary paper in a zinc oxide ethanol solution having a micro / nano hierarchical structure for 5-10 min, drying for 2-5 min at the temperature of 80-100 DEG C, then again putting into the zinc oxide ethanol solution, carrying out dipping treatment, and repeating the steps for 4-8 times; and carrying out low-surface-energy modification on the product with an ethanol or toluene solution of stearic acid with the concentration of 3-5%, to obtain the superhydrophobic filter paper. The preparation method of the self-cleaning superhydrophobic paper is simple, raw materials are cheap and easily obtained, a contact angle of the surface of the obtained paper with water is greater than 150 degrees and the roll angle is less than 5 degrees, the self-cleaning property is excellent, and industrialization production is easy.

Owner:ANHUI UNIV OF SCI & TECH

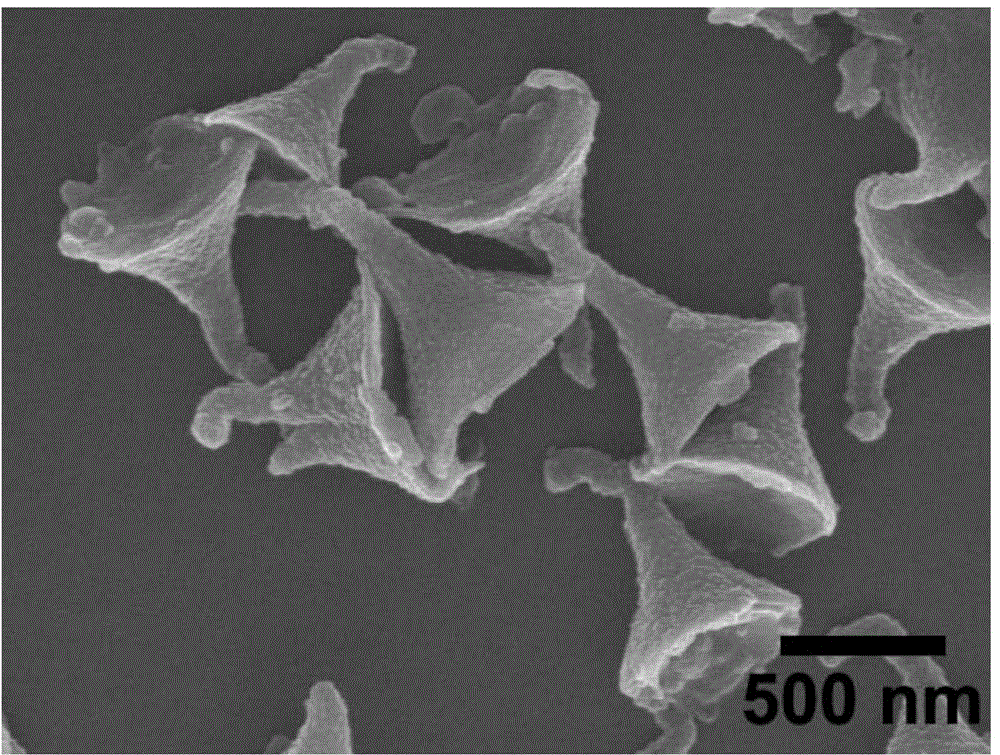

Cone-shaped Janus particle, preparation method and application thereof

InactiveCN105777998AExcellent particle emulsifierExhibit superhydrophobic propertiesJanus particlesPolymer science

The invention discloses a cone-shaped Janus particle and its preparation method and application. The underside material of the cone-shaped Janus particle is a hydrophobic polymer and is formed by polymerization of monoolefine monomer; and the side material of the particle is a hydrophilic material and is formed by sulfonation hydrophilic modification of a hydrophobic polymer or formed by hydrophobic polymer surface grafting with a hydrophilic polymer. The side face of the cone-shaped Janus particle can also undergo hydrophobic modification and the bottom surface undergoes amino-modification. The cone-shaped Janus particle can be used in particle emulsifiers, and also can be used in preparing a surface coating of a material, especially a hydrophobic surface coating.

