Super-hydrophobic coating and preparation method and application thereof

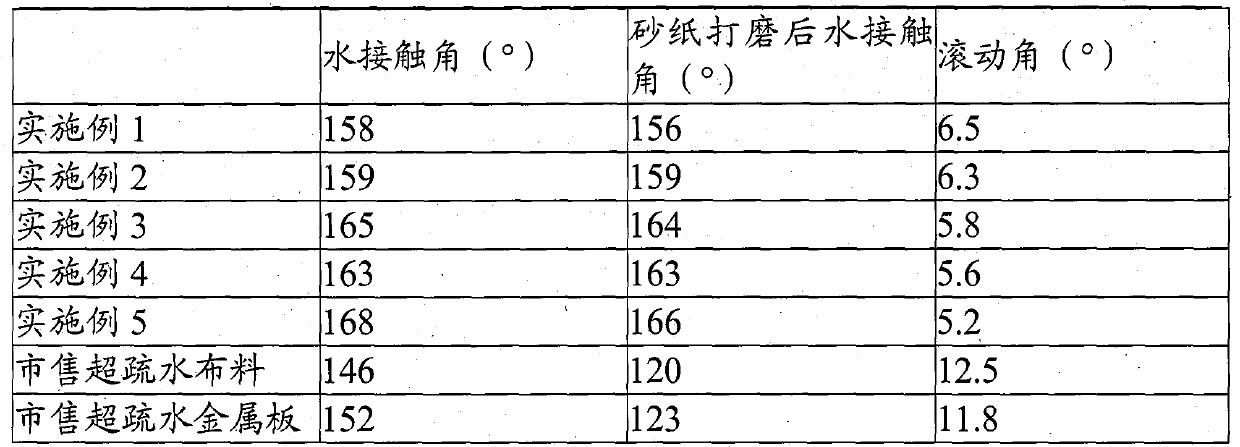

A super-hydrophobic coating and hydrophobic resin technology, which is applied in coatings, textiles and papermaking, and devices for coating liquid on the surface, etc., can solve the problem of poor stability of etching treatment effects, expensive vapor deposition equipment, and template preparation. Low efficiency and other problems, to achieve the effect of increasing the static contact angle and reducing the rolling angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Superhydrophobic coatings:

[0030] (1) Weigh 25 kg of polytetrafluoroethylene resin, 30 kg of tetrahydrofuran, 1 kg of triethylsilane, 5 kg of polystyrene, 1 kg of α, α-dimethoxy-α-phenylacetophenone, 1 kg of vinyl triethoxy Silane 8kg, diisocyanate 10kg, the tetrafluoroethylene resin and diisocyanate that weighed are dissolved in good tetrahydrofuran, obtain hydrophobicity resin solution;

[0031] (2) Add triethylsilane, polystyrene, α, α-dimethoxy-α-phenylacetophenone and vinyltriethoxysilane to the hydrophobic resin solution, at 25000r / min Disperse at high speed for 40 minutes under the same conditions to obtain a uniformly mixed suspension;

[0032] (3) Put the suspension obtained in step (2) into an airtight container, heat it in a constant temperature water bath at 20°C, and turn on magnetic stirring under the protection of nitrogen, and after fully reacting for 12 hours, remove the suspension formed in the container The reactant was poured out and left to stan...

Embodiment 2

[0035] Superhydrophobic coatings:

[0036] (1) Weigh 5kg of polyacrylic resin, 5kg of fluorinated modified polyurethane, 20kg of N-methylpyrrolidone, 5kg of monosilane, 5kg of triethylsilane, 10kg of polystyrene, 2kg of diphenyl ethyl ketone, isopropyl sulfide Xanthon 1kg, bisbenzoyl phenyl phosphine oxide 2kg, vinyltriethoxysilane 2kg, methyltriethoxysilane 3kg, propyltriethoxysilane 2kg, weighed polyacrylic resin, Fluorinated modified polyurethane, methyltriethoxysilane and propyltriethoxysilane are mixed and dissolved in N-methylpyrrolidone to obtain a hydrophobic resin solution;

[0037] (2) Add monosilane, triethylsilane, polystyrene, diphenyl ethyl ketone, isopropyl thioxanthone and vinyl triethoxysilane to the hydrophobic resin solution, at 15000r / min Disperse at high speed for 60 minutes under the same conditions to obtain a uniformly mixed suspension;

[0038] (3) Put the suspension obtained in step (2) into an airtight container, heat it in a constant temperature w...

Embodiment 3

[0041] Superhydrophobic coatings:

[0042](1) Weigh 18kg of fluorocarbon resin, 26kg of acetone, 8kg of heptadecylfluorodecyl triethoxysilane, 7kg of polystyrene, 2kg of diphenyl ethyl ketone, 2kg of isopropyl thioxanthone, vinyl triethyl Oxygen silane 6kg, propyl triethoxy silane 7kg, the fluorocarbon resin and propyl triethoxy silane that weighed are dissolved in acetone, obtain hydrophobicity resin solution;

[0043] (2) Add heptadecylfluorodecyltriethoxysilane, polystyrene, diphenylethanone, isopropylthioxanthone and vinyltriethoxysilane to the hydrophobic resin solution, at 18000r Disperse at high speed for 45 minutes under the condition of 1 / min to obtain a well-mixed suspension;

[0044] (3) Put the suspension obtained in step (2) into an airtight container, heat it in a constant temperature water bath at 30°C, and turn on magnetic stirring under the protection of nitrogen, and after fully reacting for 8 hours, remove the suspension formed in the container The reactan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com