Method for preparing super hydrophobic film on surface of zinc substrate

A substrate surface, super-hydrophobic technology, used in devices for coating liquids on surfaces, special surfaces, pretreated surfaces, etc., can solve problems such as being unsuitable for large-scale production, and achieve increased micro-roughness, easy industrialization, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

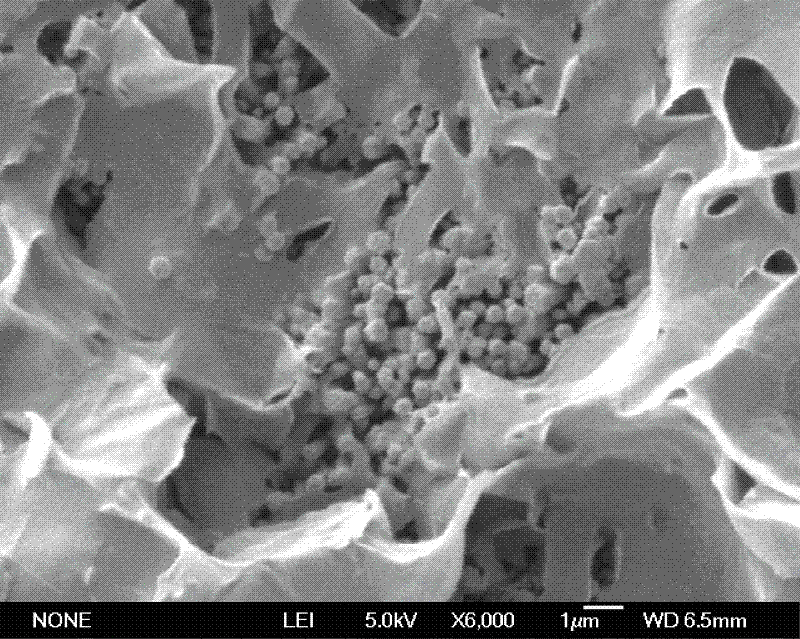

[0037] (1) Clean 7 zinc sheets (1cm×1cm) with ethanol, acetone, and secondary water ultrasonically for 2-3 times, each time for 5-10 minutes; dry them with nitrogen for later use.

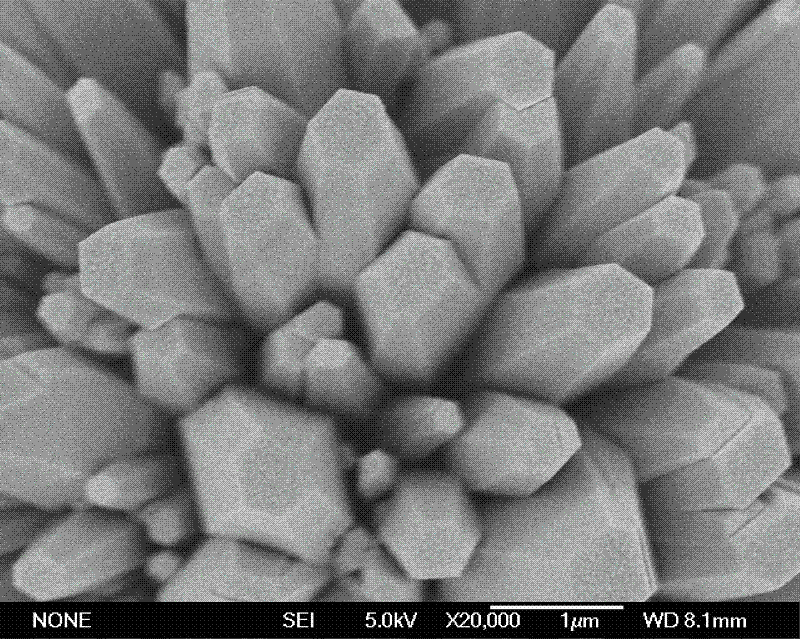

[0038] (2) Immerse the base of the zinc sheet in an aqueous solution of formamide with a volume fraction of 3-5%, place it in an oven, heat it at a constant temperature of 65°C for 10-30 hours, take it out, cool it to room temperature naturally, take out the zinc sheet, and use it twice After washing with water and ethanol and drying in air, nanorod arrays were obtained on the surface of the zinc sheet.

[0039] (3) Immerse the zinc flakes in an ethanol solution of stearic acid with a mass concentration of 1% for 4h, 8h, 12h, 16h, 20h, 24h, and 48h respectively; take out the substrate, wash it with absolute ethanol, and dry it , measured the surface contact angle; the results found that when the reaction time was 4h, the contact angle reached the maximum, which was 156.12°, and the rolling angle wa...

Embodiment 2

[0041] (1) Same as Example 1.

[0042] (2) Same as Example 1.

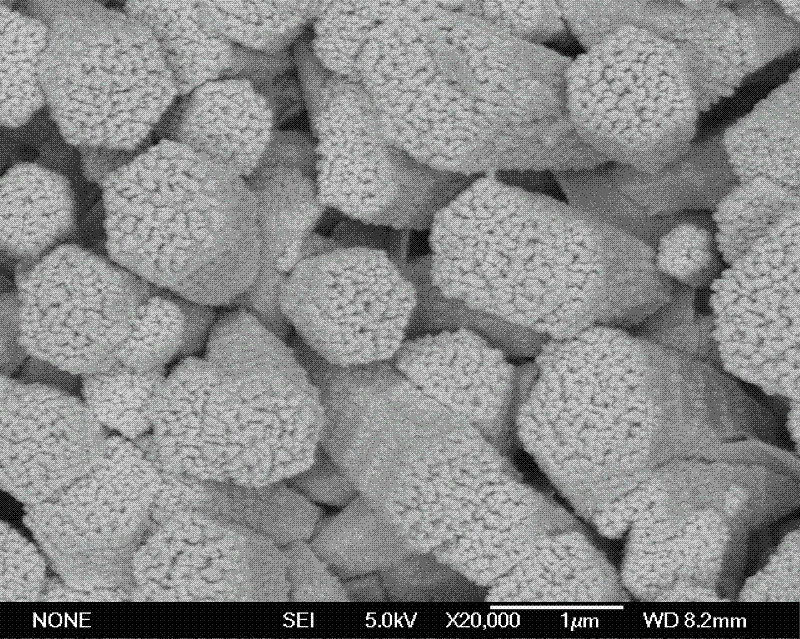

[0043] (3) Immerse the zinc flakes in ethanol solution of lauryl hydroxystearic acid with a mass fraction of 1%, soak for 4h, 8h, 12h, 16h, 20h, 24h, 48h respectively, take out the substrate, wash it with absolute ethanol, and let it dry After drying, its surface contact angle was measured; it was found that its hydrophobicity was the best when it was reacted for 16 hours (see Figure 4 a), the contact angle is 158.02°.

Embodiment 3

[0045] (1) Same as Example 1.

[0046] (2) Same as Example 1.

[0047] (3) Soak the zinc flakes in 0.5%, 1%, and 1.5% stearic acid ethanol solutions for 4 hours; take them out, wash them with absolute ethanol, and measure their surface contact angle after drying; the results show that when When the concentration of stearic acid ethanol solution is 1%, the contact angle is the largest: 156°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com