Owner:INST OF CHEM CHINESE ACAD OF SCI

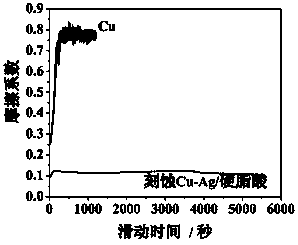

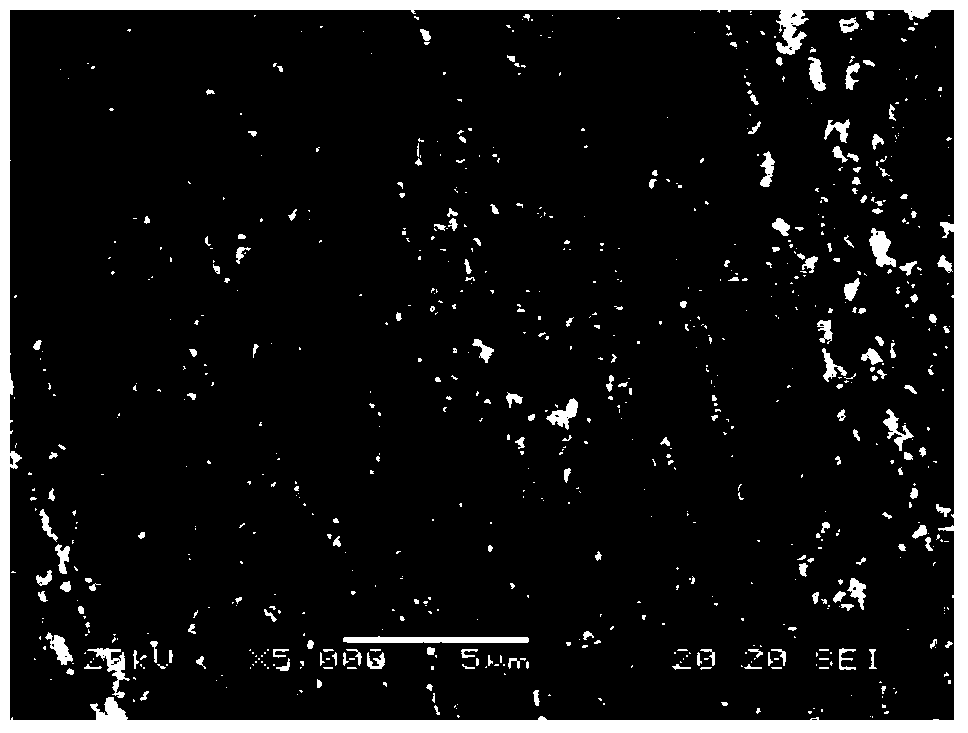

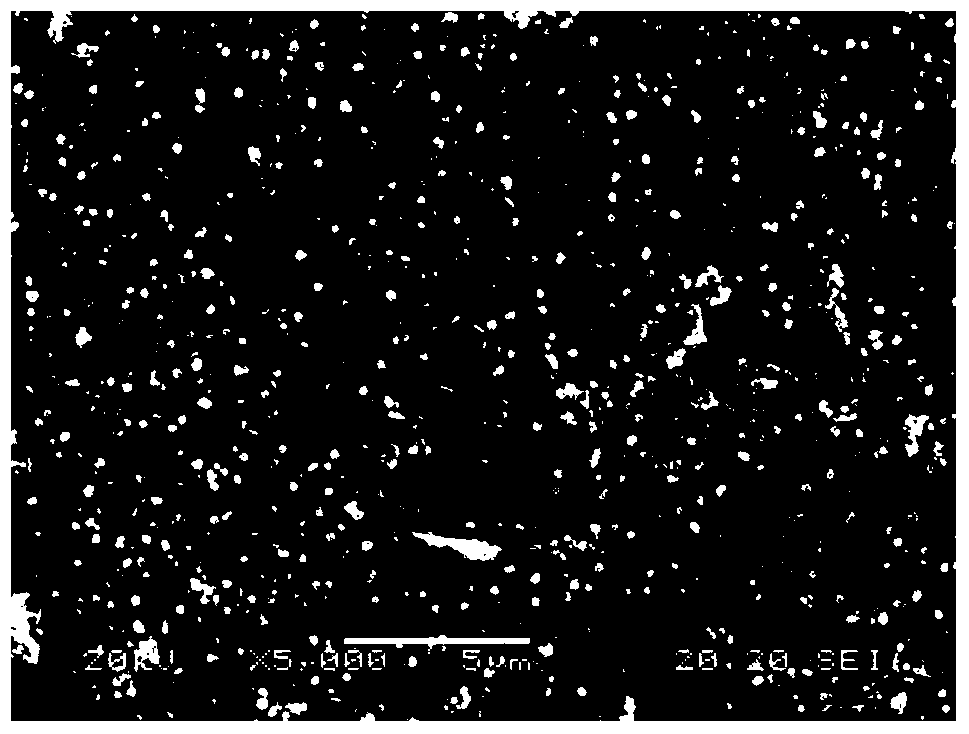

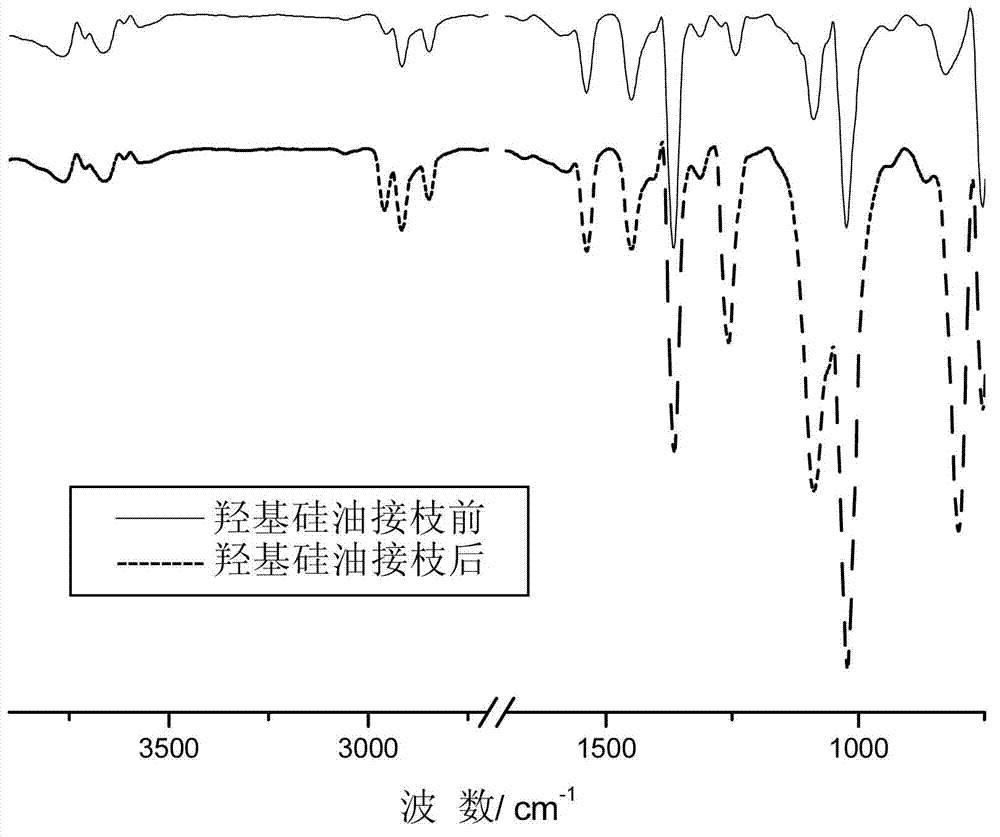

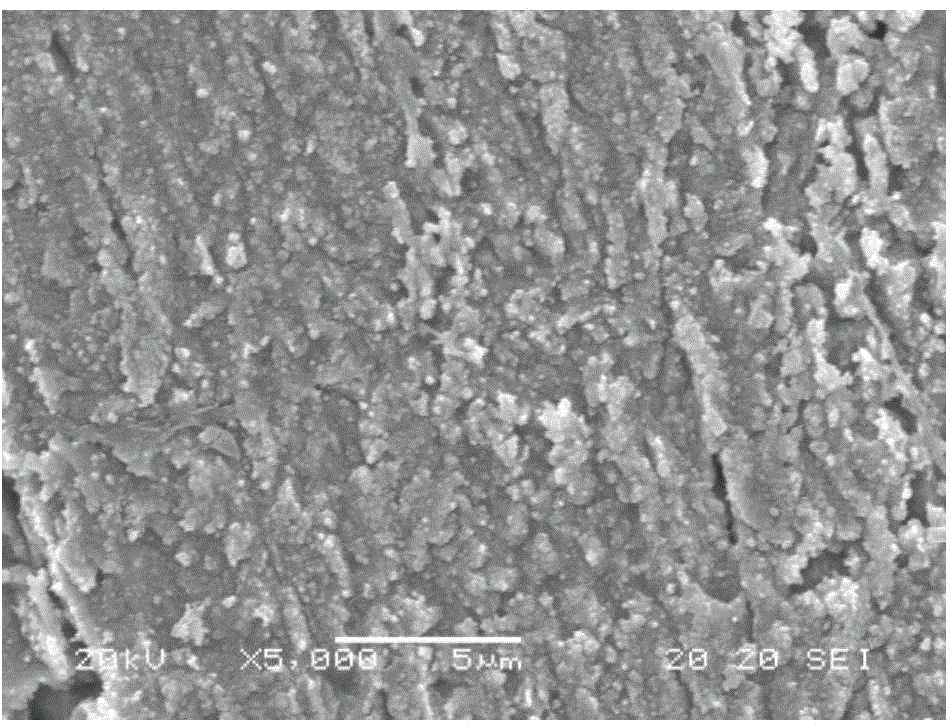

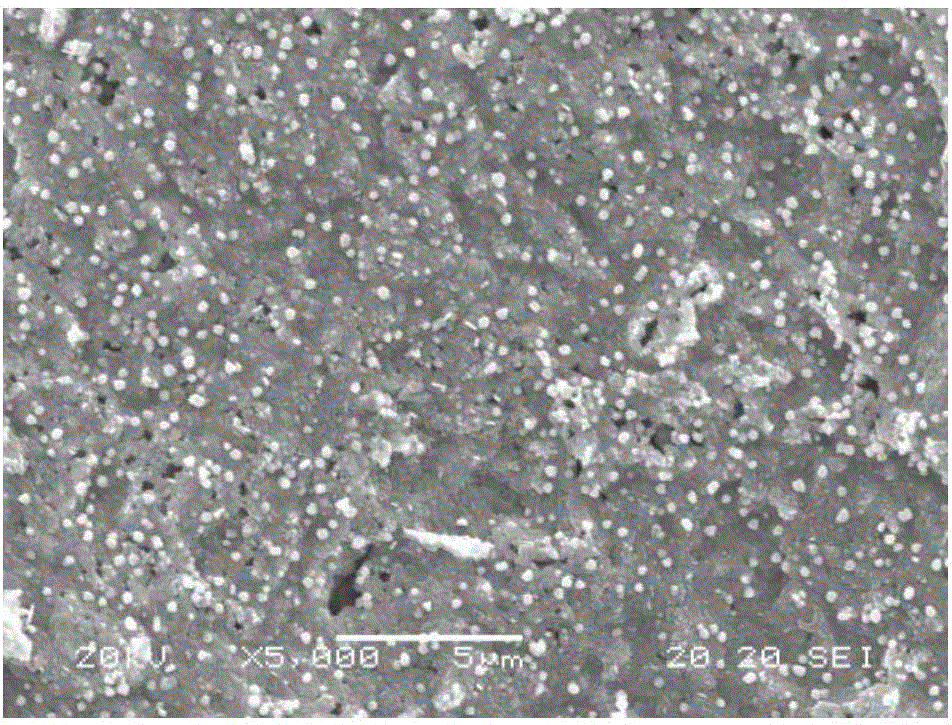

Copper-based super-hydrophobic composite film with low friction coefficient and preparation method thereof

