Graphene oxide/copper silicate composite powder, preparation method of composite powder and application thereof in super-hydrophobic coating

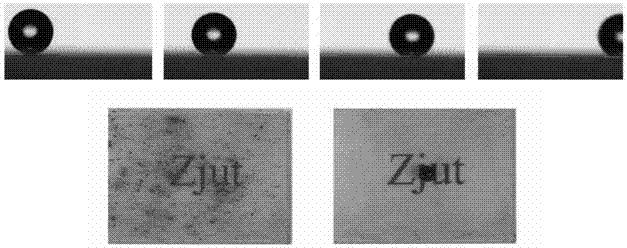

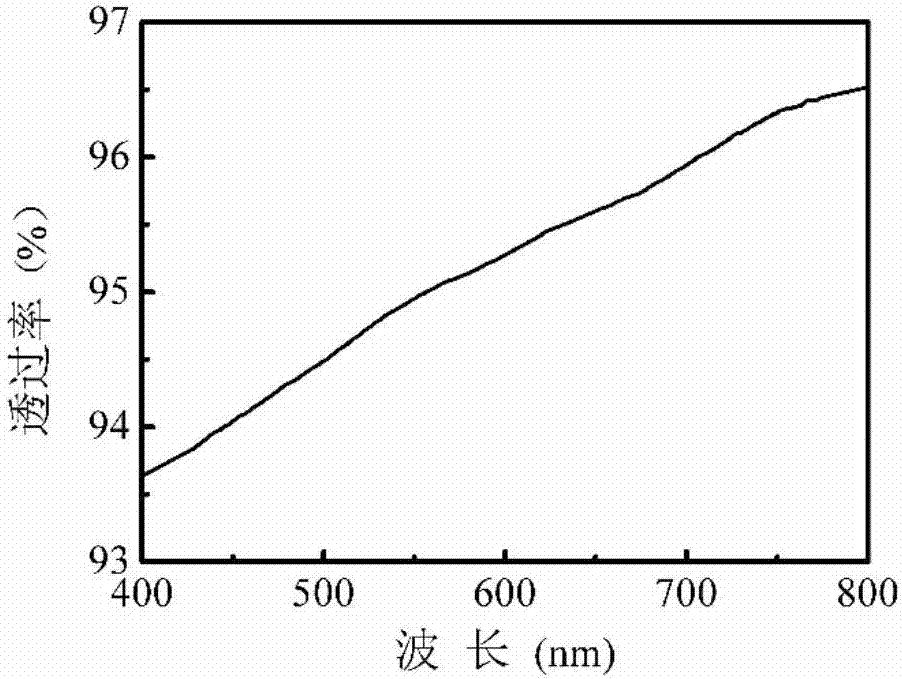

A composite powder and graphene technology, applied in chemical instruments and methods, coatings, carbon compounds, etc., can solve problems such as the inability of hydrophobic coatings to meet requirements, achieve large surface contact angles, mild reaction conditions and easy realization, and process technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

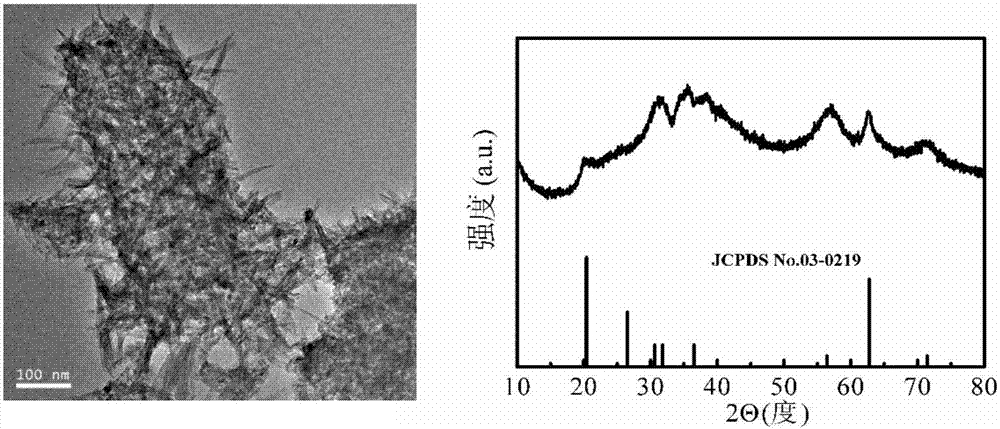

[0043] 1) Preparation of graphene oxide / copper silicate composite powder: 0.05g of dodecyltrimethylammonium bromide, 120ml of ethanol was added to 50ml of deionized water to form a mixed solution, and then 0.01g of graphene oxide was dispersed in the above-mentioned In the mixed solution, ultrasonically disperse for 20 minutes to obtain a homogeneous suspension. Then 0.5ml tetraethyl orthosilicate was added to the above solution, and stirred continuously at room temperature for 5h. After centrifugation, washing with absolute ethanol and deionized water, and drying, 0.012 g of silica-coated graphene oxide was obtained. Then 10 mg of the prepared silicon oxide-coated graphene oxide was dispersed in 20 ml of deionized water, and ultrasonically dispersed for 20 min. Add ammonia water under slight stirring to adjust the pH to 10, and add 0.5ml 0.1mol / L copper acetate compound dropwise, continue stirring for 5min, transfer the mixed suspension to a stainless steel autoclave lined w...

Embodiment 2

[0046] Preparation of graphene oxide / copper silicate composite powder: add 0.03g sodium dodecylbenzenesulfonate, 120ml propanol to 30ml deionized water to form a mixed solution, and then disperse 0.01g graphene oxide in the above mixed solution , Ultrasonic dispersion for 40min to obtain a homogeneous suspension. Then 3ml of methyl orthosilicate was added to the above solution, and stirring was continued at room temperature for 6h. After centrifugation, washing and drying, 0.015 g of silicon dioxide-coated graphene oxide was obtained. Then, 10 mg of the prepared silica-coated graphene oxide was dispersed in 40 ml of deionized water, and ultrasonically dispersed for 40 min. Add ammonia water under slight stirring to adjust the pH to 10.8, and add 0.6ml 0.1mol / L copper nitrate and 0.9ml 0.1mol / L copper acetate dropwise, continue stirring for 5min, and transfer the mixed suspension to a polytetrafluoroethylene liner. In a stainless steel autoclave made of ethylene, keep warm at...

Embodiment 3

[0049] Preparation of graphene oxide / copper silicate composite powder: 0.5g of dodecyltrimethylammonium bromide, 120ml of n-butanol was added to 50ml of deionized water to form a mixed solution, and then 0.5g of graphene oxide was dispersed in the above In the mixed solution, ultrasonically disperse for 40min to obtain a homogeneous suspension. Then 2.5ml of isopropyl orthosilicate was added to the above solution, and stirred continuously at room temperature for 6h. After centrifugation, washing and drying, 1.8 g of silica-coated graphene oxide was obtained. Then 10 mg of the prepared silica-coated graphene oxide was dispersed in 10 ml of deionized water, and ultrasonically dispersed for 40 min. Add ammonia water under slight stirring to adjust the pH to 10, and add 3ml 0.1mol / L copper chloride and 2ml 0.1mol / L copper acetate dropwise, continue stirring for 5min, and transfer the mixed suspension to a polytetrafluoroethylene-lined In a stainless steel autoclave, heat preserv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com