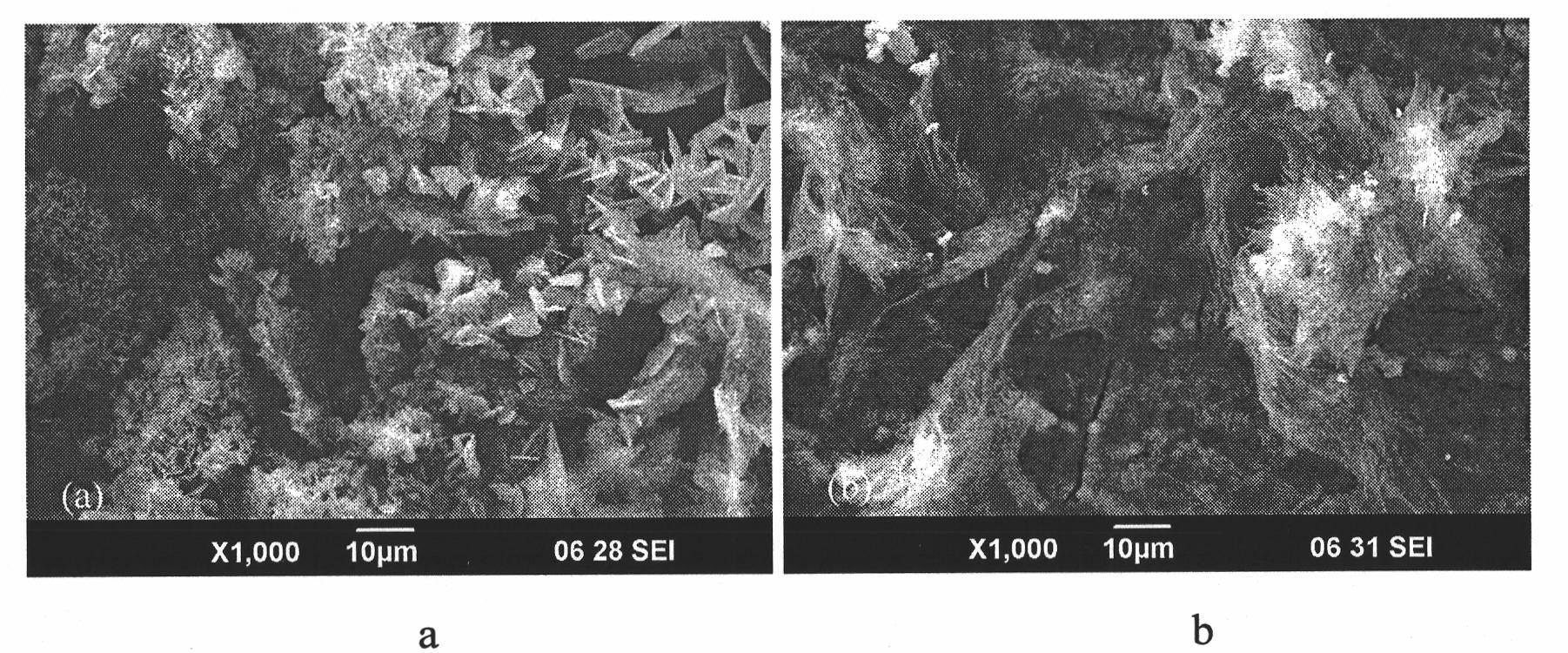

ActiveCN103448316AReduce coefficient of frictionLower contact angleLiquid/solution decomposition chemical coatingSuperimposed coating processComposite filmNano structuring

The invention belongs to the field of preparation of micro or / and nano-structures on surfaces of solids and specifically relates to a copper-based super-hydrophobic composite film with a low friction coefficient and a preparation method thereof. The copper-based super-hydrophobic composite film with the low friction coefficient is characterized in that a composite structure with a micro-scale cuprous oxide crystal structure and submicro-scale metal silver particles is firstly formed on the surface of a copper-based material, and then surface chemical modification is performed to obtain a product. Each contact angle between the copper-based super-hydrophobic composite film with the low friction coefficient and water exceeds 150 degrees, the friction coefficient is low (can be as low as about 0.1) and can be stably kept, and the copper-based super-hydrophobic composite film has good super-hydrophobic performance and relatively low friction coefficient.

Owner:XUCHANG UNIV

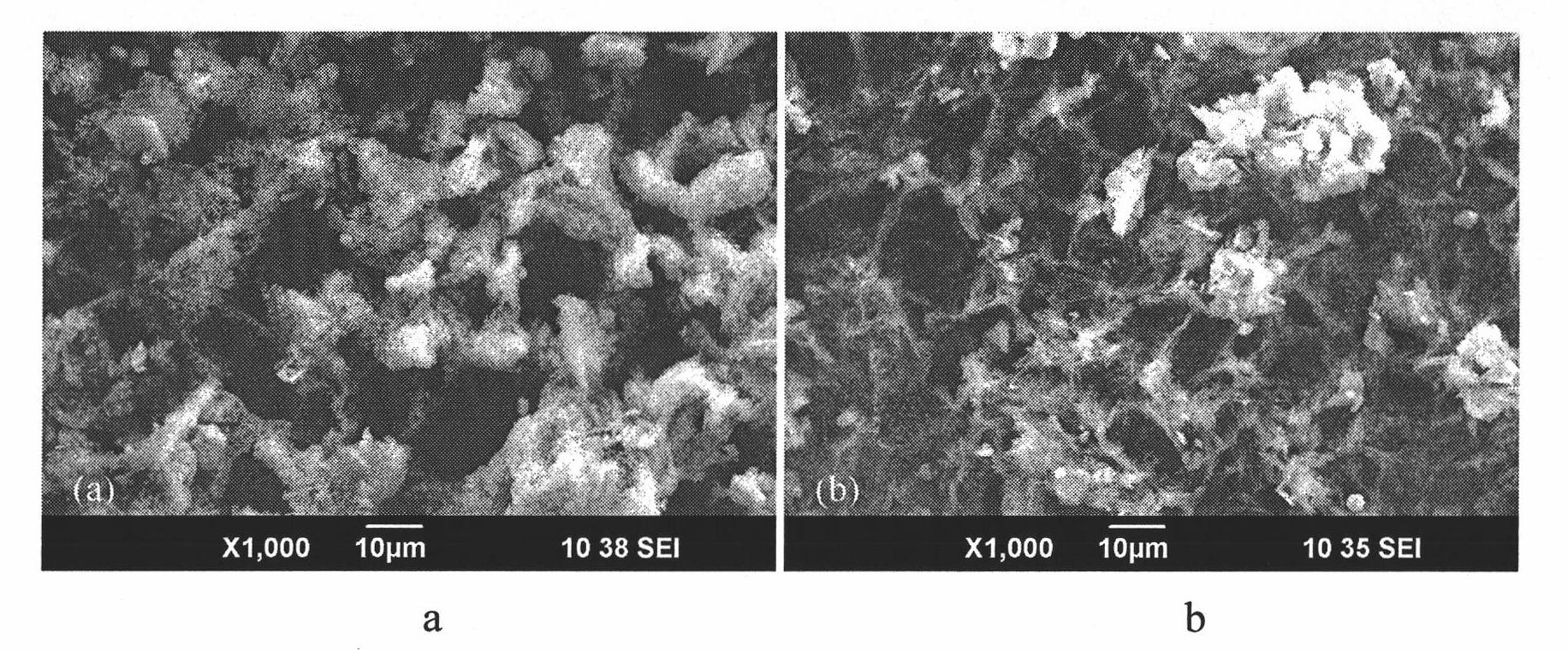

Method for simultaneously preparing two types of super-hydrophobic films by utilizing copper chloride

InactiveCN102041534AIncrease contact angleSmall rolling angleDecorative surface effectsNanotechnologyElectrolysisAlcohol

The invention relates to a method for simultaneously preparing two types of super-hydrophobic films by utilizing copper chloride, relating to a method for preparing a myristic acid copper film of a micrometer / nanometer structure and a myristic acid film inlaid with copper grains. The method is technically characterized by comprising the following steps of: dispersing the copper chloride and myristic acid powder into absolute ethyl alcohol to form uniform electrolyte; and electrolyzing two copper sheets under certain direct voltages in certain time by taking two copper sheets of 60 mm*25 mm*1.5 mm as electrodes so as to form different myristic acid copper films of the micrometer / nanometer structures on an anode and a cathode. The super-hydrophobic films are simultaneously prepared on the anode and the cathode for the first time by using the simple method; and in addition, the super-hydrophobic films have good super-hydrophobic property and extensive application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Super-hydrophobic and superoleophilic metal nickel net as well as preparation method and application thereof

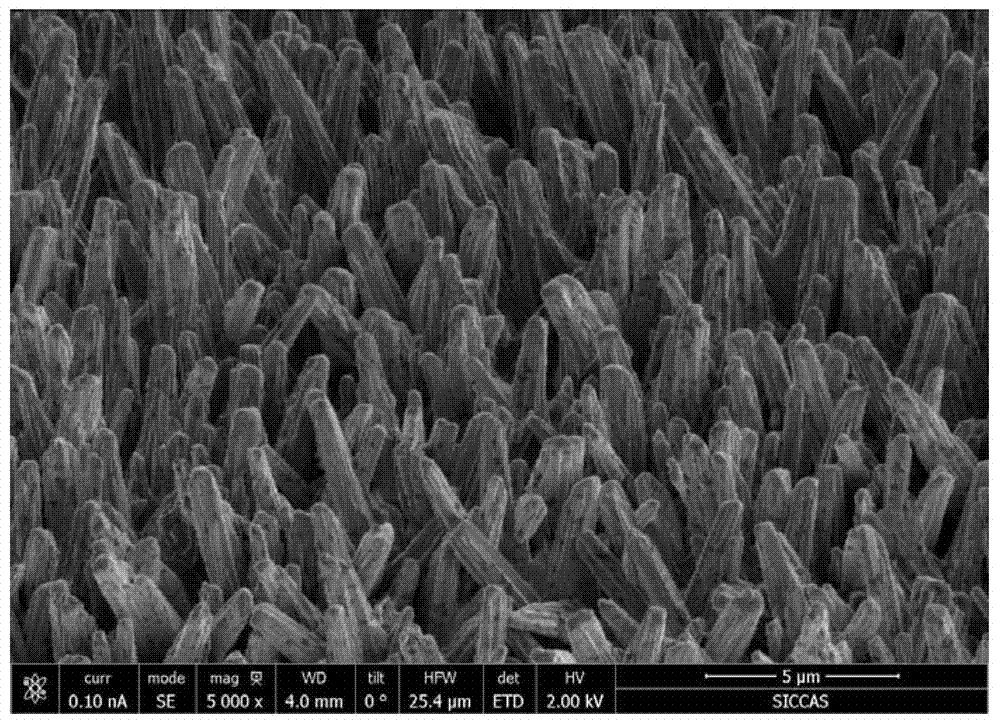

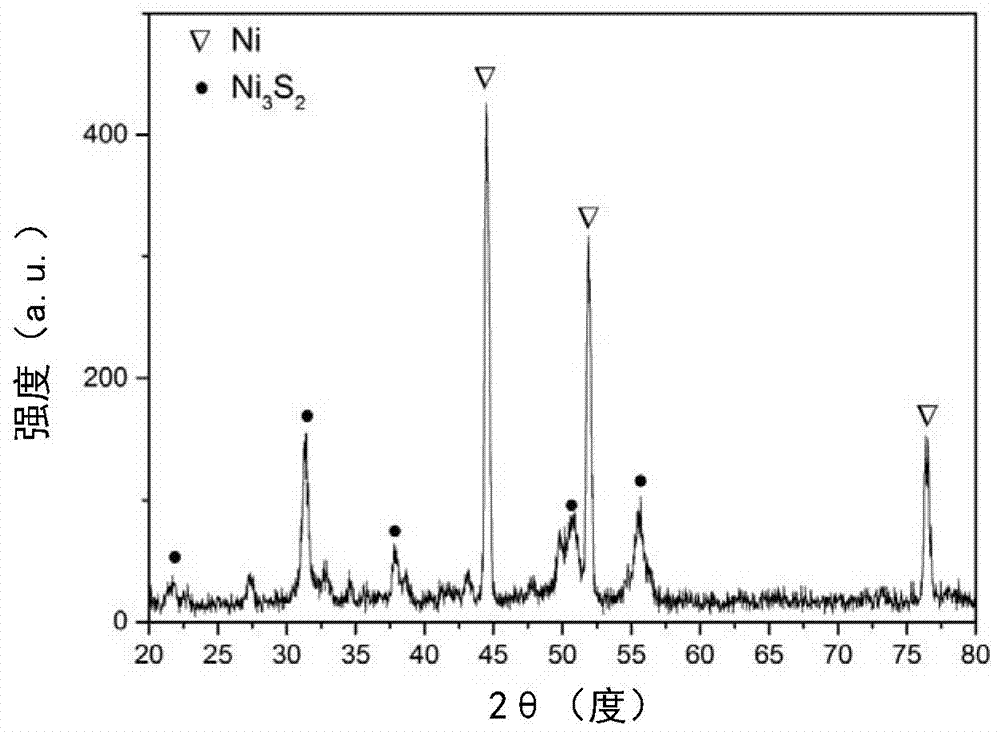

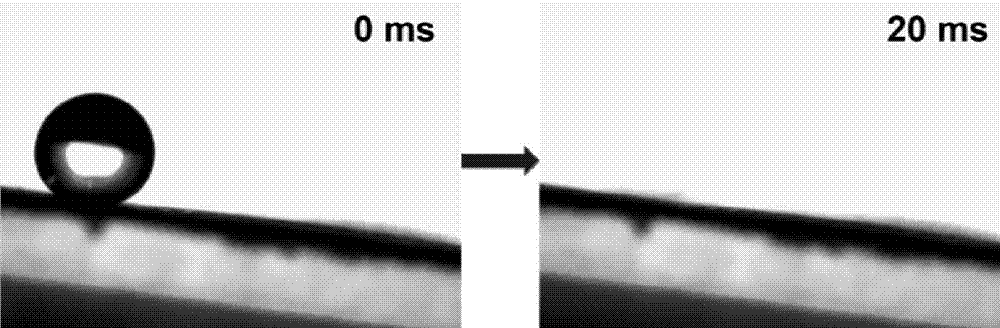

ActiveCN107362587ALow costEasy to handleNon-miscible liquid separationMetallic sulfideMicro nanostructure

The invention relates to a super-hydrophobic and superoleophilic metal nickel net as well as a preparation method and application thereof. The super-hydrophobic and superoleophilic metal nickel net comprises a nickel net and a metal sulfide coating with a micro-nanostructure; the metal sulfide coating is generated on the surface of the nickel net in situ, is modified by a surface modifier and is an Ni3S2 coating or a composite coating of Ni3S2 and MoS2; the surface modifier is a silane coupling agent or / and a mercaptan long-chain compound.

Owner:中国科学院上海硅酸盐研究所苏州研究院 +1

Super-hydrophobic anti-fouling anti-icing water-based paint

InactiveCN112724830AImprove anti-icing performanceImprove hydrophobicityAntifouling/underwater paintsOther chemical processesMicro nanoCoated surface

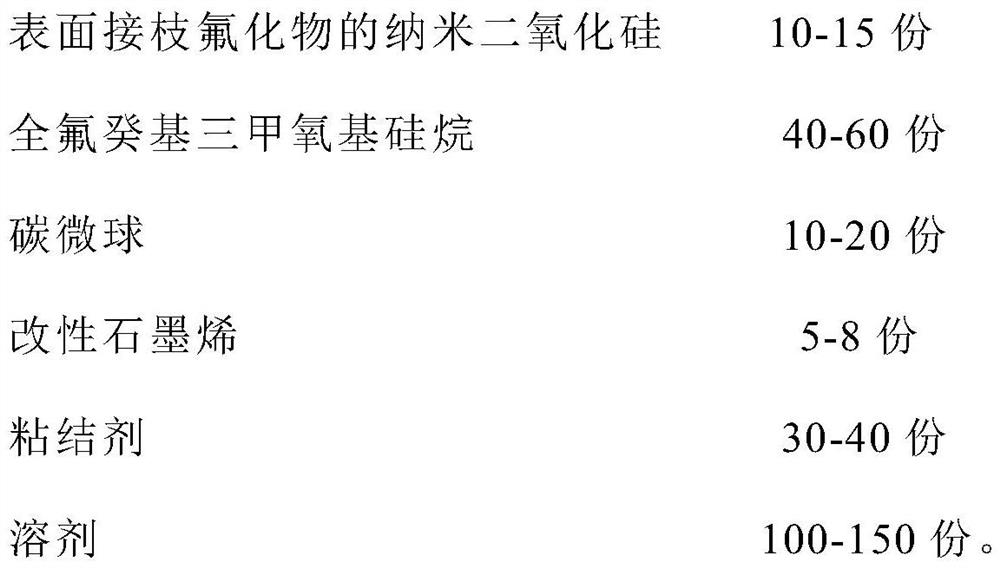

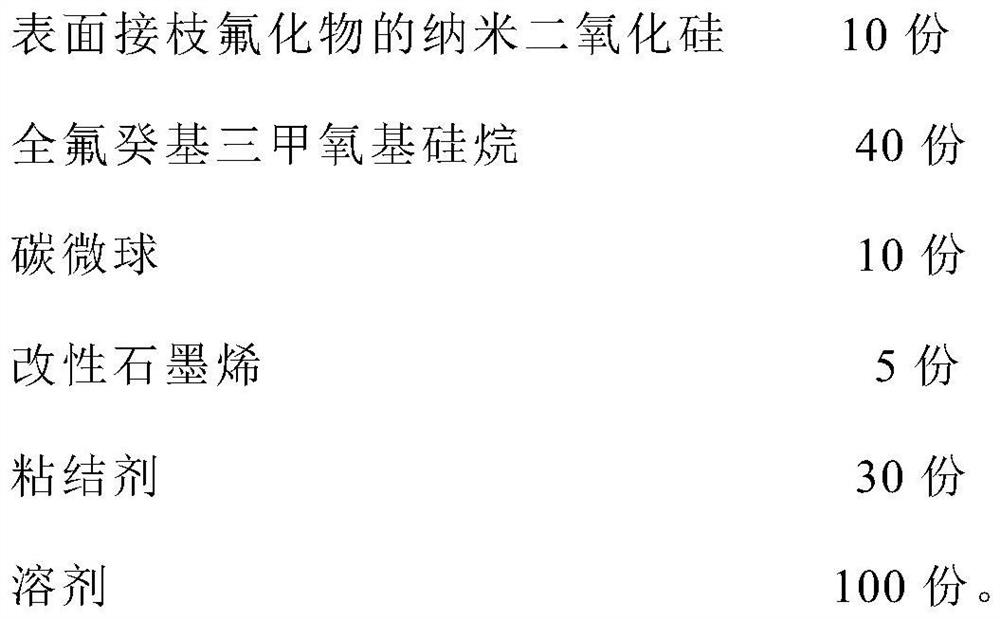

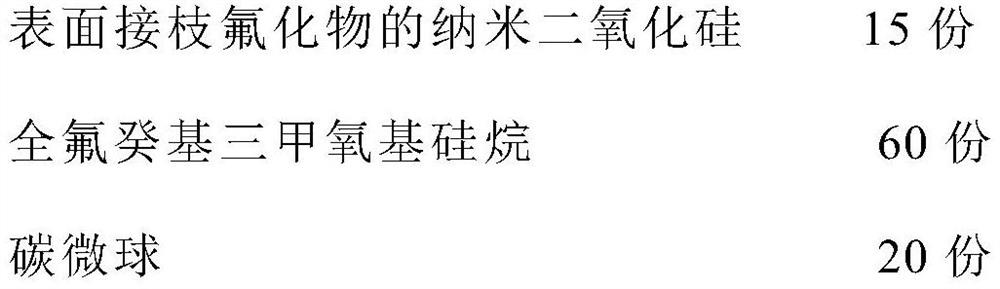

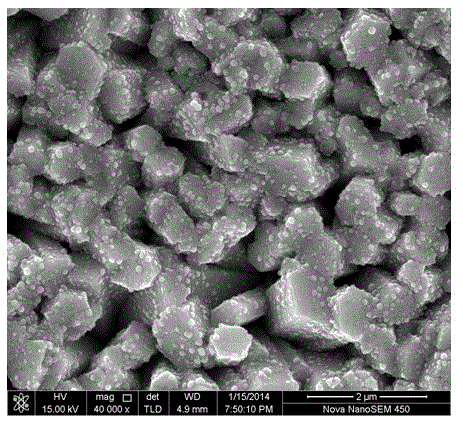

The invention relates to the technical field of material surface engineering, in particular to a super-hydrophobic anti-fouling anti-icing water-based paint which comprises the following components in parts by weight: 10-15 parts of fluoride-grafted nano silicon dioxide on the surface, 40-60 parts of perfluorodecyltrimethoxysilane, 10-20 parts of carbon microspheres, 5-8 parts of modified graphene, 30-40 parts of binder and 100-150 parts of solvent. According to the super-hydrophobic anti-fouling anti-icing water-based paint, the super-hydrophobic material and the near-infrared photothermal material are added, so that the super-hydrophobic anti-fouling anti-icing water-based paint has the dual effects of super-hydrophobicity and photothermal deicing, and the near-infrared photothermal material is modified graphene which is a compound of graphene and CdS; and the super-hydrophobic material is very beneficial to formation of a rough micro-nano structure on the surface of the coating, so that the coating can obtain a larger static contact angle and a smaller rolling angle, the icing time of water drops on the surface of the coating is further prolonged, and a better anti-icing effect is achieved.

Owner:广东绿色大地化工有限公司

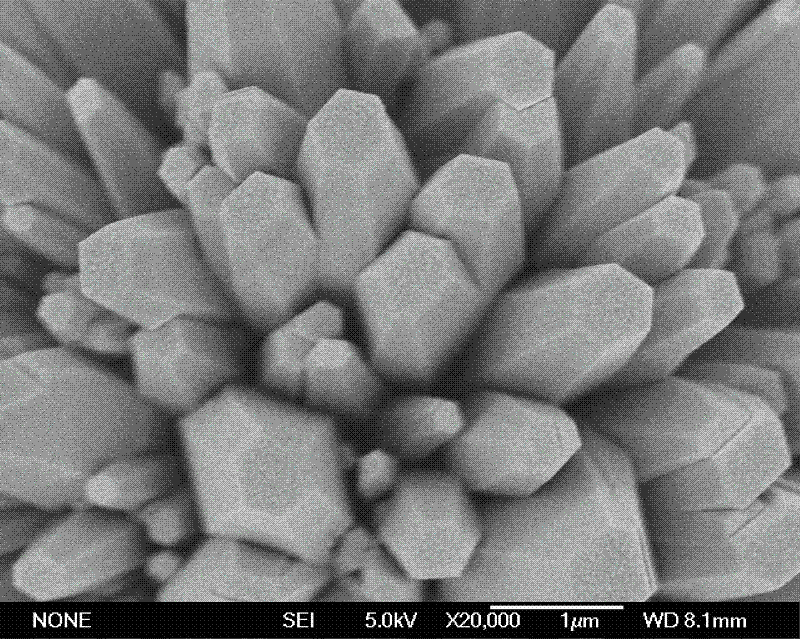

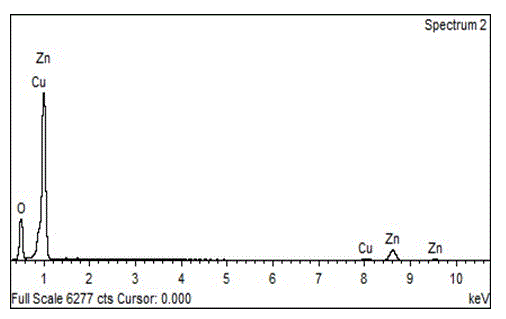

Method for enhancing surface wettability of hexagonal-prism-structure nano zinc oxide material

InactiveCN104018200AIncrease contact angleSmall rolling angleElectrolytic inorganic material coatingSurface energyRolling angle

The invention discloses a method for enhancing surface wettability of a hexagonal-prism-structure nano zinc oxide material, relating to a method for lowering surface energy of zinc oxide. The surface contact angle and roll angle of the fluorizated hexagonal-prism-structure nano zinc oxide are enhanced, and the Cu2O / ZnO composite material can enhance the photoelectric conversion efficiency. The method adopts an electrochemical deposition process and comprises the following steps: by using copper sulfate, lactic acid and sodium hydroxide as raw materials, adding cationic and nonionic surfactants; in a two-electrode system, by using graphite as an anode and an ITO (indium tin oxide) glass sheet deposited with hexagonal-prism-structure zinc oxide structure as a cathode, carrying out cathode reduction while controlling the deposition voltage, time and temperature to deposit granular cuprous oxide on the hexagonal-prism-structure zinc oxide, sintering at certain temperature, treating with a low-surface-energy substance, and measuring the surface static contact angle. The method has the advantages of low production cost, simple preparation process, low requirements for reaction equipment, mild reaction conditions and no environmental pollution, and can large-scale production.

Owner:NANCHANG HANGKONG UNIVERSITY

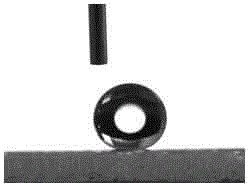

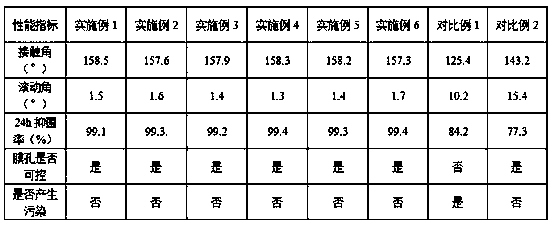

Silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and preparation method

ActiveCN109126479AGood neatnessIncrease roughnessSemi-permeable membranesMembranesEtchingPorous membrane

The invention provides a silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and a preparation method. The method comprises the following steps: first, preparing acellular polystyrene porous membrane according to a breath figure method, and performing reverse repeated etching by taking the polystyrene porous membrane as a template to produce a polyperfluorinated ethylene porous membrane with micro-nanograde bulge array, and further depositing a layer of etching silver nanowire orientation film on the surface of the polyperfluorinated ethylene porous membrane, thereby producing the silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane. Compared with the traditional method, the super-hydrophobic porous membrane prepared according to the method of the invention is not only large in water contact angle, small in rolling angle, and strong in super-hydrophobic capacity and self-cleaning ability, but also has high antibacterial capability; the preparation method is simple, the membrane pore structure can be dynamically controlled or regulated, and the pollution cannot be produced.

Owner:上海优梯熙光学材料有限公司

Method for preparing two types of super-hydrophobic membranes simultaneously by utilizing ferric chloride

InactiveCN102041535AIncrease contact angleSmall rolling angleDecorative surface effectsNanotechnologyElectrolysisIron(III) chloride

The invention relates to a method for preparing two types of super-hydrophobic membranes simultaneously by utilizing ferric chloride, in particular to a method for preparing a copper myristate membrane with a micro / nano-structure and a myristic acid membrane embedded with iron particles. The method is technically characterized in that: the ferric chloride and myristic acid powder are dispersed in absolute ethanol to form uniform electrolyte, and two copper sheets with 60mm*25mm*1.5mm are taken as electrodes and are electrolyzed under certain direct-current voltage for a certain period of time, so that the copper myristate membrane with the micro / nano-structure is formed at an anode and the myristic acid membrane embedded with the iron particles is formed at a cathode. The invention provides a simple method for preparing super-hydrophobic membranes at the anode and the cathode simultaneously for the first time; and the super-hydrophobic membranes have good super-hydrophobic performance and have wide application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

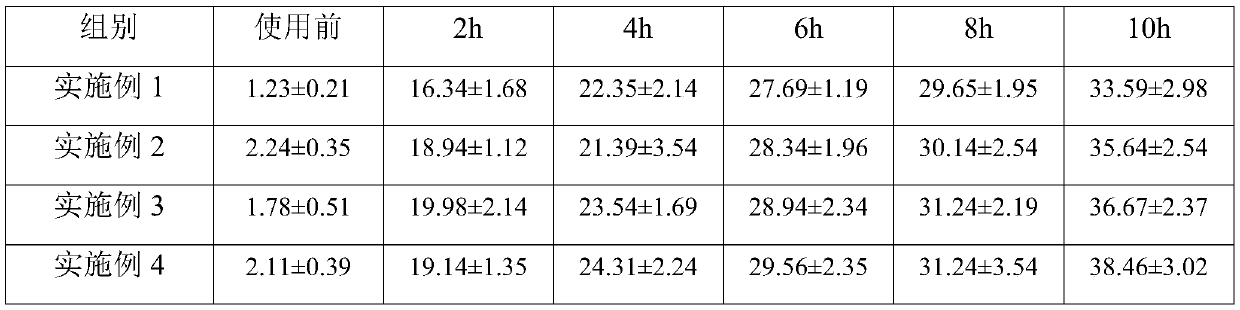

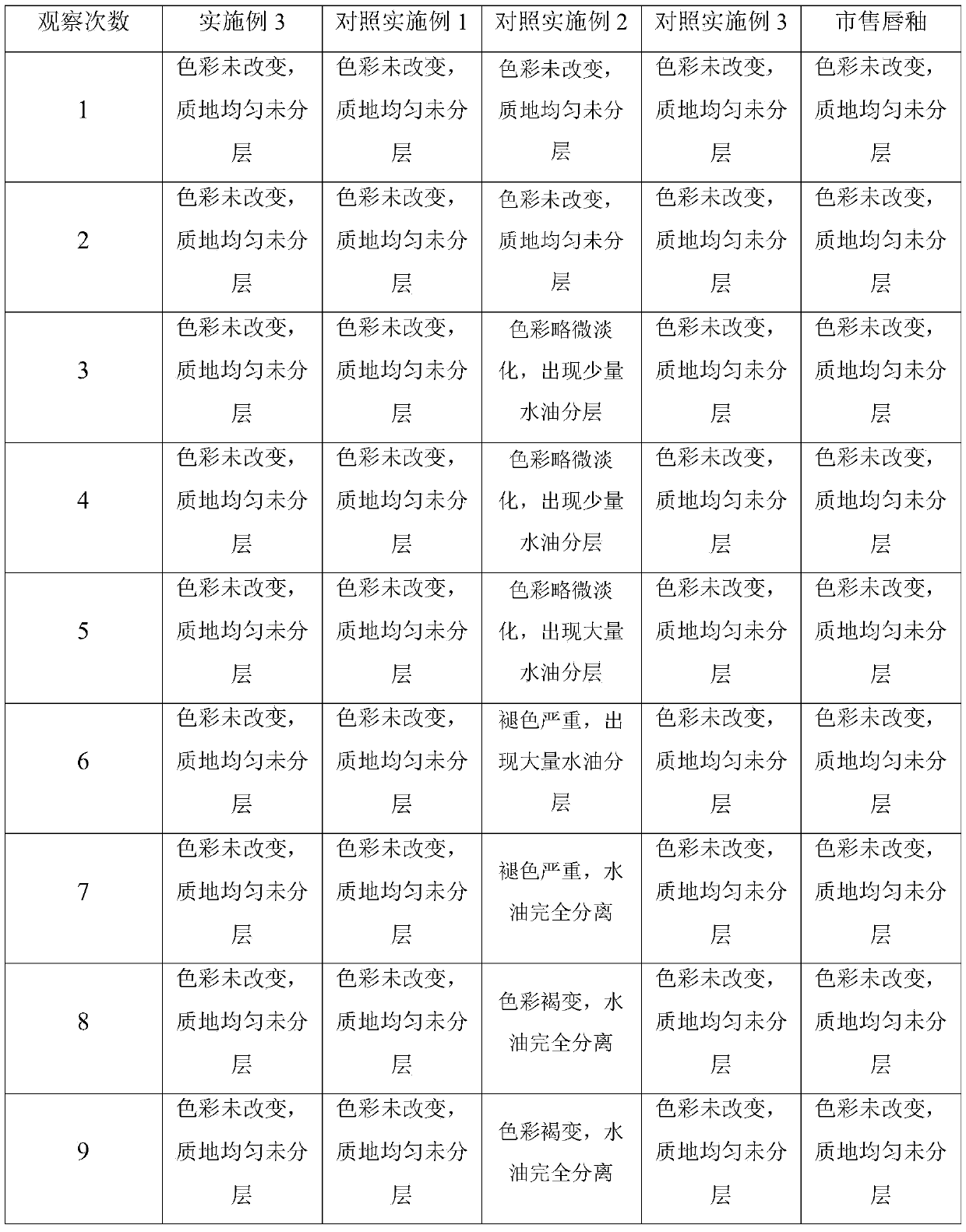

Moistening and color-retaining lip glaze and preparation method thereof

ActiveCN111084732APrevent moisture from evaporatingHigh glossCosmetic preparationsMake-upSilica gelLiposome

The invention discloses a moistening and color-retaining lip glaze and a preparation method thereof. The lip glaze is prepared from the following components in parts by weight: 35-100 parts of liposome embedding liquid, 50-200 parts of emulsion matrix and 25-50 parts of a thickening agent, wherein the liposome embedding liquid is prepared from liposome microcapsules and a nourishing solution; thenourishing solution is embedded in capsules of the liposome microcapsules, and a light-color lipid-soluble coloring agent is added in the capsule layers; the emulsion matrix is prepared from ultrapuresilicon dioxide powder having a grain size of 10-30[mu]m, silica sol and oil-in-water emulsion, and can form a lotus leaf-like hydrophobic structure after the ultrapure silicon dioxide powder and silica gel are dried and cured, so that the lipid layer is effectively prevented from being polluted by other objects, and the color duration is improved; the moisture content of the skin surface layer can be further increased on the premise that the liposome microcapsules can be moistened with mixed lipid in the emulsion matrix, and the effect of moistening and moisture supplying can be achieved; and the thickening agent can be used for effectively reducing the greasy and thick feeling of the lipid layer and improving the whole malleability, smoothness and stability of the lip glaze.

Owner:安焱

Lotus leaf effect self cleaning fluorocarbon paint

The present invention belongs to the field of self-cleaning coating technology. In the concrete, it relates to a self-cleaning fluorocarbon coating with lotus leaf effect. It is made up by using organic silicon modified fluorocarbon resin, solidifying agent, hydrophobic particles, pigment, filling material, adjuvant and solvent according to the mixing ratio of 1:0.1-0.3:0.03-0.1:0-0.36:0-0.1:0.01-0.05:0.1-0.3 through a certain preparation process.

Owner:鳄鱼制漆(上海)有限公司

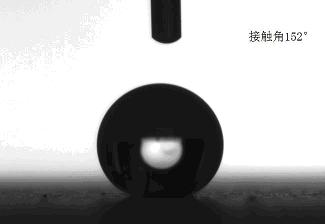

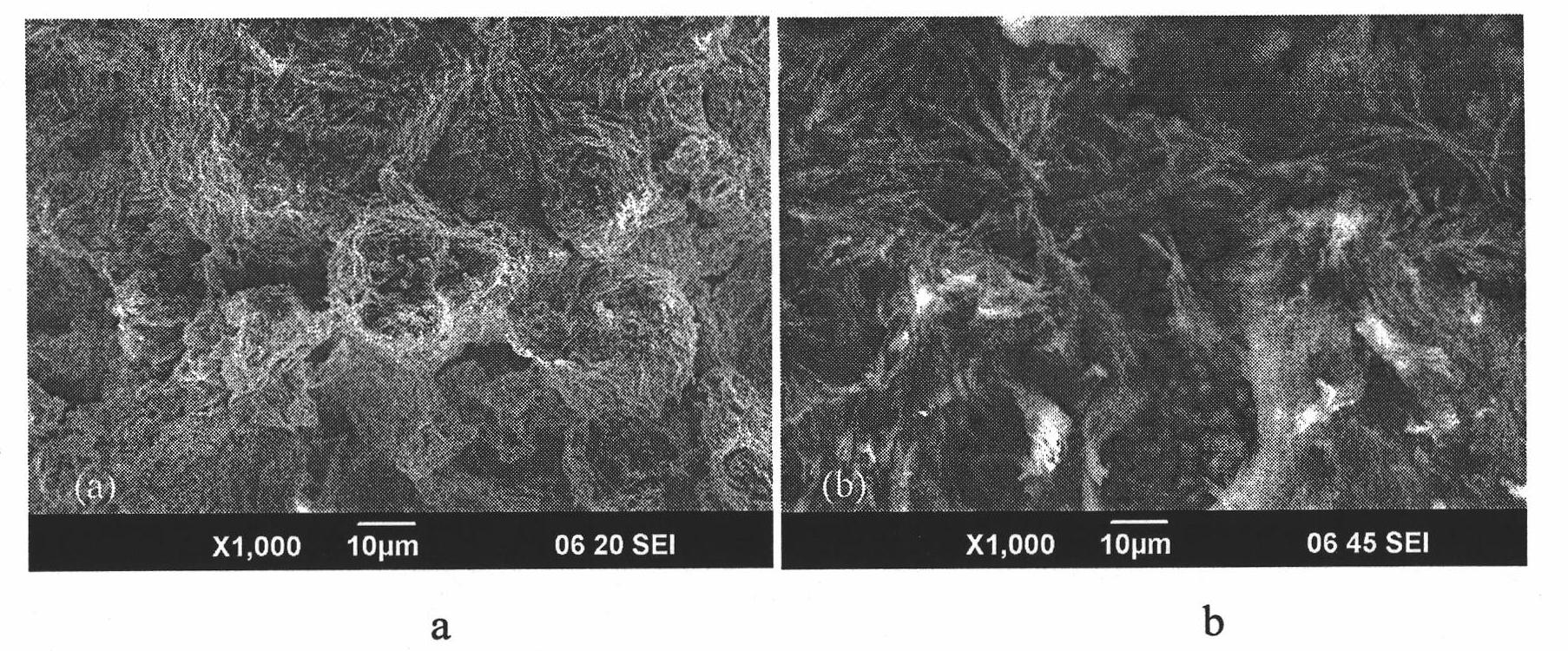

Preparation method of super-hydrophobic coating based on polydopamine self-assembly

ActiveCN113278358AFast self-assemblySmall rolling angleAntifouling/underwater paintsPaints with biocidesHydroxymethylMaterials science

The invention discloses a preparation method of a super-hydrophobic coating based on polydopamine self-assembly, which comprises the specific steps of dissolving dopamine hydrochloride and nano zero-valent iron in a tris (hydroxymethyl) aminomethane-hydrochloric acid buffer solution to obtain a mixed solution, wherein the molar concentrations of the dopamine hydrochloride and the nano zero-valent iron in the mixed solution are both 1-50 mM; dipping a material to be coated into the mixed solution at room temperature, and enabling the material to be coated and the mixed solution to be in full contact; taking out the material obtained after dipping in the step S2, washing and drying; and soaking the material obtained in the step 3 in a low-surface-energy modifier, enabling the material and the low-surface-energy modifier to make full contact, and after cleaning and drying are conducted, obtaining the super-hydrophobic coating based on polydopamine self-assembly on the surface of the material to be coated. The static water contact angle of the obtained coating can reach 160.5 degrees to the maximum, the rolling angle can reach 1 degree or below to the minimum, and the coating has excellent super-hydrophobicity and has wide application prospects in the fields of composite material preparation, self-cleaning, oil-water separation, marine corrosion prevention, antifouling and the like.

Owner:ZHEJIANG UNIV

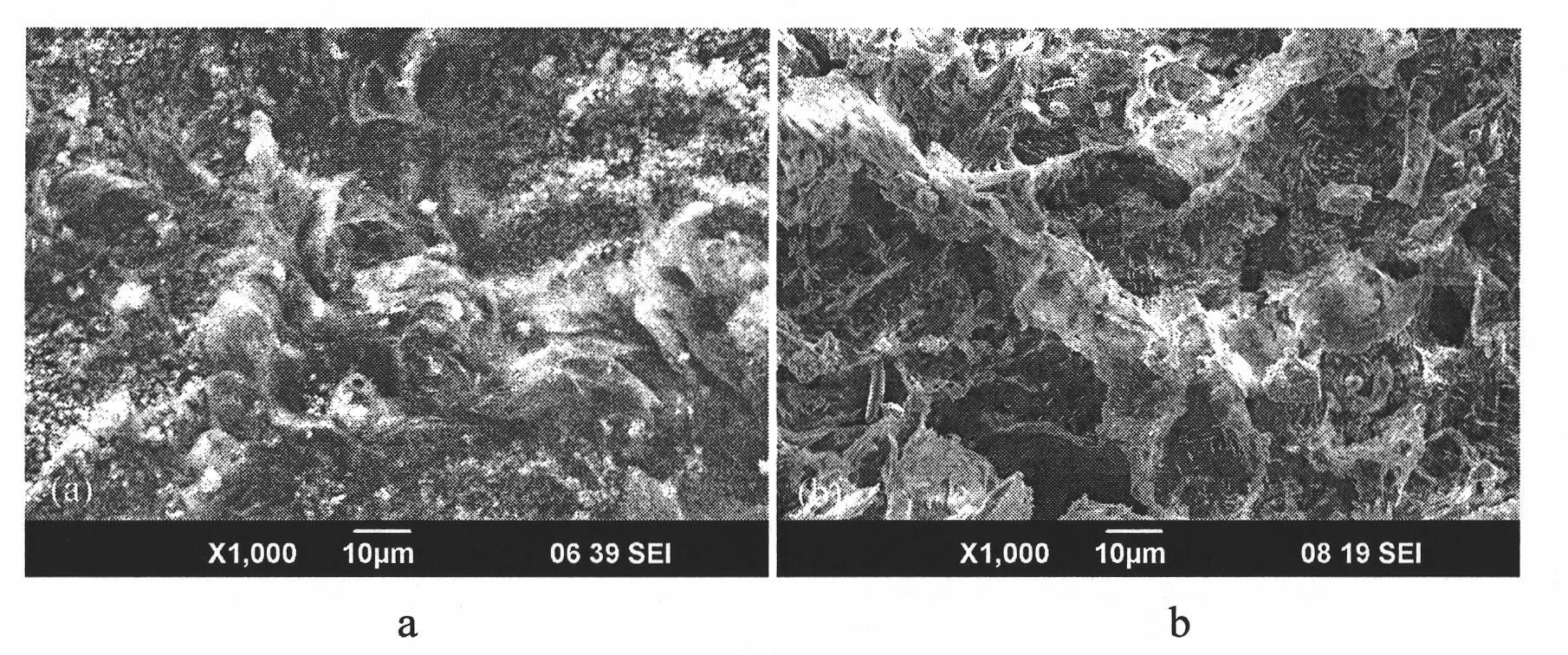

Method for preparing two types of super-hydrophobic membranes simultaneously by utilizing nickel chloride

InactiveCN102041536AIncrease contact angleSmall rolling angleDecorative surface effectsNanotechnologyNanometreMetallic Nickel

The invention relates to a method for preparing two types of super-hydrophobic membranes simultaneously by utilizing nickel chloride, in particular to a method for preparing a copper myristate membrane with a micro / nano-structure at an anode and a myristic acid membrane embedded with nickel particles at a cathode simultaneously. The method is technically characterized in that: the nickel chloride and myristic acid powder are dispersed in absolute ethanol to form uniform electrolyte, and two copper sheets with 60mm*25mm*1.5mm are taken as electrodes and are electrolyzed under certain direct-current voltage for a certain period of time, so that the copper myristate membrane with the micro / nano-structure is formed at the anode and the myristic acid membrane embedded with the nickel particles is formed at the cathode. The invention provides a simple method for preparing super-hydrophobic membranes at the anode and the cathode simultaneously for the first time; and the super-hydrophobic membranes have good super-hydrophobic performance and have wide application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing aluminum oxide nanostructure on surface of titanium alloy and improving antifouling property of titanium alloy

ActiveCN112663010AIncrease the surface contact angleDoes not change original surface propertiesVacuum evaporation coatingSputtering coatingNano al2o3Alloy deposition

The invention relates to the field of metal surface modification, in particular to a method for preparing an aluminum oxide nanostructure on the surface of a titanium alloy and improving the antifouling property of the titanium alloy. The method comprises the steps that firstly, after the surface of the titanium alloy is cleaned, a nanometer aluminum coating is arranged on the surface of the titanium alloy in a magnetron sputtering manner, through heat treatment in air, an unoxidized Al and Ti substrate forms an alloy layer through atom diffusion, a magnesium powder solid phase method is used for dealloying, and the titanium alloy with nanometer aluminum oxide particles dispersed on the surface is obtained through cleaning and drying; and then, the titanium alloy surface with the nanometer aluminum oxide particles deposited on the surface is subjected to chemical modification through an ethanol solution of (3, 3, 3-trifluoropropyl) methyldimethoxysilane, and the hydrophobic performance of the titanium alloy surface is further improved. The method is simple and feasible, an atomic diffusion alloy deposition layer and a stable aluminum oxide coating are obtained through heat treatment in air, and a dispersed aluminum oxide structure can be prepared on the titanium alloy surface.

Owner:SOUTHERN MARINE SCI & ENG GUANGDONG LAB (ZHUHAI) +1

A copper-based superhydrophobic surface with low coefficient of friction and preparation method thereof

ActiveCN103469215BIncreased static contact angleReduce coefficient of frictionLiquid/solution decomposition chemical coatingMicron scaleEtching

The invention relates to a copper based super-hydrophobic surface with a low friction coefficient and a preparation method thereof. The copper based super-hydrophobic surface with a low friction coefficient is characterized in that chemical etching is performed on the surface of a copper based material to form a coarse structure with a micron-scale pit structure and submicron / nano-scale metal silver particles, and then a product is obtained through surface chemical modification. The copper based super-hydrophobic surface with low friction coefficient has a contact angle of more than 150 degrees to water, is low in friction coefficient, can be stably maintained, and has good super-hydrophobic properties and low friction coefficient.

Owner:XUCHANG UNIV

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496BRaw materials are easy to getLow costPolyurea/polyurethane coatingsSilanesNanometre

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and the prepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

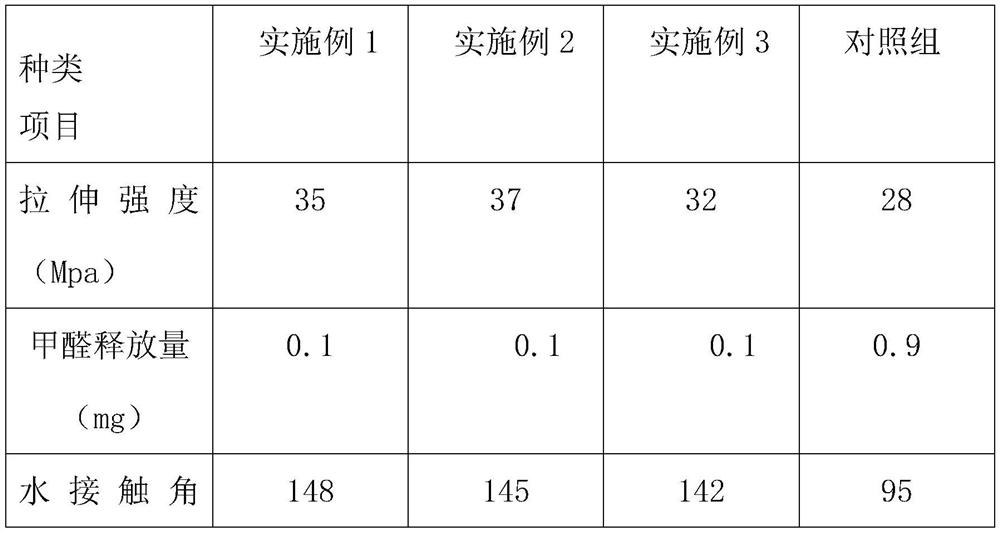

Preparation method of surface super-hydrophobic composite material

InactiveCN111376571AImprove bindingReduce processLaminationLamination apparatusResin matrixResin-Based Composite

The invention relates to a preparation method of a surface super-hydrophobic composite material. According to the technical scheme, PTFE micro-powder particles with strong super-hydrophobic property and excellent high-temperature resistance are used as super-hydrophobic components to be added into a resin matrix for an outer-layer adhesive film, so that the super-hydrophobic property of the finalcomposite material is improved; matrix resin for an inner adhesive film and an outer adhesive film is respectively prepared, the adhesive films are prepared, a prepreg is prepared by adopting a step-by-step pre-impregnation method; and finally, slitting and paving according to specified width requirements are carried out, and putting into an autoclave for high-temperature curing molding is carriedout, thereby completing the preparation of the super-hydrophobic composite material. The method has the greatest advantages that the super-hydrophobic coating can be integrally formed in the preparation process of the composite material, the binding force between the prepared super-hydrophobic surface layer and the composite material is high, and the super-hydrophobic characteristics of the prepreg and the resin-based composite material can be improved. The super-hydrophobic resin-based composite material prepared by the invention has the advantages of self-cleaning property, strong moistureabsorption resistance, strong freezing resistance, stable hydrophobic property and the like, has great technical advantages, and is of great significance to the application of novel resin-based composite materials for aerospace.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Glass self-cleaning liquid and self-cleaning glass and preparation method thereof

ActiveCN108947265AImprove self-cleaningStrong weather resistanceCoatingsGlass tempering apparatusPROPYLENE GLYCOL BUTYL ETHERPolyethylene glycol

The invention discloses a glass self-cleaning liquid and self-cleaning glass and a preparation method thereof. The glass self-cleaning liquid comprises the following ingredients (by weight): 100-300 parts of SiO2 sol, 1-5 parts of ethyl orthosilicate, 1-10 parts of ammonia water, 50-300 parts of polyethylene glycol, 10-50 parts of n-butanol, 0.1-0.5 part of PVPK30, 0.5-2.0 parts of Dipropylene glycol mono butyl ether, and 10-50 parts of water glass. The self-cleaning glass prepared by the use of the self-cleaning liquid has a good self-cleaning effect and also has good weatherability and lighttransmittance. In addition, usability of the glass is enhanced.

Owner:GUANGDONG SOUTH BRIGHT GLASS TECH

Composite material with self-cleaning function

The invention discloses a composite material with a self-cleaning function, which is prepared from the following raw materials in parts by weight: 20-30 parts of epoxy resin, 25-40 parts of thermoplastic resin, 10-15 parts of polydimethylsiloxane, 8-14 parts of polytetrafluoroethylene, 6-12 parts of a heat stabilizer, 4-8 parts of a curing agent, 6-10 parts of silane, 8-16 parts of a coupling agent, 10-16 parts of a lubricant, 10-20 parts of a processing aid and 6-12 parts of a flame retardant. The invention relates to the technical field of new materials. According to the composite material with a self-cleaning function, through the composite material with a super-hydrophobic function, condensed water drops can be quickly collected and flow away and cannot be adhered to the surface of the composite material, so that the adhesion of dust is greatly reduced, the contact angle between the surface of the composite material and water is greatly increased, the rolling angle is reduced, the water drops can freely slide on the composite material, a self-cleaning super-hydrophobic function is achieved in real sense, the the composite material can be applied to resin-based composite materials in the fields of life, industry, military affairs and the like, and the implementation process is simple and high in controllability and engineering application feasibility.

Owner:镇江博洛加新材料科技有限公司

Super-hydrophobic coating and preparation method and application thereof

InactiveCN110591007AFully dispersedEvenly dispersedPretreated surfacesLiquid repellent fibresCross-linkWater baths

The present invention discloses a super-hydrophobic coating and a preparation method and application thereof. By cross-linking and solidifying raw materials of a hydrophobic resin, a good solvent of the hydrophobic resin, organosilane, polystyrene, a photo initiator, a cross-linking agent, a curing agent and the like, through high-speed dispersion, water-bath reaction and other steps, the super-hydrophobic coating is obtained. The preparation process of the invention is simple, the reaction condition is mild, the super-hydrophobic coating prepared by the method has good adhesion and wear resistance, and has a wide application prospect in production and life.

Owner:深圳市心晴网络科技有限责任公司

Preparation process of fluorine-free superhydrophobic surface

InactiveCN109722168AEasy to makeFast preparationAntifouling/underwater paintsRosin coatingsCopper(II) chlorideHydrophobic surfaces

The invention discloses a preparation process of a fluorine-free superhydrophobic surface. The process comprises the following steps: putting metal aluminum into a hydrochloric acid solution of copperchloride, performing a reaction to obtain a sample having a rough structure, uniformly coating the sample by using a prepared rosin ethanol solution, and performing drying to obtain a sample having ahigh contact angle and a small rolling angle with water. According to the process provided by the invention, the fluorine-free low-price environmentally-friendly superhydrophobic surface can be easily prepared on the metal aluminum by chemical corrosion and rosin coating methods, and the process is simple and easy to operate; a rosin coating is used to replace a traditional modified fluoride molecular layer, so that the mechanical stability of the superhydrophobic surface is greatly improved, and the production costs are reduced; and the prepared superhydrophobic surface has the characteristics of self cleaning, icing resistance and drag reduction.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com